Teres 320 Owners manual

Contents

Teres Model 320

Turntable Manual

21-Aug-2004

I. BEARING ASSEMBLY 2

II. TURNTABLE SETUP 3

III. OPERATION 3

IV. PLATTER REMOVAL 4

V. DRIVE BELTS 4

VI. ADDITIONAL INFORMATION 4

1

I. Bearing Assembly

The Teres bearing was designed to have a lot

of viscous damping. This damping helps

swamp the effects of stylus drag, resulting in

better speed stability. For this reason heavy oil

(30 weight) is provided. With heavy oil the

bearing will turn smoothly but there will be a

lot of resistance. This is by design.

Please read this information carefully before

assembling your bearing. The Teres bearing

has been machined with very close tolerances.

The radial clearance in the bearing is only 4 to

5 ten-thousandths. This tight tolerance results

in superb stability reducing rocking to

microscopic levels. However, with these

tolerances it is imperative that the bearing is

clean and that proper procedure is used for

assembly. The objective is to have the bearing

completely full of clean oil, including the

recess in the top of the bearing housing. If air

becomes trapped in the bearing it will not seat

properly. The bearing must be assembled dry

to avoid trapping air. The procedure:

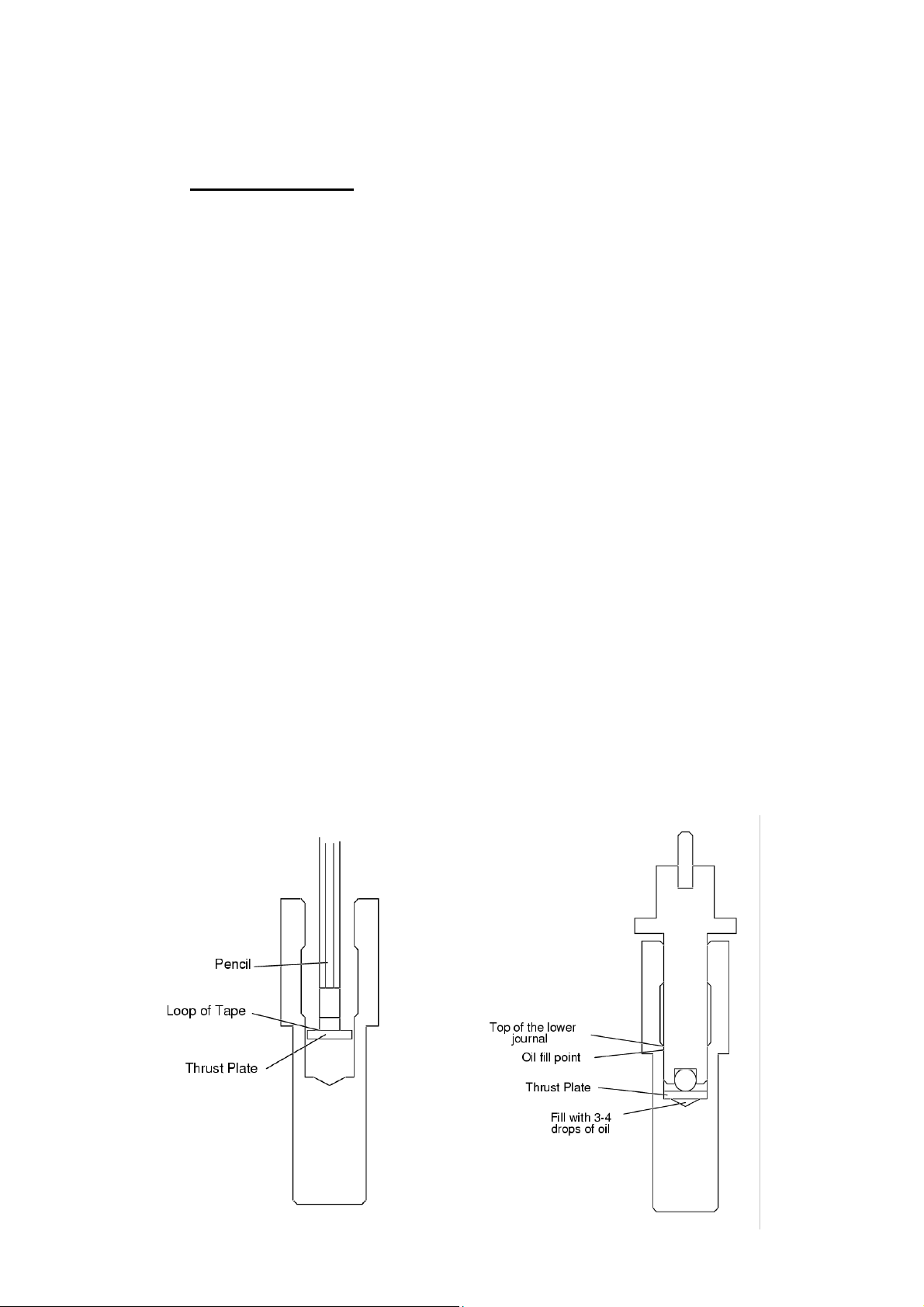

1.Using the included 6-32 screw attach the

bearing ground wire to the bottom of the

brass bearing housing. Pointing the crimp

connector toward the center of the bearing

will make it easier to install the bearing into

the base.

2.Attach the brass bearing housing to the base

using the supplied 1-1/8" nut. Hold the

bearing housing tightly in one hand and

tighten the bearing nut with a large wrench

or pliers. The bearing nut should be snug

but not excessively tight.

3. Clean the bearing housing and spindle

thoroughly. Wiping down the bearing

surfaces with rubbing alcohol on lint free

cloth works well.

4. Fill the recess in the bottom of the spindle

with oil and press in the ball bearing. This

displaces air in the recess and will hold the

ball bearing in place. Be sure to completely

wipe away any excess oil.

5. Place the brass thrust plate in the bottom of

the bearing housing with the white Delrin

button facing upward. The thrust plate needs

to be held flat as it is lowered into the

bearing. A simple method is to attach a

small loop of tape to the end of a pencil.

Then stick the thrust plate to the pencil and

lower it in place. Be sure that the Delrin

button is facing up!

6. Carefully pour about 5ml of oil into the

bearing housing without getting any oil on

the sides of the bearing. A syringe or

eyedropper makes this much easier. The oil

level should be just slightly below the top

edge of the lower journal as shown in the

illustration. This is slightly more oil than is

2

Loading...

Loading...