Page 1

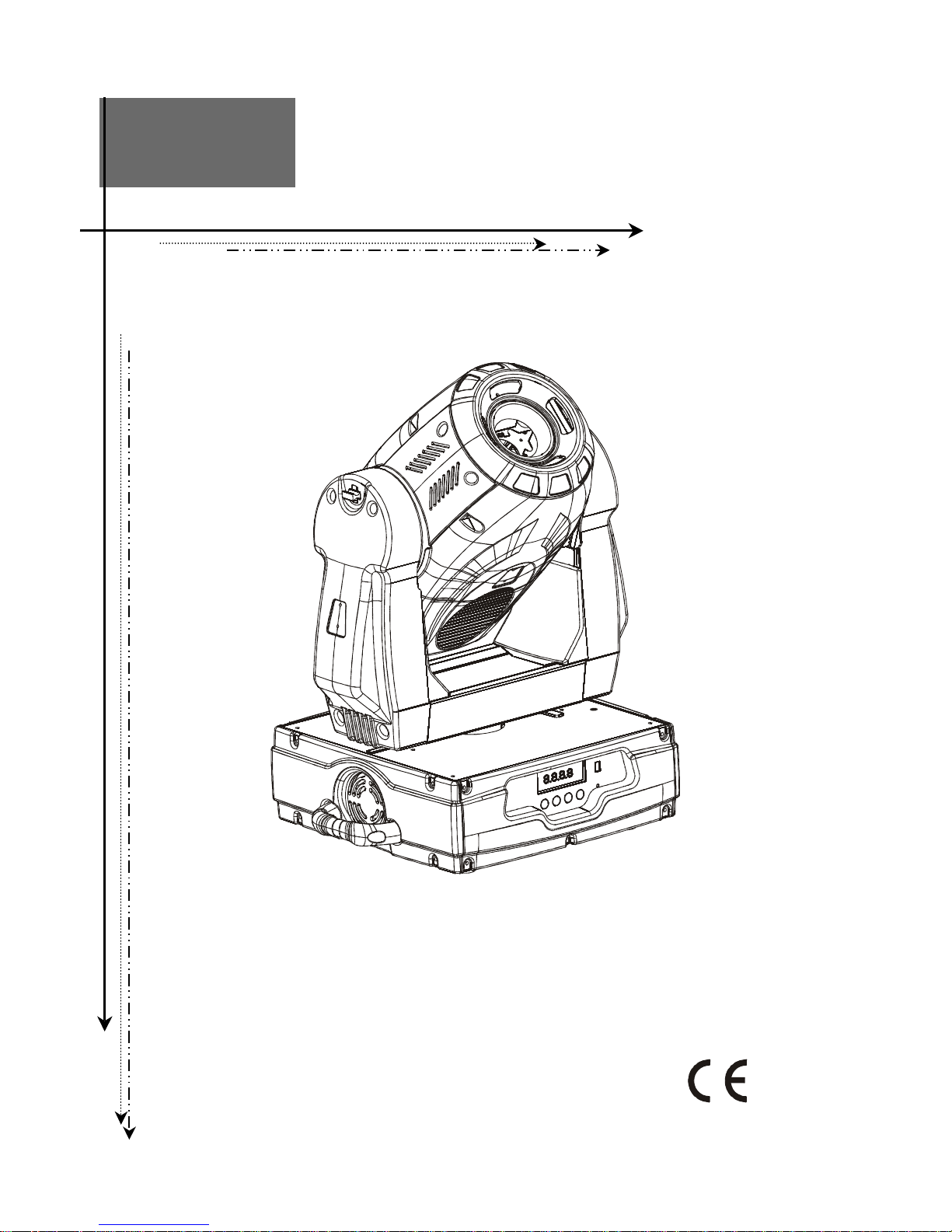

PROFESSIONAL MOVING HEAD USER’S

MANUAL

V250SP

KEEP THIS MANUAL FOR FUTURE NEEDS

Page 2

Page 3

Thank you for your patronage. We are confident that our excellent products and service can satisfy

you.

For your own safety, please read this user manual carefully before installing the device.

Keep this device away from rain and moisture !

Unplug mains lead before opening the housing.

Every person involved with the installation, operation and maintenance of this device has to:

-be qualified

-follow carefully the instructions of this manual

INTRODUCTION:

Thank you for having chosen this professional moving head.

You will see you have acquired a powerful and versatile device.

Unpack the device. Inside the box you should find: the fixture device, a power cable, an XLR

connection cable, a safety cable and this manual. Please check carefully that there is no damage

caused by transportation. Should there be any, consult your dealer and don’t install this device.

Features:

Lamp: Philips MSD 250/2

Control signal: Standard DMX-512, 16 channels (16 bit), 14 channels (8 bit)

Stand alone operation with master/slave function, can be sound activated

Pan/tilt movement: 8 bit and 16 bit resolution

For smooth and precise resolution

Movement: Pan 630°/ 540°optional, Tilt 265°

High speed of pan/tilt movement, speed of pan/tilt movement is

adjustable

Scan position memory, auto reposition after unexpected movement

8 colors plus white, with two direction rainbow effect,

Rotating gobo wheel has 7 rotating gobos plus open, with gobo indexing and different speed

gobo shake and rainbow effect

Static gobo wheel has 7 static gobos plus open with different speed gobo shaking and rainbow

effect

Simple replacement system for gobos enable freely customization

Prism and prism rotating , with 16 prism macros

Step zoom function 17°, 20 °lens can be selected

Strobe effect : 0~13 flashes per second or random strobe

Dimmer intensity from 0%~100%

Separately stepless 0%~100% frost filters to get soft beam

Local and remotely reset and lamp on/off

Preset program: 7 built in programs can be called up via DMX controller

Page 4

Editable program: Edit and save the program to inside EEPROM via the control board or external

controller, up to 48 scenes can be saved and then can be run in Stand Alone or sound activated.

Number of scenes in Program Run can be changed individually

SAFETY INSTRUCTIONS

Be careful with your operations.With a dangerous voltage you can

Suffer a dangerous electric shock when touching wires!

This device has left the factory in perfect condition. In order to maintain this condition and to ensure

a safe operation, it is absolutely necessary for the user to follow the safety instructions and warning

notes written in this user manual.

If the device has been exposed to temperature changes due to environmental changes, do not switch

it on immediately. The arising condensation could damage the device. Leave the device switched off

until it has reached room temperature.

This device falls under protection-class I. Therefore it is essential that the device be earthed.

The electric connection must carry out by qualified person.

The device shall only be used with rate voltage and frequency.

Make sure that the available voltage is not higher than stated at the end of this manual.

Make sure the power cord is never crimped or damaged by sharp edges. If this would be the case,

replacement of the cable must be done by an authorized dealer.

Always disconnect from the mains, when the device is not in use or before cleaning it. Only handle

the power cord by the plug. Never pull out the plug by tugging the power cord.

During initial start-up some smoke or smell may arise. This is a normal process and does not

necessarily mean that the device is defective, it should decrease gradually.

During initial start-up some smoke or smell may arise. This is a normal process and does not

necessarily mean that the device is defective, it should decrease gradually.

Please don't project the beam onto combustible substances.

Fixtures cannot be installed on combustible substances, keep more than 50cm distance with wall for

smooth air flow, so there should be no shelter for fans and ventilation for heat radiation.

If the external flexible cable or cord of this luminaire is damaged, it shall be exclusively replaced by

the manufacturer or his service agent or a similar qualified person in order to avoid a hazard.

Page 5

Never look directly into the light source,

as sensitive persons may suffer an epileptic shock.

Never touch the device during operation!

The housing may heat up

Please be aware that damages caused by manual modifications to the device are not subject to

warranty. Keep away from children and non-professionals.

GENERAL GUIDELINES

This device is a lighting effect for professional use on stages, in discotheques, theatres, etc.

This fixture is only allowed to be operated with the max alternating current which stated in the

technical specifications in the last page of this manual, the device was designed for indoor use only.

Lighting effects are not designed for permanent operation. Consistent operation breaks may ensure

that the device will serve you for a long time without defects. Do not shake the device.

Avoid brute force when installing or operating the device.

The device shall only be used complete with its protective shield.

While choosing the installation-spot, please make sure that the device is not exposed to extreme heat,

moisture or dust. The minimum distance between light-output from the projector and the illuminated

surface must be more than 0,5 meter.

Always fix the fixture with an appropriate safety cable if you use the quick lock cam in hanging up

the fixture, please make sure the 4 quick lock fasteners turned in the quick lock holes correctly.

Operate the device only after having familiarized with its functions. Do not permit operation by

persons not qualified for operating the device. Most damages are the result of unprofessional

operation.

Please use the original packaging if the device is to be transported.

For safety reasons, please be aware that all modifications on the device are forbidden.

If this device will be operated in any way different to the one described in this manual, the product

may suffer damages and the guarantee becomes void. Furthermore, any other operation may lead to

short-circuit, burns, electric shock, lamp explosion, crash, etc.

INSTALLATION INSTRUCTIONS

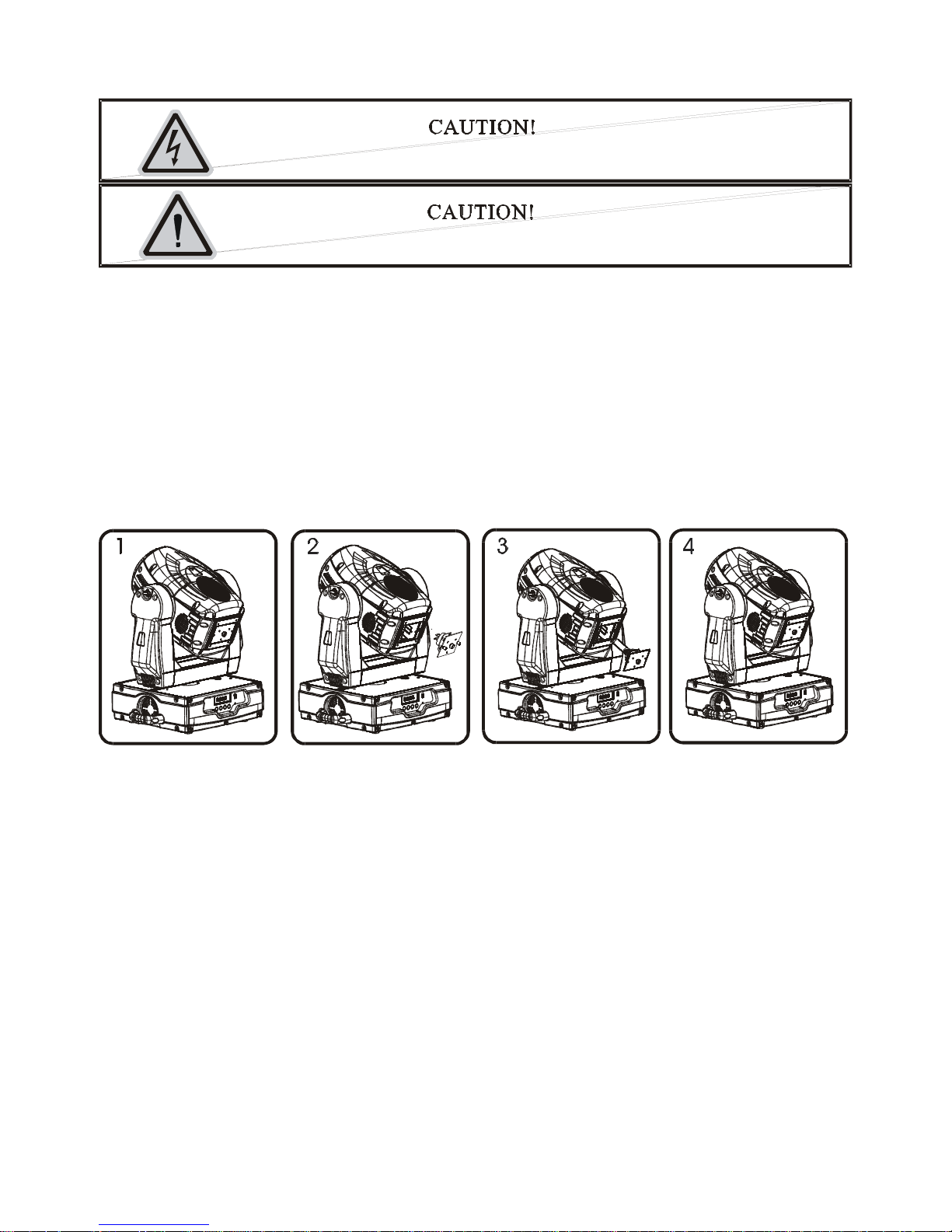

a) Installing or replacing the lamp

Page 6

Only install the lamp with the device unplugged from the mains.

The lamp has to be replaced when it is damaged or deformed.

Before replacing the lamp let the lamp cool down, because during operation, the lamp can reach very

high temperature.

During the installation of halogen lamps do not touch the glass bulbs bare handed. Always use a

cloth to handle the lamps during insertion and removal.

Do not install lamps with a higher wattage. They generate higher temperatures than which the device

was designed for.

For the installation, you need one MSD 250/2 lamp.

Procedure:

1) Unscrew the 2 screws A, B on the bottom of the housing, holding the plate where the lamp is

underneath.

2) Gently pull the socket holder using the knob in the middle.

3) Carefully insert the lamp into the socket. Please remember there is only one way to insert the lamp.

Gently slide the lamp and its lamp holder back into place and fasten the 2 screws.

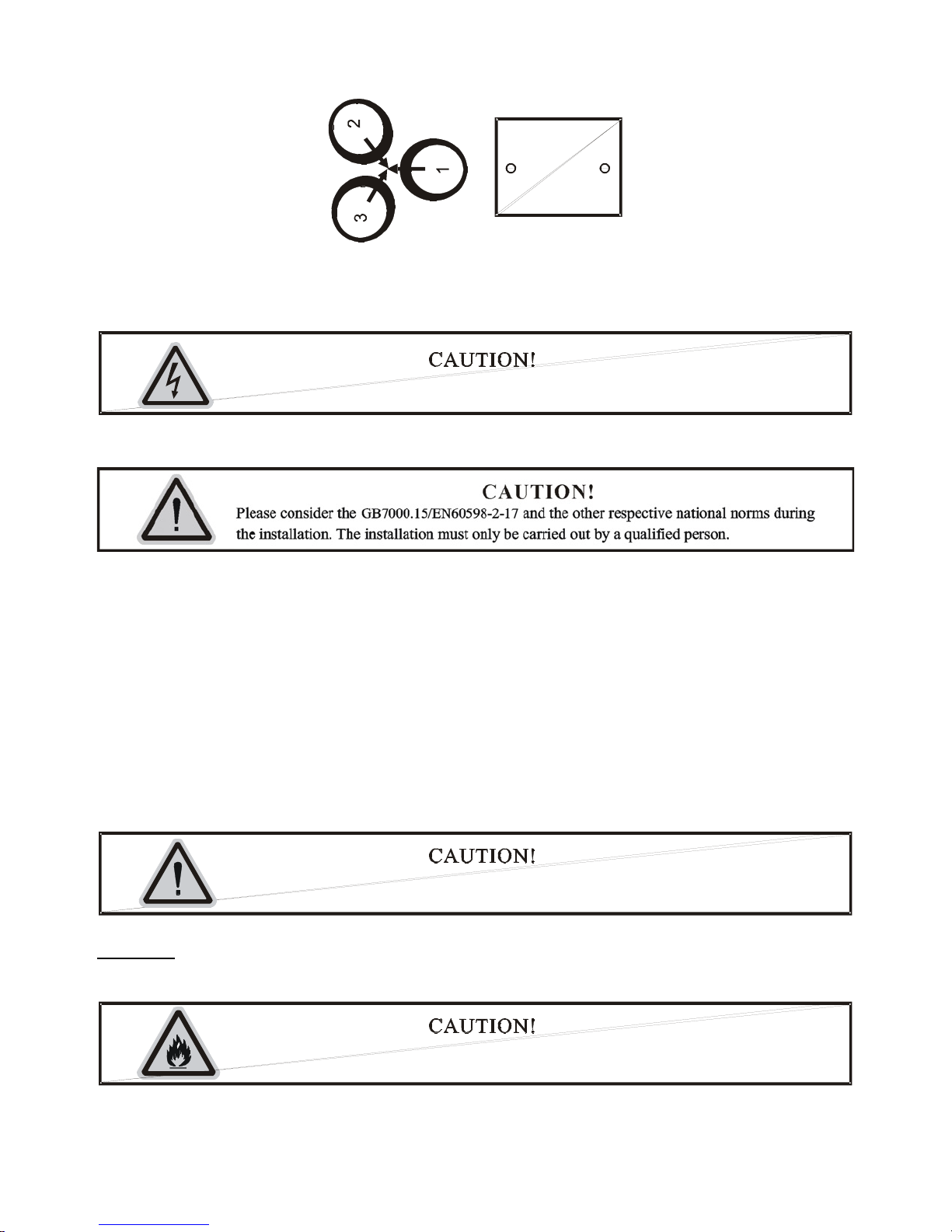

4) On the access plate there are 3 small screws marked 1, 2 and 3.which are used to adjust the lamp

holder in the lamp housing. You can adjust the 3 screws to fine-turn the position of the lamp to

get

the maximum light output as shown below.

Page 7

A

B

Please remember the lamp is not a hot-restrike type, you must wait for approximately 10 minutes

after having turned off the lamp before you can turn it back on again.

Do not operate this device with open cover

b) Mounting the device

The applicable temperature for the lighting is between -25°C to 45°C. Do not use the lighting under

or above the temperature.

The installation of the effect has to be built and constructed in a way that it can hold 10 times the

weight for 1 hour without any harming deformation.

The installation must always be secured with a secondary safety attachment, e.g. an appropriate

safety cable.

Never stand directly below the device when mounting, removing or servicing the fixture.

The operator has to make sure the safety relating and machine technical installations are approved by

an expert before taking the device into operation for the first time.

These installations have to be approved by a skilled person once a year.

Before taking into operation for the first time,

the installation has to be approved by an expert.

Cautions:

The effect should be installed outside areas where persons may reach it, walk by or be seated.

When installing the device, make sure there is no highly

inflammable material within a distance of min. 0,5m

Page 8

Overhead mounting requires extensive experience, including amongst others calculating working

load limits, installation material being used, and periodic safety inspection of all installation material

and the device. If you lack these qualifications, do not attempt the installation yourself. Improper

installation can result in bodily injury.

The electric connection must only be carried out by a qualified electrician.

Before mounting make sure that the installation area can hold a minimum point load of 10 times the

device’s weight.

Connect the fixture to the mains with the power plug.

Installation method via clamp

Please refer to the picture below:

Page 9

Screw one clamp each via a M12 screw and nut onto the Omega holders.

Insert the quick-lock fasteners of the first Omega holder into the respective holes on the bottom of the

device. Tighten the quick-lock fasteners fully clockwise. Install the second Omega holder.

Pull the safety-rope through the holes on the bottom of the base and over the trussing system or a safe

fixation spot. Insert the end in the carabine and tighten the safety screw.

DMX-512 control connection

Connect the provided XLR cable to the female 3-pin XLR output of your controller and the other

side to the male 3-pin XLR input of the moving head. You can chain multiple

Moving head together through serial linking. The cable needed should be two core, screened cable with

XLR input and output connectors. Please refer to the diagram below.

DMX-512 connection with DMX terminator

For installations where the DMX cable has to run a long distance or is in an electrically noisy

environment, such as in a discotheque, it is recommended to use a DMX terminator. This helps in

preventing corruption of the digital control signal by electrical noise. The DMX terminator is simply

an XLR plug with a 120 _ resistor connected between pins 2 and 3,which is then plugged into the

output XLR socket of the last fixture in the chain. Please see illustrations below.

1

2

3

PIN 3

PIN 2

120 Ω

Projector DMX starting address selection

Page 10

Address 33 Address 17

Address 1

All fixtures should be given a DMX starting address when using a DMX signal, so that the correct

fixture responds to the correct control signals. This digital starting address is the channel number

from which the fixture starts to “listen” to the digital control information sent out from the DMX

controller. The allocation of this starting address is achieved by setting the correct number on the

display located on the base of the device.

You can set the same starting address for all fixtures or a group of fixtures, or make different address

for each fixture individually.

If you set the same address, all the units will start to “listen” to the same control signal from the same

channel number. In other words, changing the settings of one channel will affect all the fixtures

simultaneously.

If you set a different address, each unit will start to “listen” to the channel number you have set,

based on the quantity of control channels of the unit. That means changing the settings of one

channel will affect only the selected fixture.

In the case of the spot head, which is a 16 channel fixture, you should set the starting address of the

first unit to 1, the second unit to 17(16 + 1), the third unit to 33 (17+ 16), and so on.

Control Board

The Control Board offers several features: you can simply set the starting address, switch on and off the lamp, run

the pre-programmed program or make a reset.

The main menu is accessed by pressing the Mode/esc-button until the display starts flashing. Browse through the

menu by pressing the Up-button or Down-button. Press the Enter-button in order to select the desired menu. You

can change the selection by pressing the Up-button or Down-button. Confirm every selection by pressing the

Enter-button. You can leave every mode by pressing the Mode/esc-button. The functions provided are described in

the following sections.

Default settings shaded

Function Mode

Set Dmx Address

Value Display

Set To Slave

Auto Program

Music Control

A001~AXXX

PAN……

Slave1,Slave2,Slave3

Master / Alone

Master / Alone

DMX address setting

DMX value display

Slave setting

Auto program

Music control

Time Information

Current Time

Total Run Time

Total Lamp Time

Lamp Off Time

Clear Lamp Time

XXXX(Hours)

XXXX(Hours)

XXXX(Hours)

XXXX(Minute)

ON/OFF

Power on running time

Fixture running time

Lamp running time

Lamp off time

Clear lamp time

Temperature Info

Base Temperature

Head Temperature

XX ℃/

XXX℃/

Temperature on the display

board of the base

Temperature in the head

Information

Software Version

Ver1.0

Software version of each IC

Page 11

Lamp Control

Lamp On or Off

Automatic La-On

Lamp On Via DMX

Lamp Off Via DMX

Lamp Off No DMX

Lamp On at Temp.

Lamp Off at Temp.

ON/OFF

ON/OFF

ON/OFF

ON/OFF

OFF, OFF~19M

20~79℃,45℃ /68~174 113

80~139℃, 130℃ /176~282 , 266

Lamp on/off

Lamp on/off when Power on

Lamp on via DMX

Lamp off via DMX

Lamp off if no DMX

Lamp restart at temp.

Lamp off at temp.

Status Settings

Address via DMX

No DMX Status

Pan Reverse

Tilt Reverse

Fine Resolution

Pan Degree

Dimmer Speed

Feedback

Movement Speed

Mic Sensitivity

ON/OFF

Close/Hold/Auto/Music

ON/OFF

ON/OFF

ON/OFF

630/540

Slow/Quick

ON/OFF

Speed 1~ 4

70%, 0~99%

Add. via DMX

Auto run if no DMX

Pan Reverse movement

Tilt Reverse movement

Fine resolution switch

Pan Degree Select

Dimmer Speed Select

Movement Feedback switch

Movement Mode Select

Sensitivity of Mic.

Service Setting

Service Password

Fan Voltage

Gobo Speed

Password=XXX

High/Low

Quick/Slow

Service Code=050

Fan Voltage Select

Gobo Change Speed

Fans Control

Auto Fans Speed

High Fans Speed

Low Fans Speed

Fans Speed Mode Select

Display Setting

Shutoff Time

Display shutoff time

Temperature C/F

Celsius

Fahrenheit

Temperature switch

between ℃/

Initial Effect

PAN……

PAN =XXX

Initial effect position

Personality

Reset Default

ON/OFF

Restore factory sett.

Reset Function

Reset All

Reset Pan&Tilt

Reset Colors

Reset Gobos

Reset Shutter

Reset Others

Reset all motors

Reset Pan/Tilt

Reset color wheel

Reset gobos

Reset shutter and/or dimmer

Reset other motors

Test Channel

PAN ……

Test function

Manual Control

PAN:PAN =XXX

:

Fine adjustment of the lamp

Effect Adjust

Calibrate Values

--Password-Color wheel

:

Password=XXX

Color wheel=XXX

:

Calbrate and adjust the

effects to standard/right

position Password “050”

User Mode

XXXXXX(Band)

User Mode A

User Mode B

User Mode C

User’s mode to change

channel numbers

Users Mode Set

Edit User Mode

PAN:PAN = CH01

:

Preset User modes

Page 12

Select Programs

Auto Pro Part 1

Auto Pro Part 2

Auto Pro Part 3

Program 1 ~ 10 Program 1

Program 1 ~ 10 Program 2

Program 1 ~ 10 Program 3

Select programs to be run

Edit Program

Program 1

:

Program 10

Program Test

Step 01=SCxxx

Step 64=SCxxx

(“STEP XX”)

Testing program

Program in loop

Save and exit

Edit Scenes

Edit Scene 001

~ Edit Scene 250

Pan,Tilt,……

--Secne Time-Input By Outside

Pan=xxx……

TIME=xx.xs

Save and automatically

return

manual scenes edit

Edit Program

Rec. Controller

XX~XX

Automat. scenes rec

Function Mode

DMX address setting

With this function, you can adjust the desired DMX-address via the Control Board.

• Select “Set DMX address” via the encoder.

• Press the encoder, adjust the DMX address by turning the encoder.

• Press the encoder to confirm.

• Press the Mode/Esc-button in order return to the main menu.

Display the DMX 512 value of each channel

With this function you can display the DMX 512 value of each channel. The display automatically shows the channel

with a value changing.

Slave setting

With this function, you can define the device as slave.

Auto Program

With this function, you can run the internal program. You can select the desired program under “Select program”.

You can set the number of steps under “Edit program”. You can edit the individual scenes under “Edit scenes”.

With this function, you can run the individual scenes either automatically, i.e. with the adjusted Step-Time.

Music control

With this function, you can run the internal program sound-controlled.

Information

Time information

Power on time

With this function, you can display the temporary running time of the device from the last power on. The display

shows “XXXX”, “XXXX” stands for the number of hours. The counter is resetted after turning the device off.

Total run time

With this function, you can display the running time of the device. The display shows “XXXX”, “XXXX” stands for

the number of hours.

Total lamp time

With this function, you can display the running time of the lamp. The display shows “XXXX”, “XXXX” stands for

the

number of hours.

Lamp off time

With this function, you can display the temporary running time of the lamp from the last lamp on. The display

Shows “XXXX”, “XXXX” stands for the number of hours. The counter is resetted after turning the lamp off.

Clear lamp time

With this function you can clear the running time of the lamp. Please clear the lamp time every time you replace the

Page 13

lamp.

• Select “Clear lamp time” by turning the encoder.

• Press the encoder, the display shows “ON” or “OFF”.

• Press the encoder to confirm.

• Press the Mode/Esc-button in order to return to the main menu.

Temp. Info.

Base Temp

With this function you can display the temperature in the projector base (near LCD-display) in Celsius.

Head Temp

With this function you can display the temperature on the display board of the base (near CMY-filter) in Celsius.

Software version

With this function, you can display the software version of the device.

• Select “Software version” by turning the encoder.

• Press the encoder, the display shows “V-X.X”, “X.X” stands for the version number, e.g. “V-1.0”, “V-2.6”.

• Turn the encoder in order to read the version of every individual IC.

• Press the Mode/Esc-button in order to return to the main menu.

LAMP CONTROL

When the real temperature around the lamp is higher than the preset value, the lamp will be shut down

in 5 minutes automatically.

·When the LCD display shows “Off”, it means the lamp must be turned on again manually;

·When the LCD display shows “Hot”, it means the actual temperature around the lamp is still higher than the

preset value, so even the lamp can not be striked even the menu Lamp is turned to ON, as the lamp switch is

compelled to turned off.

·When the temperature unit after the temperature value come to lowercase letter “c” or “f”, it means

menu Lamp is turned to ON, but the lamp is not full dimming up.

·When the temperature unit after the temperature value come to capital letter “C” or “F”, it menu Lamp

is turned to ON, and the lamp is full intensity.

Lamp on/off

With this function you can switch the lamp on or off via the Control Board.

• Select "Lamp on/off" by turning the encoder.

• Press the encoder, the display shows “ON” or “OFF”.

• Turn the encoder to select “ON” if you wish to strike the lamp or “OFF” in order to switch it off.

• Press the encoder to confirm.

• Press the Mode/Esc-button in order to return to the main menu.

Remark: The menu Lamp On/Off is the software command only, the lamp can be striked successfully only when

the menu Lamp is set to ON and the actual temperature is lower than the limited value.

Lamp on/off when power on

With this function you can select if the lamp will be switched on when switching the power on. Select “ON” by

turning the encoder if you wish to enable this function or “OFF” if you don’t.

Lamp on via external controller

With this function you can select if you can switch the lamp on via an external controller (DMX-16 channel of

internal program, value 40-59). Select “ON” by turning the encoder if you wish to enable this function or “OFF” if

you don’t.

Lamp off via external controller

With this function you can select if you can switch the lamp off via an external controller (DMX-16 channel of

internal program, value 60-79). Select “ON” by turning the encoder if you wish to enable this function or “OFF” if

you don’t.

Page 14

Lamp Off if no DMX

With this function you can select to switch off the lamp off automatically if there is no DMX signal). Select “ON” by

turning the encoder if you wish to enable this function or “OFF” if you don’t.

Lamp on at temp.

With this function you can set the inside temperature from which the projector will restrike the lamp after automatic

lamp shut off.

Lamp off at temp.

With this function you can set the inside temperature at which the projector will automatically switch the lamp off.

Turn the encoder to select the maximum inside temperature between 60° C and 159° C. Inside temperatures below

90° C are not critical. 90° C and more should lead to the lamp being switched off. Please note that the outside

temperature should not exceed 45° C.

When the temperature around the lamp is higher than the preset value continuously up to 5 minutes, the

lamp will be shut off automatically.

If the lamp be shut off automatically due to over heat, it can not be striked again automatically, it must

be turned on again by manually.

PERSONALITY

Status setting

Address via DMX

With this function, you can adjust the desired DMX-address via an external controller.

• Select “Address via DMX” by turning the encoder.

• Press the encoder, the display shows “ON” or “OFF”.

• Turn the encoder to select “ON” if you wish to enable this function or “OFF” if you don’t.

• Press the encoder to confirm.

• Press the Mode/Esc-button in order to return to the main menu.

• On the controller, set the DMX-value of channel 1 to "7".

• Set the DMX-value of channel 2 to "7"or "8". When set to "7" you can adjust the starting address between 1 and 255.

When set to "8" you can adjust the starting address between 256 and 511.

• Set the DMX-value of channel 3 to the desired starting address. If you want to set the starting address to 57, set

channel 1 to "7", channel 2 to "7" and channel 3 to "57". If you want to set the starting address to 420,set channel

1 to "7", channel 2 to "8" and channel 3 to "164" (256+164=420).

• Wait for approx. 20 seconds and the unit will carry out a reset. After that, the new starting address is set.

Auto If No DMX

With this function, when the drive is not DMX signal, it runs automatism, close, hold and music, the default is hold.

Pan Reverse

With this function you can reverse the Pan-movement.

Tilt Reverse

With this function you can reverse the Tilt-movement.

Fine resolution

With this function, you can fine resolution switch of pan movement or tilt movement.

Pan Degree

With this function, you can select pan degree for 630 or 540.

Dimmer Speed

With this function, you can select dimmer speed for slow or quick.

Feedback

With this function, you can feedback switch of pan movement or tilt movement.

Page 15

Movement Speed

With this function, you can select scan mode from 1 to 4.

Mic Sensitivity

With this function, the default is 70%, you can select the desired microphone sensitivity from 0 % to 99 %.

Service setting

Service Password

With this function, you can set the service password.

Fan Voltage

With this function, you can select fan voltage for high or low.

Attention: The model is not recommended when ambient temperature is higher than 15 Celsius degree.

Gobo speed

With this function, you can select GOBO speed for quick or slow, the default is slow.

Fans Control

With this function, you can set the speed of the running fans. The selections have Auto、high and low.

Display settings

Shut off time

With this function you can shut off the LCD display after 2 to 59 minutes. Turn the encoder in order to select the

desired shut off time.

Temperature C/F

With this function, Display the temperature for Celsius or Fahrenheit.

Initial effect

With this function, Display initial effect position.

Reset Default

With this function, you can select restore factory set for ON or OFF, the default is OFF.

Reset-functions

With this function you can reset the device via the Control Board. You can select the different reset functions by

turning the encoder.

Effect Adjust

Test function of each channel

With this function you can test each channel on its (correct) function.

Lamp adjustment

With this function, you can adjust the lamp more easily. All effects will be canceled, the shutter opens and the

dimmer intensity will be set to 100 %. With the individual functions, you can focus the light on a flat surface (wall)

and erform the fine lamp adjustment.

Calibrate values

With this function, you can calibrate and adjust the effect wheels to their correct positions. The password of calibrate

values is 050.

Page 16

Users mode set

In this menu, user can select different channels list by different sequence:

For example, after the user enter this manual, if select Auto Program = CH 15, means in this User’s mode, the

“Dimmer” is in Channel 11.

User mode

With this function, you can create user defined channel orders.

Preset User mode

With this function, you can adjust the rest user defined channel order.

Edit program

Select program

With this function, you can select the program for the Program Run.

Edit program

With this function, you can edit the internal programs.

Edit scenes

With this function, you can edit the scenes of the internal programs.

Auto scenes rec.

The moving head features an integrated DMX-recorder y which you can transmit the programmed scenes from your

DMX-controller to the moving head. Adjust the desired scene numbers via the encoder (from – to). When you call up the

scenes at your controller, they will automatically be transmitted to the moving head.

Excursion:

A Master unit can send up to 3 different data groups to the Slave units, i.e. a Master unit can start 3 different Slave units,

which run 3 different programs. The Master unit sends the 3 program parts in a continuous loop.

The Slave unit receives data from the Master unit according to the group which the Slave unit was assigned to. If e.g. a

Slave unit is set to “Slave 1” in the menu “Set to Slave”, the Master unit sends “Auto Program Part 1” to the Slave unit.

If set to “Slave 2”, the Slave unit receives “Auto Program Part 2”.

To start a Auto Program please proceed as follows:

1. Slave-Setting

・ Select “Function Mode” by turning the encoder.

・ Press the Enter button to confirm.

・ Select “Set to slave” by turning the encoder.

・ Press the Enter button to confirm.

・ Turn the encoder to select “Slave 1”, “Slave 2” or “Slave 3”.

・ Press the Enter button to confirm.

・ Press the Mode/Esc button in order to return to the main menu.

2. Automatic Program Run

・ Select “Function Mode” by turning the encoder.

・ Press the Enter button to confirm.

・ Select “Auto Program” by turning the encoder.

・ Press the Enter button to confirm.

Page 17

・ Turn the encoder to select “Master” or “Alone”. The selection "Alone" means Stand Alone-mode and "Master" that

the device is defined as master.

・ Press the Enter button to confirm.

・ Press the Mode/Esc button in order to return to the main menu.

3. Program selection for Auto Pro Part

・ Select “Edit program” by turning the encoder.

・ Press the Enter button to confirm.

・ Select “Select programs” by turning the encoder.

・ Press the Enter button to confirm.

・ Turn the encoder to select “Auto Pro Part 1”, “Auto Pro Part 2” or “Auto Pro Part 3”, and thus select which Slave

program is to be sent. Selection “Part 1” means, that the Slave unit runs the same program as the master units.

・ Press the Enter button to confirm.

・ Press the Mode/Esc button in order to return to the main menu.

4. Program selection for Edit Program

・ Select “Edit program” by turning the encoder.

・ Press the Enter button to confirm.

・ Select “Edit program” by turning the encoder.

・ Press the Enter button to confirm.

・ Turn the encoder to select the desired program. With this function you can edit specific scenes into a specific

program.

・ Press the Enter button to confirm.

・ Press the Mode/Esc button in order to return to the main menu.

5. Automatic Scene Recording

・ Select “Edit program” by turning the encoder.

・ Press the Enter button to confirm.

・ Select “Edit scenes” by turning the encoder.

・ Turn the encoder to select the desired scene numbers. You can program a maximum number of 250 ・ Turn the

encoder to select the desired scene numbers. You can program a maximum number of 250 scenes.

・ Press the Enter button to confirm.

・ Press the Mode/Esc button in order to return to the main menu.

Example:

Program 2 includes scenes: 10, 11, 12, 13

Program 4 includes scenes: 8, 9, 10

Program 6 includes scenes: 12, 13, 14, 15, 16

Auto Pro Part 1 is Program 2;

Auto Pro Part 2 is Program 3;

Auto Pro Part 3 is Program 6

The 3 Slave groups run the Auto Program in certain time segments, as shown in the following picture:

Page 18

DMX channel´s functions and their values (16 DMX channels):

Channel 1 - Color Wheel :

0-13

Open / white

14-27

Color 1

28-41

Color 2

42-55

Color 3

56-69

Color 4

70-83

Color 5

84-97

Color 6

98-111

Color 7

112-127

Color 8

128-189

Forwards rainbow effect from fast to slow

190-193

No rotation

194-255

Backwards rainbow effect from slow to fast

Channel 2 - Rotating gobos, cont. rotation :

0-9

Open

10-19

Rot. gobo 1

20-29

Rot. gobo 2

30-39

Rot. gobo 3

40-49

Rot. gobo 4

50-59

Rot. gobo 5

60-69

Rot. gobo 6

70-79

Rot. gobo 7

80-99

Gobo 1 shake slow to fast

100-119

Gobo 2 shake slow to fast

120-139

Gobo 3 shake slow to fast

Page 19

140-159

Gobo 4 shake slow to fast

160-179

Gobo 5 shake slow to fast

180-199

Gobo 6 shake slow to fast

200-219

Gobo 7 shake slow to fast

220-255

Rot. gobo wheel cont. rotation slow to fast

Channel 3 - Rotating gobo index, rotating gobo rotation :

0-127

Gobo indexing

128-189

Forwards gobo rotation from fast to slow

190-193

No rotation

194-255

Backwards gobo rotation from slow to fast

Channel 4- Fixed Gobos :

0-13

Open/hole

14-27

Gobo 1

28-41

Gobo 2

42-55

Gobo 3

56-69

Gobo 4

70-83

Gobo 5

84-97

Gobo 6

98-111

Gobo 7

112-127

Gobo 1 shake slow to fast

128-143

Gobo 2 shake slow to fast

144-159

Gobo 3 shake slow to fast

160-175

Gobo 4 shake slow to fast

176-191

Gobo 5 shake slow to fast

192-207

Gobo 6 shake slow to fast

208-223

Gobo 7 shake slow to fast

224-255

Gobo wheel rotation from slow to fast

Channel 5 - PAN movement 8bit :

Channel 6 - TILT movement 8bit :

Channel 7 - Speed pan/tilt movement:

0-225

max to min speed

226-235

blackout by movement

236-245

blackout by all wheel changing

246-255

no function

Channel 8- 3 facet rotating prism, Prism / Gobo macros:

0-3

open

Page 20

4-63

Forwards rotation from fast to slow

64-67

No rotation

68-127

Backwards rotation from slow to fast

128-135

Macro 1

136-143

Macro 2

144-151

Macro 3

152-159

Macro 4

160-167

Macro 5

168-175

Macro 6

176-183

Macro 7

184-191

Macro 8

192-199

Macro 9

200-207

Macro 10

208-215

Macro 11

216-223

Macro 12

224-231

Macro 13

232-239

Macro 14

240-247

Macro 15

248-255

Macro 16

Channel 9 – Focus :

0-255

Continuous adjustment from far to near

Channel 10 - Shutter, strobe:

0-31

Shutter closed

32-63

No function (shutter open)

64-95

Strobe effect slow to fast

96-127

No function (shutter open)

128-159

Pulse-effect in sequences

160-191

No function (shutter open)

192-223

Random strobe effect slow to fast

224-255

No function (shutter open)

Channel 11- Dimmer (intensity):

0-255

Intensity 0 to 100%

Channel 12 – Iris:

0-191

Max. diameter to Min.diameter

192-223

Pulse opening fast to slow

224-255

Pulse closing slow to fast

Channel 13 –Frost:

Page 21

0-191

Frost 0~100%

192-223

Pulse opening fast to slow

224-254

Pulse closing slow to fast

255

100% Frost

Channel 14– Lamp on/off, reset, internal programs:

0-19

Color&Gobo change normal

20-29

Color change to any position

30-39

Color&Gobo change to any position

40-59

Lamp on

60-79

Lamp switch off

80-84

All motor reset

85-87

Scan motor reset

88-90

Colors motor reset

91-93

Gobo motor reset

94-96

Shutter & Dimmer motor reset

97-99

Other mo reset

100-119

Internal program 1 (secne1~8 of EEPROM)

120-139

Internal program 2 (secne9~16 of EEPROM)

140-159

Internal program 3 (secne17~24 of EEPROM)

160-179

Internal program 4 (secne25~32 of EEPROM)

180-199

Internal program 5 (secne33~40 of EEPROM)

200-219

Internal program 6 (secne41~48 of EEPROM)

220-239

Internal program 7 (secne49~56 of EEPROM)

240-255

Music Control (secne of Program 1)

Channel 15 – Pan fine 16bit

Channel 16– Tilt fine 16bit

ERROR CODES:

When you turn on the fixture, it will make a reset first. The display may show “XXer” while there are problems

with one or more channels. “XX” stands for channel 1,2,3,4,5,6,8,9 who has the testing sensor for position.

For example, when the display shows “01Er”, it means there is some error in channel 1. If there are some errors on

channel 1, channel 5, channel 6 at the same time, you may see the error message “01Er”, “05Er”,”06Er” flash

repeated for 5 times, and then the fixture will generate a reset signal, all the stepper reset. If the fixture remain error

message after performing reset more than 3 times, it will detect whether the fixture has more than 3 errors. If the

fixture has more than 3 errors (including 3 errors), all the channels can not work properly; but if the fixture has less

than 3 errors, only the channels which have errors can not work properly, others can work as usual.

Color-wheel error:

This message will appear after the reset of the fixture if the magnetic-indexing circuit malfunctions (sensor failed or

magnet missing) or the stepping-motor is defective (or its drive circuit on the main PCB). The color wheel is not

located in the default position after the reset.

Page 22

Rotating gobo-wheel error:

The gobo-wheel is not located in the default position after start-up or after a reset command. This message will

appear after a fixture reset if the magnetic-indexing circuit malfunctions (sensor failed or magnet is missing) or

there is a stepper motor failure (defective motor or a defective motor IC drive on the main PCB).

Rotating gobo indexing error:

The gobo is not located in the default position after start-up or after a reset command. This message will appear

after a fixture reset if the magnetic-indexing circuit malfunctions (sensor failed or magnet is missing) or there is a

stepper motor failure (defective motor or a defective motor IC drive on the main PCB).

Fix Gobo-wheel error

This message will appear after the reset of the fixture if the magnetic-indexing circuit malfunctions (sensor failed or

magnet missing) or the stepping-motor is defective (or its drive circuit on the main PCB). The fix gobo wheel is not

located in the default position after the reset.

PAN-yoke movement error

(PAN-yoke movement error) This message will appear after the reset of the fixture if the yoke’s magnetic-indexing

circuit malfunction (sensor failed or magnet missing) or the stepping-motor is defective (or its driving IC on the

main PCB). The yoke is not located in the default position after the reset.

TILT-head movement error

(TILT-head movement error) This message will appear after the reset of the fixture if the head’s magnetic-indexing

circuit malfunctions (sensor failed or magnet missing) or the stepping-motor is defective (or its driving IC on the

main PCB). The head is not located in the default position after the reset.

Prism-wheel error

This message will appear after the reset of the fixture and if the magnetic-indexing circuit malfunctions (sensor

failed or magnet missing) or the stepping-motor is defective (or its driver circuit on the main PCB). The prismwheel is not located in the default position after the reset.

Focus error

This message will appear after the reset of the fixture and if the magnetic indexing circuit malfunctions (sensor

failed or magnet missing) or the stepping-motor is defective (or its driver circuit on the main PCB). The focus is not

located in the default position after the reset.

CLEANING AND MAINTENANCE

The following points have to be considered during the inspection:

1) All screws for installing the devices or parts of the device have to be tightly connected and must

not be corroded.

2) There must not be any deformations on the housing, color lenses, fixations and installation spots

(ceiling, suspension, trussing).

3) Mechanically moved parts must not show any traces of wearing and must not rotate with

unbalances.

4) The electric power supply cables must not show any damage, material fatigue or sediments.

Further instructions depending on the installation spot and usage have to be adhered by a skilled

installer and any safety problems have to be removed.

Page 23

We recommend a frequent cleaning of the device. Please use a moist, lint- free cloth. Never use

alcohol or solvents.

There are no serviceable parts inside the device except for the lamp. Please refer to the instructions under

“Installation instructions”.

Should you need any spare parts, please order genuine parts from your local dealer.

TECHNICAL SPECIFICATIONS

Power supply:

□AC 100V ~, 50Hz; □AC 120V ~, 50Hz; □AC 208V ~, 50Hz; □AC 220V ~, 50Hz; □AC

230V ~, 50Hz; □AC 240V ~, 50Hz;

□AC 100V ~, 60Hz; □AC 120V ~, 60Hz; □AC 208V ~, 60Hz; □AC 220V ~, 60Hz; □AC

230V ~, 60Hz; □AC 240V ~, 60Hz;

Power consumption: max. 400W

Lamp: MSD 250/2

Packing dimensions: 59.5x45x50cm

Net weight: 26KGS

Gross weight: 30KGS

Remark: errors and omissions for every information given in this manual excepted. All information is subject to change

without prior notice.

Loading...

Loading...