Page 1

(#)*"*&'-.

TI2000 GPU-24

!"#$%&'(#)*"'$%+,

!"#$%& '()*#+,-"#& '(./

012&3"(+",45-(+&6$7)/

8"9&3%#+$":&;<&02=>1

?@1>A@>BCD201&4E5("

?@1>A&@>BCD20>&F%G

www.TESLAind.com

Page 2

WARNING

*******SHOCK HAZARD POTENTIAL*******

IMPROPER USE/FAILURE TO FOLLOW INSTRUCTIONS IN OPERATORS MANUAL CAN

RESULT IN UNIT FAILURE AND/OR POSSIBLE INJURY, OR DEATH, BY ELECTRICAL SHOCK.

THE TI2000GPU-24 IS A MAINTENANCE FREE, SEALED UNIT

NO REPAIRS ARE AUTHORIZED.

WARRANTY WILL BE VOID IF

UNIT IS TAMPERED WITH.

FOR TECHNICAL SUPPORT CONTACT:

TESLA INDUSTRIES INC.

109 CENTERPOINT BLVD.

CENTERPOINT INDUSTRIAL PARK

NEW CASTLE,DELAWARE 19720

PH.(302)324-8910

FAX (302)324-8912

WARNING

*******SHOCK HAZARD POTENTIAL*******

ATTEMPTS TO OPEN OR ENTER THE INSIDE OF THIS UNIT (BY USING ANY TOOL

OR DEVICE; i.e. PROBE, BORESCOPE, etc.) CAN RESULT IN UNIT FAILURE

AND/OR POSSIBLE INJURY BY ELECTRICAL SHOCK. THIS UNIT IS MAINTENANCE

FREE AND SHALL NOT BE OPENED OR DISASSEMBLED FOR ANY REASON.

***SHIPPING HAZARDS***

“NONE”

“DRY” Non-spillable, POWER CELL (battery),

No Free liquids, to leak or toxic gases.

Always protect unit from short circuit.

Return Power cells to Tesla for Recycling.

Page 3

i

TABLE OF CONTENTS

TITLE Page

CHAPTER 1 INTRODUCTION 1-1

CHAPTER 2 UNIT DESCRIPTION AND OPERATION 2-1

Section I Unit 2-1

Section II Description 2-2

CHAPTER 3 OPERATING LIMITS AND RESTRICTIONS 3-1

Section I General 3-1

Section II Operational Restrictions and Safety Limits 3-1

CHAPTER 4 OPERATING PROCEDURES 4-1

Section I Unit Operation 4-1

Section II Operating Procedures 4-2

Section III Functional Check Procedures 4-5

CHAPTER 5 PERFORMANCE DATA 5-1

Section I Introduction 5-1

Section II Data Criteria 5-2

CHAPTER 6 CARE AND MAINTENANCE 6-1

Section I Unit Care 6-1

Section II Maintenance 6-2

INDEX Index 1

LIST OF ILLUSTRATIONS

Figure Title Page

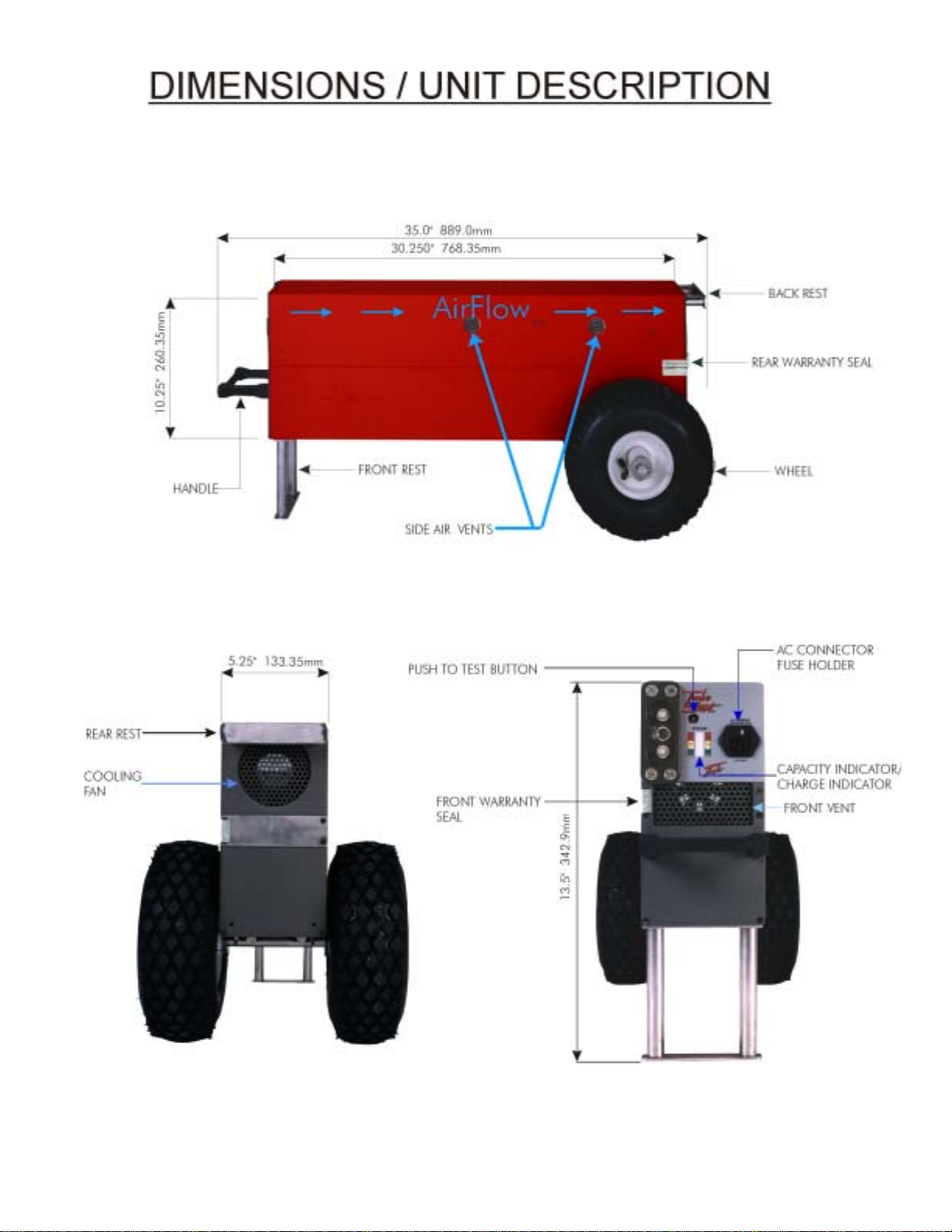

2-1 Dimensions 2-3

2-2 General Details 2-2

2-3 Fuse Setting Procedures 2-4

5-1 Temperature Conversion Chart 5-3

5-2 Discharge Load Curve 5-4

5-3 Maximum Output Current 5-5

Page 4

ii

CHAPTER 1

INTRODUCTION

1-1. GENERAL

These instructions are for use by the owner/operator. They apply to

handling and operation of the TI2000GPU-24 (Turbo Start 2000) ground

power unit.

1-2. WARNING, CAUTION, AND NOTE DEFINED

A warning, caution, or note is used to emphasize important and critical instructions as defined for the following conditions:

WARNING

An operating procedure, practice, etc., which,

if not correctly followed, could result in

personal injury or loss of life.

CAUTION

An operating procedure, practice, etc., which,

if not strictly observed, could result in

damage to or destruction of equipment.

NOTE

An operating procedure, condition, etc., which

is essential to highlight.

1-3. DESCRIPTION

This manual contains the complete operating instructions and procedures for the TI2000GPU-24 (Turbo Start 2000) ground power unit. The

Turbo Start 2000 is intended to provide DC electrical ground power

for aircraft flight line and maintenance ground support operations.

The unit is designed to provide 24 volt DC electrical power output

for aircraft engine starting and 24 or 28.5 volts DC electrical support for ground maintenance, avionics/electrical trouble shooting and

testing. The observance of procedures, limitations and performance

criteria is essential to ensure peak operating efficiency and to

maximize operational capabilities and life of the Turbo Start 2000

ground power unit.

Page 5

1-1

䩞䩯

1-4. INDEX

The index lists, in alphabetical order, every titled paragraph and

figure contained in this manual.

1-5. ABBREVIATIONS AND SYMBOLS

Abbreviations and symbols are used within text, headings and titles.

Unless otherwise indicated, the following list of abbreviations and

symbols are used in this manual:

LIST OF ABBREVIATIONS AND SYMBOLS

Abbreviation Definition

amp Ampere

AC Alternating Current

C Celsius

cont Continuous

DC Direct Current

F Fahrenheit

Ft Feet

FWD Forward

GPU Ground Power Unit

Hr Hour

Hz Hertz

Kg Kilograms

Kw Kilowatts

° Degree

LED Light Emitting Diode

MAX Maximum

MIN Minimum

VAC Volts, Alternating Current

VDC Volts, Direct Current

Explosion Hazard Potential

Shock Hazard Potential

Guard from moisture

䩢䩰䩜䩭䩟䨻䩡䩭䩪䩨䨻䩤䩩䩞䩪䩭䩭䩠

䩫䩪䩲䩠䩭䨻 䩮䩪䩰䩭䩞䩠

Guard from incorrect power source

Page 6

Guard from incorrect power source

1-2

1-6. FORMS AND RECORDS

NONE REQUIRED.

1-7. USE OF WORDS SHALL, SHOULD, AND MAY.

Within this technical manual the word “shall” is used to indicate a

mandatory requirement for proper operation and warranty purposes.

The word “should” is used to indicate a non-mandatory but preferred

method of accomplishment. The word “may” is used to indicate an acceptable method of accomplishment.

Page 7

1-3

CHAPTER 2

UNIT DESCRIPTION AND OPERATION

SECTION I. UNIT

2-1. GENERAL

The TI2000GPU-24 (Turbo Start 2000) (Figure 2-1 and 2-2) is a compact, portable

and highly versatile 24/28.5 VDC electrical ground power unit. The unit incorporates a 120-240 VAC to 28.5 VDC converter, a 24 volt unique (dry) power cell

and an internal intelligent 120 to 240 volt AC charger to recharge the power

cells. These built-in features give the Turbo Start 2000 self-sufficiency and

mobility for short-term operations without AC electrical power or long term

operations with AC electrical power. Short term operations rely solely on

power cell output and the fast recharge rates that the unit’s internal charger

provides from any standard 120 or 240 VAC electrical outlet. Longer term operations incorporate the continuous 20 amp output of the 120-240 VAC to 28.5

VDC converter, or a combination of converter and power cell output to provide

24 VDC output. The following are the unit’s four (4) main operational support

capabilities:

a. 24 VDC 3000 amp peak power output for engine starting or constant (one

hour) rated power output (without a 120-240 VAC power source) for short term

trouble shooting and flexible flight line support ground power.

b. 24 VDC constant (one hour) rated power output or variable high load demand output (less than one hour) with a 120-240 VAC power source for extended

maintenance (hangar) and routine flight line maintenance, ground support

power.

c. 28.5 VDC continuous rated (AC to DC converter) power output with a 120240 VAC power source for hangar and routine flight line maintenance support,

and avionics bench testing.

d. Rapid recharge of the unit’s power cells from any 120-240 VAC common

power source. This feature eliminates the need for special recharge equipment and dedicated maintenance support man-hours.

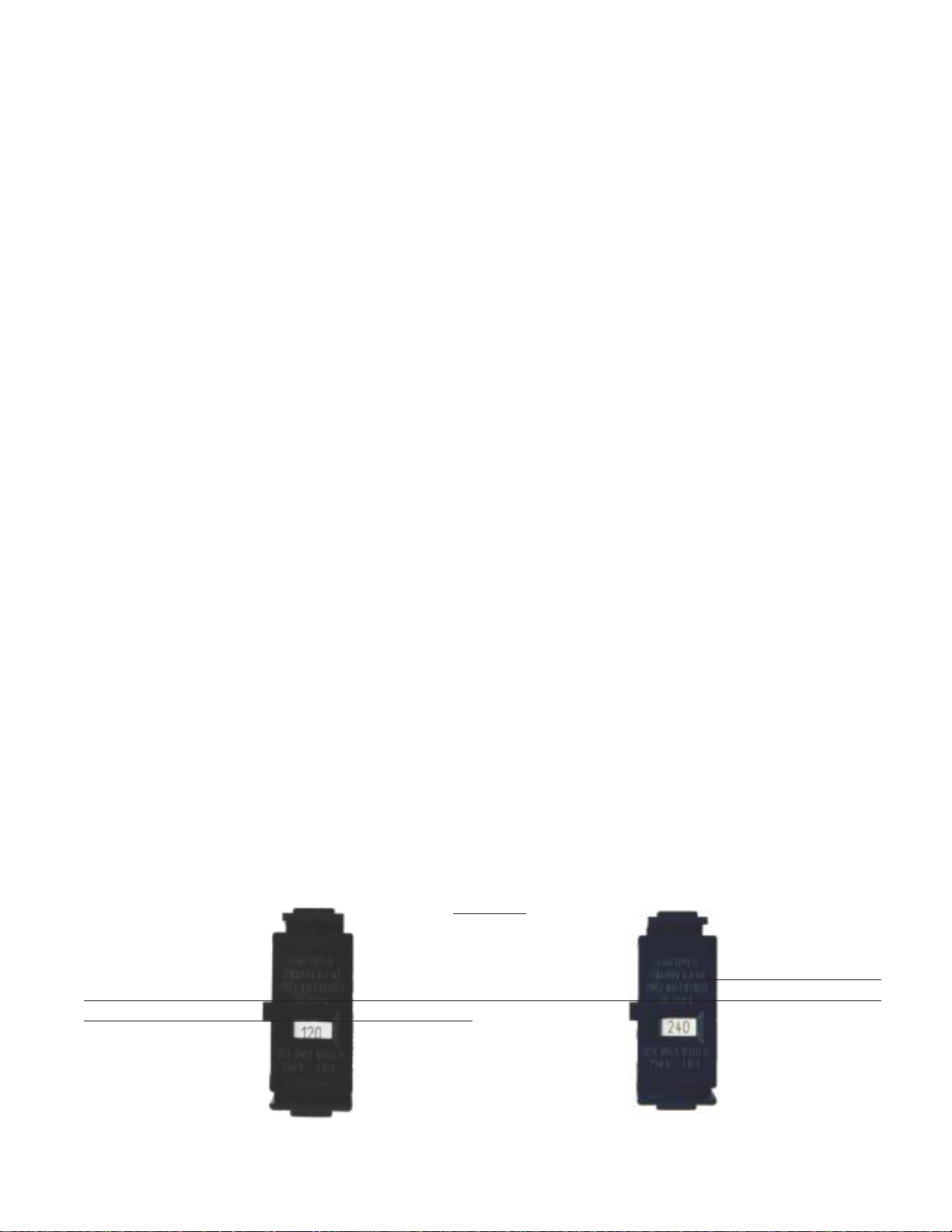

WARNING

Check fuse holder window to ensure the fuse setting reads either 120 or

240 prior to connecting recharge cord to AC power source.

Fuse setting (120/

240) must match AC power source (hangar wall, flight line AC power) prior to

connecting TURBO START for recharging.

(SEE PAGE 2-4 FOR

FUSE SETTING PROCEDURES)

Page 8

120 VAC Setting 2-1 240 VAC Setting

SECTION II DESCRIPTION

2.2. GENERAL SPECIFICATIONS

WEIGHT

UNIT: 111 lbs (50.39 Kg)

DC POWER CABLE: 8.5 lbs (3.86 Kg)

AC POWER CORD: 0.4 lbs (0.18 Kg)

INPUT POWER AC

TI2000GPU-24:

TI2000GPU-24-UNV:

TI25000-U01 NORTH AMERICAN LINE CORD

TI25000-U04 OLD BRITISH LINE CORD

TI25000-U03 EUROPEAN 10A/250V

TI25000-U05 ENGLAND 10A/250V

OUTPUT POWER DC

CONVERTER: 28.5 VDC TO 20 AMPS, 24 VDC 21 AMPS AND ABOVE.

POWER CELLS: 24 VDC

PEAK OUTPUT: 3000 AMPS

105-125 VAC 60 Hz 6.50 amps max.

210-250 VAC 50/60 Hz 3.25 amps max.

105-125 VAC 60 Hz 6.50 amps max.

210-250 VAC 50/60 Hz 3.25 amps max.

210-250 VAC 50/60 Hz 3.25 amps max.

210-250 VAC 50/60 Hz 3.25 amps max.

POWER CELL

DRY, HIGH RATE DISCHARGE, RECHARGEABLE, MAINTENANCE-FREE

DC POWER CABLE

LENGTH: 8 FT

AIRCRAFT CONNECTOR: 3 PIN RECEPTACLE (MS25488)

Page 9

2-3

Page 10

Fuse Setting Procedures

for Switching Voltages or Changing Blown Fuses

1) Grab both tabs

on left and right side

of the fuse clip. Press

tabs inward and pull

fuse clip out of housing

GENTLY.

TABS

ENLARGEMENT 1

2) Completely pull

fuse clip from housing,

being careful not to

drop the fuses from

the fuse clip.

5) Completely remove

the white clip from the

fuse clip.

3) Note: The fuses

are not fastened into

the fuse clip, they are

lose. Take care to ensure

fuses are not dropped or

lost.

ENLARGEMENT 2 120 VAC SETTING

ENLARGEMENT 3 240 VAC SETTING

6) Ensure that the

proper voltage is selected

on the white clip. (See

Enlargement 2 & 3)

4) GENTLY pull the

white clip from the

fuse clip, taking care

not to bend any of

the tabs. (See

enlargement 1)

7) Replace the

white clip back into

the fuse clip. Take

care not to damage

the tabs.

8) Completely insert

white clip in to fuse

clip (GENTLY) until

it snaps into place.

9) Insert fuse clip

back into fuse housing

EVENLY on both sides.

DO NOT FORCE, if fuse

clip does not go in easy,

it means fuses are misaligned, realign fuses and

insert again.

2-4

10) Snap fuse clip

back into the housing

(GENTLY). DOUBLE

CHECK VOLTAGE

WINDOW PRIOR

TO PLUGGING UNIT

INTO AC POWER

Page 11

2-2

CHAPTER 3

OPERATING LIMITS AND RESTRICTIONS

SECTION I. GENERAL

3-1. PURPOSE

Chapter 3 includes all important operating limits and restrictions

that must be observed for proper and safe operation of the TI2000GPU24 (Turbo Start 2000) ground power unit.

3-2. GENERAL

The operating limitations set forth in this chapter are the direct

result of design analysis, testing, and operating experience. Compliance with these limitations and restrictions will ensure that owners/operators obtain maximum continued capability from the Turbo

Start 2000 ground power unit.

SECTION II. OPERATIONAL RESTRICTIONS AND SAFETY LIMITS

3-3. POWER CELL RECHARGE LIMITS

Any time the unit’s power cells are fully discharged the unit shall

be recharged within 24 hours to prevent performance degradation and

ensure maximum life.

CAUTION

Unit’s power cells may be damaged if recharged by NiCad or Lead Acid-

type battery chargers. Power cells should only be charged by either

the TURBO START internal charger and the AC power cord furnished with

the equipment, or when connected aircraft external DC power recep-

tacle.

Page 12

3-1

3-4. 120-240 VAC CHARGER AND AC TO DC CONVERTER LIMITS

The unit is designed with a single point AC receptacle for external

power to operate both the internal charger and converter. The units

AC voltage range can be factory set from 105 to 250 VAC at 50 to 60

Hz depending upon customer requirements. The AC power cord provided

with the unit is the mechanism that ensures the specified AC power

source is properly supplied to the unit (see paragraph 3-5).Use no

others

INTERNAL CHARGER: NO LIMIT AC power cord can remain connected

when power cells are fully charged. When the power cells are fully

charged the unit’s intelligent charger will go to a stand-by mode,

monitor the power cells state of charge, and only charge the power

cells to ensure they stay at maximum capacity.

*8$5’ )520 ,1&255(&7

32:(5 628 5&(

INTERNAL AC TO DC CONVERTER: LIMITED (see paragraph 3-6, 3-8 and

3-10). AC power cord does not have to be disconnected when converter power output is no longer required. Once DC power demand

is terminated the unit’s intelligent charger will remain on line to

ensure power cells are charged to maximum capacity.

CAUTION

Unit will be damaged if unapproved AC power is applied.

3-5 AC POWER CORD LIMITS

The AC power cord governs which AC power source the unit is set to

operate from. The Turbo Start 2000 is supplied with a single customer specified AC power cord. Some customers may specify a universal AC option (for worldwide mobility), which comes with two (2)

power cords, one for 120 VAC 60 Hz and the other for 240 VAC 50 Hz

(SEE APPENDIX A). Each power cord is marked accordingly. Below are

the following three (3) types of AC power cords available and their

limits.

120 VAC 60 Hz power cord (USA): LIMITED TO 105-125 VAC 60 Hz power

source only.

120 VAC 60 Hz power cord (Universal): LIMITED TO 105 VAC to 250 VAC

50/60 Hz power source using proper cord set.

240 VAC 50 Hz power cord (European): LIMITED TO 210-250 VAC 50-60 Hz

power source only.

FOR MORE INFORMATION ON POWER CORDS SEE APPENDIX A

Page 13

3-2

乆乗

AC Line Cords

乊乘乄乕乇丣义乕乒乐丣乌乑乆乒乕乕么

乓乒乚么乕丣 乖乒乘乕乆么

Cont. Europe U.K. Old British North American

CAUTION

Unit will be damaged if unapproved AC power is applied by fitting

120 or 240 VAC power cord with any kind of unapproved modification or

adapter that changes the specified input power characteristics.

WARNING

********SHOCK HAZARD POTENTIAL*********

Failure to use proper grounding can cause a potential shock hazard!

In different countries, the 240 VAC 50 Hz power cord may require

the use of a plug adapter to achieve plug style compatibility for

240 VAC 50 Hz operation. Use only adapters with proper grounding

mechanism.

3-6. ONE (1) HOUR RATE, 24 VDC CONSTANT OUTPUT

46 amp hour (without AC power connected), power cell output.

(see Figure 5-2)

66 amp hours (with AC power connected), both power cell and AC to

DC converter output.

NOTE

If power output is greater than rated amp hour rate, power cell

discharge rate will increase correspondingly.

3-7. RATED PEAK OUTPUT (ENGINE STARTING)

3000 peak amps at 25oC (77oF) (See Figure 5-3).

Page 14

3-3

3-8. CONTINUOUS OUTPUT RATE, 28.5 VDC CONSTANT OUTPUT

20 amp hours (with AC power connected)

NOTE

If current demand exceeds 20 amps, converter output voltage will drop

below 28.5 VDC and two or more LED status indicator bars will illumi-

nate. If all LED status indicator bars illuminate, both the con-

verter and power cells are supplying 24 VDC power output (see para-

graph 3-4 and 4-7.4.).

3-9. ENGINE STARTING POWER

Operators should always ensure the unit is charged above 80% prior to

ground support engine starting. However, circumstances may exist

during use where unit recharge is not readily available and immediate

external engine starting power is required. The following provides

minimum states of charge necessary to provide ample power for an efficient engine start under specific current load demands.

ENGINE START CURRENT LOAD DEMAND MINIMUM CHARGE

650-850 peak starting amps 40% charged

850-1000 peak starting amps 50% charged

1000-1500 peak starting amps 60% charged

1500-1800 peak starting amps 70% charged

1800-2500 peak starting amps 80% charged

2500-3000 peak starting amps 90% charged

3-10. TEMPERATURE

Temperatures refer to the unit’s cold/heat soaked temperature. A

unit’s cold/heat soaked temperature shall be established by the ambient temperature that a unit is exposed to for one (1) hour or more.

If unit’s cold/heat soaked temperature exceeds operating temperature

range, unit shall be stabilized prior to operation as follows: COLD

SOAKED, warmed for a minimum of 3 hours above +10Co (+41oF) or 2

hours above +20Co (+68oF); WARMED SOAKED, cooled for 1 hour below

+38Co (+100oF).

Operating range:

without

with

AC power -40Co (-40oF) TO +60Co (+140oF)

AC Power -30Co (-22oF) TO +50Co (+124oF)

Page 15

Storage range:

-60Co (-76oF) TO +60Co (+140oF)

(C0NTINUED ON NEXT PAGE)

3-4

CAUTION

Unit may be damaged if operated when unit’s cold or heat soaked tempera-

ture exceed the specified limit. If unit is operated when cold or heat

soaked temperature limit is exceeded, a full functional check should be

accomplished prior to continued use.

NOTE

If unit should overheat, an over-temperature sensor will shut down 120-

240 VAC functions (charger and converter) until unit cools to normal

operating temperatures.

3-11. ENVIRONMENTAL

Operating any electrical equipment in the presence of moisture creates possible safety hazards and/or potential for equipment damage.

Every effort has been made, within the scope of existing technology

to prevent foreseeable safety hazards and make the Turbo Start 2000

moisture resistant to prevent damage or failure. If the Turbo Start

3000 is exposed to moisture, preventive measures and precautions

shall be taken to:

a. prevent accumulation of moisture on AC and DC connectors/receptacles

b. minimize moisture entering FWD inlet and AFT outlet cooling fan vent ports

The limits and operational constraints listed below shall apply for

the following environmental (weather) conditions:

Heavy or steady rain: OPERATION NOT RECOMMENDED

Light rain, drizzle: NO CONVERTER OR CHARGER 120-240 VAC

fog, snow or sleet: POWER SHALL BE APPLIED.

Unit inlet and outlet vent ports shall be covered from exposure.

Unit shall be kept horizontal.

Page 16

3-5

WARNING

********SHOCK HAZARD POTENTIAL*********

Severe injury, or Death, from electrical shock is possible when per-

sonnel and/or Turbo Start 2000 are wet during use and when 120-240

VAC power is being supplied to unit.

CAUTION

Damage may occur if unit is operated after exposure to moisture

(rain, drizzle, fog, sleet or snow) or moisture contamination is sus-

pected. DO NOT USE until unit’s exterior and receptacles are dried.

Operation shall be restricted to use

DO NOT CONNECT 120 or 240 VAC power cord until unit has been dried

for a MINIMUM of one (1) hour, prior to use.

Blowing sand or dust: Minimize exposure to sand and dust

when 120-240 AC power is used. Unit shall be kept horizontal during use.

without 120 or 240 power cord

.

3-12. OPERATING POSITION

Without 120-240 VAC power cord: Horizontal or vertical.

Horizontal only

cord is plugged in and exhaust fan is running.

Unit may be damaged if blown over by propeller, rotor or jet wash, or

accidentally knocked over. Unit should be kept horizontal during

use.

, for propper unit ventilation, when 120-240 VAC line

CAUTION

Page 17

3-6

CAUTION

Unit damage may occur if inlet and outlet vent ports are obstructed

and/or cooling air flow is restricted.

3-13. UNIT OPERATION DURING AIRCRAFT FUELING/DEFUELING

Power output is restricted to 24 VDC power cell output only. DO

NOT CONNECT 120 or 240 VAC POWER SUPPLY. 120-240 VAC power

(charger or AC-DC converter) functions of unit shall not be operated during any aircraft fuel handling operation.

WARNING

*******FIRE/EXPLOSION HAZARD POTENTIAL********

Severe injury, or Death, may occur from fire or explosion, as a

result of electrical sparks produced near fuel vapors.

Page 18

3-7

CHAPTER 4

OPERATING PROCEDURES

SECTION I. UNIT OPERATION

4-1. GENERAL

Correct operation of the TI2000GPU-24 (Turbo Start 2000) includes

both pre-use and operational checks of the unit. Knowledge of the

operating limits, restrictions, performance, unit capabilities and

functions is fundamental to correct and safe operation. The operator

shall ensure compliance with the instructions in this manual that

affect operational safety and the warranty of the unit.

4-2. OPERATING LIMITS AND RESTRICTIONS

The minimum, maximum and normal operating ranges result from careful

engineering and evaluation of test data. These limitations must be

adhered to during all phases of operation. Refer to Chapter 3, Section II, OPERATING LIMITS AND RESTRICTIONS, for detailed information.

4-3. PERFORMANCE

Refer to Chapter 5, PERFORMANCE DATA to determine the capability of

the Turbo Start. Consideration must be given to changes in performance resulting from variations in ambient temperature, mode of operation, state of charge (with or without 120 or 240 VAC power), and

aircraft DC bus system inefficiency (voltage drops).

Page 19

4-1

SECTION II. OPERATING PROCEDURES

4-4. OPERATING PROCEDURES

This section deals with normal procedures, and includes all steps

necessary to ensure safe and efficient operation of the TI2000GPU-24

(Turbo Start 3000). As experience is gained with the Turbo Start

3000, the user will be able to maximize the unit’s unique capabilities to enhance the flexibility of aircraft maintenance and support

operations.

NOTE

When the TURBO START 2000 is not in use, it should

plugged into a suitable AC power source to insure operational readiness at all times. REMEMBER,when the AC line cord is plugged in, the

unit must be placed in the horizontal position to allow the cooling

fan to operate properly!

4-5. BEFORE OPERATION CHECK

1.

UNIT INTO THE AC POWER SOURCE TO BE USED

cord is plugged in, the unit must be placed in the horizontal position to allow the cooling fan to operate properly!

blinking green bar at the bottom of the bar graph column.The fan will

CHECK FUSE WINDOW FOR PROPER SETTING (120/240) BEFORE PLUGGING

. REMEMBER,when the AC line

STA TUS

NOTE:

A full charge is indicated by Either a steady lighted green bar or a

also exhibit ratcheting but will not come on when the unit is fully

charged.

always

remain

2. CHECK UNIT FOR EVIDENCE OF DAMAGE - Check for dents, punctures,

case distortion or misalignment, cracked or loose connectors, and

Page 20

that cooling fan is functioning.

4-2

CAUTION

REMEMBER,when the AC line cord is plugged in, the unit must be placed

in the horizontal position to allow the cooling fan to operate prop-

erly!

Unit may overheat if cooling fan fails. Do not operate if cooling

fan fails.(More than one green bar present on bar graph)

3. CHECK DC POWER CABLE/CONNECTORS FOR DAMAGE - Check cable for

cuts, chafing or evidence of being crushed. Check connectors for

cracks, cuts, distortions, excessive wear, broken/loose fasteners or

loose cable attachment.

4-6. 24 VDC GROUND POWER (NO 120 OR 240 VAC POWER SUPPLY) ENGINE

STARTING OR DC SYSTEM POWER

1. TRANSPORT UNIT - The Turbo Start 2000 is easily transported using

the wheels that are incorparated into the unit. The AXEL EXTENTION

kit (included with the unit) ensures that the Turbo Start 2000 is

stable. The unit is engineered to be pushed rather than pulled.

2. CONNECT DC POWER CABLE TO UNIT - Ensure power cable connector is

fully seated into unit’s connector. Set

the unit down horizontally

ensuring vent ports are un-blocked.

3. CONNECT DC POWER CABLE TO AIRCRAFT - Ensure ground power

cable connector is fully seated into aircraft ground power recep-

tacle. DC bus power should come on and aircraft volt meter should

indicate 24 VDC to 23.5 VDC (23 VDC minimum).

4. ENGINE STARTING - Check power cable for security and correct

installation prior to engine start. Follow ground power engine

Page 21

starting procedure as specified in aircraft operators manual.

5. REMOVING DC POWER SUPPLY FROM AIRCRAFT

a. Remove DC power cable GPU connector from aircraft.

b. Remove DC power cable connector from Turbo Start

(if necessary).

4-3

4-7. 24 VDC GROUND POWER (WITH 120/240 VAC POWER) SYSTEM HIGH POWER DEMAND (21 amps and above) OR ENGINE STARTING.

1.

ing the wheels that are incorparated into the unit. The AXEL

EXTENTION kit (included with the unit) ensures that the Turbo Start

2000 is stable. The unit is engineered to be pushed rather than

pulled.

2.

TING

an approved AC power supply.

ensure unit’s vent ports are free from blockage

5-8 seconds, unit’s LED status indicator will illuminate indicating

power cell state of charge. Cooling fan will operate. Ensure LED

status indicator and cooling fan are operational prior to continuing

to step 3.

3. CONNECT DC POWER CABLE TO UNIT - Ensure power cable connector is

fully seated into unit’s receptacle.

4. CONNECT DC POWER CABLE TO AIRCRAFT - Connect to aircraft ground

power receptacle. DC bus power should come on and aircraft volt

meter should indicate 27.5 VDC to 23.5 VDC (23 VDC minimum). If current demand is above 20 amps, converter output voltage will drop below 28.5 VDC and two or more LED status indicator bars will illuminate. At approximately 21 amps of current demand, converter output

voltage will be regulated at 24 VDC output and the last (RED) LED

status indicator bar will illuminate.

TRANSPORT UNIT - The Turbo Start 2000 is easily transported us-

CONNECT AC POWER CORD TO UNIT (

).- - Ensure 120 or 240 VAC power cord is properly connected to

CHECK FUSE WINDOW FOR PROPER SET-

Unit shall be in horizontal position to

. After approximately

NOTE

When all LED status indicator bars illuminate, both the converter and

power cells are supplying 24 VDC power output for current demands

above 21 amps (see paragraph 3-4).

5. ENGINE STARTING - UNPLUG AC POWER CORD BEFORE STARTING

ENGINE WITH TURBO START. (see paragraph 4-6.). Prior to engine

start, ensure power cell charge is sufficient to provide an efficient

engine start (see paragraph 3-7).

6. REMOVING DC POWER SUPPLY FROM AIRCRAFT

a. Remove DC power cable GPU connector from aircraft.

b. Remove DC power cable connector from Turbo Start

Page 22

(if necessary).

4-4

4-8 28.5 VDC GROUND POWER (WITH 120/240 VAC POWER) SYSTEM LOW POWER

DEMAND (20 amps or less).

1. TRANSPORT UNIT - The Turbo Start 2000 is easily transported using the wheels that are incorparated into the unit. The AXEL

EXTENTION kit (included with the unit) ensures that the Turbo Start

2000 is stable. The unit is engineered to be pushed rather than

pulled.

2. CONNECT AC POWER CORD TO UNIT (

TING

).- Ensure 120 or 240 VAC power cord is properly connected to an

approved AC power supply.

Unit shall be in horizontal position to

ensure unit’s vent ports are free from blockage

5-8 seconds, unit’s LED status indicator will illuminate indicating

power cell state of charge. Cooling fan will operate. Ensure LED

status indicator and cooling fan are operational prior to continuing

to step 3.

3. CONNECT DC POWER CABLE TO UNIT - Ensure power cable connector is

fully seated into unit’s receptacle.

4. CONNECT DC POWER CABLE TO AIRCRAFT - Connect to aircraft ground

power receptacle. DC bus power should come on and aircraft volt

meter should indicate 28.5 VDC to 27 VDC (26.5 VDC minimum). If aircraft power demand is less than 20 amps converter output will remain

at 28.5 VDC (only one GREEN LED status indicator bar will illuminate). If aircraft power demand exceeds 20 amps converter voltage

output will decrease and two or more LED status indicator bars will

illuminate (see paragraph 3-4, and 7-4.4.).

CHECK FUSE WINDOW FOR PROPER SET-

. After approximately

5. REMOVING POWER SUPPLY FROM AIRCRAFT

a. Remove DC power cable GPU connector from aircraft.

b. Remove DC power cable connector from Turbo Start (if neces-

sary).

4-9 POWER CELL RECHARGE

1. CONNECT AC POWER CORD TO UNIT -

sition to ensure unit’s vent ports are free from blockage

FUSE WINDOW FOR PROPER SETTING

properly connected to an approved AC power supply. After approximately 5-8 seconds, ensure unit’s LED status indicator illuminates

).- Ensure 120 or 240 VAC power cord is

Unit shall be in horizontal po-

. (

CHECK

Page 23

indicating power cell state of charge and cooling fan is operating.

4-5

CAUTION

Unit may overheat if cooling fan fails.

Do not operate if cooling fan fails.

2.

charge indicator should show a single steady or flashing green LED

bar when fully charged, the last LED bar. AC power may be left connected to unit when power cells are fully charged.

CHECK FOR FULL CHARGE INDICATION - After 2 HR 30 minutes, LED

NOTE

Under a full charge, two things will be observable with the unit. A

non-blinking lighted green bar or a blinking green bar at the bottom

of the bar graph, both indicate a full charge.Also the fan will dis-

play ratcheting but not come on whe the unit is fully charged.

Page 24

4-6

SECTION III.

FUNCTIONAL CHECK PROCEDURES

4-10. FUNCTIONAL CHECK PROCEDURES

This section deals with normal functional check procedures, and includes all steps necessary to ensure the Turbo Start 2000 is functioning within specific operational parameters prior to operational

use. As users gain experience with the Turbo Start 2000, they will

incorporate these functional checks as a routine practice.

4-11. REQUIRED EQUIPMENT FOR FUNCTIONAL CHECK.

FLUKE OR EQUIVALENT TYPE DIGITAL MULTIMETER.

4-12. DC FUNCTIONAL CHECK.

1. CHECK UNIT FOR EVIDENCE OF DAMAGE - Check for dents, punctures,

case distortion or misalignment, cracked or loose connectors. If no

damage is evident proceed to step two.

IF DAMAGE IS EVIDENT contact distributor or manufacturer.

2. ENSURE UNIT IS NOT PLUGGED INTO 120 OR 240 VDC. Unplug AC power

if plugged in.

3. CHECK UNIT INTERNAL RESISTANCE (TEST FOR SHORTS) - Better than 10

Megohms. Ensure no short exists.

Negative (-) DC receptacle terminal and unit case.

Positive (+) DC receptacle terminal and unit case.

4. CHECK DC VOLTAGE READING AT DC RECEPTACLE TERMINALS.

24 to 25.5 VDC depending on state of charge.

5. PLUG IN 120 OR 240 POWER CORD. (

TING

).-Ensure power unit is connected to a suitable AC power source

(120 USA or 240 European).

6. CHECK UNIT FOR STATE OF CHARGE -

position to ensure unit’s vent ports are free from blockage

approximately 5-8 seconds, unit LED status indicator shall illuminate

indicating power cell state of charge. Ensure LED status indicator

CHECK FUSE WINDOW FOR PROPER SET-

Unit shall be in horizontal

. After

Page 25

and cooling fan are operational. Prior to continuing to step 7, the

LED status indicator should show a single green bar (last LED bar) to

indicate the unit’s power cells are fully charged. Also under full

charge the fan will ratchet but not enable.

4−7

NOTE

Under a full charge, the last green LED bar may blink. This does not

indicate a malfunction. A nonblinking lighted green bar or a blinking

green bar at the bottom of the LED column, both indicate a full

charge.

7. CHECK DC VOLTAGE READING AT DC RECEPTACLE TERMINALS. Ensure

power cells are fully charged (see step 6.)

28.5 (+-0.57 VDC) with power cells at full state of charge.

8. FUNCTIONAL CHECK COMPLETE - Unit should remain plugged in to AC

power until required for use.

Page 26

4−8

CHAPTER 5

PERFORMANCE DATA

SECTION 1. INTRODUCTION

5-1. PURPOSE

This chapter provides performance data for the TI2000GPU-24 (Turbo

Start 2 000). Continual reference to this information will enable the

user to obtain maximum performance, utilization and service life from

the Turbo Start. Although maximum performance is not always required,

regular referral to this chapter is recommended for the following reasons:

a. To generate knowledge of unit’s performance margins to enable

the operator to make sound judgment when unexpected conditions or

alternate operational requirements are encountered.

b. To enable the user to readily recognize situations requiring

maximum performance.

c. To gain experience in accurately estimating the effects of

variables for which data is not presented.

d. To help the operator determine if an aircraft system malfunction exists by comparing actual performance with expected performance.

NOTE

The information provided in this chapter is primarily intended for

operational planning and is most useful when planning operations under

unfamiliar conditions or environmental extremes. The data may also be

used to establish local operating procedures and to ensure unit’s

operational life is maximized.

5-2. GENERAL

The data presented covers the maximum range of conditions and performance that can reasonably be expected. In each area of performance,

the effects of temperature and DC electrical load demand relating to

Page 27

the ground power support requirements are presented. Wherever practical, data is presented conservatively. However, NO GENERAL CONSERVATISM

HAS BEEN APPLIED. All performance data presented is within the applicable limits of the Turbo Start.

5-1

SECTION II

DATA CRITERIA

5-3 DATA BASIS

The type of data used is indicated at the bottom of each performance

chart under DATA BASIS. The applicable report and date of the data

are also given. The data provided generally are based on one of

three categories:

a.

obtained on a similar unit type.

b.

unit type placed under a controlled test.

c.

ics, mathematics, and electrical engineering principles and concepts, but not verified by tests.

5-4. SPECIFIC CONDITIONS

The data presented are accurate only for specific conditions listed

under the title of each chart or graph. Variables for which data are

not presented, but which may affect that phase of performance, are

discussed in associated text. Where data are available or reasonable

estimates can be made, the amount that each variable affects performance will be given.

5-5. GENERAL CONDITIONS

In addition to the specific conditions, the following general conditions are applicable to the performance data.

Derived From Actual Controlled Testing.

Calculated Data.

Estimated Data

Data based on tests, but not on a similar

. Data based on estimates using rules of phys-

Controlled test data

a.

vidual aircraft of the same make and model are known to exist due

to variations in DC electrical system efficiency. These differences, however, are considered insignificant and are not individually accounted for.

b.

Variation in Aircraft.

Power demand differences between indi-

Ground Support and Aircraft Instrument Variations.

The data

Page 28

shown in the performance charts do not account for instrument toler-

ance differences or inaccuracies.

5-6. DEFINITIONS OF ABBREVIATIONS

Unless otherwise indicated, the abbreviations defined in Chapter 1 will

be applicable to all charts and graphs in this chapter.

5-2

FIGURE 5-1

Page 29

OUTPUT VOLTAGE

TI2000GPU-24 OUTPUT VOLTAGE

24

20

16

5-3

12

8

4

0

0

10 20

30

40

50

60

MINUTES

46 AMP CONSTANT CURRENT LOAD

FIGURE 5-2

Page 30

MAXIMUM OUTPUT CURRENT

3000

2700

2400

2100

1800

1500

AMPS

1200

900

600

300

*

*

*

*

*

*

*

*

*

(+25 C Temp)

*

*

*

(-29 C Temp)

0

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

5-4

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

0

0

0

Calculations based on actual test data at Pratt-Whitney Canada on 30 March 1992.

5

10

15

SECONDS

FIGURE 5-3

20

25

30

Page 31

5-5

CHAPTER 6

CARE AND MAINTENANCE

SECTION I. UNIT CARE

6-1. GENERAL

Although the TI2000GPU-24 (Turbo Start 2000) has been ruggedized

and made weather resistant within the scope of unit’s intended use,

it is essential that good general care be taken to maintain unit in

good operating condition and to maximize unit’s operational life.

6-2. AFTER USE - Unit should be protected from the environmental

elements and man made hazards. Ideally unit should be secured in a

building or shed. Most importantly, unit shall be fully covered if

stored exposed to environmental elements.

1. KEEP UNIT RECEPTACLES AND OUTER CASE CLEAN - wipe with dry cloth.

2. KEEP FOREIGN OBJECTS OUT OF UNIT - Cover unit to prevent

foreign objects, water, and dirt from entering vent ports and recep-

tacles.

3. KEEP FROM PROLONGED EXPOSURE TO EXTREMELY DAMP ENVIRONMENTS

Cover unit to prevent migration of moisture. If unit is operated in

extremely damp environments unit should be kept in an environmentally

controlled building.

4. KEEP UNIT PLUGGED INTO AC POWER SUPPLY WHEN NOT IN USE. (

FUSE WINDOW FOR PROPER SETTING

to ensure unit is always ready for use, unit should remained plugged

in to AC power when not in use. NEVER LET DISCHARGED UNIT SIT FOR

MORE THAN 24 HOURS WITHOUT FULLY RECHARGING POWER CELLS.

5. PROTECT DC POWER CABLE AND AC POWER CORD FROM DAMAGE - Prevent

from being cut, gouged, crushed, dragged or otherwise abused.

). To maximize life of power cells and

CHECK

Page 32

6-1

SECTION II.

MAINTENANCE

6-3. MAINTENANCE OF UNIT - The Turbo Start 2000 is a maintenance-

free unit, no repairs are authorized. Warranty will be void if unit

is tampered with. If unit fails to operate contact Manufactures Warranty Claim (see unit warranty).

WARRENTY VOID STICKERS

Page 33

Chapter 7

Push To Test Modification

General Information And Operation

7-1. General

THIS MODIFICATION HAS BECOME STANDARD EQUIPMENT FOR EACH OF OUR

UNITS. BOTH MILITARY AND CIVILIAN CLIENTS HAVE FOUND THIS MODIFICATION TO BE CRITICAL TO THEIR OPERATION. THE PUSH TO TEST BUTTON IS

USED TO INDICATE THE CAPACITY OF THE POWER CELLS WITHOUT APPLYING AC

INPUT POWER. IT ALLOWS THE END USER TO CHECK THE STATUS OF THE POWER

CELLS. THIS LETS THE OPERATOR KNOW IF THERE IS ENOUGH POWER TO PERFORM ANOTHER ENGINE START, OR IF THE UNIT HAS TO BE RETURNED TO AC

POWER TO ALLOW IT TO RECHARGE.

7-2. OPERATION

1) MAKE SURE THAT YOU WAIT AT LEAST 2 MINUTES AFTER AC POWER IS APPLIED, OR

DC POWER IS EXTRACTED FROM THE UNIT, BEFORE YOU DEPRESS THE PUSH TO TEST

BUTTON. THIS WILL ENSURE A CORRECT READING.

2) WITHOUT AC POWER INPUT OR DC POWER OUTPUT, SIMPLY DEPRESS THE PUSH TO TEST

BUTTON ON THE FACE PLATE AND HOLD FOR APPROXIMATELY 15 SECONDS.

3) AT THIS TIME THE LED BAR GRAPH SHOULD LIGHT UP INDICATING THE STATUS OF

THE POWER CELLS.

4) THE FAN SHOULD ALSO OPERATE AT THIS TIME. IF YOU DO NOT HEAR THE FAN

RUNNING, STOP DEPRESSING THE BUTTON AND CHECK FOR ANY OBSTRUCTIONS TO THE

FAN.

5) NEVER DEPRESS THE PUSH TO TEST BUTTON WHILE THE UNIT IS PLUGGED INTO AC

POWER FOR RECHARGE, OR PLUGGED INTO AIRCRAFT FOR DC POWER OUTPUT.

6) NEVER DEPRESS THE PUSH TO TEST BUTTON FOR MORE THAN 30 SECONDS. THIS MAY

CAUSE A TEMPERATURE SENSOR TO TEMPORARILY DISRUPT PUSH TO TEST FUNCTION. (IF

THIS SENSOR IS TRIPPED, ALLOW TEN MINUTES FOR UNIT TO COOL BEFORE OPERATING

PUSH TO TEST BUTTON.)

7-1

ST ATUS

R

Y

G

0

1/2

OK

Page 34

PARAGRAPH INDEX

120-240 VAC Charger and AC to DC Converter Limits, 3-4

24 VDC Ground Power (NO 120 or 240 VAC Power Supply) Engine Starting

or DC system Power, 4-6

24 VDC Ground Power (With 120/240 VAC Power) System High Power Demand

(21-1500 Amps) or Engine Starting, 4-7

28.5 VDC Ground Power (with 120/240 VAC Power) System Low Power Demand (20 Amps or less), 4-8

Abbreviations, 1-5

AC Power Cord Limits, 3-5

After Use, 6-2

Appendix A Line Cord Table

Before Operation Check, 4-5

Continuous Output Rate, 28.5 VDC Constant Output, 3-8

Data Basis, 5-3

DC Functional Check, 4-12

Definitions of Abbreviations, 5-6

Dimensions, Figure 2-1

Discharge Load Curve, Figure 5-2

Description 1-3

Engine Starting Power, 3-9

Environmental, 3-11

Functional Check Procedures, 4-10

Forms and Records, 1-6

General, Chapter 1, 1-1

General, Chapter 2, 2-1

General, Chapter 3, 3-2

General, Chapter 4, 4-1

General, Chapter 5, 5-2

General, Chapter 6, 6-1

General Conditions, 5-5

General Details, Figure 2-2

General Specifications, 2-2

Page 35

PARAGRAPH INDEX

Index, 1-4

Maintenance of Unit, 6-3

Maximum Output Current, Figure 5-3

One (1) Hour Rate, 24 VDC Constant Output, 3-6

Operating Limits and Restrictions, 4-2

Operating Procedures, 4-4

Operating Position, 3-12

Performance, 4-3

Power Cell Recharge, 4-9

Power Cell Recharge Limits, 3-3

Purpose, Chapter 3, 3-1

Purpose, Chapter 5, 5-1

Rated Peak Output (Engine Starting), 3-7

Required Equipment for Functional Check, 4-11

Specific Conditions, 5-4

Temperature, 3-10

Temperature Conversion Chart, Figure 5-1

Unit Operation During Aircraft Fueling/Defueling, 3-13

Use of Word Shall, Should and May, 1-7

Warning, Caution and Notes Defined, 1-2

Page 36

APPENDIX A

OPTIONAL LINE CORDS FOR WORLDWIDE OPERATIONS

COUNTRY VOLTS HZ TESLA PART #

Afganistan 220 50 TI25000-004 Old British Line Cord Set

Algeria 220 50 TI25000-004 Old British Line Cord Set

American Samoa 240 60 TI25000-011 Australian Line Cord Set

Angola 220 50 TI25000-100 Europlug Line Cord Set

Anguilla (U.K.) 240 50 TI25000-005 United Kingdom Line Cord Set

Antigua 230 60 TI25000-005 United Kingdom Line Cord Set

Argentina 220 50 TI25000-011 Australian Line Cord Set

Aruba 115 60 TI25000-001 North American Line Cord Set

Australia 240 50 TI25000-011 Australian Line Cord Set

Austria 220 50 TI25000-003 Cont. European Line Cord Set

Azores (Portugal) 220 50 TI25000-004 Old British Line Cord Set

Bahamas 120 60 TI25000-001 North American Line Cord Set

Bahrain 220 50 TI25000-005 United Kingdom Line Cord Set

Bangladesh 220 50 TI25000-004 Old British Line Cord Set

Barbados 115 50 TI25000-001 North American Line Cord Set

Belguim 220 50 TI25000-003 Cont. European Line Cord Set

Belize (Br. Hond.) 110 60 TI25000-001 North American Line Cord Set

Benon 220 50 TI25000-004 Old British Line Cord Set

Bermuda 120 60 TI25000-005 United Kingdom Line Cord Set

Bolivia 220 50 TI25000-003 Cont. European Line Cord Set

Botswana 220 50 TI25000-005 United Kingdom Line Cord Set

Brazil 110 60 TI25000-001 North American Line Cord Set

Bulgaria 220 50 TI25000-003 Cont. European Line Cord Set

Burkina Faso 220 50 TI25000-100 Europlug Line Cord Set

Burma (Now Myanmar) 230 50 TI25000-005 United Kingdom Line Cord Set

Burundi 220 50 TI25000-003 Cont. European Line Cord Set

Cambodia 220 50 TI25000-100 Europlug Line Cord Set

Cameroon 230 50 TI25000-003 Cont. European Line Cord Set

Canada 120 60 TI25000-001 North American Line Cord Set

Canary Islands (Spain) 220 b TI25000-003 Cont. European Line Cord Set

Cape Verde, Rep. of 220 50 TI25000-003 Cont. European Line Cord Set

Cayman Islands 120 60 TI25000-001 North American Line Cord Set

Central African Republic 220 50 TI25000-100 Europlug Line Cord Set

Chad 220 50 TI25000-003 Cont. European Line Cord Set

Channel Islands 240 50 TI25000-005 United Kingdom Line Cord Set

Chile 220 50 TI25000-002 Italian Line Cord Set

China, Peoples Republic of 220 50 TI25000-011 Australian Line Cord Set

Christmas Island (Australia) 240 50 TI25000-011 Australian Line Cord Set

Cocos Islands (Australia) 240 50 TI25000-011 Australian Line Cord Set

Columbia 220 60 TI25000-100 Europlug Line Cord Set

Congo, Republic of 220 50 TI25000-100 Europlug Line Cord Set

Cook Island (New Zealand) 240 50 TI25000-011 Australian Line Cord Set

Costa Rica 12 0 60 TI25000-001 North American Line Cord Set

Curacao Islands 110 60 TI25000-001 North American Line Cord Set

Cyprus 240 50 TI25000-005 United Kingdom Line Cord Set

Czech, Republic of 220 50 TI25000-003 Cont. European Line Cord Set

Denmark 220 50 TI25000-300 Denmark Line Cord Set

Djibouti, Republic of 22 0 50 TI25000-003 Cont. European Line Cord Set

Dominica 230 50 TI25000-005 United Kingdom Line Cord Set

Dominican Republic 110 60 TI25000-001 North American Line Cord Set

A-1

Page 37

APPENDIX A (Cont.)

OPTIONAL LINE CORDS FOR WORLDWIDE OPERATIONS

COUNTRY VOLTS HZ TESLA PART #

Ecuador 120 60 TI25000-001 North American Line Cord Set

Egypt 220 50 TI25000-100 Europlug Line Cord Set

El Salvador 115 60 TI25000-001 North American Line Cord Set

England 240 50 TI25000-005 United Kingdom Line Cord Set

Equatorial Guinea 220 50 TI25000-100 Europlug Line Cord Set

Estonia 220 50 TI25000-003 Cont. European Line Cord Set

Ethiopia 220 50 TI25000-003 Cont. European Line Cord Set

Fiji 240 50 TI25000-011 Australian Line Cord Set

Finland 220 50 TI25000-003 Cont. European Line Cord Set

France 220 50 TI25000-003 Cont. European Line Cord Set

French Guiana 220 50 TI25000-003 Cont. European Line Cord Set

Gabon 220 50 TI25000-003 Cont. European Line Cord Set

Gambia 220 50 TI25000-005 United Kingdom Line Cord Set

Georgia 220 50 TI25000-003 Cont. European Line Cord Set

Germany 220 50 TI25000-003 Cont. European Line Cord Set

Ghana 220 50 TI25000-005 United Kingdom Line Cord Set

Gibraltar 240 50 TI25000-005 United Kingdom Line Cord Set

Greece 220 50 TI25000-003 Cont. European Line Cord Set

Greenland (Denmark) 220 50 TI25000-300 Denmark Line Cord Set

Grenada 230 50 TI25000-005 United Kingdom Line Cord Set

Guadeloupe 220 50 TI25000-003 Cont. European Line Cord Set

Guam 110-120 6 0 TI25000-001 North American Line Cord Set

Guatemala 120 60 TI25000-001 North American Line Cord Set

Guinea 220 50 TI25000-003 Cont. European Line Cord Set

Guinea-Bissau 220 50 TI25000-003 Cont. European Line Cord Set

Guyana 110 50/60 TI25000-001 North American Line Cord Set

Haiti 110-120 50-60 TI25000-001 North American Line Cord Set

Honduras 110 60 TI25000-001 North American Line Cord Set

Hong Kong 22 0 50 TI25000-005 United Kingdom Line Cord Set

Hungary 220 50 TI25000-003 Cont. European Line Cord Set

Iceland 220 50 TI25000-003 Cont. European Line Cord Set

India 220-250 50 TI25000-004 Old British Line Cord Set

Indonesia 220 50 TI25000-003 Cont. European Line Cord Set

Iran 220 50 TI25000-003 Cont. European Line Cord Set

Iraq 220 50 TI25000-005 United Kingdom Line Cord Set

Ireland, Republic of 220 5 0 TI25000-005 United Kingdom Line Cord Set

Isle of Man 240 5 0 TI25000-005 United Kingdom Line Cord Set

Israel 230 50 TI25000-200 Israel Line Cord Set

Italy 220 50 TI25000-002 Italy Line Cord Set

Ivory Coast 220 5 0 TI25000-100 Europlug Line Cord Set

Jamaica 110 50 TI25000-001 North American Line Cord Set

Japan 110 50/60 TI25000-001 North American Line Cord Set

Jordan 220 50 TI25000-005 United Kingdom Line Cord Set

Kenya 240 50 TI25000-005 United Kingdom Line Cord Set

Korea, South 220 60 TI25000-003 Cont. European Line Cord Set

Kuwait 240 50 TI25000-005 United Kingdom Line Cord Set

A-2

Page 38

APPENDIX A (Cont.)

OPTIONAL LINE CORDS FOR WORLDWIDE OPERATIONS

COUNTRY VOLTS HZ TESLA PART #

Laos 220 50 TI25000-001 North American Line Cord Set

Latvia 220 50 TI25000-003 Cont. European Line Cord Set

Lebanon 220 50 TI25000-100 Europlug Line Cord Set

Lesotho 240 50 TI25000-004 Old British Line Cord Set

Liberia 120 60 TI25000-005 United Kingdom Line Cord Set

Liechtenstein 220 50 TI25000-006 Switzerland Line Cord Set

Lithuania 220 50 TI25000-003 Cont. European Line Cord Set

Luxembourg 220 50 TI25000-003 Cont. European Line Cord Set

Libya 230 50 TI25000-002 Italy Line Cord Set

Macao 220 50 TI25000-004 Old British Line Cord Set

Madagascar 220 50 TI25000-003 Cont. European Line Cord Set

Maderia (Portugal) 220 50 TI25000-004 Old British Line Cord Set

Majorca 220 50 TI25000-003 Cont. European Line Cord Set

Malawi 230 50 TI25000-005 United Kingdom Line Cord Set

Malaysia 240 50 TI25000-005 United Kingdom Line Cord Set

Maldives 230 50 TI25000-004 Old British Line Cord Set

Mali, Republic of 22 0 50 TI25000-003 Cont. European Line Cord Set

Malta 240 50 TI25000-005 United Kingdom Line Cord Set

Martinique 220 50 TI25000-003 Cont. European Line Cord Set

Mauritania 220 50 TI25000-100 Europlug Line Cord Set

Mauritius 230 50 TI25000-005 United Kingdom Line Cord Set

Mexico 127 60 TI25000-001 North American Line Cord Set

Monaco 220 50 TI25000-003 Cont. European Line Cord Set

Mongolia 220 50 TI25000-100 Europlug Line Cord Set

Montseurrat 230 60 TI25000-005 United Kingdom Line Cord Set

Morocco 220 50 TI25000-003 Cont. European Line Cord Set

Mozambique 220 50 TI25000-003 Cont. European Line Cord Set

Namibia (W.S. Africa) 220-250 50 TI25000-004 Old British Line Cord Set

Nepal 220 50 TI25000-004 Old British Line Cord Set

Neth. Antilles 220 50/60 TI25000-003 Cont. European Line Cord Set

Netherlands 220 50 TI25000-003 Cont. European Line Cord Set

New Caledonia 220 50 TI25000-003 Cont. European Line Cord Set

New Zealand 230 50 TI25000-011 Australian Line Cord Set

Nicaragua 120 60 TI25000-001 North American Line Cord Set

Niger 220 50 TI25000-100 Europlug Line Cord Set

Nigeria 230 50 TI25000-005 United Kingdom Line Cord Set

Norfolk Islands (Australia) 240 50 TI25000-011 Australian Line Cord Set

North Ireland 220 50 TI25000-005 United Kingdom Line Cord Set

North Mariana Islands (U.S.) 1 15 60 TI25000-001 North American Line Cord Set

Norway 220 50 TI25000-003 Cont. European Line Cord Set

Okinawa 100-120 60 TI25000-001 North American Line Cord Set

Oman 240 50 TI25000-005 United Kingdom Line Cord Set

Pakistan 230 50 TI25000-004 Old British Line Cord Set

Panama 110 60 TI25000-001 North American Line Cord Set

Papua New Guinea 240 50 TI25000-011 Australian Line Cord Set

Paraguay 220 50 TI25000-100 Europlug Line Cord Set

Peru 110 50/60 TI25000-001 North American Line Cord Set

Philippines 115 60 TI25000-001 North American Line Cord Set]

Piccairn Islands (U.K.) 240 50 TI25000-004 Old British Line Cord Set

Poland 220 50 TI25000-003 Cont. European Line Cord Set

Portugal 220 50 TI25000-003 Cont. European Line Cord Set

Puerto Rico 120 60 TI25000-001 North American Line Cord Set

Qatar 240 50 TI25000-005 United Kingdom Line Cord Set

A-3

Page 39

APPENDIX A (Cont.)

OPTIONAL LINE CORDS FOR WORLDWIDE OPERATIONS

COUNTRY VOLTS HZ TESLA PART #

Romania 220 50 TI25000-003 Cont. European Line Cord Set

Russia 220 50 TI25000-003 Cont. European Line Cord Set

Rwanda 220 50 TI25000-100 Europlug Line Cord Set

Saudia Arabia 220 50/60 TI25000-003 Cont. European Line Cord Set

Scotland 220 50 TI25000-005 United Kingdom Line Cord Set

Senegal 220 50 TI25000-003 Cont. European Line Cord Set

Seychelles 240 50 TI25000-005 United Kingdom Line Cord Set

Sierra Leone 230 50 TI25000-005 United Kingdom Line Cord Set

Singapore 230 50 TI25000-005 United Kingdom Line Cord Set

Slovakia 220 50 TI25000-003 Cont. European Line Cord Set

Somalia 220 50 TI25000-003 Cont. European Line Cord Set

South Africa 220-250 50 TI25000-004 Old British Line Cord Set

Spain 220 50 TI25000-003 Cont. European Line Cord Set

Sri Lanka 23 0 50 TI25000-004 Old British Line Cord Set

St. Pierre & Miquelon (France) 115 6 0 TI25000-001 North American Line Cord Set

St. Kitts & Nevis 230 60 TI25000-005 United Kingdom Line Cord Set

St. Lucia 24 0 50 TI25000-005 United Kingdom Line Cord Set

St. Vincent 230 50 TI25000-005 United Kingdom Line Cord Set

Sudan 240 50 TI25000-005 United Kingdom Line Cord Set

Surinam 115 60 TI25000-003 Cont. European Line Cord Set

Svalbard (Norway) 220 50 TI25000-003 Cont. European Line Cord Set

Swaziland 230 50 TI25000-004 Old British Line Cord Set

Sweden 220 50 TI25000-003 Cont. European Line Cord Set

Switzerland 220 50 TI25000-006 Switzerland Line Cord Set

Syria 220 50 TI25000-100 Europlug Line Cord Set

Tahiti 220 50 TI25000-003 Cont. European Line Cord Set

Taiwan 110 60 TI25000-001 North American Line Cord Set

Tanzania 230 50 TI25000-005 United Kingdom Line Cord Set

Thailand 220 50 TI25000-100 Europlug Line Cord Set

Togo 220 50 TI25000-003 Cont. European Line Cord Set

Tonga 115 60 TI25000-004 Old British Line Cord Set

Trinadad & Tobango 230 6 0 TI25000-005 United Kingdom Line Cord Set

Tunisia 220 50 TI25000-100 Europlug Line Cord Set

Turkey 220 50 TI25000-003 Cont. European Line Cord Set

Uganda 220 50 TI25000-004 Old British Line Cord Set

United Arab Emir. 22 0 50 TI25000-005 United Kingdom Line Cord Set

United Kingdom & Ireland 240 5 0 TI25000-005 United Kingdom Line Cord Set

United States 120 60 TI25000-001 North American Line Cord Set

Uraguay 220 50 TI25000-011 Australian Line Cord Set

Venezuela 120 60 TI25000-001 North American Line Cord Set

Vietnam 220 50 TI25000-003 Cont. European Line Cord Set

Virgin Islands 120 60 TI25000-001 North American Line Cord Set

Wales 220 50 TI25000-005 United Kingdom Line Cord Set

Western Samoa 230 50 TI25000-005 United Kingdom Line Cord Set

Yemen 220 50 TI25000-005 United Kingdom Line Cord Set

Yugoslavia 220 50 TI25000-003 Cont. European Line Cord Set

Zaire, Republic of 220 5 0 TI25000-003 Cont. European Line Cord Set

Zambia 220 50 TI25000-005 United Kingdom Line Cord Set

Zimbabwe 220 50 TI25000-005 United Kingdom Line Cord Set

A-4

Page 40

APPENDIX A (Cont.)

UNIVERSAL LINE CORD KIT FOR WORLDWIDE OPERATIONS

NOTE: TESLA UNIVERSAL AC LINE CORD KIT, P/N: TI25000-U00, IS FOR

UNITS ORIGINALLY BUILT WITH THE UNIVERSAL AC LINE CORD OPTION ONLY.

THE AC ADAPTER OPTION IS TESLA P/N TI16000-19 AND MUST BE ORDERED

WITH THE ORIGINAL PROCUREMENT OF UNIT(S). UNIT(S) MAY BE RETURNED TO

TESLA INDUSTRIES, FOR A NOMINAL COST, AND MODIFIED TO ALLOW OPERATION

WITH THE UNIVERSAL AC LINE CORD KIT.

TESLA UNIVERSAL AC LINE CORD KIT, P/N: TI25000-U00, IS COMPRISED OF

THE FOLLOWING FOUR PART NUMBERS:

TI25000-U01 NORTH AMERICAN LINE CORD

TI25000-U04 OLD BRITISH LINE CORD

TI25000-U03 EUROPEAN 10A/250V

TI25000-U05 ENGLAND 10A/250V

TESLA REPLACEMENT 8 FOOT DC POWER CORD, P/N: TI2006-501, IS AVAILABLE

UPON REQUEST. (CUSTOM LENGTHS ARE ALSO AVAILABLE TO SUIT THE CUSTOMERS OPERATIONAL REQUIREMENTS.)

A-5

Loading...

Loading...