H E A T I N G S Y S T E M S

EKY SERIES SOLID FUEL HOT WATER BOILER

WITH MANUAL LOADING

INSTALLATION AND USAGE MANUAL

EKY 125-1000

Digital and mechanical control panel...

H E A T I N G S Y S T E M S

FOREWORD

Dear Customer;

First of all, thank you for choosing our product. We hope you will get

complete satisfaction from DEK Series Electric Combi Boiler.

We would like you to use your device with maximum efficiency, therefore

please read this instruction book carefully before you start using the

product and save it to refer to in the future.

This manual will help you to operate your device safely and efficiently. For

this reason you should pay attention to these:

Please read this instruction book carefully before you install and operate

the product.

Follow the instructions and the rules on safe usage.

The instruction book may apply to other models as well; the differences

between the models are clearly described inside.

H E A T I N G S Y S T E M S

CONTENTS

Foreword

EKY 17-100 Technical Specifications..................................................................1

EKY 125-250 Technical Specifications................................................................3

EKY 125-500 (3 bar) Technical Specifications.....................................................5

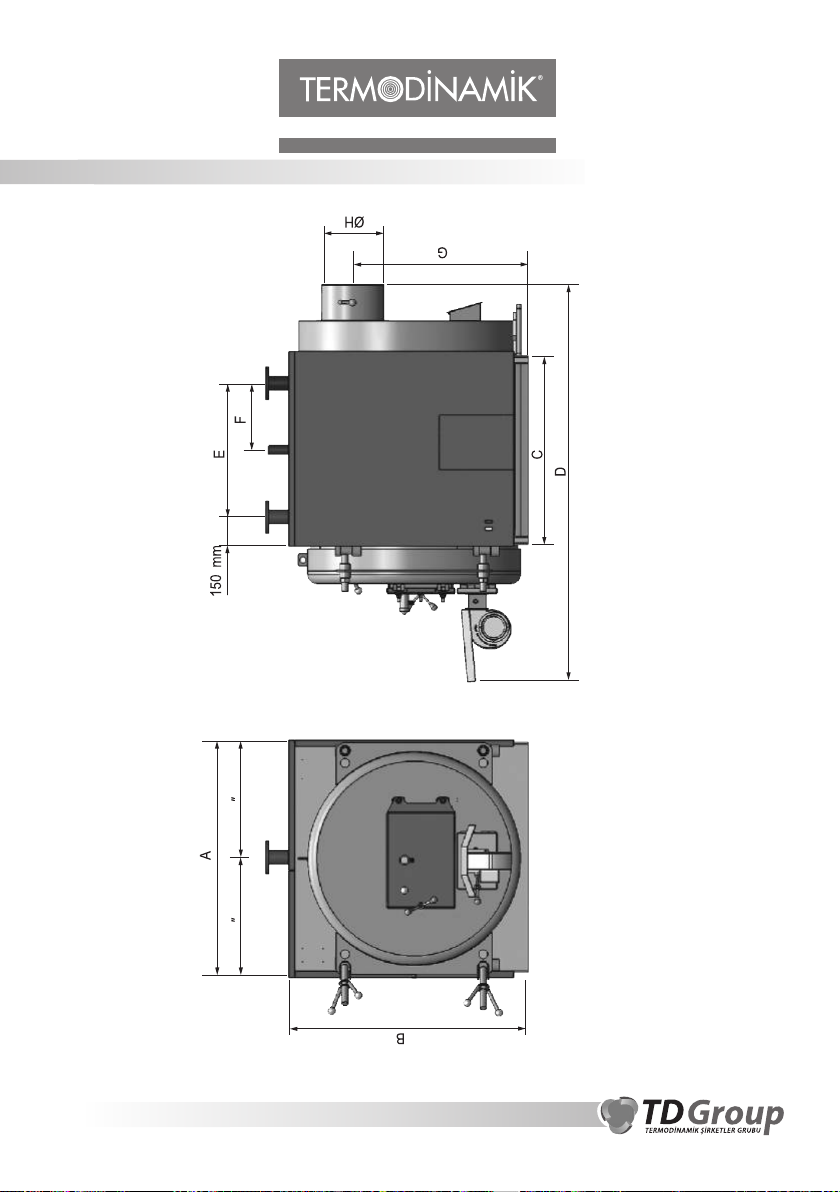

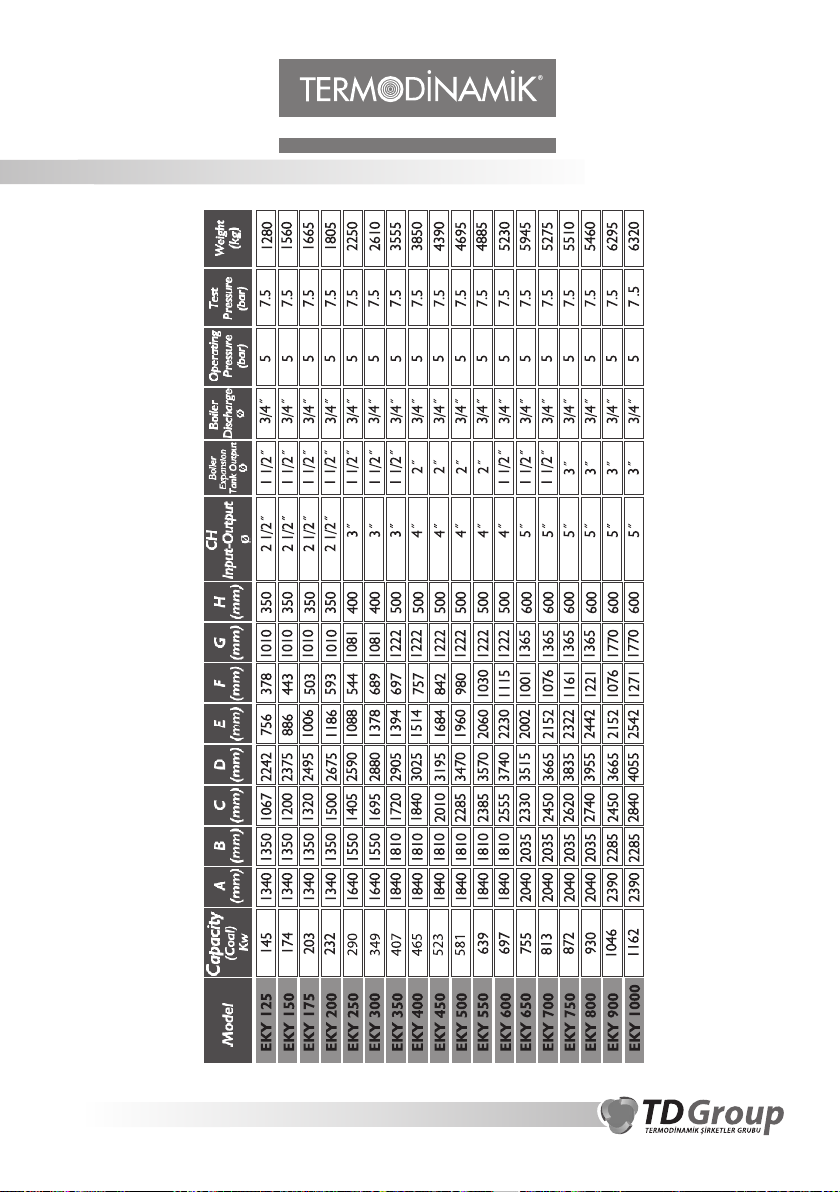

EKY 125-1000 (5 bar) Technical Specifications...................................................7

Appliance Information......................................................................................9

Expansion Tank Volumes Suitable for Capacities.............................................11

EKY 17-100, EKY 125-250 Installation Chart................................................12

EKY 125-1000 Installation Chart......................................................................14

EKY 125-1000 Expansion Connection Chart.....................................................15

Common Chimney...........................................................................................16

EKY Digital Control Panel.................................................................................17

Error Codes and Solutions...............................................................................20

EKY Digital Panel Electrical Connection Chart.................................................22

EKY Mechanical Panel Electrical Connection Chart(125-250)......................24

EKY Mechanical Panel Electrical Connections Chart (250-1000)......................25

Use of the Boiler..............................................................................................26

Malfunctions and Troubleshooting.................................................................31

H E A T I N G S Y S T E M S

EKY 17-100 TECHNICAL SPECIFICATIONS

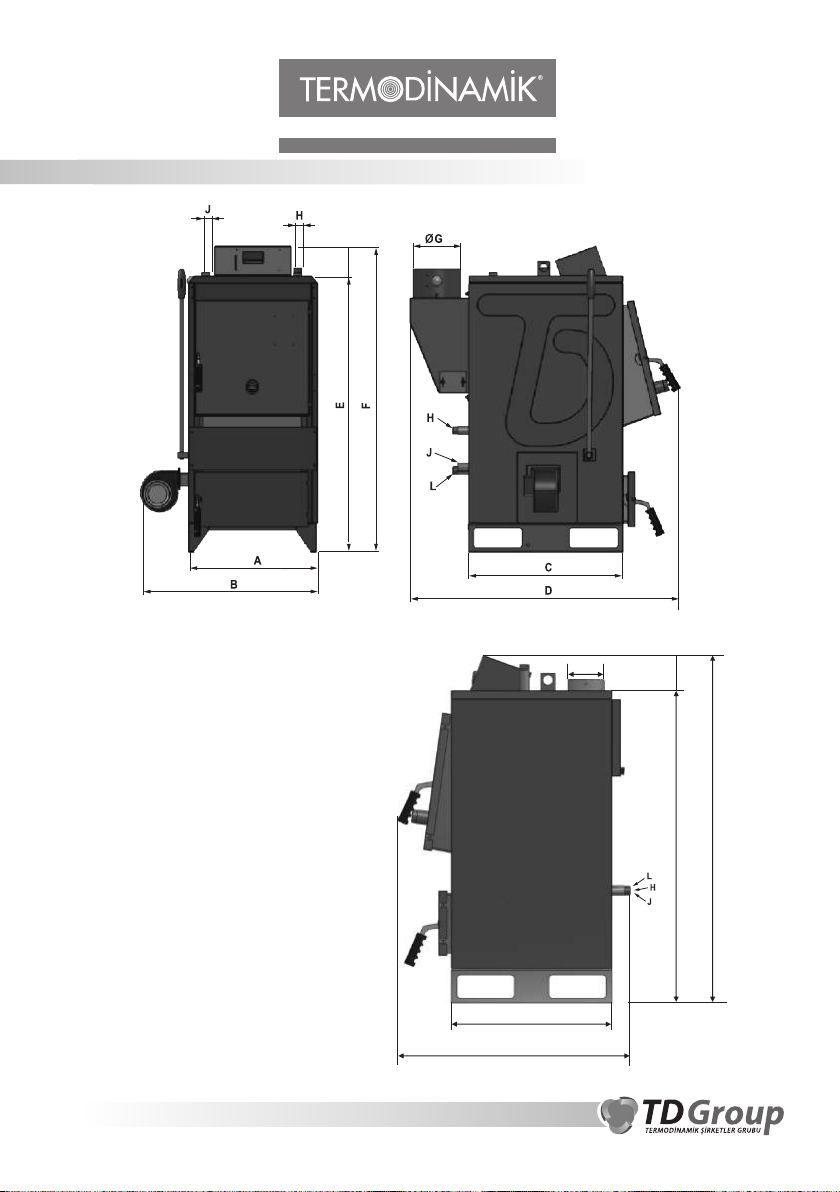

G

EKY 17 SIDE VIEW

1

F

E

C

D

H E A T I N G S Y S T E M S

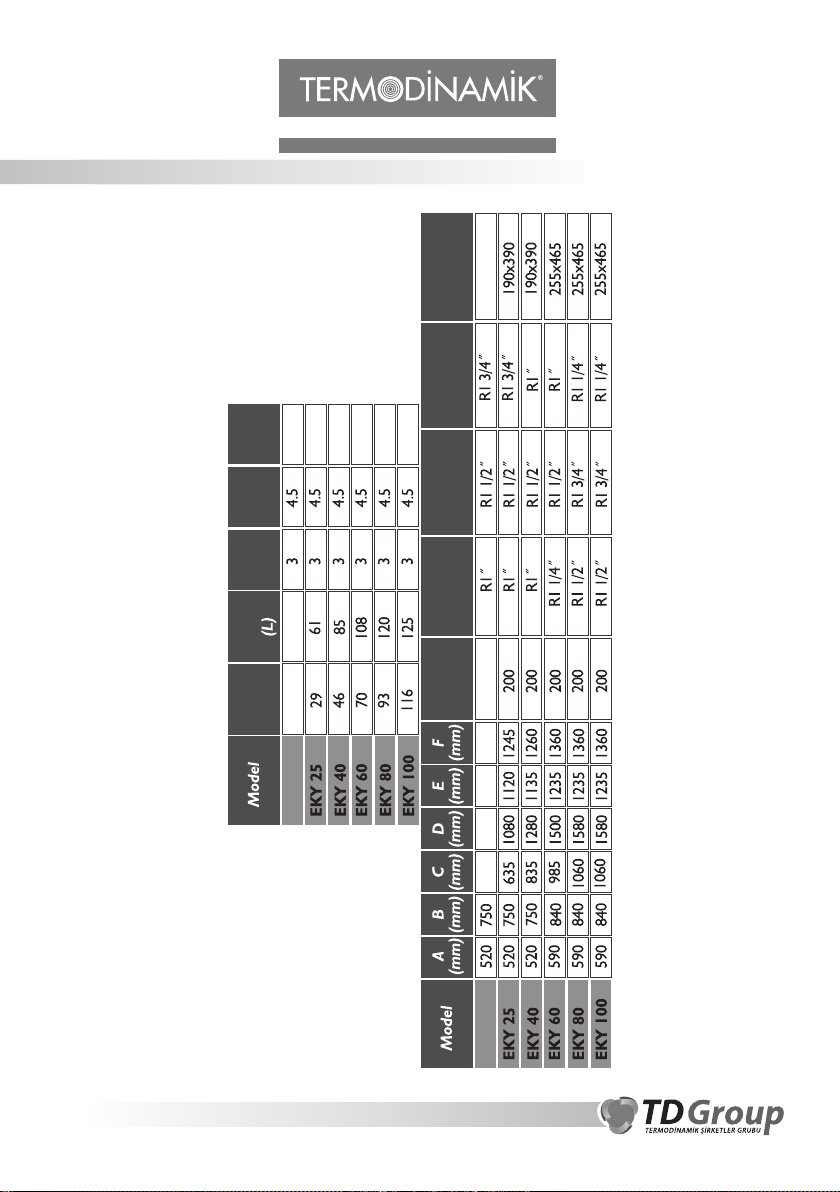

EKY 17-100 TECHNICAL SPECIFICATIONS

kg

255

300

420

Weight

450

Fuel Loading

Lid Dimensions

J (Safety

470

(mm)

Input-Output)

Test

(bar)

Pressure

(bar)

Pressure

Operating

Water

Volume

Kw

(Coal)

Capacity

49

20 183

EKY 17

L (Boiler

Filling-Discharge)

H (Boiler

Input-Output)

(mm)

G Flue

Diameter

560 190x390820 1100 1225 130

EKY 17

We are reserved the right to make changes in dimensions and appearance.

2

H E A T I N G S Y S T E M S

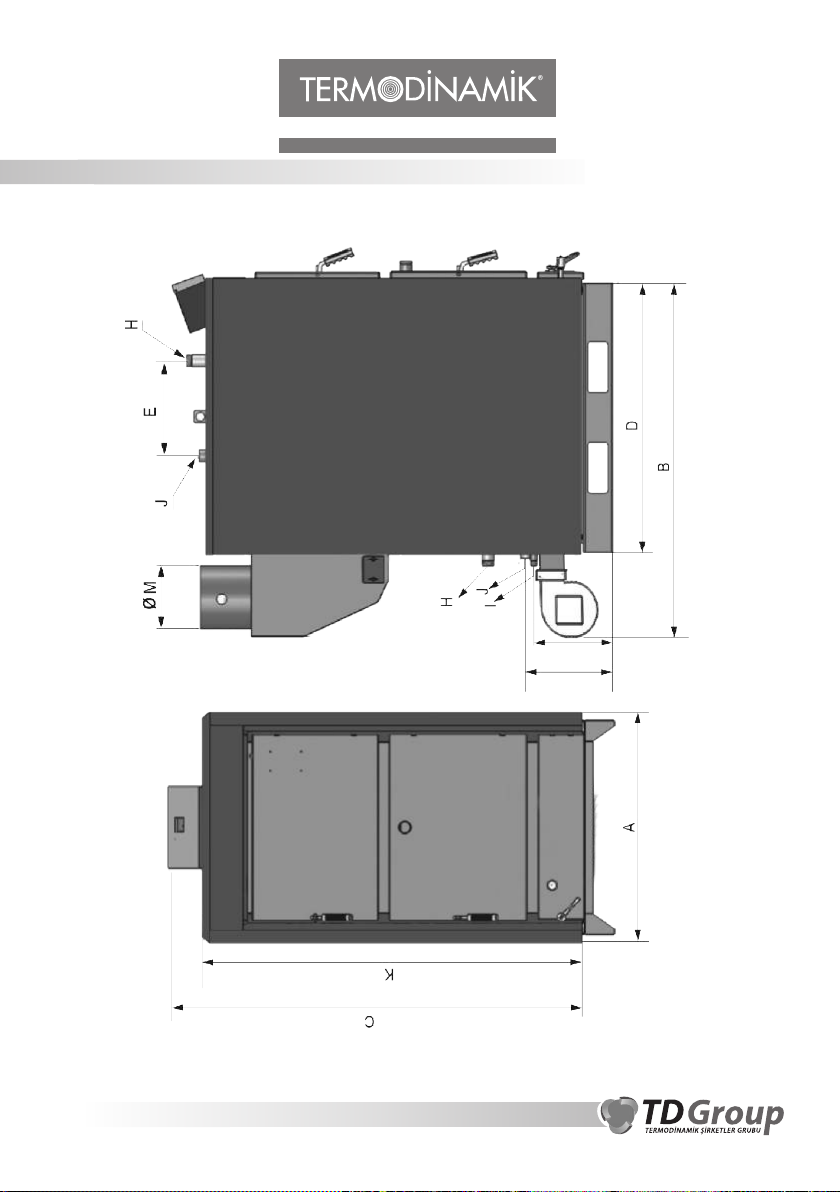

EKY 125 - 250 TECHNICAL SPECIFICATIONS

338 mm

365 mm

3

H E A T I N G S Y S T E M S

EKY 125 - 250 TECHNICAL SPECIFICATIONS

250

250

250

250

Flue

ØM(mm)

Diameter

250

(kg)

Weight

930

950

1000

1050

1290

Filling

L (Boiler

Discharge)

K

(mm)

E

(mm)

D

(mm)

C

(mm)

B

(mm)

A

(mm)

Kw

(Coal)

Capacity

Model

R 3/4?

R 3/4?

1520

1520

370

520

1220

1060

1650

1650

1680

1520

790

790

145

174

EKY 125

EKY 150

R 3/4?

R 3/4?

1605

1605

520

680

1380

1220

1735

1735

1680

1840

790

790

203

232

EKY 175

EKY 200

Water

R 3/4?

1630

700

Operating

1570

1760

1980

942

291

EKY 250

(L)

Volume

Test

(bar)

Pressure

(bar)

Pressure

J (Safety

Input-Output)

H (Boiler

Input-Output)

Model

246

236

4.5

4.5

3

3

R 1 1/4?

R 1 1/4?

R1 1/2?

R1 1/2?

EKY 150

EKY 125

256

290

4.5

4.5

3

3

R 1 1/4?

R 1 1/4?

R 2?

R 2?

EKY 175

EKY 200

518

4.5

3

R 1 1/4?

R 2 1/2?

EKY 250

We are reserved the right to make changes in dimensions and appearance.

4

H E A T I N G S Y S T E M S

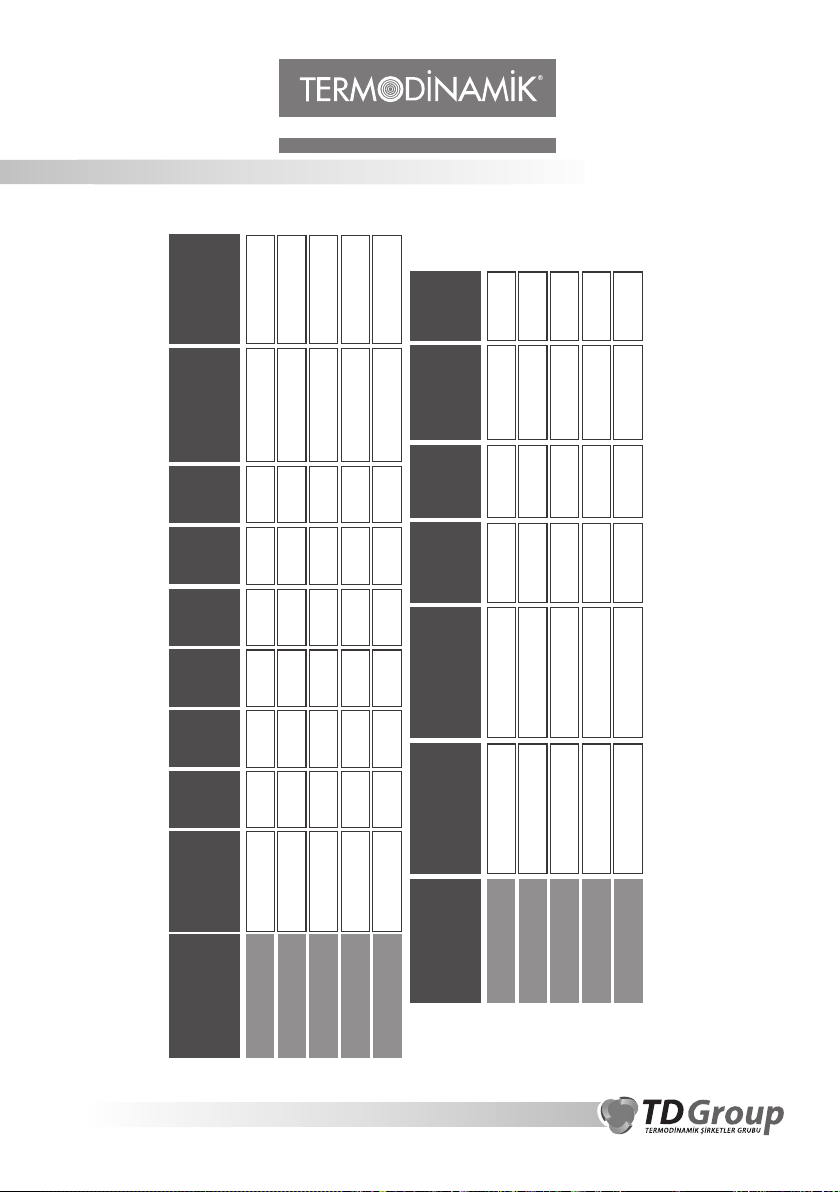

EKY 125 - 500 (3 BAR) TECHNICAL SPECIFICATIONS

5

H E A T I N G S Y S T E M S

EKY 125 - 500 (3 BAR) TECHNICAL SPECIFICATIONS CHART

Model

EKY 125

EKY 150

EKY 175

EKY 200

EKY 250

EKY 300

EKY 350

EKY 400

EKY 450

EKY 500

(Coal)

Kw

145

174

203

232

290

349

407

465

523

581

CH

Capacity

Model

EKY 125

EKY 150

EKY 175

EKY 200

Input-Output

2 1/2?

2 1/2?

2 1/2?

2 1/2?

EKY 250

EKY 300

EKY 350

EKY 400

EKY 450

EKY 500

We are reserved the right to make changes in dimensions and appearance.

A

(mm)B(mm)C(mm)D(mm)

1340 1350

1340 1350

1340 1350

1340 1350

1640 1550

1640 1550

1840 1810

1840 1810

1840 1810

1840 1810

3?

3?

3?

4?

4?

4?

Expansion

1 1/2?

1 1/2?

1 1/2?

1 1/2?

1 1/2?

1 1/2?

1 1/2?

Boiler

Tank

Output

2?

2?

2?

1065

1195

1315

1495

1400

1690

1706

1826

1996

2272

Boiler

Discharge

3/4?

3/4?

3/4?

3/4?

3/4?

3/4?

3/4?

3/4?

3/4?

3/4?

E

(mm)F (mm)

2240 1010

2370 1010

756 378 350

886 443 350

2490 10101006

2670 10101186

2585 10811088

2875 10811378

2891 12221394

3011 12221514

3181 12221684

3457 12221960

Operating

Pressure

(bar)

3

3

3

3

3

3

3

3

3

3

G

(mm)

(mm)

503 350

593 350

544 400

689 400

697 500

757 500

842 500

980 500

Test

Pressure

(bar)

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

4.5

Weight

(kg)

1220

1420

1530

1660

2120

2470

3150

3430

3950

4220

H

6

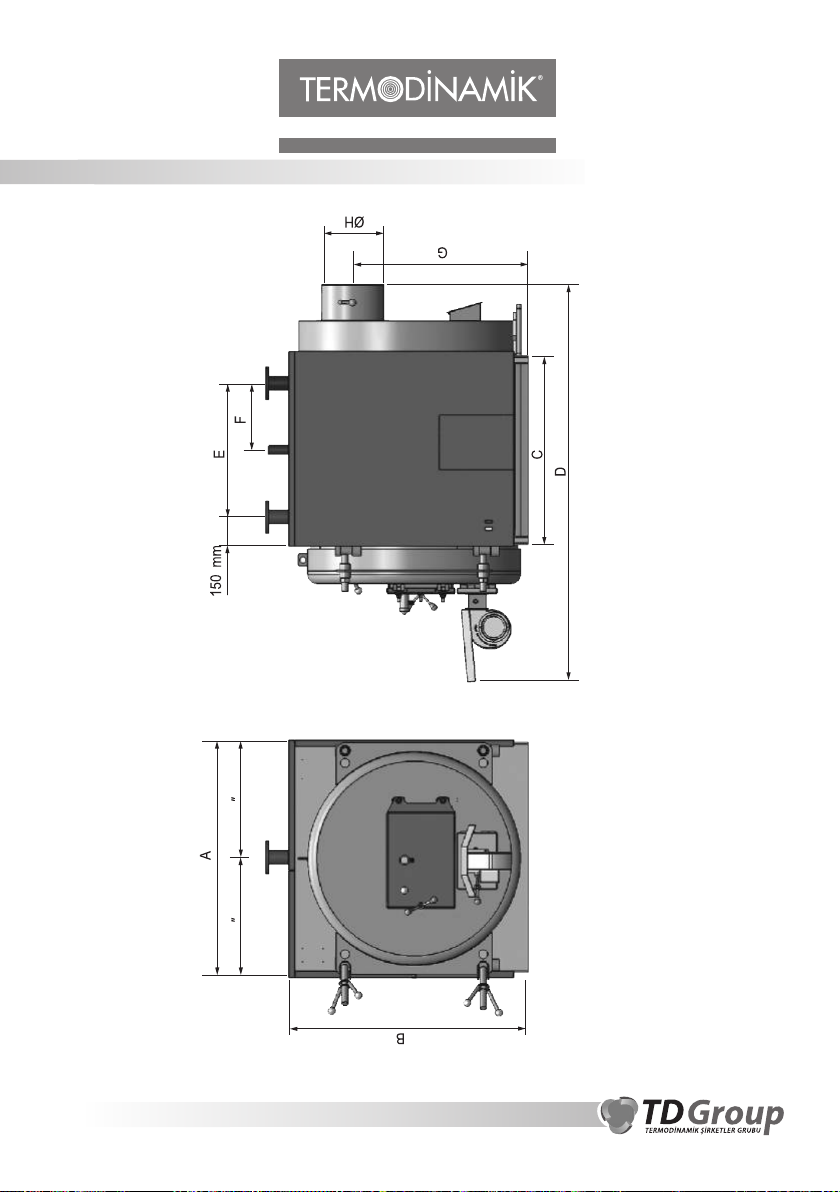

H E A T I N G S Y S T E M S

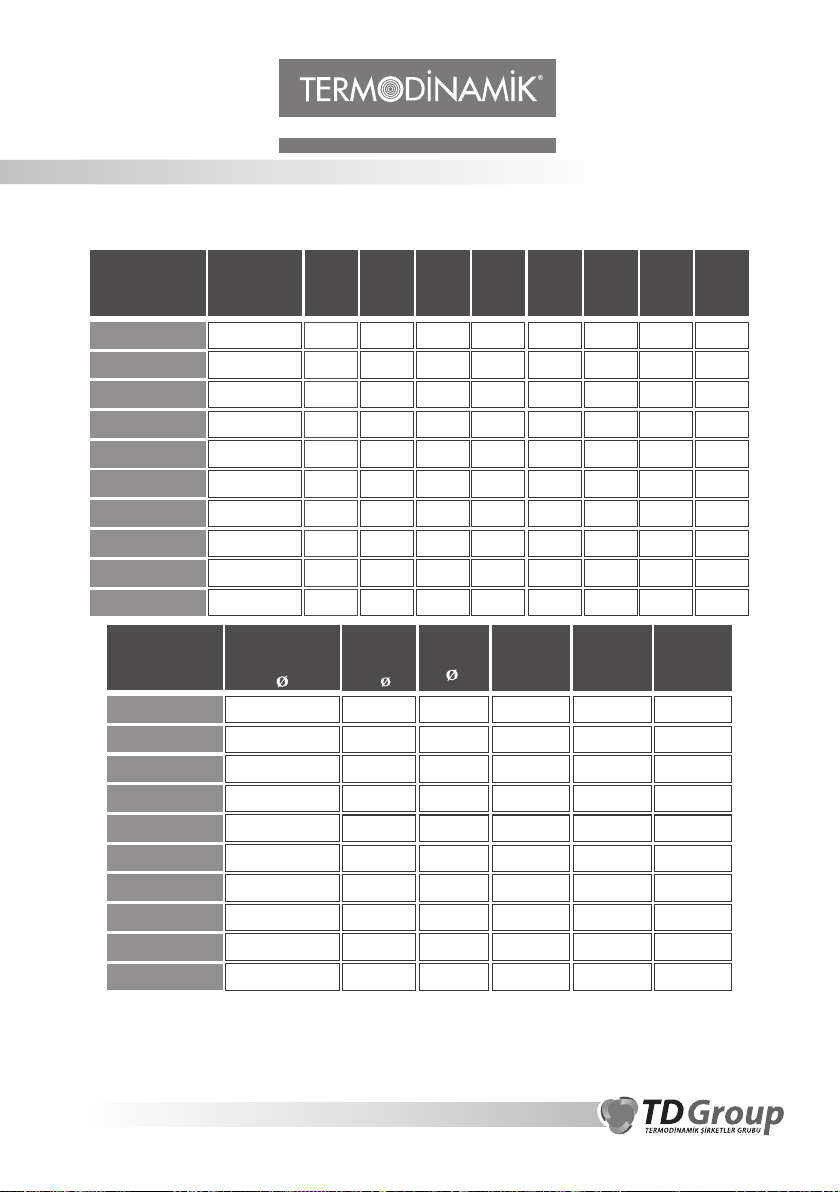

EKY 125 - 1000 (5 BAR) TECHNICAL SPECIFICATIONS CHART

7

H E A T I N G S Y S T E M S

EKY 125 - 1000 (5 BAR) TECHNICAL SPECIFICATIONS CHART

We are reserved the right to make changes in dimensions and appearance.

8

H E A T I N G S Y S T E M S

APPLIANCE INFORMATION

EKY series boilers are designed to burn different types of fuels such as wood, walnut coal, quince

coal and low-calorie brown coal in ranging capacities. As it is known, the shaft gasses which

occur as a result of burning wood and coal, and condensation of water vapors shall take place.

Make sure not to operate the boiler below 45°C. In case of operation below 45°C, the temperature

of the shaft will be low and this will cause the shaft draft to be insufficient and result in

condensation. Therefore, the life span of the boiler shall be shorter due to corrosion in short time.

The circulation pump in EKY Model boilers stops operating when the boiler water temperature

decreases below 32°C. This is designed to prevent the substantial decrease in the boiler output

water temperature and acid drop (sulfuric acid) resulting from condensation by means of cooling

the firebox.

The fan allowing for burning air stops operating when the boiler water temperature falls under

28°C and the “fuel out” light on the panel indicator is on. This is designed to prevent the fan from

cooling more the shaft gasses in case the boiler fuel decreases. When the shaft gas cools down,

condensation occurs in the shaft. Such condensed water contains acid.

ASSEMBLY INSTRUCTIONS

The boiler should be leveled and installed at least at a distance of 20 cm from ground in boiler

rooms on a durable surface.

The boiler room should be regularly ventilated according to regulations and rule.

When assembling EKY series boilers, it is required to use open expansion tank. The expansion

tank should be located at the top of the installation and the safety pipes should be connected to the

inputs and outputs of the boiler in the shortest route possible. There should never be any flow

control units (valve, check valve, etc.) over the safety pipes. Make sure that the open expansion

tank is always full. The expansion tank volumes suitable for each boiler are given in the table (at

the page 11).

The pump should be installed in such way to avoid boiler and expansion tank flow and return

pipes should not create an air pocket. On points where there is possibility for air to be

accumulated, air tubes or vent systems shall be provided to purge the air.

CORRECT WRONG CORRECT

WRONG

9

H E A T I N G S Y S T E M S

In order to provide for the safety of the boiler and the assembly in case of power outages,

the installation should have a by-pass line.

Make sure to use a suitable check valve for all solid-fuel boilers and the pressure of the

check valve should be equal to the maximum operating pressure of the boiler. On boilers

operating with 3 bar working pressure 3-bar safety valves should be used. (For cylindrical

boilers (25-100) and prismatic (125 and 250) boilers operating with 3-bar).

In regions prone to risk of freezing, expansion tank and insulation should be used.

The diameter of the shaft should not be smaller than the output diameter of the boiler shaft

and the instructions on the shaft assembly specified in this manual should be followed.

During the installation of the appliance, make sure to leave some space around the

appliance depending on the properties of the appliance enough for the technical service to

handle the appliance.

Make sure the location where the appliance and the waste gas disposal line are situated is

not a living space.

In order to minimize the heat loss, the installation pipes should be heat-insulated.

When selecting mono-phase pump, connect the power cable with an open end sticking

out of the panel on the boiler into the electric terminal of the pump. If 3-phase pump is being

used, get a separate panel for the pump.

Connectors and valves should be placed on inlet and outlet lines.

Expansion tank flow and return pipes should be installed with continuous upward

inclination from the boiler to the tank without any downward bending.

WRONG

CORRECT

WRONG

The boiler should be connected to the chimney of

the building without narrowing the diameter at the

flue outlet and through pipes having minimum the

same or larger diameter at the flue outlet and

through pipes having minimum the same or larger

diameter as the boiler flue outlet.

For installation of the boiler warning points indicated in the user manual must be

taken into consideration. The supplier will not take any responsibility for wrong

installation of the boiler and chimney.

10

H E A T I N G S Y S T E M S

EXPANSION TANK VOLUMES SUITABLE FOR BOILER CAPACITIES

Boiler Capacity

(Kcal/h)

25.000

40.000

60.000

80.000

100.000

120.000

150.000

175.000

200.000

250.000

300.000

350.000

400.000

450.000

500.000

550.000

600.000

650.000

700.000

750.000

800.000

900.000

1.000.000

If Cast Sectional

Heating Radiators

are used

45 L17.000 26 L

65 L

100 L

150 L

200 L

250 L

292 L

333 L

417 L

500 L

625 L

750 L

857 L

1000 L

1125 L

1250 L

1375 L

1500 L

1625 L

1750 L

1875 L

2000 L

2250 L

2500 L

If Panel Radiators

are used

42 L

67 L

100 L

135 L

167 L

200 L

250 L

292 L

333 L

417 L

500 L

583 L

667 L

750 L

833 L

917 L

1000 L

1083 L

1167 L

1250 L

1333 L

1500 L

1667 L

The values given above are intended for nominal conditions. The contractor company shall

perform the precise evaluation and calculations depending on the location and operation

conditions of the boiler.

11

H E A T I N G S Y S T E M S

EKY 25-100, EKY 125-250 INSTALLATION CHART

PUMP ON OUTLET

A. Input to the Radiators

B. Output from the Radiators

C. Open Expansion Tank

D. Input to the Expansion Tank

E. Output from the Expansion Tank

F. Messenger Line

G. Radiators

H. Air-Purge Valve

I. By-Pass Line Valve

J. Main Valve Pump

K. Main Valve

L. Filling Valve

G G

H

C

K

J

J

A

I

D

12

B

E

L

F

H E A T I N G S Y S T E M S

EKY 25-100, EKY 125-250 INSTALLATION CHART

PUMP ON INLET

A. Input to the Radiators

B. Output from the Radiators

C. Open Expansion Tank

D. Input to the Expansion Tank

E. Output from the Expansion Tank

F. Messenger Line

G. Radiators

H. Air-Purge Valve

I. By-Pass Line Valve

J. Main Valve Pump

K. Main Valve

L. Filling Valve

G

H

C

G

A

D

13

B

K

J J

I

L

E

F

H E A T I N G S Y S T E M S

EKY 125-1000 INSTALLATION CHART

(EXCEPT FOR PRISMATIC 125-250 SERIES)

Air Vent

O

A

TO RADIATORS

B

FROM RADIATORS

C

OPEN EXPANSION TANK

EXPANSION LINE

D

E

FROM EXPANSION TANK

F

MESSENGER LINE

G

RADIATORS

H

AIR PURGE VALVE

14

BY-PASS LINE VALVE

I

J

MAIN PUMP VALVE

K

MAIN PUMP

L

FILLING VALVE

M

SECONDARY PUMP VALVE

N

SECONDARY PUMP

O

SAFETY VALVE

H E A T I N G S Y S T E M S

EKY 17-1000 EXPANSION CONNECTION CHART

AIR VENT

These are containers open to

atmosphere and they should be

installed a distance from the top of the

pipe system for hot water systems or at

a distance from the radiator level at the

top.

For the manual feeding boiler, do not

INPUT TO

EXPANSION

OUTPUT

FROM

EXPANSION

MESSENGER

PIPE

use open expansion.

In places where the weather is very cold or there is risk of freezing, the expansion tank,

expansion input and output pipes should be insulated.

The input pipes connecting to the expansion tank should be assembled without turning

downwards and should steadily level up when going from the boiler to the expansion tank.

A hydrometer should be installed to the assembly in order to control the water level of the

system.

Make sure not to install units like valves, filters, check valve, etc. over the safety pipes

between the expansion tank and the boiler.

When water comes out of the messenger pipe, it means that the expansion tank is full and

the boiler has reached a specific pressure level. This should be checked at times when water

is pumped to the boiler from the main water supply.

POSTURE OF THE SHAFT ON THE ROOF

The shaft opening should be at a distance from

the roof ridge for slant tiled roofs.

The shaft opening at a distance from the roof

ridge (only tiled roofs).

15

The shaft opening should be at a distance

from of at least 80 cm from the roof ridge

for slant roofs.

Roofs with little slant.

H E A T I N G S Y S T E M S

SHAFT ASSEMBLY (FOR ALL MODELS)

COMMON CHIMNEY

Connecting two solid fuel boilers to the same chimney is not recommended. Where this is

not achievable and if calculations based to chimney cross section and height also allow

using of other solid fuel boilers, then it is possible to connect multiple boilers into a common

flue system. In such cases the configuration indicated in the figure should be considered.

Another point to be observed is that, the

Minimum 50 cm

angle of the flue connection with

horizontal axis of the second boiler to be

connected should be less than the first one.

The second boiler’s flue connection to

main flue connection should be in “swept

connection” as shown in the picture.

Keep easily flammable materials away from boiler flue connections and hot areas,

which may occur around the boiler.

Shaft is one of the most important units of the system. When the shaft is

not high-quality, the burning is not sufficient and no efficiency is

obtained. And this results in smoking and soot.

Fire proof metarial must be used for flue pipe and chimney should have

enough resistance to restrain the fire outside the chimney into the other

parts of the building through the chimney for certain time.

Do not install an aluminium folding pipe between boiler’s and

building’s flue.

Do not install any apparatus such as windrose/weathercock at outlet of

chimney.

Boiler Shaft Pipe Diameter

Shaft pipes should be connected to the

shaft in a way having the same diameter

with the boiler shaft output as much as

possible.

In order to intensify the shaft draft, do

not install shaft extractor hoods, fans, etc.

to the output of the shaft.

Make sure not to use bendy pipes at the

distance where the pipes shall be installed

to the shaft from the shaft output of the

boiler.

16

H E A T I N G S Y S T E M S

If the shaft is made of iron sheet material, insulate the surrounding of the shaft and prevent

the heat loss.

The shaft should not have a sectional narrowness at any spot.

Make sure not to install another appliance or more than one boiler to the same shaft.

The boiler should not be installed to the shaft at a reverse angle preventing draught (see

page 16).

The shaft should be periodically cleaned not allowing for the formation of tarry soot

inside which makes it impossible to clean the shaft.

The flue pipe (chimney) mustn’tbe mounted with level which prevent the drought of it.

End of the chimney must be 40 cm higher than tip of the roof.

Chimney should be well insulated and heat losses should be reduced. When the chimney

cools down the draught also decreases and in the cooled chimney the formed acids

combined with the effect of condensation can lead corrosion on the inner surfaces of the

chimney or down inside the boiler, therefore chimneys should also be insulated.

ELECTRICAL CONNECTION

The electrical connections should be performed by the technical service. The connections

should be performed as shown in the pages 22, 24 and 25. In case of damages resulting from

different connection or the arbitrary change of the thermostats, the manufacturer cannot be

held liable.

EKY DIGITAL CONTROL PANEL

6

KEYS

1.ENTER

Used for confirming the values

entered in the appliance.

3.UP/DOWN KEYS

Used to enter new values in

the appliance.

17

4

1 2

2.ESC

4.TEMPERATURE SETTINGS

5

3

Used for canceling the operation of the

new value entered in the appliance and

returning to the previous value in the

memory.

Used for setting the boiler temperature

setting.

7

H E A T I N G S Y S T E M S

5.FAN SET

The fan set is changed using

this button.

6.FAN ON

Used to switch the fan on or off.

7.ON/OFF

Used to turn on-off the appliance.

INDICATORS AND SCREENS

APPLIANCE SCREEN

The set values of the appliance and operating information are displayed on this screen.

Fan Set

1

Measured Boiler

2

Temperature

Boiler Temperature

3

Set

Room Thermostat is On

Child-safety Lock is On

4

5

FAN INDICATOR

It shows the fan speed levels. The speed level increases from left to right

in 6 ranges.

INDICATOR LED LIGHTS

Fan is on,

Pump is on,

There is no fuel

are shown with these led lights. No fuel warning is also signaled on the screen of the appliance.

18

H E A T I N G S Y S T E M S

TURNING THE APPLIANCE ON / OFF

Press ON/OFF button to turn on the appliance. The screen lights will turn on and values shall be

displayed on the screen.

Press ON/OFF button to turn off the appliance. The screen lights will turn off and values shall

disappear from the screen.

When the appliance is off, the engines shall be turned off too. Only the pump engine shall continue

operating until the boiler cools down if the boiler temperature is higher than 32°C. the pump shall

automatically turn off after the boiler cools down. Therefore, the main power supply should not be cut

off.

4. ENTERING SET VALUES

To enter the temperature set values, press the TEMPERATURE SET button. The boiler

temperature value set shall be active on the screen. Enter the desired value by using UP/DOWN arrow

keys . Confirm the value you have entered with ENTER key. If you want to cancel the new

value and turn back to the previous value, press the button and cancel the new value.

To enter the fan set values, press the FAN SET button. The fan speed set shall be active on the screen.

Set the desired value by using UP/DOWN arrow keys . Confirm the value you have entered with

ENTER key. If you want to cancel the new value and turn back to the previous value, press the

button and cancel the new value

5. OPERATION OF THE BOILER

After entering the set values, press the FAN ON button to turn on the boiler. The “led” light near

the button shall turn on and the fan shall be active. You can turn off the boiler by means of pressing this

button again.

6. CHILD SAFETY LOCK

You can activate the child safety lock by pressing the UP and ESC keys at

the same time for 2 seconds. When the child safety lock is active, all keys are

deactivated. In order to reactivate the keys, press UP and ESC keys at the

same time for 2 seconds.

19

H E A T I N G S Y S T E M S

7. ERROR CODES AND SOLUTIONS

OVERHEAT: If the temperature of the boiler is above 95°C, this error occurs; the

appliance stops operating and gives out a signal. This error may result from a malfunction in

the heat sensor. There can be a problem in the pump engine.

PROBE ERROR: In case the heat sensor of the boiler malfunctions, this error occurs and

the appliance stops operating. This error can result from a malfunction in the heat sensor.

NO FUEL: When the boiler cools down not being able to keep the temperature steady after

it is heated, the appliance gives out this error and is stops working. This error can result from

a malfunction in the heat sensor. The appliance might have run out of fuel. The fan may have

stopped blowing air.

ROOM THERMOSTAT: When the room thermostat is on, this warning shall appear on

the screen.

LIMIT THERMOSTAT ERROR – RESET THE LIMIT THERMOSTAT: There is a

limit thermostat located on the back lid of the appliance box. This thermostat starts working

when the boiler is overheated (generally 95°C is selected) and deactivates the fan and the

reducer. At the same time, it activates the Pump engine.

In this condition, which is expressed as the “thermostat blew”, LIMIT THERMOSTAT

ERROR – RESET THE LIMIT THERMOSTAT error is displayed on the screen.

The boiler needs to cool down for the solution of the limit thermostat problem. When the

temperature of the boiler decreases under 95C (+/-10 degrees), the limit thermostat recovers

from the error yet its contact do not change their positions. In order for the contacts to change

their positions, turn the lid of the limit thermostat and open it. Press the red button you see

when you open the lid. This way, you reset the limit thermostat.

The appliance is reset via ON/OFF button. This way, the error is removed from the screen.

8. RESTORE THE FACTORY SETTINGS

In order to restore the factory settings of the appliance parameters;

Press the ENTER button and supply the appliance with power.

You will be required to enter a password. Enter the password as “30”. Confirm with

ENTER.

The appliance will require confirmation as “YES / NO”. Select “YES” with up and down

arrow keys and then confirm with ENTER.

The Appliance Parameter settings shall be restored to the factory settings.

The Factory Settings are as follows;

1. Language Selection : Turkish:0

2.Fan Mode: DIMMER :0

3.Pump Opening Temperature: 37 degrees

4.Pump Closing Temperature: 32 degrees

5.Air Relay Pre-temperature : 60 degrees

6.Limit Thermostat Error: YES

20

H E A T I N G S Y S T E M S

9. LAST ERRORS LIST

The appliance can store the last 20 errors in its memory. This information is important for the

technical services. The service may get informed on the problems of the boiler.

In order to display the last errors list;

Cut off the power of the appliance.

Supply the appliance with power by means of pressing on the ENTER key.

You will be required to enter a password. Enter the password as “250”. Confirm with

ENTER.

You can see the last errors on the screen. The error on top with nr. 1 is the last error which

has occurred. You can see the previous errors by means of using the up and down arrow keys.

After the appliance stores 20 errors in its memory, it adds new errors on top of the list and the

previous errors are deleted beginning from the oldest one. This way, the latest 20 errors are

kept in the memory of the appliance.

In order to reset the error list;

Press the ENTER key while on the error list display screen.

“RESET THE ERROR LIST” “YES / NO” options shall be displayed on the screen. Use

the up and down arrow keys to select “YES” and press ENTER.

10. TOTAL OPERATION TIMES

The appliance always stores the period of operation of the PUMP and FAN engines on the

boiler in its memory. Additionally, if the PUMP is on and the temperature is 45 degrees or

more, the HEATING time is continuously recorded in the memory. Thus, you can

understand since how long the appliance has been operating.

In order to display the total operation times;

Cut off the power of the appliance.

Supply the appliance with power by means of pressing on the ENTER key.

You will be required to enter a password. Enter the password as “245”. Confirm with

ENTER.

You can display the total operation times by using the up and down arrow keys.

The PUMP, FAN and HEATING counters shall be displayed on the screen, respectively.

You may reset any total operating time. For this;

Press ENTER while on the total operating time screen you want to reset.

For instance, “RESET THE PUMP COUNTERS” “YES / NO” question shall be

displayed on the screen.

Use the up and down arrow keys to select “YES” and press ENTER.

21

H E A T I N G S Y S T E M S

EKY DIGITAL PANEL ELECTRICAL CONNECTION CHART

NEUTRAL (BLUE) 4,5 Socket Numbers

PHASE (Red)

NEUTRAL (Blue)

Neutral

Neutral

Neutral

Neutral

Phase

SHARED THERMOSTAT (Black)

TERMOSTAT NO (Black)

Limit Com

Limit No

Assembled to

the panel sheet nr. 7,8

GROUND (yellow/Green)

FAN (White) NR.3

THERMOSTAT NC (Black)

PUMP (Kahverengi) NR.2

PUMP

AN

F

REDUCER

Limit NC

MAIN FEED INPUT

(Yellow/Green)

GROUND

PANEL SHEET

BACKSIDE APPEARANCE

SOCKET

ENGINE CABLE

THERMOSTAT

95- DEGREE RESET

Room thermostat (Red) Nr. 6

Room thermostat (Yellow) Nr. 9

PUMP ENGINE

2=PHASE (BROWN)

5=NEUTRAL (BLUE)

8=GROUND (YELLOW/GREEN)

FAN ENGINE

3=PHASE (BROWN)

4=NEUTRAL (Blue)

7=GROUND (Yellow/Green)

220V Grounded cable

22

Heat sensor

PTC 1K %1

Room thermostat

contactinput (NC)

H E A T I N G S Y S T E M S

MECHANICAL CONTROL PANEL:

FAN ON

PUMP ON

NO FUEL

LIMIT THERMOSTAT

FAN ON-OFF

DIGITAL SCREEN

TEMPERATURE SETTING BUTTON

FAN SPEED BUTTON

FOR EKY MECHANICAL CONTROL PANEL:

ON/OFF switch: The switch which turns on and off the power supplied to the panel.

FAN switch: The switch which turns on and off the power supplied to the FAN SPEED

SETTING button.

FAN setting: The key which sets the fan air sent to the boiler for stronger burning. When

turned clockwise, the fan speed and the amount of air increase.

TEMPERATURE setting: The thermostat setting key. When turned left and right, you can

see the current thermostat value on the DIGITAL INDICATOR. The appliance shall display

the boiler water temperature after a while when the button is steady.

DIGITAL INDICATOR: Shows the boiler water temperature and the thermostat degree set

in figures. There are three small lights in the indicator: Fan, Circulation Pump and Fuel Out.

FAN: Shows that the fan is active and it operates.

CIRCULATION PUMP: Shows that the circulation pump is active and it operates.

FUEL OUT: When the temperature of the water in the boiler falls under 28°C, the appliance

gives out NO FUEL warning.

Reset: In case the setting thermostat does not work, when the temperature of the water in the

boiler reaches 95°C, the limit thermostat is activated. This thermostat is called security

thermostat as well. In case of the foregoing condition, remove the hexagon screw cap on the

RESET button and press the red button in the middle. Only this way the boiler shall operate

again.

23

H E A T I N G S Y S T E M S

EKY MECHANICAL PANEL ELECTRICAL CONNECTION CHART

(EKY 125-250)

120v

Input

Fan Output

Fan Setting Rheostat

green

LIMIT THERMOSTAT

blue

green

grey

grey

FAN

yellow-green

3 x 1 mm PUMP CABLE

EKY

SENSOR

Fuse

Connector

blue

brown

yellow-green

3 x 1 CABLE

ELECTRONIC CARD

DIGITAL INDICATOR

PUMP

FAN

red

Neutral

blue

ROOM THERMOSTAT

24

blue

brown

EKY ELECTRONIC PANEL ELECTRIC CHART

H E A T I N G S Y S T E M S

EKY MECHANICAL PANEL ELECTRICAL CONNECTION CHART EKY 250-1000)

LIMIT THERMOSTAT

Brown

DIGITAL INDICATOR

ROOM THERMOSTAT

SENSOR

white

brown

Green

blue

1 PUMP

2 FAN

Neutral

Connector

EKY

ELECTRONIC

CARD

Fuse

3x1 PUMP CABLE

to nr. 13 in yellow-green panel

to nr. 11 in black panel

to nr. 12 in blue (grey) panel

to nr. 10 in brown panel

25

blue

Brown

4x1,5 Cable

Blue

Black

Yellow-green

Yellow-green

H E A T I N G S Y S T E M S

USE OF THE BOILER:

1. Fully open the shaft valve before operating the boiler.

2. Make sure that the system is full of water and the air in the system is removed before

operation. The system should be slowly supplied with water to prevent air formation in the system.

3. The system should be supplied with water until water comes out of the messenger pipe for

the systems with open expansion tank.

4. After the system is filled with water, the system should be removed from air and it should

be inspected for any possible leakages.

5. In the systems with open expansion tank, the base pressure level on the hydrometer should

be marked.

6. The user of the boiler should be informed on the boiler settings, operation of the boiler and

what to do in case of emergencies.

7. Place the fuel on the sieves as shown in the burning instructions which is provided with the

boiler. Place igniting materials such as pieces of wood, firewood, etc. on the fuel to light it

manually and close the feeding lid. Leave the lower lid open and do not turn the fan on until

the coal catches fire. After it catches fire, close the lower lid and turn on the fan at low speed.

In the first operation, a thick smoking may be experienced. In this case, turn down the fan air

rate from the setting button on the panel in order to prevent soot.

8. The circulation pumps should be checked whether they operate or not. The circulation

pump shall not automatically start working until the temperature reaches 37°C. This

parameter is set this way in order to prevent the water vapor from condensing and damaging

the boiler by means of heating the boiler as soon as possible.

9. The boiler water temperature may fall down since the pump shall be reactivated. You may

observe the activation of the pump and the fan looking at the red (led) lights on the digital

indicator.

10. After the normal burning starts in the boiler and the system is activated, the fan continues

operating until the system water temperature reaches the desired value.

If you turn on the temperature set button on the mechanical control panel or press the

temperature set button on the digital panel, you can set the temperature as desired on the

digital screen where the boiler water temperature is displayed.

11. Do not open the feeding lid when the fan is operating.

12. Note that the quality of the fuel you shall use shall directly affect the efficiency of the

boiler, quality of the burning, amount of ashes and cleaning periods and the amount of bunt

coal. Therefore, we recommend you to buy some amount of sample fuel to check the

performance of the coal before purchasing large amounts.

26

H E A T I N G S Y S T E M S

The lever located near the boiler, which allows for the movement of the sieve, allows for

13.

the ashes accumulated on the sieve to fall down. Thus, the contact of the air with fuel is

minimized and the burning quality increases (for EKY 17-100 Prismatic boilers).

14. Do not use high-calorie brown coals in the boiler. This may cause the sieves to melt and

damage the firebox sheet.

15. For the boiler to have a long life span and for its durability, the water used should have

the nominal hardness.

16. Do not operate the boiler without water and regularly control the level of water.

17. When the boiler is operating, do not touch the hot spots with bare hands (smoke box,

front lid and interior parts of the boiler). Use protective equipments.

18. Do not open the covers of the smoke box when the boiler is operating.

19. Perform the periodical cleanings. Such cleanings shall allow you to obtain efficient and

proper burning from your boiler.

20. If you observe an abnormal condition regarding the boiler, take the necessary

precautions immediately and contact our authorized services.

You should contact Termodinamik Company for appliance fuel conversion. You should

be informed by the Company on the conditions of conversion and the procedure to be

followed.

Boiler must be operated according to the operation instructions.

Open expansion tank must be used for EKY boilers.

Hydrometer must be installed to an easly visible location.

The Company cannot be held liable if the boiler consumes too much fuel in case the

boiler is not used according to the user and maintenance manual provided with the

boiler or the desired comfort temperature is not reached, of heat loss due to the

heated area and of low calorific value of the fuel that is being used.

Inside of the boiler any petrolium metarials (such as styrofoam, nylon, cloth etc...)

which will cause pitch, should not be burned.

Gas tightness of the chimney must be ensured.

Smooth surfaces should be used as far as possible in order to reduce friction on the

inside surfaces of the chimney.

27

H E A T I N G S Y S T E M S

BOILER FEEDING WATER PROPERTIES

In order to prevent calcification of water inside of the boiler and pipes, not so hard water

should be used. (The water used in system must be over FS 25 which is international

standarts for water hardness.)

Parameter

Appearance

Conductibility at 25 C

iletkenlik

pH value at 25°C

Total hardness (Ca+Mg)

Iron concentration

Compound alkaline

value

Diesel/oil concentration

Organic particles

°

Unit

-

µS/cm

-

mmol/l

mg/l

mmol/l

mg/l

-

Boiler Feeding

Water

Clean, clear. There are solid materials and

stabile foam in it.

> 7,0

-

< 1

See the footnote

b

TS EN 12953-10 Boilers: Properties of boiler and feeding water as per the Feeding and Boiler Water

Quality

a If there are units made of materials other than steel found in the heating system (copper pipes,

aluminum radiators, etc.), they may require lower pH values and conductivity. However, the

protection of the boiler is primary in the system and the abovementioned values should be followed.

b Organic materials are generally formed by several compounds. It is hard to specify before the

effects of such compounds and their each component on the boiler. Organic compounds may

decompose and may form carbonic acid and other acidic compounds ad these may cause corrosion

and punctures in the boiler. This may cause the formation of materials such as limestone and foaming

which should be experienced at the minimum level.

< 1500

< 0,05

< 0,2

Boiler Filling

Water

From 9,0 115ª

< 5

-

It should be considered that waters with high level of hardness shall cause

calcification. The malfunctions and low performance due to calcification are not

covered in the warranty.

The problems resulting from the use of the appliance for the purposes not

intended for use (industrial use, etc.) are not covered by the warranty.

The appliance is not covered by the warranty if types of water other than

potable water are used in the boiler (artesian water, waste water, etc.).

POWER OUTAGES

Since the circulation pump shall not operate in power outages, the temperature of the boiler

water shall increase to some extent. With the boilers having good shaft draft, the temperature

of the water in the boiler may reach the boiling point. Therefore, you should perform the

following in order in case of power outages:

28

H E A T I N G S Y S T E M S

Fully close the shaft valve.

Tighten the knurled screw in front of the fan in order to prevent air from passing through

the fan flaps.

Turn on the by-pass line valve, if there is.

Do not open the lid covers of the boiler.

Do not drain the water in the boiler.

Make sure the valves are closed.

After the power is back on, do not forget to set the boiler to its previous condition.

If possible, use uninterrupted power supply (Ups) to prevent the circulation pump from

stopping operation in case of power outages.

CLEANING AND MAINTENANCE

In order to obtain efficient burning from the boiler and allow the boiler operate efficiently,

the ashes accumulated on the sieves should be periodically let down by means of moving the

ashes with the help of sieve discharge lever before adding fuel to the boiler for prismatic

boilers.

When the flames become glowing in the cylindrical boilers, the fuel should be added to the

boiler after the ashes among the glows are let down with the help of fire rake. This way, the

ashes preventing the burning air shall be removed from the sieve.

For a more efficient burning, regularly clean the ash sieve. Also;

Check the water level in the boiler before each operation.

The boiler should be operated as per the burning instructions and the flame in the burning

chamber should be controlled and full burning should be provided.

Smoke pipes, the turbulators inside the smoke pipes and the smoke box where the boiler

is connected to the shaft should be cleaned at least once a week.

Clean the shaft at least 3 times in a season.

Clean the ashes accumulating in the shaft daily. You may want to perform the cleaning

two times a day depending on the quality of the coal used (ash rate).

Make sure that dust and burning coals do not fall onto the electrical equipments of the

boiler and the fan.

Do not clean the boiler when it is operating.

You are recommended to get your boiler maintained and controlled (paid) by the

TERMODÝNAMÝK AUTHORIZED SERVICE before the winter.

29

H E A T I N G S Y S T E M S

RADIATOR INSTALLATION CHART FOR MULTIPLE-STORY BUILDINGS

OPEN EXPANSION

TANK

1

RADIATOR

2

BOILER

3

ROOM HEATER INSTALLATION CHART

BOILER

3

30

OPEN EXPANSION

TANK

1

RADIATOR

2

H E A T I N G S Y S T E M S

MALFUNCTIONS AND TROUBLESHOOTING

PROBLEM REASON SOLUTION

Inefficient burning in the

burning chamber.

No fuel light is on.

Digital screen is not working.

The on-off button light of

panel is on.

Fan is not working.

Circulation pump is not

working.

- Inefficient shaft draught

- Low-calorie non-quality fuel

- Improper fan settings

- No fuel in the burning chamber.

- The fuse might have blown.

- The boiler water temperature

might have reached the

thermostat degree selected.

- The boiler may have run out of fuel.

- The limit thermostat might

have increased.

- The power cable of the fan

may be loosened.

- The system water temperature

may be under 37°C.

- The capacitor of the circulation

pump may be broken.

- The circulation pump may be

blocked.

- The electronic card may be broken.

- Get your shaft controlled and

have it cleaned every year.

- Use high-quality and dry fuel.

- Add fuel and turn off the

thermostat and turn it on again.

- Replace the fuse.

If the problem is not removed,

contact the authorized service.

- The boiler shall start operating

after the temperature falls from

the thermostat degree selected.

- Add some fuel.

- Reset the limit thermostat.

- Check the electrical connection.

- Wait for the temperature to

increase.

- Contact the technical service.

4°C

31

H E A T I N G S Y S T E M S

Loading...

Loading...