Terrco 2000 Operating Instructions Manual

®

Terrco

Model 2000

, Inc.

OPERATING INSTRUCTIONS

MAINTENANCE INSTRUCTIONS

ILLUSTRATED PARTS LIST

222 1st Avenue NW • Watertown, SD 57201

Phone: (605) 882-3888 • Fax: (605) 882-0778 • Email: info@terrco.com

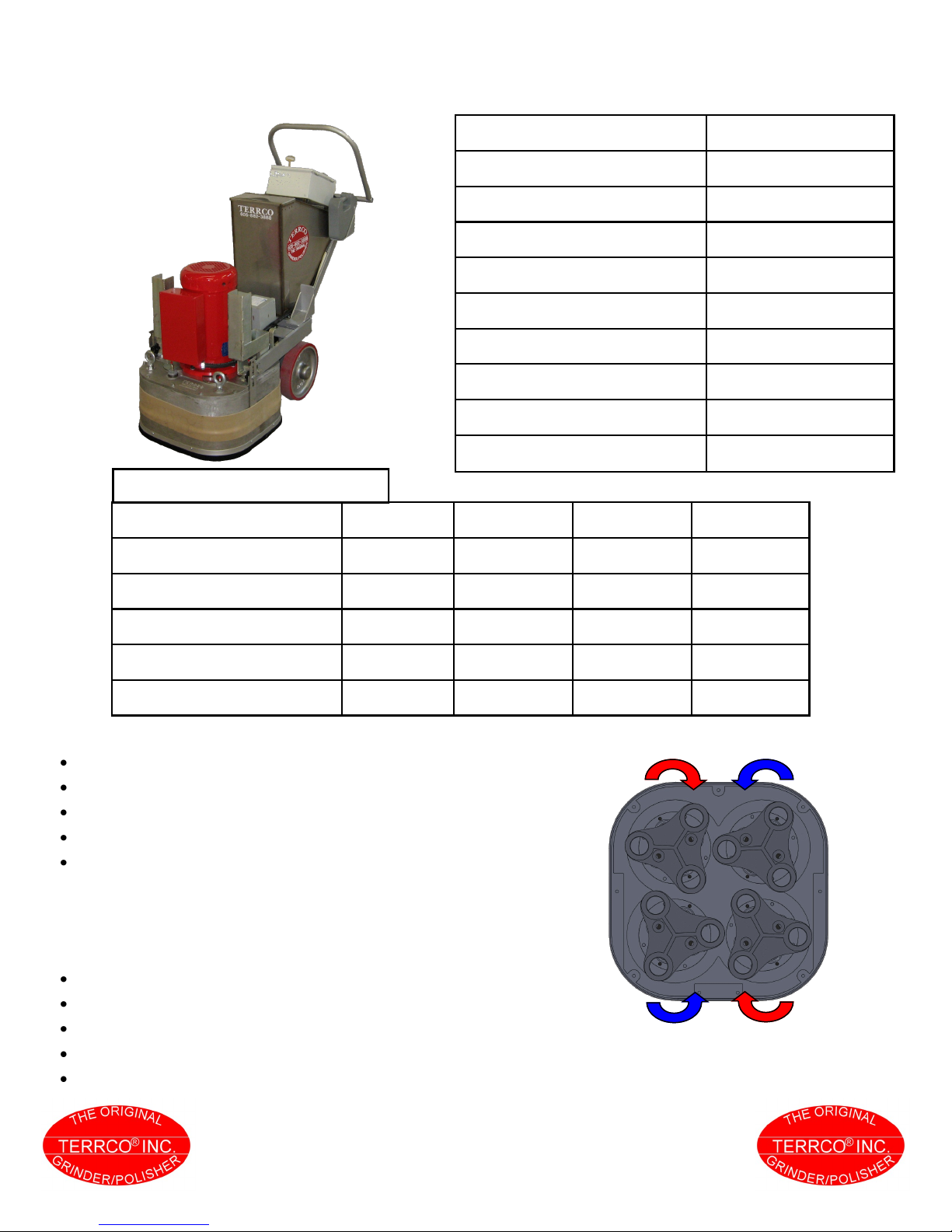

Terrco®, Inc.

Model 2000

HP/KW 15/11.2 or 10/7.5

SWEEP OF DISCS 22-1/2” (571.5 mm)

ABRASIVE PRESSURE 650 LBS (295 kg)

WIDTH OF MACHINE 24” (610 mm)

LENGTH OF MACHINE 67-1/2” (1715 mm)

HEIGHT OF MACHINE 48” (1219 mm)

NET WEIGHT 800 LBS (363 kg)

SHIPPING WEIGHT 975 LBS (442 kg)

WATER TANK 20 gallon (75,7 L)

POWER CORD (6-3) 100 ft. (30,5 m)

ELECTRICAL OPTIONS

VOLTAGE 230 230 460 230

PHASE 1 1 3 3

DRIVE MANUAL VARIABLE VARIABLE MANUAL

AMP DRAW 40 40 14 37

BREAKER (AMPS) 60 60 30 60

STONE HOLDER RPM 550 500-740 500-740 550

VALUES BASED ON A 10 HP MOTOR

Optimal for jobs exceeding 5,000 sq. ft.

Stainless Steel Guards and Water Tanks

Wet/Dry Setup

Direct Drive, No Belts

Uses Plug Stone Shape, Bolt on to Universal Tool

Plate, or Speed Shift System

Production Rates

Mastic removal rate of 800 sq. ft. per hour

Thin-Set removal rates of 1,200 sq. ft. per hour

Thin-Mil coatings removal of 600 sq. ft. per hour

Concrete polishing rates of 2,000 sq. ft. per polishing pad per hour (depending on grit)

Rough Terrazzo rate of 1,000 sq. ft. per day

222 1st Avenue NW • Watertown, SD 57201

Phone: (605) 882-3888 • Fax: (605) 882-0778

Email: info@terrco.com • Website:www.terrco.com

INTRODUCTION:

Operating Instructions

This manual has been prepared to assist you in

the proper operation and maintenance of your

machine. Please bear in mind that your

TERRCO® 2000 is a precision piece of

machinery manufactured to exacting standards.

In order for you to obtain maximum use of your

TERRCO® 2000, we suggest that you read this

manual completely and thoroughly before

attempting to operate your machine. A parts

diagram and parts reference sheet are included

to assist you in ordering the proper parts.

Always give the machine number and model

number when ordering repair parts.

PLELIMINARY PROCEDURES TO FOLLOW BEFORE PUTTING THE 2000 IN OPERATION FOR

THE FIRST TIME.

A. Delivery of the Machine

1. On delivery, the contractor should very

carefully examine the shipping crate to see that

no part of the machine is damaged. If damage

is noted, request an inspection immediately and

request a copy of the claim report. When

accepting the machine from the delivering

carrier, note the damage on the Freight Bill

before signing. TERRCO® WILL NOT honor

any claims for broken, damaged, or missing

parts that may have occurred in shipment, as

each machine is checked and inspected for the

same, before leaving our plant.

B. Installation and Replacement of Grinding

Stones

1. Move the counterbalancing weights to the

upper weight baskets.

2. Tilt machine back so that the caster wheel

rests on the floor.

3. Clean mounting surface both on plug

stone and stone holder. On 2” or 3” diameter

plug stone, push stone in the hole and give the

stone a slight twist to be certain it is securely in

place.

4. Grasp machine handle and lower machine

to the floor slowly so that all stones are resting

on the floor. Make certain no stones have

fallen or loosened while lowering the machine

to the floor.

C. Transport of Machine

1. With counterbalancing weights in the

upper weight baskets, tilt the machine so that

the caster wheel is firmly on the floor. You can

push from gear case side.

D. To operate the 2000

1. Disconnect electrical source.

2. Install stones per instructions in #1B.

3. After stones are installed, lower the

machine until it is in operating position.

CAUTION - Never attempt to start the machine

while lowering machine to the floor, as rear

stones will strike on corners resulting in thrown

stones and possible damage to the machine.

4. Before plugging into the electrical

system, check the voltage at the source. The

minimum acceptable voltage is (208 Volt, 60

HZ, single phase), (210/420 Volt, 60 HZ, 3

phase), or (380 Volt, 50 HZ, 3 Phase).

Anything lower than this can result in blown

heaters and possible motor burnout.

5. If the machine is to operate in an area

more than 100 feet from the source, it will be

necessary to use the next larger size cable (#4-

4) from the source to the 100 feet of #6-4 wire

cable that was furnished with the machine.

6. After you have the cable in place, relieve

pressure on the stones by applying your weight

on the handle and push the start button on the

starter switch, then releasing pressure on the

handle to lower the machine to the floor.

7. We recommend that the first pass over

the floor be made with the weights in the upper

weight baskets. After the floor is “roughed”

out, move the weights to the weight baskets

located on the gear case for maximum abrasive

pressure.

8. Be sure to periodically check stone wear,

to prevent grinding with the steel plugs, rather

than the stones.

Loading...

Loading...