TES E-TES SD Operator's Manual

1

LMANMB120LP

Copyright Tes Drying Systems, 2014

REVISED: 01/29/2015

2

Table of Contents

LMANMB120LP

Introduction 3

General Information 4

Warranty 6

SECTION 1

Heater Operation Safety 7

Warning Labels 9

SECTION 2

Menu Navigation 10

Air Flow Set-up 13

Remote Probe Set-up 14

Remote Fan Control 17

Dual Circuit Indicator 18

Software Updates 19

Data Charting 20

SECTION 3

Heater Operation 23

Troubleshooting 29

Re-initializing Memory 33

Resetting Processor 35

Wiring Diagrams 36

Revised: 11/09/12

SECTION 4

Maintenance 40

Parts 41

SECTION 5

Drying Carpet 50

Drying Wood Floors 52

Drying Walls 54

Copyright Tes Drying Systems, 2014

3

Introduction

Congratulations on your purchase of the Tes Drying Systems E-TES SD 120 Volt

Low Profile Electric Thermal Energy System. This manual is a guide for safe

operation and maintenance of this unit.

Read and understand this manual completely before operating this unit.

The temperature controls of the E-TES SD 120 Volt Low Profile Electric

Thermal Exchange unit are designed for safe operation in a variety of drying

operations. If setup improperly the E-TES SD can raise the room temperature to

140°F with an output temperature up to 210°F before it shuts off. Proper setup

and use of the temperature controls is required to protect the structure and

contents.

Improper operation, alteration, service or

maintenance can cause property damage, personal injury or loss of life.

Service must be performed by a qualified technician, service agency or electrician.

Tes Drying Systems is in no way responsible and is excluded from liability in

respect to any loss or damage which may arise due to improper operation,

maintenance or repair.

This manual should be maintained in legible condition adjacent to the unit or in a

secure location for future reference.

Any questions pertaining to the operating or servicing of this unit should be

directed to your nearest Tes Drying Systems distributor.

This manual is written specifically for the E-TES SD 120 Volt Low Profile

Electric Thermal Exchange units manufactured by:

Tes Drying Systems

4282 S 590 W

Salt Lake City, UT 84123

801-261-1282

Information in this manual is subject to change without notice and does not

represent a commitment on the part of Tes Drying Systems.

Copyright Tes Drying Systems, 2014

4

General Information

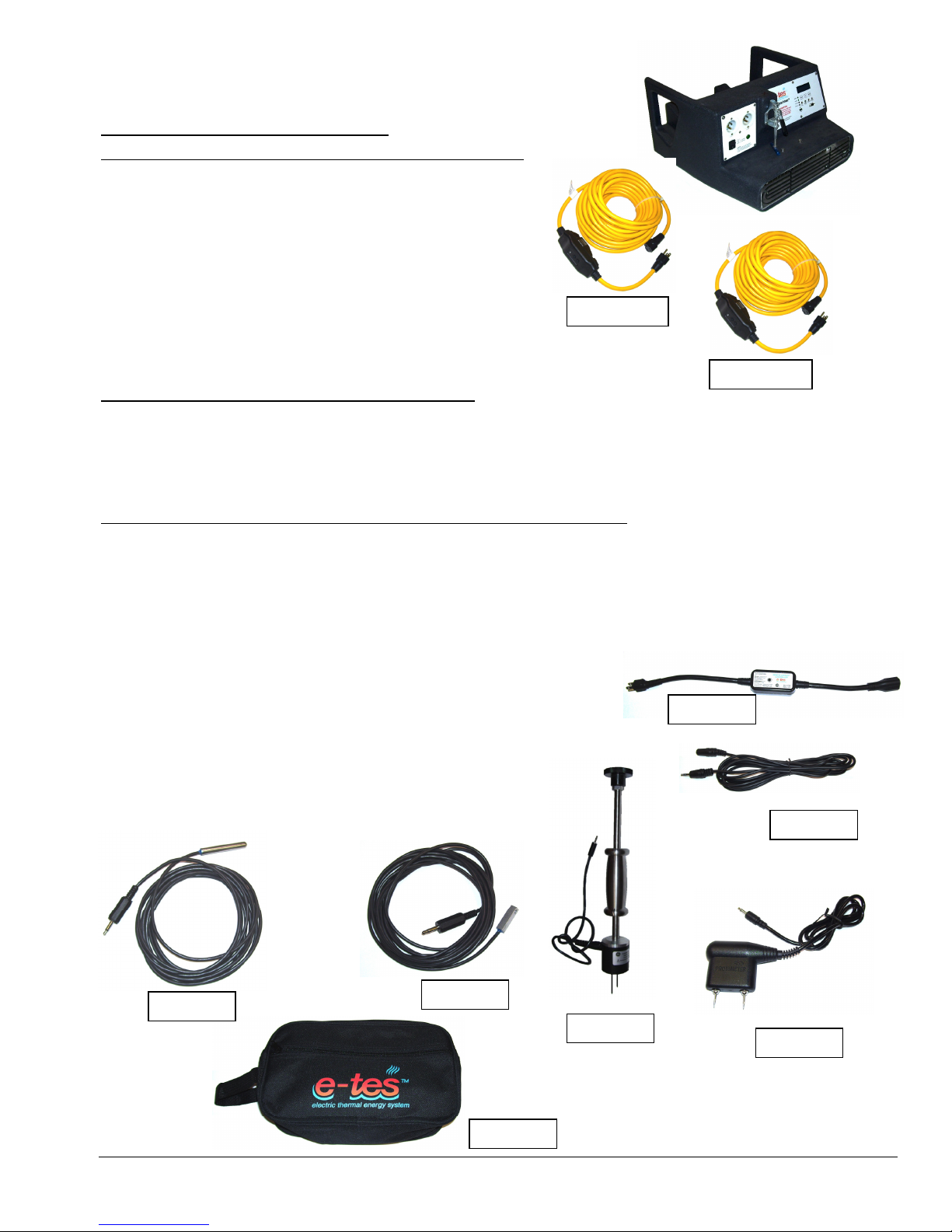

PGE5060

AT206

AT204

AT208

NM4407

A

AT200

AC102

NM4407

A

AT202

E-TES SD 120 Volt Low Profile

ELECTRIC THERMAL ENERGY SYSTEM

10,000 Btu 120vac Electric Model

Height: 13.5”

Length: 26.5”

Width: 22.75”

Weight: 30 lbs.

Heater watt rating: 3000 watts

Cord 1 Amp Draw: 12amps

Cord 2 Amp Draw: 12amps

E-TES SD 120 Volt Standard Equipment

ELECTRIC THERMAL EXCHANGE UNIT

NM4407A (2) 50’ - 12/3 GFCI Power Cords w/ 5-15P& 5-15R ends

SMART E-TES SD 120 Volt Optional Sensors & Controls

ST001 E-TES Charter Software (Available free online at tesdryingsystem.com)

AT210 E-TES SD Smart Package

Smart Package includes:

(1) AT200, (1) AT202, (1) PGE5060, (2) AT204, (1) AT206 & (1) AT208

AT200 Surface Temperature Sensor w/ 10ft cord

AT202 Air Temperature Sensor w/ 10ft cord

PGE5060 Moisture Level Sensor w/ 4ft cord

AT204 10 ft. sensor extension cord M-F jack & plug

AT206 Remote Exhaust Controller

AT208 Travel Bag for Sensor Storage

AC102 Hammer Probe w/ 4ft cord

Copyright Tes Drying Systems, 2014

5

Additional / Optional Equipment

AX33

AC25A

MB230

AC514

AX68

AC128

AC246

MI22

AT56

PGE500 Replacement Needles for Moisture Probe (Package of 20)

PGE0501 Replacement Retaining Nuts for Moisture Probe (Package of 2)

AX33 50’ - 12/3 Extension Cord w/ 5-15P & 5-15R

AC262A Lay Flat Ducting 14” Dia. (22.5” flat) x 500’

AT56 Duct Ring 14”

AC25A Omni Dry 2.9 Centrifugal Air Mover

AC246 OmniDry Focal Point Axial Air Mover

AC128 SureTest Circuit Analyzer

AX68 Breaker Buddy II

MB230 Single Stage Exhaust Controller

AC514 Flexi Dry Wall Drying System

MI22 Injectidry HP60FDP Floor Drying Package

Copyright Tes Drying Systems, 2014

6

Warranty

Your E-TES SD 120 Volt Low Profile Electric Thermal Exchanger is designed to give you years of reliable service.

If a problem should arise use the troubleshooting section in the operation manual to diagnose and correct the

problem if possible. If you are unable to determine the cause or solution to the problem contact your distributor or

Tes Drying Systems for assistance.

Tes Drying Systems warrants the roto-molded body of the E-TES SD 120 Volt Low Profile Electric Thermal

Exchanger to be free from defects in material or workmanship for five years from the date of purchase.

Warranty coverage does not include damage to body due to overheating after the first year.

All other components of the E-TES SD 120 Volt Low Profile Electric Thermal Exchanger are warranted to

be free of defects in material and workmanship for one year from the date of purchase.

During the warranty period, Tes Drying Systems will, at its option repair or replace components which

prove to be defective.

• This warranty does not provide for replacement of complete units due to defective components.

• Service Labor is only covered for the first 90 days after the date of purchase.

• Any costs for transportation are not covered in this warranty.

• Replacement parts are warranted only for the remainder of the original warranty period.

This warranty shall not apply to defects resulting from improper operation, lack of maintenance,

condensation, chemical corrosion, unauthorized modification, misuse or abuse.

This warranty does not cover normal wear to items such power cords, plug adapters or other items which

require replacement as a result of ordinary usage.

To obtain warranty service for the E-TES SD 120 Volt Low Profile Electric Thermal Exchanger, contact

your distributor or Tes Drying Systems. If the unit must be returned to Tes Drying Systems or an

authorized service center, the purchaser shall prepay shipping charges for products returned for warranty

service.

• No returned items will be accepted by Tes Drying Systems without prior authorization. All returns must

have a return authorization number, issued by Tes Drying Systems, clearly marked on the exterior of the

package.

Tes Drying Systems makes no other warranty either expressed or implied with respect to this product.

The remedies provided herein are the purchaser’s sole and exclusive remedies.

In no event shall Tes Drying Systems be liable for any direct, indirect, special, incidental or consequential

damages.

This warranty gives you specific legal rights. You may also have other rights which vary from jurisdiction

to jurisdiction.

Copyright Tes Drying Systems, 2014

7

Section

1

Heater Operation Safety

When using electrical appliances, basic precautions should always be

followed to reduce the risk of fire, electric shock, and injury to persons, including the following:

• Read all instructions before using this heater. Use this heater only as described in this manual.

Any other use not recommended by the manufacturer may cause fire, electric shock, or injury to

persons.

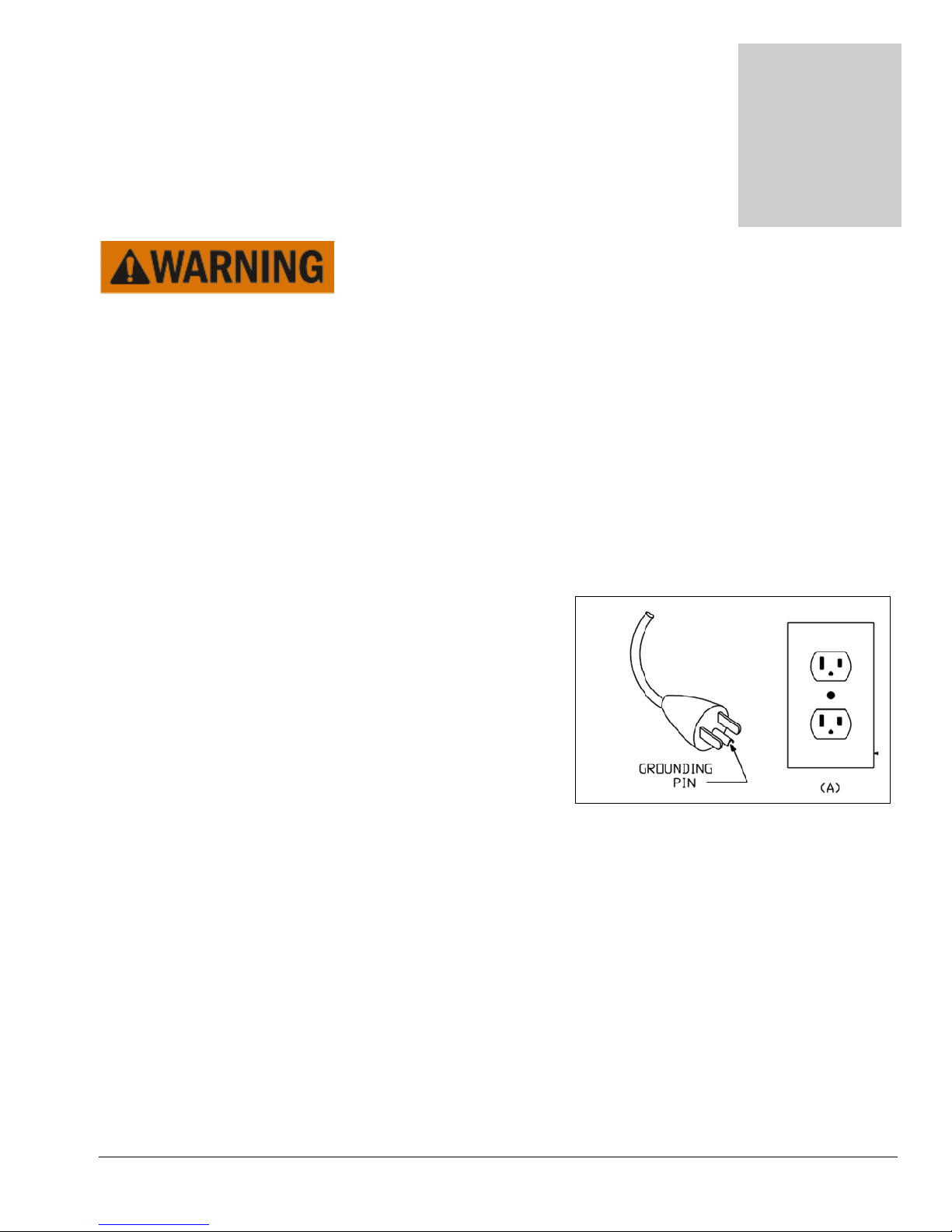

• This machine shall be grounded while in use to protect the operator from electric shock. The machine is

provided with two three-conductor cords with three-contact grounding type attachment plugs to fit the

proper grounding type receptacles. The green (or green and yellow) conductor in the cord is the

grounding wire. Never connect this wire to other than the grounding pin of the attachment plug.

• Connect to properly grounded outlets only. The 120volt power source must be wired and have 15 or 20

amp circuit breaker to safely handle the rated amperage of the unit. Examine the electric outlet before

connecting your E-TES SD. A Loose fitting or damaged outlet can cause the power cord to overheat. Do

not use a loose fitting or damaged outlet. If necessary, have an electrician repair the outlet before

connecting your E-TES SD to prevent cord or outlet

damage.

• This machine is for use on two separate nominal 120-volt

15 amp circuits and the power cords have grounding plugs

that resembles the plug illustrated in the sketch shown to

the right. Make sure that the machine is connected to an

outlet having the same configuration as the plug. No

adapter should be used with this machine.

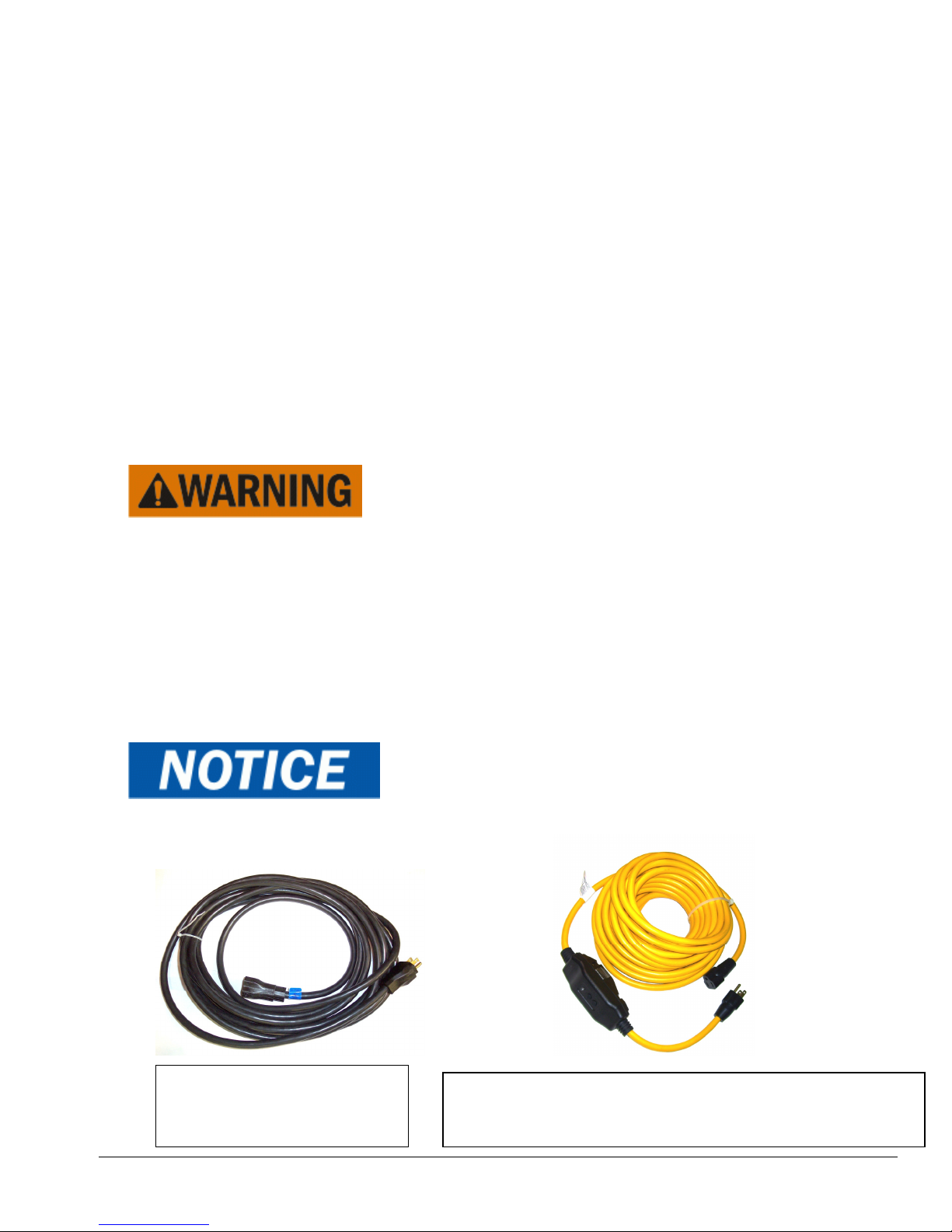

• Use no more than one 50 ft. 12 gauge extension cord

(100’ total cord length) per circuit when operating this

heater. Any extension cord used with this heater must be

12 gauge or 10 gauge three-conductor cords with three-contact grounding type attachment plugs to fit the

proper grounding type receptacles.

• The Ground Fault Circuit Interrupting (GFCI) protected cords supplied with the E-TES SD provide additional

safety when operating the E-TES SD on wet surfaces. Keep cord connections off wet floors. Protect cord

connections from damp surfaces and water sources. Always use the GFCI cords to reduce the risk of electrical

shock. Test operation of GFCI before each use. (See Page 40) Do not use outdoors. Do not use in standing

water.

• Do not run cord under carpeting. Do not cover cord with throw rugs, runners, or similar coverings. Do

not route cord under furniture or appliances. Arrange cord away from traffic area and where it will not be

tripped over.

• Do not operate any heater with a damaged cord or plug or after the heater malfunctions, has been

dropped or damaged in any manner. Discard damaged cord or heater, or return to authorized service

facility for examination and/or repair.

Copyright Tes Drying Systems, 2014

8

• This heater is hot when in use. To avoid burns, do not let bare skin touch hot surfaces. Use handles when

NEMA 5

-

15P & 5

-

15R ends

moving this heater. Keep combustible materials, such as furniture, pillows, bedding, papers, clothes, and

curtains at least 3 feet (0.9 m) from the front of the heater and keep them away from the sides and rear.

• Do not operate this heater unless all panels and guards are in place and properly secured.

• Extreme caution is necessary when any heater is used by or near children or invalids and whenever the

heater is left operating and unattended.

• Always unplug the heater when not in use. To unplug the heater, turn E-TES SD switch to off, then

remove plugs from outlets.

• Unplug machine power cords from outlets & then disconnect cords from the E-TES SD before performing

any repair on the heater.

• This heater is not intended for use in bathrooms, laundry areas and similar indoor locations. Never locate

heater where it may fall into a bathtub or other water container.

• Do not insert or allow foreign objects to enter any ventilation or exhaust opening as this may cause an

electric shock or fire, or damage the heater.

• To prevent a possible fire, do not block air intakes or exhaust in any manner. Do not use on soft surfaces,

like a bed, where openings may become blocked.

• A heater has hot and arcing or sparking parts inside. Do not use it in areas where gasoline, paint, or

flammable liquids are used or stored.

•

Always turn Heater OFF and keep air mover running for 5 minutes to

cool heater before turning air mover OFF. If air flow is turned off and the unit is not cooled properly the

heater box and front grill may get very hot, creating a burn hazard or damaging the unit.

• Restriction of the air flow from the heater snout may cause E-TES SD to overheat and shutoff.

• Adequate air flow must be maintained across heating elements for proper, safe operation. Do not disable

airflow sensor or other safety switches, doing so may result in damage to heater and will void warranty.

• Do not direct the outlet air flow towards objects which may be damaged by heat.

• Remove Feet or carpet clamps from snout of air mover before placing air mover into E-TES SD Electric

Thermal Exchanger to prevent damage to air seal gasket.

•

Always use Remote Temperature Sensors, Remote Power

Controllers or other form of temperature control to keep room temperature below 105ºF

during the drying process.

AX33

12/3 X 50’ Extension Cord

NEMA 5-15P & 5-15R ends

Copyright Tes Drying Systems, 2014

NM4407A

12/3 X 50’ GFCI Protected Extension Cord – Auto Re-set

9

WARNING LABELS

Copyright Tes Drying Systems, 2014

Navigation – Remote Sensor Set-up & Data

Section

2

Charting

E-TES SD MENU NAVIGATION:

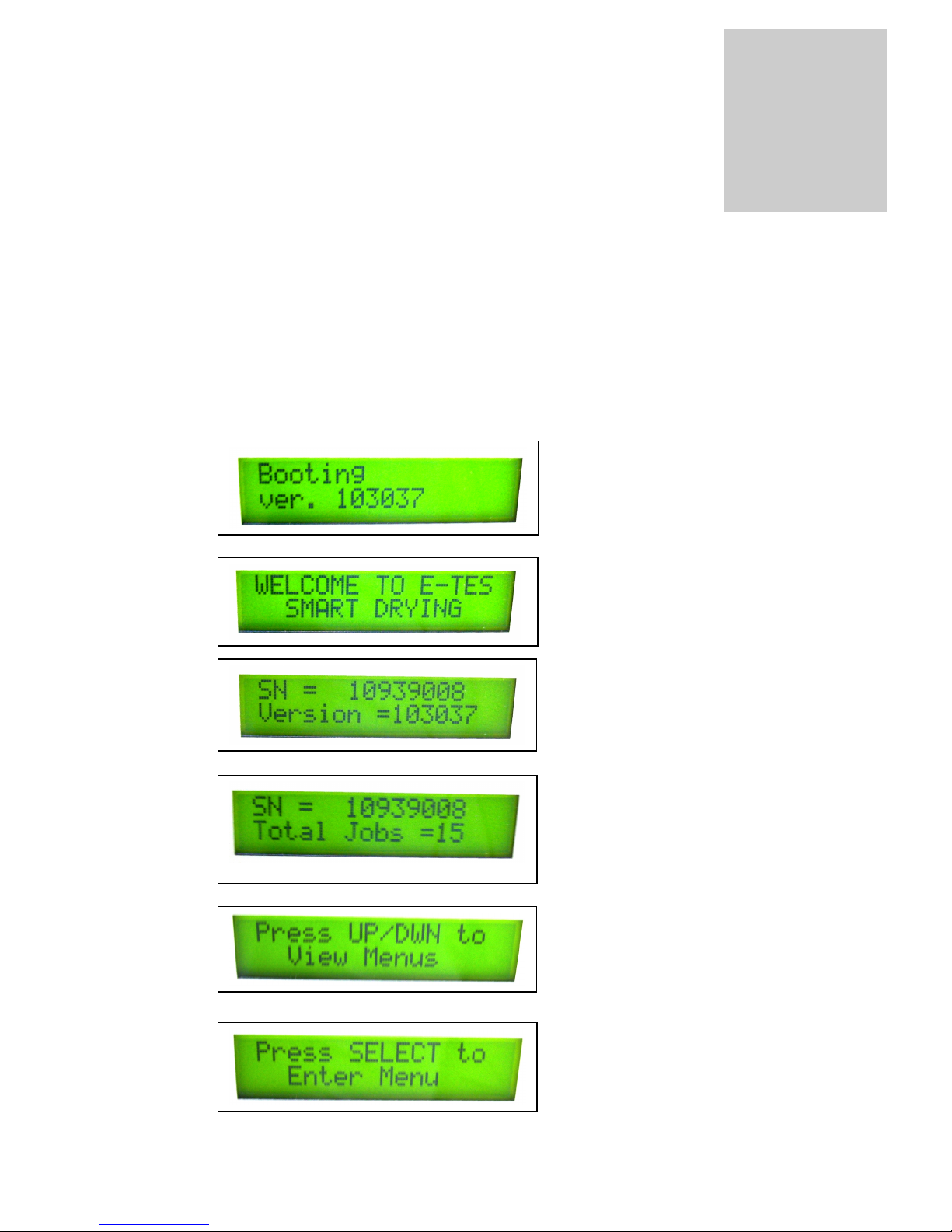

With the GFCI reset and the power cord connected to the E-TES SD, turn power switch to the ON position.

Display will quickly scroll through the first six screens, before stopping at the Main Screen.

First screen:

Second screen:

Third screen:

Fourth screen:

Fifth screen:

Sixth screen:

Copyright Tes Drying Systems, 2014

10

Booting Screen

Software version booting up

Welcome Screen

Unit serial number and

software version

Unit serial number and

number of jobs logged

Directions for how to view

menus

Directions for how to enter

menus to change settings

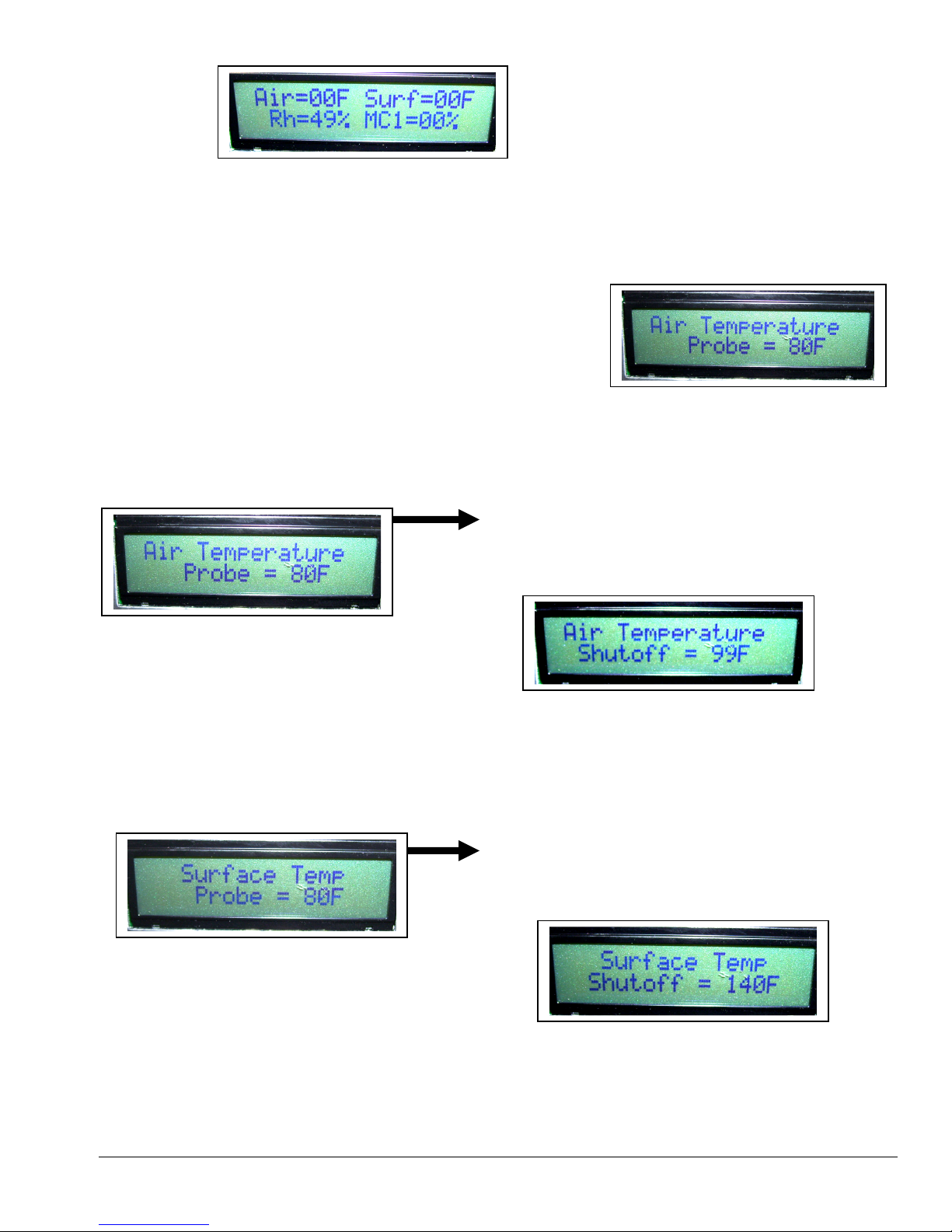

MAIN SCREEN:

Main screen will display current probe

temperatures or default settings if no probes are

connected.

• Air Default Setting: 00F

• Surface Default Setting: 00F

• Moisture 1 Default Setting: 00%

• Rh (Relative Humidity): Current value

Press UP / DOWN to move from Main Screen and scroll through Menu

From the Main Screen

PRESS DOWN: TO ACCESS AIR TEMPERATURE SCREEN

OR

PRESS UP: TO CURRENT DATE & TIME SCREEN

Air Temperature Screen: This tells you the current reading of the Air Temperature Sensor

probe if it is connected to the E-TES SD or the default value of 00F if the probe is not

connected.

• Press DOWN to move to Surface Temp Screen

• Press UP to return to Main Screen

Surface Temperature Screen: This tells you the current reading of the Surface Temperature

Sensor probe if it is connected to the E-TES SD or the default value of 00F if the probe is

not connected.

• Press DOWN to move to Moisture 1 Value Screen

• Press UP to return to Air Temperature Screen

Press SELECT to set Air Temperature Probe

shutdown temperature. Use UP/DOWN to

change Air Temperature shutoff setting.

Press SELECT to set Surface Temperature

Probe shutdown temperature. Use UP/DOWN

to change Surface Temperature shutoff setting.

Copyright Tes Drying Systems, 2014

11

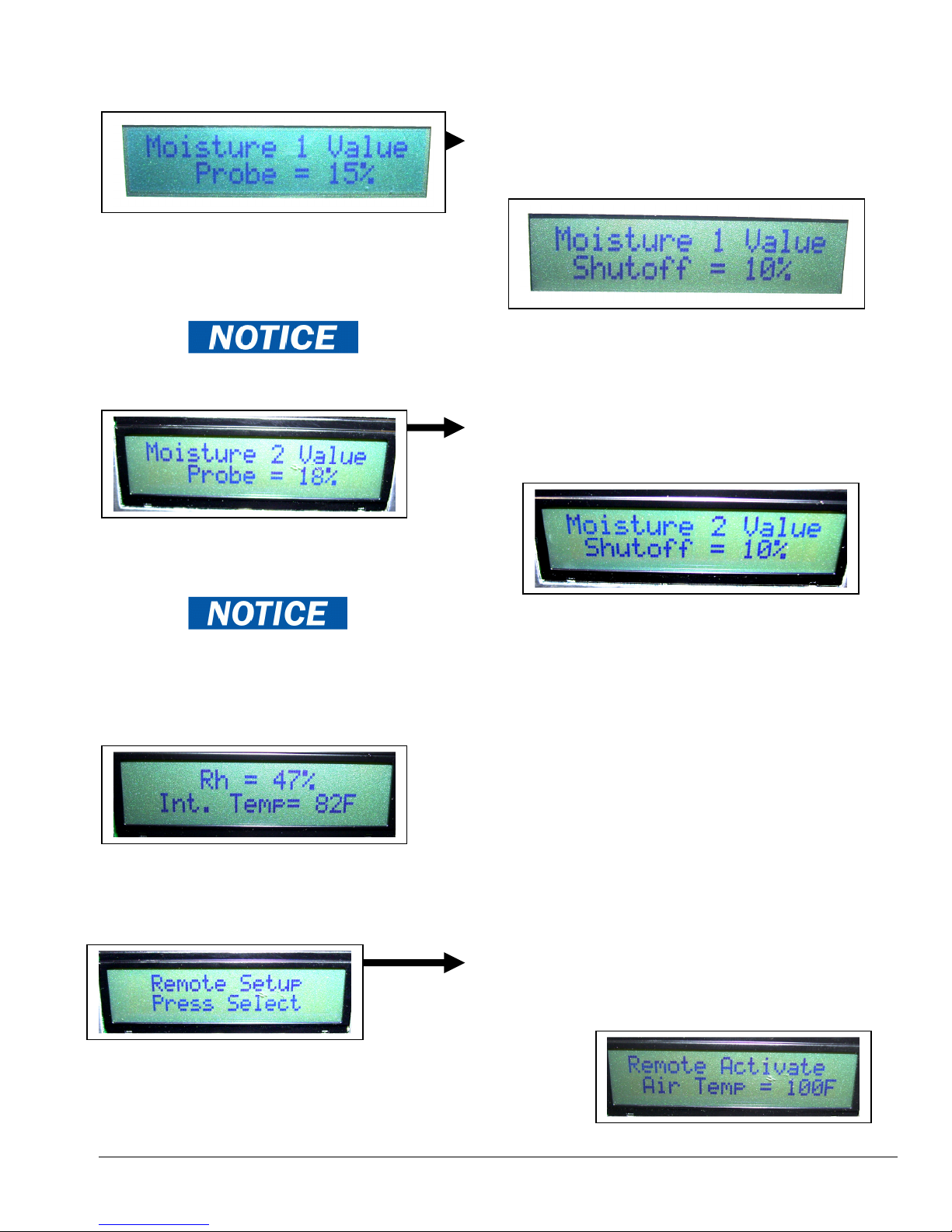

Moisture 1 Value Screen: This tells you the current reading of the Moisture probe if it is

• Press

UP to return to Humidity Internal Temperature Screen

connected to the E-TES SD or the default value of 00% if the probe is not connected.

• Press DOWN to move to Moisture 2 Value Screen

• Press UP to return to Surface Temp Screen

Press SELECT to set Moisture Probe shutdown

percentage. Use UP/DOWN to change moisture

percentage level set point.

Moisture 2 Value Screen: This tells you the current reading of the Moisture probe if it is

connected to the E-TES SD or the default value of 00% if the probe is not connected.

• Press UP to return to Moisture 1 Value Screen

• Press DOWN to move to Humidity / Internal Temperature

Screen

Press SELECT to set Moisture Probe shutdown

percentage. Use UP/DOWN to change moisture

percentage level set point.

Humidity / Internal Temperature Screen: This tells you the relative humidity percentage

and temperature inside the E-TES SD box.

• Press DOWN to move to Remote Setup screen

• Press UP to return to Moisture 2 Value screen

Remote Setup Screen: This allows you to set temperature at which the E-TES SD will turn

on Remote Exhaust Controller. (Remote Air Temperature Sensor to operate remote control.)

• Press DOWN to move to Air Flow Setup Screen

Press SELECT to set the E-TES Remote Exhaust

Controller turn on temperature. Use UP/DOWN to

change temperature.

Copyright Tes Drying Systems, 2014

12

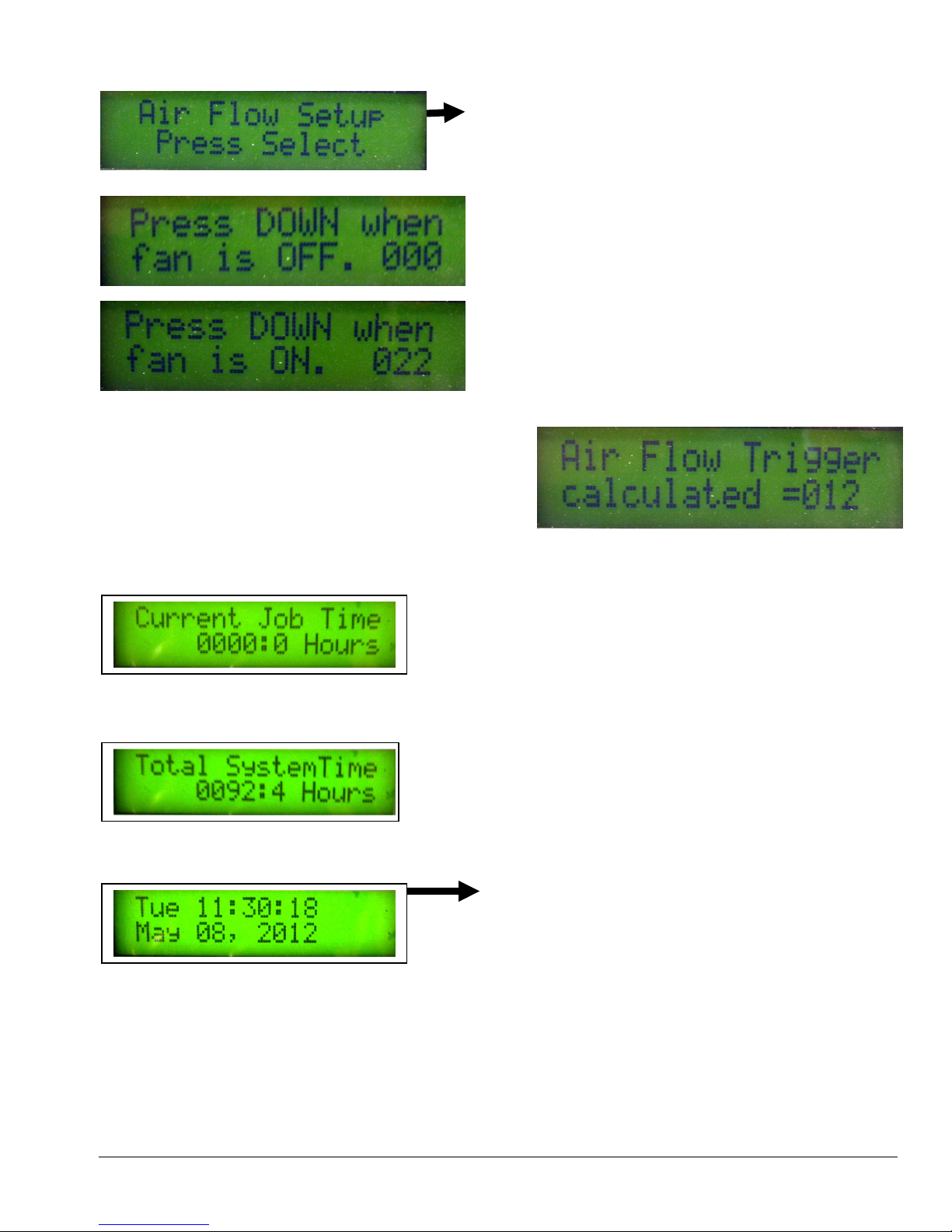

Air Flow Setup Screen: This allows you to recalibrate the Air Pressure Sensor to maintain

DAY NUMBER or YEAR.)

proper air pressure sensor function for reliable heater operation.

• Press DOWN to move to the Current Job Time Screen.

• Press UP to return to the Remote Setup Screen

Press SELECT to set the Air Pressure Sensor trigger point.

Follow the screen directions using the DOWN button to set

the levels with the air mover OFF & ON.

1. First turn the air mover OFF. When the fan is off and

the number stops changing, press DOWN.

This is the Off Set Point.

(Shown as 000 in this example)

2. Then turn the air mover ON at low speed. Press

DOWN as soon as the fan on number is about 15-25

points higher than the Off Set Point. This is the ON

Set Point. (Shown as 022 in this example)

3. The Air Flow Trigger point is now set. The Air Flow

Trigger is approximately half way between the Off Set

Point and the On Set Point.

(Shown as 012 in this example)

Current Job Time Screen: This shows the time the system has run since the switch was last

turned on.

• Press DOWN to move to Total System Time Screen

• Press UP to return to Air Flow Setup Screen

Total System Time Screen: This shows the total time the system has been run on all jobs.

• Press DOWN to move to Date & Time Screen

• Press UP to return to Current Job Time Screen

Current Date and Time Screen

• Press DOWN to return to Main Screen

• Press UP to return to Total System Time Screen

Press SELECT to set the E-TES SD Date & Time

Clock.

HOUR will flash first. Use the UP/DOWN buttons

to change the HOUR setting. When correct, press

SELECT to move to MINUTES, then SECONDS,

MONTH, DAY NUMBER & finally YEAR. Use

UP/DOWN to change each setting and SELECT

to move to next option. When correct, press

SELECT to save setting

(The DAY will change as you change MONTH,

Copyright Tes Drying Systems, 2014

13

Remote pr

obe jacks.

E-TES SD REMOTE SENSOR - PROBE CONNECTION:

E-TES SD can be operated without using the optional remote sensors.

Overheating the structure may cause damage to structure or contents. Controlling the temperature is

important to prevent damage. If the external probes and remote exhaust controller are not used,

some other type of temperature control must be used to keep room temperature below 105ºF to

prevent overheating of the structure.

• Air Temperature Probe Default Setting: 00F

• Surface Temperature Probe Default Setting: 00F

• Moisture 1 Value Default Setting: 00%

• Moisture 2 Value Default Setting: 00%

To use the remote temperature or moisture probes to control the E-TES SD, simply plug the desired remote

sensor in the corresponding port on the front panel of the E-TES SD. Return to the MENU NAVIGATION

section to set the shutdown points for each probe.

Moisture Probe with 4’ cord

PGE5060

Surface Temperature Probe

with 10’ cord – AT200

Air Temperature Probe with

10’ cord – AT202

Moisture Hammer Probe with

4’ cord – AC102

Copyright Tes Drying Systems, 2014

10’ extension cord – AT204

Can be used with any of the E-TES probes

14

REMOTE PROBE SHUTDOWN:

If the measured readings of any of the remote probes exceed the set points, the green HEATING

light will turn off, indicating the unit is no longer heating.

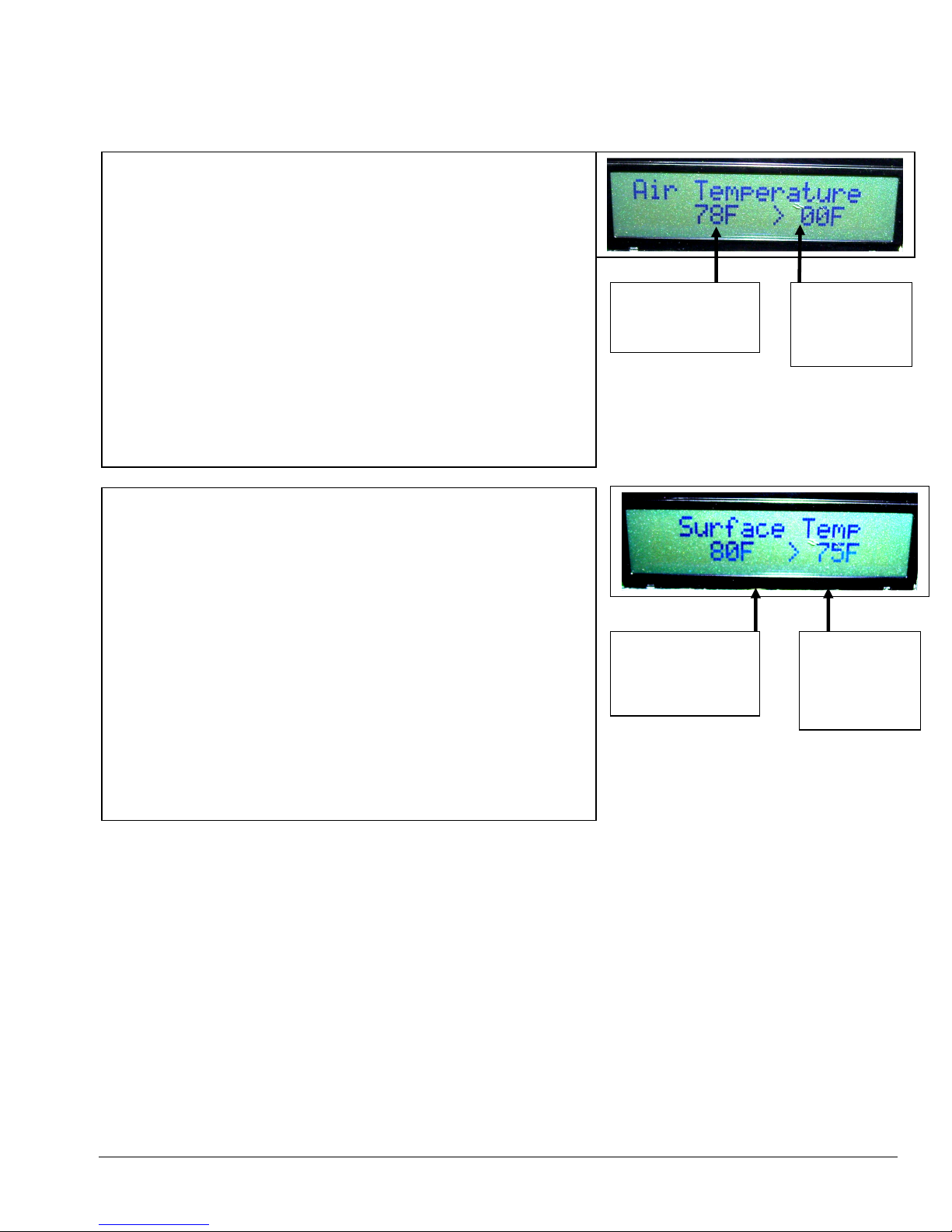

AIR TEMPERATURE SHUTOFF

When the AIR TEMPERATURE measured by the probe

exceeds the set point the green HEATING light will turn off

indicating unit has shutoff the power to the heating elements.

The AIR TEMPERATURE screen will be displayed, flashing the

current temperature and the shutoff temperature set point.

When the temperature cools sufficiently the green HEATING

light will turn back on and the unit will again heat up.

The AIR TEMPERATURE SHUTOFF will not shutoff the

power to the heating elements if the AIR TEMPERATURE

probe is not connected.

SURFACE TEMPERATURE SHUTOFF

When the SURFACE TEMPERATURE measured by the probe

exceeds the set point the green HEATING light will turn off

indicating unit has shutoff the power to the heating elements.

The SURFACE TEMPERATURE screen will be displayed,

flashing the current temperature and the shutoff temperature set

point.

When the temperature cools sufficiently the green HEATING

light will turn back on and the unit will again heat up.

The SURFACE TEMPERATURE SHUTOFF will not shutoff

the power to the heating elements if the SURFACE

TEMPERATURE probe is not connected.

Current Air

Temperature

Current Surface

Temperature

Air

Temperature

Set Point

Surface

Temperature

Set Point

Copyright Tes Drying Systems, 2014

15

Moisture Probes, then turn unit back ON.

MOISTURE 1 VALUE SHUTOFF

When the MOISTURE 1 VALUE measured by the probe drops

below the set point the green HEATING light will turn off

indicating unit has shutoff the power to the heating elements.

The MOISTURE 1 VALUE screen will be displayed, flashing the

current moisture percentage and the shutoff moisture value

percentage set point.

If the moisture level rises sufficiently the green HEATING light will

turn back on and the unit will again heat up.

The MOISTURE 1 VALUE SHUTOFF will not shutoff the power

to the heating elements if the MOISTURE 1 probe is not connected.

If the E-TES SD is ON when the Moisture 1 Probe is connected,

the MOISTURE 1 VALUE SHUTOFF will shutoff the power to

the heating elements even if the MOISTURE 1 VALUE is above the

set point. The power switch must be turned OFF & back ON to

reset E-TES to read the correct the moisture value and allow power

to the heating elements.

Do not plug-in or unplug the Moisture Probes while the E-TES SD

is ON. Turn E-TES OFF before plugging in or un-plugging

MOISTURE 2 VALUE SHUTOFF

When the MOISTURE 2 VALUE measured by the probe drops

below the set point the green HEATING light will turn off

indicating unit has shutoff the power to the heating elements.

The MOISTURE 2 VALUE screen will be displayed, flashing the

current moisture percentage and the shutoff moisture value

percentage set point.

If the moisture level rises sufficiently the green HEATING light will

turn back on and the unit will again heat up.

The MOISTURE 2 VALUE SHUTOFF will not shutoff the power

to the heating elements if the MOISTURE 2 probe is not connected.

If the E-TES SD is ON when the Moisture 2 Probe is connected,

the MOISTURE 2 VALUE SHUTOFF will shutoff the power to

the heating elements even if the MOISTURE 2 VALUE is above the

set point. The power switch must be turned OFF & back ON to

reset E-TES SD to read the correct the moisture value and allow

power to the heating elements.

Do not plug-in or unplug the Moisture Probes while the E-TES SD

is ON. Turn E-TES OFF before plugging in or un-plugging

Moisture Probes, then turn unit back ON.

Current Moisture

Level

Moisture Value

Set Point

To assure that the E-TES SD will

shut off & stay off when the

Moisture 1 Value drops below the

shutoff value, the Moisture Value 1

Shutoff MUST NOT be set below

10%.

To chart the Moisture 1 Value

without controlling the E-TES SD

set the Moisture Value 1 Shutoff to

0%.

Current Moisture

Level

Moisture Value

Set Point

To assure that the E-TES SD will

shut off & stay off when the

Moisture 2 Value drops below the

shutoff value, the Moisture Value 2

Shutoff MUST NOT be set below

10%.

To chart the Moisture 2 Value

without controlling the E-TES SD

set the Moisture Value 2 Shutoff to

0%.

Copyright Tes Drying Systems, 2014

16

REMOTE EXHAUST CONTROLLER:

This allows you to set the temperature at which the E-TES SD will send a signal to turn on a

remote exhaust fan. The Remote Exhaust Controller can be located up to 100 yards away

from the E-TES SD unit and control electrical devices with a total amp load up to 15amps.

The Remote Air Temperature Sensor must be connected to the E-TES SD

to operate the Remote Exhaust Controller.

Overheating the structure may cause damage to structure or contents. Ambient room temperature

should be maintained below 105ºF during the drying process. Controlling the temperature is

important to prevent damage. If the external probes and Remote Exhaust Controller are not used,

some other type of temperature control must be used to prevent overheating the structure.

Plug the Remote Exhaust Controller into a 120VAC wall outlet and then plug your exhaust

fan into the Remote Exhaust Fan Control. Turn the exhaust fan switch to the ON position.

When the air temperature reaches the set point the E-TES SD will activate the Remote

Exhaust Fan Control to send power to the exhaust fan to turn it on.

To adjust the set point use the UP & DOWN arrow keys to move to the REMOTE SETUP

screen. Press - SELECT to enter the temperature setup screen and use the UP & DOWN

arrows to set the Remote Exhaust Controller turn on temperature.

The Remote Exhaust Controller must be calibrated

to work with the signal from a specific E-TES SD.

To calibrate the Remote Exhaust Controller:

1. Push the reset button on the Controller as you

plug the Controller into the wall outlet. This will

clear the memory of the control.

2. Turn the E-TES SD unit on and scroll to the

REMOTE SETUP screen then press select.

3. Use the UP & DOWN arrows to set the Remote

Exhaust Controller turn on temperature. This

will send a signal to calibrate the Remote Exhaust Controller.

If you are using multiple E-TES SD units with multiple remotes, turn the other E-TES SD

units OFF as you calibrate each remote to a specific E-TES SD to prevent signals from the

other units from interrupting your calibration.

SELECT

RESET BUTTON

Copyright Tes Drying Systems, 2014

17

Loading...

Loading...