1

MANUAL HIGH-CURRENT

COUPLING/DECOUPLING

NETWORK CDN 3083-S200M

USER MANUAL 691-379C

Manual high-current coupling network CDN 3083–S200M

MANUAL HIGH-CURRENT

COUPLING/DECOUPLING

NETWORK CDN 3083-S200M

USER MANUAL

1 Explanation of the symbols used in this manual 5

2. Safety advice 7

2.1 Safety measures 8

2.2 Installation 8

2.3 Installation of an equipment under test power switch 10

2.3.1 Applicable safety standards 10

2.3.2 Leakage current 11

3. Applications 12

4 Assembling of test rig and the CDN sub-units 15

4.1 Installation of a test rig 16

4.2 Preparation of the CDN 3083-S200M 17

4.2.1 Mounting of the common earth bars 17

4.2.2 Mounting positioning plates 18

4.2.3 Assembly for IEC coupling 20

4.2.4 Assembly for extended IEC coupling 21

4.3 EUT connections 22

4.3.1 EUT power feed 22

4.4 Test conditions 23

5 Coupling modes overview 24

5.1 Phase synchronisation 24

5.2 IEC coupling modes 25

5.3 Extended IEC coupling mode 28

CDN 3083 IEC Coupling Line to Ground 29

CDN 3083 IEC Coupling Line to Line 30

CDN 3083 ANSI Coupling 31

6 Effects on the EUT 32

7 Maintenance 33

8 Technical specications CDN 3083-S200M 34

9 Warranty 37

10 Addresses 39

CONTENTS

5

Please take note of the following explanations of the symbols used in order

to achieve the optimum benet from this manual and to ensure safety during

operation of the equipment.

The following symbol draws your attention to a circumstance where nonobservation of the warning could lead to inconvenience or impairment in the

performance.

Example:

1 EXPLANATION OF THE SYMBOLS

USED IN THIS MANUAL

This connection must not be confused with the EUT

power input.

The following symbol draws your attention to a circumstance where nonobservation of the warning could lead to component damage or danger to the

operating personnel.

Example:

Never connect or disconnect the EUT while the test

system is performing a test.

Never connect or disconnect the coupling path while the

test system is performing a test.

6

Manual high-current coupling network CDN 3083–S200M

2 SAFETY ADVICE

Improper or careless handling can be fatal! The instru-

ment must only be used by trained personnel.

These operating instructions form an integral part of the equipment and must

be studied carefully before putting the device into use. It needs to be available

to the operating personnel at all times. All the safety instructions and advice

notes are to be observed.

Keeping responsibility to the instructions and recommendations that follow is

imperative.

The safety advice referring to the generators also applies and must be followed

when using the instruments together with the CDN 3083-S200M.

Neither Teseq AG, Switzerland nor any of the associated sales organizations

accept any responsibility for personal injury or for material or consequential

damage that may results through irresponsible or negligent operation of this

equipment.

When used with generator NSG 3060 and for EUT voltage

> 440 Vrms do not set pulse repetition rate <20 seconds.

The NSG 3060 may be damaged if this is not respected.

7

Lethal danger from high voltages and the risk of radiating

illegal electromagnetic interference.

The CDN 3083-S200M may only be installed and used by

authorised and trained EMC specialists (electrical engineers).

The CDN 3083-S200M must only be used for EMC tests

as set down in these operating instructions.

Personnel tted with a heart pacemaker must not

operate the instrument and must not be in the vicinity

of the test rig while it is in operation.

Lethal danger from high voltages and the risk of high

levels of electromagnetic radiation being generated.

When the system is used in conjunction with options,

accessories or other equipment the safety instructions

concerning those devices must also be observed.

8

Manual high-current coupling network CDN 3083–S200M

2.1. Safety measures

Persons tted with a heart pacemaker must not operate the instrument and

should not be in the vicinity of the test rig when pulses are generated.

The test rig must provide adequate insulation protection for up to 5 kV surge.

Particular care should be given to the connections between the CDN 3083S200M and the equipment under test (EUT).

The EUT may only be tested when placed inside a suitable protective enclosure

which should provide protection against ying fragments, re and electric shock.

The pulse voltage must not be able to nd its way to unearthed metal objects

in the event of the EUT failing.

Only use the instrument in a dry room.

Never leave the instrument unattended when the EUT is switched on.

Regularly check the heat of the CDN using the built in thermometer and switch

EUT off if the temperature exceeds 70°C.

Do not open the instrument. Repairs and adjustments must only be carried out

by qualied maintenance personnel.

Do not continue to use the CDN in case of any mechanical damage occur. The

CDNs housing and the cables have both insulating and screening function,

which can only be assured while the housing is intact. Return the damaged

CDN to a Teseq service centre immediately for repair.

2.2 Installation

The test system conforms to protection class 1. Local installation regulations

must be respected to ensure the safe ow of leakage currents.

9 Operation without a protective earth connection is for-

bidden! Therefore it is imperative to screw both earth

copper rails to the CDN.

Switch off EUT power before accessing EUT power «in»

or «out» terminals. Use the insulated allen key always

when working on the terminals.

Two independent protective earth connections are necessary (for the test

system and the EUT). These must be connected back to the local permanent

installation or to a xed, permanent protective earth conductor.

Operate the equipment only in dry surroundings. Any condensation that occurs

must be allowed to evaporate before putting the equipment into operation. Do

not exceed the permissible ambient temperature or humidity levels. Use only

ofcially approved connectors and accessory items.

It is recommended to connect the CDN 3083-S200M

through a properly rated power switch device, which

should be located close to the test setup. In order to

ensure an easy and quick acces to the EUT power, same

should be clearly and visibly labelled as a device for «EUT

power on/off» switching.

The inhouse power distribution needs to be equipped

with a proper circuit breaker and an emergency off

button as per IEC/EN 61010-1.

10

Manual high-current coupling network CDN 3083–S200M

2.3 Installation of an equipment under test power switch

It is recommended to connect the CDN through a properly rated power switch

device, which should be located close to the test setup. In order to ensure an

easy and quick access to the equipment under test (EUT) power, same should

be clearly and visibly labelled as a device for «EUT power on/off» switching.

The in-house power distribution needs to be equipped with a proper circuit

breaker and an emergency off button as per IEC/EN 61010-1.

The test setup should only be accessible to trained

personal.

Dimensioning of mains supply and rating of fuse protection of AC or DC power

supply must conform with national prescriptions and EUT requirements.

Inappropriate arrangement, mounting, cabling or handling of the device under

test or the protective elements can make the protective features that are incorporated in the concept of the instrument worthless.

2.3.1 Applicable safety standards

Development and manufacture is in compliance with ISO 9001.

The instrument complies with the safety requirements of IEC/EN 61010-1 (safety

requirements of electrical equipment for measurement, control and laboratory

use).

The interference immunity has been tested in accordance with EN 61326-1.

It is the user’s responsibility to ensure that the test rig does not emit excessive electromagnetic interference (EMI) that might affect other items. The test

system itself does not produce any excessive radiation; however, the injection

of interference pulses into the EUT can result in the device and/or its associated

cables starting to radiate EMI. To avoid radiating unwanted interference into

the environment, the standards organisations recommend that the test rig be

operated in a Faraday cage.

112.3.2 Leakage current

CDN 3083-S200M generates high leakage currents to ground, by specication.

Therefore the EUT power supply connection needs to be free of differential

circuit breaker protection.

Local installation regulations must be respected to ensure the safe ow of

leakage currents.

Always rst connect the PE wire to CDN 3083-S200M.

Use only nationally approved connectors and accessory items.

Ensure that a reliable return path for the interference current is provided

between the EUT and the coupling/decoupling network.

12

Manual high-current coupling network CDN 3083–S200M

3 APPLICATIONS

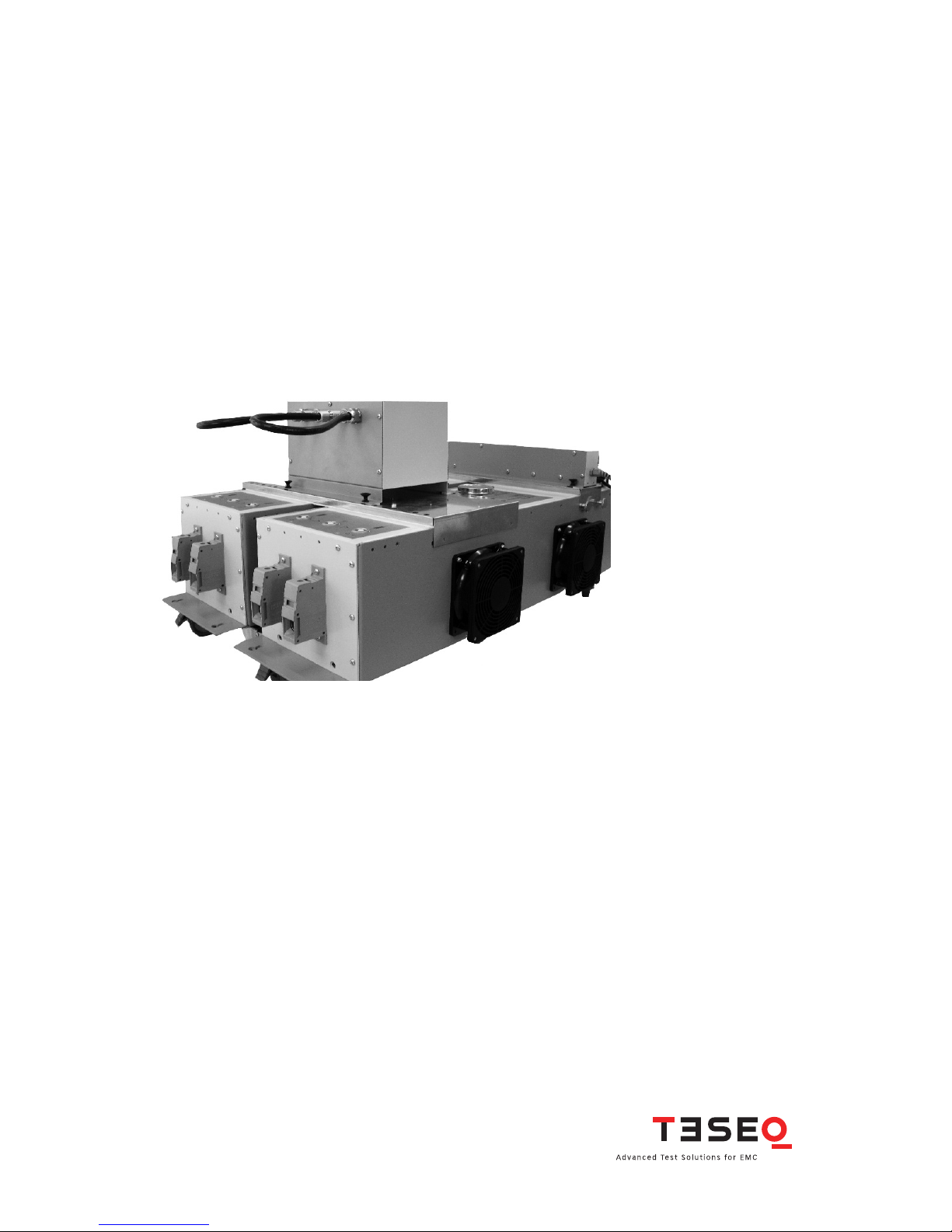

The manual coupling network CDN 3083-S200M fullls the requirements called

for in the surge standard IEC/EN 61000-4-5, including the new features concerning high currents.

The form factor perfectly suits the demands placed on the instrument in its

working environment. In its basic form, the coupler is made for use on a oor

or for table top placement in an EMC laboratory or in a development workshop.

It can be even mounted onto the wall to have free space on the test bench.

High-current couplers may need to be taken to test sites where it is commonly

impossible to move large installations in. For convenience, the CDN 3083-S200M

can be disassembled in handy parts and can be easily moved to other places.

Injecting surge pulses into power connections always involves a careful weigh-

ing up of partially conicting requirements. On the one hand the power network

has to be protected from the interference signals while the effects of the pulses

are concentrated on the equipment under test, yet on the other hand the back

lter must not result in any signicant voltage drop.

In order to keep voltage losses within reasonable limits at increasing current

levels, there are ve different classes of lter inductances dened in IEC 61000-

4-5 Ed. 3, up to 16 A, 16 to 32 A, 32 to 63 A, 63 to 125 A and 125 to 200 A including

specic tolerances for the pulse duration and the peak voltages for each class.

The CDN 3083-S200M conforms to the tolerances of the 125 to 200 A class.

The back lter inductance has been selected to be 0.2 mH.

13

The nominal maximum current rating of 200 A per phase can, during short

test periods, be considerably exceeded. The unit will tolerate the frequently

encountered inrush currents without complaint and, in extreme cases it can be

overstressed until the internal environment has reached the max. temperature

of 70°C.

CDN 3083-S200M is delivered with external fans mounted. Supply cables for the

fans are part of the delivery. It is recommended to turn on the fans when the

CDN 3083-S200M is used in the upper load range (Example: EUT current >100

A), or when environmental temperature is high (>30° C).

Figure 1

14

Manual high-current coupling network CDN 3083–S200M

The coupling network CDN 3083-S200M serves to inject the following standardized surge pulses from the surge generator into the mains supply to the device

under test:

Voltage surge of up to 6 kV which follows the 1.2/50 µs curve (open-circuit)

Current surge of up to 3 kA which follows the 8/20 µs curve (short circuit

conditions)

The CDN 3083-S200M is designed to be used with an EUT supply of up to 620

Vrms line to line and 400 Vrms line to ground at 200 A.

Coupling surge pulses with higher voltages (up to 8 kV) is in principle possible,

but in case the EUT draws low currents the backlter chokes may go in saturation due to the higher surge kickback currents and provide no more a good

backltering performance.

Operation is manual, simple and designed to be safe.

The CDN 3083-S200M is tested for safety in compliance with IEC 61010. The

rugged connection terminals together with the solid earth line assure a proper

connection, this in combination with a rugged housing.

Figure 2: EUT power supply connector

15

4 ASSEMBLING OF TEST RIG AND THE

CDN SUB-UNITS

The CDN 3083-S200M contains following parts:

1 Surge decoupling network CDN 3083-S200 N – L1

1 Surge decoupling network CDN 3083-S200 L2 – L3

2 Earth rails

1 Allen key, isolated

1 User manual CDN 3083-S200M

2 Coupling conguration sheets

1 Traceable calibration certicate

Screw set

8 wheels with brakes

Accessories:

IEC coupling set

1 INA 3080 Surge coupling unit

Extended IEC coupling set

2 INA 3080 Surge coupling unit

1 Connection cable 0.5 m Fischer/Fischer connector

16

Manual high-current coupling network CDN 3083–S200M

4.1 Installation of a test rig

This section describes the check-up and installation of the CDN 3083-S200M

coupling network after delivery and provides a checklist on the functions of

the unit after being transported or after signicant changes of the test rig were

performed.

Installation should only be carried out by qualied personnel.

a) Check the delivery for completeness.

b) Check the unit for any signs of transportation damage. Report any damage

found to the carrier immediately.

c) Study the manual.

d) Set up the surge generator in accordance with the instructions in its manual

but do not, however, switch the instrument on.

e) For convenience, place the coupling network close to the generator.

f) Connect the protective earth to the terminal. The same protective earth

should also be connected to the earth terminal of the generator.

g) Plug the high voltage connectors into the surge generator.

h) Connect the INA 3084 synchronisation unit to the generator.

i) Connect the EUT supply.

j) Switch on the mains power at the generator.

k) Choose the appropriate coupling mode.

l) Connect the device to be tested according to the relevant safety specica-

tions and with due regard to the magnitude of the pulse voltage selected.

Take the necessary measures to cope with any possible explosion or out-

break of re.

m) Switch on the EUT power supply.

n) Operate the generator as instructed in its manual and carry out the required

tests.

It is assumed that the test rig has been set up in accordance with the foregoing

notes and that the device to be tested has been connected taking the relevant

safety measures into account.

174.2 Preparation of the CDN 3083-S200M

Prepare the test setup according to the chosen standard and put both decoupling network units, etc. to the place where the CDN shall be used for testing.

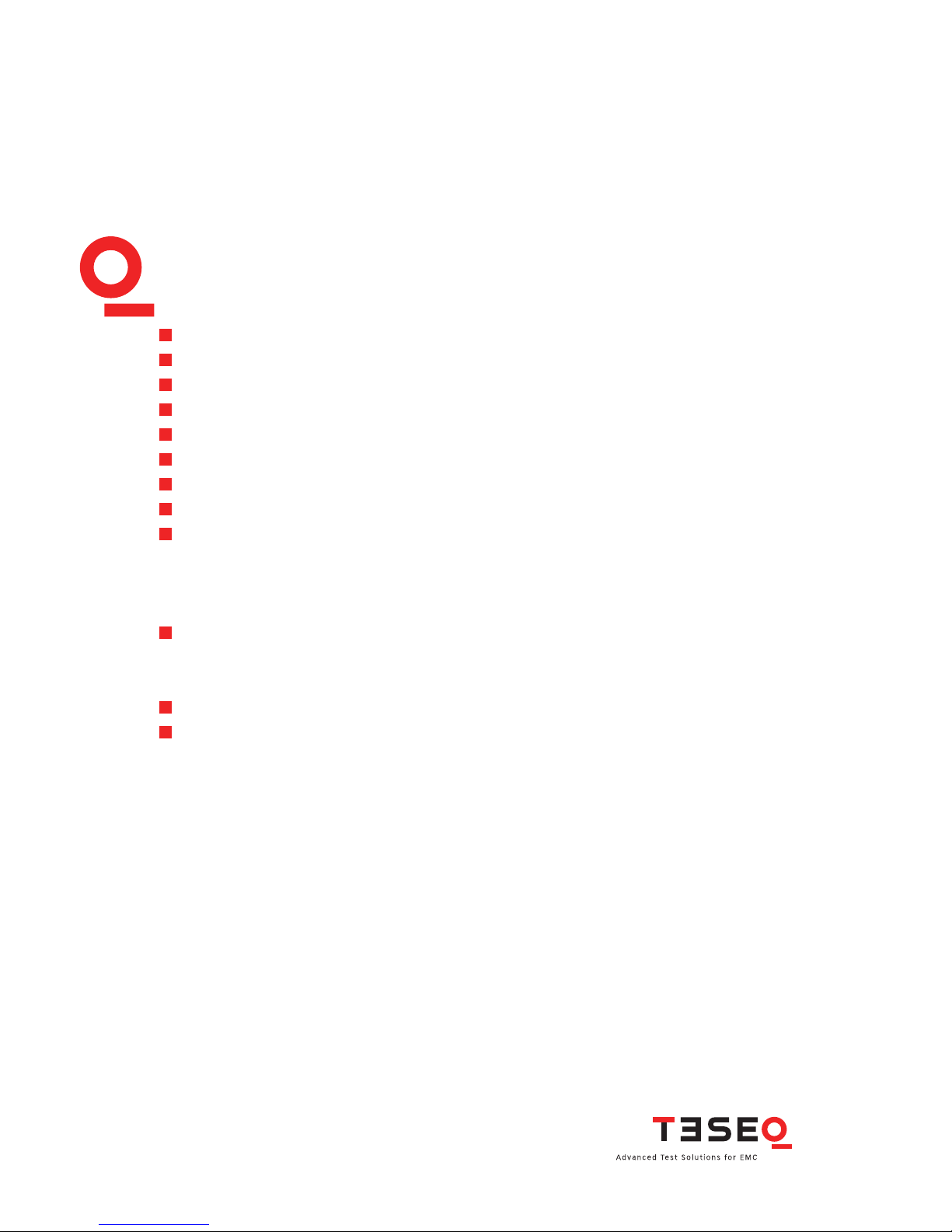

4.2.1 Mounting of the common earth rails

Place the two surge decoupling networks in parallel to each other. Looking from

the top, make sure that the N-L1 network is below the L2-L3 network.

To enable proper synchronisation, assure that side L1

being placed next to L2!

Use the delivered isolated allen key to screw the copper earth rails on to both

ends of the decoupling networks (2 x 2 screws each side per network).

Make sure that the copper rail is properly mounted and

tightened. Use only the delivered screws.

18

Manual high-current coupling network CDN 3083–S200M

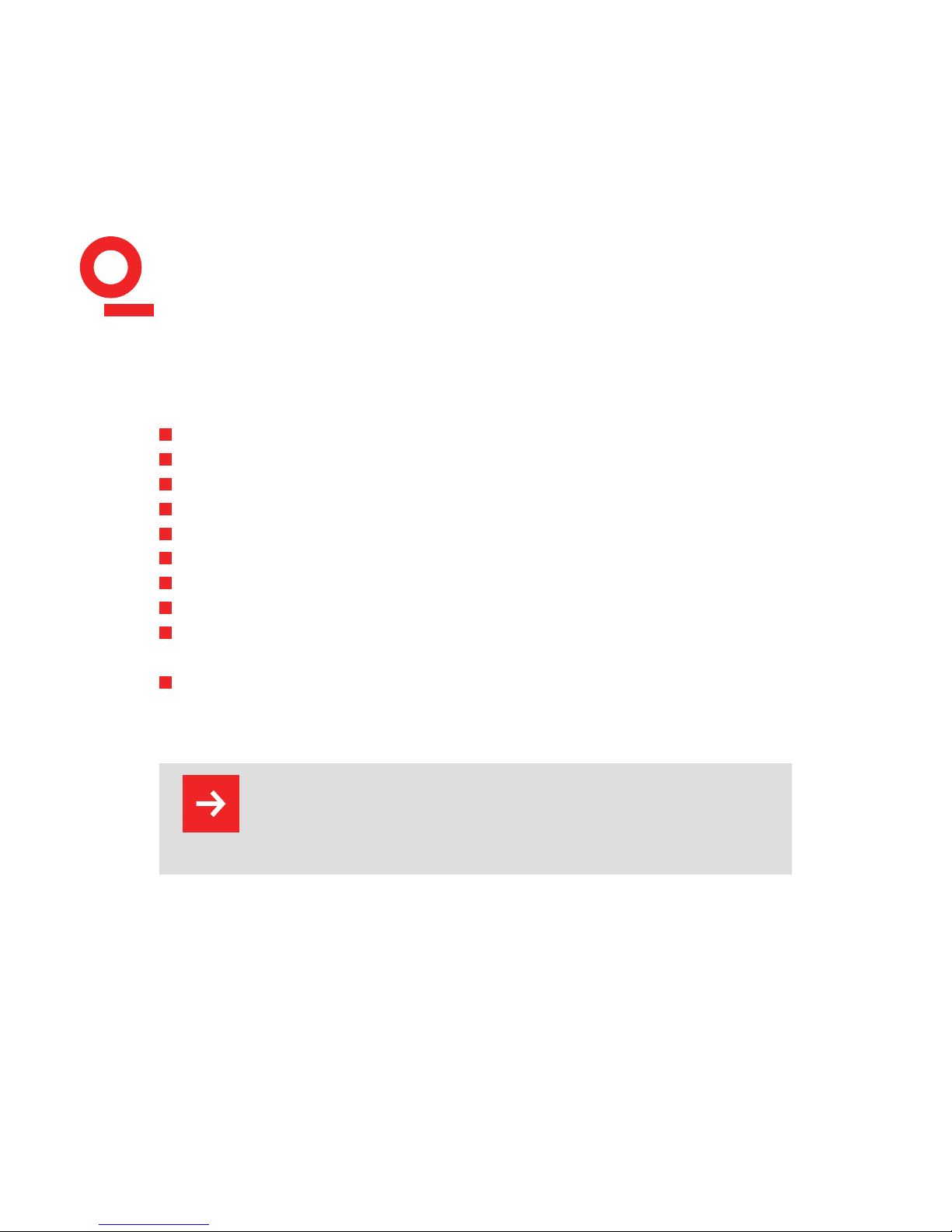

Figure 3: Top view on CDN units

Figure 4: Assembly of copper earth rail

After this preparation work, the CDN is stable enough for being turned to its side

prior to mounting the wheels at the bottom of the case, if required.

2x

M8 x 16 mm

2x

M8 x 16 mm

2x

M8 x 16 mm

2x

M8 x 16 mm

4.2.2 Mounting positioning plates

Screw the base plates (positioning plates) of the synch unit and of the coupling unit, with the knurled screws to the foreseen holes on the outside of the

decoupling networks. Connect the synch lines (safety banana connector) to

the decoupling units. If CDN 3083-S200M decoupling networks are not placed

correctly, the positioning plates can not be screwed on.

19

Figure 5: Location of synchronisation unit and of positioning plate

Figure 6: Synchronisation plate (l.h.) and positioning plate (r.h.)

20

Manual high-current coupling network CDN 3083–S200M

4.2.3 Assembly for IEC coupling

For IEC coupling, add the coupling modules INA 3080 in the middle of the

positioning plate and press it slightly down into the positioning holes. Fix the

INA by pushing the black quick snap-on knobs down. The CDN 3083-S200M is

now ready to use.

Figure 7: Location of IEC coupling module

Figure 8: View of IEC coupling module

214.2.4 Assembly for extended IEC coupling

For extended IEC coupling, add both coupling units INA 3080 on the positioning plate and press it slightly down into the positioning holes. Fix the INAs by

pushing the black quick snap-on knobs down. The CDN 3083-S200M is now

ready to use.

Figure 9: Location of extended IEC coupling modules

Figure 10: View of extended IEC coupling modules

Because of the coupling capacitors, the mains voltage

can be present at the HV connectors when the EUT power

supply is switched on. The HV connectors must therefore

always be hooked up to the generator before the mains

and the EUT power supply are switched on.

22

Manual high-current coupling network CDN 3083–S200M

4.3 EUT connections

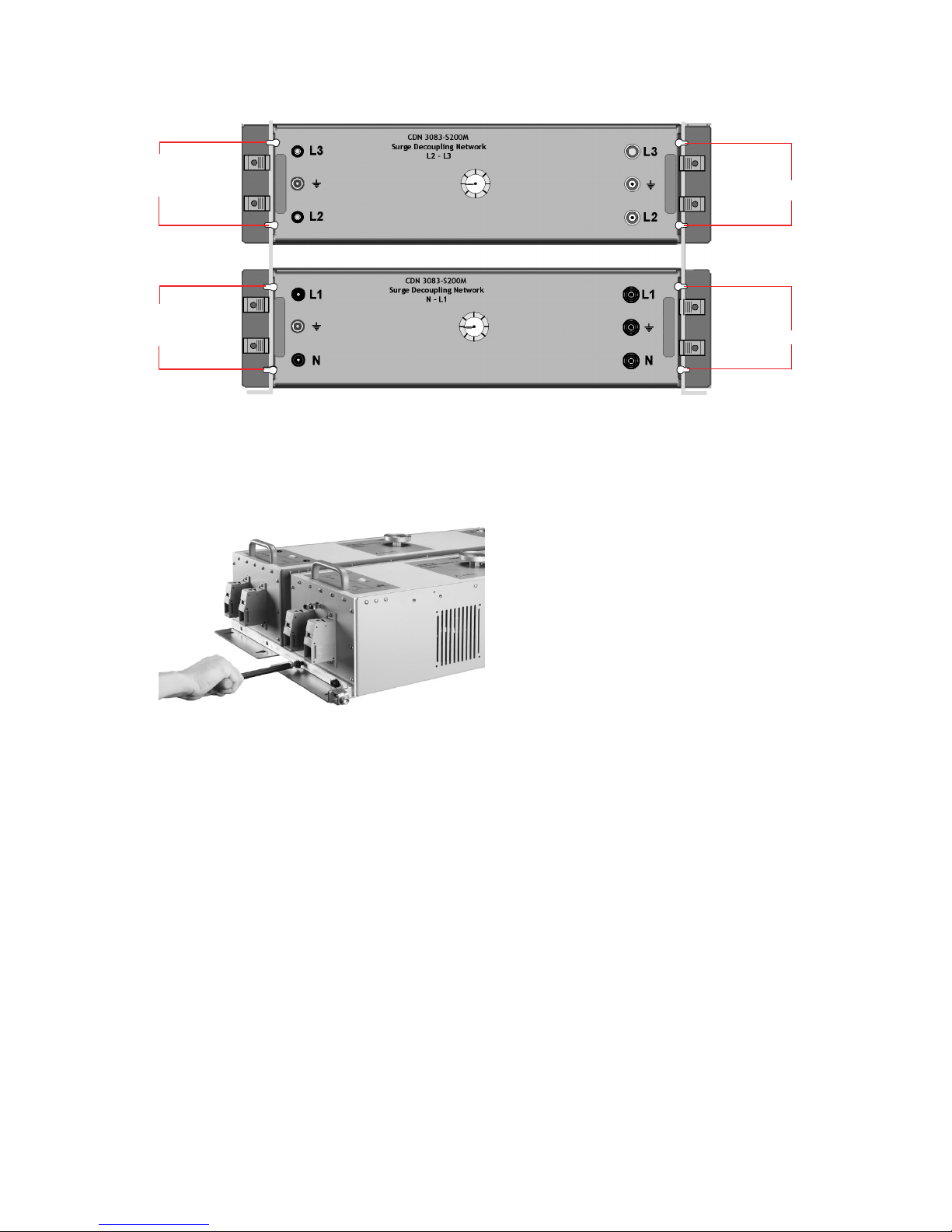

The CDN 3083-S200M is equipped with EUT terminals suitable for a max. wire

gauge of 110 mm2 AWG 4-4/0 (230 A), torque: max. 20 Nm.

The in-house power distribution needs to be equipped

with a proper circuit breaker and an emergency off

button as per IEC/EN 61010-1.

4.3.1 EUT power feed

The power is fed in via 5-core cable leads.

Do not mismatch the EUT power input of the CDN and the

EUT power output. Use only the delivered isolated allen

key to screw the cables to the terminals. Never touch the

terminals during the EUT power is on.

EUT power input EUT power output

Figure 11: Identification of EUT power input and output

23

Figure 12: View of EUT power input connection side

4.4 Test conditions

Every test rig must be planned carefully. All the instrumentation should be

readily accessible and rigidly positioned.

The whole test assembly should be supplied from the

same mains connection in order to prevent uncontrolled

ow of pu ls e curr ent in ot he r pa r t s of th e sy st em . Ins ta ll a tion in a Faraday cage ensures that non-associated items

and equipment are not disrupted by pulses radiated from

the cabling or the device under test. Connections to the

EUT must be of low impedance and be made with high

contact pressure. Otherwise welding or arcing may occur

at the contact points.

24

Manual high-current coupling network CDN 3083–S200M

In the following all possible coupling modes are described.

The following example shows a coupling from L3 to N whereby the generator

High output is connected to the INA 3080 surge coupling unit input. One end is

looped, in order to get the recommended 18 μF capacitance required for line to

line coupling according to IEC/EN 61000-4-5. The other pulsed end is connected

to L3. The generator low output is directly connected to the N line.

5.1 Phase synchronisation

In the INA 3084 synchronisation unit the input voltage L1 to N is wired out for

Sync reference. The approximately 2 meter long cable of INA 3084 needs to be

connected to the EUT mains input plug located on the rear side of the NSG 3040.

The phase angle indicated on the display of NSG 3060 is always in relation with

the L1-N reference. For coupling settings different from L1 to N coupling, it is up

to the user to make the phase angle correction, and enter the required phase

angle + phase shifting value.

The value of the phase angle shifting in relation with the selected coupling path

and is installation and wiring dependent. At rst use of the test system it is

recommended to make the phase angle setting verication using MD 200 Probe

and to edit a phase angle correction table to be used during further operation.

For synchronisation purpose the cable end of the INA 3084 synchronisation unit

needs to go to the EUT power input connection of the generator.

5 COUPLING MODES OVERVIEW

Never run the CDN with a loose end of the coupling unit.

All connectors need to be plugged.

25

Figure 13: Example of IEC coupling L3- N

Alternative connection possibilities are summarized in table 1 hereafter.

5.2 IEC coupling modes

Figure 14: IEC coupling basic configuration

All IEC/EN 61000-4-5 coupling possibilities are listed. For easy understanding,

the coupling network INA 3080 input is identied by X1 while the outputs are

marked with X2 and X3. Depending on coupling mode selected following connections are to be established for:

26

Manual high-current coupling network CDN 3083–S200M

Table 1: Selection of IEC coupling modes

IEC line to line

Generator

output

Loop on

INA 3080

Decoupling network

CDN 3083-S200

High Low L1 L2 L3

L1 – N X1 N X2 to X3 X3

L1 – L2 X1 L2 X2 to X3 X3

L1 – L3 X1 L3 X2 to X3 X3

L2 – N X1 N X3 to X2 X2

L2 – L1 X1 L1 X3 to X2 X2

L2 – L3 X1 L3 X3 to X2 X2

L3 – N X1 N X3 to X2 X2

L3 – L1 X1 L1 X3 to X2 X2

L3 – L2 X1 L2 X3 to X2 X2

Generator

output

Loop on

INA 3080

Decoupling network

CDN 3083-S200

High Low N L1 L2 L3

N – PE X1 PE X2 to X2 X3

L1 – PE X1 PE X2 to X2 X3

L2 – PE X1 PE X3 to X3 X2

L3 – PE X1 PE X3 to X3 X2

IEC line to ground

27

Figure 15: IEC coupling L1-N

Figure 16: IEC coupling L2-N

Figure 17: IEC coupling L2-PE

28

Manual high-current coupling network CDN 3083–S200M

5.3 Extended IEC coupling mode

For extended coupling modes, a second INA 3080 needs to be added on the

CDN 3083-S200M.

Figure 18: IEC coupling L1-PE

Figure 19: Extended IEC coupling basic configuration

INA 3084 / 3085

Synchronisation Unit

29

Table 2: Selection of extended IEC coupling modes

Generator

output

Loop on

INA 3080

Connection

from X1 to Y1

Decoupling network

CDN 3083-S200M

High

Low N L1 L2 L3

X1 PE –– Yes Y3 Y2 X3 X2

X1 L1 X2 to X3 No X3

X1 L2 X2 to X3 No X2

X1 L3 Y3 to Y2 No Y2

X1 PE Y2 to Y3 No Y3

X1 PE Y3 to Y2 No Y2

X1 PE X2 to X3 No X3

X1 PE X3 to X2 No X2

X1 N Y3 to Y3 Yes Y2 X3 X2

X1 PE Y3 to Y3 Yes Y2 X3 X2

CDN 3083 IEC Coupling Line to Ground

30

Manual high-current coupling network CDN 3083–S200M

CDN 3083 IEC Coupling Line to Line

31CDN 3083 ANSI Coupling

32

Manual high-current coupling network CDN 3083–S200M

6 EFFECTS ON THE EUT

The surge pulse contains considerable energy. When super-imposed on the

mains, a signicant resultant current can occur if the EUT becomes defective.

The effects can be very different, depending on the characteristics of the equipment undergoing the test:

No effect

Brief faulty operation without permanent damage

Reduction of the insulation resistance or similar

Quality affected (life expectancy)

Change in the technical specication of the device under test

Flash-over in cables, connectors and equipment

Bursting of components

Explosion of components

Burning of parts caused principally by resultant mains current when mains

superposition mode is used

Damage to equipment, systems or components that are electrically or induc-

tively coupled to the pulse current path

When testing with high energy surge pulses, a test on

a device should never be considered as being damagefree until a subsequent thorough investigation proves

that the EUT is still fully intact.

33

Basically there is no need of maintenance and the CDN 3083-S200M does not

contain serviceable parts. The housing may be cleaned with a moist cloth with

possibly just a trace of detergent liquid. Industrial spirit is also a suitable cleaning

agent. Other solvents are not permitted.

Only specialist or trained maintenance personnel may carry out internal work

on the instrument. In the event of more service or repair work being necessary,

the instrument should be returned to a Teseq service center accompanied by

an appropriate description of the problem. The instrument contains no fuses.

7 MAINTENANCE

34

Manual high-current coupling network CDN 3083–S200M

8 TECHNICAL SPECIFICATIONS

CDN 3083–S200M

The CDN 3083-S200M is a 3-phase manual coupling network for surge interference pulses as per IEC/EN 61000-4-5 and other related standards.

The CDN 3083-S200M base 1 x Surge decoupling network

set consists of: CDN 3083-S200 – L1

1 x Surge decoupling network

CDN 3083-S200 L2 – L3

2 x Earth rails

1 x Wheel set

1 x Allen key, isolated

1 x User manual CDN 3083-S200M

1 x Test certicate

2 x Coupling conguration sheets

Accessories required either:

IEC coupling set 1 x INA 3080 Surge coupling unit

or

Extended IEC coupling set: 2 x INA 3080 Surge coupling unit

1 x Connection cable

Modula/NSG 3040/CDN 3061: 1 x INA 3084 synchronisation unit for

NSG 3040 and Modula

2 x Cable 1 m, with each a Fischer/Fischer

plug

Following complementary items are required for phase synchronisation:

35Pulse voltages/current: 6.6 kV/3.3 kA max.

EUT power supply voltage: 620 Vrms line-to-line

400 Vrms line-to-ground

500 VDC, max.

Current: 200 Arms or DC max. per line

Frequency: DC to 60 Hz

Mains decoupling: 0.2 mH ± 10%

EUT connection: Screw-terminals, 230 A, up to 110 mm

2

(AWG 4-4/0)

Max. temperature: 70°C

Coupling modes: Surge differential, lines to PE, common to

PE (with optional INA 3080 coupling unit for

extended IEC coupling)

Dimensions: 850 x 520 x 345 (L x D x H) mm

(33.5 x 20.5 x 13.6”)

Weight: 80 kg approx.

Optional accessories: MD 300 Current measuring probe

MD 210 Voltage measuring probe

IEC coupling modes: Line to ground (9 μF) L1 — PE

L2 — PE

L3 — PE

N — PE

Line to line (18 μF) L1 — N

L1 — L2

L1 — L3

L2 — N

L2 — L3

L3 — N

36

Manual high-current coupling network CDN 3083–S200M

Optional IEC coupling modes (possible only with second INA 3080):

Lines to ground (9 μF) L1+L2 — PE

L1+L3 — PE

L1+N — PE

L2+L3 — PE

L2+N — PE

L3+ N — PE

L1+L2+L3 — PE

L1+L2+N — PE

L1+L3+N — PE

L2+L3+N — PE

L1+L2+L3+N — PE

37

9 WARRANTY

Teseq grants a guarantee of 2 years on this instrument, effective from the date

of delivery.

During this period, any defective component/part will be repaired or replaced

free of charge or, if necessary, the instrument will be replaced by another of

equivalent value. The decision regarding the method of reinstating the functional capability is at the sole discretion of Teseq.

Excluded from the guarantee are damages or consequential damages caused

through negligent operation or use as well as the replacement of parts subject

to degradation.

The guarantee is rendered invalid by any intervention by the customer or a

non-authorized third party.

The goods are to be returned in the original packing or other equivalent packing

suitable for the purpose of the foreseen means of transport. Teseq shall accept

no responsibility for damage in transit.

To nd your local partner within

Teseq®’s global network, please go to

www.teseq.com

© December 2018 Teseq®

Specications subject to change without

notice. Teseq® is an ISO-registered company.

Its products are designed and manufactured

under the strict quality and environmental

requirements of the ISO 9001. This document

has been carefully checked. However, Teseq®

does not assume any liability for errors or

inaccuracies.

AMETEK CTS

Manufacturer:

Switzerland

EM TEST (Switzerland) GmbH

Sternenhofstrasse 15

4153 Reinach, Schweiz

info.conducted.cts@ametek.com

Switzerland

Teseq AG

Sternenhofstrasse 15

4153 Reinach, Schweiz

info.conducted.cts@ametek.com

Germany

Teseq GmbH

Landsberger Strasse 255

12623 Berlin, Deutschland

info.rf.cts@ametek.com

United Kingdom

Milmega Ltd.

Park Road

Ryde, Isle of Wight

PO33 2BE, Großbritanien

Milmega.sales@ametek.co.uk

USA

IFI – Instruments For Industry

903 South Second Street

Ronkonkoma

New York 11779, USA

sales@i.com

Sales &

Service Center

China

AMETEK Commercial

Enterprise

(Shanghai) Co. Ltd. Beijing Branch

Western Section, 2nd Floor

Jing Dong Fang Building (B10)

Chaoyang District

Beijing, China, 100015

T: +86 10 8526 2111

chinasales@teseq.com

Shanghai Ofce:

Part A1, A4, 2nd oor, Building

No. 1

No. 526 Fute 3rd Road East

Pilot Free Trade Zone, Shanghai

200131, China

T: +86 21 5866 0969

Guangzhou Ofce:

Room 1410-12, Yian Plaza

33 Jian She Liu Ma Road

Guangzhou, China

T: +86 20 8363 4768

Germany

AMETEK CTS Germany GmbH

Lünener Straße 211

59174 Kamen, Deutschland

T: +49 2307 26070-0

info.cts@ametek.de

France

AMETEK SAS

Rond Point de l´Epine des Champs

Buroplus, Bat D

78990 Elancourt, France

T: +33 (0) 1 30 68 89 0 0

info.france@ametek.com

United Kingdom

Teseq a trading divison

of AMETEK (GB) Limited

5 Ashville Way, Molly Millars Lane

Wokingham Berkshire RG412PL

Great Britain

T: +44 845 074 0660

sales.cts@ametek.co.uk

Japan

AMETEK Co. Ltd.

Tokyo of ce

3rd oor, Shiba NBF Tower,

1-1-30 Shiba-Daimon, Minato-ku

Tokyo, 105-0012, Japan

T: +81 3 6809 2401

Nagoya Ofce

1-329 Kifune Meito-ku Nagoya-shi

Aichi-ken, 465- 0058, Japan

T +81 52 709 5501

cts-japan.sales@ametek.co.jp

Poland

AMETEK CTS Germany GmbH

ul. Ogrodowa 31/35

00-893 Warszawa, Polen

T: +48 518 643 512

infopolska.emtest@ametek.com

Singapore

AMETEK Singapore Pte. Ltd.

No. 43 Changi South Avenue 2

#04-01 Singapore 486164

T: +65 6484 2388

Singaporesales.cts@ametek.com

Taiwan

AMETEK Taiwan Corp. Ltd.

10F-5, No. 120, Sec 2,

GongDaoWu Rd.,

Hsinchu City 30072, Taiwan

T: +886 3 57 5099

USA

Teseq Inc. / AMETEK CTS

52 Mayeld Avenue

Edison, New Jersey 08837, USA

T +1 732 417 0501

For free: +1 888 417 0501

usasales.cts@ametek.com

Loading...

Loading...