Tescan Vega 3 Sem Instructions For Use Manual

Scanning Electron Microscope

Instructions For Use

The reproduction, transmission or use of this document or its contents is not permitted without express written

authority.

Offenders are liable for damages. All rights reserved.

We have checked the contents of this manual for agreement with the hardware and software described. Since

deviations cannot be precluded entirely, we cannot guarantee full agreement.

© 2011 TESCAN, a.s., Brno, Czech Republic

Contents

3

VEGA 3 SEM

Contents

Contents ........................................................................................................................... 3

1 Introduction ................................................................................................................ 5

2 Safety Information ....................................................................................................... 6

3 Installation and Microscope Repairs ............................................................................. 7

3.1 Transport and Storage .............................................................................................. 7

3.2 Installation Instructions ............................................................................................ 7

3.3 Fuse Replacement ..................................................................................................... 7

3.4 Instrument Repair and the Spare Parts Usage ............................................................ 7

4 Description of the Microscope...................................................................................... 8

4.1 Electron Column ....................................................................................................... 8

4.1.1 Electron Column Displaying Modes .................................................................. 11

4.1.2 Electron Column Microscope Centering ............................................................ 16

4.2 Chamber and Sample Stage .................................................................................... 18

5 Vacuum Modes .......................................................................................................... 19

5.1 High Vacuum Mode ................................................................................................. 20

5.2 Medium Vacuum Mode ........................................................................................... 20

5.3 Low Vacuum Mode .................................................................................................. 21

6 Detectors .................................................................................................................. 22

6.1 SE Detector ............................................................................................................. 22

6.2 LVSTD Detector ....................................................................................................... 22

6.3 BSE Detector ........................................................................................................... 23

6.4 CL detector ............................................................................................................. 24

6.4.1 Exchange of CL for BSE lightguide .................................................................... 24

6.5 Other Detectors ...................................................................................................... 25

7 Control Elements ....................................................................................................... 26

7.1 Keyboard ................................................................................................................ 26

7.2 Mouse ..................................................................................................................... 26

7.3 Trackball ................................................................................................................. 27

7.4 Control Panel .......................................................................................................... 27

8 Getting Started .......................................................................................................... 28

8.1 Starting the Microscope .......................................................................................... 28

8.2 Specimen Exchange ................................................................................................ 28

8.3 Images at Low Magnification ................................................................................... 29

8.4 Imaging of non-conductive samples without coating.............................................. 33

8.5 Images at High Magnification .................................................................................. 35

8.6 Stopping the Microscope ........................................................................................ 37

Contents

4

VEGA 3 SEM

9 Microscope Maintenance ............................................................................................ 38

9.1 Basic Microscope Accessories ................................................................................. 38

9.2 Filament Exchange .................................................................................................. 39

9.3 Starting up the Microscope after a Filament Exchange ............................................ 42

9.4 Mechanical Gun Centering ...................................................................................... 44

9.5 Aperture Exchange ................................................................................................. 44

9.5.1 Exchange of the Aperture Holder...................................................................... 45

9.5.2 Insertion of the Low Vacuum Aperture Holder .................................................. 45

9.6 Cleaning the Column .............................................................................................. 46

9.6.1 Types of Contamination or Impurities .............................................................. 46

9.6.2 Cleaning the Column Parts ............................................................................... 47

9.6.3 The Frequency of Cleaning ............................................................................... 49

9.7 Specimen Holders ................................................................................................... 49

Introduction

5

VEGA 3 SEM

1 Introduction

The VEGA 3 series is a family of modern, fully PC-controlled scanning electron microscopes

with a tungsten heated filament.

Specific Features of the VEGA 3 SEM:

An innovative and powerful four lens Wide Field Optics™ design, offering a variety

of working and displaying modes.

A range of chambers to suit all applications and a wide choice of supplementary

accessories.

Fast and precise motorized specimen stages.

Excellent analytical qualities with optimized ports geometry.

Unique live stereoscopic imaging using the 3D Beam technology.

Turbomolecular and rotary pumps ensure quick and easy sample exchange and short

times to reach a working vacuum.

Sophisticated and easy-to-use software for microscope control using a Windows™

platform.

Fully automated microscope set-up.

Comprehensive software for image archiving, processing, evaluation and network

operations comes as standard.

Minimal requirements on space, power supply and environment.

Currently the VEGA 3 family includes several models of microscope fitted with various

chambers according to the user’s requirements for chamber size, stage movements

precision and/or operation comfort. The abundant control software included in the standard

scope of delivery is one of the valued assets of the Vega microscopes.

Since the VEGA 3 SEM is installed and maintained by trained specialists, technical details and

installation procedures are limited to a short overview. In the case of necessary maintenance,

reinstallation, hardware changes, etc. the appropriate service authorities or your local

supplier have to be contacted for further assistance and instructions.

Safety Information

6

VEGA 3 SEM

2 Safety Information

The user is liable to make himself familiar with the care of the device and with the safety

rules valid in the country of the user. The microscope works with electric voltages that can

be dangerous to life.

Any operations with the device which are not mentioned in these instructions, especially the

removal of the housing and manipulation of the electric parts of the microscope, may be

carried out only by an authorized person. It is also forbidden to substitute a part of the

microscope for any other part that is not original and is not delivered by the microscope

producer (e.g. the substitution of the original steel blinds on the flanges of the microscope

chamber for light alloy blinds can cause an emission of dangerous ionizing radiation!)

The microscope is provided with a number of automatic protections making unsuitable

usage impossible (e.g. it is not possible to switch on high voltage sources if the specimen

chamber or electron gun space are open or are not evacuated to the working vacuum). The

deactivation of these protections can cause destruction of the machine and endanger the

health of the operating staff. It is strictly forbidden.

The symbols used meet the regulation standard ČSN EN 61010-1, except the symbol:

that marks the connectors with high voltage which are not dangerous in the aspect of the

mentioned regulation standard (accidental touch can only cause electrical shock).

In the documentation there are two types of additional information given: Notes and

Warnings,

Notes are designated thus:

Note:

In Italics and Blue print.

Warnings are designated thus:

WARNING:

In Italics and Red print.

Installation and Microscope Repairs

7

VEGA 3 SEM

3 Installation and Microscope Repairs

3.1 Transport and Storage

The method of delivery is defined in the contract and is determined individually according

to the destination territory. The method of delivery must be approved by the manufacturer.

The instrument is delivered partially disassembled and packed. The purchaser is obliged

to check the status of the boxes after the delivery company handover. In the case of any

damage it is necessary to catalogue the damage and inform the manufacturer of the

situation. The packed instrument must be stored in a dry and clean place with a temperature

range from -20°C to +40°C and must not be exposed to corrosive substances which can

cause oxidation (acid vapours etc.).

3.2 Installation Instructions

The microscope is delivered including installation. The installation must be ordered from the

seller. The customer shall inform the seller of the readiness of the laboratory for the

installation. Once the laboratory is ready, technicians of the manufacturer or technicians

of an approved company will carry out the installation, connection to the mains and user

training. The customer is not allowed to connect the microscope to the mains or do any

other manipulation, except moving the microscope to the storage place. The installation

company will fill in the installation protocol. The warranty period will start from this date and

the user can start using the instrument normally as described in this manual.

3.3 Fuse Replacement

The instrument does not contain any fuses which can be replaced by the user. All fuses are

located under the covers which can be removed only by the service technician from the

manufacturer or the service technician of an approved company. The fuses can be replaced

only by exactly the same type; the type is described in the documentation or on the fuse

holder.

3.4 Instrument Repair and the Spare Parts Usage

It is only permitted to use original spare parts delivered by the manufacturer. Repair and

maintenance which exceed the procedures mentioned in this manual can be performed only

by the manufacturer’s service technician or a service technician from an approved company.

Description of the Microscope

8

VEGA 3 SEM

4 Description of the Microscope

4.1 Electron Column

The scanning electron microscope displays the examined object by means of a thin electron

probe. The column forms the electron probe (beam) and sweeps the beam over the

examined specimen located in the microscope chamber. The imaging qualities of the

microscope depend on the parameters of this electron beam:

spot size, aperture angle

and

beam intensity

.

The spot size determines the resolution of the microscope as well as usable magnification

at stable picture sharpness. It is mainly considered that the spot is circular and has

a Gaussian intensity profile. We can specify its size for example with half the width of the

intensity distribution. The spot size is determined by the demagnification of the primary

electron source, optical aberrations of the final lens (objective) and the diffraction aberration

on the final aperture. The spot size is smaller at shorter working distances.

The incident electron beam is cone-shaped. The vertex angle of the cone is called the

aperture angle. The wider the cone, the lower the depth of focus.

The beam intensity (BI) is the number of electrons passing through the probe in a defined

time. The image noise of the electron microscope depends on the number of electrons used

for the information collected from each picture element. It is necessary to use more time for

image scanning at low beam intensity and vice versa.

It is evident that the incident beam parameters influence each other. The optical system

of the microscope allows operation in different modes when some parameters of the beam

can be preferred and the others can be kept down. Here are some typical examples:

Work on high magnification

. It is necessary to reach a high resolution, therefore low

beam intensity, short working distance and slow scanning speed should be used. We

recommend choosing RESOLUTION mode, working distance not more then 7 mm and

scanning speed 7 or slower. See chapter 4.1.1.

Work with high intensity.

The spot size and the aperture angle are big; resolution is

small. Useful magnification is low but fast scanning can be used because the signal

to noise ratio is better. The higher the BI index, the higher the intensity.

Work with high depth of focus

. The aperture angle must be small. Use Depth mode.

Description of the Microscope

9

VEGA 3 SEM

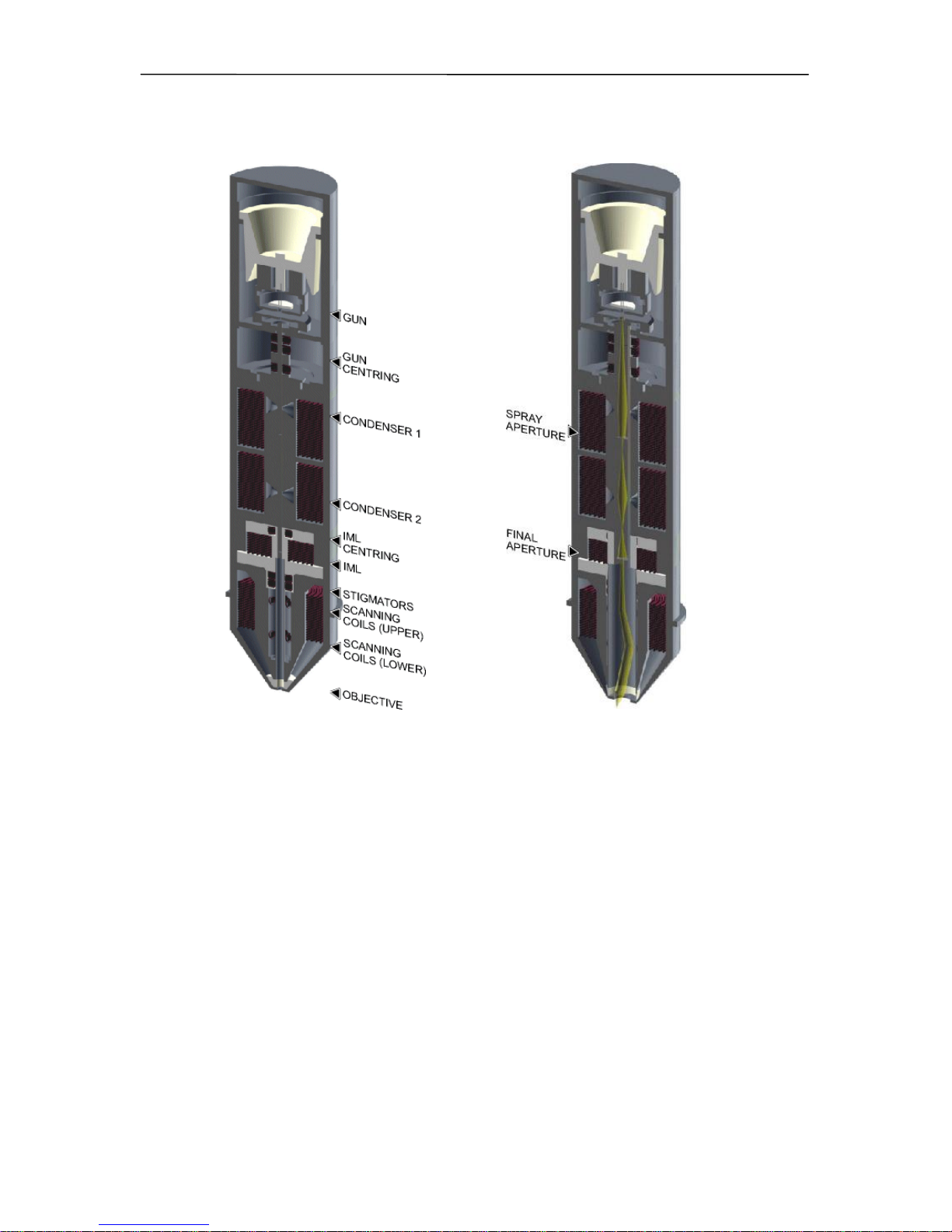

The VEGA 3 SEM cross section and schematic representation of the optical elements

The column of the microscope consists of the following main parts:

The electron gun is a source of accelerated electrons. It consists of a cathode,

Wehnelt cylinder and anode. The cathode and Wehnelt cylinder are connected to the

negative electric potential; the anode and the remaining part of the column are

on the earth potential. The cathode is a tungsten filament, heated to such a high

temperature that it causes emission of free electrons. The voltage between the

Wehnelt cylinder and the anode determinates the

accelerating voltage

of electrons

and thus their energy. The electron flow from the gun is specified with the

emission

current

. The emission current can be changed by applying negative potential between

the Wehnelt cylinder and the cathode (

bias

). The whole gun system works as a “virtual

source” of electrons with the following specifications: the dimension 25 – 50 µm, the

electrons energy from 200 eV up to 30 keV, the emission current up to 300 µA and

its brightness 106 A/cm2sr.

The gun centering is formed by a system of electromagnetic deflection coils under

the gun. It is designed for the tilting of the electron beam emitted from the gun

so that it enters the axis of the optical system of the column. It is controlled by the

Description of the Microscope

10

VEGA 3 SEM

function gun alignment. The gun is correctly centered if the most intensive part

of the electron beam is selected and the brightness of the image is the highest.

The spray aperture is placed under the centering coils of the gun. It is intended for

retaining the marginal parts of the electron beam emitted by the gun.

The pair of condensers C1 and C2 are strong magnetic lenses for the demagnification

of the virtual source. The higher the excitation of the condenser, the shorter its focal

length and the higher its demagnification.

The final aperture cuts the size of the final incident beam. It is placed in the holder

at the end of the central vacuum pipe of the column, about 60 mm under condenser

C2. The optimum size of the aperture hole is 50 µm.

The auxiliary lens IML is a magnetic lens used for the aperture change of the beam

entering the lens OBJ or for displaying if the OBJ is off. The change of the IML

excitation causes the shifting of the electron beam across the optical axis and

therefore it is necessary to compensate this shifting by means of the centering coils

IML Centering.

The Stigmator is an electromagnetic octupole. It is intended to compensate for

astigmatism in all displaying modes.

The scanning coils are formed by two stages of the deflection coils. A scanning ramp

is connected to the coils. The ramp frequency determines the scanning speed of the

electron beam; the amplitude determines the microscope's field of view and the

magnification.

Objective OBJ is the last magnetic lens of the column that forms the resulting

electron beam. In the usual modes the excitation of the OBJ is determined by the

working distance - the distance between the lower objective pole piece and the

focused specimen surface.

Description of the Microscope

11

VEGA 3 SEM

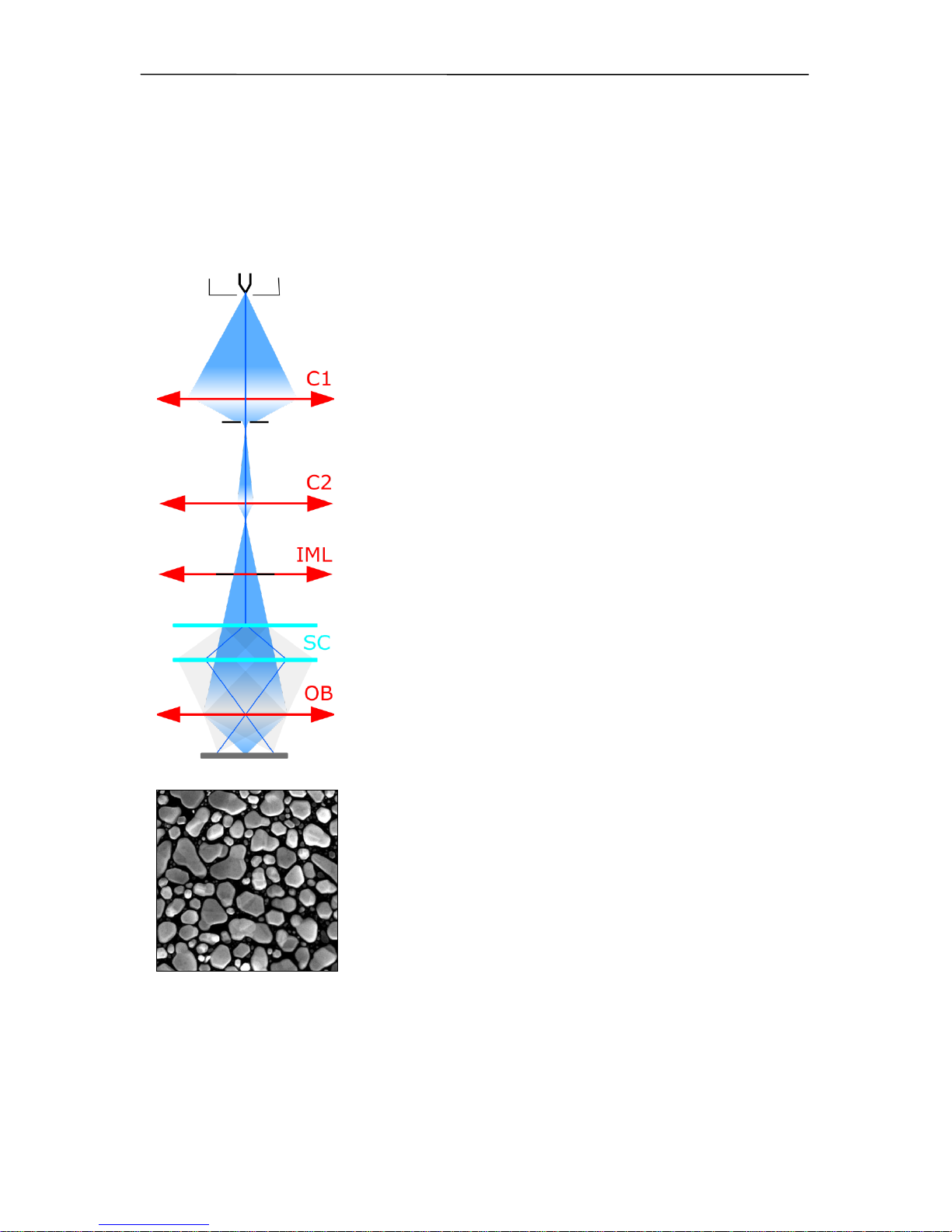

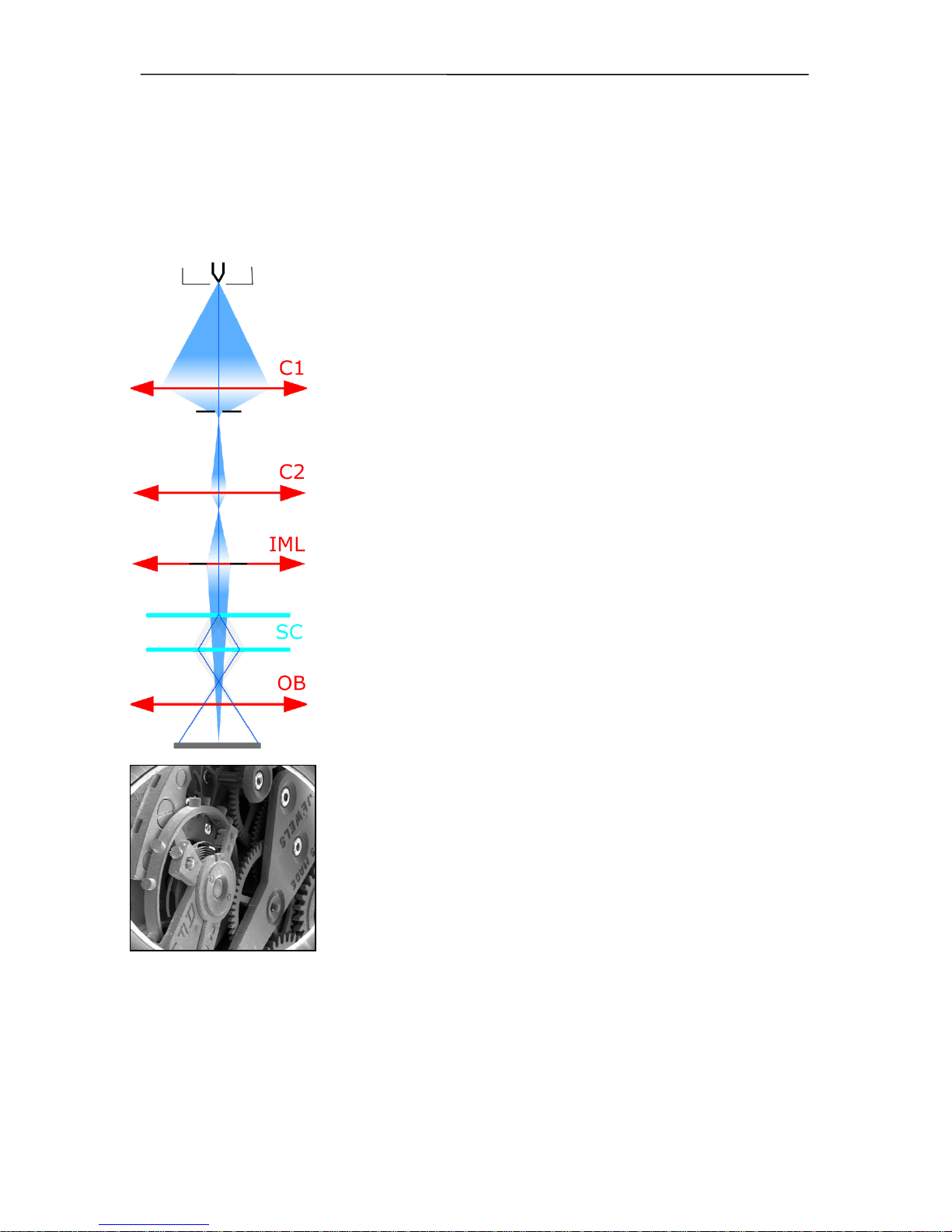

4.1.1 Electron Column Displaying Modes

RESOLUTION Mode

This is the basic and most common displaying mode. The IML lens is switched off, the OBJ

lens is excited and it focuses the final electron beam.

Characteristics:

high resolution

low depth of focus

In this mode, the VEGA 3 works like other common three lens

microscopes without IML lens. The aperture is nearly optimal for

lower BI values (small spot size, low beam current), short

working distances (4 - 5 mm) and for the accelerating voltage

30 kV. The pivot point of the scanning and the electric image

shifts are close to the principal plane of the objective OBJ,

so that the curvature of the field, distortion and field of view are

as good as possible. The centering of the objective OBJ is

performed by defined beam tilt of the central electron beam,

which does not cause image shift. This mode is intended for

displaying with the highest resolution.

Description of the Microscope

12

VEGA 3 SEM

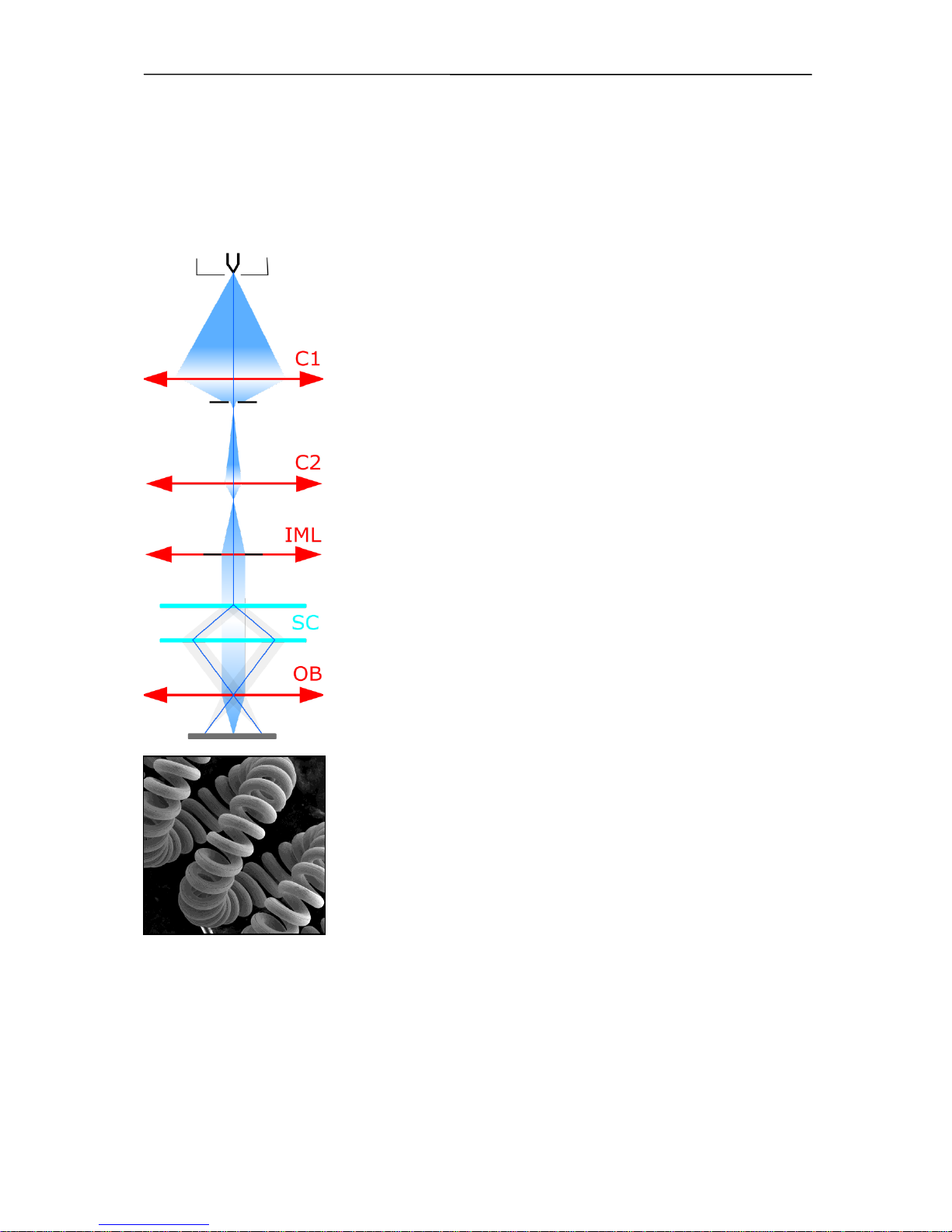

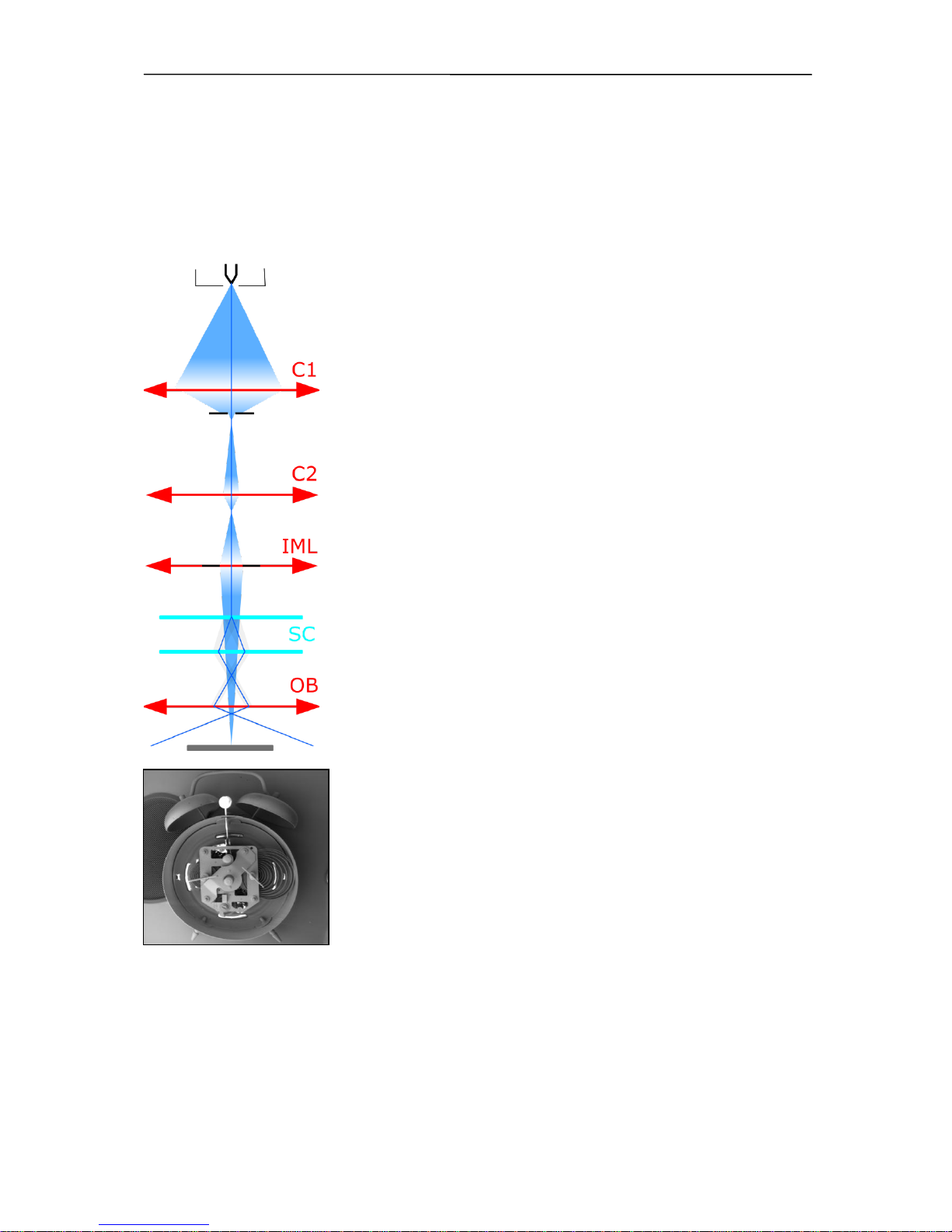

DEPTH Mode

The DEPTH mode differs from the previous mode by the auxiliary lens IML being switched

on.

Characteristics:

good resolution

increased depth of focus

The aperture of the final beam is lower, but the spot size is

bigger in comparison with the RESOLUTION mode. The beam

in the probe stays unchanged. This mode is used if it is necessary

to have a greater depth of focus.

Description of the Microscope

13

VEGA 3 SEM

FIELD Mode

The FIELD mode utilizes the intermediate lens IML for the electron beam focusing while the

objective OBJ is off.

Characteristics:

large field of view

high depth of focus

worse resolution

The beam aperture is very small and the depth of focus is usually

higher than the field of view. As the objective OBJ is off in this case,

it does not affect the middle beam and thus does not need to pass

near the centre of the objective OBJ. The position of the pivot point

of scanning is optimized according to the field of view. The

centering coils IML center the supplemental intermediate lens IML

to avoid image movement during focusing. The DC component

of the scanning coils is set up so that no image shift occurs

if switched from the RESOLUTION mode to the FIELD mode.

The characteristic of this mode is a bigger spot size. The maximum

magnification used is therefore a few thousand. The mode is used

for the searching of the parts of the specimen to be examined.

Description of the Microscope

14

VEGA 3 SEM

WIDE FIELD Mode

The WIDE FIELD mode uses the intermediate lens IML for focusing the electron beam, while

the objective OBJ is excited to a high value.

Characteristics:

extra large field of view

image distortion is corrected and minimized

only available for post-2007 devices

Highly excited objective multiplies the deflection of the beam. The

aperture of the beam is very small and the depth of focus is very

high. The IML Centering coil serves for minimizing the image shift

when focusing.

The mode is used to search for the part of the specimen to be

examined. To know the proper magnification value, the objective

must be well focused. This might be a little difficult due to the

high depth of focus.

Description of the Microscope

15

VEGA 3 SEM

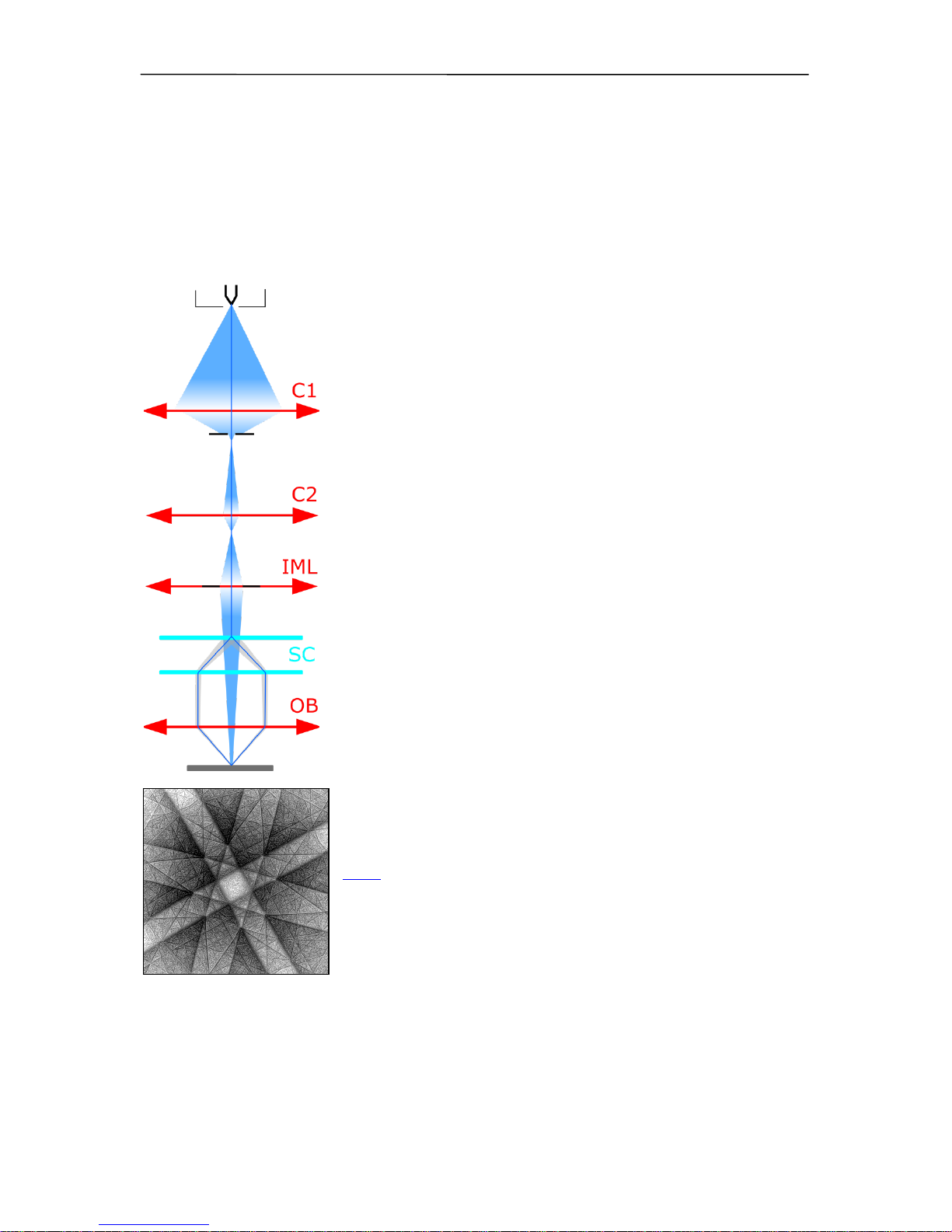

CHANNELING Mode

In the CHANNELING mode, the scanning and lens focusing is controlled so that the electron

beam touches the same point of the specimen surface all the time. By means of scanning the

beam, only the angle of incidence of the electron beam is changed, i.e. the rocking beam.

Characteristics:

the position of the specified point in the image depends

on the beam tilt

it is the mode for ECP acquisition - Electron Channeling

Pattern

The resulting image is the amount of electrons dependent on the

impacting beam angle. The excitation ratio of the scanning coils

is set up so that the beam utilizes the whole area of the objective

lens bore and enters the lens parallel to the optical axis.

All electron beams parallel to the optic axis are focused by the

lens into a single point on the specimen surface. As a consequence, the scanning is transformed into beam tilting, i.e. the

resulting pivot point of the scanning lies on the specimen

surface plane.

The intermediate lens focuses the beam into the upper focal

point of the objective lens. The result is that the beam, after

passing through the objective lens, is parallel and the angular

resolution of ECP (Electron Channeling Pattern) images is at its

maximum.

The mode is intended for the examination of crystallographic

materials. The minimum size of crystals should be 150 µm.

Note: ECP patterns are produced by back scattered electrons, it

is preferable to use a BSE detector for imaging if available.

Loading...

Loading...