Operation & Maintenance Guide

FF - MM - 108 REV - 3

Sheet 1 of 5

ISO 9001 : 2008

REQ1/3979

Product: Chisel Scaler

MODEL: SC29PG

Chisel Scaler SC29PG

Operation & Maintenance Guide

(For 12.7mm A/F Square body and releasing slot at back type Chisel)

OPERATION:

Chisel Scalers are rugged, dependable tools designed to give years of satisfactory service. Follow the instructions

mentioned here to enhance the life and performance of your scaler.

DAILY BEFORE OPERATION:

Disconnect and pour in 1 to 2 ounces of recommended oil into the tool and reconnect hose blowing out any

accumulated dirt in the hose line before connecting.

LUBRICATION REQUIREMENT:

Always install a line lubricator on the air line as close to the tool as possible. A filter regulator lubricator unit

(FRL) is strongly recommended. Keep the lubricator bowl topped up with oil and check that the oil is reaching the

tool. Running without lubrication is likely to cause damage the components causing premature replacement.

AIR SUPPLY:

Tool should not be operated at air pressure below 5.5 Bar (80psi) and above 6.9 bar (100psi).The correct

operating pressure is 6.2 bar (90 psi).

Ensure that only 3/8" (10 mm) bore airline is used and all couplings are tight, leakproof and in good condition.

The air should be clean, dry and lubricated. Install a FRL unit as close as operation will permit.

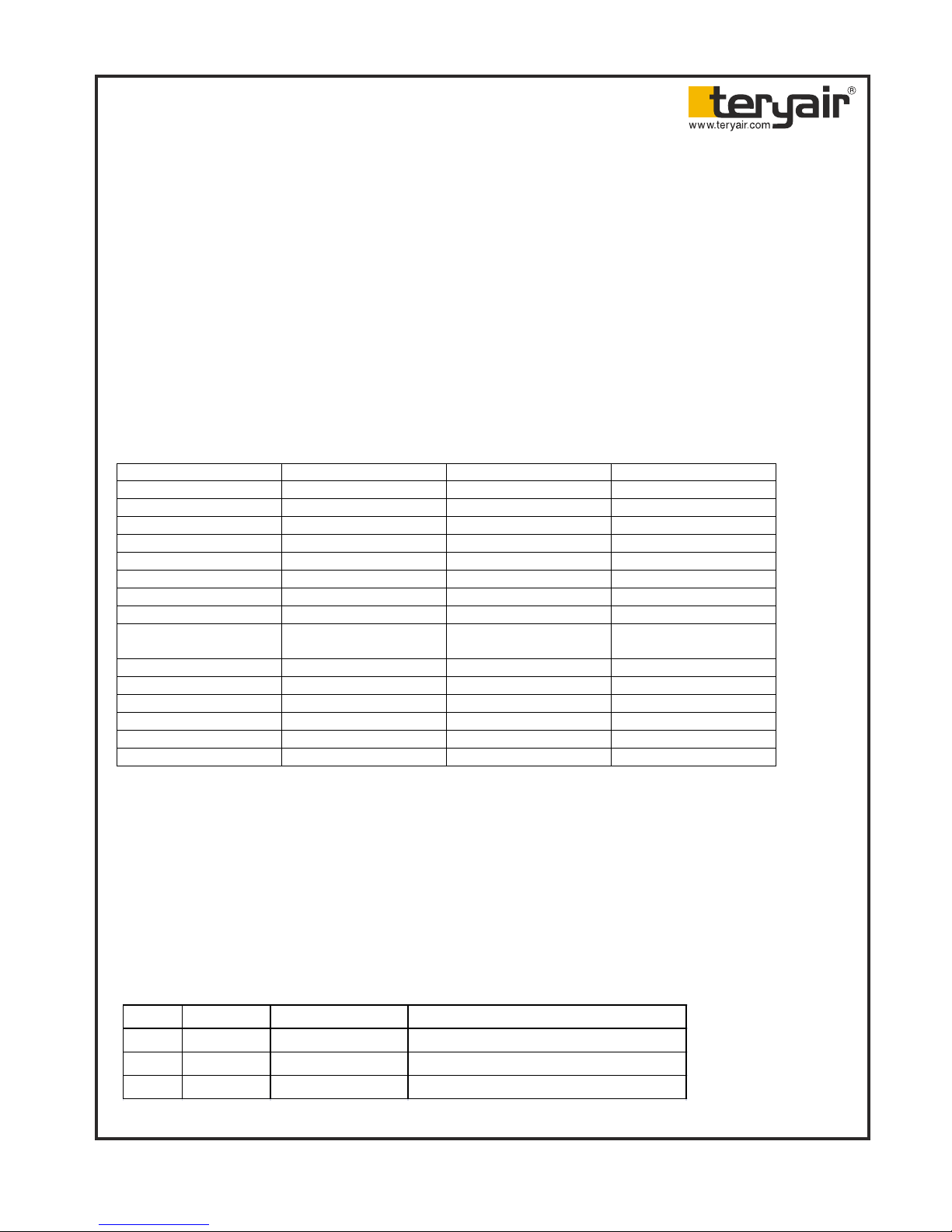

RECOMMENDED LUBRICANTS:

ABOVE 270C 800F 50C-270C 400F-800F BELOW 50C 400F

SHELL Toona R. 72 Toona R. 41 Toona R.27

MOBIL Almo 529 Almo 527 Almo 525

ESSO Arox.EP.65 Arox EP.45

CALTEX Rando Oil 150 Rando Oil 100 Rando Oil 46

CP Airolene Tool Oil

TEXACO Regal oil F (R&O) Regal Oil PE (R&O) Regal Oil B (R&O)

DALTRON Silkolene 881 Silkolene 548/T Silkolene 773

BURMAH CASTROL Castrol RD Oil 3 Castrol Rd Oil Light Magna SPX

BP POWER

PETROLEUM

RD220 HP60-C RD150 HP20-C RD80 HP10-C

DUCKHAM Garnet 7 Garnet 6 Zero Fio 5

STERNOL Merlin 87 Merlin 71 Merlin 54

PETROFINA Purifoc 53 Purifoc 46 Purifoc 32

CHEVRON Vistac Oil 18X Vistac Oil 19X Vistac Oil 9X

IOC Servoneum 100 ----- -----

HP Numatic 100 ----- -----

FF - MM - 108 REV - 3

Sheet 2 of 5

TO CHANGE CHISEL:

Rotate ring (19) in such a way so that hole on the ring (19) exactly match with steel ball(17) when chisel (22) is

pulled out, the steel ball (17) will be lifted up and chisel (22) will come out. Push another chisel having 12.7 mm / AF

square body and solt at back after the slot has crossed the steel ball(17) again rotate ring (19) so that stell ball

(17) is completely pressed in.

INTENDED USE

Sr. No. Model No. Capacity in BPM Chisel Size

1 SC24PG 3000 7” Long, 19mm Wide)

2 SC24ST 3000 7” Long, 19mm W ide)

3 SC29PG 2200 7” Long, 19mm Wide)

Chisel Scaler SC29PG

Operation & Maintenance Guide

(For 12.7mm A/F Square body and releasing slot at back type Chisel)

FF - MM - 108 REV - 3

Sheet 3 of 5

SAFETY INSTRUCTIONS:

Always wear suitable protection such as ‘eye gogles’, ear muffs, safety shoes etc. To safeguard against possibility

of flying particles etc.

INTENDED USE

Chisel Scalers are intended to use for removing layers of paint, corrosion, chemical coating etc from metal &

nonmetal surfaces & for general purpose chipping & scaling. Many different chisels options are available.

Chisel scalers are intended use for descaling of rust & corrosion from metal surfaces like sea going vessels &

offshore platforms.

Never operate the tool over the rated 6.2 bar(90psi) pressure. Do not exert excessive pressure against the work

surface. Keep hose in good condition. Check hoses for wear and ensure that fittings are secure. Accidental

disconnection while tool is in use can make the hose whip and can be a safety hazard.

Please check the hose connection prior to starting Chisel Scaler.

Be aware that these scaler can create dust & flying debris.

Keep hands & clothing away from moving parts.

Store these scaler in secure & dry environment.

Do not allow the scaler to run unattended.

Do not modify this scaler in any way as this will invalidate the warranty and could lead to serious injury.

Do not hold the exposed Chisel whilst the tool is in use this could cause vibration damage to the hands.

Do not use the scaler in potentially explosive ennments.

Do not drag this scaler by air hose.

To dis-assemble chisel scaler, remove chisel (22),from the tool described above .To remove chisel housing

assy. Remove circlip (20) with the help of circlip piler. Remove stell ball (17) through the hole of ring (19) with

little force. Pull out ring (19) remove both 'O' Rings (18) loosen socket head bolt (21) on chisel holder (16) and

unscrew and take out chisel holder holder (16) with the help of spanner size equal to the flats provided on

cylinder (1) topple down piston (4) remove both 'O' rings (2&3) on cylinder (1) To remove cover assembly (6)

with the help of spanner size equal to the flats provided on valve body (7) unscrew complete assembly and

take it out, To remove throttle lever (13) Press out roll pin (14) and remove throttle lever (13) to remove throttle

stem (11) unscrew plug throttle valve cap (8) remove throttle valve spring (10) Pull out throttle valve stem

(11) and remove O ring (12) Also remove 'O' ring (9) on valve cap (9) It rubber handle grip (5) is to be

removed, hold A /F sides of valve body (7) in soft jaw vice. Rotate cover assembly (6) and pull out rubber

handle grip (5)

Exploded view of

SC29PG

FF - MM - 108 REV - 3

Sheet 4 of 5

Assembly No.

1010000

Bill of Material for

SC29PG Chisel Scaler

Sheet 5 of 5

FF - MM - 108 REV - 3

Note : Always use genuine TERYAIR spares part for best performance.

IIIus No. Part No. Description Qty

- 100 97 01 Gun to piston complete

1 100 21 02 Cylinder 1

2 100 40 12 'O' ring for cylinder 1

3 100 40 13 'O' ring for cylinder 1

4 100 21 03 Piston 1

5 100 40 17 Rubber Handle grip 1

6 100 97 16 Cover Assembly 1

- 100 97 20 Valve body consists 1

7 100 21 07 Valve body 1

8 100 21 06 Valve cap 1

9 100 40 15 'O' ring for valve cap 1

10 100 51 14 Valve spring 1

11 100 25 11 Valve stem 1

12 124 40 01 'O' ring for valve seat 1

13 100 30 12 Throttle lever 1

14 100 50 19 Roll pin (Dia 3.17X25/26) 1

15 100 40 18 Plastic plug 1

- 101 97 04 Chisel holder Assy. 1

16 101 21 01 Chisel holder 1

17 102 50 15 Steel ball (Dia. 11.15) 1

18 101 40 03 'O' ring for chisel holder 2

19 101 21 02 Ring 1

20 102 90 16 External circlip (light A -30) 1

21 200 90 68 Cap head screw (M8X30) 1

22 JC 0175 F 19 ½' Sq shank chisel (optional) 1

Loading...

Loading...