Page 1

Power Anytime, Anywhere

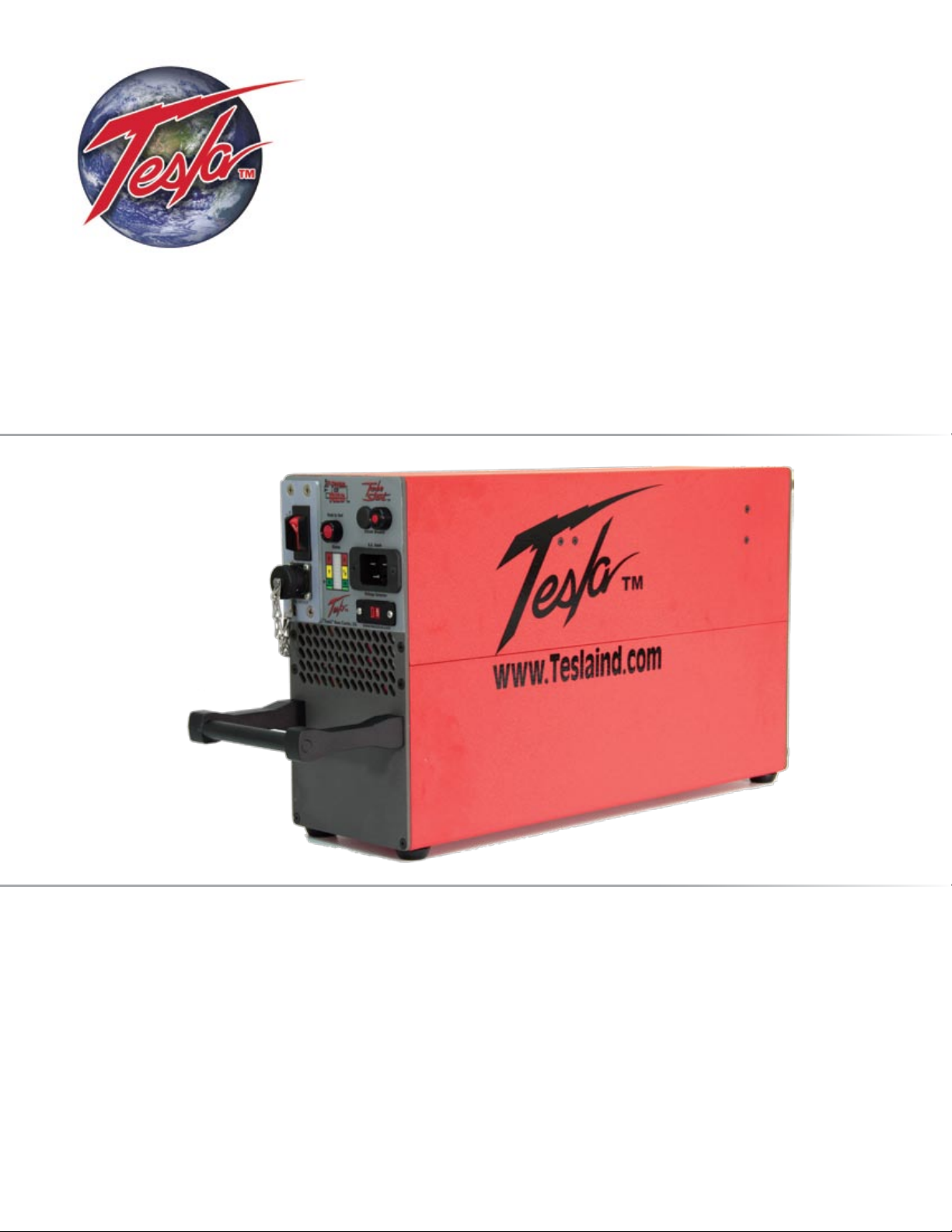

Tesla™ TI1000 GPU-24 UAV

User Manual

Built Smart...Proven Tough

Tesla Industries, Inc.

101 Centerpoint Blvd.

New Castle, DE 19720

(302) 324-8910 Phone

(302) 324-8912 Fax

www.teslaind.com

Page 2

NOTE: All users must read this entire manual prior

to operating the TI1000 GPU-24 UAV.

The TI1000 GPU-24 UAV is a limited maintenance-free and sealed unit. No repairs are authorized.

Warranty will be voided if unit is tampered with in any way, or if unauthorized repairs are made. For

technical support please contact:

TESLA™ INDUSTRIES INCORPORATED

101 CENTERPOINT BLVD.

CENTERPOINT INDUSTRIAL PARK

NEW CASTLE, DELAWARE 19720

PHONE: (302) 324-8910

FAX: (302) 324-8912

WEBSITE: www.teslaind.com

EMAIL: tesla1@teslaind.com

CAUTION

Improper use or failure to follow instructions in this user manual can result in unit damage and/or injury or

death by electrical shock.

Any attempts to open or examine the inside of the TI1000 GPU-24 UAV via a tool or device (borescope,

probe, etc.) can result in unit failure and/or injury by electrical shock. This GPU is mainte nance free and

should not be opened or disassembled for any reason.

Always protect the unit from short circuit.

Shipping Hazards: The TI1000 GPU-24 UAV contains sealed, dry cell rechargeable batteries that do not pose

a shipping hazard.

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying, recording, or any information storage and retrieval system, without

prior written permission from Tesla™ Industries, Inc.

Shock Hazard Potential

Copyright © 2015 by Tesla™ Industries, Incorporated. All rights reserved.

TI1000 GPU-24 UAV

07-13-15

Page 3

Form #: SDS 853027

Revised: 05/14/15

Supersedes: NEW

ECO #: 1001584

I. PRODUCT IDENTIFICATION

Chemical Trade Name (as used on label): Chemical Family/Classification:

Tesla™ Industries, Inc.

Sealed Lead Battery

Synonyms:

Sealed Lead Acid Battery, VRLA Battery Telephone:

For information, contact Tesla™ Industries, Inc.

Manufacturer's Name/Address:

Customer Service Dept. at 302-324-8910

Tesla™ Industries, Inc.

101 Centerpoint Blvd.

24-Hour Emergency Response Contact:

New Castle, DE 19720-4180

CHEMTREC DOMESTIC: 800-424-9300 CHEMTREC INT'L: 703-527-3877

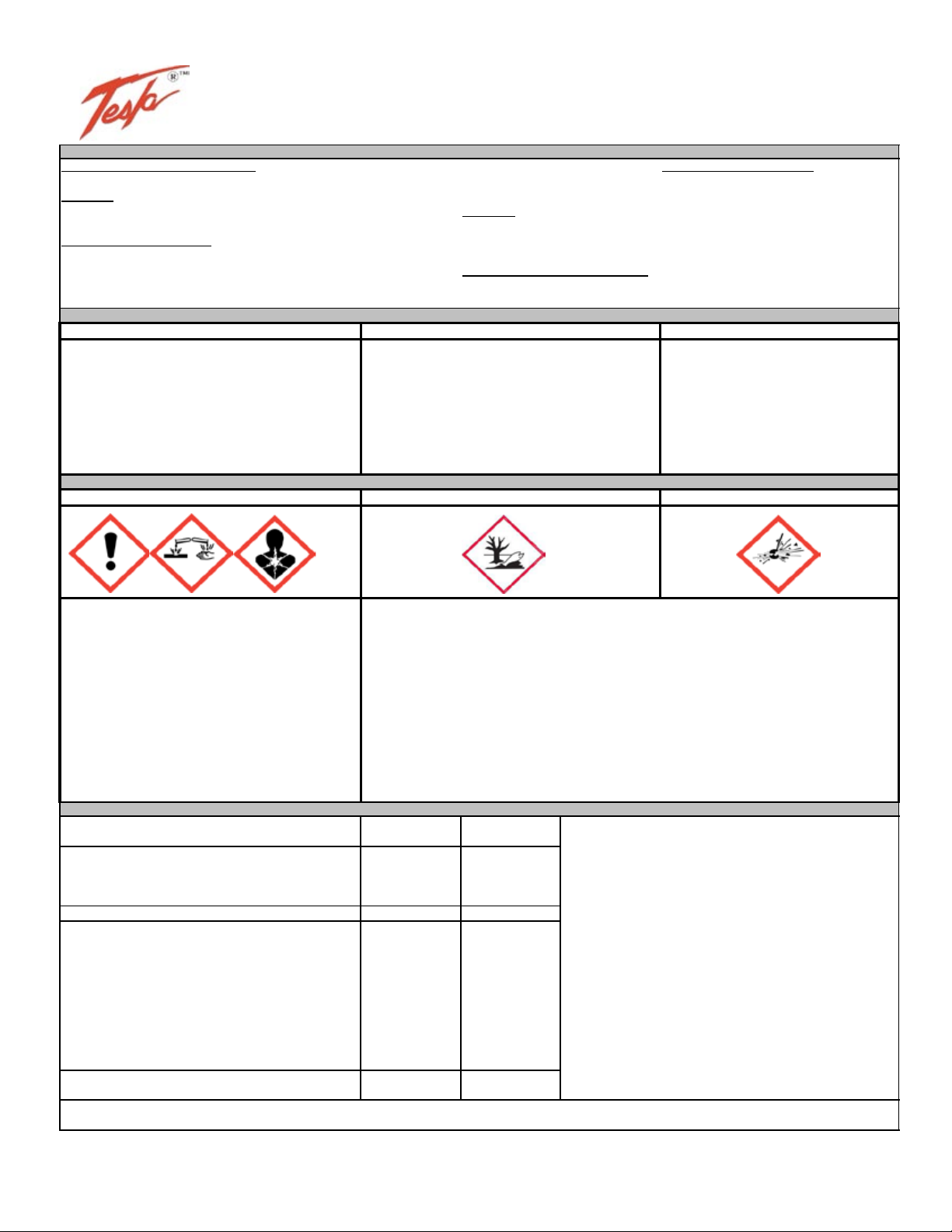

II GHS HAZRDS IDENTFICATION

Acute Toxicity

(Oral/Dermal/Inhalation) Category 4

Skin Corrosion/Irritation Category 1A

Eye Damage Category 1

Reproductive Category 1A

Carcinogenicity (lead compounds) Category 1B

Carcinogenicity (acid mist) Category 1A

Specific Target Organ Toxicity

(repeated exposure) Category 2

GHS LABEL:

Hazard Statements Precautionary Statements

DANGER! Wash thoroughly after handling.

Causes severe skin burns and eye damage. Do not eat, drink or smoke when using this product.

Causes serious eye damage. Wear protective gloves/protective clothing, eye protection/face protection.

May damage fertility or the unborn child if ingested or Avoid breathing dust/fume/gas/mist/vapors/spray.

inhaled. Use only outdoors or in a well-ventilated area.

May cause cancer if ingested or inhaled. Causes skin irritation, serious eye damage.

Causes damage to central nervous system, blood and Contact with internal components may cause irritation or severe burns. Avoid contact with internal acid.

kidneys through prolonged or repeated exposure. Irritating to eyes, respiratory system, and skin.

May form explosive air/gas mixture during charging.

Extremely flammable gas (hydrogen).

Explosive, fire, blast, or projection hazard.

III. HAZARDOUS INGREDIENTS/IDENTIFY INFORMATION

CAS Number

Approximate % by

Weight

Inorganic Lead Compound:

Lead 7439-92-1 45 - 60

Lead Dioxide 1309-60-0 15 - 25

Tin 7440-31-5 0.1 - 0.2

Sulfuric Acid Electrolyte (Sulfuric Acid/Water) 7664-93-9 15 - 20

Case Material: 5 - 10

Polypropylene 9003-07-0

Polystyrene 9003-53-6

Styrene Acrylonitrile 9003-54-7

Acrylonitrile Butadiene Styrene 9003-56-9

Styrene Butadiene 9003-55-8

Polyvinylchloride 9002-86-2

Polycarbonate, Hard Rubber, Polyethylene 9002-88-4

Polyphenylene Oxide 25134-01-4

Polycarbonate/Polyester Alloy --

Other:

Absorbent Glass Mat -- 1 - 2

Inorganic lead and sulfuric acid electrolyte are the primary components of every battery manufactured by Tesla™ Products.

There are no mercury or cadmium containing products present in batteries manufactured by Tesla™ Products.

Explosive Chemical, Division 1.3

SAFETY DATA SHEET

HEALTH

ENVIRONMENTAL

PHYSICAL

Aquatic Chronic 1

Aquatic Acute 1

HEALTH

ENVIRONMENTAL

PHYSICAL

Components

Page 4

Form #: SDS 853027

Revised: 05/14/15

Supersedes: NEW

ECO #: 1001584

SAFETY DATA SHEET

IV. FIRST AID MEASURES

Inhalation:

Sulfuric Acid: Remove to fresh air immediately. If breathing is difficult, give oxygen. Consult a physician

Lead: Remove from exposure, gargle, wash nose and lips; consult physician.

Ingestion:

Sulfuric Acid: Give large quantities of water; do not induce vomiting or aspiration into the lungs may occur and can cause permanent injury or death;

consult a physician

Lead: Consult physician immediately.

Skin:

Sulfuric Acid: Flush with large amounts of water for at least 15 minutes; remove contaminated clothing completely, including shoes.

If symptoms persist, seek medical attention. Wash contaminated clothing before reuse. Discard contaminated shoes.

Lead: Wash immediately with soap and water.

Eyes:

Sulfuric Acid and Lead: Flush immediately with large amounts of water for at least 15 minutes while lifting lids

Seek immediate medical attention if eyes have been exposed directly to acid.

V. FIRE FIGHTING MEASURES

Flash Point: N/A Flammable Limits: LEL = 4.1% (Hydrogen Gas)

UEL = 74.2% (Hydrogen Gas)

Extinguishing Media: Carbon dioxide; foam; dry chemical. Avoid breathing vapors. Use appropriate media for surrounding fire.

Special Fire Fighting Procedures:

If batteries are on charge, shut off power. Use positive pressure, self-contained breathing apparatus. Water applied to electrolyte generates

heat and causes it to spatter. Wear acid-resistant clothing, gloves, face and eye protection.

Note that strings of series connected batteries may still pose risk of electric shock even when charging equipment is shut down.

Unusual Fire and Explosion Hazards:

Highly flammable hydrogen gas is generated during charging and operation of batteries. To avoid risk of fire or explosion, keep sparks or other

sources of ignition away from batteries. Do not allow metallic materials to simultaneously contact negative and positive terminals of cells and

batteries. Follow manufacturer's instructions for installation and service.

VI. PRECAUTIONS FOR SAFE HANDLING AND USE

Spill or Leak Procedures:

Stop flow of material, contain/absorb small spills with dry sand, earth, and vermiculite. Do not use combustible materials. If possible, carefully

neutralize spilled electrolyte with soda ash, sodium bicarbonate, lime, etc. Wear acid-resistant clothing, boots, gloves, and face shield. Do not

allow discharge of unneutralized acid to sewer. Acid must be managed in accordance with local, state, and federal requirements.

Consult state environmental agency and/or federal EPA.

VII. HANDLING AND STORAGE

Handling:

Unless involved in recycling operations, do not breach the casing or empty the contents of the battery.

There may be increasing risk of electric shock from strings of connected batteries.

Keep containers tightly closed when not in use. If battery case is broken, avoid contact with internal components.

Keep vent caps on and cover terminals to prevent short circuits. Place cardboard between layers of stacked automotive batteries to avoid damage and short circuits.

Keep away from combustible materials, organic chemicals, reducing substances, metals, strong oxidizers and water. Use banding or stretch wrap to secure items for

shipping.

Storage:

Store batteries in cool, dry, well-ventilated areas with impervious surfaces and adequate containment in the event of spills. Batteries should

also be stored under roof for protection against adverse weather conditions. Separate from incompatible materials. Store and handle only

in areas with adequate water supply and spill control. Avoid damage to containers. Keep away from fire, sparks and heat. Keep away from metallic objects which

could bridge the terminals on a battery and create a dangerous short-circuit.

Charging:

There is a possible risk of electric shock from charging equipment and from strings of series connected batteries, whether or not being charged. Shut-off power to

chargers whenever not in use and before detachment of any circuit connections. Batteries being charged will generate and release flammable hydrogen gas.

Charging space should be ventilated. Keep battery vent caps in position. Prohibit smoking and avoid creation of flames and sparks nearby.

Wear face and eye protection when near batteries being charged.

For expanded detailed info, download the PDF online at...

http://www.teslaind.com/PDF/chart/Tesla-Safety-Data-Sheet.pdf

or go to

http://www.teslaind.com/support-manuals.php

and click on

“Battery Safety Data Sheet” link under “Battery Info” heading.

or use the QR Code to the right.

Page 5

Table of Contents

Section 1 – Safety Review 1

1.1 – Safety Notices 1

1.2 – Symbols 1

1.3 – Hazards 2

1.4 – Important Safety Precautions 3

1.5 – Extreme Environments 3

Section 2 – Product Overview 4

2.1 – Introduction 4

2.2 – Indication of Terms: Shall, Should and May 4

2.3 – Front Panel Overview 5

2.4 – General Specications 6

2.5 – Physical Dimensions 7

2.6 – Airow Ports 7

2.7 – Operating Positions 8

2.8 – AC Input Circuit Breaker 9

2.9 – 24 VDC Output Connector 9

2.10 – Input Voltage Selector Switch 10

2.11 – “Push to Test” Button and LED Status Indicator 11

Section 3 – Operating Procedures 12

3.1 – Operating Procedures 12

3.2 – General 12

3.3 – Operating Limits and Restrictions 12

3.4 – Performance 12

3.5 – Temperature Specications 13

3.6 – Environmental 14

3.7 – Normal Functional Test Procedures 15-16

3.8 – Pre-Operation 17

3.9 – Transporting Unit 17

3.10 – Regulated AC Power 18

3.11 – Charging Unit 18

TI1000 GPU-24 UAV

Page 6

Section 4 – Post Operation 19

4.1 – General 19

4.2 – After Use 19

4.3 – Power Cell Recharge 19-20

Section 5 – Unit Care and Maintenance 21

5.1 – Unit Care 21

5.2 – Unit Servicing 22

5.3 – Packaging and Shipping 22

5.4 – Storage 22

Section 6 – Troubleshooting and FAQ 23

6.1 - Frequently Asked Questions 23-24

6.2 - Basic Usage/Operation Questions 24

6.3 - Basic Troubleshooting 25

Section 7 – Performance Data 26

7.1 – Purpose 26

7.2 – General 26

7.3 – Data Basis 26

7.4 – Specic Conditions 26

7.5 – General Conditions 26

7.6 – Temperature Conversion Chart 27

7.7 – Output Voltage 28

7.8 – Maximum Output Current 28

Section 8 – Optional Accessories 29

8.1 – Tesla™ Shipping Case 29

8.2 – GPU Protective Covers 29

8.3 – Tesla™ AC Line Cords 29

8.4 – Transport Dolly 30

Appendix A 31-35

Repair Request Form 37

TI1000 GPU-24 UAV

Page 7

Abbreviations and Symbols

Abbreviations that may be used within the text, headings and titles of this manual.

LIST OF ABBREVIATIONS

Abbreviation Defi nition

ac Alternating Current

AFT Air ow Technology

AWG American Wire Gauge

amp or A Ampere

cont Continuous

°C Degree Celsius

°F Degree Fahrenheit

dc Direct Current

EFF Ef ciency

ft Feet

FWD Forward

GPU Ground Power Unit

Hr Hour

Hz Hertz

kg Kilograms

kHz Kilohertz

kW Kilowatts

LED Light Emitting Diode

max Maximum

MΩ megaohm

min Minimum

MPU Micro Power Unit

NEMA National Electrical Manufacturers Association

Ω ohm

PF power factor

PFC power factor correction

rms root-mean-square

THD Total Harmonic Distortion

TMDE Test, Measurement, & Diagnostic Equipment

UAV Unmanned aerial vehicle

Vac Volts, Alternating Current

Vdc Volts, Direct Current

W watts

TI1000 GPU-24 UAV

Page 8

Figure 1.2.1 – Different types of hazard and caution symbols

1.1 - Safety Notices

Safety notices appear throughout this manual to alert the user to important information regarding proper

installation, operation, maintenance and storage of the unit. These notices, as illustrated below, contain a

key word that indicates the level of hazard and a triangular icon that indicates the speci c type of hazard.

WARNING

Indicates a condition, operating procedure or practice, which if not

adhered to could result in serious injury or death.

CAUTION

Indicates a condition or operating procedure, which if not strictly

adhered to could result in damage or destruction of equipment.

NOTE

Indicates a condition, operating procedure or practice, which is

essential to highlight.

1.2 - Symbols

The following symbols will appear within the warning triangles to alert the user to the speci c type of danger

or hazard.

General Warning Electrical Hazard Explosion Hazard Fire Hazard

Battery Warning Guard from Moisture

!

Section 1 – Safety Review

!

!

!

TI1000 GPU-24 UAV

1

Page 9

1

Safety Review

1.3 – Hazards

WARNING

Severe injury or death from electrical shock may occur, if either user

or the unit is wet, while the unit is connected to a power source. If the

unit has come into contact with water, discon nect ac power from the ac

source. If AC Input Circuit Breaker has tripped due to water in ltration,

DO NOT try to reset it with the ac line voltage attached.

WARNING

Severe injury or death from electrical shock can occur when damp electrical plugs are connected to the

unit. Before making any connections, turn off unit. Failure to use proper grounding can cause potential

shock hazard! In different countries, the power cord may require the use of a plug adapter to achieve plug

style compatibility for operation. Use only adapters with proper grounding mechanism.

Shock Hazard Potential

Shock Hazard Potential

Figure 1.3.1 – Proper Ground

Grounded Plug with Grounding Pin

CAUTION

The use of unapproved ac power will damage the unit. Check the

Input Voltage Selector Switch window (outlined in blue) to ensure

the switch setting (115V or 230V) matches the ac power source

(hangar wall, ight line ac power) prior to connecting the unit for

recharging.

Unit Damage Potential

Figure 1.3.2 – Proper Ground

Adapter with Grounding Mechanism

(Secured to Outlet)

Figure 1.3.3 – Improper Ground

Plug with No Grounding Pin

Figure 1.3.4 – TI1000 GPU-24 UAV

Input Voltage Selector Switch

2

TI1000 GPU-24 UAV

Page 10

1.4 – Important Safety Precautions

Safety Review

1

WARNING

Severe injury or death from re or explosion can occur if electrical sparks are produced near fuel vapors. DO

NOT CONNECT ac power supply WHILE FUELING. AC power functions of unit shall not be operated during any

fuel handling operation. Power output is restricted to dc power only.

Fire/Explosion Hazard Potential

1.5 – Extreme Environments

CAUTION

The unit’s charger temperature switch automatically disables the unit when the internal temperature exceeds

150°F (65°C). This protects the unit from overheating and damage. If the unit shuts down, move the unit

into a cooler environment such as shade or air conditioning when possible. Perform a full function test, after

the unit has been allowed to cool, prior to use.

Unit Damage Potential

TI1000 GPU-24 UAV

3

Page 11

Section 2 – Product Overview

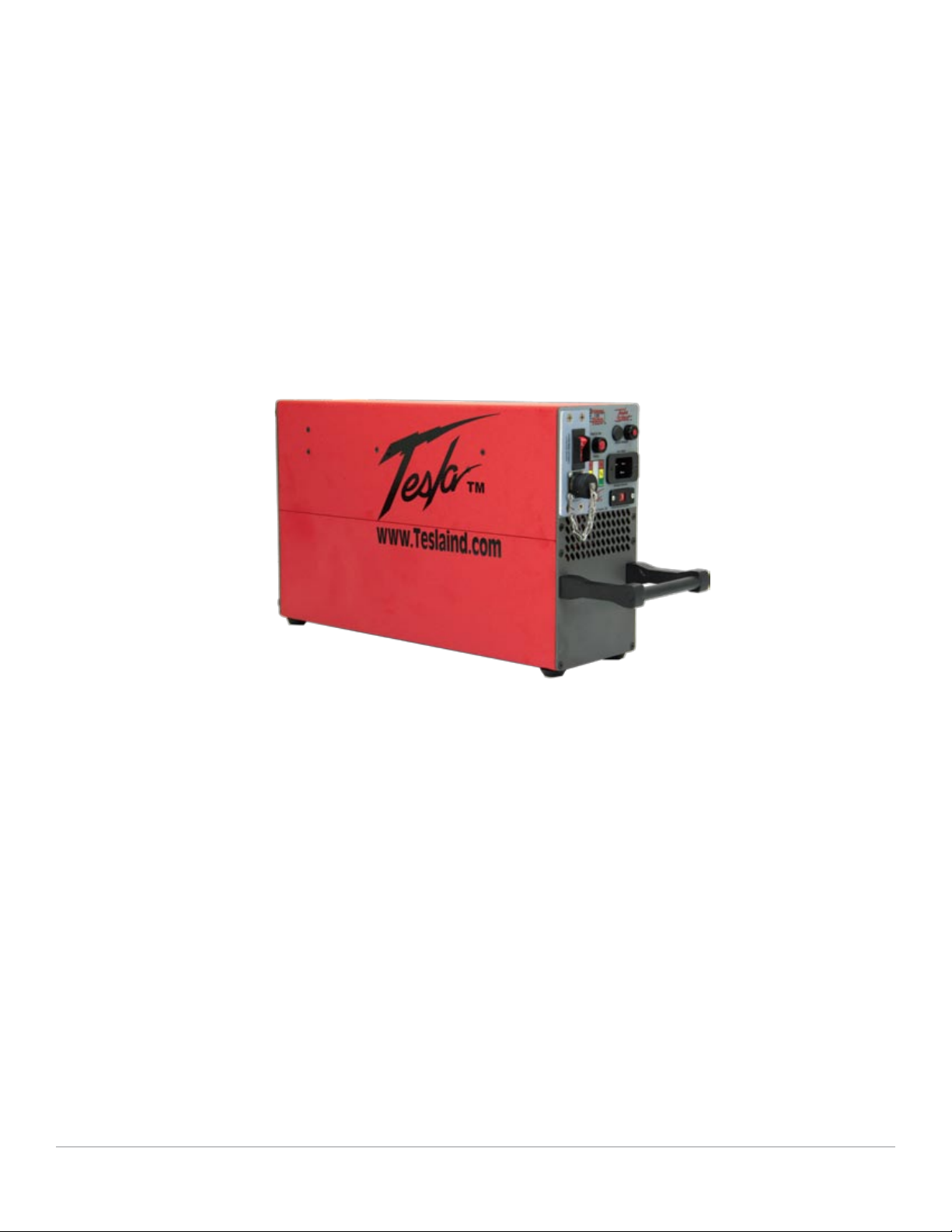

2.1 – Introduction

Thank you and congratulations on the purchase of your new TI1000 GPU-24 UAV Ground Power Unit.

The TI1000 GPU-24 UAV provides DC electrical ground power for aircraft ight line, maintenance, and

ground support operations. The unit is designed to provide 24 volt DC output for aircraft engine starting

and 24 or 28.5 volts DC output for ground maintenance, avionics/electrical troubleshooting and testing.

The observance of procedures, limitations and performance criteria ensures peak operating efciency and

maximizes operational capabilities and life of the TI1000 GPU-24 UAV.

This manual contains the complete operating instructions and procedures for the TI1000 GPU-24 UAV

needed to safely and efciently operate this GPU.

Figure 2.1.1 – TI1000 GPU-24 UAV

2.2 – Indication of Terms: Shall, Should and May

Within this technical manual the word “shall” is used to indicate a mandatory requirement for proper operation

and warranty purposes. The word “should” is used to indicate a non-mandatory but preferred method of

accomplishment. The word “may” is used to indicate an acceptable method of accomplishment.

4

TI1000 GPU-24 UAV

Page 12

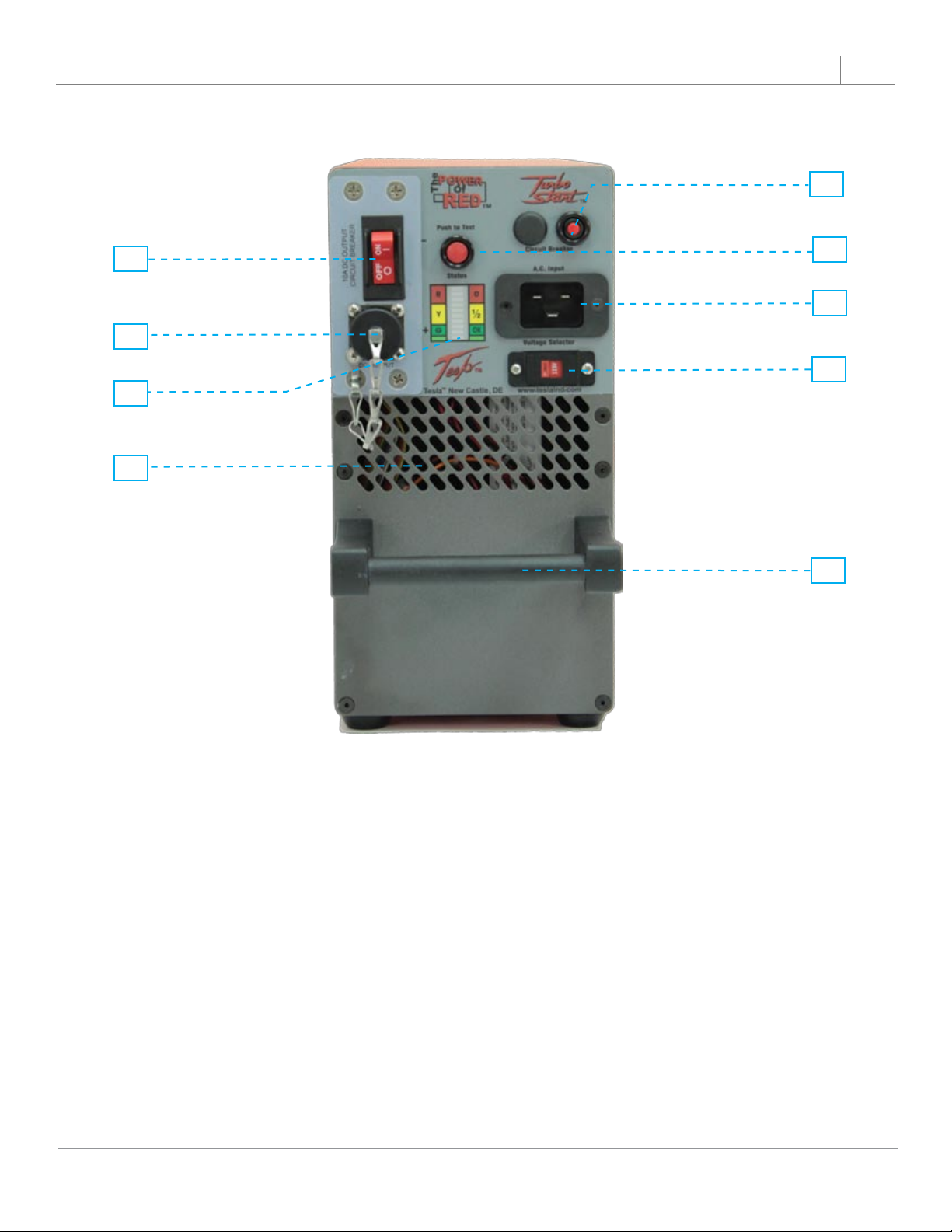

2.3 – Front Panel Overview

Product Overview

2

1

3

2

5

4

7

6

8

9

AC Input Circuit Breaker1. – Trips if over-current

fault condition occurs.

“Push to Test” Button2. – Displays current battery

charge state when pressed.

DC Output Circuit Breaker3. – Trips if over-current

fault condition occurs.

24 VDC Output Connector4. – Provides 24 Vdc to

28.5 Vdc @ 10 A.

AC Input Connector5. – Connects to Single Phase

100-260 Vac line voltage.

TI1000 GPU-24 UAV

24 VDC Capacity Meter6. – Indicates the 24V battery

charge state/power output status.

Input Voltage Selector Switch7. – Allows unit to

operate within voltage range of either 100-130

Vac or 200-260 Vac.

Air Intake Ports8. – Provide airow for cooling

internal electronics.

Carrying Handle9. – Allows for easy transport of unit.

5

Page 13

2

Product Overview

2.4 – General Specications

Electrical

AC Input:

Operates and charges from Single Phase 100-260 Vac, 50/60 Hz•

10 Amps @ 120 Vac 60 Hz - 1200 Watts•

5 Amps @ 240 Vac 60 Hz - 1200 Watts•

Power Cell:

Dry, High Rate Discharge, Rechargeable , Maintenance-free•

DC Output:

10 amps continuous @ 28.5 Vdc (when plugged into ac power)•

Rechargeable Rate:

60 minutes (from full discharge) @ 25°C•

Size:

20.61” long x 5.2” wide x 10.56” high•

523.49mm x 132.08mm x 268.25mm•

Weight

57 lbs (28.85 kg)•

Operating Temperature:

-40°C to +60°C (-40°F to 140°F) without ac power•

-40°C to +55°C (-40°F to 131°F) with ac power•

Storage Temperature:

-65°C to +105°C (-85°F to 221°F)•

Cell Capacity:

+40°C 110% ± 05%•

+25°C 100% ± 05%•

+00°C 80% ± 05%•

-20°C 65% ± 10%•

-40°C 50% ± 10%•

6

TI1000 GPU-24 UAV

Page 14

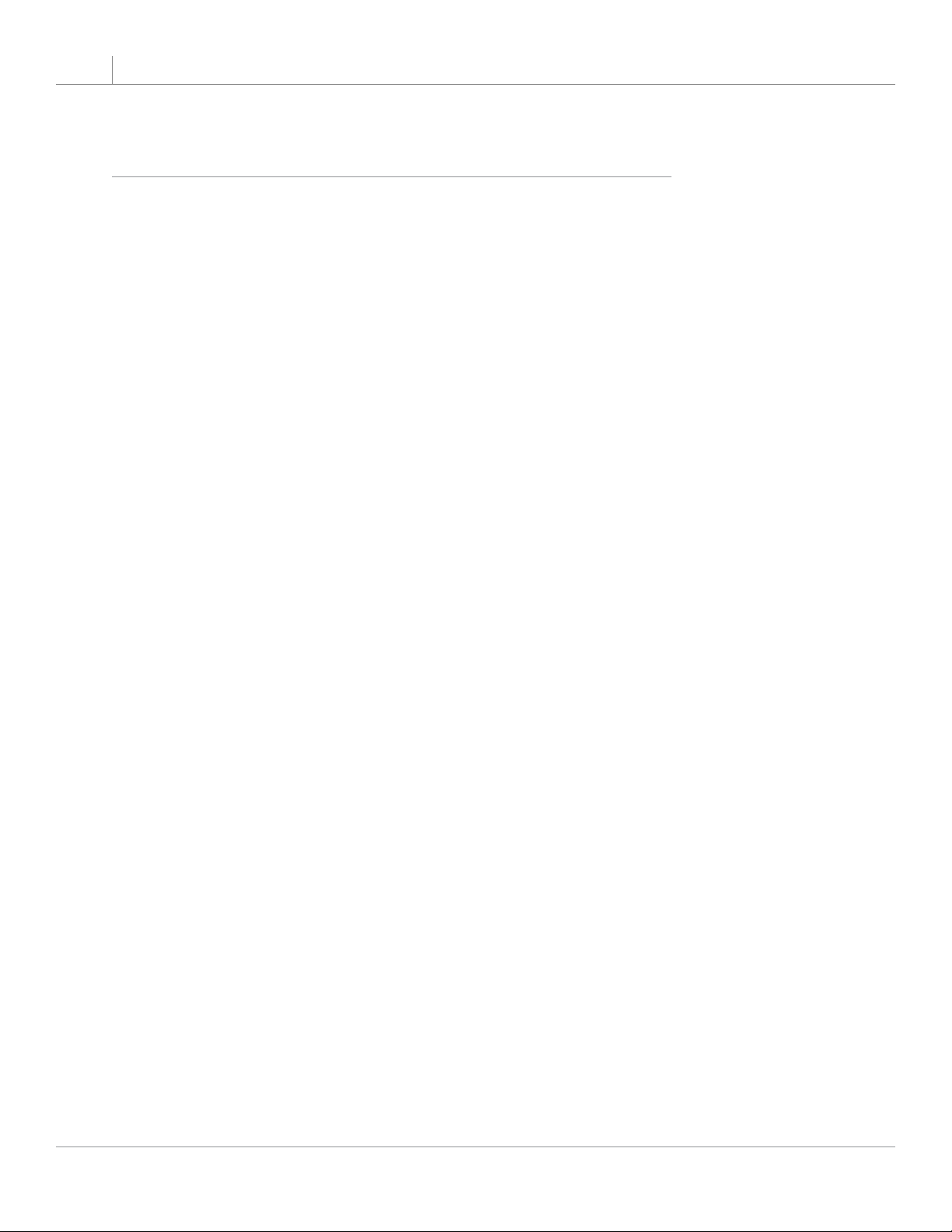

2.5 – Physical Dimensions

Product Overview

2

Figure 2.5.1 – TI1000 GPU-24 UAV physical dimensions

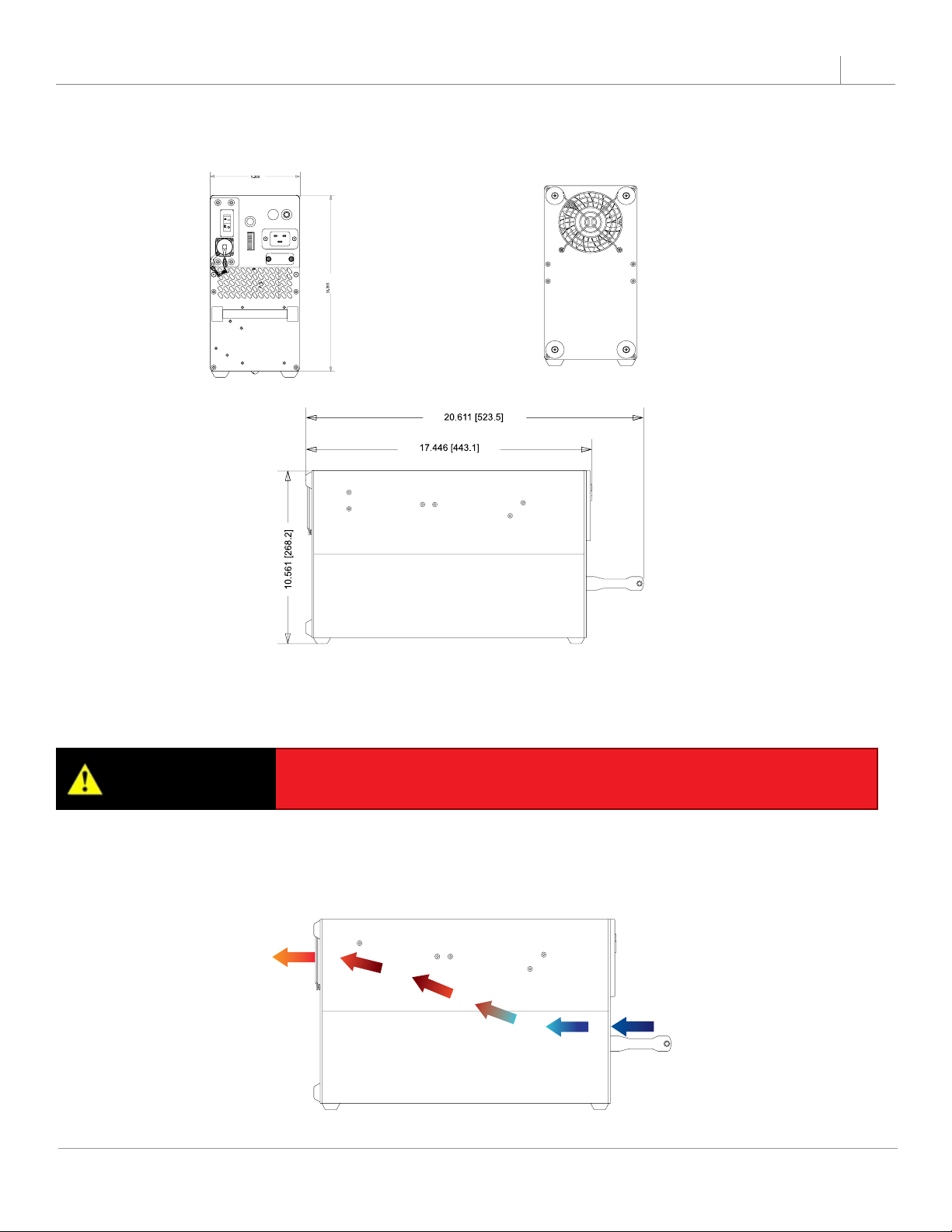

2.6 – Airow Ports

CAUTION

When the TI1000 GPU-24 UAV is plugged into ac power, the internal cooling system will efciently regulate unit

temperature regardless of load. At room temperature (+77°F) the exhaust air will not exceed the ambient

temperature by more than 5°F. In more extreme temperatures (greater than 90°F) the exhaust air will not

exceed the ambient temperature by more than 10°F.

Damage may occur if the TI1000 GPU-24 UAV’s air intake or outlet ports

are obstructed. Ensure that ports are clear at all times.

TI1000 GPU-24 UAV

Figure 2.6.1 – Air intake, exhaust ports and internal air circulation

7

Page 15

2

Product Overview

2.7 – Operating Positions

The TI1000 GPU-24 UAV can be operated in both the horizontal (Figure 2.7.1) and vertical (Figure 2.7.2)

positions as shown. Make sure that the airow is not obstructed from air intake (Figure 2.7.3) and outlet

(Figure 2.7.4).

Figure 2.7.2 Horizontal Position

Figure 2.7.1 Vertical Position

8

Figure 2.7.3 Front Inlet Figure 2.7.4 Rear Outlet

TI1000 GPU-24 UAV

Page 16

Product Overview

2

2.8 – AC Input Circuit Breaker

The ac input circuit breaker is located above the ac input connector. When the circuit breaker has been

tripped, the red button will pop out. In the event that the breaker trips:

Disconnect the ac and dc connectors. (Unplug ac line cord on military unit.)1.

Wait for a minimum of 60 seconds.2.

Reset breaker by pressing red button.3.

Reconnect ac and dc connections to the unit. (Plug in ac line cord on military unit.)4.

The unit should power up automatically. If the breaker continues to trip, return the unit to Tesla™ Industries

for repair.

Figure 2.8.1 - AC Input Circuit Breaker

(outlined in blue)

Figure 2.8.2 - Pressing Circuit Breaker

2.9 – 24 VDC Output Connector

The 24 Vdc output connector will provide 10 amps continuous @ 28.5 Vdc (when plugged into ac power).

When the output connector is not in use, cover the receptacle with the protective cover (see Figure 2.9.1).

This will protect the output connector from dust and foreign matter.

Closed

Open

TI1000 GPU-24 UAV

Figure 2.9.1 - 24 VDC Output Connector Protective Cover

9

Page 17

2

Product Overview

2.10 – Input Voltage Selector Switch

The Input Voltage Selector Switch allows the unit to operate safely within the expected voltage range

of either 100-130 Vac or 200-260 Vac.

Figure 2.10.1 Input Voltage Selector Switch (outlined in blue)

Changing Input Voltage Selector Switch

To change the input voltage from 115 Vac to 230 Vac, simply follow these steps:

With cross tip screwdriver, remove one screw and rotate the clear protective cover to one side. (see gure 1.

2.10.2)

Flip the switch to read 230V. (see gure 2.10.3)2.

Rotate cover back into place. Replace and tighten screw.3.

CAUTION

!

NOTE

!

Do not plug unit into 230 Vac when Input Voltage Selector Switch is

set on 115 Vac.

The 115 Vac setting accommodates the voltage range of 100-130 Vac.

The 230 Vac setting accommodates the voltage range of 200-260 Vac.

10

!

Figure 2.10.2 - Unscrew Protective Cover Figure 2.10.3 - Select Voltage

Do not overtighten Selector Shield screws. Be sure star locks are on

NOTE

screws and snug the screw. Overtightening will damage the Selector

Shield.

TI1000 GPU-24 UAV

Page 18

Product Overview

2

2.11 – “Push to Test” Button and LED Status Indicator

The “Push to Test” button indicates the capacity of the power cells without applying ac input power. The status

of the capacity lets the user know if there is enough power to perform another engine start. When the capacity is

low the unit should be connected to ac power to allow it to recharge.

Make sure that you wait at least 2 minutes after ac power is applied, or dc power is extracted from 1.

the unit, before you press the “Push to Test” button. This ensures a correct reading.

Without ac power input or dc power output, simply press the “Push to Test” button on the faceplate 2.

and hold for approximately 2 to 3 seconds.

The LED bar graph should light up indicating the status of the power cells.3.

In addition, the fan(s) should start operating when the button is pressed. If you do not hear the 4.

fan(s) running, stop pressing the button and check for any obstructions.

CAUTION

!

CAUTION

!

Figure 2.11.1 - “Push to Test” button location

(outlined in blue)

Never press the “Push to Test” button while the unit is plugged into

aircraft, vehicle or ac power.

Never press the “Push to Test” button for more than 5 seconds. This

may cause a temperature sensor to temporarily disrupt “Push to

Test” function. (If this sensor is tripped, allow ten minutes for unit to

cool before operating “Push to Test” button.)

Figure 2.11.2 - Pushing to Test

STATUSSTATUS STATUS

R

Y

G

Full Charge Half Charge No Charge

TI1000 GPU-24 UAV

0

1/2

OK

Y

G

R

0

1/2

OK

R

Y

G

0

1/2

OK

11

Page 19

Section 3 – Operating Procedures

3.1 – Operating Procedures

This section covers normal procedures and steps necessary to ensure safe and ef cient operation of the

unit.

NOTE

!

When not in use, the unit should always remain plugged into a suitable ac

power source to ensure operational readiness at all times.

NOTE

!

If current demand exceeds 25 amps, converter output voltage will drop below

28.5 Vdc and two or more LED status indicator bars will illuminate. If all

LED status indicator bars illuminate, both the converter and power cells are

supplying 24 Vdc power output.

3.2 – General

The user should be well-versed in both pre-use and functional checks for correct operations of this unit.

Knowledge of the operating limits, restrictions, performance, unit capabilities and functions aids in correct

and safe operations. Compliance with the instructions in this manual affect operational safety as well as the

warranty of the unit.

3.3 – Operating Limits and Restrictions

The minimum, maximum and normal operating ranges result from careful engineering and evaluation of test

data. These limitations must be adhered to during all phases of operation.

3.4 – Performance

Refer to Section 7, PERFORMANCE DATA to determine the capability of the unit. Consideration must be given

to changes in performance resulting from variations in ambient temperature, mode of operation, state of

charge (with or without ac power), and aircraft dc bus system inef ciency (voltage drops).

If current demand exceeds 10 amps, converter output voltage will drop below

28.5 Vdc and two or more LED status indicator bars will illuminate. If all

LED status indicator bars illuminate, both the converter and power cells are

supplying 24 Vdc power output.

12

TI1000 GPU-24 UAV

Page 20

Operating Procedures

Hot Soaked or Cold Soaked De nition

Simple terms: When a material is exposed to a change in temperature, its temperature will also change.

Some material changes temperature quickly, others slowly. If the ambient temperature changes and is then

held constant, the materials temperature will also change until its temperature stabilizes. Once the material

temperature has stabilized, it is considered “soaked”.

Example: A unit is moved from the cool shade into the hot sun. That unit’s temperature will increase until it

stabilizes. Once stabilized, the unit would be considered “hot soaked”.

NOTE

!

The unit’s temperature switch automatically disables ac power functions

when the internal temperature is above 150°F (65°C). This protects the unit

from overheating and damage. If the unit shuts down, move the unit into a

cooler climate, such as shade or air conditioning when possible. Perform a

full function test prior to use after the unit has been allowed to cool.

3.6 – Temperature Speci cations

Cold/Hot Soaked Temperature

Exposing the unit for one (1) hour or more to the ambient temperature establishes the unit’s cold/hot

soaked stabilization temperature. If the unit’s cold/hot soaked temperature is outside the normal operating

temperature range, the unit must be stabilized prior to operation. For COLD SOAKED tem perature stabilization,

the unit must be placed in an environment with a temperature above +10°C (+41°F) for 3 hours or a

temperature above +20°C (+68°F) for 2 hours. For HOT SOAKED temperature stabilization, the unit must

be placed in an environment with a temperature below +38°C (+100°F) for 1 hour.

120%

100%

80%

60%

40%

+40°C +25°C +0°C -20°C -40°C

Ambient

Temperature

+40°C (+104°F)

+25°C (+77°F)

+0°C (+32°F)

-20°C (-4°F)

-40°C (-40°F)

110% ±5%

100% ±5%

80% ±5%

65% ±10%

50% ±10%

Percentage of

Cell Capacity

Figure 3.6.1 – Output power capability versus ambient temperature

3

3.5 – Temperature Specications

TI1000 GPU-24 UAV

13

Page 21

3

3.7 – Environmental

If the unit is exposed to moisture, preventive measures and precautions shall be taken to:

A. Prevent accumulation of moisture on ac and dc connectors/receptacles

B. Minimize moisture entering forward inlet and aft outlet cooling fan vent ports

Unit inlet and outlet vent ports shall be covered from exposure. Unit shall be kept horizontal.

Recommendations include a Protective Rain Cover to guard the unit from moisture (see Section 8). The limits

and operational constraints listed below shall apply for the following environmental (weather) conditions:

WARNING

Operating any electrical equipment in the presence of moisture creates

possible safety hazards and/or potential for equipment damage. Every

effort has been made, within the scope of existing technology to prevent

foreseeable safety hazards and make the unit moisture resistant to prevent

damage or failure.

Conditions

With

Raincover

Without Raincover

Heavy or steady rain:

Precipitation falling with an intensity in excess of 0.30 inch

(0.76 cm) or continuously between 0.30 and 0.10 inch per hour.

OK OPERATION NOT RECOMMENDED

Light rain, drizzle or sleet:

Precipitation falling on a continuous basis between 0.10 inch

and less than 1/50 inch (0.5 mm) per hour

OK DC OPERATIONS ONLY

Heavy or steady snow:

Generally meaning an accumulation between 4 inches and less

than 1 inch in a 12 hour period.

OK OPERATION NOT RECOMMENDED

Light snow:

Snow falling intermediately with little or no accumulation.

OK DC OPERATIONS ONLY

Fog:

OK OK

Operating Procedures

3.6 – Environmental

14

TI1000 GPU-24 UAV

Page 22

Operating Procedures

3

3.7 – Normal Function Test Procedures

This section involves “normal function” test proce dures, and includes steps necessary to ensure that the

TI1000 GPU is operating within specied para meters prior to use. A digital multimeter (an example is shown

in Figure 3.7.1) capable of measuring dc and ac voltage and resistance will be required to perform some of

the tests. These functional test procedures should become routine.

Figure 3.7.1 – Digital Multimeter

Check Unit for Evidence of Damage

Check for dents, punctures, case distortion or misalignment, and cracked or loose connec tors. If no damage

is evident, proceed to the next step. If damage is evident, contact Tesla™ Industries, Inc.

Check DC Voltage Reading at DC Receptacle Terminals

To verify that the power cells are fully charged, set the digital multimeter to

measure dc voltage. Turn on the DC Circuit Breaker before testing. As shown

in Figure 3.7.2., place the positive probe (red) on the positive post (C) of the

DC Output Connector and the negative probe on the negative post (A). The

multimeter display should read approximately 28.5 Vdc (± 0.5 Vdc) when

power cells are fully charged and the unit is

plugged into an appropriate ac power source.

When the unit is not plugged into an ac power

source, the multimeter display should read

approximately 25.5 Vdc.

B = case

ground

A = (-)

C = (+)

TI1000 GPU-24 UAV

Figure 3.7.2 – Testing DC Receptacle

Figure 3.7.3 – DC Circuit

Breaker and Output

15

Page 23

3

Operating Procedures

Check Unit Internal Resistance (Test for Shorts)

!

1. Set multimeter to Ohms.

NOTE

Unit should be disconnected from any ac power sources prior to testing.

2. Turn on the DC Circuit Breaker.

2. Place the negative probe on the

ac ground post and the positive

probe to the dc positive post (C).

Multimeter should read greater

than 10 MΩ.

4. Move the positive probe to the dc

negative post (A). Multimeter should

read greater than 10 MΩ.

1. Set multimeter to Volts.

16

5. Move the positive probe to the pin

(B) on the dc receptacle. Multimeter

should read less than 1Ω.

2. Place the positive probe to the

fastener screw on the dc post.

Move the negative probe to the

dc negative post (A). Multimeter

should read 0 Volts.

6. Move the positive probe to the

fastener screw on the dc plate.

Multimeter should read less than

1Ω.

3. Place the negative probe to the

fastener screw on the dc plate.

Move the positive probe to the

dc positive post (C). Multimeter

should read 0 Volts.

TI1000 GPU-24 UAV

Page 24

Operating Procedures

3.8 – Pre-Operation

1. Be sure to check that all input and output cables are not damaged. (See Section 5.1)

2. Check unit carefully for any evidence of damage.

3. Make sure that airow is not obstructed from air intake and outlet. (See Section 2.6)

4. Check that all connections are secure and free from water.

Figure 3.8.1 - TI1000 GPU-24 UAV

3

3.9 – Transporting Unit

The TI1000 GPU-24 UAV can be carried for short distances by hand, but if the area of operation is further

then 45 meters (150 feet) it is recommended that the TI1000 GPU-24 UAV should be transported on a

vehicle or in the TI7000-184 Transport Dolly (see Section 8 Optional Accessories).

TI7000-184 Transport Dolly Dimensions:

16.87” L x 14.5” W x 49.25” H

428.50 mm x 368.30 mm x 1250.95 mm

Weight:

18.5 lbs (8.39 kg)

TI1000 GPU-24 UAV

Figure 3.9.1 TI7000-184 Transport Dolly

17

Page 25

3

Operating Procedures

3.10 – Regulated AC Power

Plugging in with AC Power

When the TI1000 GPU-24 UAV is plugged into ac power, the output is 28.5 volts. This voltage allows the

system to recondition and recharge the vehicle’s battery(s). It is also an optimum voltage for powering

avionics and lighting on most aircraft. The GPU’s ac to dc converter produces continuous amps of dc power

depending on the size of the system.

!

NOTE

Check Input Voltage Selector Switch for proper setting.

Connect AC Power Cord To Unit

Ensure 120 or 240 Vac power cord is properly connected to an approved ac power supply. After approximately

5-8 seconds, unit’s LED status indicator will illuminate indicating power cell state of charge. Cooling fan will

operate. Ensure LED status indicator and cooling fan is operational prior to continuing.

Figure 3.10.1 Connecting TI1000 GPU-24 UAV to

ac power supply

Figure 3.10.2 AC North American Line Cord

3.11 – Charging Unit

Once you have the voltage selector switch set to match the power characteristics of your line cord, you can

plug the unit into a wall socket to charge the batteries. Until the unit is fully charged, the LED status will read

half or no charge. Plug the TI1000 GPU-24 UAV into ac power to keep the cells charged whenever it is not in

use, even if it is at Full Charge. The unit will not overcharge or overheat.

If you received this manual with a new GPU.

When the Unit is fully charged the LED indicator should show a single steady green bar. The fan will also

come on at reduced speed. This is normal operation indicating the unit is in standby mode and is ready for

use.

If you own an older GPU and this is a replacement manual.

Under a full charge the LED indicator should show a single steady green bar or the entire LED will be blinking.

The fan will also exhibit ratcheting but will not come on. This is normal operation indicating the unit is in

standby mode and is ready for use.

If the GPU’s cells need to be replaced.

After 60 minutes of ac power input, the unit should be fully charged. If the “Push to Test” button is pressed

and the unit still indicates it is not fully charged then the cells should be replaced.

18

TI1000 GPU-24 UAV

Page 26

Section 4 – Post Operation

4.1 – General

Although the TI1000 GPU-24 UAV has been ruggedized and made weather resistant within the scope of unit’s

intended use, it is essential that good general care be taken to maintain unit in good operating condition and

to maximize unit’s operational life.

4.2 – After Use

Unit should be protected from environmental elements and man made hazards. Ideally unit should be secured

in a building or shed. Most importantly, unit shall be fully covered if stored while exposed to environmental

elements.

4.3 – Power Cell Recharge

!

!

NOTE

NOTE

The TI1000 GPU-24 UAV incorporates a backcharge feature that enables

the unit to be recharged from the vehicle once the engine is started and

the starter/generator is running. This feature will enable you to start

multiple vehicles without reconnecting to ac power if the GPU is allowed to

backcharge for approximately 30 seconds.

Plug the TI1000 GPU-24 UAV into ac power to keep the cells charged

whenever it is not in use, even if it is at Full Charge. The unit will not

overcharge or overheat.

Connect AC Power Cord to Unit

!

Ensure 120 or 240 Vac power cord is properly connected to an approved ac power supply. After approximately

5-8 seconds, ensure unit’s LED status indicator illuminates indicating power cell state of charge and cooling

fan is operating.

Any time the unit’s power cells are fully discharged the unit shall be recharged within 24 hours to prevent

performance degradation and ensure maximum life.

NOTE

Check Input Voltage Selector Switch for proper setting.

Figure 4.3.1 Connecting TI1000 GPU-24 UAV to

ac power supply

TI1000 GPU-24 UAV

Figure 4.3.2 AC North American Line Cord

19

Page 27

4

Post Operations

CAUTION

The TI1000 GPU-24 UAV’s power cells may be damaged if recharged by NiCad or Lithium Ion battery chargers.

Power cells should only be charged by either the TI1000 GPU-24 UAV’s internal charger and the ac power

cord furnished with the equipment, or when connected to vehicle or aircraft’s external dc power receptacle.

Guard From Incorrect Power Source

OKOK

20

Figure 4.3.3 - Proper and Improper Charging Methods

TI1000 GPU-24 UAV

Page 28

5.1 - Unit Care

Avoid Prolonged Exposure to Extremely Damp Environments

If the unit has come into contact with water, disconnect ac power from the ac source. If the AC Input Circuit

Breaker has tripped due to water in ltration, allow the unit to dry out before attempting to reset circuit

breaker. Cover the unit to prevent water seepage. If the unit is operated in extremely damp conditions, it

should be stored in an environmentally controlled building when not in use. Wipe unit clean periodically with

a soft cloth to remove dust, dirt, etc.

Protect Cables from Damage

Do not cut, crush, or drag the input or output power cables when handling the unit. Always inspect cables

prior to use. If no damage is evident, proceed to the next step. If damage is evident, contact Tesla™

Customer Service. Do not attempt to use any other type of power cables other than the Tesla™ cables

included with the unit.

Figure 5.1.1 – Damaged cable

WARNING

Severe injury or death from electrical shock may occur, if either the user

or the unit is wet, while the unit is connected to a power source.

CAUTION

The use of unapproved or modi ed ac line cable or input plug may damage

the unit. Do not use any type of ac voltage converter.

Section 5 – Unit Care and Maintenance

TI1000 GPU-24 UAV

21

Page 29

5

Figure 5.2.1 – Warranty Void stickers Front and Back on the unit

5.2– Unit Servicing

This unit is a maintenance-free, sealed unit. No repairs outside of Tesla™ are authorized. Warranty will be

voided if unit is tampered with in any way including any damage to the WARRANTY VOID stickers located

on the case (see Figure 5.2.1 below). If the unit requires maintenance, please contact Tesla™ Customer

Service at (302) 324-8910. A Repair Request Form can be found in the back of this manual.

5.3 – Packaging and Shipping

Ensure proper packaging when returning the unit. Transport the unit only in a sturdy shipping crate or

Tesla™ Shipping Case. It is important to enclose the Repair Request Form. Seal the crate on all sides and

return it to Tesla™ at the address listed below. Please contact Tesla™ Customer Service at (302) 324-8910

with any questions or concerns.

TESLA™ INDUSTRIES, INCORPORATED

101 CENTERPOINT BLVD.

CENTERPOINT INDUSTRIAL PARK

NEW CASTLE, DELAWARE 19720

PHONE: (302) 324-8910 FAX: (302) 324-8912

Website: www.teslaind.com

Email: Tesla1@teslaind.com Figure 5.3.1 – Tesla™ Industries Shipping Case

5.4 – Storage

If unit can not be connected to ac power while in storage, we recommend to charge the unit once a year. The

shelf-life of 12 months is due to the battery /cells inside the unit. We guarantee the unit will hold 80% of its

charge for a period of 12 months without being recharged. When the GPU’s leave the facility, they are fully

charged and if they are to go into storage (without being used), they will maintain 80% of their charge after

12 months. The units has a life expectancy of 5 to 7 years, if maintained properly.

Unit Care and Maintenance

22

TI1000 GPU-24 UAV

Page 30

Section 6 – Troubleshooting and FAQ

6.1 – Frequently Asked Questions

1. How does a Tesla™ TI1000 GPU-24 UAV work?

The Tesla™ TI1000 GPU-24 UAV incorporates an intelligent charging system with a pure dc output that allows it to rapidly

charge and condition a battery without overcharging or damaging it.

2. How much dc power will the TI1000 GPU-24 UAV provide?

The TI1000 GPU-24 UAV will provide up to 50 conti nuous amps @ 28.5 Vdc.

3. How long will it take to charge my battery?

Battery charge time can be determined by taking the battery’s rated amp hours and dividing this number by the TI1000’s

maximum output current. For example, a 24 V / 50 Ah battery will take one hour to charge using a TI1000 GPU-24 UAV.

4. What is included with my TI1000 GPU-24 UAV?

This unit comes with a Tesla™ approved 8ft. DC Aviation Cable Assembly or a 15ft. DC NATO Cable Assembly, a North

American line cord, a user manual, and a limited two-year warranty.

5. Is the TI1000 GPU-24 UAV waterproof?

The TI1000 GPU-24 UAV is NOT waterproof. See Section 5.1 for further information regarding safe operation in damp

environments.

6. Are there any HAZMAT or disposal issues?

No. Contact Tesla™ for more information.

7. Are Tesla™ TI1000 GPU-24 UAV used in shop maintenance and testing?

Tesla systems are gaining popularity throughout maintenance facilities, instructional facilities, laboratories, manufacturing

plants, aircraft hangars and many other locations. The reason is due to the precise at line dc power, the small, portable

and quiet nature of our systems and the maintenance free aspect. We can custom tailor ground power systems to t your

individual requirements.

8. Can one person transport it?

The TI1000 GPU-24 UAV is designed to be handled by one person. The TI1000 GPU-24 UAV system weighs 57 lbs. and can

be carried or wheeled on a dolly. See section 8 for Transport Dolly info.

9. How do I get my unit serviced?

Contact Tesla. We can be reached at (302) 324-8910. Ask for customer service. You can also email us at

tesla1@teslaind.com. Once we receive the unit at our facility, we will examine it. Systems that are protected under warranty

will be repaired at no charge. If the warranty has expired, you will receive a quote for necessary repairs prior to work being

done. Our turnaround time is 48 hours once repairs are authorized.

TI1000 GPU-24 UAV

23

Page 31

6

Troubleshooting & FAQ

10. Can I make my own repairs to unit?

During the warranty period, the unit can only be repaired by Tesla™ Industries for the warranty to remain in effect. Regardless,

we strongly recommend allowing Tesla to repair any unit as we will analyze the complete system and re-calibrate it.

11. What type of maintenance does the unit require?

Although the systems are maintenance free, please keep the vent areas clean and free of debris. Keep units in a well

ventilated area. Keep the unit in a protected environment when not in use (maintenance facility, shed).

6.2 - Basic Usage/Operation Questions

1. What’s the best position to place the unit for use vertical or horizontal?

Preferred position is horizontal for stability and airow considerations.

2. How do I check the status of the Available Power?

The “Available Power” LED Indicator provides a way for the user to visually see the amount of available power that the unit

can supply. This lets the operator know if there is enough power to perform ground maintenance. For more information see

Section 2.11.

3. Why is the cooling fan always running when I am plugged into AC power?

Constant cooling fan operation ensures proper and consistent ventilation of the unit.

4. Why does the cooling fan slow down?

Cooling fan rpm varies for better temperature regulation.

5. What do I do if a circuit breaker trips?

The AC input circuit breakers are located above the AC Input Connector. When the circuit breaker has been tripped,

either of the red buttons will pop out. In the event that the breaker trips:

1. Disconnect the AC and DC connectors. (Unplug AC line cord on military unit.)

2. Wait for a minimum of 60 seconds.

3. Reset breaker(s) by pressing red button(s).

4. Reconnect AC and DC connections to the unit. (Plug in AC line cord on military unit.)

The unit should power up automatically. If the breaker continues to trip, return the unit to Tesla Industries for repair.

24

TI1000 GPU-24 UAV

Page 32

6.3 - Basic Unit Troubleshooting

Fault Possible Cause Remedy

Troubleshooting & FAQ

6

1. Output Capacity LED does not come

on.

2. Unit will not power from AC Outlet. AC line cord is damaged or bad.A.

3. Unit failed function test. Internal failure.A. Please contact Tesla™ Customer Service A.

4. Unit emits sparks when plugged into

power source.

5. Unit works then shuts down. Unit is overheating.A.

6. Circuit breaker continuously trips Unit is overheating. A.

Circuit Breaker has tripped.A.

No outlet power.B.

Is ac line cord fully plugged into B.

unit and wall outlet.

AC circuit breaker has been C.

tripped.

No ac power at outlet.D.

Water or moisture has seeped A.

in unit

Internal failure.B.

Cooling fans and vents are B.

obstructed or inoperable.

Internal ShortB.

Plug the unit in to the appropriate ac A.

power outlet.

If LEDs still do not illuminate, B.

Please contact Tesla™ Customer Service C.

at (302) 324-8910

Do a continuity test on the ac line cordA.

Check if line cord is properly secured. B.

Check to make sure ac circuit breaker is C.

placed in the “ON” position.

at (302) 324-8910

Move unit to dry warm air and allow to A.

dry for over 48 hours.

Do Not Use Unit. Please contact Tesla™ B.

Customer Service at (302) 324-8910

Move the unit to an area 10°-20° less A.

than ambient temperature.

Clean and clear cooling vents, turn on B.

unit and inspect if air is owing through

unit. If no airow please contact Tesla™

Customer Service at (302) 324-8910.

Disconnect unit from ac input and dc A.

output.

Switch breaker to ON position.B.

TI1000 GPU-24 UAV

Reconnect unit to cables and run.C.

If LEDs still do not illuminate, D.

Please contact Tesla™ Customer Service E.

at (302) 324-8910

25

Page 33

Section 7 – Performance Data

7.1 – Purpose

This section provides performance data for the unit. Continual reference to this information will enable the user

to obtain maximum performance, utilization and service life from the unit. Although maximum performance

is not always required, regular referral to this section is recommended for the following reasons:

To generate knowledge of unit’s performance margins to enable the operator to make sound judgment when A.

unexpected conditions or alternate operational requirements are encountered.

To enable the user to readily recognize situations requiring maximum performance.B.

To gain experience in accurately estimating the effects of variables for which data is not presented.C.

To help the operator determine if a vehicle or an aircraft system malfunction exists by comparing actual D.

performance with expected performance.

!

NOTE

The information, in this section, provides data for operational planning.

This is helpful when planning operations under unfamiliar conditions or

environmental extremes. The data may also be used to establish local

operating procedures and to ensure maximum usage of the unit.

7.2 – General

The data presented covers the maximum range of conditions and performance that can reasonably be

expected. In each area of performance, the effects of temperature and dc electrical load demand relating to

the ground power support requirements are presented. Wherever practical, data is presented conservatively.

However, NO GENERAL CONSERVATISM HAS BEEN APPLIED. All performance data presented is within the

applicable limits of the unit

7.3 – Data Basis

The type of data used is indicated at the bottom of each performance chart under DATA BASIS. The applicable

report and date of the data are also given. The data provided generally are based on one of three categories:

Derived From Actual Controlled Testing: Controlled test data obtained on a similar unit type.A.

Calculated Data: Data based on tests, but not on a similar unit type placed under a controlled test.B.

Estimated Data: Data based on estimates using rules of physics, mathematics, and electrical engineering C.

principles and concepts, but not veri ed by tests.

7.4 – Speci c Conditions

The data presented are accurate only for speci c conditions listed under the title of each chart or graph.

Variables for which data are not presented, but which may affect that phase of performance, are discussed

in associated text.

7.5 – General Conditions

In addition to the speci c conditions, the following general conditions are applicable to the performance data.

Variation in Aircraft: Power demand differences between individual aircraft of the same make and model A.

are known to exist due to variations in dc electrical system ef ciency. These differences, however, are

considered insigni cant and are not individually accounted for.

Ground Support and Aircraft Instrument Variations: The data shown in the performance charts do not B.

account for instrument tolerance differences or inaccuracies.

26

TI1000 GPU-24 UAV

Page 34

12.6 – Temperature Conversion Chart

°C °F °C °F °C °F °C °F

-60.0 -76.0 -27.0 -16.6 6.0 42.8 39.0 102.2

-59.0 -74.2 -26.0 -14.8 7.0 44.6 40.0 104.0

-58.0 -72.4 -25.0 -13.0 8.0 46.4 41.0 105.8

-57.0 -70.6 -24.0 -11.2 9.0 48.2 42.0 107.6

-56.0 -68.8 -23.0 -9.4 10.0 50.0 43.0 109.4

-55.0 -67.0 -22.0 -7.6 11.0 51.8 44.0 111.2

-54.0 -65.2 -21.0 -5.8 12.0 53.6 45.0 113.0

-53.0 -63.4 -20.0 -4.0 13.0 55.4 46.0 114.8

-52.0 -61.6 -19.0 -2.2 14.0 57.2 47.0 116.6

-51.0 -59.8 -18.0 -0.4 15.0 59.0 48.0 118.4

-50.0 -58.0 -17.0 1.4 16.0 60.8 49.0 120.2

-49.0 -56.2 -16.0 3.2 17.0 62.6 50.0 122.0

-48.0 -54.4 -15.0 5.0 18.0 64.4 51.0 123.8

-47.0 -52.6 -14.0 6.8 19.0 66.2 52.0 125.6

-46.0 -50.8 -13.0 8.6 20.0 68.0 53.0 127.4

-45.0 -49.0 -12.0 10.4 21.0 69.8 54.0 129.2

-44.0 -47.2 -11.0 12.2 22.0 71.6 55.0 131.0

-43.0 -45.4 -10.0 14.0 23.0 73.4 56.0 132.8

-42.0 -43.6 -9.0 15.8 24.0 75.2 57.0 134.6

-41.0 -41.8 -8.0 17.6 25.0 77.0 58.0 136.4

-40.0 -40.0 -7.0 19.4 26.0 78.8 59.0 138.2

-39.0 -38.2 -6.0 21.2 27.0 80.6 60.0 140.0

-38.0 -36.4 -5.0 23.0 28.0 82.4 61.0 141.8

-37.0 -34.6 -4.0 24.8 29.0 84.2 62.0 143.6

-36.0 -32.8 -3.0 26.6 30.0 86.0 63.0 145.4

-35.0 -31.0 -2.0 28.4 31.0 87.8 64.0 147.2

-34.0 -29.2 -1.0 30.2 32.0 89.6 65.0 149.0

-33.0 -27.4 0.0 32.0 33.0 91.4 66.0 150.8

-32.0 -25.6 1.0 33.8 34.0 93.2 67.0 152.6

-31.0 -23.8 2.0 35.6 35.0 95.0 68.0 154.4

-30.0 -22.0 3.0 37.4 36.0 96.8 69.0 156.2

-29.0 -20.2 4.0 39.2 37.0 98.6 70.0 158.0

-28.0 -18.4 5.0 41.0 38.0 100.4 71.0 159.8

7.6 – Temperature Conversion Chart

TI1000 GPU-24 UAV

Performance Data

7

27

Page 35

7

MAXIMUM OUTPUT CURRENT

AMPS

Calculation based on actual test data at Pratt-Whitmey on 30 March 1992

SECONDS

1500

1350

1200

1050

900

750

600

450

150

300

0

0

5

10

15

20

25

30

(-29 C Te mp)

(+25 C Te mp)

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

TI25000-211 North American Line Cord

TI25000-212 Italian Line Cord

TI25000-213 Continental European Line Cord

TI25000-214 Old British Line Cord

TI25000-215 England / UK Line Cord

TI25000-216 Swiss Line Cord

TI25000-201 Australian Line Cord

TI25000-203 Israel Line Cord

TI25000-304 Denmark Line Cord

TI25000-032 North American Commercial Line Cord

*To be used for TI3000 Commercial Unit only.

8.2 – Tesla™ AC Line Cords

These power cables come in several lengths or can be custom-ordered to t your needs. Tesla™ specializes

in out tting cables with a variety of connectors and junction boxes. Contact Tesla™ Customer Service to nd

out more about our selection of cables.

Regular Line Cords

TI25000-001 North American Line Cord

TI25000-002 Italian Line Cord

TI25000-003 Continental European Line Cord

TI25000-004 Old British Line Cord

TI25000-005 England / UK Line Cord

TI25000-006 Swiss Line Cord

TI25000-011 Australian Line Cord

TI25000-200 Israel Line Cord

TI25000-300 Denmark Line Cord

For units with a fuse and old-style receptacle.

Line Cords

For units with a circuit breaker and new-style receptacle.

NEMA 515P Italian Continental European Old British England/UK

Swiss Australian Israel Denmark NEMA 520P

8.1 – Tesla™ AC Line Cords

AC line cords come in several lengths or can be custom-ordered to t your needs. Tesla™ specializes in

out tting cables with a variety of connectors and junction boxes. Contact Tesla™ customer service to nd out

more about our selection of cords.

Universal Line Cords

TI25000-111 North American Line Cord

105-125 Vac 60 Hz 6.50 amps max

NSN: 5935-01-576-4422 (CL IX)

TI25000-112 Italian Line Cord

10A/250V

TI25000-113 European Line Cord

10A/250V-210-250 Vac 50/60 Hz 3.25 amps max

TI25000-114 Old British Line Cord

210-250 Vac 50/60 Hz 3.25 amps max

TI25000-115 England Line Cord

10A/250- 210/250 Vac 50/60 Hz 3.25 amps max

TI25000-120 Israel Line Cord

6/10A/250V

Performance Data

7.7 – Output Voltage

TI1000 Output Voltage Without AC Power

7.8 – Maximum Output Current

TI1000 Maximum Output Current

28

TI1000 GPU-24 UAV

Page 36

Section 8 – Optional Accessories

TI25000-211 North American Line Cord

TI25000-212 Italian Line Cord

TI25000-213 Continental European Line Cord

TI25000-214 Old British Line Cord

TI25000-215 England / UK Line Cord

TI25000-216 Swiss Line Cord

TI25000-201 Australian Line Cord

TI25000-203 Israel Line Cord

TI25000-304 Denmark Line Cord

TI25000-032 North American Commercial Line Cord

*To be used for TI3000 Commercial Unit only.

8.2 – Tesla™ AC Line Cords

These power cables come in several lengths or can be custom-ordered to t your needs. Tesla™ specializes

in out tting cables with a variety of connectors and junction boxes. Contact Tesla™ Customer Service to nd

out more about our selection of cables.

Regular Line Cords

TI25000-001 North American Line Cord

TI25000-002 Italian Line Cord

TI25000-003 Continental European Line Cord

TI25000-004 Old British Line Cord

TI25000-005 England / UK Line Cord

TI25000-006 Swiss Line Cord

TI25000-011 Australian Line Cord

TI25000-200 Israel Line Cord

TI25000-300 Denmark Line Cord

For units with a fuse and old-style receptacle.

Line Cords

For units with a circuit breaker and new-style receptacle.

NEMA 515P Italian Continental European Old British England/UK

Swiss Australian Israel Denmark NEMA 520P

8.1 – Tesla™ AC Line Cords

AC line cords come in several lengths or can be custom-ordered to t your needs. Tesla™ specializes in

out tting cables with a variety of connectors and junction boxes. Contact Tesla™ customer service to nd out

more about our selection of cords.

Universal Line Cords

TI25000-111 North American Line Cord

105-125 Vac 60 Hz 6.50 amps max

NSN: 5935-01-576-4422 (CL IX)

TI25000-112 Italian Line Cord

10A/250V

TI25000-113 European Line Cord

10A/250V-210-250 Vac 50/60 Hz 3.25 amps max

TI25000-114 Old British Line Cord

210-250 Vac 50/60 Hz 3.25 amps max

TI25000-115 England Line Cord

10A/250- 210/250 Vac 50/60 Hz 3.25 amps max

TI25000-120 Israel Line Cord

6/10A/250V

8.1 – Tesla™ Shipping Case

The optional Shipping Case is the safest way to transport the TI1000 GPU-24 UAV. This custom case weighs

23 lbs and comes equipped with side handles and locking latches.

TI7000-024

NSN: 8145-01-445-3666

Length: 24” (609.60 mm)

Width: 8.50” (215.90 mm)

Height: 19.50” (495.30 mm)

Weight: 23 Lbs (10.5 kg)

8.2 – GPU Protective Covers

Protects unit from moisture, sand and other damaging elements. Custom

t for the TI1000 GPU-24 UAV.

TI7000-046

8.3 – Tesla™ AC Line Cords

DC power cables come in several lengths or can be custom-ordered to t your needs. Tesla™ specializes in

outtting cables with a variety of connectors and junction boxes. Contact Tesla™ Customer Service to nd

out more about our selection of cables.

TI1000 GPU-24 UAV

29

Page 37

8

Optional Accessories

8.4 – Transport Dolly

The Tesla™ TI7000-184 is a custom aluminum dolly designed especially to transport Tesla’s™

TI1000 GPU. The TI7000-184 is the safest and easiest way to support and transport the

TI1000 models out in the eld and through hangars and ight lines. Tesla™ stands behind

the Transport Dolly with a team of customer service professionals and a 2-year warranty.

TI7000-184 Transport Dolly Dimensions:

16.87” L x 14.5” W x 49.25” H

428.50 mm x 368.30 mm x 1250.95 mm

Weight:

18.5 lbs (8.39 kg)

30

TI1000 GPU-24 UAV

Page 38

APPENDIX A

OPTIONAL LINE CORDS FOR WORLDWIDE OPERATIONS

COUNTRY VOLTS HZ TESLA™ PART #

Afghanistan 220 50 TI25000-004 Old British Line Cord

Algeria 220 50 TI25000-004 Old British Line Cord

American Samoa 240 60 TI25000-011 Australian Line Cord

Angola 220 50 TI25000-003 Continental European Line Cord

Anguilla (U.K.) 240 50 TI25000-005 United Kingdom Line Cord

Antigua 230 60 TI25000-005 United Kingdom Line Cord

Argentina 220 50 TI25000-011 Australian Line Cord

Aruba 115 60 TI25000-001 North American Line Cord

Australia 240 50 TI25000-011 Australian Line Cord

Austria 220 50 TI25000-003 Continental European Line Cord

Azores (Portugal) 220 50 TI25000-004 Old British Line Cord

Bahamas 120 60 TI25000-001 North American Line Cord

Bahrain 220 50 TI25000-005 United Kingdom Line Cord

Bangladesh 220 50 TI25000-004 Old British Line Cord

Barbados 115 50 TI25000-001 North American Line Cord

Belgium 220 50 TI25000-003 Continental European Line Cord

Belize (Br. Hond.) 110 60 TI25000-001 North American Line Cord

Benin 220 50 TI25000-004 Old British Line Cord

Bermuda 120 60 TI25000-005 United Kingdom Line Cord

Bolivia 220 50 TI25000-003 Continental European Line Cord

Botswana 220 50 TI25000-005 United Kingdom Line Cord

Brazil 110 60 TI25000-001 North American Line Cord

Bulgaria 220 50 TI25000-003 Continental European Line Cord

Burkina Faso 220 50 TI25000-003 Continental European Line Cord

Burma (Now Myanmar) 230 50 TI25000-005 United Kingdom Line Cord

Burundi 220 50 TI25000-003 Continental European Line Cord

Cambodia 220 50 TI25000-003 Continental European Line Cord

Cameroon 230 50 TI25000-003 Continental European Line Cord

Canada 120 60 TI25000-001 North American Line Cord

Canary Islands (Spain) 220 50 TI25000-003 Continental European Line Cord

Cape Verde, Rep. of 220 50 TI25000-003 Continental European Line Cord

Cayman Islands 120 60 TI25000-001 North American Line Cord

Central African Republic 220 50 TI25000-003 Continental European Line Cord

Chad 220 50 TI25000-003 Continental European Line Cord

Channel Islands 240 50 TI25000-005 United Kingdom Line Cord

Chile 220 50 TI25000-002 Italian Line Cord

China, Peoples Republic of 220 50 TI25000-011 Australian Line Cord

Christmas Island (Australia) 240 50 TI25000-011 Australian Line Cord

Cocos Islands (Australia) 240 50 TI25000-011 Australian Line Cord

Columbia 220 60 TI25000-003 Continental European Line Cord

Congo, Republic of 220 50 TI25000-003 Continental European Line Cord

Cook Island (New Zealand) 240 50 TI25000-011 Australian Line Cord

Costa Rica 120 60 TI25000-001 North American Line Cord

Curacao Islands 110 60 TI25000-001 North American Line Cord

Cyprus 240 50 TI25000-005 United Kingdom Line Cord

Czech, Republic of 220 50 TI25000-003 Continental European Line Cord

Denmark 220 50 TI25000-300 Denmark Line Cord

Djibouti, Republic of 220 50 TI25000-003 Continental European Line Cord

Dominica 230 50 TI25000-005 United Kingdom Line Cord

Dominican Republic 110 60 TI25000-001 North American Line Cord

TI1000 GPU-24 UAV

31

Page 39

APPENDIX A (Cont.)

OPTIONAL LINE CORDS FOR WORLDWIDE OPERATIONS

COUNTRY VOLTS HZ TESLA™ PART #

Ecuador 120 60 TI25000-001 North American Line Cord

Egypt 220 50 TI25000-003 Continental European Line Cord

El Salvador 115 60 TI25000-001 North American Line Cord

England 240 50 TI25000-005 United Kingdom Line Cord

Equatorial Guinea 220 50 TI25000-003 Continental European Line Cord

Estonia 220 50 TI25000-003 Continental European Line Cord

Ethiopia 220 50 TI25000-003 003 Continental European Line Cord

Fiji 240 50 TI25000-011 Australian Line Cord

Finland 220 50 TI25000-003 Continental European Line Cord

France 220 50 TI25000-003 Continental European Line Cord

French Guiana 220 50 TI25000-003 Continental European Line Cord

Gabon 220 50 TI25000-003 Continental European Line Cord

Gambia 220 50 TI25000-005 United Kingdom Line Cord

Georgia 220 50 TI25000-003 Continental European Line Cord

Germany 220 50 TI25000-003 Continental European Line Cord

Ghana 220 50 TI25000-005 United Kingdom Line Cord

Gibraltar 240 50 TI25000-005 United Kingdom Line Cord

Greece 220 50 TI25000-003 Continental European Line Cord

Greenland (Denmark) 220 50 TI25000-300 Denmark Line Cord

Grenada 230 50 TI25000-005 United Kingdom Line Cord

Guadeloupe 220 50 TI25000-003 Continental European Line Cord

Guam 110-120 60 TI25000-001 North American Line Cord

Guatemala 120 60 TI25000-001 North American Line Cord

Guinea 220 50 TI25000-003 Continental European Line Cord

Guinea-Bissau 220 50 TI25000-003 Continental European Line Cord

Guyana 110 50/60 TI25000-001 North American Line Cord

Haiti 110-120 50-60 TI25000-001 North American Line Cord

Honduras 110 60 TI25000-001 North American Line Cord

Hong Kong 220 50 TI25000-005 United Kingdom Line Cord

Hungary 220 50 TI25000-003 Continental European Line Cord

Iceland 220 50 TI25000-003 Continental European Line Cord

India 220-250 50 TI25000-004 Old British Line Cord

Indonesia 220 50 TI25000-003 Continental European Line Cord

Iran 220 50 TI25000-003 Continental European Line Cord

Iraq 220 50 TI25000-005 United Kingdom Line Cord

Ireland, Republic of 220 50 TI25000-005 United Kingdom Line Cord

Isle of Man 240 50 TI25000-005 United Kingdom Line Cord

Israel 230 50 TI25000-200 Israel Line Cord

Italy 220 50 TI25000-002 Italian Line Cord

Ivory Coast 220 50 TI25000-003 Continental European Line Cord

Jamaica 110 50 TI25000-001 North American Line Cord

Japan 110 50/60 TI25000-001 North American Line Cord

Jordan 220 50 TI25000-005 United Kingdom Line Cord

Kenya 240 50 TI25000-005 United Kingdom Line Cord

Korea, South 220 60 TI25000-003 Continental European Line Cord

Kuwait 240 50 TI25000-005 United Kingdom Line Cord

32

TI1000 GPU-24 UAV

Page 40

APPENDIX A (Cont.)

OPTIONAL LINE CORDS FOR WORLDWIDE OPERATIONS

COUNTRY VOLTS HZ TESLA™ PART #

Laos 220 50 TI25000-001 North American Line Cord

Latvia 220 50 TI25000-003 Continental European Line Cord

Lebanon 220 50 TI25000-003 Continental European Line Cord

Lesotho 240 50 TI25000-004 Old British Line Cord

Liberia 120 60 TI25000-005 United Kingdom Line Cord

Liechtenstein 220 50 TI25000-006 Switzerland Line Cord

Lithuania 220 50 TI25000-003 Continental European Line Cord

Luxembourg 220 50 TI25000-003 Continental European Line Cord

Libya 230 50 TI25000-002 Italian Line Cord

Macao 220 50 TI25000-004 Old British Line Cord

Madagascar 220 50 TI25000-003 Continental European Line Cord

Maderia (Portugal) 220 50 TI25000-004 Old British Line Cord

Majorca 220 50 TI25000-003 Continental European Line Cord

Malawi 230 50 TI25000-005 United Kingdom Line Cord

Malaysia 240 50 TI25000-005 United Kingdom Line Cord

Maldives 230 50 TI25000-004 Old British Line Cord

Mali, Republic of 220 50 TI25000-003 Continental European Line Cord

Malta 240 50 TI25000-005 United Kingdom Line Cord

Martinique 220 50 TI25000-003 Continental European Line Cord

Mauritania 220 50 TI25000-003 Continental European Line Cord

Mauritius 230 50 TI25000-005 United Kingdom Line Cord

Mexico 127 60 TI25000-001 North American Line Cord

Monaco 220 50 TI25000-003 Continental European Line Cord

Mongolia 220 50 TI25000-003 Continental European Line Cord

Montseurrat 230 60 TI25000-005 United Kingdom Line Cord

Morocco 220 50 TI25000-003 Continental European Line Cord

Mozambique 220 50 TI25000-003 Continental European Line Cord

Namibia (W.S. Africa) 220-250 50 TI25000-004 Old British Line Cord

Nepal 220 50 TI25000-004 Old British Line Cord

Neth. Antilles 220 50/60 TI25000-003 Continental European Line Cord

Netherlands 220 50 TI25000-003 Continental European Line Cord

New Caledonia 220 50 TI25000-003 Continental European Line Cord

New Zealand 230 50 TI25000-011 Australian Line Cord

Nicaragua 120 60 TI25000-001 North American Line Cord

Niger 220 50 TI25000-003 Continental European Line Cord

Nigeria 230 50 TI25000-005 United Kingdom Line Cord

Norfolk Islands (Australia) 240 50 TI25000-011 Australian Line Cord

North Ireland 220 50 TI25000-005 United Kingdom Line Cord

North Mariana Islands (U.S.) 115 60 TI25000-001 North American Line Cord

Norway 220 50 TI25000-003 Continental European Line Cord

Okinawa 100-120 60 TI25000-001 North American Line Cord

Oman 240 50 TI25000-005 United Kingdom Line Cord

Pakistan 230 50 TI25000-004 Old British Line Cord

Panama 110 60 TI25000-001 North American Line Cord

Papua New Guinea 240 50 TI25000-011 Australian Line Cord

Paraguay 220 50 TI25000-003 Continental European Line Cord

Peru 110 50/60 TI25000-001 North American Line Cord

Philippines 115 60 TI25000-001 North American Line Cord

Piccairn Islands (U.K.) 240 50 TI25000-004 Old British Line Cord

Poland 220 50 TI25000-003 Continental European Line Cord

Portugal 220 50 TI25000-003 Continental European Line Cord

Puerto Rico 120 60 TI25000-001 North American Line Cord

TI1000 GPU-24 UAV

33

Page 41

APPENDIX A (Cont.)

OPTIONAL LINE CORDS FOR WORLDWIDE OPERATIONS

COUNTRY VOLTS HZ TESLA™ PART #

Romania 220 50 TI25000-003 Continental European Line Cord

Russia 220 50 TI25000-003 Continental European Line Cord

Rwanda 220 50 TI25000-003 Continental European Line Cord

Saudi Arabia 220 50/60 TI25000-003 Continental European Line Cord

Scotland 220 50 TI25000-005 United Kingdom Line Cord

Senegal 220 50 TI25000-003 Continental European Line Cord

Seychelles 240 50 TI25000-005 United Kingdom Line Cord

Sierra Leone 230 50 TI25000-005 United Kingdom Line Cord

Singapore 230 50 TI25000-005 United Kingdom Line Cord

Slovakia 220 50 TI25000-003 Continental European Line Cord

Somalia 220 50 TI25000-003 Continental European Line Cord

South Africa 220-250 50 TI25000-004 Old British Line Cord

Spain 220 50 TI25000-003 Continental European Line Cord

Sri Lanka 230 50 TI25000-004 Old British Line Cord

St. Pierre & Miquelon (France) 115 60 TI25000-001 North American Line Cord

St. Kitts & Nevis 230 60 TI25000-005 United Kingdom Line Cord

St. Lucia 240 50 TI25000-005 United Kingdom Line Cord

St. Vincent 230 50 TI25000-005 United Kingdom Line Cord

Sudan 240 50 TI25000-005 United Kingdom Line Cord

Surinam 115 60 TI25000-003 Continental European Line Cord

Svalbard (Norway) 220 50 TI25000-003 Continental European Line Cord

Swaziland 230 50 TI25000-004 Old British Line Cord

Sweden 220 50 TI25000-003 Continental European Line Cord

Switzerland 220 50 TI25000-006 Switzerland Line Cord

Syria 220 50 TI25000-003 Continental European Line Cord

Tahiti 220 50 TI25000-003 Continental European Line Cord

Taiwan 110 60 TI25000-001 North American Line Cord

Tanzania 230 50 TI25000-005 United Kingdom Line Cord

Thailand 220 50 TI25000-003 Continental European Line Cord

Togo 220 50 TI25000-003 Continental European Line Cord

Tonga 115 60 TI25000-004 Old British Line Cord

Trinidad & Tobago 230 60 TI25000-005 United Kingdom Line Cord

Tunisia 220 50 TI25000-003 Continental European Line Cord

Turkey 220 50 TI25000-003 Continental European Line Cord

Uganda 220 50 TI25000-004 Old British Line Cord

United Arab Emir. 220 50 TI25000-005 United Kingdom Line Cord

United Kingdom & Ireland 240 50 TI25000-005 United Kingdom Line Cord

United States 120 60 TI25000-001 North American Line Cord

Uruguay 220 50 TI25000-011 Australian Line Cord

Venezuela 120 60 TI25000-001 North American Line Cord

Vietnam 220 50 TI25000-003 Continental European Line Cord

Virgin Islands 120 60 TI25000-001 North American Line Cord

Wales 220 50 TI25000-005 United Kingdom Line Cord

Western Samoa 230 50 TI25000-005 United Kingdom Line Cord

Yemen 220 50 TI25000-005 United Kingdom Line Cord

Yugoslavia 220 50 TI25000-003 Continental European Line Cord

Zaire, Republic of 220 50 TI25000-003 Continental European Line Cord

Zambia 220 50 TI25000-005 United Kingdom Line Cord

Zimbabwe 220 50 TI25000-005 United Kingdom Line Cord

34

TI1000 GPU-24 UAV

Page 42

APPENDIX A (Cont.)

UNIVERSAL LINE CORD KIT FOR WORLDWIDE OPERATIONS

NOTE: TESLA™ UNIVERSAL AC LINE CORD KIT, P/N: TI25000-U00, IS FOR UNITS ORIGINALLY BUILT WITH THE UNIVERSAL AC

LINE CORD OPTION ONLY.

THE AC ADAPTER OPTION IS TESLA™ P/N TI16000-19 AND MUST BE ORDERED WITH THE ORIGINAL PROCUREMENT OF UNIT(S).

UNIT(S) MAY BE RETURNED TO TESLA™ INDUSTRIES, FOR A NOMINAL COST, AND MODIFIED TO ALLOW OPERATION WITH THE

UNIVERSAL AC LINE CORD KIT.

TESLA™ UNIVERSAL AC LINE CORD KIT, P/N: TI25000-U00, IS COMPRISED OF THE FOLLOWING FIVE PART NUMBERS:

TI25000-111 NORTH AMERICAN LINE CORD

TI25000-113 EUROPEAN 10A/250V

TI25000-114 OLD BRITISH LINE CORD

TI25000-115 ENGLAND 10A/250V

TI7000-131 LINE CORD POUCH

TI1000 GPU-24 UAV

35

Page 43

Repair Request Form

Please complete the information below to ensure prompt and accurate service. Include this form with the unit you are returning.

Thank you.

Date of return: ________________________

Company name & ____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

Billing address: ____________________________________________________________________

____________________________________________________________________

____________________________________________________________________

Contact person: ________________________________________________________________________________

Phone #: _____________________________________ Fax #: ______________________________________

Email: _______________________________________________________________________________________

Purchase Order #: ______________________________________________________________________________

Model #: ____________________________________ Serial #: ________________________________________

Model #: ____________________________________ Serial #: ________________________________________

Shipping method to Tesla™: ______________________________________________________________________

Description of shipping package: ________________________________________________________________

Description of problem: _________________________________________________________________________

_________________________________________________________________________________________________

_________________________________________________________________________________________________

_________________________________________________________________________________________________

Return to Tesla™ Industries, Inc.

101 Centerpoint Boulevard, New Castle, DE 19720 Attention: Repair Department

TI1000 GPU-24 UAV

37

Page 44

Tesla™ Industries, Inc.

101 Centerpoint Blvd.

New Castle, DE 19720 USA

Tel: 302-324-8910

Fax: 302-324-8912

9475 Double R Blvd., Suite 2

Reno, NV 89521

Tel: 775-622-8801

Fax: 775-622-8810

www.teslaind.com

Loading...