TERMOSTROJ TERMO-Blok, TERMO-Blok PTV, TERMO-Extra Instruction Manual

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

ELECTRIC BOILERS FOR CENTRAL HEATING

TERMO-Blok

TERMO-Extra

TERMO-Blok PTV

INSTRUCTIONS FOR USE

‘Ulaganje u budućnost’

‘Investing for the future’

Projekt sufinancira Europska unija iz Europskog fonda za regionalni razvoj.

Project is co-founded by the European Union’s Regional Development Fond.

INSTRUCTIONS FOR USE

We reserve the right of alternations

TMS-UT-0114-T03-1

INSTRUCTIONS FOR USE

We rese rve the right of al ternations

TMS-UT-0114-T03-1

Contents

1. Introduction ....................................................................................................................... 1

1.1. Applicable documents ................................................................................................. 1

1.2. Retention of documents .............................................................................................. 1

1.3. Introduction ................................................................................................................. 1

1.4. Heating curves ............................................................................................................ 1

1.4.1. Availability of heating curves................................................................................. 1

1.4.2. About heating curves ............................................................................................ 2

1.4.3. Why does the characteristic heating curve have to be set? .................................. 2

1.4.4. Corrections of the room temperature .................................................................... 2

1.4.5. Limiting the minimum and maximum temperature of the water in the boiler .......... 4

1.5. Functionality of hot domestic water ............................................................................. 4

1.5.1. Availability ............................................................................................................ 4

1.5.2. Description ........................................................................................................... 4

1.6. Frost protection ........................................................................................................... 5

1.6.1. Availability ............................................................................................................ 5

1.6.2. Domestic water ..................................................................................................... 5

1.6.3. Central heating ..................................................................................................... 5

2. Using control panels .......................................................................................................... 6

2.1. Working with standard control panel ........................................................................... 6

2.2. Working with electronic control panels (option E) ........................................................ 7

2.3. Working with electronic control panels (option C and W and Termo Blok PTV) ........... 8

2.3.1. General ................................................................................................................ 8

2.3.2. Central heating functions .....................................................................................11

2.3.3. Domestic water functions (control panel type 2)...................................................13

2.3.4. Central heating functions with heating curves disabled ........................................15

3. Maintenance .....................................................................................................................16

3.1. Periodic checking .......................................................................................................16

3.2. Cleaning.....................................................................................................................16

3.3. Central heating system ..............................................................................................16

3.4. Starting the pump manually .......................................................................................16

4. Survey of possible malfunctions and irregularities in operation .........................................18

INSTRUCTIONS FOR USE

We rese rve the right of al ternations

TMS-UT-0114-T03-1

1. Introduction

Thank you for your confidence you have shown to us by purchasing our central heating boiler.

In order to use the boiler to the utmost correctly and safely, and above all economically, read

thoroughly these instructions before continuing with installation.

The appliances must be installed by a competent person, who is responsible for adhering to

the existing regulations, rules and g u idelines.

1.1. Applicable documents

The following additional documents are provided with the appliance:

For the owner of the system:

Instructions for use

Warranty card

For the qualified technician:

Instructions for installation

Electrical drawing for the appliance

1.2. Retention of documents

Please pass on this installation manual to the owner of the system. The owner should retain the

manuals so that they are available when required.

1.3. Introduction

TERMO-Extra and TERMO-Blok are economical central heating boilers that may be used as an

independent or additional source of heat.

TERMO-Extra and TERM O-Blok boilers offer you the possibility, to reduce the po wer of a heater if

necessary. The power may be switched on when necessary automatically with the built-in step

regulator or manually with switches on the c ontrol board. In this way it is possible to ad apt t he boiler to

the utmost to circumstances on the spot.

The boiler operates on the principle of rapid heating smaller water quantities, so that exploiting of

energy is already 100%.

They are particularly suitable for heating smaller business premise, where you are short of space

(small apartm ents, efficiency apartments, represent ation offices, smaller coffee-shop s paces etc.) or

for heating larger spaces in early season when the main boiler is over dimensioned.

TERMO-Extra boilers are manufactured only with upper connecti ons. Temperature operation area is

from 20

o

C to 90 oC.

TERMO-Extra and TERMO-Blok are designed in such a way that in apartment-contained central

heating they can fit well with your furniture.

1.4. Heating curves

1.4.1. Availability of heating curves

Use of heating curves, temperature compensation, is limited to Termo Extra boilers with options C and

W, Termo Blok boilers with option C and Termo PTV boilers.

INSTRUCTIONS FOR USE

We reserve the right of alternations

page 1

TMS-UT-0114-T03-1

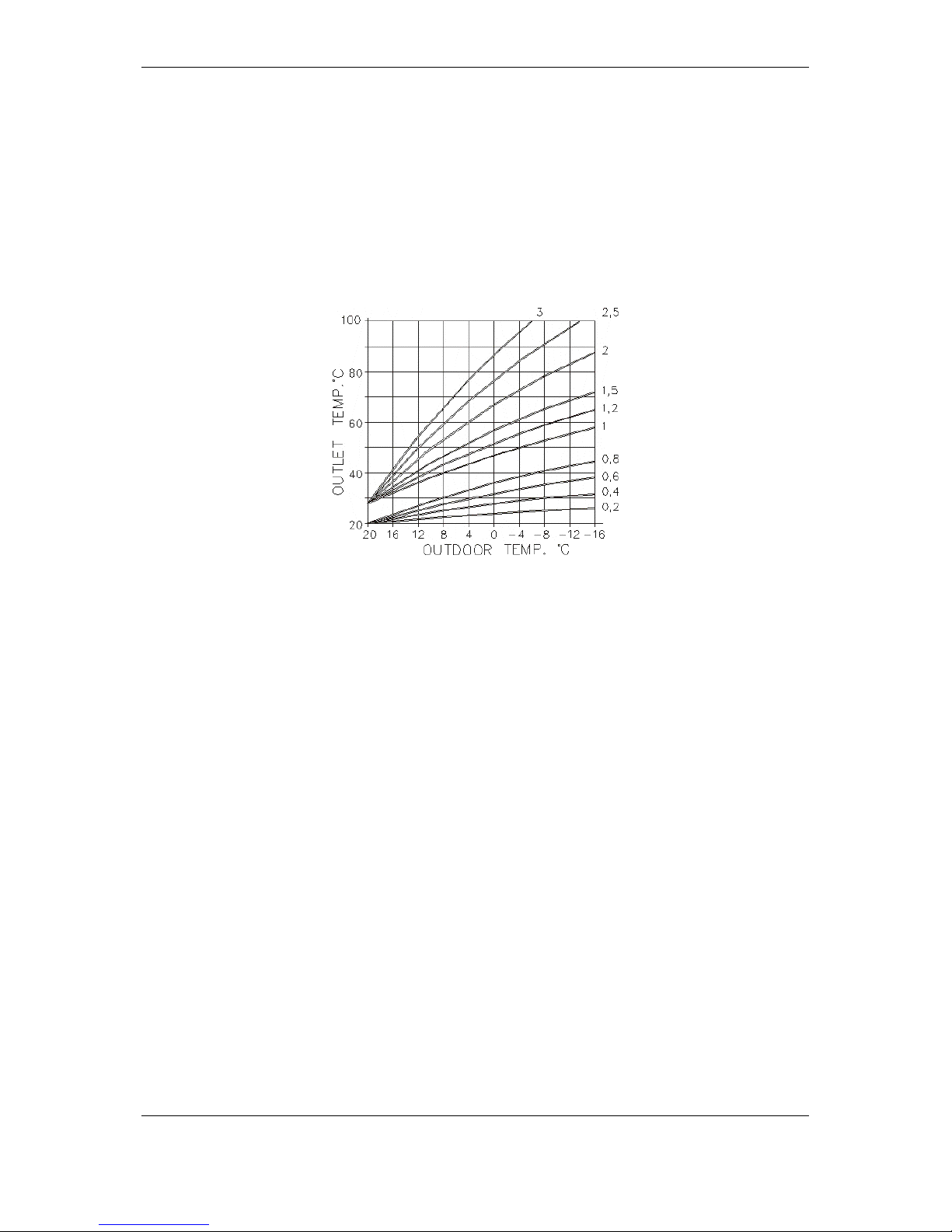

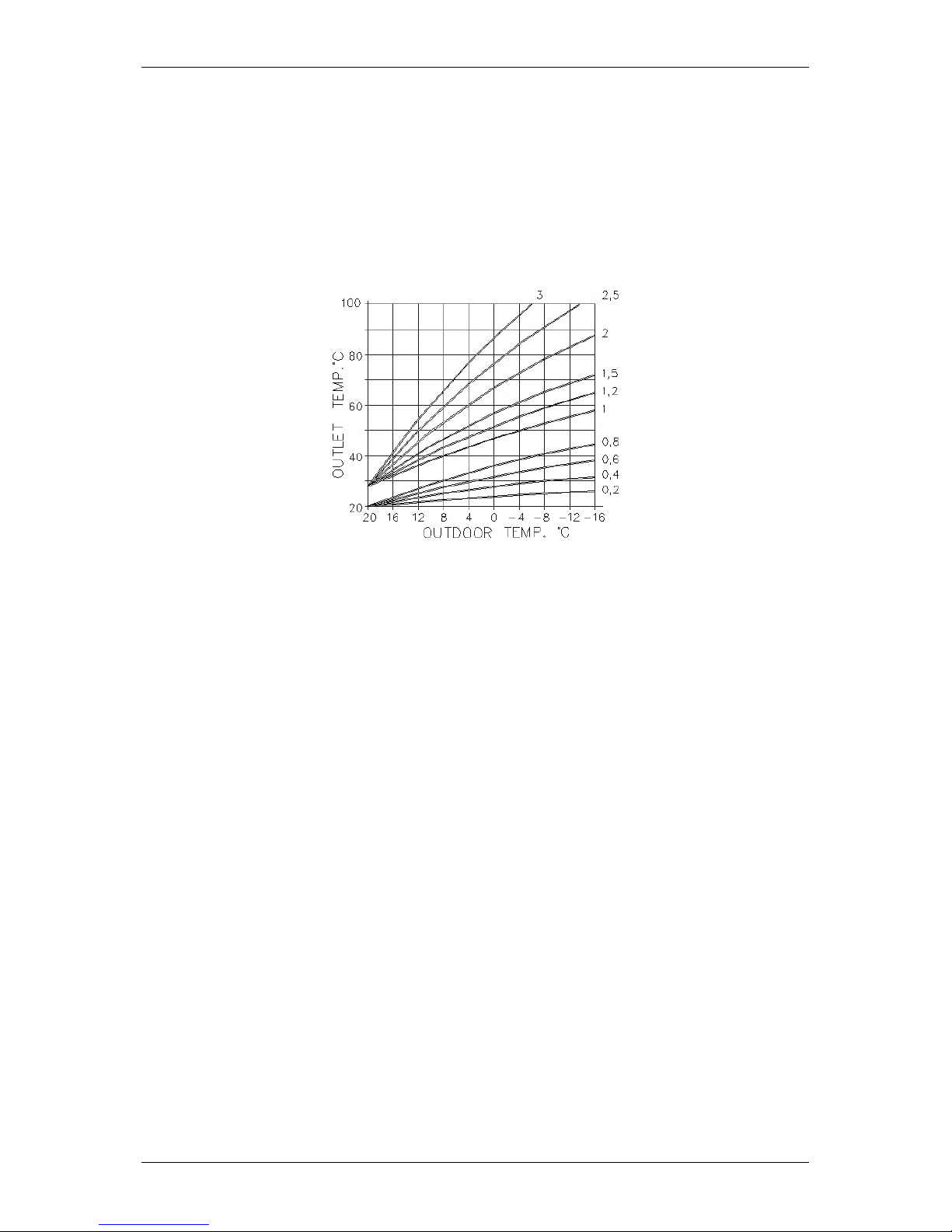

1.4.2. About Heating curves

The modern wa y of heating is based on energ y savings and automatic adjustment s to worm up the

space.

To achieve the required tem perature electric bo iler with electronic contro l panel heats the water in the

boiler automaticall y depend ing on the ex tern al tem perat ure. T here is no need to look af ter the minimal

working temperature because electric boilers do not dew and that m eans that the temper ature of the

water in the boiler is at the same time the temperature in the heating elements (for example in

radiators, convectors etc.).

To achieve the desired room temperature, the characteristic heating curve has to be chosen

depending on the characteristics of the object and the heating system.

Factory defined curves

If the heating curve is set optimally for heating your apartment or a house, corrections will not

be necessary.

1.4.3. Why does the characteristic heating curve have to be set?

After the first settings of the heating curve an authorized person can adjust, correct that curve if

necessary.

Every heating room is bui lt up d if f er entl y. Dif f erent hea t ing el ements and heating syst ems can be used

(radiators, under floor heating or combined heating) and every building has a different thermal

insulation.

For the maximum exploitation of the heating and maximum energy savings, characteristic heating

curve has to be set using the parameter on the control panel, in a way that the chosen heating curve is

suitable for the heating system and for quality of the building.

1.4.4. Corrections of the room temperature

Based on experience, factory settings of the device are for the average insulated object and room

temperature of 22

o

C. If factory settings are not adeq uate for achieving the desired room temperat ure,

supplemental adjustments of the standard heating curves can be made.

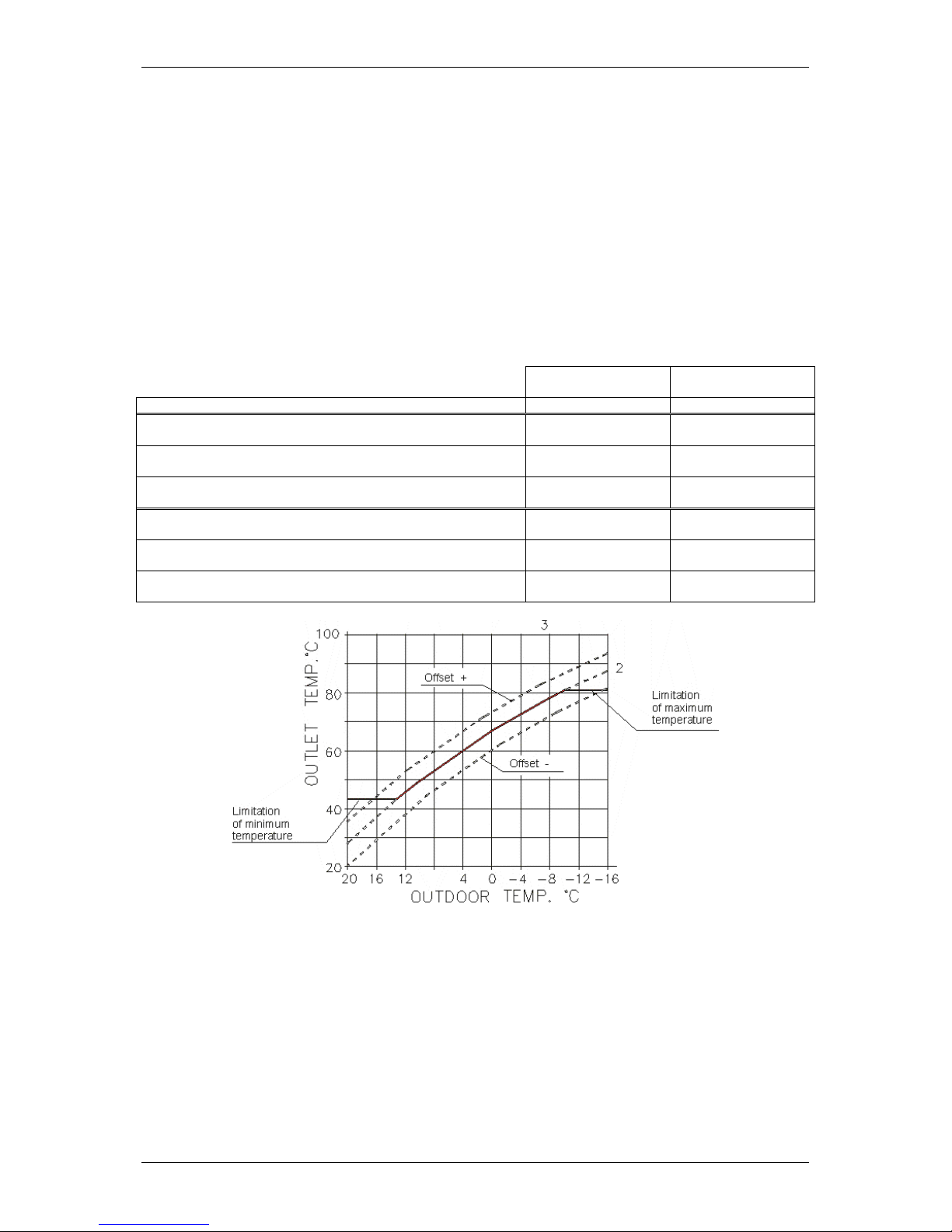

Changing the inclination

When changing the heat ing curve, inclination is changing too, an d that way temperature of the water

in the boiler is changing when the external temperature is low (below + 5

o

C).

Level changes - offset

By offsetting the heating curve for the chosen value, the temperature of the water in the boiler is

changing without changing the shape of the curve.

INSTRUCTIONS FOR USE

We reserve the right of alternations

page 2

TMS-UT-0114-T03-1

Values in the table below are used for the orientation and the user can change them any time as

he/she wishes.

The experience has shown the following (for the average building quality):

when the temperature of the water for the heating changes from 5 to 7

o

C that will change the

room temperature by approximately 2

o

C.

Thermal (heating) processes are slow, all corrections function after some period of time. It

would be better if further corrections were made a day or two later.

To gain experience, we su ggest th at you should write all corr ections ( in th e perio d of s earching f or th e

right parameters) in the protocol of the corrections.

In the table belo w you can find instr uctions how to correct the heating curve for the r adiator heating

depending on the achieved room temperature.

Inclination of the

curve

Offset

Factory settings

1,5

0

Room temperature is too low if the external temperature i s

above + 5oC

Change with the first

lower curve

Add with offset

+ 6oC

Room temperature is too low if the external temperature i s

between + 5oC and - 5oC

Leave the curve 1,5

Add with offset

+ 3oC

Room temperature is too low if the external temperature i s

below - 5oC

Change with the first

higher curve

Leave offset

0oC

Room temperature is too high if the external temperature is

above + 5oC

Change with the first

higher curve

Lower with offset

- 6oC

Room temperature is too high if the external temperature is

between + 5oC - 5oC

Leave the curve 1,5

Lower with offset

- 3oC

Room temperature is too high if the external temperature is

below- 5oC

Change with the first

lower curve

Leave offset

0oC

Sample of modified curve

In combined heating s ystem, radiator and under floor he ating or other heating elem ents, temperature

of the water in the boiler has to be chosen in a way to achieve the highest desired temperature. On the

parts of heating where temperature of the pr imar y flow has to be lower, on e elem ent has to be bui lt in

such as motorized three-way valve that is controlled by room thermos tat, thermostat valve for lim iting

the temperature of the return flow or something similar.

INSTRUCTIONS FOR USE

We reserve the right of alternations

page 3

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

1.4.5. Limiting the minimum and maximum temperature of the water in the boiler

If the heating curves and offset are selected correctly and the room temperature is falling, in

transitional period in heating seasons (fall, spring) minimal temperature of the water in the boiler has to

be changed.

If the building cannot accumulate heat (sudden and short worming during the day) the necessary

temperature of water in the boiler will be too low and will not keep up the desired room temperature.

Limitation of the maximum temperature of water in the boiler serves more as a protection. Factory

setting is 90

o

C, and we suggest lowering it to approximately 80oC. Limitation of the maximum

temperature of water in the boiler is also used in central heating and domestic water preparation

system, and because of that it is not advisable to lower that temperature too much because the

domestic water will warm up slowly on higher tem per atures .

1.5. Functionality of hot domestic water

1.5.1. Availability

Termo Extra boilers with options W, and Termo PTV boilers enable the preparation of hot water in

separate water storage with heat exchanger.

1.5.2. Description

Domestic water conditi on in g has t he preference order over central heating. At t he moment of signaling

the need for warming up the dom estic water container by the domestic water tem perature sensor, th e

circulation pump of central heating is switched off, and the circulation pump for domestic water

conditioning is switched on.

Heaters regulate the d esired water tem perature in th e boiler th at is 25°C higher t han set va lues of th e

desired domestic water temperature (independent of central heating curve).

Circulation pum p for domestic water conditionin g supplies the container until the desired temperature

of domestic water is re ached, upon which it is switc hed of f with previousl y des crib ed and pro gram m ed

time delay.

If the central heating is off, either floor or radiators’ heating , at the moment of reaching the desired

domestic water tem perature, the desired water temperature in the boiler is set to minimum value of

water temperature in the boiler (stand by).

At repeated requests for heating the domestic water c ontainer, the desired water tem perature in the

boiler is set to 25°C higher than set values of the desired domestic water temperature.

Circulation pump for domestic water cond itioning is s witched on as late as the water tem perature in a

boiler reaches the same or higher temperature than desired value of domestic water temperature.

The 5°C difference for warm water conditioning is programmed. It means that if the desired

temperature of dom estic water tank is 60°C , then the central heat ing wil l be sw itched off and domes tic

water conditioning switc hed on as la te as domestic water temperature is lo wer tha n 55°C, an d heati ng

will be switched on a nd domestic water conditi oning switched off when the temperature in domes tic

water tank reaches 60°C, and when the programmed time of supplemental operation of domestic

water circulation pump has passed.

If the time for domestic water conditioning is longer than 30 minutes, i.e. if the desired temperature of

domestic water tank is not reached within 30 minutes, the process will be automatically interrupted and

switched to the heating regime, which in this case lasts at least 30 minutes.

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

1.6. Frost protection

1.6.1. Availability

Frost protection, as bo iler’s function, is limited to Termo Ex tra boilers with opt ions E, C and W, Termo

Blok boilers with option C and Termo PTV boilers. F or other vers io ns of boilers, frost protecti on c a n b e

provided with the usage of an appropriate room therm ostat. Where frost protec tion is controlled by

room thermostat, please consult room thermostat manuals for more details.

Following topics explain how frost protection is working when it is boiler controlled function (options

C,W).

1.6.2. Domestic water

If the boiler is on for supply and only warm water conditioning is on or only heating or both, the

protection from freezing the water in warm water container switches on automatically when the

temperature sensor of warm water container reads the value below 7°C, signaling switching on by

blinking display, as wel l as the LED diode of the heat er and warm water conditioning, reg ulating the

warm water container temperature to 7°C.

1.6.3. Central heating

If the boiler is on f or supply and heating or both (heating and warm water con ditioning) are off, the

protection from free zing the water in the central hea ting system switches automatica lly on if the water

temperature sensor in th e boiler reads the val ue below 8°C. In this cas e the temperature of water in

the boiler is maintained at 8°C, as long as the conditions of possible freezing do not disappear.

Switching on is signaled by a blinking display as well as the LED diode of the heater and the boiler.

In this case, domestic water conditioning has priority.

In order for the freezing protection system of central heating to operate, the room thermostat should be

in the position of freezing protection as well (other wise, the circulation pum p of central heating would

not operate).

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

2. Using control panels

2.1. Working with standard control panel

Standard electromechanical control panel

The automatics consists of the following el ements:

1 – Indicator of temperature /pressure in boiler

2 – Working thermostat

3 – Switch for the 2

nd

and 3rd operation stage

4 – Cutout thermostat with manual deactivation (switches off on ca 115

o

C)

5 – Indicator of air appearance in the boiler - air-indicator (also indicates low voltage protection)

6 - Switch for ON/OFF and the 1

st

heating stage

7 – Fuse 2,5A protecting the pump and switches

8 – Indication of heater operation

9 - Indicates low voltage protection - under 180V

Putting on central heating

By switching the switch (6) ON, the central heati ng system is switched on and the firs t power stage is

active. With switch (3) it is possible to control manually the second or the third po wer stage of boiler.

Boilers with 3 stages ha ve soft start for the second and the third stage and s witches (3) have only

limiting function. If the boiler is heating, the light of heat er in operation (8) is on, if heaters are not

working and boiler is in standby only ON/OFF light is on.

Adjustment of desired temperature of central heating

With the help of working thermost at (2) it is possible to select the fixed desire d temperature in boiler.

Working thermostat has range from 20ºC to 80ºC. Recommended temperature is about 60ºC (12

o’clock position).

Air in the boiler (5), red light

If the air appears in the boil er, the signal ization of air in the boiler tur ns on (5) an d the boiler s tops the

operation. In this way the boiler is protected against burning through due to presence of air. To

continue th e operation the boiler should be vented. If the boiler is correctly vented, th e operation of

boiler continues automatically.

Voltage drop (9), red light

If the voltage in the network line drops below 180V by phase, the signalization of under voltage

protection (9) turns on, the boiler automatically switches off in order to protect electronics and

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

contactors inside the boiler. The boiler will automatically continue the operation when the network

voltage reaches values above 180V.

Cutout thermostat - turning on

Cutout thermostat (safety thermostat) (4) protects the boiler against rapid increase of temperature

above 115°C. The fuse turns the boiler off and ejects the RCCB (RCD)-switch.

For boiler to continue working it is necessary to take off the protection cover from the cutout

thermostat and press the red key, upon which the RCCB (RCD)-s witc h sh ould be s witc hed on aga in.

NOTE:

If the room thermostat is on, make sure that it is set on the required room temperature and if

supply batteries are in order, otherwise the boiler will not operate.

2.2. Working with electronic control panels (option E)

Electronic control panel without external temperature compensation

1. Multipurpose – temperature indicator (temperature of boiler,

adjustment of temperature)

2. Signalization of operation degree of heaters (1, 2, 3)

3. Signalization of the presence of air in the boiler (red light)

4. Signalization of under voltage protection (red light)

5. Signalization of boiler operation (green light)

6. Adjustment of temperature in boiler

7. Switch for central heating switching on and off

8. Thermal fuse

Switching on of central heating

By switching the switch (7) to the p os ition 1, t he c entra l heat in g system is switched on. Upon s witc h ing

on the desired water tem perature in boiler is displa yed for 5 seconds, si gnalization of boiler oper ation

is twinkling (5). After 5 seconds the real temperature in the boiler is displayed (1); if the current

temperature in the boiler meets the desired on e, the signalization lamp of the boiler operation (5) is

switched off.

Adjustment of desired temperature of centra l heating

By pressing the key for te mperature adjus tment (6) the desir ed temperature in the boiler app ears, the

signalization lamp of the boiler operation (5) is twink ling. B y repeated pressing u pw ards or do wnwar ds

it is possible to increase or decreas e the des ired sa nitar y water tem per ature. W hen the tem peratur e is

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

adjusted it is suffic ient to wait for 5 seconds (signalization lam p of the boiler operation ( 5) does not

twinkle) in order for the boiler to memorize new temperature.

Air in the boiler (3), red light

If air appears in the boiler, the signalization of air in t he boiler turns on (3) and the boiler stops the

operation. In this wa y the boil er is protec ted ag ains t burnin g through because of appearance of air. T o

continue the oper ation, the boiler should be vented. If the boiler is c orrectly vented, the opera tion of

boiler continues automatically.

Voltage drop (4), red light

If the voltage in the network line drops below 180V by phase, the signalization of under voltage

protection (4) turns on, the boiler automatically switches off in order to protect electronics and

contactors inside the boiler. The boiler will automatically continue the operation when the network

voltage reaches values above 180V.

Cutout thermostat - turning on

Cutout thermostat (safety thermostat) (8) protects the boiler against rapid increase of temperature

above 115°C. The fuse turns off the boiler and ejects the RCCB (RCD)-switch.

To continue the operation it is necessary to t ake off the protection cover f rom the cutout thermostat

and press the red key, after which the RCCB (RCD)-switch should be switched on again.

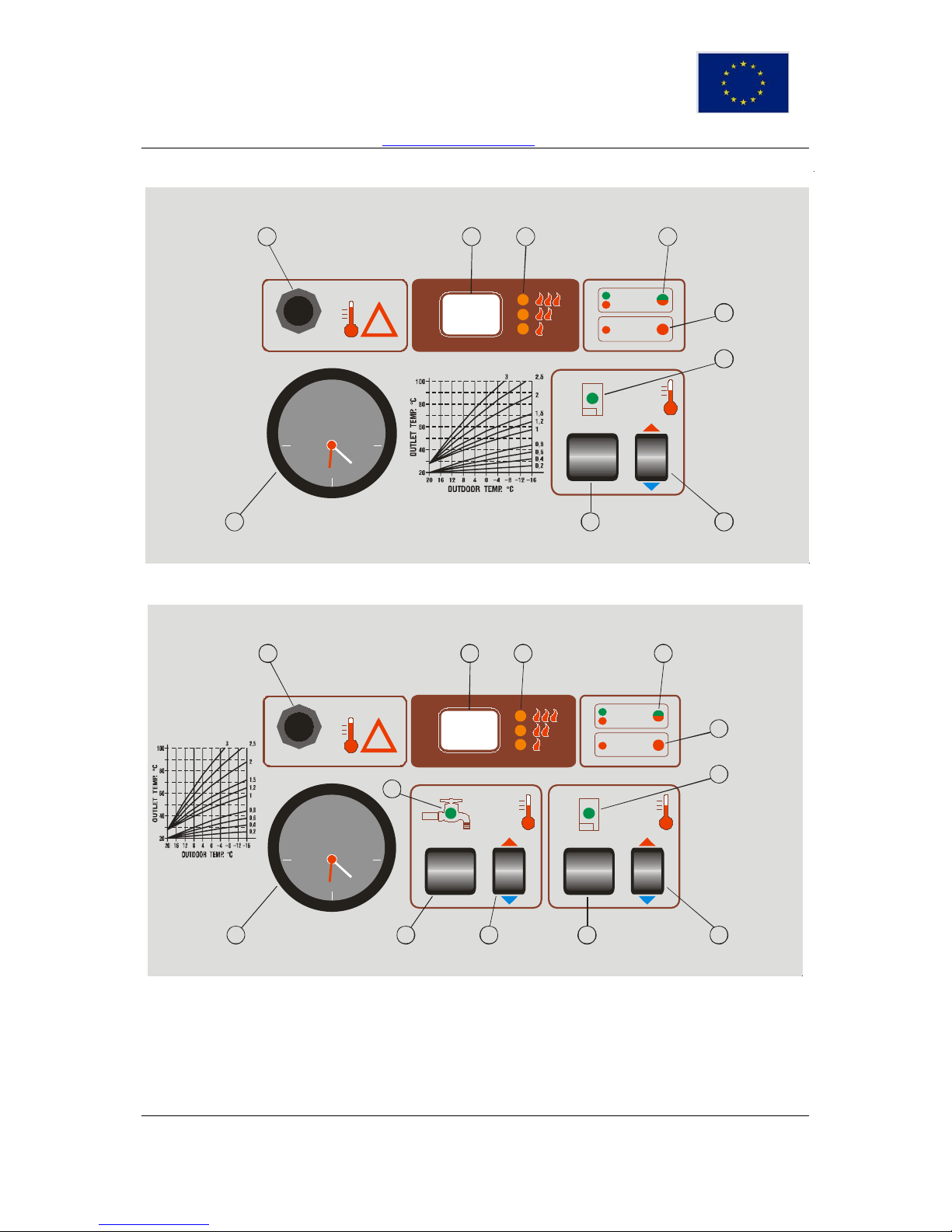

2.3. Working with electronic control panels

(option C and W and Termo Blok PTV)

2.3.1. General

Regardless of the selected regulation c urve, the m axim um water temperatur e in the boiler is limited to

90°C for radiator heating and 50°C for floor heating.

Factory setting of the curve is 1,5 for radiator heating.

Factory setting of the curve is 0,6 for under floor heating.

Refer to chapter 1.4. for detailed description of heating curves.

Refer to chapter 1.5. for detailed description of DHW functions.

Refer to chapter 1.6. for detailed description of frost protection.

Refer to chapter 4.8 for detailed description of selecting desired set of heating curves.

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

!

4 0

bar

0

I

OK

AIR

U<

12 1 2

3

4

5

52

2

6

7

11

Type 1 – Outdoor temperature compensation

!

4 0

2

bar

0

I

0

I

OK

AIR

U<

12 1 2 3

4

5

6789

10

11

52

Type 2 – Outdoor temperature compensation and sanitary water on Termo Extra or Termo Blok PTV

1. Display

Display of temperatures values reading from KTY probes from + 99

o

C (above +99oC display is blinking)

up to -19oC (below -19oC the display shows - -). Display of desired temperature or curve during setup.

Following warning signals can be displayed:

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

P1 – frost protection for sanitary water is active

P2 – frost protection for central heating is active

o1 or c1 – thermal sensor for boiler temperat ur e is not connected or is short-circuited

o2 or c2 – thermal sensor for external temperature is not connected or is short-circuited

o3 or c3 – thermal sensor for DHW temperature is not connected or is short-circuited

2. Led diodes of heaters stages

The number of lighted diodes corresponds to the number of momentarily active heater operations

stages.

3. Led diode OK/air in boiler

If there is no air in the boiler, the diode becomes green. If the air appears in the boiler, the diode

becomes red and at the same time the operation of the device is stopped. After venting, the diode

automatically changes the color to green and operation of the boiler is continued.

4. Led diode too low supply voltage

If the net voltage falls below 170 V red light appears and at the same time the operation of the device is

stopped.

5. Led diode of central heating

It indicates the operation of circulation pump of heating, provided that the room thermostat is on.

6. Push button for adjustment of heating characteristics

7. Switch – heating on/off

8. Push-button for adjusting characteristics of sanitary water conditioning

9. Sanitary water conditioning on/off

10. Led diode in course of sanitary water conditioning,

Indicates the circulation pump operation for sanitary warm water conditioning.

11. Indicator of water pressure in heating syste m.

12. Safety thermostat

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

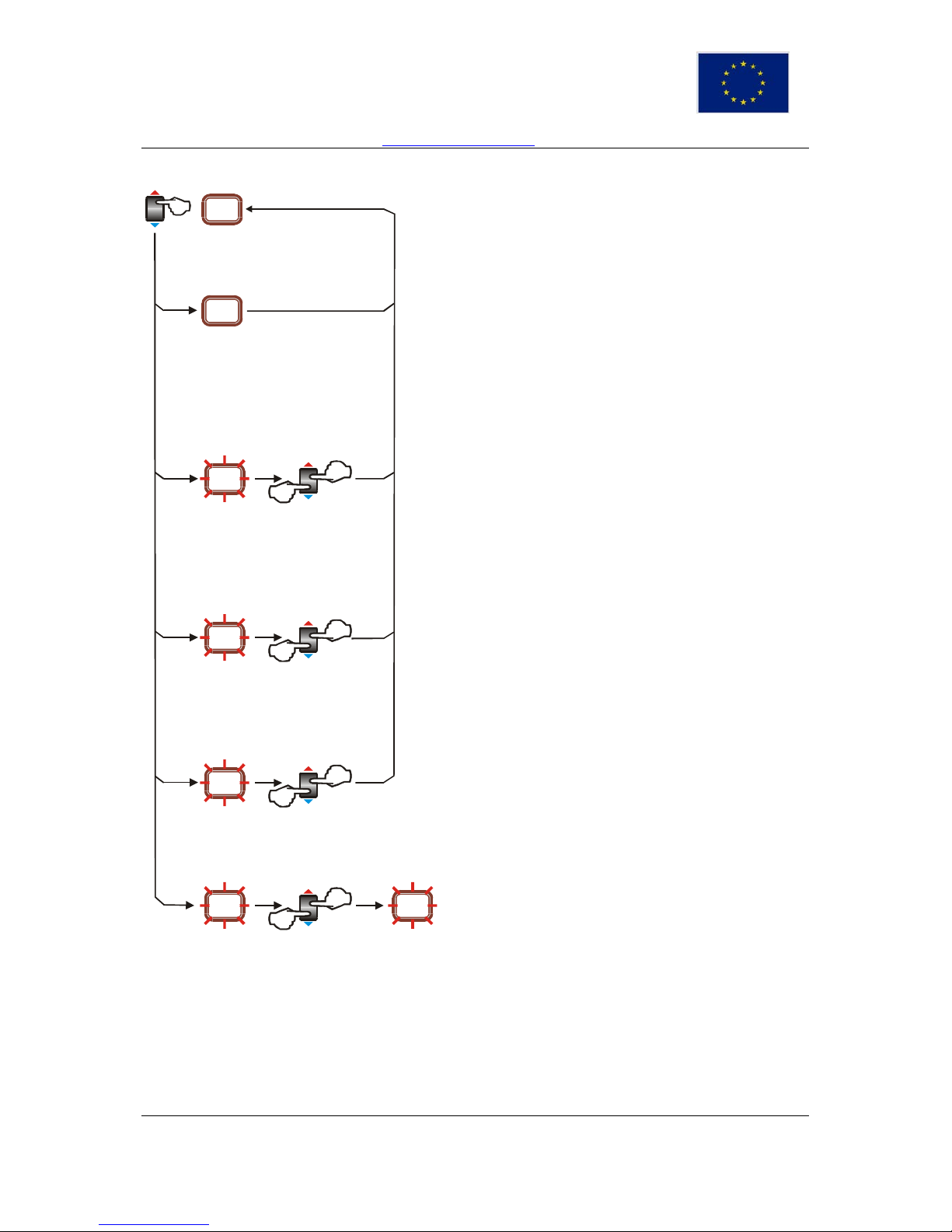

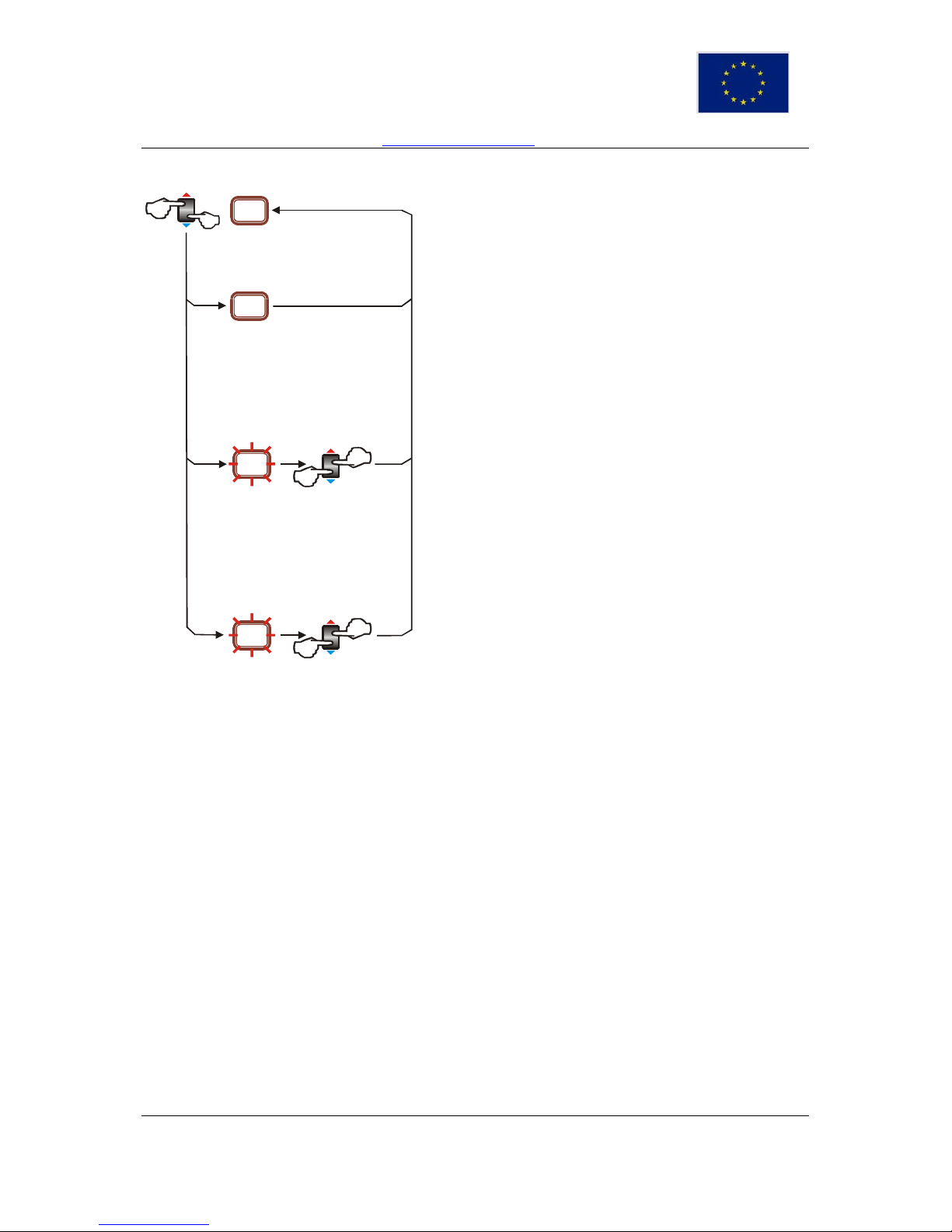

2.3.2. Central heating functions

>5 sec

0.6

41

>5 sec

>10 sec

>5 sec

3

32

>5 sec

<5 sec

>15 sec

>5 sec

90

>20 sec

60 32

>5 sec

Display of desired temperature inside the boiler

By pressing the key (6) user can see the desired temperature inside the

boiler.(calculated from the selected correction curve)

The Display shows the desired temperature of water in the boiler. The value

is displayed for 5 s, after which display normally shows the real temperature

of water in the boiler.

Correction curve selection

By pressing the key (6) user can enter curve selection menu.

The number of set curve is blinking, according to which the correction of

water temperature in the boiler is corrected in relation to external

temperature. Values are between 1 and 3 or 0,2 and 0,9. Curves between 1

and 3 are for radiators’ central heating and curves 0,2 to 0,9 are for under

floor heating.

By pressing the key, numbers of curves are changing with the step of 0, 1

within the set, according to the diagram on t he front plate. If t he key is hel d

pressed less than 5 s the display value becomes valid regulation curve.

Limiting maximum boiler power

By pressing the key (6) user can limit the power level.

By pressing the key it is possible to select 1 2 or 3 as number of avai labl e

power levels. If the key is held pressed less than 5 s the selected power

level mode will become active.

Boilers from 6 to 16 kW have only two power levels.

Limiting maximum temperature inside the boiler

By pressing the key (6) user can limit maximum temperature inside the

boiler.

Factory defined maximum temperature starts to blink. By pressing up or

down user can set new maximum temperature. If the key (6) is held pressed

less than 5 s the selected maximum temperature will become active.

This temperature represents maximum

temperature that can be

achieved regardless of selected curve.

Manual selection of desired t emper atur e inside the boiler

By pressing the key (6) user can set temperature in the boiler, regardless of

previously selected curve.

Desired temperature starts t o blink. By pressing the key up or down user

can select fixed temperature in the boiler. If the key is held pressed less

than 5 s the fixed temperature becomes active.

When boiler is in fixed temperature mode, the LED display blinks while

displaying current temperature in the boiler. Us er can just press the key (6)

up or down for next change of fixed temperature.

When boiler is in fixed temperature mode, all correction curves are

disregarded. To return to the correction curve mode, the boiler must

be switched off and back on using ON/OFF switch.

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

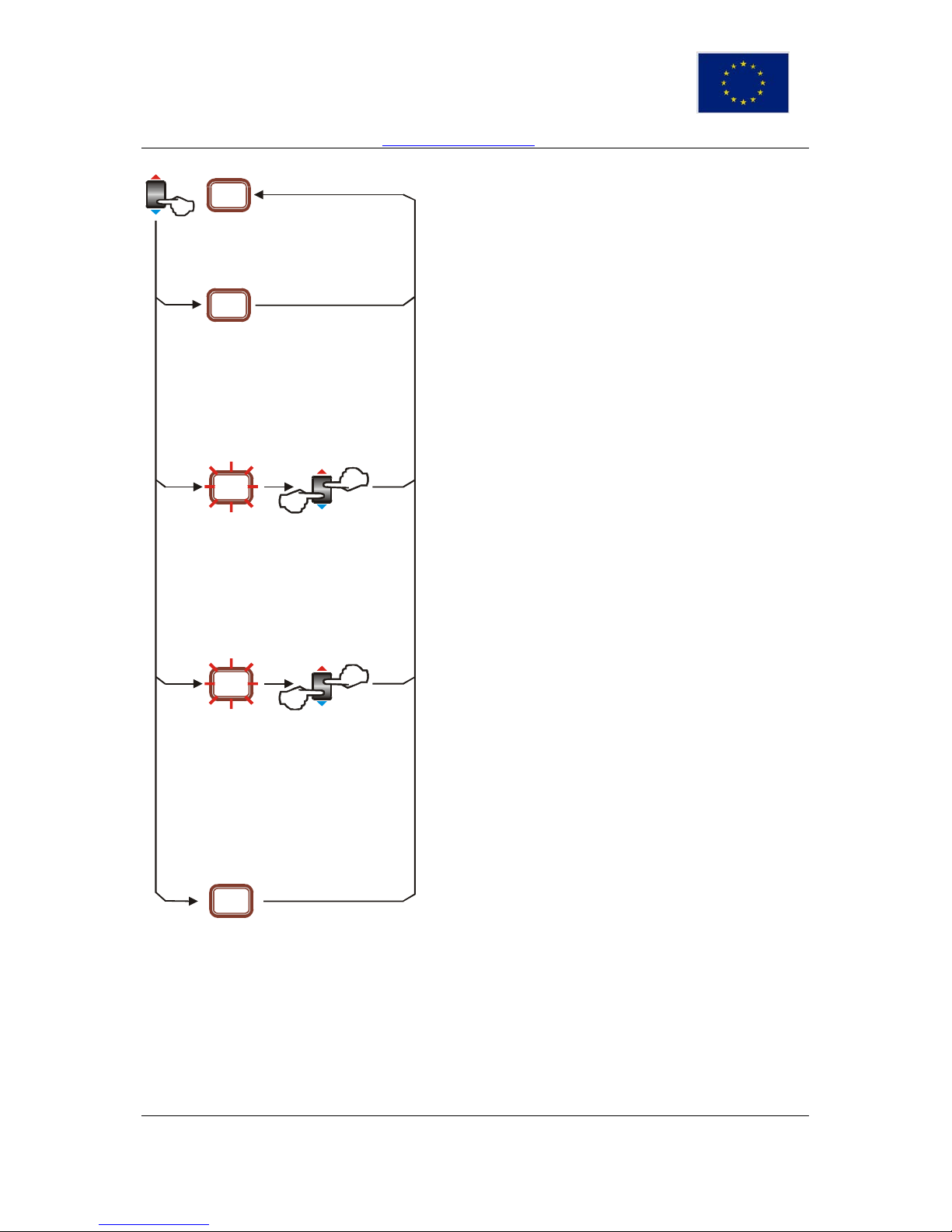

Continuation...

>5 sec

0

-1

>5 sec

>10 s ec

>5 sec

20

32

>5 sec

<5 sec

>15 s ec

1.4

Display of external temperature

By pressing the key (6) user can see external temperature.

The Display shows the external temperature. The value is displayed for 5 s, after

which the display normally shows the real temperature of water in the boiler.

Offset of currently selected correction curve

By pressing the key (6) user can enter the curve selection menu.

The LED display will show current offset in ˚C. Offset does not affec t maxim al o r

minimal temperature, they are set in absolute values

By pressing the key (6) it is possible to change offset in steps of 1˚C.

Factory setting is 0˚C.

Offset range is from –9 to +20˚C.

If the key is held pressed less than 5 s t he displayed value becom es valid offset

in ˚C.

Setting the minimal temperature inside the boiler

By pressing the key (6) user can select minimal temperature inside the boiler.

Minimal temperature starts blinking.

Factory setting is 27°C for radiator heating.

Factory setting is 20°C for under floor heating.

By pressing the key user can select the des ired temperature in range from 10 to

50°C. Temperature changes in steps of 1°C. If the key is held pressed less t han

5 s the value from the display becomes the desired minimal boiler temperature.

Displaying software version and factory reset

By pressing the key (6) longer than 15 seconds, the LED will show the software

version and the factory reset of central heating parameters will occ ur.

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

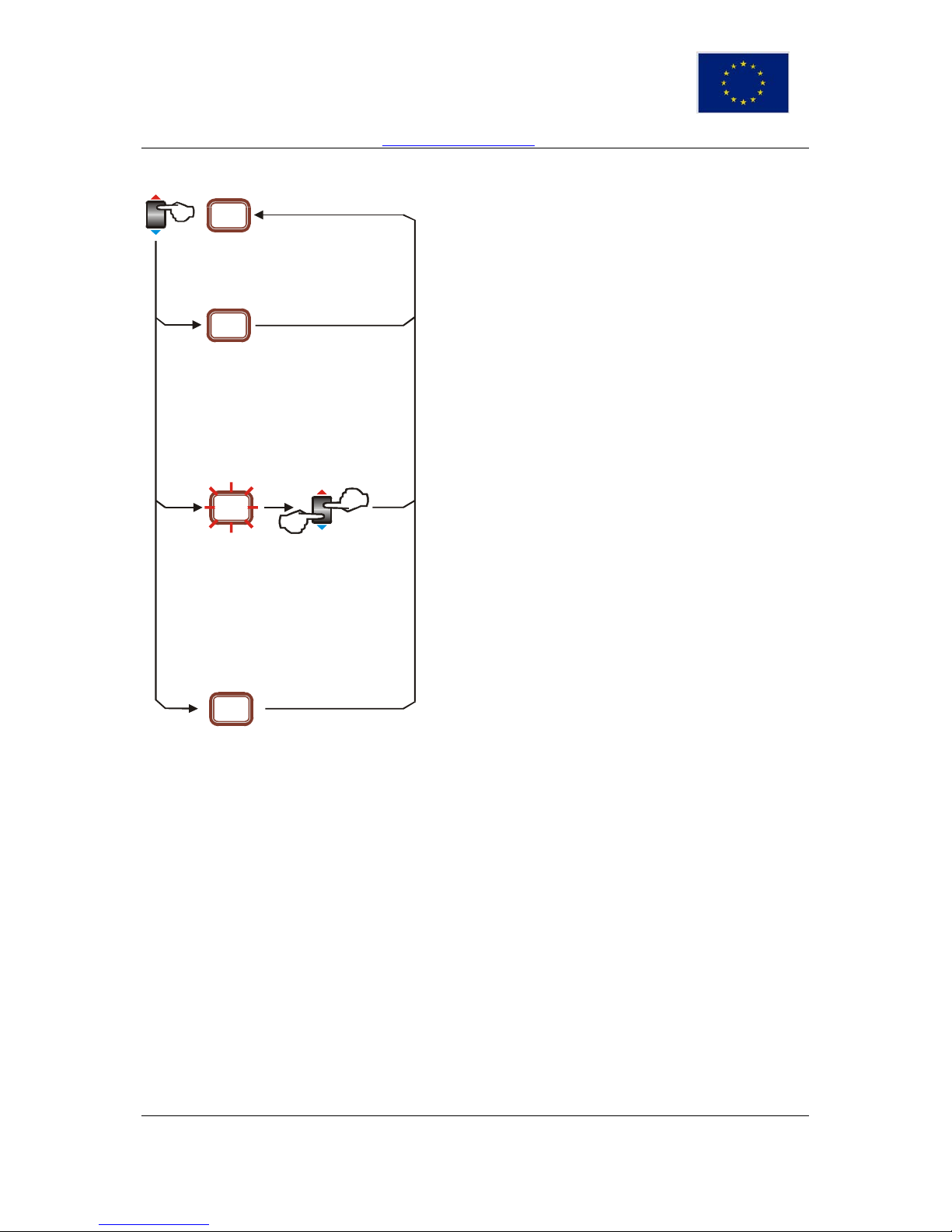

2.3.3. Domestic water functions (control panel type 2)

>5 sec

50

50

>5 sec

>10 s ec

32

>5 sec

<5 sec

1.4

Display of desired temperature of domestic water

If the key is held pressed less than 5 s the LE D display will show the desired

temperature in domestic water storage. The value is dis played for 5 seconds,

after which the display normally shows the real temperature of water in the

boiler.

Setting the desired temperature in domestic water storage

By pressing the key (8) user can enter the domestic water temperature menu.

The desired water temperature in domestic water storage is blinking.

By pressing the key (8) the value of desired domestic water temperature in

domestic water storage is changing in steps of 1°C. I f the key is held pressed

less than 5 s the value from the display becomes the desired dom estic water

temperature.

Possible adjustment is from 10°C up to 65°C.

Factory adjustment is 50°C.

Displaying software version and factory reset

By pressing the key (8) longer than 15 seconds, the LED will show the software

version and the factory reset of the central heating parameters will occur.

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

Continuation...

>5 sec

1.0

36

>5 sec

>10 s ec

>5 sec

20

32

>5 sec

<5 sec

>15 s ec

1.4

Display of current temperature in domestic water storage

By pressing the key (8) user can s elect the display of current tem perature in the

domestic water storage. The value is dis played for 5 s, after which the display

normally shows the real temperature of water in the boiler.

Setting additional working time of domestic water pump

By pressing the key (8) user can set up addi tional working time of domestic water

pump.

The time of s upplemental operation of circulation pump operation for domestic

water conditioning is blinking.

By pressing the key the time is changing from 0,1 min up to 19 min. with the step

of 1 digit. If the key is held pressed less than 5 s, the value from a display

becomes valid time of supplemental operation of circulation pump for domestic

warm water conditioning.

Factory setting is 1 min.

Setting stand by temperature inside boiler

By pressing the key (8) user can setup stand by temperature inside the boiler.

The LED will show current standby temperature inside the boiler.

Pressing the key (8) will change standby temperature in range from 10°C to

50°C by 1°C. If t he key is held pressed less than 5 s the value from the display

becomes the valid standby temperature inside the boiler.

Displaying software version and factory reset

By pressing the k ey (8) longer than 15 seconds, the LED will show the software

version and the factory reset of central heating parameters will occ ur.

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

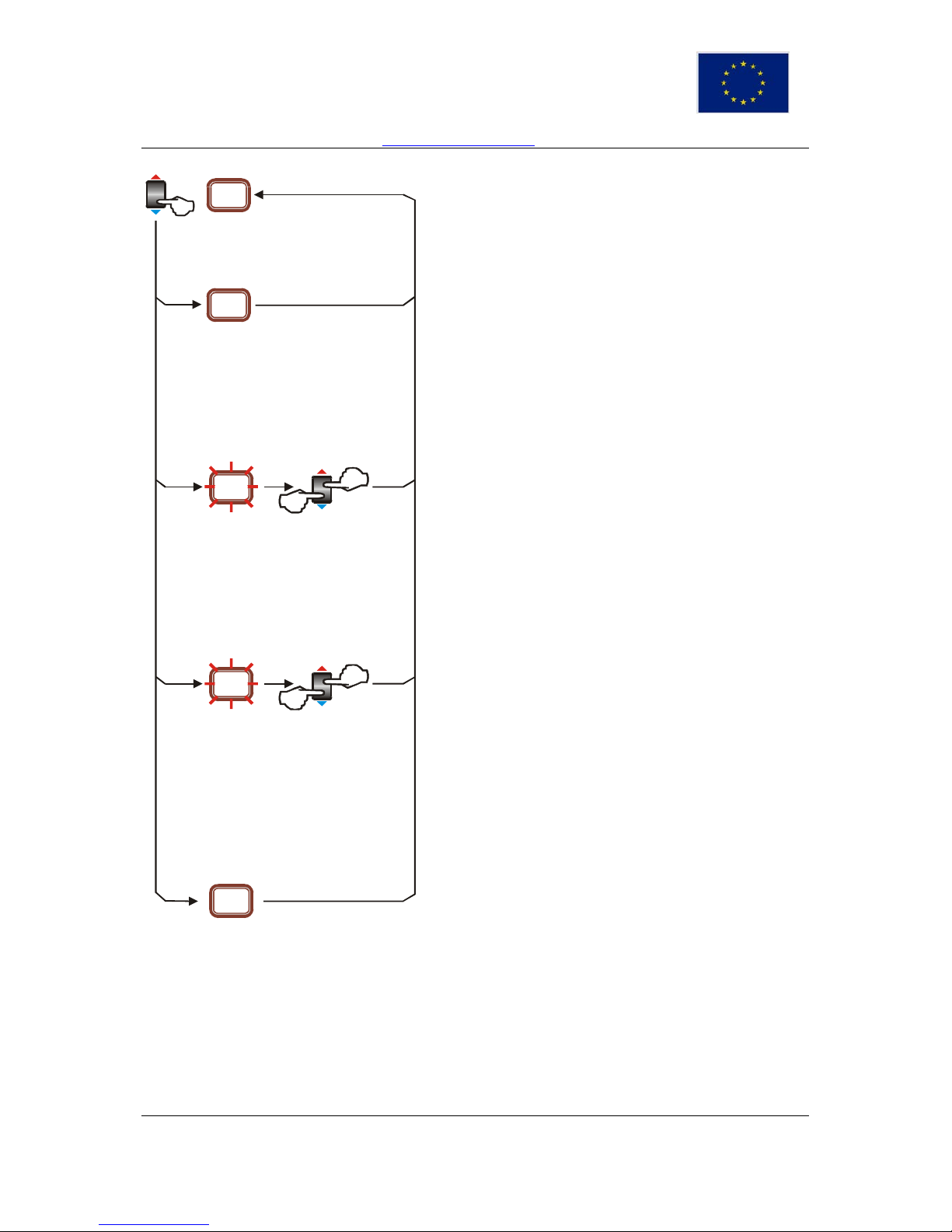

2.3.4. Central heating functions with heating curves disabled

>5 sec

4 1

4 1

>5 sec

>10 sec

>5 sec

3

32

>5 sec

<5 sec

Display of desired temperature in boiler

If the key (6) is held pressed less than 5 s the LED display will show the desired

temperature in the boiler. The value is displayed for 5 seconds, after which the

display normally shows the real temperature of water in the boiler.

Setting of the desired temperature in the boiler

By pressing the key (6) user can enter the boiler temperature menu.

The desired boiler temperature is blinking.

By pressing the key (6) UP or DOW N, the desi red boiler temperat ure can be set

in steps of 1°C.

If the key is held pressed less than 5 s the value from the display becomes the

desired boiler temperature.

Possible adjustment is from 20°C up to 90°C for radiator heating.

Possible adjustment is from 15°C up to 45°C for under floor heating.

Limiting maximum power of the boiler

By pressing the key (6) user can limit the power level.

By pressing the key it is possible to select 1 2 or 3 as number of the available

power levels. If the key (6) is hel d pressed less than 5 s the s el ected power level

mode will become active.

Boilers from 6 to 16 kW have only two power levels.

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

3. Maintenance

3.1. Periodic checkin g

We recommend the inspection of the d evice once a year by the auth orized service provider (before

heating season). This s ervice is not included in the warr anty. During the inspection all electric and

water connections should be tightened, the system should be vented and – if necessary – filled

up, valves and general functionality of the device should be checked.

RCCD switch - pressing the TEST button must disconnect the RCCD switch. This testing

procedure insures that switch is functioning properly. We recommend this test once or twice in

heating season.

Safety thermostat – we r ecommended to check safety thermostat before every heating season

by heating up the sensor with heating fan or lighter over 100°C

must actuate overheating

protection by switching off the RCCD switch.

Safety valve should be checked once a year (before the beginning of heating season) to ensure

proper functioning and avoiding appearance of water calculus.

If the boiler is not conn ected to the room ther mostat or if the boiler is out of function duri ng the winter

time, there is a danger of installation freezing.

In this case the system should be filled with antifreeze liquid for central heating, and if this is not

possible water should be drained out.

3.2. Cleaning

It is not permitted to use aggressive media (e.g. gasoline, kerosene or solvent) for cleaning

the product. Media for cleaning plastics or dishwashing media can be used for the external

shell and decorative cover. Control panel should be cleaned with dry or moist cloth (not wet).

3.3. Central heating system

If the boiler is not connect ed to the room thermost at (Termo boilers without C or W option), or if the

boiler is out of function during wintertime, there is a danger of installation freeze. In this case the

system should be filled with antifree ze liquid for central h eating, if this is not possible w ater should be

drained out of the system with the help of charge and discharge.

The recommended pressure of central heating installation is 0,15 mpa (1,5 bar), the

maximum pressure is 0,25 mpa (2,5 bar).

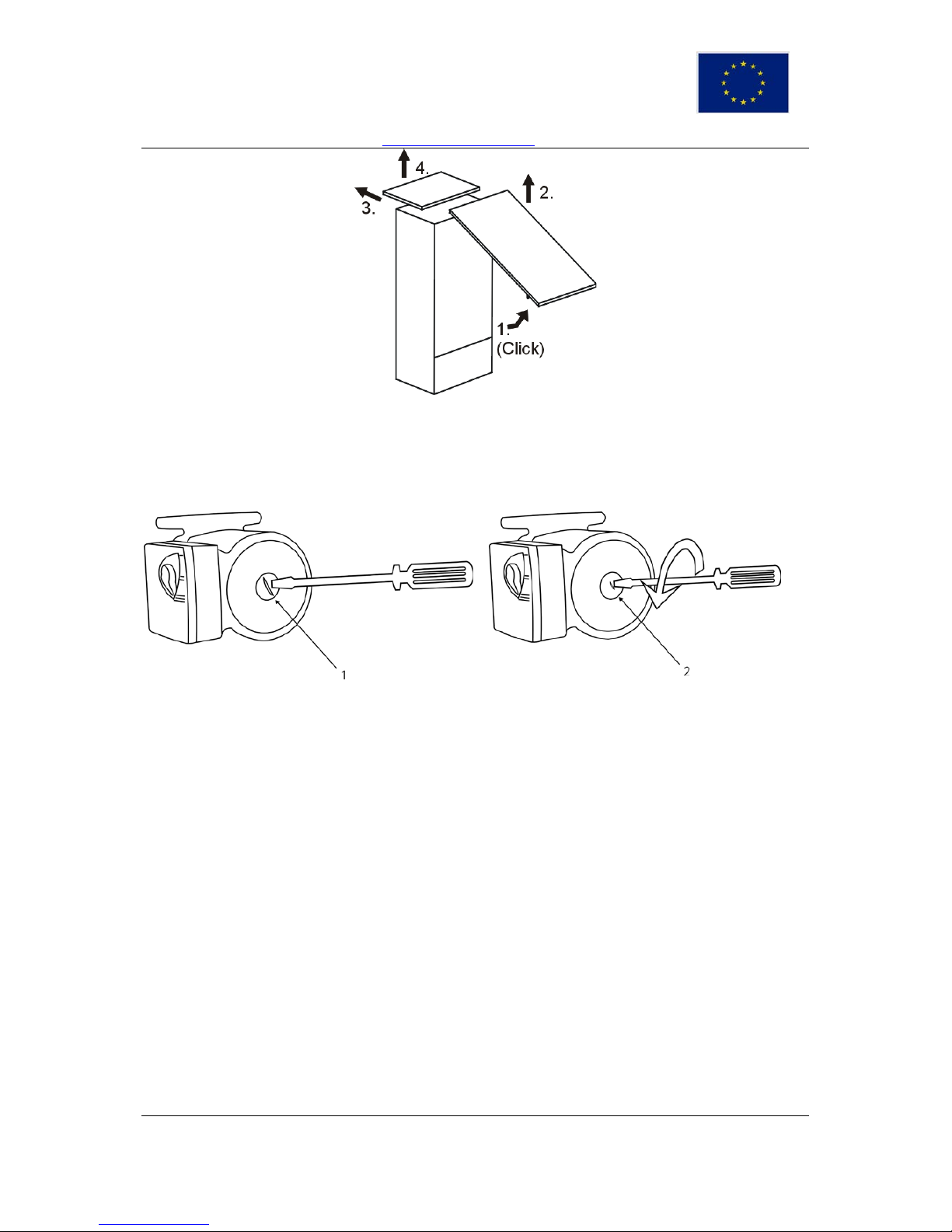

3.4. Starting the pump manually

In order to access the pump, remove the front cover of the boiler as described below. In most cases

steps 1 and 2 are sufficient.

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

Grasp the front case by its sides, pull it towards the front and remove it by lifting it off the unit, push the

top cover backwards and lift it of the unit.

To start the pum p it is nec essar y to turn off the prote ction pl ug on its f ront s ide (1) , below which ther e

is an axis with the groove for screwdriver. Using the screwdriver, the pump (2) should be turned

several times in the direction of the arrow on the pump head and the boiler should be put on again.

When the pump starts the operation the temperature of water in the boiler and the temperature of

sanitary water should be selected. The optimal temperature for central heating is between 60 and

70°C.

If the room thermostat is connected to the boiler, the desired r oom temperature should be adjus ted

according to the instructions of the producer of the room thermostat.

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

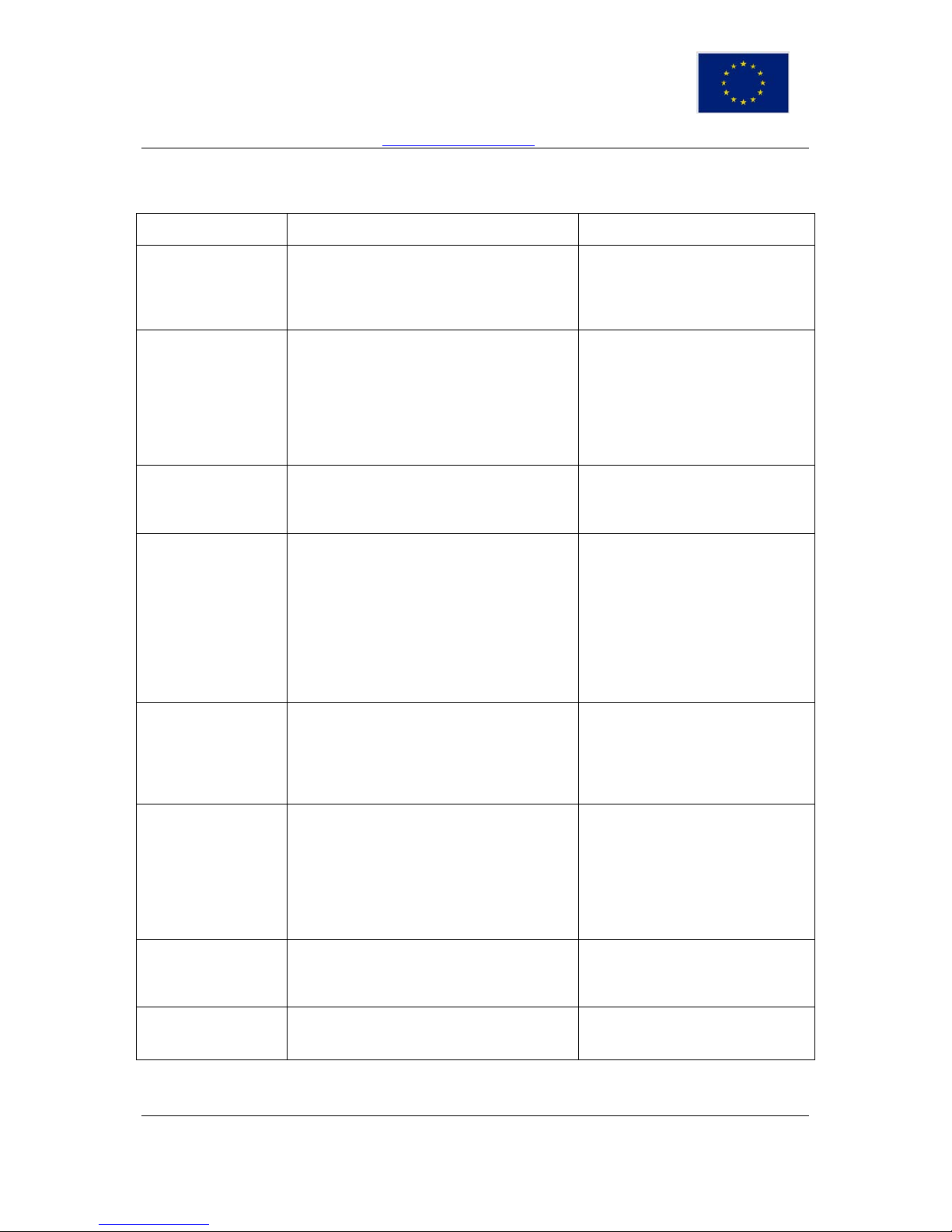

4. Survey of possible malf unct ions and irregularities in opera t ion

MALFUNCTION CAUSE ELIMINATION

- there is no voltage

on the control panel

at switching on

- there is no power supply from the net

on one or more phases

- fuse 2,5A on the control panel is

burned through

- RCCB switch is disconnected

- replace fuse 2,5A and check

the cause of burning

- contact authorized service

personnel to resolve the

problem

- By switching on,

the switches on the

control panel display

the voltage, but the

boiler does not heat

- check the adjustment of the room

thermostat,

- limiting thermostat is activated

- indicator of air presence in the boiler

blocked the operation,

- defective switch,

- operation thermostat is defective,

- heaters are burned through

- check the set temperature on

the room thermostat, replace

batteries, or the room

thermostat is faulty,

- deaerate the boiler in order to

turn off the lamp “air in boiler”

- temperature in

boiler is on desired

value, but radiators

do not heat

- circulation pump does not operate,

- air stopper on central heating

install ation prevents circulation

- start mechanical pump

(CHAPTER 4.)

- deaerate installation

- boiler does not

provide enough

heat

- one phase is m is sing on supply

- in two-stage thermostats the second

stage is not functioning

- the second or the third stage is not

manually turned on,

- one switcher is defective,

- a part of heater is burned through

- in a three-phase system the three

different phases are not brought to the

boiler

- check fuses on the main

panel,

- contact authorized service

personnel to resolve the

problem

- the switcher can

be heard while

operating (it

buzzes)

radio and TV-

interferences

- poor voltage in the net

- defective switcher

- contact authorized service

personnel to resolve the

problem

- when tur n ing on

or off the

operation

thermostat,

radio and TVinterferences

occur

- defective operation thermostat,

- defective blockade (RC – protection)

- contact authorized service

personnel to resolve the

problem

- boiler in

operation “roars”

- the system is not well deaerated,

- defective heater

- deaerate the system

- contact authorized service

personnel to resolve

problem

- pressure in the

system varies

- defective expansion vessel,

- the vessel pressure is too low or too

high

- contact authorized service

personnel to resolve the

problem

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

- the actual

temperature in the

boiler is higher than

the desired

temperature and the

safety thermostat is

activated

- defective contactors

- defective operation thermostat

- contact authorized service

personnel to resolve the

exact source of the

problem

- RCCB switch

disconnects

- defective heater,

- humidity on conductors,

- safety thermostat is activated

- check leakage,

- contact authorized service

personnel to resolve the

exact source of the

problem

- RCCB switch

cannot be reset

- safety thermostat is activated

- pre-reset safety thermostat

and then the RCCB switch

- contact authorized service

personnel to resolve the

exact source the of

problem

‘Ulaganje u budućnost’

‘Investing for the future’

Projekt sufinancira Europska unija iz Europskog fonda za regionalni razvoj.

Project is co-founded by the European Union’s Regional Development Fond.

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

INSTALACIJSKE UPUTE

Zadržavamo pravo izmjene uputa bez posebne najave

TRGOVINA TERMOSTROJ d.o.o. 10250 Lučko, F. Puškarića 1d

Tel/Fax +385 1 6531-008, 6531-015, 6531-016 Eurposka unija

e-mail: info@termostroj.com web: http://www.termostroj.com European Union

ELECTRIC BOILERS FOR CENTRAL HEATING

TERMO-Blok

TERMO-Extra

TERMO-Blok PTV

INSTRUCTIONS FOR INSTALLATION

‘Ulaganje u budućnost’

‘Investing for the future’

Projekt sufinancira Europska unija iz Europskog fonda za regionalni razvoj.

Project is co-founded by the European Union’s Regional Development Fond.

INSTRUCTIONS FOR INSTALLATION

We reserve the right of alternations

TMS-UT-0114-T01-1

INSTRUCTIONS FOR INSTALLATION

We reserve the right of alternations

TMS-UT-0114-T01-1

Contents

1. Introduction ....................................................................................................................... 1

1.1. Applicable documents ................................................................................................. 1

1.2. Retention of documents .............................................................................................. 1

1.3. Introduction ................................................................................................................. 1

1.4. Heating curves ............................................................................................................ 1

1.4.1. Availability of heating curves................................................................................. 1

1.4.2. About Heating curves ........................................................................................... 2

1.4.3. Why does the characteristic heating curve have to be set? .................................. 2

1.4.4. Corrections of the room temperature .................................................................... 2

1.4.5. Limiting the minimum and maximum temperature of water in the boiler ................ 4

1.5. Functionality of hot domestic water ............................................................................. 4

1.5.1. Availability ............................................................................................................ 4

1.5.2. Description ........................................................................................................... 4

1.6. Frost protection ........................................................................................................... 5

1.6.1. Avaliability ............................................................................................................ 5

1.6.2. Domestic water ..................................................................................................... 5

1.6.3. Central heating ..................................................................................................... 5

2. Boiler specifications ........................................................................................................... 6

2.1 Dimensions .................................................................................................................. 6

2.2 Expansion Vessel Characteristics (Termo Blok and Termo Blok TV Boilers) ...............10

2.3. Power supply characteristics 230V/400V ...................................................................10

2.4. Function elements of Termo boilers ...........................................................................11

3.0 General requirements .....................................................................................................14

3.1. Contents included in delivery .....................................................................................14

3.2 Preliminary remarks ....................................................................................................14

3.3. Recommendations for various installation types.........................................................15

3.4. Installation site ...........................................................................................................15

3.4.1. Position of a boiler ...............................................................................................15

3.4.2. Power supply .......................................................................................................16

3.5. System requirements ..............................................................................................16

3.5.1. Pipe work.............................................................................................................16

3.5.2. Cleansing and flushing the system ......................................................................16

3.5.3. Filling and preparing heating system ...................................................................17

3.5.4. Pressure relief valve ............................................................................................17

3.5.5. Pressure gauge ...................................................................................................17

3.5.6. Expansion vessel .................................................................................................17

3.5.7. Circulating pump..................................................................................................17

3.5.8. Venting ................................................................................................................17

4. Boiler installation sequence ..............................................................................................18

4.1. Transporting the appliance .........................................................................................18

4.2. Select position for boiler .............................................................................................18

4.3. Fitting the boiler hanging bracket ...............................................................................18

4.4. Removing/fixing the front and top case ......................................................................19

4.5. Pipe work connection .................................................................................................19

4.6. Power supply connection ...........................................................................................20

4.7. Connecting temperature sensors or external electrical controls .................................20

4.7.1. Accessing connection plate .................................................................................20

4.7.2. Connecting external temperature sensor .............................................................21

4.7.3. Connecting domestic hot water temperature sensor ............................................21

INSTRUCTIONS FOR INSTALLATION

We reserve the right of alternations

TMS-UT-0114-T01-1

4.7.4. Connecting room thermostat and time switch ......................................................23

4.7.5. Connecting external pump on Termo Extra boilers ..............................................23

4.8. Selecting set of heating curves ..................................................................................24

4.9 Filling the heating system ........................................................................................24

5. Commissioning .................................................................................................................25

5.1. Central heating system check ....................................................................................25

5.2. Preliminary electrical check ........................................................................................25

5.3. Changing the speed of pump for central heating ........................................................25

5.4. Working with standard control panel ..........................................................................26

5.5. Working with electronic control panels (option E) .......................................................27

5.6. Working with electronic control panels (option C and W and Termo Blok PTV) ..........28

5.6.1. General ...............................................................................................................28

5.6.2. Central heating functions .....................................................................................30

5.6.3. Domestic water functions (control panel type 2)...................................................32

5.6.4. Central heating functions with heating curves disabled ........................................34

5.6.4.1 Access to special service menu .........................................................................35

5.7. Starting the pump manually .......................................................................................36

6. Maintenance .................................................................................................................36

6.1. Periodic checking .......................................................................................................36

6.2. Cleaning.....................................................................................................................36

7. Survey of possible malfunctions and irregularities in operation .........................................37

INSTRUCTIONS FOR INSTALLATION

We reserve the right of alternations

TMS-UT-0114-T01-1

1. Introduction

Thank you for the confidence you have shown to us by purchasing our central heating boiler.

In order to use the boiler to the utmost correctly and safely, and above all economically, read

thoroughly these instructions before continuing with installation.

The appliances must be installed by a competent person, who is responsible for adhering to

the existing regulations, rules and g u idelines.

1.1. Applicable documents

The following additional documents are provided with the appliance:

For the owner of the system:

Instructions for use

Warranty card

For the qualified technician:

Instructions for installation

Electrical drawing for the appliance

1.2. Retention of documents

Please pass on this installation manual to the owner of the system. The owner should retain the

manuals so that they are available when required.

1.3. Introduction

TERMO-Extra and TERMO-Blok are economical central heating boilers that may be used as an

independent or additional source of heat.

TERMO-Extra and TERMO-Blok boilers offer you a possibility to reduce the power of the heater if

necessary. The power may be switched on automatically whe n necessary with built -in step regulator

or manually with s witches on the contr ol board. In this way it is possible to adapt the boiler to the

utmost to circumstances on the spot.

The boiler operates on a principle of rapid heat in g s maller water quantities, s o th at exploiting energy is

already 100%.

They are particularly suitable for heating smaller business premise, where you are short of space

(small apartments, ef ficiency apartments, representation offices, smaller coffee-shop spaces etc .) or

for heating larger spaces in early season when the main boiler is over dimensioned.

TERMO-Extra boilers are manufactured only with upper connecti ons. Temperature operation area is

from 20

o

C to 90 oC.

TERMO-Extra and TERMO-Blok are designed in such a way that in apartment-contained central

heating they can fit well with your furniture.

1.4. Heating curves

1.4.1. Availability of heating curves

Use of heating curves, temperature compensation, is limited to Termo Extra boilers with options C and

W, Termo Blok boilers with option C and Termo PTV boilers.

Page 1

TMS-UT-0114-T01-1

1.4.2. About Heating curves

The modern way of heat ing is based on energy savi ng and automatic adjustments to warm up the

space.

To achieve the required tem perature electric bo iler with electronic contro l panel heats the water in the

boiler automaticall y depend ing on th e extern al tem per ature. T here is no need to look af ter the m inimal

working temperature bec ause electric boiler s do not dew and t hat means that th e temperature of the

water in the boiler is at the same time the temperature in the heating elements (for example in

radiators, convectors etc.).

To achieve the desired room temperature, the characteristic heating curve has to be chosen

depending on the characteristics of the object and the heating system.

Factory defined curves

If the heating curve is set optimally for heating of your apartment or house, corrections will not

be necessary.

1.4.3. Why does the characteristic heating curve have to be set?

After the first settings of the heating curve authorized person can adjust, correct that curve if

necessary.

Every heating room is bui lt up d if f er entl y. Dif f erent hea t ing el ements and heating syst ems can be used

(radiators, under floor or combined heating) and every building has a different thermal insulation.

For the maximum exploitation of the heating and maximum energy savings, characteristic heating

curve has to be set using the parameter on the control panel, in a way that the chosen heating curve is

suitable for the heating system and for the quality of the building.

1.4.4. Corrections of the room temperature

Based on the experie nce, fac tory settin gs of th e device are f or the average insulated object and room

temperature of 22

o

C. If factory settings are not adeq uate for achieving the desired room temperat ure,

supplemental adjustments of the standard heating curves can be made.

Changing the inclination

When changing the heating curve, inclination is changing too, and in that way the temperature of

water in the boiler is changing when the external temperature is low (below+ 5

o

C).

Level changes - offset

By offsetting the he ating cu rve for th e chosen value the temperat ure of water in t he boiler is chang ing

without changing the shape of the curve.

Page 2

TMS-UT-0114-T01-1

Values in the table below are used for the orientation and the user can change them any tim e as

he/she wishes to.

Experience has shown the following (for the average building quality):

when the temperature of water for heating changes from 5 to 7

o

C that will change the room

temperature by approximately 2

o

C.

Thermal (heating) pro cesses are slow, all corrections function after a period of time. It would

be better if further corrections were made a day or two later.

To gain experience, we su ggest that you should write all corrections ( within a period of searchin g for

the right parameters) in the protocol of the corrections.

In the table belo w you can find instructions how to correct the heat ing curve for the radiator heating

depending on the achieved room temperature.

Inclination of the

curve

Offset

Factory settings

1,5

0

Room temperature is too low if the external temperature is

above + 5oC

Change with the first

lower curve

Add with offset

+ 6oC

Room temperature is too low if the external temperature i s

between + 5oC and - 5oC

Leave the curve 1,5

Add with offset

+ 3oC

Room temperature is too low if the external temperature is

below - 5oC

Change with the first

higher curve

Leave offset

0oC

Room temperature is too high if the external temperature is

above + 5oC

Change with the first

higher curve

Lower with offset

- 6oC

Room temperature is too high if the external temperature is

between + 5oC - 5oC

Leave the curve 1,5

Lower with offset

- 3oC

Room temperature is too high if the external temperature is

below - 5oC

Change with the first

lower curve

Leave offset

0oC

Sample of modified curve

In a combined heating system, radiator and under floor heating, or other heating elements, the

temperature of water in the boiler has to be chosen in a way to achieve the highest desired

temperature. On the parts of heating where temperature of the primary flow has to be lower, one

element has to be built in suc h as motorized three-way v alve that is controlled by room therm ostat,

thermostat valve for limiting the temperature of the return flow or something similar.

Page 3

Loading...

Loading...