Page 1

Technical information

and assembly

instruction

Expenditure July 2008

TERRA-SW-TWIN_230V_installation_jul08-engl.cdr

Expenditure July 2008

TERRA-SW-TWIN_230V_installation_jul08-engl.cdr

heatpump

TV

V

IN

TERRA S/W-TWIN 230V

for

brine- or groundwaterplants

Type Basic

Page 2

Table of contents

Page

1. General Information

2. Heat pump

3. Heat source systems

4. Brine Horizontal Collector

5. Brine bore - hole system

6. Ground and Surface water systems

7. Advice for the Installation 20

8. Operation 21

9. Faults / Fault removal 22

1

2

2.1 Description 2

2.2 Rang of operation 2

2.3 Delivery content 2

2.4 Accessories 2

2.5 Technical Data- Brine heat pumps 3

Technical Data- Groundwater heat pumps 4

2.6 Operation limits 5

2.7 Technical dimensions 6

2.8 Installation 7

2.9 Hydraulic schematics 8

2.10 Connection ofthe heating side 12

2.11 Electrical scheme 12

2.12 Electrical connection 13

3.1 General information 15

4.1 Description 16

4.2 Rang ofApplication 16

4.3 Delivery Content 16

4.4 Technical Data 17

4.5 Installation schematic 17

5.1 Description

6.1 Description 19

6.2 Range ofApplication 19

6.3 Accessories 19

18

5.2 Rang ofApplication 18

5.3 Delivery Content 18

5.4 Technical Data 18

Changes in technology and Design reserve!

IDM-Energiesysteme GmbH,A-9971 Matrei i.O.,

C

(

General information for operation of the

heat pump.

Very important information for assembling and operation of the heat pump.

These informations are to be kept absolutely.

General information for assembling the

heat pump.

Place for the phone numberof your service partner.

Page 3

1. general information

Page 1

With the acquisition of this plant you have decided

yourself for a modern and economic heating system

Regular quality controls and improvements,

as well as functional tests in the factory, guarantees

a technically faultless device.

Read these documents attentively.

You will contain important notes and for the sure and

economical operation of the plant.

Installation and maintenance can involve dangers by

high Plant pressures, high temperatures and voltage-carrying Parts andbeing and must be done by experts.

Heat pumps may only be installed by competent experts and put intooperation onlyby a company which

is trained by IDM energy systems GmbH

For work on the heat pump all safety data in the corresponding documents, the sticker at the heat pump

itself and all the othersafety regulations haveto been

observed.

By transport, never incline the thermal pump more

then 15°.

The transportation packing should be removed just

after the thermal pump is positioned at the place of installation.

Terra heat pumps are very quiet in operation due to

their construction.

Nevertheless it is important that the heating room

should be positioned outside of sensitive to noise

living quarter and should be provided with a well closing door closing.

The heat pump isn't setup for the increased need of

heat for drying subfloor or carcass.

This must be done by equipment specially designed

for this task.

Tip for security:

Transport:

Sound emission:

Drying of subfloor orcarcass:

Service and maintenance:

Aregular maintenance as well as a check and

Care of all important plant parts guarantees at last a

safe and thrifty operation of the plant.

We recommend acontract formaintenance.

Cleaning:

If required, the Terra heat pump can be cleaned with

a damp cloth.The use of cleansers is not recommended.

Correct EC guidelines

Correct harmonized EN

Correct national norms/guidelines

Important safety reference

EC machine guideline (89/392/EEC)

EC low voltage guideline (73/23/EEC)

EC-EMV guideline (89/366/EEC)

EN378

EN60529

EN292/T1/T2

EN294

EN349

EN60335 1/2-40

EN55014

EN55104

ÖNORM M7755 2 (Austria)

:

The heat pump is filled with refrigerant. This

Cryogen is non-poisonous and not combustible.

In case of damage however, refrigerant is could flow

out of the plant, and could cause superseding of

oxygen.

Due to open fire, toxic disintegration products can ari-

se

By leaving refrigerant (smell)leave theinstallation site

immediately leaving and close the door.

Contact the customer service.

Works at and in the equipment are permitted only for

authorized experts

Reference to disturbances and error messages see

Page 20.

Page 4

2.1 Description

Heat pump with gas inlet cooled scroll-cachetcompressors, with large dimensioned stainless steel

heat exchangers as vaporizer, condenser on a robust frame with heat and noise emission insulated casing.

A console with all operational and safety equipment

is integrated in the body.

The device is prepared for the operation with a weather compensating flow temperature control (accessory).

The heat pump is accomplished in compact design

and the vaporizer is already built inside the heat

pump casing.

2.2 Range of operation

For a monovalent heating of one totwo family homes

with geothermal usage, whereby the house should

be equipped with a low temperature heating (e.g. under floor heating, wall heating or low temperature radiators)

2.3 Delivery content

2.4 Accessories

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Heat pump aggregate with gas inlet cooledscrollcachet-compressors

stainless steel heat exchanger as condenser

stainless steel heat exchanger as vaporizer

coolant collector and dryer

Thermostatic expansion valve

coolant observing window

coolant heat exchanger

High and low pressure manometer

console with all operational and safety equipment

Thermorelais to protect the compressor

Internal motor protection

Robust frame

heat and noise emission insulated casing

Plastic brine-horizontal-collector Ø 25 x 2,3mm in

loops of 100m each, incl. manifold, connection

set and brine circulating pump

Brine-bore-hole Ø 40mm incl. connection set and

brine circulating pump

Manifold for brine bore-hole collector

!

5 flexible connection pipes

2. Heat pump for Brine or Groundwater operation

TERRAheat pumps operate with the safety coolant R

407 C, which circulates, if properly installed in a closed circuit and is practically no hazard for the environment.

As lower the maximal flow temperature is

designed as higher is the heat pump efficiency

Page 2

Page 5

- TWIN 2x8 S/W 2x10 S/W 2x12 S/W

Heating output at B 0°C/W 35°C in kW 15,34 18,24 22,56

for brine application

COP at B 0°C/W 35°C 4,02 4,07 4,08

Heating output at B 0°C/W 45°C in kW 14,86 17,68 21,66

Required electr. power at B 0°C/W 35°C in kW 3,82 4,48 5,54

B 5°C/W 45°C in kW 2,84 5,72 7,06

Electrical connection

Maximal current 34,6A 46,1 A 47,0 A

Blocked runner current 76 A 100 A 114 A

Upstream fuse 35 A, D 50 A, D 50 A, D

Fuse for control current 10 A 10 A 10 A

Maximal flow temperature 55 °C 55 °C 55 °C

Minimal heating water quantity 2 800 l/h 3 300 l/h 4.000 l/h

Minimal circulating brine quantity 3

Pressure loss on heating circuit 10 kPa 10 kPa 11 kPa

Pressure loss on collector circuit 14 kPa 15 kPa 17 kPa

Heating flow and return R 1 1/4" A.G. 1 1/4" A.G. 1 1/2" A.G.

Brine inlet and outlet R 1 1/4" A.G. 1 1/4” A.G. 1 1/2" A.G.

Used coolant R 407 C R 407 C R 407 C

Coolant quantity 2x2,0 kg 2x2,1 kg 2x2,6 kg

Compressor oil quantity 2x1,1 lt. 2x1,1 lt. 2x1,85 lt.

Amount of collector circuits 7 9 10

Total pipe length 700 900 1000

Brine quantity (mixture) 245 lt. 315 lt. 350 lt.

Recommended resp. integrated buffer

loading pump

Recommended pump power

Heating output at B 5°C/W 35°C in kW 17,86 21,02 26,70

Heating output at B 5°C/W 45°C in kW 17,12 20,34 25,46

Required electr. power at B 0°C/W 45°C in kW 4,80 5,66 6,88

Required electr. power at B 5°C/W 35°C in kW 3,78 4,48 5,58

Required electr. power at

230V/50 Hz 230V/50 Hz 230V/50Hz

for brine collector up to 40m

.600 kg/h 4 500 kg/h 5 500 kg/h

UPS 25-80 UPS 25-80 UPS 25-80

UPS 25-80 UPS 25-80 UPS 25-80

40 x 2,3 50 x 3,2 50 x 3,2

Note:

For large enough boiler rooms it is enough to have a natural venting with a min. venting opening dimensions,

like listed in the EN 378.

A mechanical venting of the boiler room is only required if the boiler room dimensions are not achieved.

5. Technical Data

Page 3

in line with the EN 14511in line with the EN 14511

Page 6

- TWIN 2x8 S/W 2x10 S/W 2x12 S/W

Heating output at W 10°C/W 35°C in kW 20,16 24,00 30,14

COP at W 10°C/W 35°C 10,08 12,00 15,07

for groundwater application

Heating output at W 10°C/W 45°C in kW 20,68 23,04 29,00

Heating output at W 15°C/W 35°C in kW 23,42 27,84 34,76

Heating output at W 15°C/W 45°C in kW 21,88 25,72 32,06

Required electr. power at

Required electr. power at W 10°C/W 45 °C in kW 5,02 5,98 7,38

Required electr. power at W 15°C/W 35 °C in kW 4,02 4,78 5,92

Required electr. power at

Electrical connection

A 26,1 A 47 A

Blocked runner current 76 A 100 A 114 A

Upstream fuse 50 A, D 50 A, D 50 A, D

Maximal flow temperature 55 °C 55 °C 55 °C

Minimal heating water quantity 3 500 l/h 4 200 l/h 5 200 l/h

Minimal groundwater quantity 3 700 l/h 4 500 l/h 5 500 l/h

Pressure loss on heating circuit 15 kPa 17 kPa 19 kPa

Pressure loss on collector circuit 16 kPa 18 kPa 18 kPa

Heating flow and return R 1 1/4” A.G. 1 1/4" A.G. 1 1/2" A.G.

Brine inlet and outlet R 1 1/4” A.G. 1 1/4" A.G. 1 1/2" A.G.

Used coolant R 407 C R 407 C R 407 C

Coolant quantity 2x2,0 kg 2x2,1 kg 2x2,6 kg

Compressor oil quantity 2x1,1 lt. 2x1,1 lt. 2x1,85 lt.

Recommended resp. integrated buffer

loading pump

W 10°C/W 35 °C in kW 3,88 2,68 5,88

W 15°C/W 45 °C in kW 5,04 5,94 7,36

Maximal Current 34,6

Sicherung Steuerstrom 10 A 10 A 10 A

230V/50Hz 230V/50Hz 230V/50Hz

UPS 25-80 UPS 25-80 UPS 25-80

Note:

For large enough boiler rooms it is enough to have a natural venting with a min. venting opening

dimensions, like listed in the EN 378.

A mechanical venting of the boiler room is only required if the boiler room dimensions are not achieved.

Page 4

Page 7

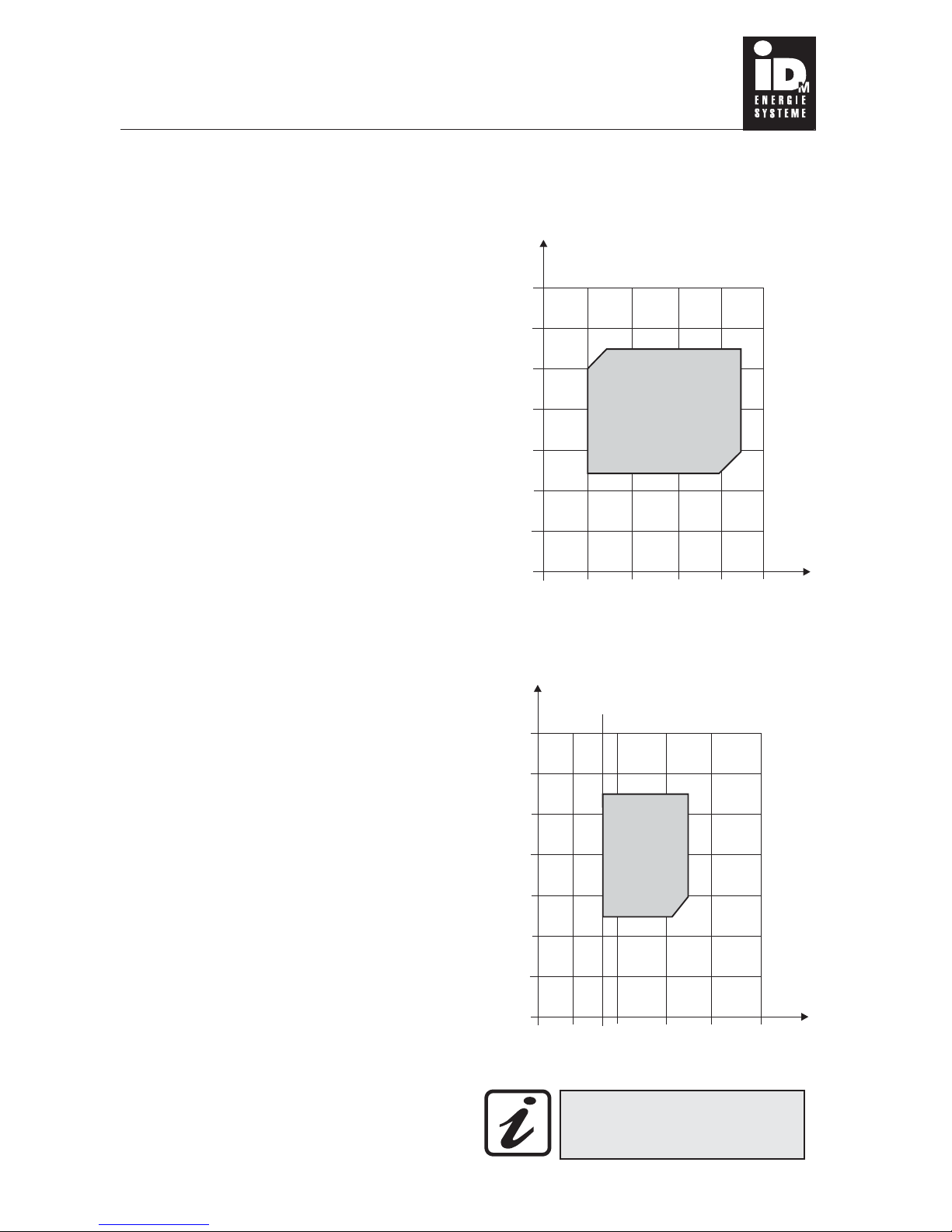

2.6 Operational limits

Seite 5

TERRA-S resp. TERRA-W heat pumps must be

only operated with the heat carrier medium brine

or Groundwater. Other heat carrier media are not

permitted.

Further it is not allowed to heat other fluids than

heating water.

(Heating water quality see page 10)

Heat pumps have natural pressure resp. tempe-

rature operation limits. (See illustration)

It is not allowed to operate the TERRAheat pump

outside these operational limits.

With groundwater heat pumps the groundwater

has to have a certain waterquality,see page18. If

one of those values is below or exceeds these limits it is not allowed to use the groundwater heat

pump with this groundwater.

There are several safety applications integrated

to protect the heat pump

A combined high and low pressure manometer which can be reset by switching the machine off and backon.

Max. flow temperature limit with will automatically reset.

A Thermorelais which can be reset by switching the machine off and back on.

Internal winding protection

With groundwater heat pumps: minimum temperature limit for the groundwater return temperature and integrated water pressure

switch.

Note:

?

?

?

?

?

°C

70

60

50

40

30

20

10

0

flow temperature

Range of application for brine heat pumps

Range of application for groundwater heat

-10010 20 3040°C

groundwater inlet temperature

°C

70

60

50

40

30

20

10

0

flow temperature

Minimum groundwater

inlet temperature: 7°C!

Also during the winter the

groundwater inlet temperature

must not drop below 7°C!

-20 -10 0 10 20 30°C

brine inlet temperature

Page 8

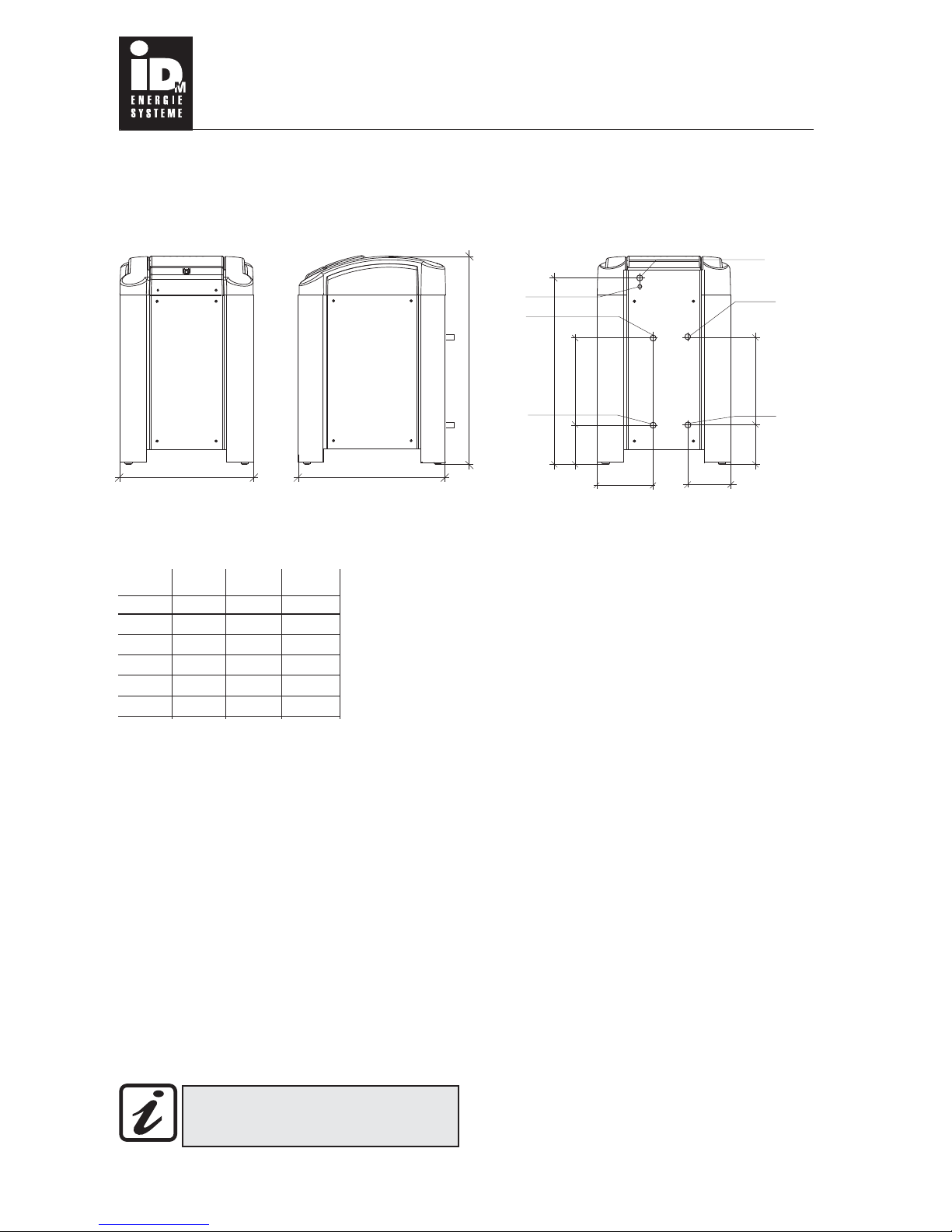

2.7 Technical dimensions

Page 6

front sidefront side

right sideright side back sideback side

762

B

A

TERRA 2x8S/W 2x10S/W 2x12S/W

A 750 750 750

B 1160 1160 1160

C 1025 1025 1025

D 465 465 465

E 465 465 465

2

1

3

2

1

3

Legend:

1 flow connection R 1 1/2” (use enclosed connection pipe 1 1/4” or 1 1/2”)

2 Opening for electrical connection with grind voltage

3 return connection

4 Brine resp. groundwater inlets

5 Brine resp. groundwater outlets

6 Opening Ø 50mm for electrical output

R 1 1/2” (use enclosed connection pipe 1 1/4” )

R 1 1/2” (use enclosed connection pipe 1 1/4” )

R 1 1/2” (use enclosed connection pipe 1 1/4” )

For brine heat pumps: see page 3

For groundwater heat pumps: see page4

Dimensions for connections:

or 1 1/2”

or 1 1/2”

or 1 1/2”

C

D

E

210

210

235310

6

4

5

6

4

5

On the backside of the heat pump is a sticker with the connecting description located

Page 9

Page 7

The TERRA heat pump must be installed in a frost

protected room by a certified Installation company.

The room temperature should be in between 5°C

and 35°C.

The installation in wet rooms or rooms that are at

high risk of dust or explosives is prohibited

The TERRA heat pump should be installed on a leveled, straight and capable ground (e.g. concrete) to

avoid noise conduction. If floor screed is used, the

screed and floor insulationhave tobe omit to ensure

a silent operation.

A minimum distance of 60cm is required in front of

and next to the heat pump. (See illustration on by)

The appropriated laws, regulationsand Normshave

to be taken into notice, specially the EN 378 Part 1..

To avoid noise conduction via the piping, the enclosed flexible connection pipes for the flow andreturn,

as well as for the brine in- and outlet resp. the

groundwater in- and outlet have to be used.

For a leveled installation of the TERRA heat pump

there are adjustable feet provided.

The en-

closed connection pipes must not be kinked!

2.8 Installation

min. 600750

850

TERRA

min. 600

The minimum distances have to be provided!

The minimum size of the boiler room has to be

provided!

The connection pipes have to be used!

Adjustable feed

Page 10

Page 8

2.8 Hydraulic schematics

System scheme 1:

TERRAheat pumpwith IDM-Hygienik

In this scheme the Hygenik is only used to provide

domestic hot water.

The heating is fed straight from the heat pump.

System scheme 1:

TERRAheat pumpwith IDM-Hygienik

It is only possible to use 1 Heating

circuit. The heating circuit must be a

pumped circuit (no mixer!) and is not

possible to use zoning control valves!

C

B9

B3

A6

heatpump

Buffer Hygienik

T

T

T

V1

P2

B2

T

A6

B9

B3

B1

layer separate plate

T

T

heatpump

Buffer Hygienik

T

B2

T

M1

V1

A

B

System scheme 2:

TERRA heat pump with IDM-Hygienik with

dividing membrane

The upper part of the buffer is loaded under priority

by a priority valve.

The lower part of the buffer is theheating buffer.

The heating circuit can be a pumped or mixed cir-

cuit, whereby it is recommended to fit a mixing valve.

System scheme 2:

TERRA heat pump with IDM-Hygienik with

dividing membrane

The sensor B2 has to be placed in the

lower buffer part.

C

The sensor B2 has to be

placed inside a sensor

pocket at the return.

P2

P1

Page 11

Page 9

A6

B3

B1

B2

T

B9

T

Buffer

Buffer Hygienik

heatpump

T

T

System scheme 3:

TERRA heat pump with IDM-Hygienik and extra

heating buffer

The Hygenik is only used to provide domestic hot

water and is loadedunder priorityby the priority valve.

The heating is supplied by an extra buffer.

The heating circuit can be a pumped or mixed cir-

cuit, whereby it is recommended to fit a mixing valve.

System scheme 3:

TERRA heat pump with IDM-Hygienik and extra

heating buffer

The sensor B2 has to be placed inside

the buffer.

The sensor B2 has to be placed inside

the buffer.

C

M1

V1

P2

P1

A

B

Page 12

C

2.10 Connection on the heating side

Wrong water flows by reason of wrong

pipe dimensions, wrong fittings or incorrect pump operation can cause fatal

disfunction.

Page 10

The appropriated laws, regulations and Norms for

heating installations are also valid for installations

that include heat pumps.

It is obligatory to fit a filter into the heating return

before the heat pump.

!

!

!

!

!

!

The circulating pump power has to matchthe installation (see technical data on page 3 and 4)

The safety and expansion installations for closed

heating systems relevant to EN 12828 have to be

provided.

The connection pipes should be as short as possible. The pipe dimensions have to match the required water flow.(See technical data on page 3 and 4)

The enclosed flexible connection pipes for the heating flow and return as well as for the brine and

groundwater circuit have to be used. The connection pipes can be shortened to a desired length

though not shorter than 60cm! Further the connection pipes must not be kinked!

At the highest pointof the pipes has to be an airvent

as well as a drain on the lowest point.

To avoid heat losses, the connection pipes have to

be insulated with an appropriate material.

Oxygen diffusion

If not diffusion proof plastic pipes for the under floor

heating or a vented heating system is used, it can

happen that, if steel pipes, steel radiators or steel buffer are installed, corrosion occurs onto these steel

parts.

Corrosion particles cansettle downinto the liquidizer

and can cause power losses ofthe heat pumpor high

pressure faults.

Therefore it should be avoided to use vented heating

systems or steel pipe installations in connection with

non diffusion proof underfloor heatingpipes.

Heating water quality

Depending on the Heating waterquality stoneformation (solids mainly from calcium carbon) especially

onto the heat exchanger surface can occur. With a

high Calcium hydrocarbon content it is a higher risk

of stone formation.

Therefore at Installations with a water hardness of

more than 14°dH resp. with a Calcium hydrocarbon

concentration of more than 2,5 mol/m³ the heating

water has to be treated. (Softened/desalted)

The Calcium hydrocarbon concentration

c(Ca(HCO3)2) of you heating water can be got from

your local water supplier.

The ph-value also needs to be checked and has to be

in between 8 and 9,5.

Page 13

2.11 Electrical scheme

The electrical connection has to be reported with

your local electricity supply.

The required size of the upstream fuse for the main

electric circuit can be seen within the technical data

on page 3and 4. It is importantto use a sluggish fuse

(characteristic D). The relevant wire diameter has to

be calculated by an electrician.

A to protect thecompressor isalready

integrated.

A for the brine or ground-

water pump and adjusted.

The heat pump is usually operated with a weather

compensating flow temperature control.

The connections to control the heat pump with a

are prepared inside the console.(Look

up the electrical connections on page 12)

The has to be inside certain tolerance

margins to insure a trouble free operation of the heat

pump (it can be asked at your local electricity supp-

lier)

Thermorelais

suitable motor protection

needs to be installed

room sensor

grid voltage

Main electricity connection

230 V/50 Hz

control current connection

230 V/50 Hz

activation of the brine or

groundwater pump

230 V/50 Hz

Page 11

The starting current limitation equipment can be inserted.The starting currents can be reduced around

approx. 50% (after pressure balance).

For TERRA 5 S till 30 S Art. Nr.: 351 211

motor protection

activation of the buffer loading pump

1x230V/ 50 Hz

Legend:

F1

S1

B1

fuse 6,3 A t

control switch On/Off

line filter

232122

1

Platine IO2, idm.multitalent.wp

S1

Line

Load

B1

Grid control currency

230V/50Hz

23

L

N

Pe

F1

operator device Mecmatic - MM,

back side

output connection input connection

Master Bus A

Slave Bus

RS 485

Master Bus B

RS 485

Systembus A

Systembus B

Buskable 8-polig

EEPROM IO2

EEPROM MM

Fuse 0,5 A t

18

Page 14

2.12 Electrical connection

Before connecting the heat pump, the plastic cover

has to be removed. Now the connectors are accessible. The connectors for the main and grid electricity

are separated. (See illustration resp. next page)

.

The cables have to have the relevant strength, see

point 2.5 on the technical data on page 3 and 4.

The required connections of devices from the micro

processor chip output have to be made out of flexible

cable with 1,5mm².

Grid connection: 230V/50Hz

Main electricity connection: 230V/50Hz

The electricity supply has to be disconnected before removal of the plastic cover!

The pumps have to be commissioned before the heat pump is put into operation!

All connections have to be tightened before the heat pump is put into operation!

The whole heating system has to be filled before the heat pump is connected to

the grid and put into operation, otherwise the circulating pumps could run dry.

Page 12

One comment to the problematic of Electro magnetically compatibility: From year to year more effort and

Know-How is required from manufactures and end

user of modern electronics because of Electro magnetically compatibility.

The amount of electrical applications is steadily rising and with them the potential for faults. Together

with power lines, transmitting devices and other telecommunication installations a invisible electro smog

is created.

These disturbances affect all systems, both, biological (us humans)and electronic systems. They cause

undesired faulty currents in many ways.

We can just guess the consequences ontobiological

systems, but you can measure the consequences onto electrical systems, and in heavy cases you can

even see them.

These disturbances can have various results:

Short term measuring faults

Long term measuring faults

Short term disruption of data connection

Long term disruption of data connection

Loss of data

Damage of the facility

All electrical applications like protection coils, motors, transmitters, high voltage power lines, etc. can

cause such disruptions, whereby the disturbance

can occur in many different linked ways. (Galvanic,

inductive, capacitive or radiation)

From our side everything undertaken isto protectthe

multi talent control against those disturbances.

(Hardware design, electro magnetic emission proof

console, grid filter,etc.)

!

!

!

!

!

!

The electrician is further responsible to avoid

eventual ways of disturbance during his installation.

Release the bolts

from the plastic cover and underneath

the yellow lid to remove the cover.

Page 15

Electrical connection for all brine and groundwater heat pumps of the type TERRA

Page 13

1 2 3 4 5 6 7 12 13 14 21 22 23 28 29 30

Main electricity con-

nection 230 V / 50 Hz

N Pe N Pe

brine resp. deep well

pump 230V

Control current con-

nection 230V/50Hz

N PeL L L

Pe

water pressure

switch (accessory)

Subsequent the necessary connections that are performed as inline connections are shown. The gray

connections have to be connected on site, whereby

the rest is pre connected already.

The wire diameter for the main electricity and for the

brine resp. the deep well pump wire has to be dimensioned corresponding to the technical data. (See page 3 and 4 for brine resp. groundwater systems)

24 25 26

Pe

External activation

EW contact

31

A

C

B

P<

Connecter description:

Main electricity connecter 230V 50Hz

:

1. Compressor 230V, pre connected

Connection

connection 230V/50H

(if no control is integrated): a potential free contact has to beconnected between connecter 24 and 25

a potential free contact has to be connected between connecter 25 and 26 (remove the pre installed bridge)

Connectern 1 to 3:

Connecter 4 to 7:

Connecter 8 to 11:

Connecter 21 to 23:

Connecter 24 and25:

Connecter 25 and 27:

brine resp. deep well pump

Control current z

External activation

EW barrier:

2. Compressor 230V, pre connected

Connecter 12 to 14:

27

Connecter 28 to 31:

Water pressure switch, at groundwater systems to

be installed on site, whereby the pre installed bridge

has to be removed; at brine systems the contact 28

and 30 has to be bridged.

1. Compressor 230V,

pre installed

8 9 10

11

2. Compressor 230V,

pre installed

Page 16

Page 14

3.1 General Information

The given required area for geothermal heat pumps

is related to average ground conditions (Soil, clay).

The required collector size and therefore the area

has to be increased for poor grounds (gravel).

Contact your IDM-partner for further consultation.

A pump trial run for 48 hours at the end of February

and a water analysis is recommended for the use of

groundwater.

Following criteria decides which the suitable Heat

source system is:

?

?

?

?

?

Is enough ground or surface water available?

Is the ground or surface water temperature also

during the winter above 8°C?

Is the ground or surface water quality sufficient

enough?

Is enough space for a horizontal collector availa-

ble?

Is a bore holeas aresult ofthe available space re-

quired?

The different heat source systems are described on

the following pages.

In various countries the use of geothermal heat has to be permitted by the water right authority. A corresponding request has to be made in time.

3. Heat source systems

Page 17

Page 15

4.1 Description

In this system there are plastic pipes Ø25 x 2,3mm

with a length of 100m each placed into the ground to

transfer the heat outof the ground. Depending on the

heat pump size there are more circuits necessary.

The brine mixture circulates inside these pipes. The

heat exchange between the brine and the coolant

happens inside the vaporizer set with a stainless

steel plate heat exchanger.

Following fittings are necessary for the installation:

Brass manifold with gate valves, safety blow off, manometer, pressure vessel, thermometer and a brine

circulating pump.

The enclosed flexible connectionpipes haveto befitted to avoid noise conduction. The connection pipes

between manifold and heat pump have to be made

on site, whereby galvanized pipes can't be used.

The brine mixing ratio has to be chosen up to -15°C

(= 30% anti freeze). If too much anti freeze is added,

the specific heat capacity of the brine decreases.

4.2 Range of Application

Suitable for all heat pumps of type TERRA S

4. Brine-Horizontal Collector

4.3 Delivery Content

?

?

Plastic pipes Ø 25 x 2,3mm in loops of 100m each,

the amount of loops depends on the heat pump output.

Connection set including

- Manifold with gate valves for each circuit

- Safety blow off

- Manometer

- 2 thermometers

- Pressure vessel

- Brine circulation pump

Connecting on Site: It is not allowed to use

any galvanized pipes! The enclosed flexible

connection pipes have to be used!

PE-plastic pipe

60

190

1 1/4”

Note:

Attention:

The used anti-freeze has to be permitted by

IDM-Energiesysteme GmbH.

The brine circuit pipes have to be insulated with a

suitable and diffusion proof insulationagainst condensing water.

Brine circulation pump and pressure vessel have

to be installed onto the flow.

The brine pressure vessel has to be connected

above the pipes.

The pump electrical connection box can't

show down! The pumpmotor can'tbe insulated!

!

!

!

Page 18

Page 16

4.5 Installation schematic

4.4 Technical Data

Pipe distance: about 80cm

Pipe depth: 110 120cm

Type S5 S7 S8 S10 S12

300 300 400 500 600

For the recommended brine circulation pump see technical data on page 3.

Amount of circuits

Total length of pipe, in meter

Required area in m²

Dimensions brine circuit. DN

Length of manifold

Brine mixture in liter*

* Brine mixture (30% anti freeze content), without the amount inside the connection pipes.

3345 6

240 240 320 400 480

25 25 25 25 25

180 180 240 300 360

105 105 140 175 210

The given required area for geothermal heat pumps is relates to average ground conditions (Soil, clay). The required

collector size and therefore the area has to be increased

for poor grounds (gravel). The circuitshave tobe bedded in

fine sand (0,3 0,5mm).

Contact your IDM-partner for further consultation.

Pipes from the manifold towards the cellar

An example for a TERRA 8 S-HGL heat pump with

4 circuits and a manifold connection inside the cellar.

For a lengthof 2m, where the pipes are brought

together,they have to be insulated.

The connection pipes have to be insulated with

suitable insulation, galvanized pipes can't be

used.

Aminimum distance of 1m has to be provided to

any water supply and drainage pipes as well as

to walls

Openings inside the wall have to be insulated

and made water proof.

A warning tape has to be bedded 0,5m above

the pipes.

An installation plan and photos have to be made.

The manifold connection can also be outside the

house inside a manhole.

?

?

?

?

?

?

Pipes towards the TERRA to cellar

manifold

Page 19

Page 17

5.1 Description

In this system the collector is made out of plastic pipes with a special pipe head. This vaporizing system

requires smallest space of allground vaporizers.The

bore-hole diameter is 125mm, the depth and collector length depend on the heatpump output. The brine

mixture circulates inside the pipes. The heat exchange between thebrine and the coolant happens inside

the vaporizer set with a stainless steel plate heat exchanger.

For the brine circuit connection is required: A brass

manifold with gate valves, safety blow off, manometer,pressure vessel,thermometer andbrine circulation pump.

The enclosed flexible connection pipes have to be

used to avoid any noise conduction. The connection

between manifold and heat pump has to be built on site, whereby itis not allowed to use any galvanizedpipes!

5.2 Range of Application

Suitable for all heat pumps of type TERRA S.

5. Brine bore-hole system

5.3 Delivery content

?

?

?

Collector plastic pipes, the size depends on the

heat pump output

Connection set including

- Safety blow off

- Manometer

- 2 thermometers

- Pressure vessel

- Brine circulation pump

Manifold has to ordered separately

Connection set

manifold

5.4 Technical data

Type TS 5 TS 7 TS 8 TS 10 TS 12

Amount of bore-holes 1 1 2 2 2

Total depth collector* m 80 100 130 150 190

Length of manifold L 60 60 120 120 120

Collector-Ø mm 40 40 40 40 40 40

Connection pipe -Ø DN 40 DN 40 DN 40 DN 40 DN 40

circulation pump** 25-60 26-60 25-60 25-80 25-80

Brine mixture*** 160 200 250 290 360

* The given collector depth is an average value and is depending on the condition of the ground.

** For the bore-hole collector: Type of pump: xx-xx = Grundfos UPS, xx/xx = Wilo Top S

*** Brine mixture (= 30% Proportion of anti-freeze), without contents of the collecting line

Connecting on Site: It is not allowed to use any galvanized pipes! The enclosedflexible connectionpipes have to be used!

Note:

!

!

!

!

!

The used anti-freeze has to be permitted by IDMEnergiesysteme GmbH.

The brine circuit pipes have to be insulated with a

suitable and diffusion proof insulationagainst condensing water.

Brine circulation pump and pressure vessel have

to be installed onto the flow.

The brine pressure vessel has to be connected

above the pipes.

The circuits have to be filled with the anti freeze

mixture from the pressure vessel on (because of

volume reduction at temperature drops during

operation)

The pipes have to rise for venting

Page 20

Page 18

6.1 Description

In this system ground or surface water is used as a heat source. In the case of groundwater usage the water is pumped out of a tap well, cooled down inside

the vaporizer and via the return well brought back into the ground. Ithas tobe ensuredthat the return well

is in flow direction of the groundwater downstream of

the tap well.

The heat exchange between the water and the coolant happens inside the vaporizer with a stainless

steel plate heat exchanger.

To protect the vaporizer there is an automated minimum temperature limit control and a water pressure

switch integrated and connected. A pressure reducing valve is necessary for the operation of the water

pressure switch. (To be fitted on site, see illustration)

The enclosed flexible pipes have to be used to avoid

noise conduction.The groundwater pipes have to be

built on site.

Note:

!

!

!

!

!

!

!

To avoid a blocking of the vaporizer, settle basins

have to be provided in case of high amounts of

particles inside the well water.(Sand, muck)

Flow and return pipes have to be frost protected,

with a slope towards the well.

The pipes inside the house have to be insulated

against condensing water.

A duct with electrical wires for the deep well pump

has to be placed from the tap well towards the heat pump.

The well cover has to be light and airtight to avoid

formation of algae and a silting of the well.

The well pump should be a deep well pump.

The well should be flushed for at least 48 hours af-

ter constructing to avoid a contamination of the

system.

6. Ground and Surface water systems

6.2 Range of Application

6.3Accessories

Waterinlet temperature

Min. water flow

Groundwater quality:

: min. +7°C!

: see chart on page 3

Following values have to be reached:

To be installed on site:

- Deep well pump with suitable pipe

- Motor protection switch for the deep well pump

- Waterfilter

- Watermeter withgate valve

- Pressure reducing valve

- Maybe Thermometer

?

Ph-value: 6,5 - 9

Chloride: < 100 mg/kg

Sulfate: < 50 mg/kg

Nitrate: < 100mg/kg

Manganese: <1 mg/kg

Free Carbonic acid: < 20 mg/kg

Ammoniac: <2 mg/kg

Iron: < 2 mg/kg

Free Chloride: < 0,5 mg/kg

Electric Conduction: > 50 S/cm und < 600 S/cm

Oxygen <2mg/kg

A pump trial run for 48 hours at the end of February

and a water analysis is recommended to check the

possibility for groundwater as a heat source.

*

*

*

*If those limits are exceeded,the vaporizerand pipes can get mocked up as well as the return well

can get silted.

mm

A water meter (if required by the water authority),

otherwise blind fitting

Filter (Mash width max. 0,6mm)

galvanized, plastic

or stainless steel pipes

deep well pump,

power depends on

the depth of well

Groundwater flow direction

min. 15 m

return well, tap well

Exhaustion well

pressure reducing valve

bypass to flush the well

Page 21

Page 19

7. Advices for the Installation

The heating and brine resp. groundwater circuits have to be pressure tested, neatly flushed,filled and carefully vented before the TERRA heat pump is put into operation.

Requirements for system start up:

The heating system as well as the buffer tank has

to be filled and vented.

In case of a brine heat pump the brine circuit has

to be filled with anti freeze (-15°C), flushed and

vented.

The electrical installation has to be finished.

It is only allowed to start the heat pump if the cir-

cuits on the cooling and the heating side are properly filled and the electrical connections arechecked.

Before starting up, the flow temperature limit has

to be checked and set. The shut off limit of 55°C

has to be checked and if needed the shut off temperature has to be changed.

The heat pump has a start up delay, so that the

compressor will just start after this time.

To drain the heat pump on the heating side frost

protected the heat pump return connection has to

be opened.

The groundwater return temperature limit has to

be set before start up so that the heat pump shuts

down at a water return temperature of 3°C.

?

?

?

?

?

?

?

?

Note:

At the heat pump console there is a particular switch

to flush and vent the brine or groundwater circuits.

(See illustration)

As soon as the electrical connections (main and control current) are installed, the brine resp. groundwater pump can put into operation by switching the

switch onto “Spülen” (“Flush”). The main switch at

the front of the console does not have to be switched

on.

Flush switch for the brine resp. groundwater pump

After the proper commission the switch

has obligatory be set onto “Automatik”.

Page 22

Page 20

8. Operation

The TERRA heat pump is switched on and off fully automated by the Multi talent control.

For a proper operationof thecontrols themanual has

to be looked up.

An annual service and maintenance of the installation by a customer service is recommended in concern of warranty claims.

Display:

Humming alarm light

main switch

heating control

(accessory)

operating and fault lights flow temperature

brine flush switch

fuse

Page 23

Page 21

9. Faults / Fault removal

C

In case of a series of High pressure, low pressure or Thermorelais faults, please contact your

customer service!

Customer service phone number:___________________________________

(

The heat pump is equipped with a variety of safety applications to protect the machine for possible faults.

If the heat pump is contrary to expectation not running, so the following things have to be checked:

Note: If the fault light “ ” or “ ” is shining, but no temperature is displayed at the referring thermostat, the main electricity supply is cut off. It can be a blocking

time of the electricity supply or a fault.

Over temperature Groundwater too cold

9.1 Is the green indicator light inside the main

switch shining?

9.2 Is the humming fault light shining (see illustration on page 20)?

If not:

Is the heat pump activated by the control? Look up

the referring control manual.

Is the fuse inside the heat pump console intact?

(For the position of the fuse look up the Description

of the heat pump)

Is the fuse of the primary control intact, e.g. the

EVA-system?

See referring system description..

Open the yellow lid and check the individual fault

lights, for this see 9.3 (right) and illustration on

page 12.

!

!

!

9.3 Is one of the 5 red fault lights shining?

High pressure fault

or Low pressure fault:

Motor protection:

Over temperature:

Groundwater too cold:

If one of those lights is shining switch off the

main switch and after a few seconds back on.

The heat pump is ready for operation again.

But still the function of the heating circuit

pumps should be checked.

If this light is shining the compressor was overloaded. Switch off the main

switch and after a few seconds back on. The

heat pump is ready for operation again. But still

the main electricity connection should be checked.

If this light is shining, the

heat pump has a too high temperature, has to

cool down and will switch back on automatically.

If this light is shining, the

groundwater return temperature out of the heat

pump is too low.

The groundwater circuit has to be checked.

1

2

3

4

5

Page 24

THE POWER-FAMILY

INBETRIEBNHAME - WARTUNG - SERVICE

PRAXISWISSEN FÜR VERKAUF UND TECHNIK

IDM-Servicetechnik

IDM-Akademie

Unsere Service-Techniker helfen gerne Vorort. Ihren

regionalen Ansprechpartner mit Kontaktdaten finden

Sie auf unserer Website

www.idm-energie.com

Das umfangreiche Seminarangebot für Fachleute bei der

IDM-ENERGIEFAMILIE steht für Sie jederzeit auf unserer

Website zur Verfügung.

Wir freuen uns über Ihre Anmeldung.

www.idm-energie.com

Your IDM- Partner:

IDM- ENERGIESYSTEME GMBH

Seblas 16 - 18

9971 Matrei in Osttirol

Telefon + 43 (0)4875 6172 - 0

Telefax + 43 (0)4875 6172 - 85

E-mail team@idm-energie.at

The IDM ZENTRALE IN MATREI IN OSTTIROL

www.idm-energie.com

Seminar- News www.idm-akademie.com

Wasserhygiene- News www.krankgeduscht.com

Loading...

Loading...