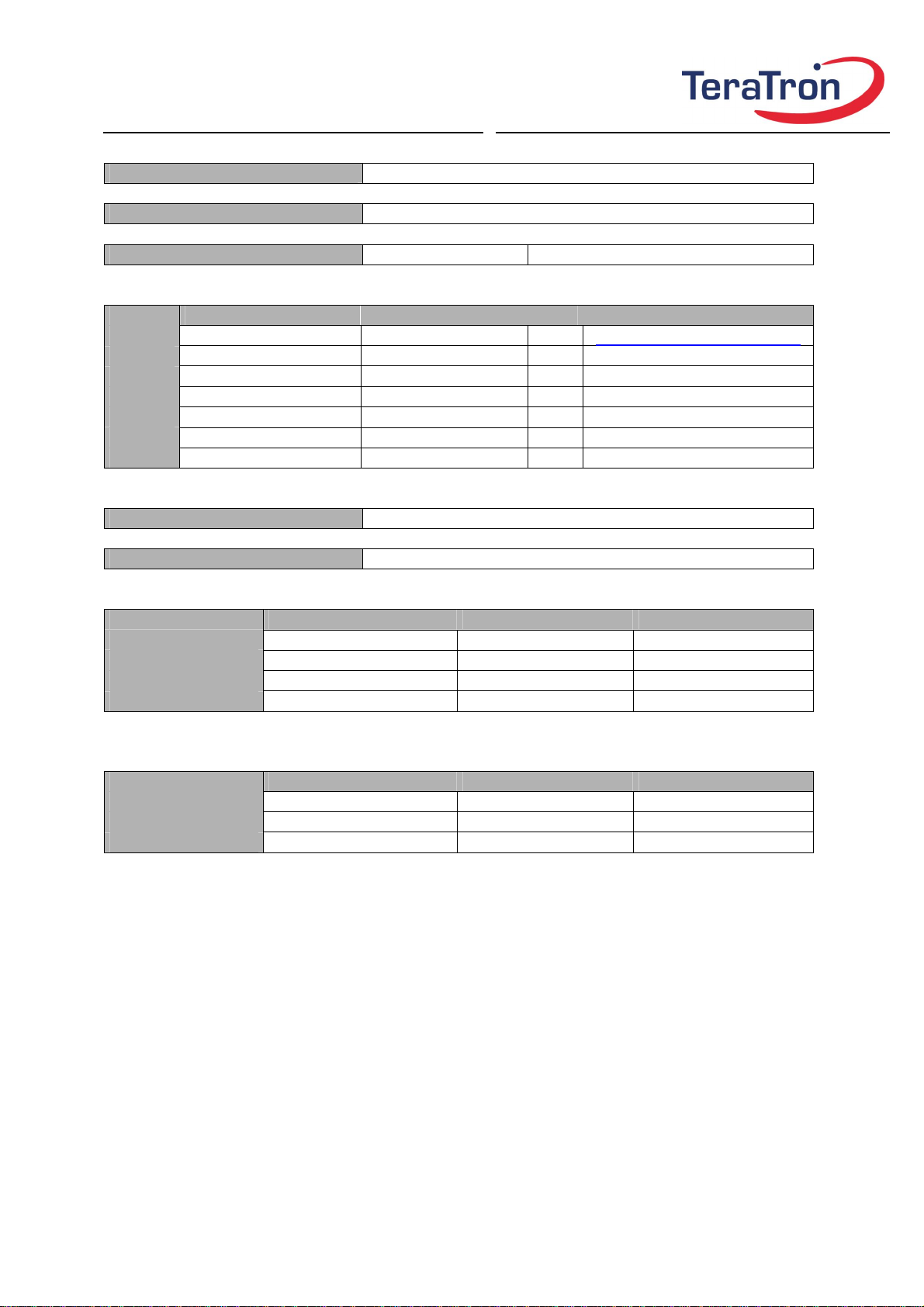

Annex No.5

Page 1 of 7

User Manual

Hilti GX 120

Technical description

RFID-Reader GX120

Von / From: RHE

Datum / Date: 03.08.07

Seite / Page: 1 / 6

Dokumenten-Nr.

Projekt

Dokumentenversion

Autor Name Tel. Fax E-Mail

V1.0

Dokumentenstatus

Vertraulichkeit

Verteiler Organisation Name

Rainer Helberg +49-2261-8082-233 -833 rainer.helberg@teratron.de

2.0

Hilti GX 120

1.0 Erstelldatum : 03.08.2007

released

Strictly confidential

Querverweise

Technical description

Von / From: RHE

RFID-Reader GX120

Datum / Date: 03.08.07

Seite / Page: 2 / 6

1. TECHNICAL DESCRIPTION.......................................................................................2

2. BLOCK DIAGRAM......................................................................................................4

3. GEOMETRY OF PCB..................................................................................................5

4. IMPORTANT REQUEST:............................................................................................5

5. LABEL:........................................................................................................................6

1. Technic al De scription

The reader is used in a gas can driven direct fastener tool for metal nail s.

It is mounted inside of the tool and communicate with special transponders which are fitted at the

gas cans.

It controls the use of the correct gas can for the tool and also it show the user the remaining gas

level inside the can by 5 LED’s. This is possible, by writing the actual needed gas consumption into

the transponder during working after each shot.

The reader is working together with a second electronic which controls the gas growd and generate

the ignition puls for the spark plug.

The communication to the tr ansponder is working with a 125kHz field.

Here you can see the the RFID reader fitted in it’s housing:

Technical description

Von / From: RHE

RFID-Reader GX120

The followi ng picture shows th e o pened tool w ith the electronics and the batt ery:

Datum / Date: 03.08.07

Seite / Page: 3 / 6

This picture shows the RFID reader PCB alone. In the left you will see the coil for the 125 kHz

communication w ith the transponder:

Technical description

processor

processor

nose-

antenna coil for

switch

RFID-Reader GX120

2. Block diagram

battery

Von / From: RHE

Datum / Date: 03.08.07

Seite / Page: 4 / 6

transponder

communication

power

converter

readercircuit

switchinfo

communication lines

power

control

logic

communication lines

switch

control

logic

gas

can switch

LED for gas consumption level

Technical description

RFID-Reader GX120

3. Geom etry of PCB

The pict ure shows the size of the PCB:

Von / From: RHE

Datum / Date: 03.08.07

Seite / Page: 5 / 6

4. Impor tant reque st:

This device complies with P art 15 of the FCC Rules. Operation is subject to the following two

conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference received, including interference that may cause

undesir ed operation o f the device."

Any changes or modifications not expressly approved by the party responsible for compliance could

void the user's authority to operate this equipment"

Technical description

RFID-Reader GX120

5. Label:

The following label will be fixed on each m odule:

Tested to comply with

FCC Standards

Model: GX120 – Reader

Von / From: RHE

Datum / Date: 03.08.07

Seite / Page: 6 / 6

IC: 4430A-GX120

Loading...

Loading...