Page 1

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

WWW.TERRAMITE.COM

Charleston, WV/USA

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 2

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

Table of Contents

SECTION ONE: INTRODUCTION/INFORMATION

History of Terramite Backhoes .................................................................................. 1.1

Before You Start ......................................................................................................... 1.2

Safety Tips .................................................................................................................. 1.2

Hand Signals .............................................................................................................. 1.3

Call First ..................................................................................................................... 1.4

SECTION TWO: PARTS

Left or Right is Determined from the Operator’s Position ...................................... 2.1

View of Front Loader Bucket .................................................................................... 2.2

View of Right Side of Loader Bucket ....................................................................... 2.3

View of Underside of Arm Center.............................................................................. 2.4

View of Right Side of Arm Assembly ...................................................................... 2.5

View of Front Axle

View of Front Axle

(Bumper Not Shown) ................................................................................. 2.6

(continued) ................................................................................................ 2.7

View of Front Axle - Ball Socket Style (Bumper Not Shown) ............................................ 2.8

View of Hub Assembly and Spindle ......................................................................... 2.9

View of Right Front Tire and Rim .......................................................................... 2.10

View of Right Side of Tractor ................................................................................. 2.11

View of Left Side of Tractor .................................................................................... 2.12

View form Right Side of Diesel Engine Compartment

(Without Air Filter) ................ 2.13

View of Diesel Air Filter Assembly ........................................................................ 2.14

View of Muffler Assembly - Diesel ......................................................................... 2.15

View Left Side of Kubota Engine............................................................................ 2.16

View Right Side of Kohler Engine ......................................................................... 2.17

View of Kohler Engine Leftside .............................................................................. 2.18

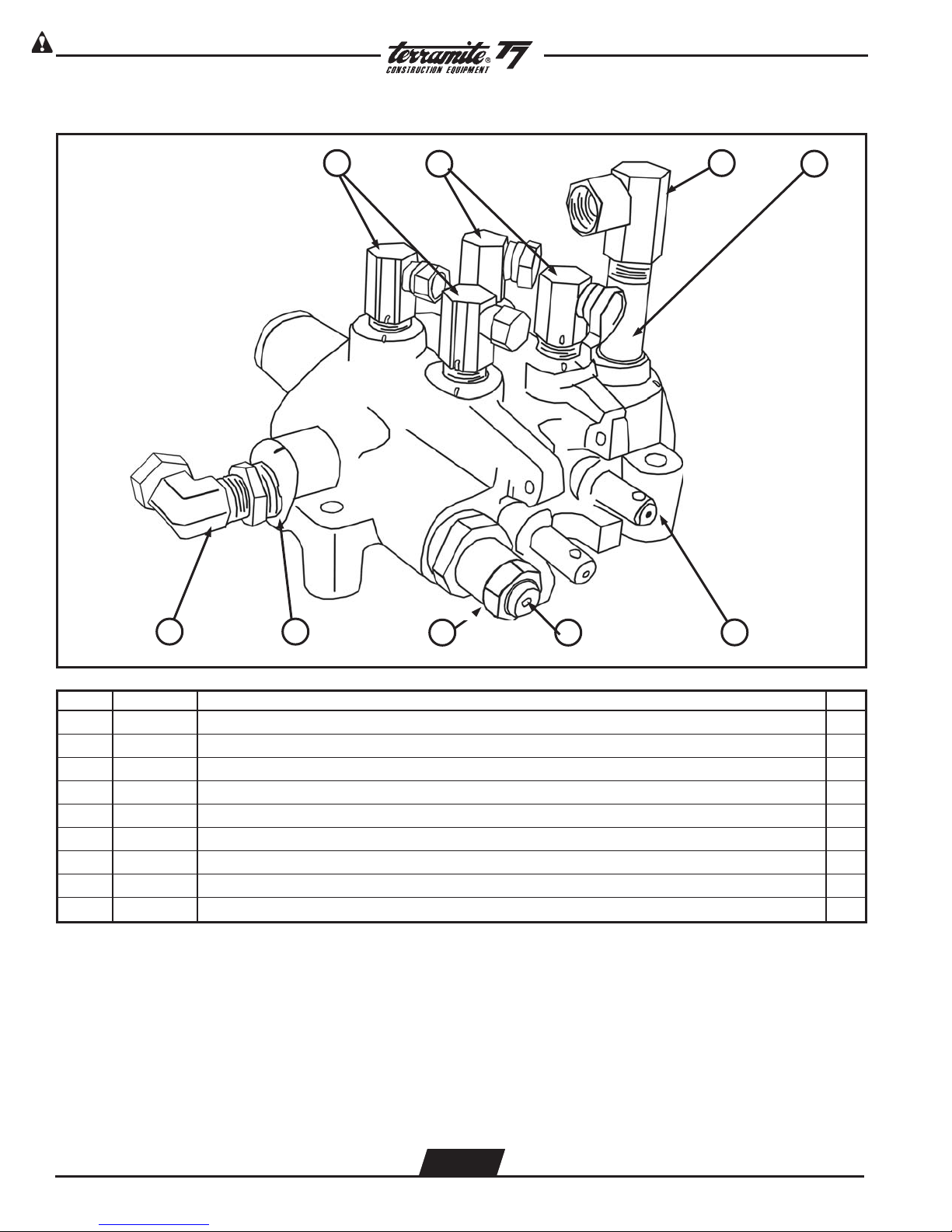

View of Power Steering Gear ................................................................................... 2.19

View of Front Valve w/Fittings .............................................................................. 2.20

View of Loader Valve Assembly and Battery - Perkins ......................................... 2.21

View of Front Valve Linkage System .................................................................... 2.22

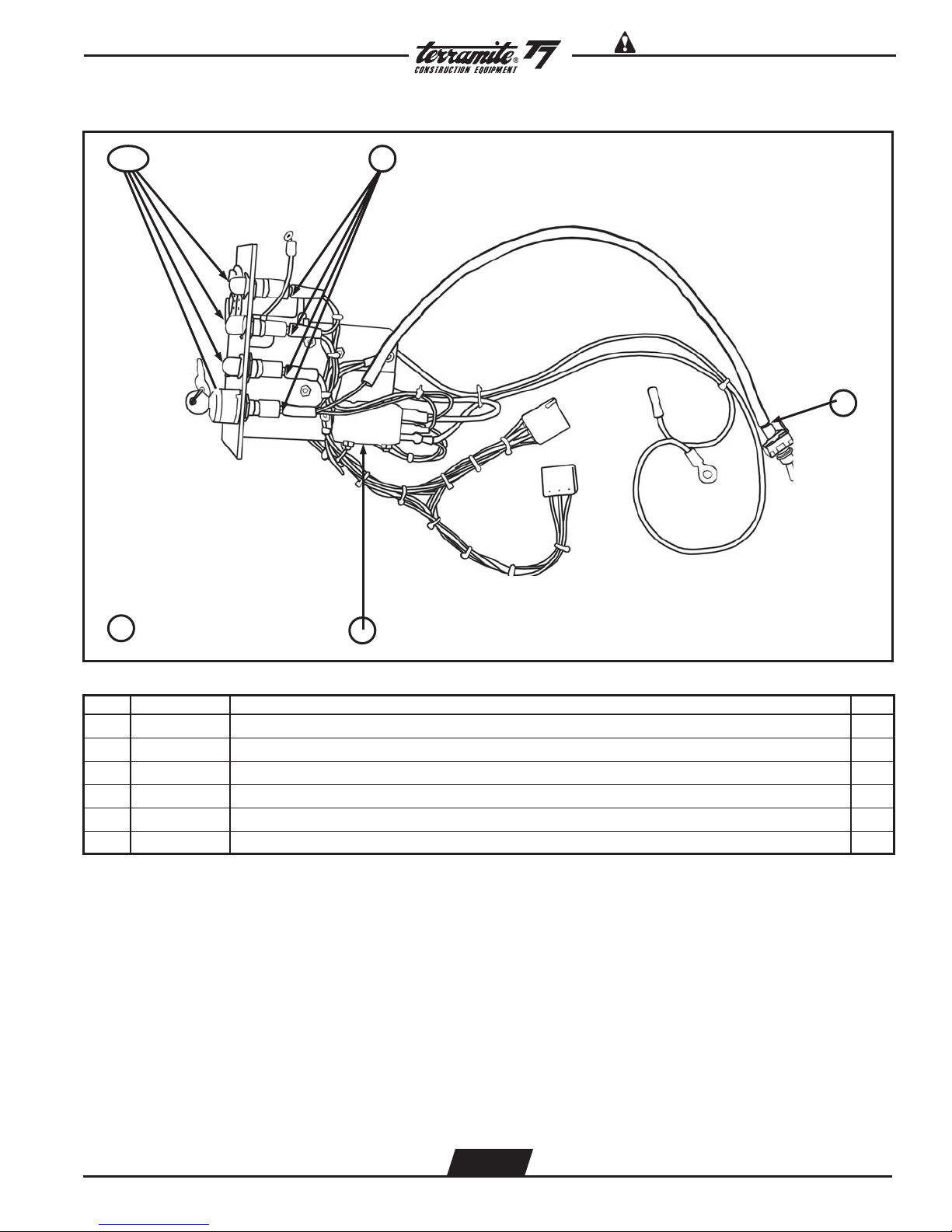

View of Left Side of Diesel Dash Wiring Harness - Perkins ................................. 2.23

View of Right Side of Diesel Dash Wiring Harness -Perkins ............................... 2.24

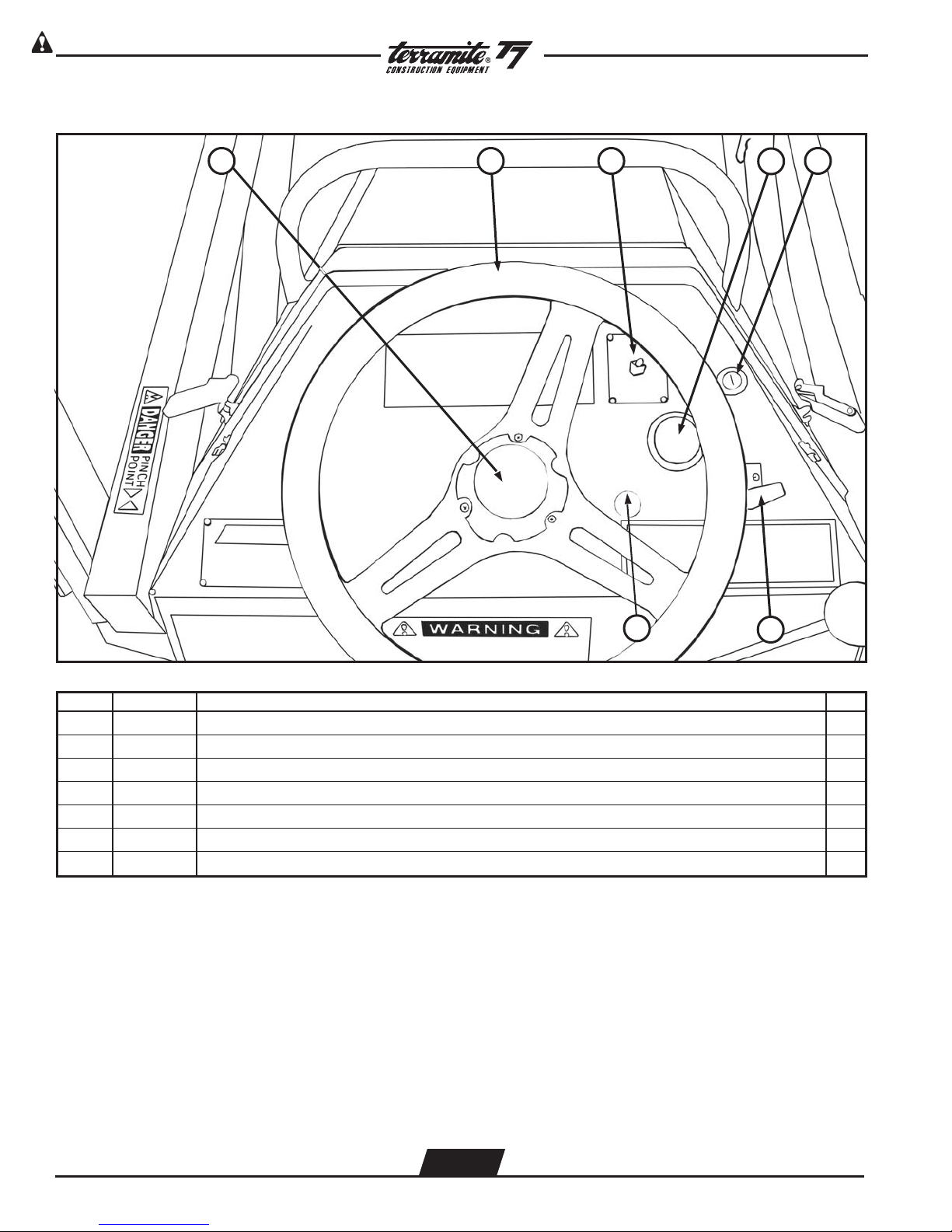

View of Operator Position Facing Dash (Diesel) ................................................... 2.25

View of Operator Position Facing Dash (Gas) ....................................................... 2.26

View of Transmission Assembly (Diesel) .............................................................. 2.27

View of Transmission Assembly (Gas) .................................................................. 2.28

View from Right of Foot Pedal Control ................................................................. 2.29

View from Right Side of Hydraulic Tank ............................................................... 2.30

View from Left Side of Fuel Tank ........................................................................... 2.31

View of Hydraulic Filter Assembly ........................................................................ 2.32

View from Back of Seat ........................................................................................... 2.33

View from Operator Position of Rear Valve

View from Operator Position of Rear Valve

(Straight Boom) ......................................... 2.34

(Straight Boom) ......................................... 2.35

View from Operator Position of Rear Valve (Prior to 1-1-01) ......................................... 2.36

View from Operator Position of Rear Valve

View from Operator Position of Backhoe Valve

(Curved Boom Prior to 1-1-01) ................... 2.37

(Curved Boom Prior to 1-1-01) ............................ 2.38

View from Operator Position of Rear Valve (Prior to 1-1-01) ..................................... 2.39

View from Operator Position of Rear Valve

View of Fitting Location for Rear Valve

(180 Swing) ............................................... 2.40

(180 Swing) ..................................................... 2.41

View of Hose Location for Rear Valve (180 Swing) ......................................................... 2.42

View of Right Rear Tire and Rim ............................................................................ 2.43

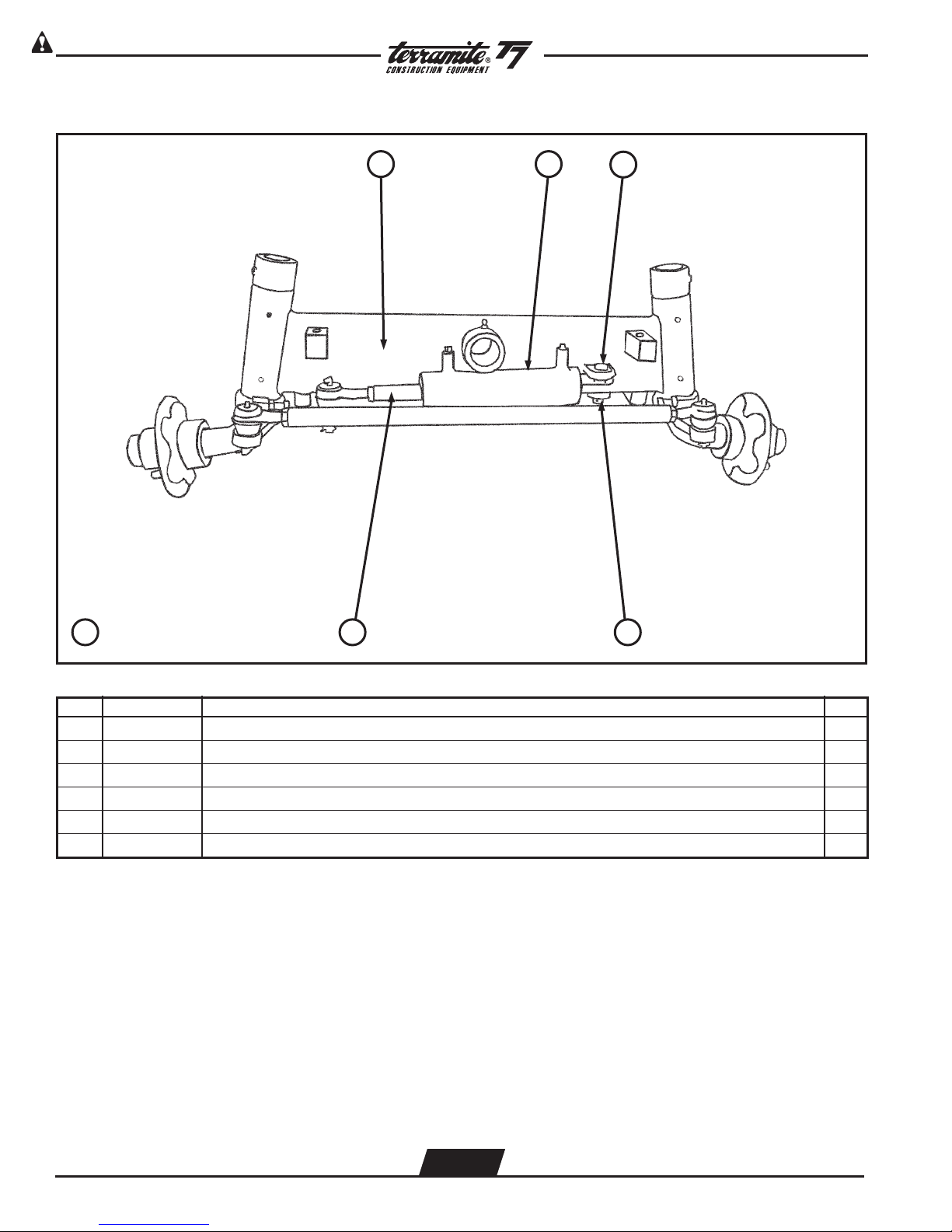

View from Front of Rear Axle ................................................................................. 2.44

Top View of Parking Brake Assembly .................................................................... 2.45

View from Left Side of Outrigger Assembly

View from Left Side of Swing Assembly

(Curved Boom) ........................................ 2.46

(Curved Boom Prior to 1-1-01) ........................ 2.47

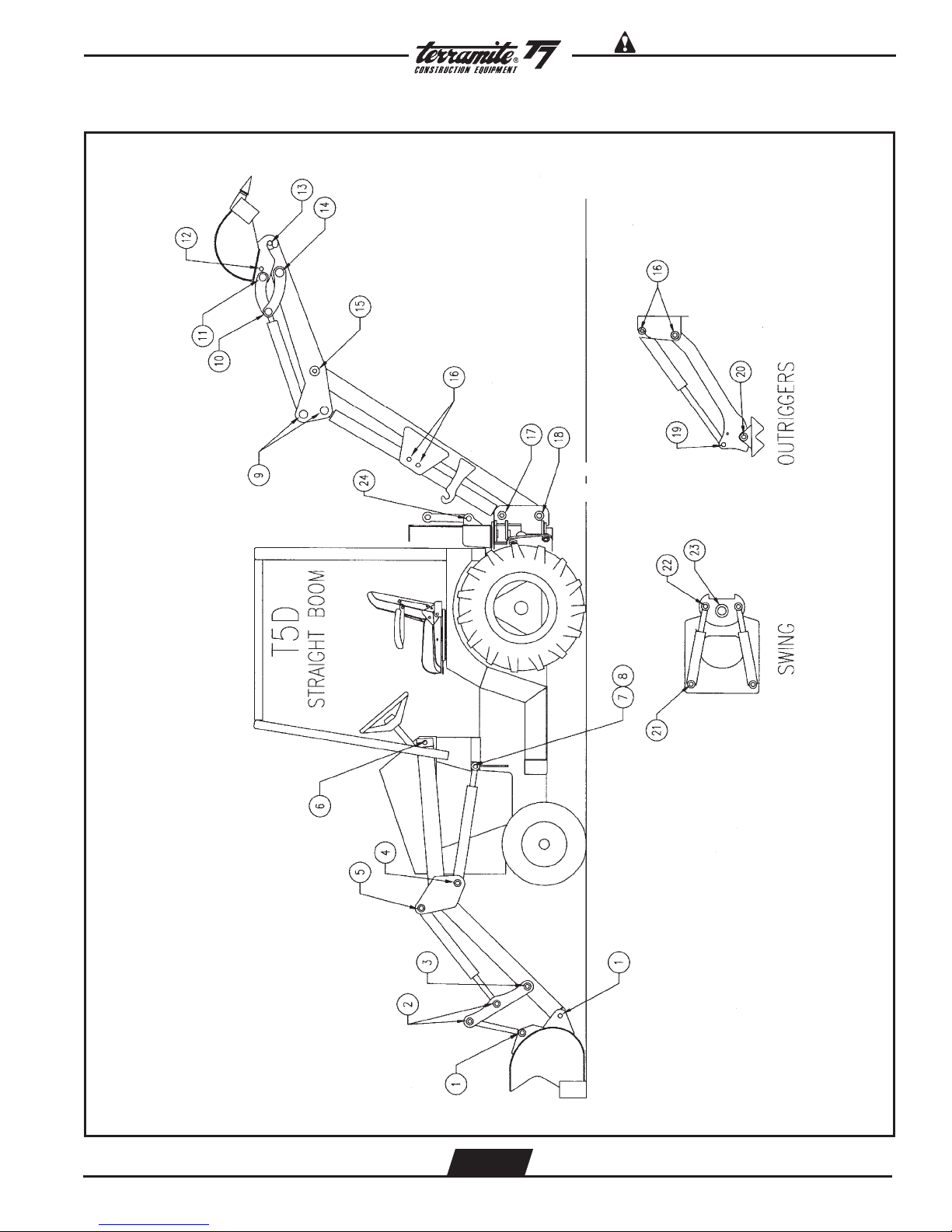

View of Backhoe Assembly for T5D with Straight Boom .................................... 2.48

View from Right Side of Swing Assembly

View of Left Side of Backhoe Assembly

(Straight Boom) .......................................... 2.49

(Prior to 1-1-01) ............................................... 2.50

View of Left Side of Rear Bucket & Linkage Assembly ....................................... 2.51

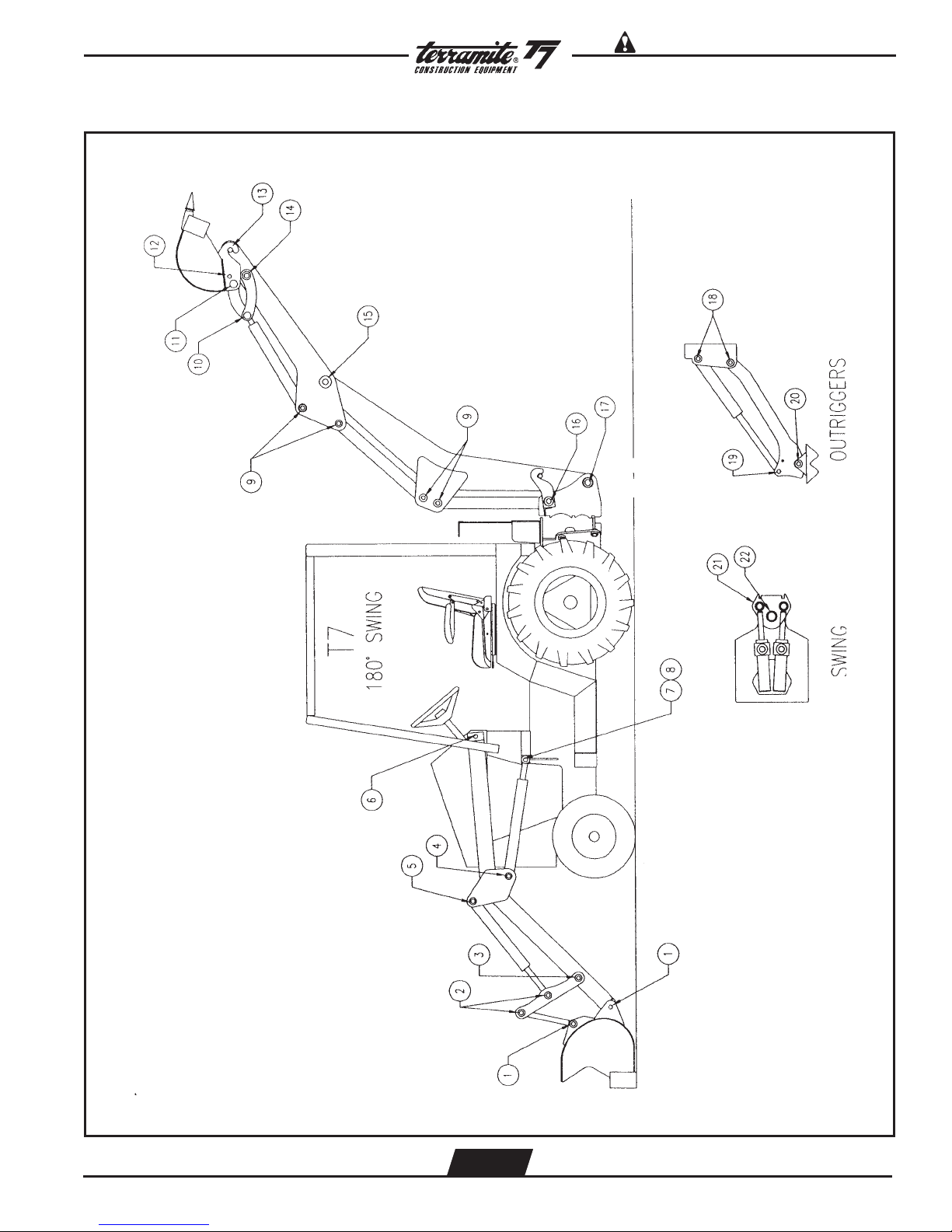

T7 Backhoe Assembly 180 Degree ......................................................................... 2.52

T7 Backhoe Assembly 180 Degree

(continued) ................................................................ 2.53

Tooth Caps ................................................................................................................ 2.54

Position to Check Proper Lever in Hydraulic Tank ............................................... 2.55

SECTION THREE: DECALS

Decal Location - Front Arms ....................................................................................... 3.1

Decal Location - Side View ......................................................................................... 3.2

Decal Location - Dash ..................................................................................................3.3

Decal Location - Dash

(continued) ............................................................................................ 3.4

Decal Location - Right Fender ....................................................................................3.5

Decal Location - Left Fender ....................................................................................... 3.6

Decal Location - Side View

(continued) .................................................................................. 3.7

Decal Location - Rear Valve ........................................................................................ 3.8

Decal Location - Rear Valve

(continued) .................................................................................. 3.9

SECTION FOUR: COMPONENTS

T5D/T7 Pin Chart

T5D/T7 Pin Chart

T7 Pin Chart

(Straight Boom) ............................................................................................. 4.1

(Straight Boom) ............................................................................................. 4.2

(Curved Boom Prior 1-1-01) ........................................................................... 4.3

T7 Pin Chart (Curved Boom Prior 1-1-01) .................................................................................... 4.4

T7 Pin Chart

T7 Pin Chart

(180 Degree Boom) ................................................................................................. 4.5

(180 Degree Boom) ................................................................................................. 4.6

Wiring Diagram Kohler Command 20HP/25HP ....................................................... 4.7

Wiring Diagram Perkins Diesel 20HP .......................................................................4.8

Wiring Diagram Perkins Terminals ............................................................................ 4.9

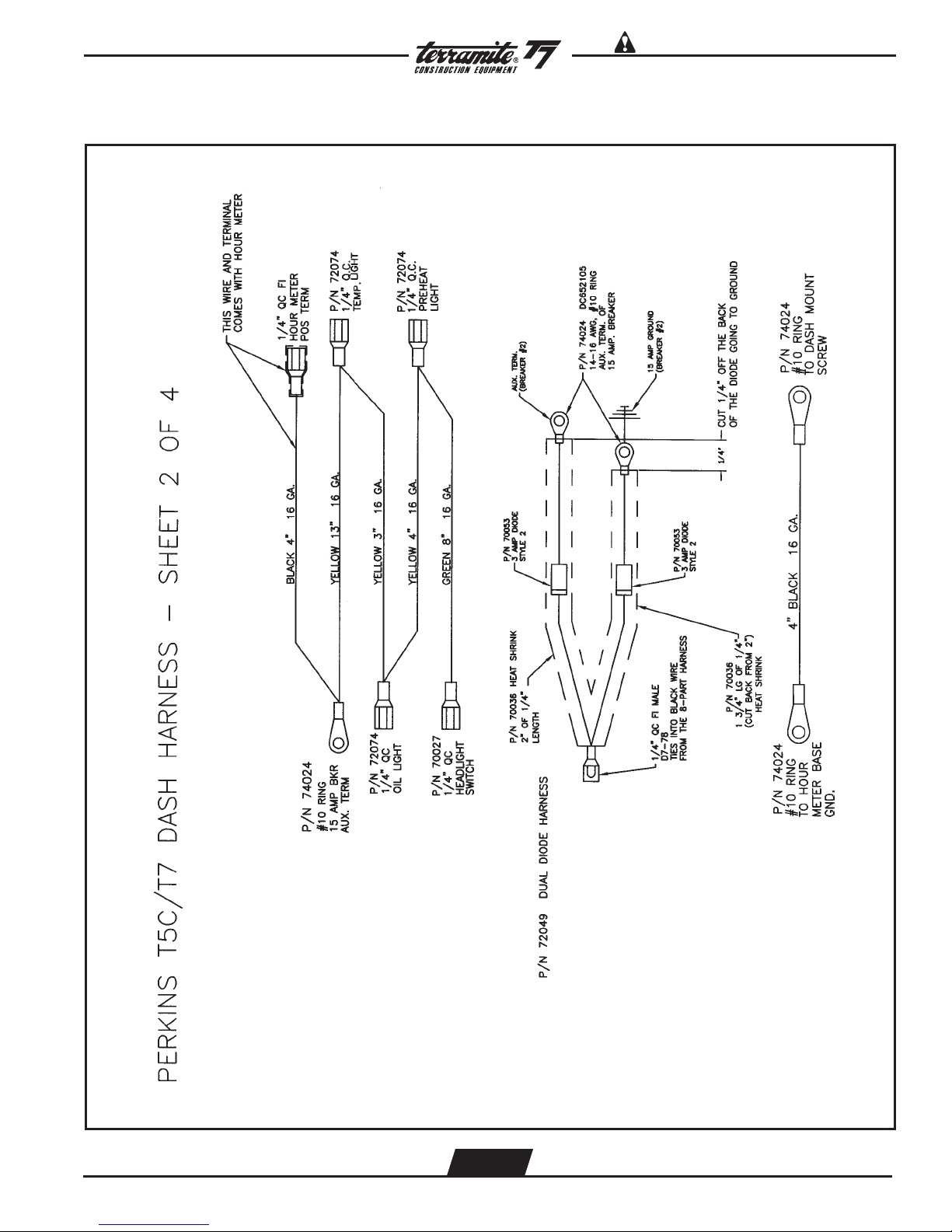

Wiring Diagram for Perkins Diesel Dash Harness .................................................. 4.10

Wiring Diagram for Perkins Diesel Dash Harness

Wiring Diagram for Perkins Diesel Dash Harness

(continued) ...................................... 4.11

(continued) ...................................... 4.12

Wiring Diagram for Perkins Diesel Dash Harness (continued) ...................................... 4.13

Wiring Diagram Kubota ........................................................................................... 4.14

Wiring Diagram Kubota

(continued) ..................................................................................... 4.15

Glow Plug Timer Relay ............................................................................................ 4.16

Hose and Fitting Location for V10 Valve

View from Operator's Position for V10 Valve

(180 Degree Swing) .......................................... 4.17

(180 Degree Swing) .................................. 4.18

Valve Section Service Kits V10 ............................................................................... 4.19

Valve Section Kits V10

Valve Section Kits V10

Valve Section Kits V10

(continued) ....................................................................................... 4.20

(continued) ....................................................................................... 4.21

(continued) ....................................................................................... 4.22

Valve Section Service Kits V10 (continued)........................................................................ 4.23

Valve Section Service Kits V10

(continued) ........................................................................ 4.24

Hydrastatic Transmission ......................................................................................... 4.25

Hydrastatic Transmission

(continued) .................................................................................. 4.26

Sunstrand Transmission ........................................................................................... 4.27

Sunstrand Transmission

(continued) ..................................................................................... 4.28

Gear Pump Part Number 66000 Gas / 66001 Diesel ............................................... 4.29

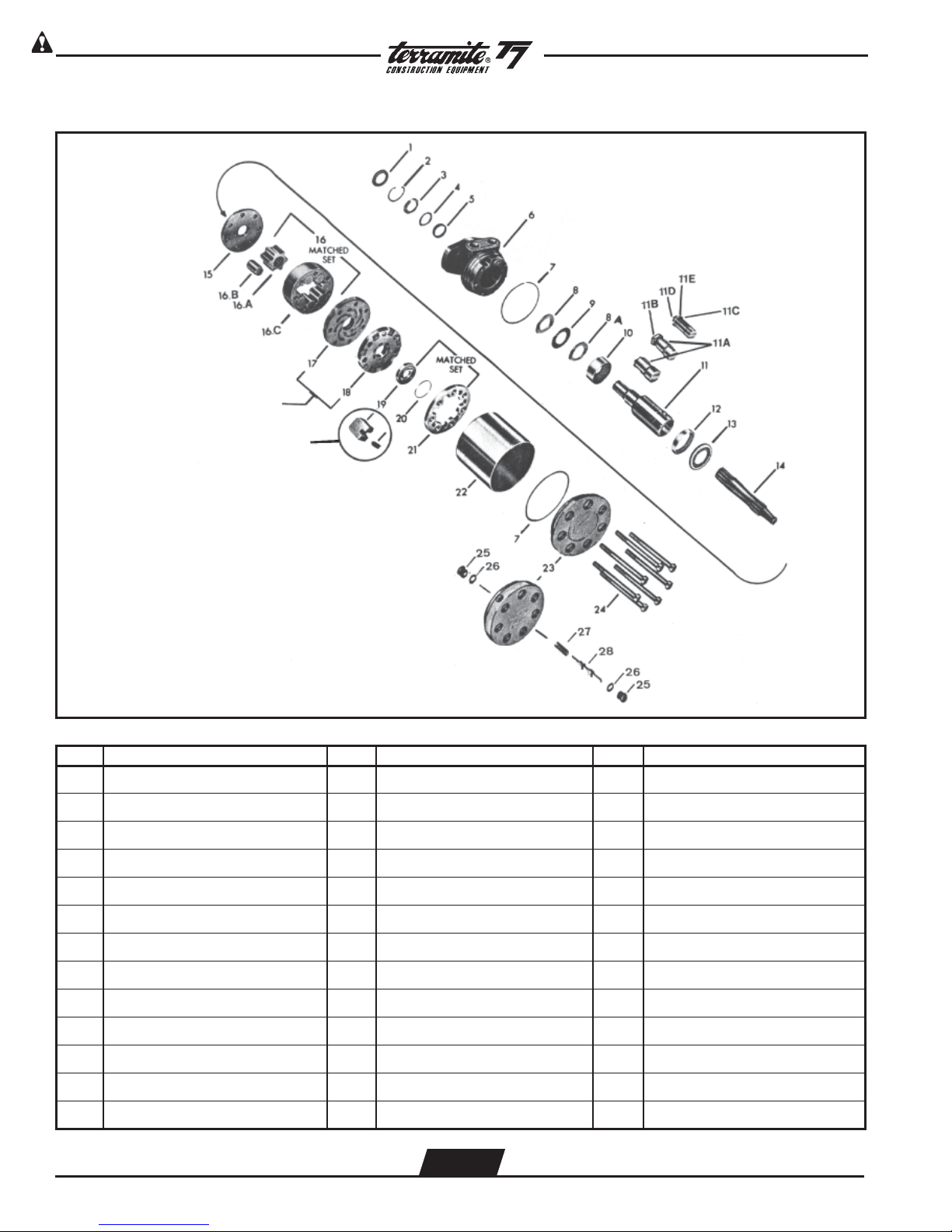

MAB/MAE Torquemotor Exploded Assembly View ............................................ 4.30

Rear Axle Assembly .................................................................................................. 4.31

Rear Axle Assembly

(continued) ............................................................................................. 4.32

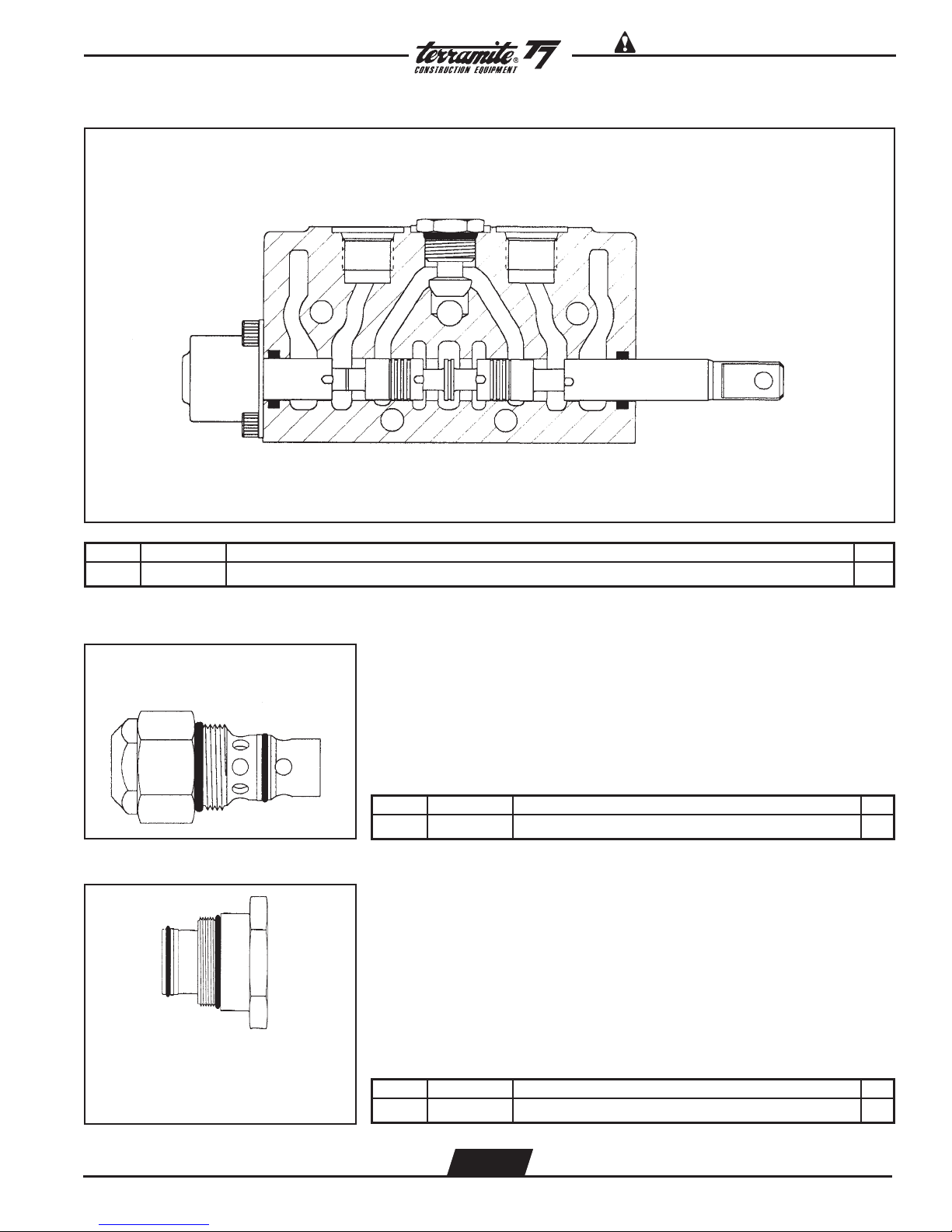

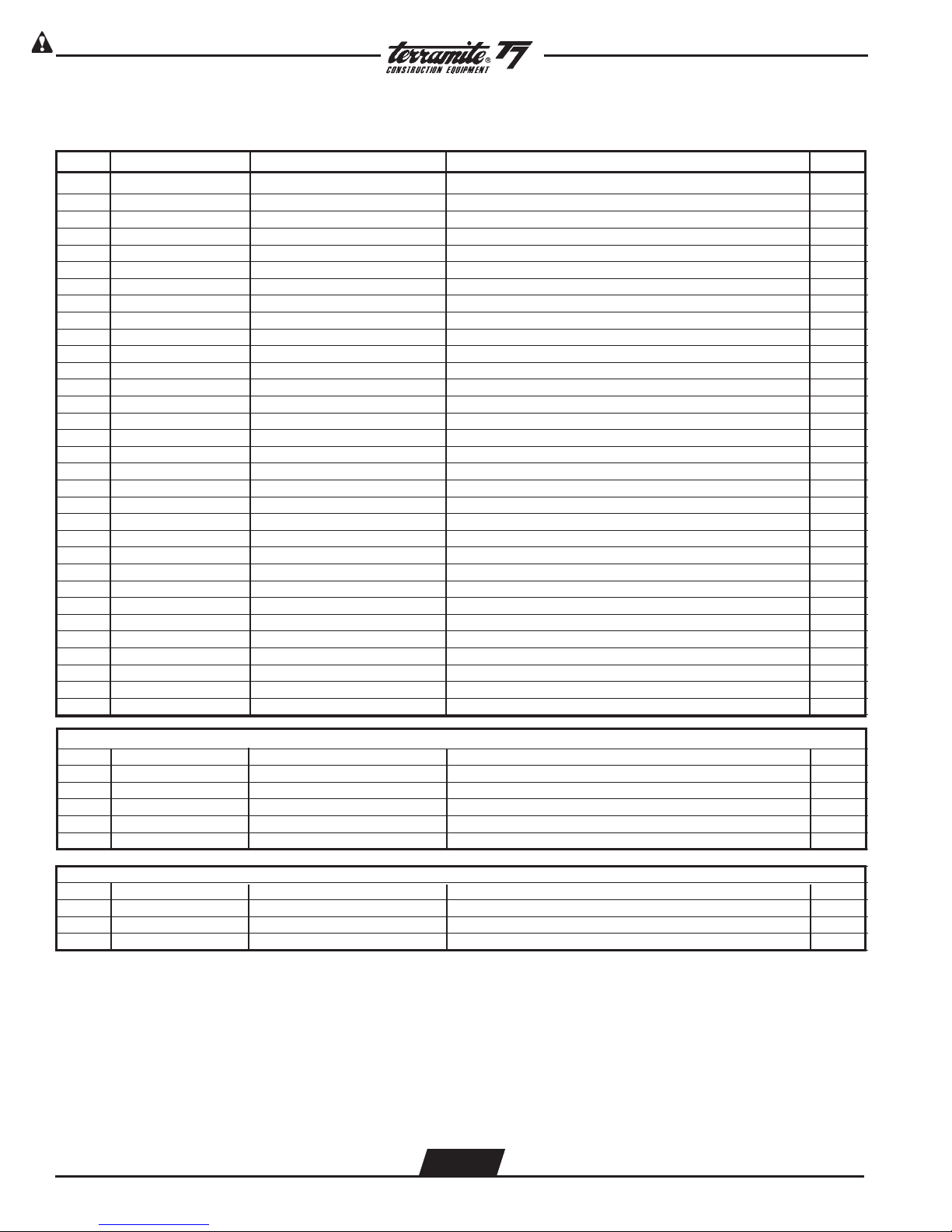

Schematic View of Typical Control Valve Assembly - V20 .................................. 4.33

General Tightening Toque for Bolts, Nuts and Taperlock Studs - V20 ................. 4.34

4 Way, 3 Position Valve Section - V20 .................................................................... 4.35

Load Check Plug Assembly - V20 ........................................................................... 4.36

Model J-HP High Pressure Relief - V20 ................................................................. 4.37

SPK Monoblock Valve ............................................................................................. 4.38

Cylinder Components .............................................................................................. 4.39

T7 Loader Hydraulic Circuit Hose Lengths

(in.) ............................................................. 4.40

T7 Rear Boom Hose Diagram V10 .......................................................................... 4.41

T7/T9 Sunstrand Diesel Hose Diagram with Oil Cooler ....................................... 4.42

SECTION FIVE: OPTIONS

Quick Attach Backhoe Buckets ................................................................................... 5.1

View of Clam Shell 4 in 1 Bucket

View of Clam Shell 4 in 1 Bucket from Drivers Position (Factory Installed Option) ..........................

View Under the Dash for Clam Shell 4 in 1 Bucket (Only as Factory Installed Option) .........................

(Factory Installed Option) ..................................................5.2

5.3

5.4

SECTION SIX: TRANSLATIONS

Translations ....................................................................................................... 6.1 to 6.6

SECTION SEVEN: INDEX

Index .................................................................................................................. 7.1 to 7.5

Sample: Limited New Product Warranty ................................................................... 7.6

WWW.TERRAMITE.COM

Charleston, WV/USA

CONTENTS

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 3

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

History of Terramite Backhoes

TERRAMITE was founded in 1965 by Kelly G. Cunningham. Mr. Cunningham realized that he could attach the digging

part of a tunneling machine he manufactured to the front of a tractor, producing a versatile piece of equipment with a

tremendous number of applications. He used the Gravely 7.6 tractor to power his patented backhoe, creating the Model 1,

the world’s first compact backhoe. During the years 1965 to 1972, the Model 1 was produced, and a new Model T-2 with an

endloader attachment was introduced.

In 1972, Mr. Cunningham purchased 19.5 acres in Cross Lanes, West Virginia and built the initial portion of the existing

plant. Terramite now has 56 acres with a plant four times as large. Constant improvement in safety, durability, strength, load

capacity and digging depth have resulted in the T-3, T3-15, T4, T5, T5B and T5C. In 1997 Terramite introduced the

Terramite T6, the largest and most powerful compact tractor loader backhoe ever. 1999 brought the addition of the Terramite

T5D. This newest member of the Terramite compact tractor loader backhoe family features center-mount steering, extended

reach arms, dual front curl cylinders, and much more.

1999 was also a year of new products for Terramite. The TX15 and TX25 Mini Excavators and the TSS36 and TSS38

Street Sweepers were introduced at the 1999 ARA Trade Show in Las Vegas early February.

June 2000 the Models T5D and T6 were renamed Models T7 and T9.

In addition to the Terramite backhoe lines, in 1985, Terramite created a concrete finishing product named the Roller

Screed. The Roller Screed is used for paving parking lots, entrance ramps, roads, sidewalks and airport runways.

WWW.TERRAMITE.COM

Charleston, WV/USA

1.1

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 4

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

Before You Start

READ OPERATOR'S HANDBOOK

Carefully read all WARNING! and DANGER! messages in handbook and be sure you understand their

IMPORTANT! If this machine is used by the owner, an

meanings.

employee, or is loaned or rented, make sure that the

following instructions are complied with:

1. The operator has read the Operation and the

Safety Rules sections of the Operator's

Handbook.

2. He has been given instructions on the safe

and correct use of the machine.

3. He has practiced operating the machine and

the use of all controls in a safe, clear area

before he operates the machine on a job site.

4. He has read all safety decals on the machine.

5. He has been informed to clear the area of

other persons and hidden hazards before

starting the machine.

Safety Tips

Safety is a prime consideration in the design of this

machine. Guards, shields and other safety features are built

in wherever possible. However, accident reports show

carelessness causes the majority of accidents. You can avoid

most accidents by observing the safety rules on these pages.

Study these rules carefully and enforce them on the job:

Never allow minors to operate or be in the vicinity

of the machine while working.

Do not allow the T9 to be operated by anyone who

is intoxicated or on medication that would affect their

judgement or ability to operate the machine.

The machine is designed to be operated by adults

who are of average size and weight. Persons who are

extremely heavy, big or tall, or those who are exceedingly

short, light or weak should not run the machine.

Before Operating the Terramite T9

Read the Operator's Handbook. Never allow anyone

to operate the backhoe without reading the Operator's Manual

and Safety Instructions. This should be followed by

supervised training, if possible.

Check Your Equipment. Always make a complete

inspection of the machine before operating it that day. Check

the hydraulic system and the engine oil level. Then check

the machine for broken, missing or defective parts. Check

the tires for cuts, bulges, irregularities and abnormal wear

and proper inflation. Check the neutral position of the foot

pedal. A malfunctioning machine invites accidents.

Keep Your Machine Clean. Slippery surfaces are

hazardous. Remove oil, grease or mud from the operating

area of the tractor. Failure to keep these areas clean could

cause a serious accident.

Wear Whatever is Needed for Protection. Protect

yourself by wearing all the protective clothing and personal

safety devices issued to you or required by job conditions.

You may need a hard hat, safety shoes, safety glasses, heavy

gloves, hearing protection, reflective clothing, wet weather

gear and a respirator. Never take chances by wearing loose

clothing, watches or rings.

Look For Hazards. Walk around a new work area

and check for any hidden hazards, such as holes and hidden

abutments.

Read and Heed Safety Decals. Make sure the safety

and information decals can be easily read. To clean decals,

use soap and water only. Gasoline or solvents will destroy

the decals. If these decals are missing or illegible, call our

Parts/Service Department for replacements.

Roll-Over Protective Structure. All Terramite T9

tractor loader backhoes are equipped with a Roll-Over

Protective Structure. This is designed to protect the operator

in the event of a roll-over. If this machine has been rolled

over, the R.O.P.S. must be replaced. It is designed to be

used only once.

Driving Pivot Pins. When driving pivot pins in or

out, use care to guard against injury from particles that may

chip off the pin or object used in striking the pin. These

pins can fly out at high speed if they are not tapped lightly

just before they come out. Make sure there isn't anyone or

anything in the way, in case the pin flies out. Safety glasses

should be worn.

WWW.TERRAMITE.COM

Charleston, WV/USA

1.2

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 5

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

Hand Signals

Purpose and Scope

The purpose of the hand signals is to provide an easy means of communications in the interest of safety. These hand signals

are in general agreement with U.S. Army Field Manual, FM21-60, Section II, Standard Arm and Hand Signals. The standard

provides for hand signals to be used in agricultural operations especially when noise or distance precludes the use of normal

voice communications.

Fig. 1 - THIS FAR TO GO. Place palms at

ear level facing head, move laterally inward

to indicate remaining distance to go.

Fig. 2 - COME TO ME. Raise the arm

vertically overhead, palm to the front, and

rotate in large horizontal circles.

Fig. 3 - MOVE TOWARD ME. Beckon by

holding the arm horizontally to the front,

palm up, and motioning toward the body.

Fig. 4 - MOVE OUT - TAKE OFF. Face the

desired direction of movement; hold the arm

extended to the rear; then swing it overhead

and forward in the direction of desired

movement until it is horizontal, palm down.

Fig. 6 - SPEED IT UP - INCREASE SPEED.

Raise the hand to the shoulder, fist closed;

thrust the fist upward to the full extent of

the arm and back to the shoulder rapidly

several times.

Fig. 7 - SLOW IT DOWN - DECREASE

SPEED.

sideward, palm down, and wave arm

downward 45 deg. minimum several times,

keeping the arm straight. Do not move arm

above horizontal.

Extend the arm horizontally

Fig. 8 - START THE ENGINE. Simulate

cranking the vehicle by moving arm in a

circular motion at waist level.

Fig. 9 - STOP THE ENGINE. Draw right

hand palm down, across the neck in a

"throat cutting" motion from left to right.

Fig. 5 - STOP. Raise hand upward to the

full extent of the arm, palm to the front.

Hold that position until the signal is

understood.

WWW.TERRAMITE.COM

Charleston, WV/USA

1.3

Fig. 10 - LOWER EQUIPMENT. Make

circular motion with either hand pointing

to the ground.

Fig. 11 - RAISE EQUIPMENT. Make circular

motion with either hand at head level.

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 6

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

CALL FIRST

Call Your One-Call System First

Before you start any digging project, don't forget to call the

local One-Call System in your area. If you don't call, you

may have an accident or suffer injuries, cause interruption

of services, damage the environment or experience job

delays. The One-Call System will notify participating utility

companies of your proposed digging activities.

If you don't know the number for the local One-Call in

your area, dial the national One-Call referral number

toll free, 1-888-258-0808 for this information.

Utilities will then mark their underground facilities by using

the following international marking codes:

Red - Electric

Yellow - Gas, Oil or Petroleum

Orange - Communication, Telephone, TV

Blue - Potable Water

Green/Brown - Sewer

White - Proposed Excavation

Pink - Temporary Survey Markings

One-Call Safety Labels & Placards Available From

Hazard Communication Systems, Inc.

WARNING

Always contact your local One-Call system

before starting your digging project.

800-748-0241

WWW.TERRAMITE.COM

Charleston, WV/USA

1.4

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 7

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

Please Note: Left or Right is Determined from the Operator's Position

Operator Position

for Endloader Use

Operator Position for

Backhoe Operation

WWW.TERRAMITE.COM

Charleston, WV/USA

2.1

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 8

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

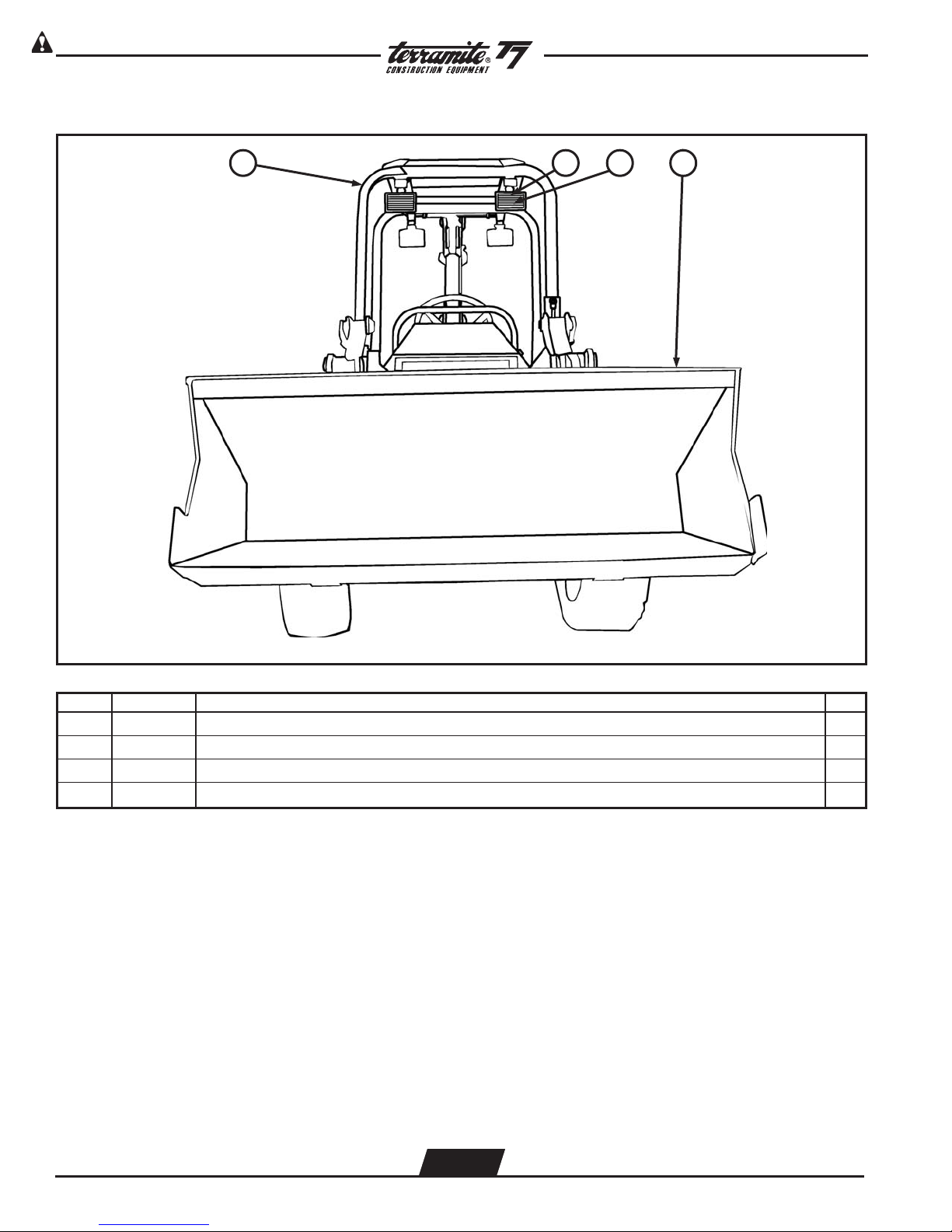

View of Front Loader Bucket

1 2 3

4

ITEM PART NUMBER DESCRIPTION QTY.

1 18043 Assembly, ROPS, Front and Rear, T5C/T5D/T6/T7/T9 (Arm Strut Included) 1

2 77075 Light, Flood, Rectangle, T5B/T5C/T5D/T6/T7/T9 4

3 74047 Bulb, Halogen, T5C/T5D/T6/T7/T9 4

4 13357 Bucket, Loader, 56” Wide, T5D/T7 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.2

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 9

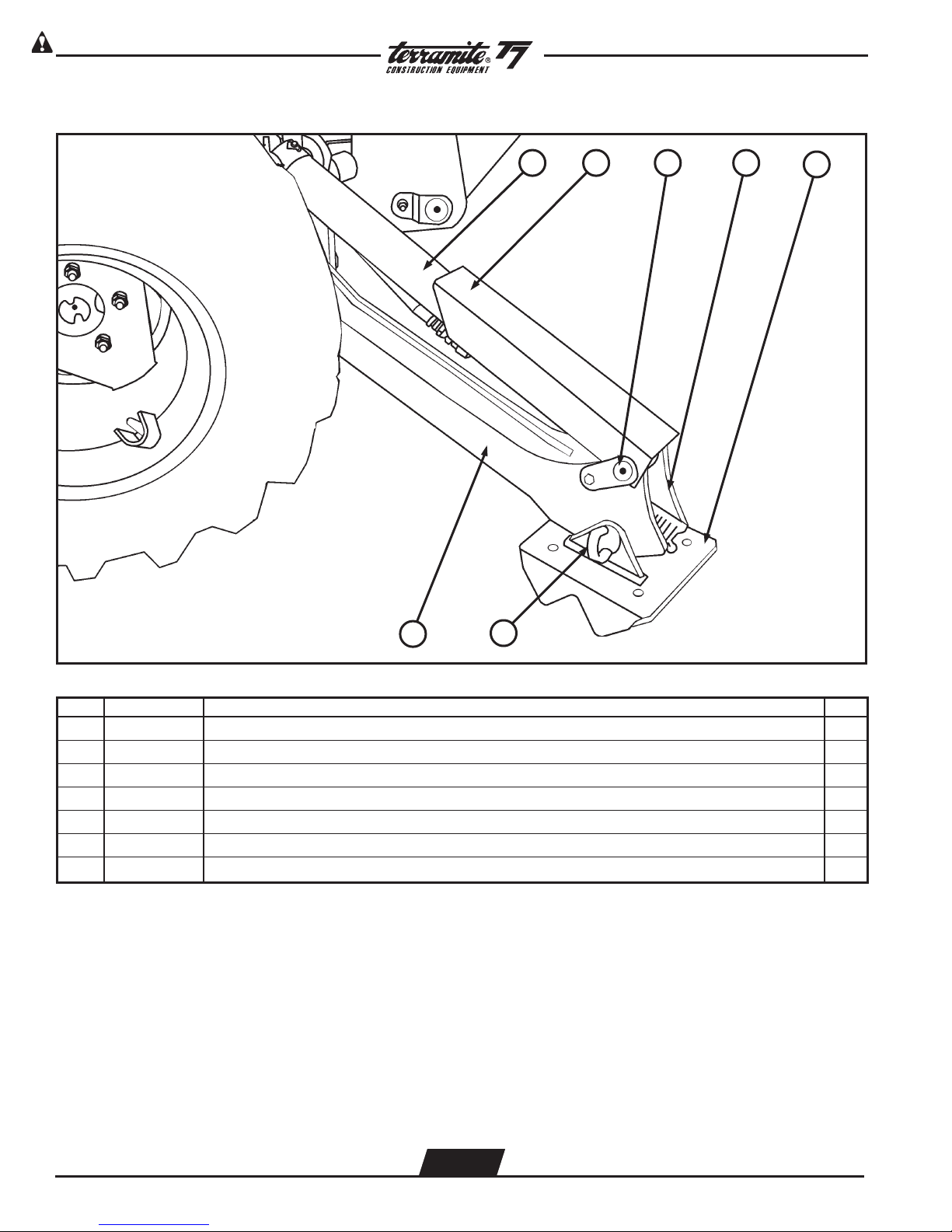

View of Right Side of Loader Bucket

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

1

2 3

4

3

4

7

ITEM PART NUMBER DESCRIPTION QTY.

3

6

233

25

1 17176 Pin, 5 1/2”, Arm Link to Arm Cylinder, T5D/T6/T7/T9 4

2 12037 Rod, Link, Loader Arm, T5D/T6/T7/T9 2

3 13200 Pin, 4 3/4”, Front Bucket to Arm, T5C/T5D/T6/T7/T9 4

4 13357 Bucket, Loader, 56” Wide, T5D/T7 1

5 13056 Edge, Cutting, 56” Loader, T5D/T7 1

6

12048 Arm Link Brace, Right, T5D/T6/T7/T9

12079 Arm Link Brace, Left, T5D/T6/T7/T9

2

7 17178 Pin, 5 1/2”, Arm Link to Arm, T5D/T6/T7/T9 2

WWW.TERRAMITE.COM

Charleston, WV/USA

2.3

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 10

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

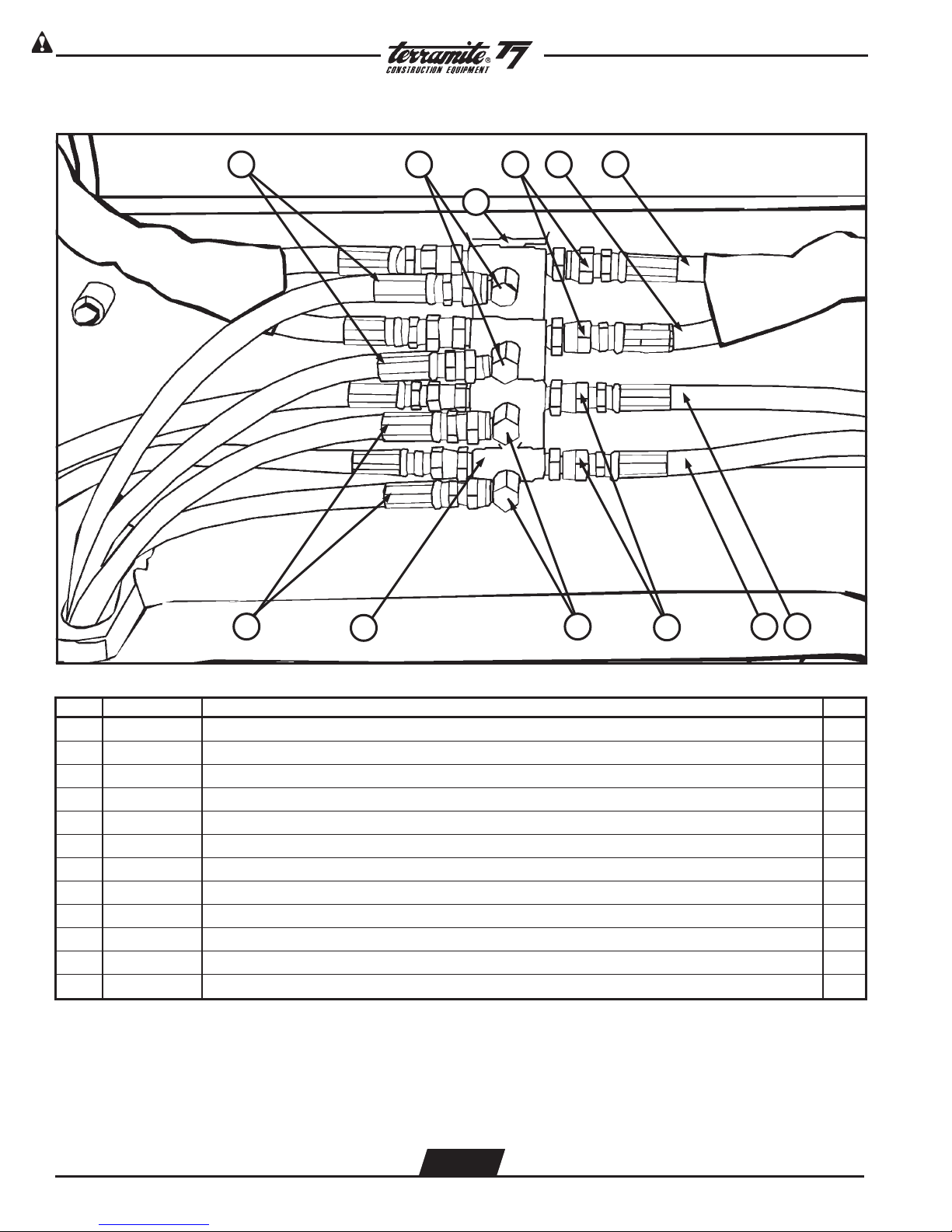

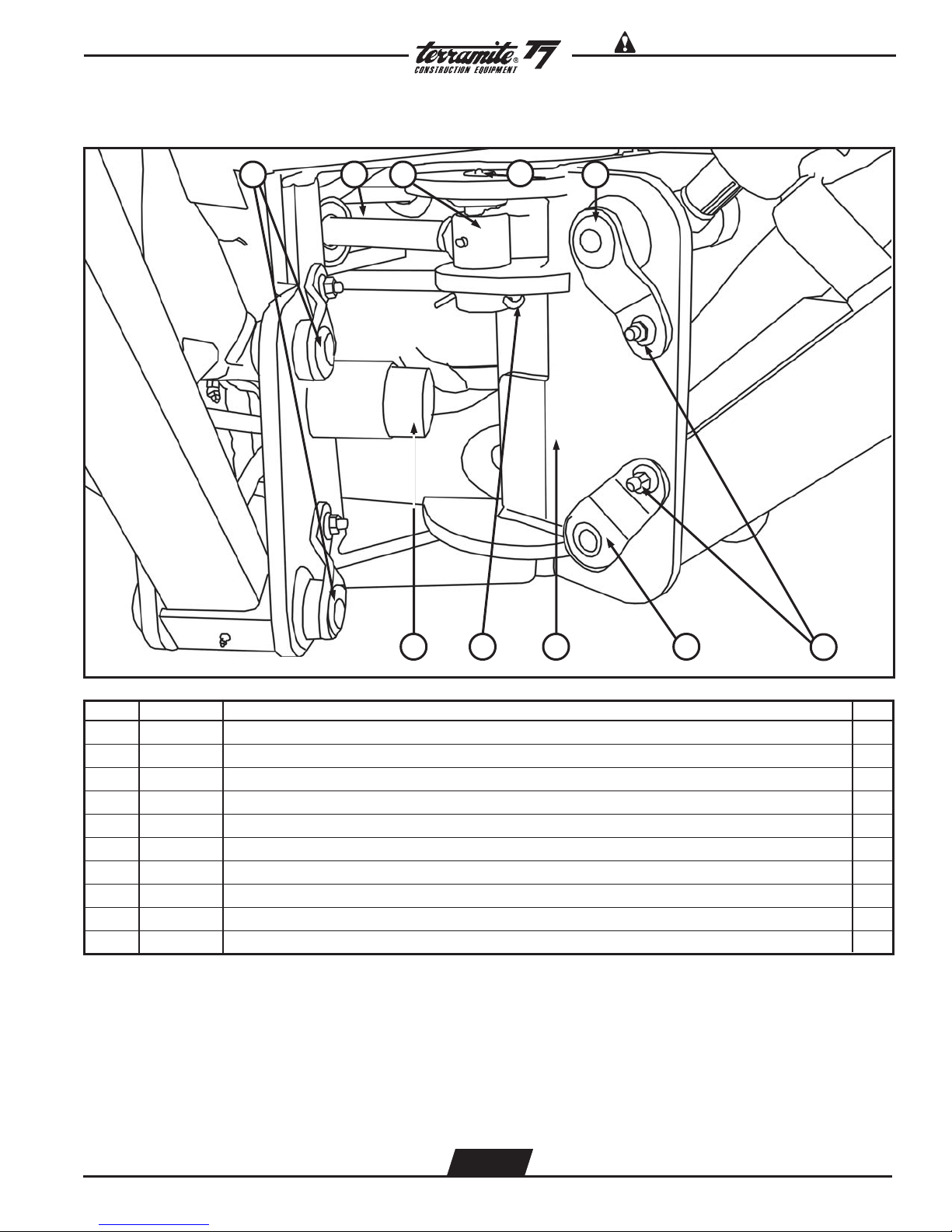

View of Underside of Arm Center

41 2 3 5

12

11

ITEM PART NUMBER DESCRIPTION QTY.

10

9

8

67

1 80132 Hose, 3/8” x 70” 4

2 20063 Fitting, 3/8” MP x 3/8” 90 Swivel, Stubby, T5D/T6/T7/T9 2

o

3 20176 Fitting, 3/8” M x 3/8” FM, Swivel 8

4 80134 Hose, 3/8” x 28” 2

5 80133 Hose, 3/8” x 26” 2

6 88418 Hose, 1/4” x 18” 2

7 80055 Hose, 1/4” x 38” 2

8 20177 Fitting, 3/8” M x 1/4” F, Straight Swivel 4

9 22118 Fitting, 3/8” M 90 x 1/4” F, Swivel 2

o

10 22266 Fitting, 3/8” Tee, Weld-On 4

11 80131 Hose, 1/4” x 70” 2

12 12046 Plate 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.4

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 11

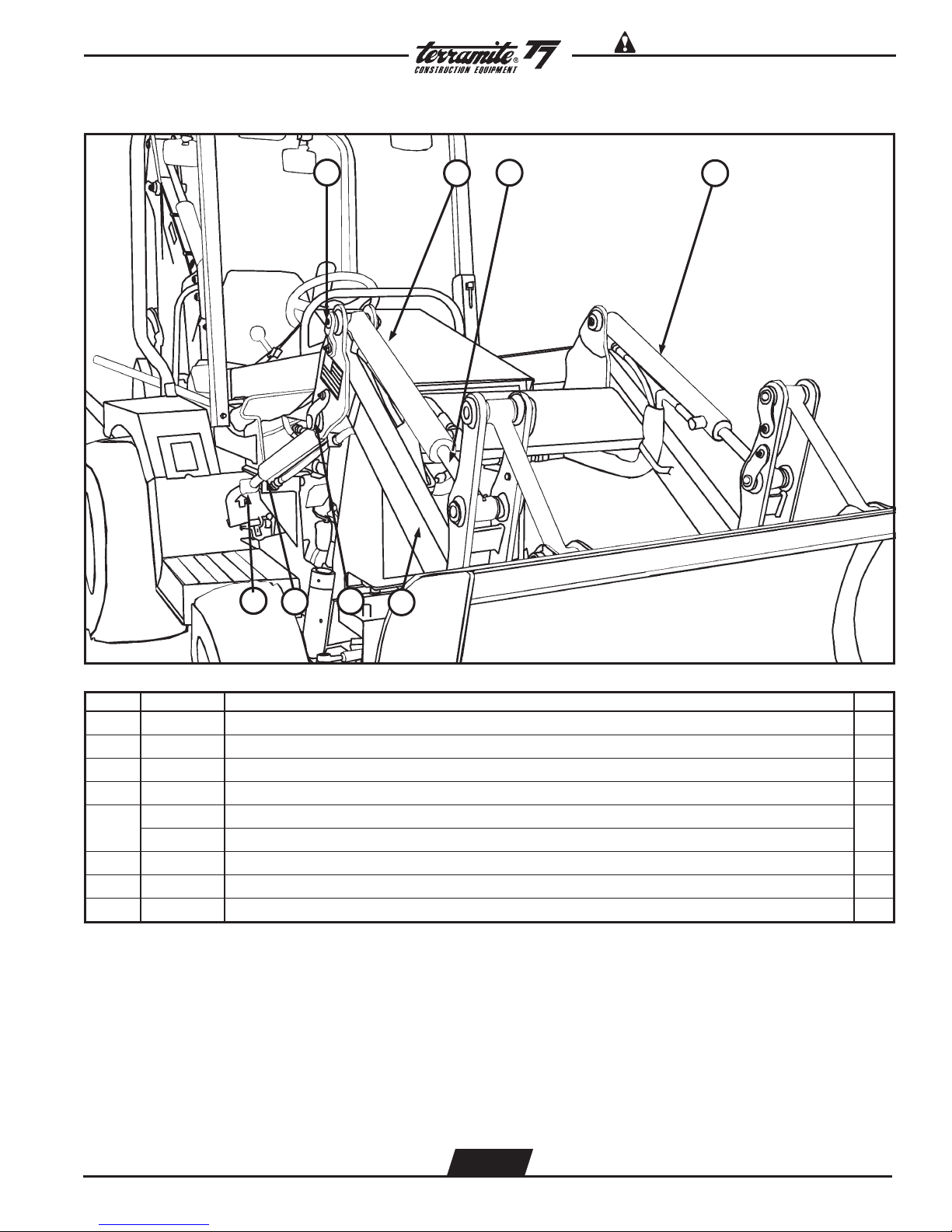

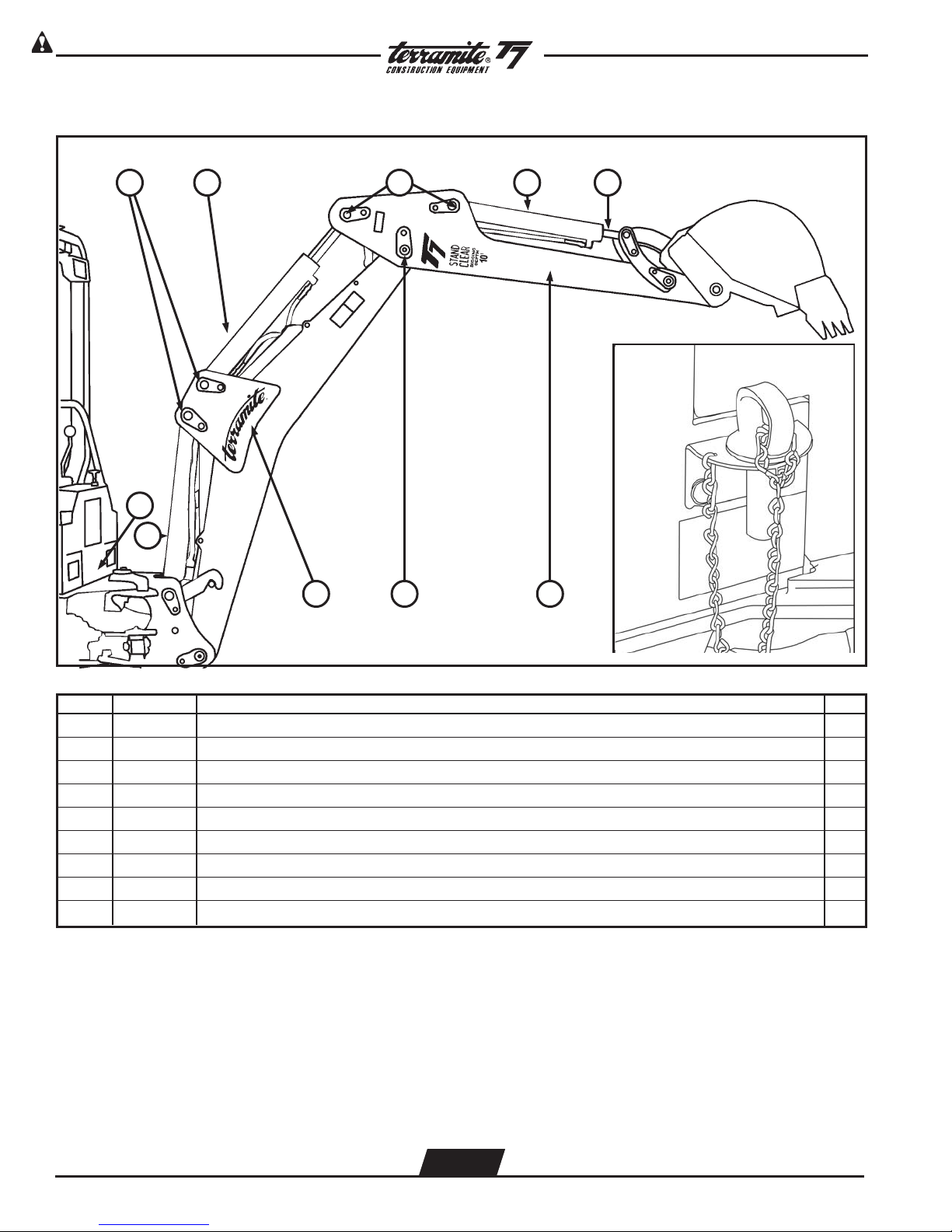

View of Right Side of Arm Assembly

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

1

3

8

7

3

6

5

2

3 4

ITEM PART NUMBER DESCRIPTION QTY.

1 12600 Pin, 5 1/4”, Arm Cylinder to Arm, T5C/T5D/T6/T7/T9 2

2 82074 Cylinder, Front Curl, Right, T5D/T6/T7/T9 1

3 82073 Rod, 22 1/4”, Front Curl, T5D/T6/T7/T9 2

4 82066 Cylinder, Front Curl, Left, T5D/T6/T7/T9 1

5

12074 Assembly, Arm, T5D (Includes Decals)

12075 Assembly, Arm, T7 (Includes Decals)

1

6 17179 Pin, 5 1/2”, Arm Bracket to Arm Cylinder, T5D/T6/T7/T9 2

7 12026 Cylinder, Arm Lift, T5C/T5D/T7 2

8 12301 Pin, 7 7/8”, Arm Cylinder Rod to Frame, T5B/T5C/T5D/T6/T7/T9 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.5

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 12

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

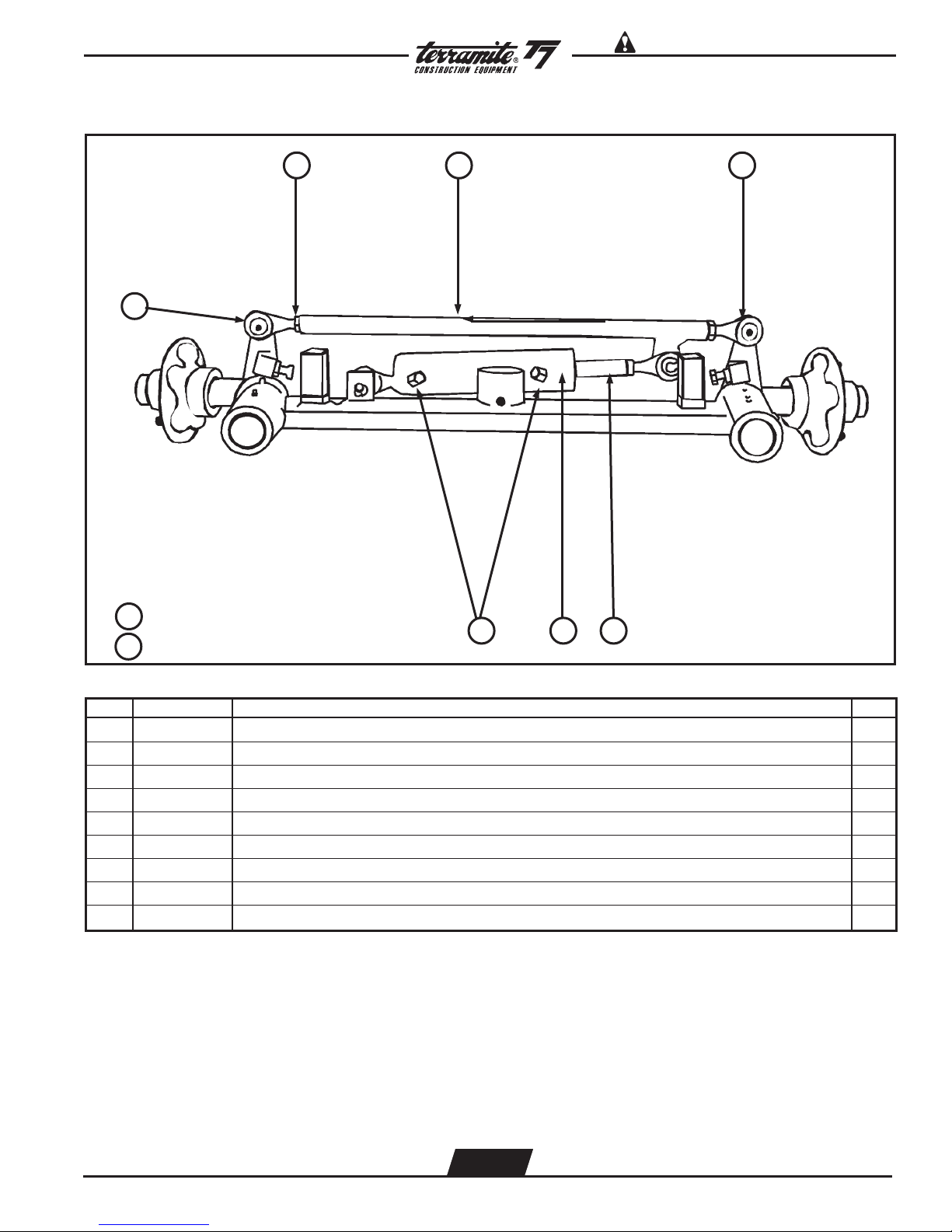

View of Front Axle (Bumper Not Shown) (Prior 1/1/01)

321

9 10 11

8

4 5

76

12

13

ITEM PART NUMBER DESCRIPTION QTY.

1 53091 Bearing, Thrust, F Spin, T5C/T5D/T6/T7/T9 2WD (not shown) 2

2 53212 Axle, Front, T5D/T7 (prior 1/1/01) 1

3 53107 Boss, Spindle Lock, T5D/T6/T9 2WD 2

4 28501 Screw, Set, 1/2” - 20 x 1/2” Plain 4

5 21428 Fitting, Grease 1/4” - 28 Straight 4

6 53050 Spindle, Front, Left, 9 5/8”, T5D/T7/T6/T9 2WD 1

7 53137 Hub, 5 on 4.5”, T5C/T5D/T6/T7/T9 2WD 2

8 53116 Spindle, Front, Right, 9 5/8”, T5D/T7/T6/T9 2WD 1

PIVOT PINS & BOLTS

9 15406 Pin, Front Axle Pivot, 11/4, T5C/T5D/T7 (prior 11/00) 1

10 53081 Nut, Hex, 1 1/4” - 12 Slotted Regular 2

11 15013 Bolt, 1/4” - 20 x 2 1/2” Gr8 Z 2

12 24008 Washer, 1/4” Flat USS 2

13 28504 Nut, 1/4” NC Lock Z 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.6

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 13

View of Front Axle (continued)(prior 1/01/01)

9

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

321

7 Complete Assembly

8 Update Kit

ITEM PART NUMBER DESCRIPTION QTY.

6 5 4

1 28503 Nut, Jam, 5/8” NF Z 3

2 53054 Tie Rod, T5C/T5D/T6/T7/T9 1

3 53043 Tie Rod End, w/Kit, T5C/T5D/T6/T7/T9 4

4 25803 Rod, Power Steering, T5C,T5D/T6/T7/T9 2WD 1

5 25815 Cylinder, Power Steering, T5C/T5D/T6/T7/T9 1

6 23174 Fitting, 1/4” M x 1/4”F 45° Degrees 2

7 53092 Assembly, Axle, Front, T5D/T7 (Completely Assembled) 1

8 53131 Update Kit for Axle (prior to 1/01/01) 1

9 53221 Tie Rod, Ball Socket After Ser# 2370201 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.7

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 14

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Front Axle - Ball Socket Style (Bumper Not Shown)(After 1/1/01)

1 2

3

6 Complete Assembly

ITEM PART NUMBER DESCRIPTION QTY.

45

1 53201 Axle, Front, T7/T9 2W 1

2 81212 Cylinder, Power Steering, Ball Socket Style, T5C/T7/T9 2WD 1

3 24028 Pin, Clevis, 5/8 x 2 1/4”1

4 53160 Pin, Cotter, 1/8 x 1 3/4”1

5 25803 Rod, Power Steering, T5C/T5D/T6/T7/T9 2WD 1

6 15162 Assembly, Axle, Front, Ball Socket,

T7/T9 2WD 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.8

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 15

View of Hub Assembly and Spindle

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

121110987654321

13 Hub Assembly

ITEM PART NUMBER DESCRIPTION QTY.

1

53116 Spindle, Front, Right, T5D/T7 T6/T9 2WD

53050 Spindle, Front, Left, T5D/T7 T6/T9 2WD

1

2 53111 Seal, Front, Hub, T5C/T5D/T6/T7/T9 1

3 53123 Bearing, Front, Inner, T5C/T5D/T6/T7/T9 1

4 53124 Race, 5 on 5.5, Front, Inner, T5C/T5D/T6/T7/T9 1

5 53137 Hub, 5 on 4.5, T5C/T5D/T6/T7/T9 1

6 53058 Race, Old Style, In & Out and New Style Outer, T5C/T5D/T6/T7/T9 1

7 53125 Bearing, Front, Outer, T5C 1

8 53140 Washer, 3/4”, SAE Z, Front Axle 1

9 53150 Nut, Castelated, 3/4”, Front Hub 1

10 53160 Pin, Cotter, 1/8 x 13/4”1

11 53170 Cap, Dust, T3/T4/T5C/T5D/T6/T7/T9 1

12 28506 Nut, Lug, 1/2” - 20 ID x 13/16” OD, Front & Rear 5

13 53136 Assembly, Hub, 5 on 4.5 (Spindle Not Included) 1

14 53227 Bearing Kit w/no Hub 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.9

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 16

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Right Front Tire and Rim

1 32

6 Tire Assembly

ITEM PART NUMBER DESCRIPTION QTY.

45

1 53170 Cap, Dust, T3/T5C/T5D/T6/T7/T9 1

2 28506 Nut, Lug, 1/2” - 20 ID x 13/16” OD, Front & Rear 5

3 51275 Tire, Front, 23” x 10.5” x 12”, T6/T7/T9 1

4 51273 Valve, Tire, Front 1

5 50017 Rim, Front, T5D/T6/T7/T9 1

6 51019 Assembly, Tire & Rim, Front, T6/T7/T9 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.10

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 17

View of Right Side of Tractor

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

1

2345678

ITEM PART NUMBER DESCRIPTION QTY.

1 15126 Hood, T5D/T7 1

2 80055 Hose, 1/4” x 38” 1

3 20174 Fitting, 1/4” MP x 1/4” FM Swivel 1

4 12301 Pin, 7 7/8”, Arm Cylinder, Rod to Frame, T5B/T5C/T5D/T6/T7/T9 1

5 80025 Wrap, Hose, 4” (Sold per Foot) 4

6 80132 Hose, 3/8 x 70” 2

7 80131 Hose, 1/4” x 70” 2

8 12300 Pin, 6 7/8”, Arm to Frame, T5B/T5C/T5D/T6/T7/T9 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.11

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 18

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Left Side of Tractor

1 2

35 46

ITEM PART NUMBER DESCRIPTION QTY.

1 12056 Strut, Lift, Arm, Loader, T5C/T5D/T6/T7/T9 1

2 17200 Pin, Quick Release w/Ring Grip, T5C/T5D/T6/T7/T9 1

3 22109 Bolt, 1/2 x 3 1/2” NC Gr8 Z 1

4 15542 Latch, Hood, T5D/T6/T7/T9 1

5 17198 Pin, 8 1/2”, Arm Lift Cylinder to Strut, T5C/T5D/T6/T7/T9 1

6 21003 Oil Filter 25HP Kubota 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.12

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 19

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

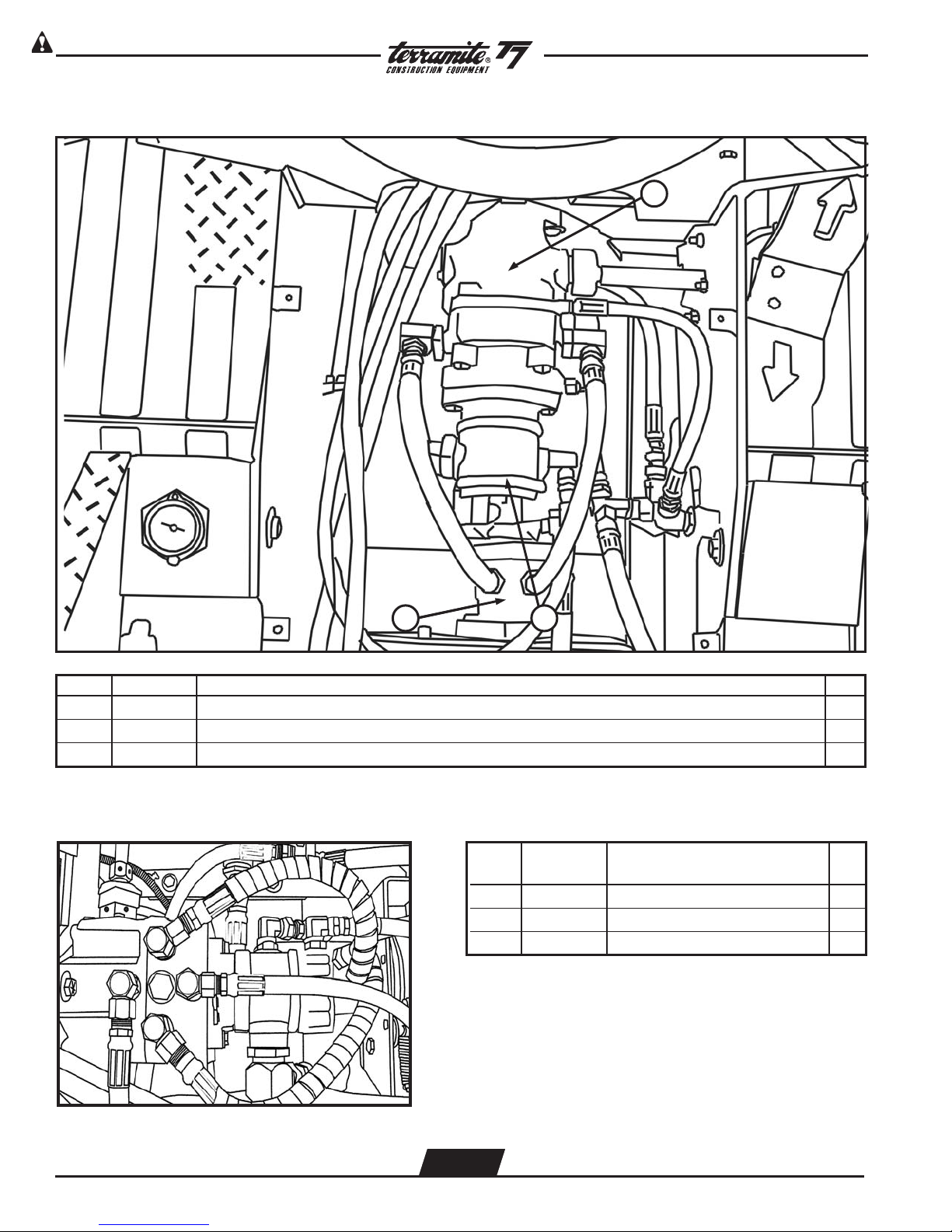

Right Side of Diesel Engine Compartment - Kubota (Without Air Filter)

3

ITEM PART NUMBER DESCRIPTION QTY.

5/

1 15506 Filter, Fuel,

16

”, T5C/T5D/T6/T7/T9 (not shown) 1

2 21003 Filter, Oil, 25hp., T5D/T6/T7/T9 1

3 43396 Filter, Fuel Element, 25 &32.5hp., T5D/T6/T7/T9 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.13

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 20

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Diesel Air Filter Assembly

1

ITEM PART NUMBER DESCRIPTION QTY.

1 41056 Kit, Air Cleaner Filter, 3 Cylinder, Kubota 1

2 41074 Filter, Air (Not Shown) 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.14

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 21

View of Muffler Assembly - Diesel

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

2

ITEM PART NUMBER DESCRIPTION QTY.

1 40037 Assembly, Engine, Kubota, 25hp. 1

2 42071 Muffler, Kubota, 25hp. 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.15

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 22

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

Left Side of Diesel Engine Compartment - Kubota (Without Air Filter)

2

ITEM PART NUMBER DESCRIPTION QTY.

1 15505

5

/16" in line (Not Shown) 1

2 21003 Filter, Oil, Engine, Kubota 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.16

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 23

View Right Side of Kohler Engine

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

1 2 3 4

ITEM PART NUMBER DESCRIPTION QTY.

1 40027 Assembly, Engine, Command 20hp. (V-Twin) 1

2 70075 Plug, Spark RC/12yc/71 1

3 43233 Starter, CH20 1

4 42023 Muffler, Center Outlet, Kohler Command 20hp. 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.17

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 24

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

Kohler Engine Leftside View

123

ITEM PART NUMBER DESCRIPTION QTY.

1 40097 Pump, Fuel, Kohler Command 20 hp 1

2 15503 Filter, Gas Fuel,

1/

"1

4

3 21014 Filter, Oil, Engine, CH 20 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.18

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 25

View of Power Steering Gear

1

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

3

2

4

5

ITEM PART NUMBER DESCRIPTION QTY.

1 15106 Gear, Power Steering, T5D/T6/T7/T9 1

2 20033 Fitting, #8 O-Ring x #6 JIC, T5D/T7/T9/Sweeper 2

3 20032 Fitting, #8 O-Ring x #4 JIC FM 2

4 80176 Hose, 1/4” X 65”, 1/4 MP x #4 Short JIC 90 2

5 88658 Hose, 3/8” x 58”, #6 Short JIC 90 x 3/8 MP 2

WWW.TERRAMITE.COM

Charleston, WV/USA

2.19

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 26

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

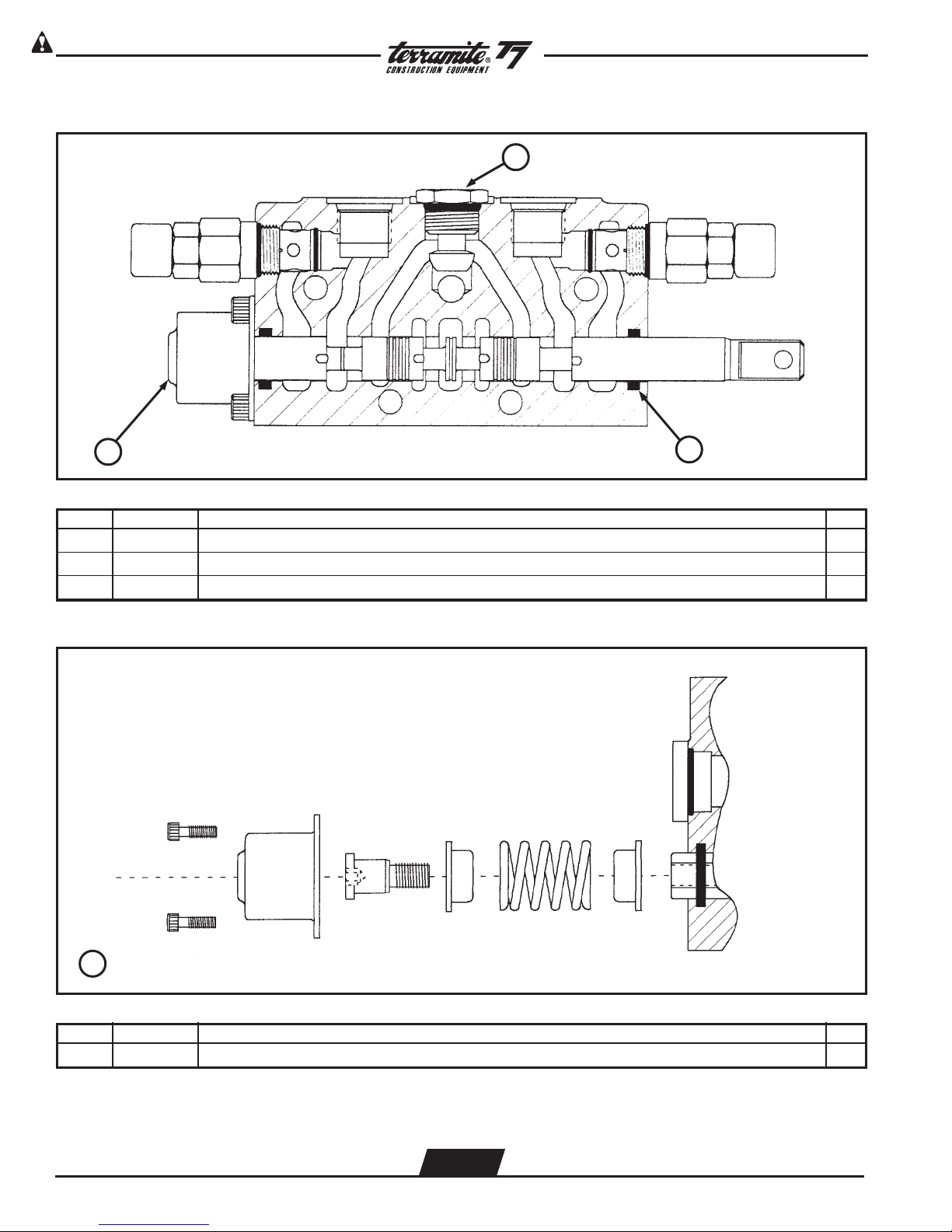

View of Front Valve w/Fittings

1

2

3

4

9 8

ITEM PART NUMBER DESCRIPTION QTY.

7 6

5

1 22784 Fitting, 1/2"M 90 x 1/4"F, Swivel 2

2 20786 Fitting, 1/2"MP x 3/8"F 90, Swivel 2

3 22278 Fitting, 1/2"F 90 x 1/2"F, Swivel 1

4 20010 Fitting, Nipple, 1/2" x 3" 1

5 85015 Valve, Front 1

6 13083 Detent. Spring (Not Shown) 1

7 13943 Relief Valve, Loader (Not Shown) 1

8 20094 Fitting, Reducer, 3/4" x 1/2" FM 1

9 21978 Fitting, 1/2"M 90 x 1/2"F, Swivel 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.20

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 27

Read Operators Manual For SafetyPARTS MANUAL

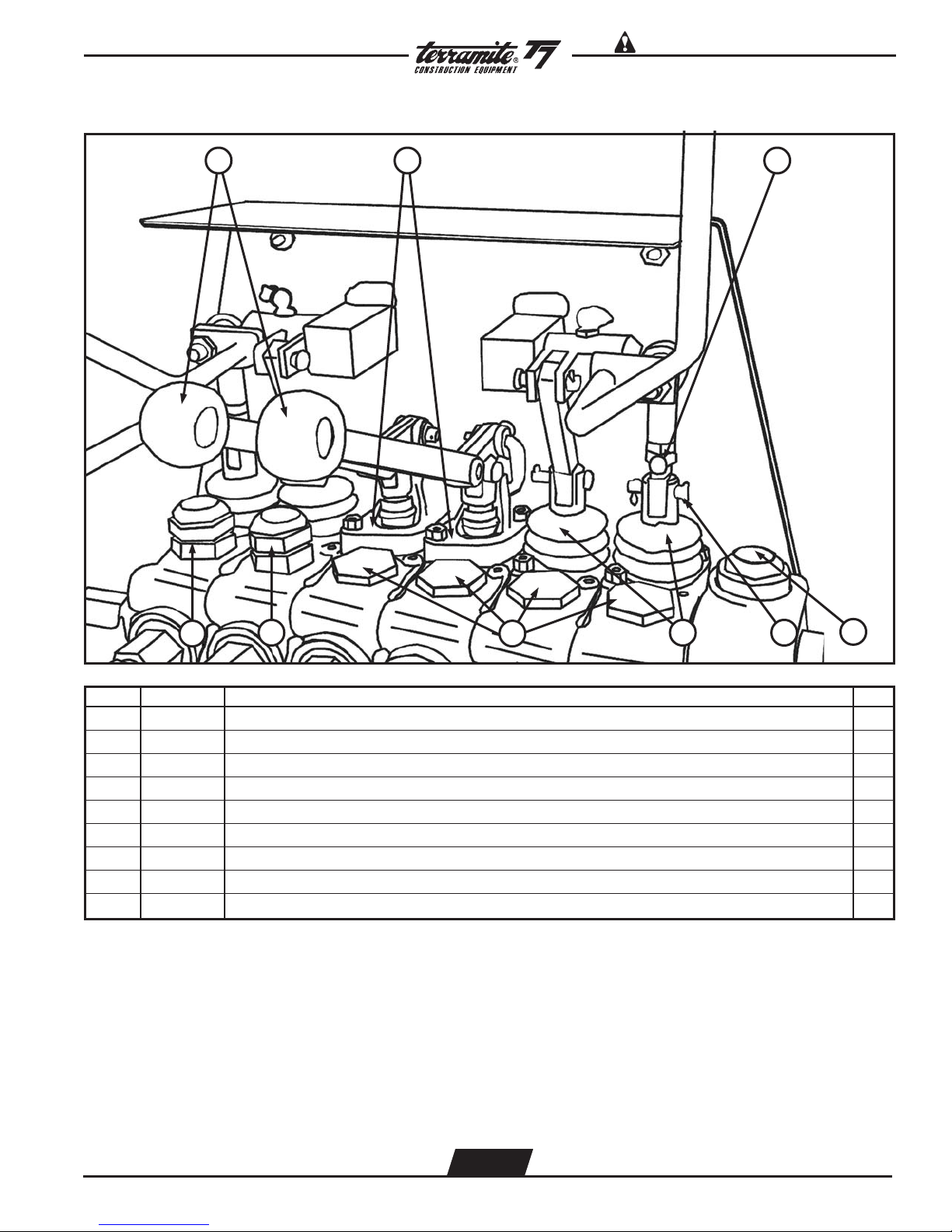

View of Loader Valve Assembly and Battery - Perkins

Copyright © 2007 Terramite Corporation

1 2 3 4 5 6

ITEM PART NUMBER DESCRIPTION QTY.

7

1 80132 Hose, 3/8" x 70" 2

2 80131 Hose, 1/4" x 70" 2

3 88878 Hose, 1/2" x 78" (not shown) 1

4 88845 Hose, 1/2" x 45" 1

5 72028 Cable, Battery to Ground, Black, T5C/T5D/T6/T7/T9 1

6 72038 Cable, Battery to Starter, T5C/T5D/T6/T7/T9 1

7 77022 Battery, Group 26, All Tractors/SCR/Sweeper 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.21

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 28

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

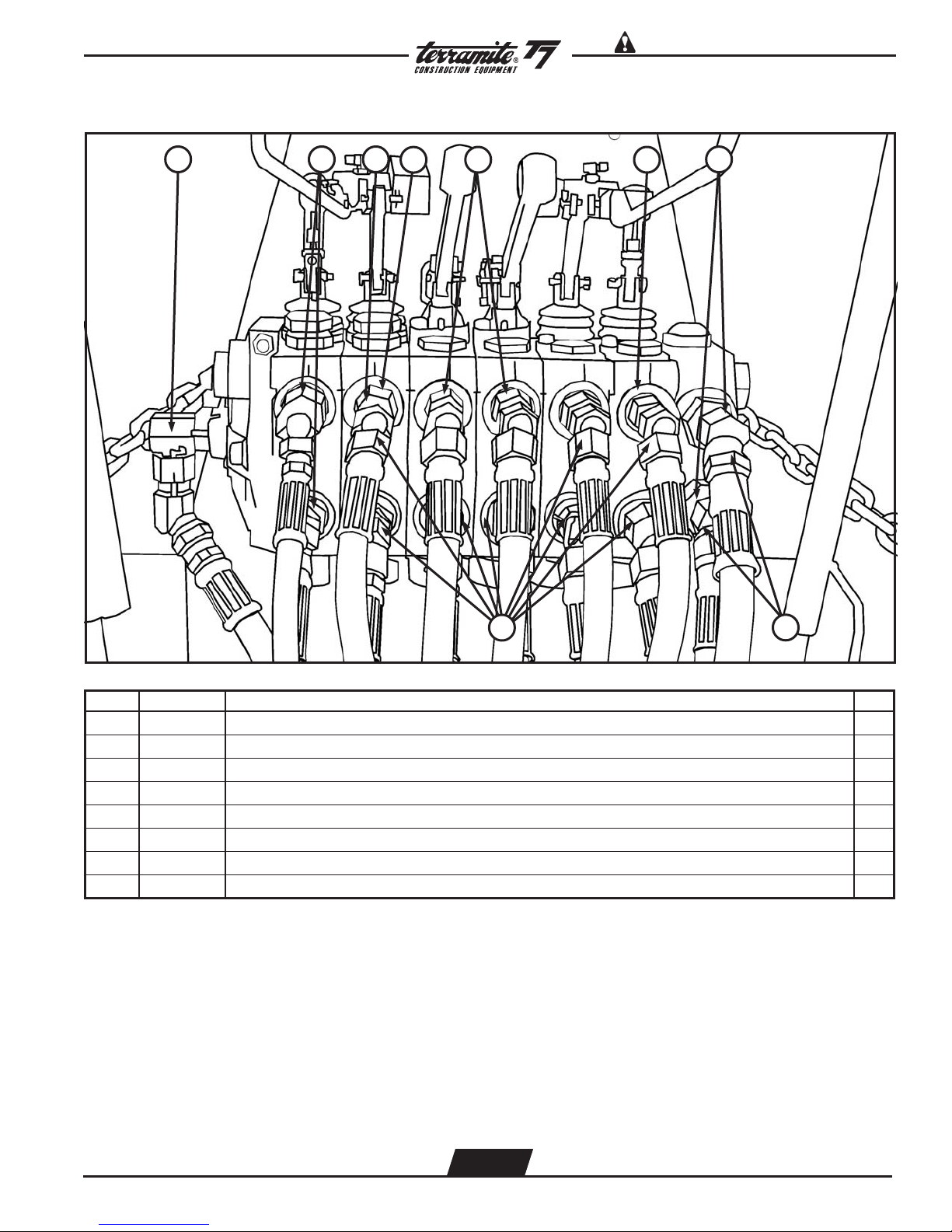

View of Front Valve Linkage Assembly

2 3 4 5 6 7

1

ITEM PART NUMBER DESCRIPTION QTY.

1 13947 Link, “L”, Front Valve, All Tractors 1

2 13965 Linkage, Ball-Socket, Wobblestick, All Tractors 1

3 13413 Pin, Cotter, 3/32” x 5/8”, Linkage, Valve, All Tractors 1

4 25500 Nut, 5/16” - 24 NF Jam 1

5 13944 Block, Pivot, Wobblestick, Front, T5C/T5D/T6/T7/T9 1

6 13411 Link, “U”, Valve, All Tractors 1

7 13995 Bolt, Wobblestick Hinge, Front, All Tractors 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.22

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 29

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Left Side of Diesel Dash Wiring Harness - Perkins

1&2

3

5

6 Entire Assembly

ITEM PART NUMBER DESCRIPTION QTY.

4

1 74038 Lens, Warning Light, Red, Diesel, T5C/T5D/T6/T7/T9 4

2 74039 Bulb, Light, Warning 4

3 74037 Base, Warning Light 4

4 70038 Relay, Timer & Glow Plug, T7/T9 1

5 74000 Switch, Toggle, Double Throw, T5D/T6/T7/T9 1

6 72059 Harness, Wiring, Dash, Perkins, T5C/T5D/T7 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.23

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 30

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Right Side of Diesel Dash Wiring Harness - Perkins

1

2

3 45

6

ITEM PART NUMBER DESCRIPTION QTY.

1 70010 Breaker, Circuit, 50 Amp. 1

2 74036 Breaker, Circuit, 15 Amp., T7/T9 2

3 77080 Hourmeter, All Tractors 1

4 14120 Plate, Instrument Panel, Diesel, Perkins, T6/T7/T9 1

5 70335 Switch, Ignition, 3 Prong 1

6 72049 Diode Harness, Dual, T6/T7/T9 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.24

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 31

View of Operator Position Facing Dash (Diesel)

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

1 2 3 4

11

12

5678

ITEM PART NUMBER DESCRIPTION QTY.

1 13140 Cable, Throttle, Diesel, T7/T9 1

2 74000 Switch, Toggle, Double Throw, T5D/T6/T7/T9 1

3 77080 Hourmeter, All Tractors 1

4

70335 Switch, Ignition, T6/T9

70111 Switch, Ignition, Perkins T6/T9 (after SN 229x0120)

1

5 13942 Knob, Red, Wobblestick Handle, Valve, All Tractors 1

6 13072 Handle, Wobblestick, Front, All Tractors 1

9 13136 Cap, Center, Steering Wheel 1

10 13003 Wheel, Steering, T5C/T5D/T6/T7/T9 1

11 70111 Perkins, Key Switch (after SN#227x0107) 1

12 70040 Kubota, Key Switch 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.25

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 32

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Operator PositionFacing Dash (Gas)

1 2 5

3

4

7

ITEM PART NUMBER DESCRIPTION QTY.

6

1 13136 Cap, Center, Steering Wheel 1

2 13003 Wheel, Steering, T5C/T5D/T6/T7/T9 1

3 74000 SwitchToggle, Double Throw, T5D/T6/T7/T9 1

4 77080 Hourmeter, All Tractors 1

5 Serial Number Must Be Provided for Correct Keyswitch and Keys 3

6 13142 Cable, Throttle Command/Honda T5C/T5D/T7 1

7 14801 Cable, Choke 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.26

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 33

View of Transmission Assembly - Diesel

1

2

17

10

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

3

4

12

11

8

9

ITEM PART NUMBER DESCRIPTION QTY.

5

6

7

1 11128 Spring Assembly 1

2 88820 Hose,1/2" x 20" 2

3 88827 Hose,3/4" x 27" 1

4 80201 Hose,1/2" x 57" 1

5 66007 Gear Pump 1

6 81624 Hose,1" x 24" 1

7 80250 Hose,3/8" x 25" 1

8 21032 Filter, In Line Hydraulic 1

9 80233 Hose,1/2" x 80" 1

10 80251 Hose,3/8" x 25" 1

11 88659 Hose,3/8" x 58" 1

12 88831 Hose,1/2" x 31" 1

13 80232 Hose,1/2" x 47" Oil Filter to Back Valve (Not Shown) 1

14 80229 Hose,1/2" x 123" Oil Cooler to Oil Filter (Not Shown) 1

15 80099 Hose,1/2" x 96" Front Valve to Oil Cooler (Not Shown) 1

16 80230 Hose, 1/4" x 65" Power Steering (Not Shown) 2

17 64200 Sauer - Danfoss Transmission 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.27

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 34

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Transmission Assembly - Gas

1

3 2

ITEM PART NUMBER DESCRIPTION QTY.

1 64055 Transmission, Eaton, T5C/T5D/T7 1

2 66000 Pump, Double Gear, T5C/T5D/T7 1

3 64003 Motor, Torque, Parker/TRW, All Tractors 1

Sunstrand Transmission Assembly

ITEM PART NUMBER DESCRIPTION QTY.

1 64200 Transmission 1

2 88820 Hose 1/2 x 20" 2

3 66000 Pump, Double Gear 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.28

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 35

View from Right of Foot Pedal Control

1 2

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

8

ITEM PART NUMBER DESCRIPTION QTY.

67

45

3

1 11600 Pedal, Foot 1

2 11628 Bolt, Pedal Stop, T5C/T5D/T7 2

3 11627 Block, Pillow, Bearing, T5C/T5D/T6/T7/T9 1

4 11629 Bolt, Spring Centering, T5C/T5D/T7 1

5 13029 Spring, Pedal, Hairpin, T5C/T5D/T6/T7/T9 1

6 11610 Block, Pedal, T5C/T5D/T6/T7/T9 1

7 11620 Shaft, Pedal, T5C/T5D/T6/T7/T9 1

8 16177 Tape, Pedal, Anti-Skid 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.29

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 36

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View from Right Side of Hydraulic Tank

1

ITEM PART NUMBER DESCRIPTION QTY.

1 22204 Cap, Hydraulic, w Dipstick & Breather, T5C/T5D/T6/T7/T9 2WD 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.30

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 37

View from Left Side of Fuel Tank

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

1

ITEM PART NUMBER DESCRIPTION QTY.

2&3

1 11299 Gauge, Fuel, T5D/T6/T7/T9 1

2 15005 Cap, Safety, Green, (Diesel) T5C/T5D/T6/T7/T9 1

3 11282 Cap, Safety, Red, (Gas), T5B/T5C/T5D/T7/Screed 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.31

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 38

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Hydraulic Filter Assembly

1

2

ITEM PART NUMBER DESCRIPTION QTY.

1 21030 Filter, Hydraulic, Spin On 1

2 21025 Assembly, Filter, Hydraulic 1

View of Hydraulic Filter

3

1

2

ITEM PART NUMBER DESCRIPTION QTY.

1 21029 Filter Head 1

2 21030 Filter Hydraulic 1

3 10357 Bracket Hydraulic Filter 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.32

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 39

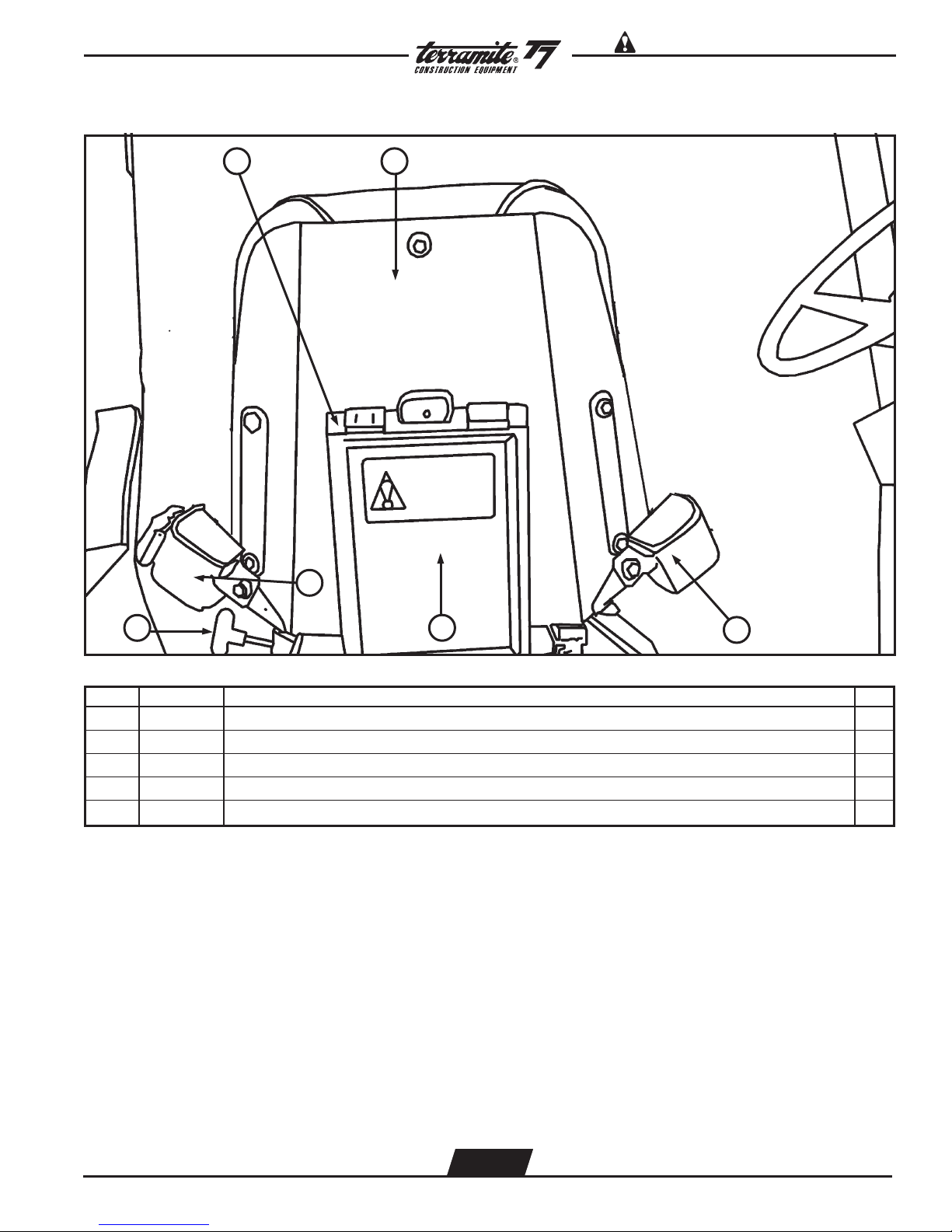

View from Back of Seat

1 2

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

3

6

ITEM PART NUMBER DESCRIPTION QTY.

4

3

1 11911 Box, Manual, Operator’s Seat 1

2 14260 Assembly, Seat, w/Swivel Disc w/Arm, T5D/T6/T7/T9 1

3 11903 Belt, Seat, T5C/T5D/T6/T7/T9/Sweeper 1

4 95086 Manual, Operator's, All Tractors (Not Shown) 1

5 14011 Knob, Seat Shaft 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.33

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 40

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View from Operator Position of Rear Valve (Straight Boom - Non 180 Only)

1 2 3 4 1

567891011

ITEM PART NUMBER DESCRIPTION QTY.

1 13942 Knob, Red, Wobblestick Handle, Valve, T5C/T5D/T6/T7/T9 2

2 13073 Handle, Wobblestick, Left Rear 2

3 14050 Decal, Wobblestick and Operator Hazard 1

4 13123 Handle, Wobblestick, Right Rear 1

5 13400 Valve, Rear 1

6 25128 Fitting, #12 O’ring x 1/2” FPT 2

7 21788 Fitting, 1/2”M x 1/2”FM 45, Swivel 2

8 25286 Fitting, 3/4”MB x 3/8”F, Bushing HD 12

9 21764 Fitting, 3/8”M x 1/4”F 45, Swivel 9

10 21765 Fitting, 3/8”MP x 1/4”FP 45, Restrictor 3

11 25718 Fitting, 7/8”MP 90 x 1/2”, Swivel 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.34

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 41

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

View from Operator Position of Rear Valve (Straight Boom - Non 180 Only)

21

3

9

ITEM PART NUMBER DESCRIPTION QTY.

8

7

56

4

1 13431 Handle, Outrigger, T5C/T5D/T6/T7/T9 2

2 13410 Bracket, Aluminum, Rear Valve Handle 2

3 16410 Wobblestick Eye Bolt 2

4 13429 Valve, Main Relief 1

5 13418 Pin, Pivot, Valve Hose Link, T5C/T5D/T7 8

6 13423 Valve, Boot Spool Protector 4

7 13401 Kit, Load Check 9

8 13456 Relief, Port 2600# 1

9 13454 Relief, Port 2000# 2

WWW.TERRAMITE.COM

Charleston, WV/USA

2.35

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 42

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Operator Position at Rear Valve (Prior to 1-1-01 Non 180 Only)

1 2 3

4

6

ITEM PART NUMBER DESCRIPTION QTY.

5

1 13073 Handle, Wobblestick, Left Rear, T5C/T5D/T6/T7/T9 1

2 13431 Handle, Outrigger, T5C/T5D/T6/T7/T9 2

3 13123 Handle, Wobblestick, Right Rear, T5C/T5D/T6/T7/T9 1

4 13942 Knob, Red Wobblestick Handle, Valve, T5C/T5D/T6/T7/T9 2

5 15102 Cover, Rear Valve (Boom Latch), T5C/T7/T9 1

6 13135 Cable, Boom Latch Control, T-Handle, T7/T9 1

7 22222 Spring For Boom Latch 1

8 22023 Washers For Latch 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.36

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 43

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

View from Operator Position of Rear Valve Curved Boom Prior to 1-1-01 Non 180 Only

1 2 3

4

2 5

6

8

ITEM PART NUMBER DESCRIPTION QTY.

1 25718 Fitting, 7/8" MP 90 x 1/2", Swivel 2

2 21765 Fitting, 3/8" MP x 1/4" FP 45 - Restrictor 2

o

o

7

3 13048 Restrictor, w/spring, Rear Valve 1

4 85031 Checks, Anti-Cavitation, (Not Shown) 2

5 25286 Fitting, 3/4" MB x 3/8" F, Bushing HD 12

6 20065 Fitting, #12 O'Ring x 1/2" FPT 2

7 21788 Fitting, 1/2" M x 1/2" FM 45, Swivel 2

8 21764 Fitting, 3/8" M x 1/4" F 45, Swivel 8

WWW.TERRAMITE.COM

Charleston, WV/USA

2.37

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 44

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

Curved Boom Prior to 1-1-01

View from Operator Position of Backhoe Valve

Non 180 Only

1 2 3 4

5

6

10

ITEM PART NUMBER DESCRIPTION QTY.

2

8

8

549

7

1 88425 Hose, 1/4” x 25” 1

2 80061 Hose, 1/4” x 72” 2

3 80058 Hose, 1/4” x 51” 2

4 80020 Hose, 1/4” x 98” 2

5 80021 Hose, 1/4” x 136” 2

6 88840 Hose, 1/2” x 40” 1

7 88857 Hose, 1/2” x 57” 1

8 80054 Hose, 1/4” x 36” 2

9 80155 Hose, 1/4” x 24” 1

10 88880 Hose, 1/2” x 80” 2

WWW.TERRAMITE.COM

Charleston, WV/USA

2.38

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 45

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

View from Operator Position of Rear Valve

1 2 3 4 2 5

Prior to 1-1-01

Non 180 Only

7869 9 6

ITEM PART NUMBER DESCRIPTION QTY.

1 25500 Nut, 5/16” - 24 NF Jam 5

2 13444 Block, Pivot, Universal Rear, T5C/T5D/T6/T7/T9 1

3 21429 Fitting, Grease, 1/4” 90°D 7

4 14052 Plate, Wobblestick & Operator Hazard, T5C/T5D/T6/T7/T9 1

5 13965 Linkage, Ball-Socket, Wobblestick, All Tractors 3

6 13418 Pin, Pivot, Valve Hose Link, T5C/T5D/T6/T7 10

7 13443 Link Bar, Wobblestick Connecting, T5C/T5D/T6/T7/T9 3

8 13411 Link, “U”, Valve All Tractors 3

9 13410 Bracket, Aluminum, Rear Valve Handle, T6/T9 2

WWW.TERRAMITE.COM

Charleston, WV/USA

2.39

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 46

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Operator Position at Rear Valve (180 Swing)

21 3

4

5

ITEM PART NUMBER DESCRIPTION QTY.

1 13135 Cable, Boom Latch Control, T-Handle, T7/T9 1

2 84046 Wobblestick, Right Rear, V10-1294 Kit Pivot Section 1

3 13942 Knob, Red Wobblestick Handle, Valve, T5C/T5D/T6/T7/T9 2

4 84045 Handle, Wobblestick Left and Right, V10-1294 2

5 85120 Handle Outrigger/Offset V10-1294 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.40

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 47

Read Operators Manual For SafetyPARTS MANUAL

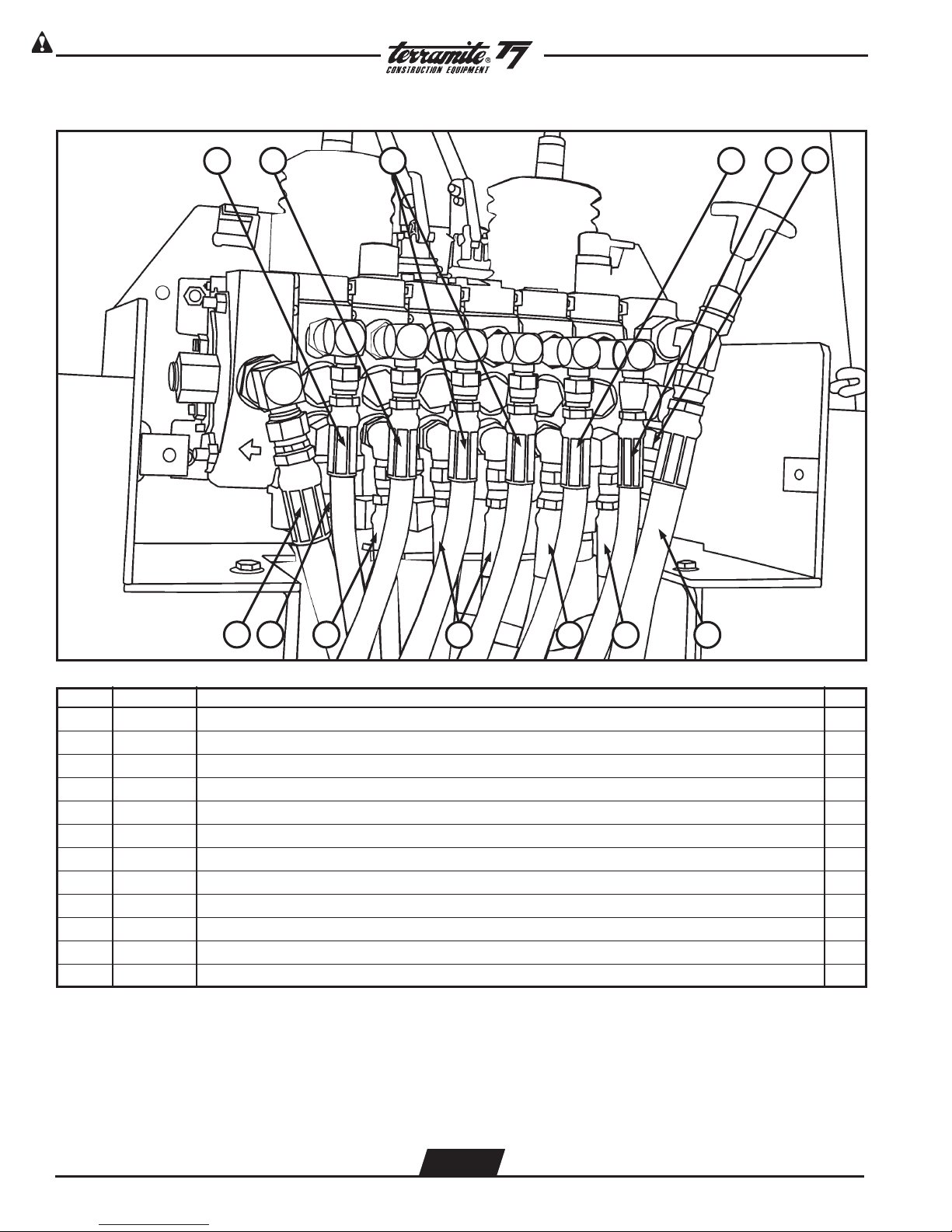

View of Fitting Location for Rear Valve (180 Swing)

21 3

Copyright © 2007 Terramite Corporation

5

4

6

ITEM PART NUMBER DESCRIPTION QTY.

1 20039 Fitting, #10 O-Ring x #8 JIC 90 1

2 20156 Fitting, #8 O-Ring x #6 JIC 90 6

3 20007 Fitting, #10 O-Ring - 7/8MB x 1/2" F, Bushing 1

4 20192 Fitting, 1/2MB x #8 JIC Long 90 1

5 20039 Fitting, #10 O-Ring x #8 JIC 90 1

6 20149 Fitting, #8 MP x #8M JIC Long 90 6

WWW.TERRAMITE.COM

Charleston, WV/USA

2.41

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 48

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Hose Location for Rear Valve (180 Swing)

6

1 4

2 3

5

1112

ITEM PART NUMBER DESCRIPTION QTY.

10

9

4

78

1 80202 Hose, 1/4" x 130" 1

2 80203 Hose, 1/4" x 91" 1

3 80188 Hose, 1/4" x 48" 2

4 80205 Hose, 1/4" x 67" 2

5 80190 Hose, 1/4" x 25" 1

6 80200 Hose, 1/2" x 47" 1

7 80201 Hose, 1/2" x 57" 1

8 80197 Hose, 1/4" x 24" 1

9 80202 Hose, 1/4" x 39" 2

10 80204 Hose, 1/4" x 87" 1

11 80191 Hose, 1/4" x 124" 1

12 80199 Hose, 1/2" x 180" 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.42

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 49

View of Right Rear Tire and Rim

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

6 Tire Tube

7 Tire Assembly

ITEM PART NUMBER DESCRIPTION QTY.

5

4

3

12

1 51173 Tire, Rear, High Flotation, 31” x 15.5” x 15”, T5C/T5D/T6/T7/T9 1

2 50016 Rim, Rear, 15” x 13”, T5C/T5D/T6/T7/T9 1

3 51003 Valve Stem 1

4 28506 Nut Lug, 1/2” - 20 ID x 13/16” OD, Front & Rear 5

5 55380 Lug Stud, Rear Wheel 5

6 51000 Tube, 9.50 x 16 Tire (Not Shown) 1

7 51018 Assembly, Tire & Rim, Rear - HFT, T5C/T5D/T6/T7/T9 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.43

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 50

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

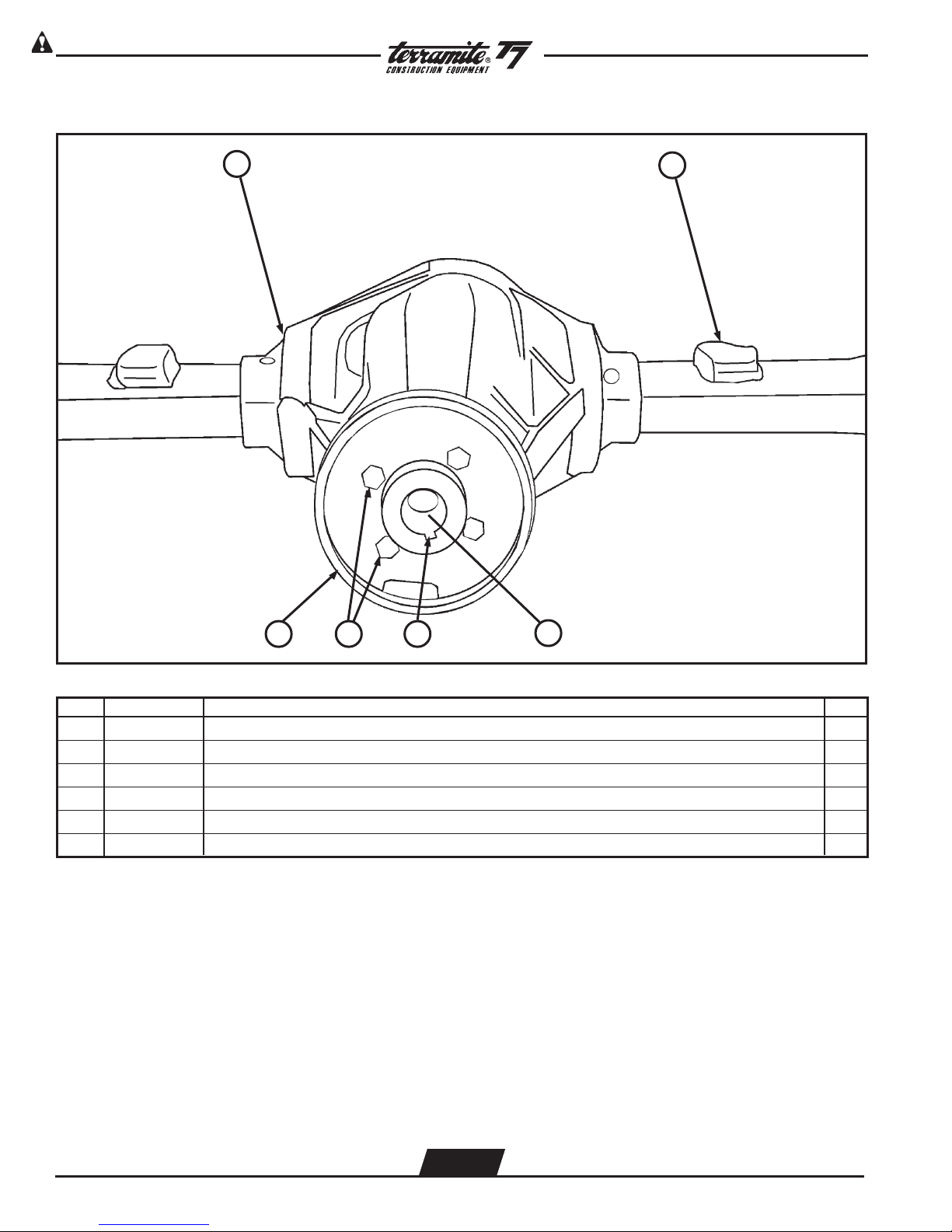

View from Front of Rear Axle

1

2

43

ITEM PART NUMBER DESCRIPTION QTY.

5

6

1 55004 Axle, Rear, T5C/T5D/T7/T9 2W 1

2 55005 Pad, Rear Axle Spring 2

3 57034 Brake Drum, Weldment 1

4 26288 Bolt, 3/8” x 1 3/4” NF GR8Z 4

5 62021 Key, Torque Motor, TRW/Parker 1

6 51800 Flange, Drive Motor, T4/T5C/T5D/T6/T7/T9 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.44

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 51

Top View of Parking Brake Assembly

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

2

1 2

8

9

7

10

6

5 4 3

ITEM PART NUMBER DESCRIPTION QTY.

NOT SHOWN

ATTACHES TO BRAKE BAND

1 55620 Brake Band 1

2 55606 Brake Cable 1

3 55613 Brake Off Set Link Not Shown - Attaches to Brake Band 1

4 64003 Drive Motor 1

5 51800 Drive Motor Flange 1

6 22034 Bolt 1

7 28500 Nut 1

8 23005 Nut 1

9 22038 Bolt 1

17028 Bushing, Brake 9/16" ID x 1" OD x 7/8" L 1

10 17029 Bushing, Brake 9/16" ID x 1"OD x 1 1/4" L 1

22042 Bolt, 14mm x 90 mm C2.0z Brake 38748 1

ITEM

SHOWN

ITEM

SHOWN

13168 Spring, Retro Fit Parking Brake 1

55621 Spring Bracket, Parking Brake 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.45

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 52

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

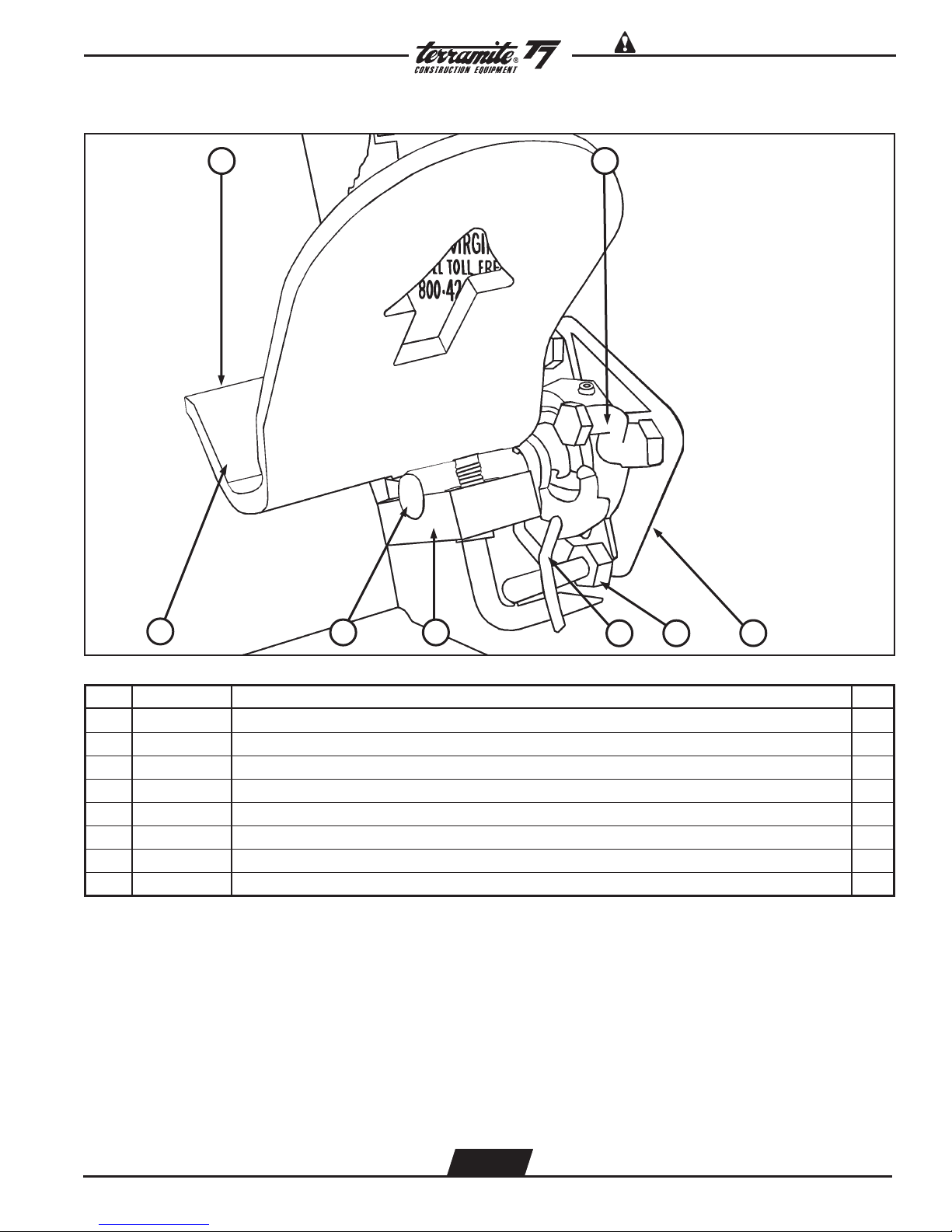

View from Left Side of Outrigger Assembly (Curved Boom)

1 2 3 4

5

7

ITEM PART NUMBER DESCRIPTION QTY.

6

1 81139 Cylinder, Outrigger, T5C/T5D/T7 1

2 11123 Guard, Outrigger, T5C/T5D/T7 1

3 11502 Pin, 4 1/8”, Outrigger to Cylinder, T5C/T5D/T6/T7/T9 1

4 10202 Pin, Linch (Not Shown) 1

5 11048 Pad, Outrigger Foot 1

6 17156 Pin, 5 1/4”, Pull, Outrigger Pad, T5D/T6/T7/T9 1

7 11112 Outrigger, T5C/T5D/T7 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.46

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 53

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Left Side of Swing Assembly (Curved Boom Prior 1-1-01)

1

2

5

8

7

6

3

9 10 9

4

11

12

ITEM PART NUMBER DESCRIPTION QTY.

14

13 12

1 15300 Pin, 4 1/8”, Swing Cylinder to Swing, T5C/T5D/T6/T7/T9 (Not Shown) 1

2 11140 Pin, 18”, Swing Pin, T5C/T5D/T7 (Not Shown) 1

3 17208 Pin, 7 3/4”, Boom Cylinder to Swing, T6/T7/T9 1

4 10237 Boom Latch, Curved Boom, T5D/T6/T7/T9 1

5 10400 Pin, 8 1/4”, Boom to Swing, T5C/T5D/T7 1

6 21420 Pin, Cotter, Case Hard 1

7 11006 Stop, Swing, T5C/T5D/T7 1

8 11100 Pin, 6 1/4”, Outrigger, Boom, T5C/T5D/T6/T7/T9 1

INSET - SWING CYLINDER SUB - ASSEMBLY

9 20025 Fitting, 1/4” Tee 2

10 80045 Hose, 1/4” Swing Crossover, 15” 2

11 82070 Cylinder, Swing w/Tee Fitting 2

12 20174 Fitting, 1/4”M x 1/4”FM Straight, Swivel 2

13 88420 Hose, 1/4” Swing to Valve, 20” 1

14 88425 Hose, 1/4” Swing to Valve, 25” 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.47

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 54

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Backhoe Assembly for T5D with Straight Boom

1 2 3 4 5 6

7

8

9101112

ITEM PART NUMBER DESCRIPTION QTY.

1 10184 Boom Lock, T5C/T5D 1

2 13114 Spring, Boom Lock, 5.5”L 1

3 10193 Handle, Boom Lock, T5C/T5D 1

4 13942 Knob, Red 1

5 21000 Cylinder,Crowd, T5/T5C/T5D 1

6 81060 Cylinder, Rear Curl,T5C/T5D 1

7 10322 Assembly, Dipper, T5D (Includes Decals) 1

8 10289 Assembly, Boom, T5D (Includes Decals) 1

9 21200 Cylinder, Boom, T5/T5C/T5D 1

10 11501 Outrigger, T5C/T5D 2

11 11123 Guard, Outrigger, T5C/T5D/T7 2

12 81139 Cylinder, Outrigger, T5C/T5D/T7 2

WWW.TERRAMITE.COM

Charleston, WV/USA

2.48

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 55

Read Operators Manual For SafetyPARTS MANUAL

View from Right Side of Swing Assembly (Straight Boom)

Copyright © 2007 Terramite Corporation

21

3 5

4

78910

ITEM PART NUMBER DESCRIPTION QTY.

6

1 11100 Pin, 6 1/4” Outrigger, Boom, T5C/T5D/T6/T7/T9 2

2 25201 Rod, Swing, T5C/T5D/T6/T7/T9 1

3 82070 Cylinder, Swing, T5C/T5D/T6/T7/T9 1

4 15300 Pin, 4 1/8”, Swing Cylinder to Swing, T5C/T5D/T6/T7/T9 2

5 10410 Pin, 7 3/4”, Boom Cylinder to Swing, T5C/T5D/T6/T7 1

6 20082 Nut, 3/8"NC Flange Z 2

7 10400 Pin, 8 1/4”, Dipper/Bucket, Boom/Swing, T5C/T5D/T6/T7 1

8 11300 Swing, T5C/T5D 1

9 21420 Pin, Cotter, Case Hard 1

10 11006 Stop, Plastic, Swing, T5C/T5D/T7 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.49

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 56

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

View of Left Side of Backhoe Assembly (Prior 1-1-01)

2

9

8

1 2 3 4

9

567

ITEM PART NUMBER DESCRIPTION QTY.

1 81190 Cylinder, Boom and Crowd, T7 2

2 10700 Pin, 6 7/8”, Crowd and Rear Curl Cylinder, Dipper, T5C/T5D/T7 4

3 81158 Cylinder, Rear Curl, T5D/T7 1

4 81048 Rod, Rear Curl, T5D/T7 1

5 10271 Assembly, Dipper, T7 (Includes Decals) 1

6 10701 Pin, 7 1/4”, Boom to Dipper, T5C/T5D/T7 1

7 10292 Assembly, Boom, Curved, T5D/T7 (Includes Decals) 1

8 81222 Cylinder, Boom, T7 1

9 17270 Pin, Lock, Swing, T7/9 1800 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.50

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 57

Read Operators Manual For SafetyPARTS MANUAL

View of Left Side of Rear Bucket & Linkage Assembly

Copyright © 2007 Terramite Corporation

1 2

3 4

5

ITEM PART NUMBER DESCRIPTION QTY.

6 7 8 9 10 11 12 13 14 15

1 17190 Pin, 8 1/4”, Quick Attach Bucket, T5C/T5D/T7 1

2 10812 Pin, 7 5/8”, Dipstick to Linkage, T5C/T5D/T6/T7/T9 1

3 20082 Nut, 3/8” NC Flange Z 2

4 11160 Bucket, 16”, Quick Attach, T5C/T5D/T7 1

5 19479 Center Assembly, Quick Attach, T5C/T5D/T7 1

6 17269 Pin, 6 1/2”, Rear Curl Cylinder to Quck Attach, T5C/T5D/T6/T7/T9 1

7 10812 Pin, 7 5/8”, Dipstick to Linkage, T5C/T5D/T6/T7/T9 1

8 10202 Pin, Linch, T5C/T5D/T6/T7/T9/Sweeper 1

9 17273 Pin, 9”, Quick Attach Pull, T5C/T5D/T7 1

10 18240 Linkage Assembly, Center, T5C/T5D/T6/T7/T9 1

11 10260 Bushing, 1 1/2” ID x 1 3/4”OD x 3” L 1

12 10819 Bushing 1 ID” x 1 1/4” OD x 1” L 1

13 17055 Bushing, 1 1/2” ID x 1 3/4” OD x 2” L 1

14 18261 Linkage Link, Right, T5C/T5D/T6/T7/T9 1

15 18260 Linkage Link, Left, T5C/T5D/T6/T7/T9 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.51

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 58

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

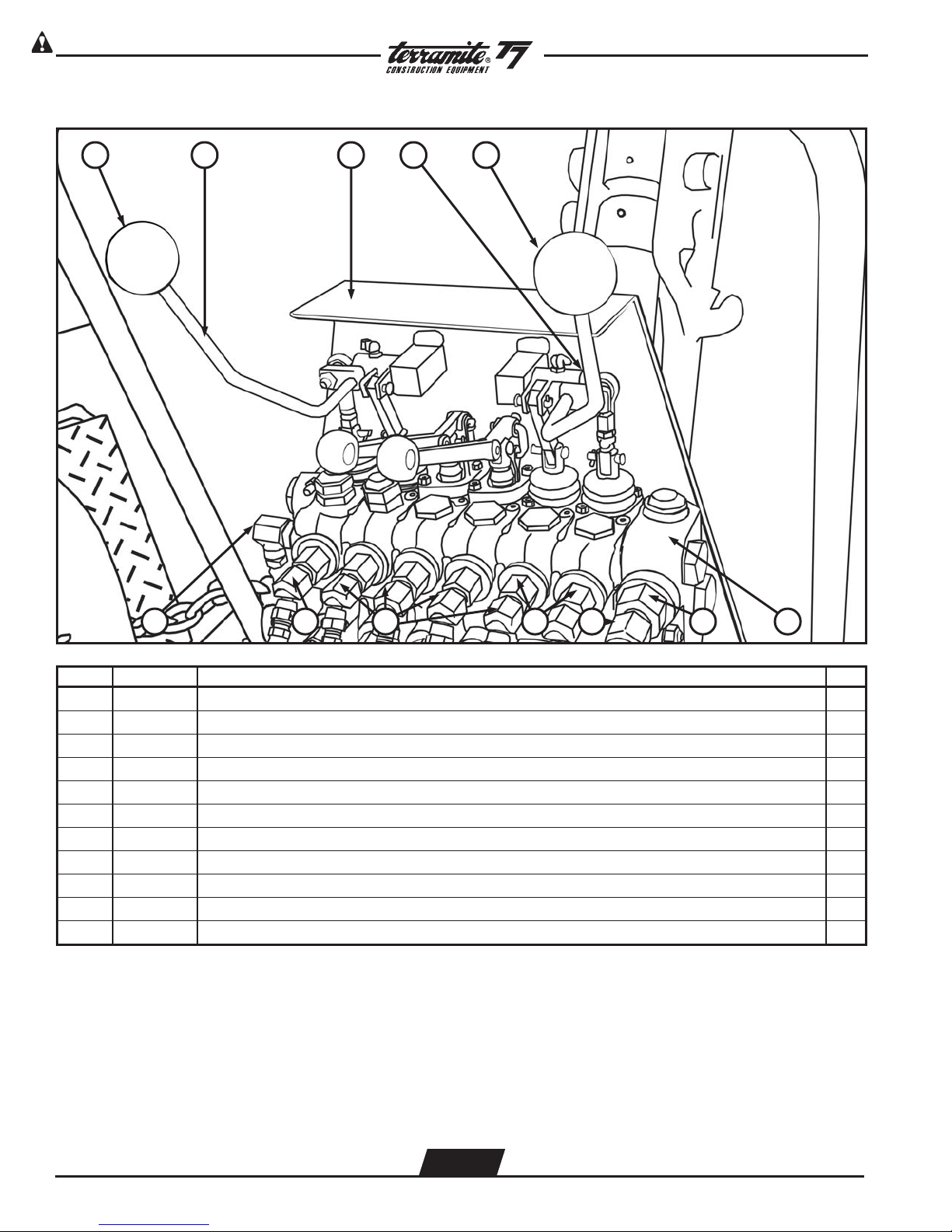

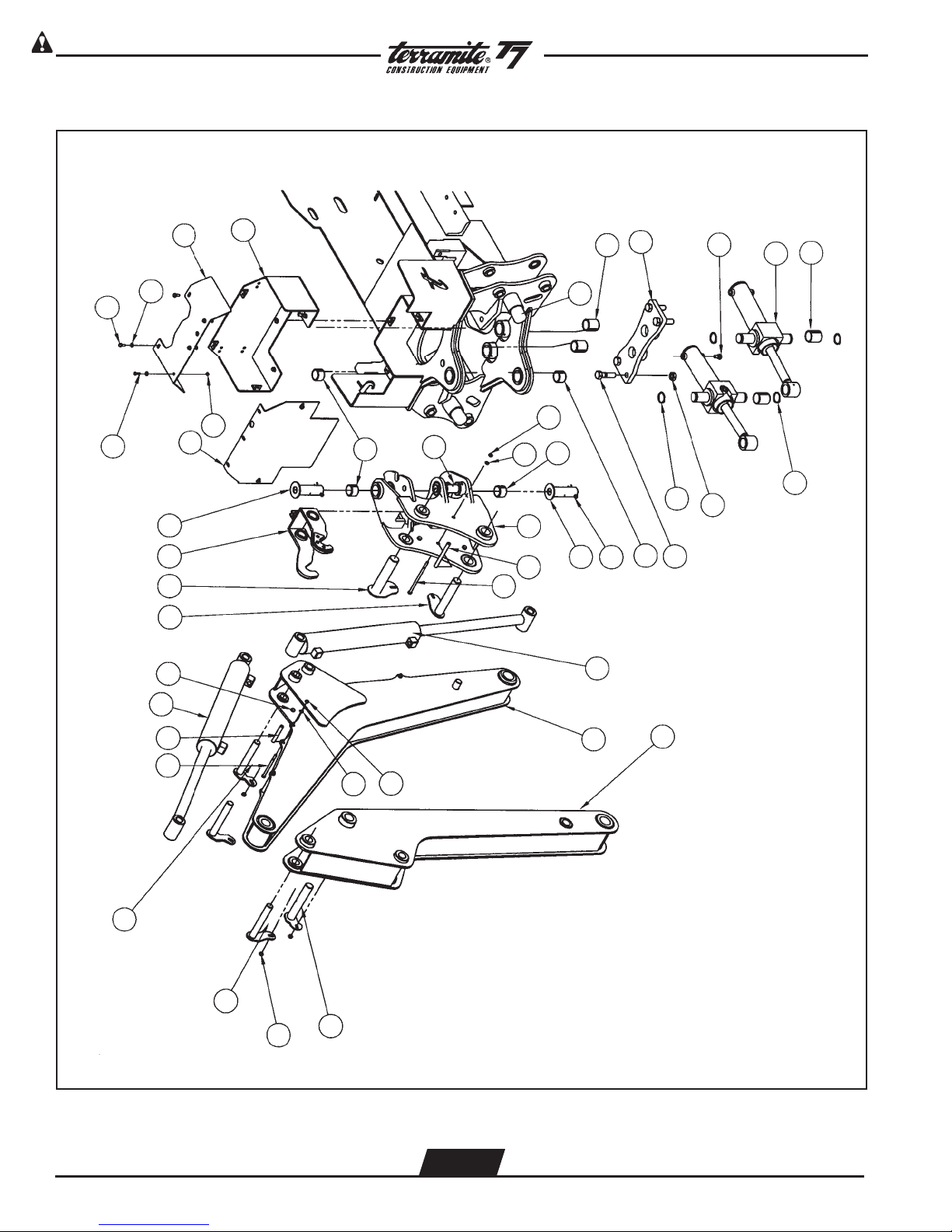

T7 Backhoe Assembly 180

33

39

38

36

35

37

34

o

4

2

46

45

5

3

44

1

5

18

20

32

2

7

18

13

12

14 17 10 6

16

41

40

13

15

14

44

45

43

42

6

47

9

19

11

5

8

WWW.TERRAMITE.COM

Charleston, WV/USA

2.52

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 59

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

T7 Backhoe Assembly 180

ITEM PART NUMBER DESCRIPTION QTY.

1 11150 Swing, 180, T7/T9 1

o

o

2 17055 Bushing, 1.5"ID x 1.75"OD x 2"L 4

3 17244 Pin, 51/2”, Swing Cylinder 2

4 11155 Plate, Swing Cylinder, 180, T7/T9 1

o

5 17252 Bushing, 1.5"ID x 1.75"OD x 1.25"L, T7/T9 6

6 17253 Pin, 4 3/4”, Swing Pivot, 180, T7/T9 2

7 81169 Cylinder, Trunnion Swing, 180, T7/T9 2

o

o

8 21420 Pin, Cotter, Case Hard 2

9 10292 Assembly, Boom, T7 (Includes Decals) 1

10 10237 Boom Latch, Curved Boom, T5D/T6/T7/T9 1

11 10271 Assembly, Dipper, T7 (Includes Decals) 1

12 81190 Cylinder, Crowd, T7 1

13 10700 Pin, 6 7/8” Crowd & Rear Curl Cylinder, T5C/T6/T7/T9 3

14 10406 Pin, 7 1/4” Boom to Dipper, T5B/T5D/T6/T7/T9 2

15 20082 Nut, 3/8" NC Flange Z 6

16 22123 Bolt, 3/8-16 x 1 1/4" Gr8 Z 6

17 17208 Pin, 8 1/4” Boom Cylinder to Swing, T6/T7/T9 1

18 22200 Ring, External, Snap, 11/2", 180, T7/T9 4

o

19 22197 Bolt, 3/4-16 x 2 3/4" Gr8 Z 4

20 22199 Nut, 3/4-16, Nylon Lock Gr8 Z 4

21 15138 Bracket, Engine Mounting, Front, Perkins, 20hp. 1

22 15136 Bracket, Engine Mounting, Rear, Perkins, 20hp. 2

23 48024 Mount, Rubber Isolator 4

24 22021 Bolt, 1/2-13 x 3" NC Gr8 Z 4

25 22081 Washer, 1/2" USS 4

26 22080 Washer, 1/2" x 2" OD Z 4

27 28500 Nut, 1/2" NC Lock Z 4

28 24007 Spacer, Frame, Front Valve Washer 4

29 10062 Bracket, Radiator Arm (Left) Perkins 1

30 10063 Bracket, Radiator Arm (Right) Perkins 1

31 22008 Bolt, 3/8-16 x 1" Gr 8 ZP, T5C/T5D/T6/T7/T9/Sweeper 4

32 20134 Fitting, #6 O-ring Plug 2

33 16279 Cover, Rear Valve, V-10, 180, T7/T9 1

o

34 15147 Plate, Back Valve Cover, V-10 6 Spool 1

35 15148 Plate, Top Valve Cover, V-10 6 Spool 1

36 22025 Bolt, 1/4" x 3/4" NC Gr8, T5C/T5D/T6/T7/T9/Sweeper 3

37 24008 Washer, 1/4" Flat USS 13

38 22045 Bolt, 5/16" x 3/4" NC Gr8 Z 7

39 28504 Nut, 1/4" NC Lock Z 3

40 22212 Bolt, 5/16" NC x 4 1/2" L, Gr8 Z 3

41 17257 Spacer, Boom Hose 3

42 17258 Spacer, Swing Hose Guide 1

43 22213 Bolt, 5/16" NC x 7" L, Gr 8 Z 1

44 28020 Washer, 5/16", Lock Z 4

45 23003 Nut, 5/16-18, Hex NC 4

46 17256 Stop, Plastic Swing 2

47 81222 Cylinder, Boom, T7 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.53

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 60

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

Tooth Caps

4

1

ITEM PART NUMBER DESCRIPTION QTY.

2 3

1 10500 Cap, Tooth, Standard Pin, T5C/T5D/T6/T7/T9 NA

2 10590 Cap, Tooth, Tiger NA

3 10591 Cap, Tooth, Tiger, HD NA

4 10530 Roll Pin, Tooth Cap, SD NA

ROLL PIN

Not Shown

Position machine must be in to check proper level in hydraulic tank.

NOTE: Filling tank with loader or backhoe in any other position will result in overfilling and spillage of fluid

through the breather cap. Replace cap if oil should ever spill out of breather cap since it will clog off

the air supply that the systems needs to operate properly.

Loader arm lifted off ground a few inches. Backhoe dipper fully extended

Front loader bucket curled back Backhoe Bucket curled all the way back

Backhoe boom in full raised position

WWW.TERRAMITE.COM

Charleston, WV/USA

2.54

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 61

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

Hydraulic System Oil Change and Type Specifications

When your machine is new, the hydraulic system oil and filter should be changed within the first 50

hours of use and every 250 thereafter. Refill the hydraulic reservoir with engine oil type API SF.CD

15W40 when outside temperature is above 40 degrees F. Use engine oil type API SF.CD 10 weight

when outside temperature is below 40 degrees F. Replace filter with Terramite / 2-200.5C filter or

NAPA / 1759 filter. It is important to follow these instructions to alleviate any cold weather engine

starting problems and any pressure or heat related component failure.

DO NOT USE HYDRAULIC OIL!

MAJOR DAMAGE WILL RESULT!

For your engine oil requirements and change intervals refer to your engine owners manual.

On Hand Spare Parts

Following is a list of spare parts we recommend you keep on hand.

Oil, Fuel and Air Filters

One of each size Cylinder Packing Kit (specify serial number of machine when ordering)

Grease Fittings

One each of a longest length and medium length Hoses and spare Cylinder Fittings

Tie Rod End

Pedal Return Spring

Wheel Bearings

Tooth Caps with Pins

Assortment of long, medium and short Pins

Control Valve Linkage Parts and Cotter Pins

Special Tools

ITEM PART NUMBER DESCRIPTION QTY.

1 10599 1-05.SDT Punch, for 1-05.SD & TT Tooth Caps 1

2 21176 A-176 Spanner wrench for cylinder repair 1

WWW.TERRAMITE.COM

Charleston, WV/USA

2.55

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 62

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

Decal Location - Front Arms

1

2

1

ITEM PART NUMBER DESCRIPTION QTY.

2

1 14194 Decal, Black, TMC Jumbo Logo, T6/T7/T9/Sweeper 1

2 16181 Kit, Complete, Skid Tape, T5D/T7/T9/T6 2

WWW.TERRAMITE.COM

Charleston, WV/USA

3.1

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 63

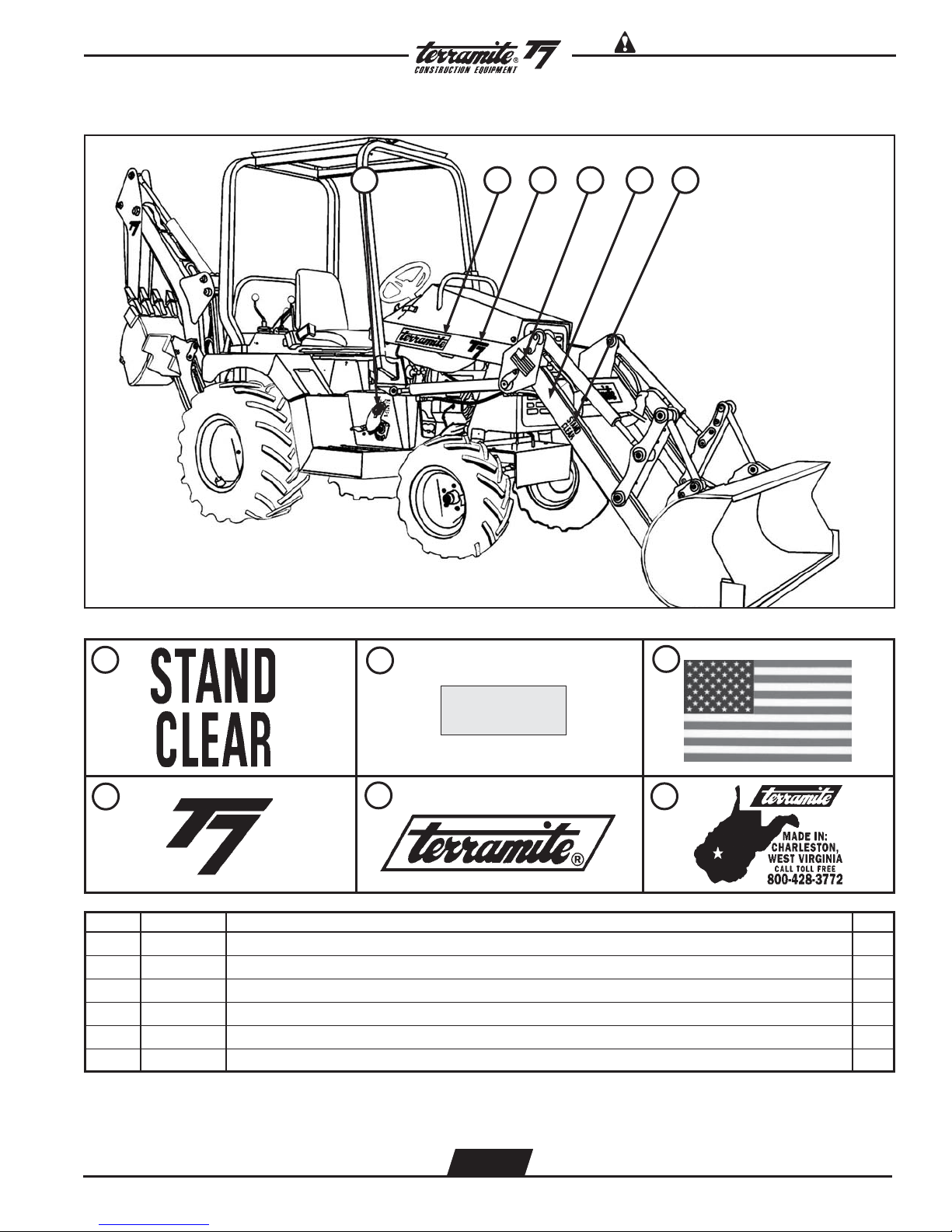

Decal Location - Side View

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

123456

1

4

ITEM PART NUMBER DESCRIPTION QTY.

2

5

3

6

1 14004 Decal, Stand Clear, Red, T5C/T5D/T6/T7/T9 4

2 14021 Decal, Reflector, Amber, T5C/T5D/T6/T7/T9 2

3 14099 Decal, American Flag, T5C/T5D/T6/T7/T9 2

4 14001 Decal, Terramite, Large, T5C/T5D/T6/T7/T9 2

5 14214 Decal, Black, Small, T7 2

6 14070 Decal, Black, W.V., T5C/T5D/T6/T7/T9/Sweeper 2

WWW.TERRAMITE.COM

Charleston, WV/USA

3.2

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 64

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

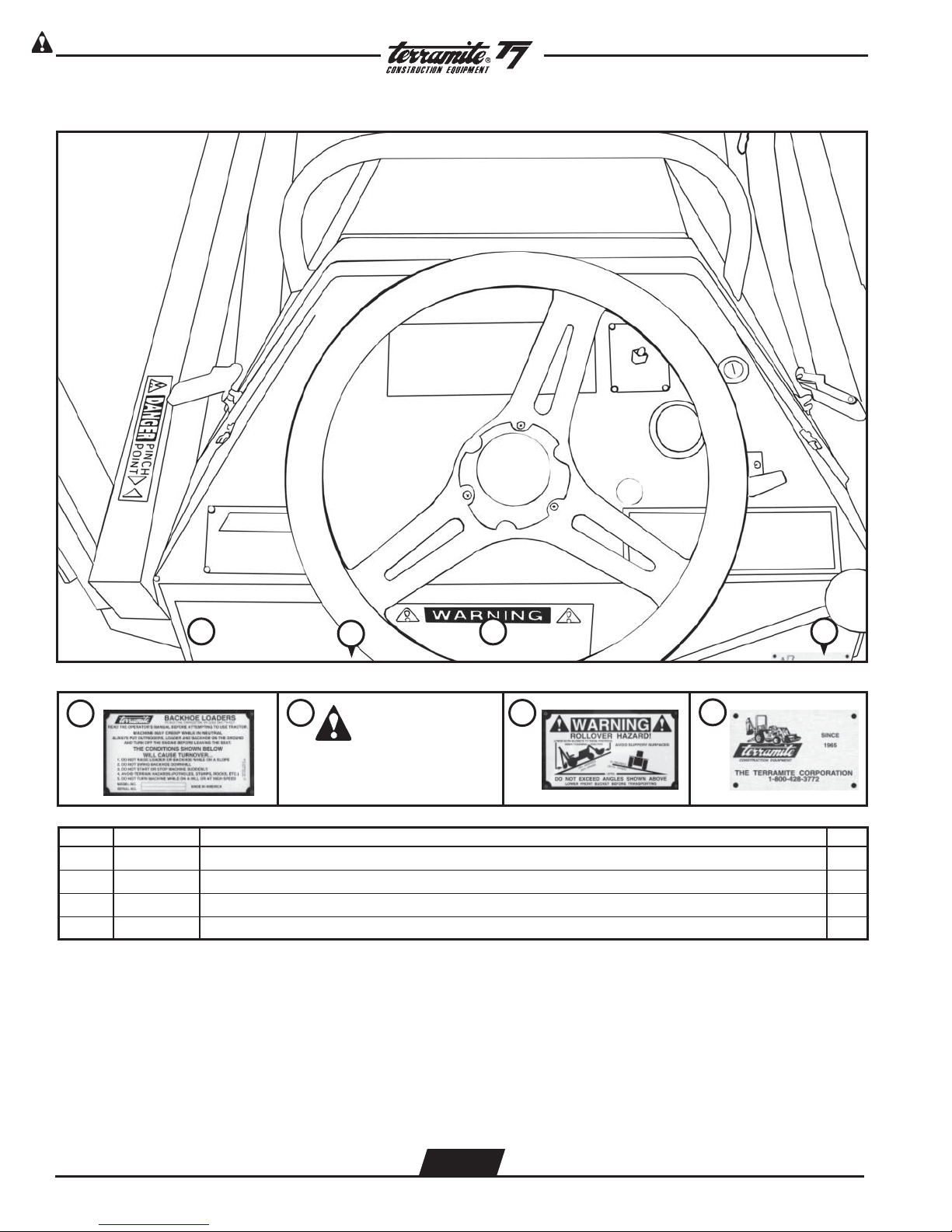

Decal Location - Dash

2

1

ITEM PART NUMBER DESCRIPTION QTY.

1 14203 Decal, Read Operators Manual, T5D/T6/T7/T9 1

2 14220 Decal, Danger, Parking Brake - NIU 1

3 14202 Decal, Warning Roll Over, T5D/T6/T7/T9 1

4 14024 Decal, Plate, TMC Starting 1965 1

2 3

DD

ANGERANGER

D

ANGER

DD

ANGERANGER

SET PARKING BRAKE

AND LOWER BUCKETS TO

GROUND WHEN MACHINE

IS NOT IN USE.

31

4

4

WWW.TERRAMITE.COM

Charleston, WV/USA

3.3

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 65

Decal Location - Dash (Diesel Shown)

1 2 3 4 5

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

67

1

DANGER

Front Work Lights

4

PINCH

POINT

5

MODEL NO.

SERIAL NO.

CHARLESTON, WV 25313 1-304-776-4231

MADE IN USA

6 7

KEEP SHIELDS, GUARDS AND SFETY DEVICES IN PLACE

KEEP HANDS AND FEET FROM MOVING PARTS

NEVER LET CHILDREN RIDE ON OR OPERATE THE TRACTOR

BE ALERT FOR DANGER TO BYSTANDERS AND PROPERTY

HANDLE FUEL WITH CARE AND USE APPROVED CONTAINERS

KEEP MACHINE LUBRICATED AND IN A GOOD STATE OF REPAIR

SAFETY FIRST

PN/ 14201

Throttle

Rear Work Lights

ITEM PART NUMBER DESCRIPTION QTY.

1 14100 Decal, Pinch Point, T5C/T5D/T6/T7/T7/T9 2

2 14012 Decal, Serial Number Plate, T5D/T7/T9/SCR/Sweeper/Dozer 1

3 14201 Decal, Safety First, T5D/G/T6/T7/T9 1

4 14104 Decal, Work Lights, Plate F&R, T5D/T6/T7/T9 1

5 14105 Decal, Throttle Plate, T5D/T6/T7/T9 1

6 14053 Decal, Call Before U Dig 1

7 14204 Decal, Controls, Front Bucket, T5D/T6/T7/T9 1

WWW.TERRAMITE.COM

Charleston, WV/USA

3.4

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 66

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

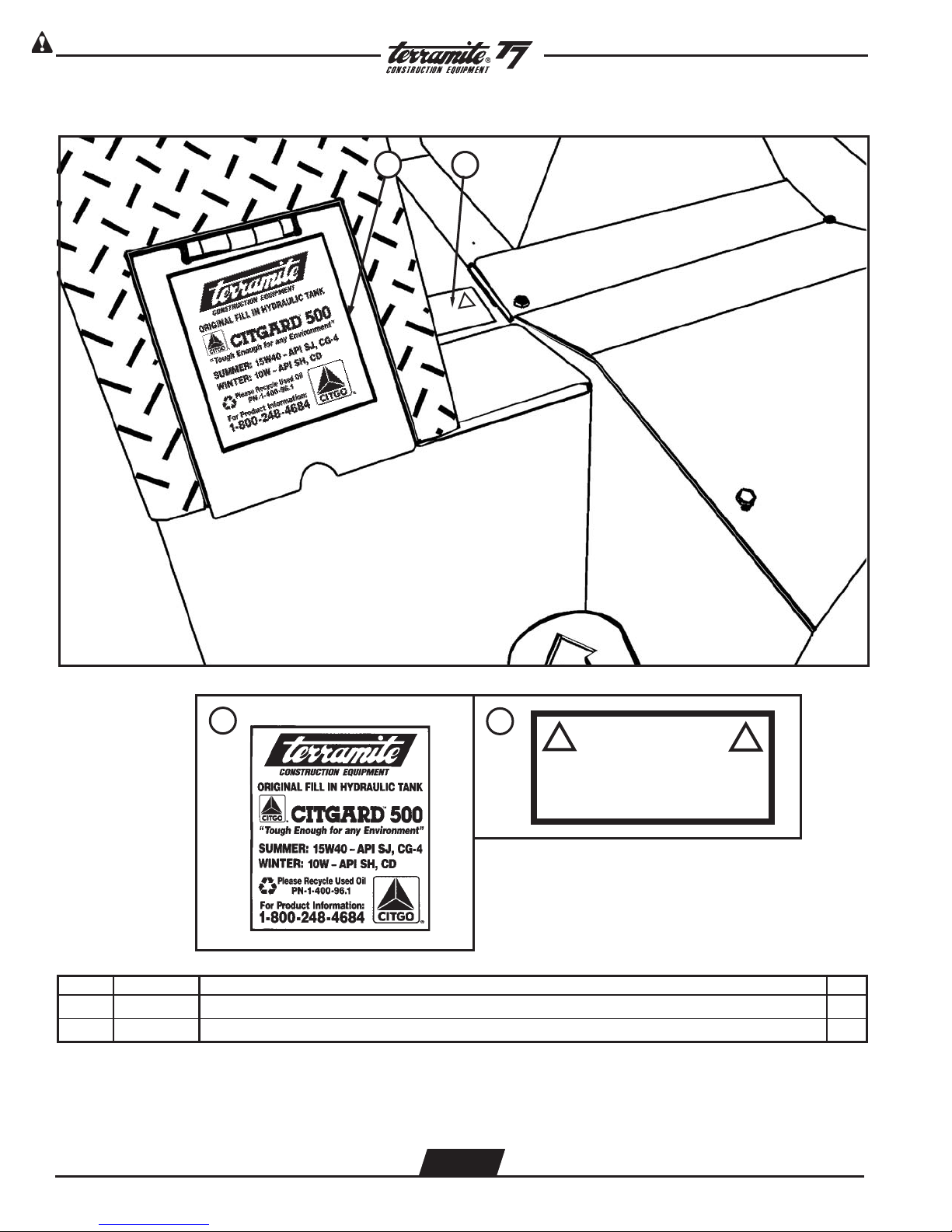

Decal Location - Right Fender

1

2

!

1

ITEM PART NUMBER DESCRIPTION QTY.

2

CAUTION

!

Regular hydraulic fluid in this system

will cause premature transmission failure.

Above 32 F use 15w40 API SG CD or equivalent.

Below 32 F use 10w API SG CD

!

Terramite Corp. PN

1-400-98

1 14017 Decal, Oil, Citgo/Terramite, T5C/T5D/T6/T7/T9 1

2 14098 Decal, Caution, Hydraulic Premature Failure, T5C/T5D/T6/T7/T9 2WD 1

WWW.TERRAMITE.COM

Charleston, WV/USA

3.5

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 67

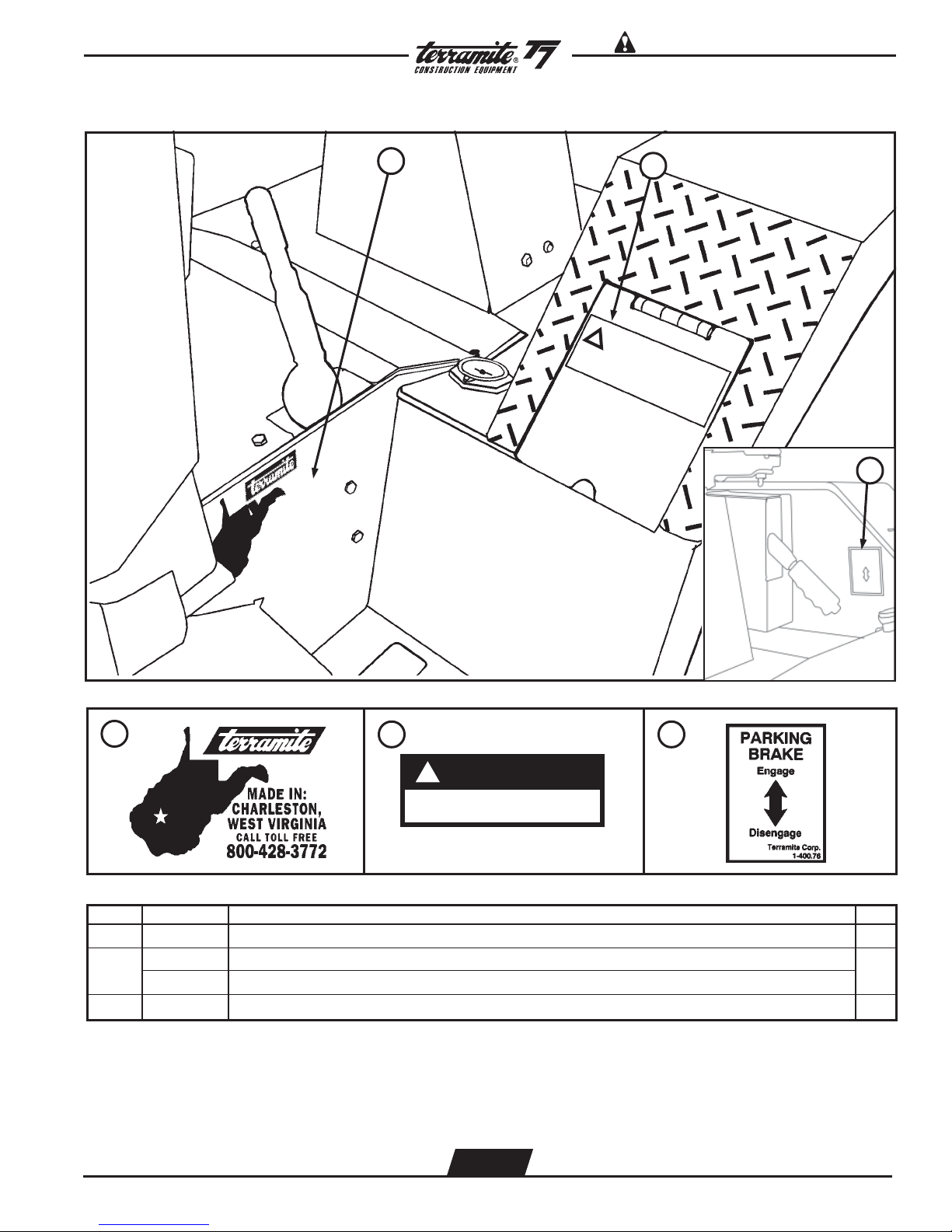

Decal Location - Left Fender

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

1

2

!

3

1

ITEM PART NUMBER DESCRIPTION QTY.

2

!

DANGER

DIESEL FUEL ONLY

NO SMOKING NO OPEN FLAMES

3

1 14070 Decal, Black, W.V., T5C/T5D/T6/T7/T9/Sweeper 1

2

14071 Decal, Diesel Fuel Only, T5C/T5D/T6/T7/T9

14051 Decal, Gasoline Only, T5C/T5D/T7

3 14076 Decal, Parking Brake 1

WWW.TERRAMITE.COM

Charleston, WV/USA

3.6

USA 1.800.428.3772

Intl. 1 .304.776.4231

1

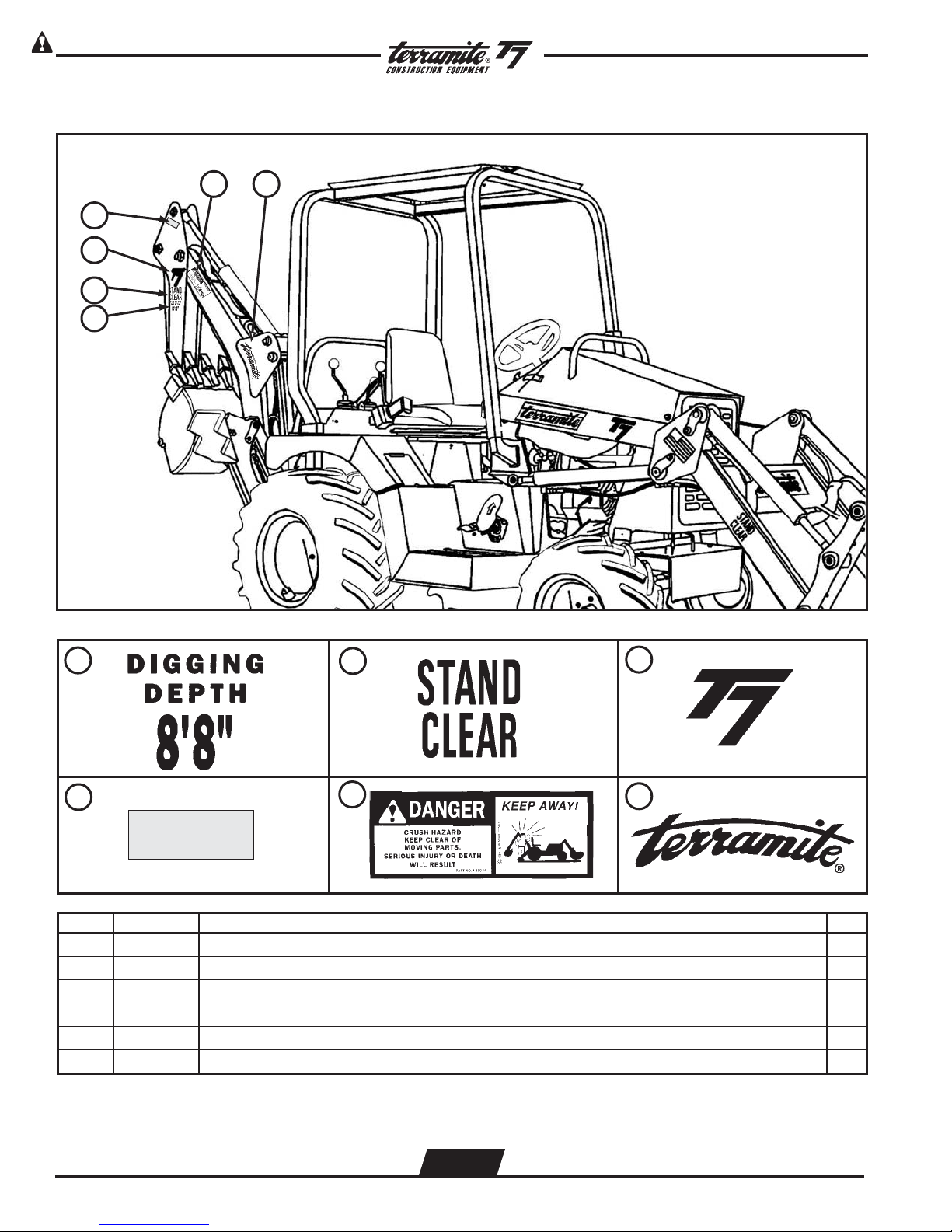

Page 68

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

Decal Location Side View (continued)

5

4

3

2

1

6

1

4

ITEM PART NUMBER DESCRIPTION QTY.

2

5

PN/ 14054

3

6

1 14093 Decal, Digging Depth 8'8", T5D/T7 2

2 14004 Decal, Stand Clear Red, T5C/T5D/T6/T7/T9 4

3 14159 Decal, Black, Large, T7 2

4 14022 Decal, Reflector, Red, T5C/T5D/T6/T7/T9 2

5 14054 Decal, Warning, Crush Hazard, T5C/T5D/T6/T7/T9 2

6 14107 Decal, Black, Radius, Terramite, T6/T9 2

WWW.TERRAMITE.COM

Charleston, WV/USA

3.7

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 69

Decal Location - Rear Valve

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

1

2

3

1

2

READ

OWNER’S

MANUAL

BEFORE

OPERATING

ITEM PART NUMBER DESCRIPTION QTY.

3

BOOM LATCH

TO ENGAGE

BOOM LATCH

1. Raise boom to

full UP position

2. Using control

cable, lower boom

latch onto pins

3. Lower boom

to lock position

TO DISENGAGE

BOOM LATCH

1. Raise boom to

full UP position

2. Pull handle and

turn clockwise

to lock boom latch

in disengaged

position

3. Operate backhoe

TMC P/N 14112

1 14284 Decal, Operator Danger T7/T9 1

2 14207 Decal, Vertical, Read Owners Manual, T5C/T5D/T6/T7/T9 1

3 14112 Decal, Boom Latch Operator, T7/T9 1

WWW.TERRAMITE.COM

Charleston, WV/USA

3.8

USA 1.800.428.3772

Intl. 1 .304.776.4231

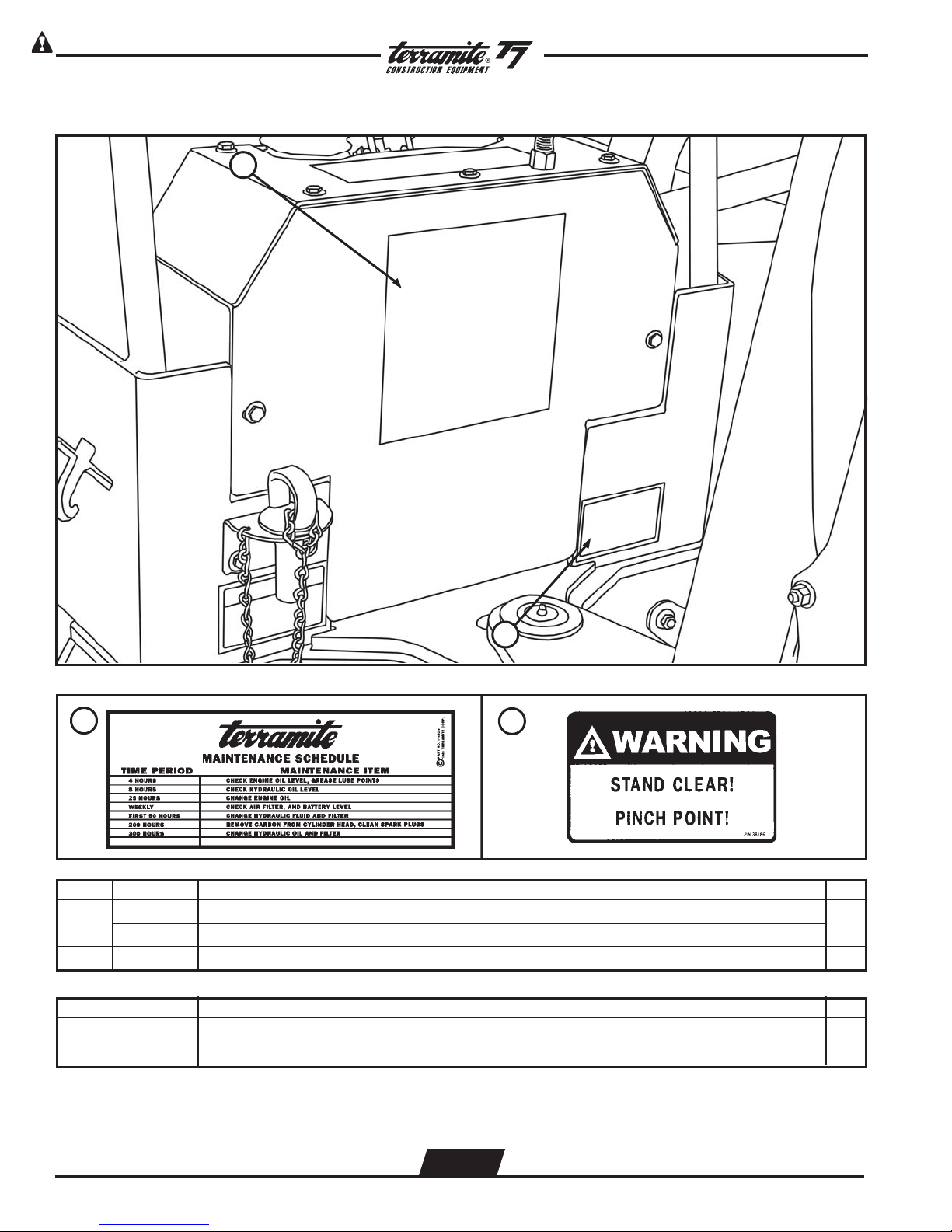

Page 70

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

Decal Location - Rear Valve (Continued)

1

2

1

ITEM PART NUMBER DESCRIPTION QTY.

1

14510 Decal, Maintenance Diesel Only

14005 Decal, Maintenance Gas Only

2

2 38186 Decal, Pinch Point, Stand Clear, T7/T9/Sweeper 2

PAINT

08026 Paint, Yellow, Spray Can Dupont Paint Code #G 9325A 1

08037 Paint, Gray, Spray Can 1

1

WWW.TERRAMITE.COM

Charleston, WV/USA

3.9

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 71

T5D/T7 Pin Chart (Straight Boom)

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

WWW.TERRAMITE.COM

Charleston, WV/USA

4.1

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 72

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

T5D/T7 Pin Chart (Straight Boom)

T5D PINS

ITEM P/N DESCRIPTION SIZE

1 13200 FRONT BUCKET/ARMS 1” x 4 3/4”

2 17176 ARM LINK/ARM CYLINDER 1” x 5 1/2”

3 17178 ARM LINK/ARM - TAPPED 1” x 5 1/2”

4 17179 ARM BUCKET/FRONT CURL 1” x 5 1/2”

5 12600 ARM CYLINDER/ARMS 1” x 5 1/4”

6 12300 ARM/FRAME 1” x 6 7/8”

7 12301 ARM CYLINDER/FRAME 1” x 7 7/8”

8 17198 ARM/CYLINDER/FRAME 1” x 8 1/2”

9 10700 CROWD & REAR CURL CYLINDER/DIPPER 1” x 6 7/8”

10 17031 LINKAGE CURL/CYLINDER 1” x 7 3/8”

11 10206 R.C. CYLINDER/BUCKET Q.D. & BOOM LATCH 1” x 6 1/2”

12 19072 REAR BUCKET PULL 1” x 8 1/2”

13 17190 Q.A. BUCKET 1 1/4” x 8 1/4”

14 10812 DIP/LINKAGE 1 1/4” x 7 5/8”

15 10701 BOOM/DIPPER 1 1/4” x 7 1/4”

16 11100 CRD-BM CYL/BM,O.R/FRAME 1” x 6 1/4”

17 10410 BOOM CYL./SWING 1 1/4” x 7 3/4”

18 10400 DIP/BKT,BOOM/SWING 11/4” x 8 1/4”

19 11502 OUTRIGGERS 1” x 4 1/8”

20 17156 OUTRIGGER PAD - PULL PIN 1” x 5 1/4”

21 17020 SWING CYL/FRAME 1” x 6 5/8”

22 15300 SWING CYL/SWING 1” x 4 1/8”

23 11140 SWING 1 1/4” x 18”

24 17174 BOOM LOCK 1 1/4” x 11”

WWW.TERRAMITE.COM

Charleston, WV/USA

4.2

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 73

T7 Pin Chart (Curved Boom Prior 1/1/01)

Read Operators Manual For SafetyPARTS MANUAL

Copyright © 2007 Terramite Corporation

WWW.TERRAMITE.COM

Charleston, WV/USA

4.3

USA 1.800.428.3772

Intl. 1 .304.776.4231

Page 74

Read Operators Manual For Safety PARTS MANUAL

Copyright © 2007 Terramite Corporation

T7 Pin Chart (Curved Boom Prior 1/1/01)

T7 CURVED BOOM PINS

ITEM P/N DESCRIPTION SIZE

1 13200 FRONT BUCKET/ARMS 1” x 4 3/4”

2 17176 ARM LINK/ARM CYLINDER 1” x 5 1/2”

3 17178 ARM LINK/ARM - TAPPED 1” x 5 1/2”

4 17179 ARM BUCKET/FRONT CURL 1” x 5 1/2”

5 12600 ARM CYLINDER/ARMS 1” x 5 1/4”

6 12300 ARM/FRAME 1” x 6 7/8”

7 12301 ARM CYLINDER/FRAME 1” x 7 7/8”

8 17198 ARM/CYLINDER/FRAME 1” x 8 1/2”

9 10700 CROWD & REAR CURL CYLINDER/DIPPER 1” x 6 7/8”

10 17031 LINKAGE CURL/CYLINDER 1” x 7 3/8”

11 10206 R.C. CYLINDER/BUCKET Q.D. & BOOM LATCH 1” x 6 1/2”

12 19072 REAR BUCKET PULL 1” x 8 1/2”

13 17190 Q.A. BUCKET 1 1/4” x 8 1/4”