Page 1

USER MANUAL

Harmony Series 2 Homelift

Through Floor Lift

Original instructions

Page 2

CONTENTS

Introduction 4

Description 5

General Do’s and Don’ts 6

Controls and Operation 8

Smoke Alarms 10

Emergency Procedures 12

Fault Finding 14

Changing Smoke Alarm Batteries 16

Changing Call Station Batteries 17

Safety Feature Check 18

Lift Disassembly / Safe Disposal of Hazardous

Materials

19

Service History Record 20

Declaration of Conformity 21

Lift Specication Sheet 22

3

Page 3

4

INTRODUCTION

Thank you for choosing the Harmony Lift, designed and

manufactured in the U.K. using the latest technology by Terry

Group Ltd. We want you to get the most out of your Harmony Lift

and to help in this aim we have produced this small booklet on

operation and maintenance of the equipment, which we hope you

will find helpful.

It is hoped that any queries you may have during day to day

operation will be answered in the text, but if you do have any

problems, technical assistance is only a phone call away.

We hope our product gives you many years of reliable service.

Peter Morrey

Managing Director

Page 4

5

DESCRIPTION

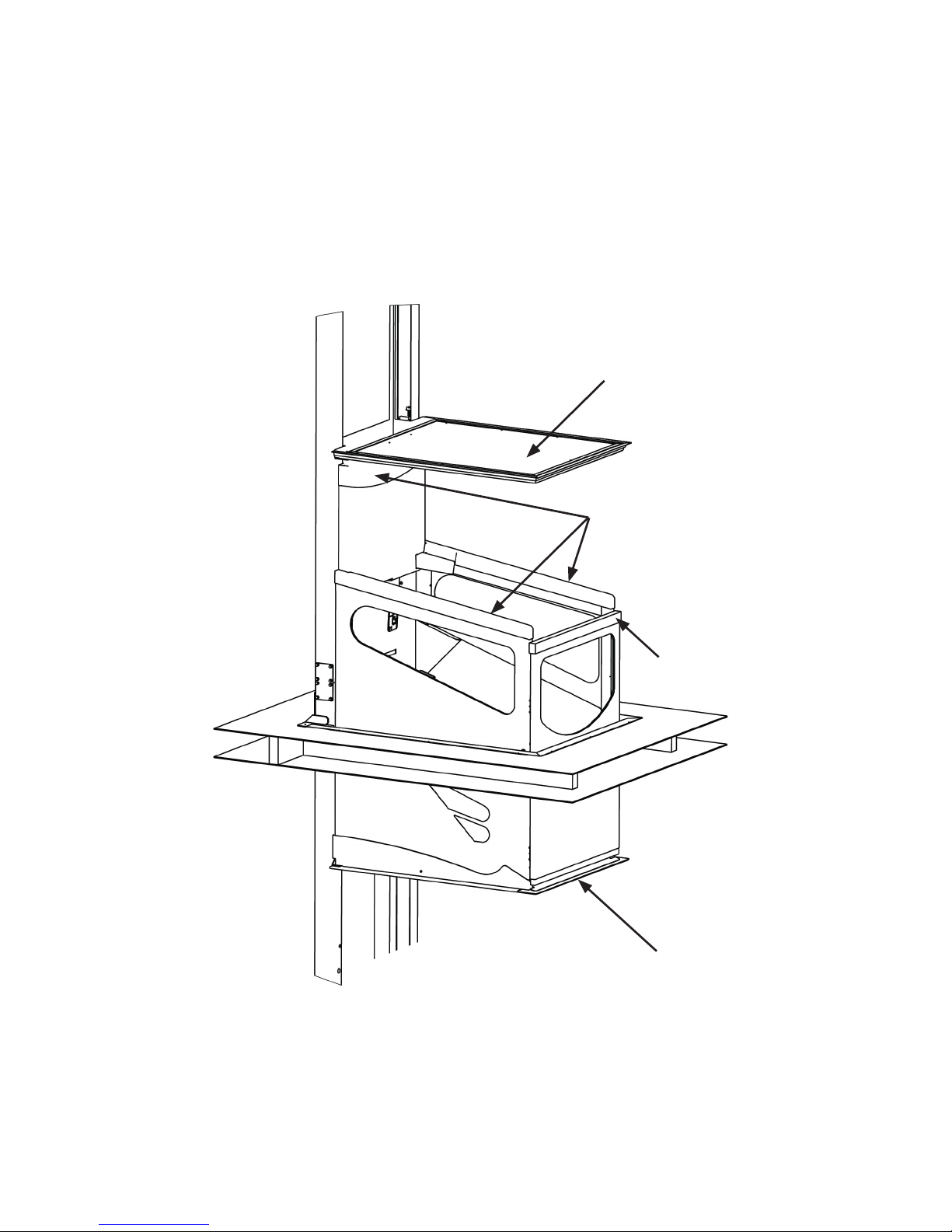

The Harmony Homelift ‘N’ is an inter floor lift that is designed for

use by persons with impaired mobility travelling between fixed

floor levels in private dwellings.

With a maximum carrying capacity of one person, with or without

a wheelchair, this lift is not intended for use as a means of

transporting goods.

The lift is designed to operate without a lift shaft and is provided

with an automatic infill panel which makes the ceiling aperture

safe when the lift is parked downstairs.

An optional telephone can be supplied in the car for emergency

communication.

A standard feature is the provision of half hour fire rated panels in

both the aperture infill and the car underpan.

The lift car panels are made from powder coated steel which can

easily be cleaned using normal household cleaners. Upholstery

is made from PVC and can be cleaned in the same way.

A smoke detection system has been installed on your lift. It has

been designed to provide adherence to British Standard BS5900

2012 Section 9.13 “Behaviour of homelift in the event of fire”.

Page 5

GENERAL DO’S AND DON’TS

• Never switch off the power supply to the lift, even when you go away. The

lift control circuits are fed by a battery, which must be kept on constant

charge.

• The lift should always be returned to the lower level when not in use. If

it is left upstairs for prolonged periods, it will occasionally re-level itself

depending on conditions. The lift must be left at the lower level if the

mains is turned off.

• If your lift is fitted with a manual door always close it after use. Powered

door units have a self closer. Do not pull or push the automatic door.

• Never allow children to play in, under or around the lift. If children are in

the house, isolate the lift using the optional remote control fob, see pg 8.

• Ensure that the area under the lift is kept clear. The underpan surface is

fitted with sensors, which automatically stop the lift if it strikes an object

(see Fig.1).

• Always keep your emergency door release key and key fob in the lift or in

a safe place near the lift.

• Do not place any object on the aperture infill or stand on it when the

lift is in operation. Ensure that as far as practical, the area around the

travelling infill panel is clear of persons (particularly children) when the lift

is being operated. This is to ensure there is no danger of them falling into

the car when the lift is in use. The infill panel is fitted with sensors that

automatically stop the lift if the infill panel is obstructed (see Fig.1)

• Do not use this lift for anything other than transporting those with

impaired mobility between fixed floor levels

• Do not lean over the car sides or door. These are fitted with safety edges

which will stop the lift if activated.

• Always treat your lift with respect that should be shown to electrical and

mechanical equipment.

• Users with wheelchairs should apply the brakes on their chair and all

other users should ensure they are using the seat provided before

moving the lift. Do not travel in the lift unless seated.

• Safety related components should only be adjusted and reset by a

competent person.

6

Page 6

7

Proceed with caution when exiting the carriage backwards

The diagram below (Fig.1) shows the position of all the sensors

on the lift, designed to prevent injury or damage if the movement

of the carriage is obstructed.

Infil panel safe edge

(sensors on upper

and lower surfaces)

Safe edges

Door safe edge

Underpan safe edge

(sensor on lower and

upper surface)

Fig. 1

Harmony lift shown part-way

through aperture

Page 7

CONTROLS AND OPERATION

There are two wall mounted call stations, one at each level (see

Fig.2) and a similar control station fitted in the lift car. The lift can

be isolated by using the optional remote control fob. When the lift

is isolated, none of the control stations will function. The call and

control stations can only be activated by using the remote fob.

When the lift is activated, the coloured indicator lights in the car

will illuminate. The lights in the car will switch on automatically

when any call or control button is pressed and will automatically

turn off after a few minutes.

Once the lift has been stopped it cannot be restarted for 3

seconds.

Users with wheelchairs should apply the brakes on their chair

and all other users should ensure they are using the seat

provided before starting the lift.

8

DOWN

DOOR

STOP

UP

Wall mounted call station

Optional remote

isolate fob

Fig. 2

Page 8

General operation

Call the lift by pressing the UP or DOWN button on either call

station and wait for it to stop. The door will automatically open.

Enter the lift and press and release the door button to close it.

Then press and release UP or DOWN on the control station. The

lift will travel uninterrupted to the next floor. If the lift does not

start, check that the door is properly closed and try again. Always

close the door after using the lift by pressing the DOOR button on

the wall mounted call station. The lift should always be returned

to the lower level when not in use.

In the event that the normal controls fail to work, emergency

controls can be found under the flap above the mirror. Green is

‘UP’, red is ‘STOP’, black is ‘DOWN’ and white is ‘DOOR’. See

Fig.3

When outside the car, in an emergency the door can be opened

by pressing the front end of the side safe edge, on the corner

where the door opens (See Fig.3a).

9

Fig. 3 Fig. 3a

Page 9

SMOKE ALARM

A smoke detection system has been installed on your lift. It has

been designed to provide adherence to British Standard BS5900

2012 Section 9.13 “Behaviour of homelift in the event of fire”.

The system utilises two smoke alarms one upper level, one lower

level, which are wirelessly connected to the main circuit board on

the lift (see illustration below).

The Smoke Alarm unit comprises two parts, the first (TOP PART)

being a Smoke alarm unit. This is the Smoke detection unit and

contains an integral battery with a 10 year life span. This is not

replaceable.

The second part (BASE UNIT) contains the radio transmitter

receiver unit. Power to this unit is supplied by two AA style

Lithium batteries. The voltage level of the batteries is monitored.

In the event of a low battery, a sounder in the carriage will beep

(see Fault Finding pg.14). If the batteries are not replaced, the lift

will be taken out of service.

Radio smoke alarm operation

When installed on a Harmony Lift, the smoke alarm system will

cause the lift to deactivate safely once the alarm is triggered.

When deactivated, the door will continue to operate as normal.

Mute/test button

Smoke Alarm (TOP PART)

Radio Transmitter/receiver

Unit (BASE UNIT)

10

Page 10

When the Lift is stationary at either level:

If smoke is detected, the alarm will sound. After a period of time,

all other smoke alarms connected to the system will then start to

sound and the lift deactivates.

When the Lift is travelling between levels:

If smoke is detected, the alarm will sound. After a period of time,

all other smoke alarms connected to the system will then start to

sound.

The lift will continue to its requested level, it will remain possible

(until that level is reached) to change the direction of the lift.

Once at the desired level, the lift will deactivate.

Reactivation of Lift

The lift will automatically reactivate when the smoke alarm no

longer detects smoke and a period of two minutes has expired.

Silencing the Smoke Alarms

In either situation, it is possible that the sounder of each

individual alarm can be silenced. The alarms that has been set

off remotely can be silenced by pressing the both the STOP and

DOOR button on one of the lift handsets. Then the alarm that

has been triggered by the smoke can be silenced by pressing

the mute button on the alarm itself. Doing this will silence the

alarms for four minutes. When silenced, the lift will automatically

reactivate when a period of two minutes has expired. If the

source of smoke is not removed, the smoke alarms will begin to

sound again and the lift will be disabled.

11

Page 11

12

EMERGENCY PROCEDURES

In the event of a mains failure during travel, the battery backed

control system of the Harmony will allow normal operation in the down

direction without loss of any safety features. This allows the user to exit

the car at the lower level in the normal way.

Emergency Manual Lowering

IMPORTANT:

During emergency manual lowering, the normal safety features will not

function, so the lift will not stop if a person, pet or object is under the

lift.

• The exact lowering procedure must be observed, because the normal

safety features will not function during manual lowering.

• The emergency lowering procedures should never be used if the lift is

fully up or no one is trapped in it.

• The emergency lowering procedures should also never be used as

the normal down travel function until an engineer attends.

PLEASE NOTE:

If the lift is fully upstairs and a person is trapped inside, please see the

section Emergency unlocking (see pg13).

If the lift has stopped mid level and the customer is unable to get the lift

up or down then the only time it should be lowered by the emergency

valve is if:

• There is a second person (B) around the lift area at the lower level to

ensure that nothing goes under the lift during the lowering by the first

person (A);

• OR the person lowering the lift has sight of the area under the lift .

Person A

• Ensure the door is fully closed.

• Turn the mains supply to the lift off.

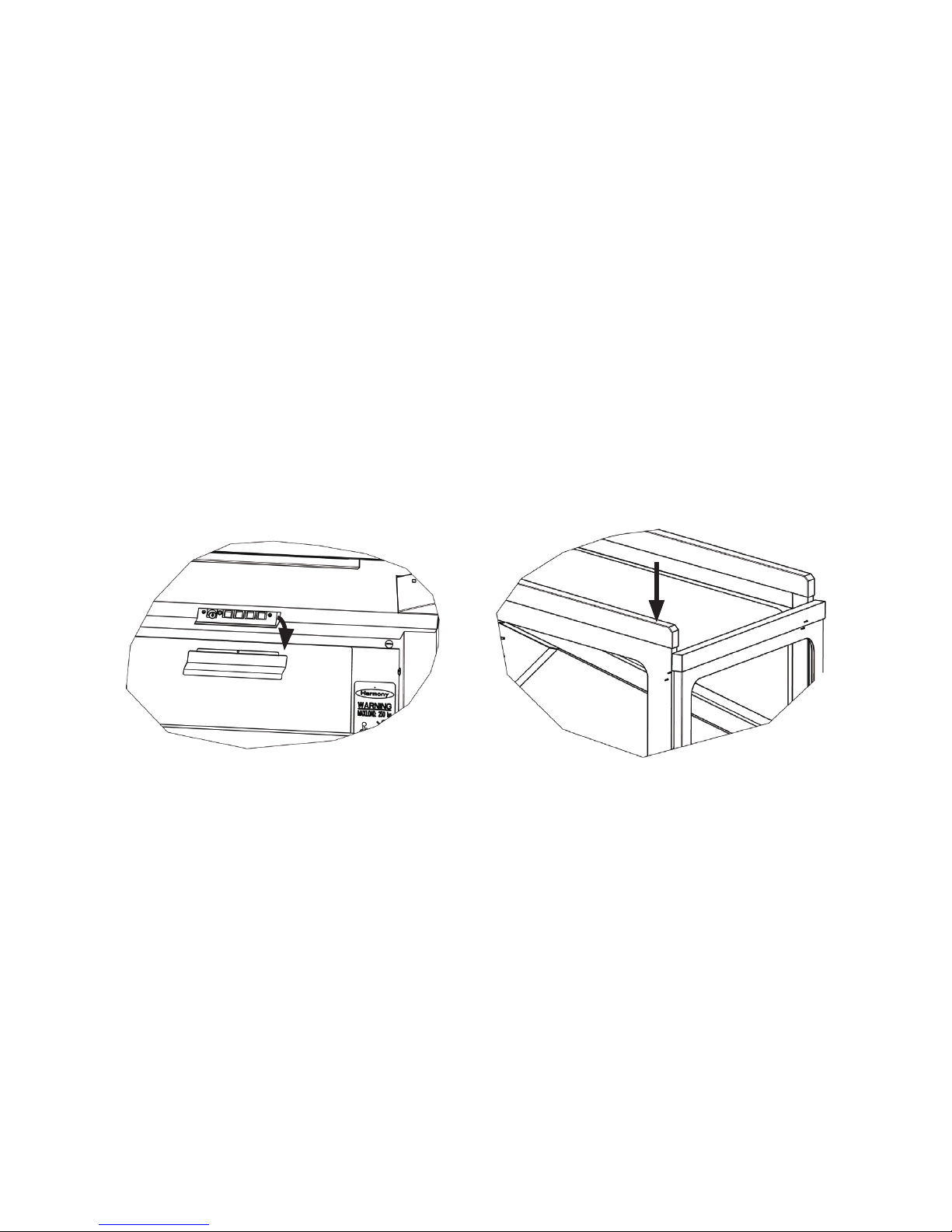

• Locate the hydraulic power unit, normally outside the property (see

Fig. 4).

• Swivel the small metal cover plate on the front face of the housing to

reveal an access hole (see Fig. 4).

• The red cord revealed in the access hole now needs to be pulled

continuously to lower the lift car slowly.

Page 12

13

• After 5 seconds release button and check with person B that the trap

door is following the carriage. If so continue to lower

• Once the lift is at the lower level turn the mains supply back on.

Person B

Remains in the house by the lift and communicates with Person A to

ensure the safe lowering of the lift.

• Ensure that no object, person or pet are in the path of the lift travel

• Confirms that the trap door follows the lift during descent and locates

fully in the floor to guard against the possibility of anyone falling down

the lift way.

Emergency unlocking

WARNING: RISK OF FALLING – Emergency unlocking must only

be undertaken when the lift is at the upper or lower landing level.

The lift car door is designed so that it will only open when the lift is at

or within 25mm of each floor served. If for any reason the door cannot

be opened, the door lock can be over-ridden from the inside using the

following steps:

• Remove the black rubber grommet by the door.

• Insert the black emergency door release key into the square hole

behind the grommet.

• Turn the key to release the mechanism.

This should release the catch. The door can be opened from the

outside in the same way.

The electrically operated door on the wheelchair model can be forced

open or closed manually. This will disengage the door from the opening

mechanism and require re-setting of the door. Re-setting of the door

can be done as follows:

Remove the screw using the

screwdriver provided at installation.

Swivel this metal plate to one

side in order to gain access to the

lowering string behind the plate.

Indicates mains power to lift

(usually ‘on’ red).

Fig. 4

Page 13

Battery warning (red) This

is normally off, but may be

on during operation.

This is OK providing it

extinguishes eventually

when lift is at either level

DOWN CAR (yellow

light). Means safe edge

car OK. Will be off when

ascending and when at

lower level.

UP CAR (green light)

Means safe edge car

OK. Will be off when

descending.

DOWN TRAP (yellow

light). Means safe edge

in fill panel OK. Will be

off when ascending.

UP TRAP (green light)

Means safe edge infill

panel OK. Will be off

when descending.

Fig. 5

• Manually close the door as far as possible.

• Press and release the door button.

• Move the door back and forth until it clicks.

• Press and release the door button again.

The door should now operate normally, otherwise repeat the

above process.

FAULT FINDING

The most likely causes of your lift failing to operate are:

• No mains power supply

• The door not being fully closed.

• Something obstructing the travel of the car or in fill panel

causing one or more of the sensors or safe edges (see Fig.1)

to operate and therefore preventing travel in the appropriate

direction.

To assist in identifying the cause the car if fitted with a simple

system of coloured indicator lights on the rear panel, one red, two

yellow and two green (see Fig.5).

14

Page 14

Lift Malfunction

Fault Indication Cause Remedy

No lift function at all. No red LED on

powerpack cover.

No mains power to

the lift.

Check mains is on

and reset RCD/Spur

if required.

Lift will not travel in either

direction.

No lights on car

panel.

Door not shut or

remote fob o.

Press door button

Press button on fob.

Flat batteries in

smoke alarms.

Replace smoke

alarm batteries.

Lift will not go up. One green o on

car panel.

Car safe edge

obstruction.

Remove obstruction

or free safe edge.

Both greens o on

car panel.

Inll panel obstructed

on upper surface.

Remove obstruction

from upper surface.

Lift will not go down. One yellow o on

car panel.

Car underpan

obstruction.

Remove obstruction

from beneath

surface.

Both yellow o on

car panel.

Inll panel obstructed

on lower surface.

Remove obstruction

from lower surface.

Powered door will not

close fully.

Can be moved

easily by hand.

Door has disengaged

from drive

mechanism.

See pg 13 & 14

Person B emergency

unlocking.

Smoke Alarm Malfunction

Indication Cause Remedy

Alarm beeps twice every 45 seconds. Unit Malfunction. Call an engineer.

Alarm does not sound upon pressing test

button.

Unit Malfunction. Call an engineer.

The operating light remains steadily on or off

(ie. Does not flash approximately once every 45

seconds when unit not in alarm).

Unit Malfunction. Call an engineer.

Low Battery Warning

Indication Cause Remedy

Single short beep on lift car every 2 minutes. Low Handset battery. Replace CR2450

batteries in handset.

Double short beep on lift car every 2 minutes. Low smoke alarm

battery.

Replace AA batteries

in smoke alarm.

Double long beep on lift car every 2 minutes. Smoke alarm battery

dangerously low.

Replace AA batteries

in smoke alarm.

Lift will not travel in either direction. Smoke alarm

batteries flat.

Replace AA batteries

in smoke alarm.

15

Page 15

CHANGING SMOKE ALARM BATTERIES

1. To change the batteries push upwards

on this part of the alarm base with any

small tool, then turn alarm clockwise.

2. Unscrew the alarm base plate from

the box

3. Fit the two AA style Lithium

batteries into the board battery

holder as shown.

16

Page 16

17

CHANGING CALL STATION BATTERIES

CR2450 (550 mAh minimum) are approved for use with these

devices.

CRITICAL:

• It is critical that all three batteries are replaced with new ones of

the same type, manufacture and age, that they are fitted at the

same time and that they are correctly oriented.

1. The call station can be

removed from the wall by

sliding the case upwards.

2. Remove the four screws in

the back with a posi-drive

screwdriver.

3. Using a screw driver, gently

push the battery out a short

way and then pull using

fingers.

Page 17

SAFETY FEATURE CHECKS

AS A PRECAUTIONARY MEASURE WE ADVISE PERIODIC

(WEEKLY) CHECKS OF THE SAFETY FEATURES BUILT INTO

YOUR HARMONY INTER FLOOR LIFT AS FOLLOWS:-

(see Fig.1)

1 CARRIAGE SIDES AND DOOR UPPER SAFE EDGE

With the lift at lower level, press the UP button on the wall

station, when lift starts to ascend press downwards on

carriage side upper surface, the lift should stop.

Lower the lift to floor level and repeat operation with other

carriage side and door.

2. CARRIAGE UNDERFLOOR SAFETY UNDERPAN

With the lift at approximately eye level press the DOWN

button on wall station, when lift starts to descend press

upwards on the carriage underpan, the lift should stop.

Raise lift and if possible, repeat operation on opposite

side of lift.

THESE CHECKS SHOULD BE CARRIED OUT WITH THE LIFT

UNOCCUPIED

If any of the above checks fail, the lift MUST NOT be used and

advice sought from Terry Group Ltd.

Servicing & Maintenance

This lift should be serviced at least every 12 months. This service

should be conducted by competent persons trained in servicing

and repair of the product.

18

Page 18

19

Lift Disassembly/Safe Disposal of

Hazardous Materials

This lift must be disassembled by a competent person who has

been fully trained in the installation of this lift and is qualified to

provide safe disconnection of the lift to the mains terminal.

Batteries & Printed Circuit Boards (PCB)

The batteries and PCB’s within this product should not be

disposed of with other household waste at the end of their

working life. Where batteries are marked with the chemical

symbols Hg, Cd or Pb, it indicates that the battery contains

mercury, cadmium or lead above the reference levels in EC

Directive 2006/66. If batteries are not properly disposed of, these

substances can cause harm to human health or the environment.

Batteries and PCB’s that are no longer required for this lift, at the

end of their working life, can be returned either to an approved

waste disposal facility or to Terry Group Ltd for safe disposal.

Oil

Oil from this lift should be disposed of via an authorised waste

disposal contractor or to an approved waste disposal facility.

Page 19

SERVICE HISTORY RECORD

An entry should be added to the following table every time the lift

is serviced.

Date Engineer Company Comments

20

Page 20

21

DECLARATION OF CONFORMITY

Lift Type: Harmony Lift

This lift was manufactured by TERRY GROUP Ltd., who declare that this lift fulfils all

the relevant provisions of the following Directives:

2004/108/EEC Electromagnetic Compatibility Directive

2006/42/EC Machinery Directive

This lift also fulfils all the relevant provisions of the following Standards:

BSEN 12015:2014 Electromagnetic compatibility. Product family

standard for lifts, escalators and moving walks.

Emission.

BSEN 12016:2013 Electromagnetic compatibility. Product family

standard for lifts, escalators and moving walks.

Immunity.

BS5900:2012 Powered homelifts with partially enclosed

carriers and no liftway enclosures – Specification

Person authorised to compile Technical File:

Greg Gnyp, Terry Group Ltd., Longridge Trading Est, Knutsford, Cheshire, WA16 8PR.

EC examination carried out by: Bureau Veritas UK Ltd., Parklands, Wilmslow Road,

Didsbury, Manchester, M20 2RE.

Notified Body Reference Number:0041

EC examination certificate number: CE-0041-MD-TER001-10-GBR

This declaration was completed at Terry Group Ltd., Longridge Trading Estate,

Knutsford, Cheshire, WA16 8PR, in August 2014.

This compliance is only valid if the installation test Certificate has been completed

and signed by a competent lift engineer trained to install this product to the latest

installation instructions.

TERRY GROUP Ltd.

P.Morrey (Managing Director)

Page 21

LIFT SPECIFICATION

Address of manufacturer:Terry Group Ltd.,

Unit 1 Longridge Trading

Estate,

Knutsford,

Cheshire,

England,

WA16 8PR.

Lift serial No: Year of manufacture:

Safe working load: Harmony S & W = 280kg

Harmony L & LW = 250kg

Maximum travel: 3.6 metres

Duty cycle: 10 cycles per hr with max load

Average noise level: 65 dB

Power supply: Dedicated 240V ~ 50/60 Hz

single phase supply

Control voltage: 12V DC

Hydraulic pump power

consumption:

1200W maximum

Hydraulic oil grade: T22

Hydraulic pump enclosure: IP54

Designed and manufactured

to:

BS5900:2012

Fire specification: Half hour fire integrity through

aperture, Exova Warrington Fire

Research assessment

No. 320925

22

Page 22

23

Page 23

24

Page 24

Ref: ED00052J

For technical help,

sales or service enquiry telephone:

This Harmony Lift has been manufactured by:

Terry Group Ltd.

Longridge Trading Estate,

Knutsford, Cheshire, WA16 8PR.

t: 0345 365 5366

e: sales@terrylifts.co.uk

w: www.terrylifts.co.uk

Certicate Number 13858

ISO 9001, ISO 14001,

OHSAS 18001

Loading...

Loading...