Page 1

TES

DNAGNITAREPO,NOITALLATSNI

ROFSNOITCURTSNIECIVRES

®

SEIRES

GAS/OIL

GASgGASAS

RELIOBDERIF-

,reliobnonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp

rebmuNledoMrelioB

rotcartnoCgnitaeH

sserddA

rebmuNlaireSrelioB etaDnoitallatsnI

rebmuNenohP

Page 2

IMPORTANT INFORMATION - PLEASE READ THIS PAGE CAREFULLY

1. THIS BOILER HAS LIMITED WARRANTIES, COPIES OF WHICH ARE PRINTED ON THE BACK COVER OF THIS

MANUAL.

2. THIS BOILER IS SUITABLE FOR INSTALLATION ON COMBUSTIBLE FLOORING. BOILER CAN NOT BE INSTALLED

ON CARPETING.

3. ALL BOILERS MUST BE INSTALLED IN ACCORDANCE WITH NATIONAL, STATE AND LOCAL PLUMBING, HEATING

AND ELECTRICAL CODES AND THE REGULATIONS OF THE SERVING UTILITIES WHICH MAY DIFFER FROM THIS

MANUAL. AUTHORITIES HAVING JURISDICTION SHOULD BE CONSULTED BEFORE INSTALLATIONS ARE MADE.

IN ALL CASES, REFERENCE SHOULD BE MADE TO THE FOLLOWING STANDARDS:

USA BOILERS

A. Current Edition of American National Standard ANSI/NFPA 31, “Installation of Oil Burning Equipment”, for clearances between boiler, vent connector and

combustible material.

B. Current Edition of American National Standard ANSI/NFPA 211, “Chimneys, Fireplaces, Vents, and Solid Fuel Burning Appliances”, For Chimney require-

ments, type of venting material and clearances between vent connector pipe and combustible materials.

C. Current Edition of American Society of Mechanical Engineers ASME CSD-1, “Controls and Safety Devices for Automatically Fired Boilers”, for assembly

and operations of controls and safety devices.

A. Current Edition of Canadian Standards Association CSA B139, “Installation Code for Oil Burning Equipment”, for recommended Installation Practices.

4. ALL HEATING SYSTEMS SHOULD BE DESIGNED BY COMPETENT CONTRACTORS AND ONLY PERSONS

KNOWLEDGEABLE IN THE LAYOUT AND INSTALLATION OF HYDRONIC HEATING SYSTEMS SHOULD ATTEMPT

INSTALLATION OF ANY BOILER.

5. THE BOILER MUST BE CONNECTED TO AN APPROVED CHIMNEY IN GOOD CONDITION. SERIOUS PROPERTY

DAMAGE COULD RESULT IF THE BOILER IS CONNECTED TO A DIRTY OR INADEQUATE CHIMNEY. THE INTERIOR

OF THE CHIMNEY FLUE MUST BE INSPECTED AND CLEANED BEFORE THE START OF THE HEATING SEASON

AND SHOULD BE INSPECTED PERIODICALLY THROUGHOUT THE HEATING SEASON FOR ANY OBSTRUCTIONS. A

CLEAN AND UNOBSTRUCTED CHIMNEY FLUE IS NECESSARY TO ALLOW NOXIOUS FUMES THAT COULD CAUSE

INJURY OR LOSS OF LIFE TO VENT SAFELY AND WILL CONTRIBUTE TOWARD MAINTAINING THE BOILER’S

EFFICIENCY.

6. READ THE LITERATURE ENCLOSED BY THE MANUFACTURER WITH THE VARIOUS ACCESSORY DEVICES. THESE

ACCESSORY DEVICES MUST BE INSTALLED AND USED ACCORDING TO THE RECOMMENDATIONS OF THE

MANUFACTURER.

7. IT IS THE RESPONSIBILITY OF THE INSTALLING CONTRACTOR TO SEE THAT ALL CONTROLS ARE CORRECTLY

INSTALLED AND ARE OPERATING PROPERLY WHEN THE INSTALLATION IS COMPLETED.

8. FOR OPTIMUM PERFORMANCE AND SERVICEABILITY FROM THIS UNIT ADHERE TO THE FOLLOWING

RECOMMENDATIONS:

A. DO NOT TAMPER WITH THE UNIT OR CONTROLS. Retain your contractor or a competent serviceman to assure that the unit is properly adjusted and

maintained.

B. Clean Firetubes at least once a year - preferably at the end of the heating season to remove soot and scale. Inside of Combustion Chamber should also be

cleaned at the same time.

C. Have Oil Burner and Controls checked at least once a year or as may be necessitated.

CANADA BOILERS

WARNING

THIS BOILER IS DESIGNED TO BURN NO. 2 FUEL OIL ONLY. DO NOT USE GASOLINE, CRANKCASE

DRAININGS, OR ANY OIL CONTAINING GASOLINE. NEVER BURN GARBAGE OR PAPER IN THIS BOILER.

DO NOT CONVERT TO ANY SOLID FUEL (I.E. WOOD, COAL) OR GASEOUS FUEL (I.E. NATURAL GAS, LP/

PROPANE). ALL FLAMMABLE DEBRIS, RAGS, PAPER, WOOD SCRAPS, ETC., SHOULD BE KEPT CLEAR OF

THE BOILER AT ALL TIMES. KEEP THE BOILER AREA CLEAN AND FREE OF FIRE HAZARDS.

All boilers equipped with burner swing door have a potential hazard which can cause severe property damage,

personal injury or loss of life if ignored. Before opening swing door, turn off service switch to boiler and

disconnect two halves of Burner Swing Door Interlock wiring harness to prevent accidental ring of burner

outside the combustion chamber. Be sure to tighten swing door fastener completely and reconnect two

halves of Burner Swing Door Interlock when service is completed

CAUTION

This boiler contains controls which may cause the boiler to shut down and not restart without service. If

damage due to frozen pipes is a possibility, the heating system should not be left unattended in cold weather;

or appropriate safeguards and alarms should be installed on the heating system to prevent damage if the

boiler is inoperative.

2

Page 3

IMPORTANT

Before starting to install this oil boiler, read these instructions carefully. Keep instructions in legible condition

and posted near oil boiler for reference by owner and service technician.

TAbLE OF CONTENTS

I. General Information ..................................3

II. Installation Instructions ............................

5

IV. Boiler Cleaning

.............................................

14

III. Operating and Service Instructions ..........

I. General Information

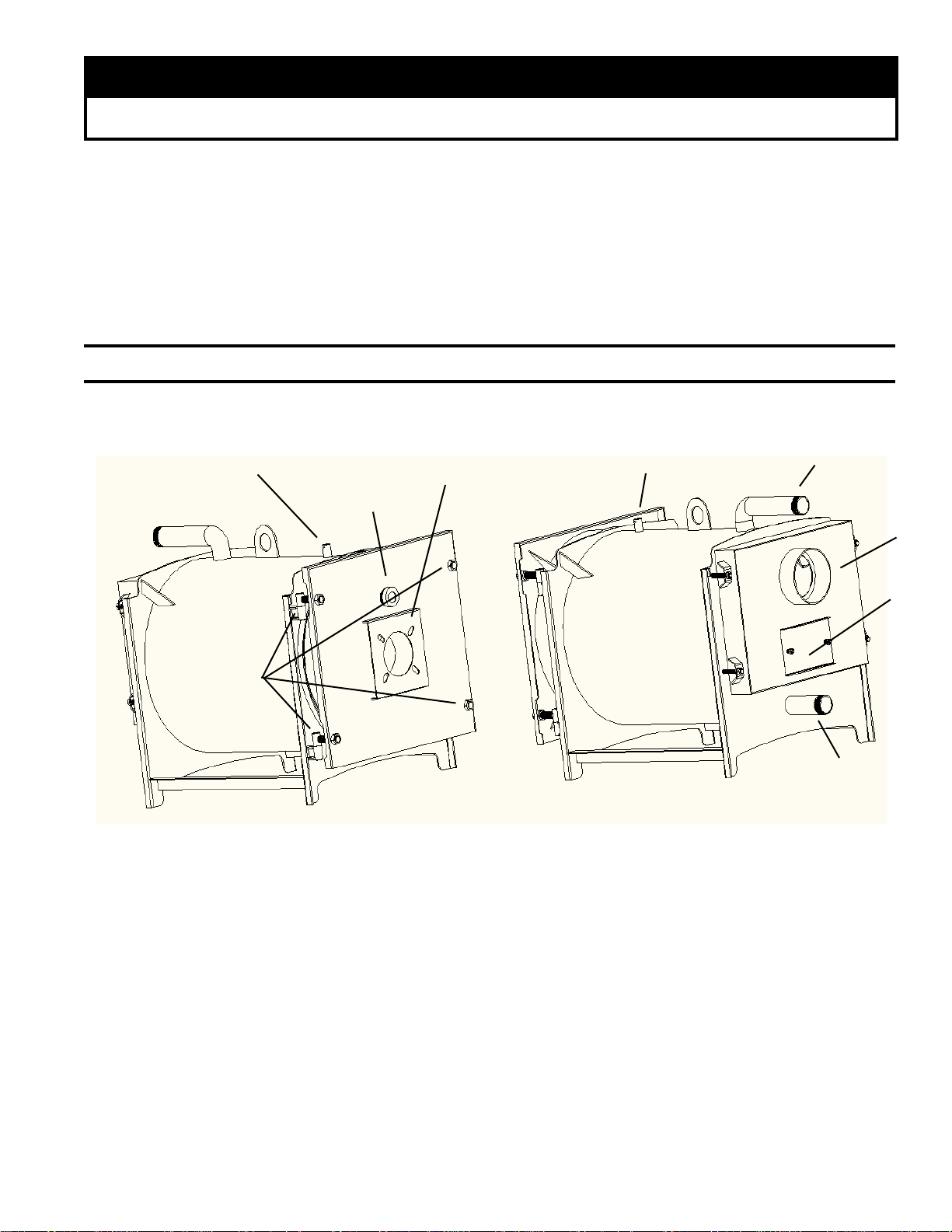

3-sensor pocket

Burner mount position

Fire inspection hole

Door hinges

11

Water outlet

3-sensor pocket

Chimney

Cleaning access

Figure 1: TES® Packaged Boiler

1

. INSPECT SHIPMENT carefully for any signs of

damage.

A. ALL EQUIPMENT is carefully manufactured,

inspected and packed. Our responsibility ceases

upon delivery of crated Boiler to the carrier in good

condition.

B. ANY CLAIMS for damage or shortage in shipment

must be led immediately against the carrier by the

consignee. No claims for variances from, or

shortage in orders, will be allowed by the manufacturer unless presented within sixty (60) days after

receipt of goods.

Water Inlet

2

. LOCATE BOILER in front of nal position before

removing crate. See Figure 1.

A. LOCATE so that smoke pipe connection to chimney

will be short and direct. BOILER IS SUITABLE

FOR INSTALLATION ON COMBUSTIBLE

FLOOR. Boiler can not be installed on carpeting.

B. FOR BASEMENT INSTALLATION, provide a

solid base, such as concrete, if oor is not level or

if water may be encountered on oor around Boiler.

C. PROVIDE SERVICE CLEARANCE of at least 24”

clearance in front for servicing.

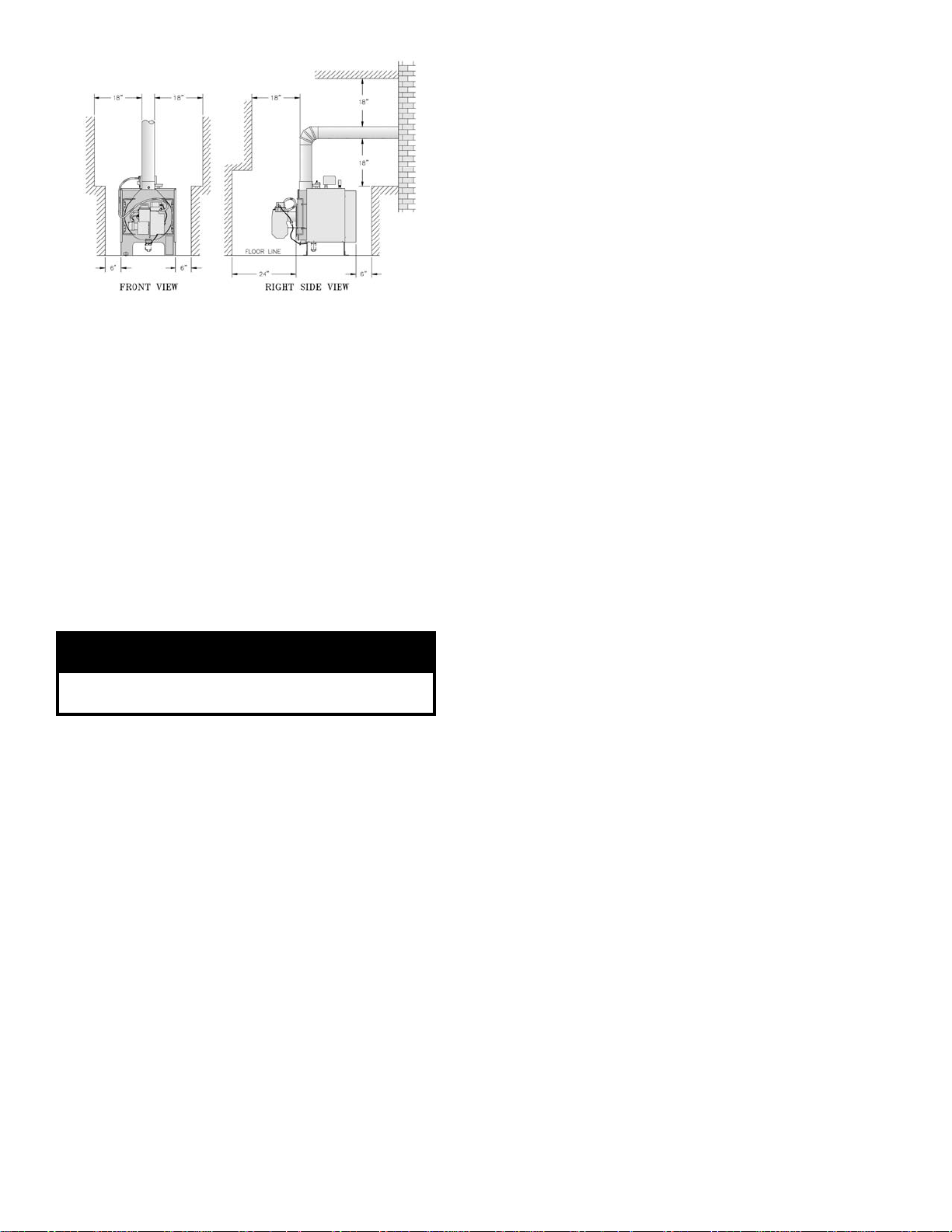

D. For minimum clearances to combustible materials

See Figure 2.

3

Page 4

Figure 2: Minimum Installation Clearances To

Combustible Materials

NOTE 1: Listed clearances comply with American

National Standard ANSI/NFPA 31,

Installation of oil burning equipment.

NOTE 2: TES Series boilers can be installed in rooms

with clearances from combustible material as

listed above. Listed clearances can not be

reduced for alcove or closet installations.

NOTE 3: For reduced clearances to combustible

material, protection must be provided as

described in the above ANSI/NFPA 31

standard.

3. PROVIDE COMBUSTION AND VENTILATION

AIR. Local code provisions may apply and should be

referenced.

WARNING

Adequate combustion and ventilation air must be

provided to assure proper combustion.

A. Determine volume of space (boiler room). Rooms

communicating directly with the space in which the

appliances are installed, through openings not

furnished with doors, are considered a part of the

space.

Volume(ft

B. Determine total input of all appliances in the space.

Add inputs of all appliances in the space and round

the result to the nearest 1000 BTU per hour.

C. Determine type of space. Divide Volume by total

input of all appliances in space. If the result is

greater than or equal to 50 ft3/1000 BTU per hour,

then it is considered an unconned space. If the

result is less than 50 ft3/1000 BTU per hour then the

space is considered a conned space.

D. For boiler located in an unconned space of a

conventionally constructed building, the fresh air

3

) = Length(ft) x Width(ft) x Height(ft)

inltration through cracks around windows and

doors normally provides adequate air for combustion and ventilation.

E. For boiler located in a conned space or an uncon

ned space in a building of unusually tight con-

struction, provide outdoor air with the use of two

permanent openings which communicate directly or

by duct with the outdoors or spaces (crawl or attic)

freely communicating with the outdoors. Locate

one opening within 12 inches of top of space.

Locate remaining opening within 12 inches of

bottom of space. Minimum dimension of air

opening is 3 inches. Size each opening per

following:

Direct communication with outdoors.

(1)

Minimum free area of 1 square inch per 4,000

BTU per hour input of all equipment in space.

(2) Vertical ducts. Minimum free area of 1 square

inch per 4,000 BTU per hour input of all

equipment in space. Duct cross-sectional area

shall be same as opening free area.

(3) Horizontal ducts. Minimum free area of 1

square inch per 2,000 BTU per hour input of all

equipment in space. Duct cross-sectional area

shall be same as opening free area.

Alternate method for boiler located within

conned space. Use indoor air if two permanent openings communicate directly with

additional space(s) of sufcient volume such

that combined volume of all spaces meet

criteria for unconned space. Size each

opening for minimum free area of 1 square

inch per 1,000 BTU per hour input of all

equipment in spaces, but not less than 100

square inches.

F. Louvers and Grilles of Ventilation Ducts

(1) All outside openings should be screened and

louvered. Screens used should not be smaller

than 1/4 inch mesh. Louvers will prevent the

entrance of rain and snow.

(2) Free area requirements need to consider the

blocking effect of louvers, grilles, or screens

protecting the openings. If the free area of the

louver or grille is not known, assume wood

louvers have 20-25 percent free area and metal

louvers and grilles have 60-75 percent free

area.

(3) Louvers and grilles must be xed in the open

position, or interlocked with the equipment to

open automatically during equipment operation.

-

4

Page 5

II. Installation Instructions

1.

REMOVE CRATE

A. Remove all fasteners at crate skid.

B. Lift outside container and remove all other inside

fittings.

2.

REMOVAL OF BOILER FROM SKID

A. Tilt boiler, "walk" boiler backward, and set rear legs

down on oor. Tilt boiler backward, pull skid

forward and set front legs down on edge of skid.

Install close coupling, tee, and plug in return

coupling, see Step 7 and Figure 1. Point tee toward

permanent return location.

B. Tilt boiler backward and remove skid. Be careful not

to damage Burner and Jacket.

3.

CHANGE HINGE POSITION if necessary.

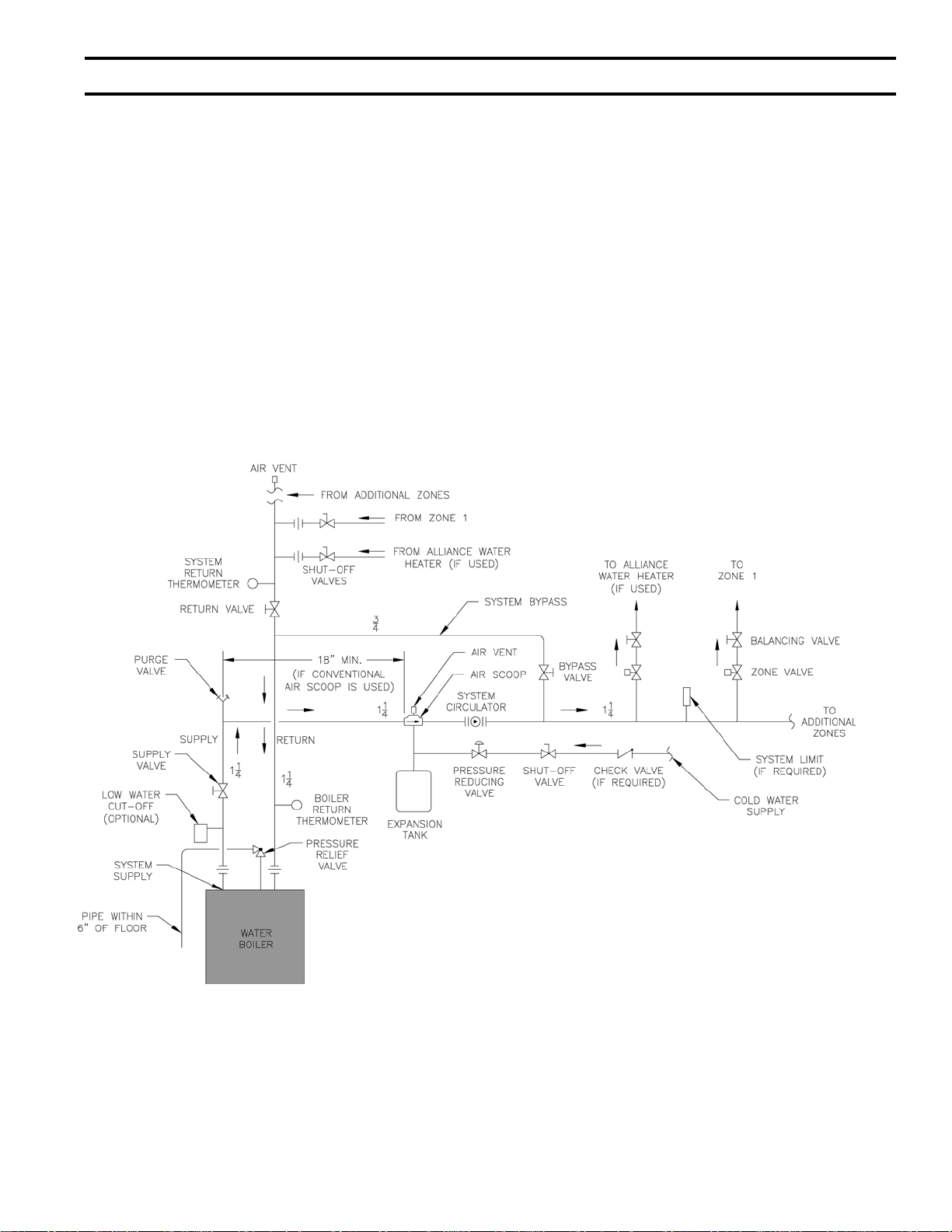

Figure 4: Recommended Water Piping for Zone Valve Zoned Heating Systems

5

Page 6

Figure 5: Recommended Water Piping for Circulator Zoned Heating Systems

6

Page 7

4.

INSTALL BOILER CONTROL.

A. Pull bulb and capillary tube out of hole in back of

control. Insert bulb in immersion well on top of

boiler and secure control with set screw in control.

B. Secure exible conduit to Jacket Wrapper side with

conduit clamp and sheet metal screw. Conduit must

be on same side of boiler as Swing Door hinges.

5.

MOVE BOILER TO PERMANENT POSITION by

sliding or walking.

6.

INSPECT FRONT AND REAR DOOR INSULATION

PIECES AND COMBUSTION CHAMBER LINER

A. OPEN SWING DOOR on front of boiler. Use

ashlight to inspect insulation pieces secured to

front and rear doors. Inspect Ceramic Fiber Blanket

secured to bottom of combustion chamber with

water glass adhesive. Replace any damaged pieces.

7.

CONNECT SUPPLY AND RETURN PIPING TO

HEATING SYSTEM

A. Hot water pipes shall have clearances of at least ½”

from all combustible construction.

B. Use a system by-pass if the boiler is to be operated

in a system which has a large volume or excessive

radiation where low boiler water temperatures may

be encountered (i.e. converted gravity circulation

system, etc.).

Valves should be located in the by-pass and return

line as illustrated in Figures 4 and 5 in order to

regulate water ow for maintenance of higher

boiler water temperature.

Set the by-pass and return valves to a half throttle

position to start. Operate boiler until the system

water temperature reaches its normal operating

range.

Adjust the valves to maintain 75°C to 85°C boiler

water temperature and greater than 45°C return

temperature. Adjust both valves simultaneously.

Closing the boiler return valve while opening the

by-pass valve will raise the boiler return temperature. Opening the boiler return valve while closing

the by-pass valve will lower the boiler return

temperature.

C. If this boiler is used in connection with refrigeration

systems, the boiler must be installed so that the

chilled medium is piped in parallel with the heating

boiler using appropriate valves to prevent the

chilled medium from entering the boiler, see Figure

6. Also consult I=B=R Installation and Piping

Guides.

D. If this boiler is connected to heating coils located in

air handling units where they may be exposed to

refrigerated air the boiler piping must be equipped

with ow control valves to prevent gravity circulation of boiler water during the operation of the

cooling system.

Figure 6: Recommended Piping for

Combination Heating & Cooling

(Refrigeration) Systems

E. A hot water boiler installed above radiation level

must be provided with a low water cutoff device as

part of the installation.

If a low water cut-off is required, it must be mount-

ed in the system piping above the boiler.

The minimum safe water level of a hot water boiler

is just above the highest water containing cavity of

the boiler; that is, a hot water boiler must be full of

water to operate safely.

F. There are many possible causes of oxygen contami-

nation such as:

(1) Addition of excessive make-up water as a

result of system leaks.

(2) Absorption through open tanks and ttings.

(3) Oxygen permeable materials in the distribution

system.

In order to insure long product life, oxygen sources

should be eliminated. This can be accomplished by

taking the following measures:

(1) Repairing system leaks to eliminate the need

for addition of make-up water.

(2) Eliminating open tanks from the system.

(3) Eliminating and/or repairing ttings which

allow oxygen absorption.

(4) Use of non-permeable materials in the distribu-

tion system.

(5) Isolating the boiler from the system water by

installing a heat exchanger.

CAUTION

Oxygen contamination of boiler water will cause

corrosion of iron and steel boiler components,

and can lead to boiler failure. TES Standard

Warranty does not cover problems caused by

oxygen contamination of boiler water.

7

Page 8

8.

INSTALL SMOKEPIPE — The TES boiler should be vented

into a reclay tile-lined masonry chimney or a chimney

constructed from Type L Vent or a factory built

chimney that complies with the Type HT requirement,

of UL103. The chimney and vent pipe shall have a

sufcient draft at all times, to assure safe proper

operation of the boiler. See Figure 7 for recommended

installation.

a home without insulation or storm windows. With

increasing fuel prices that home probably has been

insulated and tted with storm windows so that the

heat loss of the home has been reduced. This

requires less fuel to be burned and sends less heat

up the chimney.

A new boiler probably has a higher efciency than

the boiler being replaced. That probably means that

the stack temperature from the new boiler will be

lower than that from the old boiler and with less

room air being drawn up the chimney to dilute the

stack gases. The combination of a large uninsulated

chimney, reduced ring rate, reduced ring time,

lower stack temperature and less dilution air can, in

some cases, contribute to the condensing of small

amounts of water vapor in the chimney. Such

condensation, when it occurs, can cause chimney

deterioration. In extreme cases, condensed water

may be visible on the outside of the breeching or

chimney. In those extreme cases, the chimney may

have to be lined to insulate the chimney and thus

prevent the condensation. The addition of dilution

air into the chimney may assist in drying the

chimney interior surfaces.

C. Heat extractors mounted into the breeching are not

recommended.

Figure 7

A. Install the draft regulator following the instructions

furnished with the regulator. See Figure 8 for

alternate draft regulator locations.

Figure 8

B. Consider the chimney overall. Chimneys that have a

high heat loss may become less suitable as the heat

loss of the home goes down and the efciency of

the boiler installed goes up. Most homes have a

chimney appropriate for the fuel and the era in

which the home was built. That may have been a

coal red or an inefcient oil red boiler built into

9.

INSTALL ELECTRIC WIRING

A. Follow the National Electrical Code and local

regulations. A separate electrical circuit must be run

from the main electrical service with an overcurrent device/disconnect in the circuit. A service

switch is recommended and may be required by

some local jurisdictions. Wiring should conform to

Figures 11A, 11B and 11C.

B. CANADA — Refer to CSA standard C22.2 Part 1,

1990, Electrical Features of Fuel Burning Equipment (Gas and Oil).

C. If boiler is installed in Canada, a blocked vent safety

switch must be installed. Refer to Blocked Vent

Safety Switch Instruction Supplement provided

with boiler (Canada only).

10.

FUEL UNITS AND OIL LINES

Use exible oil line(s) so that Swing Door can be

opened without disconnecting oil supply.

A supply line fuel oil lter is recommended as a

minimum for all ring rates but a pleated paper fuel oil

lter is recommended for the lowest (.6 GPH) ring

rate application to prevent nozzle fouling.

SINGLE-PIPE OIL LINES — Standard burners are

provided with single-stage 3450 rpm fuel units with the

by-pass plug removed for single-pipe installations.

The single-stage fuel unit may be installed single-pipe

with gravity feed or lift. Maximum allowable lift is 8

feet. See Figure 9.

8

Page 9

Figure 9

IMPORTANT

Single-pipe installations must be absolutely airtight

or leaks or loss of prime may result. Bleed line and

fuel unit completely.

TWO-PIPE OIL LINES - For two-pipe systems where

more lift is required, the two-stage fuel unit is

recommended. Tables 2 (single-stage) and 3 (two-stage)

show allowable lift and lengths of 3/8-inch and ½-inch

OD tubing for both suction and return lines. Refer to

Figure 10.

TABLE 2: SINGLE-STAGE UNITS (3450 RPM)

TWO-PIPE SYSTEMS

Maximum Length of Tubing

"H" + "R"

Lift "H"

3/8" OD

Tubing (3 GPH)

0' 84' 100'

1' 78' 100'

2' 73' 100'

3' 68' 100'

4' 63' 100'

5' 57' 100'

6' 52' 100'

7' 47' 100'

8' 42' 100'

9' 36' 100'

10' 31' 100'

11' 26' 100'

12' 21' 83'

13' --- 62'

14' --- 41'

1/2" OD

Tubing (3 GPH)

Figure 10

Be sure that all oil line connections are absolutely

airtight.

Check all connections and joints. Flared ttings are

recommended. Do not use compression ttings.

Open the air-bleed valve and start the burner. For clean

bleed, slip a 3/16” ID hose over the end of the bleed

valve and bleed into a container. Continue to bleed for

15 seconds after oil is free of air bubbles. Stop burner

and close valve.

TABLE 3: TWO-STAGE UNITS (3450 RPM)

TWO-PIPE SYSTEMS

Maximum Length of Tubing

"H" + "R"

Lift "H"

0' 93' 100'

2' 85' 100'

4' 77' 100'

6' 69' 100'

8' 60' 100'

10' 52' 100'

12' 44' 100'

14' 36' 100'

16' 27' 100'

18' --- 76'

3/8" OD

Tubing (3 GPH)

1/2" OD

Tubing (3 GPH)

9

Page 10

Wiring Diagram for TES Boiler Control Panel

10

Page 11

III. Operating and Service Instructions

WARNING

All boilers equipped with burner swing door have a potential hazard which can cause severe property damage,

personal injury or loss of life if ignored. Before opening swing door, turn off service switch to boiler and

disconnect two halves of Burner Swing Door Interlock wiring harness to prevent accidental ring of burner

outside the combustion chamber. Be sure to tighten swing door fastener completely and reconnect two

halves of Burner Swing Door Interlock when service is completed.

1.

ALWAYS INSPECT INSTALLATION BEFORE

STARTING BURNER.

2.

FILL HEATING SYSTEM WITH WATER.

NOTE: It is important to properly remove the oil and

dirt from the system.

CLEAN HEATING SYSTEM If boiler water is dirty,

refer to step 13 for proper cleaning instructions.

A. Fill entire Heating System with water and vent air

from system.

3.

CHECK CONTROLS, WIRING AND BURNER to be

sure that all connections are tight and burner is rigid,

that all electrical connections have been completed and

fuses installed, and that oil tank is lled and oil lines

have been tested.

4.

LUBRICATION — Follow instruction on burner and

circulator label to lubricate, if oil lubricated. Most

motors currently used on residential type burners

employ permanently lubricated bearings and thus do

not require any eld lubrication. Water lubricated

circulators do not need eld lubrication.

Do not over-lubricate. This can cause as much trouble as no

lubrication at all.

5.

ADJUST CONTROLS SETTINGS with burner service

switch turned “ON”.

11

Page 12

Important Product Safety Information

Refractory Ceramic Fiber Product

Warning:

The Repair Parts list designates parts that contain refractory ceramic fibers

(RCF). RCF has been classified as a possible human carcinogen. When

exposed to temperatures about 985°C, such as during direct flame contact,

RCF changes into crystalline silica, a known carcinogen. When disturbed as a

result of servicing or repair, these substances become airborne and, if inhaled,

may be hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace RCF parts or attempt any service or repair work

involving RCF without wearing the following protective gear:

1. A National Institute for Occupational Safety and Health (NIOSH)

approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an airtight plastic bag. RCF

and crystalline silica are not classified as hazardous wastes in the United

States and Canada.

First Aid Procedures

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location

with clean fresh air. Seek immediate medical attention if breathing

difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

:

12

Page 13

There are various test kits available to trace air

leaks, such as electronic sight glasses. Follow the

manufacturers' instructions to nd air leaks.

The following actions can eliminate air leaks:

(1) Bleed pump as detailed previously.

(2) Replace are ttings.

(3) Replace oil supply line.

(4) Repair oil lter leaks.

(5) Replace or repair tank ttings.

NOTICE

CHECK TEST PROCEDURE. A very good test for

isolating fuel side problems is to disconnect the

fuel system and with a 2' length of tubing, re

out of an auxiliary ve gallon pail of clean, fresh,

warm #2 oil from another source. If the burner runs

successfully when drawing out of the auxiliary

pail then the problem is isolated to the fuel or fuel

lines being used on the jobsite.

E. GASKET LEAKS — If 11.5 to 12.5% CO

#1 smoke or less cannot be obtained in the

breeching, look for air leaks around the ue collar.

Such air leaks will cause a lower CO2 reading in the

breeching. The smaller the ring rate the greater

effect an air leak can have on CO2 readings.

F. DIRT — A fuel lter is a good investment. Acci-

dental accumulation of dirt in the fuel system can

clog the nozzle or nozzle strainer and produce a

poor spray pattern from the nozzle. The smaller the

ring rate, the smaller the slots become in the

nozzle and the more prone to plugging it becomes

with the same amount of dirt.

G. WATER — Water in the fuel in large amounts will

stall the fuel pump. Water in the fuel in smaller

amounts will cause excessive wear on the pump,

but more importantly water doesn’t burn. It chills

the ame and causes smoke and unburned fuel to

pass out of the combustion chamber and clog the

ueways of the boiler.

with a

2

H. COLD OIL — If the oil temperature approaching

the fuel pump is 5°C or lower poor combustion or

delayed ignition may result. Cold oil is harder to

atomize at the nozzle. Thus, the spray droplets get

larger and the ame shape gets longer. An outside

fuel tank that is above grade or has fuel lines in a

shallow bury is a good candidate for cold oil. The

best solution is to bury the tank and lines deep

enough to keep the oil above 5°C.

I. HIGH ALTITUDE INSTALLATIONS

Air settings must be increased at higher altitudes.

Use instruments and set for 11.5 to 12.5% CO

J. START-UP NOISE — Late ignition is the cause of

start-up noises. If it occurs recheck for electrode

settings, ame shape, air or water in the fuel lines.

K. SHUT DOWN NOISE — If the ame runs out of air

before it runs out of fuel, an after burn with noise

may occur. That may be the result of a faulty cutoff valve in the fuel pump, or it may be air trapped

in the nozzle line. It may take several ring cycles

for that air to be fully vented through the nozzle.

Water in the fuel or poor ame shape can also cause

shut down noises.

. ATTENTION TO BOILER WHILE NOT IN

15

OPERATION.

A. Spray inside surfaces with light lubricating or

crankcase oil using gun with extended stem so as to

reach all corners.

B. Always keep the manual fuel supply valve shut off

if the burner is shut down for an extended period of

time.

C. To recondition the heating system in the fall season

after a prolonged shut down, follow the instructions

outlined in Section III — Operating and Service

Instructions, Items 1 through 8.

.

2

13

Page 14

IV. Boiler Cleaning

WARNING

All boiler cleaning must be completed with burner service switch turned off. Boilers equipped with burner

swing door have a potential hazard which can cause severe property damage, personal injury or loss of

life if ignored. Before opening swing door, turn off service switch to boiler to prevent accidental ring of

burner outside the combustion chamber. Be sure to tighten swing door fastener completely when service is

completed.

1.

CLEAN THE FIRETUBES

A. For access to reside of boiler, pull two halves of

Burner Swing Door Interlock wiring harness apart,

remove hex nuts holding door closed and open

swing door.

B. Prior to cleaning boiler, lay a protective cloth or

plastic over combustion chamber liner.

C. Using a 1 1/2" diameter wire brush (30" handle),

clean retubes. Measure 15" from end of brush

opposite handle, and mark handle. DO NOT allow

this mark to go past front end of retube during

cleaning, or brush will hit rear door insulation

piece.

2

. CLEAN THE COMBUSTION CHAMBER

Using wire or ber bristle brush, clean inside of

combustion chamber. DO NOT let brush hit rear door

insulation piece or combustion chamber liner.

3

. AFTER CLEANING

Vacuum debris inside bottom of rear door, remove

protective cloth, and vacuum remaining reside of

boiler as necessary. BE CAREFUL not to damage liner

or rear door insulation piece. Inspect front and rear door

insulation pieces, front door gaskets and combustion

chamber liner for damage. Replace any damaged

pieces.

. CLOSE BOILER

4

CAUTION: Do not start burner unless burner swing door is

securely closed. Close door, install hex nuts, and tighten

securely. Door should be parallel to tubesheet when

viewed from top and sides. Reconnect two halves of

Swing Door Interlock.

WARNING

The boiler must be connected to an approved

chimney in good condition. Serious property

damage could result if the boiler is connected

to a dirty or inadequate chimney. The interior of

the chimney ue must be inspected and cleaned

before the start of the heating season and

should be inspected periodically throughout the

heating season for any obstructions. A clean and

unobstructed chimney ue is necessary to allow

noxious fumes that could cause injury or loss

of life to vent safely and will contribute toward

maintaining the boiler's efciency.

14

Page 15

SERVICE RECORD

DATE SERVICE PERFORMED

5

1

Loading...

Loading...