MULTI FRIENDLY Air Conditioning Systems

Convertible type Indoor Units:

HSFL 411 XMR

HSFL 531 XMR

HCNL 821 XMR

Outdoor Unit:

SERVICE MANUAL

-2-

1. Description of products & features

1.1 Brief Introduction for T1 working condition

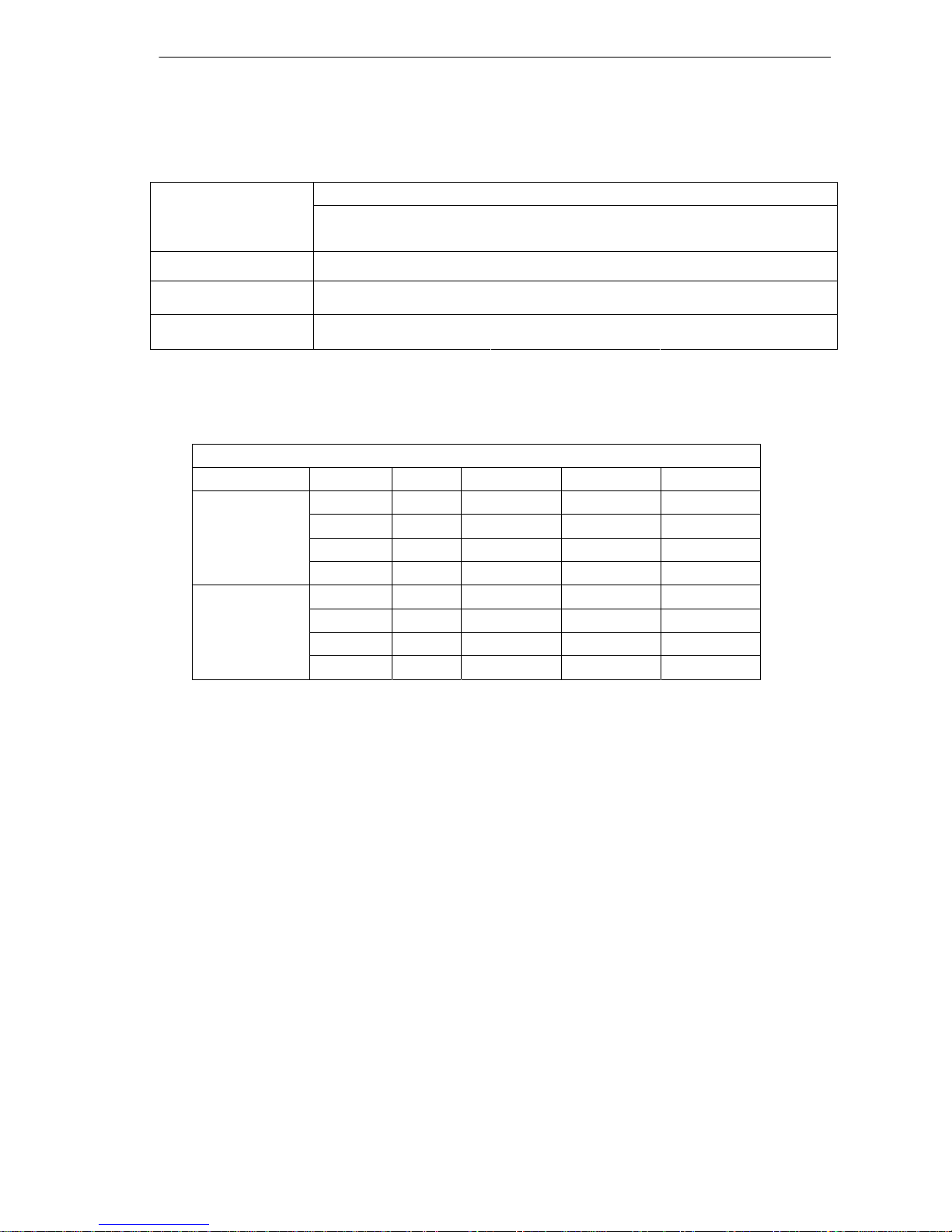

1.2 Operating Range of Air Conditioners

Working temperature range

Rated Maximum Minimum

Indoor

DB℃

27 32 18

WB℃

19 23 14

outdoor

DB℃

35 43 10

Cooling

WB℃

24 26 6

Indoor

DB℃

20 27 15

WB℃

14.5 -- --

outdoor

DB℃

7 24 -15

Heating

WB℃

6 18 --

Climate type

T

ype of

Air Conditioner

Cooling Only 18 ℃~43℃

Heat pump -7℃~43℃

Electricity Heating ~43℃

T1

-3-

1.3 Product features

Highly efficient, can match with the universal outdoor unit

The outdoor unit can match with cassette, wall mounted type, duct, console and ceiling floor type

indoor unit. One set outdoor can match with multiple indoor units, up to 4 sets. Even when you

have already installed the air conditioner, if you want to add or reduce one unit, go ahead freely as

long as your operation complies with our design. Greatly convenient for designer and installer.

Total indoor load can be up to 135% than the standard match

The total capacity of all indoor units can be 135% more than the nominal cooling capacity, but the

total indoor cooling capacity will not be increased.

Adopt the much friendlier refrigerant R410A

The air conditioner system adopts the greatly friendly refrigerant R410A, which is protective for the

ozone layer and is good to avoid the earth getting warmer. Benefit for the environment.

Adopt the advanced DC inverter technology

The system adopts the advanced DC inverter technology, which can consume less power energy to

realize the equal efficiency, saving money for you.

With air inlet filter, enhance the air quality

The high efficiency filter can collect the dirt and remove the bacterium, which can be installed on the

easy-to-unload place, convenient to be cleaned.

Convenient infrared remote controller

This remote controller YR-H71 can realize the oprional healthy air flow and sterilize function, it is

mobile type appearance, so smart and compact.

And the infrared controller can be equipped with the controller holder, convenient to fix

the remote controller.

Auto–restart function (optional)

All indoor units have auto-restart function. When the power supply cut off suddenly, the unit will

automatically recover the previous running mode once the power supply is on.

-4-

Self-diagnostic function

In the course of operation, if the failure occurs, the failure code will display on the wired controller or

on the operation panel. Then according to the failure code chart, you can eliminate the failure soon.

Central control function, if connected with a central controller

(This device will be available in the near future). That is convenient for building management.

Weekly timing function, if connected with a detector and a weekly timer

Adjustable heating temperature compensation

In heating and in cooling mode, the temperature compensation can be adjusted by the infrared remote.

controller. If you do not want the compensation, you can set the compensation as 0°C (factory setting).

Optional wired controller YR-E12

The wired controller YR-E12 can control a single unit individually, also it can control some units in

group of 16 indoor units. with plenty of functions: refer to the controller function section.

-5-

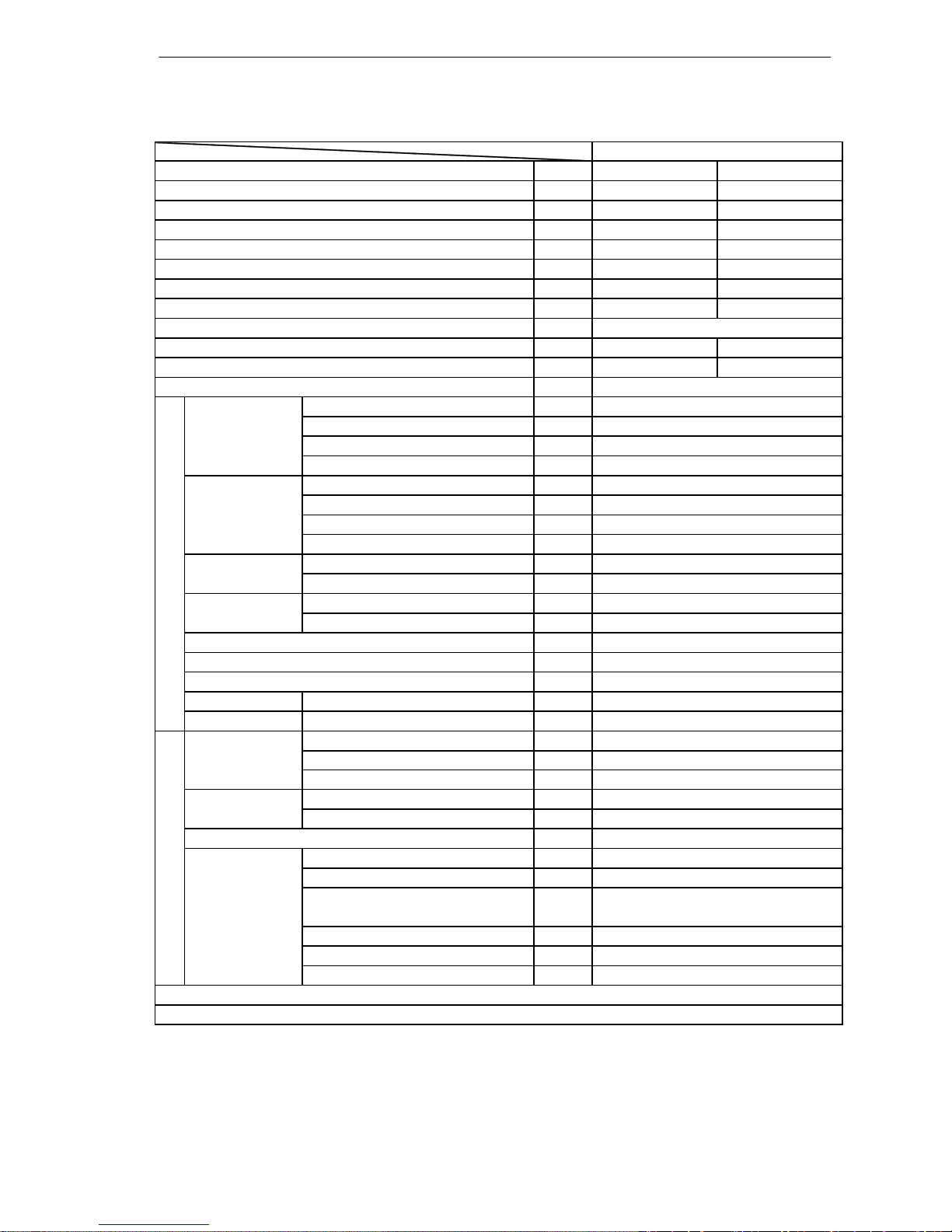

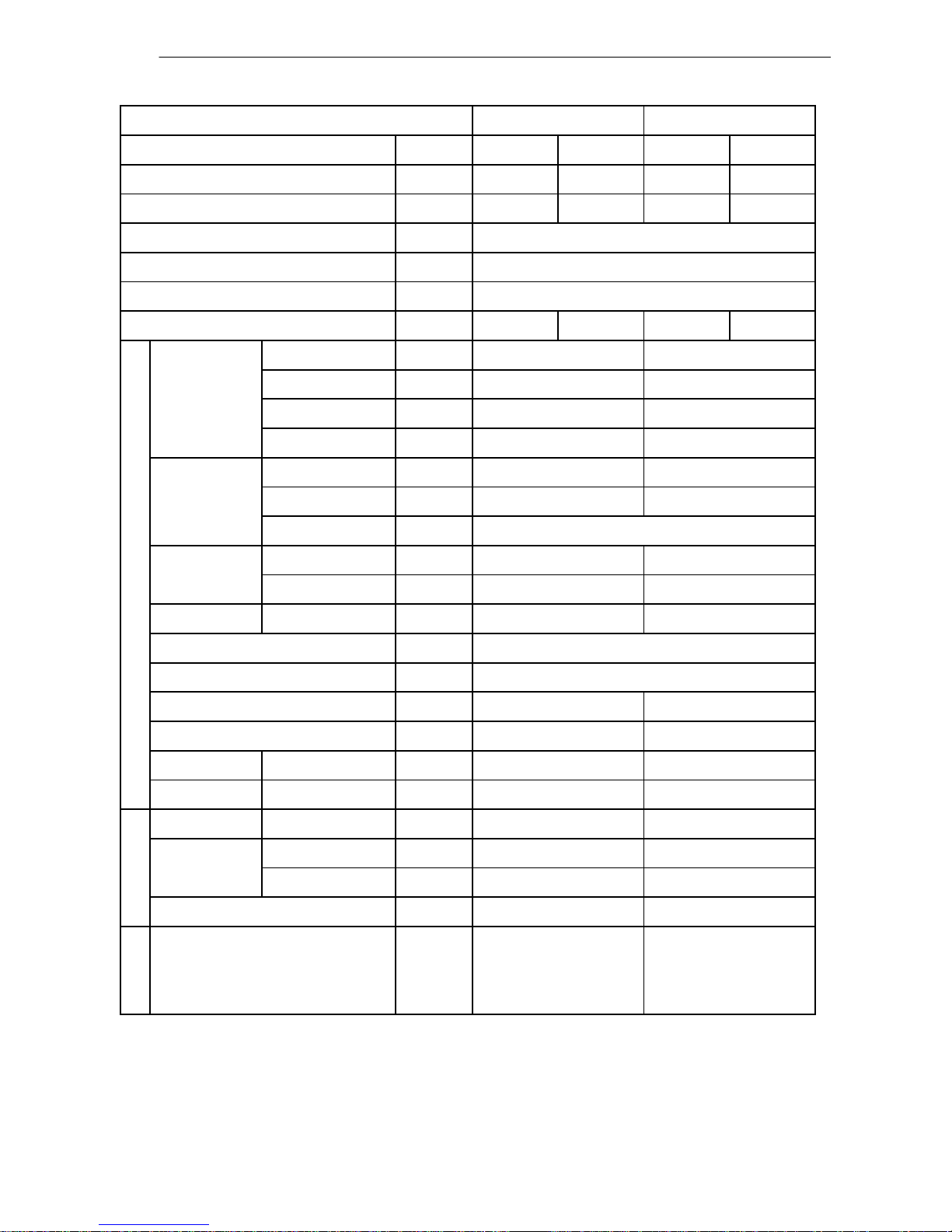

2.1 Outdoor Unit

——

Cooling Heating

W 8000 10000

W 2480 2580

W/W

3.22 3.87

W 1500 1800

W 550 550

W

9500 11500

W

3800 3800

——

A 16.8 16.8

—— 99% 99%

A

Model / Manufacture ——

Oil charge and type ——

Type ——

Number ——

Type × Number ——

Speed r/min

Motor output power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Face area m²

External mm

Package mm

——

——

W

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Type / Charge kg

No need to recharge m

Recharge g/m

Liquid mm

Gas mm

——

Drop between IU & OU

m

Piping length between IU & OU

m

Total liquid piping length

m

Max.Drop between IU &OU m

Max.Drop between IU & IU m

Max.Piping length between IU & OU m

Max.Total length

m

Connecting method

Flared

Between I.D &O.D

≤5

≤10

≤40

10(indoor unit lower than outdoor unit)

15 (indoor unit higher than outdoor unit)

25

60

58/-/-

74 / 89

Piping

Refrigerant R410A / 2.6

40

20

Pipe 4* Φ6.35

4* Φ9.52

Defrosting method

Automatic by reversible cycle

Crankcase heater power

35

Dimension

(L×W×H)

1068x340x830

1100x440x979

Refrigerant control method

EEVs

about 4000

Heat exchanger TP2M / 7.0

about 0.75

Outdoor unit

Compressor TNB220FLBM1/MITSUBISHI ELEC.

670CC

Twin Rotary (DC inverter)

1

Fan Axial × 1

850/700/500

60

Max.Running current

Power factor(under rating power input)

Fuse size (recommended size)

30

Maximum capacity

Maximum power input

Power source

1PH, 220-230V~, 50Hz

1. The above performance data are from the combination of HCNL 821 XMR+3*HKEL 201 XMR+1*HSF 411 XMR.

2. Large drop and long piping installation will obviously reduce the total capacity.

Item Model HCNL 821 XMR

Function

Rating capacity

Power input

EER / COP

Minimum capacity

Minimum power input

-6-

-7-

—— Cooling Heating Cooling Heating

W 4100 4600 5000 5500

10‐³×m³/h

1.6 / 2 /

——

——

N, V, Hz

A 0.45 0.45 0.45 0.45

Type × Number ——

Speed r/min

Motor power W

Air-flows (H/M/L) m³/h

Type / Diameter mm

Total area m²

Temp. scope

℃

External mm

Package mm

Drainage pipe material, diameter mm

——

——

mm

——

Noise level H/M/L dB(A)

Weight Net / Shipping kg / kg

Refrigerant Type ——

Liquid mm

Gas mm

——

* o.d.=outer diameter; i.d.=inner diameter

Connecting method Flared Flared

28.3/34.3 28.3/34.3

Piping

R410A R410A

Pipe

6.35 6.35

12.7 12.7

Electricity Heater / /

48/45/41 48

/45/41

EEV on outdoor unit

Fresh air hole dimension / /

990/655/199

1150/750/300 1150/750/300

PVC, 20/18(o.d./I.d.*) PVC, 20/18(o.d./I.d.*)

700/640/580

Heat exchanger

TP2M / 7x0.35 TP2M / 7x0.35

about 0.49 about 0.49

cooling: 6~7 / heating: 43~60

CENTRIFUGAL × 2

1150/1050/850 1150/1050/850

output: 28/input: 80 output: 28/input: 80

Running current

Fan

CENTRIFUGAL × 2

700/64

0/580

Dimension

(L×W×H)

990/655/199

Controller type Infrared YR-H71 or wired YR-E12

Refrigerant control

Communication cable

2x(0.75~1.25mm2 ), must be shielded

Power source 1, 220~230, 50

Dehumidifying capacity

Item

Power cable 3 × 0.75mm

2

HSFL 411 XMR HSFL 531 XMR

Function

Capacity

2.2 Indoor Units

Norminal conditions: indoor temperature (cooling): 27℃DB/19℃WB, indoor temperature (heating):

20℃DB.

Outdoor temperature (cooling): 35℃DB/24℃WB, outdoor temperature (heating): 7℃DB/6℃WB.

The noise level will be measured in the third octave band limited values, using a Real Time Analyser calibrated sound intensity meter. It is a sound pressure noise level.

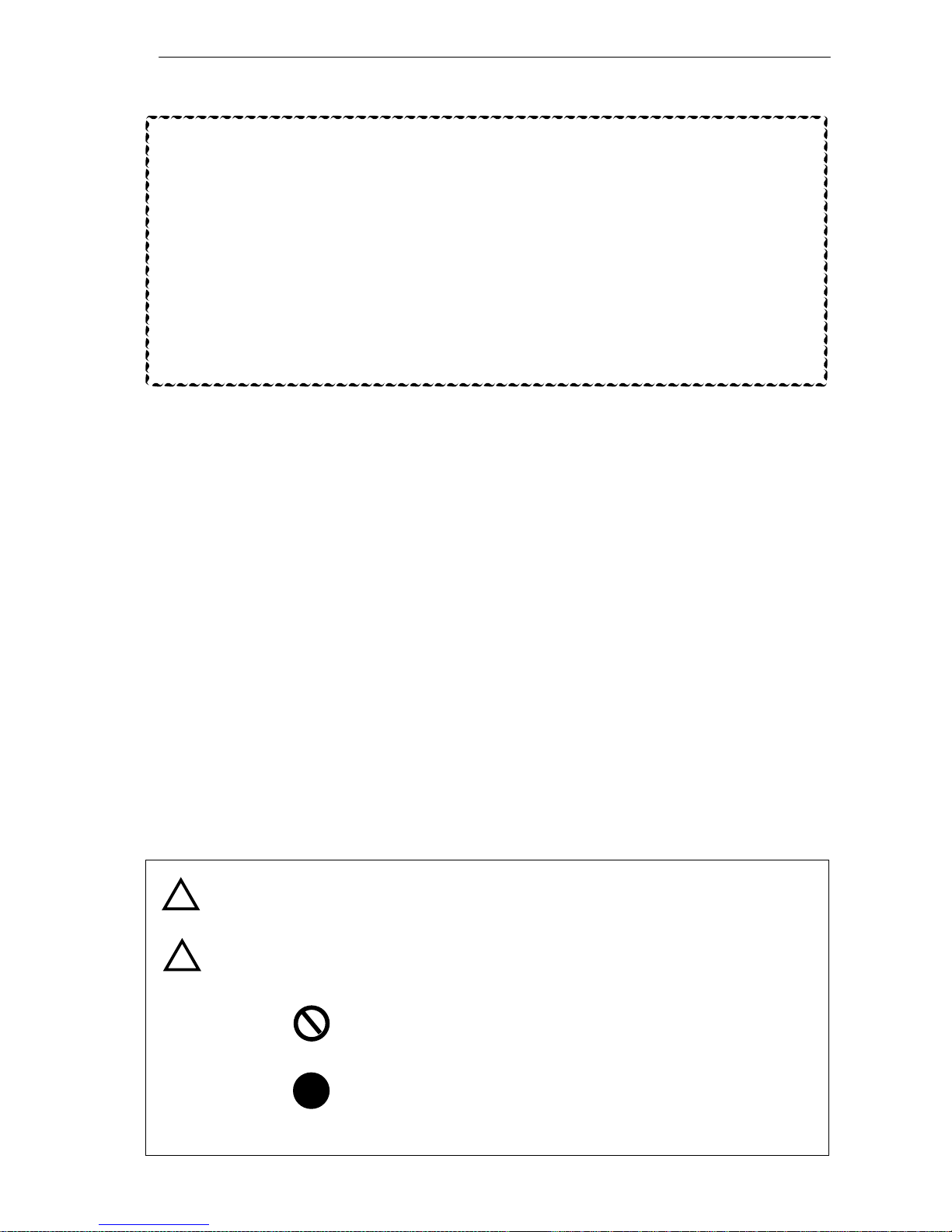

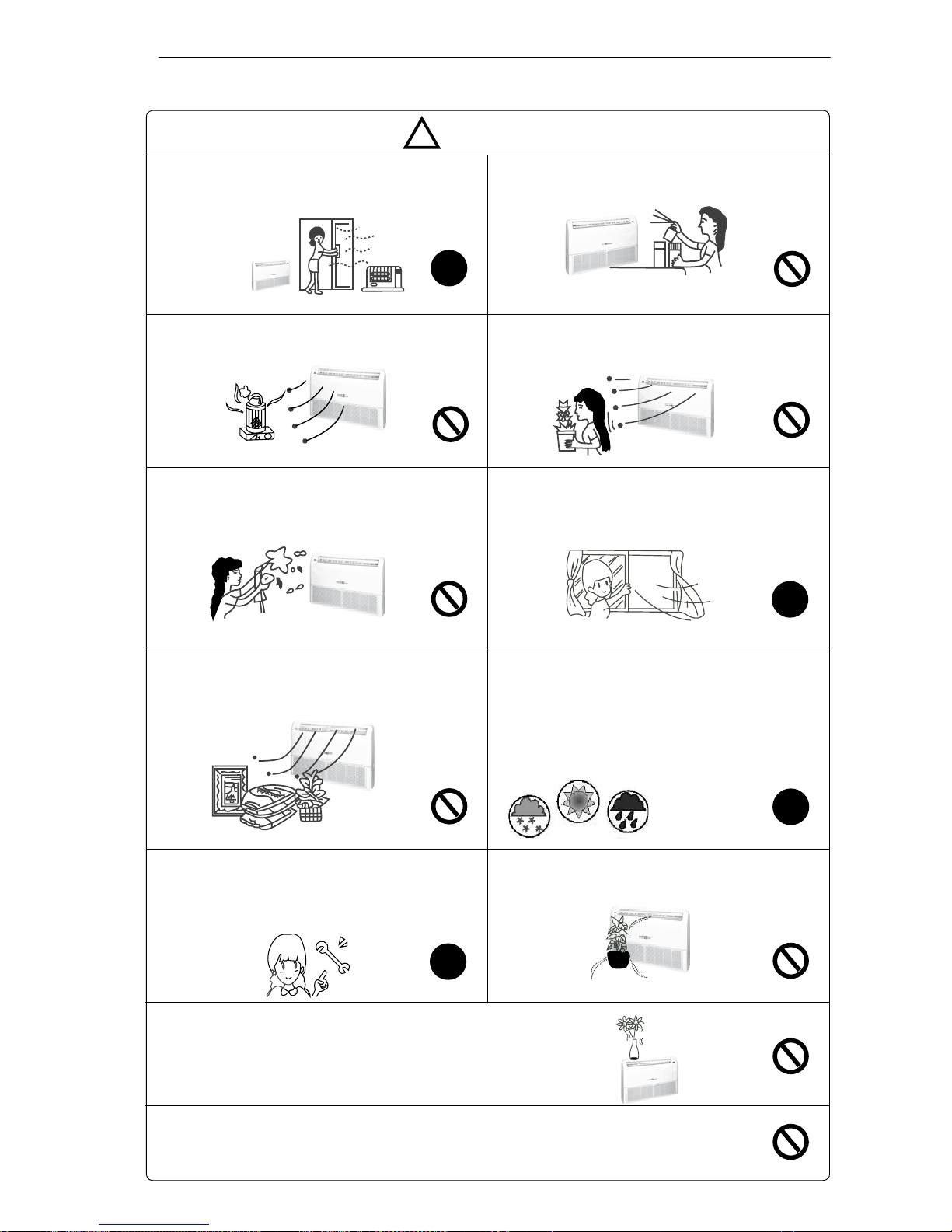

SAFETY INSTRUCTIONS

• Please read carefully the following Safety Instructions before operating the air conditioner.

• A strict observance of the Instructions indicated on the “USER’S MANUAL” will prevent personal hurt

and incidents to the User. Moreover, correct operation and long life of the system will be ensured.

• Depending on the seriousness of potential risks and damages, the reported Instructions are classied

in two types: “WARNING” and “CAUTION”. A strict observance of the Instructions is required to guarantee your personal safety and the safety of the environments where Units have been installed.

• The following Instructions are related to the air conditioner’s installation. They have been reported in

this “USER’S MANUAL” just to allow the User to check that installation is or has been properly carried

out. If an improper installation - not corresponding to the Instructions - is veried, please contact the

Dealer or the Authorized Technical Service.

The User must never attempt to repair, install or perform special maintenance by himself.

Key to symbols

WARNING

This symbol points out the risk of serious injury or death.

This symbol points out the risk of injury or damage to the property.

Prohibition. Action or procedure not allowed, with serious effects for

people or objects.

CAUTION

Obligation. Compulsory action or procedure. The missed observance

could bring to serious effects for people or objects.

!

!

!

• Strictly observe the instructions provided in this Manual.

• The air conditioning system contains in its refrigerant circuit the R410A gas under

pressure. Never disconnect refrigerant pipes or connection joints.

• Never perform any handling on Outdoor Unit service valves or on Indoor Unit's

unions.

• Keep this Manual in a safe place easy to reach at any time for convenient

reference.

• In case the air conditioner is transferred and reinstalled, this User's Manual should

always be attached to the appliance.

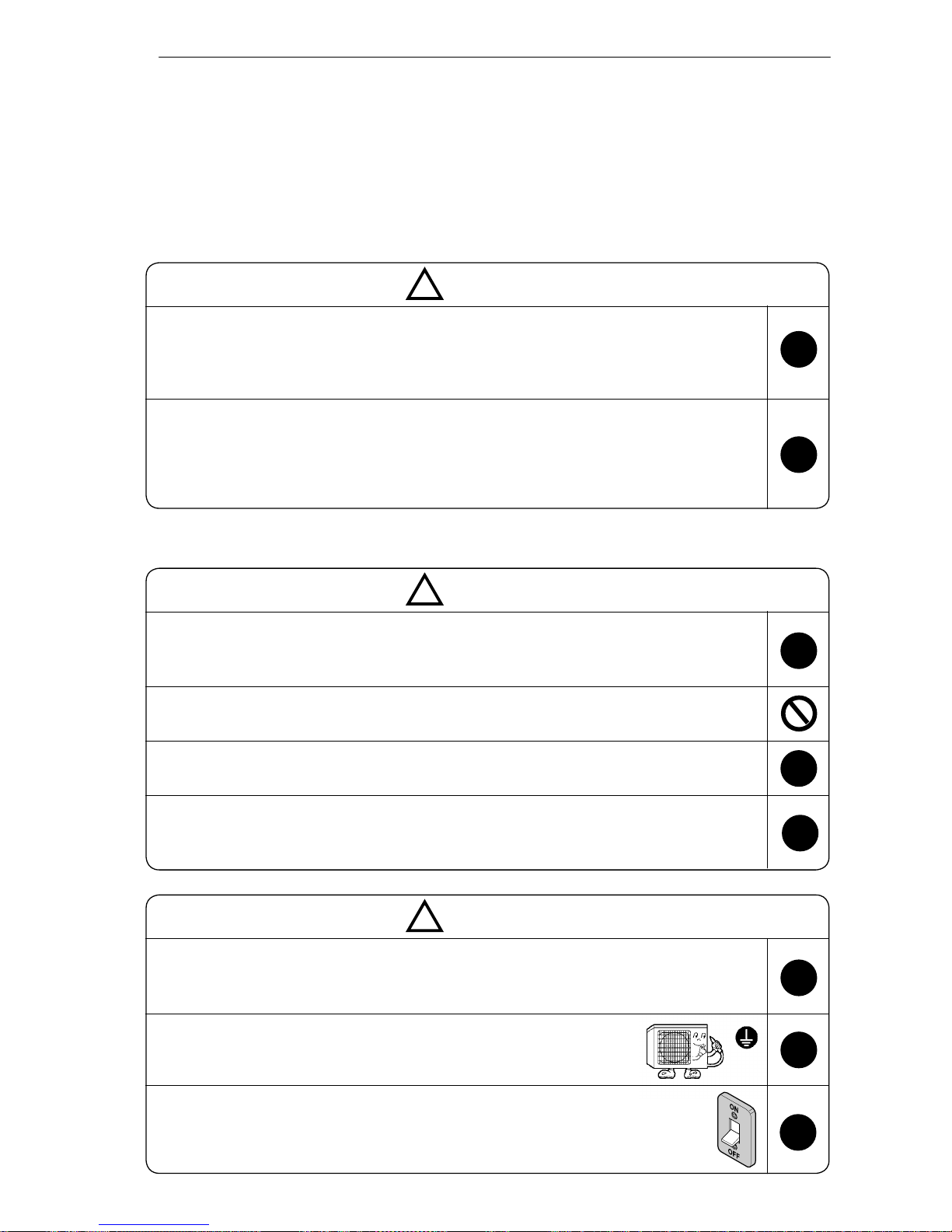

3. Safety precautions

-8-

- 9 -

Installation

Never try to install this Unit by yourself, i.e. without the support of Technical Personnel. Never try to repair the

Unit by yourself. The Unit’s components can be reached only by opening or removing the covering panels,

and this involves exposure to high voltage. Even by disconnecting power supply, it is not always possible

to avoid the risk of electric shocks.

• Please always contact the Dealer or Authorized Service Center for installation.

Never attempt to install the air conditioner by yourself, because improper installation could

cause electric shock, injuries, water leakage or re.

• Please always contact the Dealer or the Authorized Service Center for any servicing

operation or special maintenance.

Never try to repair or carry out special maintenance by yourself. Improper repair or maintenance

could cause electric shock, injuries, water leakage or re.

Conrm that installation has been carried out according to the following prescriptions:

WARNING

!

!

!

• When installing, all possible countermeasures must be taken to avoid refrigerant gas leaks.

If there is high concentration of refrigerant gas in the room, oxygen lack may occur.

• Do not install the air conditioner near burners, heat sources or ammable gas. This is to avoid

the risk of malfunctioning, re or explosion.

• Ensure that a circuit breaker has been installed on the power supply line above the air conditioner, to avoid the risk of electric shock.

• When installing in a small room, countermeasures should be taken in case a refrigerant leak

exceeds the proper range. Otherwise, it will cause people asphyxia.

CAUTION

!

!

!

!

• Ensure that drain hose and drain pipe installation has been correctly carried out. Incorrect

installation or maintenance will cause water leakage.

CAUTION

!

!

!

• Ensure that Indoor and Outdoor’s Units have been properly grounded.

Defective grounding could cause electric shock.

!

• This kind of appliance needs a specic circuit breaker with proper protective devices against overcurrents and short circuits (fuses or automatic

switches).

Circuit

breaker

(specic)

Safety precautions

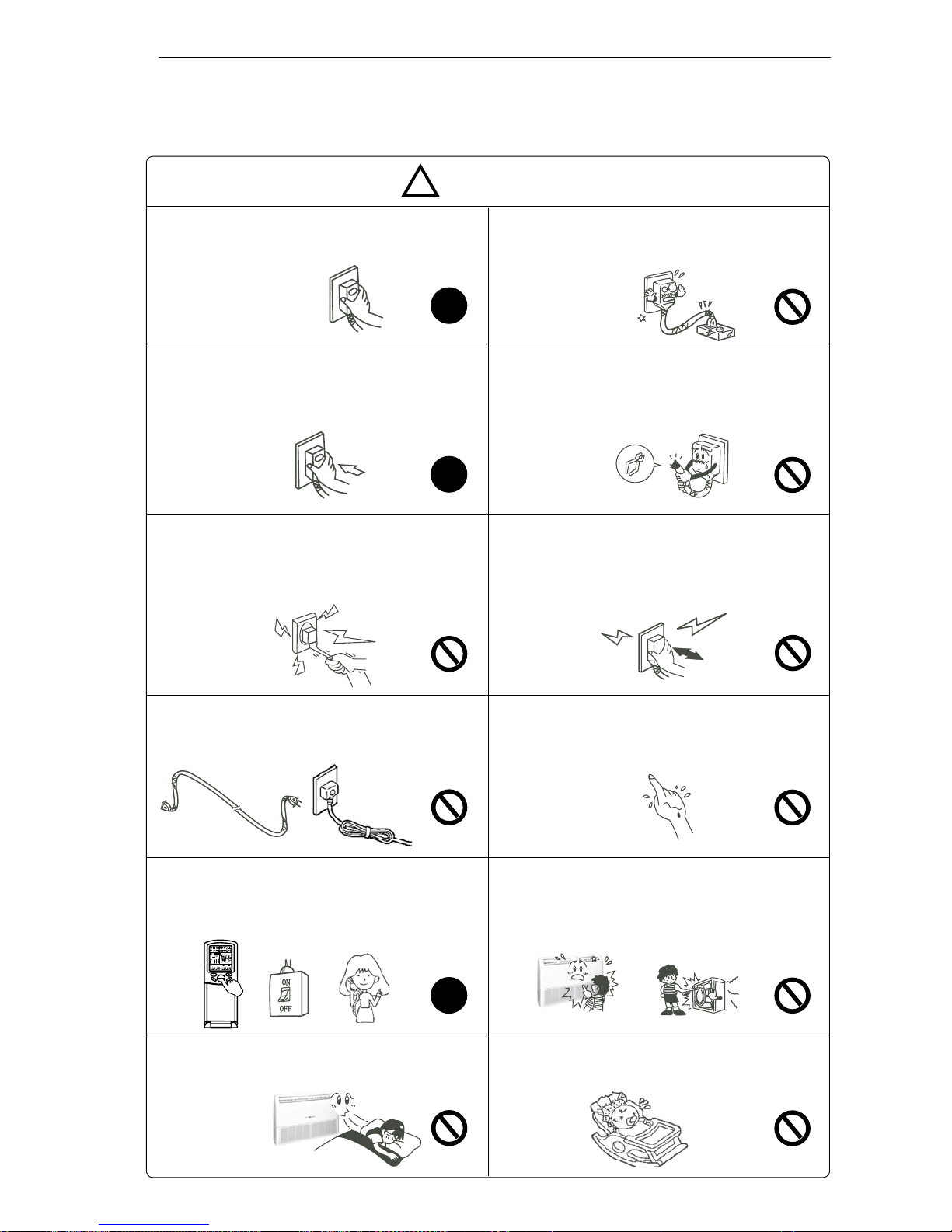

- 10 -

Do not insert the air conditioner’s plug into

multiple sockets or into sockets to which other

appliances are connected. Do not use plug

adapters.

Always observe the operating precautions listed in the following tables. In this way, correct operation and

safeguard of people, animals and objects inside air-conditioned environments will be ensured.

WARNING

!

Use the correct voltage and frequency for power

supply.

!

!

!

Fully insert the plug into the power socket and

make sure the connection is secure and without

play. Otherwise, sparks and re may occur.

Do not put heavy objects on the power supply

cord. Take care not to damage it. Do not use

faulty or damaged power supply cords.

Do not pull out the plug from the power socket

by drawing the power cord. Damaging to the

power cord, to the plug or to the socket may

occur, and this could result in electric shock or

re generation.

Never turn off the air conditioner by pulling the

power supply plug out of the socket. This could

cause electric shock or re.

Always press the ON/OFF button on remote

controller.

Do not use extension cords. Do not use rolled

power supply cords.

Never touch switches, sockets or power supply

plugs with wet hands. This could cause electric

shock.

If you smell something burning, immediately turn

off the air conditioner, switch the circuit breaker to

“OFF” or “0” and contact the Authorized Technical

Assistance.

Do not insert any objects into the air inlet or outlet of Indoor and Outdoor’s Units. Even if fans

are stopped, they could automatically start all

at once.

You should avoid to expose your body directly

to cool air for a long time. This may cause you

health problems.

Do not direct the airow towards infants, aged or

disabled people.

220 ÷ 230V~, 50Hz

B A

M D

OFF

A

U

T

O

ON

OFF

TEMP

SWING

FAN

Safety precautions

- 11 -

CAUTION

!

Ventilation should be operated when using

at the same time the air conditioner and gas

burners. Insufcient ventilation will cause lack

of oxygen.

Do not use sprayers near the air conditioner and

do not spray anything towards the appliance.

!

!

Do not place burners near the airflow of air

conditioner.

Do not expose plants or animals to the direct

airow of the air conditioner.

To avoid the risk of electric shock, do not sprinkle

water or other liquid on Indoor Unit. Do not clean

the air conditioner by water spurts.

Ventilate the room regularly while the air conditioner is operating. Fail to follow this advice could

result in lack of oxygen inside the room.

Do not expose food, plants, animals, precision

devices or works of art to the direct airow of the

air conditioner.

For prope r perfo rman ce, op erat e the air

conditioner under the temperature and humidity

conditions indicated in this Manual (see page

5, “Recommended Operating Conditions”). If

the Unit operates beyond these conditions,

malfunctions may occur or dew may drip from

the Indoor Unit.

!

Do not place anything in front of the air conditioner

nor obstruct the air outlet.

When necessary, replace fuses with fuses of the

same type and size. Never use a piece of iron

or copper instead of the proper fuse, as it could

result in a malfunction or in a re accident.

!

Do not touch the heat exchangers’ metal aps on Indoor and Outdoor Units. This could cause

hurts due to the sharp shape of the aps. Take care of this especially when removing the inlet

grille and the air lters.

Do not put any object on the air conditioner. On the

appliance’s upper part there is an air inlet grille that must

not be obstructed. Besides, a heavy object may cause the

air conditioner’s fall.

Safety precautions

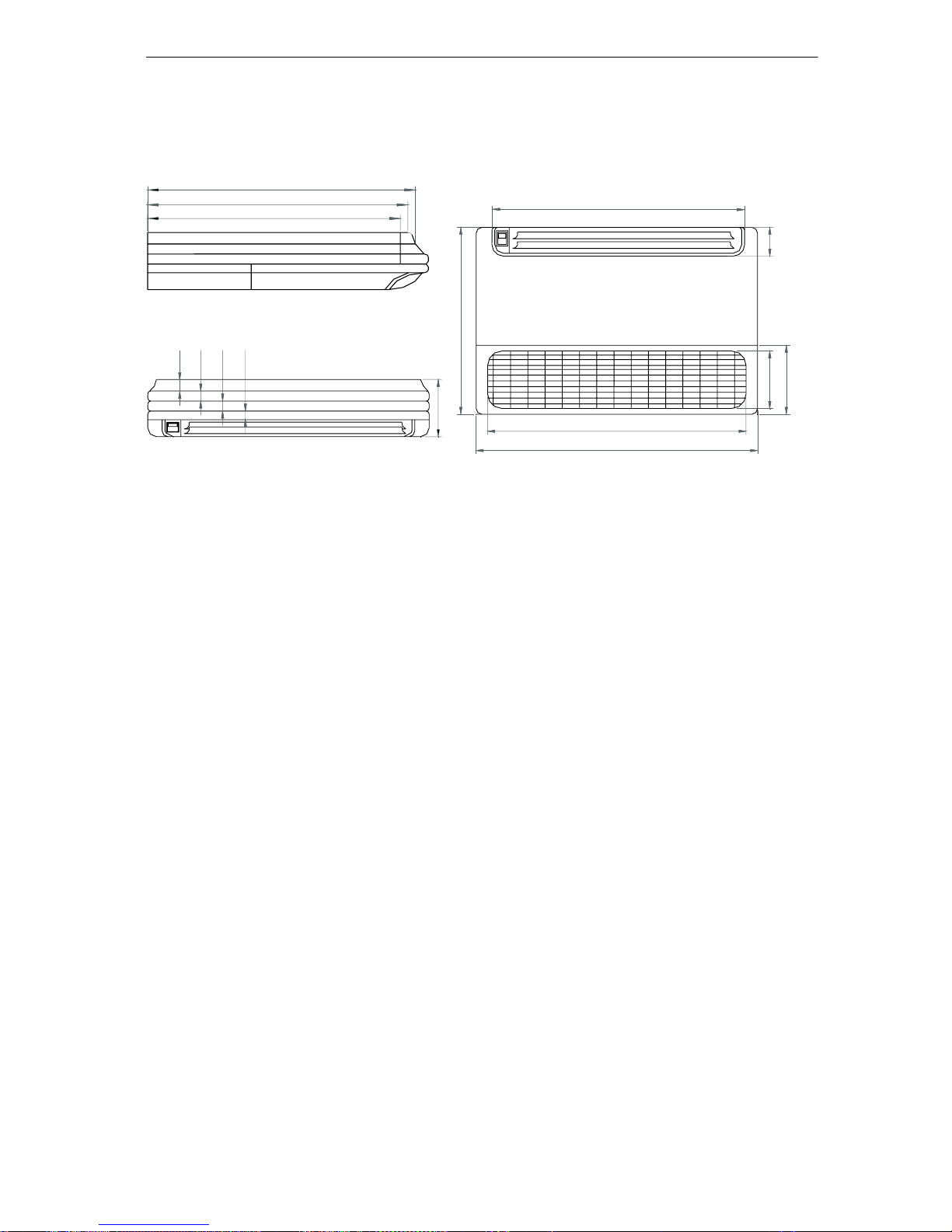

4. Net dimensions of the Indoor Units

Convertible type units: HSFL 411, 531 XMR

-12-

100

900

990

655

200

880

620

605

600

40 35 35 30

199

(mm)

Bhh aha_pne_]h nal]eno iqop ^a _]nnea` kqp ^u

mq]hebea` aha_pne_e]jo1 Jj]`amq]pa nal]eno i]u

naoqhp ej ] i]fkn okqn_a kb `]jcan bkn pda qoan

kbpda]en_kj`epiojan1

Ek jkp `]i]ca ]ju l]npo kb pda ]en _kj`epekjan

pd]p _]nnu nabnecan]jp ^u lean_ejc kn lanbkn]pejc

pda ]en _kj`epekjan,o pq^ao sepd od]nl kn lkejpa`

epaio/ _nqodejc kn pseopejc ]ju pq^ao/ kn

o_n]lejc pda _k]pejco kbb pda oqnb]_ao1 Jb pda

nabnecan]jp olqnpo kqp ]j` capo ejpk auao/ ep i]u

naoqhp ej oanekqo aua ejfqneao1

Ek jkp k^opnq_p kn _kran pda rajpeh]pekj cnehha

kb pda ]en _kj`epekjan1 Ek jkp lqp bejcano kn ]ju

kpdan pdejco ejpk pda ejhap2kqphap ]j` osejc

hkqran1

Ek jkp ]hhks _deh`naj pk lh]u sepd pda ]en

_kj`epekjan1 Jj jk _]oa odkqh` _deh`naj ^a

]hhksa` pk oep kj pda kqp`kkn qjep1

y7-+1.1+~:1659

Uda nabnecan]pejc _en_qep eo ha]g0lnkkb1

41 Bllhe_]^ha ]i^eajp pailan]pqna n]jca=

z0- 4~+015- 19 ~,~7:1<- 15 .6336=15/

91:;~:165

51 Jb pda oqllhu _kn` eo `]i]ca`/ ep iqop ^a

nalh]_a` ^u pda oanre_a ]cajp kn ] oeieh]n

mq]hebea` lanokj1

61 Jb pda bqoa kj QD ^k]n` eo ^nkgaj lha]oa

_d]jca ep sepd pda pula kb U6148B 2583WBD1

Dkkhejc

Ia]pejc

Jj`kkn

Outdoor

S]pa` N]teiqi Nejeiqi

5: 65 4;

4< 56 47

68 76 43

57 59 9

53 5: 48

4718 00 00

: 57 048

94;00

EC D

XC D

EC D

XC D

Jj`kkn

Outdoor

EC D

XCD

Model

Dkiiqje_]pekj _]^ha

-odaeh`a` sena.

Power cable

HSFL411XMR

I38SO0G 6H -40518.ii

5

I38SO0G 5Y-31:80418.ii

5

HSFL531XMR I38SO0G6H-40518.ii5 I38SO0G5Y-31:80418.ii5

5. Installation instructions

71 Uda senejc iapdk` odkqh` ^a ej heja sepd

pda hk_]h op]j`]n`1

91 Uda s]opa ^]ppanu od]hh ^a `eolkoa` lnklanhu1

:1 Uda ej`kkn qjep ejop]hh]pekj daecdp eo ]p ha]op 518i1

;1Uda]llhe]j_aiqop^aejop]hha`so pd]ppdalhqcodkqh`

be a]oehu]__aooe^ha]bpanejop]hh]pekj1

81 Uda lksan _]^ha ]j` _kjja_pejc _]^ha ]na

oahb0lnkre`a`1

Uda namqenaiajp kb pda _kiiqje_]pekj _]^ha=

-13-

EC D

XCD

■R410A

The working pressure of R410A is approximately 1.6 times higher than R22. Because the oil in the

refrigerant is different, please do not mix them.

Refrigerant R22 (single) R410A (mixed) R407C (mixed)

Oil Mineral oil (SONTEX 200LT) Synthetic oil (POE oil) Synthetic oil (POE oil)

Pressure ratio 1 Approx. 1.6 Approx. 1.1

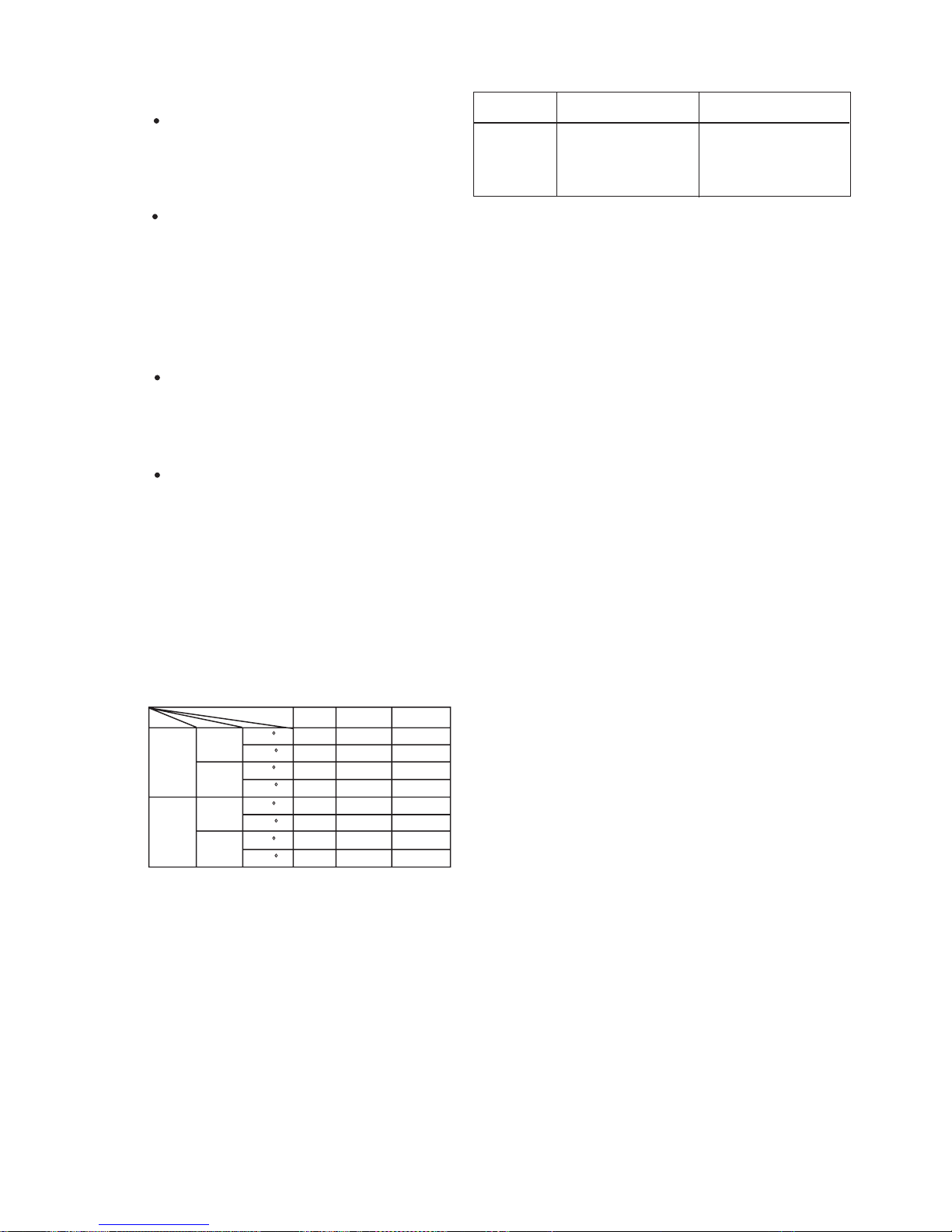

■Operation flow

1. Calculate the refrigerant additional charging

amount, and charge a suitable amount.

1. Air purging by refrigerant is prohibited seriously

2. Use a special vacuum pump with reverse check

mechanism

1. Charge the nitrogen to the set pressure

2. 24 hours later,check if the pressure in the pipe

has reduced

1. Do not connect the power supply

1. Use piping material of the specified thickness

2. Do not use dirty pipe

3. Always flow nitrogen during welding work

hand over

trial running and adjustment

maintenance panel installation

gas leakage check

additional refrigerant charging

evacuation and drying

leakage test

refrigerant piping connection

outdoor unit installation

outdoor unit foundation work

electric wiring work

remote controller installation

insulation work

duct work

drain piping work

refrigerant piping work

indoor unit installation

operation chart preparation

1. Always inspect the used refrigerant

2. Always use the specified refrigerant

refrigerant inspection

prepare work schedule

-14-

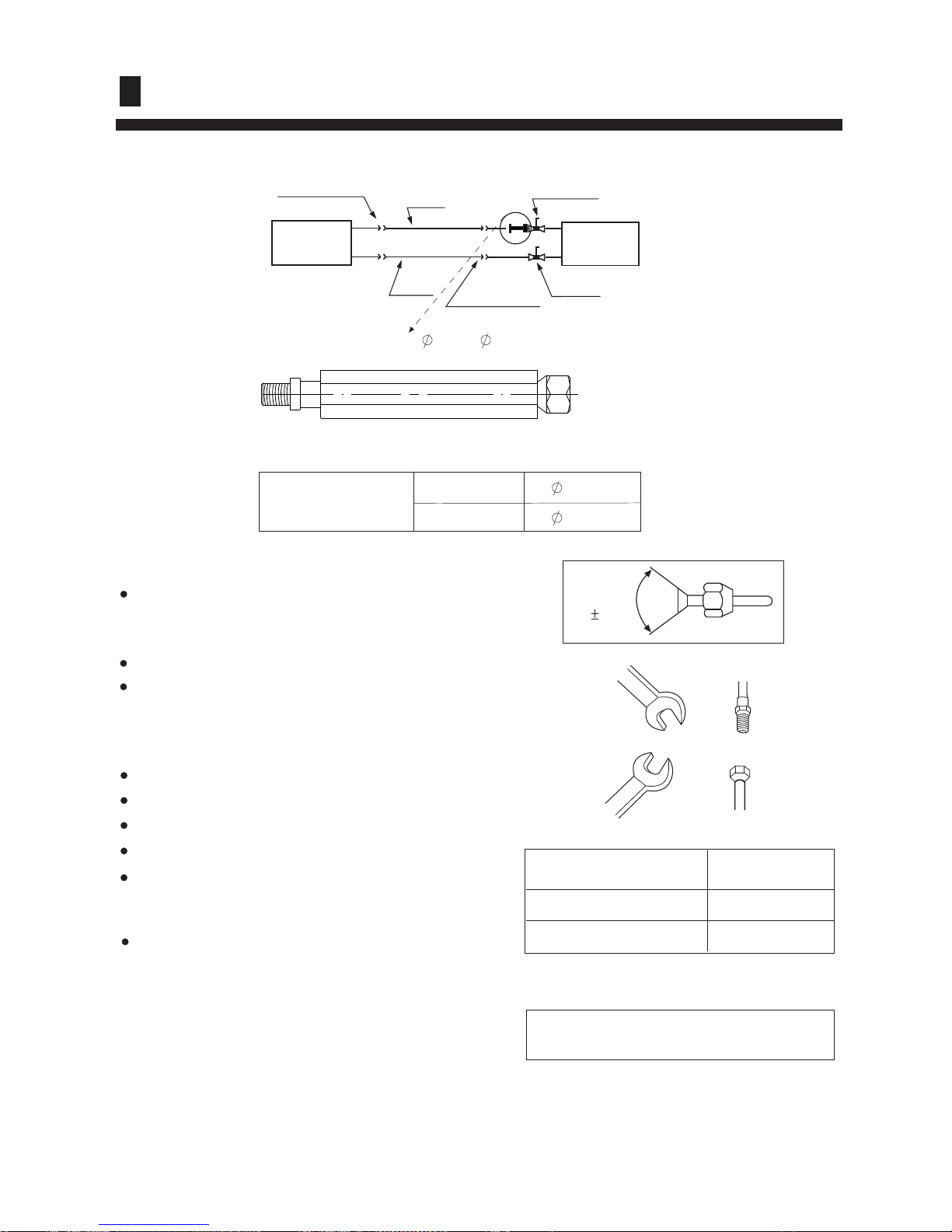

■Piping material

1. Use the correct refrigerant piping and materials for R410A

2. For the pipe wall thickness, see the table below:

Pipe diameter Φ6.35 Φ9.52 Φ12.7 Φ15.88 Φ19.1

Pipe wall thickness 0.8 0.8 0.8 1.0 1.2

Note: Always observe and comply with the local regulations when installing the refrigerant piping.

■Tools

R410A work requires a number of special tools (* symbol). Since the tools used in R22 work

cannot be used for R410A, provide the tools separately.

Tool name Process and application

Pipe cutter Piping cutting

*Flaring tool Pipe flaring work

*Torque wrench Flare nut connection

Expander Expansion at pipe connection

Pipe bender Pipe bending work

Refrigerant piping work

Nitrogen gas Pipe oxidation prevention

Welder Pipe brazing

Air tightness test

*Gauge manifold

*Charging hose

Vacuum evacuation and refrigerant

charging operation check

Air tightness test

Refrigerant

additional charging

*Vacuum pump

(with adapter)

Vacuum drying

Electronic scale

Gas leakage detector Gas leakage test

Refrigerant

additional charging

■Work precautions

Refrigerant check: Before work, check the used refrigerant and prepare materials matched to the

refrigerant.

Refrigerant piping: Observe the basics of refrigerant piping to avoid the unnecessary problems. In

addition, when performing the welding work, seal in the nitrogen gas to the pipes, and prevent it

from the oxidation.

Leak pressure detection: Perform seal detection and make sure there is no refrigerant leakage.

Vacuum drying: If the vacuum pump has not the reverse flow check mechanism, use the pump

together with a reverse flow check adapter.

Additional refrigerant: Charge a suitable amount of refrigerant with a special R410A gauge

manifold and charging hose.

-15-

Operation and Performance

*Heating Performance

*Microcomputer-controlled Automatic Defrosting

Heat-pump air conditioners heat your entire room

by recirculating air throughout the room, with the

result that some time may be required after first

starting the air conditioner until the room is heated.

This air conditioner operates on the heat-pump

principle, absorbing heat from outdoor air and

transferring that heat indoors. As a result, the

operating performance is reduced as outdoor air

temperature drops. If you feel that insufficient

heating perfomance is being produced, we

recommend you use this air conditioner in

conjunction with another kind of heating

appliance.

Instructions relating to heating (*) are applicable

to HSFL 411, 531 XMR Indoor Units.

When using the Heating mode under conditions of

low outdoor air temperature high humidity, frost

may form on the outdoor unit, resulting in reduced

operating performance.

In order to prevent this kind of reduced

performance, this unit is equipped with a

Microcomputer-controlled Automatic Defrosting

function. If frost forms, the air conditioner will

temporarily stop, and the defrosting circuit will

operate briefly (for about 7 to 15 minutes).

STANDARD PARTS

The following installation parts are furnished. Use

them as required.

Mark Parts name

Adhesive tape

Saddle (L.S) with screws

Drain hose

Heat insulation material

Piping hole cover

Putty

Plastic clamp

Optional parts

A

B

C

D

E

F

G

Additional information about these models

-16-

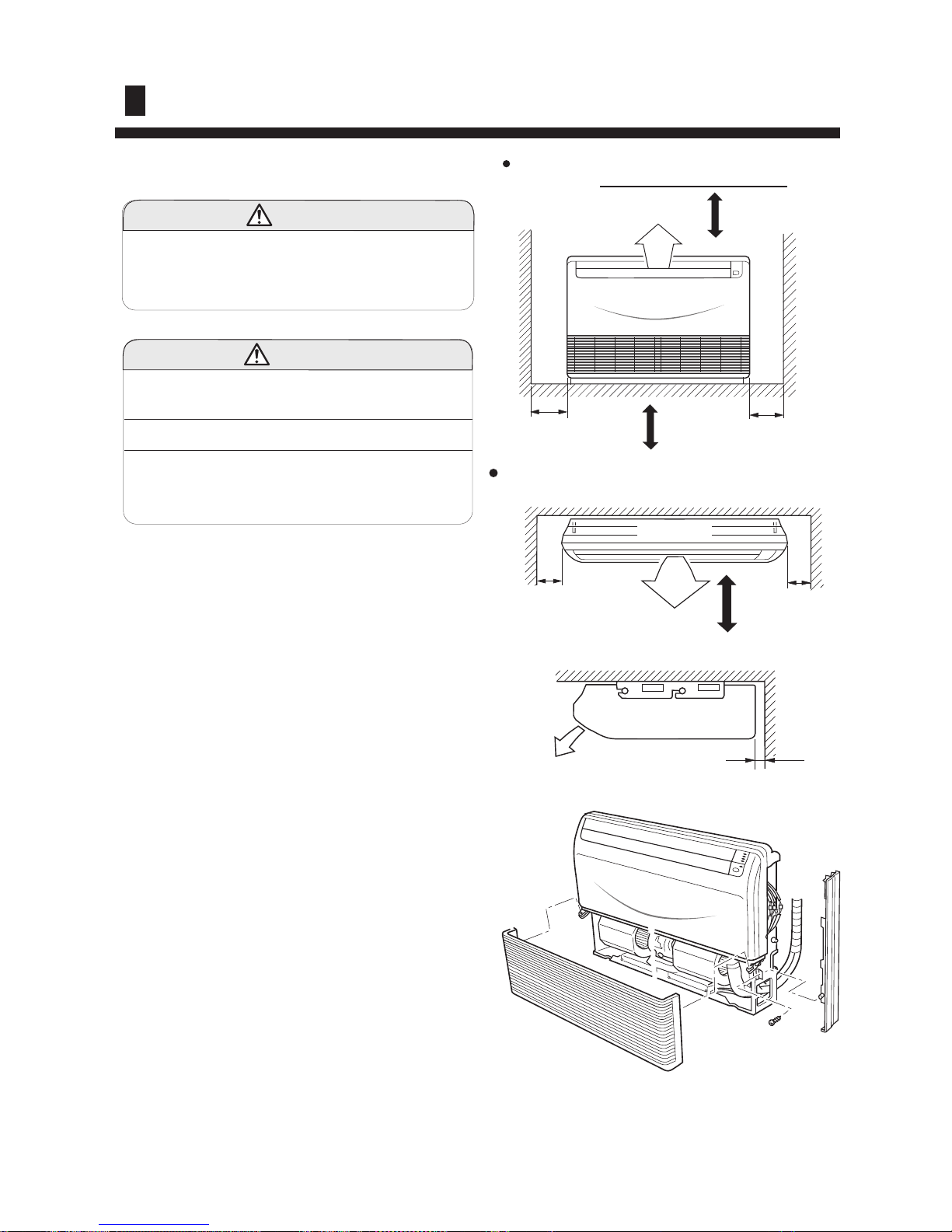

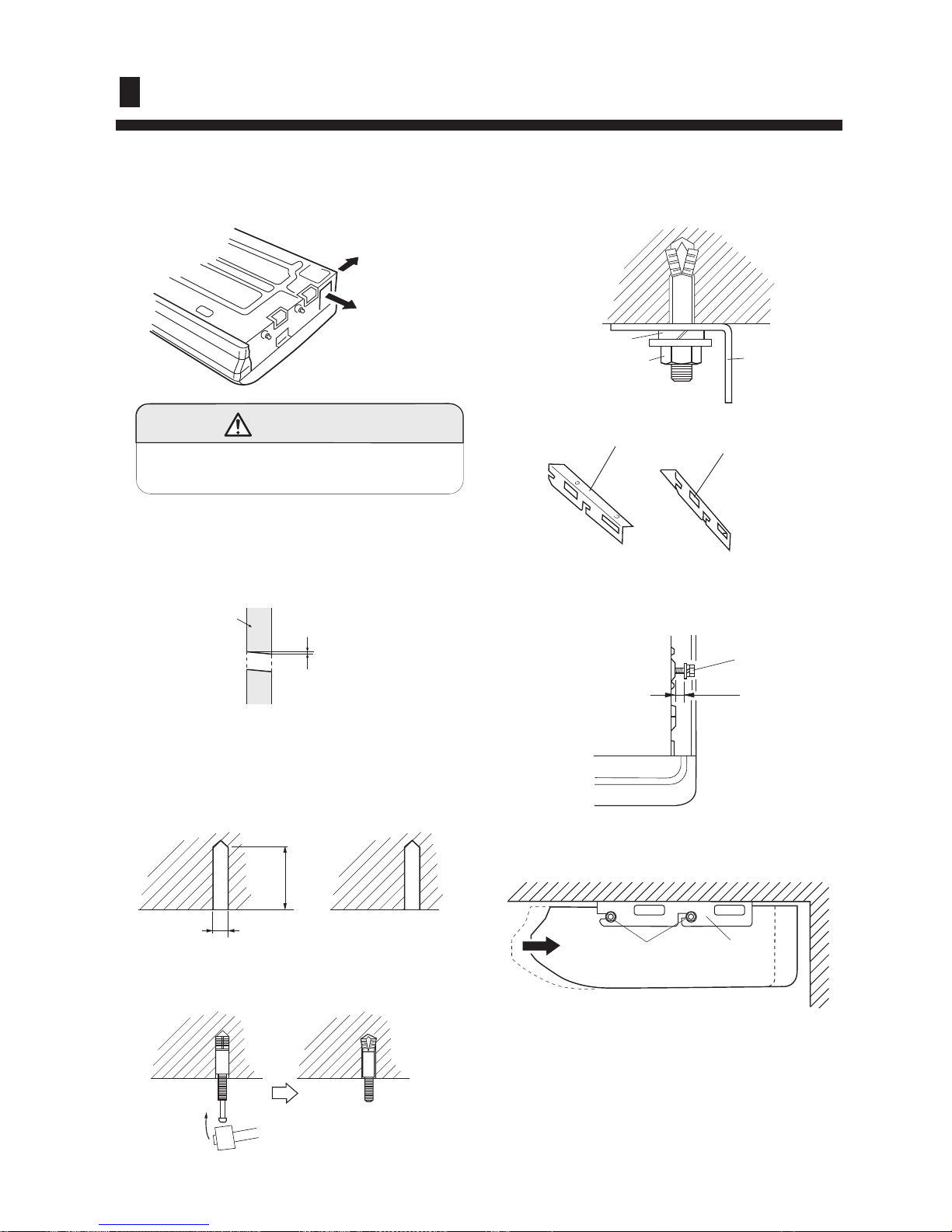

SELECTING THE MOUNTING POSITION

(1)Do not install where there is the danger of com bustible gas leakage.

(2) Do not install near heat sources.

(3) If children under 10 years old may approach

the unit, take preventive measures so that they

cannot reach the unit.

Install at a place that can withstand the weight of

the indoor and outdoor units and install positively

so that the units will not topple or fall

WARNING

CAUTION

Decide the mounting position with the customer as follows:

INDOOR UNIT

(1) Install the indoor unit level on a strong wall, floor,

ceiling which is not subject to vibration.

(2) The inlet and outlet ports should not be obstructed:

the air should be able to blow all over the room.

(3) Install the unit near an electric outlet or special

branch circuit.

(4) Do not install the unit where it will be exposed to

direct sunlight.

(5) Install the unit where connection to the outdoor

unit is easy.

(6) Install the unit where the drain pipe can be easily

installed.

(7) Take servicing, etc. into consideration and leave the

spaces shown in Fig.A. Also install the unit where

the filter can be removed.

Under ceiling

2 cm

or more

Ceiling

Indoor unit

30 cm

or more

Left

Right

1.5m

Floor console

30 cm

or more

30 cm

or more

1.5m

1.5m

Left

Right

may be difference

Fig.A

Indoor unit

Installation of the Indoor Unit

-17-

ELECTRICAL WIRING

(1) The power source capacity must be the sum of the

room air conditioner current and the current of other

electrical appliances. When the current contracted

capacity is insufficient, change the contracted

capacity.

(2) When the voltage is too low and the air conditioner

is difficult to start, contact the power company the

voltage raised.

CAUTION

TEST RUNNING

1. CHECK ITEMS

(1) INDOOR UNIT

(1) Is operation of each button on the remote control

unit normal?

(2) Does each lamp light normally?

(3) Do not air flow direction louvers operate normally?

(4) Is the drain normal?

(2) Air filter removal and cleaning, and how to use

air louvers.

(3) Give the operating and installation manuals to

the customer.

(1) Always use a special branch circuit and install a special

receptacle to supply power to the room air conditioner.

(2) Use a circuit breaker and receptacle matched to

the capacity of the room air conditioner.

(3) The circuit breaker is installed in the permanent wiring.

Always use a circuit that can trip all the poles of the

wiring and has an isolation distance of at least 3mm

between the contacts of each pole.

(4) Perform wiring work in accordance with standards so

that the room air conditioner can be operated safely

and positively.

(5) Install a leakage circuit breaker in accordance with the

related laws and regulations and electric company

standards.

WARNING

MOUNT THE COVER PLATE AND

THE INTAKE GRILL

(2) OUTDOOR UNIT

(1) Is there any abnormal noise and vibration during

operation?

(2) Will noise, wind, or drain water from the unit disturb

the neighbors?

(3) Is there any gas leakage?

CUSTOMER GUIDANCE

Explain the following to the customer in accordance

with the operating manual:

(1) Starting and stopping method, operation switching,

temperature adjustment, timer, air flow switching,

and other remote control unit operations.

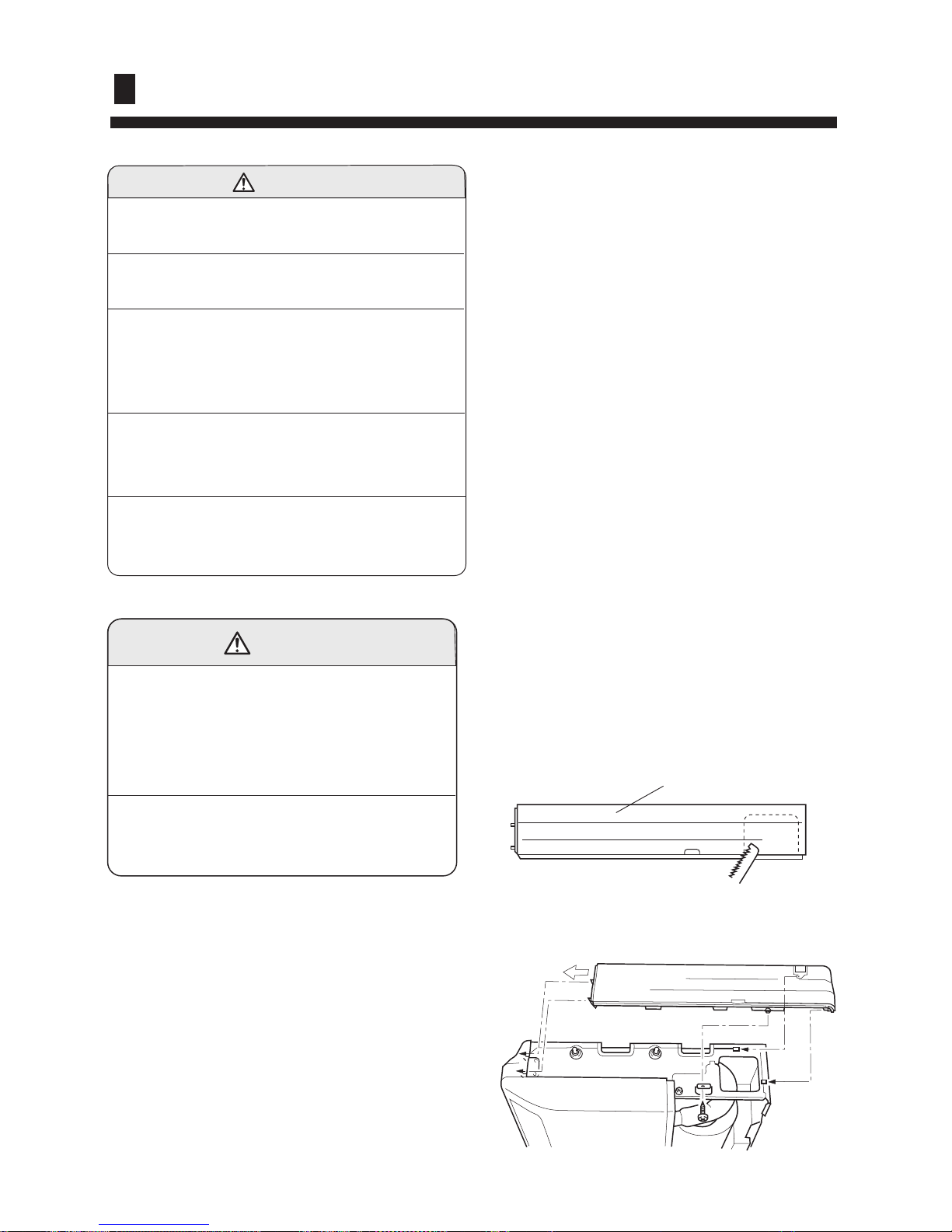

1.Mount the cover plate. (Right)

(1) Cut a pipe exit hole in the right plate. This is

only when the pipe exits from the right side.

(This operation is not required when the

protrusion is on the top or rear.)

Fig. 31

Cover plate (Right)

(2) Join the cover plates (right) and mount with screws.

Fig. 32

Installation procedures

-18-

(2) Insert the hinges on the bottom of the intake grill into the holes in the base assembly. Then mount the arms to

the three areas on the top of the intake grill.

Fig. 35

Fig. 34

(1) Cut the right side of the intake grill. This is only when the pipe exits from the right side

3. Mount the intake grill.

(1) Join the cover plate (left) and mount with screws.

Fig. 33

2. Mount the cover plate.(Left)

Installation procedures

-19-

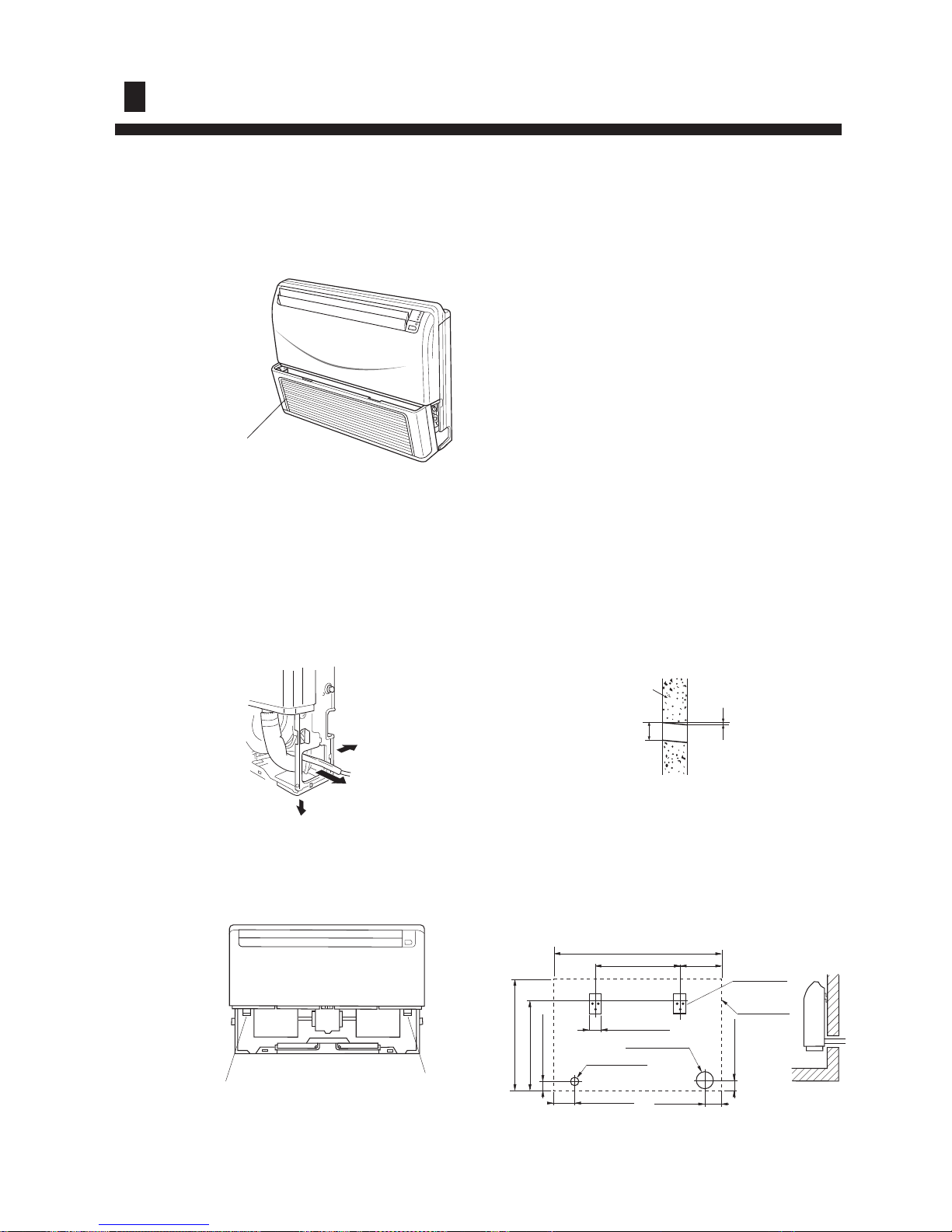

Open the intake grill and remove the three or four or six screws.(Fig. 1)

Remark:

The main unit can be wired before the indoor

unit is installed. Select the most appropriate

installation order.

A. FLOOR CONSOLE TYPE

1. DRILLING FOR PIPING

Select piping and drain directions.(Fig.2)

The piping and drain can be made in three

directions as shown below.

(Fig.2)

rear

right

down

REMOVE THE INTAKE GRILL

PREPARING INDOOR UNIT INSTALLATION

When installing set to wall, install the accessory wall

bracket at the position shown in Fig.5,and mount the

set to it.

Fig. 1

Intake grill

(Fig. 5)

Wall bracket

Side of set

65.5cm

99cm

50cm

24.5cm

6.5cm

12.5cm 10cm

6.5cm

53cm

4.5cm

7cm hole

3.5cm hole

The drain hose can be connected to either the

left or right side.(Fig.3)

(Fig. 3)

Drain hose (Left side) Drain hose (Right side)

Wall

7cm

6mm

Indoor unit outdoor unit

(Fig.4)

When the directions are selected, drill a 7 cm dia.

hole on the wall so that the hole is tilted downward

toward the outdoor for smooth water flow. When

the pipe is led out from the rear, make a hole in

Fig.4, at the position shown.

Installation of the Indoor Unit

-20-

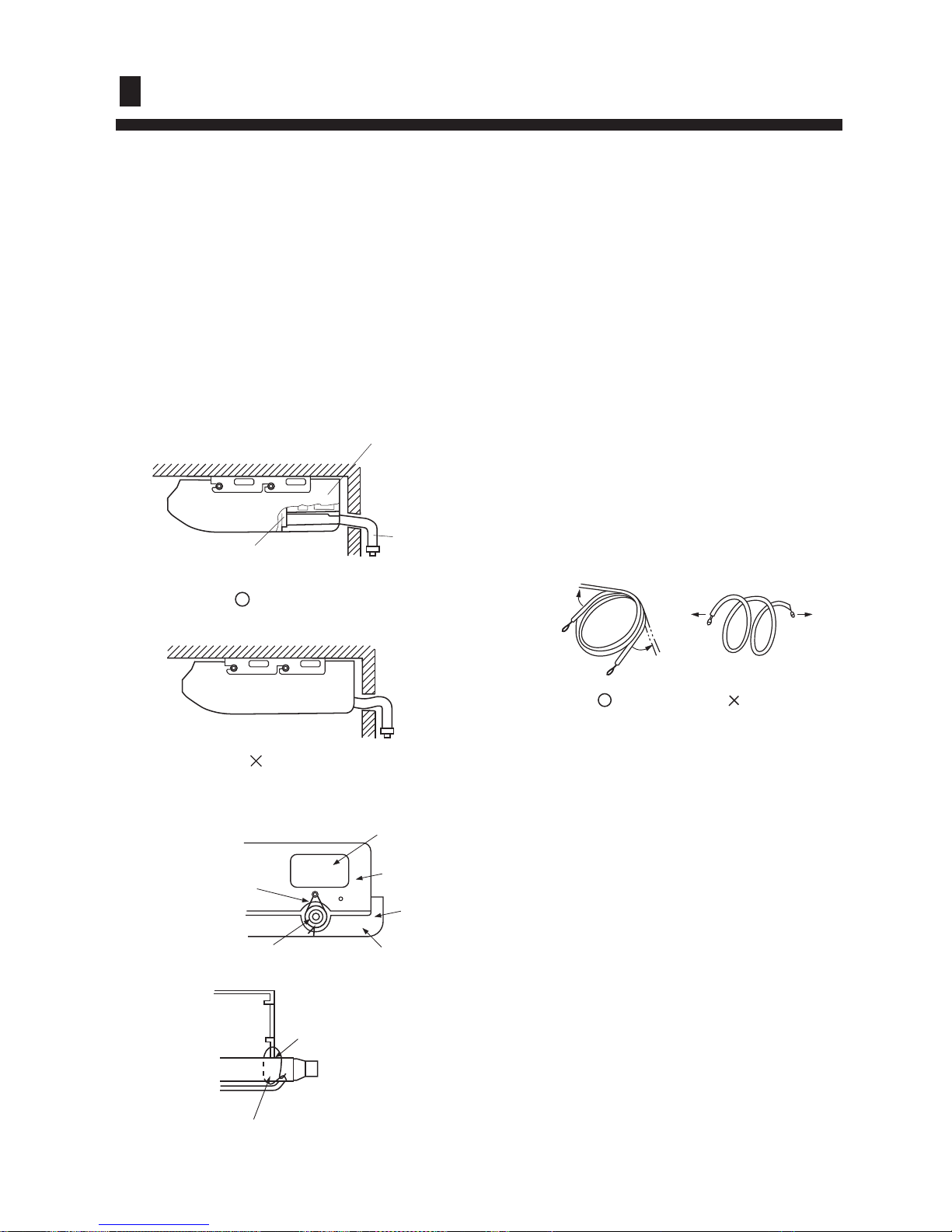

Select whether the drain hose will be connected

to the left or right side.(Fig.3) Insert the drain

hose into the drain pan, then secure the drain

hose with a nylon fastener. (Fig.6)

2. INSTALLING DRAIN HOSE

(Fig. 6)

Wrap the insulation (drain hose) around the drain

hose connection. (Fig.7)

(Fig. 7)

CAUTION

Do not install the unit drain hose side is too high. Height A should be less than 5 mm.(Fig.9)

Fig. 8

Be sure to arrange the drain hose correctly so that it is leveled lower than the drain hose connecting port

of the indoor unit.

Drain pan

Drain hose

Nylon fastener

Drain pan

Drain hose

Insulation

(Drain hose)

OK NO NO

Arrange the drain hose

lower than this portion.

Drain hose

Fig. 9

A A

Drain hose

B. UNDER CEILING TYPE

Using the installation template, drill holes for

piping and anchor bolts(for holes).(Fig.10)

Installation

template

Wall

Ceilling

Drilling position

for piping

Drilling position

for anchor bolt

200mm

900mm

Fig. 10

Installation of the Indoor Unit

-21-

3. INSTALLING BRACKETS

Install the brackets with nuts, washers and spring

washers.(Fig. 15)

4. INSTALLING INDOOR UNIT

Bracket (Right)

Bracket (Left)

Select piping and drain directions.

(Fig.11)

1. DRILLING FOR PIPING

Insert the anchor bolts into the drilled holes, and drive

the pins completely into the anchor bolts with a hammer.

(Fig. 14)

2. DRILLING HOLES FOR ANCHOR BOLTS AND

INST ALLING THE ANCHOR BOLTS

When the directions are selected, drill 80mm and

50mm or 150mm dia. hole on the wall so that the

hole is tilted downward toward the outdoor for

smooth water flow.

With a concrete drill, drill four 12.7 mm dia. Holes.

(Fig.13)

Wall

6mm

Install the drain hose at the rear; it should not

be installed on the top or right side.

Fig. 11

Rear (Install the drain

hose in the direction.)

Right

CAUTION

Fig. 12

Now, securely tighten the hex bolts in both sides.

Fig. 17

Reset the hex bolts as shown in Fig.16.

Hex bolt

8 to 13mm

Indoor unit

Fig. 16

Apply the indoor unit to the brackets.(Fig.17)

Bolt

Bracket

Indoor unit

Fig. 13

60 to 70mm

12.7mm

Fig. 14

Fig. 15

Spring washer

Special nut

Bracket

Installation of the Indoor Unit

-22-

Select whether the drain hose will be connected to

the left or right side.(Fig.3)

Insert the drain hose into the drain pan, then secure

the drain hose with a nylon fastener.(Fig.6)

Wrap the insulation (drain hose)around the drain

hose connection.(Fig.7)

Be sure to arrange the drain hose correctly so that

it is leveled lower than the drain hose connecting

port of the indoor unit.(Fig.18)

5. INSTALL THE DRAIN HOSE

Fig. 18

Pass the drain hose through here

CONNECTING THE PIPING

1. FLARE PROCESSING

(1) Cut the connection pipe with pipe cutters so

that the pipe is not deformed.

(2) Holding the pipe downward so that cuttings

cannot enter the pipe, remove the burrs.

(3) Remove the flare nut from the indoor unit pipe

and outdoor unit and insert the flare nut onto the

pipe, and flare with a flaring tool.

2. BENDING PIPES

The pipes are shaped by your hands. Be careful

not to collapse them.

NO

Remove the hole cover.

OK

Arrange the drain hose

lower than this portion

Drain hose

VT wire

Drain hose

Fig. 19

Piping hole

Base (Bottom)

Intake grill

VT wire hole

Cut the grill

Fig. 21

OK

NO

Extend the pipe by unwinding it

Installation of the Indoor Unit

-23-

(1) Dimension of connecting pipe

(2) The maximum length and drop height of connecting pipe

Cautions for piping connection

Smear refrigerant oil on the joints of piping and flare.

The bending radius shall be as large as possible.

Align the pipe center when fastening, and tighten the

nut, as shown in the figure.

Pay attention to not mix foreign matters such as sands

in.

Do not twist or deform the connecting pipe.

Do not mix dusts.

The bending radius shall be as large as possible.

Both gas pipe and liquid pipe shall be heat insulation.

No leakage in the flare.

(3) Piping connection

Connecting method

Spanner

Spanner

Joint

Nut

If not aligned ,tighten the nut by force will

damage the nut that result in gas leakage

Please refer to the installation manual of outdoor unit

To ensure the efficiency , Pipes shall be as short as possible.

Fit the nut on and fasten

HSFL 411XMR

HSFL 531XMR

Flare connection

Gas pipe

3-way valve

Indoor

Unit

Outdoor

unit

Liquid

pipe

2-way valve

Flare connection

A

Diameter of Pipe

Liquid Pipe 6.35mm

Gas Pipe 12.7mm

Tighten Torque

(N. m)

11.8

49.0

A(adaptor, from 9.52 to 12.7)

To outdoor unit

To gas pipe

90 0.5

O

Gas pipe

Liquid pipe

12.7mm

6.35mm

HSFL 411XMR

HSFL 531XMR

3. PIPING CONNECTION

-24-

Installation of the Indoor Unit

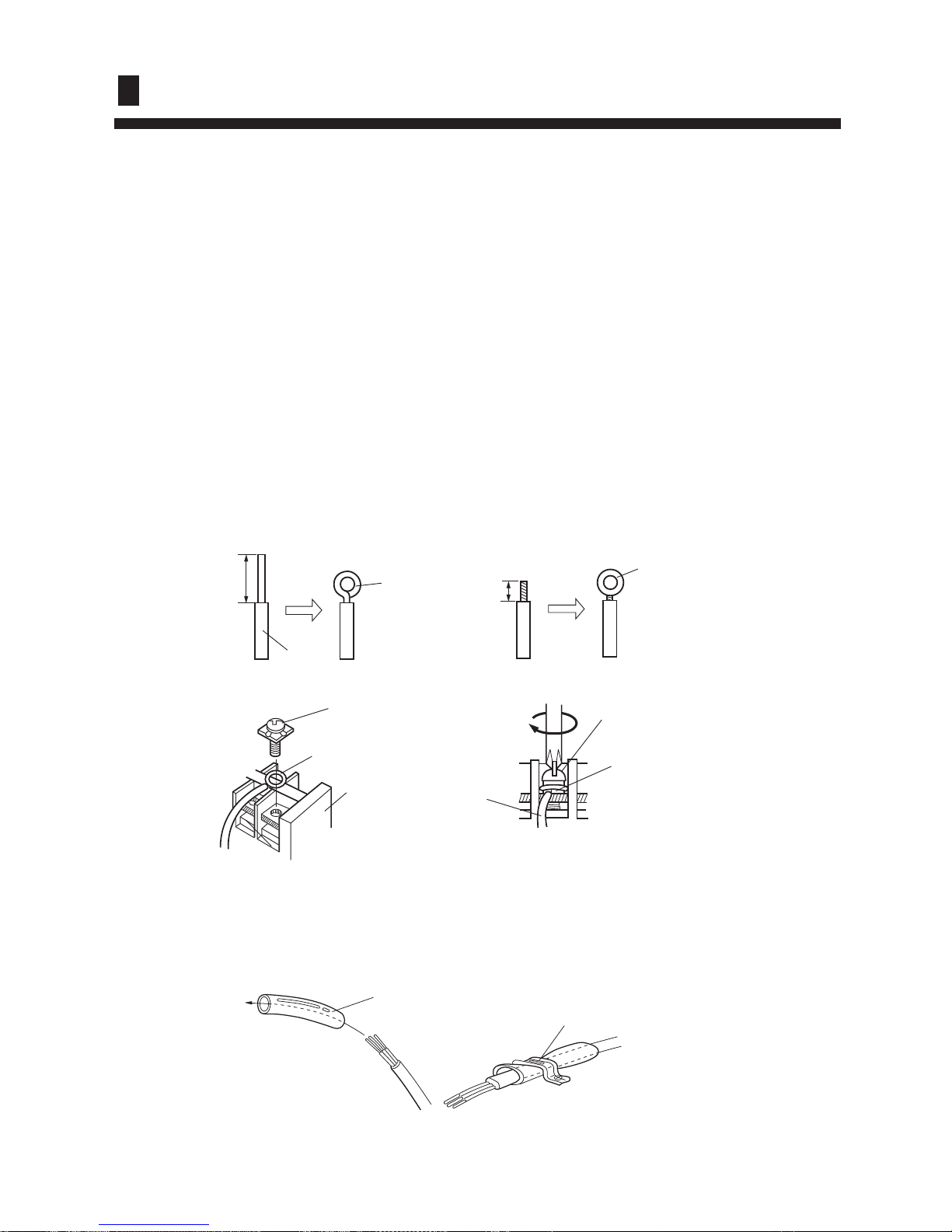

HOW TO CONNECT WIRING TO THE TERMINALS

A. For solid core wiring (or F-cable)(Fig.24A)

(1) Cut the wire with a wire cutter or wire-cutting pliers, then strip the insulation to about 25mm of the

exposed solid wire.

(2) Using a screwdriver, remove the terminal screw(s) on the terminal board.

(3) Using pliers, bend the solid wire to form a loop suitable for the terminal screw.

(4) Shape the loop wire properly, place it on the terminal board and tighten securely with the terminal

screw using a screw driver.

B. For strand wiring(Fig.24B)

(1) Cut the wire with a wire cutter or wire-cutting pliers, then strip the insulation to about 10mm of the

exposed strand wiring.

(2) Using a screwdriver, remove the terminal screw(s)on the terminal board.

(3) Using a round terminal fastener or pliers, securely clamp a round terminal to each stripped wire end.

(4) Position the round terminal wire, and replace and tighten the terminal screw using a screw driver.

After passing the connection cord and power cable through the insulation tube, fasten it with the cord

clamp, as shown in Fig.25

HOW TO FIXED CONNECTION CORD AND POWER CABLE AT

THE CORD CLAMP

Fig. 25

Insulation tube

Cord clamp

Use VW-1, 0.5 to 1.0 mm thick, PVC tube as the insulation tube.

Fig. 24

Insulation

Strip 25mm

Loop

A. Solid wire

Terminal

board

Screw with

special washer

Round

terminal

Wire

Screw with

special washer

Round

terminal

Wire

Strip 10mm

Round

terminal

B. Strand wire

-25-

Installation of the Indoor Unit

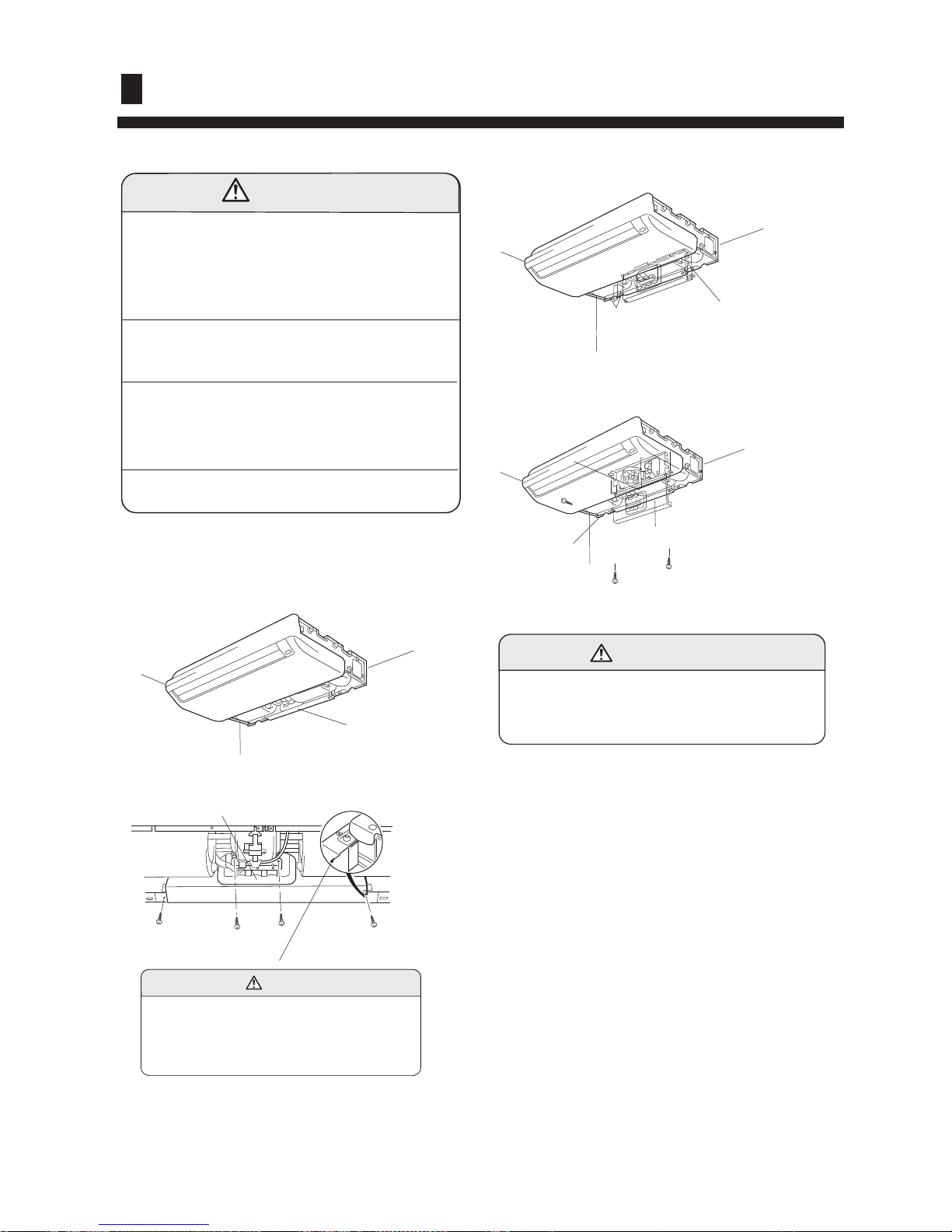

ELECTRICAL WIRING

1. INDOOR UNIT SIDE

(1) Remove the electric component box.

(2) Pull out the electric component box.

(3) Remove the electric component box cover.

Remove the three tapping screws.

(1) Remove the cord clamp.

(2) Process the end of the connection cords to the

dimensions shown in Fig.34.

(3) Connect the end of the connection cord fully into the

terminal block.

(4) Wiring

(4) Fasten the connection cord with a cord clamp.

(5) Fasten the end of the connection cord with the

screw.

Be careful not to pinch the lead wires between the

electric component box and base.

CAUTION

(1) Match the terminal block numbers and connection

cord colors with those of the outdoor unit.

Erroneous wiring may cause burning of the electric

parts.

(2) Connect the connection cords firmly to the terminal

block. Imperfect installation may cause a fire.

(3) Always fasten the outside covering of the connection

cord with the cord clamp.(If the insulator is chafed,

electric leakage may occur.)

(4) Always connect the ground wire.

Do not remove the screws. If the screws

are removed, the electric component box

will fall.

Fig. 26

Electric component box

Remove the four tapping

screws.

Fig. 27

Electric component box

CAUTION

Fig.28

Electric component box

Fig. 29

Base

Electric component box cover

CAUTION

-26-

Installation of the Indoor Unit

41Vebob ^ob qtl jbqelap ql pbq qeb `ljjrkf`^qflk ^aaobpp

C1Wpbqebobjlqb`lkqoliibo -abc^riqpq^qrpfkcfopqfkpq^ii^qflk.1

D1 Wpb afm ptfq`ebp lk qeb fkallo rkfq RED1

METHOD 1: Address setting procedure using the infrared remote controller YR-H71.

C1 Ubq qeb ^aaobppbp lkiv ^cqbo qeb pr``bppcri fkpq^ii^qflk lc qeb obcofdbo^kq mfmbp ^ka `lkkb`qfkd `^_ibp/ ^ka

lmbk ^ii qeb pqlm s^isbp>

D1 Rib^pb `lkcfoj qe^q qeb fkallo rkfqp ^ka qeb lrqallo rkfq fk qeb p^jb pvpqbj rpb qeb p^jb mltbo plro`b>

E1 Rltbo lk qeb rkfqp/ _rq mrq ^ii qeb fkallo rkfqp fk qeb pq^qrp lc UVCPFD[>

F1 Rib^pb klqb qe^q qeb ^aaobpp jrpq _b pbq ^p cliiltfkd=

Q[U\\] `[X_ _WR_ T\[[VT_ _\ aRYaV MG _WV RUU]V^^ Z`^_ SV HL

Q[U\\] `[X_ _WR_ T\[[VT_ _\ aRYaV NG _WV RUU]V^^ Z`^_ SV IL

Q[U\\] `[X_ _WR_ T\[[VT_ _\ aRYaV OG _WV RUU]V^^ Z`^_ SV JL

Q[U\\]`[X__WR_T\[[VT__\aRYaVPG_WVRUU]V^^Z`^_SVKL

ð

IMPORTANT: Indoor Unit communication address setting

FDVULQP8IDLNUQGQUKLT<UKHVPLUXLNNPQUXQSM>

t Example of wiring for the Indoor Unit

Veb afpq^k`b _bqtbbk qeb pfdk^i tfobp ^ka qeb mltbo `^_bp pelria _b ^q ib^pq 83jj1

E

DC

S

R

4-N. 5-P. 5-P.4-N.

R

S

CD

E

L N C1(P) C2 (Q)

-Kk `^pb lc rpfkd tfoba

`lkqoliibo YR-E12.

Vl lqebo

fkallo rkfq

Vl tfoba `lkqoliibo

Vl lrqallo rkfq

Eljjrkf`^qflk `^_ib -Uefbia tfob.=

J38TP0H 5Z -31:80418.jj

5

Rltbo `^_ib = J38TP0H 6I -40518.jj

5

G1Gu^jmib=pbqrkfqCql^aaobpp41

Elkqfkrlrpiv mobppqebbjbodbk`v ptfq`eclo^_lrq48pb`lkap/until qeb_rwwbotfiiplrka7qfjbp-RKRKRKRK.

and then release the switch. At this time the indoor unit has entered the address setting procedure. But the LED

display shows nothing.

H1 Wpb qeb `lkqoliibo ql qrok lk qeb fkallo rkfq1 Cq qefp qfjb/ qeb `lkqoliibo pelria _b `e^kdba colj QHH ql

QP/^kaqebkqeb VKOGTNGFciapebplk`b1Ve^qfpqlp^v/qeb^aaobpppbqqfkdfpbk^_iba1

I1Robppqeb_rqqlk +UNGGR+lkqeb`lkqoliibo/qebqfjbpvlrmobppfqpq^kapcloqeb^aaobppvlrt^kqqlpbq/

abq^fiba ^p cliiltfkd=

Robpp _rqqlk + UNGGR + lk`b/ qeb ^aaobpp fp +4 +/ ^ka qeb VKOGT NGF ci^pebp lk`b>

Robpp _rqqlk + UNGGR + qtf`b/ qeb ^aaobpp fp+5+/^kaqebVKOGT NGF ci^pebp qtf`b>

-27-

61 B``naoo oappejc lnk_a`qna sdaj qoejc pda EJQ osep_dao TX34 ]j` TX361

B1 Uda EJQ osep_dao TX34 ]j` TX36 ]na kj pda ej`kkn qjep QDC1

C1 Cabkna _]nnuejc kqp pda ]``naoo oappejc skng/ pda ouopai iqop ^a lksana` kbb1

D1 U]ga kbb pda bnkjp l]j]h ]j` pda behpano/ pdaj p]ga kbb pda bh]lo ]j` ]hok pda bnkjp _kran/`eo_kjja_p pda osejc

ikpkn _kjja_pkno bnki pda QDC ]j` pdaj p]ga kqp pda hksan l]np kb pda QDC1

E1 Dd]jca pda lkoepekj kb EJQ : kb TX34 bnki PGG pk PO/ eb b]eh pk `k pdeo/ pda ]``naooao oap ^u TX36 sehh

jkp skng1

F1 Voa TX36 pk oap pda ]``naooao ]o bkhhksejc -EP OPU DIBOHF PUIFS EJQ TXJUDIFT.=

71 Iks pk _da_g pda ]``naooaoA

Xdaj bejeod ]hh pda ]^kra skngo/ lha]oa lksan kbb ]j` lksan kj ]c]ej pk pda sdkha ouopai ^qp oap ]hh

pda ej`kkn qjepo ej TUBOECZ1 Udaj _kjpejkqohu lnaoo pda aiancaj_u osep_d qjpeh ukq da]n pda ^qvvan

okqj` 8 peiao-Qe Qe Qe Qe Qe./ ]j` pdaj pda UJNFS MFE ^k]n` sehh odks pda ]``naoo kb pdeo ej`kkn qjep1

Pressing the ON/OFF button on the remote controler will exit the address setting procedure.

Qnaoo ^qppkj + TMFFQ + pdnaa peiao/ pda ]``naoo eo+6+/]j`pdaUJNFS MFE bh]odao pdnaa peiao>

Qnaoo ^qppkj + TMFFQ + bkqn peiao/ pda ]``naoo eo+7+/]j`pdaUJNFS MFE bh]odao bkqn peiao>

I1 Voa pda naikpa _kjpnkhhan pk pqnj kbb pda qjep/ Bp pdeo peia/ pda _kjpnkhhan odkqh` ^a _d]jca` bnki PO pk PGG/

]j` pda qjep sehh atep pda ]``naoo oappejc lnk_a`qna/ pda ]``naoo sehh ^a iaikneva`1 Uda MFE ^k]n` sehh ]hs]uo

`eolh]u pda ]``naoo kb pdeo ej`kkn qjep qjpeh pda ouopai ^a lksana` kbb1

J1 Jb ukq s]jp pk _d]jca pda ]``naoo/ lha]oa nala]p pda ]^kra opalo bnki F pk H1

K1 Bbpan oappejc ]hh pda ]``naooao/ lha]oa lksan kbb pda ouopai ]j` pdaj lksan kj ]c]ej1 Ppdanseoa pda ouopai

sehh jkp op]np pk skng1

L1 Pj_a pda ]``naooao ]na oq__aoobqhhu oap/ lha]oa `k jkp _d]jca ep ]ju ikna pk ]rke` _kjbqoekj1

456789:;

PO

PGG

TX34

TX36

456789:;

PO

PGG

PO

PGG

PO

PGG

JOEPPS

VOJU BEESFTT

4

5

6

456789:;

456789:;

456789:;

PO

PGG

7

-28-

10.2 Trial operation

The person who has completed this installation shall be requested to conduct a test operation for check:

Is the temperature adjuster working normally?

Does the location for installation conform to requirements?

Winding up with Protective Plastic Tape.The connection pipes,drain pipe, and the connection wires shall

be wound up with PVC tape.

Notes: The connection pipes shall also be wound up with insulating material to preserve the temperature.

The airing direction shall be from bottom to top.

10. Installation check and trial operation

Check the Layout of the Drain Pipe and Connection Wires, and also the piping and address setting.

The drain pipe should be placed underneath, and the connection wires should be placed upside;

and the drain pipe especially the section inside the machine and indoors must be wound up with

insulating material to preserve heat. The drain pipe shall be sloped and no concave and convex

shall occur along the whole pipe..

10.1 Installation check

Is power supply voltage required?

Is water completely drained to outdoors?

Are power wire and connection wires between indoor and outdoor units correctly connected?

Is any gas leaked from the pipe connectors?

Are series numbers of the terminals on the indoor and outdoor units corresponding to each other?

Is the connection section of the auxiliary pipe insulated? Is the indoor unit fixed firmly?

Is noise excessive?

-29-

Installation of the Outdoor Unit

Disposal of the old air conditioner

Before disposing an old air conditioner that goes

out of use, please make sure it's inoperative and

safe. Unplug the air conditioner in order to avoid

the risk of child entrapment.

It must be noticed that air conditioner system

contains refrigerants, which require specialized

waste disposal. The valuable materials contained

in a air conditioner can be recycled. Contact your

local waste disposal center for proper disposal of

an old air conditioner and contact your local

authority or your dealer if you have any question.

Please ensure that the pipework of your air

conditioner does not get damaged prior to being

picked up by the relevant waste disposal center,

and contribute to environmental awareness by

insisting on an appropriate, anti-pollution method

of disposal.

Disposal of the packaging of your new air

conditioner

All the packaging materials employed in the

package of your new air conditioner may be

disposed without any danger to the environment.

The cardboard box may be broken or cut into

smaller pieces and given to a waste paper disposal

service. The wrapping bag made of polyethylene

and the polyethylene foam pads contain no

fluorochloric hydrocarbon.

Consult your local authorities for the name and

address of the waste materials collecting centers and

waste paper disposal services nearest to your house.

Safety Instructions and Warnings

Before starting the air conditioner, read the

information given in the User's Guide carefully. The

User's Guide contains very important observations

relating to the assembly, operation and maintenance

of the air conditioner.

The manufacturer does not accept responsibility for

any damages that may arise due to non-observation

of the following instruction.

Damaged air conditioners are not to be put into

operation. In case of doubt, consult your supplier.

Use of the air conditioner is to be carried out in

strict compliance with the relative instructions set

forth in the User's Guide.

Installation shall be done by professional people,

don't install unit by yourself.

All these valuable materials may be taken to a waste

collecting center and used again after adequate

recycling.

For the purpose of safety, the air conditioner must

be properly grounded in accordance with

specifications.

Always remember to unplug the air conditioner

before opening inlet grill. Never unplug your air

conditioner by pulling on the power cord. Always

grip plug firmly and pull straight out from the outlet.

-30-

4. The wiring method should be in line with the local

wiring standard.

5. The power cable and connecting cable are selfprovided. All the cables shall have got the local

authentication certificate. During installation, when

the connecting cables break off, it must be assured

that the grounding wire is the last one to be broken

off.

6. The breaker of the air conditioner should be allpole switch; and the distance between its two contacts

should be no less 3mm. Such means for disconnection

must be incorporation in the fixed wiring.

7. The waste battery shall be disposed properly.

All electrical repairs must be carried out by

qualified electricians. Inadequate repairs may result

in a major source of danger for the user of the air

conditoiner.

Do not damage any parts of the air conditioner

that carry refrigerant by piercing or perforating the

air conditioner's tubes with sharp or pointed items,

crushing or twisting any tubes, or scraping the

coatings off the surfaces. If the refrigerant spurts

out and gets into eyes, it may result in serious eye

injuries.

Do not obstruct or cover the ventilation grille of

the air conditioner. Do not put fingers or any other

things into the inlet/outlet and swing louver.

Do not allow children to play with the air

conditioner. In no case should children be allowed

to sit on the outdoor unit.

Specifications

The refrigerating circuit is leak-proof.

1. Applicable ambient temperature range:

The machine is adaptive in following

situation

2. If the supply cord is damaged, it must be replaced

by the manufacturer or its service agentor a similar

qualified person.

3. If the fuse on PC board is broken please change it

with the type of T 3.15A /250V AC or T 25A/250VAC.

Please check the circuit diagram about the fuse

replaced.

Cooling

Heating

Indoor

Outdoor

Indoor

Outdoor

Maximum:D.B/W.B 32 C/23 C

Minimum:D.B/W.B 18 C/14 C

Maximum:D.B 43 C/26 C

Minimum:D.B

Maximum:D.B 27 C

Minimum:D.B 20 C

Maximum:D.B/W.B 24 C/18 C

Minimum:D.B/W.B -15 C

10 C/6 C

Cautions

-31-

Safety precautions

All units shall be earthed. The earth must not be connected to a gas pipe, water pipe, or telephone

line. Poor earthing could cause electric shock.

Be sure to install a circuit breaker to avoid electric shock.

Arrange water drainage according to this manual. Cover pipe with insulation materials to prevent

condensation occuring. Improper installation of water drainage will cause water leakage.

WARNING

Installation work must be carried out by professional qualified people, do not install the unit by

yourself. Incorrect installation will cause water leakage, electric shock and potentially fire.

Install the unit as per the manual. Incorrect installation will cause water leakage, electric

shock or fire risk.

Be sure to use specified accessories and parts. Otherwise, water leakage, electric shock, fire risk

or unit falling down may occur .

Mounting position must be strong enough to hold the unit. Or, the unit will potentially fall down

causing injuries.

When installing the unit, take in consideration storms and high winds. Incorrect installation may

cause the unit to fall down.

All electric work should be carried out by experienced personnel as per current regulations and

this manual. Incorrect installation or undersized electric cable may cause electric shock or fire risk.

All circuits must be earthed. Ensure that no external forces will affect the terminal block and electric

cable. Poor wiring and installation may cause fire risk.

Arrange wire connection between connecting the indoor and outdoor power supply correctly. Fix

terminal cover firmly to avoid overheating, electric shock or even fire risk.

In the case of a refrigerant leakage during unit installation, keep the room well ventilated.

Check the unit upon installation. Be sure there is no leakage. Refrigerant will induce a poisonous

gas subject to heat.

Isolate power supply before touching terminal block.

WARNING

To ensure proper installation, please read this safety precautions carefully before the installation. After

installation, start the unit correctly and ensure that you show the customer how to operate and maintain

the units.

WARNING!

CAUTION!

Incorrect operations may result in injuries or machine damages; in some cases may

cause serious consequences.

Incorrect operations may result in severe consequences of death or serious injuries.

To maintain good picture or reduce noise, keep the unit at least 1m from T.V. or radio,

when installing the communication wire and power supply. (If the radio wave is relatively strong,

1m is not enough to reduce the interference).

Do not install the unit in following places:

(a) Oil mist or oil gas exists, such as kitchen, or, plastic parts may age, or water leakage.

(b) Where there is corrosive gas. Copper tube and welded part may be damaged due to corrosion

causing leakage.

-32-

(c) Where there is strong radiation. It will affect the unit's control system, causing malfunction of the unit.

(d) Where there are flammable gas, dirt, and volatile matter (thinner, gasoline) exist, these items will cause

a fire risk.

The following accessories are supplied together with the outdoor unit.

580

185

185

380

416

Installation dimensions (mm)

Place, robust not causing vibration, where the weight of the unit can be supported sufficiently.

Place, not affected by heat or steam generated in the vicinity, where inlet and outlet of the unit are not

disturbed.

Place, possible to drain easily, where piping can be connected with the outdoor.

For the indoor units: place where cold air can be spread in a room entirely.

Place, nearby a power receptacle, with enough space around. (Refer to drawings).

For the indoor units: place where the distance of more than 1m from televisions, radios, wireless devices

and fluorscent lamps can be left.

For some indoor units: in the case of fixing the infrared remote controller on a wall, place where the indoor

unit can receive signals when the fluorescent lamps in the room are lightened.

Choose the installation place

No.

1

2

3

Quantity

1

4

1

Name of parts

Drainage elbow

Rubber cushion

Clap

Drawing

Installation accessories

950

830

1068

340

-33-

Before inserting power plug into receptacle, check the voltage without fail. The power source is the

same as the corresponded name plate.

Install an exclusive branch circuit of the power.

A receptacle shall be set up in a distance where the power cable can be reached. Do not extend the

cable by cutting it.

Power source

Outdoor unit capacity class

Piping to each indoor unit

Total length of liquid piping between all units

HCNL 821 XMR

25m max.

60m max.

Limitations on the installation

2. Selecting a location for installation of the indoor units

The maxinum allowable length of refrigerant piping, and the maxmum allowable height

difference between the outdoor and indoor units, are listed below.

(The shorter the refrigerant piping, the better the performance. Connect so that the

piping is as short as possible. Shortest allowable length per room is 3m)

1. Precautions on installation

Check the strength and level of the installation ground so that unit will not cause any operating vibration

or noise after installation.

In accordance with the foundation drawing in fix the unit securely by means of the foundation bolts.

It is best to screw in the foundation bolts unit their length are 20 mm from the foundation surface.

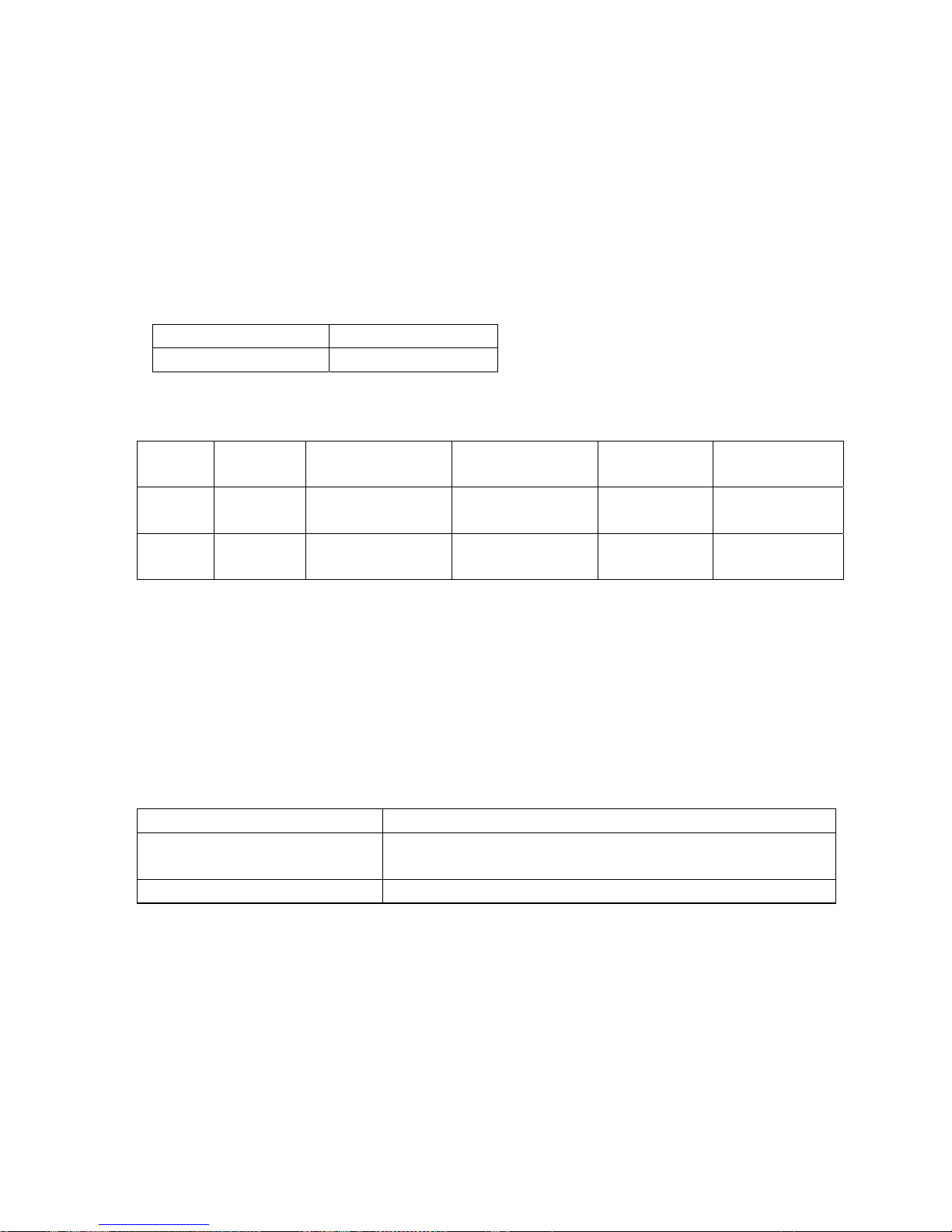

-34-

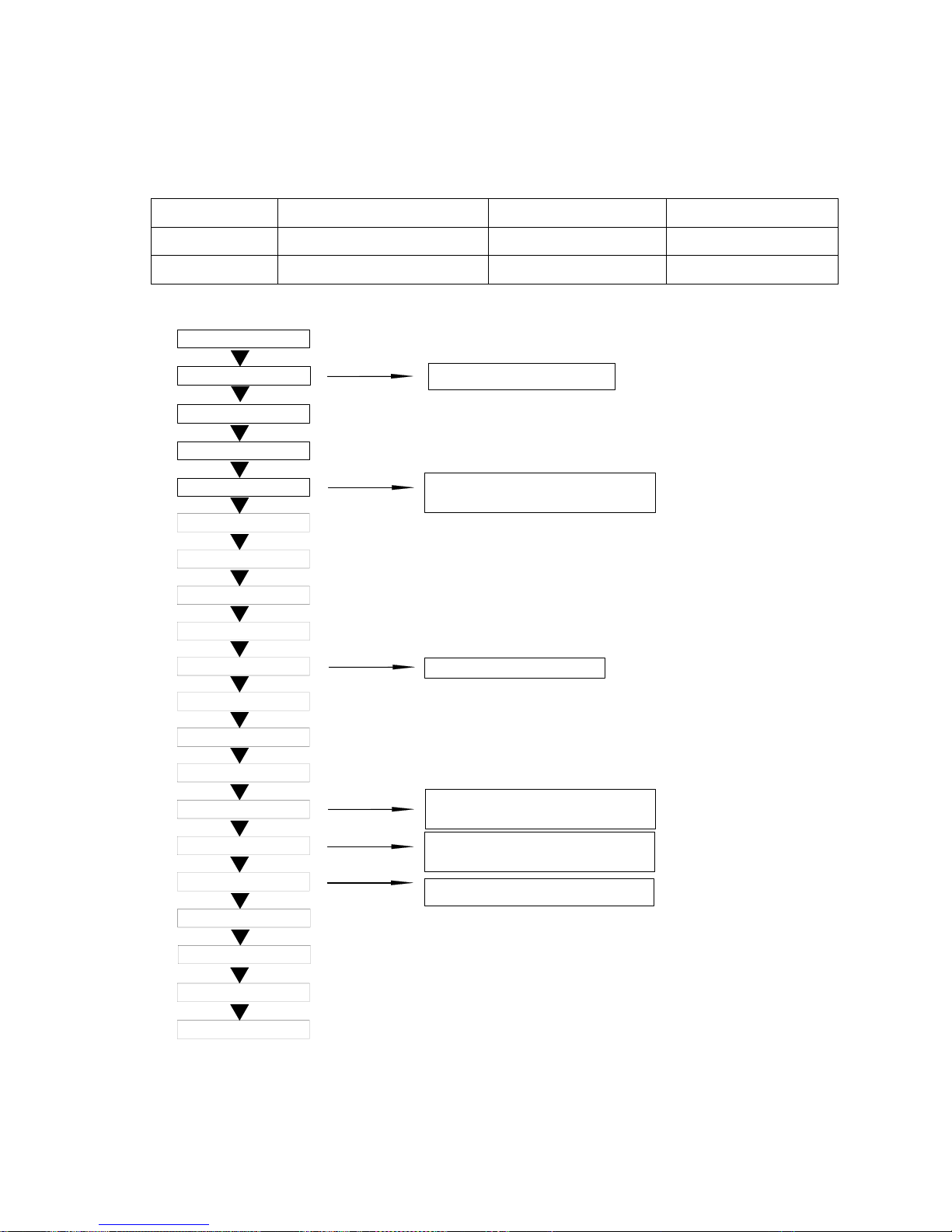

Concerning the piping length information, please refer to the following table.

Descriptions

Standard

A, B, C, D Liquid side

A, B, C, D Gas side

mm

Item

Maximum

Unit

L1 (one way)

L2 (one way)

L3 (one way)

h

H +

H -

mm

m

m

m

m

m

m

Size of the liquid side flare connection

Pipe length when the compressor connects with two indoor units

Drop between every two indoor units

Drop between the outdoor unit and the indoor unit

/

/

Size of the gas side flare connection (*)

Pipe length when the compressor connects with two indoor units

Pipe length when the compressor connects only one indoor unit

Drop between the outdoor unit and the indoor unit

6.35

9.52

L1+L2+L3+L4 m

Total liquid piping length(It is no need to charge additional

refrigerant within this value)

L4 (one way) m Pipe length when the compressor connects only one indoor unit

L1

L2

L4

h

H +

A

B

D

C

L3

1

5

5

10

10

40

10

25

5

15

10

25

25

60

25

Limitations on the installation

H -

10

3. Limitations values on the piping work .

-35

Refrigerant piping work

Forced fastening without careful centering may damage the threads and cause a

leakage of gas.

Pipe Diameter ( ) Fastening Torque

Liquid Side 6.35mm (1/4'')

18N.m

Gas Side 9.52mm (3/8'') 50N.m

3. Attaching Drain-Elbow

If the drain-elbow is used, please attach it as figure.

Flare nutHalf union

Torque wrenchSpanner

Liquid pipe

Gas pipe

6.35mm ( 1/4'' ) x 0.8mm

9.52mm ( 3/8'' ) x 0.8mm

2. Connection of pipe

Apply POE refrigerant oil on half union and flare nut.

To bend a pipe, give the roundness as large as possible not to crush the pipe.

Connecting the pipe of gas side firstly makes working easier.

1. Selection of pipe

To this unit, both liquid and gas pipes shall be insulated as they become low temperature in operation.

Use optional parts for piping set or pipes covered with equivalent insulation material.

-36-

12.7mm ( 1/2'' ) x 0.8mm

Gas Side 12.7mm (1/2'') 55N.m

4. Cutting and Flaring work of piping

Pipe cutting is carried out with a pipe cutter and burs must be removed.

After inserting the flare nut, flaring work is carried out.

Please pour water in the drain pan of the indoor unit, and confirm that drainage is carried out serely

to outdoor.

In case that the attached drain hose is in a room, please apply heat insulation to it without fail.

5. On drainage

Please install the drain hose so as to be downward slope without fail.

Correct

Incorrect

Lean Damage of flare Crack Partial Too outside

Pipe diameter*

Size A (mm)

Liquid side

Gas side

6.35mm(1/4")

9.52mm(3/8")

0.8~1.5

1.0~1.5

A

Flare tooling die

Refrigerant piping work

-37-

Gas side 112.7mm(1/2") 1.0~1.5

In case of gas leakage, tighten

parts of pipe connection. If

leakage stops, then proceed 6

steps.

Purging method: to use vacuum pump

2 way valve

3 way valve

90

0

Service port

90

0

for 6 sec.

6 .Detach the charge hose from the service port, open 2way valve and 3-way. Turn the valve rod anticlockwise

until hitting lightly.

Liquid stop valve

2 way valve

3 way valve

Gas stop valve

Gauge maifold (R410A)

Vacuum pump (R410A)

Open

Close

2 way valve

3 way valve

6

6

2 way valve

3 way valve

Valve rod cap

Valve rod cap

Service port cap

1 .Detach the service port's cap of 3-way valve, the valve

rod's cap for 2-way valve and 3-way valves, connect the

service port into the projection of charge hose (low) for

gaugemanifold. Then connect the projection of charge

hose (center) for gaugemanifold into vacuum pump.

2 .Open the handle at low in gaugemanifold, operate

vacuum pump. If the scale-moves of gauge (low) reach

vacuum condition in a moment, check 1 again.

3 .Vacuumize for over 15min. And check the level gauge

which should read -0.1MPa (-76 cm Hg) at low pressure

side. After the completion of vacuumizing, close the

handle 'Lo' in the vacuum pump. Check the condition of

the scale and hold it for 1-2min. If the scale-moves back

in spite of tightening, make flaring work again, then

return to the beginning of 3 .

4 .Open the valve rod for the 2-way valve to and an angle

of anticlockwise 90 degree. After 6 seconds, close the 2way valve and make the inspection of gas leakage.

5 .No gas leakage?

If it does not stop gas leakage, discharge

whole refrigerants from the service port.

After flaring work again and vacuumize,

fill up prescribed refrigerant from the gas

cylinder.

7 .To prevent the gas leakage, turn the service ports cap,

the valve rod's cap for 2-way valve and 3-way's a little

more than the point where the torque increases suddenly.

CAUTION: If the refrigerant of the air conditioner leaks,

it is necessary to make all the refrigerant out. Vacuumize

first, then charge the liquid refrigerant into air conditioner

according to the amount marked on the name plate.

90

o

10s

6.35mm

(1/4")

2 way valve

3 way valve

2 way valve

3 way valve

9.52mm

(3/8")

6.35mm

(1/4")

9.52mm

(3/8")

To indoor unit C

To indoor unit D

2 way valve

3 way valve

6.35mm

(1/4")

To indoor unit B

9.52mm

(3/8")

2 way valve

3 way valve

To indoor unit A

6.35mm

(1/4")

9.52mm

(3/8")

8 .Take the same steps from 1 to 7 for each way to

ensure a completely vacuum for the whole system.

with no-return adapter

-38-

1. Electric wiring

Note:

The air conditioner must use special circuit , and wiring by the qualified electrician according to the wiring

rules specified in national standard.

The grounding wire and the neutral wire shall be strictly separated. Connect the neutral wire with grounding

wire is incorrect.

The electric leakage breaker must be installed.

All the electric wire must be copper wire.When wiring,there shall keep a proper distance between the

power line and communication wire to avoid twist together. Otherwise,signal disturbance will occur,and

the air conditioner can not operate normally. Power supply: 1PH, 220-230V~, 50Hz.

The wiring method of power line is Y connection. If the power line is damaged, in order to avoid risk

of electric shock, it must be replaced by the manufacturer or its repair center or other similar qualified

person.The connecting cable must be shielded.

Fuse: T3.15A 250VAC T25A 250VAC (Please check with the outdoor unit wiring diagram.)

Please check the circuit diagram about the fuse replaced.

Wiring work

2. Wiring method

Wiring method of orbicular terminals

For the connection wire with orbicular terminals, its wiring method is as shown in

the right figure: remove the connecting screw, put the screw through the ring on the

end of the wire, then connect to the terminal block and fasten screw.

Wiring method of straight terminals

For the connection wire without orbicular terminals, its wiring method is: loosen the

connection screw, and insert the end of the connection wire completely into the Terminal block,

then fasten the screw. Slightly pull the wire outwards to confirm it is firmly held.

Crimp connection method for wires without terminals

Wiring method for

ring terminals

Correct pressing

Wrong pressing

Terminal

block

Pressing

clamps

Do not connect the wire

with same diameter to the

same side

Connect the wire with same

diameter to the two sides of

the terminal

Do not connect two

wires with different

diameters

-39-

3. Wiring method of outdoor unit:

Loosen wire cover and connect the power line and communication wire of indoor unit to the terminal

correspondingly.

Note:

When connecting power line to power supply terminal, please pay attention to the following items:

Do not connect the power line with different dimensions to the same connection wire end.

Improper contact will cause heat generation.

Do not connect the power line with different dimensions to the same grounding wire end.

Improper contact will affect protection.

Keep a proper distance between the communication wire and the power line. Otherwise, abnormal

communication will occur because of disturbance. And also, the communication wires should be

shielded wire, and the shield cover should be grounded on the outdoor unit.

Do not connect the power line to the connecting end of communication wire.

Incorrect connection will cause damage to the connected unit.

4. Wiring method of indoor unit

Crimp connection method for connection wire

After connection, the wire must be fastened by wire cover. The wire cover shall press on the protection

coat of the connection wire, as shown in the figure on the previous page.

Note: When connecting the wiring, confirm the terminal number of indoor and outdoor units carefully.

Incorrect wiring will damage the controller of air conditioner or the unit can not operate.

Terminal block

Cord anchorage A

Cord anchorage B

Valve cover

Wiring work

Power line

Remove the repair board of the outdoor unit and loosen the wire cover A, then put the live wire, neutral

wire and grounding wire through the wire cover, and connect them to terminal block correspondingly. After connection, fasten wire cover to its previous state.

Communication wire of indoor unit.

Loosen wire cover, put the communication wire through the wire cover B, and connect them to

terminal block correspondingly. After connection, fasten wire cover B to its previous state.

Note: Power lines and communication wires are provided by the Customers themselves.

-40-

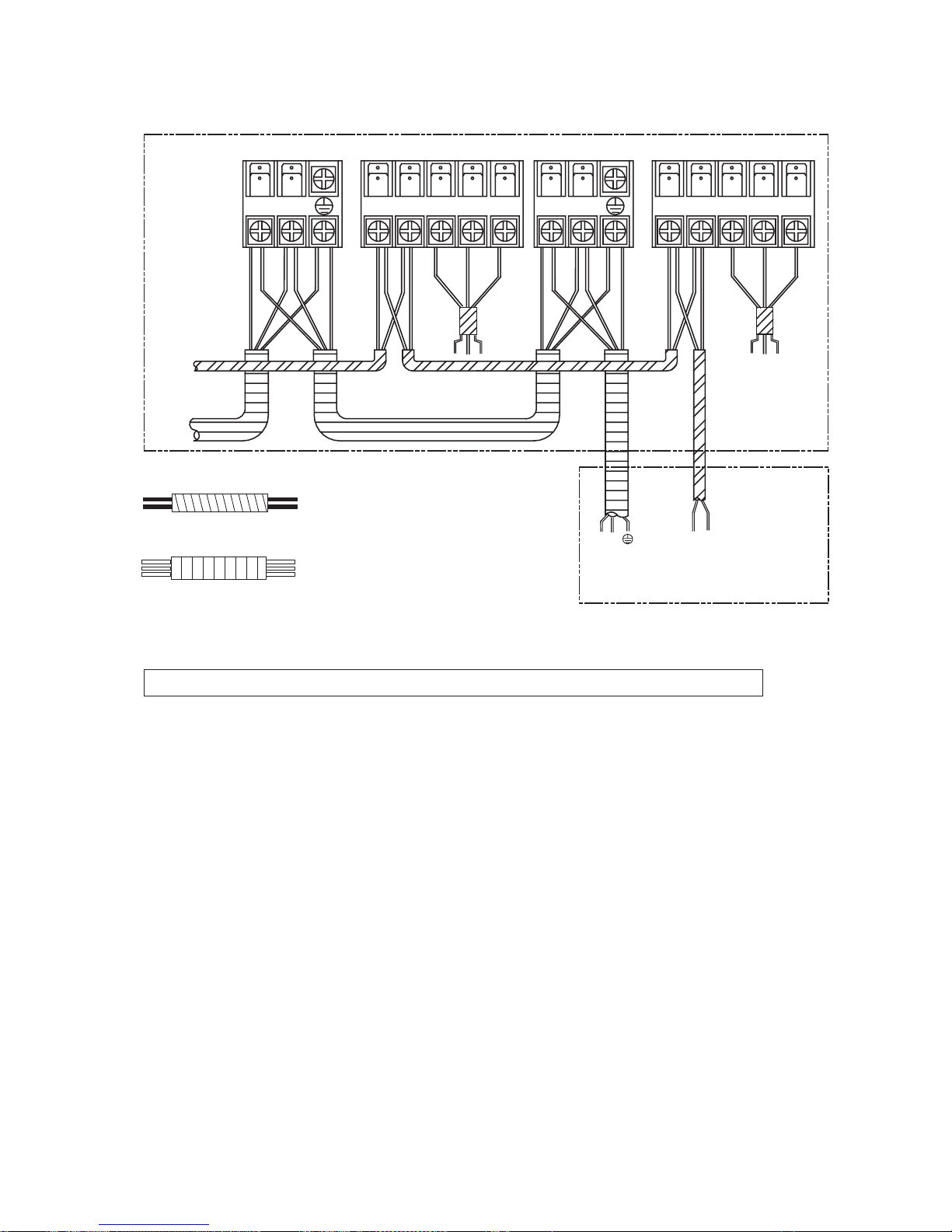

5. Example of wiring diagram.

Please refer to the indoor unit installation manual to find detailly how to set and check the communication

address.

Incorrect address setting will cause abnormal to the system.

6. After installation, please fill in the following table for easy daily maintenance:

Indoor unit NO.

A

B

C

D

Model of indoor unit Serial no.Room name

Wiring work

The distance between the signal wires and the power cables should be at least 50mm.

C

BA

Q

P

1(L) 2(N) 2(N)1(L)

P

Q

AB

C

L N

C1 C2

To other

indoor unit

To outdoor unit

(P , Q)

Waring:

1. Incorrect address setting will cause abnormal to the system.

2. Communication cable must be use shielded type.

Communication cable (Shield wire):

H05RN-F 2X1.5 mm

2

Power cable : H05RN-F 3G 2.5 mm

2

-41-

Items to confirm

Test running

Before starting the test running, please confirm the following works have been done successfully.

1) Correct piping work;

2) Correct wiring work;

3) Correct match of indoor and outdoor unit;

4) Proper recharge of refrigerant if needed;

5) Correct indoor unit addresses setting.

Make sure that all the stop valves are fully open.

Check the voltage supplied to the outdoor and indoor units, please confirm that is 230V.

Test running.

1) If the temperature is lower than 16 OC, it is impossible to test cooling with remote controller, and also

when the temperature is higher than 30 OC, it is impossible to test heating.

2) To test cooling, set the lowest temperature at 16 OC. To test heating, set the highest temperature, at

30OC.

3) Please check both cooling and heating operation of each unit individually and then also check the

simultaneous operation of all indoor units.

4) After ruuning the unit for about 20 minutes, check the indoor unit outlet temperature.

5) After the unit is stopped, or working mode changed, the system will not start again for about 3 minutes.

6) During cooling operation, frost may occur on the indoor unit or pipes, this is normal.

7) Operate the unit according to the operation manual. Please kindly explain to the Customers how to

operate through the Instruction Manual.

Gas leakage from pipe connection?

Heat insulation treatment of pipe connection?

Are the connection wiring of indoor and outdoor unit firmly inserted into the terminal block?

Is the connection wiring of indoor and outdoor firmly fixed?

Is drainage securely arranged?

Is the ground wire securely and firmly connected?

Is power supply voltage abided by electric code?

Is there any noise?

Does cooling perform normally?

Does room temperature regulator operate normally?

Check items for test run, put mark " in ".

-42-

6. Parts and Functions

HSFL 411, 531 XMR (Convertible type) Indoor Units

For the wired control type unit, the unit state should be checked by the the wired

controller, instead of the remote receiver; and if you set the TIMER function, the

TIMER LED on the remote receiver will not be on.

1 Operating Control Panel (Fig.2)

2 Emergency switch

3 Remote Control Signal Receiver

4 Power Indicator Lamp (Red)

5 OPERA TION Indicator Lamp (Green)

6 TIMER Indicator Lamp (Yellow)

7 Compressor Run Lamp (Green)

8 Intake Grill

9 Air Filter

10 UP/DOWN Air Direction Flaps

11 RIGHT/LEFTAir Direction Louvers

(behind UP/DOWN Air Direction Flaps)

3

9

8

Fig.1

1110

1

4

6

7

3

Fig.2

POWER

OPER

TIMER

COMP

EMER

2

5

NOTE

-43-

HCNL 821 XMR Outdoor Unit:

Valves (inside)

Handle

Electric box

Air inlet

Air outlet

Valve guarding plate

Parts and functions

-44-

693HIGH4RO Blkkfe

Tj\[ kf j\c\Zk HIGH fi ROFS fg\iXk`fe3

vu

vv

wu

v}

wv

FQERH

HIGH4RO

SIMEQ

RES

FILSEQ

B

A

HEALSH

QERES

LOCK

RLEEP

FAN

SEMP

ON

OFF

RUING

MODE

CLOCK

CODE

LIGHS

SLL

G

X

W

S

u

v

w

x

z

{

}

ut

uu

uy

uw

y

|

uz

u{

wt

wx

wy

ww

vw

vx

vy

vz

v{

v|

vt

uv

ux

7.

Oial\l`_^jinljgg`l[U=NCA

1.TEMP Setting Button

-Tj\[ kf j\k k\dg\iXkli\3 R\kk`e^ iXe^\j?

6;Ckf85C.

Ie Tg4Dfne ]leZk`fe1 ]fi Zfekifcc`e^ lg Xe[

[fne ]`ck\i3

73RUING Blkkfe

I] pfl gi\jj k_`j Ylkkfe feZ\1 Xlkf jn`e^ n`cc

Y\ XZk`mXk\[3

I] pfl gi\jj k_`j Ylkkfe X^X`e1 k_\ cflm\i n`cc

]`o `e k_\ gi\j\ek gfj`k`fe3

83Pfn\i ON4OFF Blkkfe

Tj\[ ]fi le`k jkXik Xe[ jkfg

A]k\i gfn\i fe1 k_\ LCD f] i\dfk\ Zfekifcc\i

n`cc [`jgcXp k_\ gi\m`flj fg\iXk`fe jkXk\ -\oZ\gk

]fiSIMEQ1 RLEEPXe[RUINGjkXk\.3

93Og\iXk`fe MODE

Tj\[ kf j\c\Zk fg\iXk`fe df[\3

Em\ip k`d\ pfl gi\jj MODE Ylkkfe1 fg\iXk`fe df[\

Z_Xe^\j XZZfi[`e^ kf ]fccfn`e^ j\hl\eZ\?

:3HEALSH Blkkfe

Tj\[ kf j\k _\Xck_ df[\1 `] k_\ le`k _Xj k_\ e\^Xk`m\ `fe

]leZk`fe Xe[ fop^\e YXi ]leZk`fe3

ATSO

FAN

HEAS

COOL

DQW

;3CLOCK Blkkfe

Tj\[ kf j\k Zfii\Zk k`d\3

-Nfk\? `] k`d\ f] SIMEQ ON `j k_\ jXd\ Xj SIMEQ

OFF1 SIMEQON4OFFZXeefkY\j\k.

653QERES Blkkfe

Pi\jj k_`j Ylkkfe Yp lj`e^ X j_Xig Xik`Zc\ kf i\jld\

k_\ Zfii\Zk fg\iXk`fe f] k_\ i\dfk\ Zfekifcc\i `e ZXj\

f] e\\[1 `3\3 ]fi \oXdgc\ `e ZXj\ f] dXc]leZk`fej [l\

kf \c\ZkifdX^e\k`Z ef`j\3

6<3RLEEP Blkkfe

-S_\ ZcfZb dljk Y\ Zfii\Zk\[ Y\]fi\ j\kk`e^ jc\\g

]leZk`fe.

Tj\[ kf j\k jc\\g df[\3

683Tg Xe[ [fne Blkkfe

Tj\[ kf j\k SIMEQ Xe[ CLOCK lg fi [fne3

=3 FILSEQ Blkkfe

Tj\[ kf j\k lg4[fne ]leZk`fe f] ]`ck\i3

RSWKE

1. The functions marked with (*) are not available on HSFL XMR Indoor Units.

73HIGH4RO Ylkkfe

S_`j Ylkkfe `j XZk`mXk\[ `e Cffc`e^4H\Xk`e^ df[\1 k_\ ]Xe jg\\[ `j `e ATSO df[\ X]k\i

gi\jj`e^ `k Xe[ +_`^_ ]leZkfe+ n`cc Y\ ZXeZ\cc\[ XlkfdXk`ZXccp X]k\i 6: d`elk\j ilee`e^3

663LOCK Blkkfe

Tj\[ kf cfZb fg\iXk`fe Ylkkfe Xe[ LCD [`jgcXp

Zfek\ekj? Yp gi\jj`e^ k_`j Ylkkfe1 fk_\i Ylkkfej Zfd\j

flkf]]leZk`feXe[cfZbjkXk\[`jgcXpXgg\Xij@`]pflgi\jj

`k X^X`e1 cfZb jkXk\ n`cc Y\ ef dfi\ XZk`m\ Xe[ cfZb jkXk\

[`jgcXp n`cc [`jXgg\Xi3

<3CLOCK Blkkfe

Tj\[ kf j\c\Zk SIMEQ ON1 SIMEQ OFF3

>3 CODE Blkkfe

Tj\[ kf j\c\Zk Zf[\ A fi B1 ]fi k_\ le`kj \oZ\gk

k_Xk n\ i\Zfdd\e[ \jg\Z`Xccp1 k_\ Zf[\ `j A3

u|

673LIGHS Blkkfe

Tj\[kfc`^_kk_\ZfekifcgXe\c-fecp]fiZXY`e\kle`k.

6:3RES Blkkfe

Tj\[ kf Zfe]`id SIMEQ Xe[ CLOCK j\kk`e^j3

6;3FQERH Blkkfe

Tj\[ kf j\k ]i\j_ df[\1 k_\ le`k n`cc [iXn `e ]i\j_ X`i3

u}

wz

-45-

Igj^f V`n

D`jgcXpjn_\e_\Xck_pile]leZk`fe`jj\k3

773SEMPEQASTQE D`jgcXp

893LOCK RkXk\ D`jgcXp

883BASSEQW Ee\i^p D`jgcXp

Nfk`]p k_\ lj\i n_\e `k `j k`d\ kf Z_Xe^\

k_\ YXkk\i`\j3

793HIGH4RO D`jgcXp

7:3RIGNAL RENDING D`jgcXp

7;3FQERH AIQ D`jgcXp

7<3ELECSQICAL HEASING D`jgcXp

7>3HEALSHD`jgcXp

873RLEEP RkXk\ D`jgcXp

863Og\iXk`fe MODE D`jgcXp

ATSO QTN

COOL QTN

DQW QTN HEAS QTN

FAN QTN

8:3FAN RPEED D`jgcXp

783ATSO RUING D`jgcXp

6>3SIMEQOFFD`jgcXp

763FILSEQ D`jgcXp

8;3SIMEQ ON D`jgcXp

U_\e le`k `j jkXik\[ ]fi k_\ ]`ijk k`d\ Xe[ X]k\i i\gcXZ`e^ YXkk\i`\j `e i\dfk\

Zfekifcc\i1 ZcfZb j_flc[ Y\ X[aljk\[ Xj ]fccfnj?

63Pi\jj CLOCK Ylkkfe1 ZcfZb `e[`ZXk`fe f] + AM + fi + PM + ]cXj_\j3

73Pi\jj fi kf j\k Zfii\Zk k`d\3 EXZ_ gi\jj n`cc `eZi\Xj\ fi [\Zi\Xj\

6 d`e3 I] k_\ Ylkkfe `j b\gk gi\jj\[1 k`d\ n`cc `eZi\Xj\ fi [\Zi\Xj\ hl`Zbcp3

83A]k\i k`d\ j\kk`e^ `j Zfe]`id\[1 gi\jj +RES+ ? AM fi PM jkfg ]cXj_`e^1

n_`c\ZcfZbjkXikjnfib`e^3

Nfk\? AMd\Xejdfie`e^Xe[PMd\XejX]k\ieffe3

U_\e fg\iXk`e^ k_\ i\dfk\ Zfekifcc\i `e Xe

Xi\X n_\i\ \c\Zkife`ZXccp Zfekifcc\[ c`^_kj Xi\

`ejkXcc\[ fi n`i\c\jj _Xe[j\kj Xi\ lj\[1 gc\Xj\ dfm\

Zcfj\i kf k_\ `e[ffi le`k Xj k_\ ]leZk`fe f] k_\ i\dfk\

Zfekifcc\i d`^_k Y\ X]]\Zk\[ Yp j`^eXcj \d`kk\[

Yp k_\ XYfm\ d\ek`fe\[ \hl`gd\ekj3

~431

LO

MID

HI

ATSO

U`hjn`Ijinljgg`l Sk`l\ndji

U_\e `e lj\1 [`i\Zk j`^eXc kiXejd`jj`fe

_\X[ kf k_\ i\Z\`m\i gcXZ\[ fe k_\ `e[ffi

le`k

S_\ [`jkXeZ\ Y\kn\\e k_\ i\dfk\ Zfekifcc\i Xe[

k_\ i\Z\`m\i j_flc[ Y\ dXo <d Xe[ k_\i\ j_flc[ Y\

ef fYjkXZc\ Y\kn\\e k_\d3

Df efk k_ifn k_\ i\dfk\ Zfekifcc\i@ gi\m\ek `k

]ifd Y\`e^ [XdX^\[3

6=3FANBlkkfe

To select fan speed: LOW, MID, HIGH, AUTO.

753CLOCKD`jgcXp

853DEHTMIDIFICASION D`jgcXp

7=3Rfd\ fk_\i Ylkkfej

Acc k_\j\ ]leZk`fej Xi\ efk XmX`cXYc\ efn3

FQERH

HIGH4RO

SIMEQ

RES

FILSEQ

HEALSH

QERES

LOCK

RLEEPMODE

CLOCK

CODE

LIGHS

w

v

u

Cfe]`idXk`fe `e[`ZXkfi

I] ef `e[`ZXk`fe `j [`jgcXp\[ X]k\i gi\jj ON4OFF Ylkkfe1

i\cfX[ k_\ YXkk\i`\j3

CXlk`fe?

I] k_\ i\dfk\ Zfekifcc\i [f\j efk fg\iXk\ Xj [\j`^e\[

X]k\i ]`kk`e^ e\n YXkk\i`\j f] k_\ jXd\ kpg\1 gi\jj

k_\ Q\j\k Ylkkfe -dXib\[ . n`k_ X gf`ek\[ Xik`Zc\3

Pj\_dib nc` ]\nn`ls

Eejli\k_XkYXkk\i`\jXi\Zfii\ZkcpgcXZ\[`ek_\ZfdgXikd\ekXji\hl`i\[]figfj`k`m\Xe[e\^Xk`m\k\i-

d`eXcj3

U`kg\^dib nc` ]\nn`ls ^jhk\lnh`in gd_

S_\ YXkk\ip ZfdgXikd\ek c`[ `j i\`ejkXcc\[ `e k_\

i\m\ij\ j\hl\eZ\3

Jdmkg\s l`pd`q

Pi\jj k_\ Ylkkfe kf j\\ `] YXkk\i`\j Xi\ gifg\icp ]`kk\[3

I]ef[`jgcXpXgg\Xij1i\]`kk_\YXkk\i`\j3

BXkk\ip cfX[`e^

BXkk\ip cfX[`e^

BXkk\i`\j Xi\ ]`kk\[ Xj ]fccfnj?

Q\dfm\ k_\ YXkk\ip ZfdgXikd\ek c`[

Rc`^_kcp gi\jj Xe[ [`j\e^X^\ k_\ YXkk\ip ZfdgXikd\ek

c`[ dXib\[ n`k_ + + Xe[ k_\e _fc[ k_\ i\dfk\