Termomont TKU3 PELLET 20, TKU3 PELLET 35, TKU3 PELLET 50, TKU3 PELLET 40, TKU3 PELLET 25 Instruction Manual

...Page 1

Wood pellet boiler TKU3 PELLET 20-50 KW with wood pellet burner

TERMEC 20-50 KW

INSTRUCTIONS MANUAL

for usage and maintenance

Prhovacka bb 22310 Simanovci, Srbija

Tel/Fax. +381 22 480404 +381 63 259422

oce@termomont.rs www.termomont.rs

September 30, 2011

Page 2

Contents

1 Boiler design 2

1.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Technical data chart according to EN 303-5 . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 On Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 How It Works 3

3 Recommendations for boiler shipment and storage 5

3.1 Delivery form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 What's in the box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Boiler installation 5

4.1 Boiler placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 Chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Connecting the boiler with a central heating system 7

5.1 Closed system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.2 Closed system combined heating with solar panels . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Open system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Boiler in function 11

6.1 First operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Burner in operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.3 Using conventional solid fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.4 Circulation Pump Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.5 Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Safety features 13

7.1 Thermal safety in case of overheat (closed systems) . . . . . . . . . . . . . . . . . . . . . . 13

A Declaration Of Conformity 15

1

Page 3

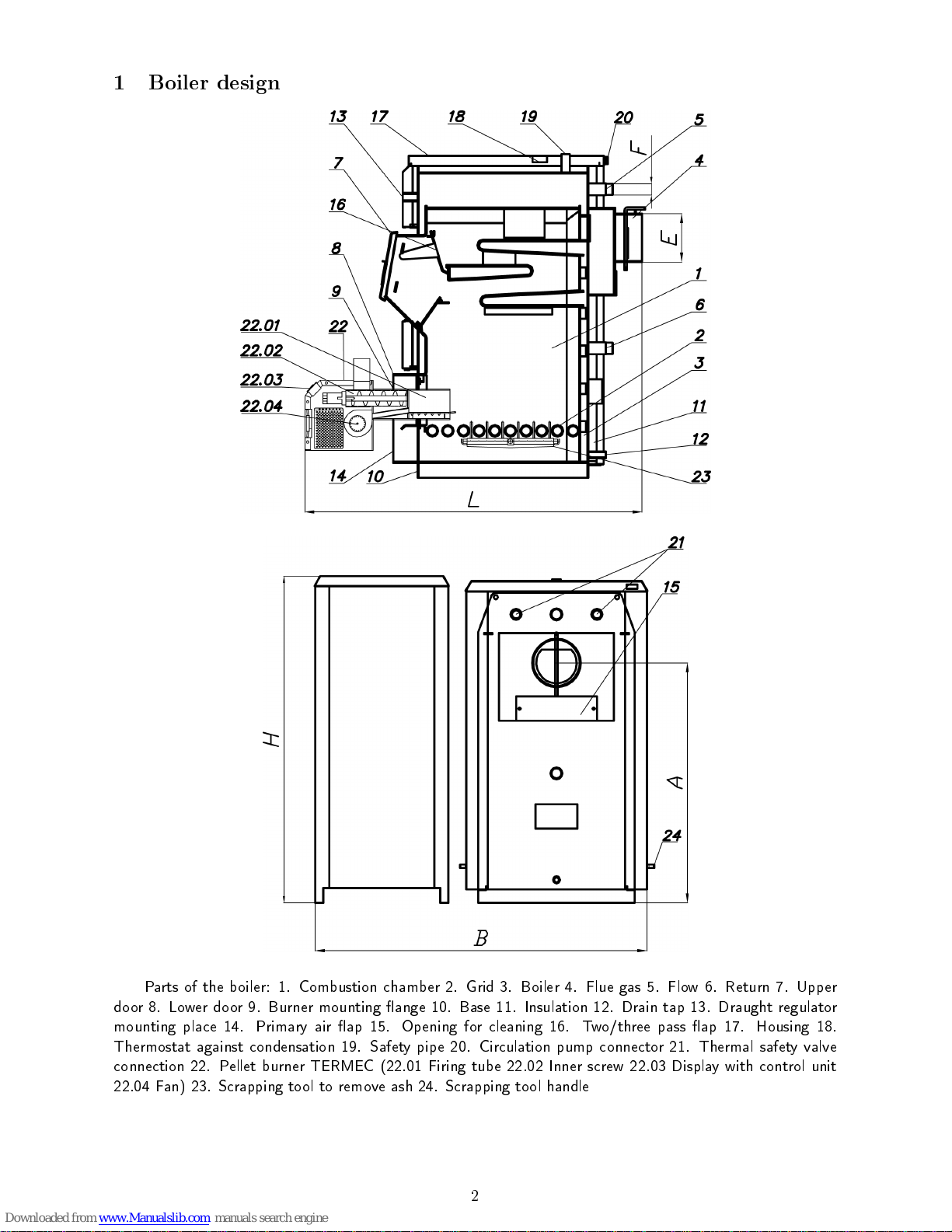

1 Boiler design

Parts of the boiler: 1. Combustion chamber 2. Grid 3. Boiler 4. Flue gas 5. Flow 6. Return 7. Upper

door 8. Lower door 9. Burner mounting ange 10. Base 11. Insulation 12. Drain tap 13. Draught regulator

mounting place 14. Primary air ap 15. Opening for cleaning 16. Two/three pass ap 17. Housing 18.

Thermostat against condensation 19. Safety pipe 20. Circulation pump connector 21. Thermal safety valve

connection 22. Pellet burner TERMEC (22.01 Firing tube 22.02 Inner screw 22.03 Display with control unit

22.04 Fan) 23. Scrapping tool to remove ash 24. Scrapping tool handle

2

Page 4

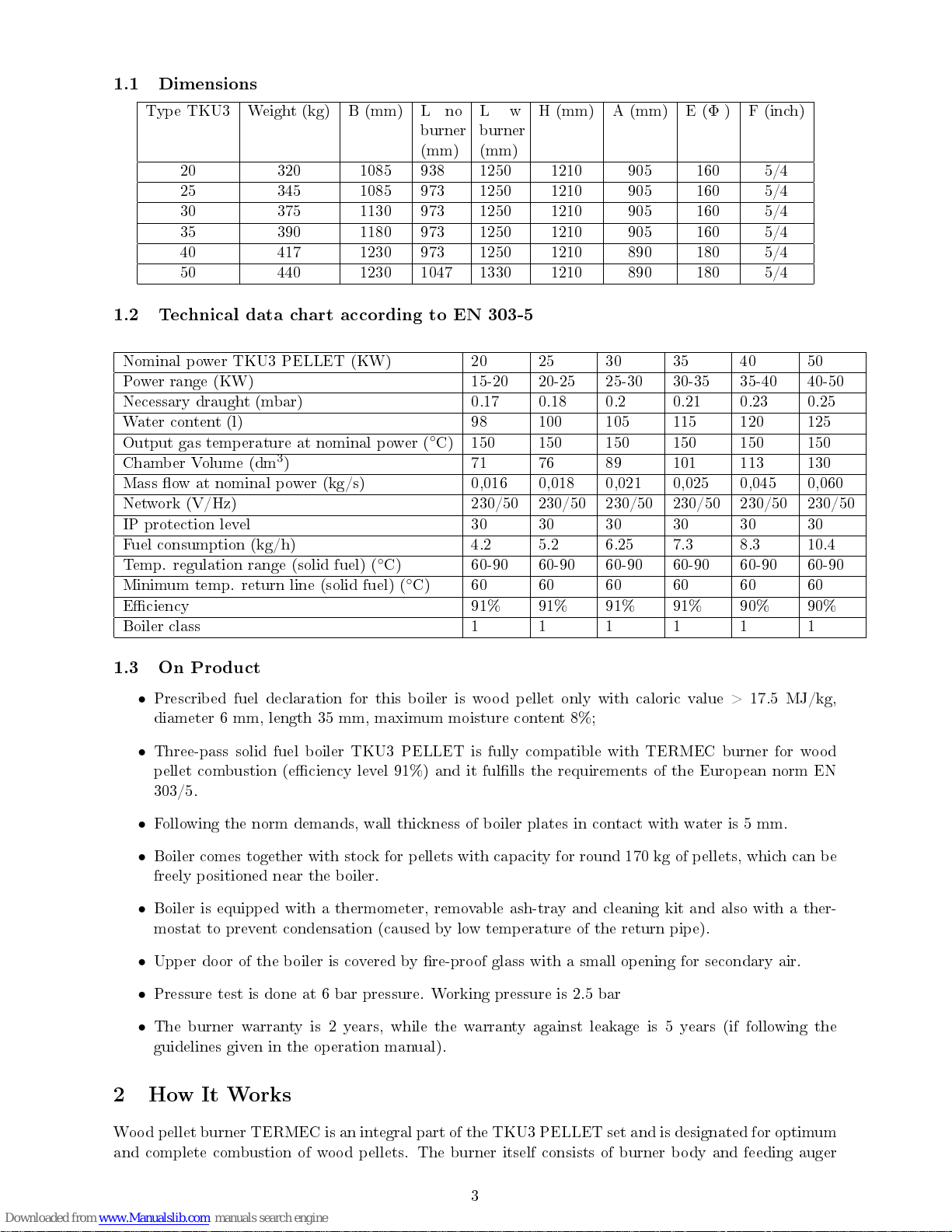

1.1 Dimensions

Type TKU3 Weight (kg) B (mm) L no

burner

(mm)

L w

burner

(mm)

H (mm) A (mm) E (Φ) F (inch)

20 320 1085 938 1250 1210 905 160 5/4

25 345 1085 973 1250 1210 905 160 5/4

30 375 1130 973 1250 1210 905 160 5/4

35 390 1180 973 1250 1210 905 160 5/4

40 417 1230 973 1250 1210 890 180 5/4

50 440 1230 1047 1330 1210 890 180 5/4

1.2 Technical data chart according to EN 303-5

Nominal power TKU3 PELLET (KW) 20 25 30 35 40 50

Power range (KW) 15-20 20-25 25-30 30-35 35-40 40-50

Necessary draught (mbar) 0.17 0.18 0.2 0.21 0.23 0.25

Water content (l) 98 100 105 115 120 125

Output gas temperature at nominal power (◦C) 150 150 150 150 150 150

Chamber Volume (dm3) 71 76 89 101 113 130

Mass ow at nominal power (kg/s) 0,016 0,018 0,021 0,025 0,045 0,060

Network (V/Hz) 230/50 230/50 230/50 230/50 230/50 230/50

IP protection level 30 30 30 30 30 30

Fuel consumption (kg/h) 4.2 5.2 6.25 7.3 8.3 10.4

Temp. regulation range (solid fuel) (◦C) 60-90 60-90 60-90 60-90 60-90 60-90

Minimum temp. return line (solid fuel) (◦C) 60 60 60 60 60 60

Eciency 91% 91% 91% 91% 90% 90%

Boiler class 1 1 1 1 1 1

1.3 On Product

•

Prescribed fuel declaration for this boiler is wood pellet only with caloric value > 17.5 MJ/kg,

diameter 6 mm, length 35 mm, maximum moisture content 8%;

•

Three-pass solid fuel boiler TKU3 PELLET is fully compatible with TERMEC burner for wood

pellet combustion (eciency level 91%) and it fullls the requirements of the European norm EN

303/5.

•

Following the norm demands, wall thickness of boiler plates in contact with water is 5 mm.

•

Boiler comes together with stock for pellets with capacity for round 170 kg of pellets, which can be

freely positioned near the boiler.

•

Boiler is equipped with a thermometer, removable ash-tray and cleaning kit and also with a ther-

mostat to prevent condensation (caused by low temperature of the return pipe).

•

Upper door of the boiler is covered by re-proof glass with a small opening for secondary air.

•

Pressure test is done at 6 bar pressure. Working pressure is 2.5 bar

•

The burner warranty is 2 years, while the warranty against leakage is 5 years (if following the

guidelines given in the operation manual).

2 How It Works

Wood pellet burner TERMEC is an integral part of the TKU3 PELLET set and is designated for optimum

and complete combustion of wood pellets. The burner itself consists of burner body and feeding auger

3

Page 5

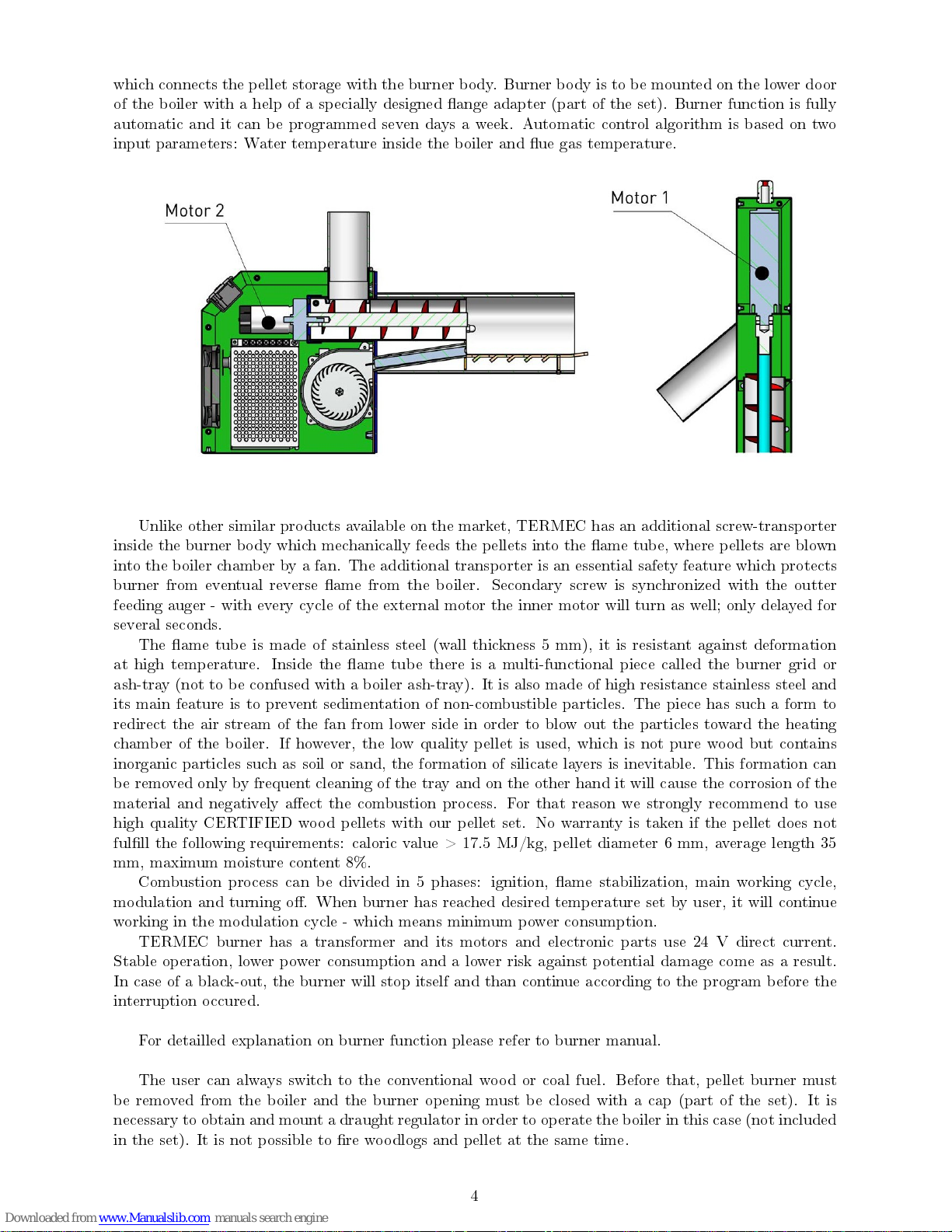

which connects the pellet storage with the burner body. Burner body is to be mounted on the lower door

of the boiler with a help of a specially designed ange adapter (part of the set). Burner function is fully

automatic and it can be programmed seven days a week. Automatic control algorithm is based on two

input parameters: Water temperature inside the boiler and ue gas temperature.

Unlike other similar products available on the market, TERMEC has an additional screw-transporter

inside the burner body which mechanically feeds the pellets into the ame tube, where pellets are blown

into the boiler chamber by a fan. The additional transporter is an essential safety feature which protects

burner from eventual reverse ame from the boiler. Secondary screw is synchronized with the outter

feeding auger - with every cycle of the external motor the inner motor will turn as well; only delayed for

several seconds.

The ame tube is made of stainless steel (wall thickness 5 mm), it is resistant against deformation

at high temperature. Inside the ame tube there is a multi-functional piece called the burner grid or

ash-tray (not to be confused with a boiler ash-tray). It is also made of high resistance stainless steel and

its main feature is to prevent sedimentation of non-combustible particles. The piece has such a form to

redirect the air stream of the fan from lower side in order to blow out the particles toward the heating

chamber of the boiler. If however, the low quality pellet is used, which is not pure wood but contains

inorganic particles such as soil or sand, the formation of silicate layers is inevitable. This formation can

be removed only by frequent cleaning of the tray and on the other hand it will cause the corrosion of the

material and negatively aect the combustion process. For that reason we strongly recommend to use

high quality CERTIFIED wood pellets with our pellet set. No warranty is taken if the pellet does not

fulll the following requirements: caloric value > 17.5 MJ/kg, pellet diameter 6 mm, average length 35

mm, maximum moisture content 8%.

Combustion process can be divided in 5 phases: ignition, ame stabilization, main working cycle,

modulation and turning o. When burner has reached desired temperature set by user, it will continue

working in the modulation cycle - which means minimum power consumption.

TERMEC burner has a transformer and its motors and electronic parts use 24 V direct current.

Stable operation, lower power consumption and a lower risk against potential damage come as a result.

In case of a black-out, the burner will stop itself and than continue according to the program before the

interruption occured.

For detailled explanation on burner function please refer to burner manual.

The user can always switch to the conventional wood or coal fuel. Before that, pellet burner must

be removed from the boiler and the burner opening must be closed with a cap (part of the set). It is

necessary to obtain and mount a draught regulator in order to operate the boiler in this case (not included

in the set). It is not possible to re woodlogs and pellet at the same time.

4

Page 6

3 Recommendations for boiler shipment and storage

3.1 Delivery form

The boiler comes in three parts, boiler chamber, pellet storage and the boiler housing packed separately.

Chamber is wrapped with plastic sheet, and upper door containing reproof glass should have a small

styrofoam protection sheet. The whole set is transported on wood pallet.

The boiler must always stand in its vertical position. The rotation of the boiler during the shipment or

installation represents a serious risk and can lead to damaging the boiler. It is forbidden to stack boilers

vertically one onto other.

The boiler can be stored only in closed rooms with no atmospheric inuence. The humidity in the storing

room also must not exceed the critical value of 80%, so as not to create any condensate. The temperature

of the storing room must be in the range of +/- 40 C.

3.2 What's in the box

The following parts are supplied together with the boiler:

•

Wood pellet burner TERMEC with feeding auger, regulation panel and connecting tube

•

Special ange to mount burner body on boiler lower door opening

•

Cap to close boiler opening in case of using conventional solid fuel

•

Two pieces of boiler ash-tray

•

Cleaning kit

•

Warranty note for both boiler and burner (separately)

4 Boiler installation

4.1 Boiler placement

The boiler room should have air-conditioning. The boiler should be mounted in the boiler room permiting

access to all its parts as shown below:

5

Page 7

4.2 Chimney

Boiler connection to the chimney is shown in the gure:

Proper dimensioning of the chimney is a very important premise for optimum boiler performance.

The purpose of the chimney is to take out the products of combustion but also to secure necessary air

draught in the boiler. The graph shows how to chose the necessary height for the chimney as a func-

tion of chimney opening. Proper chimney insulation is very important and should be at least 50 mm thick.

Depending on the necessary draught of the boiler, the cross section and the height of the chimney are

determined. Please advise technical material given by chimney producer. Minimum chimney height for

wood boilers is 6 m. Round chimney made of stainless steel modules is recommended in order to keep

the condensation inuence low.

6

Page 8

5 Connecting the boiler with a central heating system

5.1 Closed system

The following schemes show how to connect the boiler to the central heating installation with or without

a heat accumulator tank:

System parts: 1. Boiler 2. Heat accumulator 3. Heat exchanger 4. Non-return valve 5. Mixing valve 6.

Pump of the radiator heating 7. Automatic regulation for the radiator heating 8. Expansion vessel 9. Exchanger

pump 10.Valve 11.Thermo-manometer 12. Safety valve 13. Four-arm mixing valve 14. Dirt remover 15. Safety

valve

7

Page 9

Schemes for connecting both radiators and oor heating:

System parts: 1. Boiler 2. Heat accumulator 3. Heat exchanger 4. Non-return valve 5. Distributor 6.

Mixing valve 7. Pump of the radiator heating 8. Pump of the oor heating 9. Regulator of the automatic

regulation for the radiator heating 10. Regulator of the automatic regulation for the oor heating 11. Receiver

12. Expansion tank 13. Exchanger pump 14.Valve 15.Thermo-manometer 16. Filth catcher 17. Four-arm

mixing valve 18. Safety valve

8

Page 10

It is not necessary to install the heat accumulator. However, it is recommended.For 1 KW power of

the boiler, a capacity of the heat accumulator of 25-50 l is recommended. One must also bear in mind

that the power of the boiler must be enough in order to both warm up the water in the accumulator,

as well as to provide direct feed to the installation in very cold periods the chosen power of the boiler

should be 1.5 higher than the power of an oil-gas boiler for the given squaring.

It is recommended that the closed central heating system is supplied with an expansion tank, the

capacity of which must amount to at least one tenth of the total capacity of the system (including the

water volume in the boiler). The system must also have an automatic aeration valve with the help of

which air will be eliminated from the system. The use of a safety valve is obligatory (with a 2-3 bar

threshold, depending on the power of the boiler) and it must be mounted near the boiler.

It is also necessary that the system has a thermometer and manometer in order to read the temperature

and pressure in the system. In case of using conventional solid fuel, the temperature of the return line

should not fall below 60C, so as to avoid leaking, i.e. condensation in the boiler, which can further lead

to corrosion. The temperature of the starting line should not fall below 70C. It is recommended to use

a four-arm mixing valve on the return line of the boiler or a regulation group such as LADDOMAT 21.

It is also recommended to mount a lth catcher on the return line.

Qualied installer should be entrusted with the mounting of the heating and the initial operation.

This must be a person who will take over the responsibility and guarantee the correct operation of the

boiler and of the complete central heating system. In the case of an incorrectly planned system with

manifesting deciencies caused by the respective person's incorrect installation of the system, which can

again lead to an incorrect operation of the boiler, the complete liability for the material damage and

potential new costs arising in relation to it is borne exclusively by the person who was entrusted with

the mounting of the central heating system, and not by the boiler manufacturer, sales representative or

seller.

5.2 Closed system combined heating with solar panels

The following scheme depicts a heating system connected over a hybrid solar boiler within an accumalation

tank:

Termomont in its oer of solar boilers also has a 'hybrid' version of a heat accumulation tank and

stainless steel solar boiler in one: ATS combined tank. When boiler heats up the 'technical' water inside

the boiler - as do the solar panels through the spirale. The drinking water is inside the inner vessel which

is heaten indirectly by the technical water.

9

Page 11

5.3 Open system

The following scheme shows how to connect the boiler to the open central heating system:

System parts 1. Boiler TKU3 PELLET 2. Valve 3. Thermo-manometar 4. Boiler circle pump 5. Three-way

mixing valve or LADDOMAT 21 6. Heat accumulator tank 7. Three-way mixing valve 8. Automatic three-way

mixing valve 9. Circulation pump for radiator heating 10. Open expansion vessel 11. Automatic regulation

MRTR Plus (First) 12. Heating circle 13. Sanitary water circulation pump 14. Sanitary water accumulation

tank SOLAR I

10

Page 12

6 Boiler in function

6.1 First operation

When putting the boiler and burner in operation for the rst time (this job can be performed by authorized

and qualied person only) it is necessary to check if the factory settings are

6.2 Burner in operation

To turn the burner on perform the following steps:

1. Turn the main switch for power supply.

2. By pressing the manual feed button, it is necessary to ll the feeding auger with pellets and the

burner itself. Before that make sure that there are enough pellets in the pellet storage and if not

please rell it.

3. The burner is tuned on/o by pressing the corresponding button. When all the parameters are set

at the time of the initial burner operation, this is all the end-user has to do.

Burner operation can be divided into several zones:

1.

Start-up / Ignition.

Burner is put into operation by pressing the corresponding button. Ignition

process is controlled automatically by the preprogrammed parameters. When the burner is turned

on, the electrical heater starts to heat up pellets (for 4 minutes by default setting) and after that

the fan starts to blow. Ignition process lasts until the ue gas temperature reaches 70 C. The burner

goes into another phase ("stabilization"). If for some reason, after 15 minutes the 70◦C temperature

is not reached, the burner will be turned o and the message on the display will tell that the burner

ignition did not succeed.

2.

Flue gas stabilization.

After the ignition process is successfully completed, it is necessary to allow

burner some time to stabilize the ame. This period is according to default setting one minute long.

After that, the burner is ready to start the feeding process according to adjusted power range and

start increasing the water temperature toward the desired one.

3.

(Main) working cycle.

The burner remains in this state until one of the following conditions is

completed:

•

water temperature inside the boiler has reached the set value

•

ue gas temperature has reached 250◦C;

if one of the conditions is fullled the burner will enter the "modulation" cycle.

4.

Modulation.

Modulation means the burner operates with minimum power necessary only to retain

not to increase the (reached) water temperature. According to factory presets modulation range

is set between 2◦C below the desired temperature (the lower threshold) and 5◦C above the desired

temperature (the upper threshold). For instance, if the desired temperature is set at 50◦C, between

48◦C and 55◦C burner will feed minimum amount of pellets. If the temperature exceeds the upper

threshold burner will turn o. If it goes below the lower threshold, burner will be in main working

cycle (again).

5.

Turning o.

When the burner is turned o by pressing the button, no pellets are fed to the

burner and the fan starts to blow out the remaining pellets through the ame tube until the ue

gas temperature is below 60◦C.

Burner display should indicate the current working zone of the burner.

For the cleaning purpose, fan blows out the particles in the ame tube every 60 minutes (by default)

and this operation takes 30 seconds. If there is an electricity black-out, and there is no alternative power

11

Page 13

supply, the burner will be extinguished and after the black-out is over, it will continue its operation

automatically.

The power consumption of the burner is in the range of a light bulb, except when ignition takes place

- then it can reach up to 300W. The ignition itself cannot take longer than 15 minutes. All technical

parameters and values mentioned above are preset by the factory, but the authorized person can change

them on the spot.

Important notes:

1. To turn on/o hold the corresponding button for 3 seconds.

2. Main switch should be always turned on - during the heating season.

3. Manual feed button is situated on the side of the burner and it is important that burner is lled

with pellets before start.

6.3 Using conventional solid fuel

6.4 Circulation Pump Thermostat

Boiler is equipped with a thermostat for the system circulation pump. The thermostat threshold can

be set on certain value and only when the temperature is higher than that, the circulation pump will be

turned on.

This thermostat is primarily used when ring with solid fuel, in order to prevent the low temperature

of the return line which can lead to condensation as a consequence. As the heating up process with wood

pellets is usually much faster compared to conventional wood, the eect of condensation should not take

place at all when burning pellets. The default value for temperature threshold is set at 60◦C. When

ring pellets the threshold should be at lower value, some 20◦C below the desired water temperature.

12

Page 14

6.5 Maintenance and cleaning

Using wood pellets as a primary fuel means very low level of ashes (less than 1%). The cleaning of the

boiler can thus be performed once per week and does not take more than 5 minutes. Burner ash-tray

should be however cleaned every day or two - operation which takes less than a minute.

Using pellets means also low temperature of the ue gases due to the high eciency of combustion.

This means the boiler would last much longer compared to combustion with traditional solid fuels such

as wood or coal.

7 Safety features

7.1 Thermal safety in case of overheat (closed systems)

Burner has two main safety features: The internal feeeding auger prevents re passing from the boiler to

the burner body. The other feature is that if the temperature of the ue gases does not drop below 250

◦

C the burner will be forced to work with minimum power (which means minimum quantity of pellets

added every time).

For additional hydraulic protection in the closed systems it is necessary to install to safety thermal

valve shown on image (to be bought separately, not an integral part of the boiler).

If for some reason the temperature of the water inside the boiler should exceed 95◦C this valve would

release the water from the water supply system to cool down the water temperature inside the boiler.

13

Page 15

Connection scheme for the thermal safety valve: 1. Cold water entering from the water supply system 2.

Cold water entry into boiler 3. Hot water going outside the boiler 4. hot water ending in the sewage water

system 5. Thermo-valve sensor

To connect the safety valve:

•

Connect the sensor of the valve (outter thread 1/2") at depicted place on the boiler, position 5

(inner thread 1/2")

•

Connect the cold water entry (on valve's input is marked with C) than connect the exit line (valve

marked with:→) with the corresponding exit line on the boiler (position 21)

•

Connect position 21 (on the boiler) with the input line on the valve (valve is marked with:←)

•

Connect the valve (marked with S) to the sewage system.

14

Page 16

A Declaration Of Conformity

We, Termomont d.o.o. with legal seat on the address Prhova£ka street bb, 22310 imanovci, Republic

of Serbia, under sole responsibility declare that:

Wood pellet boilers TKU3 PELLET 20, TKU3 PELLET 25, TKU3 PELLET

30, TKU3 PELLET 35 TKU3 PELLET 40, TKU3 PELLET 50

produced 2010. and 2011. as by its construction, design and performances are in accordance with the

following norms and directives prescripted by the European Union:

•

97/23 EEC Pressure device directive

•

EN 303/5 Norm for solid fuel boilers"

Test report made at Univerza v Ljubljani, Fakulteta za strojni²tvo, Laboratorij za ogrevalno tehniko,

Ljubljana, Slovenia, May 2011.

Report number: Poro£ilo t- 13-2/1-11-MP

imanovci, September 30, 2011

Signature of the responsible person

. .. ... .. . .. ... .. . .. ... .. . .. . .. ... .. .

15

Loading...

Loading...