Page 1

Operations Manual

DOPSM2064X012

October 2019

TESCOM™ ER5000 Series

User Manual

Do not attempt to select, install, use or maintain

this product until you have read and fully

understood the Safety, Installation & Operations

Precautions section of this manual.

WARNING

If your application is rated as a Hazardous Location,

you MUST use model ER5050. Models ER5000,

ER5020, ER5040, ER5100 and ER5110 are not

intended for or rated for use in Hazardous Locations.

Page 2

Safety, InStallatIon &

BACK

o

www.emerson.com/tescom

peratIonS precautIonS

2

Page 3

ER5000 — 3Safety, Installation & Operations Precautions

BACK

TESCOM™ ELECTRONIC CONTROLLERS

WARNING

DO NOT ATTEMPT TO SELECT, INSTALL, USE OR MAINTAIN THIS

CONTROLLER OR ACCESSORY UNTIL YOU HAVE READ AND FULLY

UNDERSTOOD THESE INSTRUCTIONS.

BE SURE THIS INFORMATION REACHES THE OPERATOR AND STAYS WITH THE

PRODUCT AFTER INSTALLATION.

DO NOT PERMIT UNTRAINED PERSONS TO INSTALL, USE OR MAINTAIN THIS

CONTROLLER OR ACCESSORY.

IMPROPER SELECTION, IMPROPER INSTALLATION, IMPROPER MAINTENANCE,

MISUSE OR ABUSE OF THIS CONTROLLER OR RELATED ACCESSORIES CAN CAUSE

DEATH, SERIOUS INJURY AND/OR PROPERTY DAMAGE.

OXYGEN SERVICE REQUIRE S SPECIAL EXPERTISE AND KNOW LEDGE OF SYSTEM

DESIGN AND MATERIAL COMPATIBILITY IN ORDER TO MINIMIZE THE POTENTIAL

FOR DEATH, SERIOUS INJURY AND/OR PROP ERTY DAMAGE.

Possible consequences include but are not limited to:

• High velocity uid (gas or liquid) discharge

Electrocution

•

• Parts ejected at high speed

• Contact with uids that may be hot, cold, toxic or otherwise injurious

• Explosion or burning of the uid

• Lines/hoses whipping dangerously

• Damage or destruction to other components or equipment in the system

CAUTION

SAFETY PRECAUTIONS

1. Read and underst and the user’s manual before operating the contro ller.

2. Inspe ct the control ler and accessor ies before each use.

3. Operate the un it only under specied environment al conditions .

4. Follow instructions in the manuals for proper wiring.

5. Never co nnect the cont roller or accessorie s to a supply source having a voltag e

greater t han the maximum rated vo ltage of this controll er or accessor y.

6. Nev er connect the c ontroller or a ccessories to a su pply source hav ing a pressure

greater t han the maximum rat ed pressure of this co ntroller or acces sory.

7. Never use anything bu t clean dry inert gases or air into the

electropneumatic controller.

8. Star t up sequence for e lectropne umatic control lers is:

a. Fe edback loop mus t be installed a nd operationa l.

b. Elec trical power should be applie d and system set point reduced to

its low est pressure ou tput before turning on the pneumatic supply to

the controller.

9. Refer to produc t label (modica tion specic) for maximum inlet p ressures. If

this rated pressure cannot be found, cont act your local TESCO M representa tive

for the ra ted pressure pr ior to installation an d use. Verify the designed pressu re

rating of all equi pment (e.g., supply lines, t tings, connec tions, lter s, valves,

gauges, etc.) in your s ystem. All must b e capable of handling the supply a nd

operating pressure.

www.emerson.com/tescom

Page 4

ER5000 — 4Safety, Installation & Operations Precautions

BACK

10. Cl early establ ish ow direct ion of the uid before installat ion of controll ers,

regulators, valves and accessories. It is the responsibility of the user to install

the equipment in the correct direction.

11. Remove pressure from the system before tighteni ng ttings, ga uges

or components.

12. Ne ver turn controller, regulator or v alve body. Instead, hold the contr oller body

and turn tti ng nut.

13. If a controller, regul ator or valve leaks or mal functions, t ake it out of

service immediately.

14. Do n ot modify equ ipment or add at tachments not approved by

the manufacturer.

15. Apply pr essure to the sys tem gradually, avoiding a sudden surge of uid o r

pressure shock to the equipment in the sy stem.

16. Reg ulators are not shut-of f valves. Inst all a pressure relief de vice downstream

of the regulator to prote ct the process equipm ent from operating pressure

increas es. Shut off the supply p ressure when the regulator is not in use.

17. Periodic inspection and scheduled maintenance of your equipment is required

for continued safe operation.

18. Th e frequency of ser vicing is the responsibilit y of the user based o n the

applic ation. Never allow problems or l ack of maintenance to go unre ported.

19. Read and follow precautions on compressed gas cylinder labels.

20. It is impor tant that you analyze a ll aspects of your applicati on and review

all available informat ion concerning the pro duct or syste m. Obtain, read

and understand the Ma terial Safet y Data Sheet (MSDS) for each uid used in

your system.

21. Never use materials for controllers, regulators, valves or accessories that are

not compa tible with the uids being used.

22. Users must test under normal operating conditions to determine suitability of

materials in an application.

23. Vent u ids to a safe environment and in an area away from employees. B e sure

that vent ing and disposal m ethods are in acco rdance with Fed eral, State and

Local requirement s. Locate and construc t vent lines to prevent condensat ion

or gas accumulati on. Make sure the ven t outlet is not obstruc ted by rain, snow,

ice, vegetation, insects, birds, etc. Do not interconnect vent lines; use separate

lines if m ore than one vent is n eeded.

24. Do not lo cate controll ers, regulators, val ves or accessories using amma ble

uids near open ames or any other source of igni tion. Use of Hazardous Location

contro llers may be ne cessary to be i n accordance wit h local elec tric codes.

25. So me uids, when burning, do not ex hibit a visible ame. Use extre me caution

when inspect ing and/or servicing systems using ammable uids to avoi d

death or serious injur y to employees. P rovide a device to warn em ployees of

these dangerous conditions.

26. Many gases can cause suffo cation. Make cer tain the area is well vent ilated.

Provide a device to warn e mployees of lack of Oxygen.

27. Ne ver use oil or grease on these contro llers, regul ators, valves or access ories.

Oil and gr ease are easily ign ited and may combi ne violently w ith some uids

under pressure.

28. Have emergency e quipment in the area if toxic or ammable uids are used.

29. Up stream lters are recommended for us e with all uids.

30. Do n ot bleed system by loos ening ttings.

31. Pr event icing of the e quipment by removing e xcess moisture f rom the gas.

32. Always us e proper thread lubricants a nd sealants on tapere d pipe threads.

www.emerson.com/tescom

Page 5

ER5000 — 5Safety, Installation & Operations Precautions

BACK

INSTALLATION

Inspec t the controll er and accessories for physical d amage and contam ination.

Do not connect the contr oller or accessory if you dete ct oil, grease or damaged

part s. If the controller or accessory is damaged, co ntact your lo cal TESCOM™

representative to have the controller cleaned or repaired.

WARNING

Make sure t hat the compone nts and materia ls used in the fluid hand ling

system a re compatible w ith the fluid an d have the proper pr essure rating .

Make sure t hat the compone nts used in the electronic system are

compatible with and have the proper voltage rating.

REPAIR SERVICE

If a controller leaks or malfunctions, take i t out of servic e immediately. You must

have inst ructions before doing any mai ntenance. Do not make a ny repairs you do

not understa nd. Have qualie d personnel make repair s. Return any equipment

in need of s ervice to your equipment supp lier for evaluat ion and prompt se rvice.

Equipment is restored to the ori ginal factor y performance spe cications, i f

repair able. There are at fee rep air charges for eac h standard mod el. The original

equipment warranty applies after a complete overhaul.

WARNING

SAFE COMPONENT SELECTION

1. Consid er the total sys tem design when selec ting a component to ensure s afe,

trouble-free performance.

2. The use r is responsible for assur ing all safety and warning requirem ents of the

application are met through his/her own analysis and testing.

3. TESCOM may sugg est material for us e with spe cic media upon request.

Suggestions are based on technical compatibility resources through

associations and manufacturers. TESCOM does NOT guarantee materials to be

compatible with speci c media — THIS IS THE RE SPONSIBILITY OF THE USER!

4. Component function, adequate ratings, proper installation, operation and

maintenance are the responsibilities of the system user.

5. The user is responsible to be in accordance with all the necess ary mechanical

and electrical codes required for installation and operation of the system. These

requirements include but are not limited to all Hazardous Location controllers.

6. The use r is responsible for the select ion of the proper model number of t he

controller that would meet the application’s possible hazardous environment

or conditions.

WARNING

Do not mod ify equipme nt or add attachments not approved by

the manufacturer.

www.emerson.com/tescom

Page 6

ER5000 — 6Safety, Installation & Operations Precautions

BACK

TESCOM™ REGULATORS

WARNING

DO NOT ATTEMPT TO SELECT, INSTALL, USE OR MAINTAIN THIS

REGUL ATOR, VALVE OR ACCESS ORY UNTIL YOU HAVE RE AD AND FULLY

UNDERSTAND THESE INSTRUCTIONS.

BE SURE THIS INFORMATION REACHES THE OPERATOR AND STAYS WITH THE

PRODUCT AFTER INSTALLATION.

DO NOT PERMIT UNTRAINED PERSONS TO INSTALL, USE OR MAINTAIN THIS

REGULATOR, VALVE OR ACCESSORY.

IMPROPER SELECTION, IMPROPER INSTALLATION, IMPROPER MAINTENANCE,

MISUSE OR ABUSE OF REGULATORS, VALVES OR RELATED ACCESSORIES CAN CAUSE

DEATH, SERIOUS INJURY AND/OR PROPERTY DAMAGE.

OXYGEN SE RVICE REQUIR ES SPECIAL EX PERTISE AND K NOWLEDGE OF SY STEM

DESIGN AND MATERIAL COMPATIBILITY IN ORDER TO MINIMIZE THE POTENTIAL

FOR DEATH, SERIOUS INJURY AND/OR PROPERTY DAMAGE.

Possible consequences include but are not limited to:

• High velocity uid (gas or liquid) discharge

• Parts ejected at high speed

• Contact with uids that may be hot, cold, toxic or otherwise injurious

• Explosion or burning of the uid

• Lines/hoses whipping dangerously

• Damage or destruction to other components or equipment in the system.

www.emerson.com/tescom

CAUTION

SAFETY PRECAUTIONS

1. Inspe ct the regulat or, valve and a ccessories before each use.

2. Never co nnect regulators , valves or access ories to a supply s ource having a

pressure great er than the maximum rate d pressure of the r egulator, valve

or accessory.

3. Refer to produc t label (model specic) for ma ximum inlet pressure s. If this

rated pr essure cannot b e found, contac t your local TE SCOM represent ative for

the rate d pressure pri or to installation and us e. Verif y the designed pr essure

rating of all equi pment (e.g., supply lines, t tings, connec tions, lter s, valves,

gauges, etc.) in your s ystem. All must b e capable of handling the supply a nd

operating pressure.

4. Clear ly establish ow direction of the ui d before installatio n of regulators,

valves and accessories. It is the r esponsibilit y of the user to ins tall the

equipment in the correct direction.

5. Remove pressur e from the syst em before tightening t tings, gauges

or components.

6. Never t urn regulator o r valve body. Instead hold r egulator or val ve body and

turn t ting nut.

7. If a regulator or valve leaks or malfunctions, take it out of ser vice immediately.

8. Do not mo dify equipm ent or add atta chments not app roved by

the manufacturer.

9. Appl y pressure to the s ystem gradual ly, avoidin g a sudden surge of uid or

pressure shock to the equipment in the sy stem.

Page 7

ER5000 — 7Safety, Installation & Operations Precautions

BACK

10. Reg ulators are not shut-of f devices. Ins tall a pressure relief d evice downstream

of the regulator to prote ct the process equipm ent from overpr essure

conditions. Shut off t he supply pressure whe n the regulator is not in use.

11. Periodic inspection and scheduled maintenance of your equipment is required

for continued safe operation.

12. Th e frequency of ser vicing is the responsibilit y of the user based o n

the application.

13. Ne ver allow problems or lack of mainte nance to go unrepo rted.

14. Read and follow precautions on compressed gas cylinder labels.

15. It is impor tant that you analyze a ll aspects of your applicati on and review

all available informat ion concerning the pro duct or syste m. Obtain, read

and understand the Ma terial Safet y Data Sheet (MSDS) for each uid used in

your system.

16. Ne ver use materials for regu lators, valve s or accessories that are n ot

compatible wi th the uids being used.

17. User s must test component s for material compatibi lity with the system

operat ing conditions prior to use in the syste m.

18. Vent u ids to a safe environment and in an area away from employees. B e sure

that vent ing and disposal m ethods are in acco rdance with Fed eral, State and

Local requirement s. Locate and construc t vent lines to prevent condensat ion

or gas accumulati on. Make sure the ven t outlet is not obstruc ted by rain, snow,

ice, vegetation, insects, birds, etc. Do not interconnect vent lines; use separate

lines if m ore than one vent is n eeded.

19. Do not locate re gulators, valves or accessor ies controlling ammable uid s near

open am es or any other sour ce of ignition. Use of Hazar dous Location contro llers

may be necessar y to be in accordan ce with local el ectric

codes.

20. So me uids when bur ning do not exhibit a visi ble ame. Use extreme c aution

when inspect ing and/or servicing systems using ammable uids to avoi d

death or serious injur y to employees. P rovide a device to warn em ployees of

these dangerous conditions.

21. Many gases can cause suffo cation. Make cer tain the area is well vent ilated.

Provide a device to warn e mployees of lack of Oxygen.

22. Ne ver use oil or grease on these regula tors, valves o r accessories. Oil and gr ease

are easil y ignited and may co mbine violent ly with some uids under pressu re.

23. Have emergency e quipment in the area if toxic or ammable uids are used.

24. Up stream lters are recommended for us e with all uids.

25. Do n ot bleed system by loos ening ttings.

26. Pr event icing of the e quipment by removing e xcess moisture f rom the gas.

27. Always us e proper thread lubricants a nd sealants on tapere d pipe threads.

www.emerson.com/tescom

Page 8

ER5000 — 8Safety, Installation & Operations Precautions

BACK

INSTALLATION

WARNING

Investigate and apply the most recent standards for Hazardous Locations for

your area set by ANS I, ISO and OSHA, as well as all elec trical codes a nd fire and

safet y standards, t o determine if you r application w ill require a Hazardo us

Location model.

CAUTION

Do not open packaging until ready for installation or in a clean environment. Product

is clean ed in accordan ce with CGA 4.1 and AST M G93, Verificat ion Type 1, Test 1 and

Test 2. With p eriodic veri fication of c leaning pro cess to MIL-STD-1330D.

WARNING

Make sure t hat the compone nts and materia ls used in the fluid hand ling

system a re compatible w ith the fluid an d have the proper pr essure rating .

Failure to d o so can result in death, se rious injury and/or propert y damage.

Inspect the regulator, valve and accessories for physical damage and contamination.

Do not con nect the regu lator, valve or acces sory if you de tect oil, grea se or damaged

part s. If the regul ator, valve or access ory is damage d, contact yo ur local TESCO M™

representative to have the regulator cleaned or repaired.

REPAIR SERVICE

If a regulator or valve lea ks or malfunc tions, take it ou t of service immediat ely.

You must have instruc tions before doing any mainten ance. Do not make any

repair s you do not under stand. Have qual ied personnel make repairs. Retur n any

equipm ent in need of ser vice to your equipment su pplier for evaluation and prom pt

serv ice. Equipment is r estored to the origina l factory perfo rmance specicatio ns,

if repai rable. There are at fee repair cha rges for each standard mo del. The original

equipment warranty applies after a complete overhaul.

CAUTION

PROPER COMPONENT SELECTION

1. Consid er the total sys tem design when selec ting a component for use in

a system.

2. The use r is responsible for assur ing all safety and warning requirem ents of the

application are met through his/her own analysis and testing.

3. TESCO M may suggest material for use with speci c media upon request.

Suggestions are based on technical compatibility resources through

associations and manuf acturers. TESCOM does NOT guarante e materials to be

compatible wi th specic media -- THIS IS THE RE SPONSIBILITY OF T HE USER!

4. Component function, adequate ratings, proper installation, operation and

maintenance are the responsibilities of the system user.

WARNING

Do not mod ify equipme nt or add attachments not approved by the

manufacturer. Failure to do s o can result in death, ser ious injury and/or

property damage.

www.emerson.com/tescom

Page 9

table of contentS

BACK

www.emerson.com/tescom

9

Page 10

ER5000 — 10Table of Contents

BACK

Table of Contents

Safety, Installation & Operations

Precautions 2

TESCOM™ ELECTRONIC CONTROLLERS . . . . . 3

TESCOM REGULATORS . . . . . . . . . . . . . 6

Table of Contents 9

Table of Contents . . . . . . . . . . . . . . . 10

Conventions of This Manual . . . . . . . . . . 13

Navigating This Manual . . . . . . . . . . . . 13

Features and Specifications 14

ER5000 Series Part Numbering System . . . . 15

ER5000 Standard Features . . . . . . . . . . 15

ER5000 Dimensions – Side Views . . . . . . . 16

ER5000 Dimensions – Top and Bottom View . . 17

ER5050 Hazardous Location Model . . . . . . 18

Dimensions – Side Views . . . . . . . . . . . 18

ER5050 Hazardous Location Model . . . . . . 19

Dimensions – Top and Bottom View . . . . . . 19

ER5000 Specifications . . . . . . . . . . . . 20

Hazardous Location Model (ER5050)

Specifications . . . . . . . . . . . . . . . . 22

Accessories . . . . . . . . . . . . . . . . . . 24

What’s New 25

New Features . . . . . . . . . . . . . . . . . 26

Replacing an ER3000 with an ER5000 . . . . . 27

How It Works 29

The ER5000: How It Works . . . . . . . . . . 30

Understanding PID Controllers . . . . . . . . 31

PID Controllers: Three Components

Are Better Than One 32

A Typical PID Control System 33

Tuning a PID Controller 35

Rules of Thumb for PID Tuning 35

The ER5000: Typical Application

(Non-Hazardous Location) . . . . . . . . . . 39

Controlling System Pressure 39

A Note Concerning Non-Venting

Regulators in Closed Loop Applications 41

Monitoring System Control Limits 42

The ER5000: Control Modes . . . . . . . . . . 43

Internal Feedback Mode 43

External Feedback Mode 43

Cascade Mode 43

Glossary of Terms 44

Terms Relating to PID Controllers

and Controller Tuning . . . . . . . . . . . . 45

Terms Relating to Regulators . . . . . . . . . 52

Getting Started 57

Before You Begin . . . . . . . . . . . . . . . 58

ER5000 Quick Reference: Jumpers,

Terminal Blocks and Wires and LEDs . . . . . 59

Verify your shipment . . . . . . . . . . . . . 60

Additional items not included: 61

Tools you will need for the installation: 61

Additional items and tool you will need for

an installation in a Hazardous Location: 61

Verify the configuration of your application . . . . 62

Verify that all operational requirements

have been met . . . . . . . . . . . . . . . . 63

Verify that all safety requirements

have been met . . . . . . . . . . . . . . . . 63

Mount the ER5000 on the regulator . . . . . 64

Connect and verify the power supply . . . . . 65

Verify the Jumper J6 configuration . . . . . . 68

Connect the USB cable

Install the ERTune

Connect pressure to the system . . . . . . . . 73

Start up and tune the system . . . . . . . . . 75

(not supplied with ER5050) 71

™

program . . . . . . . . . 72

Installation Variations 76

Before You Begin . . . . . . . . . . . . . . . 77

ER5000 Installation Variations —

Wiring Diagrams . . . . . . . . . . . . . . . 78

Terminal Blocks and Wires . . . . . . . . . . 79

www.emerson.com/tescom

Page 11

ER5000 — 11Table of Contents

BACK

Voltage/Current Select Jumpers . . . . . . . 80

LED Indicators . . . . . . . . . . . . . . . . 81

Power Supply Wiring — All Applications . . . 82

Setpoint Wiring Variations . . . . . . . . . . 83

Analog Setpoint Source — Potentiometer 83

Analog Setpoint Source — Current/Voltage 84

Analog Setpoint Source —

Passive PC or PLC D/A Card 85

Analog Setpoint Source —

Active PC or PLC D/A Card 86

Prole with External Control/Digital Inputs 87

Digital Setpoint Source — RS485 Connection,

RS232 to RS485 Converter

(TESCOM™ Model #85061) 89

Digital Setpoint Source — RS485 Connection,

USB to RS485 Converter

(TESCOM Model #82948) 90

Digital Setpoint Source — RS485 Network,

RS232 to RS485 Converter

(TESCOM Model #85061) 91

Digital Setpoint Source — RS485 Network,

USB to RS485 Converter

(TESCOM Model #82948) 93

Feedback Wiring Variations . . . . . . . . . . 95

Two Wire Transducer 95

Three Wire Transducer 96

Four Wire Transducer 97

4–20 mA External Feedback, Floating Input,

Feedback Signal Monitored by PC or PLC A/D Card 98

4–20 mA External Feedback, Ground

Referenced Input, Feedback Signal Monitored

by PC or PLC A/D Card 99

Two Wire Transducer, PC or PLC A/D Card

Used to Monitor Voltage Produced by the

4–20 mA External Feedback 100

Three Wire Transducer, PC or PLC A/D Card

Used to Monitor Voltage Produced by the

4–20 mA External Feedback 101

Four

Wire Transducer, PC or PLC A/D Card Used

to Monitor Voltage Produced by the 4–20 mA

External Feedback 102

Switch Feedback Control to a Second

Feedback Source 103

Wiring Variations for

Additional Functions . . . . . . . . . . . . . 104

Monitoring Additional Analog Inputs 104

Monitoring the ER5000’s Internal Sensor

Using the Analog Output, 4–20 mA Wiring 105

Monitoring the ER5000’s Internal Sensor

Using the Analog Output, 0–10V Wiring 106

Digital Outputs 107

Suspend Mode 109

Installing a Hazardous Location

Model (ER5050) . . . . . . . . . . . . . . . 110

The ERTune™ Pro gra m 111

ER5000 Software

Development Support 196

ER5000 Communication Requirements . . . . 197

ER5000 Software Development Support . . .197

Windows Programming Examples . . . . . .198

Accessing the Windows DLL File . . . . . . .199

The TESCOM Protocol . . . . . . . . . . . . . 200

Troubleshooting 202

Installation . . . . . . . . . . . . . . . . . . 203

Operation . . . . . . . . . . . . . . . . . .206

RS485 Communication . . . . . . . . . . . . 216

Using Profiles to Control the ER5000 . . . . . 217

Internal Variables 221

Table of ER5000 Internal Variables . . . . . .222

ER5000 Internal Variables . . . . . . . . . . 225

ER5000 Setpoint and Feedback Variables 225

ER5000 Conguration Variables 226

ER5000 Inner Loop Tuning Var iables 227

ER5000 Outer Loop Tuning Variables 228

ER5000 Analog Input Variables 229

ER5000 Pressure Prole Variables 230

www.emerson.com/tescom

Page 12

ER5000 — 12Table of Contents

BACK

ER5000 Single “Puff” Solenoid

Control Variable 231

ER5000 Pulse Mode Variables 231

ER5000 Analog and Digital Output Variables 232

ER5000 Pulse Width Modulation (PWM)

Control Variables 233

ER5000 Gain/Offset Variables 234

ER5000 Control Limit Variables 235

Control Limits for Specied Signals 235

Certifications and Warranty 236

Certifications . . . . . . . . . . . . . . . . . 237

Hazardous Locations Special Requirements

and Certifications for the ER5050 . . . . . . . 238

LIMITED WARRANTY . . . . . . . . . . . . . 240

Appendix A: Setting up the

ERTune

™

Program on

Windows 8 PCs 241

Installing the .NET Framework 3.5 . . . . . .242

Installing the ER5000 Device Driver . . . . . . 244

www.emerson.com/tescom

Page 13

ER5000 — 13Table of Contents

NOTENOTE

IMPORTANT!IMPORTANT!

BACK

Conventions of This Manual

refer to

page 41

Click the Add

Variable button

CAUTION

WARNING

Text formatted as gray and italic denotes a clickable cross

reference. Clicking this text moves you to the referenced page

in the manual. After reading the referenced material, you can

return to your original page by clicking the BACK button at the

bottom of the page.

Cross references link to gures, tables and section headings.

Also, words which are described in the Glossary are cross

referenced to their Glossary description the rst time they

appear in the body text.

Text formatted as gray and narrow denotes a part of the

user interface, either of the Windows operating system or

the ERTune™ program. This includes menu items, buttons,

windows, screens, commands and onscreen instructions.

Paragraphs highlighted by the NOTE icon contain information

that should be given particular attention.

Paragraphs highlighted by the IMPORTANT! icon contain

information that references specic requirements of your

operating system.

Paragraphs highlighted by the CAUTION icon contain

information that must be followed to maintain a safe and

successful operating environment.

Paragraphs highlighted by the WARNING icon contain

information about practices or circumstances that can lead to

personal injury or death, property damage or economic loss.

Navigating This Manual

Clicking any item in the Table of Contents moves you to that page

in the manual.

You can also open the Bookmarks panel at any time to access an

interactive set of links based on the Table of Contents.

Clicking the PREVIOUS button moves you to the previous

consecutive page in the manual.

Clicking the NEXT button moves you to the next consecutive page

in the manual.

BACK

Clicking the BACK button moves you to the previously viewed page

in the manual. This button returns you to your original page after

you click a cross reference.

Microsoft®, Windows®, Windows XP®, Windows Vista®, Windows 7®,

Windows 8® and Windows® Explorer® are registered trademarks of

Microsoft Corporation in the United States and other countries.

www.emerson.com/tescom

Page 14

featureS and

BACK

pecIfIcatIonS

S

www.emerson.com/tescom

14

Page 15

ER5000 Series — 15Features and Specications

IMPORTANT!IMPORTANT!

BACK

ER5000 Series Part Numbering System

As Figure 1 indicates, several base styles are available, including a

compact OEM model for tight spaces where the NEMA 4 enclosure

isn’t needed. Please consult with your TESCOM™ representative

for special modications or requirements.

ER5 XX X X X – X

Base Style

00 Standard NEMA 4X

02 Integrated Double Piston*

04 OEM Style (No Cover)*

05 Hazardous Location Enclosure**

10 Integrated with 44-4000*

11 Integrated with 44-5200*

Internal Sensor Configuration

0 0–100 psig, 0.1% Accuracy

* Contac t the factory for dimensions and sp ecications of these ER5000 Series mo dels.

** Click this link to view all Hazardous Location certications for ER5050 model.

Figure 1: Breakdown of the ER5000 Part Number

Feature s

S Standard Features

F Enhanced Features

Cv Configuration

1 Standard Valves, Cv = 0.01

Analog Signal Type

I 4–20 mA / 1–5V DC

V 0–10V DC

ER5000 Standard Features

• USB and RS485 communications

• USB cable with integrated strain relief***

• 1/8" NPTF Inlet and Exhaust Ports

• 1/2" SAE controlled Outlet Port

• Adaptor tting 1/2" SAE x 1/8" NPTF

• Maximum inlet pressure = 120 psig / 8.2 bar***

• 0–100 psig / 0–6.9 bar internal sensor

™

• ERTune

Windows 8

with previous Windows operating systems, the ERTune™ program uses

the .NET Framework 3.5, which is not installed by default in Windows

8. If you are using Windows 8, you will need to download and install

.NET Framework 3.5 before installing the ERTune™ program. You may

also need to disable Driver Signature Enforcement to install the ER5000

driver. We have provided step-by-step instruc tions for both these tasks

in Appendix A: Setting up the ERTune™ Program on Windows 8 PCs.

*** These fea tures do not apply to ER5 050 Hazardous Lo cation mode l.

program for Windows XP, VISTA, Windows 7 and

Windows 8 users: In order to maintain compatibility

www.emerson.com/tescom

Page 16

ER5000 Series — 16Features and Specications

BACK

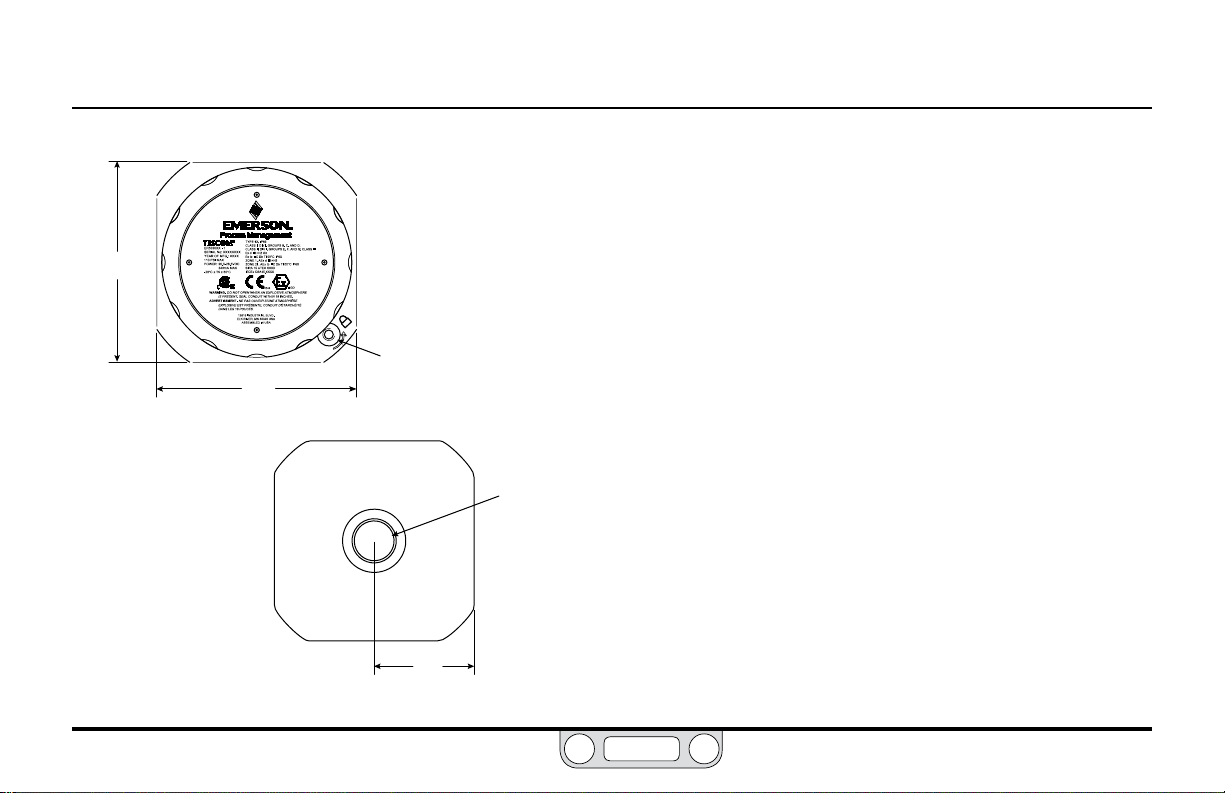

ER5000

Dimensions – Side Views

3.90

[99.0]

.98

[24.9]

1/2-14 NPTF

Conduit

Connection for

USB Wiring

.54

[13.77]

Gauge Port

1/8–27 NPTF

.63

[16.0]

[13.77]

Contact the factor y for dimensions an d specicatio ns

of model s ER5020, ER5040, ER5100 and ER 5110.

Refer to th e ER5000 Series Part Numbering System.

All dimensions are called out in

inches [millimeters]

1/2-14 NPTF

Conduit

Connection for

Internal Wiring

.54

Inlet Port

1/8–27 NPTF

Atmospheric

Reference for

Internal Sensor

.75

[19.0]

.93

[23.7]

.93

[23.7]

.75

[19.0]

4x

Exhaust Port

1/8–27 NPTF

Not Used

.87

[22.1]

Mounting

Holes

#10-32 UNF

.50 FULL THREAD

[M5 X 0.8

12.7 FULL THREAD]

(4 Places)

Not Used

.20

[5.1]

www.emerson.com/tescom

Page 17

ER5000 Series — 17Features and Specications

BACK

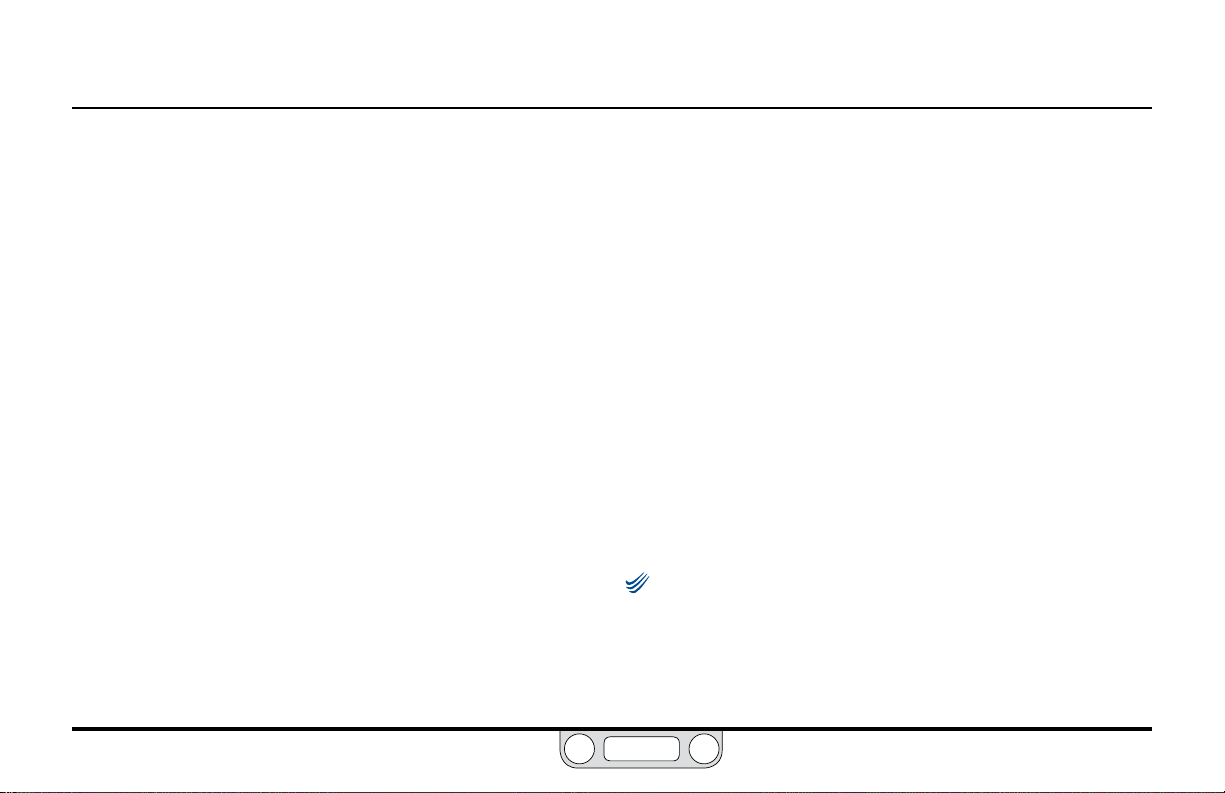

ER5000

Dimensions – Top and Bottom View

3.72

[94.5]

ER5000 Series

Electropneumatic Controller

3.72

[94.5]

Bottom View

Top View

Contact the factor y for dimensions an d specicatio ns

of model s ER5020, ER5040, ER5100 and ER 5110.

Refer to th e ER5000 Series Part Numbering System.

All dimensions are called out in

inches [millimeters]

Outlet Port

1/2 SAE (3/4-16 UNF)

1.86

[47.2]

www.emerson.com/tescom

Page 18

ER5000 Series — 18Features and Specications

BACK

DO NOT REMOVE

4.09

[103.8]

1/8" NPTF Plug

Not Used

.98

[24.9]

1/2-14 NPTF

Conduit

Connection for

USB Wiring

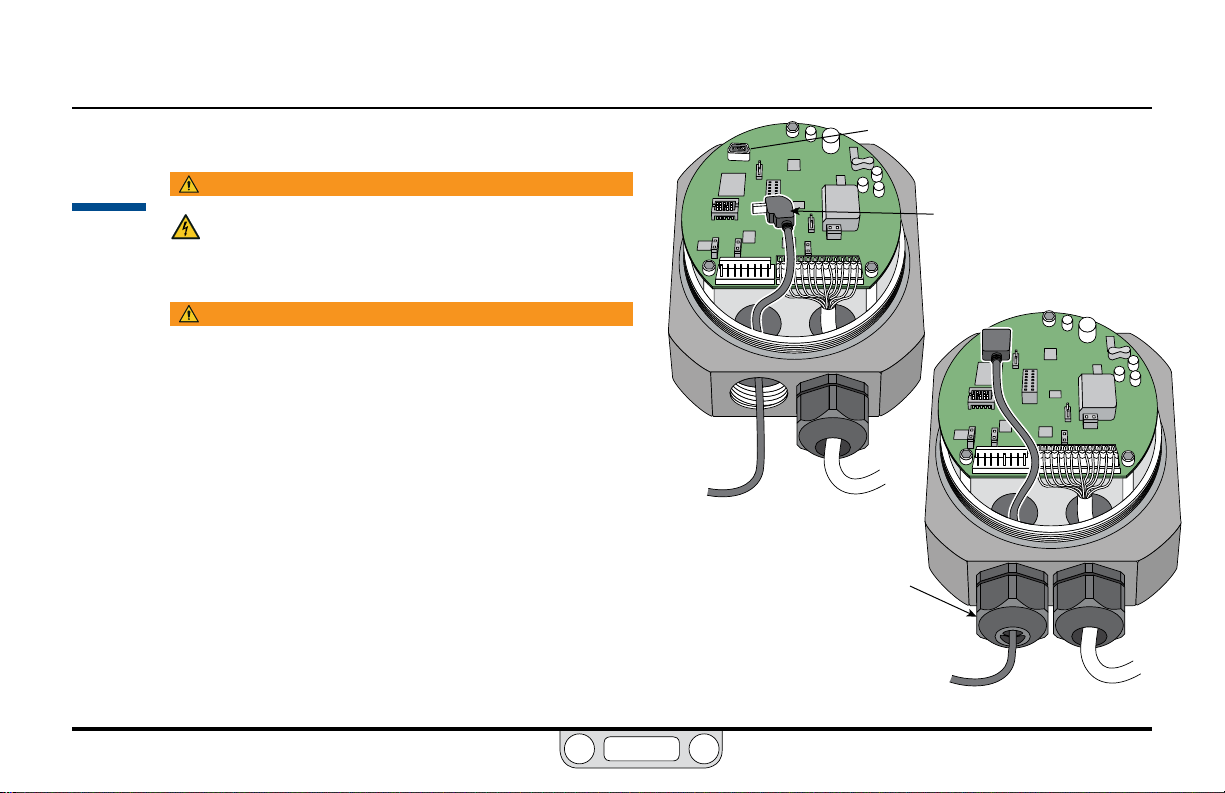

ER5050 Hazardous Location Model

Contact the factor y for dimensions an d specicatio ns

of model s ER5020, ER5040, ER5100 and ER 5110.

Refer to th e ER5000 Series Part Numbering System.

Gauge Port

1/8–27 NPTF

.43

[11.0]

.54 [13.77] .54 [13.77]

Dimensions – Side Views

External Ground

Atmospheric Reference

for Internal Sensor

CAUTION

Removal of ANY of the 1/8" NPTF

plugs called out on this page, other

than the Gauge Port plug, will

invalidate the Hazardous Location

certification for the ER5050.

1/2-14 NPTF

Conduit

Connection for

Internal Wiring

All dimensions are called out in

inches [millimeters]

Inlet Port

1/8–27 NPTF

.75

[19.0]

.93

[23.7]

.75 [19.0] (4x)

.93

[23.7]

Exhaust Port

1/8–27 NPTF

.83

1/8" NPTF Plug – Not Used

DO NOT REMOVE

[22.0]

Mounting

#10-32 UNF

.50 FULL THREAD

[M5 X 0.8

12.7 FULL THREAD]

(4 Places)

1/8" NPTF Plug

Not Used

DO NOT REMOVE

Holes

.20

[5.1]

www.emerson.com/tescom

Page 19

ER5000 Series — 19Features and Specications

BACK

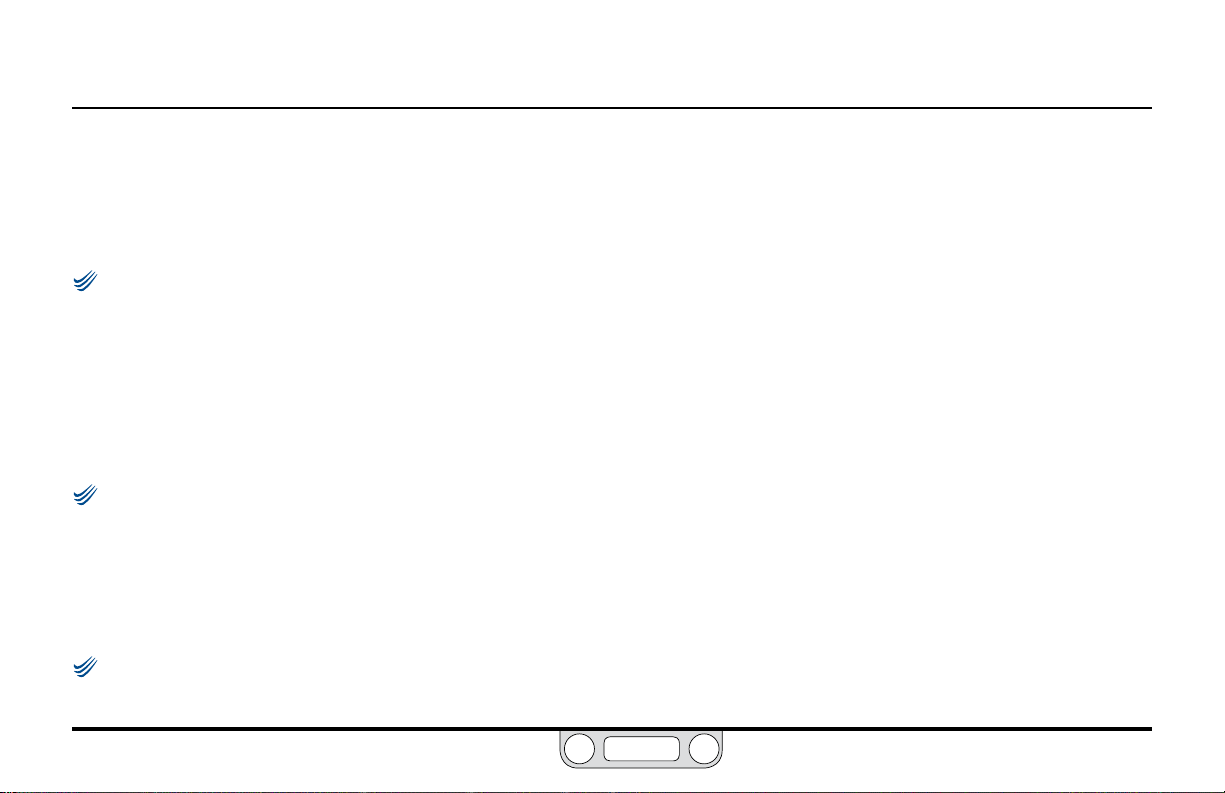

ER5050 Hazardous Location Model

Dimensions – Top and Bottom View

3.72

[94.5]

3.72

[94.5]

Bottom View

Top View

Cover Lock Screw

1.86

[47.2]

Contact the factor y for dimensions an d specicatio ns

of model s ER5020, ER5040, ER5100 and ER 5110.

Refer to th e ER5000 Series Part Numbering System.

All dimensions are called out in

inches [millimeters]

Outlet Port

1/2 SAE (3/4-16 UNF)

www.emerson.com/tescom

Page 20

ER5000 Series — 20Features and Specications

NOTENOTE

BACK

ER 5000 Specifications

Contact the factor y for dimensions and specications of models ER5020, ER5040, ER5100 and ER5110. Refer to the ER5000 Series Part Numbering System.

Enclosure

Type 4X, IP66. If the two 1/2-14 NPTF ports are unused, properly

seal with a plug.

CE Approved Wiring Instructions

Use shielded, twisted pair cable.

Weight

3.1 lbs / 1.4 kg

Media

Supply pressure must be clean, dry inert gas or instrument grade

air that meets the requirements of ISA Standard 7.0.01. Use of an

in-line lter that meets the requirements of ISA standard 7.0.01

and is less than 40 microns and as small as 10 microns, is highly

recommended to prevent damage to the solenoid valves. Moisture

should be kept to a minimum.

Ports

Conduit: 1/2" NPTF

Pneumatic: 1/8" NPTF — Inlet, Exhaust and Gauge Ports

1/2" SAE — Controlled Outlet Port

www.emerson.com/tescom

Power Requirement

Voltage: 24V DC (22V DC to 28V DC)

Current: 340 mA max, 180 mA nominal

Environment

Temperature: -30°C to 75°C (dry Nitrogen supply gas)

Pressure: 28" to 32

Humidity: To 100% R.H. (non-condensing) @ 0°C to 75°C.

Inlet Pressure

Minimum: Outlet pressure + 1 psig

Maximum: 120 psig / 8.2 bar

Typical: 110 psig / 7.5 bar

Sensor Update Rate

25ms (rate of sensor reading and processing task)

USB Communication Interface

USB: 2.0

Maximum cable length: 15 ft / 4.5 m

Connector: Mini-B

5°C to 75°C (shop air)

" Hg / 71 mm to 762 mm Hg

Response time is affected by input pressure.

Page 21

ER5000 Series — 21Features and Specications

NOTENOTE

NOTENOTE

BACK

ER 5000 Specifications (cont.)

RS485 Communication Interface

Networking: Up to 32 controllers on one network

Maximum cable length: 4000 ft / 1219 m

Baud rate: 9600

Flow Rate

Cv: 0.01

The ow rate can be increased using a booster regulator.

Accuracy

Room temp: 0.1% of span maximum

Response Time

Rise Time: 257ms — 10 psig to 90 psig / 0.7 bar to 6.2 bar

Fall Time: 552ms — 90 psig to 10 psig / 6.2 bar to 0.7 bar

Step response into dead-end system (1 cubic inch volume).

External Analog Input Impedance

4–20 mA: 250Ω

1–5V: 220KΩ — single input pin to ground

0–10V: 100K Ω

www.emerson.com/tescom

1.7MΩ — differential input

Digital Inputs

Voltage Range/Input Impedance:

4–20 mA: 250Ω

1–5V: 220KΩ — single input pin to ground

1.7MΩ — differential input

0–10V: 100K Ω

Digital Outputs

Current: 50 mA continuous, 100 mA instantaneous

Voltage: 5V to 28V

Type: Open collector, grounded emitter

Analog Output

4–20 mA: Better than 0.5% accuracy;

loads from 50Ω to 1000Ω

0–10V DC: Better than 0.5% accuracy;

loads no less than 5000Ω

Page 22

ER5000 Series — 22Features and Specications

NOTENOTE

BACK

Hazardous Location Model (ER5050) Specifications

Certifications

Refer to Hazardous Locations Special Requirements and Certication

for the ER5050 for a complete list of hazardous location certications.

Enclosure

Type 4X/IP66. If the two 1/2-14 NPTF ports are unused, properly

seal with a metal plug.

CE Approved Wiring Instructions

Use shielded, twisted pair cable. Use rigid metal conduit to

enclose the wiring entering the ER5050 when required per local

electrical code.

Weight

2.6 lbs / 1.2 kg

Media

Supply pressure must be clean, dry inert gas or instrument grade

air that meets the requirements of ISA Standard 7.0.01. Use of

an in-line lter that meets the requirements of ISA standard

7.0.01 and is less than 40 microns and as small as 10 microns, is

highly recommended to prevent damage to the solenoid valves.

Moisture should be kept to a minimum.

www.emerson.com/tescom

Ports

Conduit: 1/2" NPTF

Pneumatic: 1/8" NPTF — Inlet, Exhaust and Gauge Ports

Power Requirement

Voltage: 24V DC (22V DC to 28V DC)

Current: 340 mA max, 180 mA nominal

Environment

Temperature: -20°C to 60°C (dry Nitrogen supply gas)

Pressure: 28" to 32

Humidity: To 100% R.H. (non-condensing) @ 0°C to 60°C.

Inlet Pressure

Minimum: Outlet pressure + 1 psig

Maximum: 110 psig / 7.5 bar

Typical: 110 psig / 7.5 bar

Sensor Update Rate

25ms (rate of sensor reading and processing task)

1/2" SAE — Controlled Outlet Port

5°C to 60°C (shop air)

" Hg / 71 mm to 762 mm Hg

Response time is affected by input pressure.

Page 23

ER5000 Series — 23Features and Specications

NOTENOTE

NOTENOTE

NOTENOTE

BACK

Hazardous Location Model (ER5050) Specifications (cont.)

USB Communication Interface

USB: 2.0

Maximum cable length: 15 ft / 4.5 m

Connector: Mini-B

Due to var ying hazardous location wiring requirements, a USB

cable is not included with the ER5050.

RS485 Communication Interface

Networking: Up to 32 controllers on one network

Maximum cable length: 4000 ft / 1219 m

Baud rate: 9600

Flow Rate

Cv: 0.01

The ow rate can be increased using a booster regulator.

Accuracy

Room temp: 0.1% of span maximum

Response Time

Rise Time: 257ms — 10 psig to 90 psig / 0.7 bar to 6.2 bar

Fall Time: 552ms — 90 psig to 10 psig / 6.2 bar to 0.7 bar

Step response into dead-end system (1 cubic inch volume).

www.emerson.com/tescom

External Analog Input Impedance

4–20 mA: 250Ω

1–5V: 220KΩ — single input pin to ground

1.7MΩ — differential input

0–10V: 100K Ω

Digital Inputs

Voltage Range/Input Impedance:

4–20 mA: 250Ω

1–5V: 220KΩ — single input pin to ground

1.7MΩ — differential input

0–10V: 100K Ω

Digital Outputs

Current: 50 mA continuous, 100 mA instantaneous

Voltage: 5V to 28V

Type: Open collector, grounded emitter

Analog Output

4–20 mA: Better than 0.5% accuracy;

loads from 50Ω to 1000Ω

0–10V DC: Better than 0.5% accuracy;

loads no less than 5000Ω

Page 24

ER5000 Series — 24Features and Specications

BACK

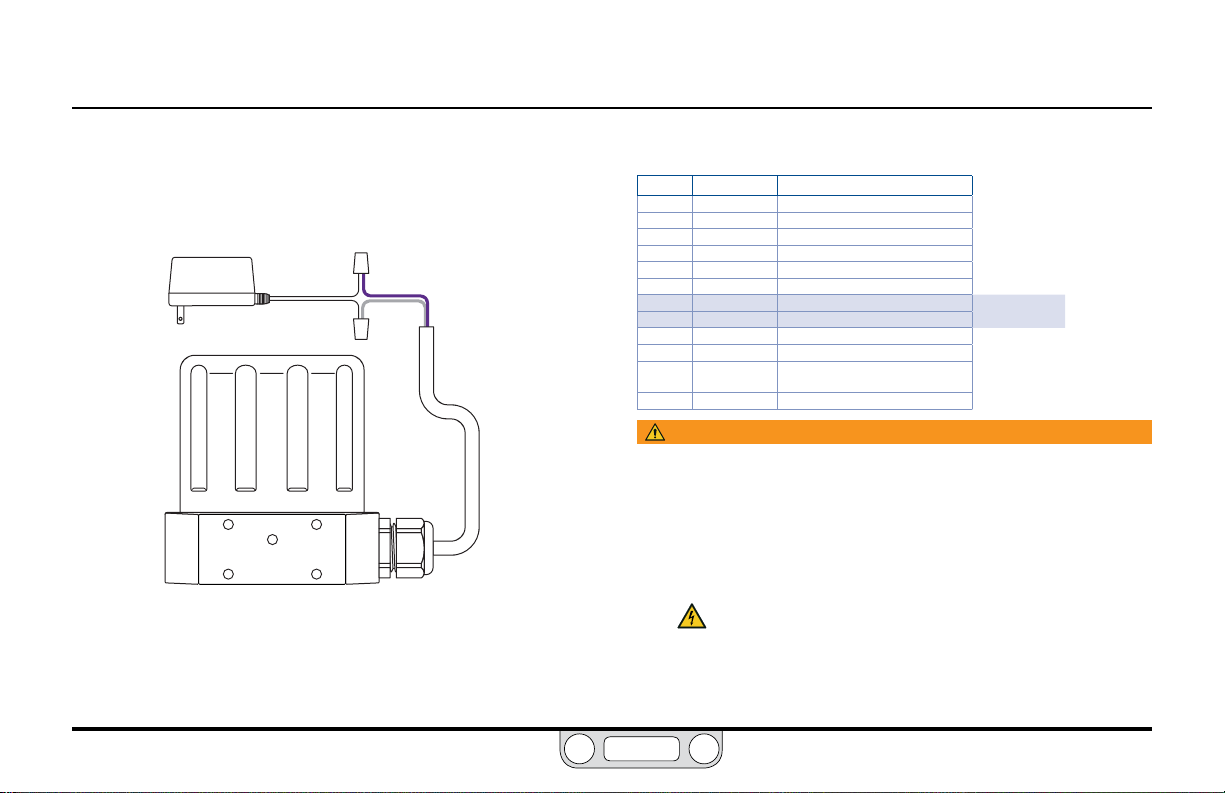

Accessories

Part # Description

80129 1/8" NPTF male tube connector

82575-25

82575-50

82919

82948

85061

85121

ERSA04539 20-wire, shielded, twisted pair cable assembly — 24" / 61 cm Included with “F” model ER5000s

85138-X 12-wire, shielded, twisted pair cable assembly — 5, 10, 20, 50 and 100 ft / 1.5, 3, 6, 15 and 30 m options

ERSA04539-X 20-wire, shielded, twisted pair cable assembly — 5, 10 and 20 ft / 1.5, 3 and 6 m options

85145 Filter kit

ERAA03458-02 Adaptor tting 1/2" SAE x 1/8" NPTF — mates ER5000 to most TESCOM™ air actuated regulators Included with all standard ER5000s

ERAA03458-04 1/2" SAE X 1/4" NPTF

ERAA03409 USB Cable with Mini-B connector Included with all standard ER5000s NOT for use with ER5050s

ERAA05146 MTA Connector Replacement Kit

250 mA / 24V DC power supply — input voltage 120V AC, 60 Hz

500 mA / 24V DC power supply — input voltage 120V AC, 60 Hz

Potentiometer with digital display

USB to RS485 converter

RS232 to RS485 converter

12-wire, shielded, twisted pair cable assembly — 24" / 61 cm Included with all standard ER5000s

www.emerson.com/tescom

Page 25

What’S neW

BACK

www.emerson.com/tescom

25

Page 26

ER5000 — 26What’s New

BACK

New Features

• Built-in USB connectivity

• Improved resolution for data acquisition with 16-bit A/D

converter

• For “F” model ER5000s, single 20-wire cable replaces separate

12-wire and 8-wire cables

• Suspend Control, a new operational mode available on

“F” models, gives you the ability to lock output at a stable

pressure over an extended period of time for operations, such

as sensor calibration, where system stability is critical.

• The

ERTune™

advantage of the Windows graphic user interface, with a

single, unied operating environment and quick, tab-based

access to all functions. Other enhancements include:

> Setup Wizard and COM Port Search speed up installation.

> The Tuning Tab now features highly responsive sliders,

with optimal ranges for all congurable parameters clearly

displayed in the interface.

> Data acquisition can now be triggered automatically

by system events such as digital input detection or a

monitored variable reaching a target value.

program has been upgraded to take full

> Proles can now include up to 100 command segments. Loop

counts are now displayed in real time.

> For “F” model ER5000s, Proles can now include these new

commands:

Soak, which waits until feedback indicates a new setpoint

has been reached before initiating a Dwell.

If and Goto, which allow you to create complex branching

command sequences that respond to real-time operating

conditions and inputs.

> The Diagnostic Tools Tab now gives you one-click access to

tuning and troubleshooting recommendations.

> The Automated Solenoid Leak Test gives you a quick,

intuitive and accurate assessment of the controller’s

solenoid valves.

> Regulator Diaphragm Protection is a new feature that gives

an added layer of protection for applications where rapidly

changing ow demands put undue stress on the sensing

element of diaphragm sensed regulators, particularly those

with metal diaphragms.

www.emerson.com/tescom

Page 27

ER5000 — 27What’s New

BACK

Replacing an ER3000 with an ER5000

IMPORTANT!IMPORTANT!

WARNING

Safety standards are subject to continual revision. Investigate and apply

the most recent standards for Hazardous Locations for your area set by

ANSI, ISO and OSHA, as well as all electrical codes and fire and safety

standards, before replacing a controller in a hazardous location.

Click this link to view all Hazardous Location certifications and

specifications.

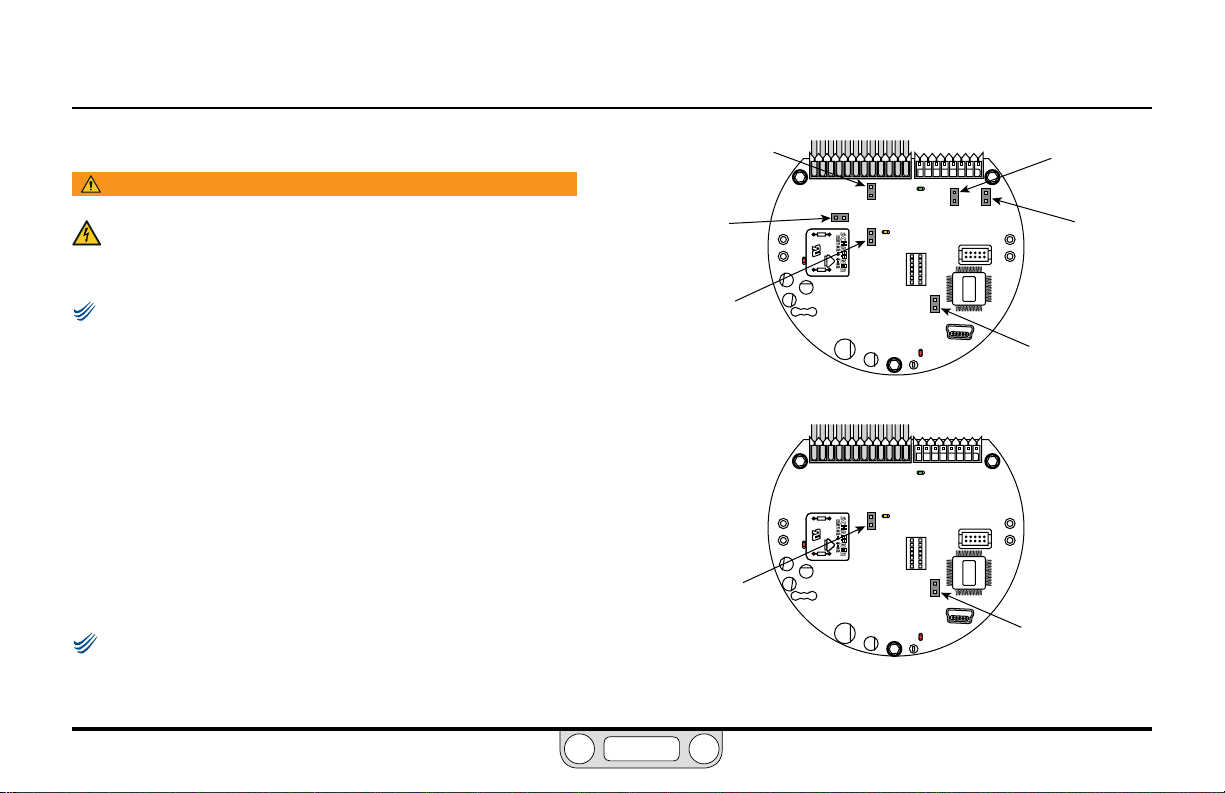

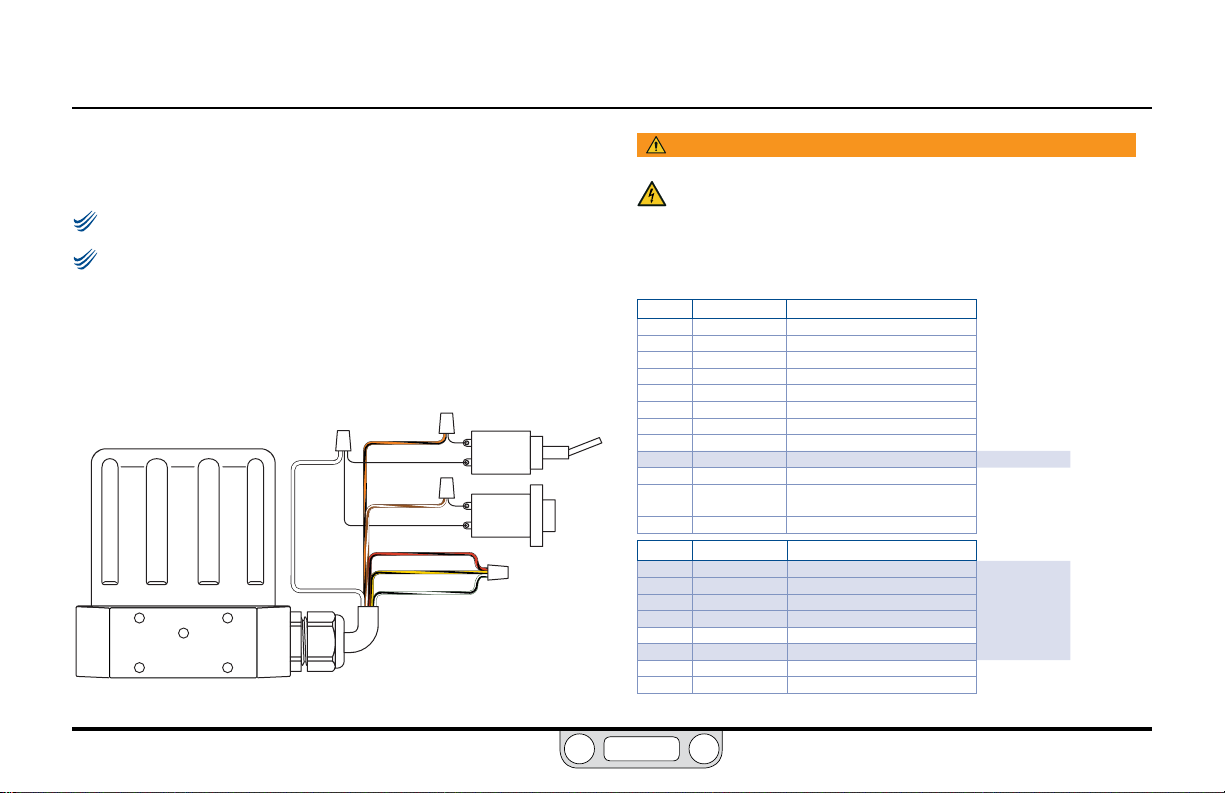

Wiring for the Standard Model ER5000

The wiring for the 12-pin MTA connector is the same for the

ER5000SI-1 as it was for the ER3000SI-1. An MTA connector

replacement kit is available to allow use of the existing installation

cable with the new ER5000.

Reference current Hazardous Location

standards when replacing a Hazardous Location

ER3000 with an ER5050.

Wiring for the “F” Model ER5000

For “F” model ER5000s, the 12-pin MTA connector and 8-pin

auxiliary MTA connector, which were previously fed by separate

cables, are now fed by a single 20-wire cable. All wires feeding the

8-pin connector are color striped to distinguish them visually from

the solid color wires feeding the 12-pin connector. Refer to

Figure 18 to see all wire colors and pin terminations.

The function of the green/white wire (J4 Pin 5), which was

previously the Analog Signal Ground, has changed: it now

activates the Suspend Control function, which closes both valves

and locks the controller at the current pressure. If your current

application makes use of this wire, refer to the Installation

Variations section for recommended wiring congurations.

For standard model ER5000s, there are two wires which act

as signal/board grounds: the black wire (J3 Pin 10) and the tan

wire (J3 Pin 12).

For “F” model ER5000s, the black/white wire (J4 Pin 6) also acts as

signal/board ground.

www.emerson.com/tescom

Page 28

ER5000 — 28What’s New

NOTENOTE

BACK

Using the ER5000 with ER3000 software

If you wish to continue using the Windows Tune or other software

that controlled your ER3000, you must install Jumper J9 to put

the ER5000 into ER3000 Mode (refer to Figure 19). The ER5000

uses a 16-bit A/D converter to translate analog input signals into

the digital language the microprocessor understands, while

the ER3000 uses a 12-bit converter. In order for the ER5000 to

correctly interpret the signals generated by a program written for

the ER3000, it must use a 12-bit scale.

Installing the ER3000 Mode Jumper will also turn off the new

Suspend Control feature, as well as the new Prole commands.

UI3000 or UI4000

The ER5000 is NOT compatible with either the UI3000 or

the UI4000.

www.emerson.com/tescom

Page 29

hoW It

BACK

W

www.emerson.com/tescom

orkS

29

Page 30

ER5000 — 30How It Works

BACK

The ER5000: How It Works

The ER5000 (Electronic Regulator 5000) is a microprocessor-based

PID (Proportional, Integral, Derivative) controller that brings precise

algorithmic pressure control to a wide range of applications.

It can be used as a standalone unit to control the pressure of clean,

dry inert gases from 0–100 psig / 0–6.9 bar or be connected to any

pneumatically actuated regulator or valve. Used with TESCOM™

regulators, the ER5000 provides distributed pressure control of

gases and liquids from vacuum to 30,000 psig / 2068 bar, with a Cv

of up to 12.

The ER5000 can be controlled from any PC via a direct USB or

RS485 connection. The ER5000 also accepts analog setpoint

signals from 4–20 mA, 1–5V or 0–10V analog sources, such as

from a PC or PLC D/A card. The ER5000 can be wired to allow for

multiple input/output congurations and daisychaining of up to 32

controllers within the same RS485 network.

The ER5000 senses pressure using either its internal sensor or an

external transducer (4–20 mA, 1–5V or 0–10V) placed within the

actual process line. You can operate the ER5000 in one of three

control modes:

• Internal Feedback, which uses only the internal sensor

• External Feedback, which uses only the external source;

• Cascade, which uses both internal and external sources in a

“loop within a loop” conguration.

During setup, you can download PID settings that have been

programmed by TESCOM to meet the needs of most commercial

applications. The included ERTune™ program provides an intuitive

interface to customize the performance parameters of the ER5000

by directly tuning the Proportional, Integral and Derivative values.

Using the ERTune™ program, you can create Proles, which guide

the ER5000 through command sequences that may include

multiple setpoint changes, precisely timed digital inputs and

outputs and modication of response characteristics and other

internal variables based on real-time operational conditions.

The ER5000 installs in just minutes, yet provides the precision,

dependability and exibility to meet the needs of the most

demanding user.

;

www.emerson.com/tescom

Page 31

ER5000 — 31How It Works

BACK

Understanding PID Controllers

PID Controllers allow mechanical systems to operate at a high

level of precision and dependability with only occasional oversight

by human operators. They can control virtually any measurable

physical property within the system, including pressure, ow,

temperature, position, speed, force, consistency, torque

and acceleration.

PID controllers operate in a continuous loop of monitoring and

response. The ER5000 performs one loop every 25 ms (milliseconds).

At the start of each loop, the controller reads the input from a sensor

within the system to nd the current level of a measured property

such as system pressure (the Feedback) and compares it to a preset

target value (the Setpoint).

If the two values match, a Zero Error is generated and no action is

taken. If the two values do not match, a positive or negative Error is

generated and the controller activates to correct the error.

When the error is the result of an unintended change in the

operating environment, the controller works to return the system

to its previous level. When the error is the result of a scheduled

change in the setpoint, the controller works to raise or lower the

system to the new target level.

In either case, the controller continues to act until setpoint and

feedback are equal. The controller then generates a zero error and

returns to its monitoring function. At this point, the system is said

to be in a Stable State.

The response of the PID controller, from error generation to

stable state, is shaped by a complex algorithm that incorporates

three independent but interrelated values (also referred to

as Ter ms).

• The Proportional (P) term is a function of the value of the

error generated during the current loop. With each loop,

the P value changes in direct proportion to the amount of

error. Proportional is largest when the error is rst detected

and grows progressively smaller as the controller brings the

system closer to setpoint.

• The Integral (I) term is a function of the combined values

of all errors generated while the system is in operation. The

I value continues to increase as long as the system is in error

and will only decrease when an error is recorded in the opposite

www.emerson.com/tescom

Page 32

ER5000 — 32How It Works

BACK

direction. Signicantly, Integral retains its value after the error

has been corrected. This is known as Integral Windup.

• The

Derivative

change. The D value decreases, then begins to dampen the other

values, as the controller brings the system closer to setpoint.

(D) term is a function of the current rate of

PID Controllers: Three Components Are Better Than One

Why three independent values? Consider this scenario:

• You are behind the wheel of a car that needs to turn through a

curve in the road.

• As the car enters the turn, you simply steer to match the

curve. At this point, you are a Proportional controller.

• As the car continues through the turn, however, peripheral

force pushes it outward. Matching the curve (Proportional

only) is no longer sufcient. You now nd it necessary to

oversteer (add Integral) to stay in the curve. Then a gust of

wind hits the side of the car; now you need to oversteer more

to compensate for both the wind and the peripheral force

(accumulated Integral).

• As the car passes the midpoint of the curve, the peripheral

force decreases and the wind dies down. Now the oversteer

(Proportional and accumulated Integral) threatens to put

the car into a skid. You respond by understeering (adding

Derivative) through the rest of the curve until you are back on

straight road.

• As you drive on, you remember the wind that hit at the most

inopportune moment, so you keep a close hand on the wheel

in case there is another gust (Integral windup).

Like the driver who knows when to follow the road, when to

oversteer and when to understeer, controllers that can combine

the effects of Proportional, Integral and Derivative have the

exibility to respond effectively to the widest range of application

requirements and environmental conditions.

Now consider the same curve with three different drivers.

• The rst driver spots a police car in the next lane. This driver’s

primary goal will be to stay squarely within the lane through

the whole length of the turn. This controller carefully balances

Proportional, Integral and Derivative.

www.emerson.com/tescom

Page 33

ER5000 — 33How It Works

BACK

• The second driver notices that there is a full cup of hot coffee

in the cup holder. This driver will take the curve as widely

and as slowly, as possible, because this driver’s primary goal

is to make sure the hot liquid does not spill. This controller

has lowered the Proportional and Integral and increased the

Derivative, to make the response as stable as possible, at the

expense of some speed and precision.

• The third driver is participating in a road race. This driver will

take the curve as tight and fast as possible, pushing the limits

right up to the point of spinning the car out of control. This

controller has maxed out the Proportional and Integral to get

the fastest response possible, then set Derivative just enough

to reestablish control at the end.

Three controllers, three different goals, three different responses

to the same change. By raising and lowering the relative amounts

of Proportional, Integral and Derivative (a process called Tuning

the controller) you can set up your ER5000 to meet the specic

response characteristics and work within the specic limitations,

of any system.

A Typical PID Control System

Figure 2 shows a simplied diagram of a typical PID

control system.

In this drawing, the dashed line represents the controller. The

setpoint (r) is sent from the internal board or an external source.

The feedback (y) is sent from internal or external sensors that

monitor the current state of the system. The controller reads

both values and subtracts the feedback signal from the setpoint.

Setpoint = r

Controller

Error = e

+-

Figure 2: Simplified PID Control System

Output

Feedback = y

System

Under

Control

www.emerson.com/tescom

Page 34

ER5000 — 34How It Works

BACK

If setpoint and feedback match, the controller generates a zero

error and does not activate.

If setpoint and feedback do not match, the controller generates

an error value (e), activates and sends an output to the system

to correct the error. For example, in the ER5000 the output is

directed to Solenoid Valves within the controller.

A positive error is generated when feedback is lower than setpoint.

The ER5000 responds to positive error by activating to increase

system pressure.

A negative error is generated when feedback is higher than

setpoint. The ER5000 responds to negative error by activating to

decrease system pressure.

The controller determines how much output to send by

summing two values:

• The Proportional term, which is the product of the generated

error and the constant Kp (the Proportional Constant).

• The Integral term, which is the product of the integral of all

accumulated errors and the constant Ki (the Integral Constant).

Control systems based on just the Proportional term or just

the Proportional and Integral terms, are known as a P and PI

congurations. The ER5000 can operate in a P or PI conguration

if this is appropriate for the application. The PID conguration,

which includes the Derivative term, offers the greatest level of

precision and exibility.

The Derivative term is often used to attenuate the feedback before

it is compared to setpoint. It is shown this way in Figure 2. The

Derivative of the feedback is multiplied by the constant Kd (the

Derivative Constant) and the resulting value is summed with

the feedback.

Because the Derivative is a function of the rate of change, its

primary function is to act as a damper and suppress oscillations as

the system approaches setpoint.

www.emerson.com/tescom

Page 35

ER5000 — 35How It Works

BACK

Tuning a PID Controller

Tuning a controller is the process of selecting the optimal

Kp, Ki and Kd settings to yield the best response. The “best”

response depends on what is most important for the application

and usually entails a compromise between speed of response

and stability.

Your ER5000 is pre-tuned at the factory and a default PID setting

congured by TESCOM™ to match your TESCOM regulator can

be downloaded to the controller during setup. For many users,

the default tuning will provide effective system control right

out of the box. Others will nd that the specic requirements

of their application or operating environment call for some

additional manual tuning, using the ERTune

optimal performance.

The mathematics of PID algorithms are complex and beyond the

scope of this manual. Understanding the response characteristics of

your system will inevitably involve trial and error.

Nonetheless, PID tuning can also be understood in basic functional

terms. There are predictable effects, both positive and negative,

to watch for as settings are increased or decreased. If necessar y,

™

program, to achieve

default settings can be restored with the click of a button (see To

reset the ER5000 to its default PID settings).

Using a few rules of thumb and the real-time visual feedback

™

provided by the ERTune

program, all operators, regardless of

experience, can achieve positive results through manual tuning of

their controllers.

Rules of Thumb for PID Tuning

• The Proportional setting controls the overall response curve

of the controller. It is set rst. Integral and Derivative are

added to ne tune the response.

• The Integral setting accelerates the response, particularly

as the system approaches setpoint and the Proportional

decreases. It is primarily used to minimize a condition known

as Steady State Error or Offset, where the system settles into

a stable state without reaching the targeted setpoint. The

Integral also remains “charged up” with Integral windup after

an error has been corrected.

• The Derivative setting dampens the response and is used to

prevent the system from overcorrecting. Generally set next

after Proportional.

www.emerson.com/tescom

Page 36

ER5000 — 36How It Works

BACK

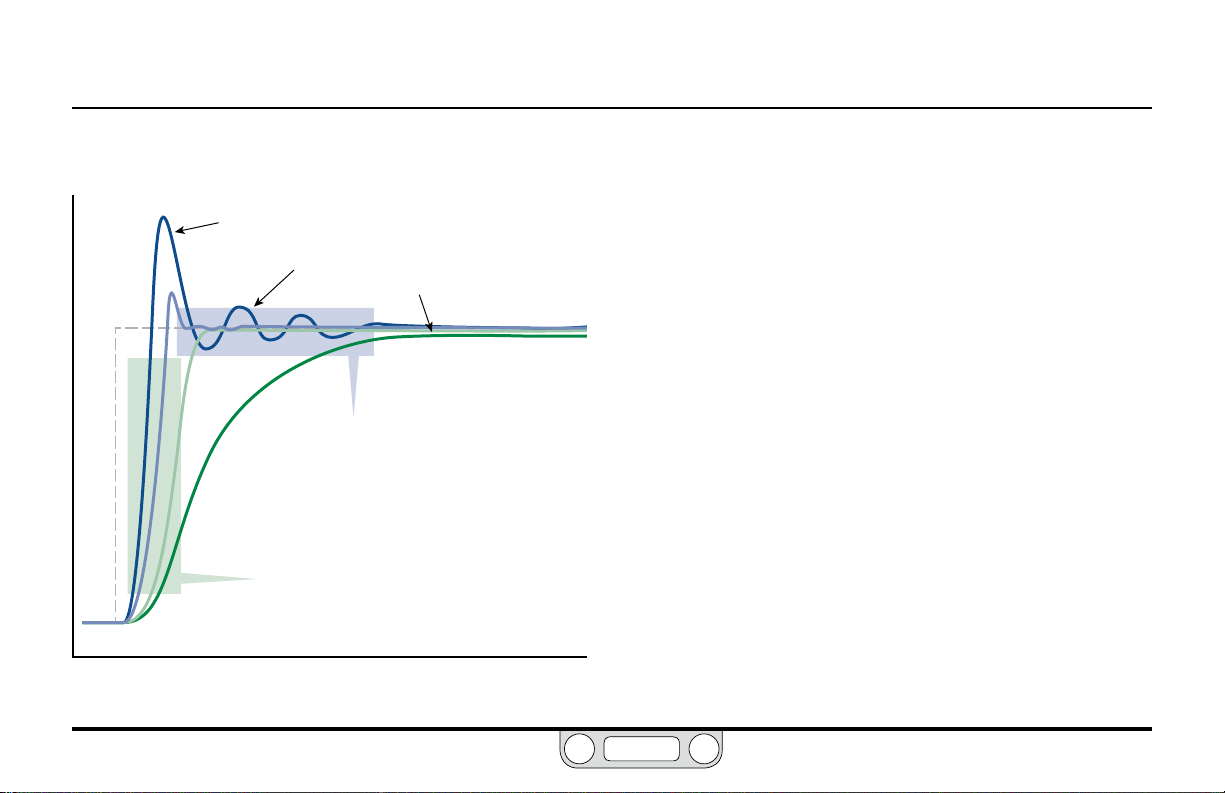

Figure 3 shows four typical response curves to a step

(instantaneous) change in setpoint.

A

Overshoot

Ringing

B

P

R

E

S

S

U

R

E

Figure 3: Typical Response Curves to Programmed Setpoint Change

C

D

Settling Time

Rise Time (10%–90%)

TIME

Offset

The controller in Curve A responds with a Rise Time that is short

and sharp. It also overcorrects (Overshoots) the error and oscillates

around the new setpoint, a condition known as Ringing. There is a

prolonged Settling Time before the system reaches its new stable

state. The overall response is quick but unstable.

The controller in Curve D has a long, gradual rise time and ends

up in Steady State Error, settling into a stable state that is slightly

below the new setpoint.

Curve A demonstrates the unwanted effects of a fast, but also

unstable, response. Tuning this controller will entail lowering the

Proportional setting and perhaps the Integral setting as well.

Alternatively, increasing the Derivative will help to stabilize the

response. Curve D demonstrates the unwanted effects of a

stable, but overly slow, response. Tuning this controller will entail

increasing Proportional. Integral also should be increased to

eliminate the offset. Derivative should be checked to see if it is

overdamping the response.

The controllers in Curves B and C have been tuned to achieve a

balance between speed and stability. Curve B allows a small amount

of overshoot and ringing in exchange for the fastest rise time

possible, with a settling time that is short and stable. Curve C is

www.emerson.com/tescom

Page 37

ER5000 — 37How It Works

BACK

“critically damped,” with just enough Derivative added to eliminate

overshoot completely. Both tunings have no offset. Curve B

would be an optimal tuning for an application which can tolerate

overshoot, Curve C for one which cannot.

To restate the rules of thumb for each component:

Proportional (P):

• Higher settings result in shorter rise times and faster response.

• Higher settings also make the response less stable, with

overshoot and ringing. Overshoot may tax the physical

limitations of the system.

• Lower settings result in slower response.

Integral (I):

• Higher settings accelerate the response.

• Higher settings also increase instability.

• Lower settings result in a less responsive controller.

• Because Integral windup continues to push the response even

after the system has reached stable state, higher Integral

settings can eliminate offset.

• Windup can delay the controller’s response to new errors, as

accumulated errors must “spool out” before new errors can

begin “charging up” Integral. The ER5000 features exclusive

Integral Limits to control positive and negative windup, allowing

you to use higher Integral settings.

• The Integral of small errors can, over time, accumulate to the

point of causing unwanted activation of the controller. The

ER5000 features an exclusive lter called Integral Deadband

to mitigate this effect.

Derivative (D):

• Higher settings correct overshoot and ringing.

• Higher settings also decrease settling time and increase

system stability.

• Higher settings may overdamp the system, causing a slow

rise time.

• Paradoxically, higher Derivative settings can make some

systems unstable by increasing sensitivity to transient

changes (noise) in the operating environment. This sensitivity

can decrease the operational lifespan of the ER5000’s

solenoid valves due to frequent activation.

www.emerson.com/tescom

Page 38

ER5000 — 38How It Works

BACK

Table 1 gives a summary of the rules of thumb for Proportional,

Integral and Derivative.

Table 1: Effect of P, I and D Increases on Response Curve of Controller

Increased

P Value

Rise Time Faster Faster Slower

Instability

(Overshoot/Ringing)

Settling Time Varies Longer Shorter

Offset Less Eliminate Varies

* Exces s D Value can, h owever, result in mor e instabilit y rather than less. Refer to

the restatem ent of the rules of thumb for D erivative on p age 37.

More More Less*

Increased

I Value

Increased

D Value

The ERTune™ program gives you a rich visual environment and

precise, intuitive controls for tuning the ER5000. Refer to The

Tuning Tab: Controls and Functions for Tuning the ER5000

for a detailed explanation of the program’s capabilities and

features, as well as tips and techniques to achieve optimal

system performance.

Every system has unique characteristics, every operational

environment presents unique challenges and every application

has unique requirements. Optimal tuning will invariably involve

both trial and error and compromise. Fast rise time usually comes

at the expense of increased instability. Minimizing overshoot may

result in response lag or offset. Eliminating offset may introduce

unwanted windup. It is important to know your priorities and

understand the trade-offs.

www.emerson.com/tescom

Page 39

ER5000 — 39Typical Application

BACK

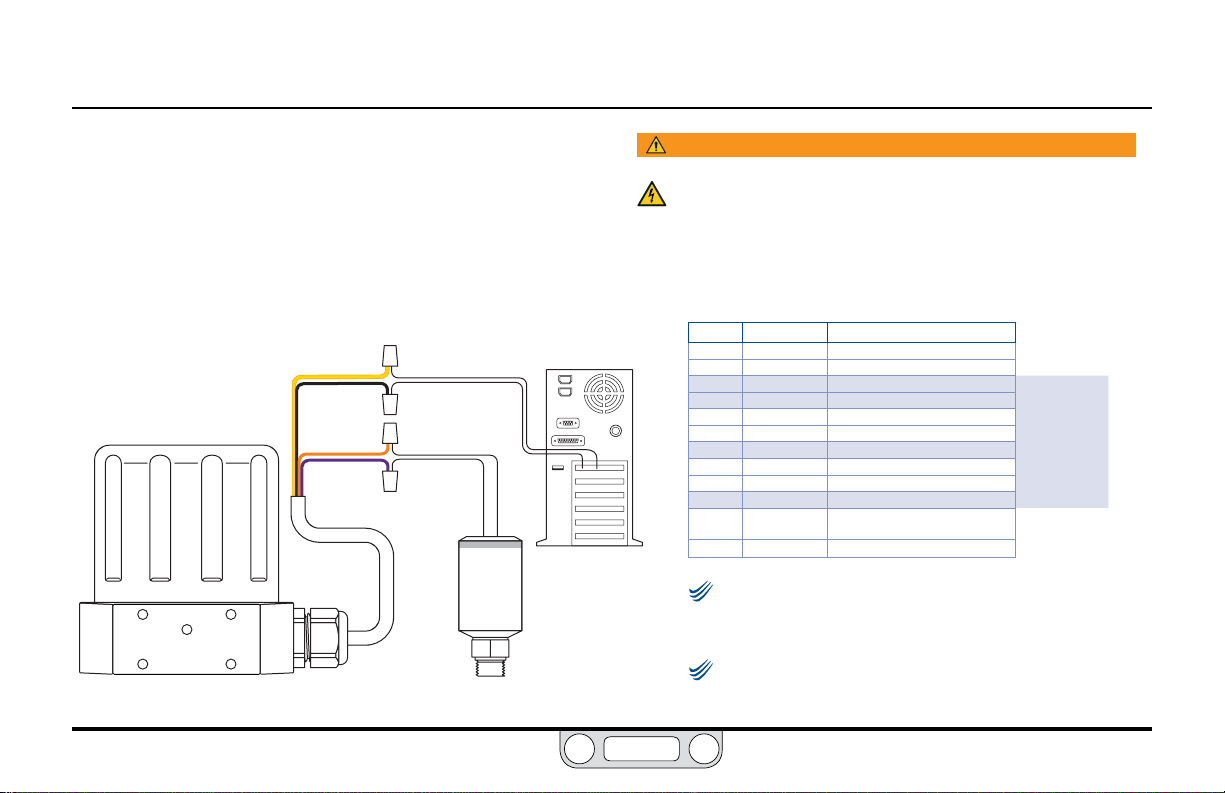

The ER5000: Typical Application

WARNING

(Non-Hazardous Location)

Investigate and apply the most recent standards for Hazardous Locations

for your area set by ANSI, ISO and OSHA, as well as all electrical codes and

fire and safety standards, to determine if your application will require

a Hazardous Location model. If your application requires a Hazardous

Location model (ER5050), refer to

Installing a Hazardous Location

Model (ER5050) on p age 110.

Controlling System Pressure

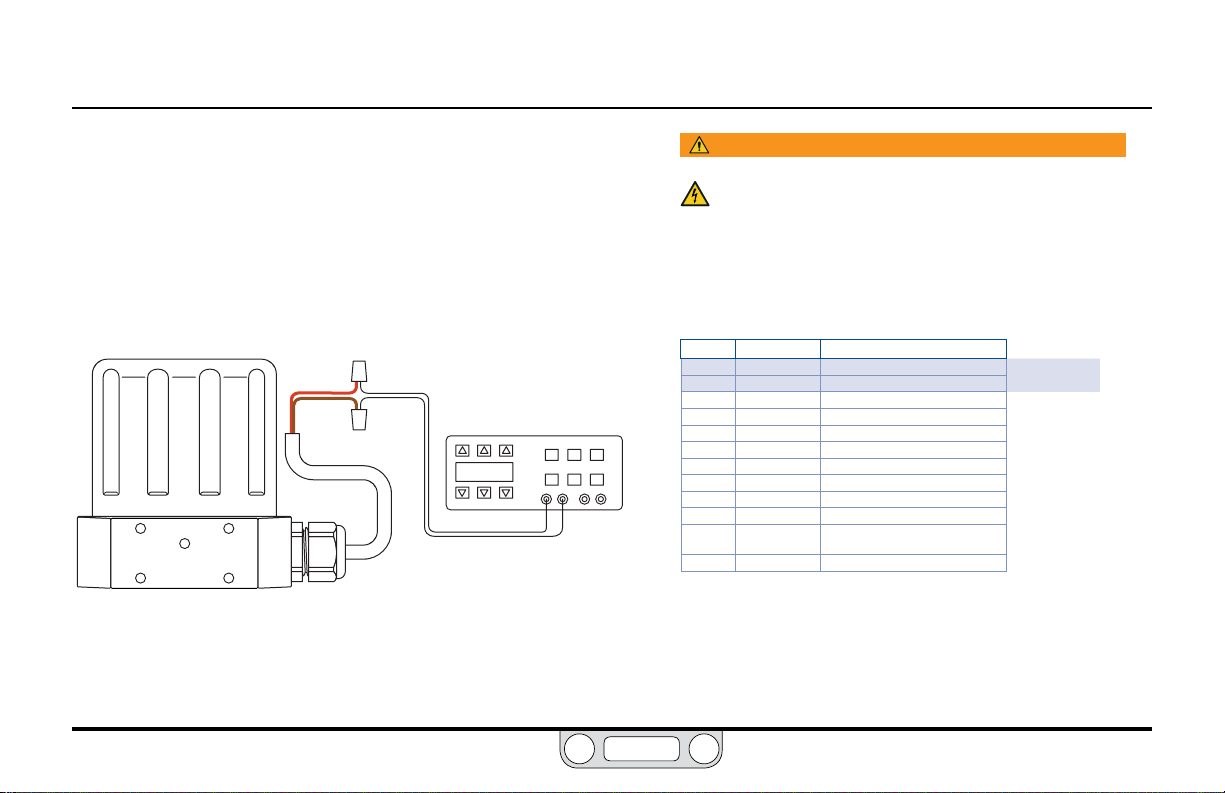

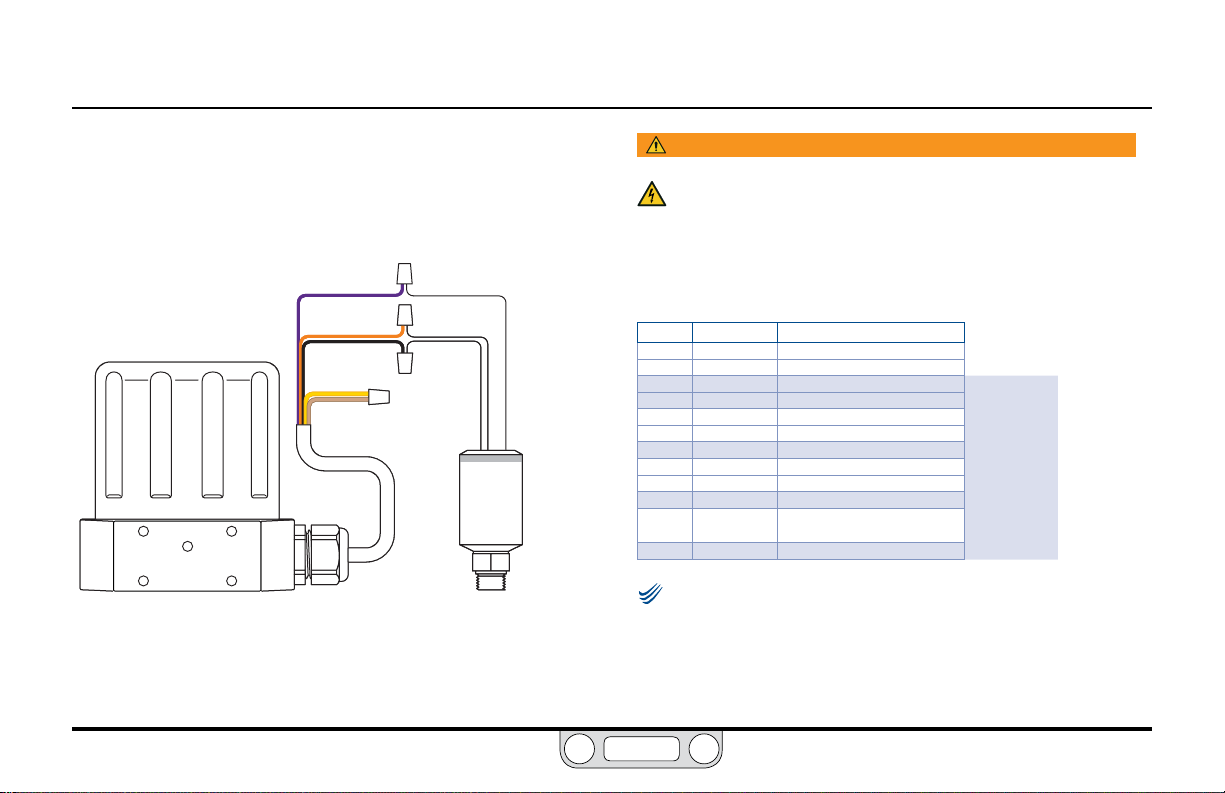

In a typical application, the Outlet Port of the ER5000 connects

to the top of a Dome Loaded or Air Actuated pressure reducing

Regulator, usually through the included 1/2" SAE x 1/8" NPTF

adaptor. This is shown in Figure 4.

Supply Pressure of up to 120 psig / 8.2 bar, with 110 psig / 7.5 bar

being typical, is provided to the ER5000 by an external source.

The ER5000 increases Pilot Pressure to the air actuator of the

regulator by opening the Pulse Width Modulation (PWM) solenoid

valve at the Inlet Port and reduces pilot pressure by opening the

PWM solenoid valve at the Exhaust Port. Normally, the exhaust

vents to atmosphere.

The controller, congured in External Feedback mode, senses

System Pressure through input from a transducer mounted

downstream in the Process Line.

USB

Connection

ER5000 Supply

Pressure

110 psig / 7.5 bar

Adaptor

Regulator

Inlet Pressure

Figure 4: Typical ER5000 Application

Controller, with adaptor, is mounted to an air actuated regulator. Feedback is from the external

transducer. Setpoint is from a Prole downloaded from the PC through the USB connection.

External

Transducer

Outlet Pressure

To Process

PC

www.emerson.com/tescom

Page 40

ER5000 — 40Typical Application

BACK

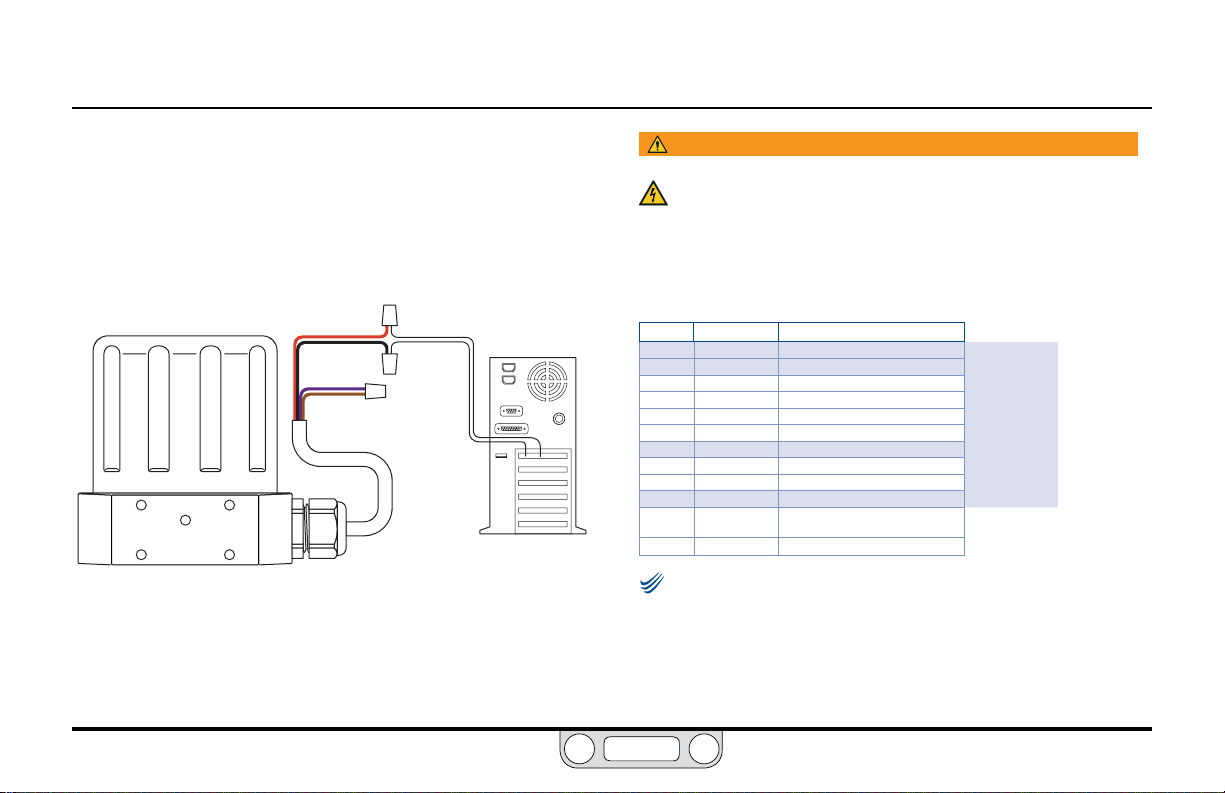

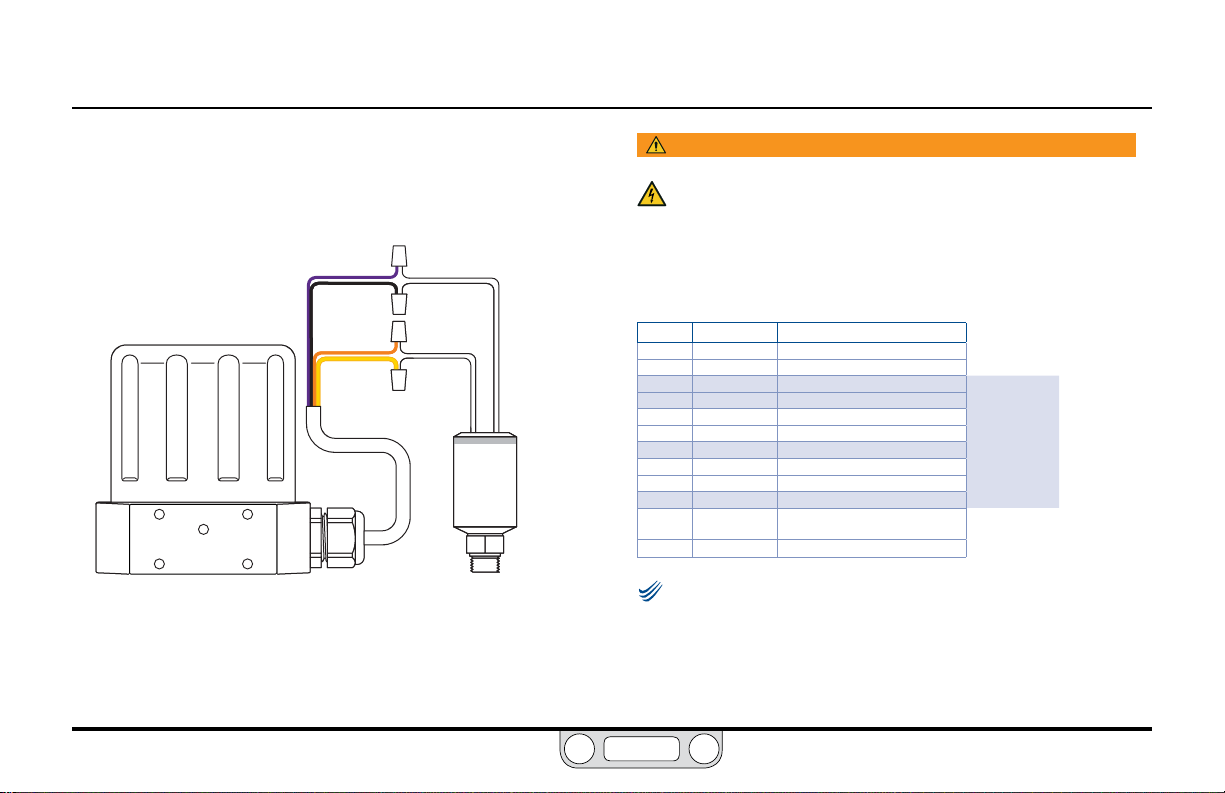

Every 25 milliseconds, the controller reads the feedback and

compares it to the setpoint, which it receives from an external

source or from a Prole in its onboard memory.

than setpoint, the ER5000 activates the inlet valve, allowing Pilot

Pressure to ow into the actuator of the regulator. This causes the

main valve of the regulator to open up, resulting in an increase in

downstream System Pressure. The ER5000 will continue to send

pilot pressure into the air actuator of the regulator until feedback

and setpoint are equal. At that point, the inlet valve closes,

stabilizing the system at that pressure.

If feedback is higher than setpoint, the ER5000 activates the

exhaust valve, releasing pilot pressure from the regulator. The

decrease in pilot pressure causes the main valve of the regulator

to close up and also causes the regulator vent to open, exhausting

excess system pressure (if your application uses a non-venting

regulator, refer to page 41). The result is a decrease in

downstream system pressure. The ER5000 will continue to exhaust

pilot pressure until the feedback signal is equal to the setpoint.

At that point, the exhaust valve closes, stabilizing the system at

that pressure.

If feedback is lower

Supply

Pressure

110 psig /

7.5 bar

Air Actuator

Regulator

Inlet

Pressure

ER5000

Inlet Port

Vent Valve

Inlet

Valve

Pilot

Pressure To

Air Actuator

Pilot

Pressure From

Air Actuator

Captured Vent

Exhaust

Valve

ER5000 Outlet Port

and Adaptor

Main Valve

exhausts excess pressure

ER5000

Exhaust Port

Pressure Vents

to Atmosphere

Regulator

Outlet

Pressure

USB Connection

Setpoint

Source can be either a digital

signal provided over USB or

RS485, an analog signal or a

Prole stored in onboard memory.

Feedback

For optimal system

performance, an accuracy of

0.1% or better is required. A

less accurate transducer can

be used, but doing so will

degrade the accuracy of the

overall system.

Figure 5: Internal Operation of the ER5000 Controller

PC

www.emerson.com/tescom

Page 41

ER5000 — 41Typical Application

BACK

A Note Concerning Non-Venting Regulators in Closed Loop Applications

Non-venting regulators, which do not feature a regulator vent to

exhaust excess system pressure, pose a particular challenge in

closed loop applications when the downstream ow is blocked.

When downstream ow stops suddenly, for example when a

downstream valve is closed, feedback rises rapidly. The regulator

responds by closing its main valve. However, due to Lock-up in the

regulator, a small amount of excess pressure escapes through the

main valve before it achieves a completely tight seal.

In venting regulators, this excess downstream pressure is

exhausted by the regulator vent, allowing the system to return

to stable state. In non-venting regulators, this excess pressure is

trapped in the downstream pipe.

The PID controller senses the rise in feedback and activates to

lower system pressure. But the regulator cannot respond, since it

cannot vent. Because the excess system pressure is trapped, the

error will not change. The controller could continue to respond

until the pilot pressure is completely vented through the exhaust

valve. This can create two different undesirable conditions:

• If the regulator is a metal diaphragm sensed regulator, the

differential between the high downstream pressure beneath

the diaphragm and the low (or even zero) pilot pressure above

the diaphragm can critically stress the diaphragm.

• Regardless of regulator type, if the downstream ow suddenly

restarts, the PID controller’s response will be delayed,

because it will need to completely rell the regulator’s dome

or air actuator cavity.

When the Diaphragm Protection feature of the ER5000 is

activated, the controller responds to error only up to a set

percentage of the original pilot pressure, then stops. This allows

the controller and regulator to be reset quickly once system ow

has been restored and minimizes pressure differentials that can

effect regulator components.

The Regulator Diaphragm Protection feature is strongly

recommended for applications using metal diaphragm sensed

regulators. It provides a control benet for applications using non-

venting regulators. It is not required for applications using venting

regulators or piston sensed regulators.

Refer to The Diaphragm Protection Panel to learn more about

this feature.

www.emerson.com/tescom

Page 42

ER5000 — 42Typical Application

BACK

Monitoring System Control Limits

The ER5000 also can be congured to monitor the system and

respond if user-specied limits are exceeded. This function is

deactivated by default and can be activated using controls in the

ERTune™ program. Refer to The Control Limits Panel section for

more information.

This feature provides added security in the event of a system

failure such as broken transducer wiring, lack of supply pressure or

pipe ruptures.

CAUTION

The Control Limits feature provides an additional level of system

monitoring. Activation indicates a potential problem, but will not, by

itself, prevent problems from occurring. It should not be considered

to be a safet y mechanism, nor is it intended to be a safety feature or

pressure limiting device.

When an ER5000 congured to monitor Control Limits detects a signal

indicating that a limit has been exceeded, it activates its solenoid valves

to reach one of three Control Limit Conditions:

• Inlet Closed/Exhaust Closed

• Inlet Closed/Exhaust Open

• Inlet Open/Exhaust Closed.

The default Condition is Inlet Closed/Exhaust Open, which

ensures that a pressure reducing system will be vented if a limit is

exceeded. If your application uses a non-venting regulator, refer

to A Note Concerning Non-Venting Regulators in Closed Loop

Applications if you intend to use the ER5000 in this condition.

Minimum and maximum limits can be monitored for any or all of

these variables:

• Analog Setpoint

• Internal Sensor

• External Sensor

• Inner Error

• Outer Error.

www.emerson.com/tescom

Page 43

ER5000 — 43Control Modes

NOTENOTE

BACK

The ER5000: Control Modes

Internal Feedback Mode

Internal Feedback Mode uses the ER5000’s internal

sensor to monitor the pressure within the controller’s 0–100 psig /

0–6.9 bar internal pressure range. This mode is typically used

when the ER5000 is used as a standalone unit or when open-loop

control of a regulator is desired.

External Feedback Mode

External Feedback Mode uses a user-supplied external transducer

to monitor the system pressure. The transducer is installed in the

process line and provides direct feedback to the ER5000. This mode

is typically used when the ER5000 acts as the pilot regulator for a

regulator or valve.

An external transducer may also be installed in the ER5000’s

pressure line when the ER5000 is used as a standalone unit. This

may be preferable to Internal Feedback mode when:

• The application requires precise control within a small pressure

range. For example, the ER5000 will respond more efciently

to a 5% change in a 0–10 psig / 0–0.7 bar range than to a 0.5%

change in its full 0–100 psig / 0–6.9 bar range.

• There is a need to monitor downstream pressure. For example,

if the output passes through a length of pipe to a vessel and it is

expected that there will be pressure drops in the pipe, an external

sensor installed at the vessel will provide a more responsive

feedback signal than the controller’s internal sensor.

Cascade Mode

Cascade Mode implements one PID loop within another PID loop.

The inner loop uses the controller’s internal sensor and the outer

loop uses an external sensor. This mode of operation creates more

stability, but slows down the response of the system.

For proper operation in Cascade Mode, the following

recommended defaults for the Integral Limits of the external feedback

loop (also known as the outer loop) are downloaded into the controller

during setup: Maximum: 32767; Minimum: 0. These settings are optimal

for most applications.

Refer to The Cascade Tuning Tips and The Integral Limits

Controllers for more information on these settings.

www.emerson.com/tescom

Page 44

GloSSary

BACK

of termS

www.emerson.com/tescom

44

Page 45

ER5000 — 45Glossary of Terms

BACK