Teryair EW200 Operation & Maintenance Manual

Electric Heavy Duty cold water

High – Pressure Washer

EW200

Operation & Maintenance Guide

Sheet 1 of 12

FF-MM-155-REV-1

ISO 9001 : 2008

RQ91/3979

Sheet 2 of 12

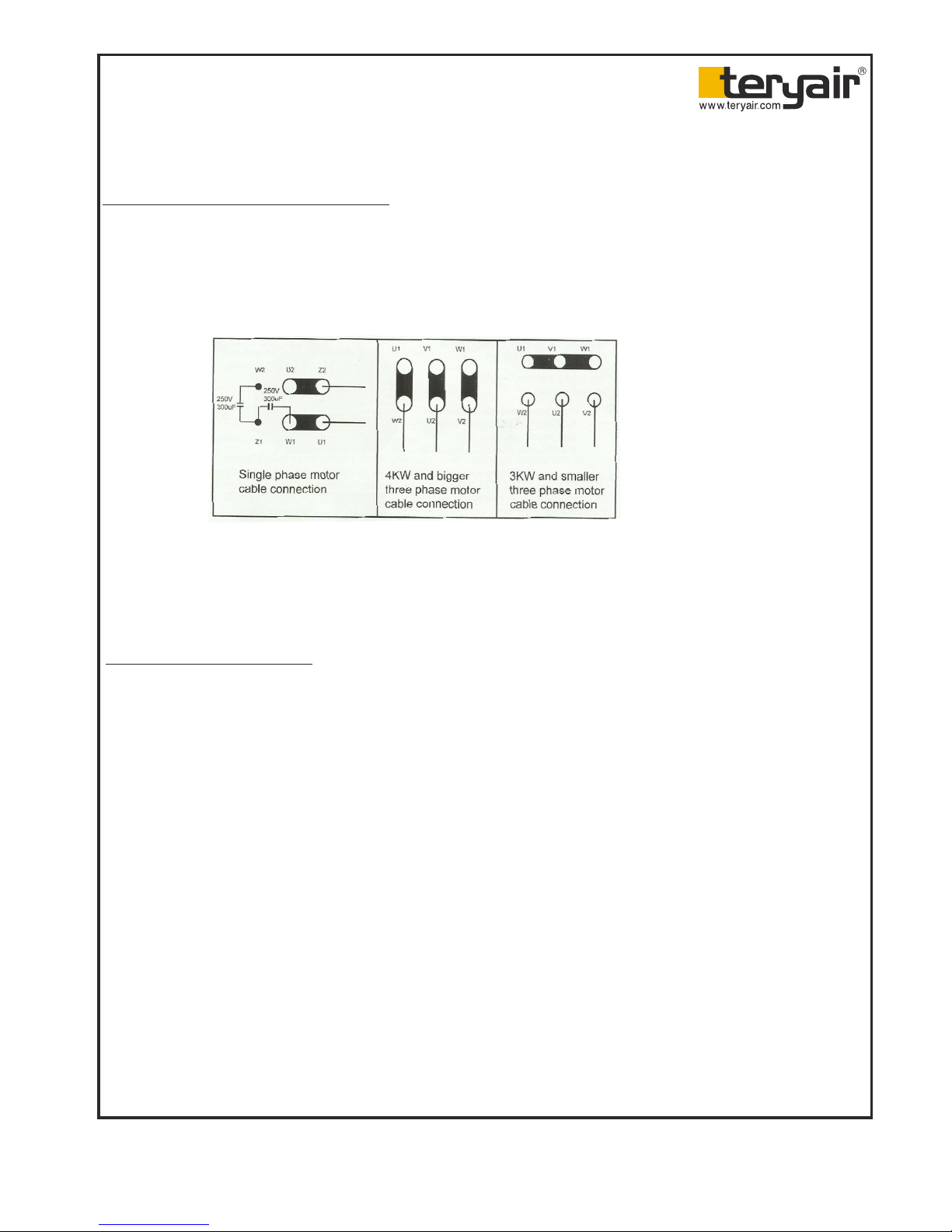

CONNECT THE ELECTRICAL MOTOR CABLE

AUCTION: Check the electrical supply voltage and frequency (HZ) Correspond to those specified on the appliances data

plated. The appliances should only be connected to a mains power supply equipped with an adequate earth connection.

1. The motor should be grounded properly. Grounding structure is in the right lower part of the junction box, if necessary, the foot

of motor or flange fastening bolts could be used for grounding.

2. Please reference the blow connecting method for the different motor.

5. Protection and short-circuit protection device should be used by the motor. Adjust all parameters of heat protection and shortcircuit protection device according to the numbers written in the name plate of the motor.

6. When the frequency is 1% at variance of rated frequency or the voltage of power is 5% at variance with rated voltage, the motor can

not maintain working at rated wattage. For consistent working motor , no overload is permitted.

7. When operating at no load or normal load, there should be no intermittent sound stranger noise or vibration, The temperature of

bearing should not be over 95 C

STARTING THE POWER WASHER

prior to starting , Please check the electrical supply Voltage (V) and the Frequency (HZ) Corresponding to those specified on

the appliances data plate

1. Make sure that the switch of the machine is in OFF position.

2. Check that the mains power supply has adequate earth connection.

3. Make sure that the power cord, hose, any connector and gun is without any damage.

4. Make sure that the filter screen is in water inlet of pump. * Cone side faces out

5. Turn water source on, and trigger on the gun to relive the pressure while starting.

NOTE – must point the gun to a safety direction.

WARNING : Failure to turn on the water could cause damage to the pump .

Operation starting the unit without water will cause the sealing to get worn out.

6. Insert the plug or switch the machine in the ON position to start the machine.

NOTE – If the motor does not start after switched on, or the motor start noise, please stop the motor

immediately and check the electrical supply voltage (V) and the Fr-equency (HZ) corresponding to data

plate.

7. Pull the trigger on the gun to start water jetting

* Stand on a stable surface and grip gun / spray wand firmly with both hands.

* Expect the gun to kick when the trigger is pulled.

8. Release trigger to stop water flow.

NOTE – The power washer will automatically go into bypass mode.

WARNING :-Do not allow unit to operate in bypass mode for more than two. minutes at any time.

Overheating of pump can cause damange to pump

Electric Heavy Duty cold water

High – Pressure Washer

EW200

Operation & Maintenance Guide

FF-MM-155-REV-1

Sheet 3 of 12

GENERAL SAFETY RULES

WARNING – water at high pressure can be dangerous and can cause damage to persons or property if the operator is

careless. Never allow anyone to operate this equipment unless they are thoroughly reliable, and familiar with

the safety precautions.

1.NEVER : direct the spray towards any person or animal.

2.NEVER : direct the spray towards electrical wiring or equipment.

3.NEVER : hold your finger over the high pressure nozzle.

4.NEVER : allow childern to use this machine .

5.NEVER : operate the machine with any of the covers removed.

6.NEVER : attempt any repairs to this machine always refer to a qualified service agent.

7.NEVER : supply any liquid other than water to water inlet.

8.NEVER : use the chemical injuction facility to introduce solvents, e.g. Paints thinners petrol , oil etc

9.ALWAYS: release any residual pressure in the system by turning off the water supply and operating the trigger before disconnecting

any hose or accessory.

10.ALWAYS: keep the machine itself dry and well clear of water spray. When not use, ALWAYS disconnect from the water supply, and

ensure the system is completely drained . Store in a cool dry place

11.Always: wear protective clothing and safety glasses. Loose particles and other debris may be propelled at high speed by the water

jet.

12.ALWAYS : grip the gun firmly before pressing the trigger, expect the gun to 'Kick' back

when starting

13.ALWAYS : respect the requirements of the local water company. Power washers may only be connected to the mains drinking

water supply, if a backflow preventer valve is installed in the supply hose.

14.When using the chemical injection facility, use only the chemical clearing agents (detergents), that are approved for power washers

or recommended from the dealer

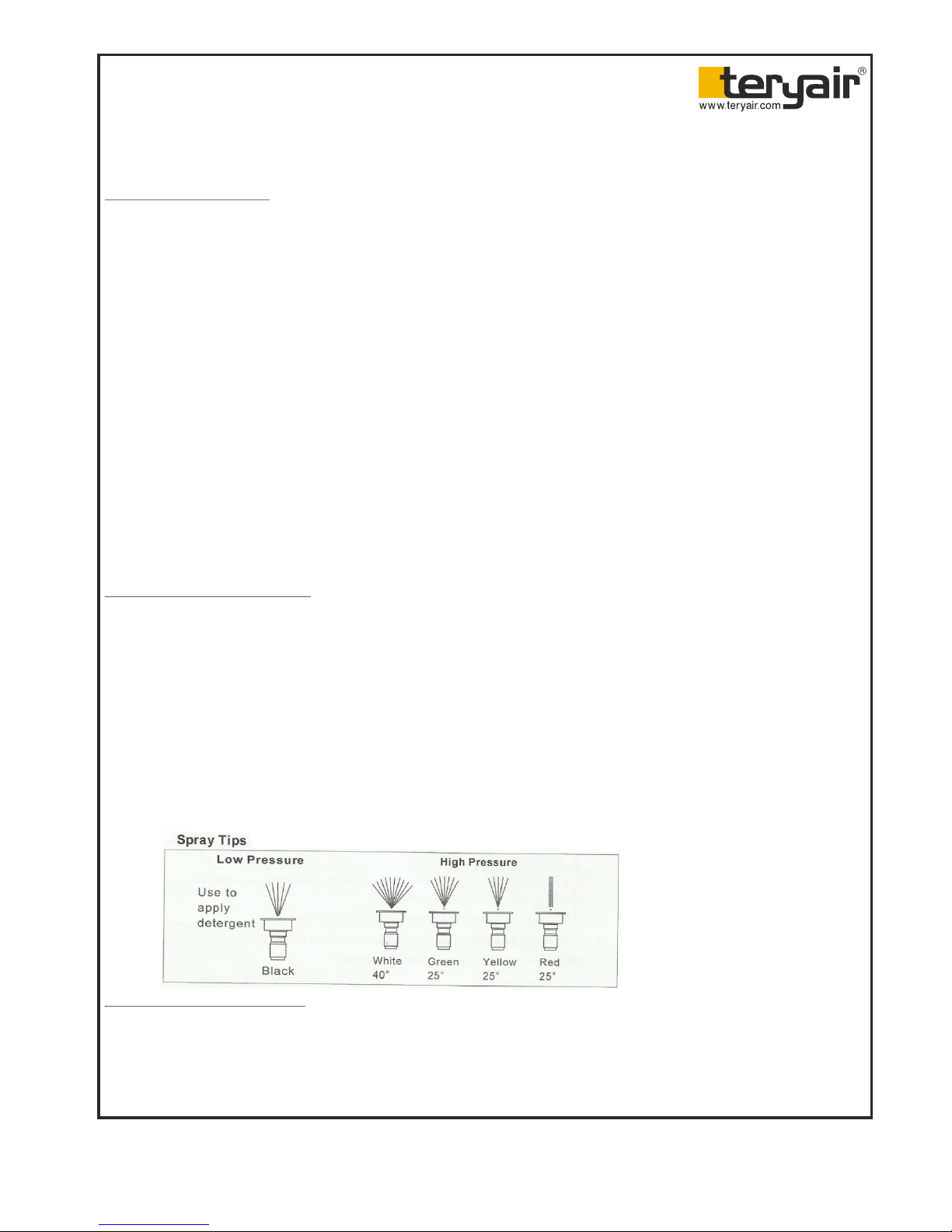

USING THE SPRAY NOZZLE TIPS

Follow these instructions to change spray tips :

1.Engage trigger lock on spray gun.

2.Pull back collar on quick-connect and pull current spray tip off.

3.Select desired spray tip: For gentle rinse, select white 40 or green 25 spray tip. To scour surface, select yellow 15 or red 0 spray tip.

To apply chemical, select black spray tip.

4.Pull back on coller , insert new spray tip and release collar. Tug on spray tip to make sure it is securely in place.

5.For most effective cleaning, keep spray tip from 8 to 24 inches away from cleaning surface.

6.DO NOT get closer than 6 inches when cleaning automobile tires

SPRAY NOZZLE MAINTENANCE

A pulsing sensation felt while squeezing the spray gun trigger may be caused by excessive. Pump pressure . The principal cause of

excessive pump pressure is a nozzle colgged or restricted with foreign materials, such as dirt, etc. To correct the problem, immediately

clean the nozzle.

Electric Heavy Duty cold water

High – Pressure Washer

EW200

Operation & Maintenance Guide

FF-MM-155-REV-1

Sheet 4 of 12

ADJUSTING THE PRESSURE

The pressure setting is preset at the factory. To lower the pressure.

1. Adjust the pressure reulator on the pump. Turn the pressure regulator knob

counter clockwise to lower pressure. Once you have finished using your

power washer return the pressure regulator to its original Position.

2. Back away from the surface to be cleaned. The further away you are the

less the pressure will be on the surface being cleaned.

3. Adjust the spray to a wider angle .

APPLYING CHEMICALS AND CLEANING SOLVENTS

1. Push the chemical hose onto the barbed fitting located near high pressure

hose connection of pump as shown.

2. Place other end of chemical hose with filter on it into container holding

chemical / cleaning solution.

* The water / chemical ratio is 7:1, for every 7 gallons of water pumped 1 gallon

of chemical / claening solution will be used.

SHUTTING DOWN

1.After each use, if you have applied chemicals, place chemical hose into container of clean water and run

clean water through chemical injection system to flush the system thoroughly. NOTE – Failure to do so

could cause damage the pump.

2.Switch the motor in the OFF position, or pull out the plug to stop the motor

NOTE – NEVER turn the water off with the unit is in running.

3.Turn water source off.

4.Pull trigger on spray gun to relieve any water pressure.

5.See storage section in this manual for proer storage procedures.

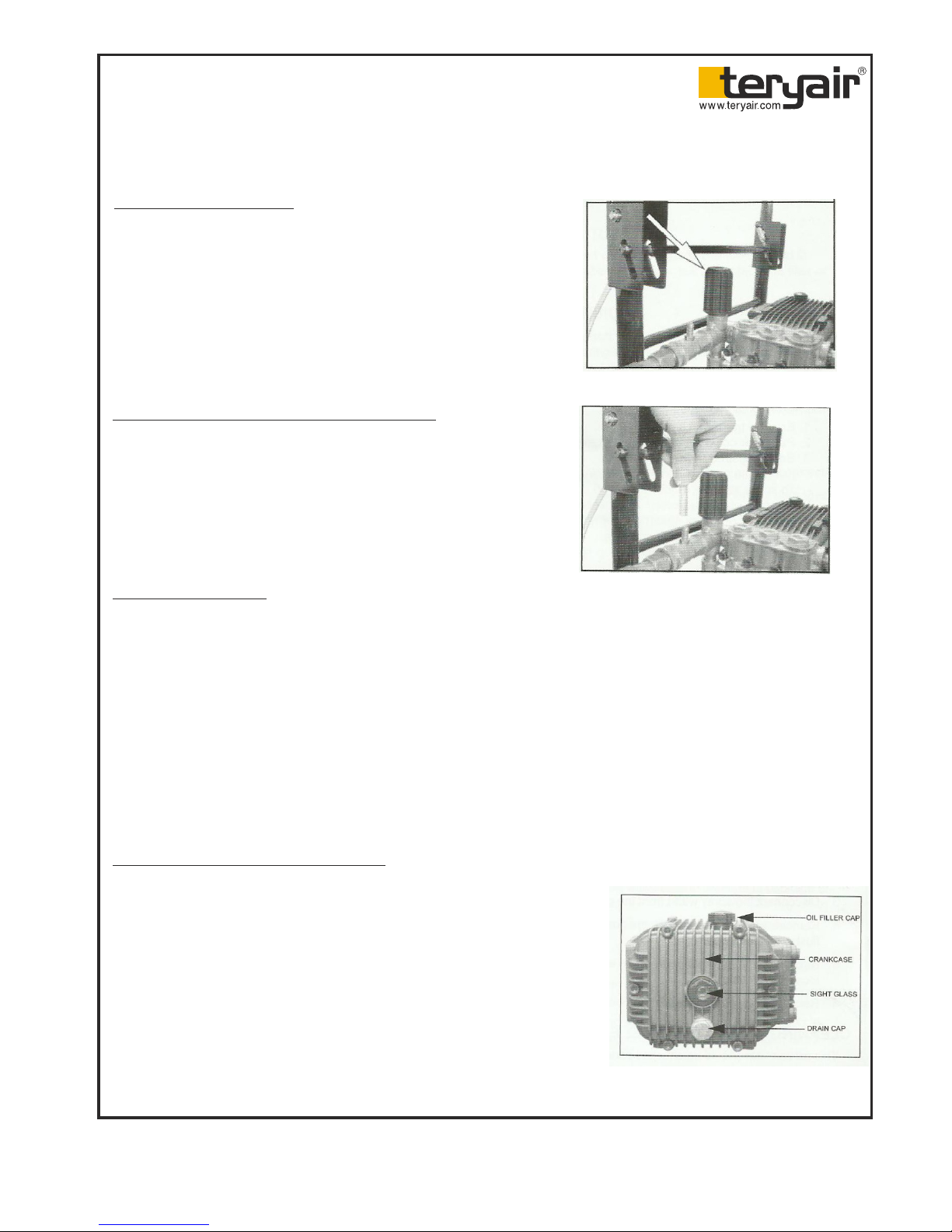

MAINTENANCE CHANGING THE PUMP OIL

CAUTION- Prolonged exposure to used oil is dangerous, always wash your

hands thoroughly after handling used oil.

1.Unscrew and remove the oil filer cap

2.Place the oil collection tray (not supplied ) under the drain cap

3. Unscrew the drain cap, and allow the used oil to drain out from the crankcase into

the oil collection tray.

NOTE –Drain the oil when the engine is warm ,this will ensure the oil flows out

quicker.

4.Replace the drain plug and its ring sea

5.with fthe power washer in a level position, fill to the centre of the sight glass with

the recommended oil.

6.Replace the oil filler cap.

Electric Heavy Duty cold water

High – Pressure Washer

EW200

Operation & Maintenance Guide

FF-MM-155-REV-1

Loading...

Loading...