Tescom ER1200 Series, ER1200-1-1, ER1200-1, ER1200-2, ER1200-2-1 Operation & Service Manual

Page 1

Form # 1925 Rev. 4/06 TESCOM

TABLE OF CONTENTS

Page

GENERAL OPERATION

ER1200 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Internal Feedback Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

External Feedback Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

ER1200 CONFIGURATION

Configure Setpoint Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Configure Analog Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Configure Feedback Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

TUNING THE ER1200

Deadband . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Zero & Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Gain & Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ER1200

Operations &

Service Manual

Page 2

Form # 1925 Rev. 4/06 TESCOM

1

GENERAL OPERATION

INTRODUCTION

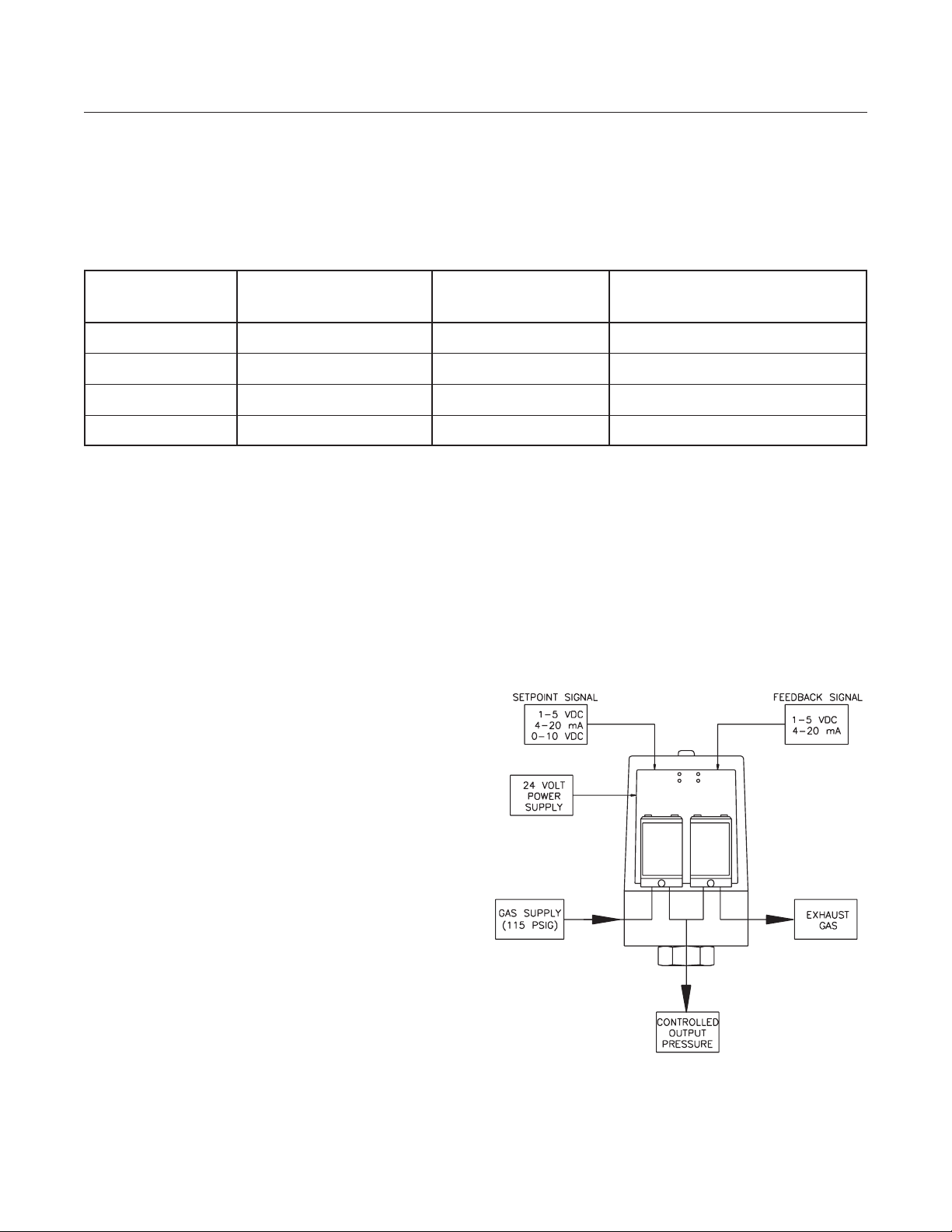

The ER1200 is a closed loop pressure control system capable of operating in two different modes.

In the “Internal Feedback” mode, the control is based on the internal pressure sensor, which has a

range of 0 - 100 PSIG. In “External Feedback” mode, the PID algorithm is based on an external,

customer provided transducer. The ER1200 requires both a setpoint, which is the desired output

pressure, and a feedback, the actual output pressure.

INTERNAL FEEDBACK MODE

In internal mode, the ER1200 compares the

feedback signal from the internal pressure

sensor to the setpoint input. Inside the unit,

there are two solenoid valves that control the

output pressure. If the feedback signal is

below setpoint, the ER1200 opens its inlet

valve and increases output pressure. If the

feedback is above setpoint, the ER1200

opens its exhaust valve to decrease the

output pressure. Every 25 milliseconds, the

feedback is compared to the setpoint and a

correction is made to make the output

pressure equal to the desired.

Inlet pressure:

Typical – 110 PSIG

Maximum – 120 PSIG

Minimum – 10 PSIG above required controlled

output pressure

ER1200 VERSIONS

This manual is a comprehensive documentation of specifications and operations of all versions of

the ER1200 Series regulator. The following table summarizes the differences in features for

different ER1200 versions. Use this table to check the version number of your ER1200. The

versions without an internal sensor do not have an “internal feedback” mode option.

PART NUMBER INTERNAL SENSOR 18" CABLE AND WATER TIGHT CONNECTOR

(0-100 PSIG) STRAIN RELIEF AND 2' MATING CABLE

ER1200-1 Yes Yes No

ER1200-2 Yes No Yes

ER1200-1-1 No Yes No

ER1200-2-1 No No Yes

Figure 1

Page 3

Form # 1925 Rev. 4/06 TESCOM

GENERAL OPERATION Continued

2

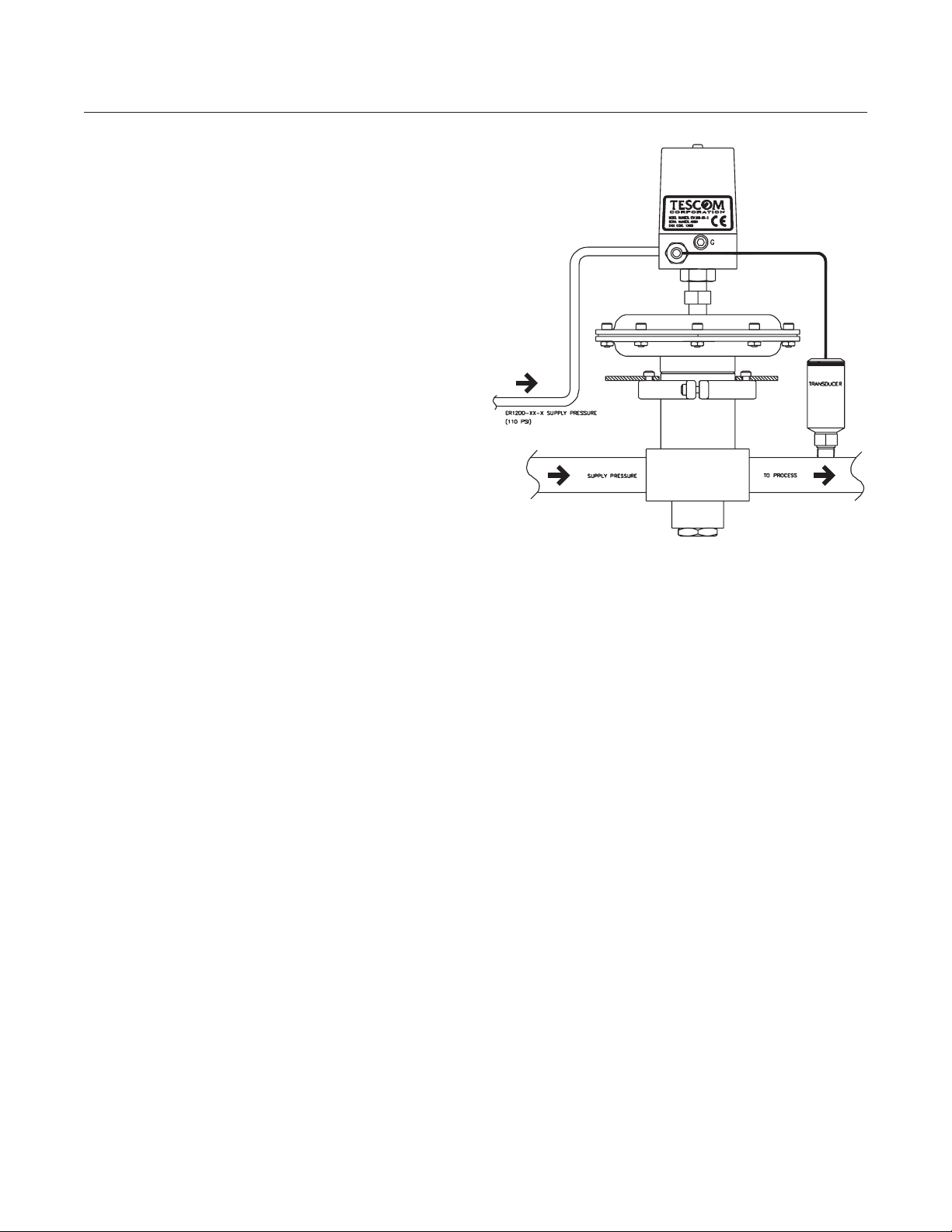

EXTERNAL FEEDBACK MODE

In External Feedback mode, the ER1200 can

be used to control flow, position, temperature,

or any other variable that can be affected by a

change in pressure. For the purpose of this

operation manual, we will discuss the control

of pressure. In this mode, the ER1200

compares an external feedback signal from a

customer supplied transducer to the setpoint.

Typically, this mode is used when the ER1200

is combined with either a pressure reducing or

back pressure regulator (shown with a ratio

actuated, pressure reducing regulator, Figure 2).

If the feedback signal is below setpoint, the

ER1200 opens its inlet valve and increases

output pressure. This increases pressure on

the dome of the regulator, opening the main

valve and increasing downstream pressure. If

the feedback is above setpoint, the ER1200

opens its exhaust valve, which decreases

dome pressure, allowing the regulator to

decrease output pressure.

Pressure Connections:

ER1200 inlet pressure is the same as in

internal mode. Refer to regulator installation

and operation instructions and the product

label for maximum inlet pressure information.

Figure 2

Page 4

SPECIFICATIONS

Enclosure

NEMA 4 housing

Mounting

2 10-32 UNF mounting holes

Power Requirement

24 Volts DC +/- 2 volts

150 milliAmp typical current draw

Input Signals

All signals are field configurable using

onboard jumpers:

Setpoint: 4-20 mAmp, 1-5 VDC or

0-10 VDC

Feedback: Internal (0-100 PSIG) or

external

External

Feedback: 4-20 mAmp, 1-5 VDC or

0-10 VDC

Inlet Pressure

Maximum: 120 PSIG

Typical: 110 PSIG

Minimum: 10 PSIG above desired

output pressure

Media

Clean, dry, inert gas

Environment

Temperature: -10°F to +150°F

Flow Stream Materials

300 Series SST, Buna-N, 6000 Series

Aluminum, Brass, Nickel, Silicon, Gold,

Glass, RTV

Performance

Total Accuracy: +/- 0.25%

Linearity: +/- 0.1%

Repeatability: +/- 0.12%

Flow Capacity: Cv= 0.03

3

Form # 1925 Rev. 4/06 TESCOM

1 White + Setpoint

2 Brown - Setpoint

3 Green + Feedback

4 Yellow + Analog Output

5 Black Power Ground

6 Red + TTL Output

7 Orange + 24 VDC Power

8 Violet* Secondary Ground

Wire Number Wire Color Function

ELECTRICAL INSTALLATION

*Not available for ER1200-2 and ER1200-2-1

Page 5

Form # 1925 Rev. 4/06 TESCOM

4

Current Setpoint - Active Source

Voltage Setpoint

Current Setpoint - Passive Source

Page 6

ER1200 CONFIGURATION

There are two printed circuit boards inside

the ER1200. The bigger, vertical board is

the control board. All the jumpers used to

configure the ER1200 are located on this

board. The tuning and calibration pots are

also located on the control board. (See

page 6 for details on tuning the ER1200.)

The smaller, horizontal board has two pots

used to zero and span the internal sensor.

These pots are set at the factory and should

NOT be adjusted.

CAUTION: CONFIRM POWER SUPPLY

IS OFF BEFORE MOVING JUMPERS.

CONFIGURE SETPOINT SIGNAL

MODE – JP1

• Current Setpoint Mode:

Install Jumper

• Voltage Setpoint Mode:

Remove Jumper

RANGE – JP2

• 4-20 mAmp/1-5 Volts:

Install Jumper on pins 1 & 2

• 0-10 Volts:

Install Jumper on pins 2 & 3

CONFIGURE ANALOG OUTPUT SIGNAL

MODE – JP6

• Current Output Mode:

Not available

• Voltage Output Mode:

Install Jumper on pins 2 & 3

RANGE – JP7

• 1-5 Volts:

Install Jumper on pins 1 & 2

• 0-10 Volts:

Install Jumper on pins 2 & 3

CONFIGURE FEEDBACK SIGNAL

MODE – JP5

• Current Feedback Mode:

Install Jumper

• Voltage Feedback Mode:

Remove Jumper

RANGE – JP4

• 0-10 Volts:

Install Jumper on pins 1 & 2

• 4-20 mAmp/1-5 Volts:

Install Jumper on pins 2 & 3

SOURCE – JP3

• Internal Feedback Mode:

Install Jumper on pins 1 & 2

• External Feedback Mode:

Install Jumper on pins 2 & 3

5

Form # 1925 Rev. 4/06 TESCOM

Figure 3

Page 7

TUNING THE ER1200

There are 5 adjustments located on the control

card. The initial factory pot settings are listed

in the following table.

CLOCKWISE

FUNCTION TURNS

Gain 11

Stability (Integral) 5

Deadband 7

Zero 18

Span 13

Note: The counter-clockwise end point from

which to start turning the pots is found by

rotating the pot counter-clockwise 25 turns.

• The easiest method for calibrating and

tuning the system is to use a volt meter to

monitor the setpoint and feedback voltages.

• Turn all the pots back to the factory settings.

• Apply a setpoint signal of at least 12.5%

(6 mAmps, 1.5 VDC if 1 - 5 VDC, or 1.25

VDC if 0 - 10 VDC).

• Rotate the Deadband pot until exhaust gas

can barely be felt escaping from the

exhaust port (see Figure 1, page 1) on the

base of the unit. Rotating the deadband pot

clockwise will decrease the deadband to the

point that the inlet and exhaust solenoid

valves will operate continuously. This will

result in a very accurate tracking response,

but obviously consumes gas. If the

deadband is increased by rotating the pot

counter-clockwise, pilot gas will be

conserved, but the system will not respond

to a change in setpoint or feedback until the

error signal is larger than the imposed

deadband voltage. This can result in drifting

of the feedback signal or no response to a

small change in setpoint signal.

• Apply a setpoint signal of about 2.5% (4.4

mAmps, 1.1 VDC if 1 - 5 VDC, or 0.25 VDC

if 0 - 10 VDC). Measure the feedback signal

and adjust the zero pot until the feedback

signal matches the setpoint signal. Rotating

the zero pot clockwise will increase the

feedback signal and a counter-clockwise

rotation will decrease the feedback signal.

Sufficient time should be given for the

system to respond between each

adjustment of the pots, especially if there is

a large control volume. Rotate the pots

slowly and observe the system reaction.

Zero Pot Rotation Effect

Figure 4: Zero Adjustment

• Apply a setpoint signal of about 95% (19.2

mAmps, 4.8 VDC if 1 - 5 VDC, or 9.5 VDC if

0 - 10 VDC). Measure the feedback signal

and adjust the span pot until the feedback

signal matches the setpoint signal. Again,

sufficient time should be given for the

system to respond between each

adjustment of the pots. Since the zero and

span adjustments interact with one another,

it is necessary to readjust the zero after

adjusting the span. Recheck the zero and

adjust it if the feedback signal does not

match the setpoint signal of 2.5%. Continue

to recheck zero and span until the feedback

signal and setpoint signal match at both the

low and high setpoint values.

6

Form # 1925 Rev. 4/06 TESCOM

Output

Signal (mA)

Page 8

TUNING THE ER1200 Continued

Span Pot Rotation Effect

Figure 5: Span Adjustment

Typically, Gain and Stability adjustments are

not needed. However, the following general

guidelines can be followed to fine tune your

system:

Rotating the gain pot clockwise increases the

system gain and decreases the system

response time. Too little gain will result in slow

response and inaccurate signal tracking. Too

much gain will result in system instability, fast

vibration, or in the feedback signal

overshooting the setpoint signal when a large

step change in setpoint is initiated.

Rotating the stability pot clockwise will

decrease the reset time and quicken the

addition of gain into the system. This can

again result in setpoint overshoot. Rotating

the pot counter-clockwise will increase the

reset time and dampen the control response

to a step change in setpoint.

The stability adjustment does not interact with

any of the other adjustments, however, if the

gain or deadband pots are turned at this point,

the zero and span will need to be readjusted

per the procedure outlined above.

Reaction To Step Change In Setpoint

Figure 6: System Response

If the system is experiencing a slow oscillation,

decrease the gain by rotating the pot counterclockwise until the oscillation stops. If the

oscillation is rapid, increase the reset action by

rotating the stability pot clockwise until the

oscillation stops. These settings will be the

maximum gain and minimum reset time that

can be used with the system as it is configured.

If the feedback signal severely overshoots the

setpoint signal when a change in setpoint is

made, turn the stability pot counter-clockwise

alternately with the gain pot (also counterclockwise), until the overshoot is eliminated.

For very precise tuning of the control, a dual

channel storage oscilloscope is recommended

so that the user can see the effect of gain and

integral adjustment on the response of the

system. One channel of the scope is used to

monitor the setpoint voltage and the other

channel to monitor the feedback voltage. The

gain and integral adjustments have the

greatest effect on the system response to a

step change in setpoint signal. The control

can be tuned in this fashion for millisecond

response to step changes in setpoint from 0 to

100%. Remember, after adjusting the gain

pot, the control will need to have its zero and

span readjusted.

7

Form # 1925 Rev. 4/06 TESCOM

Output

Signal (mA)

Under Damped

Critically

Damped

Over Damped

Feedback Response

0

Time

Page 9

TROUBLESHOOTING

ER1200 Symptom Cause Remedy

8

Form # 1925 Rev. 4/06 TESCOM

Unable to maintain outlet

pressure

Positive output pressure

with zero setpoint

Outlet pressure is equal

to inlet pressure

Outlet pressure does not

follow setpoint changes

Outlet pressure becomes

uncontrollable (unstable

or unable to establish

setpoint)

ER1200 exhaust valve

leaking

ER1200 supply pressure is

not high enough

ER1200 inlet solenoid valve

leaking

ER1200 supply pressure

exceeds the maximum

ER1200 not getting a

feedback signal

ER1200 jumpers not

configured correctly

ER1200 GAIN, INTEGRAL,

or DEADBAND are out of

adjustment

The feedback signal reacts to

a process change at a slower

bandwidth than the ER1200

(25 milliseconds)

There are leaks in the

downstream pressure line

The system design has

components that can cause a

delay in down stream

transducer response while

the up stream pressure is

allowed to build up (pressure

differential between

measurement point and

source)

Return unit to factory for

replacement of valve

Check the incoming pressure

to the ER1200 and ensure that

it is between 10 to 20 PSIG

above the maximum desired

output pressure

Return unit to factory for

replacement of valve

Lower supply pressure to less

than 115 PSIG

Check transducer wiring and

feedback jumper settings

Reconfigure jumper settings

according to page

Read TUNING THE ER1200

(page 6) in this manual and

readjust the gain and pots per

that section

Replace the transducer with

one that has a full range

response time at least as fast

as that of the ER1200

Locate and eliminate all leaks

Eliminate the flow restriction, or

slow down the ER1200

response time by restricting the

flow of supply pressure into the

ER1200

Page 10

Form # 1925 Rev. 4/06 TESCOM

Tescom

Industrial Controls

Systems Group

12616 Industrial Boulevard

Elk River, Minnesota 55330-2491

Toll Free 800-447-1250

Tel 763-241-3238

Fax 763-241-3224

e-mail: systems@tescom.com

www.TESCOM.com

Loading...

Loading...