Terri 2040 Instruction Book

Instruction book

From 199561010

2040

604732

1

Foreword

By studying this Manual you will learn how to

operate and look after your new Terri 2040. For

those of you already familiar with Terri, this

Manual also contains certain information which

you must know.

Apart from lubrication and simpler maintenance

tasks, which you can easily do yourself, you

should let your dealer, who has trained personnel,

be responsible for the servicing.

We reserve the right to change without previous

notice data and equipment, as well as maintenance

and other service instructions.

Manufacturer: Tranells Heby Terrängfordon

THT AB

S-744 31 HEBY, Sweden

Tel: +46-224- 341 40

Fax: +46-224-318 95

Machine type: TERRI 2040

Machine nameplate:

front of the engine

compartment

Serial number: .............................

Engine number; .............................

Located to the left in the

2

ICONTENTS

1 Foreword

1 Manufacturer

1 Machine nameplate

1 Serial number

2 Contents

3 Description

4 Safety

5 Working close to overhead lines

6 Main components of Terri 2040

7 Instrumentation and controls

8 Front dashboard

8 Rear dashboard

15 Driver’s seat

16 Driving instructions

18 Maintenance

18 Diesel engine

20 Fuel system

21 Air lter

22 Cooling system

23 Electrical system

25 Hydraulic system

26 Hydraulic oil tank

27 Tracks-Bogie system

29 Brakes

30 Winch

31 Gearbox

32 Trailer adjustments

33 Lubrication

34 Recommended lubricants

35 Maintenance schedule

36 Troubleshooting

37 Technical specication

39 Alphabetical index

3

DESCRIPTION

TERRI 2040

Terri 2040 is a articulated-steered off-road tracked vehicle (forwarder), with a load capacity of 1.2 m².

Terri 2040 is a special machine with a wide and versatile range of applications.

A 3-cylinder Kubota D1105 diesel engine with precombustion chamber is used as power source in Terri

2040.

Terri 2040 has a hydrostatic/mechanical transmission with a closed hydraulic circuit. The system is

driven by a power-limited variable hydraulic pump, which is directly coupled to the diesel engine. In the

trailer a high-speed hydraulic motor drives a 2-speed preselector gearbox with mechanical differential

lock. The gearbox drives the tracks via two sprocket wheels.

Terri 2040 is easy to operate, having smooth driving charactristics and providing a substantial pulling

power in all situations. The closed hydraulic system is just as effective as a brake as a power unit, when,

for example, the forwarder is driven with a full load down a slope.

The safety cab is spacious and the controls used during normal work are in easy reach of the driver. The

number of functions needed to operate Terri 2040 has been reduced to a minimum. The driver therefore

sits comfortably when both driving and working. The versatile grab-loader is operated with a conventional multi-stick system. Different driver seats with mechanical or air suspension are available.

At the front of the machine there is a built-in winch. This can be used to pull the machine loose or to haul

timber from inaccesible terrain.

TRAILER WITH HYDRAULIC DRIVE

The trailer has two low-speed hydraulic motors, which drive the tracks via sprocket wheels. It is

equipped with an automatic hydraulic differential brake. An electric switch in the cab is used to engage

and disengage the trailer drive. When the trailer drive is disengaged, the hydraulic motors are disconnected at the same time from the load, which enables the trailer to move freely. The highest transport speed is

obtained with the trailer drive disengaged and the gearbox in top gear engaged. The trailer has a built-in

parking brake, which is operated with an electric switch in the cab. When the diesel engine is stopped, the

trailer is automatically braked.

Remember that safety always depends on the driver. Therefore always follow the safety instructions

carefully.

4

SAFETY

This chapter summarizes the rules, which must

always be followed when you are working with

Terri 2040. These rules do not exempt the driver,

however, from taking into account statutory or

other valid national regulations and directives concerning trafc safety and industrial safety.

To be on the safe side

Get throughly acquainted with Terri 2040 and its

operating instructions.

Don’t lend Terri 2040 to anybody who is not used

to operating your machine. You may be held responsible for any injury or damage that may occur.

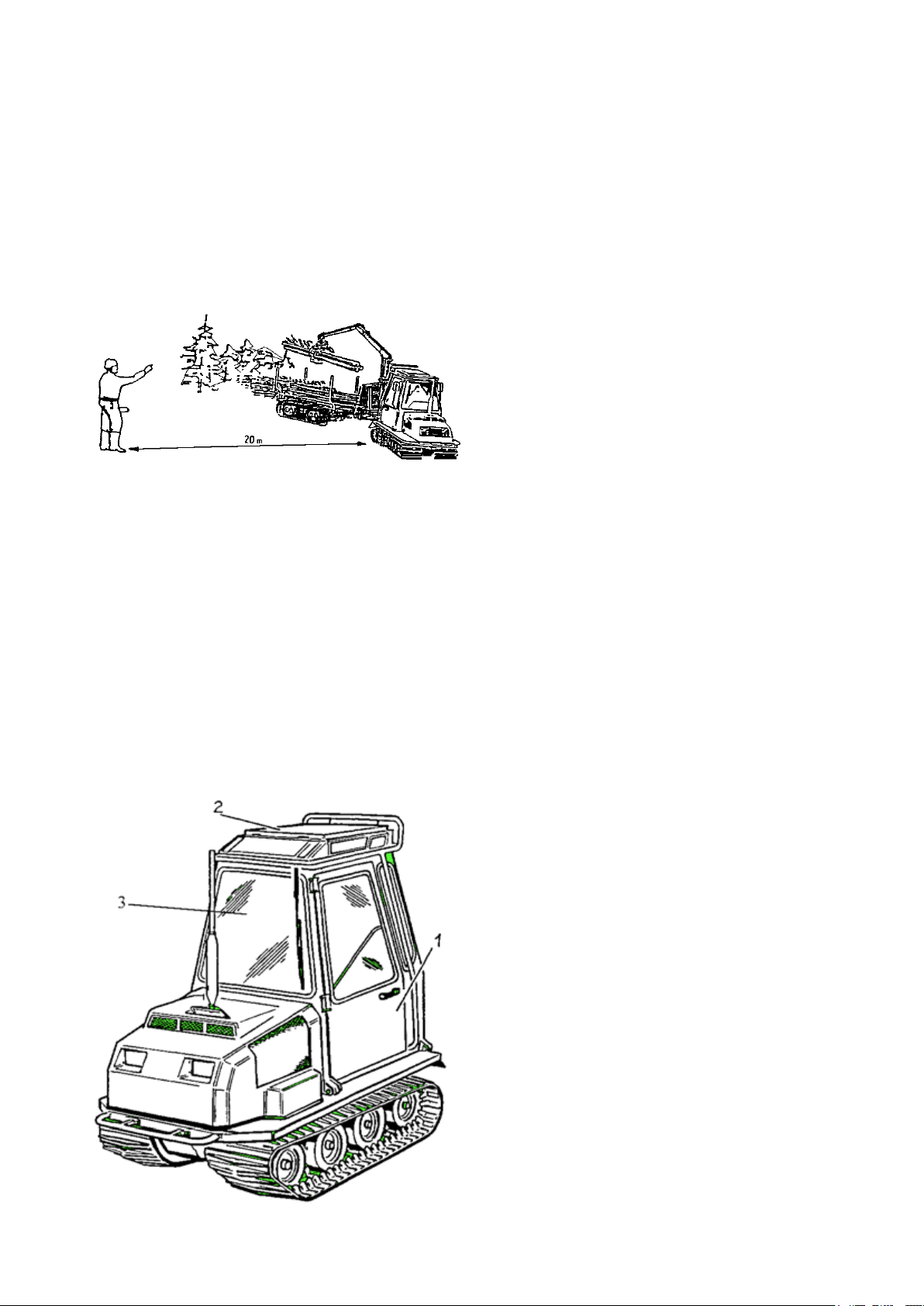

T H E D A N G E R Z O N E I S 2 0 M E T R E S!

Nobody may stay in the danger zone when the

machine is in use.

Terri 2040 does not have any room for a passenger.

Never start the diesel engine, or let it run indoors

in premises with closed doors. Warning for carbon

monoxide poisoning.

If the machine overturns, hold on to the seat or

handles. DON’T JUMP OUT!

Don’t drive the forwarder with a load hanging

from the grab-loader.

Before getting out of your Terri 2040, lower the

gripper, stop the engine and turn off the main

switch.

Don’t walk or stand under a hanging load.

Carry out regularly the maintenance points according to the schedule. Before servicing or checking

the machine, always stop the engine.

Familiarize yourself with the emergency exits in

the cab:

1. Side doors 2. Roof opening

The safety bolts of the roof opening must be

withdrawn when you drive on a lake or river covered with ice.

When checking the level of the fuel tank and the

battery electrolyte, never use a naked ame.

5

If possible, inspect in advance the terrain on the

route to be taken, particularly during the winter,

when snow may cover unevenness in the ground.

Note the slope of the terrain and its inuence on

the stability of the tractor.

Be aware of the total height of the grab-loader and

load, before driving anywhere with height restrictions. Pay particular attention to any temporary

structures, sagging overhead lines, etc.

Never load the trailer above the height of the load

protection.

Never allow children to stay in the cab or in the vicinity of the machine, when the engine is running.

WORKING CLOSE TO OVERHEAD

LINES

When you are working in the vicinity of electric overhead lines, no part of the machine or

the load must come closer to the line than the

distances given in the following:

Low voltage 2 metres

High voltage <40 kV 4 metres

High voltage >40 kV 6 metres

If it is difcult to follow the above-mentioned

safety regulations, contact the owner of the overhead line in order to de-energize it. Under no circumstances whatsoever can you rely on good luck

when working close to an overhead line. Where

applicable, material must be moved by some other

means a sufcient distance from the overhead line

before it is loaded.

When driving in forests and along forest roads,

remember that it is difcult to see an overhead line

crossing the route. In addition, the line may be

sagging heavily due to snow and ice.

ELECTRICITY DOES NOT NEED ANY DIRECT CONTACT. A HIGH VOLTAGE CAN

JUMP ACROSS EVEN LONGER DISTANCES.

6

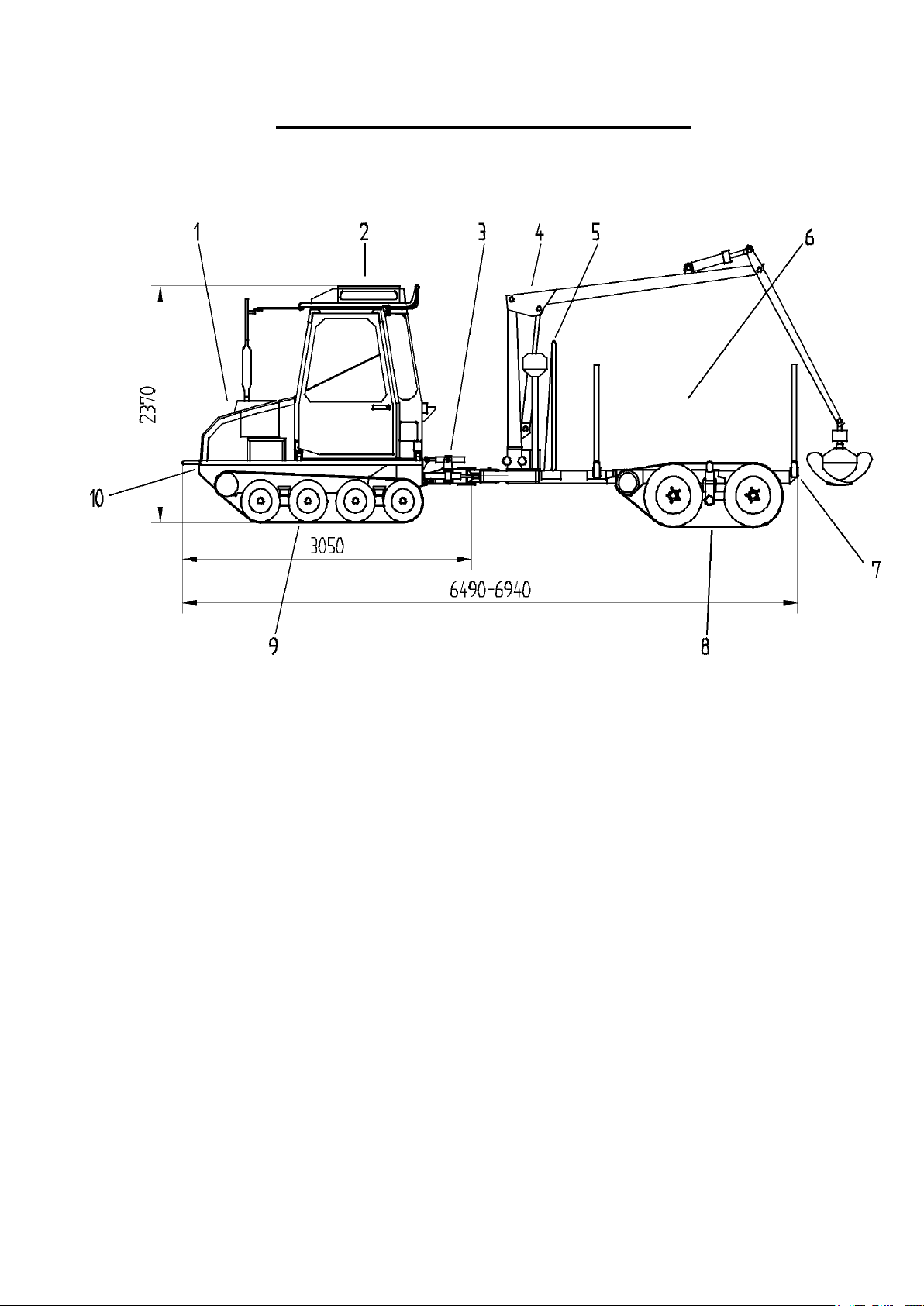

Main components of Terri 2040

1 Drive unit

2 Cab

3 Pulling bar with support cylinder

4 Grab-loader

5 Load shifting protection

6 Load area

7 Trailer

8 Track-bogie system

9 Track-bogie system

10 Winch

7

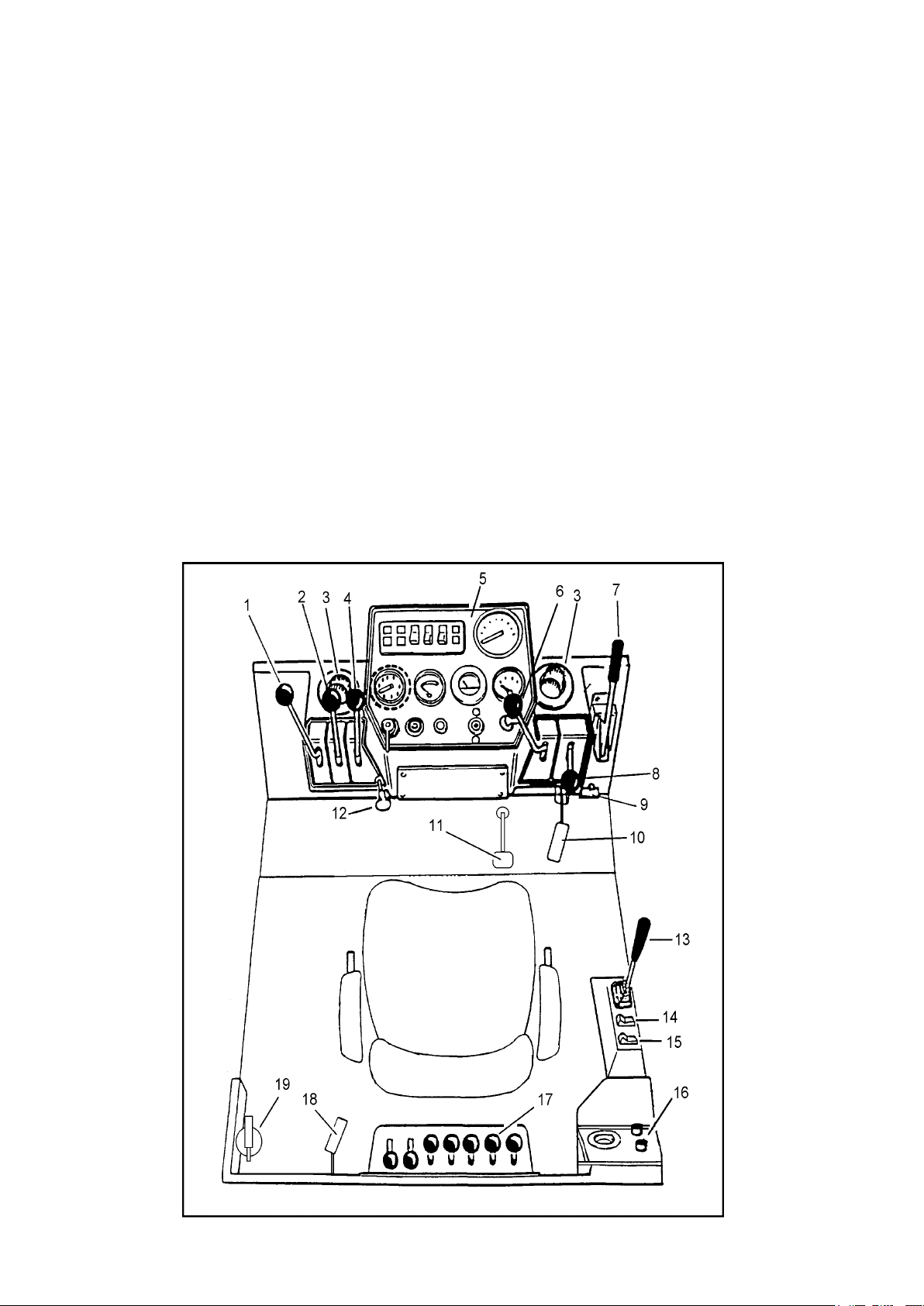

Instrumentation and controls

1 Load cylinder control lever

2 Differential lock (not Sweden)

3 Air vents

4 Winch lock control lever

5 Front dashboard

6 Winch control lever

7 Parking brake

8 Gear shift lever

9 Main switch

10 Accelerator pedal, front

11 Brake (only Sweden)

12 Hand throttle (optional equipment)

13 Drive lever

14 Switch with indicator for trailer drive

15 Switch with indicator for trailer parking brake

16 Rear dashboard

17 Grab-loader controls

18 Accelerator pedal, rear

19 Fire extinguisher

8

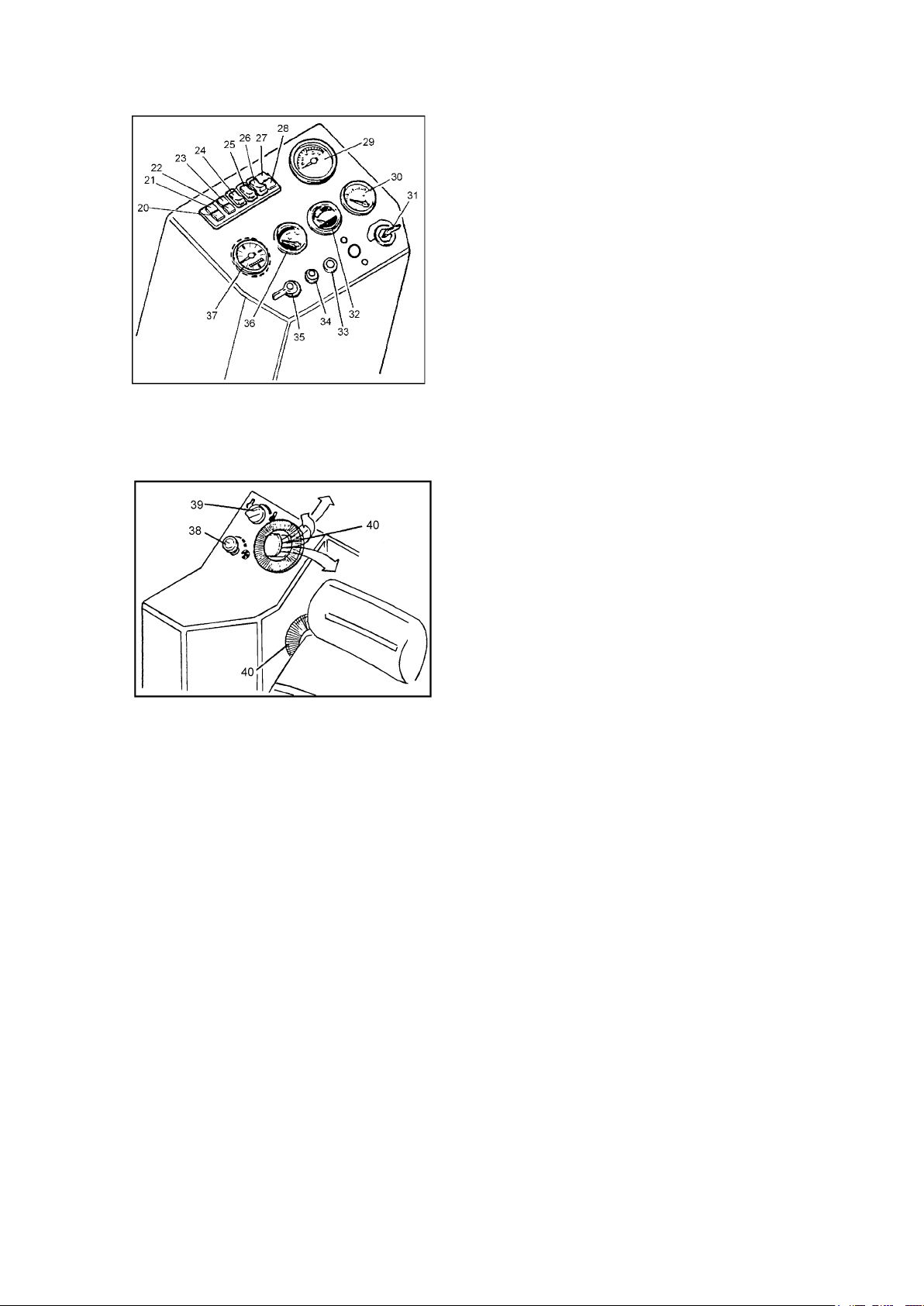

5 Front dashboard

20 Warning light for low hydraulic oil level

21 Warning light for differential lock engaged

22 Indicator for main beams

23 Glow plug indicator

24 Switch with indicator for main-dipped beams

25 Switch with indicator for working lights, side

26 Switch with indicator for working lights, rear

27 Warning light for low oil pressure in diesel engine

28 Charging indicator

29 Tachometer

30 Engine temperature gauge

31 Ignition switch

32 Hydraulic oil temperature gauge

33 Pushbutton for windscreen washer

34 Pushbutton for horn

35 Direction indicator

36 Fuel gauge

37 Running-time meter

16 Rear dashboard

38 Ventilation blower control

39 Cab heating control

40 Air vents

9

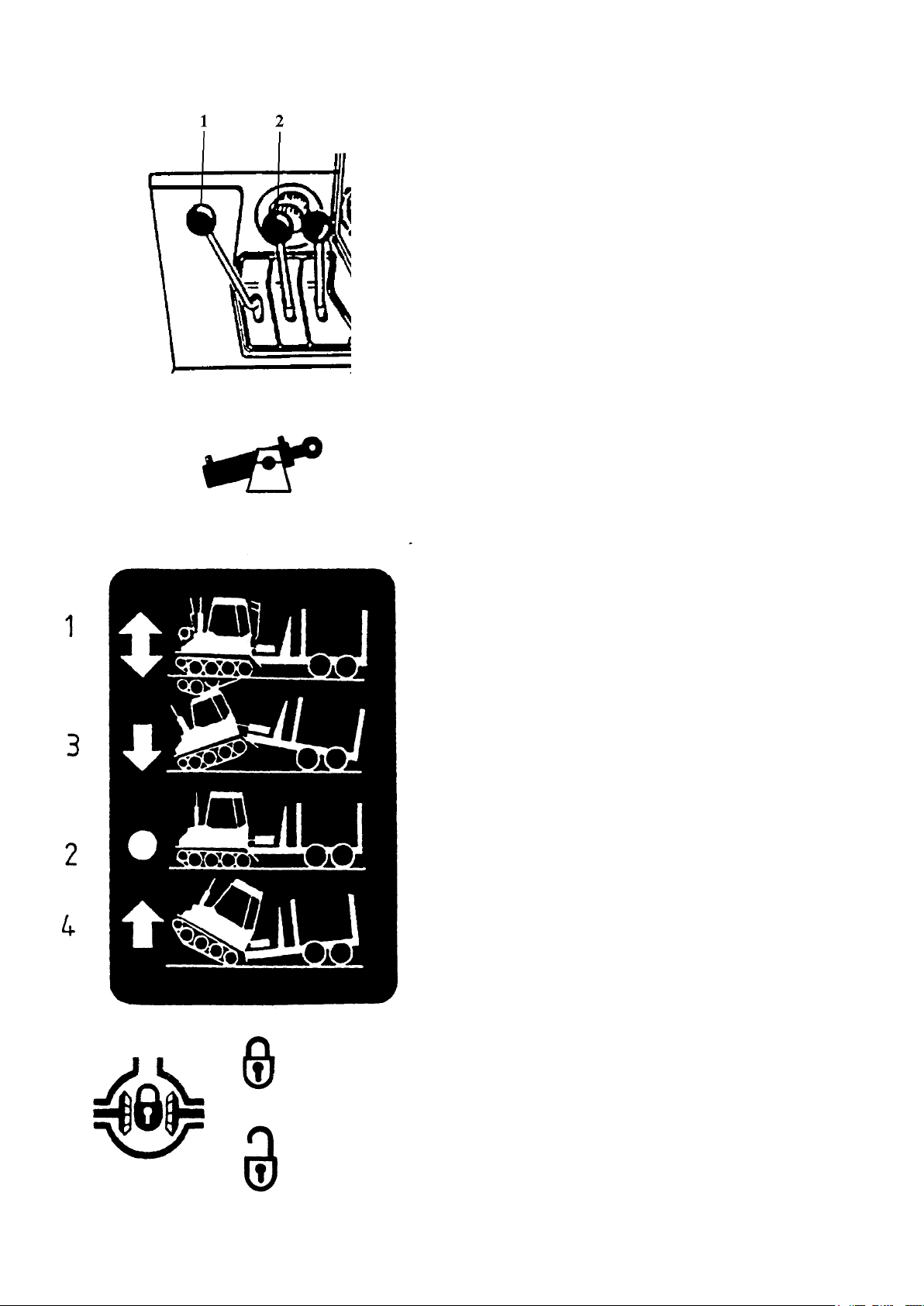

1 Load cylinder

With the help of the load cylinder, which is located

between the tractor and the trailer, it is possible to

adjust the position of the front of the tractor depending on different situations. The load cylinder

is operated with a lever to the left on the dashboard.

Position 1: The lever pushed upwards = the tractor

‘moves freely’, i.e., the tractor can freely follow

the terrain. It is recommended that this position

should always be used.

N.B. Spring-loaded locking of the lever in this position!

Position 2: The lever in the mid-position, with

spring loading in the centred position = ‘locked

position’. The position of the tractor in relation to

the trailer is locked. It is recommended that this

position should only be used during driving in

loose snow without any track or when the tractor

is driven over a ditch or the like.

Locked

Position 3: When the lever is moved forwards, the

front of the tractor is lowered. The lever returns

with spring loading to the ‘locked position’ (2),

when it is released.

CAUTION! Do not turn sharply when the front of

the machine is lowered.

Position 4: When the lever is moved downwards,

the front of the tractor is raised. The lever returns

with spring loading to the ‘locked position’ (2),

when it is released.

Practical example: Driving over a ditch of normal

size:

•Raise the front slightly when approaching the ditch.

•Lower the front before the tractor’s bogie has com-

pletely crossed the ditch so that the front of the bogie

touches the ground on the other side of the ditch.

•Drive the vehicle with the load cylinder in the

locked position until the trailer wheels have

crossed the ditch.

•Continue to drive the vehicle with the load cylinder in the ‘free position’.

Free

2 Differential lock

The tractor’s gearbox is provided with a mechanical differential lock, which is controlled with a

lever on the dashboard. When the lever is in its

lowest position, the differential lock is disengaged.

10

Locked

Free

3 Front air vents

The direction of the incoming air is controlled

with the air vents. The air is directed towards the

front windscreen to provide a defroster action.

4 Winch lock

The winch lock prevents the wire rope from running out. It is operated with a lever to the left on

the dashboard. The winch lock is released when

the lever is in its upper position. Release the

winch lock and draw out the wire rope.

N.B. Wear protective gloves!

N.B. Never drive backwards with the drive lever

while using the winch! This may damage the gearbox.

Engaged

Disengaged

6 Winch

The winch is operated with a lever to the right

on the dashboard. When the lever is in the upper position, the gear in neutral, the trailer drive

disengaged, the drive lever forwards and the accelerator pedal is pushed, the wire rope is wound

up on the drum

N.B. Never drive backwards with the drive lever

while using the winch! This will cause the wire

rope to be wound up in the wrong direction on the

winch drum.

7 Parking brake

This lever actuates a mechanical brake yoke.

When the lever is moved backwards, the machine

is braked. The lock is released with the button at

the end of the lever.

High gear

Low gear

Gear shift lever

8

Two gears can be selected with the lever. If the

lever is moved upwards, the low gear is engaged,

while if the lever is moved downwards, the high

gear is engaged. When the lever stands in the

middle, the gearbox is in neutral.

11

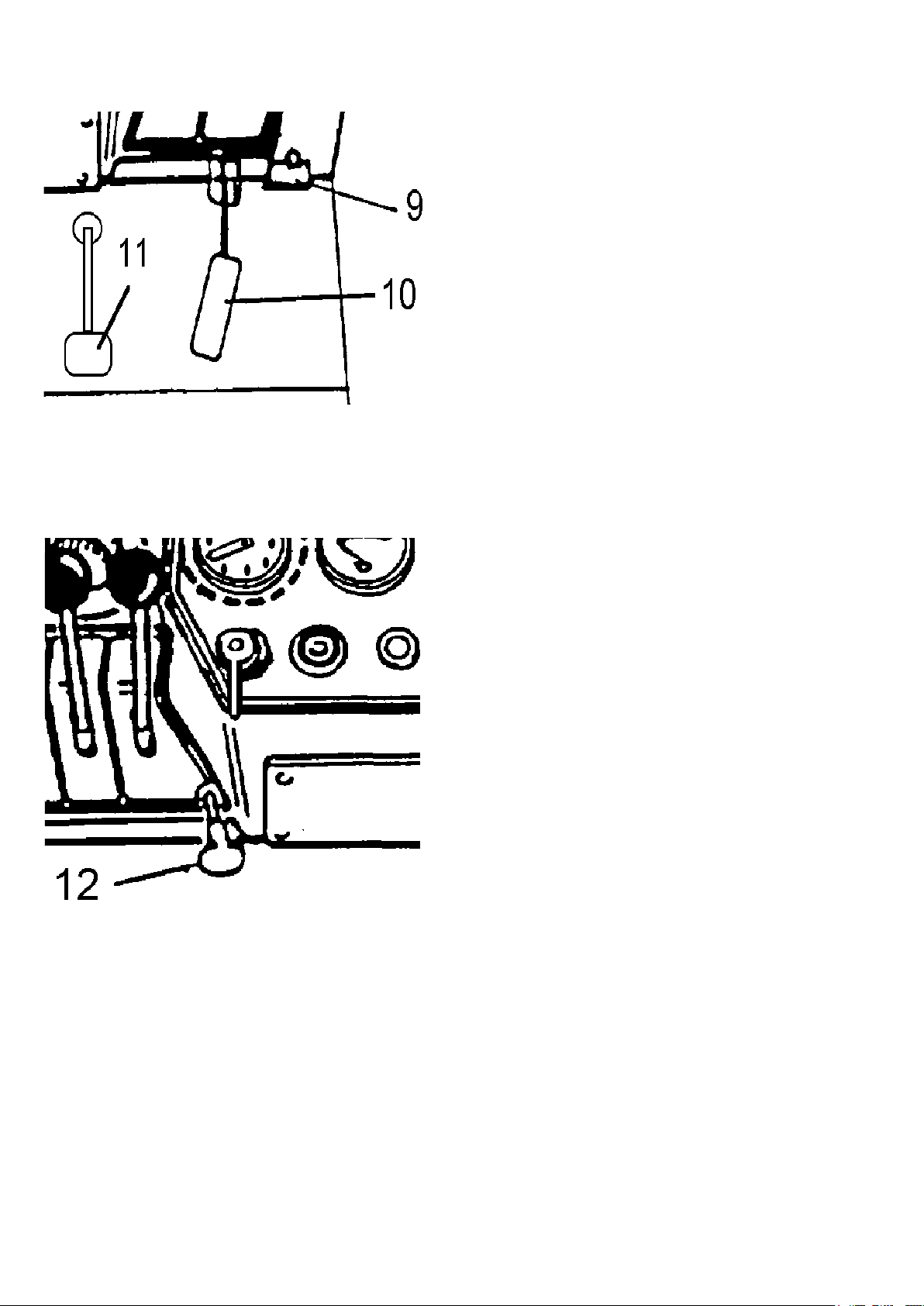

9 Main switch

All the power supply is disconnected with the

main switch.

N.B. Never open the main switch when the engine

is running!

10 Accelerator pedal, front

The engine speed is controlled with the accelerator

pedal during driving.

11 Brake pedal

The machine is braked with the brake pedal.

12 Hand throttle

(optional equipment)

The engine speed can be set with the hand throttle.

Rough setting: press the button and withdraw it.

Fine setting: turn the knob.

12

Loading...

Loading...