Safety Tips

Safety is a prime consideration in the design of this

machine. Guards, shields and other safety features are

built in wherever possible. However, accident reports

show carelessness causes the majority of accidents. You

can avoid most accidents by observing the safety rules on

these pages. Study these rules carefully and enforce them

on the job:

Never allow minors to operate or be in the

vicinity of the machine while working.

Do not allow the T5C to be operated by anyone

who is intoxicated or on medication that would affect

their judgement or ability to operate the machine.

The machine is designed to be operated by

adults who are of average size and weight. Persons

who are extremely heavy, big or tall, or those who

are exceedingly short, light or weak can not run the

machine.

Before Operating the Terramite T5C

Read the Operator's Handbook. Never

allow anyone to operate the backhoe without

reading the Operator's Manual and Safety

Instructions. This should be followed by supervised

training.

Check Your Equipment. Always make a

complete inspection of the machine before

operating it that day. Check the hydraulic system

and the engine oil level. Then check the machine

for broken, missing or defective parts. Check the

tires for cuts, bulges, irregularities and abnormal

wear and proper inflation. Check the neutral

position of the foot pedal. A malfunctioning

machine invites accidents.

"Do Not Operate" Tag. When you service

the machine, put a "DO NOT OPERATE" Tag on

the instrument panel. This tag (Terramite Part

Number 1-400.82) is included with each machine.

Keep Your Machine Clean. Slippery

surfaces are hazardous. Remove oil, grease or mud

from the operating area of the tractor. Failure to

keep these areas clean could cause a serious

accident.

Wear What is Needed for Protection.

Protect yourself by wearing all the protective

clothing and personal safety devices issued to you

or required by job conditions. You may need a hard

hat, safety shoes, safety glasses, heavy gloves,

hearing protection, reflective clothing, wet weather

gear and a respirator. Never take chances by wearing

loose clothing, watches or rings.

Look For Hazards. Walk around a new work

area and check for any hidden hazards, such as holes

and abutments.

Read and Heed Safety Decals. Make sure

the safety and information decals can be easily read.

To clean decals, use soap and water only. Gasoline

or solvents will destroy the decals. If these decals

are missing or illegible, call our Parts/Service

Department for replacements.

Roll-Over Protective Structure. All

Terramite T5C tractor loader backhoes are equipped

with a Roll-Over Protective Structure. This is

designed to protect the operator in the event of a

roll-over. If this machine has been rolled over, the

R.O.P.S. must be replaced. It is designed to be used

only once.

Driving Pivot Pins. When driving pivot pins

in or out, use care to guard against injury from

particles that may chip off the pin or object used in

striking the pin. These pins can fly out at high speed

if they are not tapped lightly just before they come

out. Make sure there isn't anyone or anything in

the way, in case the pin flies out. Safety glasses

should be worn.

See Operator's Manual For More Safety Information

1.1

Before Your Start

READ OPERATOR'S HANDBOOK

Carefully read all WARNING! and DANGER! messages in handbook

and be sure you understand their meanings.

IMPORTANT! If this machine is used by the owner, an employee, or is

loaned or rented, make sure that the following instructions are complied

with:

1. The operator has read the Operation and the Safety Rules

sections of the Operator's Handbook.

2. He has been instructed on the safe and correct use of the

machine.

3. He has practiced operating the machine and the use of all

controls in a safe, clear area before he operates the machine on a

job site.

4. He has read all safety decals on the machine.

5. He has been informed to clear the area of other persons and

hidden hazards before starting the machine.

1.2

Table of Contents

Safety - Important ................................................ 1.1

Before Operating the Terramite T5C................... 1.2

Section Two: HYDRAULICS

Oil Change and Type Specifications .................... 2.1

Front with Loader Arm Assembly Raised ............. 2.2

Loader Valve Hoses and Fittings

Under Fuel Tank Hood Assembly ........................ 2.3

Transmission Assembly ......................................... 2.4

Rear Valve ...................................................... 2.5-2.7

Gear Pump Part #66045 ...................................... 2.8

Rod Assembly ....................................................... 2.9

Hydrastatic Transmission .................................... 2.10

Hydraulic Main Power Circuits(Gas Model) ...... 2.11

Hydraulic Main Power Circuit ........................... 2.12

Loader Circuit .................................................... 2.13

Woddlestick Hose Diagram Backhoe Circuit ..... 2.14

MAB/MAE Torquemotor Exploded................... 2.15

Power Steering Column Exploded ..................... 2.16

Schematic - Backhoe Control Valve .................. 2.17

Parts Ordering Information ................................ 2.18

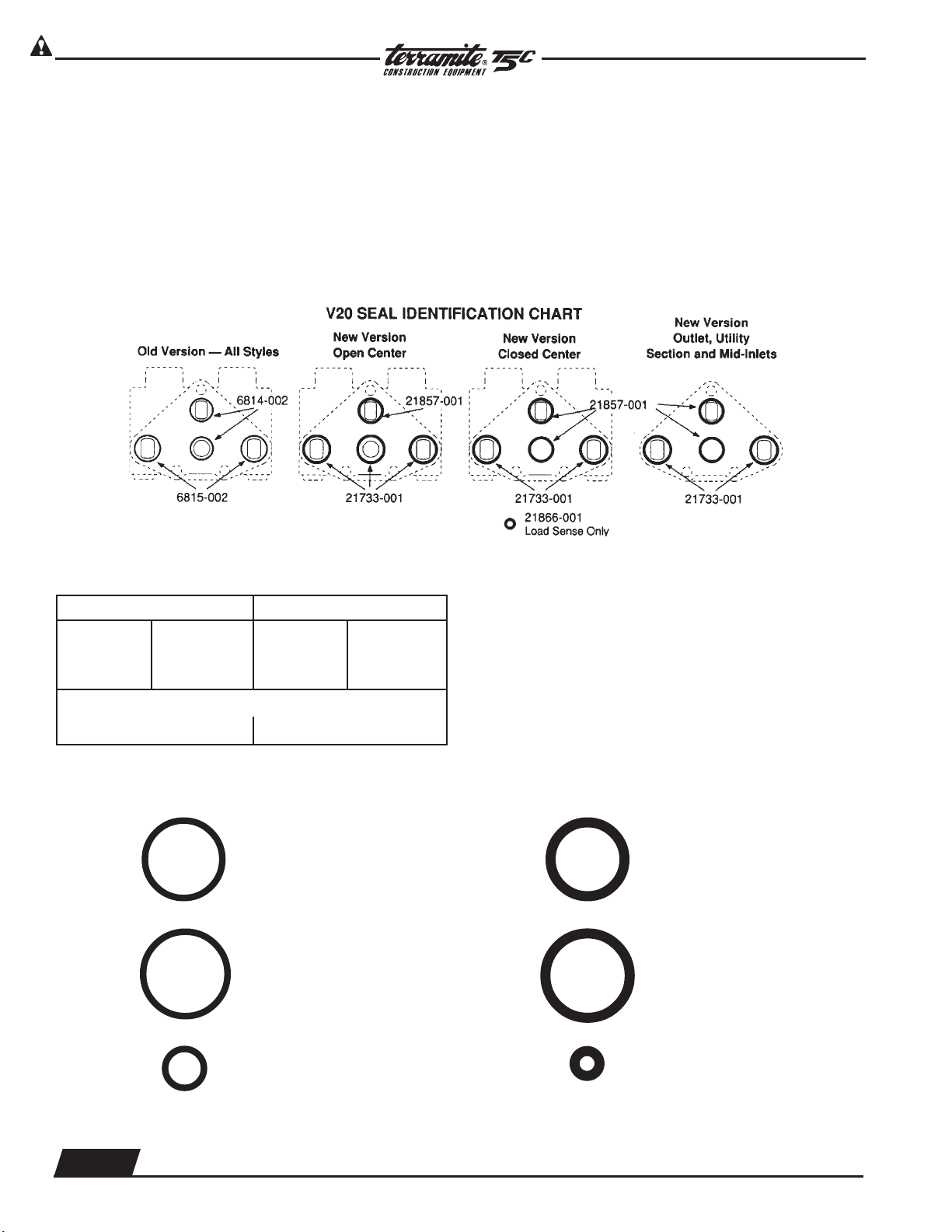

V20 Seal Identification Chart

Loader Valve ...................................................... 2.19

4-Way, 3-Position Valve Section ......................... 2.20

Loader Check Plug / High Pressure Releif .......... 2.21

Section Four: ELECTRICAL WIRING

Diagram Kohler Magnum 20 HP ......................... 4.1

Diagram Kohler Command 20/25 HP .................. 4.2

Harness/A-Kohler Command ............................... 4.3

Diagram Honda 20 HP ........................................ 4.4

(Pre - 1997 Model) .......................................... 4.5

Harness/A-Relay Harness ..................................... 4.6

Harness/Honda Engine ........................................ 4.7

Harness/Honda Voltage Regulator Harness/

A-Relay Harness ............................................... 4.8

Harness - Honda Dash ......................................... 4.9

Section Five: OPTIONS

Tires ..................................................................... 5.1

Work Lights and Canopy/Mounted Lights

Strobe Light ..................................................... 5.2

Clam Shell 4 in 1 Bucket ..................................... 5.3

Under Dash for Clam Shell 4 in 1 Bucket ........... 5.4

Drive Position

Dash for Clam Shell Buck ................................ 5.5

Street Pads/Flip Over Pads/Tooth Caps ................ 5.6

Quick Attach Backhoe Buckets (After 5-1-98) ... 5.7

Auger (Bradco./McMillen)................................... 5.8

Auger Connections .............................................. 5.9

Back-up Alarm and Connections....................... 5.10

Section Three: COMPONENTS

Seat Assembly ...................................................... 3.1

Exploded View of Front End Loader .................... 3.2

Exploded View of Dash ........................................ 3.4

Under the Hood - Kohler Command Engine ....... 3.6

Drive Shaft Coupler ............................................. 3.7

View from Behind Center Steer ........................... 3.8

View from Behind Dash ..................................... 3.10

Front Wheel Hubs / Hub Assembly and Spindle 3.12

Front / Rear Tires and Rims ................................ 3.13

Parking Brake Assembly ..................................... 3.14

Retro Fit Parking Brake Spring Assembly ........... 3.16

Front of Rear Axle - Parking Brake Assembly .... 3.16

Exploded View of Dipstick ................................. 3.17

Backhoe Assembly ............................................. 3.18

Rear Axle Assembly ........................................... 3.20

Pin Schematic .................................................... 3.22

General Tightening Torque for Bolts, Nuts

and Taperlock Studs ........................................... 3.23

Decal Location Right Side ................................. 3.24

Decal Location - Dash ....................................... 3.25

Decal Location - Rear ........................................ 3.26

Couplings ........................................................... 3.27

Section Six: TRANSLATIONS

Translations ................................................ 6.1 to 6.6

Section SEVEN: INDEX & SAMPLE WARRANTY

Index .......................................................... 7.1 to 7.5

Sample Warranty .................................................. 7.6

RECORDS

Serial Number _________________________

Model# ______________________________

Engine Type: __________________________

Engine Serial Number: __________________

Accessories: ___________________________

____________________________________

____________________________________

____________________________________

1.3

1.4

Read Operators Manual For Safety

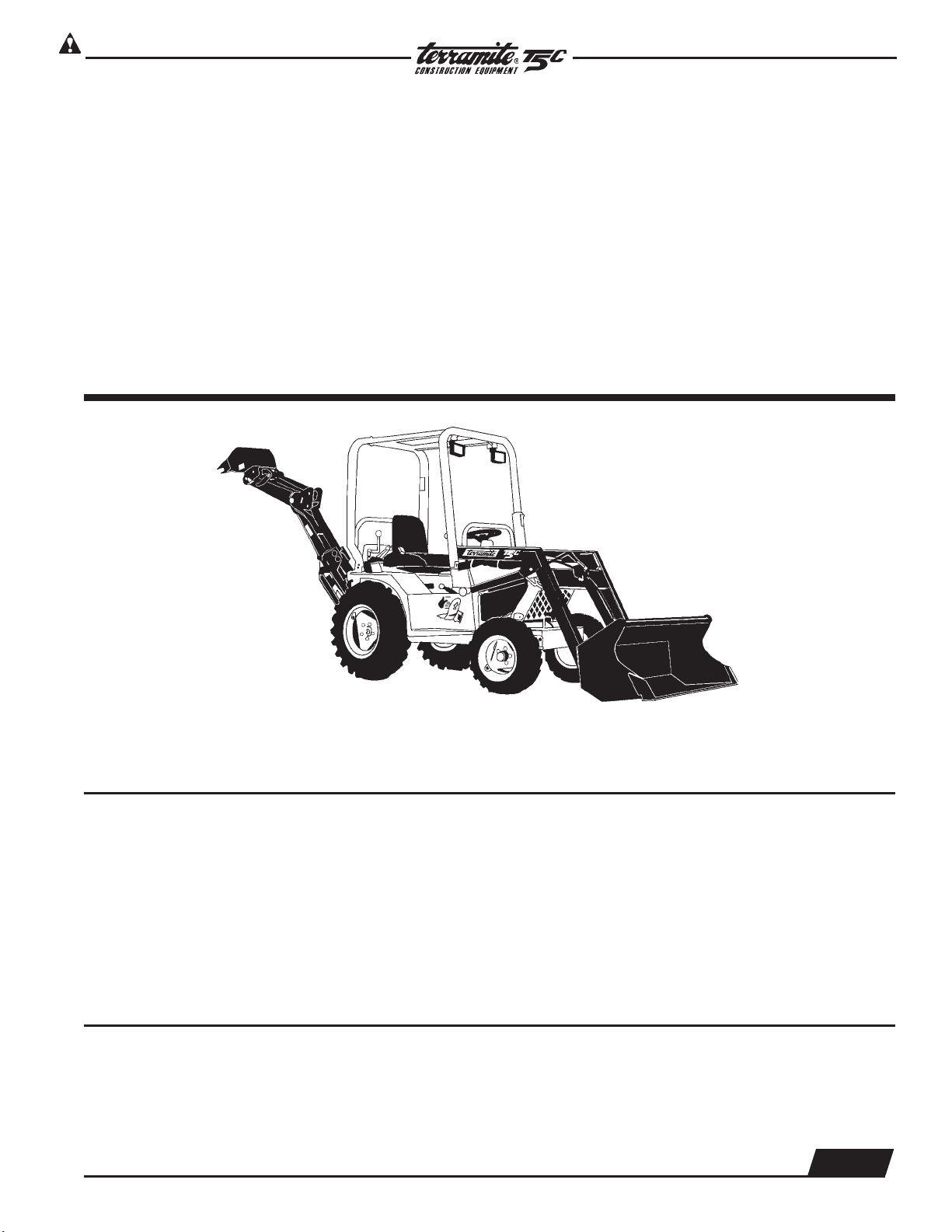

PARTS MANUAL

Hydraulics

Oil Change and Type Specifications

When your machine is new, the hydraulic system oil and filter must be changed within the first 50

hours of use and every 250 thereafter. Refill the hydraulic reservoir with engine oil type API SF.CD

15W40 when outside temperature is above 40 degrees F. Use engine oil type API SF.CD 10 weight

when outside temperature is below 40 degrees F. Replace filter with Terramite / 21002 filter. It is

important to follow these instructions to alleviate any cold weather engine starting problems and any

pressure or heat related component failures.

DO NOT USE REGULAR HYDRAULIC OIL!

MAJOR DAMAGE WILL RESULT!

This is the position machine must be in to check proper level in

hydraulic tank.

Required Pre-Fuel Filter Changes for Gasoline and Diesel Machines

ALL Terramite Backhoes and Street Sweepers require their pre-fuel filters to be changed at the first

20 hours and again at 40 hours. These pre-fuel filters should be changed every 20 to 50 hours

thereafter using a 10 micron filter.

The following Pre-fuel filters are designed for gasoline and diesel engines.

Terramite 15506

NOTE:NOTE:

NOTE: Filling tank with loader or backhoe in any other position will result in overfilling and spillage of fluid

NOTE:NOTE:

through the breather cap. Replace cap if oil should ever spill out of breather cap since it will clog off

the air supply that the systems needs to operate properly.

1.800.428.3772

Intl. 1 .304.776.4231

WWW.TERRAMITE.COM/SAFETY

Copyright © 2006 Terramite Corporation

Charleston, WV/USA

2.1

Read Operators Manual For Safety

Hydraulics

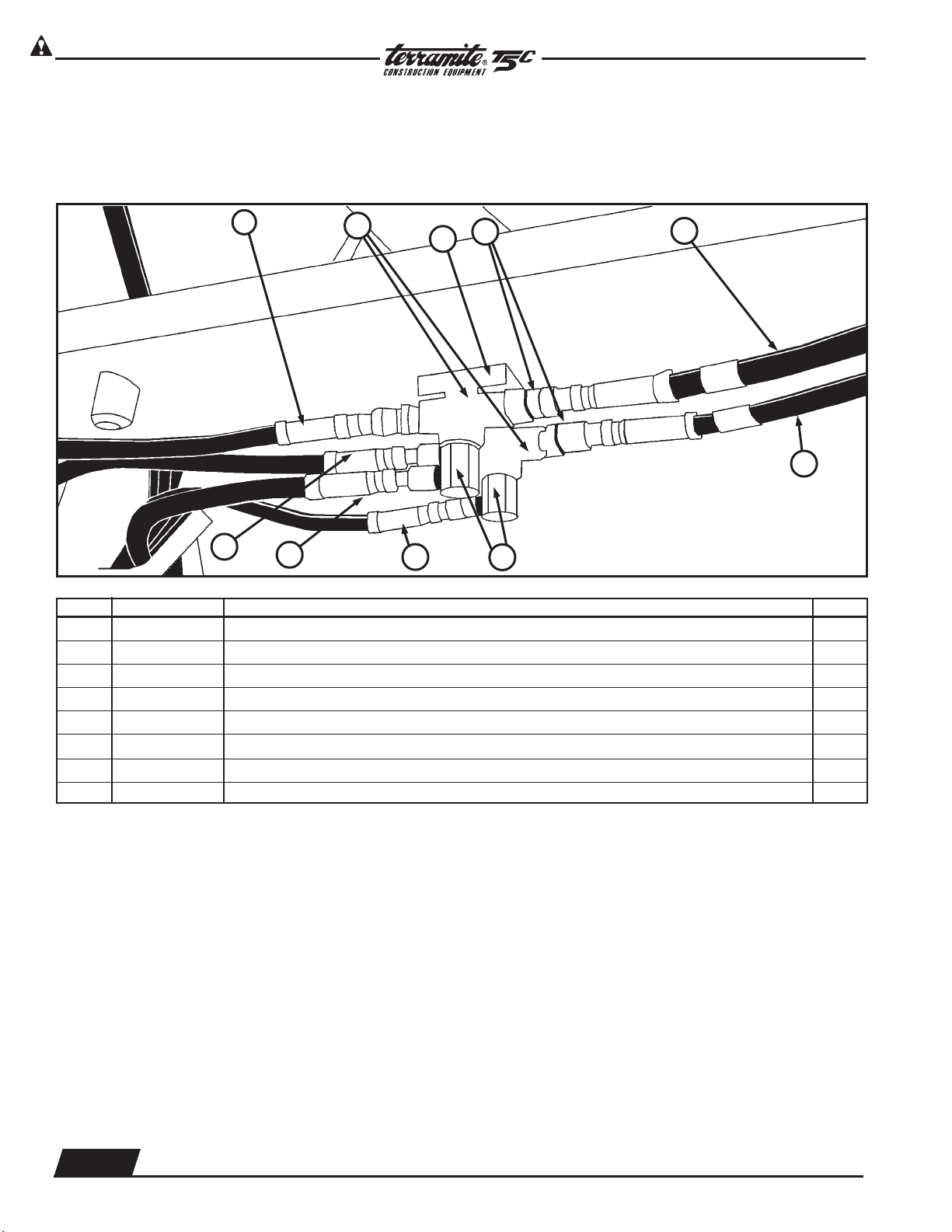

View from Front with Loader Arm Assembly Raised

PARTS MANUAL

1

4

ITEM PART NUMBER DESCRIPTION QTY.

7

2

6

3

8

5

1

4

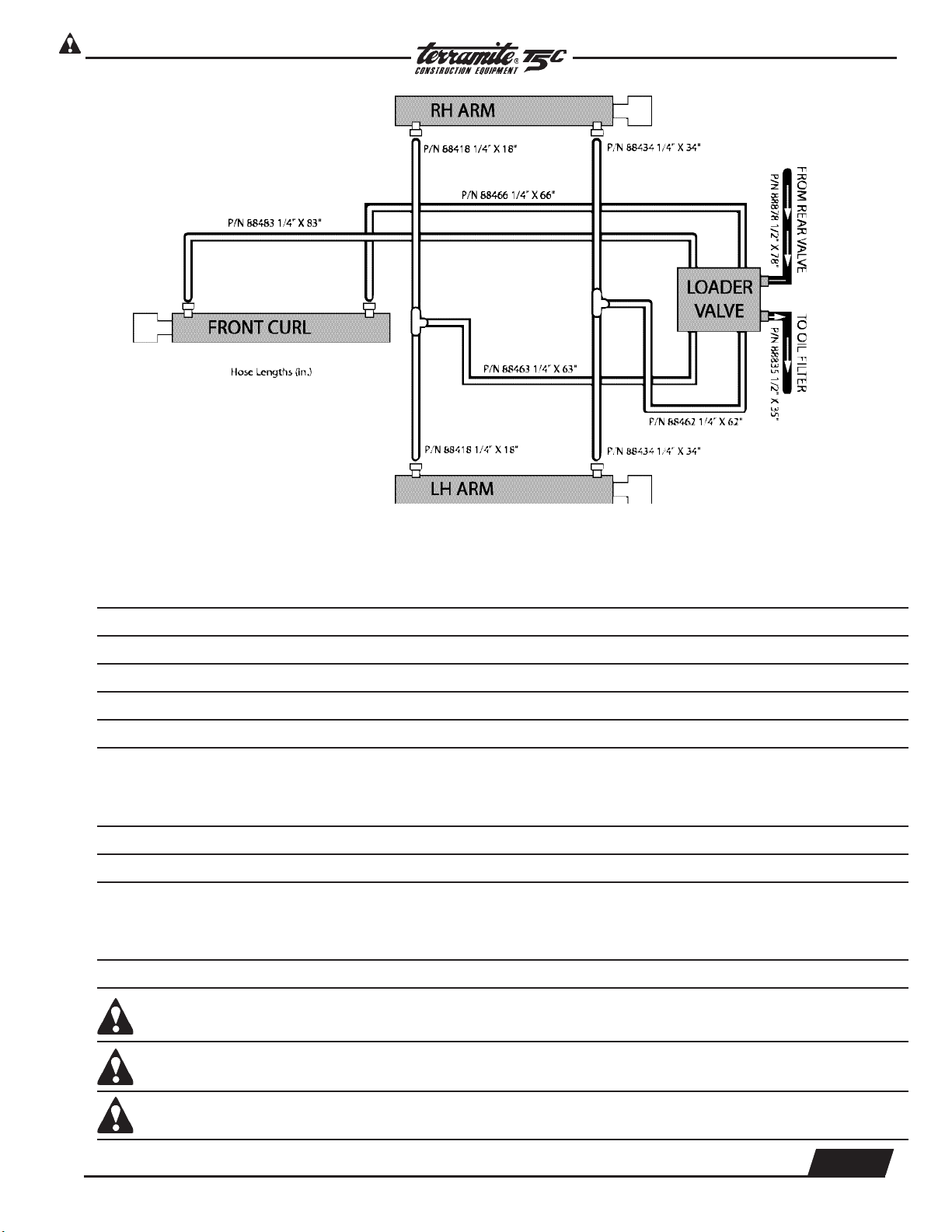

1 88418 Hose, 1/4" x 18" (front hose set) 2

2 22244 Fitting, 1/4" Tee (front hose set) 2

3 20174 Fitting, 1/4" (front hose set) 26

4 88434 Hose, 1/4" x 34" (front hose set) 2

5 22174 Fitting, 1/4" x 90° (front hose set) 5

6 88462 Hose, 1/4" x 62" (front hose set) 1

7 88463 Hose, 1/4" x 63" (front hose set) 1

8 12033 Distributor Block 1

2.2

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

Copyright © 2006 Terramite Corporation

1.800.428.3772

Intl. 1 .304.776.4231

Read Operators Manual For Safety

PARTS MANUAL

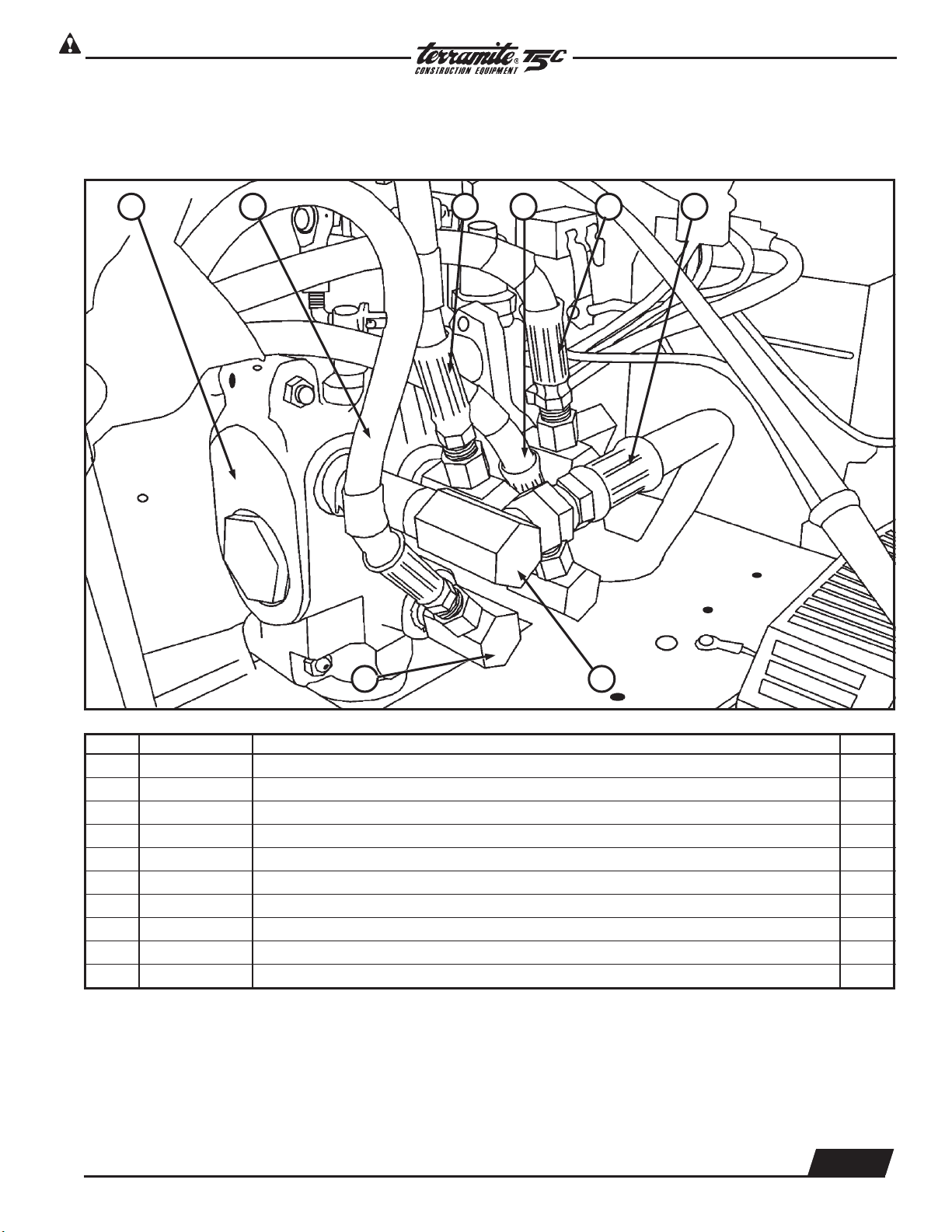

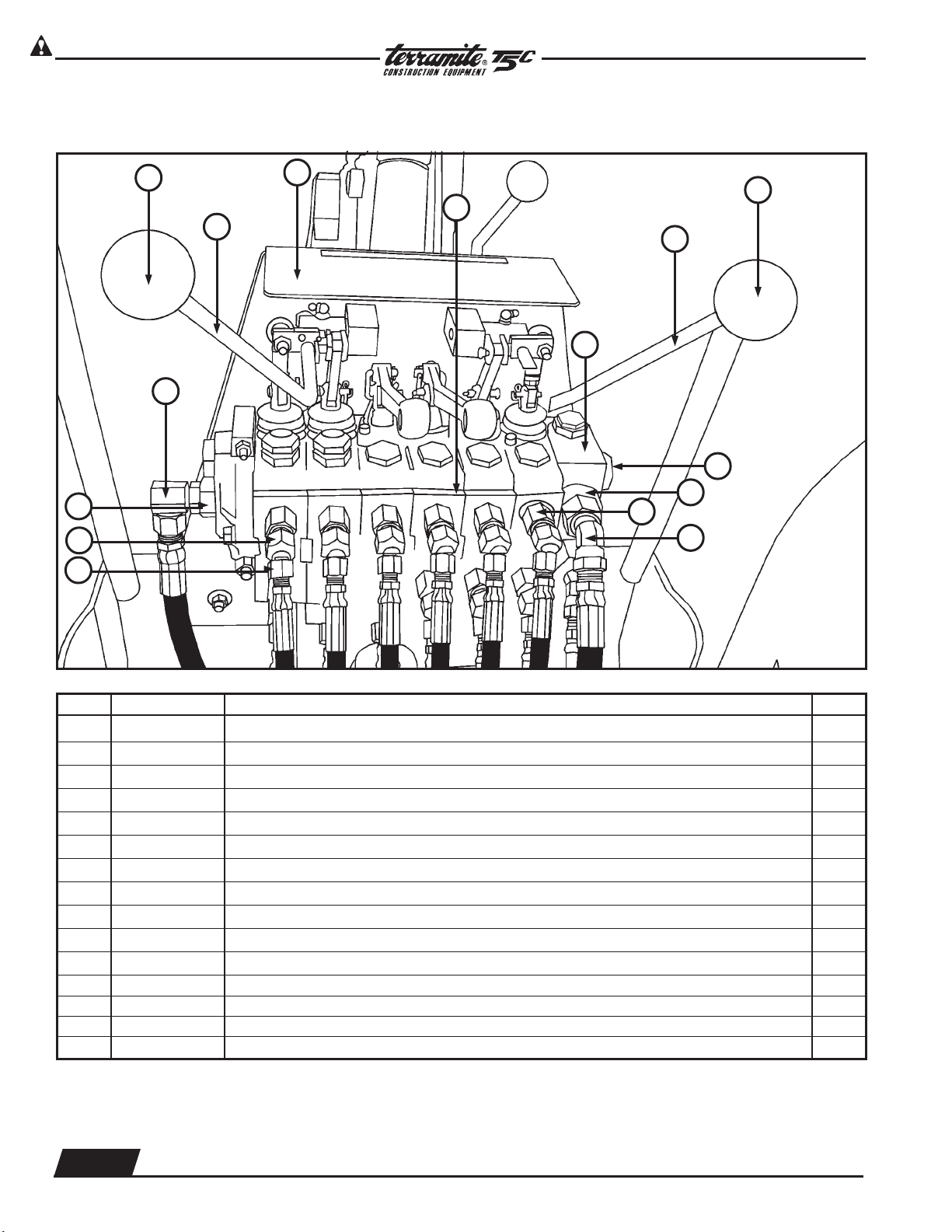

View of Loader Valve Hoses and Fittings from Right Side of Engine

Compartment Under Fuel Tank Hood Assembly

1 2 3 4 5 6

Hydraulics

78

ITEM PART NUMBER DESCRIPTION QTY.

1 85015 Valve, Loader(No Fittings) 1

1 84070 Valve, Loader(With Fittings) 1

2 88483 Hose, 1/4" x 83", Loader Valve 1

3 88466 Hose, 1/4" x 66", Loader Valve 1

4 88463 Hose, 1/4" x 63", Loader Valve 1

5 88462 Hose, 1/4" x 62", Loader Valve 1

6 88835 Hose, 1/2" x 35", Loader Valve 1

7 22278 Fitting, 1/2" x 90°, Loader Valve 1

8 22784 Fitting, 1/2" x 1/4" x 90°, Loader Valve 4

13096 Front Valve Seal Kit 1

1.800.428.3772

Intl. 1 .304.776.4231

WWW.TERRAMITE.COM/SAFETY

Copyright © 2006 Terramite Corporation

2.3

Charleston, WV/USA

Read Operators Manual For Safety

Hydraulics

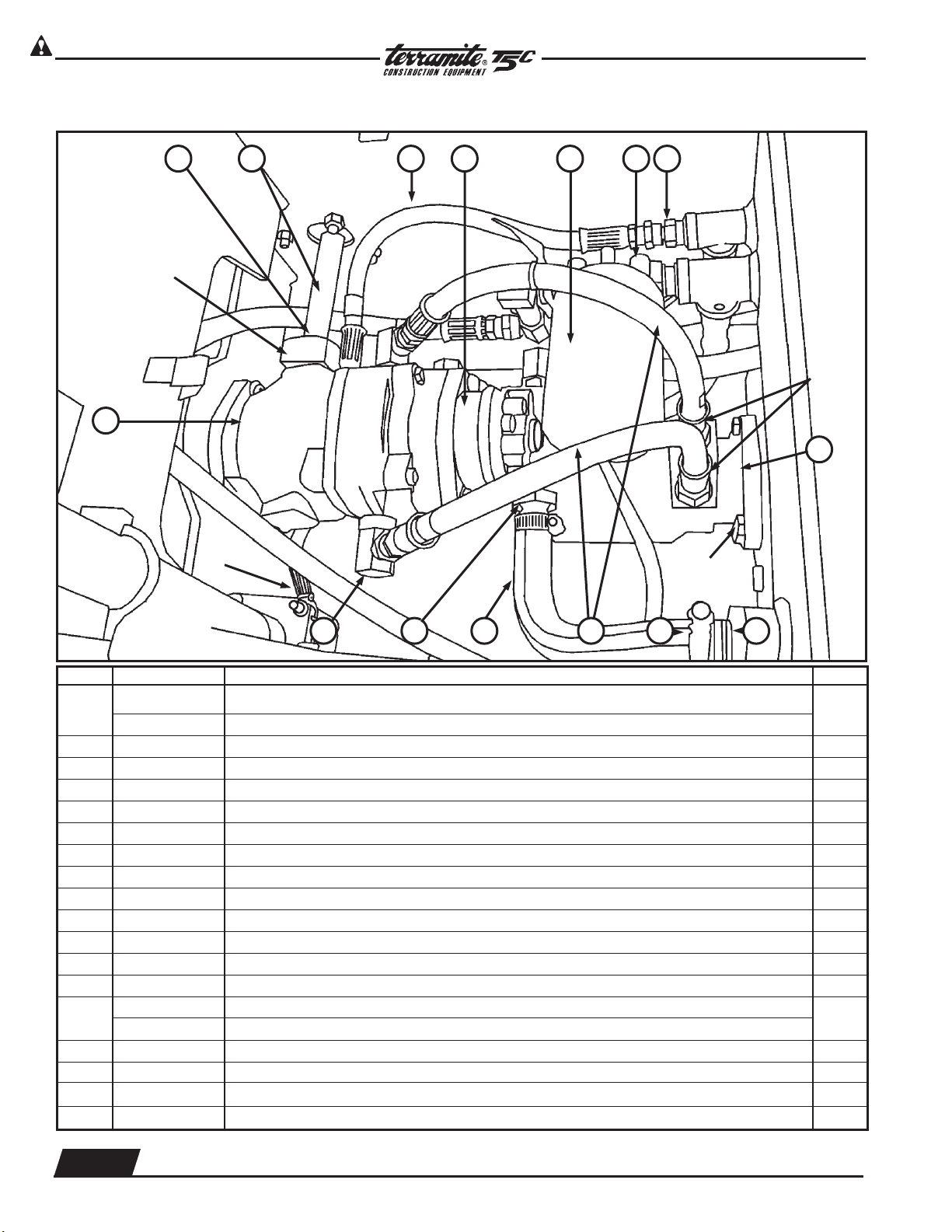

View from Top - Transmission Assembly

PARTS MANUAL

Block #13054

Roll Pin #17005

1

2

PN#80037

3 4 5 6 7 8

Fitting

#20007

10

Bolt #22034

Nut #28500

111213141516

ITEM PART NUMBER DESCRIPTION QTY.

1

64064 Hydrostatic Transmission Gas Only (Resale)

1

64012 Hydrostatic Transmission Diesel Only

2 11620 Pedal Shaft 1

3 61623 Pedal Shaft Bushing 1

4 88615 Hose, 3/8” x 15”, Transmission 1

5 66045 Gear Pump 1

6 21002 Filter, Hydraulic 1

7 22003 Filter Base 1

8 21786 Fitting, 1/2” x 3/8”, Trans. 1

9 15900 Tank, Hydraulic, T5 1

10 64003 Torquemotor 1

11 22201 Filter, Strainer (Inside Tank) 1

12 22020 Clamp, Hose 2

13 88820 Hose, 1/2” x 20”, Trans. 2

14

81012 Hose, 3/4" x 12", Trans. prior to 11-92

81010 Hose, 3/4" x 12", Trans. after 11-92

1

15 81612 Fitting, 11/16” x 3/4”, Trans. 1

16 27128 Fitting, #12 x 1/2" x 90°, Trans. 2

25286 Fitting On Bottom of Transmission

22118 Fitting For Charge Plate Adapter 3/8 90%

2.4

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

Copyright © 2006 Terramite Corporation

1.800.428.3772

Intl. 1 .304.776.4231

Read Operators Manual For Safety

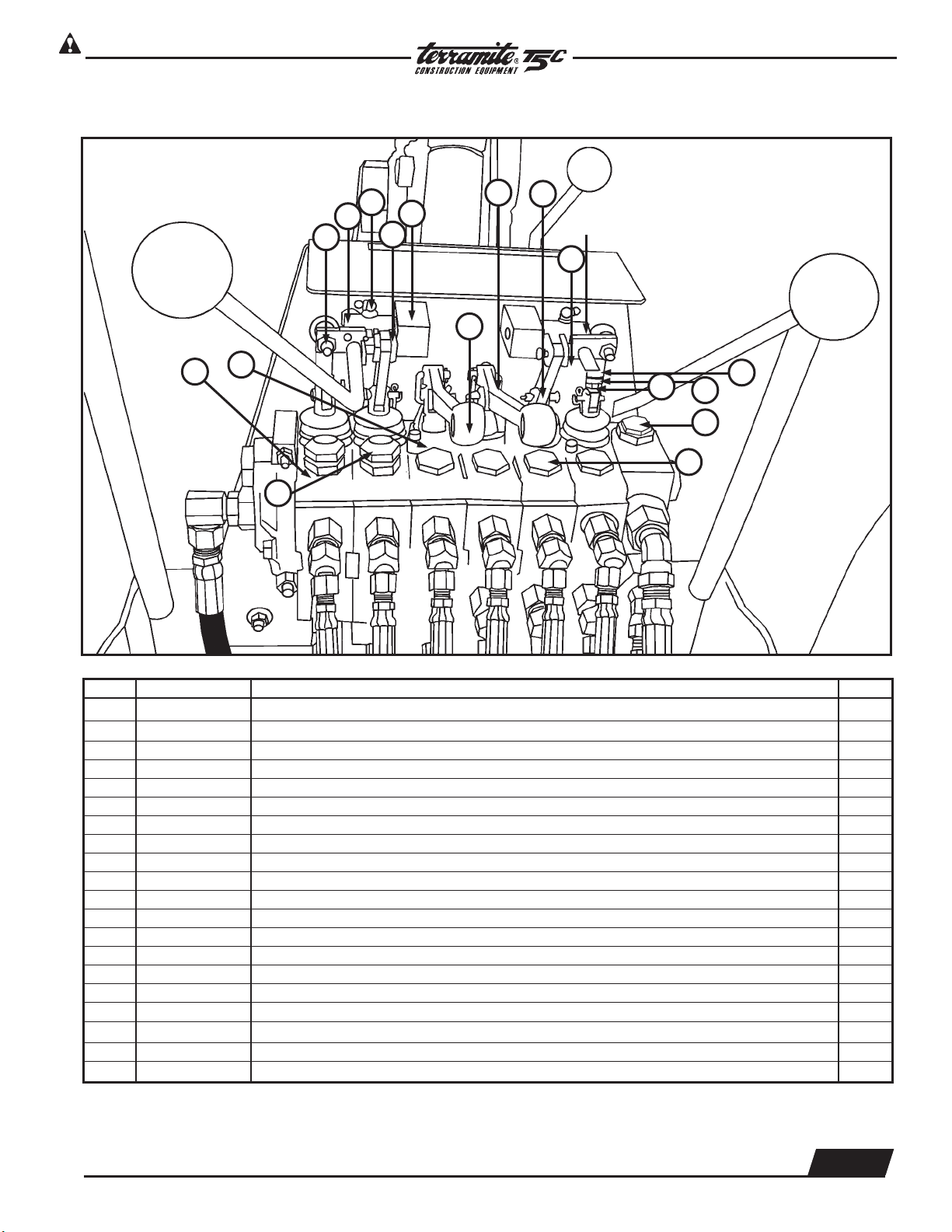

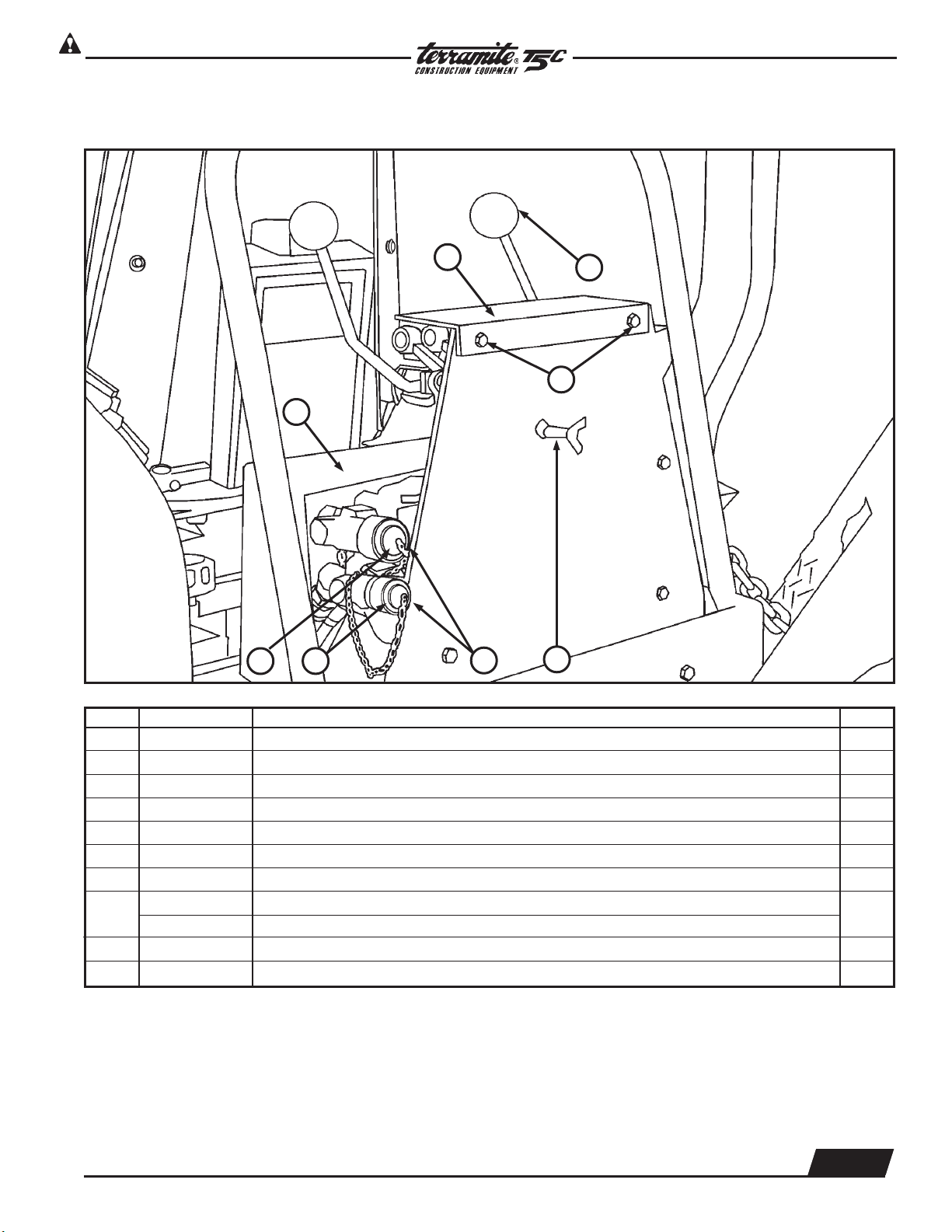

View from Operator Position of Rear Valve

1

PARTS MANUAL

Hydraulics

6

3

2

18

8

12

5

Bolt 10

14

17

7

3

4

7

13

15

16

ITEM PART NUMBER DESCRIPTION QTY.

1 25500 Nut, 5/16" NF Jam 2

2 13444 Wobblestick Pivot Block, Universal 1

3 16410 Eye Bolt 2

4 13965 Linkage 3

5 13443 Connecting Link 2

6 13411 Valve Link 3

7 13410 Aluminum Valve Handle Bracket 2

8 13418 Pin, Valve Hose Link Pivot 8

9 21429 90o Grease Fitting 1

10 23008 Nut on back of Wobblestick 1

11 13443 Lock Nut 1

12 13431 Outrigger Handles 2

13 13429 Main Relief Rear Valve 1

14 13423 Valve Boot Spool Protector 4

15 13401 Load Check Plug Assembly 9

16 13456 Port Relief 2600# 1

17 13454 Port Relief 2000# 2

18 13444 Uni Blocks

85041 Orings 6

13499 Pressure Shims

1.800.428.3772

Intl. 1 .304.776.4231

WWW.TERRAMITE.COM/SAFETY

Copyright © 2006 Terramite Corporation

2.5

Charleston, WV/USA

Read Operators Manual For Safety

Hydraulics

View from Operator Position of Rear Valve

PARTS MANUAL

12

10

9

1

2

11

3

1

18

4

5

End Cap

13

6

8

7

ITEM PART NUMBER DESCRIPTION QTY.

1 13942 Knob 2

2 13073 Handle, Wobblestick, Left Rear 1

3 14050 Decal, Wobblestick & Operator Hazard 1

4 13123 Handle, Wobblestick, Right Rear 1

5 13400 Rear Valve Assembly 1

6 20065 Fitting, #12 x 8" adaptor 2

7 21788 Fitting, #8 x 1/2" x 45° 2

8 25286 Fitting, #8 x 6" adaptor 12

9 21764 Fitting, 3/4" x 1/4" x 45° 9

10 21765 Fitting, Restrictor 3

11 25108 Fitting, #10 x 1/2" x 90° 1

13444 Block

12 84029 Power Beyond - Sleeve Kit

13 85156 End Cap

14 26002 Restrictor Sets Screws

2.6

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

Copyright © 2006 Terramite Corporation

1.800.428.3772

Intl. 1 .304.776.4231

Read Operators Manual For Safety

PARTS MANUAL

Hydraulics

View from Right Rear

5

9

1

2

3

6

8

4

ITEM PART NUMBER DESCRIPTION QTY.

1 25054 Q.A. Plug 1

2 27010 Threaded Q.A. Plug 1

3 28890 Auxiliary P.T.O. Kit 1

NOT

SHOWN

21188 Fittings, 1/2” x 90° 2

4 26485 P.T.O. Depress Lever 1

5 14052 Decal Plate For Handle Operations 1

6 13942 Wobblestick Knob 2

14005 Maintenance Decal (Gas Only) Located Under Dash Not Shown

7

14510 Maintenance Decal (Diesel Only) Located Under Dash Not Shown

8 Bolts 2

9 15017 Hose Cover

1.800.428.3772

Intl. 1 .304.776.4231

Copyright © 2006 Terramite Corporation

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

1

2.7

Read Operators Manual For Safety

PARTS MANUAL

Hydraulics

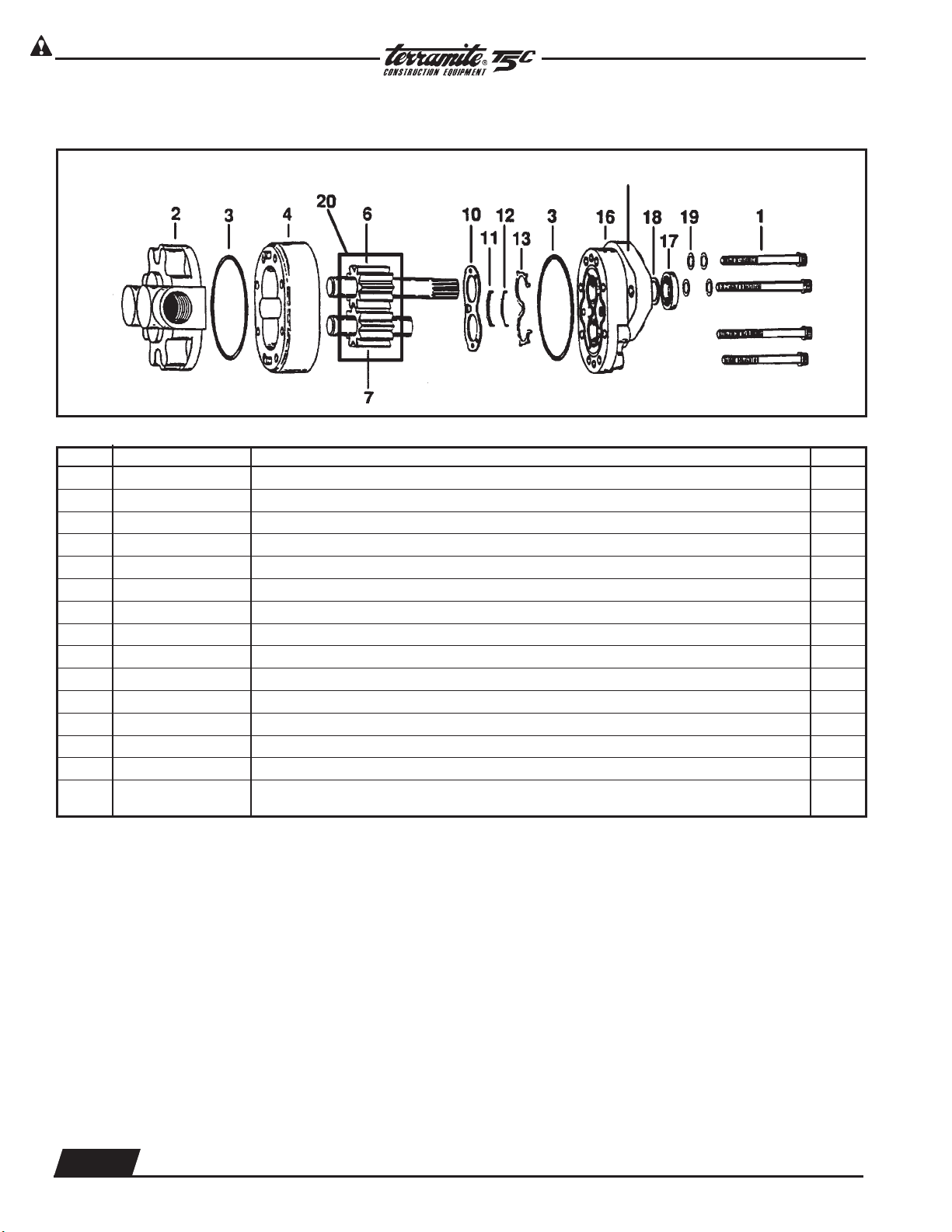

Gear Pump Part # 66045

Serial Code and Assembly Number

ITEM PART NUMBER DESCRIPTION QTY.

1 NSS* Cap Screws 8

2 64501 Backplate Assembly 1

3 60464 O-Ring 1/16" x 3" 1

4 64504 Body 1

6 64505 Drive Gear Assembly 1

7 64506 Idler Gear Assembly 1

10 NSS* Wear Plate 1

11 NSS* Bearing Seal 1

12 NSS* Molded O-Ring 1

13 NSS* Back Up Gasket 1

16 64513 Front Plate 1

17 64514 Seal, Gear Pump, Shaft 1

19 65131 Washer, Gear Pump 4

SP 65101 Seal Repair Kit 1

20 66010 2-Keys 2

NSS* Not Sold Separately

2.8

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

Copyright © 2006 Terramite Corporation

1.800.428.3772

Intl. 1 .304.776.4231

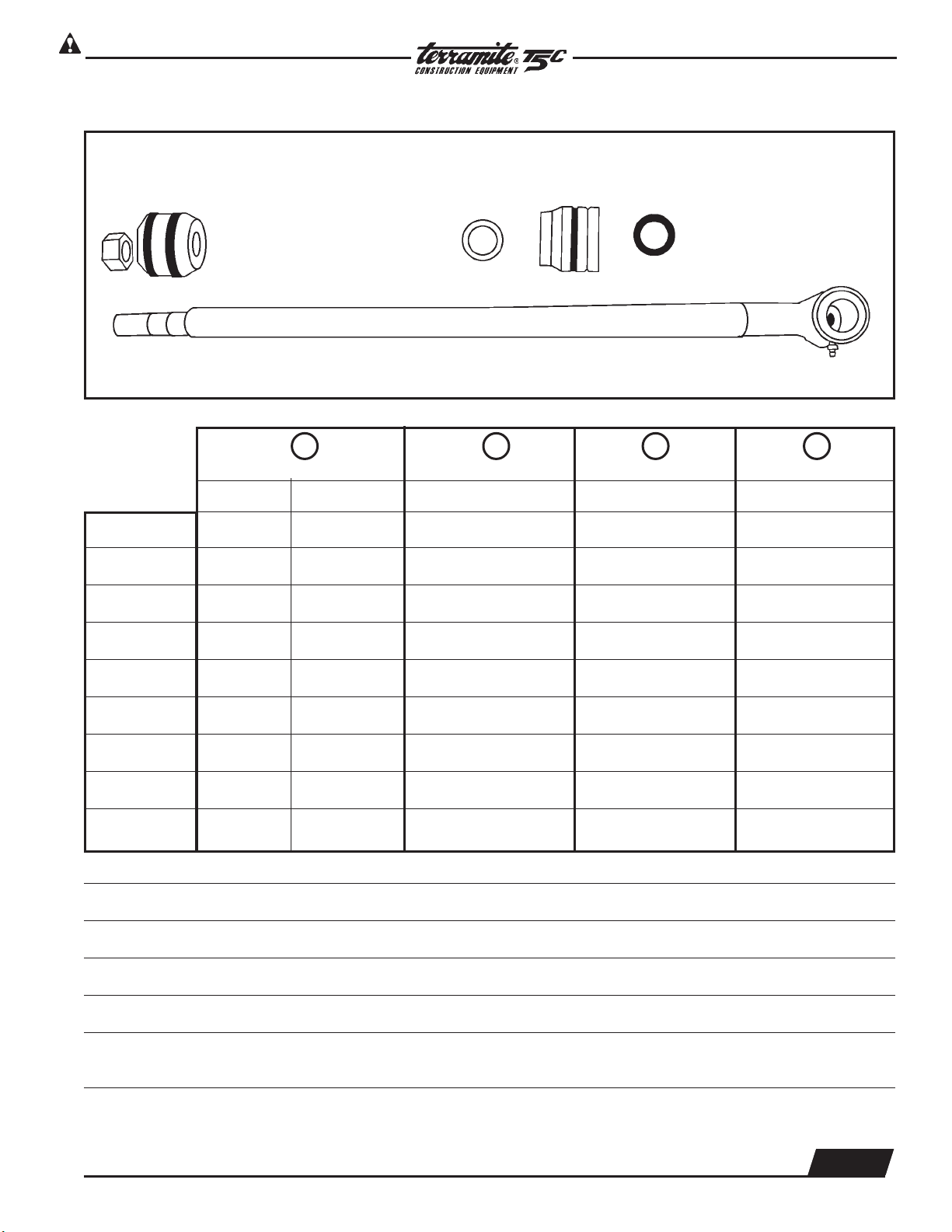

Read Operators Manual For Safety

1 2 3 4

ROD BEARING BLOCK PISTON SEAL KIT

RO D PART PART PART PART

DIAMETER NUMBER NUMBER NUMBER NUMBER

PARTS MANUAL

Hydraulics

Rod Assembly

Arm 1" 22501 22103 21111 21151

Power Steering 1" 25803 22103 21111 21151

Swing 1" 25201 22103 21111 21151

Front Curl 11/8" 23101 22203 21111 21125

Rear Curl* 11/8" 20301 22203 21111 21125

Outrigger 11/8" 21601 22203 21111 21125

Boom Lift 11/4" 21201 82058 23110 21525

Boom Crowd 11/4" 21201 82058 23110 21525

2 inch 11/4" 81048 82104 21111 82051

*Standard

**On machines manufactured before 6-96 part number is 25801 (Previous Part Number 1-58.1).

NOT SHOWN: Rear Curl Rod 1

1

/4" Part Number: 81048

NOTE: All rod assemblies use the same locknut Part Number 23420 (Previous Part Number 1N12FL).

NOTE: Units dated before 4-91 use aluminum pistons in 2" ID Cylinder Barrels only.

Use Seal Kit 2-15.1 (New #82049 for 1" kit-Prior to 4/94 Aluminum)

and 2-15.1125 (New #82050 for 11/8" kit-Prior to 4/94 Aluminum).

SPECIAL TOOL 21176 Spanner wrench for cylinder repair

1.800.428.3772

Intl. 1 .304.776.4231

Copyright © 2006 Terramite Corporation

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

2.9

Read Operators Manual For Safety

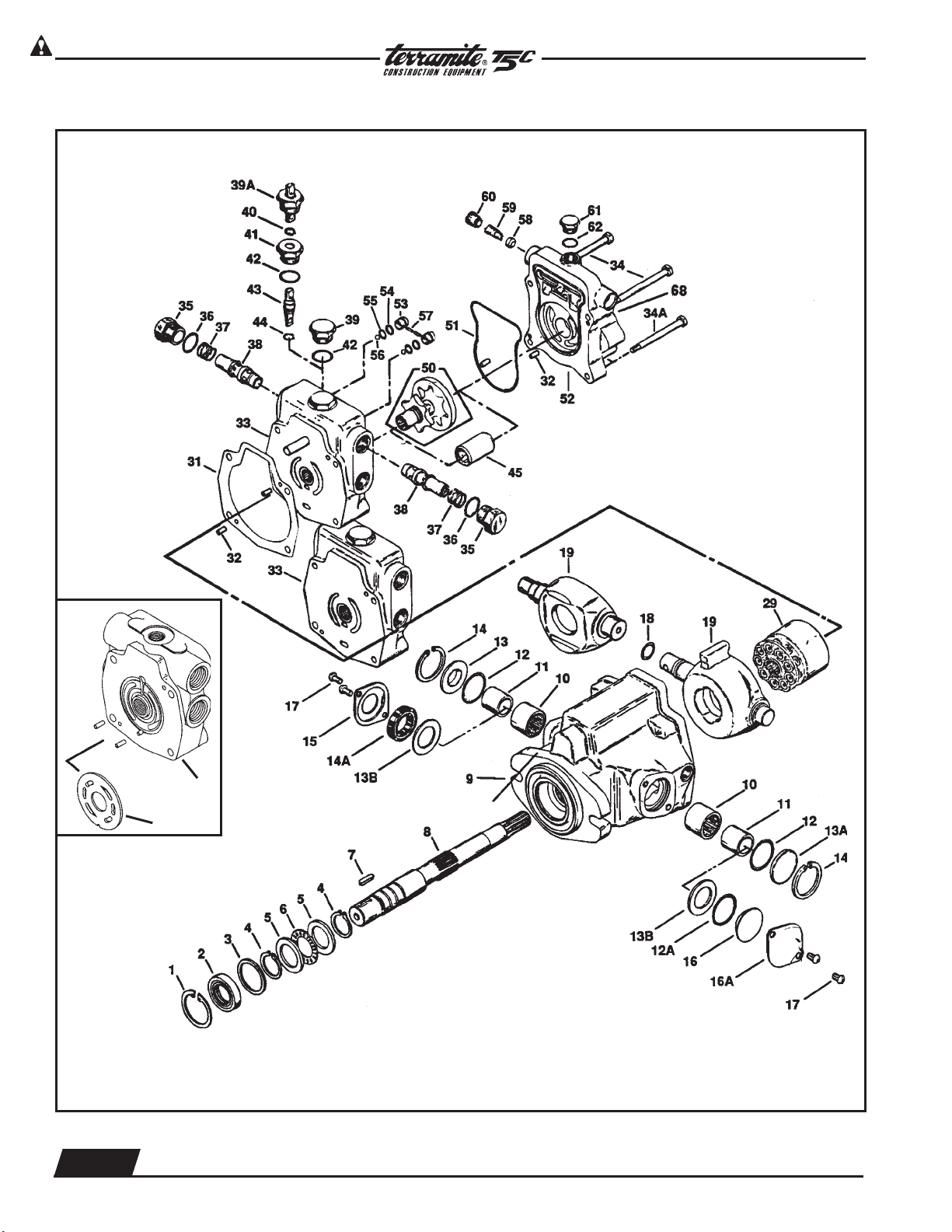

Hydraulics

CESSNA

B

PARTS MANUAL

Hydrastatic Transmission

EATON

67

33A

EATON

Serial Code and Assembly Number

Location

EATON

CESSNA

PLEASE PROVIDE SERIAL NUMBER OF MACHINE WHEN ORDERING ANY COMPONENT PARTS.

*

2.10

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

Copyright © 2006 Terramite Corporation

1.800.428.3772

Intl. 1 .304.776.4231

Read Operators Manual For Safety

PARTS MANUAL

Hydraulics

ITEM PART NUMBER DESCRIPTION QTY.

1 60401 Retaining Ring 1

2 60402 Shaft Seal 1

3 60403 Washer 1

4 60404 Retaining Ring 2

5 60405 Bearing Race 2

6 60406 Bearing, Thrust 1

7 60471 Key 1

8 60407 Drive Shaft 1

9 60409 Housing Assembly 1

10 60410 Bearing 2

11 60411 Inner Race 2

12 60412 O-Ring, 3/32" x 15/16", Outer Pintle 2

13 60465 Sleeve Cover 1

13A 60415 Trunnion Cover 1

13B 60561 Washer 1

14 60414 Retaining Ring 2

14A 60562 Seal, Pintle 1

15 60418 Seal Cover 1

17 60564 Screws, Trunnion Cover 2

18 60516 O-Ring, Outer Pintle 1

19 60517 Camplate, For Eaton Trans. 1

19 60417 Camplate, For Cessna Trans. 1

29 60422 Rotating Kit Assembly 1

31 60429 Housing, Gasket 1

33 60533 Backplate Assy., Eaton, with Power Steering 1

33A 60535 Backplate Assy., w/valve plate, Eaton 1

33B 60432 Backplate Assy., Cessna, without Power Steering 1

35 60436 Plug Assembly 2

36 60435 O-Ring 33/32" x 7/8" ID, Back Plate 1

37 60434 Spring, Transmission, Relief Valve 2

38 60467 Relief Valve Assembly 2

39 60433 Plug Assembly 1

40 60440 Retaining Ring 1

41 60441 Separator Plug 1

42 60442 O-Ring, 33/32" x 7/8" 1

43 60454 Spreader 1

44 60437 O-Ring, 1/16" x 3/8" 1

45 60443 Coupler 1

50 64050 Gerotor and Coupler 1

51 60449 O-Ring, Molded 1

60453 Adapter Assembly without Power Steering

52 60553 Adapter Assembly with Power Steering 1

64058 Adapter Assembly with Power Steering - Diesel

53 60450 Check Valve Assembly 2

54 60452 Back Up Washer 2

55 60455 O-Ring,1/16" x 7/16" 2

56 60456 Steel Ball 2

57 60457 Pin 2

58 60461 Poppet Filter Relief 1

59 60463 Spring 1

60 60560 Spring Retainer 1

61 60469 Plug Assembly 1

62 60466 O-Ring, 33/32" x 41/64"1

64 60464 O-Ring, 1/16" x 31/4" 1

65 60465 Cover Plate 1

66 60459 Cap Screw 2

67 60534 Plate, Valve 1

*S 64100 Seal Repair Kit, Cessna 1

*S 64101 Seal Repair Kit Eaton 1

*S 60043 Rotating Rebuild Kit, Cessna 1

*S 60564 Screws, Trunnion Cover 2

68 60464 O-Ring in Back 1

1.800.428.3772

Intl. 1 .304.776.4231

WWW.TERRAMITE.COM/SAFETY

Copyright © 2006 Terramite Corporation

2.11

Charleston, WV/USA

Read Operators Manual For Safety

Hydraulics

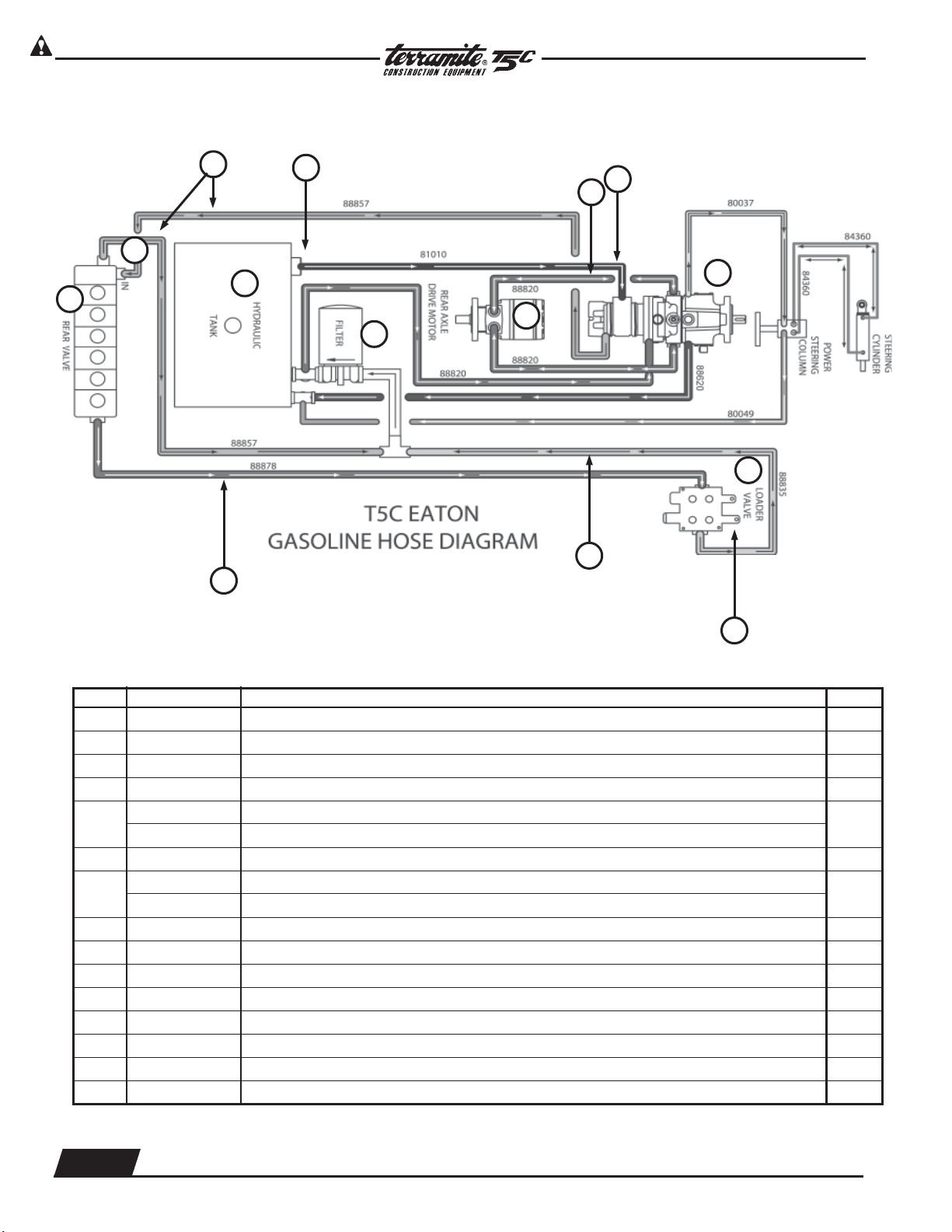

Hydraulic Main Power Circuit (shown is for gas model)

PARTS MANUAL

15

2

1

14

11

3

4

13

5

6

7

8

10

9

ITEM PART NUMBER PREVIOUS PART NUMBER DESCRIPTION QTY.

1 13429 Main Relief Rear Valve 1

2 88857 Hose 1/2" x 57" (back valve section) 2

3 22201 Filter, Strainer (Inside Tank) 1

4 64003 Drive Motor 1

5

81012 Hose, 3/4" x 12"(back valve section) Prior to 11-92

81010 Hose, 3/4" x 12"(back valve section) After 11-92

1

6 88820 Hose, 1/2" x 20"(back valve section) 3

7

66005 Transmission Gasoline Type

66006 Transmission Diesel Equipped

1

8 13900 Valve Loader 1

9 13943 Loader Circuit Relief Valve 1

10 88836 Hose, 1/2" x 36"(back valve section) 1

11 88878 Hose, 1/2" x 78"(back valve section) 1

12 88620 Hose, 3/8" x 20"(back valve section) 1

13 21002 Filter, Hydraulic 1

14 22204 Cap, Hyd. Breather Filter w/Dipstick 1

15 13400 Rear Valve Assembly 1

Continued On Next Page

2.12

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

Copyright © 2006 Terramite Corporation

1.800.428.3772

Intl. 1 .304.776.4231

Read Operators Manual For Safety

Loader Circuit

PARTS MANUAL

Hydraulics

Hydraulic Main Power Circuit (Continued)

HYDRAULIC FILTER TYPES:

PARKER 921999

NAPA 1551-1259

WIX 51551

FRAM P-1653

AC PF16

BALDWIN BT-839-10

HOSE TYPES:

3

/8" 2 WIRE BRAID MP6-6 & MB6-6F

1

/2" 2 WIRE BRAID NPT

3

/4" SUMP LINE HOSE

OIL:

ABOVE 40°F - API 15W-40 SF/CC/CD

BELOW 40°F - API 10w SF/CC/CD

WARNING: USE ONLY 2 WIRE BRAID HOSES AS SPECIFIED ABOVE. SYNTHETIC OR OTHER TYPES OF

HOSES MAY FAIL CAUSING SERIOUS INJURY OR DEATH.

WARNING: DO NOT USE ORDINARY HYDRAULIC OIL OR MAJOR DAMAGE TO TRANSMISSION AND

MOTOR WILL RESULT.

NOTE: For Diesel, switch hoses marked A and B

1.800.428.3772

Intl. 1 .304.776.4231

WWW.TERRAMITE.COM/SAFETY

Copyright © 2006 Terramite Corporation

2.13

Charleston, WV/USA

Read Operators Manual For Safety

Hydraulics

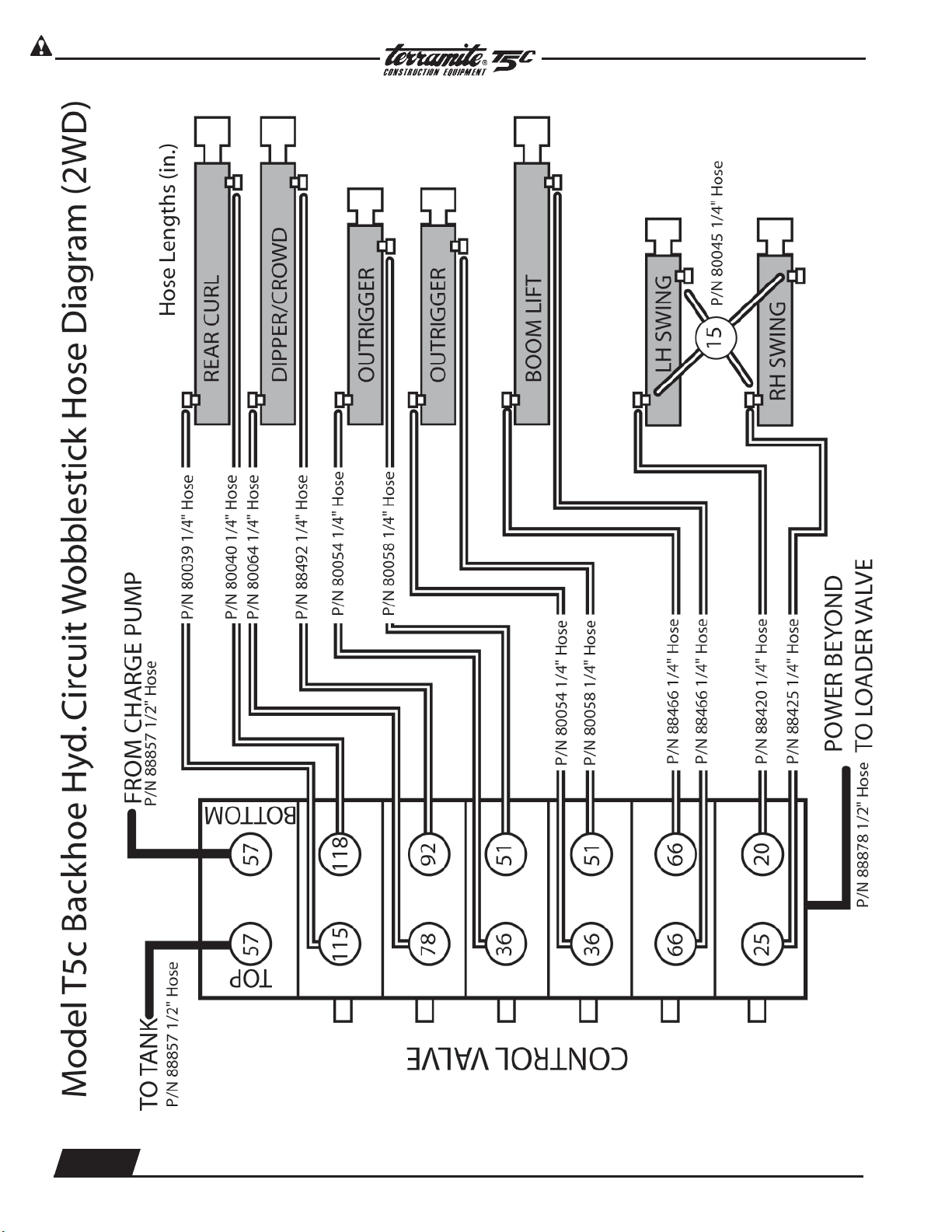

T5C Wobblestick Hose Diagram Backhoe Circuit

PARTS MANUAL

2.14

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

Copyright © 2006 Terramite Corporation

1.800.428.3772

Intl. 1 .304.776.4231

Read Operators Manual For Safety

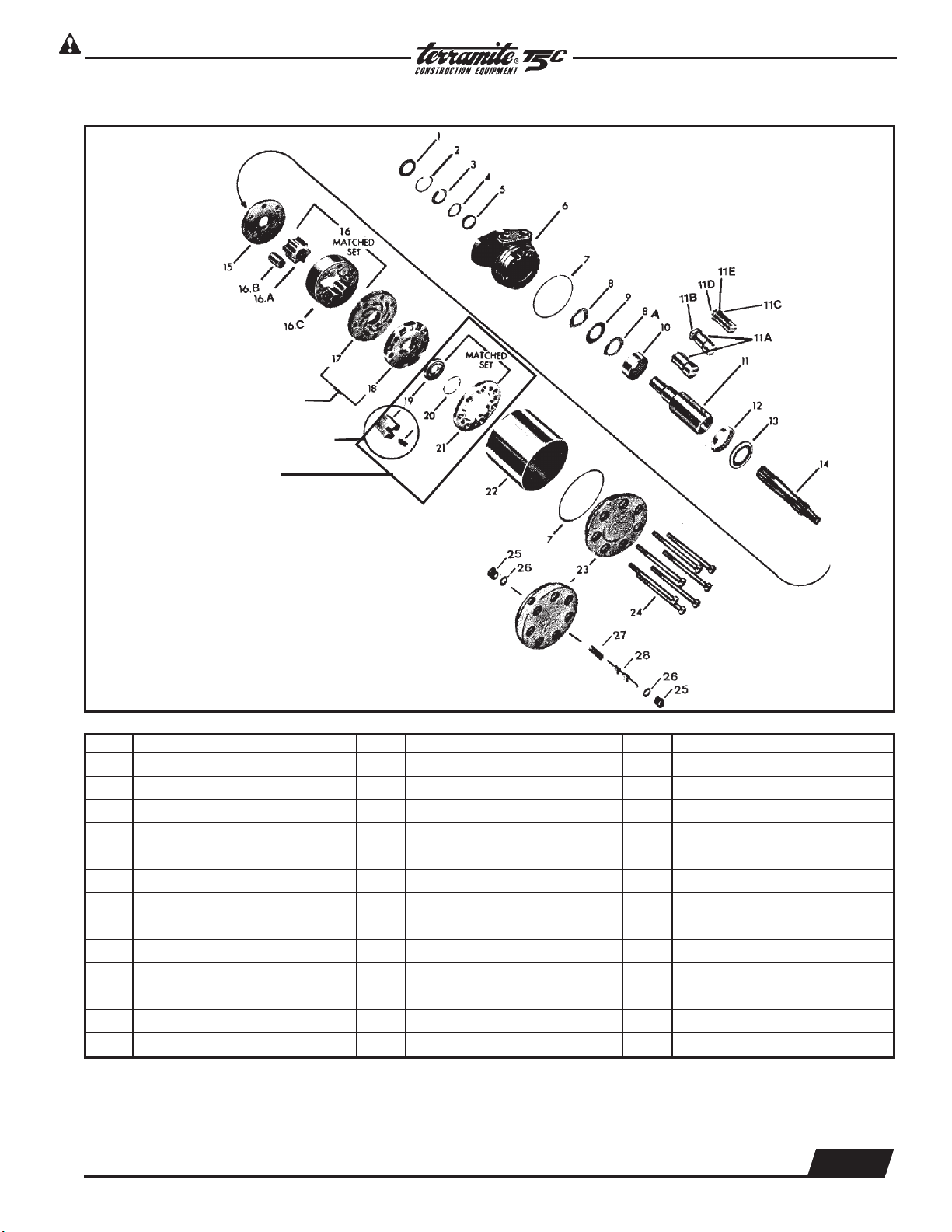

MAB/MAE Torquemotor Exploded Assembly View

Commentator and Ring

PN# 62008

PARTS MANUAL

Hydraulics

ITEM DESCRIPTION ITEM DESCRIPTION ITEM DESCRIPTION

1 Seal 11B Nut 17 Manifold Plate

2 Retaining Ring 11C Washer 18 Manifold

3 Back-Up Washer 11D Bolt 19 Commutator

4 Washer 11E Lock Washer 20 Seal Ring

5 Seal 12 Bearing 21 Commutator Ring

6 Housing 13 Thrust Bearing 22 Sleeve

7 Seal Ring (2) 14 Drive Link 23 End Cover Assembly

8 Thrust Washer 15 Wear Plate 24 Special Bolt (7)

8A Thrust Washer 16 Rotor Set 25 Plug

9 Thrust Bearing 16A Rotor 26 O-Ring

10 Bearing 16B Vane (7) 27 Sping

11 Coupling Shaft 16C Stator 28 Valve (Shuttle)

11A Key

1.800.428.3772

Intl. 1 .304.776.4231

Copyright © 2006 Terramite Corporation

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

2.15

Read Operators Manual For Safety

Hydraulics

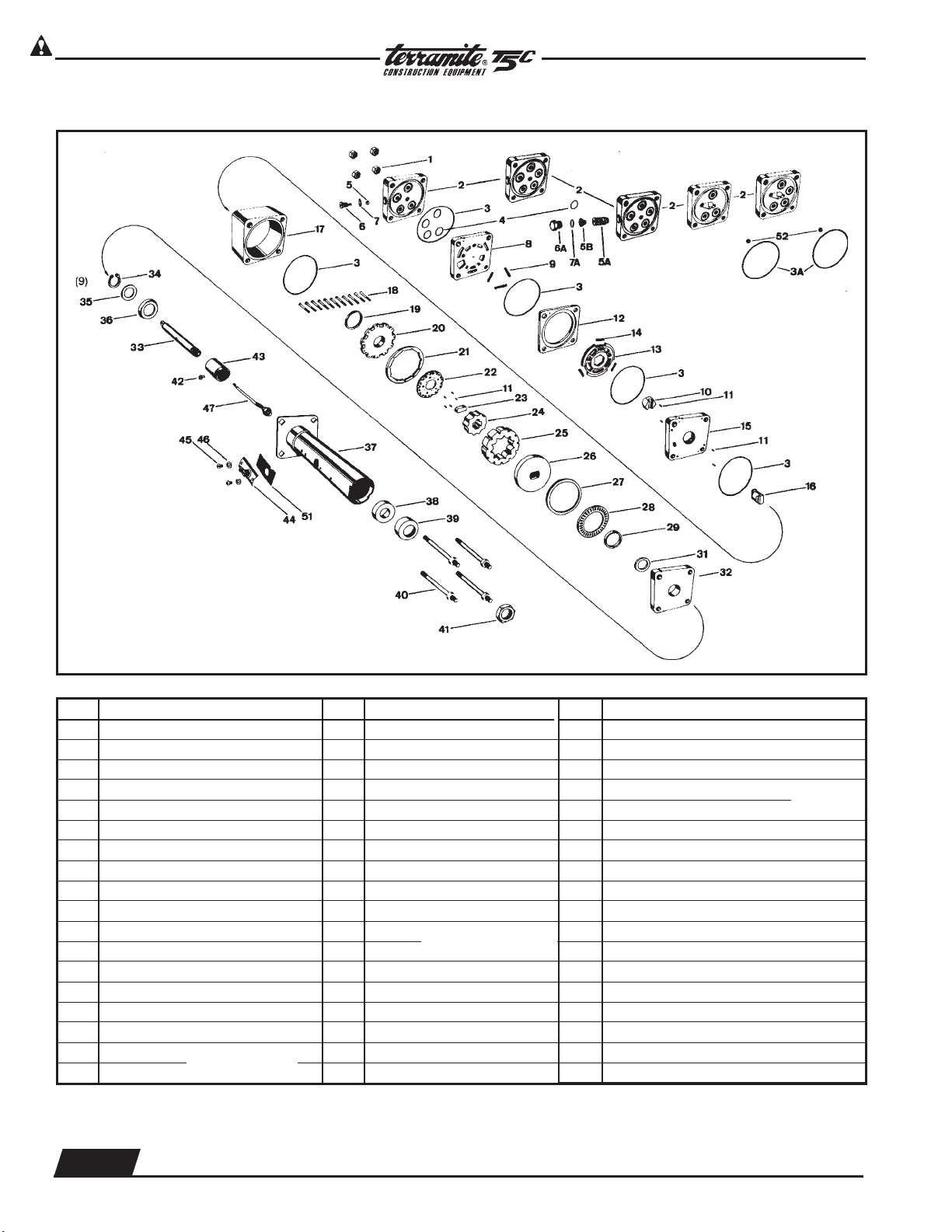

Power Steering Column Exploded Assembly View

PARTS MANUAL

ITEM DESCRIPTION

1 Nut 5/16 UNF 24 (4)

2 Port Cover

3 Seal Ring (5)

3A Seal Ring (White)

4 O'Ring (3), (4) or (5)

5 Ball-7/32 inch (6mm) dia.

5A Relief Valve Cartridge

5B Coil Spring

6 Plug

6A Hex Plug

7 O'Ring, Plug & O'Ring Assy.

7A O'Ring

8 Port Manifold

9 Spring, 3/4 inch (19mm) (3)

10 Hex Drive Assy.

11 Alignment Pin (Needle Brg.) (9)

12 Valve Ring

13 Valve Plate

Matched Set

}

ITEM DESCRIPTION

14 Spring, 1/2 Inch (13mm) (3)

15 Isolation Manifold

16 Drive Link

17 Metering Ring

18 Screw, Hex Socket Hd (11)

19 Seal, Commutator

20 Commutator Cover

21 Commutator Ring

22 Commutator

23 Spacer-Drive Link

24 Rotor

25 Stator

26 Drive Plate

27 Spacer-Trust Bearing

28 Thrust Bearing

29 Face Seal

31 Seal Spacer

32 Upper Cover Plate

Matched Set

}

ITEM DESCRIPTION

33 Input Shaft/Wheel Tube

34 Retaining Ring

35 Washer-Retaining Plate

36 Retaining Plate

37 Upper Cover & Jacket Assy.

38A7/8 Bushing

38B3/4Bushing

39 Seal

40 Special Bolt, 5/16 24UNF-2A

41 Nut

42 Screw

43 Contact Ring Assy.

44 Contact Brush Assy.

45 Screw & Lock Washer

46 Washer [for 11/2 inch (38 mm) Jacket]

47 Horn Wire Cable Assy.

51 Spacer [for 11/2 inch (38 mm) Jacket]

52 Ball 9/32 inch (22mm)

Items #44, 45, 46, 51 are not part of HGF service assembly unit. They must be

purchased as separate items of order.

Matched

}

Set

2.16

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

Copyright © 2006 Terramite Corporation

1.800.428.3772

Intl. 1 .304.776.4231

Read Operators Manual For Safety

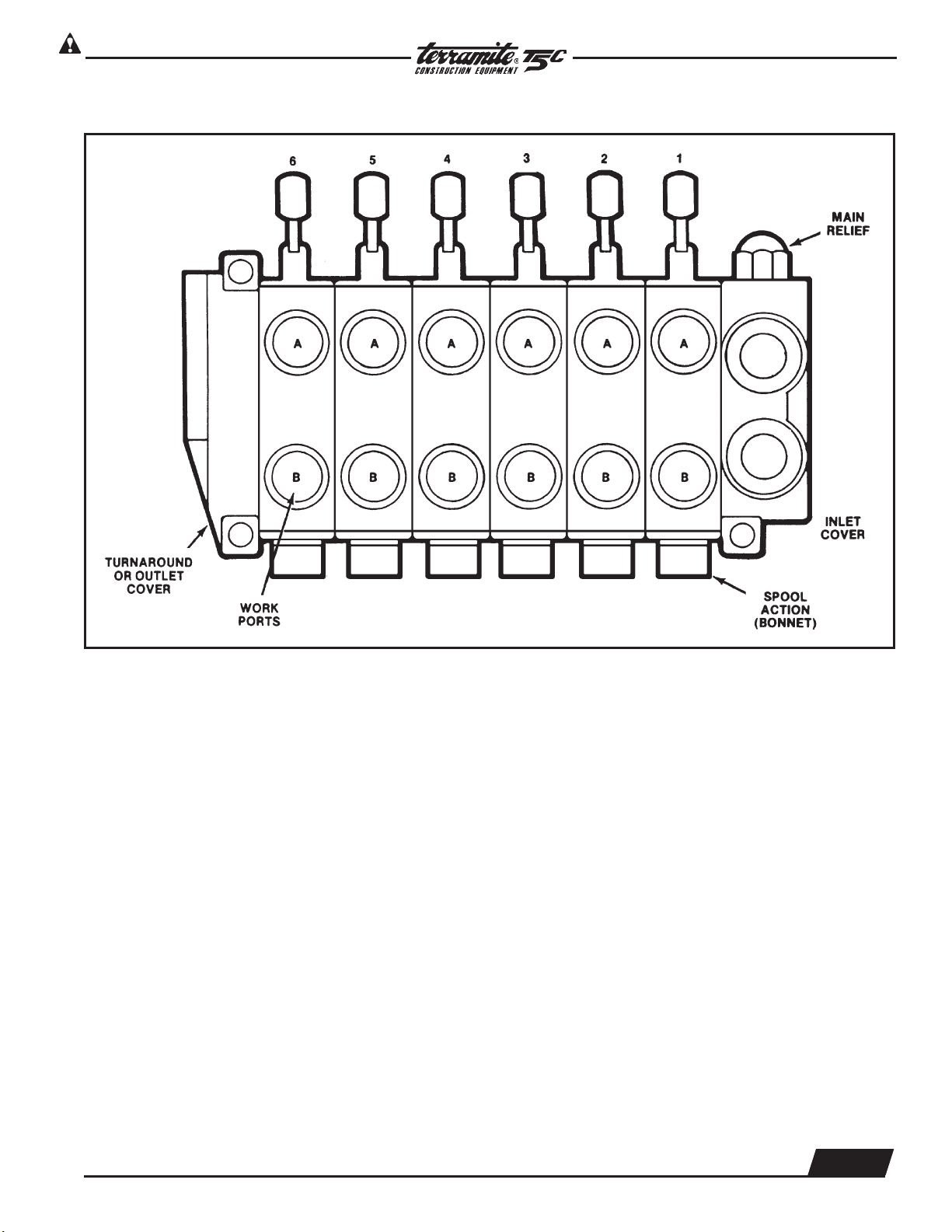

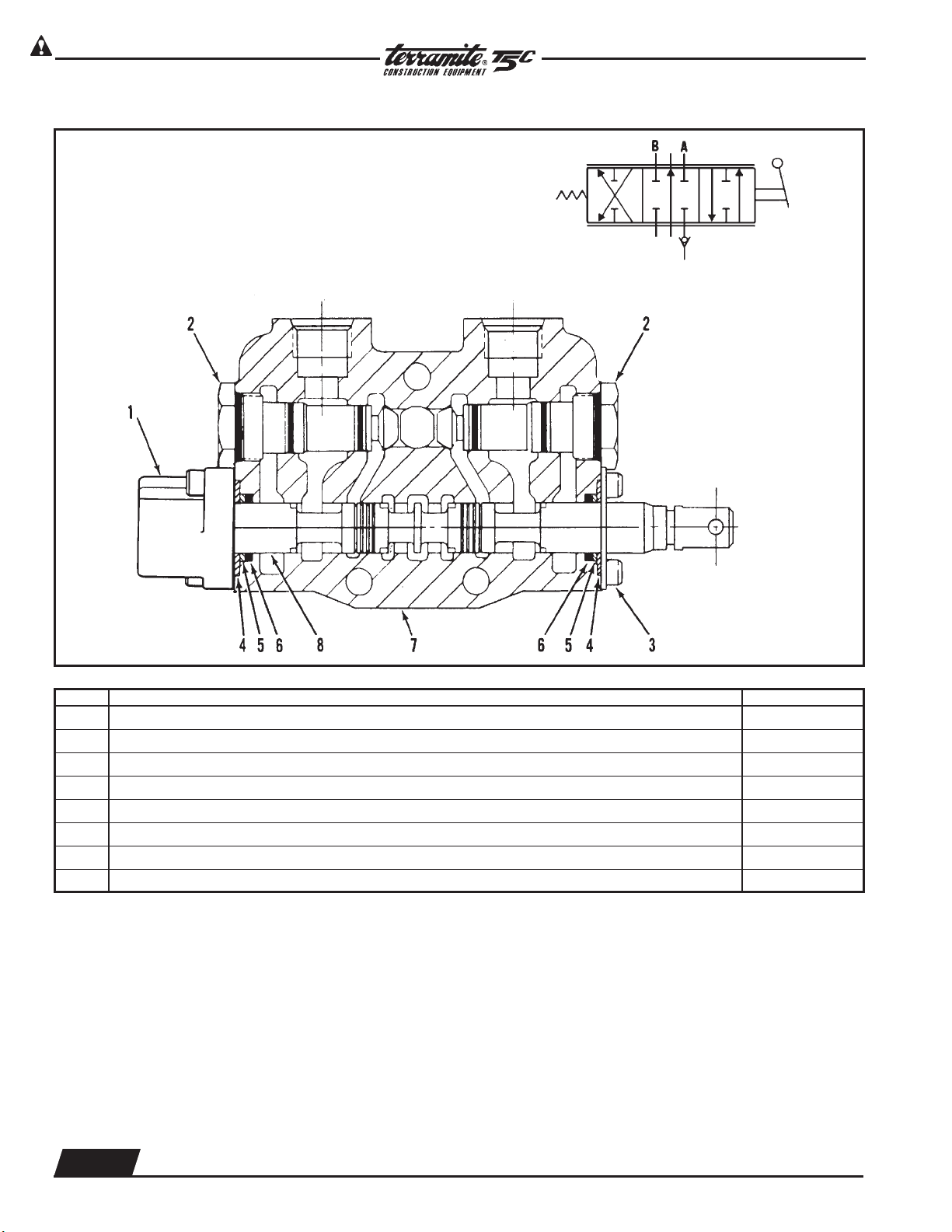

Schematic-View of Backhoe Control Valve Assembly

PARTS MANUAL

Hydraulics

1. Before disassembly, it is suggested that each valve section be marked numerically to avoid incorrect

reassembly.

2. Remove three assembly stud nuts from the left end section using a

3. Remove valve sections by sliding from assembly studs.

9

/16" thin wall socket.

1.800.428.3772

Intl. 1 .304.776.4231

WWW.TERRAMITE.COM/SAFETY

Copyright © 2006 Terramite Corporation

2.17

Charleston, WV/USA

Read Operators Manual For Safety

Hydraulics

Parts Ordering Information

As of April 1, 1991, the section seals for the

V20 changed. The new versions have larger cross

section (old was .070, new is .103) and different configurations for open center and closed center sections. The old design utilized the same seals for all

versions (two .801 I.D. and two .926 I.D.). The new

design uses one configuration for open center (three

.924 I.D. and one .799 I.D.) and another configuration

PARTS MANUAL

for closed center, load sensing and all outlet covers

(two .924 I.D. and two .799 I.D., with one .237 I.D. for

load sensing).

The following charts is provided to aid in selection of the proper seals. It is important to note that

the seal kits include all O-rings (new and Old), therefore there will be some left unused.

The following section seals are included in the Kits:

Standard Kits Viton Kits

Old New Old New

(2)6814-002 (2)21867-001 (2)7450-001 (2)9003-117

(2)6815-002 (3)21733-001 (2)7451-001 (3)9002-119

Load sensing kits (additional seals)

(1)8316-001 (1)21866-001 (1)9002-011 (1)9002-108

OLD NEW

6814-002 ....... STD

7450-001 ....... VITON

6815-002 ....... STD

7451-001 ....... VITON

Seal kit changes.

K-6121 Section Seal Kit, One Section

K-6027 Complete Seal Kit, 3 or 4 Way Section

K-6028 Complete Seal Kit, 4 Way Float Section

K-6209 Complete Seal Kit, Series 3 or 4 Way Section

K-6210 Complete Seal Kit, Series 4 Way Float Section

K-6154 Complete Seal Kit, Load Sensing 4 Way Float

K-6155 Complete Seal Kit, Load Sensing 3 or 4 Way Section

K-6156 Section Seal Kit, Load Sensing-One Section

K-6160 Viton Section Seal Kit, One Section

*Complete Seal Kits include spool seals and O-rings for check plugs.

21867-001 ..... STD

9003-117 ....... VITON

21733-001 ..... STD

9002-119 ....... VITON

Seal Kit PN#85057 Prior to 1991

THESE SEALS ARE NOT INTERCHANGEABLE. OLD AND NEW STYLE SECTIONS MAY BE USED IN THE SAME ASSEMBLY

PROVIDED THE CORRECT SEALS ARE USED FOR EACH SECTION.

2.18

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

8316-001 ....... STD

9002-011 ....... VITON

Copyright © 2006 Terramite Corporation

Seal Kit PN#85058 After 1991

21866-001 ..... STD

9002-108 ....... VITON

1.800.428.3772

Intl. 1 .304.776.4231

Read Operators Manual For Safety

PARTS MANUAL

Hydraulics

Loader Valve

Relief

Valve

Power

Beyond

Detent Assembly

1. Raise and Lower Control Section

2. Curl and Dump Section

1.800.428.3772

Intl. 1 .304.776.4231

Copyright © 2006 Terramite Corporation

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

2.19

Read Operators Manual For Safety

Hydraulics

4-Way, 3-Position Valve Section

PARTS MANUAL

Torque to

10 ft. lbs. [13,6 Nm]

ITEM DESCRIPTION QTY. PER SECTION

1 Positioner, Spool, Standard 1

2 Check, Load 2

3 Retainer Assembly, Standard, Includes Screws 1

4 Retainer, Plate Washer 2

5 Washer, Back-Up (See Note 1) 2

6 Seal, O-Ring (See Note 1) 2

7 Housing, Standard (See Note 2) 1

8 Spool, 4-Way (See Note 2) 1

Notes:

1. Seal and washer not sold separately. Order Seal Kit.

2. These are matched parts and are not sold separately.

Buna-N seals are standard for all Gresen valve assemblies. Optional Viton seals are available.

2.20

WWW.TERRAMITE.COM/SAFETY

Charleston, WV/USA

Copyright © 2006 Terramite Corporation

1.800.428.3772

Intl. 1 .304.776.4231

Read Operators Manual For Safety

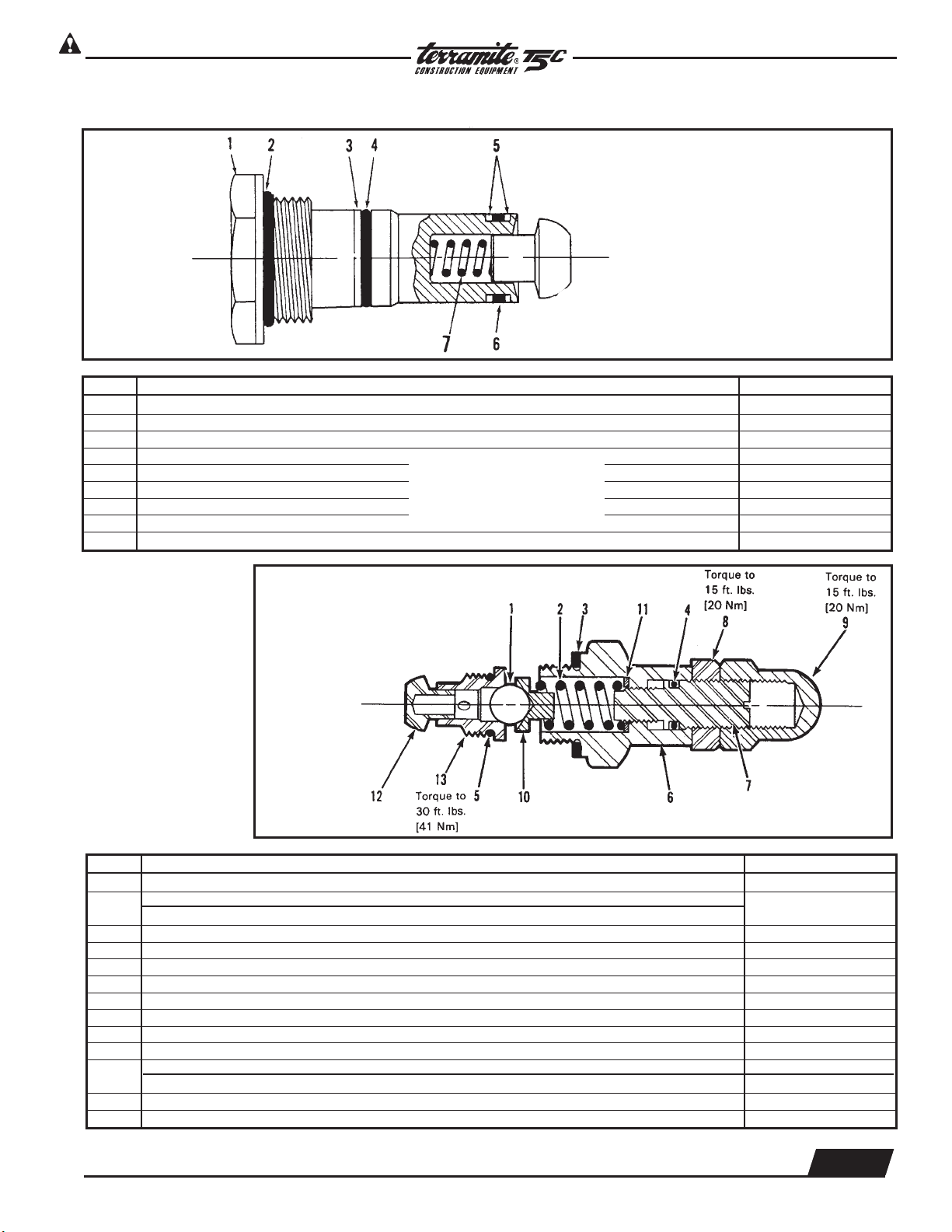

PARTS MANUAL

Hydraulics

Load Check Plug Assembly

Torque Load Check Plug

Assembly to 20 ft. lbs. [27 Nm].

ITEM DESCRIPTION QTY. PER PLUG ASSEMBLY

Replacement Load Check Plug Assembly

Seal Kit, (Contains Items 2, 3, 4, 5 & 6)

1 Plug, Lift Check, Steel (Heavy Duty) 1

2 Seal, O-Ring 1

3 Washer, Back-Up, Outer 1

4 Seal, O-Ring, Outer 1

5 Washer, Back-Up, Inner 2

6 Seal, O-Ring 1

7 Spring, Lift Check 1

Not Sold Separately

}

For Installation: Torque Relief

Valves Assembly to 45 ft. lbs.

[61 Nm]

High Pressure

Relief

ITEM DESCRIPTION QTY. PER PLUG ASSEMBLY

1 Ball 1

2

3 Gasket, Relief Body 1

4 O-Ring, Adjusting Screw 1

5 O-Ring, Valve Seat 1

6 Body 1

7 Screw, Adjusting 1

8 Nut, Jam, Adjusting Screw 1

9 Nut, Acorn Cap 1

10 Guide, Spring 1

11

12 Poppet, Check 1

13 Seat, Valve 1

Spring, Relief (Models SPK & SSK only)

Spring, Relief (Models SPK & SSK only)

Washer, Spacer (SP) 1

Washer, Spacer (SPK) 2

1

1.800.428.3772

Intl. 1 .304.776.4231

WWW.TERRAMITE.COM/SAFETY

Copyright © 2006 Terramite Corporation

2.21

Charleston, WV/USA

Loading...

Loading...