Page 1

Powerwall 2 AC Installation Manual

with Backup Gateway

Page 2

For the latest Powerwall installation documents in all supported languages, visit:

www.tesla.com/support/powerwall.

To secure the full 10-year product warranty, be sure to register Powerwall online.

Warning: Read this entire document before installing or using Powerwall. Failure to

do so or to follow any of the instructions or warnings in this document can result in

electrical shock, serious injury, or death, or can damage Powerwall, potentially

rendering it inoperable.

PRODUCT SPECIFICATIONS

All specifications and descriptions contained in this document are verified to be

accurate at the time of printing. However, because continuous improvement is a goal

at Tesla, we reserve the right to make product modifications at any time.

The images provided in this document are for demonstration purposes only.

Depending on product version and market region, details may appear slightly

different.

ERRORS OR OMISSIONS

To communicate any inaccuracies or omissions in this manual, send an email to:

energy-pubs@tesla.com.

ELECTRONIC DEVICE: DO NOT THROW AWAY

Proper disposal of batteries is required. Refer to your local codes for disposal

requirements.

MADE IN THE USA

©2017 TESLA, INC. All rights reserved.

All information in this document is subject to copyright and other intellectual property rights

of Tesla, Inc. and its licensors. This material may not be modified, reproduced or copied, in

whole or in part, without the prior written permission of Tesla, Inc. and its licensors. Additional

information is available upon request. The following are trademarks or registered trademarks

of Tesla, Inc. in the United States and other countries:

TESLA

TESLA MOTORS

POWERWALL

All other trademarks contained in this document are the property of their respective owners

and their use herein does not imply sponsorship or endorsement of their products or services.

The unauthorized use of any trademark displayed in this document or on the product is

strictly prohibited.

Page 3

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS .......................................................................................................................... 2

1. Registering Powerwall ............................................................................................................................................... 5

2. Specifications ............................................................................................................................................................... 5

Powerwall Electrical Specifications ........................................................................................................................................................................ 5

Powerwall Environmental Specifications ............................................................................................................................................................. 5

Powerwall Mechanical Specifications .................................................................................................................................................................... 5

Backup Gateway Electrical Specifications .......................................................................................................................................................... 6

Backup Gateway Environmental Specifications ............................................................................................................................................... 6

Backup Gateway Mechanical Specifications ...................................................................................................................................................... 6

3. Site Requirements ....................................................................................................................................................... 7

Powerwall Physical Requirements ........................................................................................................................................................................... 7

Powerwall Dimensions and Space Requirements ............................................................................................................................................ 8

Powerwall Temperature Requirements ................................................................................................................................................................ 8

Powerwall Installation Requirements ..................................................................................................................................................................... 9

Backup Gateway Installation Requirements ....................................................................................................................................................... 9

4. Installation Instructions ........................................................................................................................................... 10

Powerwall Box Contents ............................................................................................................................................................................................ 10

Backup Gateway Box Contents .............................................................................................................................................................................. 10

Required Tools ................................................................................................................................................................................................................ 10

Required Supplies.......................................................................................................................................................................................................... 10

Step 1. Plan the Installation Site ................................................................................................................................................................................ 11

Step 2. Transport and Unpack Powerwall .......................................................................................................................................................... 12

Step 3. Anchor the Powerwall Mounting Bracket .......................................................................................................................................... 14

Step 4. Prepare Powerwall for Mounting ............................................................................................................................................................ 21

Step 5. Mount Powerwall on the Bracket .......................................................................................................................................................... 23

Step 6. Prepare the Backup Gateway for Mounting .................................................................................................................................... 25

Step 7. Install a Circuit Breaker in the Backup Gateway .............................................................................................................................27

Step 8. Mount the Backup Gateway .................................................................................................................................................................... 28

Step 9. Connect Powerwall and the Backup Gateway ............................................................................................................................... 30

Step 10: Make AC Power Connections ............................................................................................................................................................... 34

Step 11. Close the Wiring Compartments and Turn On the System ..................................................................................................... 37

Step 12. Commission the Backup Gateway and Verify System Operation ....................................................................................... 37

Step 13. Finish Installation and Register the System.................................................................................................................................... 38

Troubleshooting ............................................................................................................................................................................................................ 38

Technical Support ........................................................................................................................................................................................................ 39

Maintenance .................................................................................................................................................................................................................... 39

Wiring Reference .............................................................................................................................. 40

Powerwall Inverter Adjustable Settings ................................................................................... 42

Powerwall Inverter Short Circuit Information ......................................................................... 44

1

Page 4

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE IMPORTANT SAFETY INSTRUCTIONS

This manual contains important instructions for the Tesla Powerwall 2 AC and Backup

Gateway that must be followed during installation and maintenance of the system.

Powerwall and Backup Gateway installation and service require knowledge of high voltage

electricity and should only be performed by Tesla Certified Installers. Tesla assumes no liability

for injury or property damage due to repairs attempted by unqualified individuals or a failure

to properly follow these instructions. These warnings and cautions must be followed when

using Powerwall and the Backup Gateway.

Symbols Used

These symbols indicate important safety information in this guide or on the equipment:

WARNING: indicates a hazardous situation which, if not avoided, could result in injury

or death.

CAUTION: indicates a hazardous situation which, if not avoided, could result in minor

injury or damage to the equipment.

NOTE: indicates an important step or tip that leads to best results, but is not safety or damage

related.

REFER TO OPERATING INSTRUCTIONS: indicates that user should refer to

operating or installation instructions before proceeding.

RISK OF ELECTRIC SHOCK: indicates components that present risk of electrical

shock.

CAUTION, RISK OF ELECTRIC SHOCK, ENERGY STORAGE TIMED

DISCHARGE. Discharge time is 5 minutes from de-energization.

BIDIREDTIONAL TERMINAL: Indicates location of combined input/output connector

on the equipment.

PROTECTIVE CONDUCTOR TERMINAL: Indicates location of grounding connection

on the equipment.

2 Powerwall Installation Manual

Page 5

General Information

WARNING: Read this entire document before installing or using Powerwall. Failure to do

so or to follow any of the instructions or warnings in this document can result in electrical

shock, serious injury, or death, or can damage Powerwall, potentially rendering it inoperable.

WARNING: A battery can present a risk of electrical shock, fire, or explosion from vented

gases. Observe proper precautions.

WARNING: Powerwall installation must be carried out only by Tesla Certified Installers

who have been trained in dealing with high voltage electricity.

WARNING: Powerwall is heavy. Use of lift equipment is recommended.

WARNING: Use Powerwall only as directed.

WARNING: Do not use Powerwall if it is defective, appears cracked, broken, or otherwise

damaged, or fails to operate.

WARNING: Before beginning the wiring portion of the installation, ensure that Powerwall

is switched off, and open any associated circuit breakers and disconnect switches (if

applicable for the installation).

WARNING: Do not attempt to open, disassemble, repair, tamper with, or modify

Powerwall. Powerwall and its components are not user serviceable. Batteries in Powerwall are

not replaceable. Contact the Tesla Certified Installer who installed the system for any repairs.

WARNING: To protect Powerwall and its components from damage when transporting,

handle with care. Do not impact, pull, drag, or step on Powerwall. Do not subject Powerwall to

any strong force. To help prevent damage, leave Powerwall in its shipping packaging until it is

ready to be installed.

WARNING: Do not insert foreign objects into any part of Powerwall.

WARNING: Do not expose Powerwall or its components to direct flame.

WARNING: Do not install Powerwall near heating equipment.

WARNING: Do not immerse Powerwall or its components in water or other fluids.

3

Page 6

CAUTION: Do not use solvents to clean Powerwall, or expose Powerwall to flammable or

harsh chemicals or vapors.

CAUTION: Do not use fluids, parts, or accessories other than those specified in this

manual, including use of non-genuine Tesla parts or accessories, or parts or accessories not

purchased directly from Tesla or a Tesla-certified party.

CAUTION: Do not place Powerwall in a storage condition for more than one (1) month, or

permit the electrical feed on the Powerwall to be severed for more than one (1) month,

without placing Powerwall into a storage condition in accordance with Tesla’s storage

specifications.

CAUTION: Do not paint any part of Powerwall, including any internal or external

components such as the exterior shell or casing.

CAUTION: Do not connect Powerwall directly to photovoltaic (PV) solar wiring.

CAUTION: When installing Powerwall in a garage or near vehicles, keep it out of the

driving path. If possible, install Powerwall on a side wall and/or above the height of vehicle

bumpers.

Environmental Conditions

WARNING: Install Powerwall in a location that prevents damage from flooding.

WARNING: Operating or storing Powerwall in temperatures outside its specified range

might cause damage to Powerwall.

WARNING: Do not expose Powerwall to ambient temperatures above 60°C (140°F) or

below -30°C (-22°F).

CAUTION: Ensure that no water sources are above or near Powerwall, including

downspouts, sprinklers, or faucets.

CAUTION: Ensure that snow does not accumulate around Powerwall.

4 Powerwall Installation Manual

Page 7

1. Registering Powerwall

Energy1

13.5 kWh

AC Voltage (Nominal)

208 V, 220 V, 230V,

100/200 V, 120/240 V

AC Voltage (Nominal) and

Maximum Continuous Current

120 V, 208 V, 240 V: 24 A

100 V, 200 V, 220 V, 230 V: 25 A

Frequency (Nominal)

50/60 Hz

Real Power, continuous

5 kW (charge and discharge)

Real Power, peak (10 s)

7 kW (discharge only)

Apparent Power, continuous

5.8 kVA (charge and discharge)

Apparent Power, peak (10 s)

7.2 kVA (discharge only)

Power Factor Range

-1 to 1

Overvoltage Category

Category III

Max Supply Fault Current

10 kA

Max Output Fault Current

32 A rms

Round Trip Efficiency (Beginning of Life)1

> 90%

Operating Temperature2

-20°C to 50°C (-4°F to 122°F)

Operating Humidity (RH)

Up to 100%, condensing

Storage Conditions (up to 12 months)

-20°C to 30°C (-4°F to 86°F)

Maximum Altitude

3000 m (9843 ft)

Noise Level @ 1 m

< 40 dBA at 30°C (86°F)

Enclosure Type

NEMA 3R

Ingress Rating

IP67 (battery and power electronics)

Wet Location Rating

Yes

Pollution Degree Rating

PD3

Seismic Rating

AC156, IEEE 693-2005 (high)

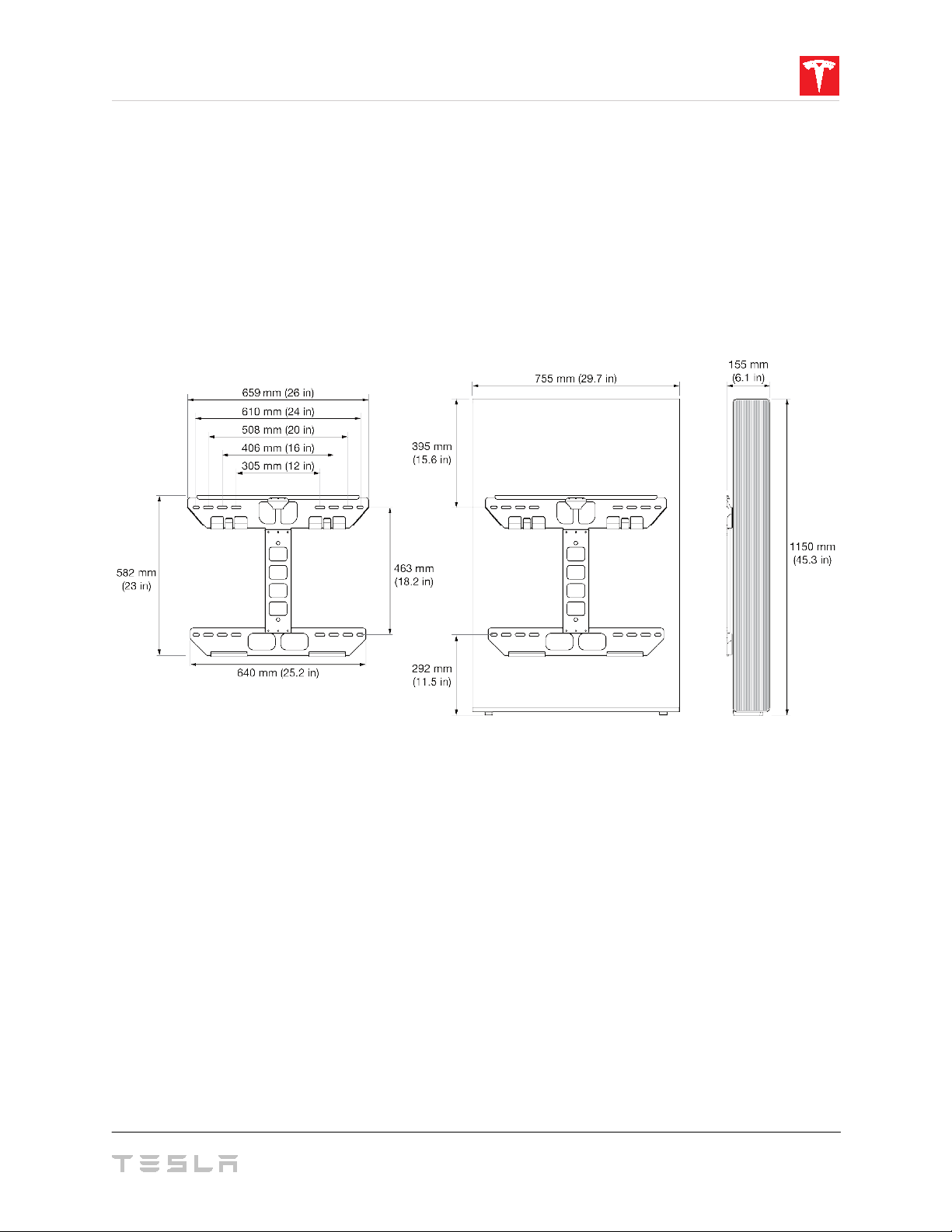

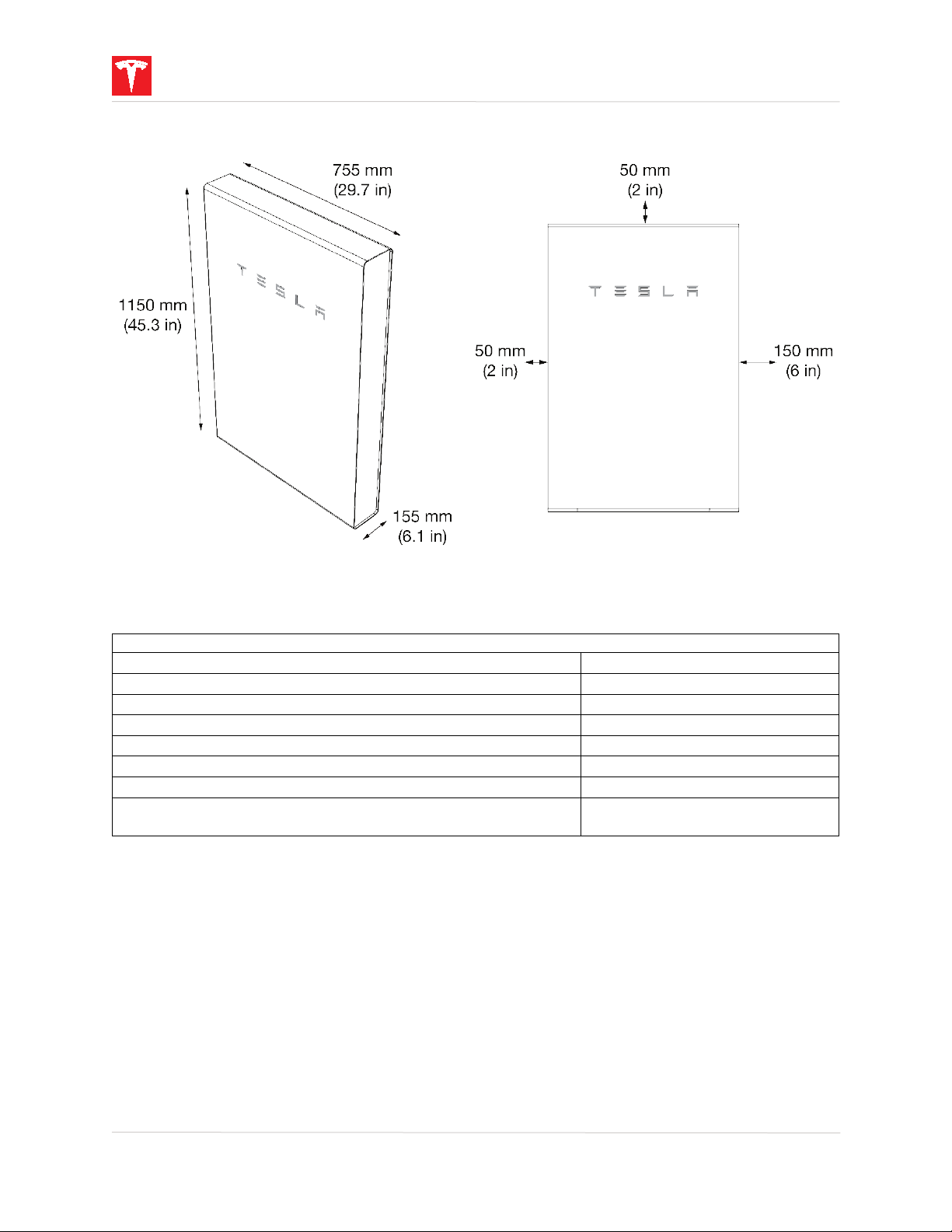

Height

1150 mm (45.3 in)

Width

755 mm (29.7 in)

Depth

155 mm (6.1 in)

Weight

125 kg (276 lbs)

Tesla Powerwall comes with a warranty whose term depends on the connection of Powerwall

to the Internet.

To secure the full 10-year warranty for Powerwall, it must be reliably connected to the Internet

to allow remote firmware upgrades from Tesla. If an Internet connection is not established or is

interrupted for an extended period, and Tesla is unable to contact the owner, the warranty

may be limited to 4 years. To ensure that the owner can receive the full 10-year warranty,

register the Powerwall by visiting www.tesla.com/support/powerwall.

For more information, refer to the Powerwall Warranty for your region at www.tesla.com.

2. Specifications

Powerwall Electrical Specifications

1

Values provided for 25°C (77°F), 3.3 kW charge/discharge power.

Powerwall Environmental Specifications

Up to 95% RH, non-condensing

State of Energy (SoE): 25% initial

IP56 (wiring)

2

Performance may be de-rated in extreme ambient temperatures.

Powerwall Mechanical Specifications

5

Page 8

Disconnect Current

200 A

Overcurrent Protection Breaker3

100-200 A

Overvoltage Category

Category III

AC Meter

Revenue grade

Operating Temperature

-20°C to 50°C (-4°F to 122°F)

Operating Humidity (RH)

Up to 100%, condensing

Maximum Altitude

3000 m (9843 ft)

Enclosure Type

NEMA 3R

Ingress Rating

IP44

Pollution Degree Rating

PD3

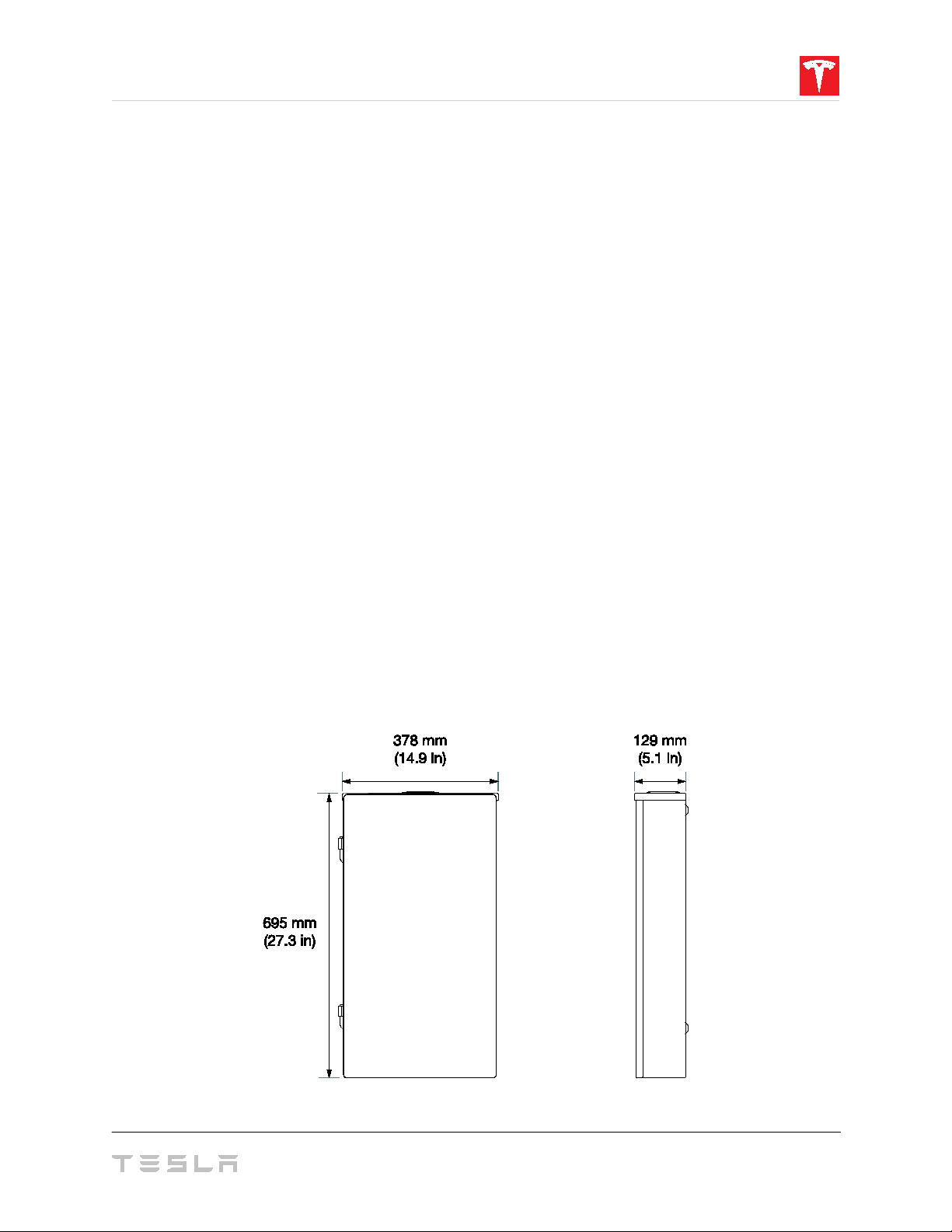

Height

691 mm (27.2 in)

Width

378 mm (14.9 in)

Depth

129 mm (5.1 in)

Weight

16 kg (36 lbs)

Backup Gateway Electrical Specifications

3

Optional

Backup Gateway Environmental Specifications

Backup Gateway Mechanical Specifications

6 Powerwall Installation Manual

Page 9

3. Site Requirements

Powerwall Physical Requirements

Powerwall can be mounted on a floor or wall. When floor-mounted, it must also be anchored

to an adjacent wall. In both types of installation, the wall must be capable of supporting the full

weight of Powerwall and its mounting hardware. The wall must extend to all edges of the

system, allowing no access to the back of the unit once it is mounted.

Powerwall includes a mounting bracket (Fig. 1) that supports the unit in both floor- and wallmount configurations, and includes shims to level the unit in floor-mount configurations. Do

not use other hardware to anchor Powerwall to the wall or floor.

Figure 1: Powerwall 2 Mounting Bracket Dimensions

Powerwall requires adequate clearance for installation, cabling, and airflow. Do not mount any

other objects within the clearance space (Fig. 2), except those explicitly required by the

installation (for example, conduit, a junction box, or an electrical disconnect, depending on

local installation codes). Do not install anything above Powerwall that limits access to the unit

or that might fall and damage the unit. Do not mount Powerwall horizontally or upside down.

NOTE: Powerwall has a pump and fan that enable Powerwall to maintain ideal battery

temperature. They produce a gentle hum during operation, comparable to a typical

refrigerator. The noise level depends on the ambient temperature and the power level of

operation. Consider these noise levels when choosing where to install Powerwall.

7

Page 10

Powerwall Space Requirements

Minimum lateral wall space

960 mm (38 in)

Minimum clearance from left side (air intake)

50 mm (2 in)

Minimum clearance from right side (air exhaust)

150 mm (6 in)

Minimum clearance above single Powerwall

50 mm (2 in)

Minimum clearance above side-by-side Powerwalls

300 mm (12 in)

Minimum clearance between side-by-side Powerwalls

250 mm (10 in)

Maximum height above ground

1 m (3.3 ft) to bottom of unit

Maximum slope

+/ – 2° side-to-side

+/– 5° front-to-back

Powerwall Dimensions and Space Requirements

Figure 2: Powerwall 2 Dimensions and Space Requirements

Powerwall Temperature Requirements

Powerwall is capable of charging and discharging within the full ambient temperature range

listed in the Specifications section. At the high and low ends of the temperature range,

Powerwall may limit charge or discharge power based on battery cell temperature to improve

battery lifespan.

Installation in full sun raises the temperature inside the enclosure above ambient temperature.

This temperature rise is not a safety risk, but may impact battery performance. To optimize

performance, avoid installing Powerwall in locations that are exposed to the sun for extended

periods.

Do not install Powerwall in locations with sustained high or low temperatures. The average

ambient temperature over the system's life should be between 0°C and 30°C (32°F and 86°F).

8 Powerwall Installation Manual

Page 11

Powerwall Installation Requirements

Powerwall comes with a separate Backup Gateway and power meter to enable integration

with solar systems and the electrical grid. The Backup Gateway communicates with the

system by means of wireless and wired connections. Wiring and conduit (where required)

must be provided by the installer. Where conduit is required, the installation must comply with

local codes and UL514B requirements.

AC disconnect and interconnection requirements between the Powerwall system and the

electrical panel are subject to local codes. Ensure that the installation meets local disconnect

and interconnection requirements.

All U.S. and Canada electrical installations must be done in accordance with local codes and

the National Electric Code (NEC) ANSI/NFPA 70 or the Canadian Electrical Code CSA C22.1.

When Powerwall is installed in a dwelling unit, a smoke alarm should be installed in the same

room as the Powerwall, in accordance with local building and fire codes.

All installations must conform to the laws, regulations, codes, and standards applicable in the

jurisdiction of installation.

Backup Gateway Installation Requirements

The Backup Gateway should be wall-mounted and can be configured for cable entry at the

top, bottom, or sides of the enclosure. It requires adequate clearance for installation and

cabling or conduit. Wiring and conduit (where required) must be provided by the installer.

Where conduit is required, the installation must comply with local codes and UL514B

requirements.

The Backup Gateway should be mounted vertically, in the orientation shown below. Do not

mount the Backup Gateway enclosure horizontally or upside down.

All installations must conform to the laws, regulations, codes, and standards applicable in the

jurisdiction of installation.

Figure 3: Backup Gateway Dimensions

9

Page 12

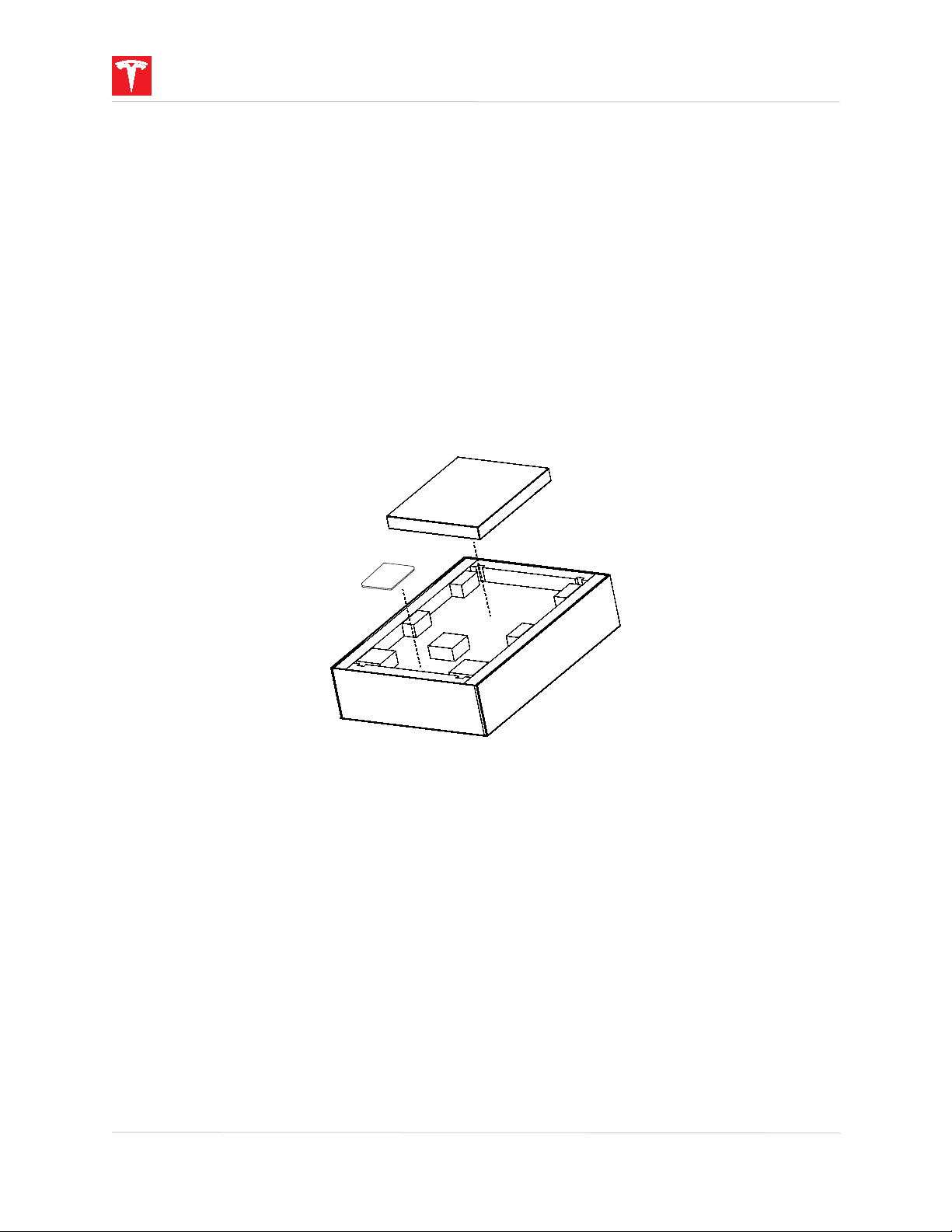

4. Installation Instructions

Powerwall Box Contents

• Powerwall 2 AC unit

• Mounting bracket

• Accessory bag containing:

o (1) 3-pin AC power harness (600 V, 90 deg C)

o (4) wirenuts for AC power connections

o (1) 4-pin terminal block connector (black) for connection to Backup Gateway

o (1) 4-pin terminal block connector (green) for connection to additional Powerwalls

o (1) T20 Torx driver bit

o (1) 1-inch insulation bushing for conduit entry to Powerwall

o (2) shims for leveling floor-mounted units

o (1) Safety Instructions document

• On the outside of the box: printed Tesla

Backup Gateway Box Contents

• Backup Gateway Enclosure

• Neurio Meter Kit

• Powerwall 2 AC Owner’s Manual

Battery Emergency Response Guide

(ERG)

Required Tools

• Personal protective equipment (safety glasses, gloves, protective footwear)

• Drill and drill bit for drilling pilot holes in mounting surface

• Torque screwdriver with 1/4-inch bit holder (for the provided T20 Torx bit)

• Large (5 mm) flathead driver bit (for ground bar)

• Small (2 mm) flathead screwdriver (for wiring connector spring terminals)

• Torque wrench with 5/15-inch Allen bit (for Backup Gateway power connections)

• Wire strippers/cutters for 0.2

• Installation tools (level, stud sensor, tape measure, pencil, painter’s tape, flashlight)

• Lift equipment capable of lifting and supporting 125 kg (276 lbs)

• Ratcheting strap to secure Powerwall to lift equipment

WARNING: Powerwall is heavy. Wear appropriate personal protective equipment (such as gloves

and protective footwear) when handling the unit. Only a sufficient number of trained movers should lift

Powerwall. Use of lift equipment is recommended.

2

mm

to 120 mm2 (24 AWG to 250 kcmil) wires

Required Supplies

• Mounting bracket hardware (see “Step 3: Anchor the Powerwall Mounting Bracket”)

• Conduit fitting or cable gland (depending on local electrical requirements)

• Conduit or raceway (depending on local electrical requirements)

• Minimum 300 V rated 4-conductor shielded copper (Cu) cable (for communication connection

between Powerwall and the Backup Gateway)

• Minimum 600 V, 90 deg C rated copper (Cu) cable (for power connections to Powerwall and the

Backup Gateway)

• Conduit adapter (if necessary for cable entry into Powerwall wiring compartment)

• Siemens HS-style conduit hub (for entry into the top of the Backup Gateway enclosure)

10 Powerwall Installation Manual

Page 13

Step 1. Plan the Installation Site

Maximum

Cable Length

The installation location for Powerwall must accommodate placement of the Backup Gateway

and meet all conditions described above in “Site Requirements.” In addition, consider the

following points when choosing where to install Powerwall.

Wall mounting: Choose a wall capable of supporting the full weight of Powerwall, with one of

the following characteristics: wood studs at regular intervals, plywood sheeting of sufficient

thickness, solid concrete or masonry, or metal studs of sufficient gauge.

Floor mounting: Choose a level surface adjacent to a wall space that meets all the

requirements for wall mounting described above. Make sure the area is isolated from hazards

that may damage the unit, such as vehicle traffic or flooding.

Cable entry: Determine whether cables will be routed into Powerwall from the side or from the

back of the unit. With side cable entry, a conduit fitting or cable gland must be used to seal

the entry into the wiring compartment. With back cable entry, a wire cover should be used to

seal the entry into the wiring compartment.

NOTE: If you mount Powerwall on a wall with studs spaced 24 in (610 mm) apart, cable entry

from the back of Powerwall may be blocked.

Backup Gateway configuration: Determine whether cable entry into the Backup Gateway will

be from the top, bottom, or side. When cable entry is from the bottom half of the enclosure,

the back panel of the unit must be removed and rotated 180 degrees.

NOTE: For cable entry at the top of the Backup Gateway enclosure, an HS-style hub should be

used in order to maintain enclosure ingress protection.

Electrical service connection: The Backup Gateway is service-entrance rated, and can be

located between the service entry and the main electrical panel. If overcurrent protection is

required, a circuit breaker can be added to the Backup Gateway at the service entry. The

Backup Gateway can accommodate two different circuit breaker sizes: 100/125A, and

150/200A.

Cable gauge and length: Powerwall requires cable connections to the Backup Gateway,

electrical service panel(s), and an Internet router. Position Powerwall, the Backup Gateway,

and other electrical components to minimize cable lengths, based on local code requirements.

Cable Type Connection Cable Gauge

Power Powerwall to electrical panel 5-8 mm2 (10-8 AWG) 45 m (150 ft)

Power Backup Gateway to electrical panel 16–120 mm2 (6 AWG-250 kcmil) [Local Code]

2

Communication Powerwall to Backup Gateway

2 twisted pairs, 1.5 mm

Communication Backup Gateway to wireless router CAT5 45 m (150 ft)

(24-16 AWG)

- or -

CAT5

50 m (165 ft)

15 m (50 ft)

11

Page 14

Conduit or raceway: Calculate the amount and size of conduit or raceway needed for the

installation, based on fill limits and local code requirements. If you are using conduit, an

adapter may be required between the entry into the Powerwall wiring compartment and the

conduit.

Step 2. Transport and Unpack Powerwall

NOTE: Powerwall is heavy. Wear appropriate personal protective equipment (such as gloves

and protective footwear) when handling the unit. Only a sufficient number of trained movers

should lift Powerwall. Use of lift equipment is recommended. For more information, refer to

Powerwall 2 Transportation and Storage Guidelines

1. Keep Powerwall in its box until ready for installation. Store the box flat on its back (front

facing up) during transport. The box can be carried in any orientation to the job site.

2. Open the box by cutting the packing straps, removing the lid, and setting it aside.

3. Remove the box containing the mounting bracket and the bag containing the accessories.

.

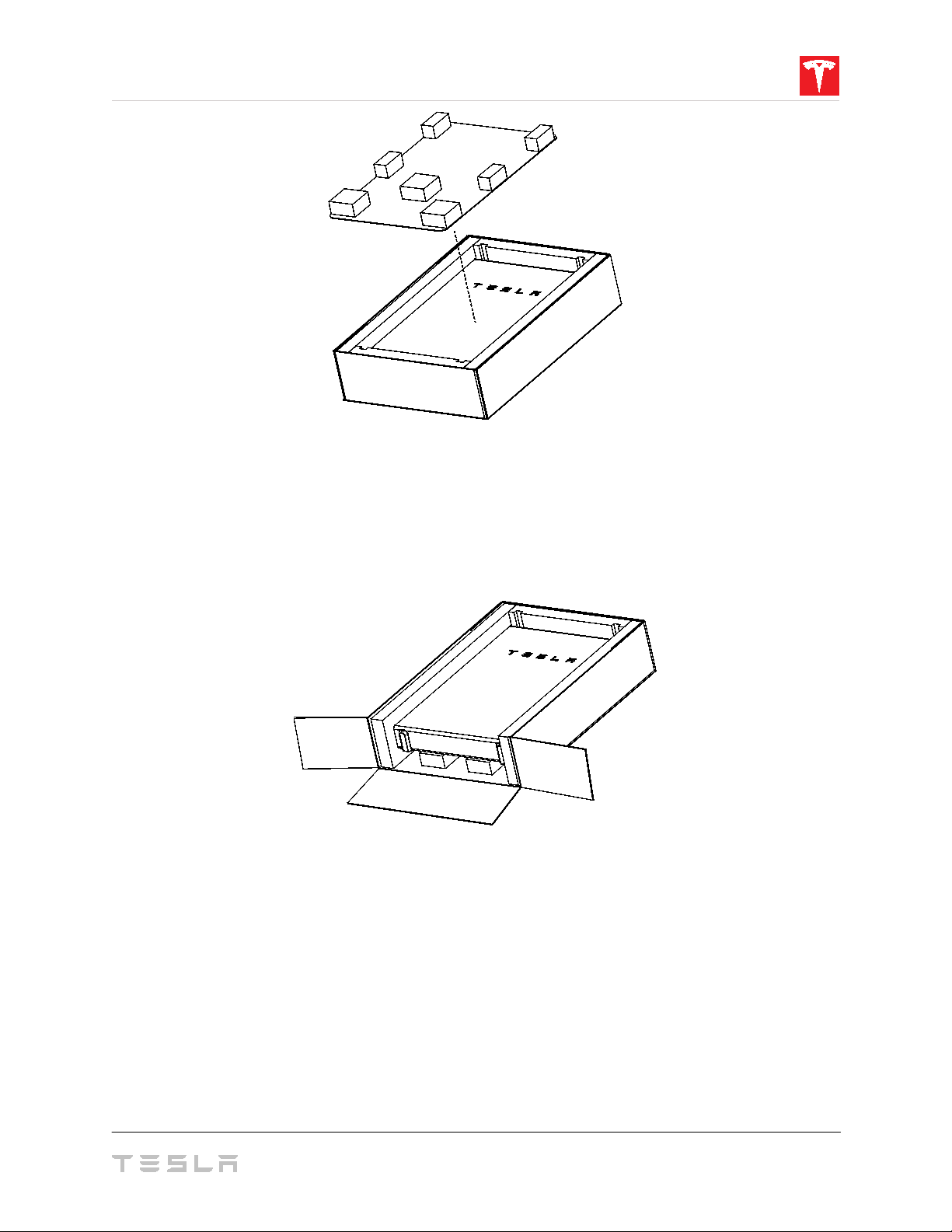

Figure 4: Removing the Mounting Bracket Box and Accessory Bag

4. Verify that the contents of the bracket box and accessory bag are complete and

undamaged (see “Powerwall Box Contents,” above).

5. Remove the top panel and set it aside.

12 Powerwall Installation Manual

Page 15

Figure 5: Removing the Top Panel

6. Find the bottom of Powerwall by identifying the feet at the base of the unit.

7. Remove the piece of foam next to the bottom of Powerwall.

8. Open the bottom edge of the box (nearest the bottom of Powerwall) by removing the

staples and folding the cardboard back.

Figure 6: Opening the Bottom of the Powerwall Box

9. Optional: Remove the foam blocks from the top panel and use the cardboard as protective

padding on the lift equipment.

10. Move the lift equipment into place next to the bottom of the Powerwall box.

11. Grasp the top of the Powerwall and carefully tilt it upright until it sits vertically in the box,

with the front of the unit facing the lift equipment.

13

Page 16

Figure 7: Removing Powerwall from Its Box

12. Position the Powerwall on the lift equipment, with the mounting cleats facing away from

the lift equipment.

13. Strap the Powerwall to the lift equipment with a ratcheting tie-down strap.

Step 3. Anchor the Powerwall Mounting Bracket

1. Before mounting the wall bracket, double-check that the mounting location will allow access

to the chosen cable entry port (side or back) during installation. If applicable, use a stud

sensor to locate and mark the centers of the studs in the wall.

2. Determine the appropriate type and number of fasteners for the mounting bracket location.

Be sure to take into account the thickness of the mounting bracket, washers, and wall material

when choosing fasteners. The following guidelines apply to both wall- and floor-mount

installations.

NOTE: The details below are minimum guidelines and are not guaranteed to be applicable.

Refer to local building codes to ensure the use of appropriate fasteners. Refer to

Anchorage Details

for complete mounting information.

Powerwall 2

14 Powerwall Installation Manual

Page 17

Wood Studs (spaced at 12, 16, 20 or 24 inches)

• If anchoring directly into wood studs, use at least

four (one in each corner) 1/4-inch

wood screws with washers, of sufficient length for at least 1.5 in (38 mm) embedment

into the studs.

Figure 8: Anchoring the Bracket to Wood Studs

• If anchoring to blocking between wood studs, use minimum 2 x 4 in blocks, end-nailed

into studs with two 16d (90 mm) nails or toe-nailed into studs with four 8d (60 mm)

nails. Use at least

four (one in each corner) 1/4-inch wood screws with washers, of

sufficient length for at least 1.5 in (38 mm) embedment into the blocking.

Figure 9: Anchoring the Bracket to Blocking between Wood Studs

15

Page 18

Plywood

• If anchoring to plywood wall material, the plywood must be minimum 1/2-inch thick.

Use at least

four (one in each corner) 1/4-inch wood screws with washers, of sufficient

length to penetrate at least 1/4 inch beyond the backside of the plywood.

Figure 10: Anchoring the Bracket to Plywood

Metal Studs (spaced at 12, 16, 20 or 24 inches)

• If anchoring directly to metal studs, studs must be minimum 18 gauge. Use at least

(one in each corner) #14 sheet metal screws with washers, of sufficient length to

penetrate at least 3 threads beyond the stud.

Figure 11: Anchoring the Bracket to Metal Studs

four

16 Powerwall Installation Manual

Page 19

• If anchoring to backing between metal studs, studs must be minimum 25 gauge, and

backing must be minimum 22 gauge. Use at least

eight (two in each corner) #14 sheet

metal screws with washers, of sufficient length to penetrate at least 3 threads beyond

the backing.

Figure 12: Anchoring the Bracket to Metal Backing

• If anchoring to backing between metal studs in an outdoor high wind area, studs must

be minimum 25 gauge, and backing must be minimum 22 gauge. Use at least

twelve

(three in each corner) #14 sheet metal screws with washers, of sufficient length to

penetrate at least 3 threads beyond the backing.

Figure 13: Anchoring the Bracket to Metal Backing – High Wind Area

17

Page 20

Concrete or Masonry

• Minimum strength must be 2500 PSI (concrete) or 1500 PSI (masonry).

• Use at least

four (one in each corner) 1/4-inch fasteners with washers, of sufficient

length for at least 1.5 in (38 mm) embedment into the material. Ensure that all fasteners

are at least 1.5 in (38 mm) away from the edges of masonry blocks or bricks.

Figure 14: Anchoring the Bracket to Concrete or Masonry

Channel Strut (Unistrut)

• Struts must be minimum 1-5/8 in x 1-5/8 in, 12 gauge.

• If mounting on wood studs, attach the strut to at least three studs, using at least one

1/4-inch wood screw with washer per stud, of sufficient length for at least 1.5 in (38

mm) embedment into the studs.

• If mounting on metal studs, attach the strut to at least three studs, using at least two

#14 sheet metal screws with washers per stud, of sufficient length to penetrate at least

3 threads beyond the studs.

• To attach the bracket to the struts, use at least

four (one in each corner) 1/4-inch

hexhead screws with washers and strut nuts.

Figure 15: Anchoring the Bracket to Channel Strut

18 Powerwall Installation Manual

Page 21

NOTE: Both floor and wall mount installations require the cleats on the back of Powerwall to

be fully engaged in the mounting bracket. Consider the floor contour when measuring for

floor-mounted installations.

3. Use the bracket as a guide to mark the location of pilot holes for the required fasteners. Use

a level tool to ensure that the bracket is level.

4. Drill the pilot holes for the fasteners.

5. Attach the bracket to the mounting surface with the required fasteners as described above.

6. Verify that the bracket is firmly attached to the wall.

7. (Back cable entry installation only) Drill a hole in the wall that corresponds to the location of

the back cable entry port on Powerwall. The diameter of the port and location of its center in

are shown below in relation to the Powerwall chassis (Fig 16) and in relation to the installed

mounting bracket (Fig 17).

Figure 16: Back Cable Entry Port Location (Viewed from Front of Powerwall)

19

Page 22

Figure 17: Back Cable Entry Port Location –DETAIL (Viewed from Front of Powerwall)

8. (Optional) Use painter’s tape to mark the location of the bracket flanges on the wall, the

location of the cleats on the front of the Powerwall, and the center lines of the bracket and

chassis to aid in aligning the unit.

20 Powerwall Installation Manual

Page 23

Step 4. Prepare Powerwall for Mounting

1. Switch off Powerwall by moving the switch on the right side of the unit to the OFF position.

WARNING: Switching off Powerwall disengages the Enable line but does not disconnect

AC voltage. High voltage may be present on the AC connection leads unless the Backup

Gateway, any associated circuit breakers, and the AC disconnect (if applicable) are switched

off.

Figure 18: Switching Powerwall Off

2. Remove the left side cover from Powerwall by carefully pulling out on the plastic straps near

the top and bottom of the cover, and detaching it from the clips along the length of the unit.

Figure 19: Removing the Left Side Cover

21

Page 24

3. (Side cable entry installations only) Remove the side cable entry door from the left side

cover by sliding it out of its slot.

Figure 20: Removing the Side Cable Entry Door

Back cable entry installations only) Remove the plug from the back cable entry port on

4. (

Powerwall and place it in the side cable entry port.

Figure 21: Moving the Back Cable Entry Plug to the Side Cable Entry Port

5. Record the serial number of the Powerwall in the back of the Owner’s Manual that came

with the Backup Gateway. The serial number can be found on a label on the left side of the

unit, and also on the lid of its packaging.

22 Powerwall Installation Manual

Page 25

Step 5. Mount Powerwall on the Bracket

1. Move the lift equipment close to the wall and remove the tie-down strap securing the

Powerwall to the lift equipment.

2. Adjust the height of the Powerwall so that its mounting cleats are just above the flanges on

the bracket. (If you marked the bracket and cleat locations, use those marks to gauge the

height.)

3. Begin to lower the Powerwall so that the top cleat engages the top flange on the bracket.

Ensure that the bottom cleat aligns with the bottom flange of the bracket.

4. With both cleats engaged, lower the Powerwall onto the bracket. When the cleats are

seated in the bracket, the locking mechanism at the center of the top flange should click into

place.

NOTE: To remove Powerwall from the mounting bracket, place a thin piece of sheet metal

between the Powerwall unit and the bracket to compress the locking mechanism, and lift the

Powerwall straight up.

Figure 22: Mounting Powerwall on the Bracket

23

Page 26

5. Make sure the unit is centered on the bracket. (If you marked the center lines of the chassis

and bracket, use those marks to align the centers.)

6. (Floor mount installations only) Use the provided shims to ensure that Powerwall is level.

The unit should be level within +/– 2 degrees side-to-side and within +/– 5 degrees front-toback.

Figure 23: Leveling Powerwall with a Shim

24 Powerwall Installation Manual

Page 27

Step 6. Prepare the Backup Gateway for Mounting

1. Remove the Backup Gateway from its packaging and verify that the contents are complete

and undamaged (see “Backup Gateway Box Contents,” above).

2. Record the serial number of the Backup Gateway in the back of the Owner’s Manual that

came with the system. The serial number can be found on a label on the inside of the

enclosure door, and also on the outside of its packaging.

3. Open the Backup Gateway enclosure and remove the enclosure door.

4. Remove the screw at the bottom of the dead front panel and remove it from the enclosure.

Figure 24: Removing the Dead Front Panel from the Enclosure

5. Determine whether cable entry to the Backup Gateway will be from the top, bottom, or side

of the enclosure. If cable entry will be from the top, skip to Step 7, “Install a Circuit Breaker in

the Backup Gateway.”

6. To configure the Backup Gateway for cable entry from the bottom or sides, do the

following:

• Remove the four fasteners holding the back panel assembly in place and remove it

from the enclosure.

• Rotate the back panel assembly 180 degrees and reinstall it in the enclosure.

25

Page 28

Figure 25: Rotating the Back Panel Assembly in the Enclosure

7. Determine if a circuit breaker is required for the installation:

• If no circuit breaker is required, remove and rotate the dead front panel insert (and its

insulation) 180 degrees, and reattach it to compensate for the inverted back panel.

Figure 26: Rotating the Dead Front Panel Insert

• If a circuit breaker is required, proceed to the next step, “Install a Circuit Breaker in the

Backup Gateway.”

26 Powerwall Installation Manual

Page 29

Step 7. Install a Circuit Breaker in the Backup Gateway

Siemens MBK 100A

100 A

EQ8681

Siemens MBK 125A

125 A

EQ8682

Siemens MBK 150A

150 A

EQ8693

Siemens MBK 200A

200 A

EQ8695

If the Backup Gateway is to be located between the electrical service entry and the main

electrical panel, a circuit breaker must be added to the service inlet of the Backup Gateway. If

no circuit breaker is required, skip to Step 8, “Mount the Backup Gateway.”

WARNING: If a circuit breaker is not added to the Backup Gateway, ensure that

appropriate overcurrent protection is provided for the installation.

CAUTION: To reduce the risk of fire, connect only to a circuit provided with 200 A

maximum branch-circuit overcurrent protection, in accordance with the National Electrical

Code, ANSI/NFPA 70.

The following circuit breaker models are supported:

Circuit Breaker Model Amperage Rating UL Type

1. Determine the level of overcurrent protection required, based on local code requirements.

2. Remove the service inlet terminal lugs from the Backup Gateway. (It may be necessary to

remove the meter current transformers to access the nuts holding the lugs in place.)

Figure 27: Removing the Inlet Service Terminal Lugs

3. Install the corresponding size circuit breaker at the service inlet terminals in the Backup

Gateway.

27

Page 30

4. Remove and rotate the dead front panel insert (and its insulation) so that the correct

punch-out will match the breaker location when the panel is replaced. For smaller (100 A and

125 A) circuit breakers, remove the small punch-out; for larger (150 A and 200 A) circuit

breakers, remove the large punch-out.

NOTE: The location of the breaker also depends on the orientation of the back panel

assembly.

Figure 28: Dead Front Panel Insert Orientations for Circuit Breakers

Step 8. Mount the Backup Gateway

1. Determine the mounting location. The Backup Gateway enclosure has 3 mounting holes

(shown below in red). If needed, two additional mounting points (shown below in grey) are

also available. To use these additional mounting points, the back panel must be removed and

the points drilled out.

Figure 29: Backup Gateway Mounting Hole Locations (Back View)

28 Powerwall Installation Manual

Page 31

2. Drill pilot holes in the mounting surface for the fasteners.

3. Attach the Backup Gateway enclosure to the mounting surface. Use a level tool to ensure

that the enclosure is level.

Figure 30: Mounting the Backup Gateway

29

Page 32

1

Communication OUT Connector (for daisy-chaining multiple Powerwalls)

2

Communication IN Connector (for single Powerwall or first Powerwall in a chain)

3

AC Connector

4

Ground Lug

Step 9. Connect Powerwall and the Backup Gateway

NOTE: When wiring Powerwall and the Backup Gateway, Class 1 wiring methods are to be

used for wiring connections to terminals of Class 2 circuits.

1. Using the provided Torx T20 bit, remove the cover from the wiring compartment on the left

side of Powerwall.

Figure 31: Removing the Wiring Compartment Cover

Depending on regional requirements, Powerwall wiring can be installed through conduit or

through a cable gland. Refer to local codes to determine wiring requirements.

Figure 32: Powerwall 2 AC Wiring Compartment Inlet and Connectors

30 Powerwall Installation Manual

Page 33

2. (Conduit installations only) Run conduit as needed and attach the conduit fitting to the inlet

of the wiring compartment. The wiring compartment inlet accepts a standard 1-inch conduit

fitting.

Figure 33: Powerwall 2 AC Side Cable Port Entry location

3. (Conduit installations only) If the conduit connector does not have an integrated bushing,

affix the provided insulation bushing to the conduit opening on the inside of the wiring

compartment.

NOTE: Ensure that all conduit joints and outlets have smooth edges so that wiring is not

damaged as it is run through the conduit.

31

Page 34

Communication Connector Wiring

Terminal

Connector Terminal Name

Recommended Wire Color

Wire Gauge

1

12V + (Logic +)

Brown

0.2–1.5 mm2 (24–16 AWG)

2

GND (Logic –)

White

0.2–1.5 mm2 (24–16 AWG)

3

CAN HI

Blue

0.2–1.5 mm2 (24–16 AWG)

4

CAN LO

Yellow

0.2–1.5 mm2 (24–16 AWG)

4. Run the 4-conductor communication cable, the high-voltage AC conductors and highvoltage grounding conductor through the conduit or cable gland and pull them into the

Powerwall wiring compartment.

5. Run the other end of the 4-conductor communication cable, the high-voltage AC

conductors and high-voltage grounding conductor into the Backup Gateway enclosure.

6. On the Backup Gateway side, strip the end of the high-voltage grounding conductor and

insert it in the ground bar in the Backup Gateway enclosure (Fig 35). The ground bar is

identified with the following symbol: . Tighten the screw in the ground bar to 5.5 Nm (50 lbin).

7. On the Powerwall side, strip the end of the high-voltage grounding conductor and insert it in

the Powerwall chassis ground lug (Fig 36). The ground lug is identified with the following

symbol: . Tighten the screw in the ground lug to 4.5 Nm (40 lb-in).

8. On each end of the 4-conductor communication cable, strip and insert the wires into the

provided 4-pin Phoenix connectors according to the following table and diagram (Fig. 34). On

the Powerwall side, use the black Phoenix connector.

Figure 34: Communication Connector Wiring

9. On the backup Gateway side, plug the 4-pin Phoenix connector into the 4-pin connector at

the bottom left of the enclosure.

32 Powerwall Installation Manual

Page 35

Figure 35: Backup Gateway Ground and Communication Connections

10. On the Powerwall side, plug the 4-pin Phoenix connector into the bottom 4-pin connector

(labeled “IN”) in the Powerwall wiring compartment.

Figure 36: Powerwall 2 AC Ground and Communication Connections

NOTE:

should be terminated at the Backup Gateway only.

Do not connect the cable shield to the Powerwall chassis ground lug

. The shield

33

Page 36

Backup Gateway AC Wiring

Service Connection

Backup Gateway Terminal

Wire Gauge

Line 1

S1

16–120 mm2 (6 AWG - 250 kcmil)

Line 2

S2

16–120 mm2 (6 AWG - 250 kcmil)

Neutral

N

16–120 mm2 (6 AWG - 250 kcmil)

Step 10: Make AC Power Connections

1. Determine whether the installation requires that neutral be bonded to ground in the Backup

Gateway. (In most cases, if the Backup Gateway is to be located between the electrical service

entry and the main electrical panel, neutral should be bonded to ground, otherwise, bonding

should be removed.)

The Backup Gateway ships with neutral bonded to ground. To remove bonding, disconnect

the green wire between the ground bar and the neutral terminals.

Figure 37: Backup Gateway Ground Bar (top left) Bonded to Neutral (bottom right)

2. Connect the electrical service from the service inlet or from the main panel (depending on

the backup configuration) to the Backup Gateway terminals according to the following table

and diagram (Fig 38). Strip the ends of the wires and insert them in the corresponding Backup

Gateway terminal lugs. Tighten the lugs to 30 Nm (22 lb-ft).

NOTE: For electrical service connections to the Backup Gateway, use 16-120 mm2 (6 AWG to

250 kcmil), 90 deg C minimum copper (Cu) wire.

34 Powerwall Installation Manual

Page 37

Figure 38: Backup Gateway Power Connector Labels (shown with breaker installed)

3. Connect Powerwall to the main or sub electrical panel of the installation (depending on the

backup configuration) according to the following tables, for your electrical service type.

NOTE: For AC power connections to Powerwall, use 5–8 mm2 (10-8 AWG) 90 deg C minimum

copper (Cu) wire.

35

Page 38

Main/Sub Panel Breaker Terminal

Powerwall Terminal

Wire Gauge

Line 1

L1

5–8 mm2 (10-8 AWG)

Neutral

L2

5–8 mm2 (10-8 AWG)

Main/Sub Panel Breaker Terminal

Powerwall Terminal

Wire Gauge

Line 1

L1

5–8 mm2 (10-8 AWG)

Neutral

N

5–8 mm2 (10-8 AWG)

Line 2

L2

5–8 mm2 (10-8 AWG)

Main/Sub Panel Breaker Terminal

Powerwall Terminal

Wire Gauge

Line 1

L1

5–8 mm2 (10-8 AWG)

Line 2

L2

5–8 mm2 (10-8 AWG)

100 V, 120 V, 200 V, 220 V, 230 V, 240 V Single-Phase Service

NOTE: For single-phase service, Neutral is not connected to the Powerwall N terminal. It is

instead connected to the Powerwall L2 terminal.

120/240 V Split-Phase Service

208 V Service

4. On the Powerwall side, strip the ends of the wires and attach them to the corresponding

leads on the 3-pin AC power harness using the provided wirenuts.

5. Plug the AC power harness into the AC connector in the Powerwall wiring compartment.

Ensure that the connector clicks into place.

NOTE: The Powerwall connection to the main electrical panel requires a 30 A circuit breaker

with a maximum short circuit current rating of 10 kA. This breaker serves as the disconnect for

the Powerwall, and must be wired in accordance with local wiring codes and regulations.

36 Powerwall Installation Manual

Figure 39: Powerwall 2 AC Power Harness Connection

Page 39

Step 11. Close the Wiring Compartments and Turn On the System

1. Arrange the communication and AC power wires inside the Powerwall wiring compartment.

2. Ensure that all conduit or cable gland junctions and cable entry points are secure and

properly sealed.

3. Replace the cover on the wiring compartment. Ensure that the cover seats properly on the

gasket so that the compartment is sealed. Tighten the fasteners using the provided Torx T20

bit. Torque to 1.5 Nm (13 lb-in).

4. Replace the left side cover on Powerwall by pushing the top into place and working toward

the bottom to reattach it to the clips along the length of the unit.

5. Replace the dead front panel in the Backup Gateway and remount its door.

6. Switch on the circuit breaker to the Backup Gateway.

7. Switch on Powerwall by moving the switch on the right side of the unit to the ON position.

When Powerwall establishes communication with the Backup Gateway, the LED on the right

side of Powerwall illuminates.

Figure 40: Switching Powerwall On

Step 12. Commission the Backup Gateway and Verify System Operation

After all components of the system have been turned on, do the following to begin the Backup

Gateway commissioning process:

1. Using any web-capable wireless device, establish communication with the Backup Gateway

over the local wireless network.

2. Connect to the Backup Gateway web interface: the username is your email address, and the

password is the Backup Gateway serial number.

3. Follow the on-screen steps to commission the system.

4. Apply any firmware updates to the Backup Gateway and Powerwall as required.

5. Verify that Powerwall is receiving commands from the Backup Gateway and is capable of

charging and discharging correctly in response to the corresponding commands.

37

Page 40

LED State

Indication

On (solid)

Powerwall enabled/Communication with Backup Gateway;

High voltage may be present on Powerwall AC connectors

On (flashing)

Powerwall enabled/No communication with Backup Gateway;

High voltage may be present on Powerwall AC connectors

On (pulsing)

Powerwall enabled and charging or discharging

Rate of pulsing proportional to power flow

Off

Powerwall not enabled or switched off

Step 13. Finish Installation and Register the System

1. After installation is complete, remove the protective film from Powerwall.

2. Remove the plastic straps from the left and right side covers by cutting them and carefully

pulling them through the slots in the covers.

3. If you have not already done so, register the system by visiting

www.tesla.com/support/powerwall.

4. Leave the Powerwall Owner’s Manual with the owner of the newly installed system.

Troubleshooting

If Powerwall is not working correctly, perform the following steps:

• Check the status of the LED on the right side of Powerwall.

The LED indicates status as follows:

• If it is not possible to communicate with the Backup Gateway through the My Tesla

app, ensure that the home Internet connection is working.

• Ensure that Powerwall is correctly connected to the Backup Gateway, based on the

wiring diagrams above and site design information.

WARNING: Before opening the Powerwall wiring compartment, make sure to

switch off the AC breakers for Powerwall and the Backup Gateway, switch off the AC

disconnect (if applicable), and switch off Powerwall.

WARNING: Switching off Powerwall disengages the Enable line but does not

disconnect AC voltage. High voltage may be present on the AC connection leads

unless the Backup Gateway, any associated circuit breakers, and the AC disconnect (if

applicable) are switched off.

• If a brownout or blackout is experienced during backup operation: reduce the loads

and check that the breakers have not opened.

• If Powerwall does not operate and the ambient temperature is high, increase ventilation

if needed.

38 Powerwall Installation Manual

Page 41

• If the Backup Gateway and Powerwall are both unresponsive:

1. Turn off Powerwall by setting its On/Off switch to the OFF position.

2. Turn off the AC breakers for the system (Backup Gateway and Powerwall).

3. Wait at least one minute.

4. Turn the AC breakers back on.

5. Turn on Powerwall.

Technical Support

Resources for Certified Installers, including service request forms and the latest versions of

installation manuals, are available at https://www.tesla.com/support/powerwall.

If further support is needed, contact the Tesla Service team at the support phone number for

your region. Support numbers for all regions are found at:

https://www.tesla.com/support/powerwall

This information is useful to have ready when contacting Tesla:

• Owner name

• Best point of contact for Tesla to return contact (name, phone number, email)

• Powerwall part number and serial number

• Brief description of the issue

Maintenance

Powerwall does not require pre-scheduled preventative maintenance. The only maintenance

required by an owner is to keep the unit free and clear of debris, especially around the air

intake and exhaust.

To clean Powerwall, use a soft, lint-free cloth. If needed, the cloth can be dampened with mild

soap and water only. Do not use cleaning solvents to clean Powerwall, or expose Powerwall to

flammable or harsh chemicals or vapors.

39

Page 42

Powerwall Wiring

Powerwall Terminal

Wire Color

Wire Gauge

1

12V + (Logic +)

Brown

0.2–1.5 mm2 (24–16 AWG)

2

GND

White

0.2–1.5 mm2 (24–16 AWG)

3

CN + (CAN HI)

Blue

0.2–1.5 mm2 (24–16 AWG)

4

CN – (CAN LO)

Yellow

0.2–1.5 mm2 (24–16 AWG)

5

L2 (Line 2)

Red

5–8 mm2 (10–8 AWG)

6

N (Neutral)

White

5–8 mm2 (10–8 AWG)

7

L1 (Line 1)

Black

5–8 mm2 (10–8 AWG)

8

Chassis Ground Lug

Green or Green/Yellow

5–8 mm2 (10–8 AWG)

Powerwall

Wiring Reference

40 Powerwall Installation Manual

Page 43

Backup Gateway

Backup Gateway Wiring

Backup Gateway Terminal

Wire Color

Wire Gauge

1

12V + (Logic +)

Brown

0.2–1.5 mm2 (24–16 AWG)

2

GND

White

0.2–1.5 mm2 (24–16 AWG)

3

CN + (CAN HI)

Blue

0.2–1.5 mm2 (24–16 AWG)

4

CN – (CAN LO)

Yellow

0.2–1.5 mm2 (24–16 AWG)

5

Ethernet

CAT5

6

Ground Bar

Green or Green/Yellow

2.5–70 mm2 (14 AWG–2/0)

7

Line 1 Source (S1)

Black

16–120 mm2 (6 AWG–250 kcmil)

8

Line 2 Source (S2)

Red

16–120 mm2 (6 AWG–250 kcmil)

9

Neutral (N)

White

16–120 mm2 (6 AWG–250 kcmil)

10

Line 1 Load x 2 (L1)

Black

16–120 mm2 (6 AWG–250 kcmil)

11

Line 2 Load x 2 (L2)

Red

16–120 mm2 (6 AWG–250 kcmil)

12

Neutral x 2 (N)

White

16–120 mm2 (6 AWG–250 kcmil)

41

Page 44

Voltage

Range*

Time

(sec)

Voltage

Range*

Time

(sec)

V ≥ 120

0.16

Powerwall Inverter Adjustable Settings

The Powerwall inverter has the following adjustable settings, which are determined when the

system is commissioned.

NOTE: Under abnormal voltage or frequency conditions or in response to a detected

unintentional island, the system will disconnect from the grid by opening its internal contactor.

NOTE: All values are for factory default 240 V @ 60 Hz.

Voltage Ride-Through

The Powerwall inverter has three voltage and time set points for low voltage ride-through,

configurable to the following ranges (measured as line to neutral for single-phase, and line-toline for split-phase):

Inverter LVRT Settings

Parameter

LVRT Point 3 0-400 V 108 V 0-60 100 ms or 1%, whichever is greater

LVRT Point 2 0-400 V 144 V 0-60 100 ms or 1%, whichever is greater

LVRT Point 1 0-400 V 192 V 0-60 100 ms or 1%, whichever is greater

LVRT Point 0 0-400 V 216 V 0-60 100 ms or 1%, whichever is greater

*Voltage accuracy 2% of nominal

Default Value*

Accuracy

The inverter has three voltage and time set points for high voltage ride-through, configurable

to the following ranges (measured as line to neutral for single-phase, and line to line for splitphase):

Inverter HVRT Settings

Parameter

HVRT Point 3 0-400 V 336 V 0-60 100 ms or 1%, whichever is greater

HVRT Point 2 0-400 V 288 V 0-60 100 ms or 1%, whichever is greater

HVRT Point 1 0-400 V 264 V 0-60 100 ms or 1%, whichever is greater

HVRT Point 0 0-400 V 254.4 V 0-60 100 ms or 1%, whichever is greater

*Voltage accuracy 2% of nominal

Default Value*

Accuracy

The above tables represent the maximum parameter values that the user can input. However,

240 VAC nominal systems are limited to a maximum HVRT of 120%.

The inverter ships with the pre-defined settings listed below.

Interconnection System Default Response to Abnormal Voltages

Voltage Range (% of base voltage) Clearing Time (s)

V < 45 0.16

45 ≤ V < 60 1

60 ≤ V < 88 2

110 < V < 120 1

42 Powerwall Installation Manual

Page 45

In addition to ride-through capability, the inverter is capable of adding or removing VARs

Default

Time

(sec)

UF2

< 59.5

2

OF1

> 60.5

2

OF2

> 62

0.16

during VRT events to help support voltage regulation during the fault event.

During a grid fault, the inverter maintains its output power set point unless it is operating in

current limit or the reactive current demand consumes the available output current capacity.

Frequency Ride-Through

The inverter has three under-frequency (UF) and three over-frequency (OF) trip points and

times. These parameters are configurable to the ranges listed below.

Inverter Frequency Trip Points

Trip Point Frequency Range*

UF Trip Point 3 35 Hz-70 Hz 3:55 0-600 100 ms or 1%, whichever is greater

UF Trip Point 2 35 Hz-70 Hz 2:57 0-600 100 ms or 1%, whichever is greater

UF Trip Point 1 35 Hz-70 Hz 1:59.5 0-600 100 ms or 1%, whichever is greater

UF Trip Point 0 35 Hz-70 Hz 0:59.5 0-600 100 ms or 1%, whichever is greater

OF Trip Point 0 35 Hz-70 Hz 0:60.5 0-600 100 ms or 1%, whichever is greater

OF Trip Point 1 35 Hz-70 Hz 1:60.5 0-600 100 ms or 1%, whichever is greater

OF Trip Point 2 35 Hz-70 Hz 2:62 0-600 100 ms or 1%, whichever is greater

OF Trip Point 3 35 Hz-70 Hz 3:65 0-600 100 ms or 1%, whichever is greater

*Frequency accuracy 0.2 Hz of nominal

Value

Accuracy

The FQRT settings are pre-programmed in the inverter to comply with IEEE 1547

requirements.

Inverter FQRT Default Settings

Function Frequency (Hz) Clearing Time (s)

UF1 < 57 0.16

43

Page 46

Powerwall Inverter Short Circuit Information

Grid-Tied Mode Inverter Short Circuit Information

Short Initial Peak Breaking

Max Current

(Amps RMS)

Duration

(ms)

Max Current

(Amps)

Duration

(ms)

Max Current

(Amps RMS)

Duration

(ms)

L1 – L2 110 16.7 248 8.9 58.2 16.7

L1 - GND 20.5 16.7 268 8.6 9.24 16.7

L2 - GND 22 16.7 264 7.2 6.82 16.7

Stand-Alone Inverter Short Circuit Information

Short

Max Current, Amps

(3 cycle RMS)

L1 – L2 51.3 248 8.9

L1 - Neutral 50.5 268 8.6

L2 - Neutral 45.6 264 7.2

Max Current, Amps

(Peak to Peak)

Peak Duration

(ms)

44 Powerwall Installation Manual

Page 47

Page 48

Tesla, Inc.

Palo Alto, CA 94304

Tesla Motors Netherlands B.V.

Tilburg, Netherlands

3500 Deer Creek Road

Rev 1.0 Mar 21, 2017

Atlasstraat 7–9, 5047 RG

Loading...

Loading...