TERIDIAN Semiconductor 71M6531 User Manual

71M6531 Demo Board User’s Manual

71M6531 Demo Board

USER’S MANUAL

6/2/2008 5:23:00 PM

v1.5

TERIDIAN Semiconductor Corporation

6440 Oak Canyon Rd., Suite 100

Irvine, CA 92618-5201

Phone: (714) 508-8800 ▪ Fax: (714) 508-8878

http://www.teridian.com/

meter.support@teridian.com

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 1 of 83

v1.5

71M6531 Demo Board User’s Manual

Page: 2 of 83 © 2007-2008 TERIDIAN Semiconductor Corporation v1.5

71M6531 Demo Board User’s Manual

TERIDIAN Semiconductor Corporation makes no warranty for the use of its products, other than expressly contained in the

Company’s warranty detailed in the TERIDIAN Semiconductor Corporation standard Terms and Conditions. The company assumes

no responsibility for any errors which may appear in this document, reserves the right to change devices or specifications detailed

herein at any time without notice and does not make any commitment to update the information contained herein.

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 3 of 83

v1.5

71M6531 Demo Board User’s Manual

71M6531

Single-Phase Energy Meter IC

DEMO BOARD

USER’S MANUAL

Page: 4 of 83 © 2007-2008 TERIDIAN Semiconductor Corporation v1.5

71M6531 Demo Board User’s Manual

Table of Contents

1 GETTING STARTED........................................................................................................................................... 9

1.1 General ............................................................................................................................................................... 9

1.2 Safety and ESD Notes ....................................................................................................................................... 9

1.3 Demo Kit Contents ............................................................................................................................................ 9

1.4 Compatibility .................................................................................................................................................... 10

1.5 Suggested Equipment not Included .............................................................................................................. 10

1.6 Demo Board Test Setup .................................................................................................................................. 10

1.6.1 Power Supply Setup ................................................................................................................................... 12

1.6.2 CABLE for Serial Connection ..................................................................................................................... 13

1.6.3 Checking Operation .................................................................................................................................... 13

1.6.4 Serial Connection Setup for the PC............................................................................................................ 14

1.7 Using the Demo Board .................................................................................................................................... 15

1.7.1 Cycling the LCD Display ............................................................................................................................. 15

1.7.2 Serial Command Line Interface (CLI) ......................................................................................................... 16

1.7.3 Communicating via Intel Hex Records ....................................................................................................... 22

1.7.4 Using the Battery Modes ............................................................................................................................ 24

1.8 Using the Demo Board for Metering Functions ............................................................................................ 25

1.8.1 Modifying Demo Code to CT or SHUNT Mode ........................................................................................... 25

1.8.2 Using the Demo Board in SHUNT and CT Modes ..................................................................................... 25

1.8.3 Adjusting the kh Factor for the Demo Board .............................................................................................. 26

1.8.4 Adjusting the Demo Boards to Different CT Winding Ratios ...................................................................... 27

1.8.5 Adjusting the Demo Boards to Voltage Transformers or Different Voltage Dividers ................................... 27

1.8.6 Wiring of the Demo Board and a Shunt Resistor ........................................................................................ 27

1.9 Calibration Parameters ................................................................................................................................... 30

1.9.1 General Calibration Procedure ................................................................................................................... 30

1.9.2 Updating the 6531_demo.hex file ............................................................................................................... 30

1.9.3 Calibration Macro File ................................................................................................................................ 31

1.9.4 Updating Calibration Data in EEPROM or Flash ........................................................................................ 31

1.9.5 Loading the 6531_demo.hex file into the Demo Board............................................................................... 31

1.9.6 The Programming Interface of the 71M6531 .............................................................................................. 33

1.10 Demo Code ...................................................................................................................................................... 34

1.10.1 Demo Code Description ............................................................................................................................. 34

1.10.2 Accessing LCD and Sleep Modes from Brownout Mode ............................................................................ 34

1.10.3 Demo Code Memory Locations .................................................................................................................. 34

1.11 Emulator Operation ......................................................................................................................................... 41

2 APPLICATION INFORMATION ........................................................................................................................ 43

2.1 Calibration Theory ........................................................................................................................................... 43

2.1.1 Calibration with Three Measurements ........................................................................................................ 43

2.1.2 Calibration with Five Measurements .......................................................................................................... 45

2.1.3 Fast Calibration .......................................................................................................................................... 46

2.2 Calibration Procedures ................................................................................................................................... 47

2.2.1 General Precautions ................................................................................................................................... 47

2.2.2 Calibration Procedure with Three Measurements ...................................................................................... 48

2.2.3 Calibration Procedure with Five Measurements ......................................................................................... 48

2.2.4 Procedure for Auto-Calibration ................................................................................................................... 49

2.2.5 Calibration Spreadsheets ........................................................................................................................... 49

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 5 of 83

v1.5

71M6531 Demo Board User’s Manual

2.2.6 Compensating for Non-Linearities .............................................................................................................. 51

2.2.7 Calibrating Meters with Combined CT and Shunt Resistor ........................................................................ 51

2.3 Calibrating and Compensating the RTC ........................................................................................................ 54

2.4 Testing the Demo Board ................................................................................................................................. 55

2.4.1 Functional Meter Test ................................................................................................................................. 55

2.4.2 EEPROM .................................................................................................................................................... 56

2.4.3 RTC ............................................................................................................................................................ 57

2.4.4 Hardware Watchdog Timer ........................................................................................................................ 57

2.4.5 LCD ............................................................................................................................................................ 57

2.4.6 Supply Current Measurements ................................................................................................................... 58

2.5 TERIDIAN Application Notes .......................................................................................................................... 58

3 HARDWARE DESCRIPTION ............................................................................................................................ 59

3.1 Demo Board Description: Jumpers, Switches, Test Points and Connectors ............................................ 59

3.2 Demo Board Hardware Specifications ........................................................................................................... 63

4 APPENDIX ........................................................................................................................................................ 65

4.1 71M6531N12A2 Demo Board Electrical Schematic ...................................................................................... 66

4.2 71M6531N12A2 Demo Board Bill of Material ................................................................................................. 69

4.3 71M6531N12A2 Demo Board PCB Layout ..................................................................................................... 70

4.4 Debug Board Bill of Material .......................................................................................................................... 75

4.5 Debug Board Schematics ............................................................................................................................... 76

4.6 Debug Board PCB Layout ............................................................................................................................... 77

4.7 TERIDIAN 71M6531 Pin-Out Information ....................................................................................................... 80

4.8 Revision History .............................................................................................................................................. 83

List of Figures

Figure 1-1: Demo Board: Basic Connections ............................................................................................................... 10

Figure 1-2: Demo Board: Ribbon Cable Connections .................................................................................................. 11

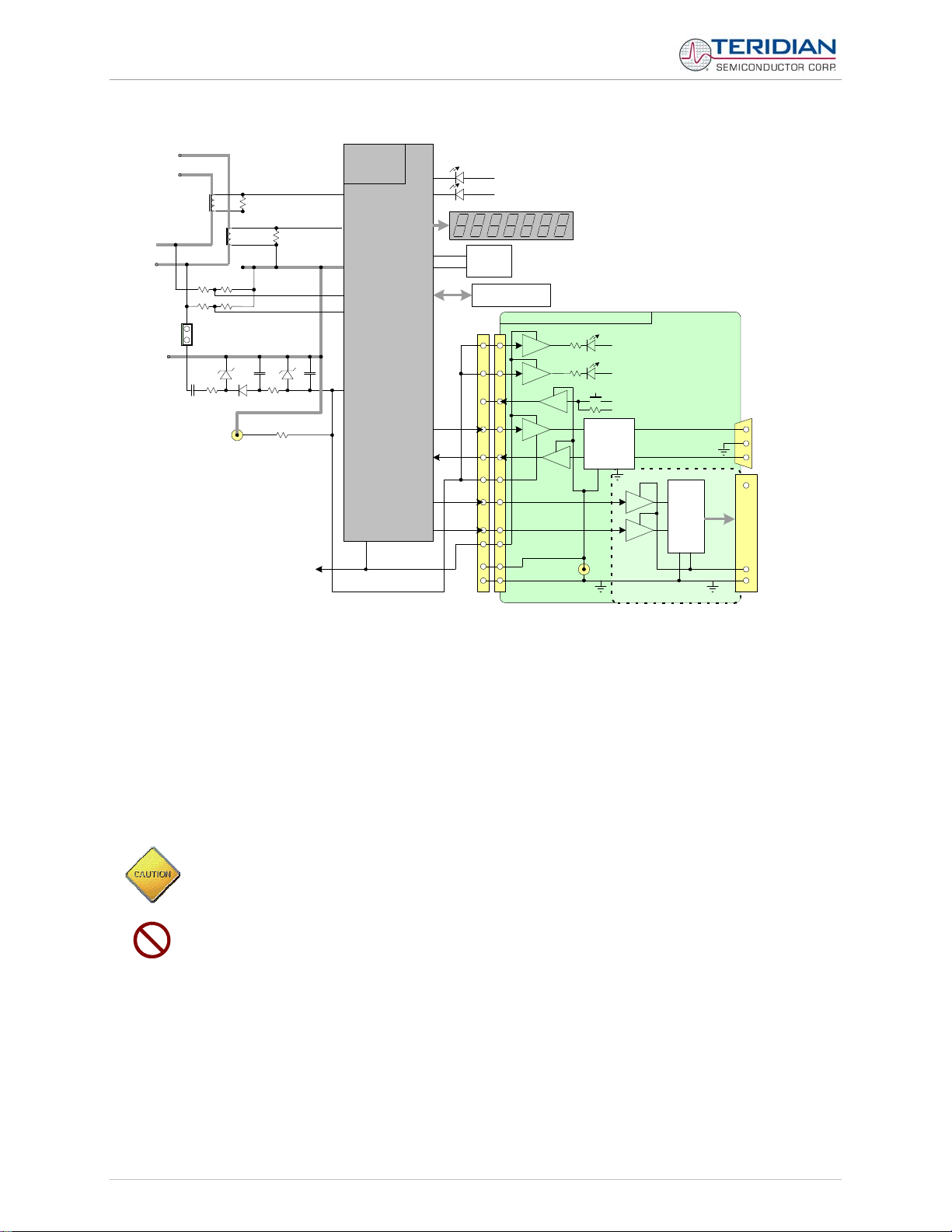

Figure 1-3: The TERIDIAN 6531 Demo Board with Debug Board Block Diagram (CT Configuration) ......................... 12

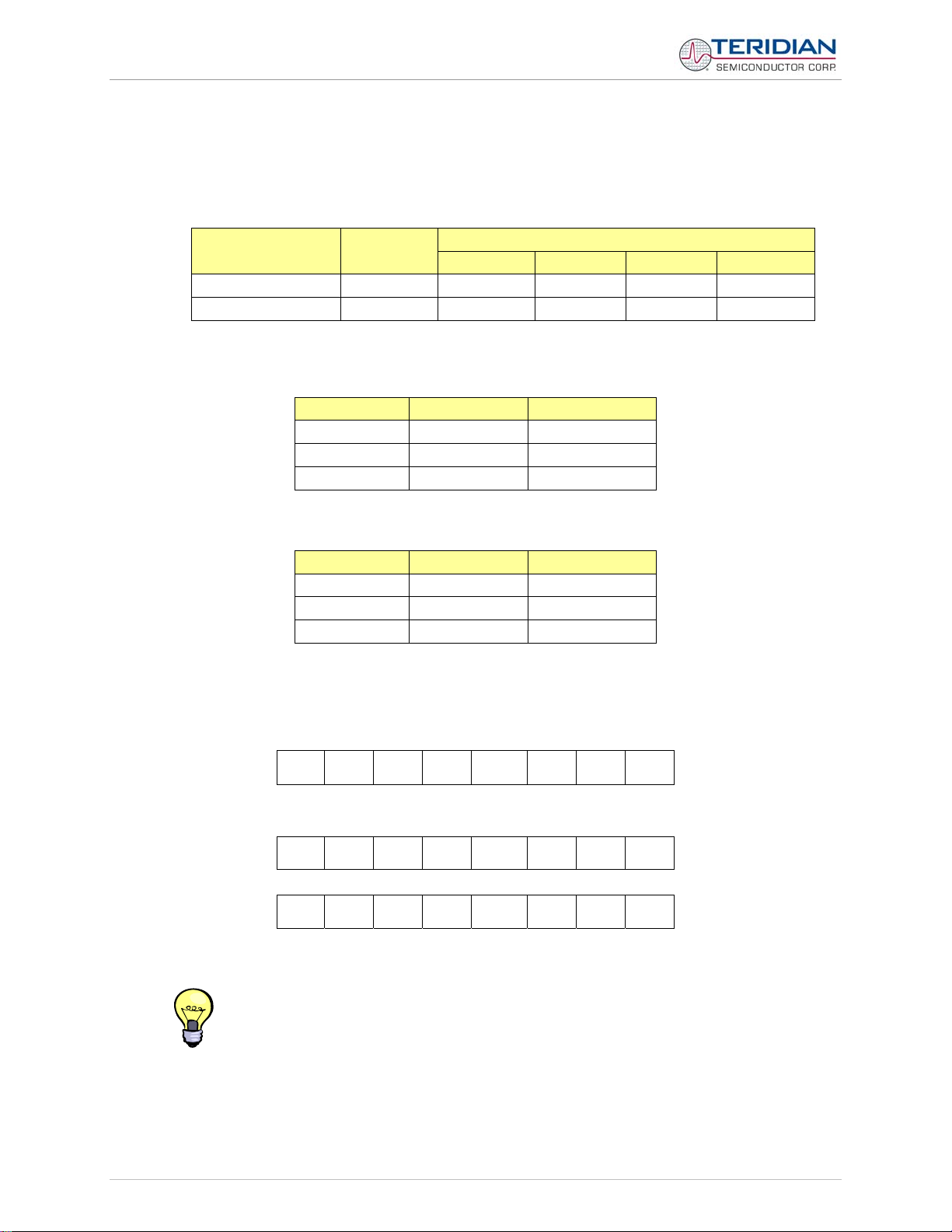

Figure 1-4: Port Configuration Setup ............................................................................................................................ 14

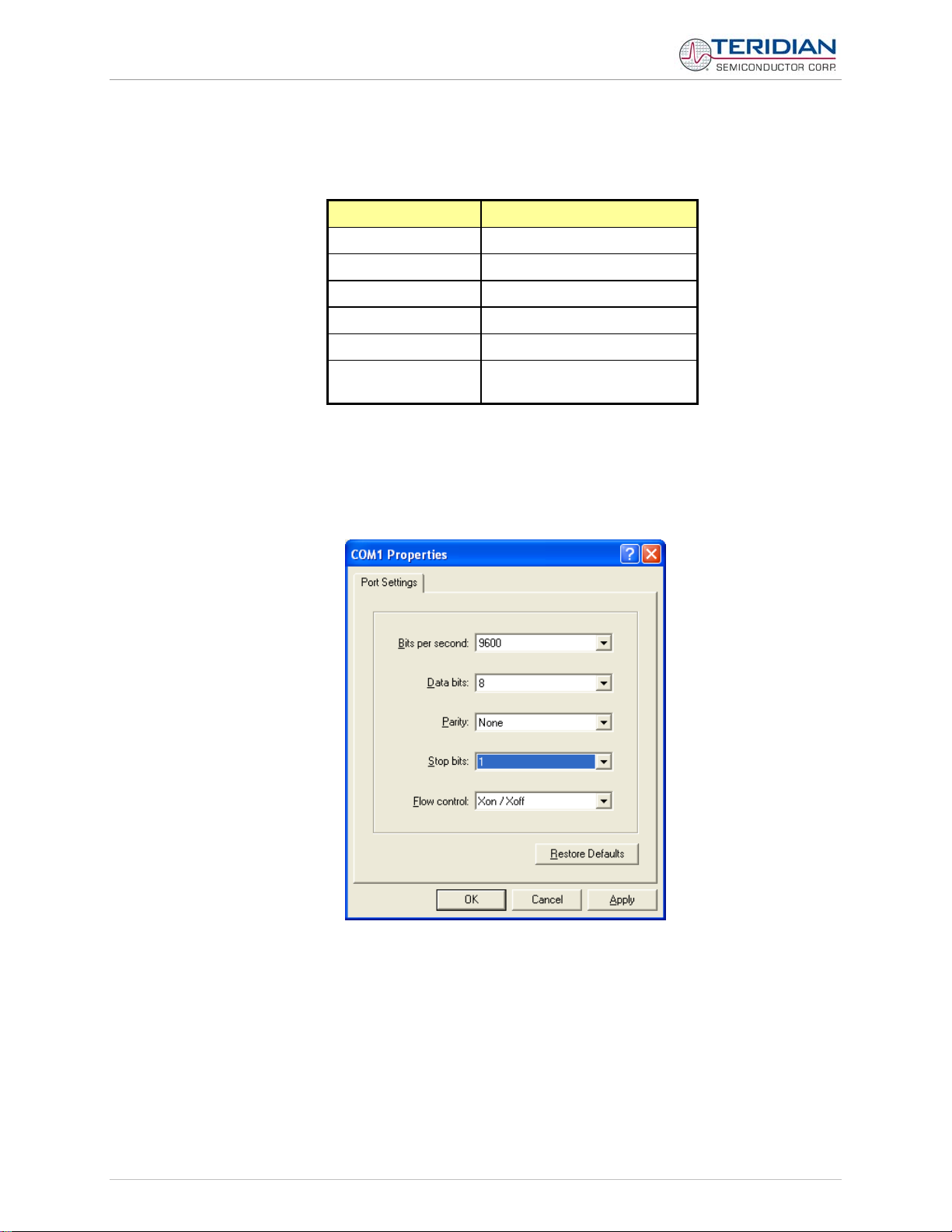

Figure 1-5: Hyperterminal Sample Window with Disconnect Button ............................................................................ 15

Figure 1-6: Pre-wired shunt resistor ............................................................................................................................. 28

Figure 1-7: Connection of the Pre-Wired Shunt Resistor ............................................................................................. 29

Figure 1-8: Typical Calibration Macro file ..................................................................................................................... 31

Figure 1-9: Emulator Window Showing Reset and Erase Buttons ............................................................................... 32

Figure 1-10: Emulator Window Showing Erased Flash Memory and File Load Menu .................................................. 32

Figure 2-1: Watt Meter with Gain and Phase Errors. ................................................................................................... 43

Figure 2-2: Phase Angle Definitions ............................................................................................................................. 47

Figure 2-3: Calibration Spreadsheet for Three Measurements .................................................................................... 49

Figure 2-4: Calibration Spreadsheet for Five Measurements ....................................................................................... 50

Figure 2-5: Calibration Spreadsheet for Fast Calibration ............................................................................................. 50

Figure 2-6: Non-Linearity Caused by Quantification Noise .......................................................................................... 51

Figure 2-7: 71M6531 with Shunt and CT ..................................................................................................................... 52

Figure 2-17: Meter with Calibration System ................................................................................................................. 56

Figure 2-18: Calibration System Screen ...................................................................................................................... 56

Figure 3-1: 71M6531N12A2 Board Connectors, Jumpers, Switches, and Test Points ................................................ 62

Figure 4-1: 71M6531N12A2 Demo Board (REV 2.0): Electrical Schematic 1/3 – Shunt Configuration ....................... 66

Figure 4-2: 71M6531N12A2 Demo Board (REV 2.0): Electrical Schematic 2/3 – CT Configuration ............................ 67

Figure 4-3: 71M6531N12A2 Demo Board (REV 2.0): Electrical Schematic 3/3 – Digital Section ................................ 68

Figure 4-4: 71M6531N12A2 Demo Board: Top Silk Screen ......................................................................................... 70

Page: 6 of 83 © 2007-2008 TERIDIAN Semiconductor Corporation v1.5

71M6531 Demo Board User’s Manual

Figure 4-5: 71M6531N12A2 Demo Board: Top Copper Layer ..................................................................................... 71

Figure 4-6: 71M6531N12A2 Demo Board: Bottom View with Silk Screen ................................................................... 72

Figure 4-7: 71M6531N12A2 Demo Board: Bottom Copper Layer – Bottom View ........................................................ 73

Figure 4-8: 71M6531N12A2 Demo Board: Bottom Copper Layer – Layer View from Top ........................................... 74

Figure 4-9: Debug Board: Electrical Schematic ........................................................................................................... 76

Figure 4-10: Debug Board: Top View ........................................................................................................................... 77

Figure 4-11: Debug Board: Bottom View ...................................................................................................................... 77

Figure 4-12: Debug Board: Top Signal Layer ............................................................................................................... 78

Figure 4-13: Debug Board: Middle Layer 1, Ground Plane .......................................................................................... 78

Figure 4-14: Debug Board: Middle Layer 2, Supply Plane ........................................................................................... 79

Figure 4-15: Debug Board: Bottom Trace Layer .......................................................................................................... 79

Figure 4-16: TERIDIAN 71M6531 LQFP64: Pinout (top view) ..................................................................................... 82

List of Tables

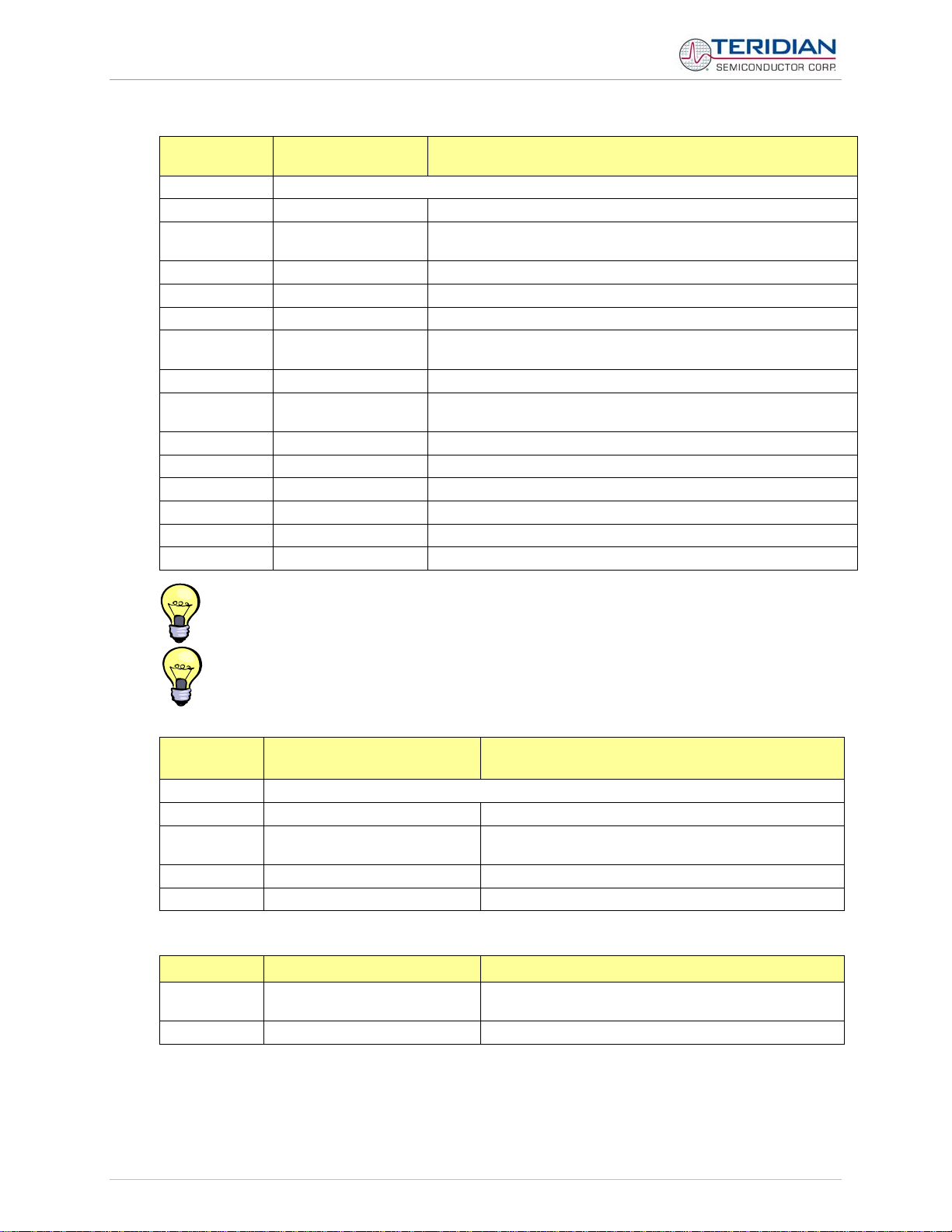

Table 1-1: Jumper settings on Debug Board ................................................................................................................ 13

Table 1-2: Straight cable connections .......................................................................................................................... 13

Table 1-3: Null-modem cable connections ................................................................................................................... 13

Table 1-4: COM Port Setup Parameters ...................................................................................................................... 14

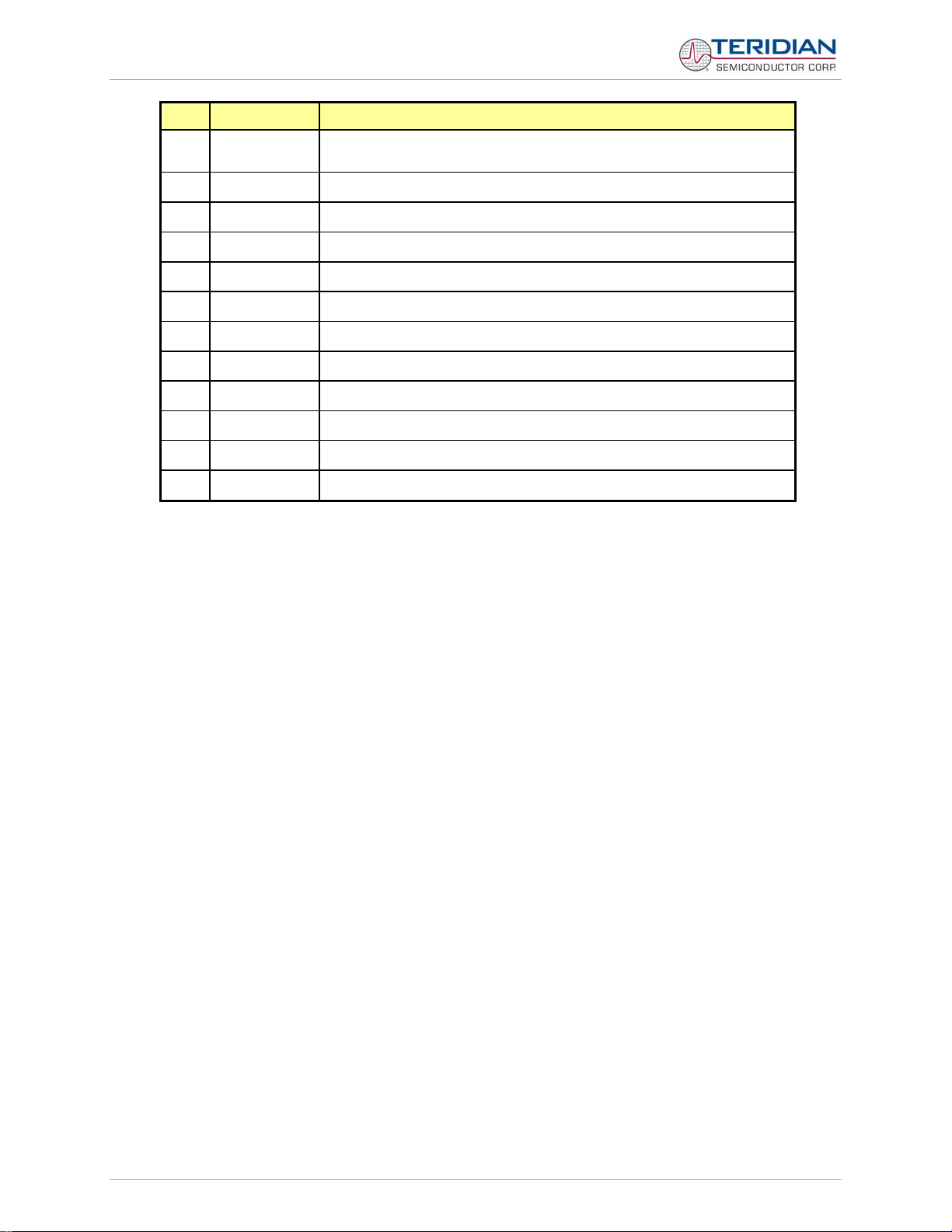

Table 1-5: Selectable Display Options ......................................................................................................................... 16

Table 1-6: Fields of a Hex Record ................................................................................................................................ 22

Table 1-7: Data (command) types ................................................................................................................................ 23

Table 1-8: Hex Record examples ................................................................................................................................. 23

Table 1-9: Pre-assembled hex records ........................................................................................................................ 24

Table 1-10: XRAM Locations for Calibration Constants ............................................................................................... 30

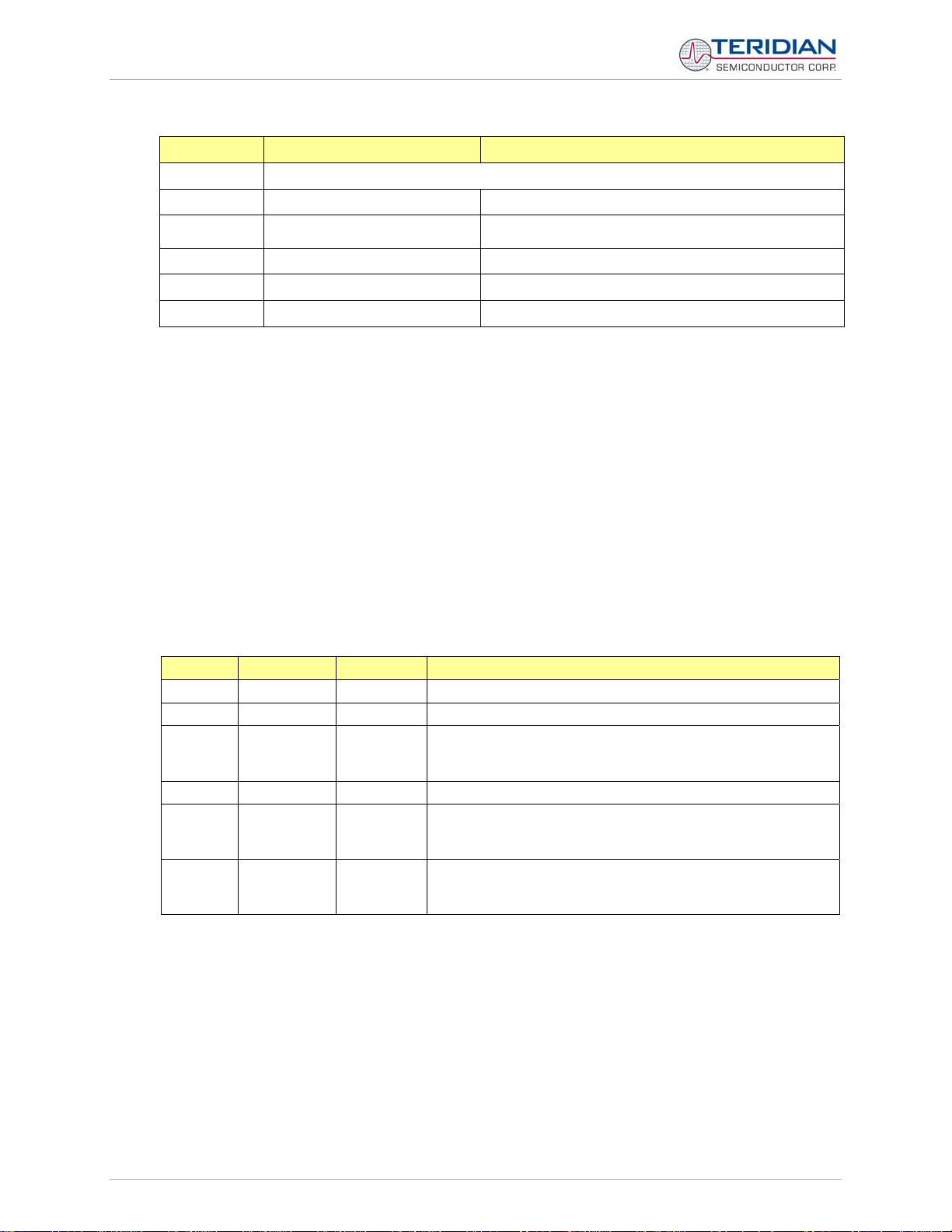

Table 1-11: Flash Programming Interface Signals ....................................................................................................... 33

Table 1-12: MPU memory locations ............................................................................................................................. 38

Table 1-13: Values for Pulse Source Registers............................................................................................................ 39

Table 1-14: STATUS register ......................................................................................................................................... 40

Table 1-15: MPU Accumulation Output Variables ........................................................................................................ 41

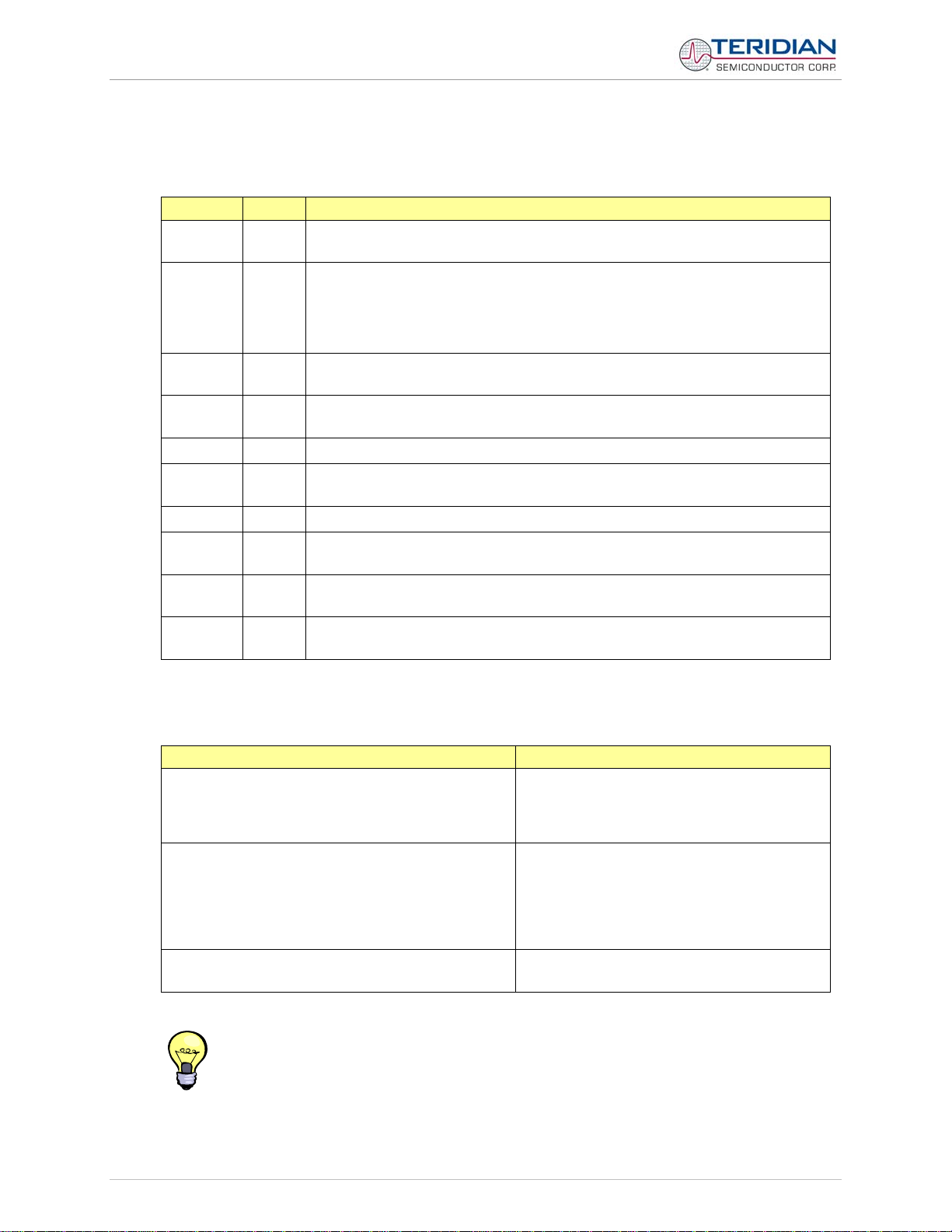

Table 2-1: Calibration Summary ................................................................................................................................... 54

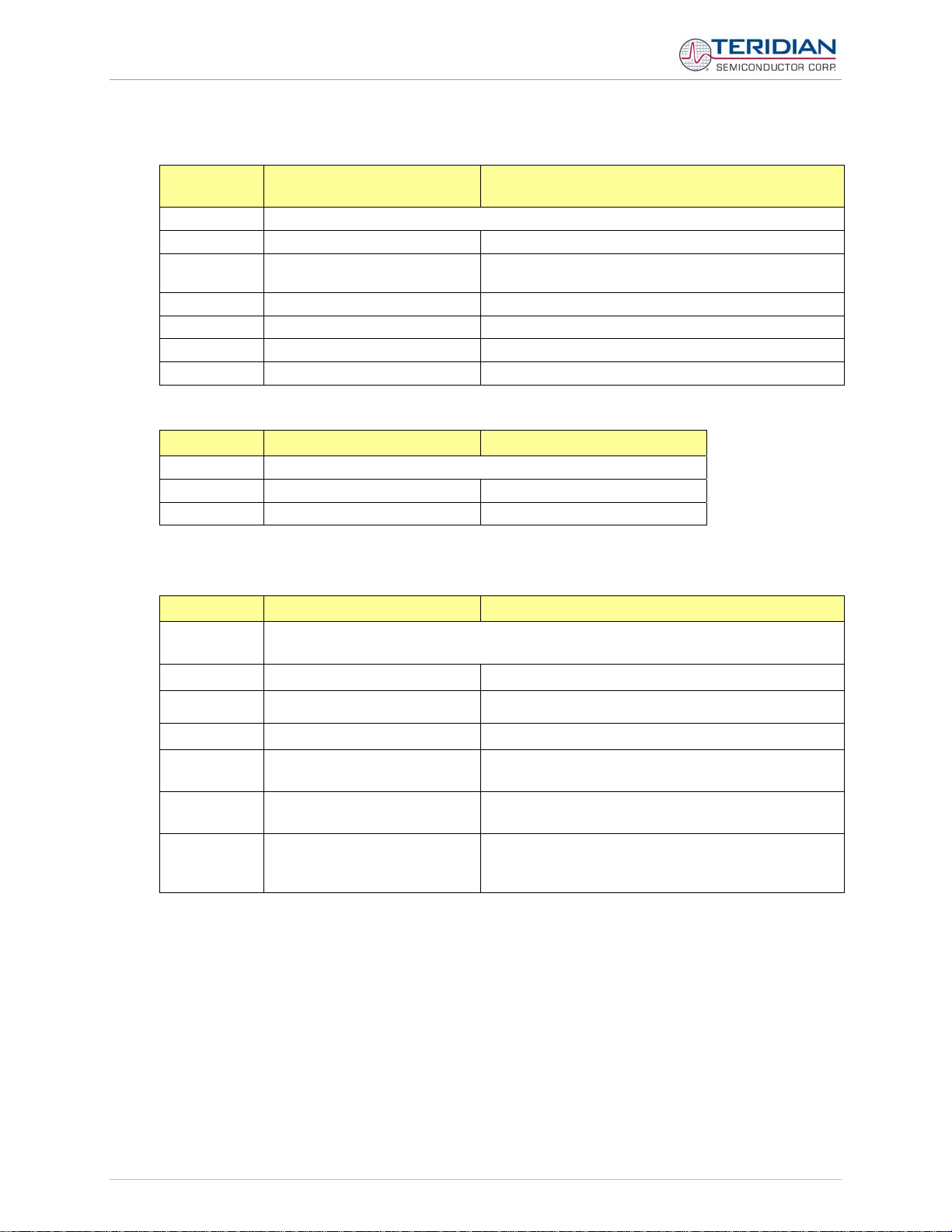

Table 3-1: 71M6531 Demo Board description: 1/3 ....................................................................................................... 59

Table 3-2: 71M6531 Demo Board description: 2/3 ....................................................................................................... 60

Table 3-3: 71M6531 Demo Board description: 3/3 ....................................................................................................... 61

Table 4-1: 71M6531N12A2 Demo Board: Bill of Material (Shunt Version) ................................................................... 69

Table 4-2: Debug Board: Bill of Material ...................................................................................................................... 75

Table 4-3: 71M6531 Pin description 1/2 ....................................................................................................................... 80

Table 4-4: 71M6531 Pin description 2/2 ....................................................................................................................... 82

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 7 of 83

v1.5

71M6531 Demo Board User’s Manual

Page: 8 of 83 © 2007-2008 TERIDIAN Semiconductor Corporation v1.5

71M6531 Demo Board User’s Manual

1

1 GETTING STARTED

1.1 GENERAL

The TERIDIAN Semiconductor Corporation (TSC) 71M6531 Demo Board is an energy meter IC demonstration board for evaluating the 71M6531D/F device for residential electronic energy metering applications. It

incorporates a 71M6531D/F integrated circuit, peripheral circuitry such as a serial EEPROM, emulator port,

and on-board power supply as well as a companion Debug Board that allows a connection to a PC through

a RS232 port. The Demo Board allows the evaluation of the 71M6531D/F energy meter controller chip for

measurement accuracy and overall system use.

The board is pre-programmed with a Demo Program (file name 6531_demo.hex) in the FLASH memory of

the 71M6531D/F IC. This embedded application is developed to exercise all low-level functions to directly

manage the peripherals and CPU (clock, timing, power savings, etc.).

1.2 SAFETY AND ESD NOTES

Connecting live voltages to the Demo Board system will result in potentially hazardous voltages on the

Demo Board.

EXTREME CAUTION SHOULD BE TAKEN WHEN HAN DLING THE DEMO BOARD

ONCE IT IS CONNECTED TO LIVE VOLTAGES!

THE DEMO SYSTEM IS ESD SENSITIVE! ESD PRECAUTIONS SHOULD BE

TAKEN WHEN HANDLING THE DEMO BOARD!

1.3 DEMO KIT CONTENTS

• 71M6531 Demo Board containing 71M6531D/F IC with preloaded Demo Program and prepared for

either CT or shunt resistor operation

• Debug Board

• Shunt resistor with wire harness, 400µΩ (for kits shipped in shunt configuration)

• Two 5VDC/1,000mA universal wall transformers w/ 2.5mm plug (Switchcraft 712A)

• Serial cable, DB9, Male/Female, 2m length (Digi-Key AE1379-ND)

• CD-ROM containing documentation (data sheet, board schematics, BOM, layout), Demo Code, and

utilities

v1.5

Note: The CD-ROM contains a file named readme.txt that specifies all files found on the media and their

purpose.

© 2007-2008 TERIDIAN Semiconductor Corporation

Page: 9 of 83

71M6531 Demo Board User’s Manual

1.4 COMPATIBILITY

This manual applies to the following hardware and software revisions:

• 71M6531D/F, chip revision A03

• Demo Boards D6531N12A2

• Demo Board Code revision 6531_4p6q_12may08_0cc.hex, 6531_4p6q_12may08_0sc.hex (EQU 0) ,

6531_4p6q_12may08_1cc.hex EQU 1), 6531_4p6q_12may08_2cc.hex (EQU 2), or later

1.5 SUGGESTED EQUIPMENT NOT INCLUDED

For functional demonstration:

®

• PC w/ MS-Windows

connector

• One or two current transformers (CTs), preferably 2,000:1 turns ratio

• For software development (MPU code):

• Signum ICE (In Circuit Emulator): ADM-51

• http://www.signum.com

• Keil 8051 “C” Compiler kit: CA51

versions XP, ME, or 2000, equipped with RS232 port (COM port) via DB9

http://www.keil.com/c51/ca51kit.htm

, http://www.keil.com/product/sales.htm

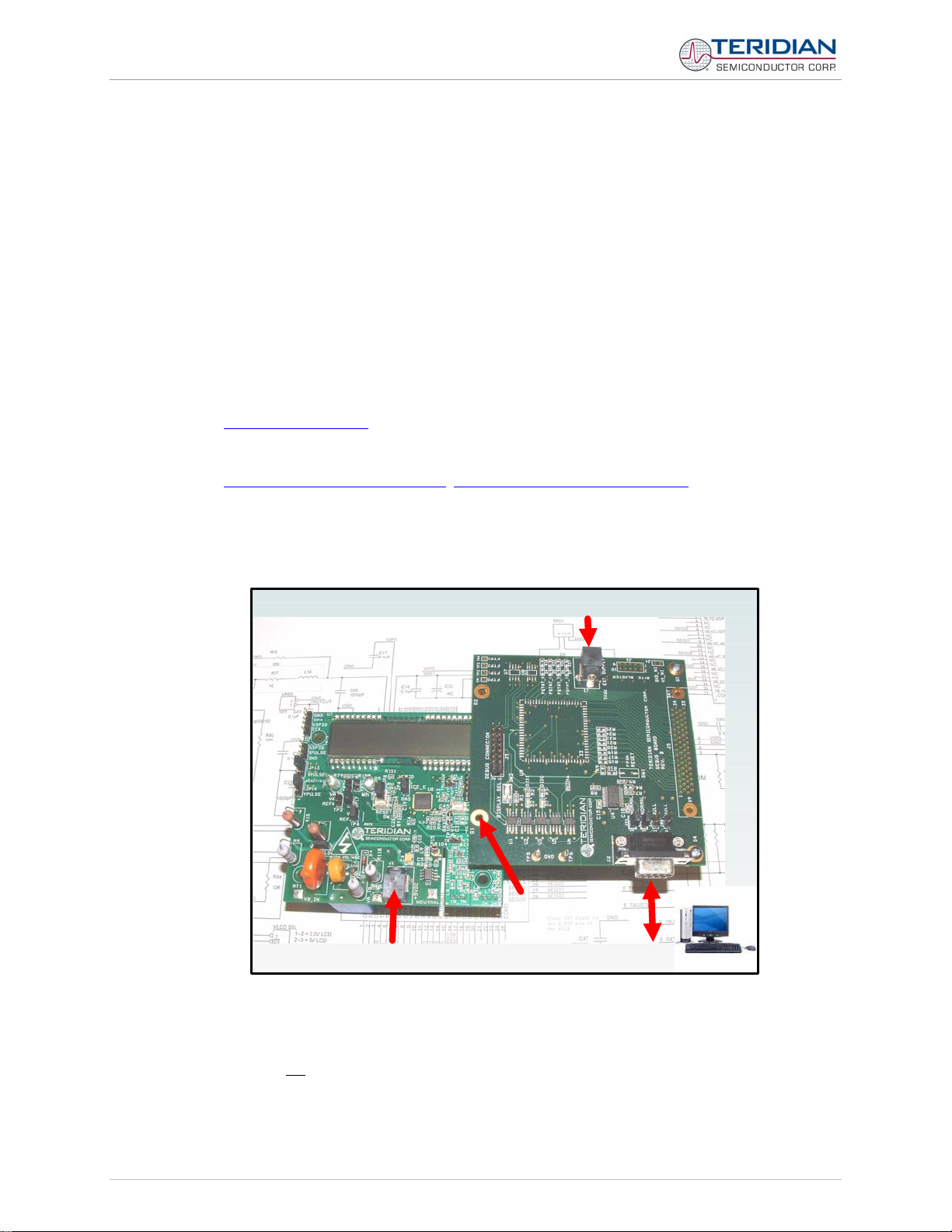

1.6 DEMO BOARD TEST SETUP

Figure 1-1 shows the basic connections of the Demo Boards plus Debug Boards with the external

equipment.

Demo

Board

5VDC Power

Debug

Board

Spacer

removed

5VDC Power

Figure 1-1: Demo Board: Basic Connections

The Debug Board can be plugged into J2 of the Demo Board. One spacer of the Debug Board should be

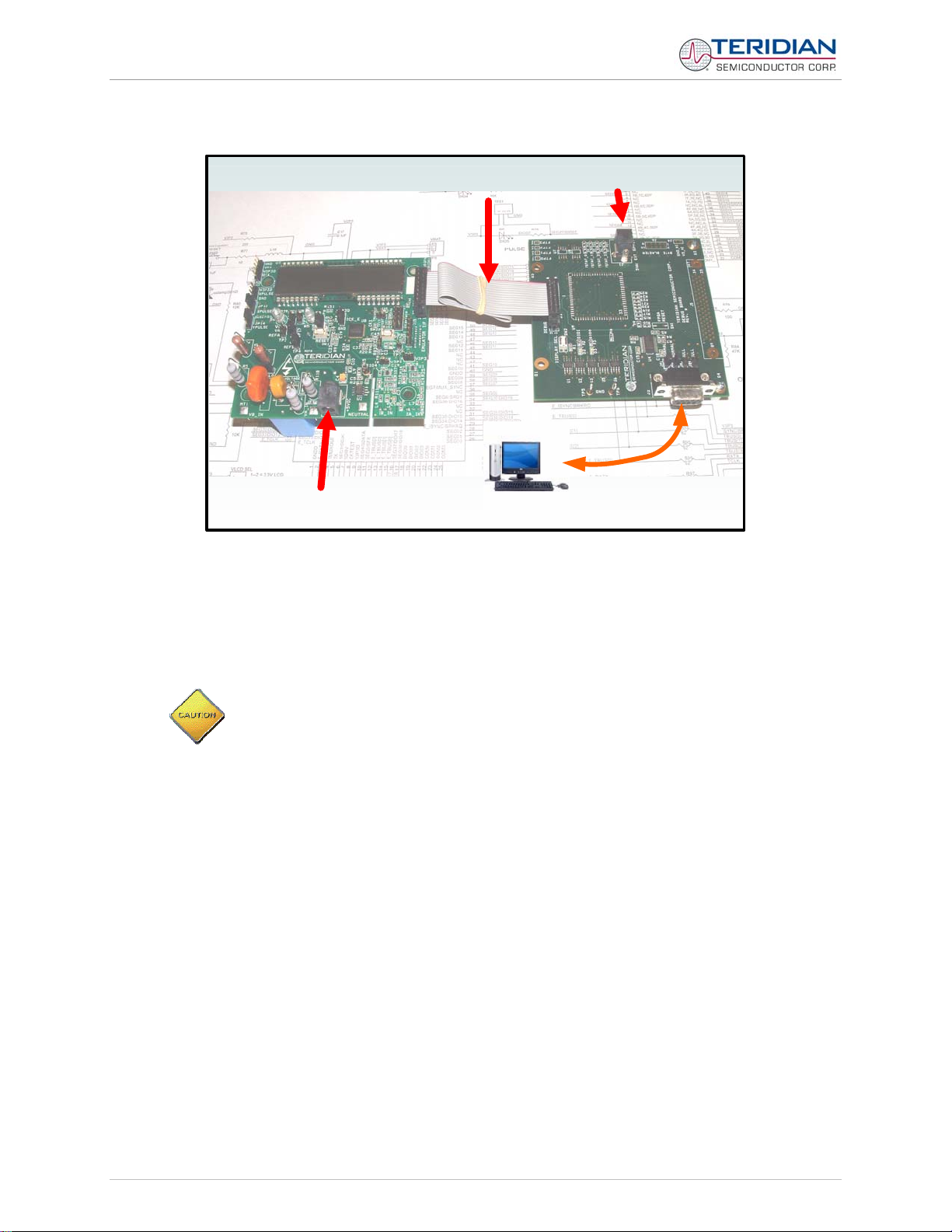

removed, as shown in Figure 1-1. Alternatively, both boards can be connected using a flat ribbon cable, as

shown in Figure 1-2. A male header has to be soldered to J3 of the Debug Board, and the female-to-female

flat ribbon cable is not

Page: 10 of 83 © 2007-2008 TERIDIAN Semiconductor Corporation v1.5

supplied with the Demo Kit (use Digi-Key P/N A3AKA-1606M-ND or similar).

Host PC

71M6531 Demo Board User’s Manual

Ribbon Cable

5VDC Power

Demo

Debug Board

Board

5VDC Power

Figure 1-2: Demo Board: Ribbon Cable Connections

The 71M6531 Demo Board block diagram is shown in Figure 1-3. It consists of a stand-alone meter Demo

Board and an optional Debug Board. The Demo Board contains all circuits necessary for operation as a

meter, including display, calibration LED, and power supply. The Debug Board, when not sharing a power

supply with the meter, is optically isolated from the meter and interfaces to a PC through a 9 pin serial port.

Connections to the external signals to be measured, i.e. scaled AC voltages and current signals derived

from shunt resistors or current transformers, are provided on the rear side of the Demo Board.

It is recommended to set up the Demo Board with no live AC voltage connected, and to

connect live AC voltages only after the user is familiar with the demo system.

Host PC

v1.5

© 2007-2008 TERIDIAN Semiconductor Corporation

Page: 11 of 83

71M6531 Demo Board User’s Manual

DEMONSTRATION METER

LOAD A

LOAD B

VB

VA

NEUTRAL

6531

Single Chip

Meter

IB

External Current

Transformers

IA

IB

IA

V3P3

DIO6

DIO7

DIO4

DIO5

VB

VA

JP1

V3P3

3.3V

GND

GND

5V DC

TMUXOUT

CKTEST

V3P3D

On-board

components

powered by V3P3D

TX

RX

Wh

VARh

3.3V LCD DISPLAY

EEPROM

ICE Connector

1

2

3

N/C

10

12

5, 7,

GND

9, 11

8

6

4

15, 16

N/C

13, 14

N/C

J2

V3P3

V3P3

DEBUG BOARD (OPTIONAL)

ISO

ISO

ISO

ISO

6

V5_DBG

RS-232

INTERFACE

ISO

5V DC

GND_DBG

JP21

MPU HEARTBEAT (5Hz)

V5_DBG

CE HEARTBEAT (1Hz)

V5_DBG

GND_DBG

V5_DBG

RTM INTERFACE

FPGA

ISO

ISO

V5_NI

DB9

to PC

COM Port

4/12/2007

DB9

to PC

COM Port

Figure 1-3: The TERIDIAN 6531 Demo Board with Debug Board Block Diagram (CT Configuration)

Note: All analog input signals are referenced to the V3P3A net (3.3V power supply to the chip).

1.6.1 POWER SUPPLY SETUP

There are several choices for meter the power supply:

• Internal (using the AC line voltage). The internal power supply is only suitable when the line voltage

exceeds 220V RMS.

• External 5VDC connector (J1) on the Demo Board

• External 5VDC connector (J1) on the Debug Board.

The power supply jumper, JP1, must be consistent with the power supply choice. JP1 connects the AC

line voltage to the internal power supply. This jumper should usually be left in place.

When the Demo Board is in shunt configuration, the shunt resistor has to be connected as shown in

Figure 1-7 for the board to be powered via J1. Alternatively, a jumper cable between any header labeled

V3P3 and the NEUTRAL terminal (J9) can be supplied.

Page: 12 of 83

© 2007-2008 TERIDIAN Semiconductor Corporation

v1.5

71M6531 Demo Board User’s Manual

1.6.2 CABLE FOR SERIAL CONNECTION

For connection of the DB9 serial port to a PC, either a straight or a so-called “null-modem” cable may be

used. JP1 and JP2 are plugged in for the straight cable, and JP3/JP4 are empty. The jumper configuration is

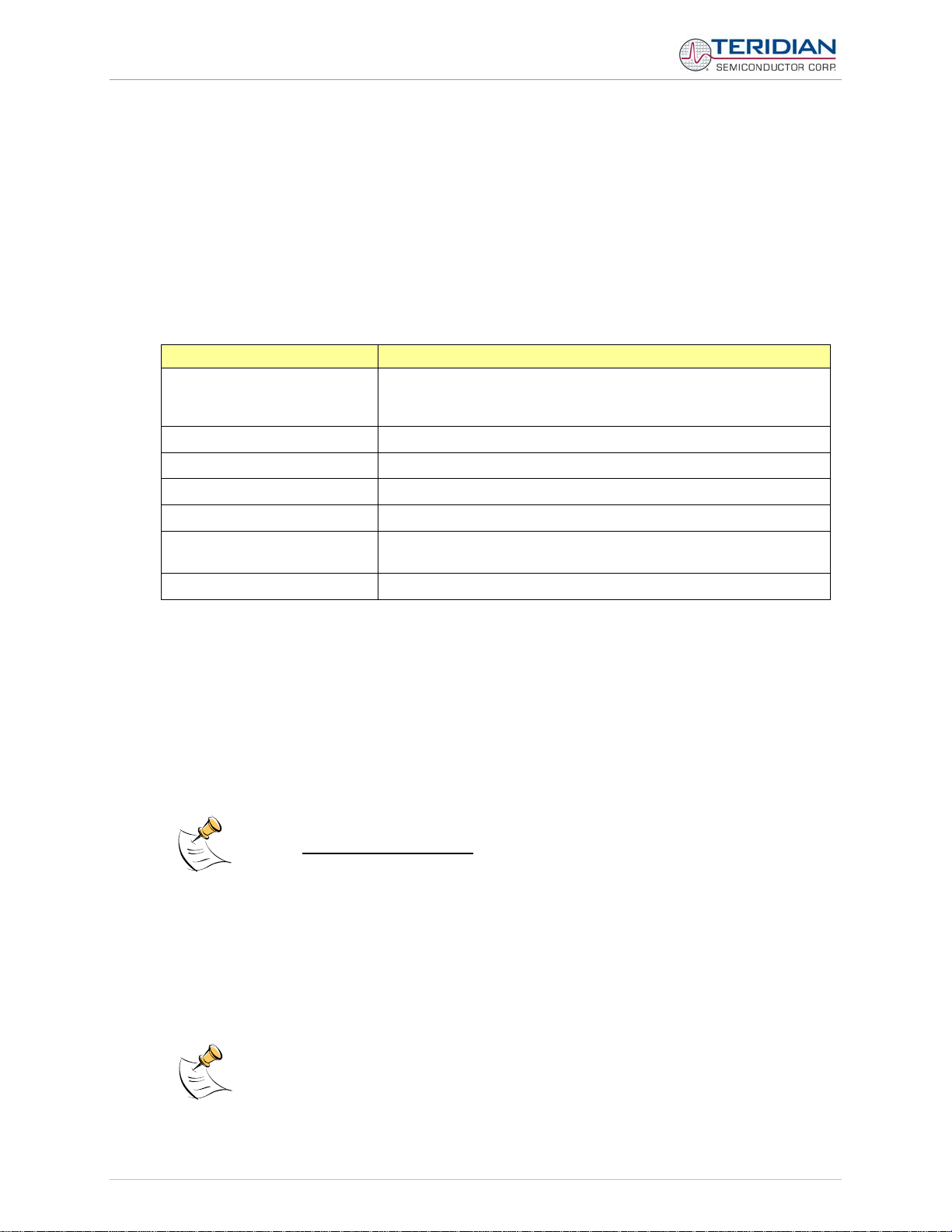

reversed for the null-modem cable, as shown in Table 1-3.

Cable

Configuration

Straight Cable

Null-Modem Cable Alternative -- -- Installed Installed

JP1 through JP4 can also be used to alter the connection when the PC is not configured as a DCE device.

Table 1-2 shows the connections necessary for the straight DB9 cable and the pin definitions.

Table 1-3 shows the connections necessary for the null-modem DB9 cable and the pin definitions.

Mode

Default

Table 1-1: Jumper settings on Debug Board

PC Pin Function Demo Board Pin

2 TX 2

3 RX 3

5 Signal Ground 5

Table 1-2: Straight cable connections

PC Pin Function Demo Board Pin

2 TX 3

3 RX 2

5 Signal Ground 5

Table 1-3: Null-modem cable connections

JP1 JP2 JP3 JP4

Installed Installed -- --

Jumpers on Debug Board

1.6.3 CHECKING OPERATION

A few seconds after power up, the LCD display on the Demo Board should briefly display the following

welcome text:

H E L L 0

After the “HELLO” text, the LCD should display the following information:

W h

and:

0. 0 0 1

The text “Wh” indicates that accumulated Watt-hours are displayed. In the case shown above, 0.001 Wh

were accumulated. The display will be cycling from numeric to text, indicating activity of the MPU inside the

D/F. 71M6531

In Mission Mode, the display can be cycled to display VARh, PF and other parameters by pressing

the pushbutton (PB).

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 13 of 83

v1.5

71M6531 Demo Board User’s Manual

r

V

1.6.4 SERIAL CONNECTION SETUP FOR THE PC

After connecting the DB9 serial port to a PC, start the HyperTerminal application (or any other suitable

communication program) and create a session using the communication parameters shown in Table 1-4.

Setup Paramete

Port speed (baud) 9600/300g

Data bits 8

Parity none

Stop bits 1

Flow control XON/XOFF

Table 1-4: COM Port Setup Parameters

HyperTerminal can be found by selecting Programs ÆAccessories Æ Communications from the Windows

start menu. The connection parameters are configured by selecting File Æ Properties and then by pressing

the Configure button (see Figure 1-4).

A setup file (file name “Demo Board Connection.ht”) for HyperTerminal that can be loaded with File Æ Open

is also provided with the tools and utilities on the supplied CD-ROM.

g depending on the jumper

alue

setting at JP12

©

Figure 1-4: Port Configuration Setup

Note: Port parameters can only be adjusted when the connection is not active. The disconnect button, as

shown in Figure 1-5 must be clicked in order to disconnect the port.

Page: 14 of 83 © 2007-2008 TERIDIAN Semiconductor Corporation v1.5

71M6531 Demo Board User’s Manual

Figure 1-5: Hyperterminal Sample Window with Disconnect Button

1.7 USING THE DEMO BOARD

The 71M6531 Demo Board is a ready-to-use meter prepared for use with an external shunt resistor.

Using the Demo Board involves communicating with the Demo Code. An interactive command line interface

(CLI) is available as part of the Demo Code. The CLI allows modifications to the metering parameters,

access to the EEPROM, initiation of auto-calibration sequences, selection of the displayed parameters,

changing calibration factors and many more operations.

Before evaluating the 71M6531 Demo Board, users should get familiar with the commands and responses

of the CLI. A complete description of the CLI is provided in section 1.7.2.

1.7.1 CYCLING THE LCD DISPLAY

The Demo Codes for the 71M6531 Demo Board allow cycling of the display using the PB button. By briefly

pressing the button, the next available parameter from Table 1-5 is selected. This makes it easy to navigate

various displays for Demo Boards that do not have the CLI.

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 15 of 83

v1.5

71M6531 Demo Board User’s Manual

r

Step Text Display Displa yed Paramete

1

2

3

4

5

6

7

8

8

8

8

8

Pulses

Bat V

Delta T

Wh

VARh

Hours

Time

Date

PF

Edges

A

V

Accumulated real energy [Wh]. The default display setting after power-up

or reset.

Accumulated reactive energy [VARh].

Expired hours after power-up or reset

Time of day (hh.mm.ss).

Date (yyyy.mm.dd).

Current power factor.

Count of zero crossings in the last accumulation interval.

Number of emitted pulses.

RMS current at phase A input [A].

RMS voltage at the VA_IN input [V].

Measured battery voltage [V].

Temperature difference from calibration temperature. Displayed in 0.1°C

Table 1-5: Selectable Display Options

1.7.2 SERIAL COMMAND LINE INTERFACE (CLI)

Once, communication to the Demo Board is established, press <CR> and the Demo Program prompt (“>”)

should appear. Type >i to verify that the Demo Program version is revision 4p6q or later.

Users should familiarize themselves with the Demo Program commands described in the tables below.

The Demo Program (Demo Code) is compiled with EEPROM specified as the non-volatile memory. This

means that the default calibration factors are stored in flash memory while the calibration factors resulting

from an actual calibration are stored in EEPROM.

The tables below describe the commands in detail. Type ‘?’ for a display of available commands.

Page: 16 of 83 © 2007-2008 TERIDIAN Semiconductor Corporation v1.5

71M6531 Demo Board User’s Manual

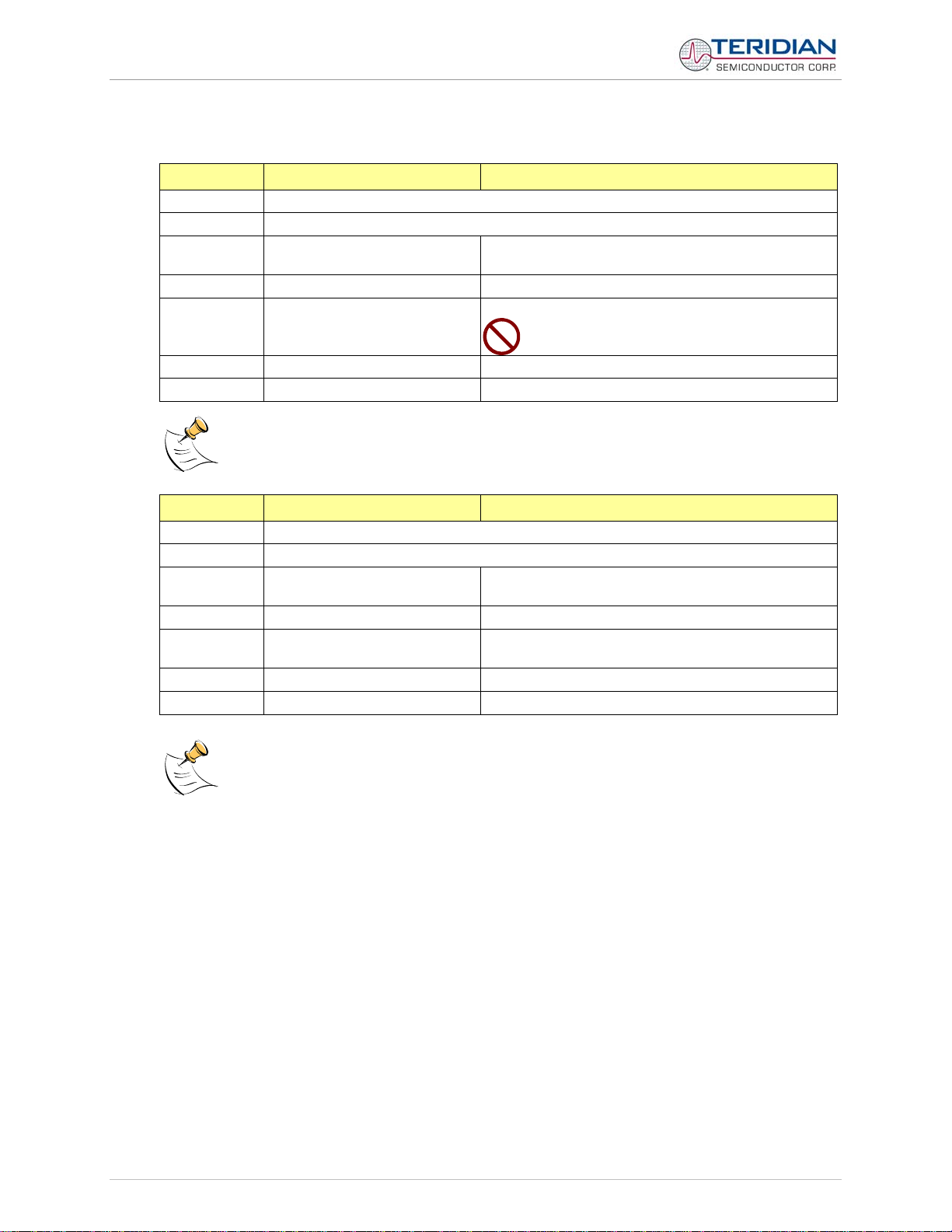

Commands for CE Data Access:

] CE DATA ACCESS Remarks

Description: Allows user to read from and write to CE data space.

Usage: ] [Starting CE Data Address] [option]…[option]

Command

]??? Read consecutive 16-bit words in Decimal

combinations:

]$$$ Read consecutive 16-bit words in Hex

Update .

]U

default version of CE Data in EEPROM

Important: The CE must be stopped (C

E0)

before issuing this command!

Example: ]40$$$ Reads s 0x40, 0x41 and 0x42. CE data word

]7E=12345678=9876ABCD Writes two words starting @ 0x7E

CE da from rds are in 4-byte (32-

ta space is the address range 0x1000 to 0x13FF. All CE data wo

bit) format. The offset of 0x1000 does not have to be entered when using the ] command, thus

typing ]A? will access the 32-bit word located at the byte address 0x1000 + 4 * A = 0x1028.

Commands for MPU/XDATA Access:

) MPU DATA ACCESS Remarks

Description: and write Allows user to read from to MPU data space.

Usage: ) [Starting MPU Data Address] [option]…[option]

Command

c :

ombinations

)??? Read three consecutiv

e 32-bit words in Decimal

)$$$ Read three consecutive 32-bit words in Hex

)a=n=m

Write the values n and m to two consecutive

addresses starting at a

Example: )08$$$$ 0x0C, 0x10, 0x14 Reads data words 0x08,

)04=12345678=9876ABCD Writes two words starting @ 0x04

MPU o XDATA for th . All MPU data words r space is the address range e MPU XRAM (0x0000 to 0x0FFF)

are in 4-byte (32-bit) format. Typing ]A? will access the 32-bit word located at the byte address 4 *

A = 0x28. The energy accumulation registers of the Demo Code can be accessed by typing two

question marks (“??”).

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 17 of 83

v1.5

71M6531 Demo Board User’s Manual

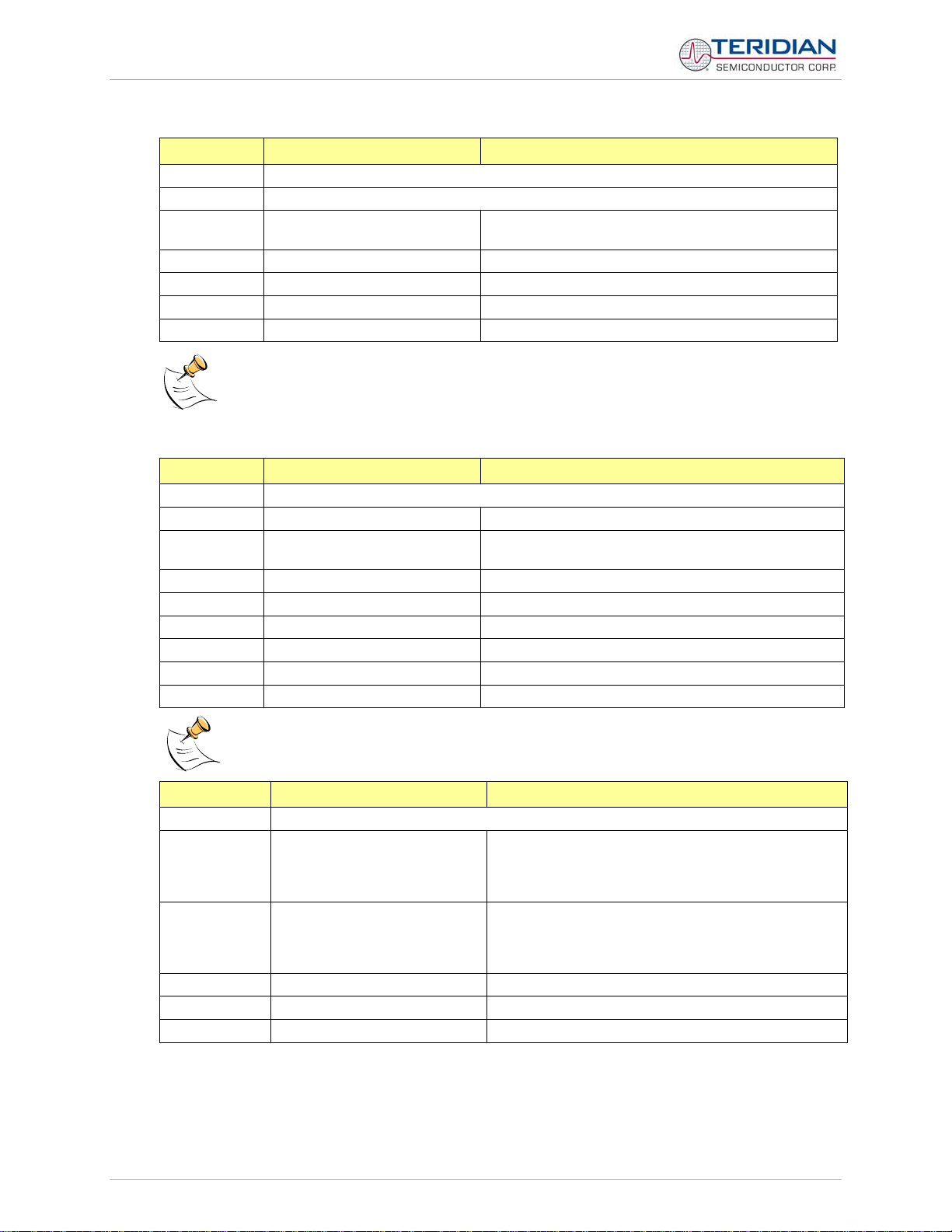

Commands for I/O RAM (Configuration RAM) and SFR Control:

R DIO AND SFR CONTROL Remarks

Description: Allows the user to read from and write to I/O RAM and special function registers (SFRs).

Usage: R [option] [register] … [option]

Command

combinations:

RIx…

Select I/O RAM location x (0x2000 offset is automatically added)

Rx… Select internal SFR at address x

Rx???... Read consecutive SFR registers in decimal

Rx$$$... Read consecutive registers in hex notation

Example: RI60$$$$ Read all four RTM probe registers

DIO or Configuration RAM space is the address range 0x2000 to 0x20FF. This RAM contains

registers used for configuring basic hardware and functional properties of the 71M6531D/F and is

organized in bytes (8 bits). The 0x2000 offset is automatically added when the command RI is

typed. The SFRs (special function registers) are located in internal RAM of the 80515 core,

starting at address 0x80.

Commands for EEPROM Control:

EE EEPROM CONTROL Remarks

Description: Allows user to enable read and write to EEPROM.

Usage: EE [option] [arguments]

Command

EECn EEPROM Access (1 Æ Enable, 0 Æ Disable)

combinations:

EERa.b Read EEPROM at address 'a' for 'b' bytes.

EEE Erase the EEPROM

EESabc..xyz Write characters to buffer (sets Write length)

EETa Transmit buffer to EEPROM at address 'a'.

EEWa.b...z Write values to buffer

Example: EEShello; EET$0210 Writes 'hello' starting at EEPROM address 0x210.

The EEC1 command must be issued before the EEPROM interface can be used. The execution of the EEE

command takes several seconds. During this time, no other commands can be entered.

Auxiliary Commands:

AUXILIARY Remarks

Description: Various

Commands: ,

Typing a comma (“,”) repeats the command issued

from the previous command line. This is very helpful

when examining the value at a certain address over

time, such as the XRAM address for the temperature.

/

The slash (“/”) is useful to separate comments from

commands when sending macro text files via the serial

interface. All characters in a line after the slash are

ignored.

? Displays the help menu.

CLC Enables communication via hex records.

BT Commands execution of a battery test.

Page: 18 of 83 © 2007-2008 TERIDIAN Semiconductor Corporation v1.5

71M6531 Demo Board User’s Manual

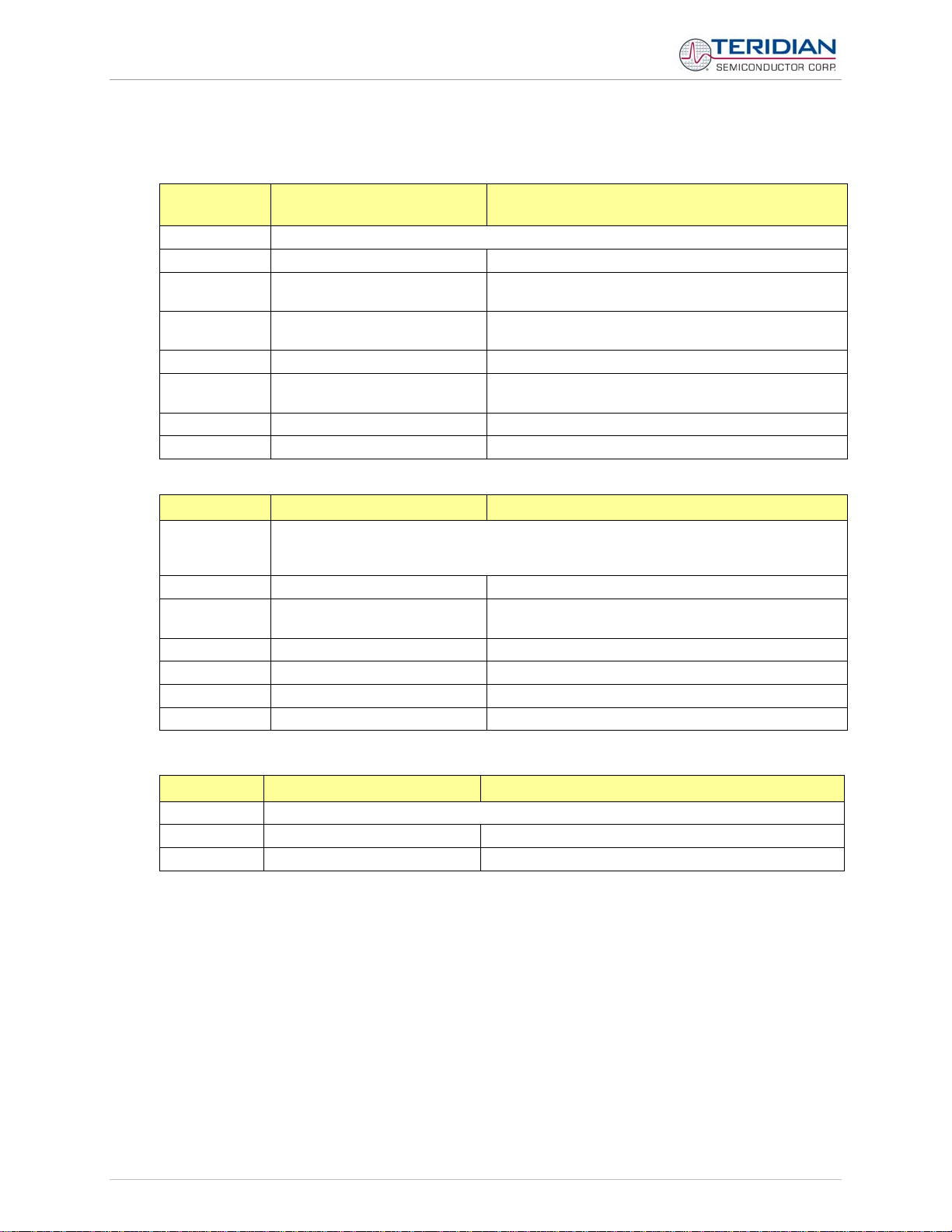

Commands controlling the CE:

C COMPUTE ENGINE

Remarks

CONTROL

Description: Allows the user to enable and configure the compute engine.

Usage: C [option] [argument]

Command

CEn Compute Engine Enable (1 Æ Enable, 0 Æ Disable)

combinations:

CTn

Select input n for TMUX output pin. Enter n in hex

notation.

CREn RTM output control (1 Æ Enable, 0 Æ Disable)

CRSa.b.c.d

Selects CE addresses for RTM output (maximum of

four)

Example: CE0 Disables the CE

CT1E Selects the CE_BUSY signal for the TMUX output pin

Calibration Commands:

CL CALIBRATION CONTROL Remarks

Description:

Calibration-related commands. A full auto-calibration can be implemented by compiling the

Demo Code with auto-calibration selected as an option. Due to space restrictions, the

auto-calibration is not implemented in the Demo Code supplied with the Demo Boards.

Usage: CL [option]

Command

CLC Loads a calibration via serial port

combinations:

CLB Starts an auto-calibration sequence

CLD Restores calibration to defaults

CLR Restores calibration from EEPROM

CLS Saves calibration to EEPROM

Commands for Identification and Information:

I INFORMATION MESSAGES Remarks

Description: Allows user to display information messages.

Usage: I

Example: I Returns the Demo Code version

The I command is used to identify the revisions of Demo Code and the contained CE code.

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 19 of 83

v1.5

71M6531 Demo Board User’s Manual

Commands for Controlling the Metering Values Shown on the LCD Display:

M

Description: Allows user to select internal variables to be displayed.

Usage: M [option]. [option]

Command

combinations:

M1 Temperature (C° delta from nominal)

M2 Frequency (Hz)

M3. [phase] kWh Total Consumption (display wraps around at 999.999)

M4. [phase]

M5. [phase] kVARh Total Consumption (display wraps around at 999.999)

M6. [phase]

M7. [phase] VAh Total (display wraps around at 999.999)

M9 Real Time Clock

M10 Calendar Date

M13. n Main edge count (n = 0: accumulated, n = 1: last second)

M17 Battery voltage. Display will return to M3 after a few seconds.

Example: M3.1 Displays Wh total consumption of phase A.

Displays for total consumption wrap around at 999.999kWh (or kVARh, kVAh) due to the

number of available display digits. Internal registers (counters) of the Demo Code are 64 bits

wide and do not wrap around.

T

he internal accumulators in the Demo Code use 64 bits and will neither overflow nor wrap

a

round under normal circumstances. The restriction to only six digits is due to the

r

equirement to provide one digit showing the display mode that is separated by a blank digit

f

rom the displayed values.

METER DISPLAY

CONTROL (LCD)

M kWh Total Consumption (display wraps around at 999.999)

Remarks

kWh Total Inverse Consumption (display wraps around at

999.999)

kVAh Total Inverse Consumption (display wraps around at

999.999)

C

ommands for Controlling the RMS Values Shown on the LCD Display:

MR METER RMS DISPLAY

CONTROL (LCD)

Description: Allows user to select meter RMS display for voltage or current.

Usage: MR [option]. [option]

Command

combinations:

MR2. [phase] Displays instantaneous RMS voltage

Example: MR1.2 Displays phase b RMS current.

Commands for Controlling the MPU Power Save Mode:

PS POWER SAVE MODE Remarks

Description: Enters power save mode

Usage: PS

Return to normal mode is achieved by issuing a hardware reset.

MR1. [phase] Displays instantaneous RMS current

Remarks

Disables CE, ADC, CKOUT, ECK, RTM, TMUX VREF,

and serial port, sets MPU clock to 38.4KHz.

Page: 20 of 83 © 2007-2008 TERIDIAN Semiconductor Corporation v1.5

71M6531 Demo Board User’s Manual

Commands for Controlling the RTC:

RT REAL TIME CLOCK

Remarks

CONTROL

Description: Allows the user to read and set the real time clock.

Usage: RT [option] [value] … [value]

Command

combinations:

RTDy.m.d.w: Day of week

(year, month, day, weekday [1 = Sunday]). Weekday is

automatically set if omitted.

RTR Read Real Time Clock.

RTTh.m.s Time of day: (hr, min, sec).

RTAs.t Real Time Adjust: (speed, trim)

Example: RTD05.03.17.5 Programs the RTC to Thursday, 3/17/2005

Reset Commands:

Z, W RESET Remarks

Description: Allows the user to cause soft or watchdog resets

Usage: Z Soft reset

W Simulates watchdog reset

The Z command acts like a hardware reset. The energy accumulators in XRAM will retain their values.

Commands for Controlling the LCD and Sleep Modes (when in Brownout Mode):

B POWER MODE CONTROL Remarks

Description: Allows the user switch to LCD and Sleep mode when the 71M6531D/F is in Brownout

mode.

Usage: B [option] [value]

Command

combinations:

BL Enters LCD mode

BS Enters Sleep mode

BWSn Prepares Sleep mode with the wakeup timer set to n

seconds

BWMm Prepares Sleep mode with the wakeup timer set to m

minutes

Example: BWS8

BS

Enters Sleep mode with the wakeup timer set to 8

seconds. The 71M6531D/F will enter Sleep mode and

return to Brownout mode after 8 seconds.

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 21 of 83

v1.5

71M6531 Demo Board User’s Manual

Commands for Error Recording:

ER ERROR RECORDING Remarks

Description: Allows the user display and clear the error log.

Usage: ER [option] [value]

Command

combinations:

ERD Displays error log

ERS+n Enters error number n in error log

Example: ERS+10 Enters error number 10 in error log

ERC Clears all errors from error log

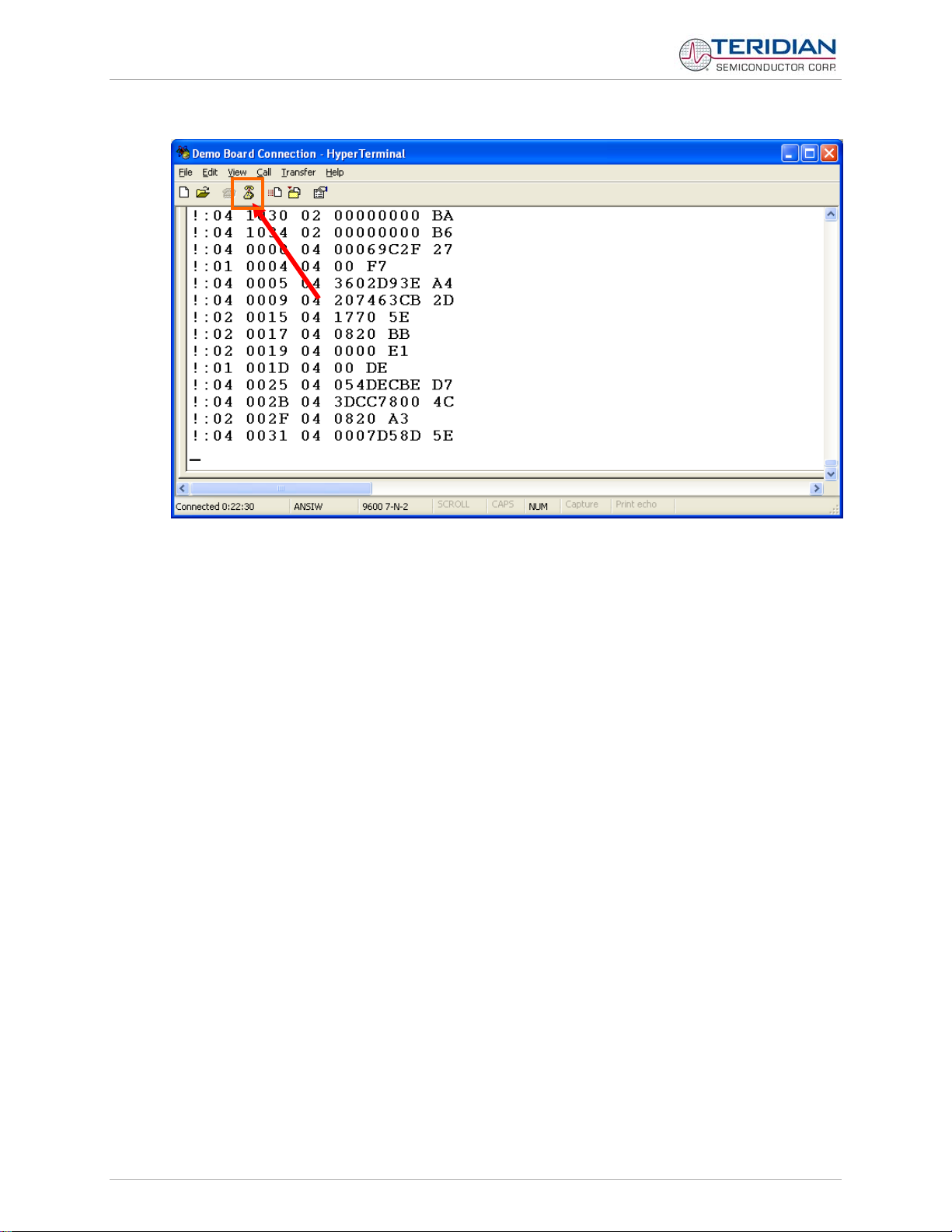

1.7.3 COMMUNICATING VIA INTEL HEX RECORDS

Communication with the 71M6531D/F IC, especially by computers and/or ATE, may also be accomplished

using a simplified protocol based on Intel Hex records. These records can still be sent and received with an

ordinary terminal, and coding and decoding of commands and responses is straight-forward.

Using the Hex-Record Format

Intel's Hex-record format allows program or data files to be encoded in a printable (ASCII) format, allowing

editing of the object file with standard tools and easy file transfer between a host and target. An individual

hex-record is a single line in a file composed of one or several Hex-records.

Entering “CLC” from the text-based command line interface enables the hex-record interface.

Hex-Records are character strings made of several fields which specify the record type, record length,

memory address, data, and checksum. Each byte of binary data is encoded as a 2-character hexadecimal

number: the first ASCII character representing the high-order 4 bits, and the second the low-order 4 bits of

the byte. The six fields that comprise a Hex-record are defined in Table 1-6.

Field Name Characters Description

1 Start code 1 An ASCII colon (":")

2 Byte count 2 The count of the character pairs in the data field.

The 2-byte address at which the data field is to be loaded into

3 Address 4

4 Type 2 00, 01, or 02.

5 Data 0-2n

6 Checksum 2

Table 1-6: Fields of a Hex Record

Each record may be terminated with a CR/LF/NULL character. Accuracy of transmission is ensured by the

byte count and checksum fields. This is important when series of values such as calibration constants are

transmitted to a meter, e.g. by ATE equipment in a factory setting. When entering hex records manually, the

user may also choose “FF” (“wild card”) as the checksum. In this case, the Demo Code omits comparing the

checksum with the received record(s).

This is how the checksum is calculated manually (if necessary):

1) The hex values of all bytes (except start code and checksum itself) are added up.

2) The last two hex digits are subtracted from 0xFF.

3) The value 0x01 is added.

memory. This is the physical XRAM or I/O RAM address, not

the 4-byte address used by the command-line interface (CLI).

From 0 to n bytes of executable code, or memory loadable

data.

n is normally 20 hex (32 decimal) or less.

The least significant byte of the two's complement sum of the

values represented by all the pairs of characters in the record

except the start code and checksum.

Page: 22 of 83 © 2007-2008 TERIDIAN Semiconductor Corporation v1.5

71M6531 Demo Board User’s Manual

As opposed to the standardized Hex-records that offer three possible types (data, termination, segment

base), six different types are supported for communicating with the 71M6531D/F. These data types basically

encode command types (read/write) along with the data source or destination, as listed in Table 1-7.

Number Code Function

1 00 Write CE data record, contains data and 16-bit CE address (CE data RAM is

located at 0x1000).

2 01 End Of File (Quit) record, a file termination record. Contains no data. This record

has to be the last line of the file, and only one record per file is permitted. The

byte pattern is always ':00000001FF'.

Upon receipt of this record, the Demo Code will transfer the received data into

non-volatile memory (EEPROM).

3 02 Alternate form of Write CE data record (optional). CE data RAM is located at

0x1000.

4 03 Read CE data record, contains empty data field and 16-bit CE address (optional).

CE data RAM is located at 0x1000.

5 04 Write MPU or I/O RAM data record, contains data and 16-bit MPU address.

6 05 Read MPU or I/O RAM data record, contains empty data field and 16-bit MPU

address (optional). I/O RAM is located at 0x2000.

7 06 Write RTC data record, contains data and 16-bit RTC address.

8 07 Read RTC data record, contains empty data field and 16-bit RTC address

(optional).

9 08 Write SFR data record, contains data and 16-bit SFR address (optional). The

MSB is always zero (0).

10 09 Read SFR data record, contains empty data field and 16-bit SFR address

(optional).

Table 1-7: Data (command) types

Table 1-8 lists a few examples of hex records.

Hex Record Function

:08 0000 06 00 00 0C 03 18 05 06 00 ff

Writes (06) eight bytes (08) to RTC, setting the

RTC to zero seconds (00), minutes (00), 12

hours (0C), Wednesday (03), 24

(05), 2006 (06). Uses the wild card checksum.

:10 0010 00 00004000 00004000 00004000

00004000 E8

:00 0000 01 FF

Writes the default values (0x4000) for the

calibration constants CAL_IA, CAL_IB,

CAL_VA, and CAL_VC to the XRAM (00),

starting at address 0x10 (0010).

The second command causes the Demo Code

to write the data to permanent storage.

:10 1020 03 FF

Causes the Demo Board to display the CE data

from address 0x1020 to 0x102F

Table 1-8: Hex Record examples

The Demo Board will not echo any inputs from the terminal (they screen will stay blank except for

the asterisk (*) issued after the user enters <CR><LF>). It is useful to configure Hyperterminal for

“auto-echo”. This can be done by selecting “Properties” from the “File” menu, then clicking on the

“Settings” tab and clicking the “ASCII Setup” button.

No <ENTER> key is necessary at the end of a manually entered record.

th

(18) of May

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 23 of 83

v1.5

71M6531 Demo Board User’s Manual

Spaces in between the fields (to increase readability), as in the example above, are ignored by the Demo

Boards.

If a hex record is accepted, the Demo Board returns a "

Board sends a "

When only a partial record is entered, the Demo Board will time out after around 30 seconds and then send

<CR>< LF>.

A number of pre-assembled hex records is supplied with the Demo Code. It is easier to send a pre-assembled record using the “send text file” feature in the “Transfer” menu of Hyperterminal, than assembling hex

record from scratch.

The pre-assembled hex records are contained in a ZIP file named 6531_scripts.zip on the CD-ROM

supplied with the Demo Kits. Table 1-9 shows the records available and their function.

Hex Record Name Function

set_6531_defaults.txt

read_6531_temp.txt

set_6531_temp.txt

read_6531_power.txt

read_6531_ce.txt

read_6531_config.txt

set_6531_rtm.txt

?" and other text, depending on the context (only the 16KB Demo Code will send text).

Sets the default configuration, including all CE variables. Transferring

this record is necessary when data in the EEPROM is lost or

compromised.

Displays the current temperature reading from the CE

This record can be edited to set the nominal (calibration) temperature

Displays the valid power data

Displays CE data from memory locations 0x1020 to 0x10FF

Displays configuration data. This hex record includes comment text

helping to interpret the received data.

Sets up the real-time monitor

!". If the hex record is not accepted, the Demo

Table 1-9: Pre-assembled hex records

1.7.4 USING THE BATTERY MODES

The 71M6531D/F is in so-called Mission mode, as long as 3.3VDC is supplied to the V3P3SYS pin. If this

voltage is below the minimum required operating voltage which is usually indicated by V1 < 1.6 (internal

VBIAS voltage), and if no battery is connected to the VBAT pin, the chip is powered off.

Battery modes can be used if a battery or other DC source supplying a DC voltage with in the operating

limits for the battery input is applied to the battery pin (VBAT, pin 49) of the chip. On the Demo Board, the

battery should be connected to pin 2 (+) and 3 (-) of JP8.

In order to prevent corruption of external memory, which could occur when main power

is removed from the Demo Board while no batter y is present, the Demo Cod e is shipped

with the battery modes DISABLED

halted once it enters brownout mode, even when a battery is present . See section 1.10.2

for instruction on how to enable battery modes.

If the main power source (internal or external power supply) is removed while a battery is connected to JP8

as described above, and if the battery modes are enabled with header JP12, the 71M6531D/F automatically

enters Brownout mode. The Demo Code will then automatically transition from Brownout mode to Sleep

mode.

By pressing the pushbutton PB, the chip is temporarily brought back to LCD mode. After a few seconds in

LCD mode, the chip returns to Sleep mode.

By pressing the RESET pushbutton while the chip is in Sleep mode, the chip will enter Brownout mode.

Both the RESET and PB buttons are powered by the battery voltage (VBAT).

In Brownout mode, the analog functions are disabled, and the MPU functions at very low speed. DIO pins

and the UART are still functional. If the chip supports the command line interface, it will signal Brownout

. When the battery modes are disabled, the MPU will be

Page: 24 of 83

© 2007-2008 TERIDIAN Semiconductor Corporation v1.5

71M6531 Demo Board User’s Manual

mode, and the command prompt “B” will be visible on the terminal connected to the Demo Board, followed

by the “>” sign:

B>

The LCD displays a decimal dot in the left-most digit to indicate that it is in Brownout mode, as shown below:

.

The following commands can be entered via the CLI in Brownout mode:

• BL – enters LCD mode

• BS – enters Sleep mode.

• BWSn – enters sleep mode for n seconds, then returns to Brownout mode

• BWMm – enters sleep mode for m minutes, then returns to Brownout mode

In Sleep Mode, almost all functions are disabled. Only the RTC and the wakeup timer are still active. The

wakeup signal from the timer and the pushbutton (SW2 on the Demo Board) take the 71M6531D/F back to

Brownout mode.

A hardware reset, while in any battery mode, takes the 71M6531D/F back to Brownout mode.

H E L L O

1.8 USING THE DEMO BOARD FOR METERING FUNCTIONS

1.8.1 MODIFYING DEMO CODE TO CT OR SHUNT MODE

Script files contained in the CD-ROM shipped with the Demo Kit can be used to modify the constants used

in the Demo Code from CT to shunt mode or vice versa. Three script files are available:

1. 6531ctct.txt sets 6531 Demo Code for IA: 2000:1 CT (Imax = 208A) and IB:

2000:1 CT (ImaxB = 208A)

2. 6531ctshunt.txt: IA: 2000:1 CT (Imax = 208A) IB: 400 μΩ shunt (ImaxB =

442A)

3. 6531shuntct.txt: IA: 400 μΩ shunt (Imax = 442A) IB: 2000:1 CT

(ImaxB = 208A)

To apply a script file, select “transfer -> send_text_file” from the HyperTerminal user interface.

1.8.2 USING THE DEMO BOARD IN SHUNT AND CT MODES

The Demo Board may be used with current shunt sensors of 400µΩ resistance or current transformers

(CTs). It is programmable for a Kh factor of 1.0 and (see Section 0 for adjusting the Demo Board for current

transformers). Section 1.8.6 describes proper wiring and safety precautions for shunt operation.

Once, voltage is applied and load current is flowing, the red LED D5 will flash each time an energy sum of

1.0 Wh is collected. The LCD display will show the accumulated energy in Wh when set to display mode 3

(command

Similarly, the red LED D6 will flash each time an energy sum of 1.0 VARh is collected. The LCD display will

show the accumulated energy in VARh when set to display mode 5 (command

The D6531N12A2 Demo Boards can be operated with CTs on channel B, which is equipped with the proper

burden resistors for 2000:1 CTs.

© 2007-2008 TERIDIAN Semiconductor Corporation Page: 25 of 83

v1.5

>M3 via the serial interface).

>M5 via the serial interface).

Loading...

Loading...