Page 1

TC-3000C Bluetooth Tester

Operating Manual

R20140925

http://www.tescom.co.kr

The information contained in this document is subject to change without prior notice.

Bluetooth is a trademark owned by Bluetooth SIG, Inc., and licensed to Tescom.

Copyright 2004 Tescom Co., Ltd., Suite 927, Unitechvil, 142, Ilsan-ro, Ilsandong-gu, Goyang-si, Gyunggi-do, Korea

Page 2

Page 3

Table of Contents

TABLE OF CONTENTS

General Information ........................................................................................................... 9

1.1 WARRANTY ....................................................................................................................................... 10

1.2 Safety Consideration .......................................................................................................................... 13

1.2.1 Injury Precautions .................................................................................................................. 13

1.2.2 Product Damage Precautions ................................................................................................ 13

1.3 Safety Symbols and Terms ................................................................................................................. 14

1.4 TESCOM Sales and Service Office .................................................................................................... 14

1.5 Manual Convention ............................................................................................................................ 14

1.6 Instruction and Key Features ............................................................................................................. 15

1.6.1 Key Features .......................................................................................................................... 15

1.7 Specification ....................................................................................................................................... 16

1.8 Connectors ......................................................................................................................................... 16

Installation ........................................................................................................................ 17

2.1 Initial Inspection .................................................................................................................................. 18

2.2 Power Requirement ............................................................................................................................ 18

2.3 Operating Environment ...................................................................................................................... 19

2.4 Carrying Handle and Caution for Moving ........................................................................................... 19

2.5 Firmware Upgrade .............................................................................................................................. 20

2.6 Cleaning, Storage and Shipment........................................................................................................ 21

2.6.1 Cleaning ................................................................................................................................. 21

2.6.2 Storage ................................................................................................................................... 21

2.6.3 Shipment ................................................................................................................................ 21

Operation .......................................................................................................................... 24

3.1 Overview ............................................................................................................................................. 25

3.1.1 TC-3000C System Architecture .............................................................................................. 25

3.1.2 Start-up Screen ...................................................................................................................... 26

3.1.3 Shutdown Screen ................................................................................................................... 26

3.1.4 Display Color Scheme ............................................................................................................ 26

3.1.5 System Information ................................................................................................................ 27

3.1.6 Front Panel View .................................................................................................................... 27

3.1.7 Rear Panel View..................................................................................................................... 29

3

Page 4

Table of Contents

3.1.8 Display Screen ....................................................................................................................... 30

3.1.9 Menu Structure ....................................................................................................................... 31

3.1.10 Access Main Functions ........................................................................................................ 32

3.1.11 Data Input and Change ........................................................................................................ 33

3.1.12 Enter and Change the Unit-of-Measure ............................................................................... 33

3.1.13 Interaction Between Screens ............................................................................................... 33

3.1.14 Tool Tips ............................................................................................................................... 33

3.1.15 Typical Test Configurations .................................................................................................. 34

3.2 Basic Operation Procedure ................................................................................................................ 35

3.2.1 Step 1. Getting Started ........................................................................................................... 35

3.3 Operation Procedure (Link Analyzer) ................................................................................................. 39

3.3.1 Step 2. Creating Connection to DUT ...................................................................................... 39

3.3.2 Step 3. Viewing the Recorded Data ....................................................................................... 41

3.4 Operation Procedure (Host Analyzer) ................................................................................................ 44

3.4.1 Step 2. Creating Connection to DUT ...................................................................................... 44

3.4.2 Step 3. Viewing the Recorded Data ....................................................................................... 47

3.5 Operation Procedure (Measurement/Measurement2) ....................................................................... 49

3.5.1 Step 3. Selecting the Measurement Screen........................................................................... 49

3.5.2 Step 4. Measuring RF Characteristics of DUT ....................................................................... 50

3.5.3 Step 5. Setting Up Test Mode and Parameters ...................................................................... 56

3.6 Operation Procedure (EDR Measurement) ........................................................................................ 57

3.6.1 Step 3. Selecting the EDR Measurement Screen .................................................................. 57

3.6.2 Step 4. Measuring EDR Characteristics of DUT .................................................................... 58

3.7 Operation Procedure (Audio Analyzer) .............................................................................................. 61

3.7.1 Step 2. Creating Connection to DUT ...................................................................................... 61

3.7.2 Step 3. Verification of Speech Loopback for Mono Headset .................................................. 63

3.7.3 Step 4. Measuring Audio Characteristics of DUT ................................................................... 64

3.8 Operation Procedure (Bluetooth Conformance Test) ......................................................................... 69

3.8.1 Step 3. Selecting the Test Cases Screen ............................................................................... 71

3.8.2 Step 4. Selecting the Test Cases and Setting Up Test Parameters ....................................... 71

3.8.3 Step 5. Running the Test Cases and Viewing the Test Results ............................................. 72

3.9 Setting up for Bluetooth LE(Low Energy) Testing .............................................................................. 73

3.10 Configuration of the TC-3000C ........................................................................................................ 74

3.10.1 Tester .................................................................................................................................... 74

3.10.2 DUT ...................................................................................................................................... 77

3.10.3 RF Settings........................................................................................................................... 79

3.10.4 Peripherals ........................................................................................................................... 79

3.10.5 Network ................................................................................................................................ 80

3.11 General Purpose Communication Analyzer ..................................................................................... 81

3.11.1 Signal Generator .................................................................................................................. 81

3.11.2 Signal Analyzer ..................................................................................................................... 82

4

Page 5

Table of Contents

3.12 Store/Recall/Preset Instrument Settings .......................................................................................... 83

3.13 Checking List for Common Problems ............................................................................................... 83

3.13.1 Unit is inoperative ................................................................................................................. 84

3.13.2 Failure of testing ................................................................................................................... 84

Performance Test ............................................................................................................. 85

4.1 General Information ............................................................................................................................ 85

4.1.1 Recommended test equipment .............................................................................................. 86

4.1.2 Calibration Cycle .................................................................................................................... 86

4.1.3 TC-3000C Initial Set Up ......................................................................................................... 87

4.2 Signal Generator ................................................................................................................................ 87

4.2.1 Frequency Accuracy ............................................................................................................... 87

4.2.2 I/Q modulation calibration ...................................................................................................... 88

4.2.3 PLL phase noise ..................................................................................................................... 89

4.2.4 FM accuracy ........................................................................................................................... 90

4.2.5 Output level accuracy test ...................................................................................................... 91

4.3 Testing Receiver ................................................................................................................................. 92

4.3.1 Power measurement accuracy ............................................................................................... 92

4.3.2 Maximum sensitivity ............................................................................................................... 94

4.3.3 Gain Roll-off ........................................................................................................................... 95

Programming Guide ........................................................................................................ 96

5.1 Introduction ......................................................................................................................................... 97

5.2 Getting Started .................................................................................................................................... 97

5.2.1 Settings for Ethernet(Host) remote control using DLL ........................................................... 99

5.2.2 Settings for USB(Host Controller) remote control using DLL ................................................. 99

5.2.3 Settings for RS-232C(Host Controller) remote control using DLL ....................................... 100

5.2.4 Settings for the RS-232C(Host) remote control without using DLL ..................................... 100

5.2.5 Preparing for your application using DLL ............................................................................. 101

5.3 Reference Guide using RS-232C commands .................................................................................. 101

5.3.1 Configuration Command ...................................................................................................... 101

5.3.2 Access Command ................................................................................................................ 109

5.3.3 RF Test Cases Command ..................................................................................................... 110

5.3.4 Output Power(OP) ................................................................................................................. 110

5.3.5 Power Density(PD) ................................................................................................................ 111

5.3.6 Power Control(PC) ................................................................................................................ 112

5.3.7 Enhances Power Control(EPC)............................................................................................. 113

5.3.8 Frequency Range(FR) .......................................................................................................... 115

5.3.9 20dB Bandwidth(20BW) ........................................................................................................ 116

5.3.10 Adjacent Channel Power(ACP) ........................................................................................... 117

5.3.11 Modulation Characteristics(MOD) ....................................................................................... 118

5.3.12 Initial Carrier Frequency Tolerance(ICFT) ........................................................................... 119

5

Page 6

Table of Contents

5.3.13 Carrier Frequency Drift(CFD) ............................................................................................. 121

5.3.14 Single Slot Sensitivity(SS) .................................................................................................. 122

5.3.15 Multi Slot Sensitivity(SM) ................................................................................................... 123

5.3.16 Maximum Input Level(ML) .................................................................................................. 125

5.3.17 Quick Test(OPMOD) .......................................................................................................... 126

5.3.18 BER & FER ........................................................................................................................ 128

5.3.19 EDR Relative Transmitter Power(ETP) .............................................................................. 130

5.3.20 EDR Carrier Frequency Stability & Modulation Accuracy(EFSMA) ................................... 132

5.3.21 EDR Differential Phase Encoding(EDPE) .......................................................................... 135

5.3.22 EDR In-band Spurious Emission(ETP) .............................................................................. 136

5.3.23 EDR Sensitivity(ES) ........................................................................................................... 137

5.3.24 EDR BER Floor Performance(EBP) ................................................................................... 139

5.3.25 EDR Maximum Input Level(EML)....................................................................................... 140

5.3.26 Audio Test Command ......................................................................................................... 142

5.4 Example using command ................................................................................................................. 147

5.5 Flow Chart for RS-232C Commands................................................................................................ 148

5.6 Sample Code(VC++) for RS-232C remote control ........................................................................... 152

5.7 Reference Guide for using DLL ........................................................................................................ 157

5.7.1 General Function .................................................................................................................. 157

5.7.2 Tester Configuration ............................................................................................................. 157

5.7.3 DUT Configuration................................................................................................................ 174

5.7.4 Access Fucntions ................................................................................................................. 186

5.7.5 Security Fucntions ................................................................................................................ 188

5.7.6 Profile Fucntions .................................................................................................................. 188

5.7.7 Audio Fucntions .................................................................................................................... 190

5.7.8 Signal Generator .................................................................................................................. 191

5.7.9 RF Test Cases ...................................................................................................................... 192

5.7.10 Measurement Functions ..................................................................................................... 198

5.8 Flow Chart for DLL functions ............................................................................................................ 202

5.9 Example using DLL .......................................................................................................................... 205

5.9.1 Measuring Output Power ..................................................................................................... 205

Appendices .................................................................................................................... 209

Appendix A. Specification ....................................................................................................................... 210

5.1.1 RF SOURCE ........................................................................................................................ 210

5.1.2 RF ANALYZER ..................................................................................................................... 210

5.1.3 SPECTRUM ANALYZER ...................................................................................................... 211

5.1.4 FM MODULATION ANALYZER ............................................................................................. 211

5.1.5 POWER-TIME ....................................................................................................................... 211

5.1.6 POWER-CHANNEL (BT Mode) ............................................................................................ 211

5.1.7 RX BER TEST (BT Mode) ..................................................................................................... 211

5.1.8 I-Q CONSTELLATION (EDR BT Mode) ................................................................................ 211

6

Page 7

Table of Contents

5.1.9 TX BER TEST (BT Mode) ..................................................................................................... 211

5.1.10 DEVM (Differential Error Vector Magnitude) ....................................................................... 211

5.1.11 FREQUENCY REFERENCE .............................................................................................. 212

5.1.12 FRONT PANEL .................................................................................................................. 212

5.1.13 REAR PANEL ..................................................................................................................... 212

5.1.14 MISCELLANEOUS ............................................................................................................. 212

Appendix B. RF Test Cases of the TC-3000C ........................................................................................ 213

5.2.1 Output Power (TRM/CA/01/C) ............................................................................................. 213

5.2.2 Power Density (TRM/CA/02/C) ............................................................................................ 214

5.2.3 Power Control (TRM/CA/03/C)............................................................................................. 216

5.2.4 TX Output Spectrum – Frequency range (TRM/CA/04/C) ................................................... 218

5.2.5 TX Output Spectrum – 20 dB Bandwidth (TRM/CA/05/C) ................................................... 220

5.2.6 TX Output Spectrum – Adjacent channel power (TRM/CA/06/C) ........................................ 222

5.2.7 Modulation Characteristics (TRM/CA/07/C) ......................................................................... 224

5.2.8 Initial Carrier Frequency Tolerance (TRM/CA/08/C) ............................................................ 226

5.2.9 Carrier Frequency Drift (TRM/CA/09/C) ............................................................................... 227

5.2.10 EDR Relative Transmit Power (TRM/CA/10/C).................................................................. 229

5.2.11 EDR Carrier Frequency Stability and Modulation Accuracy (TRM/CA/11/C) ..................... 231

5.2.12 EDR Differential Phase Encoding (TRM/CA/12/C) ............................................................ 233

5.2.13 EDR In-band Spurious Emissions (TRM/CA/13/C) ............................................................ 234

5.2.14 Sensitivity – single slot packets (RCV/CA/01/C) ................................................................ 236

5.2.15 Sensitivity - multi-slot packets (RCV/CA/02/C) .................................................................. 238

5.2.16 Maximum Input Level (RCV/CA/06/C) ............................................................................... 240

5.2.17 EDR Sensitivity (RCV/CA/07/C) ......................................................................................... 241

5.2.18 EDR BER Floor Performance (RCV/CA/08/C) ................................................................... 243

5.2.19 EDR Maximum Input Level (RCV/CA/10/C) ....................................................................... 244

5.2.20 List of abbreviations ........................................................................................................... 246

5.2.21 References ......................................................................................................................... 246

Appendix C. The list of Save/Recall parameters .................................................................................... 247

7

Page 8

Table of Contents

List of Figures

[Figure 1] Carrying Handle .............................................................................................................. 19

[Figure 2] Front Panel View ............................................................................................................. 27

[Figure 3] Rear Panel View ............................................................................................................. 29

[Figure 4] Typical Test Configurations ............................................................................................. 34

[Figure 5] Carrier frequency accuracy test ...................................................................................... 87

[Figure 6] I/Q modulation calibration test ........................................................................................ 88

[Figure 7] PLL phase noise test....................................................................................................... 89

[Figure 8] FM accuracy test ............................................................................................................. 90

[Figure 9] Output level accuracy test............................................................................................... 91

[Figure 10] Power measurement accuracy test .............................................................................. 92

[Figure 11] Maximum sensitivity test ............................................................................................... 94

[Figure 12] Gain Roll-off test ........................................................................................................... 95

List of Tables

[Table 1] Accessory List ................................................................................................................... 18

[Table 2] Power Requirement .......................................................................................................... 18

[Table 3] Access Main Functions ..................................................................................................... 32

[Table 4] Test Parameters Refer to DUT in Configuration. .............................................................. 40

[Table 5] Pattern Example ............................................................................................................... 81

8

Page 9

This chapter covers the instrument warranty, specifications, key features, and

safety consideration.

Chapter

1

General Information

Page 10

1.1 WARRANTY

1.1 WARRANTY

TESCOM warrants that this product is free from defects in terms of materials and

workmanship for a period of one (1) year from the date of shipment. During the warranty

period, TESCOM will -- at its discretion -- either repair or replace products that prove to be

defective.

For the warranty service or repair, the Customer must notify TESCOM of the defect before

the expiration of the warranty period and make suitable arrangements for the performance

of service. The Customer shall be responsible for packaging and shipping the defective

product to the service center designated by TESCOM. The Customer shall prepay the

shipping charge to a TESCOM designated service center, and TESCOM shall pay the

shipping charge to return the product to the Customer. In case the Customer is located

outside of Korea, the Customer is responsible for all shipping charges including freight,

taxes, and any other charge if the product is returned for service to TESCOM.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate

malignance by the Buyer, Buyer-supplied software or interfacing, unauthorized modification

or misuse, accident, or abnormal conditions of operation.

TESCOM`s responsibility to repair or replace defective products is the sole and exclusive

remedy provided to the Customer in case of breach of this warranty. TESCOM will not be

liable for any indirect, special, incidental, or consequential damages regardless of whether

TESCOM served advance notice of the possibility of such damages.

10

Page 11

1.1 WARRANTY

11

Page 12

1.1 WARRANTY

12

Page 13

1.2 Safety Consideration

1.2 Safety Consideration

Review the following safety precautions to avoid injury and prevent damage to this product

or any product connected to it:

1.2.1 Injury Precautions

Use the Appropriate Power Cord

To avoid fire hazard, use only the power cord specified for this product.

Avoid Electric Overload

To avoid electric shock or fire hazard, do not apply voltage beyond the specified range

to a terminal.

Ground the Product

This product is grounded through the grounding conductor of the power cord. In case no

ground is available at the power outlet, providing a separate grounding path to the

instrument is recommended by connecting wire between the instrument ground terminal

and earth ground to avoid electric shock or instrument damage. Before making

connections to the input or output terminals of the product, make sure that the product is

properly grounded.

Do Not Operate Without Covers

To avoid electric shock or product damage, do not operate this product with the

protective covers removed.

Do Not Operate in Wet/Damp Conditions

To avoid injury or fire hazard, do not operate this product in wet or damp conditions.

Do Not Use in a Manner Other than That Specified by the Manufacturer

1.2.2 Product Damage Precautions

Use Appropriate Power Source

Do not operate this product using a power source that applies more than the specified

voltage. Main supply voltage fluctuations should not exceed 10% of the nominal

voltage.

Provide Proper Ventilation

To prevent product overheating, provide proper ventilation.

Do Not Operate in case of Suspected Failures

If you think there is damage to this product, have it inspected by qualified service

personnel.

Environmental Conditions

Refrain from using this equipment in a place subject to considerable vibration, direct

sunlight, outdoors, and where the ground is not level. Likewise, do not use it where the

ambient temperature is beyond the range of 5 C - 40 C and altitude is more than

2000 m. The maximum relative humidity is 80 % for temperatures up to 31 C,

decreasing linearity of up to 50%, and relative humidity at 40 C, and Over voltage

Installation Category II for the main supply (Pollution Degree 2).

Shut down System

Do not power switch off by compulsion, to avoid injury or damage the internal host PC.

13

Page 14

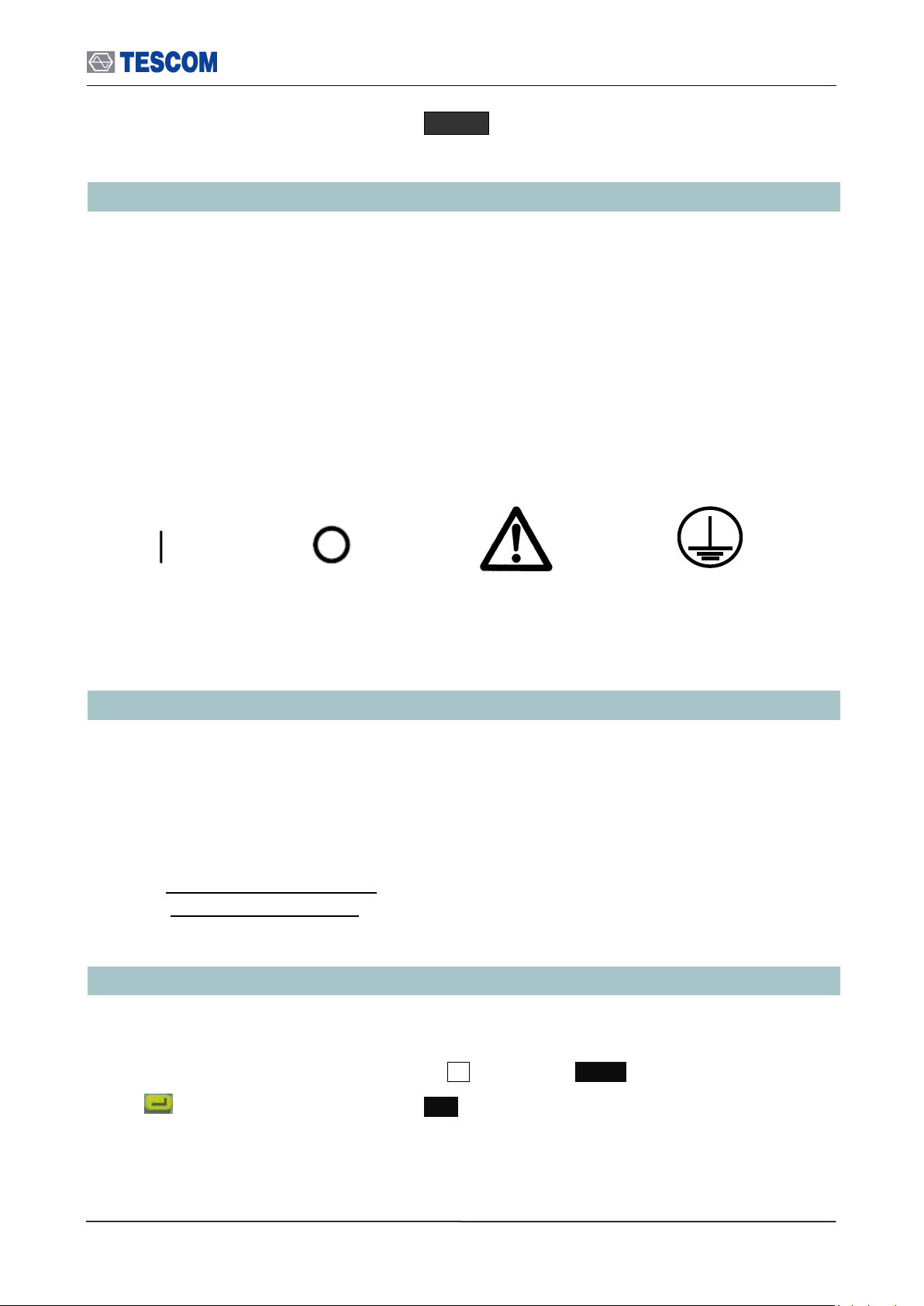

1.3 Safety Symbols and Terms

WARRING / CAUTION

Indicates earth

(ground) terminal

Power ON

Power OFF

In order to power off safely, press Menu select “Quit” press “Yes” and then

do power switch off.

1.3 Safety Symbols and Terms

These terms may appear in this manual.

WARNING: Warning statements describe the conditions or practices that could result in

injury or loss of life.

CAUTION: Caution statements describe the conditions or practices that could result in

damage to this product or other property.

Symbols on the Product: The following symbols may appear on the product:

1.4 TESCOM Sales and Service Office

If you have difficulty with the product, call or write to our Technical Support specialists at:

TESCOM Company Limited

# 927 Unitechvil., 142, Ilsan-ro, Ilsandong-gu, Goyang-si, Gyunggi-do, Korea [ZIP 410-722]

TEL.: 82-31-920-6601 FAX: 82-31-920-6607

Email: tescom-sales@tescom.org

http://www.tescom.co.kr

1.5 Manual Convention

[ ] This indicates menus following notational conventions.

Keypad buttons are indicated with the symbol. ex) FCN

key on the front is indicated as ENT.

14

Page 15

1.6 Instruction and Key Features

1.6 Instruction and Key Features

TESCOM TC-3000C Bluetooth Tester eliminates the need for several costly testers by

combining key RF and Protocol test & measurement functions in one convenient box.

Designed for a wide range of applications in R&D, manufacturing, QA and service, this

feature-packed powerful instrument is simple to use, lightweight and portable, and may be

operated with all standard AC voltages. In addition to Bluetooth testing applications, TC3000C may be used for non-Bluetooth RF testing along the 2.4 GHz ISM band.

1.6.1 Key Features

Bluetooth V1.1/V1.2/V2.0/V3.0/V4.0 Specification Compliant

RF, Audio, and Protocol Combination Tester

Bluetooth Conformance Test

Supports Audio (SCO Link) Functional Testing (3000-10)

Bluetooth RF and Baseband Measurement Functions (3000-20)

Basic Bluetooth Protocol Analyzer Functions

- Supports Master and Slave modes

- Link test in Pico-net

- Packet information in Baseband, LMP, HCI, SDP, RFCOMM, and Profile

- Direct HCI command execution from the screen

Bluetooth EDR testing (3000-40)

Bluetooth LE testing (3000-50)

Utility digital signal generator

User definable Baseband IN/OUT ports for real time signal monitoring, external

modulation, audio source and audio analyzer

Device HCI Interface Options: USB and RS-232C (UART, BCSP)

Remote Operation: TCP/IP (LAN) and RS-232C

Easy S/W Upgrades through USB

Listed on the Bluetooth Qualified Products List (QPL) as a Development Tool

CE Compliant: EN61010-2001, EN61326,A2:2001, EN61000-3-2, 2000, EN61000-

3-3,A1:2001

15

Page 16

1.7 Specification

Connector

Specification

RS-232C

Working Voltage: 100V

Dielectric Withstanding Voltage: 300V

N Type Connector

Impedance: 50 ohm

Voltage Rating: 250 Vpeak

Dielectric Withstanding Voltage: 750 Vrms

BNC Connector

Impedance: 50 ohm

Voltage: 1Vpk

1.7 Specification

Specifications are listed in Appendix A.

1.8 Connectors

This section contains reference information for TC-3000C’s connectors.

16

Page 17

This section provides the information needed to install the TC-3000C Bluetooth Tester,

including information pertinent to initial inspection, power requirements, environment,

upgrade, storage, and shipment.

Chapter

2

Installation

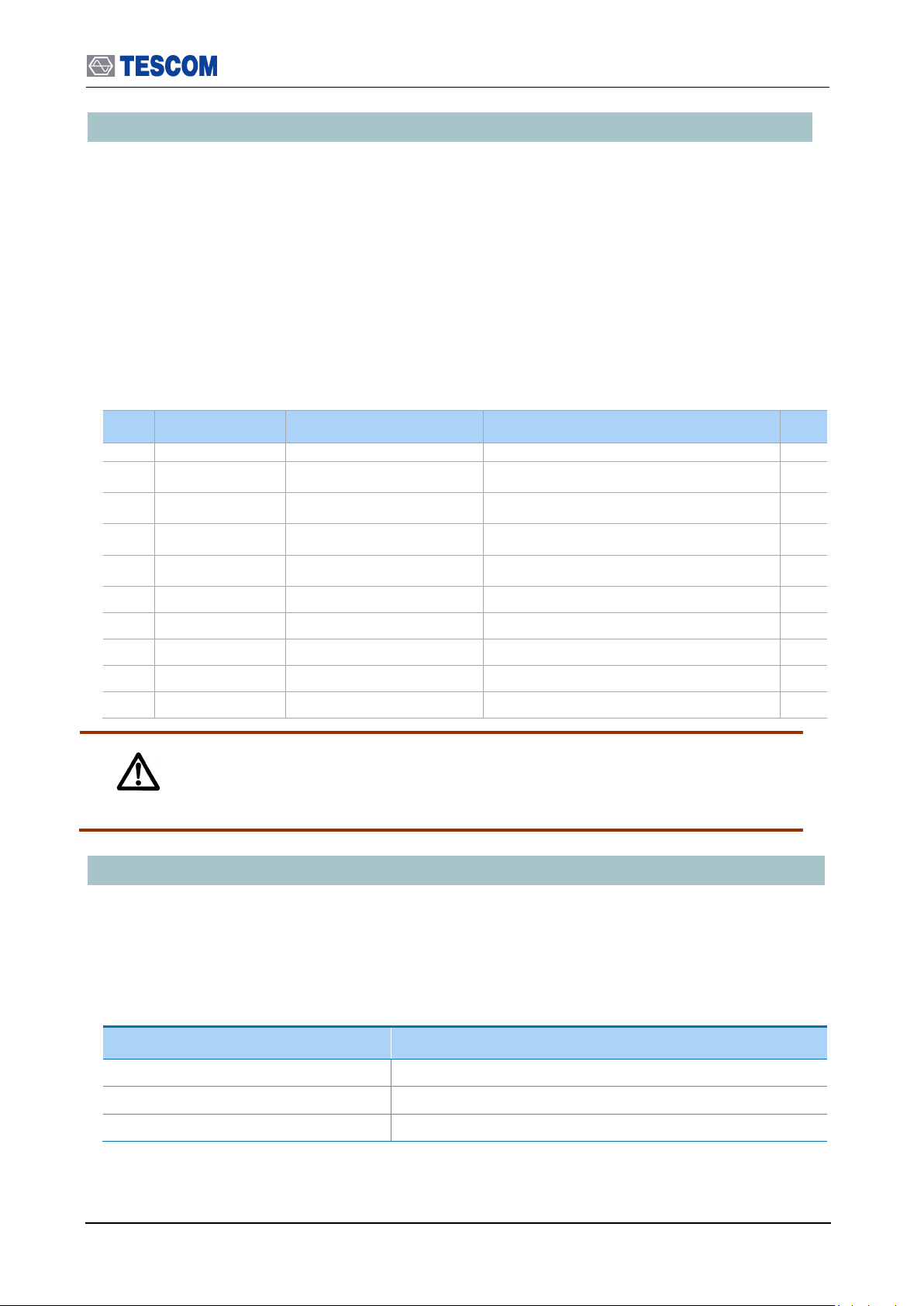

Page 18

2.1 Initial Inspection

No.

Part Number

Name

Specification

Qty.

1

3407-0004

Adaptor

N(m) to BNC(m)

1

2

4003-0012

RS-232C Cable

DB9(s) to DB9(s) cable, 2 m

1

3

4006-0004

RF Cable

N(m) to N(m) cable, 1 m

1

4

4007-0001

RF Cable

BNC(m) to BNC(m) cable, 1 m

2 5 4008-0012

LAN Cable

STP, Cross, RJ45 cable, 2 m

1

6

4008-0016

USB Cable

USB A (p) to USB A (s) cable, 1.8 m

1

7

E92050A

Antenna

Sleeve 2.4 GHz

1

8

E99912A

Attenuator

10 dB, 0.5W, N Type

1

9 Power Cord

2 m

1

10

Operating Manual

1

Characteristic

Requirement

Input voltage

100 VAC - 240 VAC

Frequency

50/60 Hz

Power Consumption

Less than 40 watt

WARNING

To avoid hazardous electrical shock, do not perform electrical tests when there are

signs of shipping damage to the equipment.

2.1 Initial Inspection

This section provides information for verifying proper shipment of the TC-3000C Bluetooth

Tester.

Product Condition and Accessory Check

1. Upon receipt of the TC-3000C Bluetooth Tester, check for damage that could

have occurred during shipment.

2. Check whether you have received all the standard accessories supplied with

TC-3000C as listed in table below.

[Table 1] Accessory List

2.2 Power Requirement

This Tester is a portable instrument, requiring no physical installation other than connection

to a power source.

[Table 2] Power Requirement

18

Page 19

2.3 Operating Environment

WARNING

If AC power is beyond the range of operation, the equipment may malfunction or

sustain permanent damage. Main supply voltage fluctuations should not exceed 10%

of the nominal voltage.

Bench-top viewing position

Carrying position

2.3 Operating Environment

Refrain from using this equipment in a place subject to considerable vibration, direct

sunlight, outdoor, and where the ground is not level. Likewise, do not use it in areas where

the ambient temperature is beyond the range of 5 C ~ 40 C, and altitude is more than

2000 m.

The maximum relative humidity is 80 % for temperatures up to 31 C, decreasing linearity

to 50% relative humidity at 40 C. (Over voltage Installation Category II for main supply;

Pollution Degree 2)

The storage temperature range for this equipment is –20 C ~ 70 C, when this equipment

is not used for a long period of time, store in a dry place away from direct sunlight by

covering with vinyl or placing in a cardboard box.

2.4 Carrying Handle and Caution for Moving

Carrying Handle Adjustment

To adjust the handle position, push both caps covering the rotary joints on each side. .

Then, rotate the handle to the desired position.

[Figure 1] Carrying Handle

Caution for moving

When you are moving the TC-3000C, please use USB cable protector on rear panel. If not,

USB cable between host and host controller could be damaged.

19

Page 20

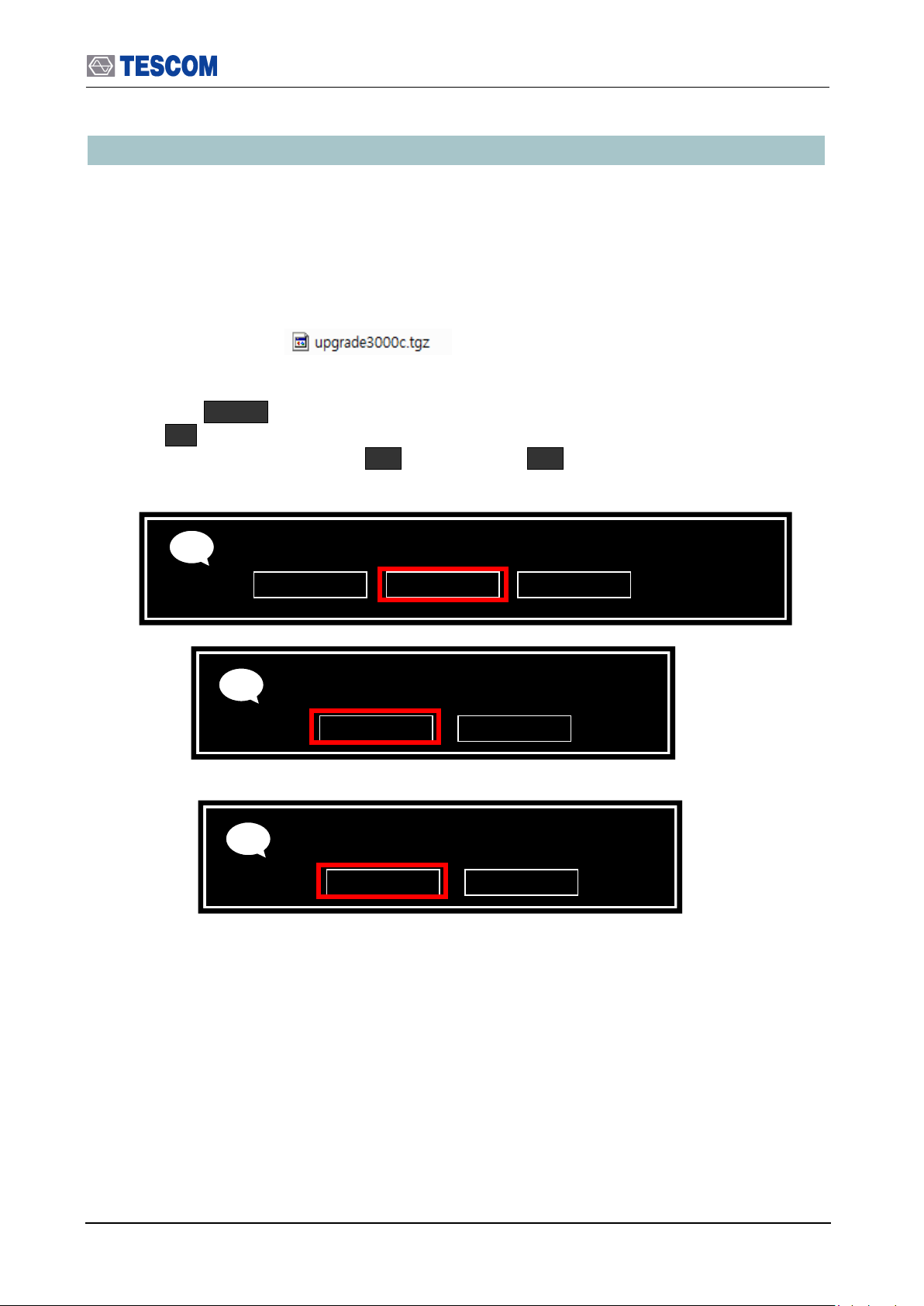

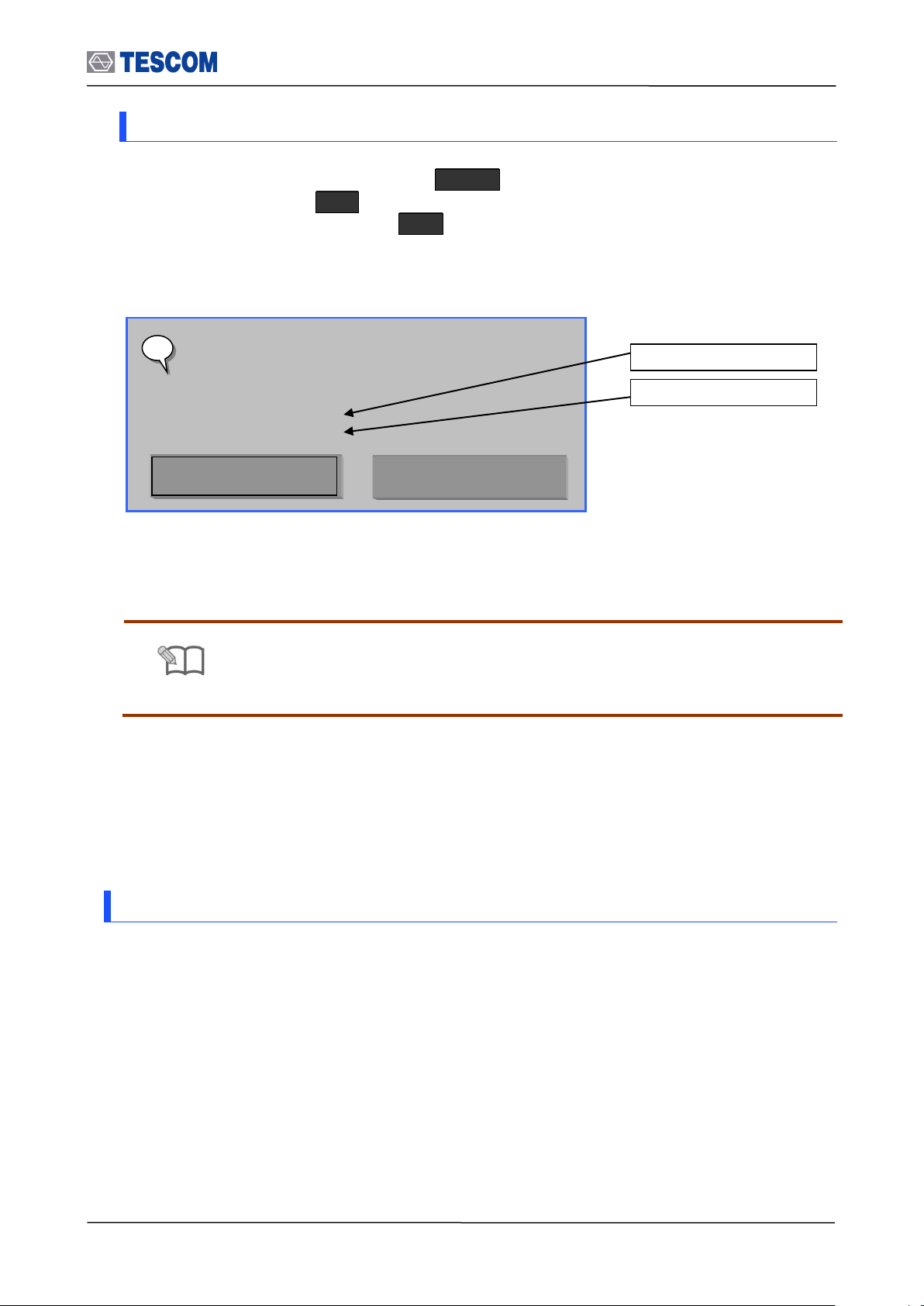

2.5 Firmware Upgrade

i

Get SBC s/w from:

Please never downgrade to v2.30 or earlier unless you have BT option

Remote FTP

USB Memory

Cancel

i

Connect an USB Memory to USB Port;

And Please wait 5 seconds before pressing OK

Cancel

OK

Upgrading DONE. Reboot to activate

i

Cancel

OK

2.5 Firmware Upgrade

TC-3000C Firmware can be upgraded easily using USB memory. You can download the

upgrade data file from Tescom website.

Upgrade from the USB Memory

1. Download Firmware files from Tescom website.

2. Unzip the firmware files.

3. When you unzip file is created.

4. Save the “upgrade3000c.tgz” files to the USB Memory

5. Plug in the USB Memory at front panel USB port.

6. Press Menu select “Configuration” from the pop-up menu on the screen

M5 (Network” )

7. Move “more 3/3” using the F8 key and press F3 ( “Upgrade S/W” )

8. Select “USB Memory” from the pop-up menu and select “ok” button.

9. When Upgrade is completed successfully, select “ok” button

10. When the TC TC-3000C is turned off, turn off and on the rear panel power switch.

11. Turn on the front panel SW switch.

20

Page 21

2.6 Cleaning, Storage and Shipment

NOTE

If download is failed, please check following cases.

[Case 1]: The connection cable between Host and Host Controller on rear panel

must be a USB cable.

[Case 2]: USB recognition time is different depends on USB Memory, so upgrade

should be started after recognition is finished. Usually, you can check it using the

LED lamp of USB memory.

[Case 3]: Even if you cannot upgrade using above cases, perform following steps

for Emergency Upgrade.

1. Turn off the TC3000C.

2. Locate the “DOWNLOAD/NORMAL switch” at rear panel and set it to

DOWNLOAD.

3. Turn on the TC-3000C and repeat the upgrade procedure above.

4. When the upgrade is completed, turn off TC-3000C and return the download

switch to NORMAL position.

5. Turn on TC-3000C

2.6 Cleaning, Storage and Shipment

2.6.1 Cleaning

Periodically wipe the case with a damp cloth mild detergent; do not use abrasives or

solvents.

Keep the power supply free of dust. Clean the power inlet regularly. If dust accumulates

around the power pins, there is a risk of fire.

Clean the input terminal as follows:

1) Turn the TC-3000C off and remove all test leads.

2) Shake out any dirt that be in the terminals.

3) Soak a new swab with alcohol and work around in each terminal.

2.6.2 Storage

The storage temperature range for this equipment is –20 C to 70 C. When this

equipment is not used for a long period of time, covered with vinyl or placed in a

cardboard box, store it in a dry place away from direct sunlight.

2.6.3 Shipment

When shipping this equipment, use the original packing materials. If they are not available,

pack the equipment as follows:

1) Wrap this equipment, in appropriate shock absorbing materials and put it in a

corrugated cardboard box at least 5 mm thick. (If shipping to a TESCOM Service

Office, attach a tag indicating the type of service required, return address, model

number and full serial number.)

2) Wrap its accessories separately in the same shock absorbing material and put

21

Page 22

2.6 Cleaning, Storage and Shipment

CAUTION

Never use any chemical cleaner other than alcohol for the maintenance of this

equipment. Organic solvent such as benzene, toluene or acetone may spoil the

plastic parts of this equipment

them in the same corrugated cardboard box together with this equipment.

3) Fasten the corrugated cardboard box with packing strings.

4) Mark the shipping container FRAGILE to assume careful handing.

22

Page 23

2.6 Cleaning, Storage and Shipment

23

Page 24

This section describes the basic concepts and details of operating TC-3000C Bluetooth

Tester. Understanding the basic concepts of TC-3000C helps you use it effectively. Operation

Overview quickly shows you how TC-3000C is organized and gives some very general

operating instructions. After you read Operating Overview you can use Operation Procedure

for detail information.

Chapter

3

Operation

Page 25

3.1 Overview

Note

HOST and HOST controller must be connected to each other by USB except

for a case when TC-3000C uses an external HOST or HOST controller.

3.1 Overview

The Overview section contains illustrations of the display, the front and rear panels, and the

menu system. These illustrations will help you understand and operate the TC-3000C.

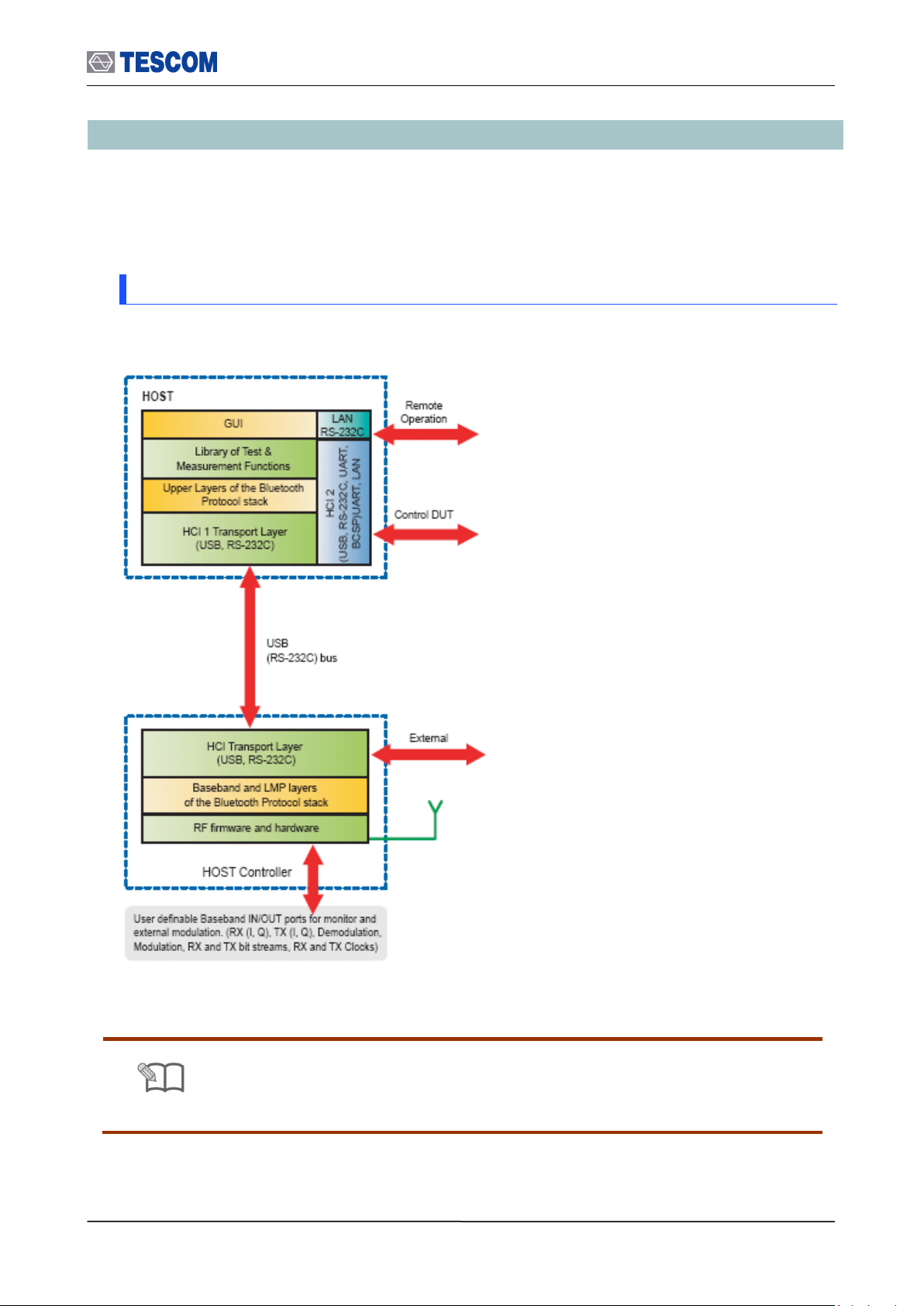

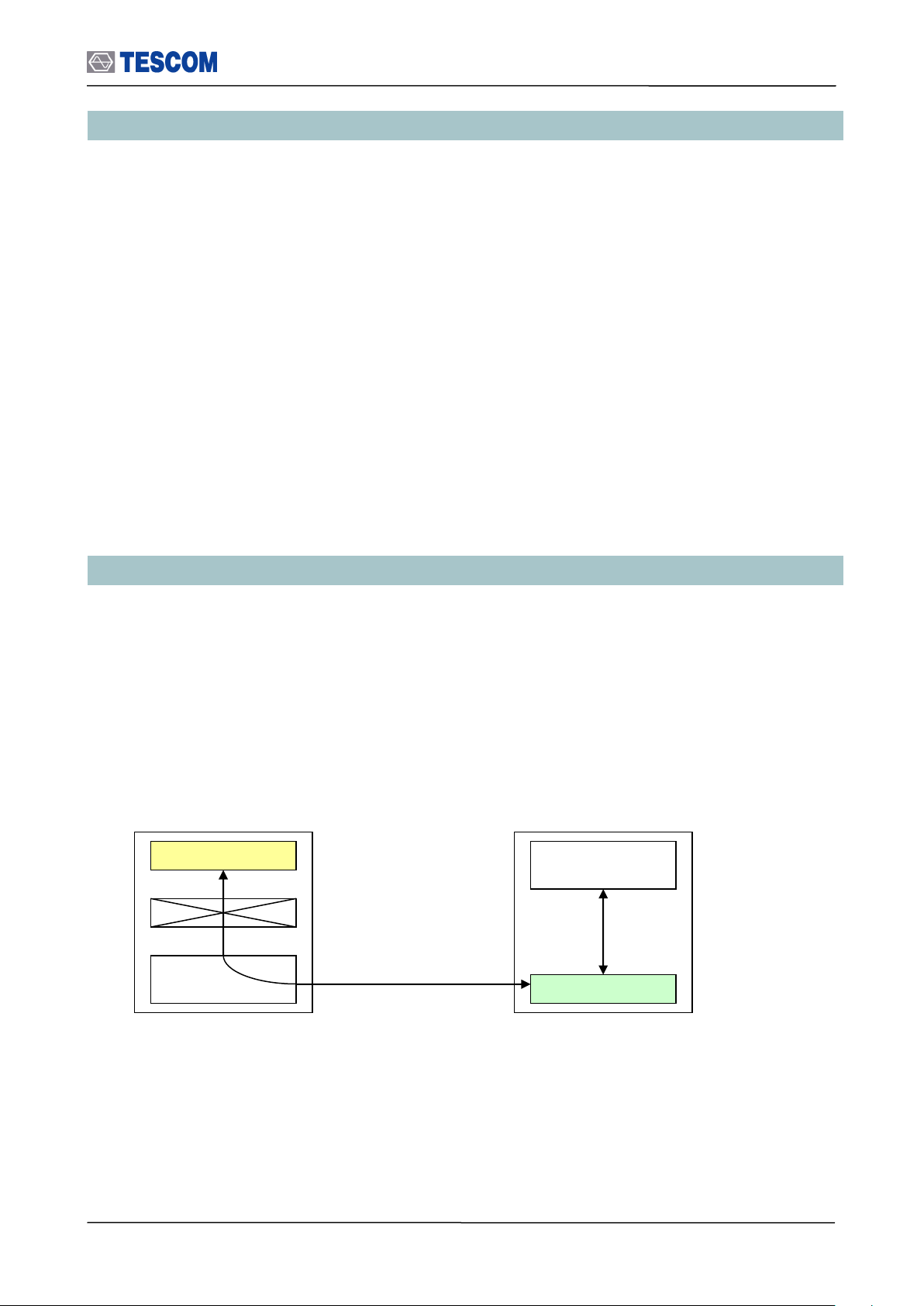

3.1.1 TC-3000C System Architecture

TC-3000C is made up of two main blocks,

a RF/DSP module and host CPU module,

and is connected by a host controller

interface (HCI) that is identical to

Bluetooth system architecture. The

RF/DSP module provides an RF interface

to DUT, performs physical measurements

and manages the Bluetooth link. The

internal host CPU (PC), which runs on

Linux platform, takes care of user

interface (UI) functions including display,

key input and I/O controls for RS-232C,

USB, LAN and other standard peripheral

devices. The adoption of open OS

minimizes unnecessary constraints on

system optimization. This simple, elegant

system architecture takes advantage of

both power of DSP and convenience of

PC.

25

Page 26

3.1 Overview

Note

When TC-3000C is turned on, the instrument does not return to the power-off

condition –except for the Test Cases parameters which were saved - but

recalls the settings from the most recently saved memory location (STORE

Number).

TC-3000C

Bluetooth Tester

S/N:

S/W Options:

OK

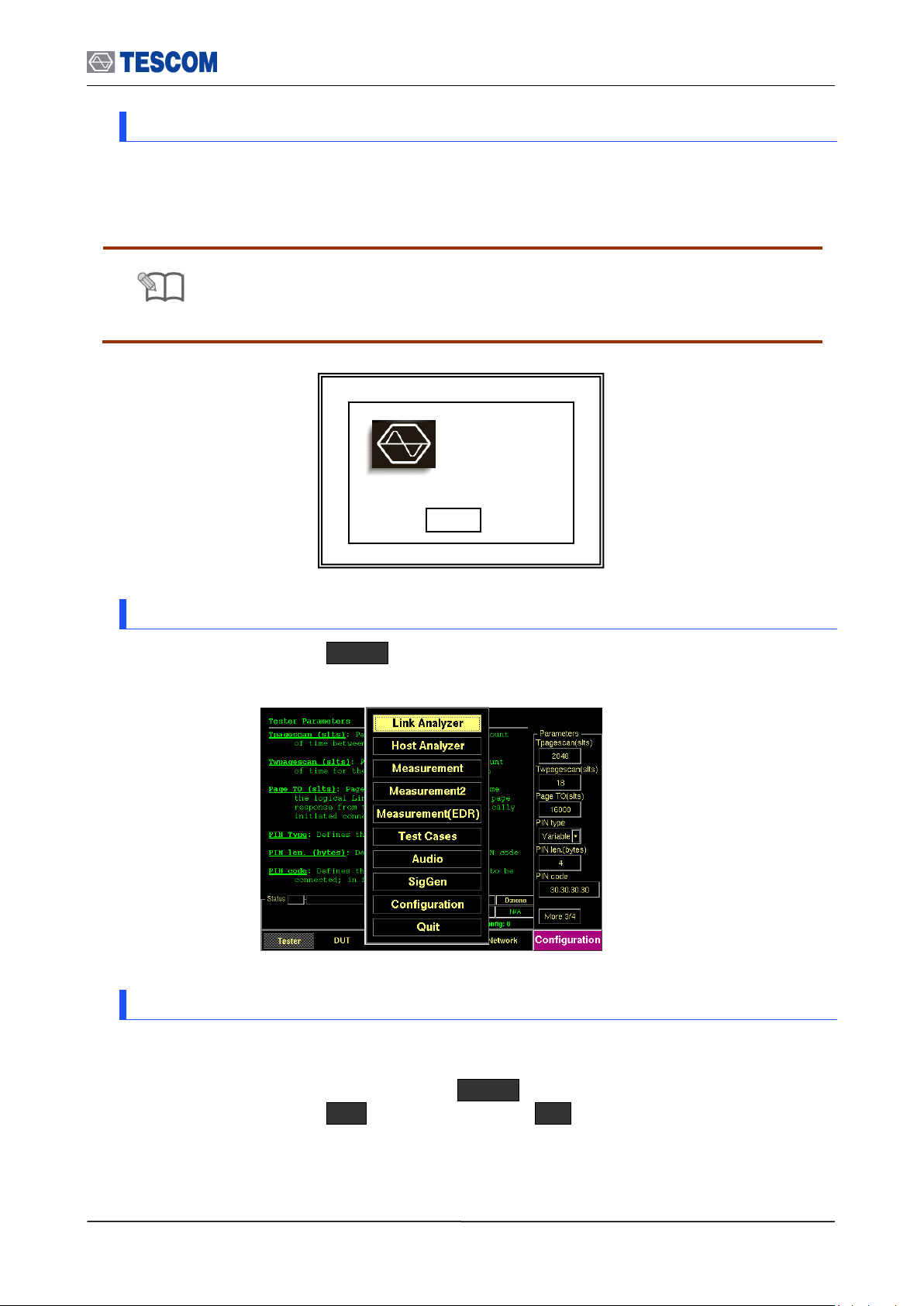

3.1.2 Start-up Screen

When power on, the start-up screen will be displayed after booting process and will change

to initial screen 10 seconds later. Pressing any key will change the display immediately.

3.1.3 Shutdown Screen

In order to power off, press Menu select “Quit” from the pop-up menu on the screen

press “Yes” . Or you can turn off the TC-3000C using the front panel soft switch

3.1.4 Display Color Scheme

The display color option allows you to change the display color scheme for the front panel

display. To change the color scheme, press Menu select “Configuration” from the popup menu on the screen M4 ( “Peripherals” ) F5 ( “color scheme” ) select the

color scheme which you want to use.

26

Page 27

3.1 Overview

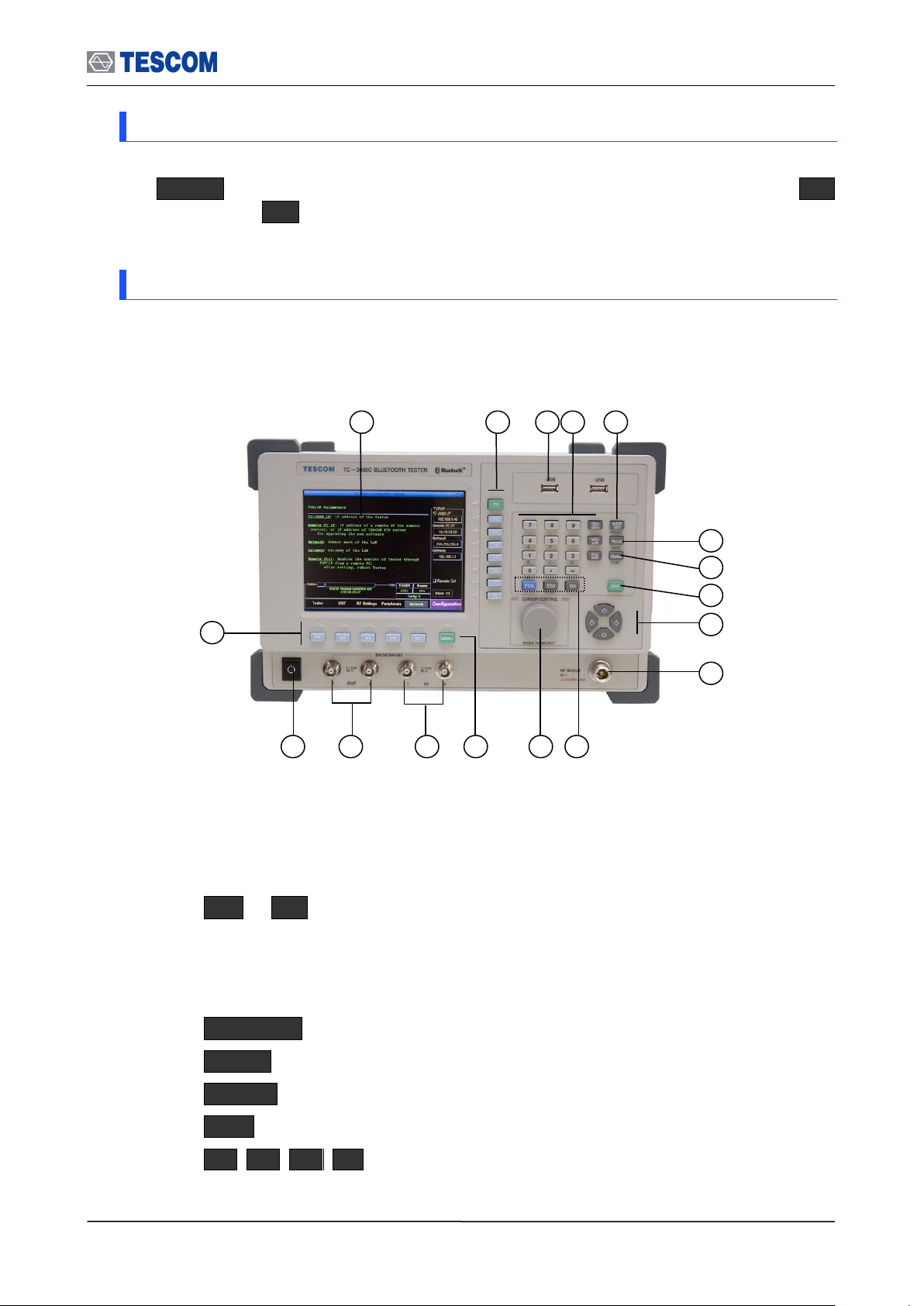

1 2 3 4 5

6 7 8 9 10

17

13

14

15

11

12

16

3.1.5 System Information

In order to check system information of TC-3000C,

press Menu select “Configuration” from the pop-up menu on the screen M4

( “Peripherals” ) F8 ( “System Info” ) Verify: Serial Number, Version, Core Version,

DSP Version, FPGA Version, Software Options

3.1.6 Front Panel View

The front panel controls and connector are illustrated below; and the detailed descriptions

are as follows:

[Figure 2] Front Panel View

① Color Graphic LCD

The LCD display color is configured in the Peripherals of the Configuration

screen.

② F1 ~ F8 : Soft keys. Soft keys select submenus.

③ USB port : It is used for testing the BT USB Dongle, storing the test result,

capturing screen or system upgrade.

④ Data Input keypad. Provides the means for entering data.

⑤ INCR SET : Defining data increasing step. The default value is 1.

⑥ Recall : Recall stored data.

⑦ Marker : Enable a line-shaped marker on the Measurement screen to activate.

⑧ ENT : It is used to enter your chosen function or accept input.

⑨ : Cursor movement.

27

Page 28

3.1 Overview

Note

Purpose of the front panel USB port

① for Bluetooth USB Dongle testing

② for copying test case report file, screen capture or firmware upgrade

③ When the USB memory stick is used, it should be used after the device is

recognized (2 ~ 3 sec).

Some USB memories could not be recognized. (For normal operation, the

USB device should support LINUX OS and composed only one drive.)

④ If the USB memory were removed during Reading/Writing operation, the

TC3000C could be shut down. Previous operation should be finished before

doing next operation.

⑩ RF IN/OUT Port: N type RF connector

⑪ BS : Back space key

ESC : Return to the previous state.

FCN : Access second functions

⑫ Rotary knob: Move cursor. Push to accept data or function such as ENT .

⑬ MENU : Main menu key. When this key is pressed the pop-up menu is

displayed on the center of screen. This menu presents seven options including

main functions.

⑭ Baseband Input Ports: I-Rx, Q-Rx, I-Tx, Q-Tx, Rx-bit, Tx-bit. For using

external baseband signals. It is used for stereo headset test using A2DP

⑮ Baseband OUT ports: Rx (I, Q), Tx (I, Q), Demodulation, Modulation, RX and

TX bit streams, RX and TX Clocks. It is used for stereo headset test using A2DP.

16

○

Soft switch.

17

○

M1 thru M8 : Soft keys. Soft keys select test screen.

Second Functions (Blue Label Functions)

Additional functions available by FCN key.

FCN INCR SET (= PRESET): Preset the instrument to a predefined state.

FCN Recall (= SAVE): Store the current instrument settings into memory (1 to 7)

FCN Marker (= STEP): Defining moving step of the line markers in the measurement

screens.

FCN 0 , 1 , 2 , 3 , 4 , 5 (= A,B,C,D,E,F) : It is used when you enter

hexadecimal data.

FCN ESC (=Screenshot): Capturing current displayed screen.

28

Page 29

3.1 Overview

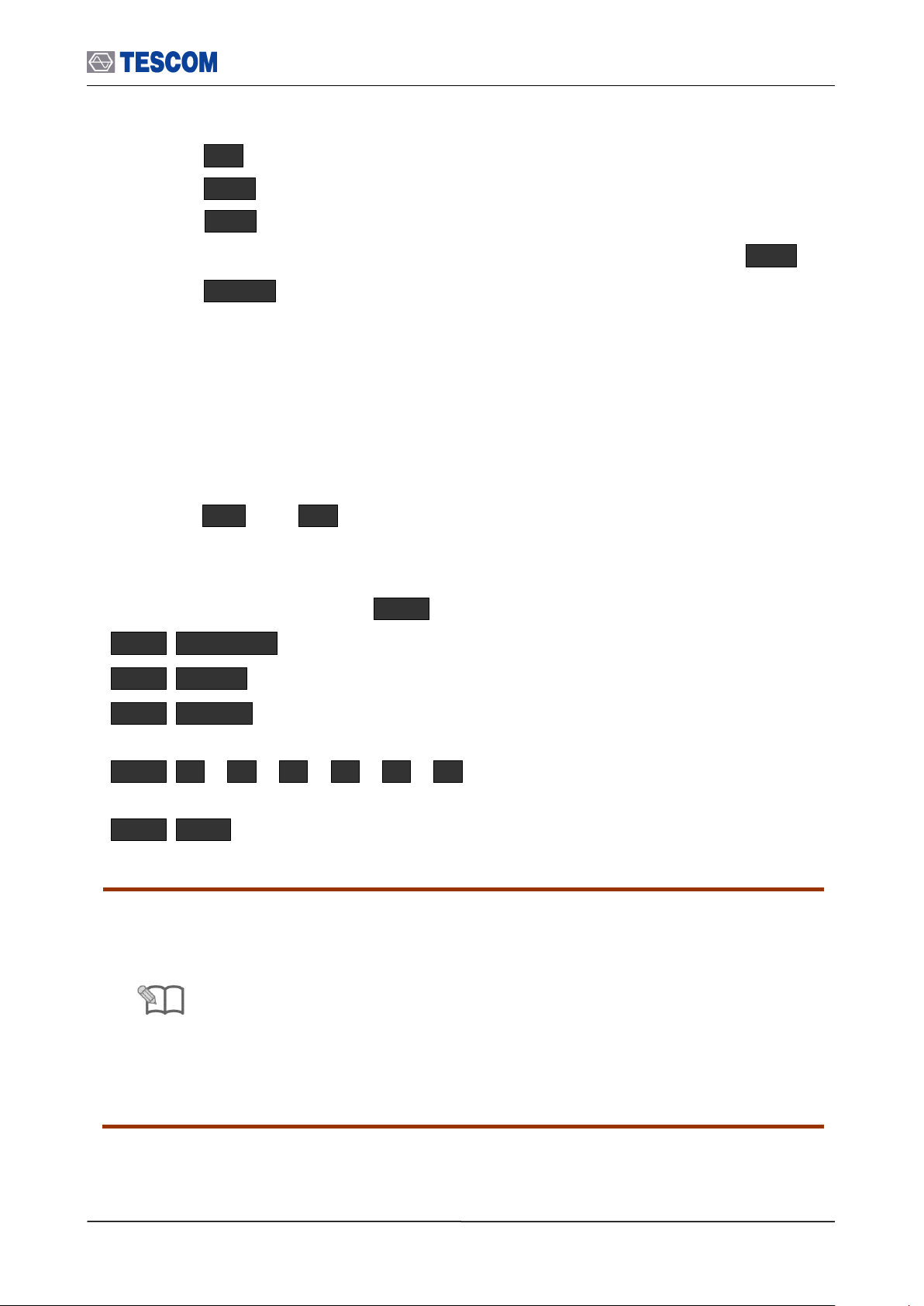

1 3 2

4

6

9

12

7

5

11

10

8

3.1.7 Rear Panel View

The Rear panel connectors are illustrated below; detailed descriptions are as follows:

[Figure 3] Rear Panel View

① RS-232C: This port is a serial port to Host Controller.

② RS2/UART2/BCSP2: This port is a RS2/UART2/BCSP2/ port to Host.

③ EXT 10 MHz: This port is an external 10 MHz reference signal.

④ Power switch

⑤ AC Power Input: 100-240 VAC, 50/60 Hz

⑥ Emergency Firmware download switch: For upgrading firmware when Host

Controller doesn’t boot. This switch is not used after normal firmware

upgrading

⑦ Monitor connector: For using an external monitor.

⑧ RS-232C/UART 1/BCSP1 connector: This port is the first serial port to Host.

It can be used for the remote control.

⑨ LAN connector

⑩ USB : This port is a USB port to Host.

⑪ USB : This port is a USB port to Host.

⑫ USB : This port is a USB port to Host controller. It is for the remote control

with DLL.

29

Page 30

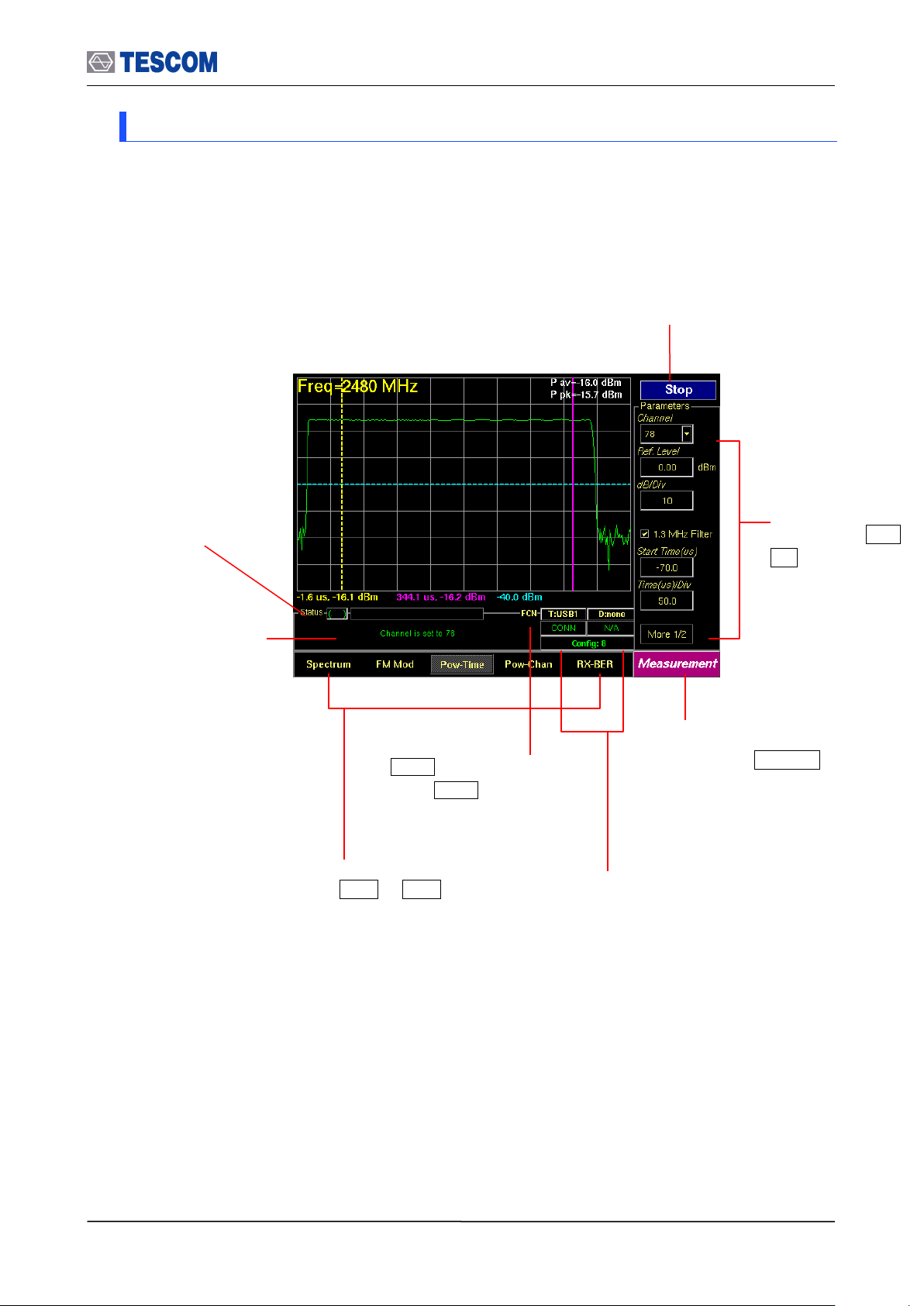

3.1 Overview

Submenus related

to soft keys, F1 ~

F8

Status window: Some

messages are displayed

to help you to understand

current status easily.

FCN Key Indicator:

When FCN key is pressed

the indicator is brightened.

Test progress

Indicator:

This progressive bar

indicates the status of

test proceeding.

Screen menus related to

soft keys, M1 ~ M5

Main function menu related

to hard key, MENU . This

menu always displays the

selected function.

Start/Stop: When this menu is pressed

the tests will run once. When pressed

again while the tests are running, the

testing will stop.

Link Status Indicator: It presents link

status, a HCI type that is connected to

Host and the number of current

configuration.

3.1.8 Display Screen

30

Page 31

3.1 Overview

Link Analyzer

Measurement

Test Cases

Audio

Configuration

Link

Pkt Info

LMP

HCI

Baseband

Pressing MENU key

Spectrum

FM Mod

Pow-Time

Pow-Chan

RX-BER

RF

SCO Link

Audio Test

Audio Spec

Audio Sweep

FSK

Tester

DUT

RF Settings

Peripherals

Network

Submenus

Submenus

Submenus

Submenus

Submenus

Submenus

Host Analyzer

Link

L2CAP

RFCOMM

(AVDTP)

SDP

PROFILE

(AVRCP)

Submenus

Measure(EDR)

BER Search

Submenus

Measurement2

Constel

TX-BER

DEVM

Submenus

SigGen

3.1.9 Menu Structure

TC-3000C has tree-like structure. 9 main functions have subcategories (screen menus)

respectively. Each subcategory has several submenus for setting up test parameters.

31

Page 32

3.1 Overview

Main Function ( MENU key)

Test Screen ( MI ~ M5 )

Link Analyzer

Basic Actions – Discover/Connect/Discoverable

Tx/Rx Packet Information – Inquiry/Page/Channel

LMP Messages

HCI Commands / Events

Baseband Packets Analysis

Host Analyzer

Basic Actions – Discover/Connect/Pairable

L2CAP

RFCOMM (AVDTP)

SDP

PROFILE (AVRCP)

Measurement

Spectrum

FM Modulation

Power vs. Time

Power vs. Channel

RX-Bit Error Rate (RX-BER)

Measurement2

BER Search

Measurement(EDR)

Constellation

TX-BER

DEVM

Test Cases

RF (13 test cases, “Quick Test Function”, BER/FER, 7

EDR test cases for EDR option )

RF (7 test cases for BT LE option)

Audio

SCO Link / SCO Loopback Test

Audio Test

Audio Spectrum

Audio Sweep

RF Signal Generator

FSK Modulation

Configuration

Tester

DUT

RF Settings

Peripherals

Network

3.1.10 Access Main Functions

The TC-3000C Bluetooth Tester contains key RF and protocol test & measurement functions

in one package. Controls for these functions are arranged on several screens. The Link

Analyzer, Host Analyzer, Measurement, EDR Measurement, Audio Test, Signal Generator,

Test Cases, and Configuration screens contain most of the functions and fields associated

with testing Bluetooth receivers and transmitters. The screens are accessed using the

MENU key and soft keys, M1 ~ M5 .

[Table 3] Access Main Functions

32

Page 33

3.1 Overview

Field

Unit

Frequency

MHz, kHz, GHz

Power

dBm, uW, mW

3.1.11 Data Input and Change

1) Press soft key related to the desired input menu.

2) The cursor indicates data input position.

3) Change value with Rotary Knob or keys. Or enter data with Key Pad.

4) Push Rotary Knob or ENT to confirm the inputted value.

5) BS (Back Space) key be used, if necessary.

6) Many menus display a list of choices when selected. Select a new setting from the

list.

3.1.12 Enter and Change the Unit-of-Measure

When the unit is implied, the current unit is used. For example; if the present Reference

Level is 0dBm, and you want to change it to 10 dBm, you would enter this sequence:

1 0 ENT

When the unit is specified, the units change to whatever you specify. For example; if the

present Reference Level is 0 dBm, and you want to change it to 10 mW, you would

enter this sequence:

1 0 mW

To change the present unit-of-measure, position the cursor in front of current unit and

press the key labeled with the desired unit

Available units:

3.1.13 Interaction Between Screens

Some menus operate globally; changing the setting in any screen automatically changes

that setting in all screens where it is available. Test Mode is an example of this menu type.

Ex) Configuration: DUT: Test Mode: Transmitter MEASUREMENT: Spectrum: Test

Mode: Transmitter MEASUREMENT: FM Modul.: Test Mode: Transmitter

MEASUREMENT: Pow-Time: Test Mode: Transmitter MEASUREMENT: PowChan: Test Mode: Transmitter Link Analyzer: LINK: Test Mode: Transmitter

3.1.14 Tool Tips

Throughout the GUI, tool tips provide useful information.

To display a tool tip, press FCN and Soft keys related to a menu. The tool tip

disappears when any key is pressed.

33

Page 34

3.1 Overview

TC-59XX Shield Box

Probe/ Connector

HCI

Set Test Mode

TC-59XX Shield Box

Set Test Mode

RF Coupler

HCI

HCI

Set Test Mode

TC506X

TEM Cell

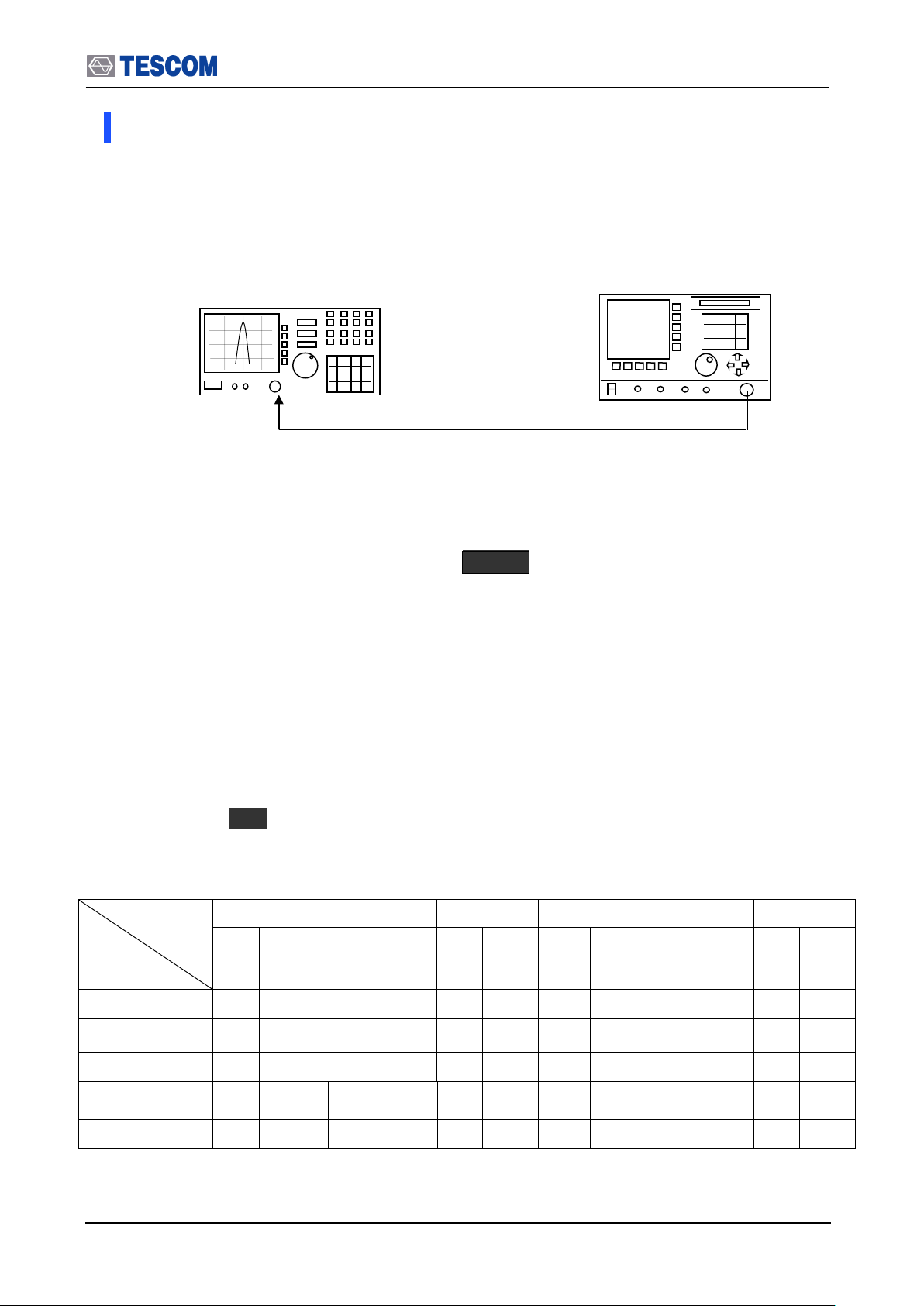

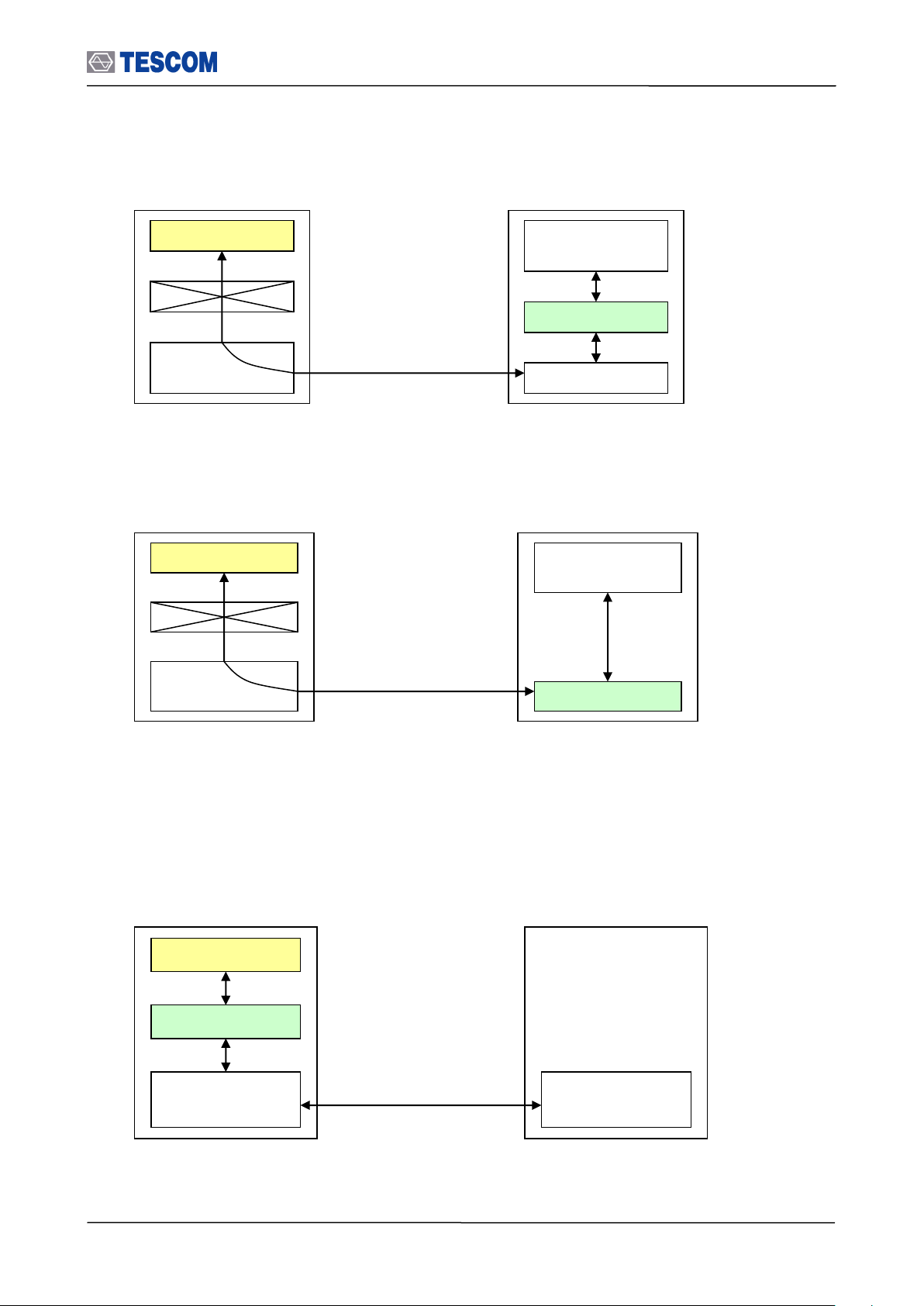

3.1.15 Typical Test Configurations

Diagrams below are an ideal set up for testing Bluetooth devices. Since most

Bluetooth devices use sealed antenna due to their size, final RF tests must be done

over the air (OTA). In case of module or PCB testing, contact probes may also be

used. In either case, testing must be completed under an adequately RF isolated

condition with reliable RF coupling.

If the DUT has a standard HCI, the TC-3000C can communicate with the DUT via

USB(HCI) of TC-3000C for control DUT.

[Figure 4] Typical Test Configurations

34

Page 35

3.2 Basic Operation Procedure

Caution

To maintain regulatory compliance, OTA (over to air) connection to the DUT

must be carried out within an adequately RF isolated environment with reliable

RF coupling.

Caution

Before running a test the DUT must be initialized so that it is Inquiry/Page

scanning. If test mode is not enabled, the TC-3000C will use null packet mode

for measurement and test.

3.2 Basic Operation Procedure

The following steps should be formed before other operation procedure to take

measurements.

3.2.1 Step 1. Getting Started

1. Make sure the connections have been made between HOST and HOST Controller on

the rear panel of the TC-3000C via RS-232C or USB.

2. Connect the RF port of theTC-3000C to the DUT using RF cable or the 2.4GHz

antenna.

3. If DUT has the HCI port, connect the DUT to the USB ports on the front panel of the

TC-3000C.

4. Set DUT to the Inquiry/Page scanning mode with test mode enabled. If the DUT is

connected to the TC-3000C by using a standard USB(HCI), you don’t need to do this

step because the TC-3000C can control the DUT automatically.

5. Press the soft switch (Item #16 in the figure on page 24) on the front panel. After the

system booting process, the TC-3000C display the Start-up screen that is going to be

changed to initial test screen 10 seconds later.

6. Make sure the “HCI Port” of DUT configuration: Press Menu Select

“Configuration” from the pop-up menu on the screen M2 (DUT) F3 (HCI

port). Make sure the “HCI Port” of DUT configuration is correct for the HCI port of the

TC- 3000C in use. If the DUT is not connected to the HCI port of the TC-3000C, “None”

must be selected.

35

Page 36

3.2 Basic Operation Procedure

Caution

When TC-3000C is turned on, the instrument always recalls the settings from

the most recently saved register. But if the TC-3000C can’t find any DUT in

the preset HCI port while the TC-3000C is turned on, “HCI Port” of DUT

configuration is set to “None”..

7. Make sure the “DUT Type” of DUT configuration: Press Menu Select

“Configuration” from the pop-up menu on the screen M2 (DUT) F2 (DUT

Type). Make sure the “DUT Type” of DUT configuration is correct.

8. Input the Path Loss: Press Menu Select “Configuration” from the pop-up menu

on the screen

M2 (DUT) F7 (Path Loss). Input the path loss value from the TC-3000C to the

DUT.

9. Select the Test mode (Transmitter, Loop back or Null Packet): Press Menu

Select “Configuration” from the pop-up menu on the screen M2 (DUT) Press F8

three times for “More 4/4” menu Press F2 and select a test mode from the drop

down menu.

36

Page 37

3.2 Basic Operation Procedure

HCI Port: The HCI port on the rear

panel of the TC-3000C, which the

DUT is connected.

Path Loss: The path loss between

the TC-3000C and the DUT.

More 4/5: Press F8 in sequence to

access “More 4/5” screen.

Test Mode: You can choose Loopback or Transmitter or

Null Packet. Null Packet mode is used to test DUT that

has no test mode support. In this mode, the TC-3000C

uses the packets without payloads and measurements are

not performed in accordance with the Bluetooth Test

specification and some test cases can’t be carried out. A

NULL packet has no payload but can be used for power,

initial frequency, and spectrum without having to activate

test mode.

PIN Type: Fixed or Variable

PIN len. (Byte): Length of PIN

code in bytes

PIN code

DUT Type: Select DUT Type from

General, BT and BT LE

10 Input the PIN code: In case DUT requires authentication to connect, press Menu

Select “Configuration” from the pop-up menu on the screen M1 (Tester)

Press F8 two times for “More 3/5” menu. Configure PIN type, PIN length, and PIN

code.

11 If you want to configure the TC-3000C, the DUT, and RF conditions more in detail,

press Menu Select “Configuration” from the pop-up menu on the screen.

37

Page 38

3.2 Basic Operation Procedure

Note

Skip pairing by using Link Key

Bluetooth encryption is a multi-staged process that provides devices with secure,

encrypted communications. The process begins with a device prompting the user

for a Personal identification Number (PIN). When the right PIN is entered, the DUT

begins an encryption setup dialogue with the TC-3000C. At the beginning of this

dialogue, the DUT and the TC-3000C agree on a Link Key. A Link Key is a 128-bit

value that the two devices use for authentication. When the DUT and TC-3000C

agree on a Link Key, the DUT then negotiates for the transfer of the Encryption Key

from the TC-3000C. The Encryption Key is used to encrypt and decrypt messages.

If you know the Link Key, you can skip the process with PIN code and reduce the

test time. To enter Lin key, press Menu Select “Configuration” from the pop-

up menu on the screen M1 (Tester) Press

F8 three times for “More 4/6” menu. Press F6 , to check Skip Paring menu

Press F7 and enter Link key.

Skip the inquiry procedure

The inquiry procedure enables a Bluetooth Device to discover which units are in

range, and what their device addresses and clocks are. It take 5 ~ 10 seconds to

complete. If you already know the BD address of DUT, you can skip the inquiry

procedure. To enter BD address, press Menu Select “Configuration” from the

pop-up menu on the screen M2 (DUT) Press F8 one times for “More

2/4” menu. Press F2 , to uncheck “Inq. Supported” menu Press F8 again

for “More3/4” menu Press F2 and enter the BD address.

38

Page 39

3.3 Operation Procedure (Link Analyzer)

Note

If you want to view higher protocol data; L2CAP, RFCOMM, SDP, and Profile,

use the Host Analyzer screen to create connection to DUT. In the Link Analyzer

screen, higher protocols do not use to make a connection to DUT.

Note

“ 3.2 Basic Operation Procedure” should be performed before following steps.

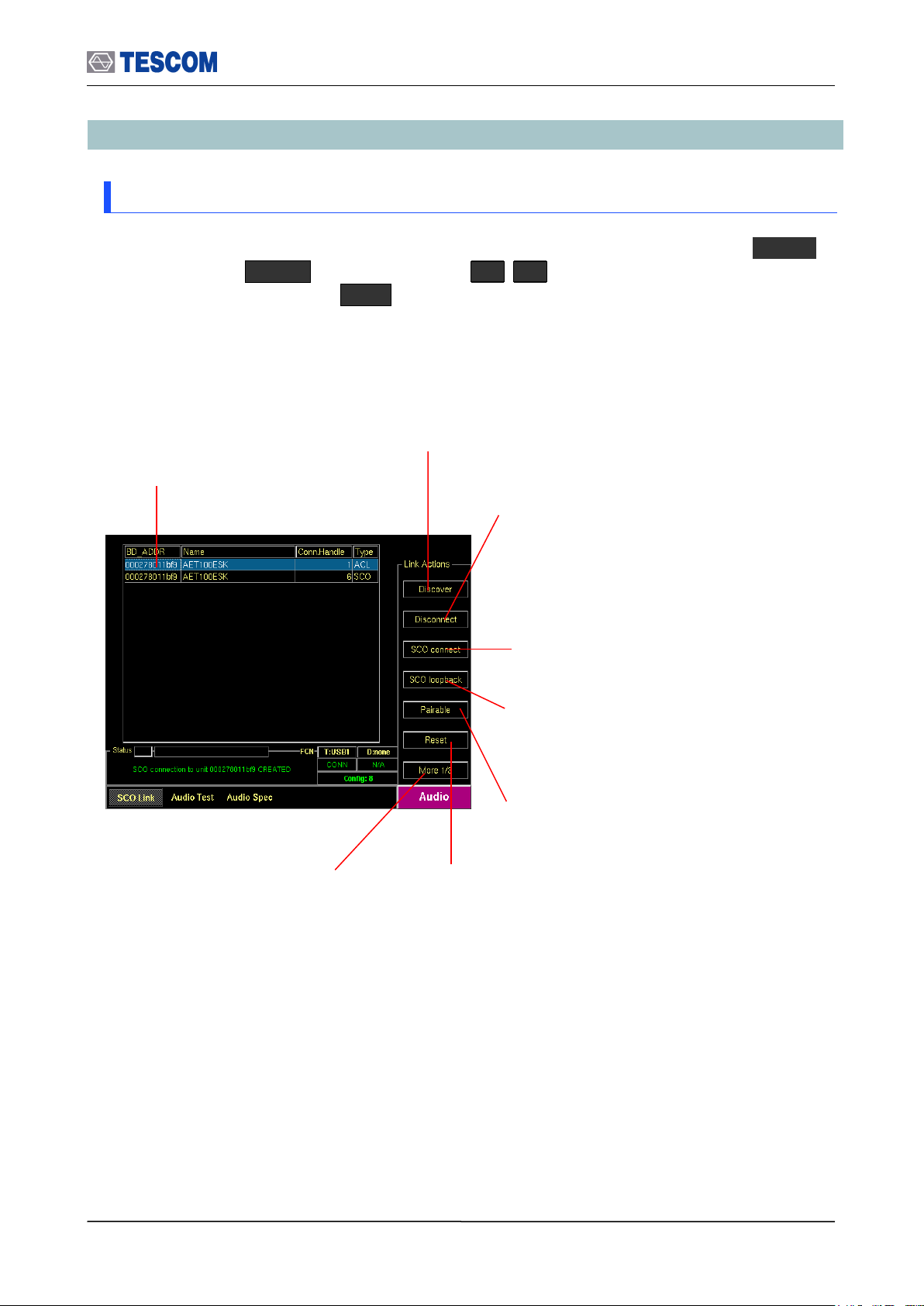

Show Devices Found: This

window display details about the

found devices.

Discover: Searches for all Bluetooth

devices that are in range and in

Inquiry Scan Mode through the Inquiry

procedure.

Connect/Disconnect: Creating connection to

highlighted DUT on the screen through the Page

procedure or disconnecting. This menu is

displayed when a DUT is discovered and listed on

the screen. If the highlighted DUT is connected,

this menu is changed to “Disconnect”.

SCO connect: Create SCO connection

to a highlighted DUT on the screen.

Discoverable: Enables the TC-3000C to

the Inquiry/Page Scan Mode.

Reset: Resets the TC-3000C. In case

DUT is connected to the TC-3000C with

HCI, the DUT is reset simultaneously.

Change submenus: For setting

up Inquiry, Page, and test mode

parameters.

Set Test Mode: Activate Baseband link

with a DUT in test mode

3.3 Operation Procedure (Link Analyzer)

3.3.1 Step 2. Creating Connection to DUT

1. Selecting the Link Analyzer Screen: Link Analyzer screen can be accessed by pressing

the Menu hard key. Press Menu Rotary Knob or Select “Link

Analyzer” from the pop-up menu on the screen Press ENT .

39

Page 40

3.3 Operation Procedure (Link Analyzer)

Note

If you want to edit test configuration in detail, you can access to configuration

menus by pressing F8 in sequence. These menus operate globally; changing the

settings in this screen automatically changes that setting in all screens where it is

available. Refer to “3.9 Configuration”

Parameters

Range

Default

Descriptions

Inq. TO (1.28s)

1 ~ 48

48

Refer to Tester in Configuration

Page TO (slts)

1 ~ 65535

16000

Refer to Tester in Configuration

# responses

0 ~ 16

1

Refer to Tester in Configuration

HCI TO (ms)

1 ~ 65535

2000

Refer to Tester in Configuration

Parameters

Range

Default

Descriptions

Access Type

Discoverable

Connectable

Full Access

Full Access

Accessibility to Tester as a slave

T inqscan (slts)

18 ~ 4096

2048

Refer to Tester in Configuration

T winqscan (slts)

18 ~ 4096

18

Refer to Tester in Configuration

T pagescan (slts)

18 ~ 4096

2048

Refer to Tester in Configuration

T wpagescan (slts)

18 ~ 4096

18

Refer to Tester in Configuration

Scan TO (ms)

10000 ~

600000

Inquiry/Page Scan Timeout of Tester

2. Setting up # Inq. Response: You can set the Inquiry to end after the “# Inq.

Responses” (1 to 16). If there are several DUT that have to respond to Inquiry, set the

number of Inquiry response to more than 1. But if there is only one DUT, set the

number of Inquiry response to 1 for testing speed. TC-3000C will stop discovering

when receives this number of inquiry responses or the Inquiry Timeout is expired.

Press F8 one times for “More 2/4” menu Press F4

3. Search for DUT: Press F8 three times for “More 1/4” menu press F2 key to

search for all Bluetooth devices that are in range and in Inquiry Scan Mode through

the Inquiry procedure. If the DUT is connected to the TC-3000C through the HCI port,

the TC-3000C read the Bluetooth device (BD) address and controls the DUT directly

through USB(HCI). If you want to stop Inquiry process, press F2 key again.

4. Select a DUT: Select a DUT that you want to test in the found devices by using

Rotary Knob or

keys.

5. Connect/Disconnect: Create connection to highlighted DUT on the screen through

the Page procedure by pressing F3 . When the highlighted DUT is connected, this

menu changes to “Disconnect”. If you want make a SCO connection, press F4 .

6. Set DUT to Test Mode: Enable DUT to the test mode by pressing F5 . If DUT is not

connected, the page procedure will be performed. If there is no DUT found, the

discovering (inquiry) procedure will start first.

[Inquiry Parameters ]

[ Scan Parameters ]

[Table 4] Test Parameters Refer to DUT in Configuration.

40

Page 41

3.3 Operation Procedure (Link Analyzer)

Channel Information: This window

displays the channel traffic information.

Inquiry/Page packet information: These windows display

how many packets are received and transmitted during

Inquiry/Page/Inquiry Scan/Page Scan procedure.

Clear Screen: Clears all messages

LMP Messages: This window displays the

LMP messages exchanged between the TC3000C and the DUT.

Cursor movement functions: For

easy scrolling the messages.

Parameters window: This window

shows detail parameters about the

highlighted LMP message.

Clear screen: Resets all values to 0

TX Power: Defines TX power of the Tester

Stop Update/Restart Update: It stops or restarts

updating of the tx/rx packet information.

3.3.2 Step 3. Viewing the Recorded Data

1. Packet Information: This screen shows how many packets received and transmitted

for each packet type. To access Pkt Info screen, press M2 soft key.

2. LMP messages: This screen shows the LMP messages exchanged between the TC-

3000C and the DUT. To access LMP screen, press M3 soft key.

41

Page 42

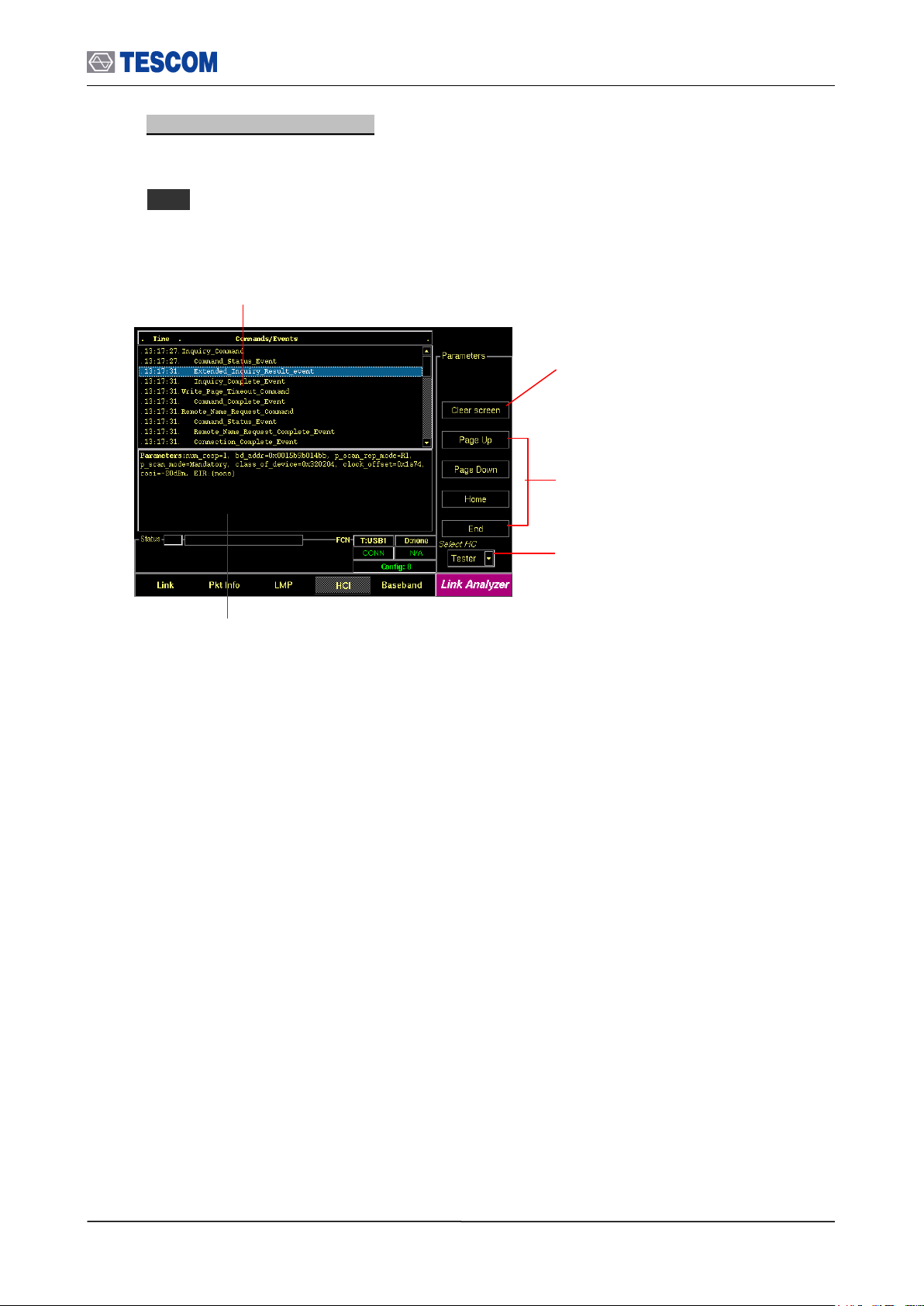

3.3 Operation Procedure (Link Analyzer)

Clear Screen: Clear all messages

Cursor movement functions: For

easy scrolling the messages

Select Source: Select TC-3000C or

DUT as the reference side to display

commands and events

Commands/Events: This window displays the

HCI commands/events sent between the TC3000C Host and Host controllers (TC-3000C and

DUT).

Parameters window: This window shows detail

parameters about the highlighted HCI commands or

event.

3. HCI commands and events: This screen shows the HCI commands and events sent

between the TC-3000C and the DUT, both from TC-3000C’s side and DUT’s side. To

access HCI screen, press

M4 soft key.

42

Page 43

3.3 Operation Procedure (Link Analyzer)

Start Record: When this menu is checked the

TC-3000C begins to record the Baseband

packets during the record time or until getting

as many packets as specified in the Num Pkts

menu. When the recording is finished this

menu is set to unchecked.

Clear Screen: Clear all packet information

Cursor movement functions: For

easy scrolling the messages

Baseband Packets: This window displays the

master clock, time offset from start of Rx slot in

hundreds nano-seconds, and the Baseband

Packets transmitted between the TC-3000C and

the DUT in hexadecimal.

Record time: The TC-3000C records

the Baseband packets during this time.

“0” mean unlimited time.

Number of packets: The TC-3000C

records the Baseband packets until

getting as many packets as specified in

the menu.

Packet Mask: This menu lets you select

the packet categories for triggering.

Access code / Header / Payload

First 9 bytes represent an Access code, next

3 bytes represent a Header after FEC (only

18 bytes are meaningful. Payload starts from

13th byte.

4. Baseband Packets: This screen shows the Baseband Packets transmitted between

the TC-3000C and the DUT in hexadecimal. To access Baseband screen, press M5

soft key.

43

Page 44

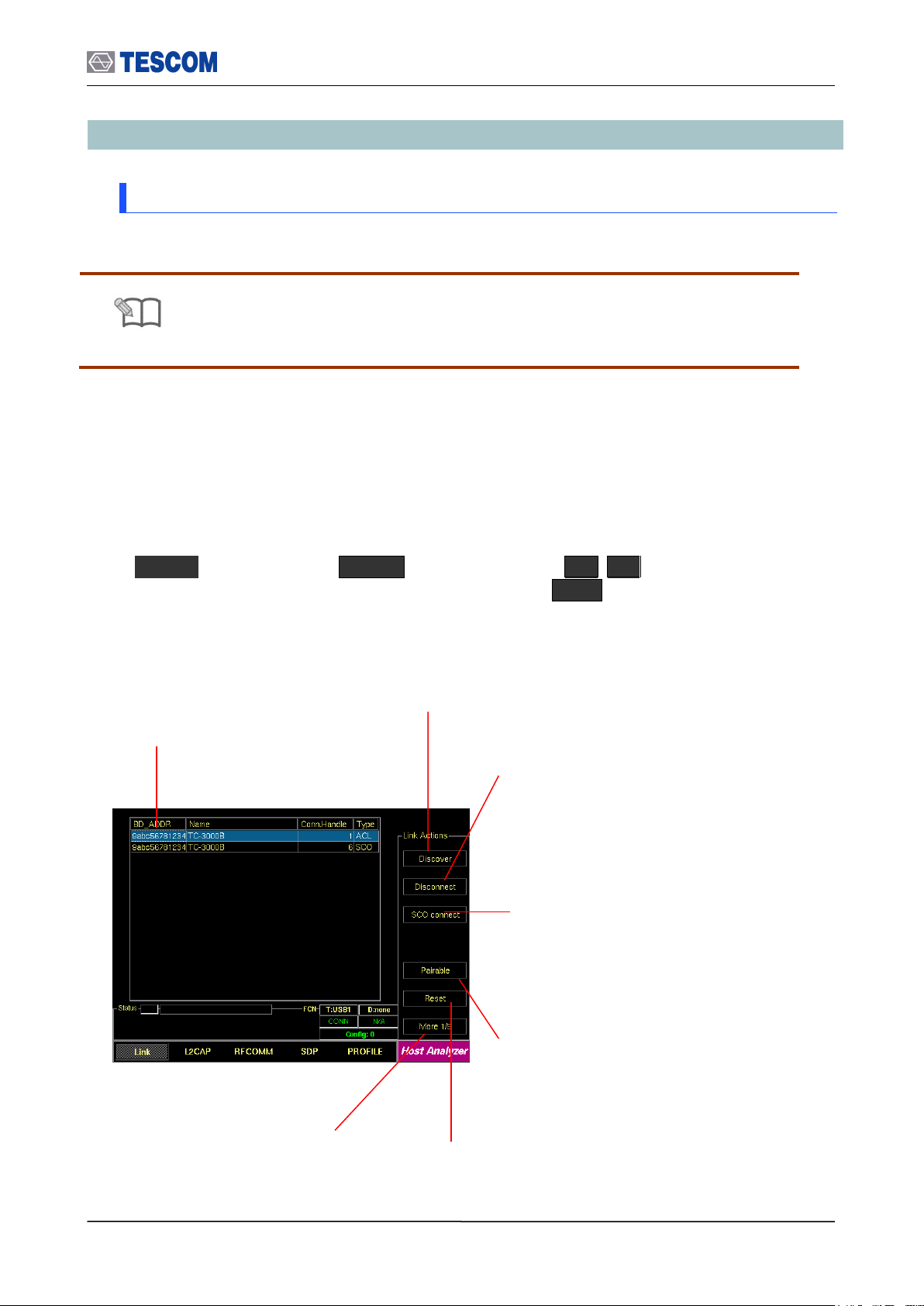

3.4 Operation Procedure (Host Analyzer)

NOTE

“ 3.2 Basic Operation Procedure” should be performed before following steps

Show Devices Found: This

window display details about the

found devices.

Discover: Searches for all Bluetooth

devices that are in range and in

Inquiry Scan Mode through the Inquiry

procedure.

Connect/Disconnect: Creating connection to

highlighted DUT on the screen through the Page

procedure or disconnecting. This menu is

displayed when a DUT is discovered and listed on

the screen. If the highlighted DUT is connected,

this menu is changed to “Disconnect”.

SCO connect: Create SCO connection

to a highlighted DUT on the screen.

Pairable: Enables the TC-3000C to be

responder in scanning and pairing

procedure.

Reset: Resets the TC-3000C. In case

DUT is connected to the TC-3000C with

HCI, the DUT is reset simultaneously.

Change submenus: For setting

up Inquiry, Page, and test mode

parameters.

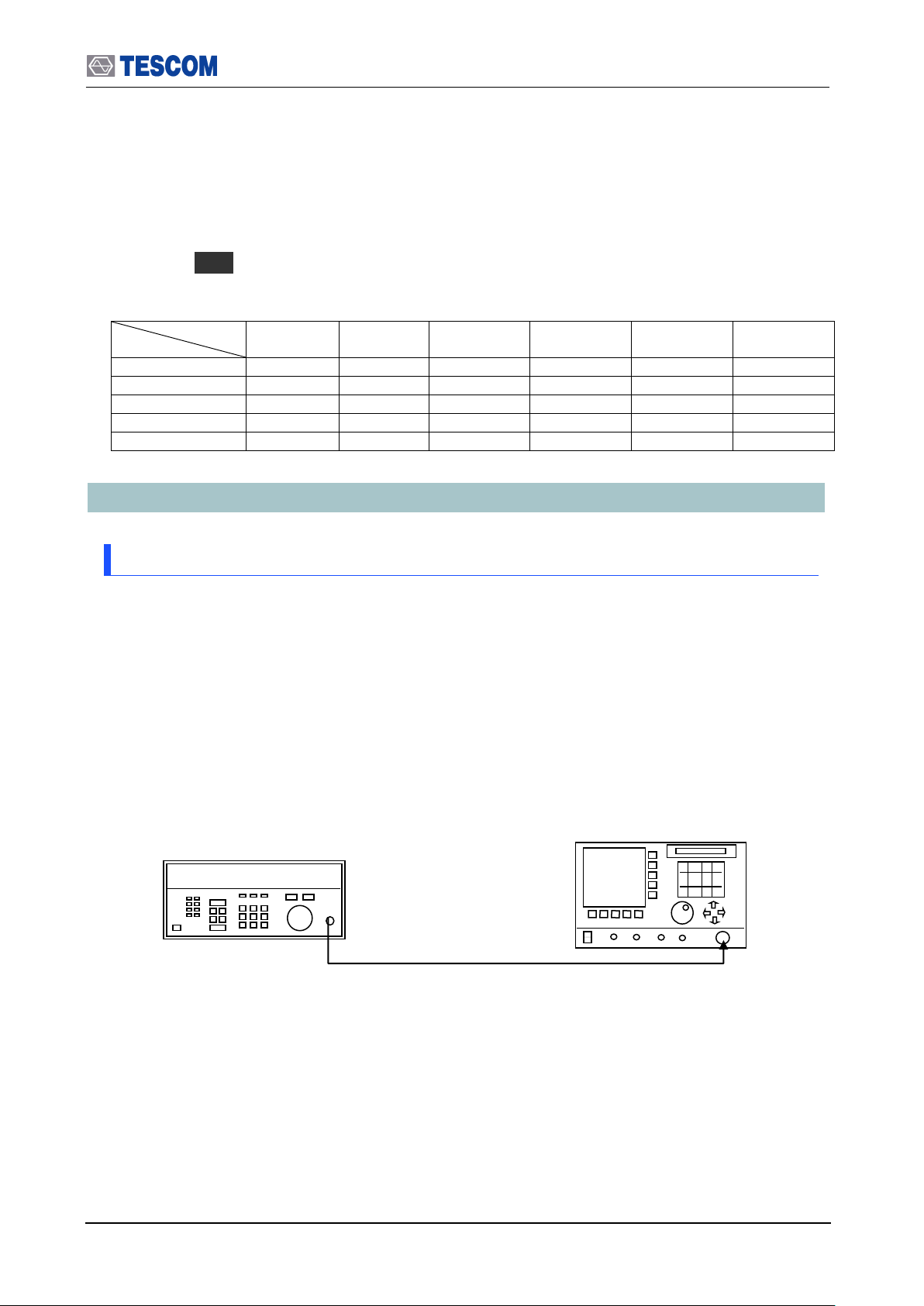

3.4 Operation Procedure (Host Analyzer)

3.4.1 Step 2. Creating Connection to DUT

Higher protocol data can be recorded in the Host Analyzer screen. In this screen, TC-3000C

also uses upper layer protocols; L2CAP, RFCOMM (AVDTP), SDP, and Profiles (AVRCP) to

make a connection to a DUT.

1. Selecting the Host Analyzer Screen: Host Analyzer screen can be accessed by pressing

the Menu hard key. Press Menu Rotary Knob or Select “Host

Analyzer” from the pop-up menu on the screen Press ENT .

44

Page 45

3.4 Operation Procedure (Host Analyzer)

Parameters

Range

Default

Descriptions

Inq. TO (1.28s)

1 ~ 48

48

Refer to Tester in Configuration

Page TO (slts)

1 ~ 65535

16000

Refer to Tester in Configuration

# responses

0 ~ 16

1

Refer to Tester in Configuration

HCI TO (ms)

1 ~ 65535

2000

Refer to Tester in Configuration

Parameters

Range

Default

Descriptions

Access Type

Discoverable

Connectable

Full Access

Full Access

Accessibility to Tester as a slave

T inqscan (slts)

18 ~ 4096

2048

Refer to Tester in Configuration

T winqscan (slts)

18 ~ 4096

18

Refer to Tester in Configuration

T pagescan (slts)

18 ~ 4096

2048

Refer to Tester in Configuration

T wpagescan (slts)

18 ~ 4096

18

Refer to Tester in Configuration

Scan TO (ms)

10000 ~

600000

Inquiry/Page Scan Timeout of Tester

NOTE

If you want to edit test configuration in detail, you can access to configuration

menus by pressing F8 in sequence. These menus operate globally;

changing the settings in this screen automatically changes that setting in all

screens where it is available. Refer to “3.9 Configuration.

2. Setting up # Inq. Response: You can set the Inquiry to end after the “# Inq.

Responses” (1 to 16). If there are several DUT that have to respond to Inquiry, set the

number of Inquiry response to more than 1. But if there is only one DUT, set the

number of Inquiry response to 1 for testing speed. TC-3000C will stop discovering

when receives this number of inquiry responses or the Inquiry Timeout is expired.

Press F8 one times for “More 2/5” menu Press F4

3. Setting up the profile type of DUT: You should define the profile type of DUT, before

beginning tests. To select the profile type, press F8 three times for “More 5/5”

menu in the Host Analyzer screen. press F2 and select the profile type of DUT.

4. Search for DUT: Press F8 for “More 1/5” menu press F2 key to search for

all Bluetooth devices that are in range and in Inquiry Scan Mode through the Inquiry

procedure. If the DUT is connected to the TC-3000C through the USB(HCI) port, the

TC-3000C read the Bluetooth device (BD) address and controls the DUT directly

through HCI. If you want to stop Inquiry process, press

F2 key again.

5. Select a DUT: Select a DUT that you want to test in the found devices by using

Rotary Knob or

keys.

6. Connect/Disconnect: Create connection to highlighted DUT on the screen through

the Page procedure by pressing F3 . When the highlighted DUT is connected, this

menu changes to “Disconnect”. To make a SCO connection, press F4 .

[ Inquiry Parameters ]

[ Scan Parameters ]

45

Page 46

[ Profile Parameters ]

Parameters

Range

Default

Descriptions

L2CAP TO (ms)

1 ~ 65535

2000

L2CAP Timeout

Defines the timeout of L2CAP commands execution

RFCOMM TO (ms)

1 ~ 65535

2000

RFCOMM Timeout

Defines the timeout of RFCOMM commands

execution

SDP TO (ms)

1 ~ 65535

2000

SDP Timeout

Defines the timeout of SDP commands execution

Profile TO (ms)

1 ~ 65535

2000

Profile Timeout

Defines the timeout of Profile commands execution

Type of Profiles

None

Headset

Handsfree

AudioGateway

Handsfree

Type of Profiles

Defines the profile type of DUT. If you select

“None”, only the lower layers of protocol are used to

make a connection with DUT in the same way as

Link Analyzer.

Gain control

Unchecked

If the DUT support the microphone and speaker

gain controls, checking this option enable TC3000C to control the volume of it.

Checking this menu causes “Speaker Volume” and

“Mic Volume” menu to be showed below.

Speaker Volume

0 ~ 15

15

Speaker Volume

Specifies the volume of DUT speaker in

consideration of the gain.

Mic Volume

0 ~ 15

15

Microphone Volume

Specifies the volume of DUT microphone in

consideration of the gain.

3.4 Operation Procedure (Host Analyzer)

46

Page 47

3.4 Operation Procedure (Host Analyzer)

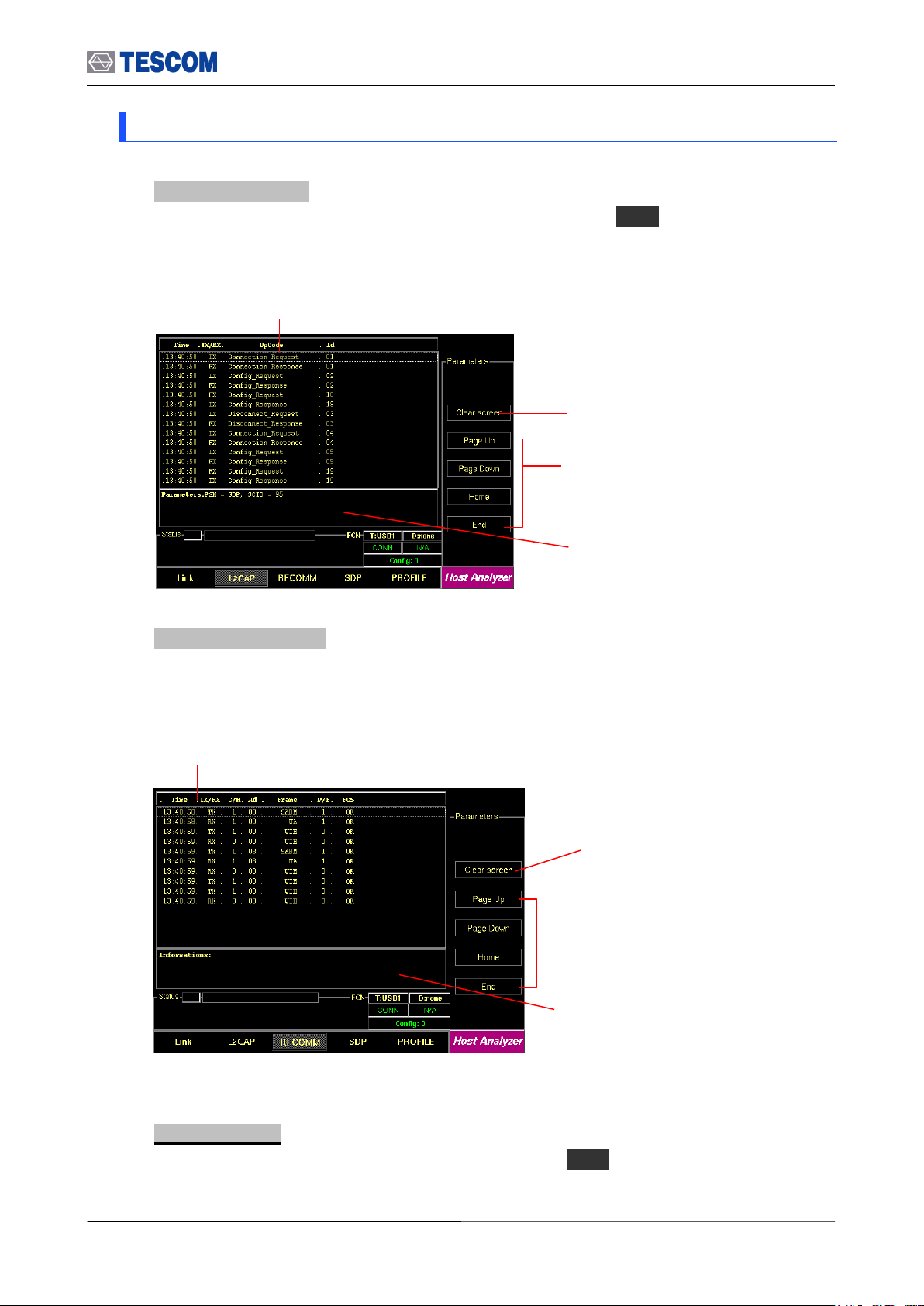

L2CAP Messages: This window displays the L2CAP

messages exchanged between the TC-3000C and the DUT.

RFCOMM Messages: This window displays the

RFCOMM messages exchanged between the

TC-3000C and the DUT.

Cursor movement functions: For

easy scrolling the messages.

Parameters window: This window

shows detail parameters about the

highlighted RFCOMM message.

Cursor movement functions: For

easy scrolling the messages.

Parameters window: This window

shows detail parameters about the

highlighted L2CAP message.

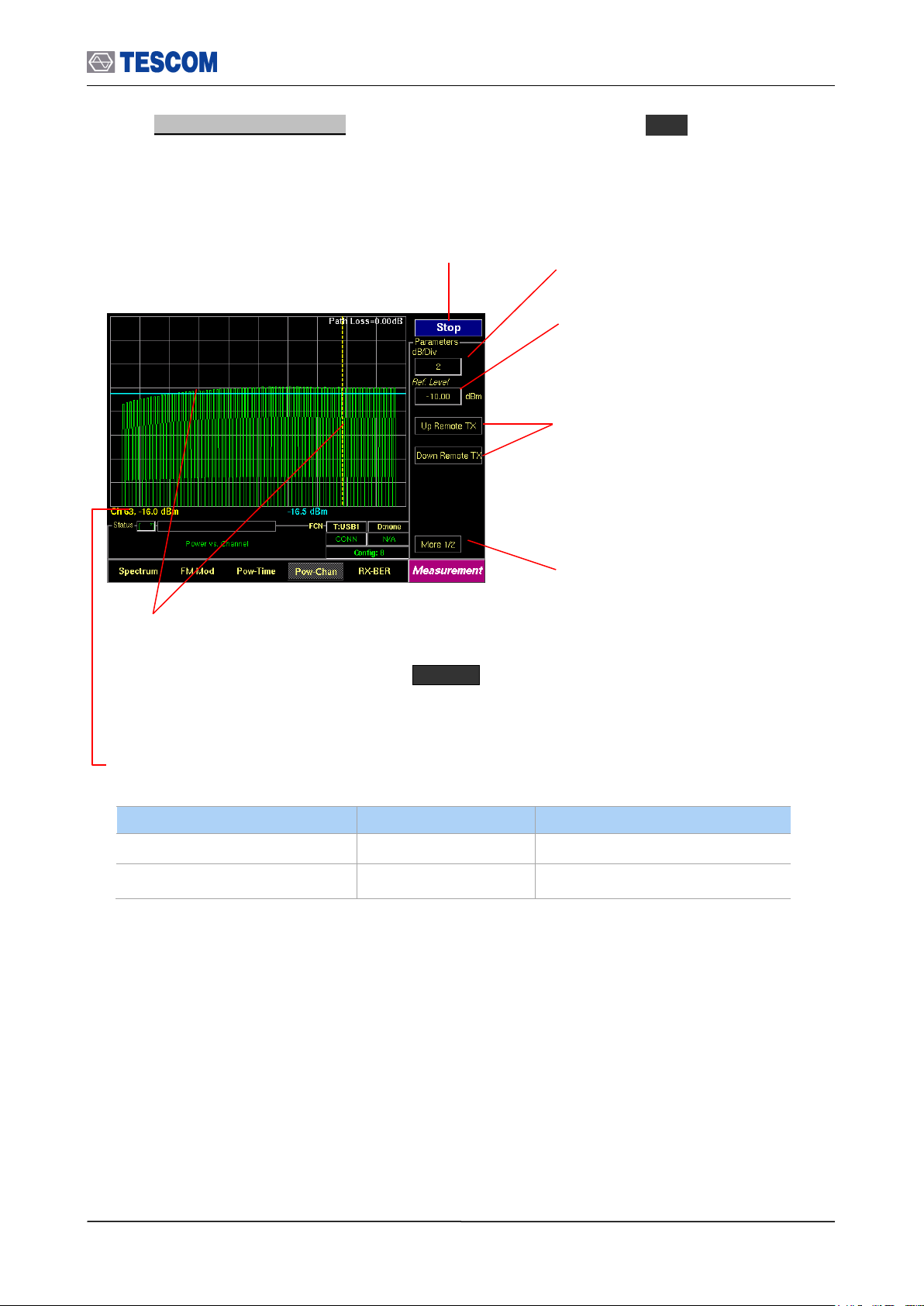

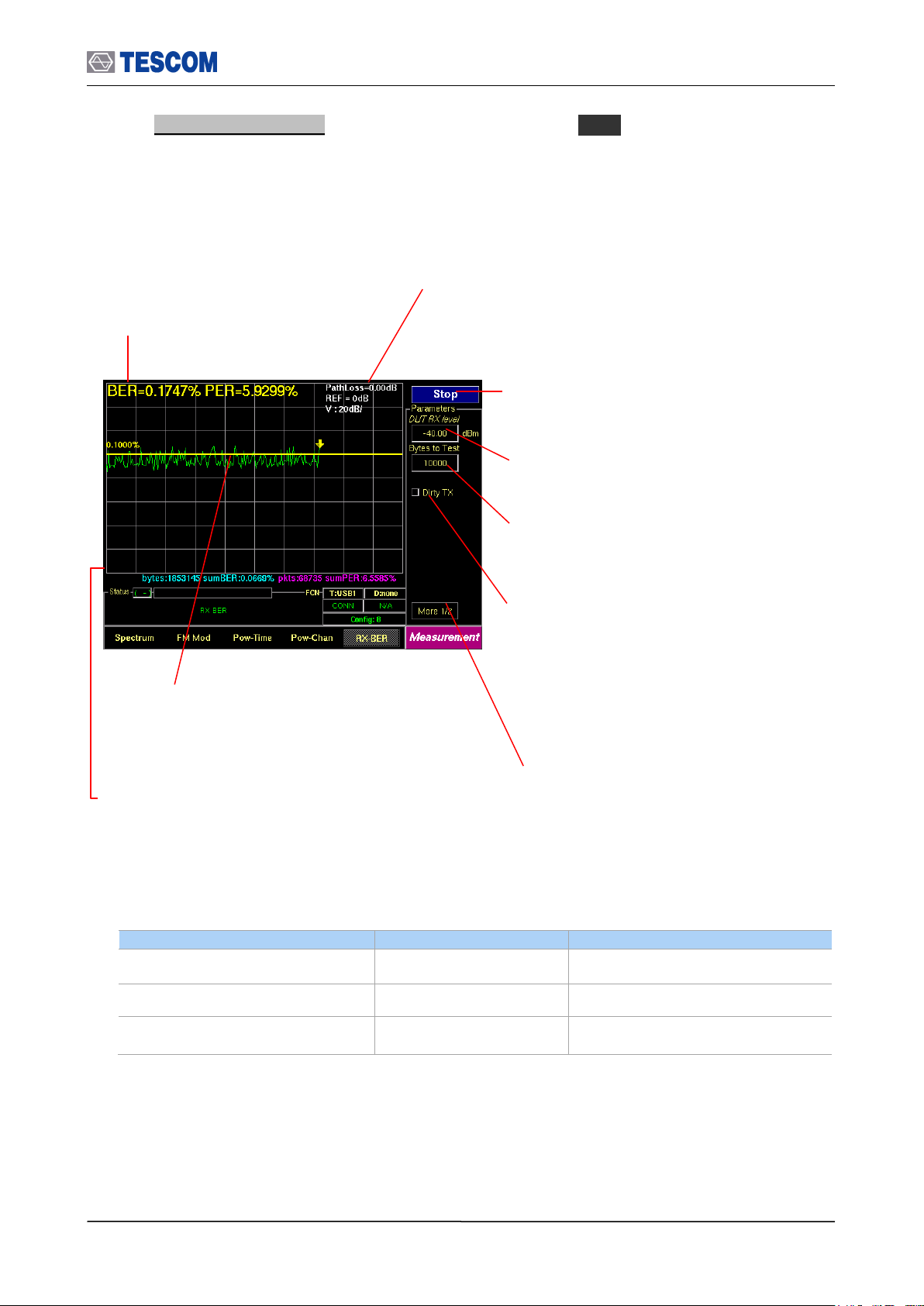

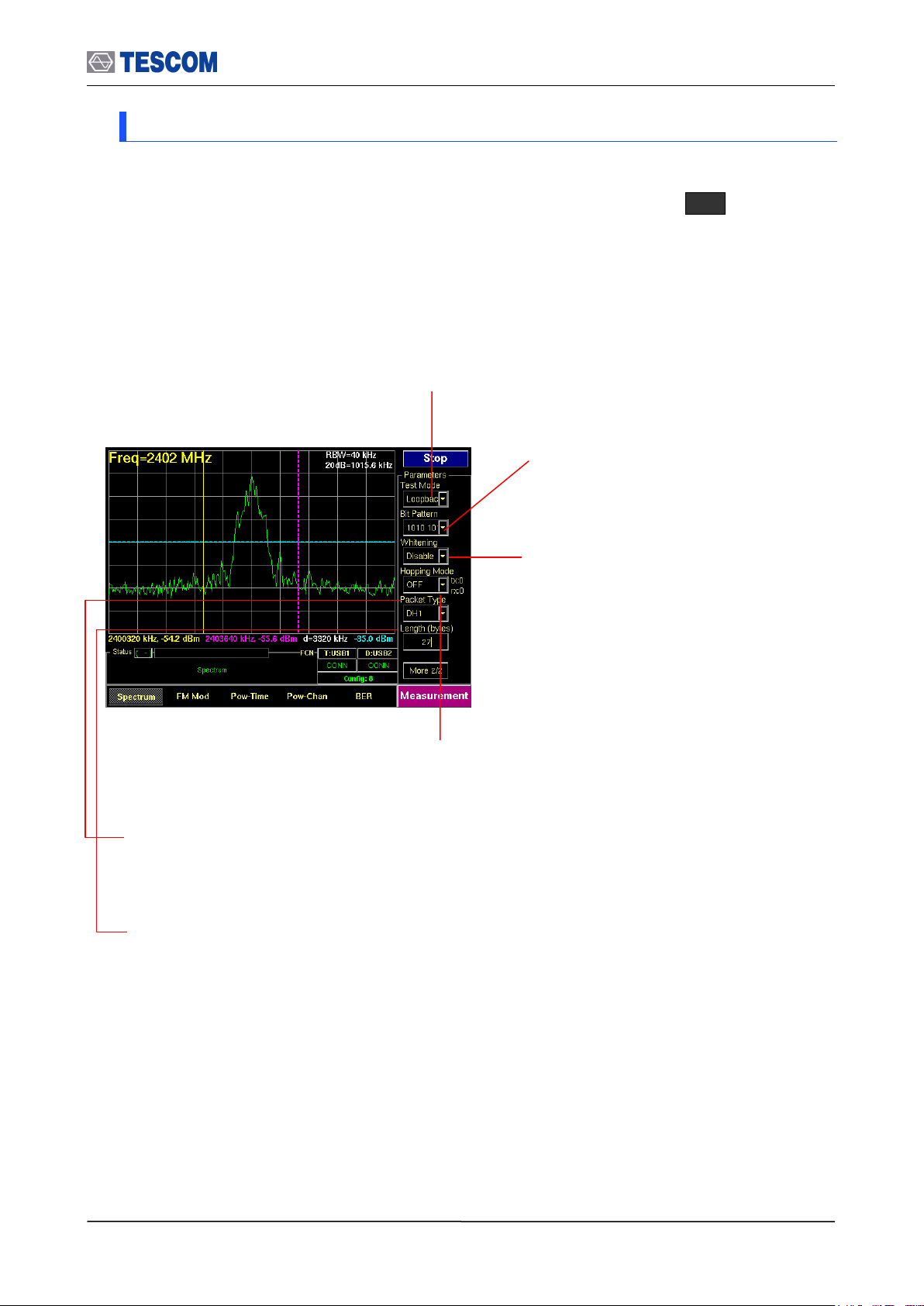

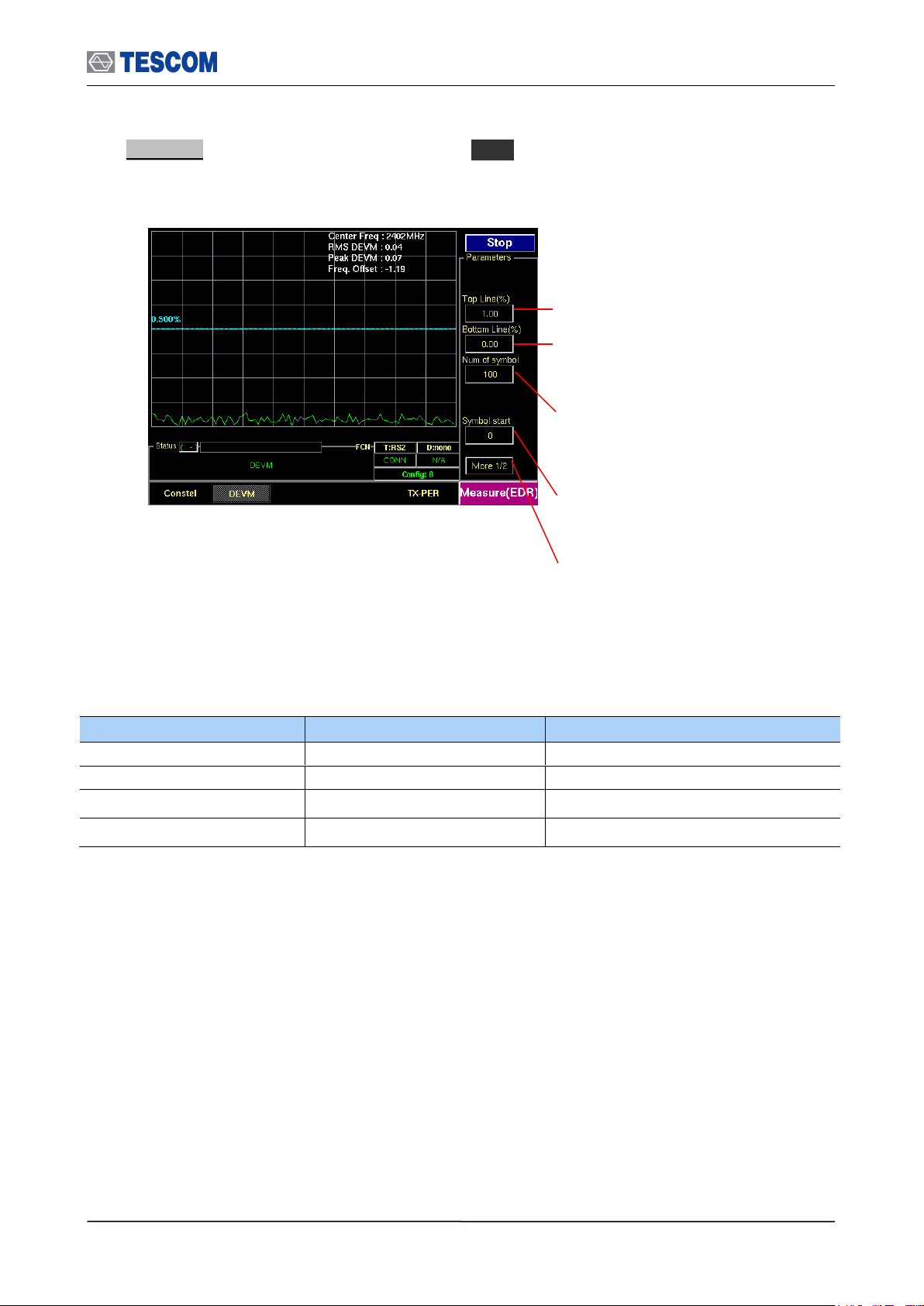

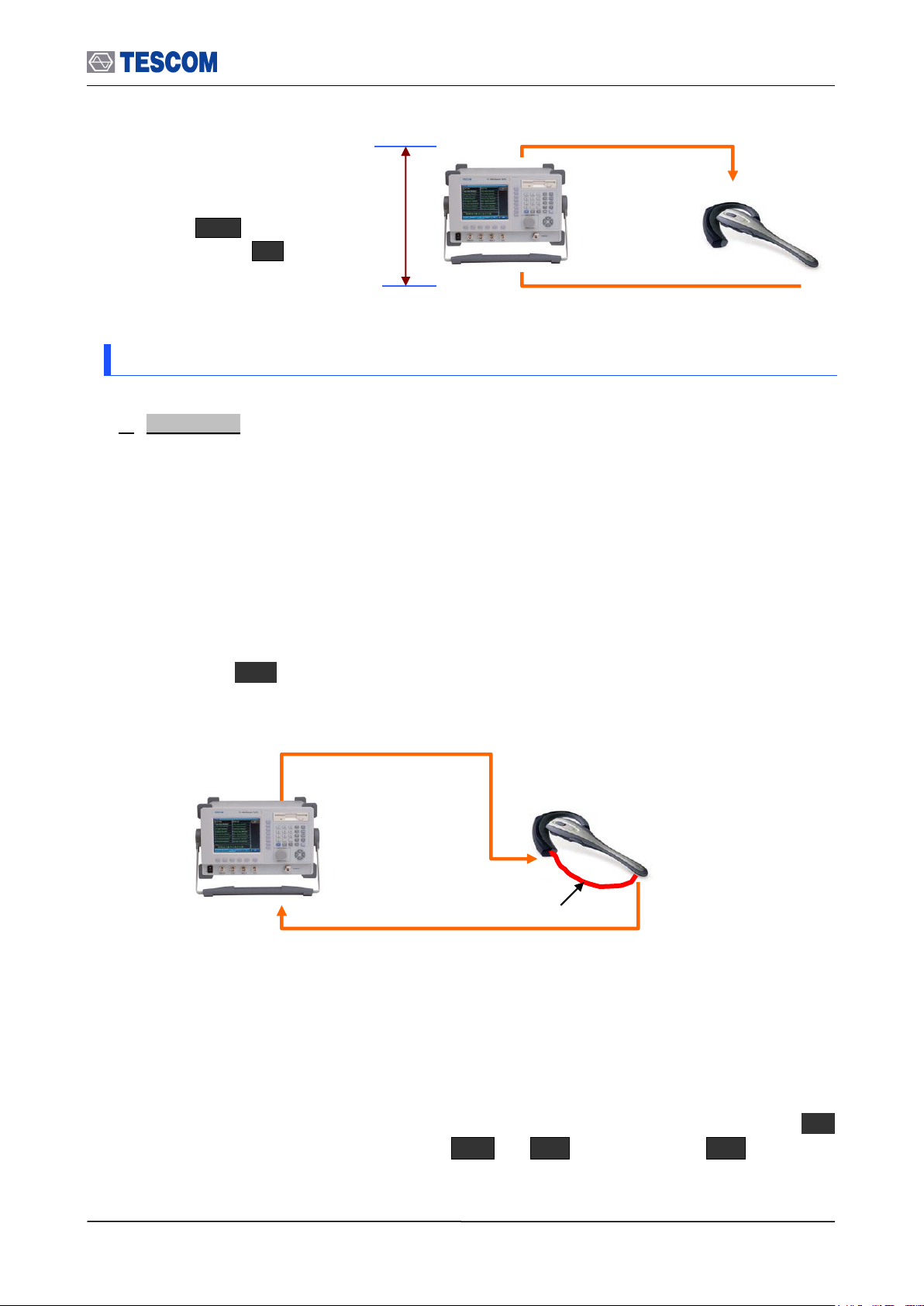

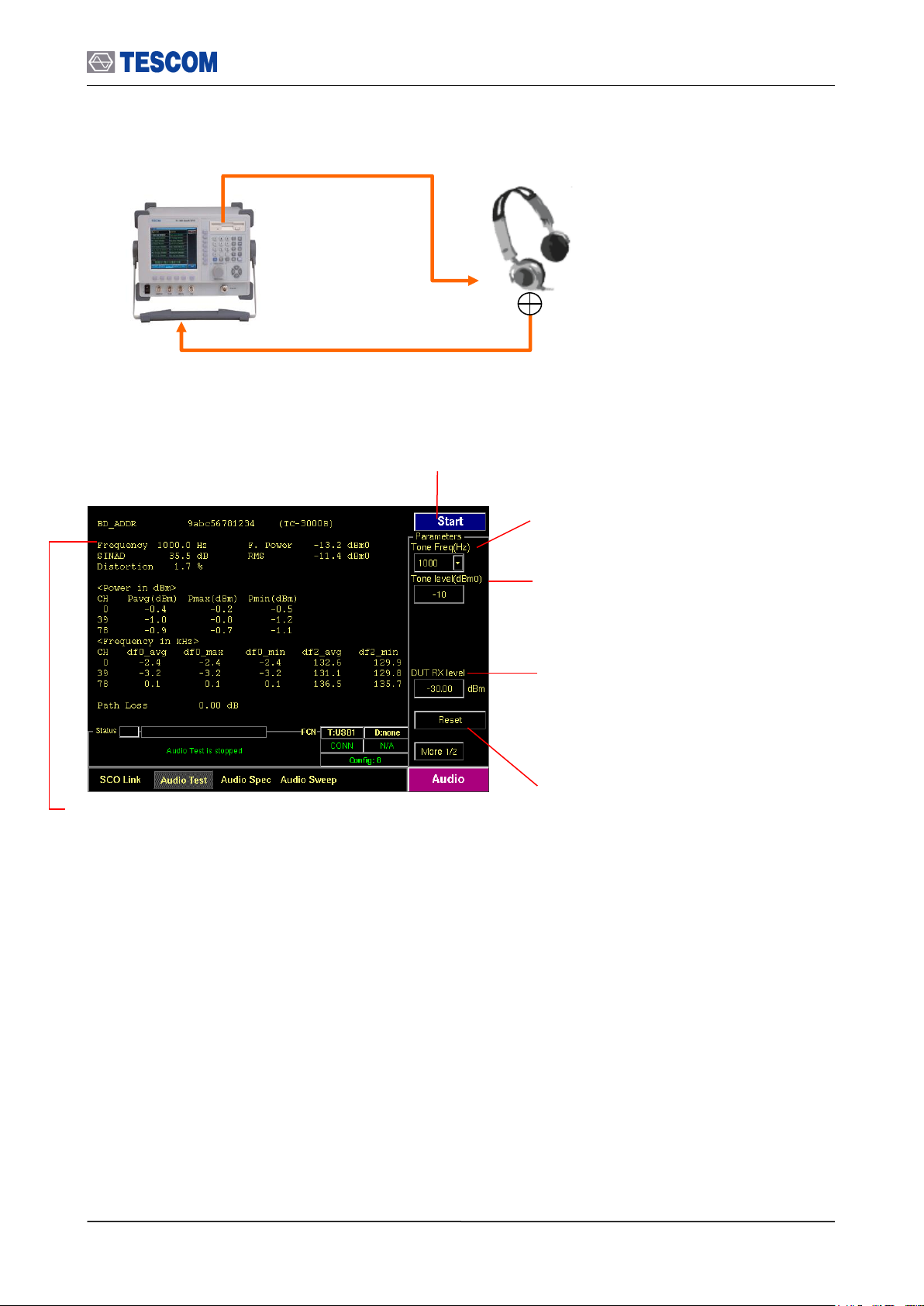

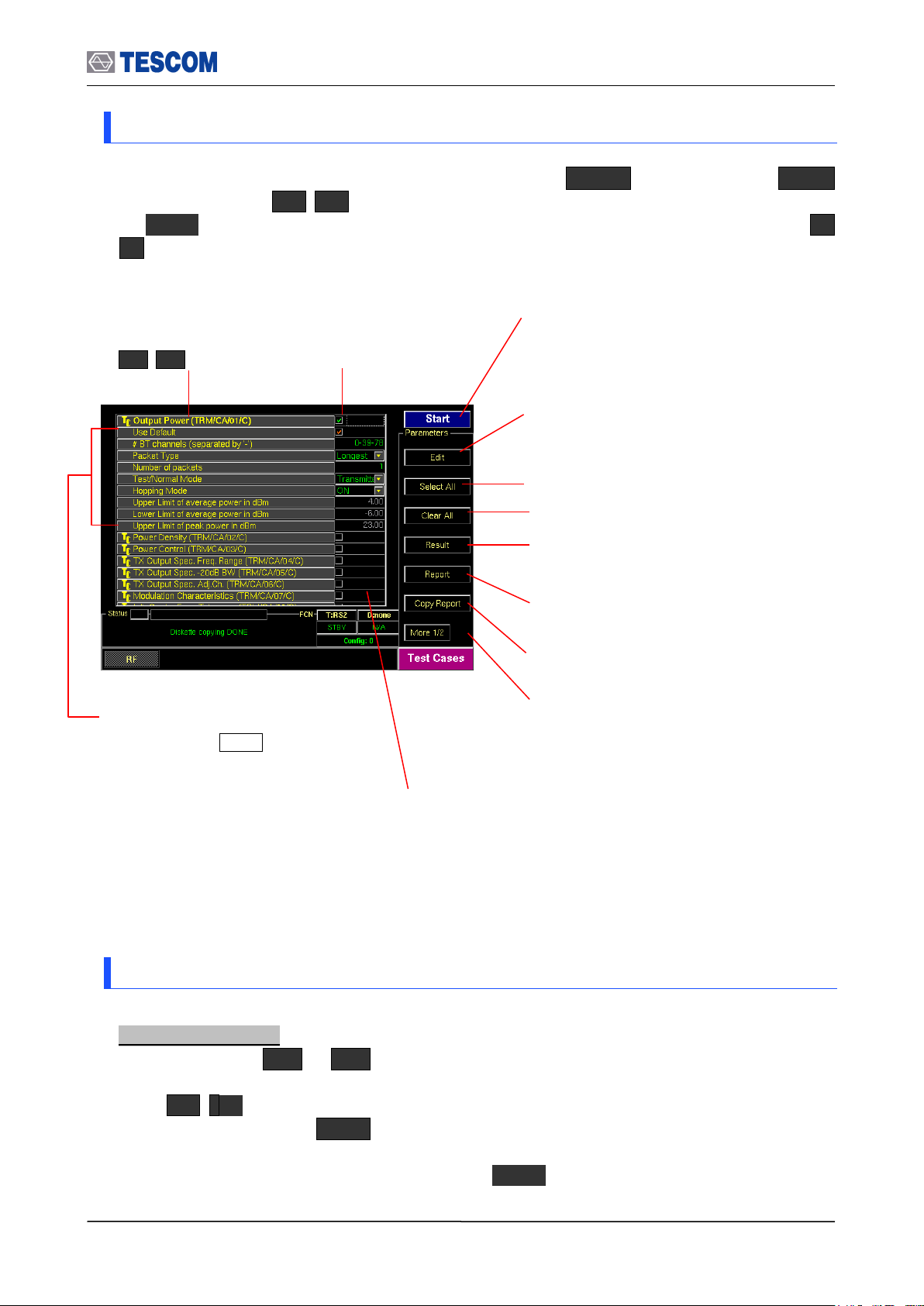

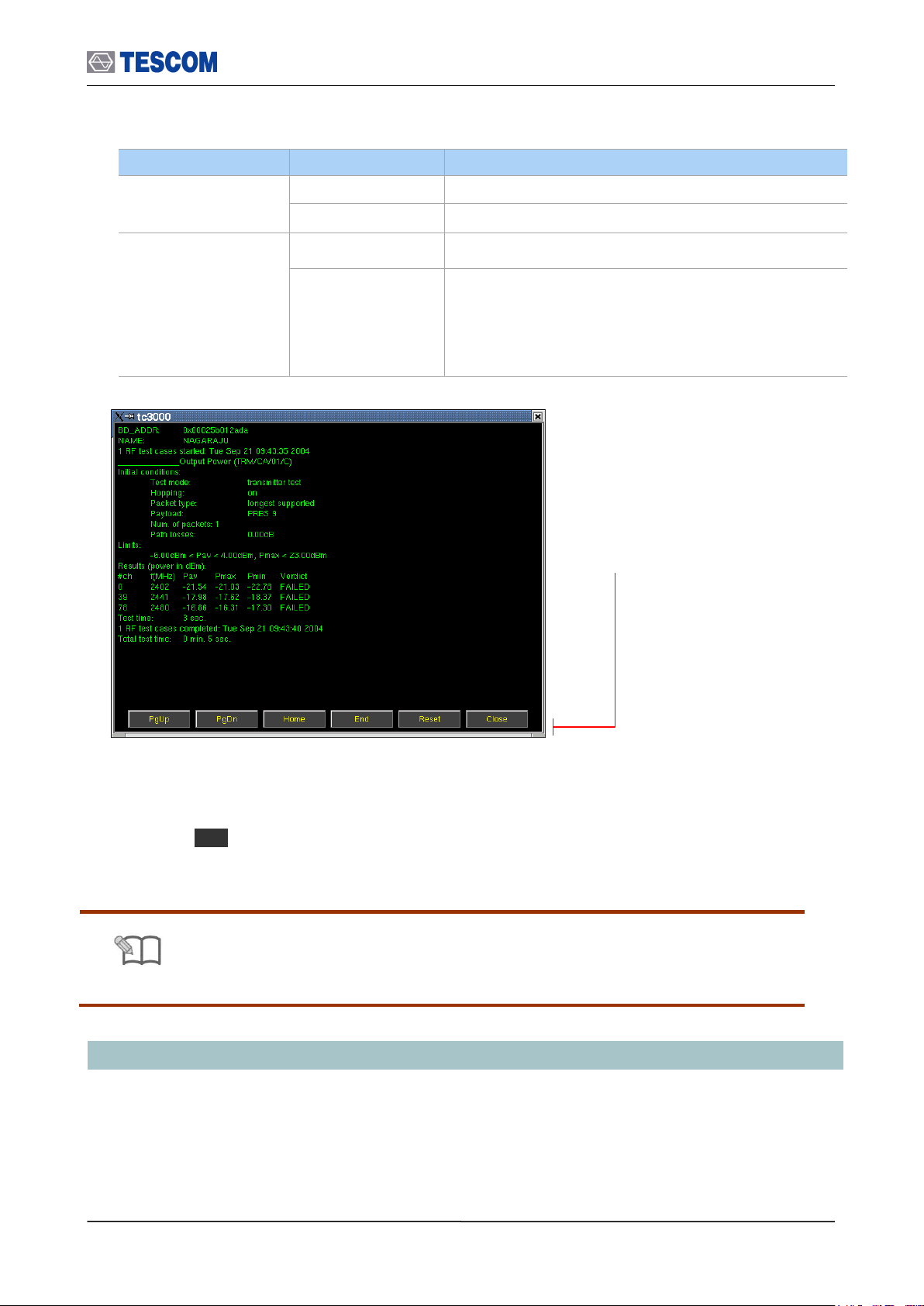

Clear screen: Clears all messages