Page 1

TI150 Series Battery

Power Anytime, Anywhere

Charger/Conditioner

TI15014-120-240 (12V)

TI15028-120-240 (24V)

User Manual

Built Smart...Proven Tough

Tesla Industries, Inc.

101 Centerpoint Blvd.

New Castle, DE 19720

(302) 324-8910 Phone

(302) 324-8912 Fax

www.teslaind.com

Page 2

NOTE: All users must read this entire manual prior to operating

the TI150 Series Battery Charger/Conditioner.

The TI150 Battery Charger/Conditioner is a limited maintenance-free and sealed unit. No repairs are authorized. Warranty will be voided if unit is tampered with in any way, or if unauthorized repairs are made.

For technical support please contact:

TESLA™ INDUSTRIES INCORPORATED

101 CENTERPOINT BLVD.

CENTERPOINT INDUSTRIAL PARK

NEW CASTLE, DELAWARE 19720

PHONE: (302) 324-8910

FAX: (302) 324-8912

WEBSITE: www.teslaind.com

EMAIL: tesla1@teslaind.com

CAUTION

Improper use or failure to follow instructions in this user manual can result in unit damage and/or injury or

death by electrical shock.

Any attempts to open or examine the inside of this unit via a tool or device (borescope, probe, etc.) can

result in unit failure and/or injury by electrical shock. This unit is mainte nance free and should not be

opened or disassembled for any reason.

Always protect the unit from short circuit.

Shipping Hazards: NONE

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying, recording, or any information storage and retrieval system, without

prior written permission from Tesla™ Industries, Inc.

Shock Hazard Potential

Copyright © 2014 by Tesla™ Industries, Incorporated. All rights reserved.

06-05-14

Page 3

Table of Contents

Section 1 – Safety Review 1

1.1 – Safety Notices 1

1.2 – Symbols 1

1.3 – Water Hazards 2

1.4 – Important Safety Precautions 2

Section 2 – Product Overview 3

2.1 – Introduction 3

2.2 – Indication of Terms: Shall, Should, and May 3

2.3 – Front and Top Panel Overview 4

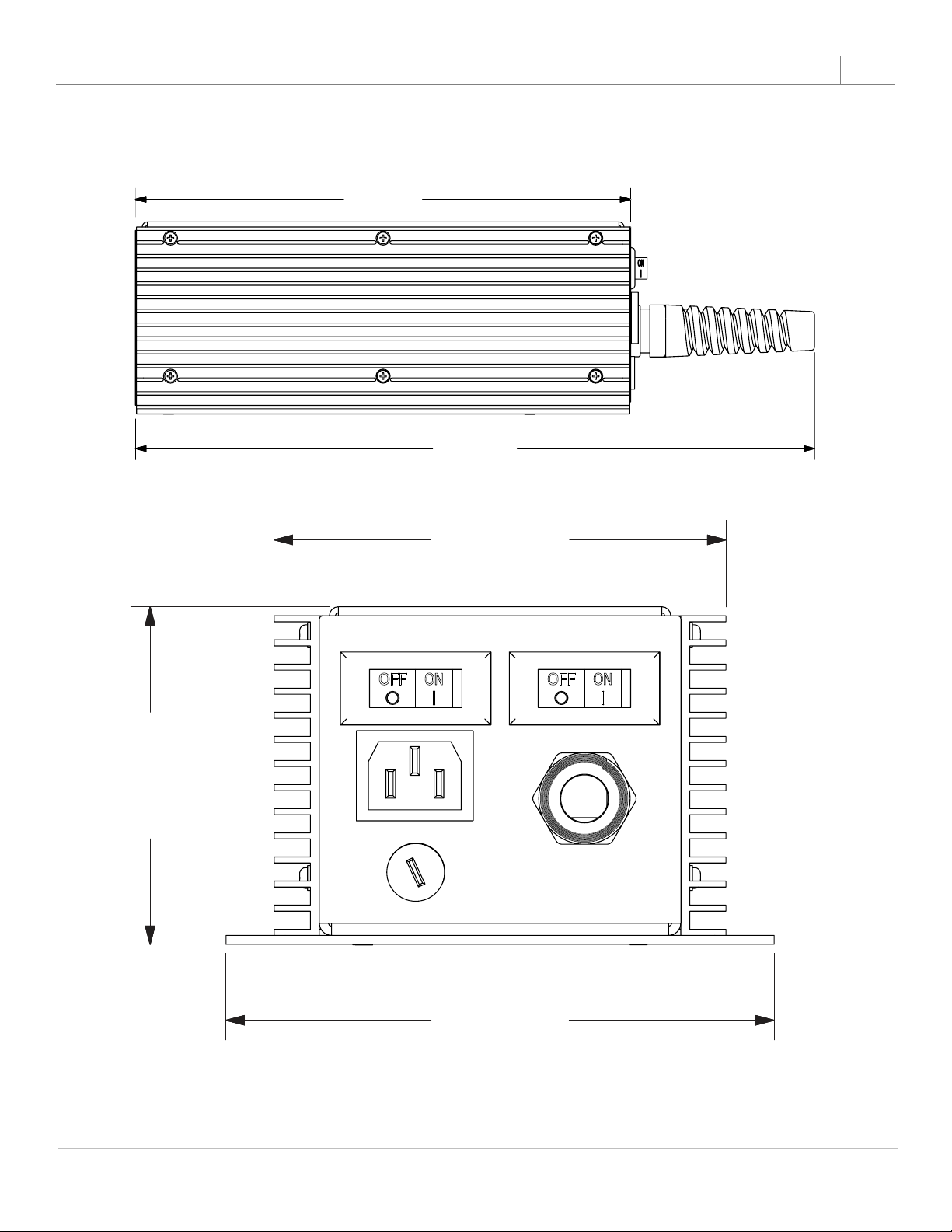

2.4 – Physical Dimensions 5

2.5 – General Specications 6

2.6 – Airow Ports 7

Section 3 – Features Overview 8

3.1 – AC Input Receptacle 8

3.1a – IEC Line Cord Options 8

3.2 – AC Input Selector Switch 8

3.3 – AC Input Circuit Breaker 9

3.4 – DC Output Cable 9

3.5 – DC Output Circuit Breaker 9

3.6 – Charge Level Indicator 10

3.7 – Integrated Heatsinks 10

3.8 – Mounting Base 10-11

Section 4 – Pre-Operation Procedures 12

4.1 – Installing the Charger 12

4.2 – Attaching AC Power 12

4.3 – Attaching the DC Power Cable 13-14

TI150 Series Battery Charger/Conditioner

Page 4

Section 5 – Operating Procedures 15

5.1 – Unit Care 15

5.2 – Connecting the Battery Charger 15

5.3 – After Operation 15-16

Section 6 – Unit Care and Maintenance 17

6.1 – Unit Care 17

6.2 – Normal Function Test Procedures 18-19

6.3 – Unit Servicing 20

6.4 – Packaging and Shipping 20

Section 7 – Frequently Asked Questions 21

Section 8 – Troubleshooting 22-23

Section 9 – Optional Accessories 24

9.1 – TI2007-013 Mini NATO Quick Disconnect Cable Assembly 24

9.2 – TI2007-019 Mini DC to 10AWG Quick Disconnect Cable Assembly 24

9.3 – Cobra™ DC Replacement Contacts and Tools 24

Section 10 – Performance Data 25

10.1 – Purpose 25

10.2 – Explanation of Data 25

10.3 – Denition of Abbreviations 25

10.4 – Performance Graph 25

10.5 – Temperature Conversion Chart 26

Glossary 27

Repair Request Form 28

TI150 Series Battery Charger/Conditioner

Page 5

Abbreviations and Symbols

Abbreviations that may be used within the text, headings and titles of this manual.

LIST OF ABBREVIATIONS

Abbreviation Defi nition

ac Alternating Current

AFT Air ow Technology

AWG American Wire Gauge

amp or A Ampere

cont Continuous

°C Degree Celsius

°F Degree Fahrenheit

dc Direct Current

EFF Ef ciency

ft Feet

FWD Forward

GPU Ground Power Unit

Hr Hour

Hz Hertz

kg Kilograms

kHz Kilohertz

kW Kilowatts

LED Light Emitting Diode

max Maximum

MΩ megaohm

min Minimum

MPU Micro Power Unit

NEMA National Electrical Manufacturers Association

Ω ohm

PF power factor

PFC power factor correction

rms root-mean-square

THD Total Harmonic Distortion

TMDE Test, Measurement, & Diagnostic Equipment

UAV Unmanned aerial vehicle

Vac Volts, Alternating Current

Vdc Volts, Direct Current

W watts

TI150 Series Battery Charger/Conditioner

Page 6

Figure 1.2.1 – Different types of hazard and caution symbols

1.1 - Safety Notices

Safety notices appear throughout this manual to alert the user to important information regarding proper

installation, operation, maintenance and storage of the unit. These notices, as illustrated below, contain a

key word that indicates the level of hazard and a triangular icon that indicates the speci c type of hazard.

WARNING

Indicates a condition, operating procedure or practice, which if not

adhered to could result in serious injury or death.

CAUTION

Indicates a condition or operating procedure, which if not strictly

adhered to could result in damage or destruction of equipment.

NOTE

Indicates a condition, operating procedure or practice, which is

essential to highlight.

1.2 - Symbols

The following symbols will appear within the warning triangles to alert the user to the speci c type of danger

or hazard.

General Warning Electrical Hazard Explosion Hazard Fire Hazard

Battery Warning Guard from Moisture

!

Section 1 – Safety Review

!

!

!

TI150 Series Battery Charger/Conditioner

1

Page 7

1

Safety Review

1.3 – Hazards

WARNING

Severe injury or death from electrical shock will occur if either the user or the TI150 Battery Charger/

Conditioner is wet while operating the unit with the 120 or 240 Vac plug attached. Be sure to discon nect

ac power from the ac outlet if the TI150 Battery Charger/Conditioner has come into contact with water.

If the DC Output Circuit Breaker has tripped due to water inltration, DO NOT try to reset it with the unit

plugged into line voltage. Follow standard procedures for resetting the DC Output Circuit Breaker under

Section 3.5.

WARNING

Severe injury or death from electrical shock can occur when damp electrical connections from the TI150

Battery Charger/Conditioner are plugged into ac line voltage. See Section 6.1 for standard procedures in

wet conditions.

CAUTION

Shock Hazard Potential

Shock Hazard Potential

Unit Damage Potential

Damage may occur if the TI150 Battery Charger/Conditioner is operated after exposure to moisture (rain,

fog, snow, etc.). If water inltration is suspected, DO NOT CONNECT to ac voltage. Move the unit to a non-

humid location and allow it to dry for a minimum of one (1) hour before operating again. DO NOT USE the

unit if the exterior is damp. See Section 6.1 for standard procedures in wet conditions.

1.4 – Important Safety Precautions

WARNING

Severe injury or death from re or explosion can occur if electrical sparks are produced near fuel vapors.

Make sure the TI150 Battery Charger/Conditioner is at least 20 feet (6 meters) away from the nearest

fueling source before connecting either the ac or dc power cables.

Fire/Explosion Hazard Potential

2

TI150 Series Battery Charger/Conditioner

Page 8

Section 2 – Product Overview

2.1 – Introduction

Thank you and congratulations on the purchase of your new TI150 Series Battery Charger/Conditioner.

This manual contains the complete operating instructions and procedures for the TI150 Series Battery

Charger/Conditioner models: TI15014-120-240 and TI15028-120-240. The TI150 Battery Charger/

Conditioner has been designed to rapidly recharge any 12 or 24 volt battery, depending on the model.

Both models incorporate an intelligent recharging circuit that prevents overcharging and provides pure dc

output for efcient battery charging and conditioning.

The TI150 Battery Charger/Conditioner is encased in a rugged enclosure, and is designed to be used as a

free standing unit, or to be mounted to a vehicle or other xed object using the integrated mounting base.

Both models include a detachable line cord and two interchangeable dc output cables (ring terminals for

direct battery connection or alligator clamps for rapid connect and disconnect. See Figure 2.1.1). Each

model’s capabilities and requirements are listed below:

•Model TI15014-120-240 accepts both 120 Vac or 240 Vac and charges 12V batteries

•Model TI15028-120-240 accepts both 120 Vac or 240 Vac and charges 24V batteries

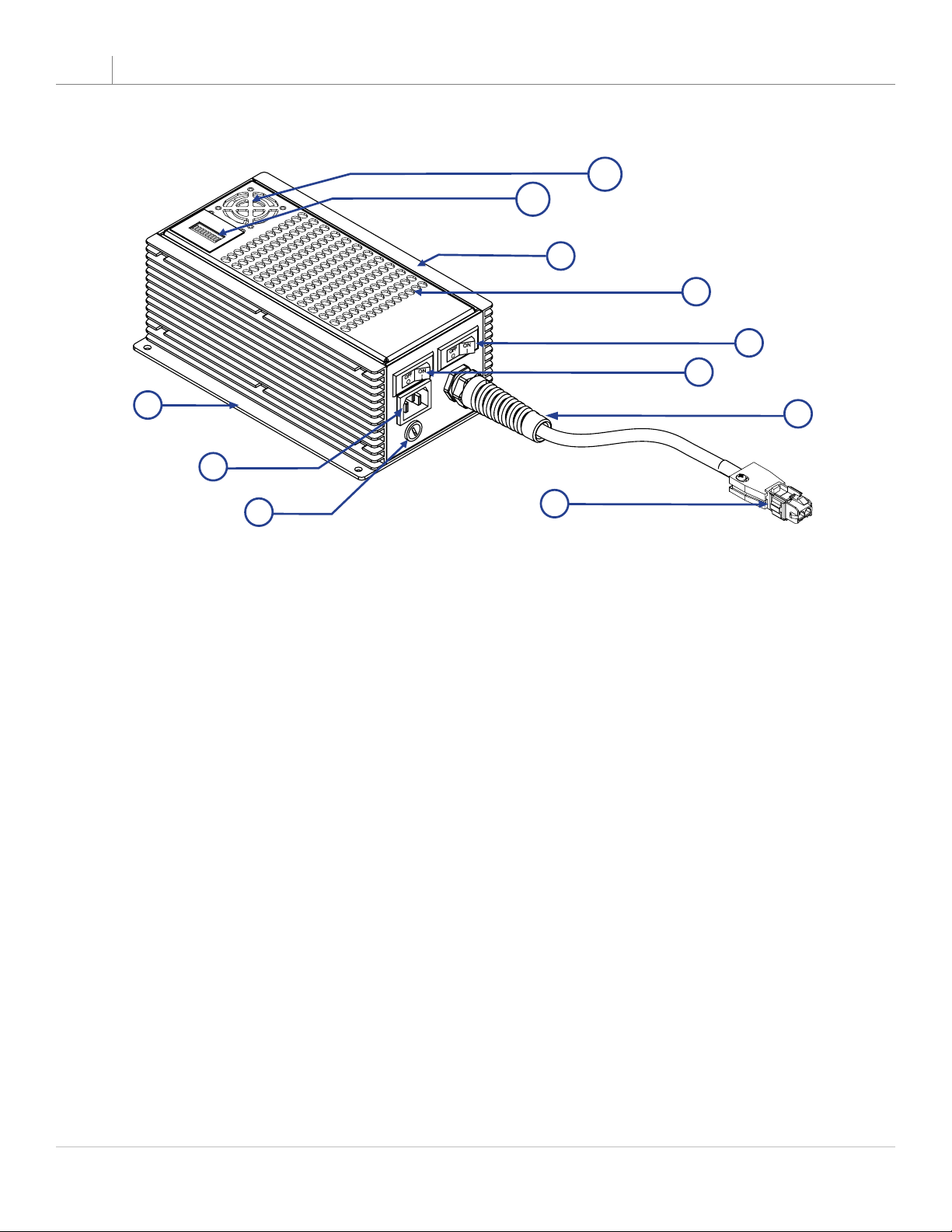

Figure 2.1.1 – TI150 Series Battery Charger/Conditioner IEC

2.2 – Indication of Terms: Shall, Should, and May

Within this technical manual the word “shall” is used to indicate a mandatory requirement for proper

operation and warranty purposes. The word “should” is used to indicate a non-mandatory but preferred

method of accomplishment. The word “may” is used to indicate an acceptable method of accomplishment.

TI150 Series Battery Charger/Conditioner

3

Page 9

2

Product Overview

2.3 - Front and Top Panel Overview

11

10

9

8

7

6

1

5

2

3

Mounting Base –1) Allows mounting of the TI150 series Battery Charger/Conditioner via four mounting holes.

AC Input Receptacle 2) – Connects to standard ac cable (Included with both the TI15014-120-240 and TI15028-

120-240).

AC Input Selector Switch 3) – Allows manual selection of either 120 Vac or 240 Vac Input voltage (see Sec-

tion 4.2 for proper selection).

Quick Disconnect Connector 4) – TI2010-095 12/24 V Cable Assembly with female connector.

DC Output Cable 5) – Provides 14.25 Vdc @ 20 A max (TI15014-120-240) or 28.5 Vdc @ 10 A max

(TI15028-120-240).

AC Input Circuit Breaker 6) – Protects the internal electrical circuit from damage caused by overload or short

circuit. Acts as an “On/Off” switch for the Battery Charger/Conditioner.

4

DC Output Circuit Breaker 7) – Trips if an over current condition occurs (30 amps for TI15014-120-240, and

15 amps for TI15028-120-240).

Air Exhaust Ports – 8) Expel heated air drawn in by Cooling Fan.

Integrated Heatsinks – 9) Provide additional cooling under heavy loading conditions.

Charge Level Indicator10) – Displays current battery charge level when connected to a battery.

Cooling Fan11) – Provides continuous airow for cooling internal circuitry (only when under a load.)

4

TI150 Series Battery Charger/Conditioner

Page 10

3.50 [88.9]

4.68 [119.0]

5.68 [144.3]

2.4 – Physical Dimensions

12.37 [314.3]

9.03 [229.3]

Product Overview

2

Measurements are in inches and millimeters

Figure 2.4.1 – TI150 Battery Charger/Conditioner Physical Dimensions

TI150 Series Battery Charger/Conditioner

5

Page 11

2

Product Overview

2.5 – General Specications

Input

Operates from Single Phase 100-260 Vac / 40-500 Hz•

4.7 amps @ 120 Vac 60 Hz•

2.35 amps @ 240 Vac 60 Hz•

Output

Models TI15014-120-240 (12 Vdc Output)•

- 20 amps continuous @ 14.25 Vdc (when plugged into ac power)•

Models TI15028-120-240 (24 Vdc Output)•

- 10 amps continuous @ 28.5 Vdc (when plugged into ac power)•

Frequency

50-450 Hz•

Temperature Ratings

Operating temperature: -40°F to +140°F (-40°C to +60°C)•

Storage temperature: -85°F to +140°F (-65°C to +60°C)•

Physical Specications

Dimensions: 13.37” L (314.3 mm) x 5.68” W (144.3 mm) x 3.50” H (88.9 mm)•

Weight: 4.11 lbs (1.87 kg)•

Warranty

2 Years (3 Year Optional)•

6

TI150 Series Battery Charger/Conditioner

Page 12

2.6 – Airow Ports

Product Overview

2

CAUTION

When the TI150 Charger/Conditioner is plugged into ac power, the internal cooling system will efciently

regulate unit temperature regardless of load. At room temperature (+77°F) the exhaust air will not exceed

the ambient temperature by more than 5°F. In more extreme temperatures (greater than 90°F) the

exhaust air will not exceed the ambient temperature by more than 10°F.

Damage may occur if the TI150's air intake or outlet ports are

obstructed. Ensure that both ports are clear at all times

Figure 2.6.1 – Air intake and exhaust ports and the internal air circulation

TI150 Series Battery Charger/Conditioner

7

Page 13

Section 3 – Features Overview

3.1 – AC Input Receptacle

WARNING

The TI150 series battery charger/conditioner comes with a quick disconnect ac receptacle (see Figure

3.1.1) and is designed to plug into either a standard 120 or 240 Vac outlet with the supplied line cord (see

Figure 3.1.2. and see also Section 3.1a for the proper line cord for your country and region). Please ensure

that the unit is properly grounded at all times (see Section 4.2 for proper grounding techniques).

Figure 3.1.1 – AC Input Receptacle

(highlighted in blue)

Failure to use proper grounding can create a shock hazard.

Please refer to Section 5.2 for proper grounding techniques.

Figure 3.1.2 – Connecting AC line cord

3.1a – IEC Line Cord Options

TI25000-053 North American Line Cord

TI25000-002 Italian Line Cord

TI25000-003 Continental European Line Cord

TI25000-004 Old British Line Cord

TI25000-005 England / UK Line Cord

TI25000-006 Swiss Line Cord

TI25000-011 Australian Line Cord

TI25000-200 Israel Line Cord

TI25000-300 Denmark Line Cord

3.2 – AC Input Selector Switch

The AC Input Selector Switch (shown in Figure 3.2.1) allows manual selection of either 120 (115) Vac or

240 (230) Vac input voltage. To change voltage input, simply insert a at head screwdriver into the opening

on the switch and select the desired voltage before plugging in the unit (see Figure 3.2.2).

Figure 3.2.1 – AC Input Selector Switch

(highlighted in blue)

8

Figure 3.2.2 – Turning switch

TI150 Series Battery Charger/Conditioner

Page 14

Features Overview

3

3.3 – AC Input Circuit Breaker

The AC Input Circuit Breaker located above the AC Input

Receptacle(shown in Figure 3.3.1) protects the internal

electrical circuit from damage caused by overload or short

circuit. The AC Input Circuit Breaker also acts as an “On/Off”

switch for the Battery Charger/Conditioner.

Figure 3.3.1 – AC Input Circuit Breaker

(highlighted in blue)

3.4 – DC Output Cable

The DC Output Cable (shown in Figure 3.4.1) will provide either 14.25 Vdc or 28.5 Vdc depending on the

model, and comes with a quick disconnect for either ring terminals or alligator clamps. When properly

connected, the TI150 can deliver up to 20 amps at 14.25 Vdc or 10 amps at 28.5 Vdc. See Section 4.3 for

proper connecting procedures.

Figure 3.4.1 – DC Output Cable

(highlighted in blue)

Figure 3.4.2 – Quick disconnect cables

3.5 – DC Output Circuit Breaker

The DC Output Circuit Breaker (30 amp in 12V and 15 amp

in 24V models) is located above the DC Output Cable (See

Figure 3.5.1). When the circuit breaker has been tripped, the

button will pop out. In the event the breaker trips, verify that all

connections are correct (polarity, line voltage, etc.) and reset

the breaker by pushing the switch to the "ON" position. The unit

should provide dc power automatically. If the breaker continues

to trips, see Section 8 under Troubleshooting.

TI150 Series Battery Charger/Conditioner

Figure 3.5.1 – DC Output Circuit Breaker

(highlighted in blue)

9

Page 15

3

Features Overview

3.6 – Charge Level Indicator

The Charge Level Indicator is located on the top of the TI150 to the left of the Cooling Fan. When attached

to a battery and ac line voltage, the Charge Level Indicator shows the power cells’ charge state (See

Figures 3.6.1 and 3.6.2). A full charge will be indicated by a single green bar next to the 100 on the

indicator.

Figure 3.6.1 - Full Charge

Figure 3.6.2 - <20% Charge

3.7 – Integrated Heatsinks

In conjunction with the Cooling system, the TI150 is equipped with heatsinks (See Figure 3.7.1) on both

sides of the unit to provide additional heat dissipation under full load conditions.

Figure 3.7.1 - Integrated Heat Sinks an Mounting Base

(highlighted in blue)

3.8 – Mounting Base

The Mounting Base allows for easy mounting of the unit to any vehicle or other hard surface. Four (4)

mounting holes have been strategically placed to properly secure the TI150. See Figure 3.8.1 for Mounting

Base dimensions and hole locations. The actual size PDF can be found on our website.

10

TI150 Series Battery Charger/Conditioner

Page 16

8.24 [209.2]

5.18 [131.6]

5.68 [144.3]

8.99 [228.3]

Actual Hole Size 0.213 [5.41]

Measurements are in inches and millimeters

TI150 Series Battery Charger/ Conditioner Mounting Base Template with

Hole Locations

Tesla™ Industries, Inc.

• 101 Centerpoint Blvd. New Castle, DE 19720 / (302) 324-8910

• 9475 Double R Blvd. Suite 2, Reno, NV 89521 / (775) 622-8801

• www.teslaind.com

Page 17

Section 4 – Pre-Operation Procedures

4.1 – Installing the Charger

The TI150 Series Battery/Charger is designed to be permanently integrated into vehicles and other

equipment, or can be used as a free standing unit. Mounting is accomplished by using the four holes in

the base of the unit. The holes are 0.190” (4.826 mm) and will accept up to 10-24 size bolts or M5 in

metric. Once the TI150 is securely mounted to the vehicle or other equipment, proceed to the next step.

4.2 – Attaching AC Power

Unit damage may occur if the wrong voltage is used.

CAUTION

Make sure the line voltage is appropriate for your specic

model. See Model numbers in Figure 4.3.2

WARNING

Failure to use proper grounding can create a shock hazard. Depending on geographic location, the

standard 220 Vac 50 Hz power cord may require a foreign plug adapter for compatibility. Use only

adapters with a proper grounding mechanism.

Proper Ground

Figure 4.2.1– Illustrations of proper and improper grounding

Before plugging the TI150 into ac power check the dc output cable to make sure the two output wires are

not touching (by disconnecting quick disconnect to prevent shorting).

Failure to use proper grounding can create a shock hazard. Please follow proper wiring procedures below.

Proper Ground

Improper Ground

12

TI150 Series Battery Charger/Conditioner

Page 18

Pre-Operation Procedures

4

4.3 – Attaching the DC Power Cable

Unit damage may occur if the DC output cable is im-

CAUTION

Before wiring up the DC Output Cable, make sure both the ac line voltage and the Quick Disconnect

Connector Cable are disconnected. The TI150 may have a residual charge. Allow approximately 5 minutes

for complete discharge. The wires coming out of the dc output cable are internally connected as illustrated

in Figure 3.4.1. Connect the “red” ring terminal or alligator clamp of the TI150 DC Quick Disconnect Cable

Assembly to the positive terminal of the battery. This is the terminal marked with the + symbol. Next

connect the “black” ring terminal or alligator clamp of the TI150 DC Quick Disconnect Cable Assembly to

the negative terminal of the battery. This is the terminal marked with the - symbol.

properly wired. Make sure voltage is appropriate for

your specic model. See model numbers below in

Figure 4.3.2

Red- Positive +

Black - Negative -

Figure 4.3.1 – Quick Disconnect Connectors and color coding

TI15014-120-240 14.25 Vdc @ 20 A

TI15028-120-240 28.5 Vdc @ 10 A

Figure 4.3.2– Model numbers and corresponding dc output voltages

Plug the ac line cord into the unit, then plug the ac line cord into a 120 or 240 power source. Once the unit

has been plugged in, the Quick Disconnect can be reattached.

TI150 Series Battery Charger/Conditioner

13

Page 19

4

Pre-Operation Procedures

Connecting and Disconnecting the Quick Disconnect DC Cable

The TI2010-095 12/24 V Cable Assembly is equipped with a female Quick Disconnect connector. The

TI2010-095 12/24 V Quick Disconnect Cable Assembly with Ring Terminals and the TI2010-096 12/24 V

Quick Disconnect Cable

Assembly with Alligator Clips are equipped with the male side of the connector.

To connect the ends:

Hold the male end of the connector in one hand, and the 1.

female in the other. Note that the white plastic covers around

the pins and sockets are “D” shaped.

Align the pins and sockets so that the “D” shapes are facing 2.

the same direction.

Slide the pins into the sockets until the two side latches 3.

on the until the two side latches on the male end click into

place. Gently pull on each end to ensure that the two ends

are locked together.

Gently pull on each end to ensure that the two ends are 4.

locked together.

Figure 4.3.5 – Correctly connected ends

To disconnect the ends:

Hold the male end of the connector in one hand, and 1.

the female in the other.

Figure 4.3.3 – Male

end of connector

Figure 4.3.4 –

Female end of

connector

14

Gently press them together2.

Grasp the two side latches of the male connector and 3.

press them together until latches clear the catch.

While holdings the latches, pull the ends apart.4.

Figure 4.3.6 –

Disconnecting the

ends

TI150 Series Battery Charger/Conditioner

Page 20

Section 5- Operating Procedures

5.1 – Unit Care

The TI150 Series Battery Charger/Conditioner is engineered to provide continuous output power. Thus, the

charger can be left connected to a battery until it is ready for use. This is due to the intelligent recharging

system that prevents the TI150 from overcharging the battery. Prior to connecting the TI150 to an ac

power source, be sure that the charger is at least 20 feet away from any fuel source to avoid a potential

explosion due to sparking.

Make sure that the unit is at least 20 feet (6 meters)

WARNING

5.2 – Connecting the Battery Charger

When you are ready to charge the battery in question, simply follow procedures on page 16. The LED will

show the battery’s state of charge, and the cooling fan will start running after approximately one second.

Let the battery fully recharge. The amount of time needed to charge the battery can be determined by

dividing the amp hour rating of the battery by the output of the charger. For example, a 12 V battery with

a 20 Ah rating using a 12 V model TI150 will take approximately 1 hour to charge. The TI150 can be left

connected to the battery past the charge time due to the intelligent recharge system and will continue to

maintain and condition the battery while connected.

away from the nearest fueling source before connecting

ac power.

5.3 – After Operation

Although the battery charger is ruggedized, good general care should be taken to maximize its life.

Therefore, protect the unit from the elements and man-made hazards whenever possible. Do not expose

to wet or dusty environments (rain, snow, sand, etc.) as this may damage internal circuitry. See Section 1.3

for more information concerning water inltration.

TI150 Series Battery Charger/Conditioner

15

Page 21

5

Operating Procedures

Connecting the TI150 Battery Charger.

1. If the TI150 Battery Charger is already connected to the battery and hard

mounted to the vehicle:

Plug the ac line cord into the appropriate AC Source.A.

Check to see that the LED shows that status of the charge. B.

Check to see that the fan is running when the Battery Status LED is below C.

100%.

CAUTION

2. If the TI150 Battery Charger is not connected to the battery:

Disconnect the DC Quick Disconnect (QD) and remove the QD Cable As-A.

sembly from the DC Output Cable Assembly.

Attach the either the QD Alligator Clips or Ring Terminals to the Battery. B.

Positive connector rst, then negative.

Plug in the ac line cord to the TI150 (if disconnected).C.

Plug in the ac line cord to the appropriate AC source.D.

Connect the DC Output QD.E.

Check to see that the LED shows that status of the charge. F.

Failure to follow these steps in order can cause arcing

and or sparks.

Disconnecting the TI150 Battery Charger

1. If the TI150 Battery Charger is hard mounted to the vehicle:

Disconnect the ac line cord from the ac source.A.

16

Disconnect the ac line cord from the Battery Charger.B.

Stow the ac line cord for later use.C.

2. If the TI150 Battery Charger is not hard mounted to the vehicle:

Disconnect the DC Output cable QD.A.

Unplug the ac line cord from AC Source.B.

Unplug the ac line cord from the TI150.C.

Disconnect the Negative (Black) lead of the QD Alligator or Ring Terminal D.

from the Battery.

Disconnect the Positive (Red) lead of the QD Alligator or Ring Terminal E.

from the Battery.

TI150 Series Battery Charger/Conditioner

Page 22

Section 6- Unit Care and Maintenance

6.1 – Unit Care

Avoid Prolonged Exposure to Extremely Damp Environments

Be sure to disconnect the TI150 Series Battery Charger/Condi tioner from ac

power if has come into contact with water. If the DC Output Circuit Breaker

has tripped due to water inltration, allow the unit to dry out before attempting

to reset circuit breaker. Cover the unit to prevent water inltration. If the unit

is operated in extremely damp conditions, it should be stored in an environmentally controlled building when not in use.

Severe injury or death from electrical shock will occur if

DANGER

either the user or the TI150 Battery Charger/Conditioner

is wet while operating the unit with an ac power source

attached.

Protect Cables from Damage

Do not cut, crush, or drag the input or output power cables when handling the TI150 Series Battery

Charger/Conditioner. Always inspect cables prior to use. If damage is evident (as shown in Figure 6.1.1),

contact Tesla™ Customer Service. Do not attempt to use any other type of power cables other than the

Tesla™ cables included with the TI150 Series Battery Charger/Conditioner. Do not use the input or output

cables as a carrying handle, damage to the cables and/or internal circuitry can occur.

Figure 6.1.1 – Damaged cable

TESLA™ INDUSTRIES, INCORPORATED

101 CENTERPOINT BLVD.

CENTERPOINT INDUSTRIAL PARK

NEW CASTLE, DELAWARE 19720

PHONE: (302) 324-8910 FAX: (302) 324-8912

WEBSITE: www.teslaind.com EMAIL: tesla1@teslaind.com

TI150 Series Battery Charger/Conditioner

17

Page 23

6

Unit Care and Maintenance

6.2 – Normal Function Test Procedure

This section deals with “normal function” test proce dures. It includes

all steps necessary to ensure that the TI150 Series Battery Charger/

Conditioner is operating within spe cied para meters prior to use. A

digital multimeter (an example is shown in Figure 6.2.1) capable of

measuring dc voltage and resis tance will be required to perform some

of the tests. These functional test procedures should become routine.

Check Unit for Evidence of Damage

Check for dents, punctures, case distortion or misalignment, and cracked or loose connec tors. If any

damage is evident, contact the Tesla™ Customer Service.

Severe injury or death from electrical shock can occur.

WARNING

Ensure that both the AC Input Cable and DC Output

Cable are disconnected before performing any tests.

Figure 6.2.1 - Digital Meter

Checking Unit Internal Resistance (Testing for Shorts)

It is essential to test for shorts to detect any problems with the unit. To do so, you will need to set your

multimeter to measure Ω or “resistance.” You can test to see if both the ac input and dc output terminals

are isolated from the case and line ground in the following steps.

Step 1 Place the negative probe (black) of the multimeter on the ac plug ground pin and the positive

probe (red) on any exposed part of the metal casing or screw.

> The multimeter should read nearly 0 Ω (see Figure 6.2.2).

Step 2 Move the positive probe to one of the two ac plug blades.

> The multimeter should now read greater than 1 MΩ (see Figure 6.2.3).

Step 3 Move the positive probe to the other ac plug blade.

> The multimeter should again read greater than 1 MΩ (see Figure 6.2.3).

Step 4 Next, move the positive probe to the dc output cable black ring terminal.

> The multimeter should read greater than 1 MΩ (see Figure 6.2.3).

Step 5 Finally, move the positive probe to the dc output cable red ring terminal.

> The multi meter should read greater than 1 MΩ (see Figure 6.2.3).

If the following multimeter measurements correspond to the above steps, the unit has no internal shorts.

18

TI150 Series Battery Charger/Conditioner

Page 24

Unit Care and Maintenance

6

Figure 6.2.2 – Multimeter reading

continuity

Figure 6.2.3 – Multimeter reading

open circuit

Checking DC Voltage at the DC Output Cable

In order to properly test the dc output the unit needs to be connected to a battery. Make sure to reconnect

the DC Output Cable according to Section 5 Pre-Operation procedures. Then, plug the unit into the

appropriate line voltage. Once this is accomplished, set your digital multimeter to measure dc voltage.

Place the positive probe (red) of the multimeter on the positive terminal (red) of the DC Output Cable. Next,

place the negative probe (black) on the negative terminal (black) of the DC Output Cable. The multimeter

display should read between 12.0 and 14.25 Vdc for the TI15014 series charger (see Figure 6.2.4) and

between 24.0 and 28.5 Vdc for the TI15028 series charger (see Figure 6.2.5). If the unit is not providing

any output voltage refer to Section 8 under Troubleshooting. Otherwise, contact the Tesla™ Customer

Service at (302) 324-8910.

Figure 6.2.4 – Multimeter reading typical

12 V power cell voltage

Once the TI150 Series Battery Charger/Conditioner has fully passed function

test procedures, the unit is ready for use.

TI150 Series Battery Charger/Conditioner

Figure 6.2.5 – Multimeter reading typical

24 V power cell voltage

19

Page 25

6

Unit Care and Maintenance

6.3 – Unit Servicing

The TI150 Series Battery Charger/Conditioner is a maintenance-free, sealed unit. No repairs outside

of Tesla™ are authorized. Warranty will be voided if unit is tampered with in any way including any

damage to the WARRANTY VOID stickers located on the case (see Figure 6.3.1 below). If the unit requires

maintenance, please contact Tesla™ Customer Service at (302) 324-8910. A Repair Request Form can be

found on the last page of this manual.

Figure 6.3.1 – Warranty Void Stickers

(highlighted in blue)

6.4 – Packaging and Shipping

When returning the TI150 Battery Charger/Conditioner, please ensure that it is properly packaged. Pack

the unit in a box with at least 2-3 inches of clearance on all sides (be sure to enclose the Repair Request

Form). To guarantee that the unit remains centered within the box, do not use loose packing materials

such as packing peanuts. Instead, wrap the unit tightly in foam or other dense material until it ts snugly

in the box. Seal the box on all sides and return it to Tesla™. Please contact Tesla™ Customer Service at

(302) 324-8910 with any questions or concerns.

20

TI150 Series Battery Charger/Conditioner

Page 26

Section 7 – Frequently Asked Questions

1. How does a Tesla™ TI150 Battery Charger/Conditioner work?

The Tesla™ TI150 Battery Charger/Conditioner incorporates an intelligent charging

system with a pure dc output that allows it to rapidly charge and condition a battery

without overcharging or damaging it.

2. How much dc power will the TI150 Series Battery Charger/Conditioner provide?

The TI15014-120-240 Battery Charger/Conditioner will provide up to 20 conti nuous

amps @ 14.25 Vdc. The TI15028-120-240 Battery Charger/Conditioner will provide

up to 10 continuous amps @ 28.5 Vdc.

2. How long will it take to charge my battery?

Battery charge time can be determined by taking the battery’s rated amp hours and

dividing this number by the TI150’s maximum output current. For example, a 12 V /

20 Ah battery will take one hour to charge using a TI15014 series Battery Charger/

Conditioner. Refer to Section 5.2 for more information.

3. What is included with my TI150 Series Battery Charger/Conditioner?

The Battery Charger/Conditioner comes with a Tesla™ approved ac input power

cable, a 3 ft DC Output power cable with color coded alligator clamp/ring terminal

Quick Disconnect cable assemblies(TI2010-096 12/24V Cable Assembly Quick

Disconnect DC Output with Ring Terminals & TI2010-095 12/24V Cable Assembly

Quick Disconnect DC Output with Alligator Clips), a North American line cord

(TI25000-053 American Line Cord), a user manual, and a limited two-year warranty.

4. Is the TI150 Series Battery Charger/Conditioner waterproof?

The TI150 Battery Charger/Conditioner is NOT waterproof. See Section 1.3

under Water Hazards for further information regarding safe operation in damp

environments.

5. Are there any HAZMAT or disposal issues?

No. Contact Tesla™ for more information.

TI150 Series Battery Charger/Conditioner

21

Page 27

Section 8 – Troubleshooting

1. When I connect the TI150 Battery Charger/Conditioner to ac power my battery does

not charge.

While charging, the Charge Level Indicator should be illuminated. If this LED is not

lit follow the procedure listed below.

Is there ac line voltage at the outlet?

No: Consult an electrician. Yes: Contact Tesla™ Industries.

2. The Charge Level Indicator is illuminated, but my battery still does not charge.

The Charge Level Indicator illuminates when there is voltage present at the DC

Output. The DC Output Circuit Breaker controls voltage going out to the DC Output

Cable.

Is the DC Output Circuit Breaker tripped (see Figure 4.4.2)?

No: Proceed to next step. Yes: Reset the breaker.

With the Battery Charger plugged into ac line voltage, check the dc output with a

multimeter on the dc output terminals (See Section 6.2 under Checking DC Voltage

for Proper Testing Procedures).

Does the DC Output show the proper voltage?

No: Contact Tesla™ Industries. Yes: Replace your battery

3. When I apply ac power to the Battery Charger, the Cooling Fan does not turn on.

The Cooling Fan inside the TI150 Battery Charger/Conditioner is designed to run

only when a load is applied. It will tick when no load is present. If the fan is not on

when the Battery Charger is under load, this may indicate that the Cooling Fan has

failed. Disconnect power imme diately and contact Tesla™ for further instructions.

22

TI150 Series Battery Charger/Conditioner

Page 28

Troubleshooting

4. Can I make repairs to the unit?

No. The TI150 Battery Charger/Conditioner is a maintenance-free, sealed unit.

No repairs outside of Tesla™ are authorized. Warranty will be voided if unit is

tampered with in any way, including any damage to the WARRANTY VOID stickers

located on the case.

5. How do I get my TI150 Battery Charger/Conditioner serviced?

If the unit needs to be serviced, please contact Tesla’s™ Customer Service by

phone at (302) 324-8910 or by email at tesla1@teslaind.com, and a representative

will explain the return process. For your convenience, a Repair Request Form can

be found on the last page of this manual. The form can also be found online at

www.teslaind.com.

6. What type of special maintenance does the TI150 Battery Charger/ Conditioner require?

8

Keep the unit in a well ventilated, climate-controlled environment while charging.

Always keep the vent areas clean and free of debris. See Section 1.3 regarding

Water Hazards and Section 6 under Unit Care.

TI150 Series Battery Charger/Conditioner

23

Page 29

Section 9 – Optional Accessories

9.1 – TI2007-013 Mini NATO Quick Disconnect Cable Assembly

The Tesla™ TI2007-013 Mini NATO Quick Disconnect

Cable Assembly connects to the TI150 IEC (International

Electrotechnical Commission) cord 12/24V Battery Charger/

Conditioner. The NATO plug will withstand the harshest

battleeld conditions and other extreme environments. It

is rated to 25 Amps max. and is tested to withstand 50 G

of force. Along with highly conductive contact materials,

the virtually indestructible design and fast “in-the-eld”

component replacement make it the last NATO plug you will

ever need.

9.2 – TI2007-019 Mini DC to 10AWG Quick Disconnect Cable Assembly

The TI2007-019 Mini DC to 10AWG Quick Disconnect

Cable Assembly is equipped with a male Quick Disconnect

connector. This will connect with the female end of the

connector which is attached to the TI150 IEC cord 12/24V

Battery Charger/Conditioner. Manufactured from highly

conductive alloys, the contacts feature threads that are

resistant to damage and ideal for superior torquing and

surface contact.

Figure 10.1.1 – TI2007-013 Mini NATO

Quick Disconnect Cable Assembly

10.2.1 – TI2007-019 Mini DC to 10AWG

Quick Disconnect Cable Assembly

9.3 – Cobra™ DC Replacement Contacts and Tools

Manufactured from highly conductive alloys, the negative contact is specially tapered and has memory

to maximize contact surface area and to minimize deformity over time. Once installed, contacts are

hermetically sealed within the plug. Additionally contacts can be easily replaced “in-the-eld” without

discarding the entire plug using the Insertion/Extraction Tools. The tools and contact replacements can be

ordered through Tesla™ Customer Service at 302-324-8910.

A. Positive Insertion/Extraction Tool: TI27000-082

B

A

D

C

NSN: 5120-01-527-7729

B. Negative Insertion/Extraction Tool: TI2005-126

NSN: 5120-01-523-8761

C. Cobra NATO Plug Positive Post: TI2005-117

NSN: 5935-01-523-8914

D. Cobra NATO Plug Negative Contact: TI2005-121

NSN: 5999-01-525-0582

24

TI150 Series Battery Charger/Conditioner

Page 30

Section 10- Performance Data

10.1 – Introduction

This chapter provides performance data for the TI150 Series Battery Charger/Conditioner. This

information will allow the user to obtain maximum performance and life from the unit. Regular referral to

this chapter is recommended to:

A) Gain knowledge of the unit’s performance characteristics to anticipate unexpected conditions or

extreme operational requirements.

B) Readily identify situations requiring maximum performance.

Note: The information provided in this chapter is most useful when anticipating operations under unknown

conditions or environmental extremes. The data can also be used to es tablish local operating procedures

and to maximize the unit’s life.

10.2 – Explanation of Data

The data presented covers the full range of operating conditions and expected perfor mance. In each area

of performance, temperature effects and DC electrical load demands in relation to ground power support

requirements are presented. In some cases, data is presented conservatively. In all cases, performance

data presented is within the applicable limits of the TI150 Battery Charger/Conditioner. Any attempt

to exceed maximum recommended limits will cause the unit to malfunction and may cause permanent

damage.

10.3 – Denition of Abbreviations

Unless otherwise indicated, the abbreviations dened on page 29 will be applicable to all charts and

graphs in this chapter.

10.4 – Performance Graph

Figure 10.4.1 – Estimated time needed to fully recharge battery.

TI150 Series Battery Charger/Conditioner

25

Page 31

10

12.6 – Temperature Conversion Chart

°C °F °C °F °C °F °C °F

-60.0 -76.0 -27.0 -16.6 6.0 42.8 39.0 102.2

-59.0 -74.2 -26.0 -14.8 7.0 44.6 40.0 104.0

-58.0 -72.4 -25.0 -13.0 8.0 46.4 41.0 105.8

-57.0 -70.6 -24.0 -11.2 9.0 48.2 42.0 107.6

-56.0 -68.8 -23.0 -9.4 10.0 50.0 43.0 109.4

-55.0 -67.0 -22.0 -7.6 11.0 51.8 44.0 111.2

-54.0 -65.2 -21.0 -5.8 12.0 53.6 45.0 113.0

-53.0 -63.4 -20.0 -4.0 13.0 55.4 46.0 114.8

-52.0 -61.6 -19.0 -2.2 14.0 57.2 47.0 116.6

-51.0 -59.8 -18.0 -0.4 15.0 59.0 48.0 118.4

-50.0 -58.0 -17.0 1.4 16.0 60.8 49.0 120.2

-49.0 -56.2 -16.0 3.2 17.0 62.6 50.0 122.0

-48.0 -54.4 -15.0 5.0 18.0 64.4 51.0 123.8

-47.0 -52.6 -14.0 6.8 19.0 66.2 52.0 125.6

-46.0 -50.8 -13.0 8.6 20.0 68.0 53.0 127.4

-45.0 -49.0 -12.0 10.4 21.0 69.8 54.0 129.2

-44.0 -47.2 -11.0 12.2 22.0 71.6 55.0 131.0

-43.0 -45.4 -10.0 14.0 23.0 73.4 56.0 132.8

-42.0 -43.6 -9.0 15.8 24.0 75.2 57.0 134.6

-41.0 -41.8 -8.0 17.6 25.0 77.0 58.0 136.4

-40.0 -40.0 -7.0 19.4 26.0 78.8 59.0 138.2

-39.0 -38.2 -6.0 21.2 27.0 80.6 60.0 140.0

-38.0 -36.4 -5.0 23.0 28.0 82.4 61.0 141.8

-37.0 -34.6 -4.0 24.8 29.0 84.2 62.0 143.6

-36.0 -32.8 -3.0 26.6 30.0 86.0 63.0 145.4

-35.0 -31.0 -2.0 28.4 31.0 87.8 64.0 147.2

-34.0 -29.2 -1.0 30.2 32.0 89.6 65.0 149.0

-33.0 -27.4 0.0 32.0 33.0 91.4 66.0 150.8

-32.0 -25.6 1.0 33.8 34.0 93.2 67.0 152.6

-31.0 -23.8 2.0 35.6 35.0 95.0 68.0 154.4

-30.0 -22.0 3.0 37.4 36.0 96.8 69.0 156.2

-29.0 -20.2 4.0 39.2 37.0 98.6 70.0 158.0

-28.0 -18.4 5.0 41.0 38.0 100.4 71.0 159.8

Performance Data

10.5 - Temperature Conversion Chart

26

TI150 Series Battery Charger/Conditioner

Page 32

Glossary

Amp-Hour (Ah) The technical term for how much electrical

Digital Multimeter A digital multimeter, also known as a volt/

Intelligent Recharging A system which continuously monitors

charge a particular battery will hold. This

number can also be used to determine

charge and discharge rates.

ohm meter or VOM, is an electronic measurement device that combines several functions into one unit. A standard

multimeter may include features such as

the ability to measure voltage, current and

resistance.

the cell’s charge state and automatically

adjusts the recharge rate to maximum performance and minimize cell degradation.

Lead Acid Battery A battery that uses the reaction of lead and

lead oxide with sulfuric acid electrolytes to

produce a voltage (e.g. a car battery).

Memory Effect If a NiCd battery is only partially discharged

and then recharged many times, it will

begin to "remember" the level at which it

was discharged and will no longer fully

recharge. Lead Acid Batteries do not suffer

from memory effect.

Monolithic Dry-Cell A one-piece battery that is hermetically

sealed and designed for maintenance-free

operation.

NiCd Battery The NiCd, or nickel-cadmium battery,

is a type of rechargeable battery that

uses nickelic hydroxide and cadmium as

electrodes (e.g. rechargeable power tools).

TI150 Series Battery Charger/Conditioner

27

Page 33

Repair Request Form

Please complete the information below to ensure prompt and accurate service. Include this form with the unit you are returning.

Thank you.

Date of return: ________________________

Company name & ____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

Billing address: ____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

Contact person: ________________________________________________________________________________

Phone #: _____________________________________ Fax #: ______________________________________

Email: _______________________________________________________________________________________

Purchase Order #: ______________________________________________________________________________

Model #: ____________________________________ Serial #: ________________________________________

Model #: ____________________________________ Serial #: ________________________________________

Shipping method to Tesla™: ______________________________________________________________________

Description of shipping package: ________________________________________________________________

Description of problem: _________________________________________________________________________

_________________________________________________________________________________________________

_________________________________________________________________________________________________

_________________________________________________________________________________________________

Return to Tesla™ Industries, Inc.

101 Centerpoint Boulevard, New Castle, DE 19720 Attention: Repair Department

28

TI150 Series Battery Charger/Conditioner

Page 34

Loading...

Loading...