H E A T I N G S Y S T E M S

DEK SERIES ELECTRICAL BOILER

INSTALLATION AND USAGE MANUAL

H E A T I N G S Y S T E M S

H E A T I N G S Y S T E M S

ENTRY

Termodinamik digital electric boiler provides economic, comfortable, unproblematic and

environmentally solutions for heating and water heat systems.

Termodinamik digital electrical boiler is heating equipment for apartments (flats) and small

houses. It is economic to own and operate, runs trouble-free.

The obvious advantages are;

The one and only fuel is the electricity.

Resistances go online one by one to minimize electricity usage. Takes very little space and easy to

assembly on the wall.

One unit answers your need to heat and hot water. Temperature can be adjusted to different

settings. Accident risk is almost nonexistent.

Has a safety valve opens at 2.5 / 3 bar.

Has a timer for comfort settings in a daily cycle. Has limit thermostat at 90°C for safety.

No flue gas, no chimney connection, quiet operation and safe. When voltage leakage is detected

system shuts its self off automatically.

Electricity to resistances is automatically shut off when water pressure decreases. Digital controls

for ultimate comfort.

Form No: 14KL.0.14.1.1 REV011601

H E A T I N G S Y S T E M S

WARNING

• Assembly of an el ectrical equipment must be

performed by qualifie d and certified electrician

(DIN VDE 0105).

• Gener al rules of thu mb related to working with

electricity must be fo llo we d. For instance:

Electricity must be shut down befo re any work

begins.

WARNING

If instruction s in this manual are not

followed, a serious fire and/or

explosion may ocur, resulting with

personal injury, property damage,

even death.

WARNING

:

Improper installation, adjustment,

alteration, service, or maintenance can

cause injury or property damage. Refer to

this manual for assistance or additional

information. Consult a qualified installer,

authorized service, or the electric utility.

FOR YOUR SAFETY

•

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

•

Installation and service must be

performed by a qualified installer,

service agency or the electric utility.

H E A T I N G S Y S T E M S

ENTRY

GENERAL

....................................................................................................... 3

1 INTRODUCTION

..................................................................................... ...4

2 GENERAL FEATURES

......................................................................................

5-6

3 COMPONENTS (6-9-12 kW)

...................................................................... 7

4 COMPONENTS (18-24-30-36 kW)

............................................................. 8

5 ASSEMBLY & STARTUP

................................................................................... 9

6 MOUNTING ON THE WALL

.................................................................... 10

7 CONNECTIONS OF THE BOILER

............................................................. 11

8 SYSTEM CONNECTION DETAILS

............................................................ 12

9 ELECTRICAL CONNECTIONS

.............................................................

13-15

10 WATER FILLING THE SYSTEM

............................................................... 16

11 THE FIRST INSTALLATION OF THE BOILER

............................................ 17

12 SAFETY

................................................................................................. 17

13 TERMODINAMIK DIGITAL ELECTRICAL BOILER TECHNICAL DATA…….18

14 DIGITAL BOARD USER’S GUIDE

.......................................................... 19

141. GENERAL VIEW OF THE BOARD

................................................. 19

142. BUTTONS

............................................................................. 19-20

143. DISPLAY AND INDICATORS

............................................................. 21

144. SET VALUE ENTERANCE

............................................................. 21

145. TURN ON / TURN OF

................................................................ 22

146. TIME SETTINGS.

........................................................................ 22

147. CHILDREN LOCK

........................................................................ 22

148. ROOM THERMOSTAT

..................................................................... 22

149. TIMER MENU

............................................................................ 23

1410. TIMER OPERATING

.................................................................. 25

1411. USER’S PARAMETERS

............................................................... 25

1412. ERRORS / NOTICES

................................................................. 26

CONTENT

H E A T I N G S Y S T E M S

3

1.

Electrical boiler is never worked without water. Do it only when absolutely necessary

and do it only under full supervision of service person and do it fast. When out of service

for long period of time (such as summer season), do not empty the water.

2.

Use only warm water and soap to clean external panels.

3.

Compliance with instructions in this user manual keeps your boiler efficient and

running smoothly.

4.

Termodinamik Electrical Boiler has been delivered to you all checked and adjusted at

the factory, ready to run. The service technician who will come for the start-up will

perform fine adjustments and inform you. Please do not interfere with adjustments without

the knowledge of service technician.

5.

Never run the boiler without water. You will cause serious damage to resistance.

6.

We recommend you read your manual carefully and keep it at a safe place for referral

later.

Important:

All supply equipment, installation, approvals, permits, inspections, etc. are the responsibility of

the owner of this electrical boiler. Consult your local authorities for regulations specific to your area.

TERMODINAMIK DIGITAL ELECTRICAL BOILER OPERATION MANUAL

This manual belongs to user and should be kept after assembly for referral later.

GENERAL

H E A T I N G S Y S T E M S

4

2 GENERAL FEATURES

Your electrical boiler has been subjected to various safety tests during manufacturing

processes.

Your electrical boiler has been insulated all around with aluminum foiled fiberglass insulation

and energy losses have been minimized. Surface of internal sheet metal chassis parts are

protected with high quality primer paint, external surfaces are protected with electrostatic

epoxy-polyester powder paint against the corrosion.

Closed expansion tank is a standard item with your boiler. It maintains safety of your water

systems against the pressure variations.

When the user sees that the pressure drops below 1 bar, must interfere personally and fill

water into the system. Your boiler has a water pressure switch for safety to shut off the entire

system in case of water pressure drop to 0,6 bars (lack of water) to prevent parching of

resistances. (Boiler is now in off position and water must be added and on button must be

pressed to restart).

The water heated in your boiler passes through plat e heat exchanger before goes to

radiators and heats your domestic use water to provide you with hot water.

Your boiler has been checked at the factory and ready to run. Please read this user manual

first, before using your boiler and keep it at a safe place for later referral.

Your boiler will serve you for a long time with maximum efficiency as long as

recommendations here followed.

1. INTRODUCTION

FAILURE TO FOLLOW THE INSTRUCTIONS IN THIS MANUAL MAY RESULT IN DEATH,

SERIOUS BODILY INJURY AND/OR PROPERTY DAMAGE. THOROUGHLY READ ALL

INSTRUCTIONS BEFORE YOU ATTEMPT TO INSTALL, OPERATE OR MAINTAIN THIS BOILER.

5

H E A T I N G S Y S T E M S

2. GENERAL FEATURES

QUITE: It is electrical, by nature it is quite.

SAFE: Your boiler has a water pressure switch for safety to shut off the entire system in

case of water pressure drop to 0.6 bar. (Boiler is now in off position and water must be

added and on button must be pressed to restart).

Thermostat is set to 80oC max. When this is reached electrical current to resistances is shut

off. If this thermostat malfunctions, there is a limit thermostat set for 90°C.

Digital manometer displays water pressure all the time. If pressure reaches 2.5 / 3 bar safety

valve opens, pressure is released and some water discharged.

ECONOMY: High quality subcomponents enable use of electricity as a fuel with highest

possible efficiency.

Provides independent heat. Heat as much as you want, when you want. Pay as much you

heat.

Fully programmable and has timer for your automatic setting.

One unit provides you with heat & hot water.

Electronic control card is modulated for economy.

EASY TO USE: One touch button safe & easy operation.

HIGH OUTPUT: Electricity as a fuel has high efficiency with very minimal loss. Therefore

your boiler has naturally high efficiency.

ENVIRONMENTALLY FRIENDLY: The fuel is electric. Therefore, no flue gas, no chimney,

no dirt of carbon-based fuels create.

WIDE SPREAD SERVICE NETWORK: Termodinamik has wide spread established service

network all over Turkey, ready to respond when you need.

LONG LASTING: Your boiler is protected against effects of corrosion.

WARRANTY: Your boiler has 2 years warranty against the defects resulting from

manufacturing. Defected parts are replaced with new ones.

H E A T I N G S Y S T E M S

PACKING

: External surface your boiler is painted sheet metal with protective film to prevent

stretches during handling and assembly. Please peel off the film before start-up. Your boiler

has been packed in a corrugated box for safe transport.

6

H E A T I N G S Y S T E M S

7

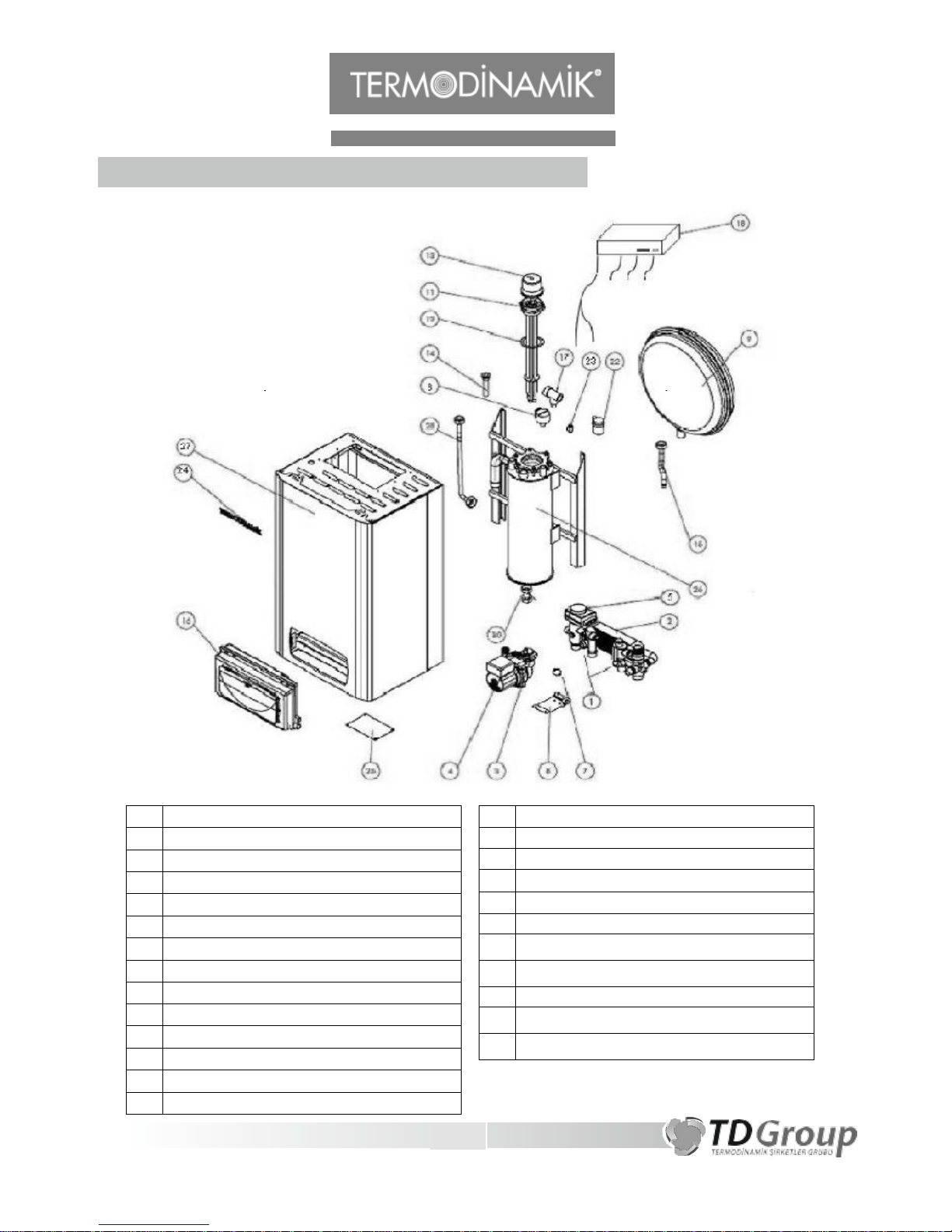

3. BOILER COMPONENTS (6-9-12 kW MODELS)

1 3 WAY VALVE HYDRO BLOCK (IN-OUT)

2 PLATE HEAT EXCHANGER

3 PUMP BODY

4 PUMP COVER

5 3 WAY VALVE MOTOR

6 WATER PRESSURE SWITCH

7 PUMP RING

8 PUMP MOUNTING PLATE

9 EXPANSION TANK (7 Liters)

10 COPPER PIPE (PUMP BOILER IN)

11 HEATING RESISTANCE

12 RESISTANCE GASKET

13 RESISTANCE PROTECTION PLASTIC COVER

14 THERMOCOUPLE PIPE

15

EXPANSION TANK HOSE

16 DIGITAL PANEL

17

AUTOMATIC SAFETY VALVE

18 RELAY BOX

22 AUTOMATIC AIR PURGER

23 MANUAL AIR PURGER

24

TERMODINAMIK LABEL

25

PRODUCT LABEL

26 INNER TANK BODY

27

EXTERNAL BODY (CASING)

28

BOILER EXIT PIPE

8

H E A T I N G S Y S T E M S

4. BOILER COMPONENTS (18-24-3 0-36 kW MODELS)

15 THERMOCOUPLE PIPE

16

EXPANSION TANK HOSE

17 DIGITAL PANEL

18

AUTOMATIC SAFETY VALVE

19 RELAY BOX

23 AUTOMATIC AIR PURGER

24

BOILER EXIT PIPE

25

TERMODINAMIK LABEL

26

EXTERNAL BODY (CASING)

27

PRODUCT LABEL

1 3 WAY VALVE HYDRO BLOCK (IN-OUT)

2 PLATE HEAT EXCHANGER

3 PUMP BODY

4 PUMP COVER

5 3 WAY VALVE MOTOR

6 WATER PRESSURE SWITCH

7 PUMP RING

8 PUMP MOUNTING PLATE

9 EXPANSION TANK (7 - 10 Liters)

10 INNER TANK BODY

11 COPPER PIPE (PUMP BOILERIN)

12 HEATING RESISTANCE

13 RESISTANCE GASKET

14 RESISTANCE PROTECTION PLASTIC COVER

H E A T I N G S Y S T E M S

9

Your boiler must be hung on a wall firmly and rigidly. Water scale should be used for

fine alignment. Minimum clearance and from the floor should be 50 cm, distance from

the ceiling 40 cm. Connections must be done as shown. Not even drop of water

should be permitted.

Do NOT install the boiler in a humid environment such a bathroom.

If the boiler to be installed in an outdoor environment, it must be under/in protective

cover.

All pipes must be connected as shown in the picture No drop of water must be

allowed to leak out.

Please comply with assembly instructions given on page 12 in order to obtain hot

water during summer months.

Pump, boiler ―to & return‖ pipes, safety ―to & return‖ pipes must be installed without

causing any air pockets. Where air bubbles possible, air discharge system must be

installed.

After completion of assembly, system must be flashed twice. This will achieve cleaning

of inside of pipes.

DO NOT FORGET to close ―in & out‖ valves of boiler when flashing the system.

Outside pipes must be insulated to minimize heat loss.

We recommend use of radiator return valves at the returns instead of standard

radiator valves.

Use of decalcification equipment is recommended at the entrance of domestic water

to prevent calcification.

During mounting of the boiler, please use all elements provided to make sure rigid

assembly on the wall.

All wiring and electrical connections must be done in accordance with TSE regulation

(in Turkey), or local codes (other countries).

5. ASSEMBLY & START-UP

Water temperature over 52°C can

cause several burns instantly or

death from scalds. Children,

disabled and elderly are at highest

risk of being scalded. Feel water

before bathing or showering.

Temperature limiting valves are

recommended.

H E A T I N G S Y S T E M S

10

Explanations:

1 – Minimum distance to ceiling should

be 400 mm to be able remove the

resistance when necessary.

2 – Please make sure that the wall

boiler is mounted rigid and strong.

Bolts hold tightly and wall is strong

enough to carry the boiler.

3 – Hot water to radiators

4 – Domestic use hot water out

5

– Domestic cold water entry

6

– Return from radiators

6. MOUNTING ON THE WALL

H E A T I N G S Y S T E M S

11

1

Radiator return ¾‖

2

Cold water entry ½‖

3

Cold water exit ½‖

4 To radiator ¾‖

Height : 723 mm

Width : 427 mm

Depth : 354 mm

Radiator in & return (3/4”)

Domestic water in & return (1/2”)

YOUR BOILER MUST BE INSTALLED ACCORDING TO ―ASSEMBLY INSTRUCTIONS‖ PROVIDED IN THE

BOX. THERE MUST BE 40 CM CLEARANCES FROM THE CEILING TO FACILITATE ASSEMBLY &

REMOVAL OF RESISTANCES WHEN BOILER MOUNTED.

7. CONNECTIONS OF THE BOILER

723

H E A T I N G S Y S T E M S

12

8. SYSTEM CONNECTION DETAILS

!

Please use ball valve for

the boiler – main water line connection

in order to facilitate maintenance and service.

H E A T I N G S Y S T E M S

13

9 ELECTRICAL CONNECTIONS

NO

GROUND

SAFETY

THERMOSTAT

Please make sure that boiler is grounded

PUMP

3 WAY

VALVE

ROOM

THERMOSTAT

6 - 9 kW (220 V)

PUMP

PUMP

3 WAY

NEUTRAL

NEUTRAL

PHASE

WINTER

SUMMER

NEUTRAL

NEUTRAL

PUMP

HEATER

HEATER

HEATER

HEATER

HEATER

HEATER

DATA CABLE

14

H E A T I N G S Y S T E M S

Please make sure that boiler is grounded

H E A T I N G S Y S T E M S

15

Please make sure that boiler is grounded

(380 V)

16

H E A T I N G S Y S T E M S

1. Open the filling valve connected to radiator return valve to fill the system with water.

Enclosed ―3/4 T’ ―mini-ball valve provided for water filling & discharge purposes.

2. During startup (the first run), please fill water until the boiler reaches 2.5 / 3 bar and

water comes out of safety bar in order to remove all air pockets in the system. After

completion of air removal, please discharge water out of the system until 2 bar is read

on digital manometer.

NOTE: Fill more water into system if manometer reads 1.0 bar or less. It is always a better

practice to add water into system the boiler is cold.

Please try to keep domestic hot water temperature below 52oC to prevent

serious burns.

Before you take a shower, feel the temperature of the water first.

It is also recommended use of temperature limiting valves.

10 WATER FILLING THE SYSTEM

17

H E A T I N G S Y S T E M S

1.

Connect boiler phase and neutral power cables than check the connections. Do not

open boiler until you are sure to be connections. Device contains mechanical high

heat circuit breaker system therefore connections of the phase, neutral and ground

connection is very important. System operation and security depends on the correct

links.

2.

Pump water the system and give energy. While system is cold, take the air of the

system. After all controls of the system, if there is no problem to work the boiler in

1.5 bar.

1

— Leak current relay:

It disconnects the power line, if a leak higher than 30 milliamps and longer than 1 micro

second. (30 milliamps is not noticeable by human sense).

2

— Mechanical high limit thermostat:

If resistance can not be controlled due to an unexpected fault, leak current relay will switch

on at 90oC and power will be cut completely.

3

— Digital high limit:

If mechanical high limit mentioned above is not activated by some reason, digital high limit

thermostat will switch on at 90oC and bring the system to ―off‖ position.

4

— Pressure control system:

Digital sensors will not allow pressure drop below 1.0 bar and get resistance damaged due to

lack of water.

5

— Zero crossing circuit: (with three phase models only)

Eliminates voltage fluctuations on the three phase system of the house by bringing triac

circuits online balanced according to zero incoming angle angles of phases.

6

— Random run program:

11 THE FIRST INSTALLATION OF THE BOILER

12 SAFETY

H E A T I N G S Y S T E M S

18

Resistance will come on & off line randomly, after the system has reached to set. This will

extend the life of resistances.

7

— Freeze protect:

If the water degree inside the boiler decreases fewer than 6 oC, the circulation pump stars

and protect the boiler from freezing.

8

— Pump protect:

If the circulation pump does not start, pump starts every day for 1 minute protecting the

system against rust and calcification.

9

— Children Lock:

Pressing the UP and ESC buttons with the same time for 3 seconds, Boiler locks the buttons

until pressing the UP and ESC buttons with the same time for 3 seconds.

13 TERMODINAMIK DIGITAL ELECTRICAL BOILER TECHNICAL DATA

MODELS >>

DEK 6

DEK 9

DEK 12

DEK 18

DEK 24

DEK 30

DEK 36

CAPACITY

kW 6 9 12 18 24 30 36

kcal/h

5160 7740

10320

15488

20650

25813

30975

Working pressure

bar 2 2 2 2 2 2 2

Water volume

L 4,2 4,2 4,2 24 24 24 24

Radiator ―to‖ – ―return‖

inch ¾

¾

¾

¾

¾

¾

¾

Domestic water ―to‖ –

―return‖

inch ½

½

½

½

½

½

½

Power supply connection

cable

qnty/mm

2

2x6

2x10

4x2.5

4x4

4x6

4x10

4x10

Nominal voltage

Volt

220

220

380 380

380

380

380

Fuse Amp

32

(Monophase)

50

(Monophase)

20

(Three-phase)

32

(Three-phase)

40

(Three-phase)

50

(Three-phase)

63

(Three-phase)

Weight, gross

kg 41 41 41 67 67 67 69

Dimensions

(h x w x d)

mm

723 x 427 x 354

*Power supply connection cable cross sections are calculated according to the line length of

15

meters.

H E A T I N G S Y S T E M S

19

141 GENERAL VIEW OF THE BOARD

142 BUTTONS

START BUTTON

Turns the boiler ON

STOP BUTTON

Turns the boiler OFF

ENTER BUTTON

Value is used to access

ESC BUTTON

Cancel the entered value access

14 DIGITAL BOARD USER’S GUIDE

19

H E A T I N G S Y S T E M S

TIMER ON BUTT

CLOCK SET

UP / DOWN BUTTONS

To change the values entered and circulation between the menu

BUTTON

Using the adjust the time

RAM BUTTON

Using to timer programming

ON

Using to set the boiler timer mode

DOMESTIC USE WATER SET / PROGRAM BUTTON

Entering the domestic use water value

RADIATOR WATER SET / PROGRAM BUTTON

Entering the radiator water value

WINTER / SUMMER MODE CHOSE BUTTON

Setting the boiler for summer and winter mode

TIMER PROG

20

H E A T I N G S Y S T E M S

21

143 DISPLAY AND INDICATORS

Display of the boiler. Any kind of value entry and

follow up can be made through this screen.

INDICATORS

HEAT LEVEL INDICATOR

Shows boiler’s working heat steps

SITUATION INDICATOR

Shows active parts and working positions. From up to down buttons are;

pump radiator active, domestic use water active and alarm activations.

144 SET VALUE ENTERANCE

For entering the domestic use water set value enter the

button. You can see

the flashing of the domestic use water set value at the display.

For entering the radiator water set value enter the

button. You can see the

radiator of the use water set value at the display.

H E A T I N G S Y S T E M S

22

Enter the value by up/down button than accept processing button. For

returning the old value use button.

145 TURN ON / TURN OFF

Set boiler winter or summer mode by button. Turn on boiler

button. You can turn off boiler button.

146 TIME SETTINGS

Push the button. Clock value is going to activate at the display. Enter the hour

values by up/down button than accept values by button. Minute value

is going to activate. Again enter the minute value by up/down button and accept

the value button.

147 CHILDREN LOCK

Pushing the (up) and (esc) button same time for 3 seconds, boiler

locks the buttons. For unlocking the boiler repeat the same p r o c e d u re .

When boiler is locked you can

key sign at the d i s p l a y

148 ROOM THERMOSTAT

When the thermostat sends signal boiler stops heating and waits for room cool. Th is

process shows sign at the display.

H E A T I N G S Y S T E M S

23

149

TIMER MENU

149.1

TIMER PROGRAMMING

Push the button. At the display you see;

TIMER MENU. You can chose TIMER PROGRAM by up/down buttons than accept

election by button. At the display you see;

Entrance menu of the TIMER MENU. Push button to activate TIMER ON. You can

see activation when time hour part appears dark. Set the hour between 023

by (up/down) button then accept hour button. After hour entrance

minute part activates . Enter between 055 minutes by (up/down)

button then accept button.

H E A T I N G S Y S T E M S

24

TIMER OFF time is activated. Repeat the same procedure as TIMER ON. After TIMER OFF

time setting, TIMER SET value will be activated. That Value shows which time period of

boiler heats TIMER ONOFF

For new time period push

button. New period P page opens. If the conflict

between time periods, display gives ―wrong value‖ notice

149.2 DELETING ALL TIMER VALUES

Chose DELETE ALL at the TIMER PROGRAM menu then push

button. Boiler asks

YES/NO question of consent. Push

than chose YES and push

button.

At the display you see COMPLETED message. That means you deleted all timer values you

have entered

149.2 ECO TIMER

Eco timer values are tested by factory to meet the demands of normal users. Those

settings are adjusted to be economic. Eco timer value entrance causes deletion of the past

entered timer values.

For Eco Timer enter;

From TIMER PROGRAM menu chose ECO TIMER than push

button. Boiler asks

YES/NO question of consent Push

than chose YES and push

button.

At the display you see COMPLETED message. That means entered ECO TIMER menu.

ECO TIMER time opening;

H E A T I N G S Y S T E M S

25

1410 TIMER OPERATING

Push button. If you have programmed any timer before, the light near the

button will flash. Those programs shown at the display P1, P2, ... If use is at the

programmed timer zone time part, P sign will flash. For leaving the timer mode push

TIMER ON button again.

1411 USER’S PARAMETERS

This parameters allows customization device for user’s. For entering the user’s parameters

page;

While device CİHAZ KAPALI mode button 5 seconds. Then you see

PARAMETER settings menu.

From this menu make entrance by button then accept entrance by

button. button exits user from parameter menu.

Parameter list;

P1: Language chose

PROGRAM

H E A T I N G S Y S T E M S

26

This is Language select parameter. It changes display language TURKISH or ENGLISH. If

user enters 0: display language sets TURKISH, 1: enter display language sets ENGLISH.

P2: Display light

If this parameter chose ―Auto Back‖ YES, while device working normal mode without

pushing any button, device shut down display light after 3 minutes later. NO case of

choosing, the display remains open continuous light.

P3: Power failure

If this parameter chose YES, device goes working after electricity interruption goes away.

When device TURN OFF before electricity interruption, device still TURN OFF If electricity

come back. If NO parameter selected and electricity interruption goes away device

TURNS OFF.

1412 ERRORS / NOTICES

1412.1 ERRORS

Boiler (down prob) error

This error accures If boiler inside water sensor (prob) breakdown. This sensor is installed to

pipe . This error turns off boiler.

Domestic use water prob error

This error accures If domestic use water sensor (prob) breakdown. This sensor is dipped

type of boiler. This error turns off boiler.

Boiler (down prob) error

This error accures if boiler inside water sensor (prob) breakdown. This sensor is dipped

type of boiler. This error turns off boiler.

Over Heating

If boiler inside water temperature reaches 90oC, digital high limit starts up and give over

heat error than cuts the electricity connected to resistors. When boiler temperature

decrease under 90oC system stops error and starts working again.

H E A T I N G S Y S T E M S

27

Low Pressure (Mechanic)

If pressure of the boiler decreases under 0.6 bar you see that error. This error turns off

boiler.

1412.2 NOTICES

Low Pressure

If pressure of the boiler decreases under 1 bar you see that notice. This notice does

not turns off boiler.

Set Timer

If user push TIMER ON button without setted timer, system gives Set Timer notice

Device Summer Mode

If device works in summer mode and user push the TIMER ON button, boiler gives that

notice. Take boiler to winter mode with summer/winter button than push TIMER ON

button.

Device Timer Mode

When boiler is at timer mode (TIMER ON flash is indicating) and user want to select

summer mode by summer/winter button that alert will appear. Exit boiler timer mode by

pushing the TIMER ON button than take boiler to SUMMER mode

WARRANTY COMPLIANCE PARTICULARS

This warranty does not cover damages arising from use of the device outside its intended purpose. However,

in the following cases the device can be handled outside the warranty, for a certain fee:

- Wrong placement, physical or chemical factors, failures and damages originating from shipment and

storage conditions. Failures and damages originating from fire, lightning strike, flood and natural disasters.

Freezing due to climate conditions. Systems not compliant with the fixture coupling instructions and

recommendations in the operation manual.

- Failures and damages that arise during loading, unloading and handling after the customer takes delivery

of the product.

- Failures and damages originating from user errors.

- Failures and damages originating from low or high power network voltage, fluctuations or irregularities in

power network frequency, electrical fixture errors, or operation of the device on a voltage level different than

the value specified on the product label.

- Scratches on the painted surfaces.

- Products for which warranty certificate or product purchase invoice cannot be presented to the authorised

service provider of our Company.

- Damages originating from the user's failure to conduct necessary periodic maintenance and controls.

- Problems with any device whose initial start-up is not performed by an authorised service provider or any

repairs or modifications,

annual general maintenance and cleanings, or periodic maintenance and cleanings which are not performed

by an authorised service provider.

- Any failure in the device should only be handled by TERMODINAMIK AUTHORISED SERVICE

PROVIDERS authorised by our Company. Otherwise the warranty will be void.

- In case the product label or the serial number of the product on the Warranty Certificate is damaged the

warranty will fall void.

- Devices whose factory standard configuration is modified.

- Failures and damages originating from wrong capacity, fuel or model choice.

- Product installation should be handled by the Contracting Firm, and the initial start-up should only be

handled by TERMODINAMIK authorised service providers. After purchasing the product please consult the

service providers booklet provided with the product and contact the closest TERMODINAMIK authorised

service provider to your location. Device failures originating from failure to have initial start-up performed by

an authorised service provider will be handled outside the warranty.

- In case you become aware of a failure in your device please consult the operation safety section of the

Operation Manual. In case the failure does not improve do not let anybody interfere with the device and

contract the TERMODINAMIK authorised service provider responsible for your area.

- In case the authorised service provider feels any doubt regarding the warranty term, product purchase

documentation or service slips and the initial start-up form must be presented upon request of the service

provider.

- The warranty shall only be valid in the term defined on the Warranty Certificate and only for the failure in

the product (the boiler). No other right or compensation shall be claimed under the warranty for any failures

outside the product, e.g. in fixture lines, radiator, fuel tank, pipe fitting materials, flue problems, radiator

valves, etc.

- Please ask for and keep one copy of the failure form filled by the service provider. This document will be

useful for you in case of any problem you might experience with your device in the future.

- Only original equipment should be used in device installation and spare part replacements.

- Have your seller certify the relevant parts in your warranty of your product when you buy it.

- The dealer, seller or agency that sells the product to the customer is responsible for delivering of warranty

to the customer.

H E A T I N G S Y S T E M S

Kemalpaşa OSB Mah. 80. Sokak No:10 KEMALPAŞA-İZMİR-TURKEY

Tel: +90 (232) 877 12 12 Fax: +90 (232) 877 08 67

www.termodinamik.com.tr

Loading...

Loading...