Terratek TBG150 User Manual

User Manual – Please

read and retain for

future reference.

See page 1 Voir page 13 Ver la págeina 27

6"Bench Grinder

Meuleuse d'établi de 6 po

Esmeril de 6"

Guide d’utilisation

– Veuillez lire et

conserver ceguide

pour vous y reporter

ultérieurement.

Manual del usuario –

Por favor lea este

manual y guárdelo para

referencia futura.

TBG150

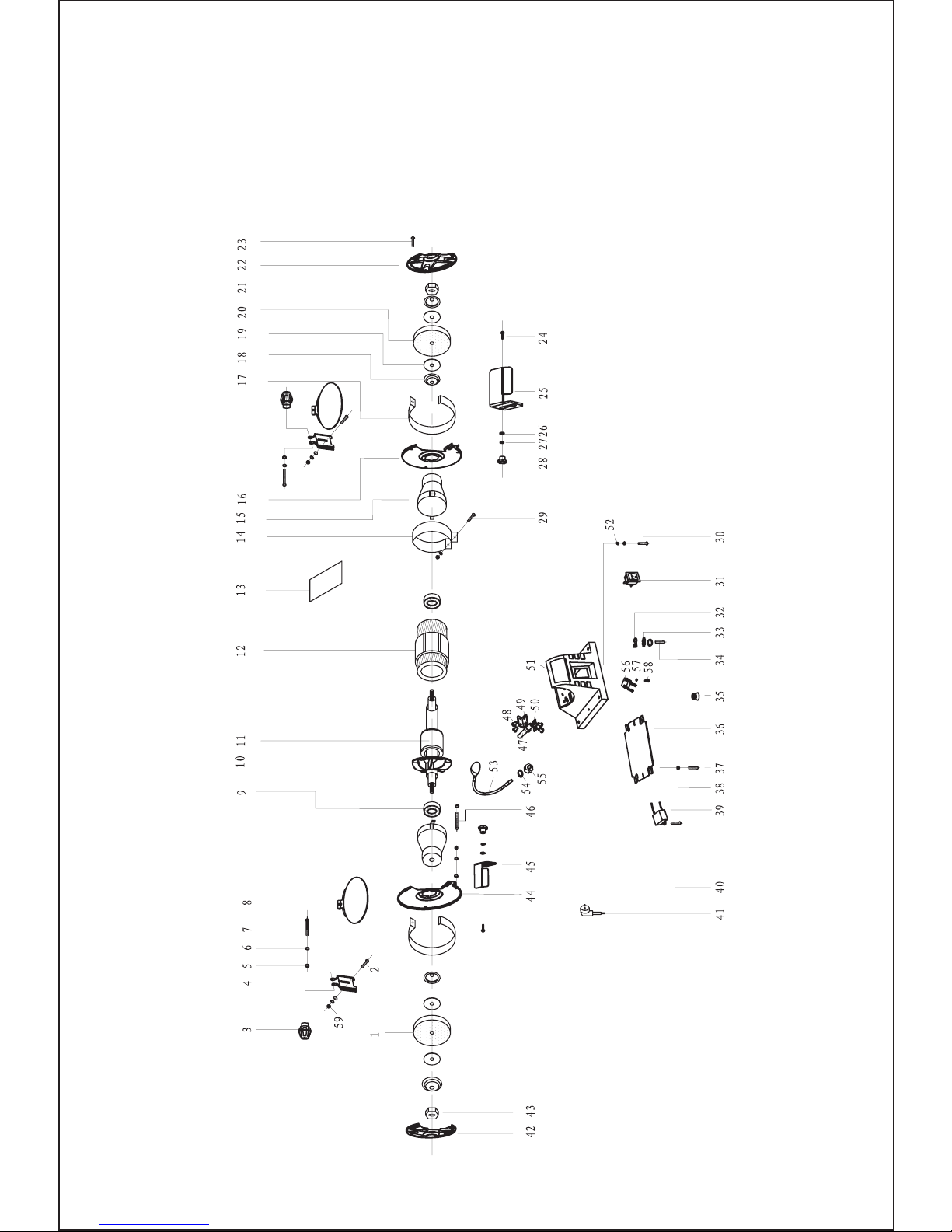

Exploded Assembly Diagram

Vue Éclatés

Dibujo despiezado del conjunto

8

4

2

1

3

5

6

7

9

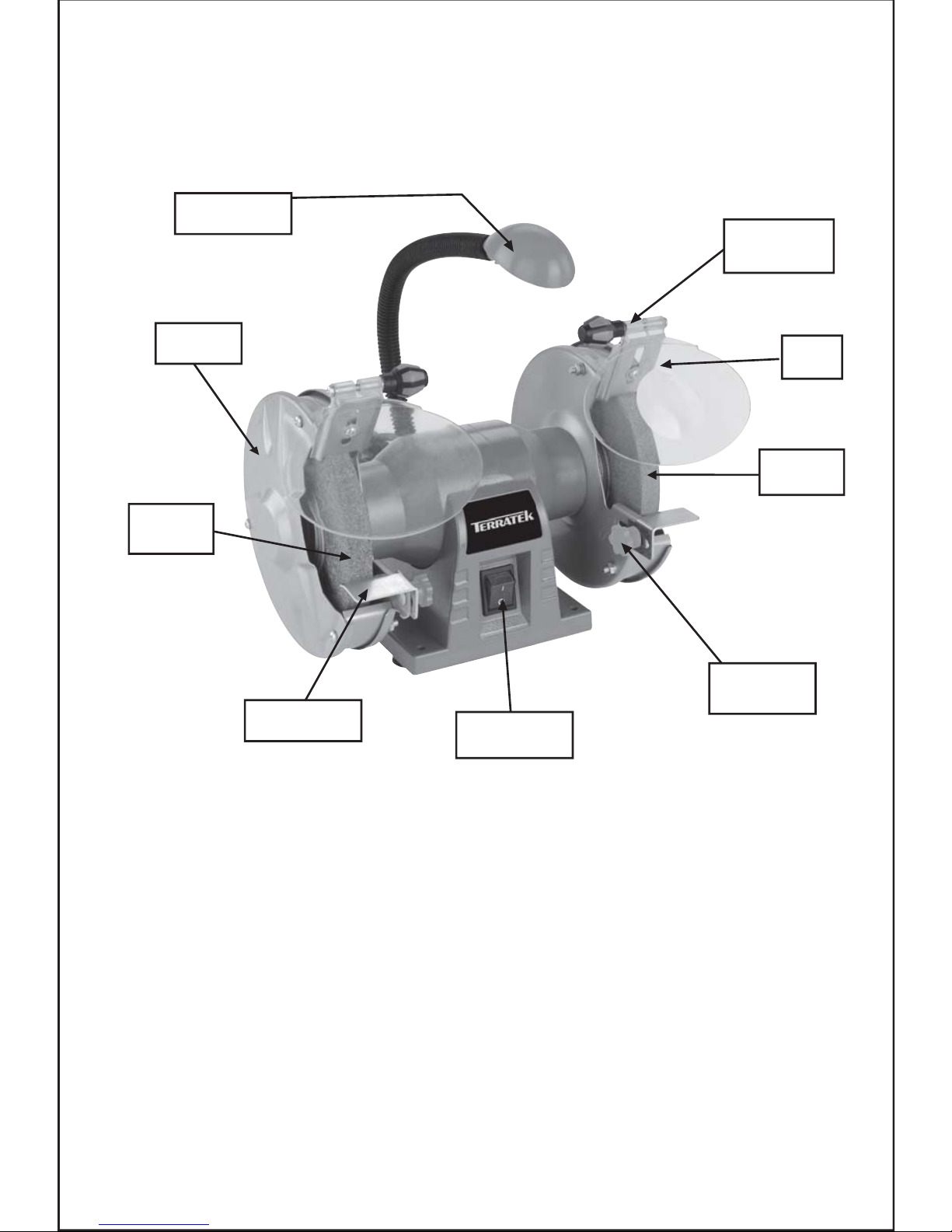

1. Wheel guard

2. Eye shield

3. Eye shield bracket

4.Wheel (fine)

5.Tool rest adj. knob

6. Switch

7.Tool rest adj. knob

8.Wheel (coarse)

9.Lamp

1. Garde de roue

2. Ecran protecteur

3. Support d'ecran protecteur

4.Roue de rectifieuse (fine)

5. Ecrou de rereglage de repos d'outil

6. Interruptor

7. Repos d'outil

8. Roue de rectifieuse (grossier)

9. Lampe

1.Guarda de muela

2.Protector ocular

3.Soporte de protector ocular

4.Muela abrasiva (fino)

5.Tuerca de ajuste del resto

6.Interruptor

7.Resto de herramienta

8.Muela abrasiva (grueso)

9.Lámpara

.QO)

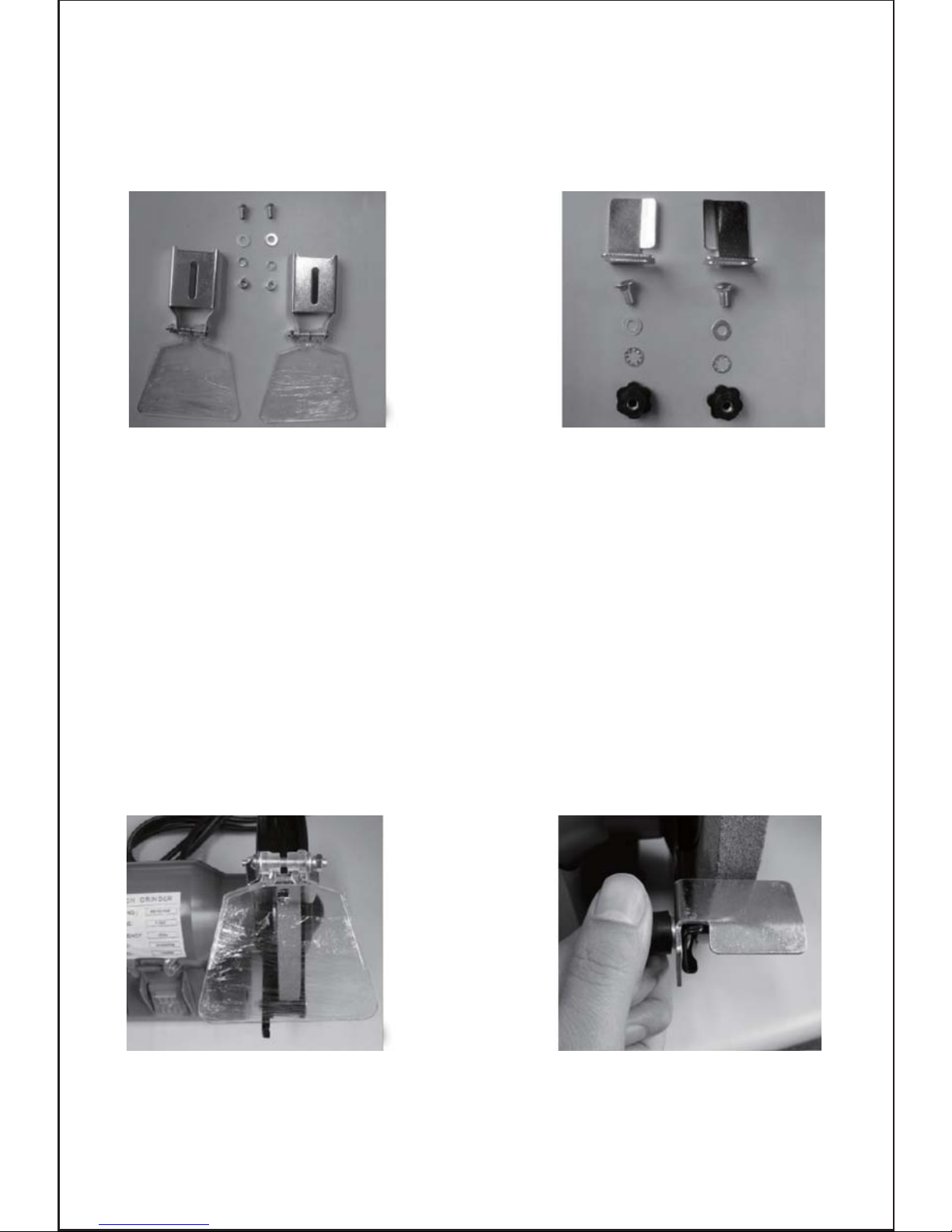

Accessories List:

Liste des accessoires:

Lista de accesorios:

Accessories for eye shield

1. Screw set-screw, flat

washer, spring washer, nut

2. Eye shield

Accessoires pour l’ecran protecteur Accessoires pour porte-outil

1. Ensemble de vis : vis, rondelle 1. Piece de porte-outil

plate,rondelle frein, ecrou 2. Ensemble de vis : vis,rondelle

2. Ecran protecteur plate, rondelle en etoile, bouton

Accesorios para la visera Accesorios para el descanso de la

1. Tornillo de fijacion, plano herramienta.

2. Visera 1. Pieza del descanso de la

herramienta

2. Tornillo de fijacion, plano arendela,

arendela estrela, manija.

Accessories for tool rest

1. Tool rest part

2.Screw set-screw,flat

washer,star washer,knob

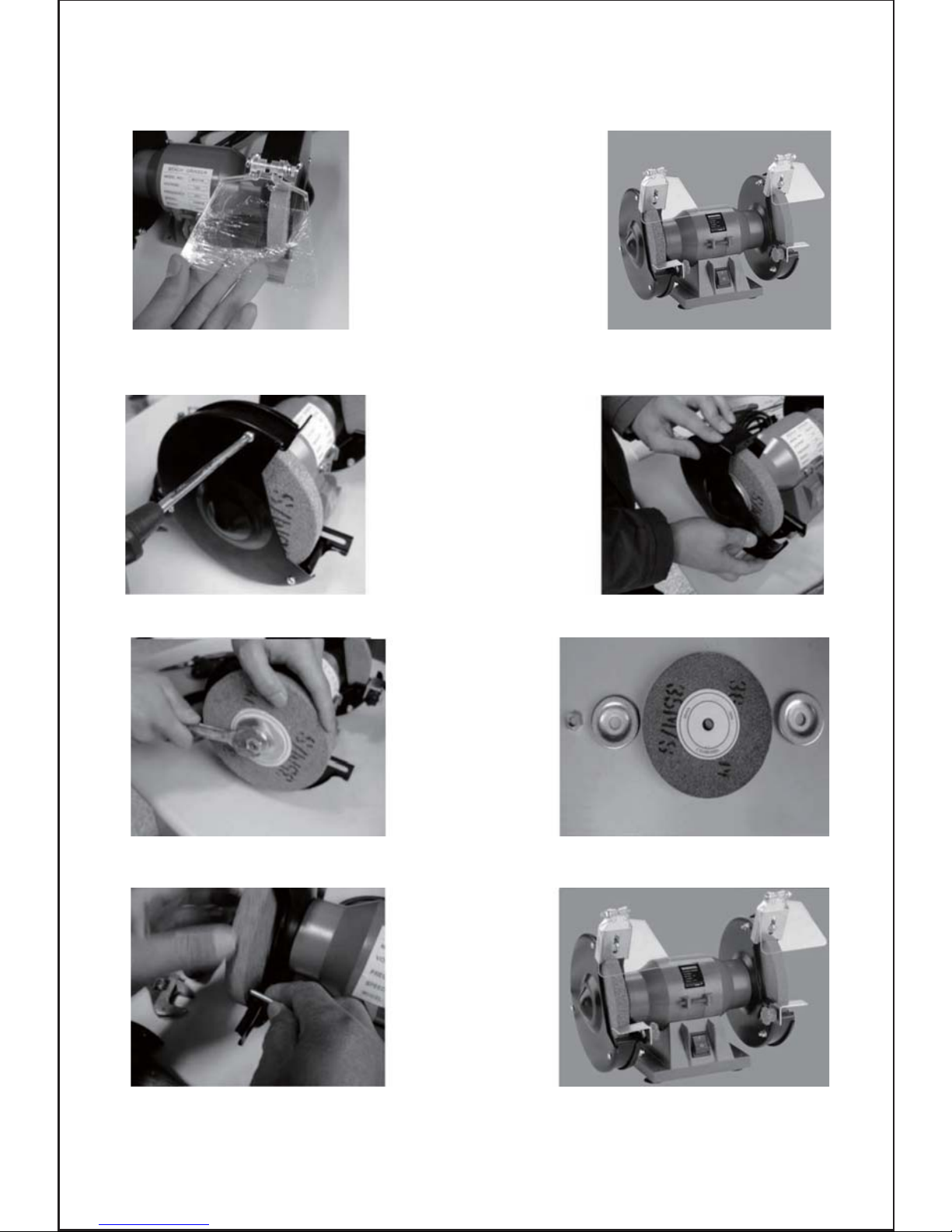

Fig.1 Fig.2

Fig.3 Fig.4

Fig.5 Fig.6

Fig.7 Fig.8

Fig.9 Fig.10

1

Contents

Parts List

Technical Spec

Safety Instructions

Using your grinder

Maintenance

Assembly

Warranty

Part List

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

Grinder Wheel

Screw

Knob nut

Eyeshield Bracket

Washer

Spring washer

Screw

Eyeshield

Bearing

Fan

Rotor

Stator

Nameplate

Middle ring

Cover

Right Inner guard

winding

Wheel flange

Nameplate of wheel

Grinder Wheel

Nut

Right outer guard

Screw

Square Neck Screw

Right tool rest

Tooth washer

Washer

Knob nut

Screw

Screw

Switch

Ground terminal

Tooth washer

Screw

Rubber Feet

Base plate

Screw

Washer

Capacitor

Screw

Plug & Cable

Left Inner guard

Nut

Left Outer guard

Left tool rest

Screw

Cable adaptor

Screw

Cable Block

Cable clip

Base

Washer

Lamp

Spring washer

Nut

transformer

Washer

Screw

Nut

No. Description Qty. No. Description Qty.

1

8

2

2

10

24

2

2

2

1

1

1

1

1

2

1

2

4

4

1

1

1

6

4

1

2

2

2

1

4

1

1

1

1

4

1

2

6

1

1

1

1

1

1

1

2

1

4

1

1

1

4

1

1

1

1

1

1

8

Technical Information

Read this entire manual before using this

product. Failure to do so can result in serious injury. Save

this manual for future reference.

2

Voltage: 120V

Rated Power: 1.1A

Speed: 3450rpm

Wheel Size: 6”x1/2”

Wheel Grits: 36/60

NW/GW: 13/15 lbs.

Copyright 2011 by ACL Group (Intl) Ltd All rights reserved. This manual or any artwork

contained herein must not be reproduced in any shape or form without the express

written consent of ACL Group (Intl) Ltd. Diagrams within this manual may not be

drawn proportionally. Due to continuing improvements. actual product may differ

slightly from the product described herein.

Important SAFETY Information

This symbol is to warn you of potential personal

injury hazards. Please read carefully the notes along side

this warning to avoid possible injury or death.

General Safety Rules

WARNING! Read all instructions. Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury. The term “power tool” in all of the

warnings listed refers to corded or cordless power tools.

Work area safety

Read and Keep This Manual

Electrical safety

Before use, ensure that the power outlet you are using matches the plug on your power

tool and that the voltage of the outlet matches that of your power tool.

Only use grounded extension cords with power tools fitted with 3 pin plugs and if using

outdoors ensure any extension cord is suitable for outdoor use.

Always try to avoid body contact with grounded surfaces, such as radiators, cooking

ranges and any other fixed appliance with metal surfaces.

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the

dust or fumes.

Keep children and bystanders away while operating a power tool. Distractions can

cause you to lose control.

Please read carefully all instructions within this manual. Failure to follow all safety

warnings can result in serious personal injury. The term “Power Tool” in all of the

following warnings refers to your mains operated (corded) or battery operated (cordless) power tool

3

Personal safety

Never use your power tool whilst under the influence of alcohol, drugs or medication.

Tiredness can often cause accidents, stay alert.

Never use your power tool without the correct guards in place.

Always use ANSI approved eye protection and dust mask. Non slip safety shoes and

hearing protectors should be worn at all times when using your power tool.

Ensure any dust collecting device supplied with your machine is connected correctly

before use.

Ensure all loose clothing, long hair or jewelry is kept clear of the machine.

Before plugging your power tool into the power outlet ensure the power tool is in the

OFF position.

Check that wrenches or adjusting keys have been removed. Any wrench or key left

attached to a moving part can result in injury.

Power tool use and care.

Service

Keep your power tool clean and well serviced at all times.

Never adjust or service any power tool before disconnecting from the mains electricity

supply.

Always use the correct tool for the job.

Never force the tool to work harder than it is designed to do.

Never use your power tool with broken parts such as switches, guide fences or leg

stands.

ALWAYS keep your power tools away from children.

Keep cutting tools sharp to ensure less stress on the motor.

Only have your power tool serviced by a qualified repair agent using manufacturers

recommended parts.

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

Develop a periodic maintenance schedule for your tool. When cleaning a tool be careful

not to disassemble any portion of the tool since internal wires may be misplaced or

pinched or safety guard return springs may be improperly mounted. Certain cleaning

agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic parts.

4

Do not expose your power tool to wet or damp conditions and NEVER use in rain.

Check regularly the power cord of your machine and any extension cord that you

are using for damage.

Do not carry or pull the machine with the power cord.

Ensure the cord is clear from hot surfaces, oil or sharp objects.

GENERAL SAFETY INSTRUCTIONS

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE ADJUSTING KEYS & WRENCHES. Before turning on the power tool, make

sure the keys and adjusting wrenches have been removed.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

4. ALWAYS REMAIN ALERT WHEN THE TOOL IS IN USE. Inattention on the part of

the operator may lead to serious injury.

5. DON’T USE IN A DANGEROUS ENVIRONMENT. Don’t use power tools in damp or

wet locations or expose them to rain. Keep work area well lit.

6. KEEP CHILDREN AWAY. All visitors should remain at a safe distance from work area.

7. MAKE WORKSHOP CHILD-PROOF with padlocks, master switches or by removing

starter keys.

8. USE THE RIGHT TOOL. Don’t force a tool or attachment to do a job for which it was

not designed.

9. USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good

condition. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table (see Table 1) shows the correct size

to use depending on cord length and nameplate ampere rating. If in doubt, use the

next heavier gauge. The smaller the gauge number, the heavier the cord.

10. DON’T FORCE THE TOOL. It has been designed to operate at maximum safety

and performance levels.

11. DO NOT FORCE THE MATERIAL BEING CUT. Always let the tool cut at its own speed.

12. WEAR PROPER APPAREL. Do not wear loose clothing, neckties, rings, bracelets

or other jewelry which may get caught in moving parts. Non-slip foot wear is reco mmended. Wear protective hair covering if you have long hair.

When servicing a tool, use only identical replacement parts. Follow instructions in

the Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

A) Wear eye protection.

B) Keep hands out of the path of blades/cutters.

C) Do not operate tool without guards in place.

D) Do not perform any operation freehand.

E) Never reach around cutting tools.

F) Turn off tool and wait for blade/cutter to stop before moving workpiece or changing

settings.

G) Disconnect power(or unplug tool) before changing blade/cutter or servicing.

WARNING: For your own safety read Instruction Manual before operating your power

tool.

5

Read this owner's manual completely and make sure you understand all of its

safety guidelines

This power tool is supplied with all the relevant safety guards and features, it should be

checked before every operation, this manual should be read and kept in a safe place.

Whilst we warn of all the possible risks attached to using power tools any operator must

have read and understood the manual and apply their own caution and common sense

when using this power tool.

6

13. ALWAYS USE SAFETY GLASSES. Also use face or dust mask for commercial

cutting operations. Everyday eyeglasses only have impact-resistant lenses, they

are NOT safety glasses.

14. SECURE WORK. Use clamps or a vise instead of your hand to hold work when

practical. This safety precaution allows for proper tool operation using both hands.

15. DON’T OVERREACH. Keep proper footing and balance at all times.

16. MAINTAIN TOOLS WITH CARE. Keep tools clean and in good working condition

for maximum safety performance. Follow instructions for lubricating and changing

accessories.

17. DISCONNECT TOOLS BEFORE SERVICING – when changing accessories, such

as blades, bits, cutters, etc.

18. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in OFF

position before plugging in.

19. USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for recom mended accessories. The use of improper accessories may increase risk of injury.

20. MAKE SURE YOU USE THE CORRECT TOOL for the job you are doing.

21. NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the

cutting tool is unintentionally contacted.

22. CHECK DAMAGED PARTS. Before further use of the tool, damaged part(s), (i.e.,

guard) should be carefully checked to determine that it will operate properly and

perform its intended function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting and any other condition that may affect the tools

operation. A guard or other part that is damaged should be properly repaired or

replaced.

23. Replace damaged blades/cutters grinding wheels immediately. DO NOT USE

DAMAGED BLADES/CUTTERS GRINDER WHEE . They may cause bodily injury.

24. DIRECTION OF FEED. Feed work into the blade/cutter against the direction of

rotation of the blade/cutter only.

25. NEVER LEAVE TOOL RUNNING UNATTENDED. Turn power off. Don’t leave tool

until it comes to a complete stop.

26. Double Insulated tools are equipped with a polarized plug (one blade is wider than

the other). This plug will fit in a polarized outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified elec trician to install a polarized outlet. Do not change the plug in any way. Double

Insulation eliminates the need for the three wire grounded power cord and grounded

power supply system.

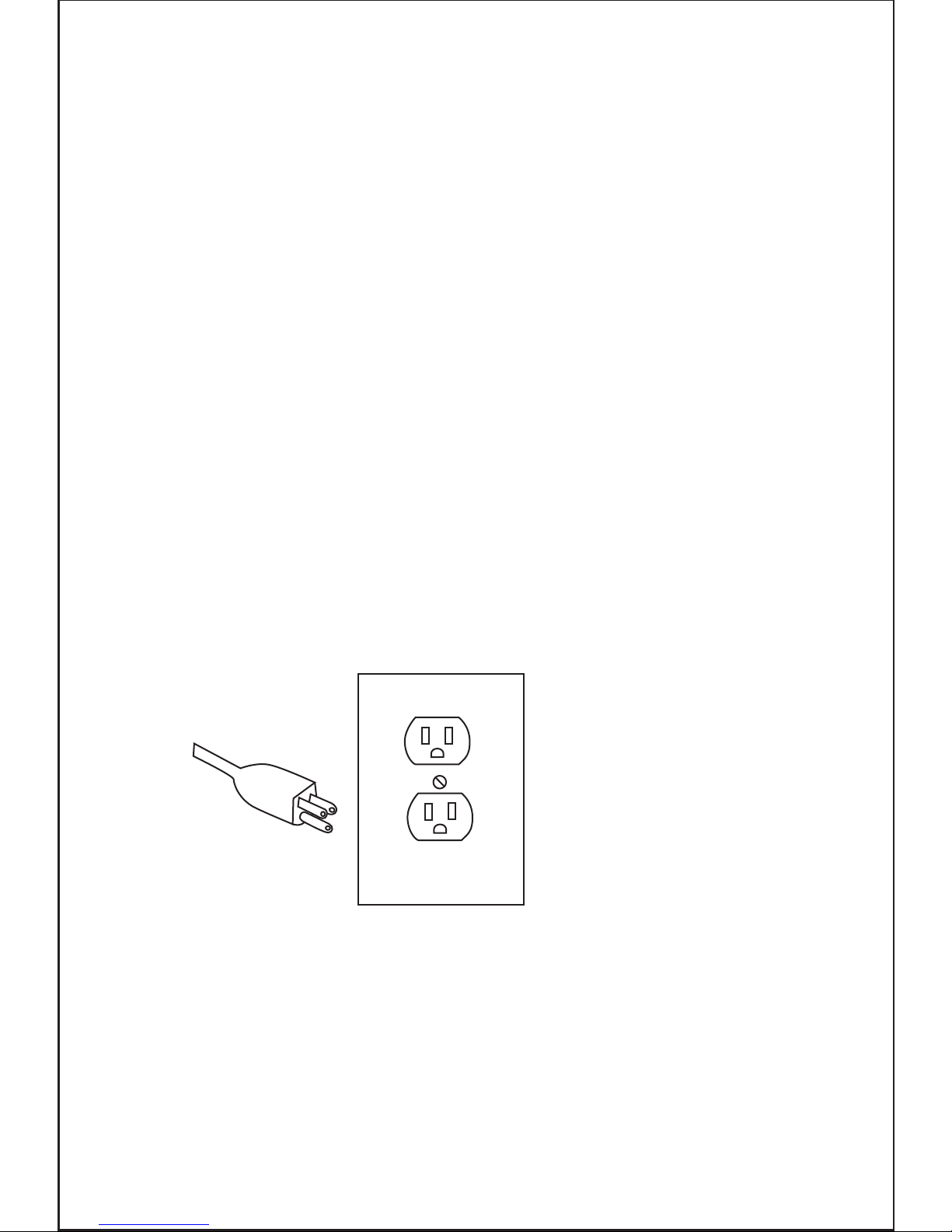

Grounding Tools

Electrical Powered Connections

Any electric powered tool that is marked Ground Required must have fitted a three

wired power cord. The main importance of this is the green wire within the cord, this

green wire must at all times be connected to the grounding prong of the plug. This

prong must never be removed or discarded. The green wire Must NEVER be connected to any other prong. The Three prong plug must only be connected to the power

supply through a three prong power outlet.

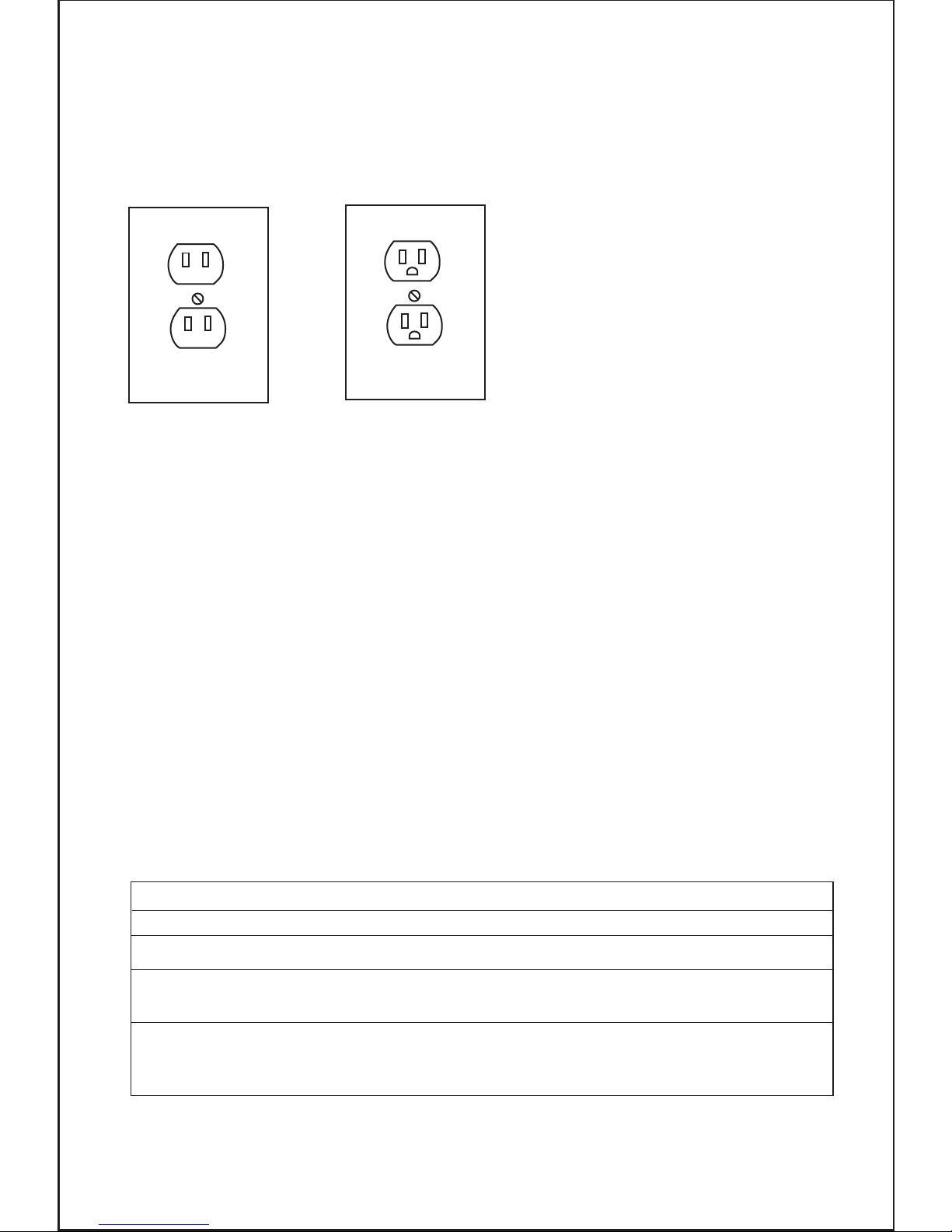

The Illustration above shows a three prong plug and outlet.

3 Prong Plug and Outlet

Only use qualified repair agents to service this power tool.

Only use qualified electrician to repair any damaged wiring.

NEVER remove the grounding prong from the power tool or extension cord.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet installed

by a qualified electrician.

Check with a qualified electrician or service personnel if the grounding instructions are

not completely understood, or if in doubt as to whether the product is properly grounded.

Repair or replace a damaged or worn cord immediately.

This product is for use on a nominal 120 V circuit and has a grounding plug similar to

the plug illustrated in Table1. Only connect the product to an outlet having the same

configuration as the plug. Do not use an adapter with this product.

7

Following this guide will greatly reduce your risk of electric shock or injury.

Grounding Instructions

Any electric powered tool that is marked Ground Required must be grounded In the event

of a malfunction or breakdown, groundingprovides a path of least resistance for electric

current to reduce the risk of electric shock.

This product is equipped with an electric cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

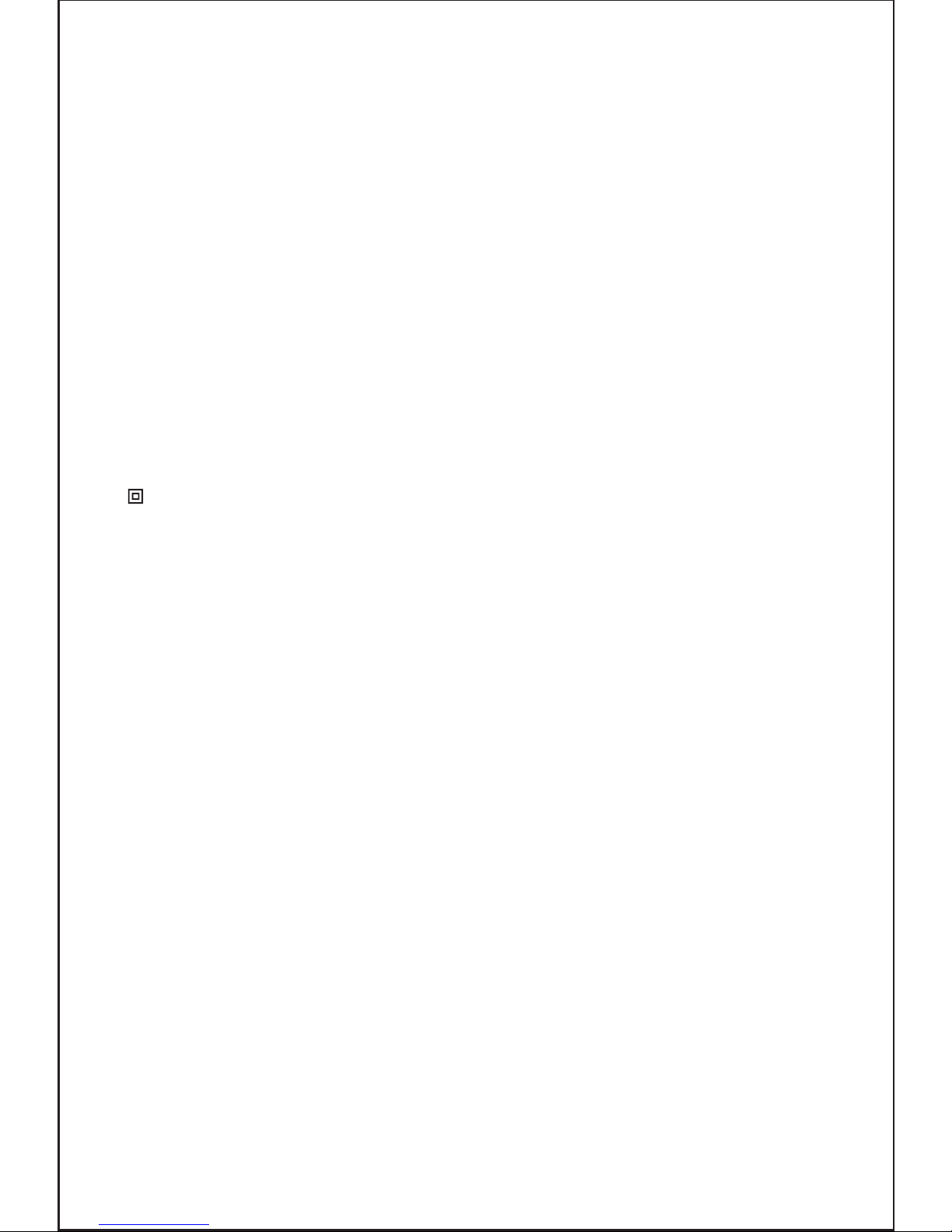

Outlets for 2-Prong Plug

Power Extension Cords

Any electric powered tool that is marked Double insulated only need a two prong

connection and will be perfectly safe to operate.

These tools do not require grounding as they are fitted with an additional insulation

system internally that complies with all relevant electrical safety standards.

Unlike the three prong tools these tools CAN be connected through outlets suitable

for two prong or three prong plugs.

The Illustration above shows the outlets that this type of tool can be connected to.

Double Insulated Power Tools

Plug and outlet, 2 prong

Any power tool marked ‘Grounding required’ MUST only be connected to a three wire

extension cord. Only double insulated tools can be connected to two wire cords.

When using any extension cord the machine will suffer a power reduction due to the

drop in voltage caused by the length of the cord. This can be partially offset by selecting

extension cords with lower gauge wire.

8

Table 1

MINIMUM GAUGE FOR CORD SETS

Total Length of Cord in Feet(Meter)

0-25 26-50 51-100 101-150

(0-7.6) (7.9-15.2) (15.5-30.5) (30.8-45.7)

Ampere Rating

AWG

0 6 18 16 16 14

18 16 14 12

16 16 14 12

14 12

Not Recommended

6 10

10 12

12 16

More Not More

Than Than

Symbols

IMPORTANT: Some of the following symbols may be used on your tool.

9

e.g. Cords marked 14 gauge can carry a higher current than cords marked 16 gauge

therefore when linking extension cords make sure each cords wire gauge matches.

Note: Outdoor extension cords used in must carry the letters “W-A” (USA) or “W”

(Canada)

Check all extension cords for damage before use.

Avoid sharp objects.

Do not position the cord where it could be subject to traffic passing over it.

Carefully remove the product and any accessories from the box. Make sure that all items

listed in the packing list are included.

1. Examine grinding wheels for cracks or other damage before using grinder. Replace

cracked,damaged or vibrating wheels immediately.

2. Never operate grinder near flammable fumes or liquids. Sparks from grinding wheel

or motor could ignite flammable material.

3. Do not over tighten wheel nuts.

4. Always use all guards and eye shields,

5. Keep spark guards close to the wheel (within 1/8”) and readjust inward as the wheel

wears.

6. Always use grinding wheels that are rated for safe use on this grinder. Never use a

wheel rated lower than 3500 R.P.M.

7. Do not move grinder until it comes to a complete stop.

8. Do not force work against the grinding wheel, excessive pressure may damage or

break the wheel, resulting in injury to operator or bystander.

9. Never grind on the side of the wheel, always grind on the face of the wheel only.

10. Dress the face of the wheel only. Dressing the side of the wheel may make it too

thin for safe use.

11. Grinding creates HEAT. Never touch the work piece until you are sure it has cooled

sufficiently.

V…………………………volts

A…………………………amperes

Hz……………………….hertz

~………………………..alternating current

…/m……………….revolutions per minute

.....................class II construction (double insulated)

Kg……………………….kilograms

No.......................No load speed

Specific Safety Rules

Unpacking

Loading...

Loading...