Ter Welding Multi 250K, Multi 400K, Multi 500K DUO, Multi 500 MAR, Multi 400K DUO Instruction Manual

...

Multi 250 - 400K - 500F- 500K - 500 MAR e Accessories

This manual must be completed by the “CE Operating and service maual”

Edition of 29/05/2013

Instruction Manual

GB

English

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

WARNING

IMPORTANT: BEFORE STARTING THE EQUIPMENT, READ THE CONTENTS OF THIS MANUAL, WHICH MUST BE STORED IN A PLACE FAMILIAR TO ALL

USERS FOR THE ENTIRE OPERATIVE LIFE-SPAN OF THE MACHINE.THIS EQUIPMENT MUST BE USED SOLELY FOR CUTTING OPERATIONS.

INTRODUCTION

To obtain the best performance from the machine and ensure the longest possible life of all its components you must careully follow the instructions for use and

maintenance detailed in this manual. In the interest of our customers we suggest any maintenance or repair of the equipment is made by qualied personnel.

All our products are subject to a constant development. We are therefore constrained to reserve the right to make any necessary or useful changes in design and

equipment.

ROUTINE MAINTENANCE

Prevent metal powder from accumulating inside the equipment. Disconnect the power supply before every operation ! Carry out the following periodic controls on

the power source:

• Clean the power source inside by means of low-pressure

compressed air and soft bristel brushes.

• Check the electric connections and all the connection cables.

For the use and maintenance of the pressure reducers, consult the specic manuals.

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

1. DECLARATION OF CONFORMITY

TER SRL - Via Leopardi, 13 - 36030 Caldogno (VI) Italy

declares that the machines descripted in this manual must be use solely for professional purposes in an industrial

environment and they are manufactured in compliance with the instructions contained in the harmonized standard:

2006/95/CE (LDV) – 2004/108/CE (EMC) – 2002/95 (RoHs)

and with the instructions contained in the harmonized standard,

if applicable:

EN 60974-1 EN 60974-2 EN 60974-3 EN 60974-5 EN 60974-7 EN 60974-10 EN 60974-12

Maurizio Terzo

Direttor Generale

Date 31/01/2012

IN CASE OF ANY TECHNICAL PROBLEM ASK FOR QUALIFIED SERVICE ASSISTANCE

The equipment don’t compiles with EN/ IEC 61000-3-12.

The installer or the user must be sure that it can be connected to the public low voltage power line,

if necessary, in consultation with the network distributor.

1

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

2. RAEE STANDARDS

The symbol on the product or on its packaging indicates that this product

may not be treated as household waste. Instead it shall be handed over to

the applicable collection point for the recycling of electrical and electronic

equipment. By ensuring this product is disposed of correctly, you will help

prevent potential negative consequences for the environment and human health,

which could otherwise be caused by inappropiate waste handling of this product.

For more detailed information about recycling of this product, please contact your

local city oce, your household waste disposal service or the shop where you

purchased the product.

3. SAFETY PRECAUTIONS

WELDING AND ARC CUTTING CAN BE HARMFUL TO YOURSELF AND OTHERS.

The user must therefore be educated against the hazards, summarized below, deriving from welding operations.

RISK of FIRE and BURNS

Sparks (sprays) may cause res and burn the skin; you should therefore

make sure there are no ammable materials in the area, and wear appropriate protective garments.

NOISE

This machine does not directly produce noise exceeding 80dB. The plasma cutting/welding procedure may produce noise levels beyond said limit;

users must therefore implement all precautions required by law.

PACE MAKER

The magnetic elds created by high currents may aect the operation of

pacemakers. Wearers of vital electronic equipment (pacemakers) should

consult their physician before beginning any arc welding, cutting, gouging

or spot welding operations.

EXPLOSIONS

Do not weld in the vicinity of containers under pressure, or in the presence

of explosive dust, gases or fumes. All cylinders and pressure regulators

used in welding operation should be handled with care.

ELECTRIC SHOCK – May be fatal

Install and earth the welding machine according to the applicable regulations. Do not touch live electrical parts or eletrodes with bare skin,

gloves or wet clothing.Isolate yourselves from both the earth and the

workpiece. Make sure your working position is safe.

FUME and GASES – May be hazardous to your health

Keep your head away from fumes. Work in the presence of adequate ventilation, and use ventilators around the arc to prevent gases from forming

in the work area.

ARC RAYS – May injure the eyes and burn the skin

Protect yuor eyes with welding masks tted with ltered lenses, and

protect your body with appropiate safety garments.

Protect others by installing adequate shields or curtains.

4. GENERAL DESCRIPTION

This machine is a constant direct current power source, designed for welding

electrically conductive materials (metals and alloys) using the electical arc

procedure.

2

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

5. PLC DEVICE POWER LINE CONTROLLER

On the MULTI single-phase generators equipped with PLC device. The domestic

(inside houses) power supply is normally limitated to 16A: the machine can be used

in such a conditions turning the PLC key, positioned on the rear panel, on 16A.

Note: use an industrial plug 25A at maximum power. The PLC key must be

positioned on 25A (industrial applications). Don’t use the 16A plug for industrial applications.

5.1 PLC function

The MULTI 250K machine is an industrial power source for light/medium applications; the duty cycle is very high and the inverter architecture allows hight current

rates. When the machine is plugged on a domestic (house) power line, a plug 16A

should be mounted; the input current must be less than 16A in order to avoid the

switching-o of the main switch protecting the power line.

The PLC feature controls the input current, automatically inhibiting the welding process when the power input rises the limit of the main line switch (16A).

The power of the machine isn’t reduced, only the welding time (duty cycle) is concerned when the demanded current is highter than the available one.

5.2 PLC display

When the PLC inhibits the welding process, the current supply is breaked

immediately, and the front panel shows the PLC timer count down.

When the timer arrives to 0, the welding job can restart.

Please refer to the plots in order to avoid unexpected welding interruptions when

the machine is used on domestic lines.

6. STANDBY

The machine stops its main functions when it is

not continuosly used, in order to reduce the

power consumption at 10W; the “STANDBY”

icon lights. The fan works only when the machine

needs to be cooled down; during ligth

applications, the fan normally doesn’t work.

The water cooling unit, if any, works only on MIG

process; at the end of the mig welding process, it

works for further 180 sec.

7. VRD VOLTAGE REDUCTION DEVICE

This feature reduces the output no load voltage <15V.

It increases the safety conditions of the operator: the no load voltage is not dangerous but any contact between human body and live parts may cause a shock

with lost of equilibrium control or similar.

The VRD feature is activated with “VRD” light on. The feature is always “on”: the

system grants ecient arc stricking even with a no load voltage <15V.

On manual MIG process it becomes automatically “o”.

3

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

Sound Function

If mode mig or mig pulse is selected, any increase or decrease of the stored job,

done by the digital buttons of the torch, determines a sequence of sounds that

indicate the number on the arc. If the adjustment, however, is made on the conventional parameters, such as voltage or the wire speed, the sound accompanying the

increase or decrease of the parameter. A dierent sequence is emitted when they

are reached the minimum and maximum limits of the adjustment.

Inch Wire Function

This function is used during loading of the wire. I press the button on the mig torch

until the display shows the word “INC”, release the button and press again within 3

seconds. Now the wire advances quickly. To stop the process release the button.

Wire Speed Calibration Function

With this process it is perfectly possible to calibrate the speed of the wire which, with the

use of dierent torches and welding wires with dierent diameter and consistency may

increase or decrease the drag. The procedure is as follows: Press the torch switch until the

ashlight shows “INC”, within 3 second press 3 times switch sw4, then, press again the

torch switch.

Welding Parameter Function

With this mode of operation the display, during the welding, indicating the actual values

of current and voltage. In default mode, however, only the set of welding parameters are

displayed. The function mode is activated by “MMA Manual”, set the encoder to the current

123 (PICTURE 1), press the button of the parameter 2 and with the encoder set “45” (PICTURE

2), now press the size button for 5 seconds, the message “SEE rEA” indicates that’ll display

the actual data (PICTURE 3). By pressing another 5 seconds will return to the original mode

and the display will read “SEE SEt” (PICTURE 4).

PICTURE 1

PICTURE 2

PICTURE 4PICTURE 3

4

sw4

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

8.3 Output failure

Fires, burns and shocks may be caused by uncorrect current outputs.

Reasons may be found on:

• involuntary failures on mig jobs which may release, without any control, the welding wire: it melt entering in contact with negative polarities generating possible re

and burn conditions

• damaged cables, with insulation losses, etc.

In case of any output failure, the machine enters in alarm condition showing:

ALL Out - Output Alarm

8.4 ED alarm

The MULTI serie generators are characterized by a high ED factor – 60% at 40°C

(40% in case of MULTI 250K) and power supply may, in certain cases, be insucient

causing damages on the exhisting supply network.

The MULTI serie controls regularly the input power value and in case of any

discrepancy display will shows:

ALL Ed xxx: The machine will be available again at the end of the count-down

shown on the display.

8.5 Thermic alarm

The MULTI serie generators are fan cooled. Forced ventilation is activated once the

inverter temperature exceed the 40°C and fan turns automatically o once internal

components are correctly cooled.

Fan cooling is anyway rarely activated: it may accur when duty cycle has been exceeded, in case of high environment temperatures, etc.

In case of overheating, output is disabled and display will shows:

ALL OL

The icon °C light on

Leave the machine on to allow a correct ventilation; when thermal conditions are

recovered, normal operations are again possible.

In case current exceeds the mentioned limits (current peaks), machine functions

stop and display shows the detected current peak. Reset the machine by switching the main ON/OFF knob.

The tri-phase version detects even the right presence of the three current phases and, should one of those fail for > 20 m/s, machine functions stop and display

will show the missing phase. Again, reset the machine by switching the main ON/

OFF knob.

Power supply alarms that may appear on display:

PS XXX ac : power supply current peak

ALL Ph : current phase failure

8.2 Short circuit protection

A circuit test is released every time you switch “ON” the machine. The correct output

polarities are checked-out and in case of an eventual short circuit detection, machine enters in alarm standby showing on the display:

ALL Ph - alarm short circuit

Once short circuit conditions are removed, machine test will continue correctly.

Short circuit conditions may appear even during the welding job: in case they persist

continuosly for more than 5 sec, generator enter in “short circuit alarm”.

The “antisticking” icon lights too.

Power Supply

169V = current peak

8. ALARMS AND SETTINGS

8.1 Power supply alarms and setting

The single-phase welding generator MULTI 250K has an imput voltage of 230V

( min 170V – max 270V ). The tri-phase welding generators MULTI 400K and 500K

have an imput voltage of 400V ( min 340V – max 500V). Both single and tri-phase

versions can be supplied with motorgenerators and/or long cables (within the

min/max imput voltage limits).

5

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

8.6 Cooling unit Alarm

When the generator is equipped with the cooling unit, the correct cooling liquid circulation is constantly controlled. The cooling unit works only when Mig, Pulsed Mig

or Tig processes are activated.

The cooling unit pump is activated switching the torch trigger and turns o 4 minutes

after the welding job end.

In case of liquid circulation failures, output is disabled and display will show:

ALL h2o

Reset the machine switching the main knob ON/OFF.

Long unactivity periods may damage the cooling unit pump or generate momentary

re-start problems. First ensure the presence of liquid inside the tank and control the

right positioning of the in/out hoses – following instructions may help:

• unplug the water-out blu hose from the machine rear panel and plug a temporary

hose

• push & release the torch trigger once: cooling unit pump test should be activated

for 15 seconds

• cooling liquid should ow from the temporary hose: if not, repeat the pump test as

above

• once ensured the correct liquid owing, restore the original hose

• if necessary, control the correct liquid owing at the intermediary levels, i.e wire

feeder unit rear and front

6

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

9. MAIN FEATURES:

Power Source Type Multi 250K Multi 400K Multi 500K Multi 500F Multi 500 MAR

Code

Power supply ( -10% / +15% ) 230V 400V 400V 400V 400V

Phases 1ph 3ph 3ph 3ph 3ph

Fuses T25A T25A T32A T32A T32A

Rated Duty Cycle in 10 min ED 40% ED 60% ED 60% ED 60% ED 60%

Rated secondary current 250A 400A 500A 500A 400A

Permanent Sec. Current 100% 160A 310A 380A 380A 380A

Rated power 8,7KVA 18KVA 26K VA 26K VA 26 KVA

Permanent power 100% 5,5 KVA 12,5KVA 17,5K VA 17,5K VA 17,5K VA

Overload protection DIGITAL DIGITAL DIGITAL DIGITAL DIGITAL

TIG Regulation eld 10A-250A 10A-400A 10A-500A 10A-500A 10A-500A

STICK Regulation eld 20A-220A 20A- 400A 20A-500A 20A-50 0A 20A-500A

Range di regolazione MIG - MAG – MIG PULS 20A-250A 20A-400A 20A-500A 20A-50 0A 20A-500A

NO LOAD voltage (S) (K) 90V 90V 90V 90V 90V

Max secondary current 320A 500A 640A 640A 640A

Short circuit limit 480A 850A 1050A 1050A 1050A

Protection class IP21S IP21S IP21S IP21S IP23

Insulating class H H H H H

Stick synergi programs N° 19 19 19 19 puls exp opt

Tig synergi programs N ° 18 18 18 18 puls exp opt

Mig-Mag syne rgi programs N° 18 18 18 18 puls exp opt

Pulsed Mig synergi progra ms N° 5 5 5 5 puls exp opt

Pulsed Mig Double Pulsation ok ok ok ok puls exp opt

Up grade 8-16-32 puls Mig program opt opt opt opt no

Optional water cooling unit no ok ok ok no

Optional kit DUO (second wire feeder) no ok ok ok no

Double gas bottle trolley opt. no no ok ok no

Digital remote control Mig torch optional ok ok ok ok puls exp opt

Remote control receptacle ok ok ok ok puls exp opt

Digital Amperometer voltmeter ok ok ok ok ok

Width - Height Length mm 340x400x620 340x400x620 650x820x960* 340x600x620* 340x600x620*

Weight Kg 24 30 85 50 50

* Height of the Multi 500

Note: dimentions and weight are without wire feeder, without cooler unit

10. JOBS and SETTING

The MULTI generators serie can be divided in three categories:

- K Serie

- K Serie + DUO kit

- F Serie and MAR Serie

7

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

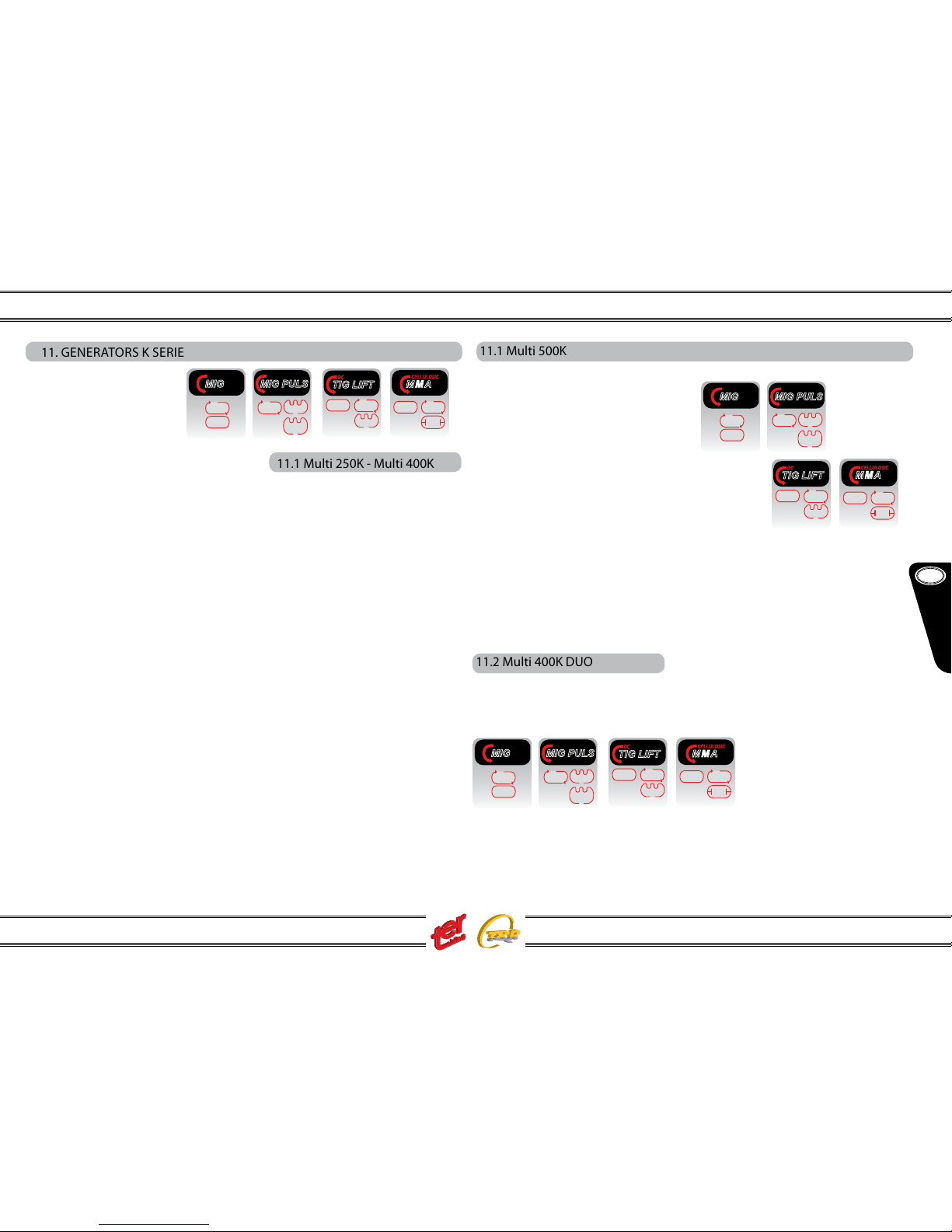

11. GENERATORS K SERIE

- Multi 250K

- Multi 400K

- Multi 500K

- Multi 400K DUO

- Multi 500K DUO

11.1 Multi 250K - Multi 400K

They can be equipped with trolley;

the 400K version even with cooling

unit. Mode and job settings

achievable directly from the front

panel.

With the rst left hand side key you can select the welding process between:

MMA (manual or synergic)

TIG (manual or synergic)

PULSED TIG (manual or synergic)

MIG-MAG (manual or synergic)

PULSED MIG (synergic and synergic/double pulsed)

Once welding mode is choosed, the machine will always recall the last used

program or the last used setting.

11.1 Multi 500K

It can be equipped with trolley and cooling unit.

Generators K Serie with Duo kit (secondary wire feeder unit)

11.2 Multi 400K DUO

It can be equipped with trolley and cooling unit.

The DUO conguration (double torch) provides

double job programs; on the main generator you

can select between:

MMA (manual or synergic)

TIG (manual or synergic)

PULSED TIG (manual or synergic)

MIG-MAG (manual or synergic)

PULSED MIG (synergic and synergic/double pulsed)

Pulsed

MIG

Sinergyc

MIG

MIG PULS

Sinergyc

MMA

VRD

MMA

CELLULOSIC

Sinergyc

TIG

TIG LIFT

DC

Sinergyc

MIG

MIG

Manual

Manual

Double

Pulsed

MIG

Pulsed

TIG

Manual

Pulsed

MIG

Sinergyc

MIG

MIG PULS

Sinergyc

MMA

VRD

MMA

CELLULOSIC

Sinergyc

TIG

TIG LIFT

DC

Sinergyc

MIG

MIG

Manual

Manual

Double

Pulsed

MIG

Pulsed

TIG

Manual

Pulsed

MIG

Sinergyc

MIG

MIG PULS

Sinergyc

MMA

VRD

MMA

CELLULOSIC

Sinergyc

TIG

TIG LIFT

DC

Sinergyc

MIG

MIG

Manual

Manual

Double

Pulsed

MIG

Pulsed

TIG

Manual

8

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

11.3 Multi 500K DUO Multi 500KT DUO without cooling unit

On the wire feeder unit you can choose between:

MIG-MAG (synergic)

PULSED MIG (synergic)

PULSED MIG (synergic/

double pulsed)

MIG-MAG (manual)

MMA

Job transfer from main generator

to wire feeder unit or viceversa is

released automatically switching

the corresponding torch trigger,

pushing the knob on the main

panel or any key on the wire

feeder panel.

When the main generator torch is working, the remote wire feeder unit will display

“INT CNT” meaning someone is using the main unit.

Once welding mode is choosed, the machine will always recall the last used program or the last used setting.

12. MULTI 500F - MULTI 500F WATER COOLING

It can be equipped with cooling unit and can work as standard MMA and TIG DC

power source.

On the generator main panel you

can select between:

MMA (manual or synergic)

TIG (manual or synergic)

PULSED TIG (manual or synergic)

while from remote wire feeder unit:

MIG-MAG (synergic)

PULSED MIG (synergic)

PULSED MIG (synergic/double pulsed)

MIG-MAG (manual)

MMA

Every welding job can work with specic dierent programs, set from the generator

main panel.

Job transfer from main generator to wire feeder unit or viceversa is released automatically switching the corresponding torch trigger, pushing the knob on the main panel or

any key on the wire feeder panel.

When the main generator torch is working, the remote wire feeder unit will display “INT

CNT” meaning someone is using the main unit.

Once welding mode is choosed, the machine will always recall the last used program

or the last used setting.

Pulsed

MIG

Sinergyc

MIG

MIG PULS

Sinergyc

MMA

VRD

MMA

CELLULOSIC

Sinergyc

TIG

TIG LIFT

DC

Sinergyc

MIG

MIG

Manual

Manual

Double

Pulsed

MIG

Pulsed

TIG

Manual

Pulsed

MIG

Sinergyc

MIG

MIG PULS

Sinergyc

MMA

VRD

MMA

CELLULOSIC

Sinergyc

TIG

TIG LIFT

DC

Sinergyc

MIG

MIG

Manual

Manual

Double

Pulsed

MIG

Pulsed

TIG

Manual

9

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

13. MULTI 500 MAR

The generator can be connected with the MIDI LPM wire feeder unit, able to provide

pulsed mig mode adding the relative kit

14. MMA MODE MANUAL

Connect the electrode holder and earth clamp to the right main generator polarities; the electrode holder can be connected even to the wire feeder unit – in that

case B and C setting steps are inhibited – on the wire feeder panel you can simply

adjust the welding current and arc dynamic (see wire feeder setting).

A - Select STICK

B - Select MANUAL

C – Adjust welding current….and weld

A - S elect S TICK

B - S elect M ANU AL

C – Ad just weld ing cur rent

A - Select STICK

B- Select MANUAL

C- Adjust welding current

MMA

CELLULOSIC

Manual

10

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

14.1 HOT START - MMA Mode (Manual)

The value can be adjusted according to the electrode type – Ex. stainless steel and

rutile electrodes demand a low value, near

to 0 – basic and the majority of the commun

electrodes a mi-value between 30/50 – cellulosic electrodes require a high value.

Push the 2nd level key until “HS” icon light on

– the led will blink for two seconds and during

this time adjust the required value. Two seconds after the last touch, “HS” setting mode

get o.

(see also wire feeder setting)

MMA mode (synergic)

MMA synergic welding is a really usefull way to avoid setting mistakes. Even skilled

welders can save job time entering the synergic mode:

2nd level key

Adjusting kno b

A -Select STICK B – Select electrode type C – Select electrode size

14.2 HOT START - MMA Mode (Synergic)

In synergic MMA mode the value is already set according to the choosed electrode.

The parameter can be changed anyway - adjustments are diplayed in % (pourcentage)

towards the original value:

push the 2nd level key until “HS” icon light on – the led will blink for two seconds and

during this time adjust the required value. Two seconds after the last touch, “HS” setting mode get o.

The adjustment is made using the main display knob, as usual.

The new parameter is automatically stored – it will be restored once recalling the same

program.

This setting is available only on the main generator panel.

NB: the welding current can be adjusted as well, remaining anyway inside the

programmed synergic values.

C – HS value increased of 15%

B – HS icon

A – 2nd level key

Welding Current

Adjusting knob

2nd level key

MMA

CELLULOSIC

Manual

MMA

CELLULOSIC

Manual

11

GB

English

Instruction Manual

Multi 250 - 400K - 500F - 500K - 500 MAR e Accessories

15.1 Current Setting - Tig Mode (Manual)

Turning the main display knob adjust the welding current.

NOTE: on manual tig mode the material tickness setting is not available.

15.2 Trigger Setting - Tig Mode (Manual)

Plug the tig torch to the negative polarity and the torch trigger plug to the respective socket. In case of remote control function, use the remote control socket.

Torch gas hose must be screwed to the machine gas nipple.

The welding generator can be equipped with cooling unit: in that case a water

cooled tig torch may be used plugging the water inlet/outlet hoses.

NOTE: generator provided with cooling unit can support even gas cooled tig

torches. Do not forget to close the water circuit by using a suitable by-pass

hose placed between the inlet and outlet nipples (front and rear).

Using an appropriate hose connect the gas bottle to the inlet gas nipple placed on

the rear panel (market with tig) – release the gas ow at 5/7 lt/min.

The MULTI generators provide tig torch arc strike by using the Lift-Arc method:

push the torch trigger

slow down the torch until the ceramic

nozzle touch the

workpiece; in this phase held the torch and

avoid any contact between tungsten and

workpiece

keeping the nozzle in contact, turn the

torch until the tungsten enters in contact

with the workpiece

maintaining the nozzle-work piece contact,

turn back the torch to the original position; the arc strikes and the welding can be

performed

A – Select TIG or TIG PULSE

B – Select MANUAL

(A) TIMER

it activates

the spot

function.

The spot arc

remains on

during the

set time

(B) 2T trigger

:

arc strikes when

torch trigger is

pressed, and

stops when

released

(C) 2T slope:

arc strikes when

torch trigger is

pressed, and

stops when

released with a

slope down

(D) 4T trigger:

arc strikes

pressing and

releasing torch

trigger. It stops

pressing and

releasing once

again

(E) 4T slope:

it’s like the 4T

trigger, adding a

current slope on

start and a slope

down current on

stop

15.TIG MODE MANUAL

TIG LIFT

DC

Manual

TIG LIFT

DC

Manual

TIG LIFT

DC

Manual

12

Loading...

Loading...