Operating instructions

Maintenance instructions

Original operating instructions

BSS0134R

BMP 8500

S/N 101 720 11 1930 >

Catalogue No.

008 059 81

Multi-purpose compactor

08/2011

Foreword

Foreword

BOMAG machines are products from the wide

range of BOMAG compaction equipment.

BOMAG’s vast experience in connection with

state-of-the-art production and testing methods, such as lifetime tests of all important

components and highest quality demands

guarantee maximum reliability of your machine.

This manual comprises:

l Safety regulations

l Operating instructions

l Maintenance instructions

l Trouble shooting

Using these instructions will

l help you to become familiar with the machine.

l avoid malfunctions caused by unprofessional

operation.

Compliance with the maintenance instructions will

l enhance the reliability of the machine on con-

struction sites,

l prolong the lifetime of the machine,

l reduce repair costs and downtimes.

BOMAG GmbH will not assume liability for the

function of the machine

l if it is handled in a way that does not comply

with the usual modes of use,

l if it is used for purposes other than the ones it

is intended for (see safety regulations).

No warranty claims can be lodged in case of damage resulting from

l operating errors,

l insufficient maintenance and

l wrong fuels and lubricants.

Please note!

This manual was written for operators and maintenance personnel on construction sites.

Always keep this manual close at hand, e.g. in the

tool compartment of the machine or in a specially

provided container. These operating and maintenance instructions are part of the machine.

You should only operate the machine after you

have been instructed and in compliance with these

instructions.

Strictly observe the safety regulations.

Please observe also the guidelines of the Civil Engineering Liability Association ”Safety Rules for

the Operation of Road Rollers and Soil Compactors” and all relevant accident prevention regulations.

For your own personal safety you should only

use original spare parts from BOMAG.

In the course of technical development we reserve the right for technical modifications

without prior notification.

These operating and maintenance instructions are

also available in other languages.

Furthermore, the spare parts catalogue is available from your BOMAG dealer against the serial

number of your machine.

Your BOMAG dealer will also supply you with information about the correct use of our machines in

soil and asphalt construction.

The above notes do not constitute an extension of

the warranty and liability conditions specified in the

general terms of business of BOMAG GmbH.

We wish you successful work with your BOMAG

machine.

BOMAG GmbH

Printed in Germany

Copyright by BOMAG

FCC Notice

1)Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate

the equipment.

2)This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television

reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

3)This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

BOMAG 3BMP 8500

Foreword

i

Note

Please fill in

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

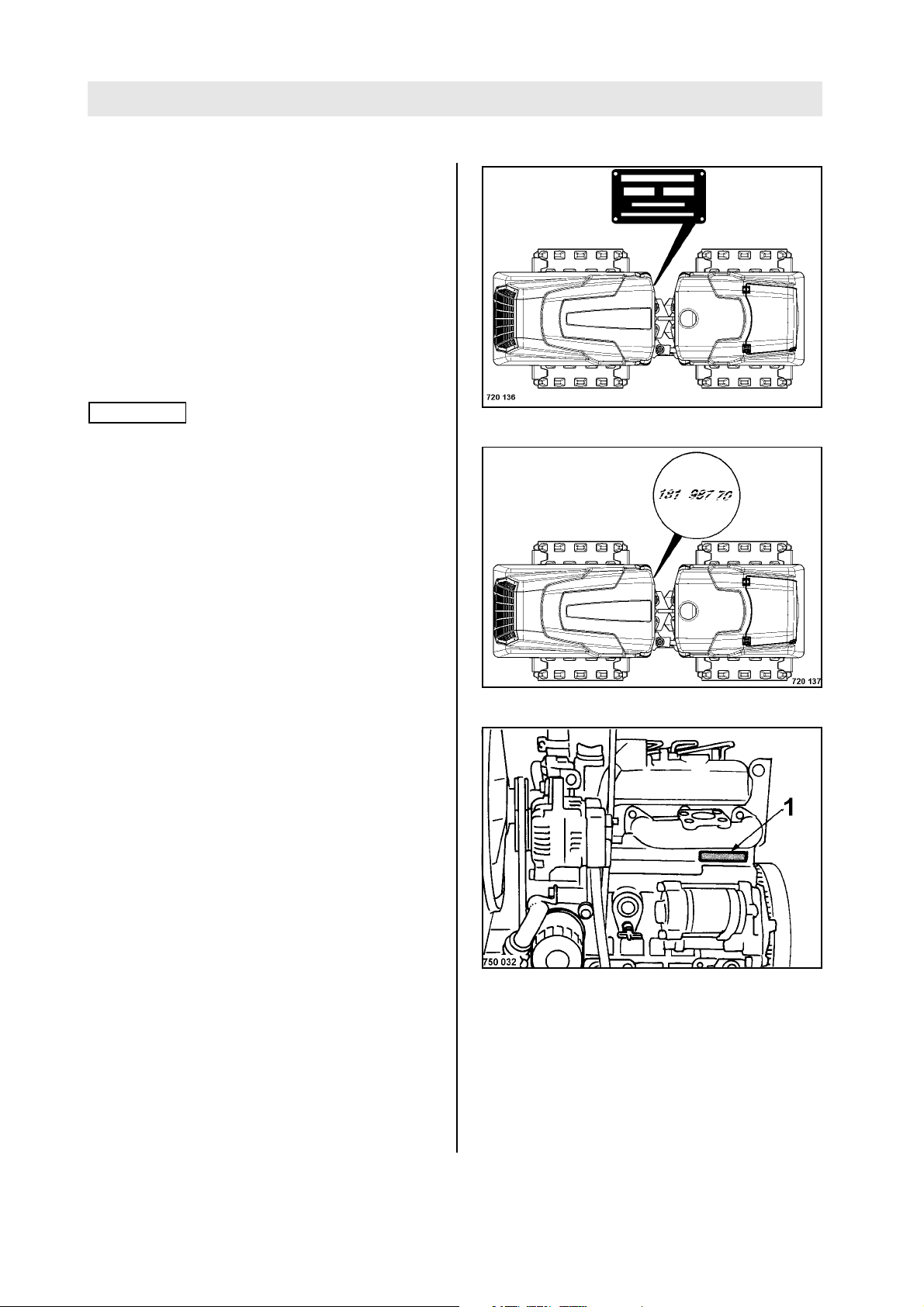

Machine type (Fig. 1)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial-number (Fig. 1 and 2)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor type (Fig. 3)

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor number (Fig. 3)

Supplement the above data together with the commissioning protocol.

During commissioning our organisation will instruct you in the operation and maintenance of the

machine.

Please observe strictly the safety regulations and

all notes on risks and dangers!

Fig. 1

Fig. 2

Fig. 3

BOMAG4 BMP 8500

Table of Contents

Technical Data 7

Safety regulations 13

Indicators and Controls 23

3.1 General notes 26

3.2 Description of indicators and control elements 26

Operation 31

4.1 General 32

4.2 Tests before taking into operation 32

4.3 BOSS safety system 33

4.4 Starting the engine 34

4.5 Driving the machine (cable remote control) 36

4.6 Safety inspection for the cable remote control 39

4.7 Switching the vibration on and off 39

4.8 Shut down the engine 41

4.9 Shutting down the engine manually 42

4.10 Starting operation of the radio remote control 43

4.11 Replacing, recharging the radio remote control power pack 47

4.12 Safety inspection for the radio remote control 49

4.13 Switching off of the radio remote control in case of radio interferences 50

4.14 Switching ECO-mode on and off 50

4.15 Entering the machine type code 51

4.16 Teaching the BOSS safety system transponder 52

4.17 Assembling/removing the drum extension 53

4.18 Loading and transport 53

Maintenance 55

5.1 General notes on maintenance 56

5.2 Fuels and lubricants 57

5.3 Table of fuels and lubricants 60

5.4 Running-in instructions 61

5.5 Maintenance table 62

5.6 Check the engine oil level 65

5.7 Checking the hydraulic oil level 65

5.8 Checking the fuel level 66

5.9 Check the water separator 66

5.10 Checking the coolant level 67

5.11 Check the air intake hose 69

5.12 Changing engine oil and oil filter 69

5.13 Checking, tensioning, replacing the V-belt 71

5.14 Clean the cooling fins on engine and hydraulic oil cooler 72

5.15 Change the oil in the vibrator shaft housing 73

5.16 Checking the central screw of the drive hub 75

BOMAG 5BMP 8500

Table of Contents

5.17 Draining the fuel tank sludge 77

5.18 Changing the fuel pre-cleaner, bleeding the fuel system 77

5.19 Battery service, checking the main battery switch 79

5.20 Check the rubber buffers 80

5.21 Checking, adjusting the valve clearance 81

5.22 Safety field measurement of the Boss safety system 82

5.23 Change hydraulic oil and filter 83

5.24 Change the coolant 84

5.25 Change the fuel lines 86

5.26 Checking the injection pressure 86

5.27 Checking the fuel injection pump 87

5.28 Checking the fuel injection timing 87

5.29 Check, clean, replace the combustion air filter 89

5.30 Adjust the scrapers 92

5.31 Tightening torques for screws with metric unified thread 92

5.32 Engine conservation 93

Trouble shooting 95

6.1 General notes 96

6.2 Engine problems 97

6.3 Problems with remote control Hetronic with spiral cable 99

6.4 Problems with radio remote control Hetronic in radio operation 102

6.5 Faults in BOSS safety system 104

6.6 Fault indicator 105

6.7 Fault code 106

6.8 Input codes for BLM control 119

BOMAG6 BMP 8500

1 Technical Data

BOMAG 7BMP 8500

Technical Data

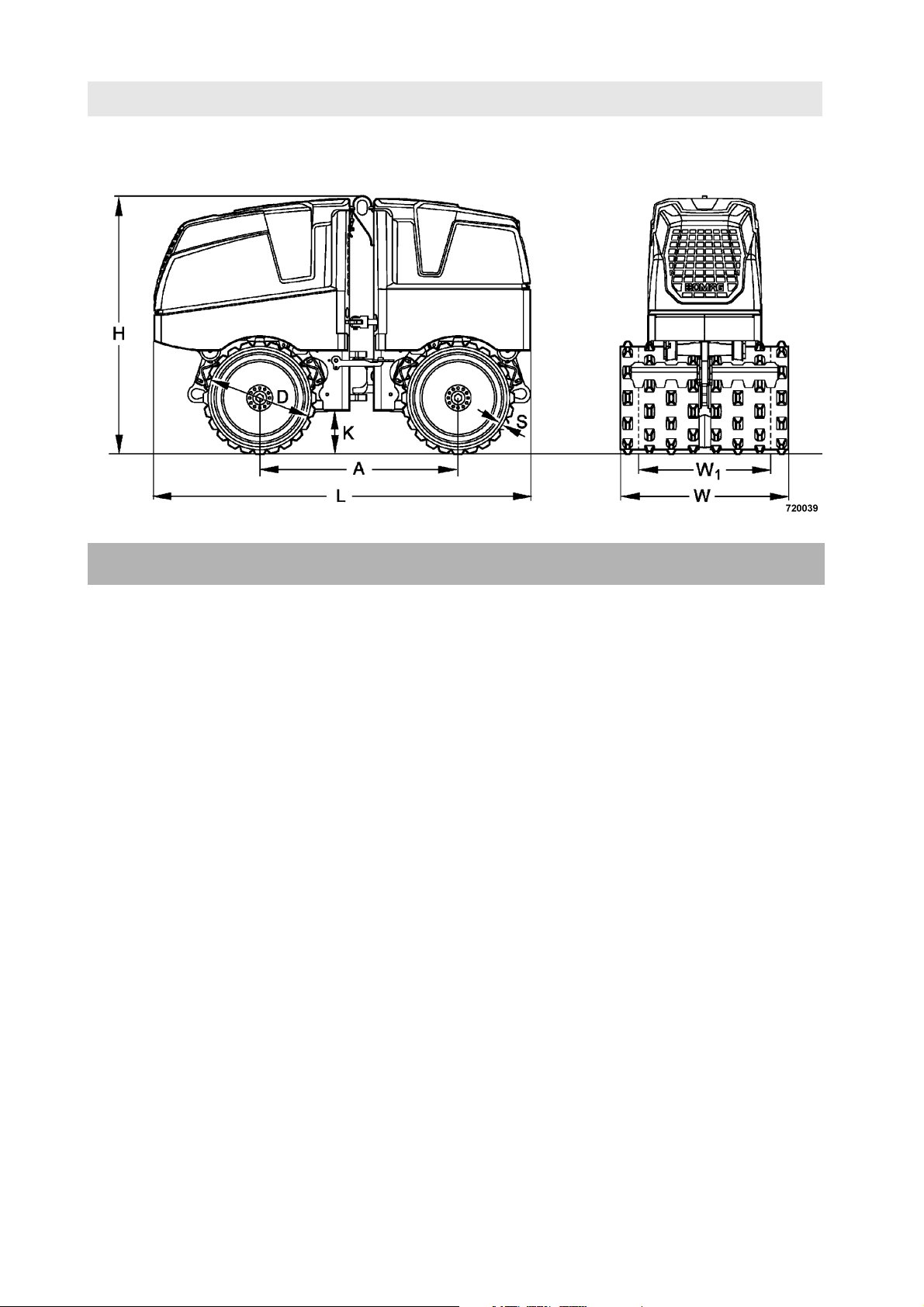

Dimensions in

A D H K L S W W

1

mm (inches)

BMP 8500

*

1000

(39.4)

520

(20.5)

1275

(50.2)

222

(8.7)

1897

(74.7)

25

(1.0)

850

(33.5)

610

(24.2)

BMP 8500

Weights

Operating weight (CECE) kg (lbs) 1595 (3516)

Basic weight kg 1585 (3494)

Mean axle load (CECE) kg 775 (1709)

Travel characteristics

Travel speed (1) forward/reverse km/h (mph) 1,3 (0.8)

Travel speed (2) forward/reverse km/h (mph) 2,5 (1.6)

Max. gradability without/with vibration (soil dependent) % 55/45

Drive

Engine manufacturer Kubota

Type D 1005

Cooling Water

Number of cylinders 3

Rated power ISO 9249 kW (hp) 14,5 (19.4)

Rated speed rpm 2600

Drive system hydrostatic

Driven drums front + rear

Brakes

Service brake hydrostatic

Parking brake mechanical

BOMAG8 BMP 8500

Technical Data

*

Steering

Type of steering Articulated joint

Steering operation hydrostatic

Vibration system

Vibrating drum front + rear

Drive system hydrostatic

Frequency Hz 42

Amplitude 1/2 mm (in) 1,12/0,56 (0.04/0.02)

Centrifugal force 1/2 kN (lbf) 72/36 (16186/8093)

Filling capacities

Fuel (diesel) l (gal us) 24 (6.3)

Hydraulic oil l (gal us) 17 (4.5)

Engine oil l (gal us) 4,7 (1.24)

Coolant l (gal us) 4,5 (1.19)

Vibration housing l (gal us) 2x 1,7 (2x 0.45)

Safety field system

Performance level PL c

Reach of the safety field infront of/behind the machine m (ft) > 1,20 (> 3,94)

BMP 8500

Safety field control

Voltage V 8 ... 30

Current consumption at 12 V A 1.5

Protection class IP 55

Safety field frequency kHz 125

Operating temperature °C (°F) -20 ... +80 (-4 ... +176)

Storage temperature °C (°F) -40 ... +85 (-40 ... +185)

Transponder in remote control

Voltage (cable operation) V 9 ... 30

Voltage (battery operation) V 3.6

Transmitting frequency range MHz 868/916

Operating temperature °C (°F) -20 ... +80 (-4 ... +176)

Storage temperature °C (°F) -40 ... +85 (-40 ... +185)

Safety field antenna

Protection class IP 55

Operating temperature °C (°F) -20 ... +80 (-4 ... +176)

Storage temperature °C (°F) -40 ... +85 (-40 ... +185)

Radio remote control

Manufacturer HETRONIC

Transmitter

Frequency band F-band

BOMAG 9BMP 8500

Technical Data

*

BMP 8500

Transmitting frequency range MHz 868 / 916

Number of channels 1

Reach, depending on environment m (ft) approx. 30 (98.4)

Current draw mA approx. 10

Weight kg (lbs) approx. 1.6 (3.5)

Receiver

Receiver frequency range MHz 868 / 916

Current draw mA approx. 10

Transmitter power pack

Voltage V 3.6

Capacity Ah 1.2

Battery charger

Operating voltage V (AC) 110/230

V (DC) 12 - 24

* The right for technical modifications remains reserved

BOMAG10 BMP 8500

Technical Data

!

Danger

The following noise and vibration data acc. to

- EC Machine Regulation edition 2006/42/EC

- the noise regulation 2000/14/EG, noise protection guideline 2003/10/EC

- Vibration Protection Regulation 2002/44/EC

were determined during conditions typical for this type of equipment and by application of harmonized standards.

During operation these values may vary because of the existing operating conditions.

Noise value

Sound pressure level on the place of the operator:

L

= 85 dB(A), determined acc. to ISO 11204 and EN 500

pA

Guaranteed sound power level:

L

= 103 dB(A), determined acc. to ISO 3744 and EN 500

WA

Wear your personal noise protection means (ear defenders) before starting operation.

BOMAG 11BMP 8500

Technical Data

BOMAG12 BMP 8500

2 Safety regulations

BOMAG 13BMP 8500

Safety regulations

General

This BOMAG machine has been built in compliance with the latest technical standard and

complies with the applicable regulations and

technical rules. However, dangers for persons

and property may arise from this machine, if:

l it is used for purposes other than the ones it is

intended for,

l it is operated by untrained personnel,

l it is changed or converted in an unprofessional

way,

l the safety instructions are not observed.

Each person involved in the operation, maintenance and repair of the machine must therefore read and comply with these safety

regulations. If necessary, this must be confirmed by obtaining the signature of the customer.

Furthermore, the following obviously also applies:

l applicable accident prevention instructions,

l generally accepted safety and road traffic reg-

ulations,

l country specific safety regulations. It is the

duty of the operator to be acquainted with

these instructions and to apply these accordingly. This applies also for local regulations

concerning different types of handling work.

Should the recommendations in these instructions be different from the regulations valid in

your country, you must comply with the safety

regulations valid in your country.

Intended use

This machine must only be used for:

l Compaction of cohesive soils in trench con-

struction

l Construction backfills

l Earthwork in sewer and pipeline construction

l Earthwork in railway and dam construction

l Earthwork in sanitary landfill construction

l Subbase and foundation work

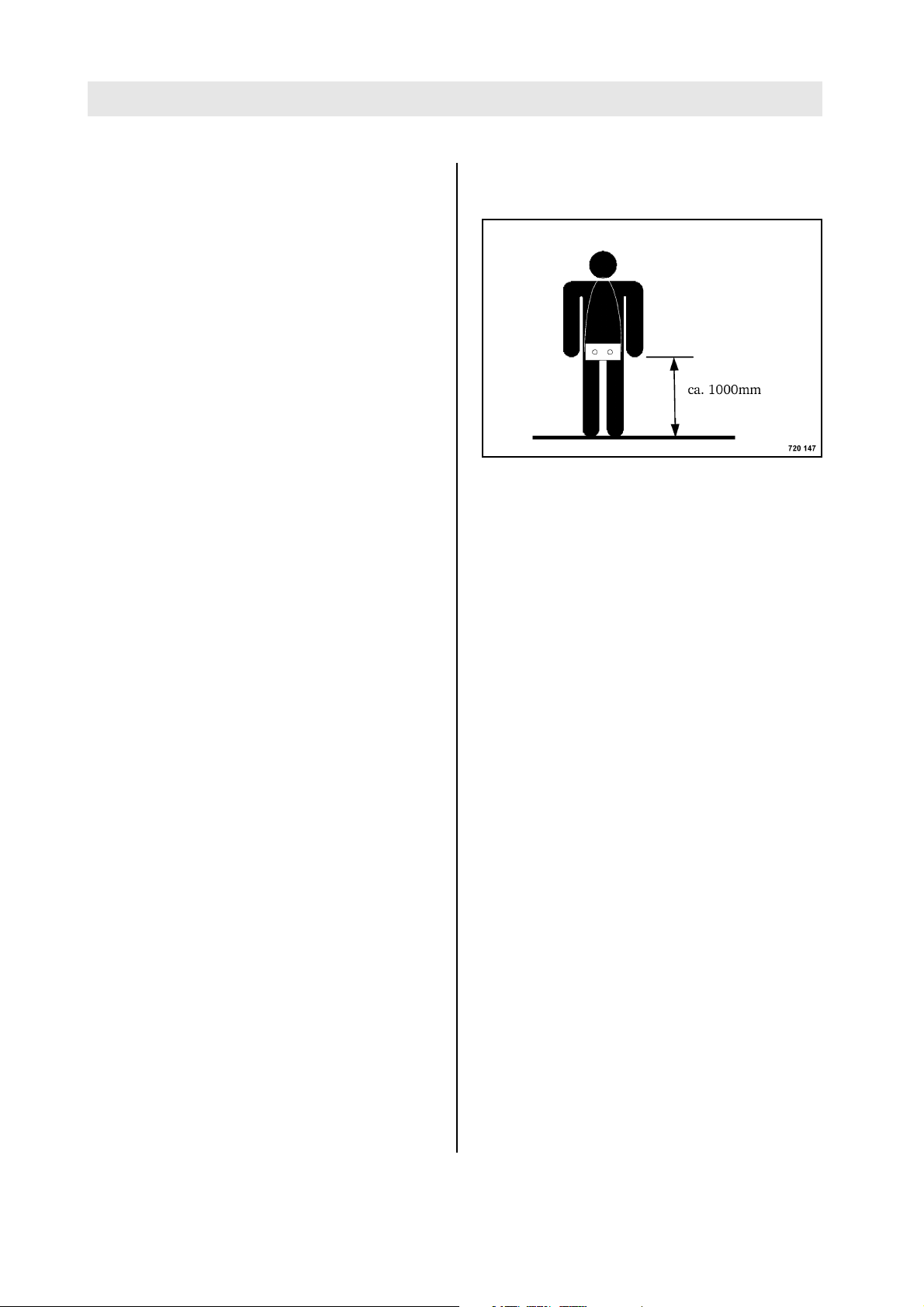

The place of the operator is behind the machine.

When operating the machine from the opposite

side, actuation of travel controls will cause ma-

chine movements, which are not in compliance

with the movement of the control elements.

Fig. 4

l The remote control must be carried in front of

the body, as intended (Fig. 4).

Unintended use

Danger may arise from the machine if it is used for

purposes other than the one it is intended for.

Any danger caused by unintended use is the sole

responsibility of the customer or driver/operator,

the manufacturer cannot be made liable.

Examples for unintended use are:

l work with vibration on hard concrete, cured bi-

tumen layers or extremely frozen ground

l driving on unstable subbases or insufficient

grip or too small contact area (danger of tipping over)

l using the machine on for towing

l operating the machine without visual contact

The transport of persons is prohibited.

Starting and operation of the machine in explosive

environments and in underground mining is prohibited.

Remaining dangers, remaining risks

Despite careful work and compliance with standards and regulations it cannot be ruled out that further dangers may arise when working with and

handling the machine.

Both the machine as well as all other system components comply with the currently valid safety regulations. Nevertheless, remaining risks cannot be

ruled out completely, even when using the ma-

BOMAG14 BMP 8500

Safety regulations

!

Danger

!

Caution

i

Note

Environment

chine for the purpose it is intended for and following all information given in the operating

instructions.

A remaining risk can also not be excluded beyond

the actual danger zone of the machine. Persons

remaining in this area must pay particular attention

to the machine, so that they can react immediately

in case of a possible malfunction, an incident or

failure etc.

All persons remaining ion the area of the machine

must be informed about the dangers that arise

from the operation of the machine.

Regular safety inspections

Have the machine inspected by an expert (capable person) as required for the conditiosn the machine is working under, but at least once every

year.

Who is allowed to operate the machine?

Only trained, instructed and authorized persons of

at least 18 years of age are permitted to drive and

operate this machine. For operation of the machine the responsibilities must be clearly specified

and complied with.

Persons under the influence of alcohol, medicine

or drugs are not allowed to operate, service or repair the machine.

Maintenance and repair work requires specific

knowledge and must therefore only be performed

by trained specialists.

Conversions and alterations to the machine

Unauthorized conversions to the machine are prohibited for safety reasons.

Original parts and accessories have been specially designed for this machine. We wish to make expressly clear that we have not tested or authorized

any original parts or special equipment not supplied by us. The installation and/or use of such

products can impair the active and/or passive driving safety. The manufacturer expressly excludes

any liability for damage resulting from the use of

non-original parts or accessories.

Damage, deficiencies, misuse of safety

installations

Machines which are not safe to operate or in traffic

must be immediately taken out of service and shall

not be used, until these deficiencies have been

properly rectified.

Safety installations and switches must neither be

removed nor must they be made ineffective.

Safety notes in the operating and maintenance instructions:

Sections marked like this point out possible

dangers for persons.

Sections marked like this point out possible

dangers for the machine or for parts of the machine.

Sections marked like this provide technical information concerning the optimal economical use of

the machine.

Sections marked like this highlight activities

for the safe and environmental disposal of fuels and lubricants as well as replaced parts.

Observe all environment protection regulations.

Loading the machine

Use only stable loading ramps of sufficient load

bearing capacity. The ramp inclination must be

less than the gradability of the machine.

Make sure that persons are not endangered by the

machine tipping or sliding off.

Always engage the articulation lock before loading, lifting and transporting the machine.

Use only safe lifting gear of sufficient load bearing

capacity Minimum lifting capacity of lifting gear:

see operating weight in chapter "Technical Data".

For lifting the machine attach the lifting gear only

to the lifting eye provided for this purpose.

BOMAG 15BMP 8500

Safety regulations

!

Danger

Check lifting eye for damage before use. Do not

use a damaged or in any other way impaired lifting

eye.

The machine must not swing about when being lifted.

Do not step or stand under suspended loads.

Lash the machine down, so that it is secured

against rolling, sliding and turning over.

Check the fastening of the central lifting hook before each use.

Recovering/towing the machine

The machine can be recovered by lifting it out of

the danger area.

Recovering/towing the machine

The machine can be recovered by lifting it out of

the danger area.

Life hazard!

Lift the machine only with suitable lifting gear.

Weight: see chapter "Technical Data".

Do not take any loose objects with you or fasten

them to the machine.

Starting

For starting set all control levers to 'neutral position'.

Do not use any starting aids like start pilot or ether.

After starting check all gauges and control lights.

Starting with jump wires

Connect positive with positive and negative with

negative (ground cable) – always connect the

ground strap last and disconnect it first! A wrong

connection will cause severe damage in the electric system.

Do not start the engine by shorting the electric terminals on the starter motor, because the machine

may start to drive immediately.

Do not use any starting aids like start pilot or ether.

Starting and operation of the machine is

closed rooms and trenches

Exhaust gases are highly dangerous! Always ensure an adequate supply of fresh air when starting

and operating in closed rooms and trenches!

Starting the machine

Before starting

When operating several machines with radio remote controls the system numbers of the individual control units must be checked.

Use only machines which are serviced at regular

intervals.

Become acquainted with the equipment, the control elements, the working principle of the machine

and the working area.

Wear your personal protective outfit (hard hat,

safety boots, etc.).

Before starting the machine check whether:

l persons or obstructions are near the machine

l the machine shows any obvious faults

l all guards and safety elements are in place

l brakes, control elements and horn are working

l engine hood is closed and locked

Do not start the machine with defective gauges,

control lights or control elements.

Driving the machine

Persons in the danger area

Before taking up work, also after breaks, you

should always convince yourself that the danger

zone is free of persons or obstructions, especially

when driving in reverse.

Give warning signals, if necessary. Stop work immediately if persons remain in the danger zone,

despite the warning.

Driving

Do not use the machine to transport persons.

In case of unusual noises and development of

smoke perform trouble shooting and have the fault

corrected.

Always keep a sufficient distance to excavation

walls and embankments and do not use working

methods that could impair the stability of the machine.

Do not work with vibration on hard concrete, cured

bitumen layers or extremely frozen ground.

BOMAG16 BMP 8500

Safety regulations

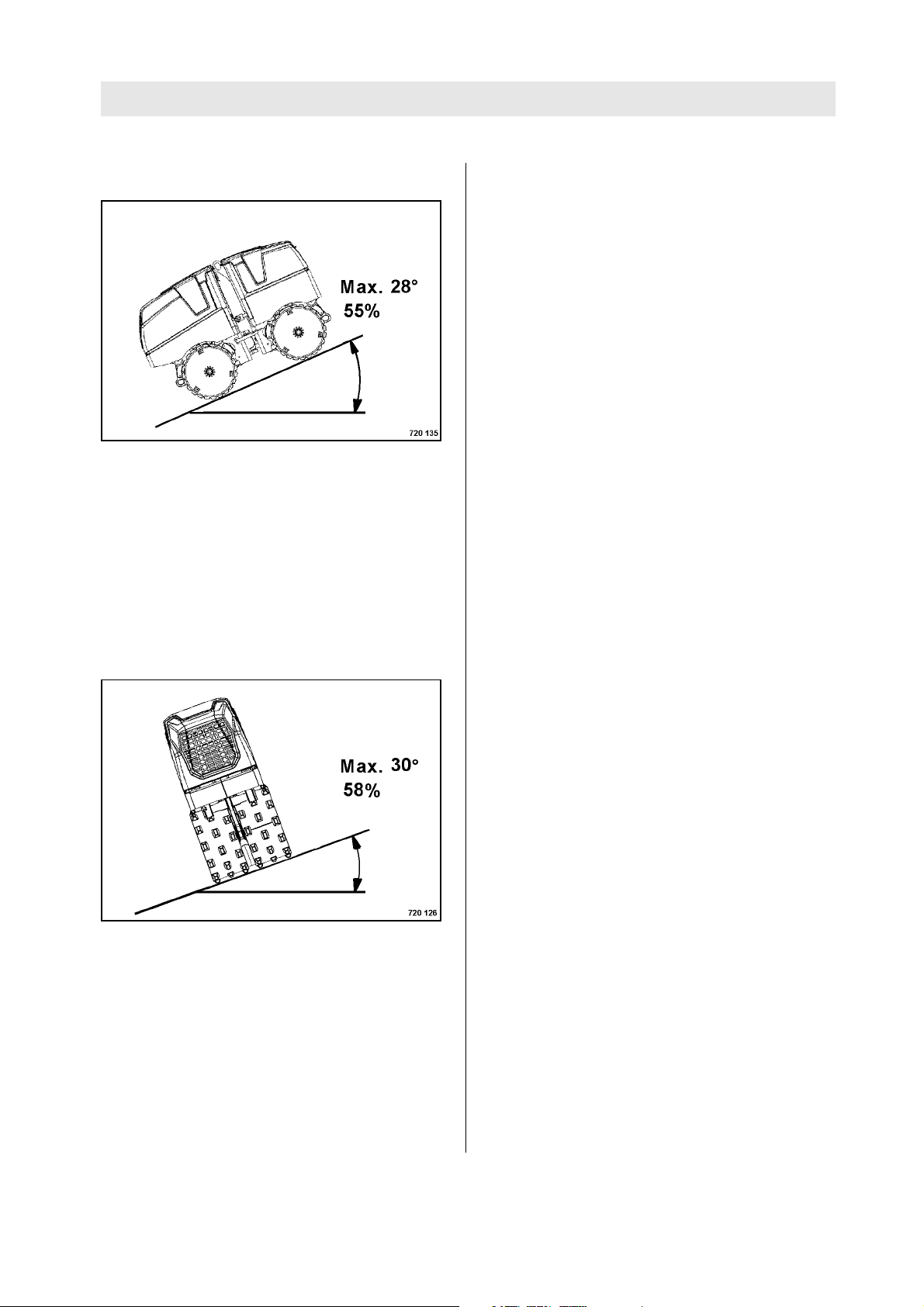

Driving on inclinations and slopes

Fig. 5

Do not drive on gradients exceeding the maximum

gradability of the machine.

On slopes drive extremely careful and always directly up or down the slope. Change to a lower

gear before starting to drive.

Wet and loose soils considerably reduce the

ground adhesion of the machine on inclinations

and slopes. Higher risk of accident!

You should therefore always drive straight up or

down a slope.

Behaviour in traffic

Match the speed to the working conditions.

Always give way to loaded transport vehicles.

Keep away from edges and embankments.

Checking the effect of vibration

When compacting with vibration you must check

the effect on nearby buildings and underground

supply lines (gas, water, sewage, electric power),

if necessary stop compaction work with vibration.

Do not activate the vibration on hard (frozen, concrete) ground. Danger of bearing damage!

Parking the machine

Park the machine on horizontal, level, firm ground.

Before leaving the machine:

l shut the engine down, pull the ignition key off

l secure the machine against unintended use.

l Pull off the main battery switch.

Inclination

Fig. 6

The tipping angle was measured in static condition

on level, hard ground with the machine stopped,

no steering and without vibration.

With loose soil, acceleration/deceleration, running

vibration, steering or attached accessoriies the tipping angle may be considerably lower.

Driving across slopes should therefore be strictly

avoided, because of the high risk of tipping over

and the related risk of severe or even fatal accidents.

Mark machines, which could be in the way, with a

clearly visible sign.

Refuelling

Do not inhale any fuel fumes.

Refuel only with the engine shut down.

Do not refuel in closed rooms.

No open fire, do not smoke.

Monitor the entire refuelling process.

Do not spill any fuel. Catch running out fuel, do not

let it seep into the ground.

Wipe off spilled fuel. Keep dirt and water away

from the fuel.

A leaking fuel tank can cause an explosion. Ensure tight fit of the fuel tank cover, if necessary replace immediately.

Fire protection measures

Familiarise yourself with the location and the operation of fire fighting equipment. Observe all fire reporting and fire fighting possibilities.

BOMAG 17BMP 8500

Safety regulations

!

Caution

Maintenance work

Comply with the maintenance work described in

the operating and maintenance instructions, including the information concerning the replacement of parts.

Maintenance work must only be performed by

qualified and authorized persons.

Keep unauthorized persons away from the machine.

Do not perform maintenance work while the machine is driving or the engine is running.

Park the machine on horizontal, level, firm ground.

Pull off the ignition key and switch off the main battery switch.

Work on hydraulic lines

Relieve hydraulic pressures before working on hydraulic lines. Hydraulic oil escaping under pressure can penetrate the skin and cause severe

injury. When being injured by hydraulic oil consult

a medical doctor immediately, as otherwise this

may cause severe infections.

Do not step in front of or behind the drums when

performing adjustment work in the hydraulic system.

Do not change the setting of pressure relief valves.

Drain the hydraulic oil at operating temperature –

danger of scalding!

Catch running out hydraulic oil and dispose of environmentally.

Always catch and dispose of hydraulic oils separately.

Do not start the engine after draining the hydraulic

oil.

Once all work is completed (with the system still

depressurized!) check all connections and fittings

for leaks.

l the hose shows deformations in pressurized

and depressurized condition, which do not

comply with the genuine shape of the hydraulic hose

l the hose shows deformations in bends, e.g.

squeezing, buckling, layer separation, formation of blisters

l parts of the hose are leaking.

l hoses are not correctly installed.

l the hydraulic hose has separated from the fit-

ting

l the fitting shows corrosion that impairs both

function and strength.

l hoses are mixed up by mistake.

l fittings are damaged or deformed, whereby

the function and strength of the hose/hose

connection is impaired.

Only genuine BOMAG replacement hydraulic hoses ensure that the correct hose type (pressure

range) is used at the right location.

Working on the engine

Shut the engine down before opening the engine

hood.

Drain the engine oil at operating temperature –

danger of scalding!

Wipe off spilled oil, catch running out oil and dispose of environmentally.

Store used filters and other oil contaminated materials in a separate, specially marked container

and dispose of environmentally.

Do not leave any tools or other objects, that could

cause damage, in the engine compartment.

Working on electric parts of the machine

Changing hydraulic hoses

Hydraulic hoses must be visually inspected at regular intervals.

Hydraulic hoses must be immediately replaced if:

l the outer layer is damaged down to the inlay

(e.g. chafing, cuts, cracks)

l the outer layer is brittle (formation of cracks in

the hose material)

Disconnect the minus pole first and the plus

pole after.

Connect the battery in reverse order. Connect

the plus pole first and the minus pole after.

Before starting to work on electric parts of the machine disconnect the battery and cover it with insulating material.

Do not use fuses with higher ampere ratings and

do not repair fuses with a piece of wire. Fire hazard!

BOMAG18 BMP 8500

Safety regulations

Working on the battery

When working on the battery do not smoke, do not

use open fire!

Do not let acid come in contact with hands or

clothes! When injured by acid flush off with clear

water and seek medical advice.

Metal objects (e.g. tools, rings, watch straps) must

not come in contact with the battery poles – danger of short circuit and burning!

When recharging non-serviceable batteries remove all plugs, to avoid the accumulation of explosive gases.

Observe the applicable instructions when starting

with an auxiliary battery.

Dispose of old batteries according to regulations.

Switch off the charging current before removing

the charging clamps.

Ensure sufficient ventilation, especially if the battery is to be charged in a closed room.

Working on the fuel system

Do not inhale any fuel fumes.

Avoid open fire, do not smoke, do not spill any fuel.

Catch running out fuel, do not let it seep into the

ground and dispose off environmentally.

Cleaning work

Do not perform cleaning work while the motor is

running.

Do not use gasoline or other easily inflammable

substances for cleaning.

When cleaning with steam cleaning equipment do

not subject electrical parts and insulation material

to the direct jet of water, or cover it beforehand.

l Do not guide the water jet into the exhaust and

into the air filter.

After maintenance work

After all maintenance work is completed reinstall

all guards and safety installations.

Repair

Mark a defective machine by attaching a warning

tag to the dashboard.

Before starting electric welding work on the machine, all electrical components must be disconnected from the power supply.

Repair work must only be performed by qualified

and authorized persons. Use our repair instructions for this work.

Exhaust gases are highly dangerous! Always ensure an adequate supply of fresh air when starting

in closed rooms!

Test

The safety of compaction equipment must be

checked by a specialist as required in dependence

on the application and the operating conditions,

however at least once every year.

Radio remote control

The machine must only be operated within the

field of vision of the operator.

The radio remote control must only be used by

trained and authorized persons.

The safety features incorporated in the radio remote control must be checked at regular intervals.

A defective radio remote control must no longer be

used.

In case of radio interferences watch the fault code

display and switch to cable remote control, if necessary

The machine will stop when the reach of the radio

remote control is exceeded.

In case of defects the radio remote control must be

immediately taken out of service. The transmitter

must be switched off via the emergency stop function. The connecting cable must be disconnected

from the machine related socket on the receiver.

The radio remote control must only be repaired by

the manufacturer or specialists authorized by the

manufacturer.

When working on plug connections the machine

battery must be disconnected or the connecting

cable of the receiver pulled off.

All work related with the initial installation of a system or with repair work must only be performed by

qualified personnel.

The person performing the work is fully liable for

professional execution of repair and maintenance

work in compliance with the regulations of the

manufacturer.

Warranty on spare parts can only be granted if

these parts were installed in compliance with our

regulations and instructions and by personnel au-

BOMAG 19BMP 8500

Safety regulations

thorized by us. We will not assume liability for

changes and modifications not performed by us.

Information and safety stickers/decals

on the machine

Keep safety stickers in good and legible condition

(see parts manual) and comply with their meaning.

Replace damaged and illegible stickers/decals.

BOMAG20 BMP 8500

Safety regulations

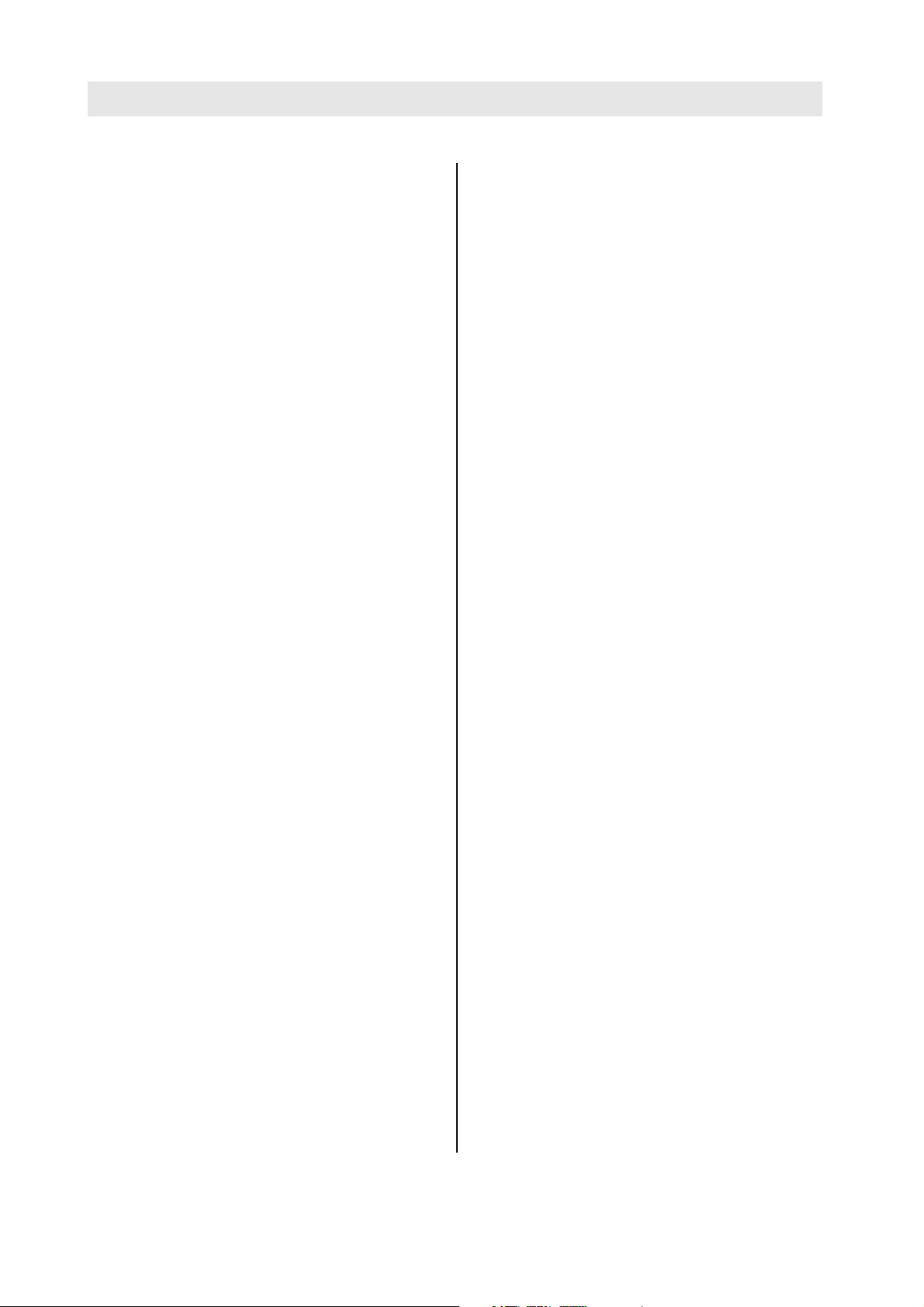

Fig. 7

Stickers and decals

1 Warning sticker: Hand injuries and hot sur-

face, read operating instructions

2 Information sticker "Engine start"

3 Warning sticker "Danger of crushing"

4 Warning sticker "Hot surface"

5 Information sticker "Lifting point"

6 Information sticker "Diesel"

7 Information sticker "Battery disconnecting

switch"

8 Brief operating instructions

9 Instruction sticker: "Wear ear defenders"

10 Information sticker "Guaranteed sound capac-

ity level"

11 Maintenance sticker "High pressure cleaner"

12 Information sticker "Lashing points"

13 Information sticker "Safety field"

14 Information sticker "Hydraulic oil"

15 Maintenance sticker

BOMAG 21BMP 8500

Safety regulations

Fig. 8

Information sticker "Bio Hydraulic Oil"

*

Fig. 9

Information sticker "Panolin 46"

* Optional equipment

** Optional equipment

**

BOMAG22 BMP 8500

3 Indicators and Controls

BOMAG 23BMP 8500

Indicators and Controls

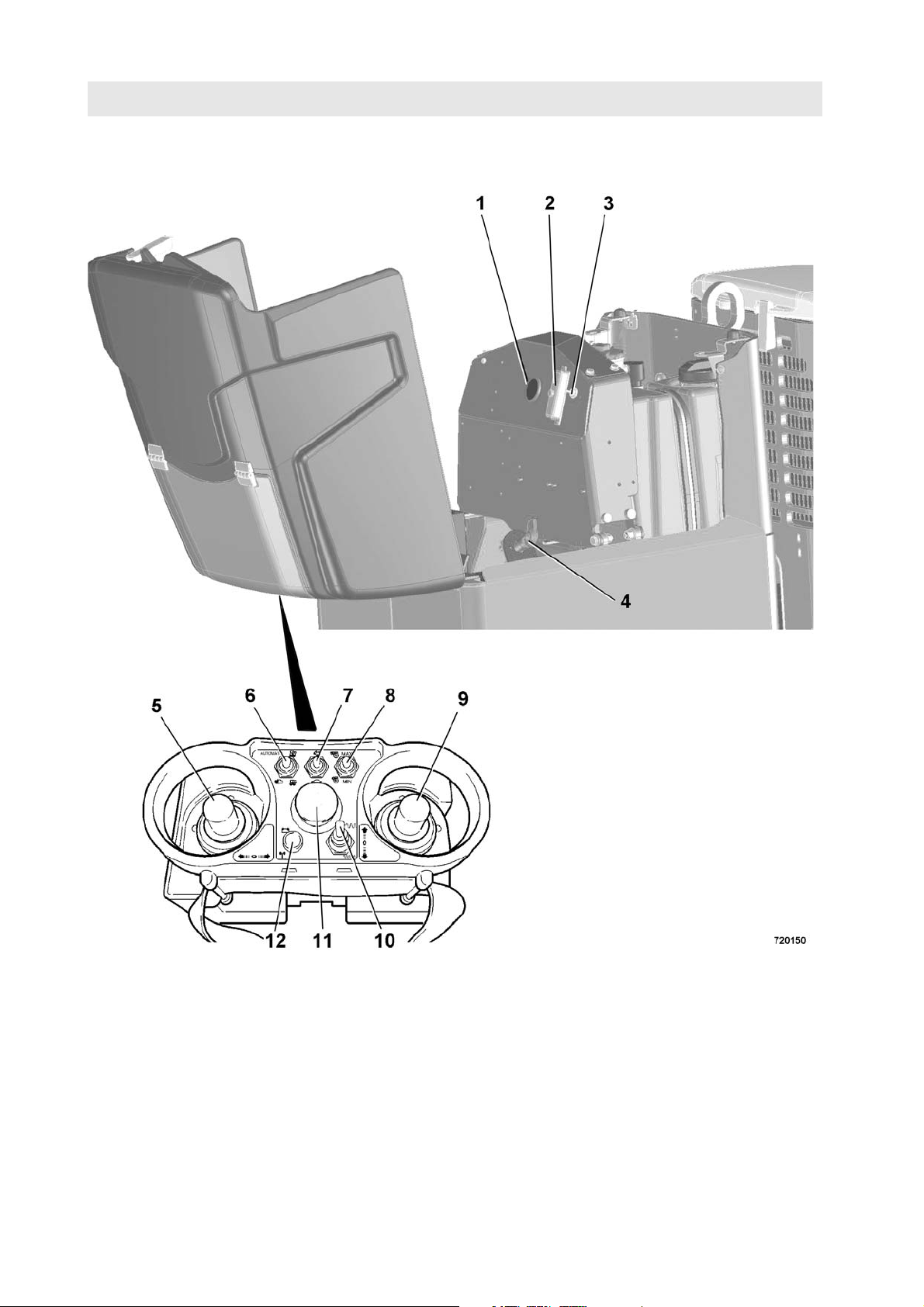

Fig. 10

BOMAG24 BMP 8500

Indicators and Controls

1 Display module

2 Fuse box

3 Toggle switch for cable remote control/radio

remote control

4 Main battery switch

5 Steering lever

6 Toggle switch, vibration automatic/manual

7 Toggle switch, travel ranges

8 Toggle switch, engine speed

9 Travel lever

10 Toggle switch for vibration high/low amplitude

11 Emergency stop switch

12 Control light data transfer/power pack radio re-

mote control

BOMAG 25BMP 8500

Indicators and Controls

h

720151

a

b

c

d

e

f

g

h

i

j

F1 F2

3.1 General notes

3.2 Description of indicators

and control elements

If you are not yet familiar with the control and display elements on this machine you should read

this section thoroughly before starting any operation on the machine. Here all functions are described in detail.

Section 4 "Operation" contains only brief descriptions of the individual control steps.

Fig. 11

No. 1 = Display module

a red = Engine oil pressure warning lamp

Lights if the engine oil pressure is too

low

Check engine oil level, repair the engine if necessary.

b yellow = Charge control lamp

Lights if the battery is not being

charged.

Check the V-belt, if necessary repair

the generator.

c red = Coolant temperature warning light

Lights red if the temperature of the

engine coolant is too high

d = Tipping angle warning indicator

Lights when the tipping angle of the

machine has reached > 45° in lateral

direction or > 60° in travel direction.

e = Preheating control

The machine will stop, vibration is

shut down.

Restart the machine and move it

carefully out of the danger area.

Preheating for starting at low temperatures.

BOMAG26 BMP 8500

f = Function key F2

i

Note

To enter code numbers in connection

with function key F1

g = Function key F1

To enter code numbers in connection

with function key F2

h = Operating hour meter

Counts the operating hours while the

engine is running.

All maintenance work must be performed according to the indicated operating hours.

Display of machine type code, remote control code and fault codes.

i = Display of safety field system

Lights when the operator is within the

safety field. The machine stops.

Move the travel lever accordingly to

free the machine from the obstruction.

j = not used

Indicators and Controls

720164

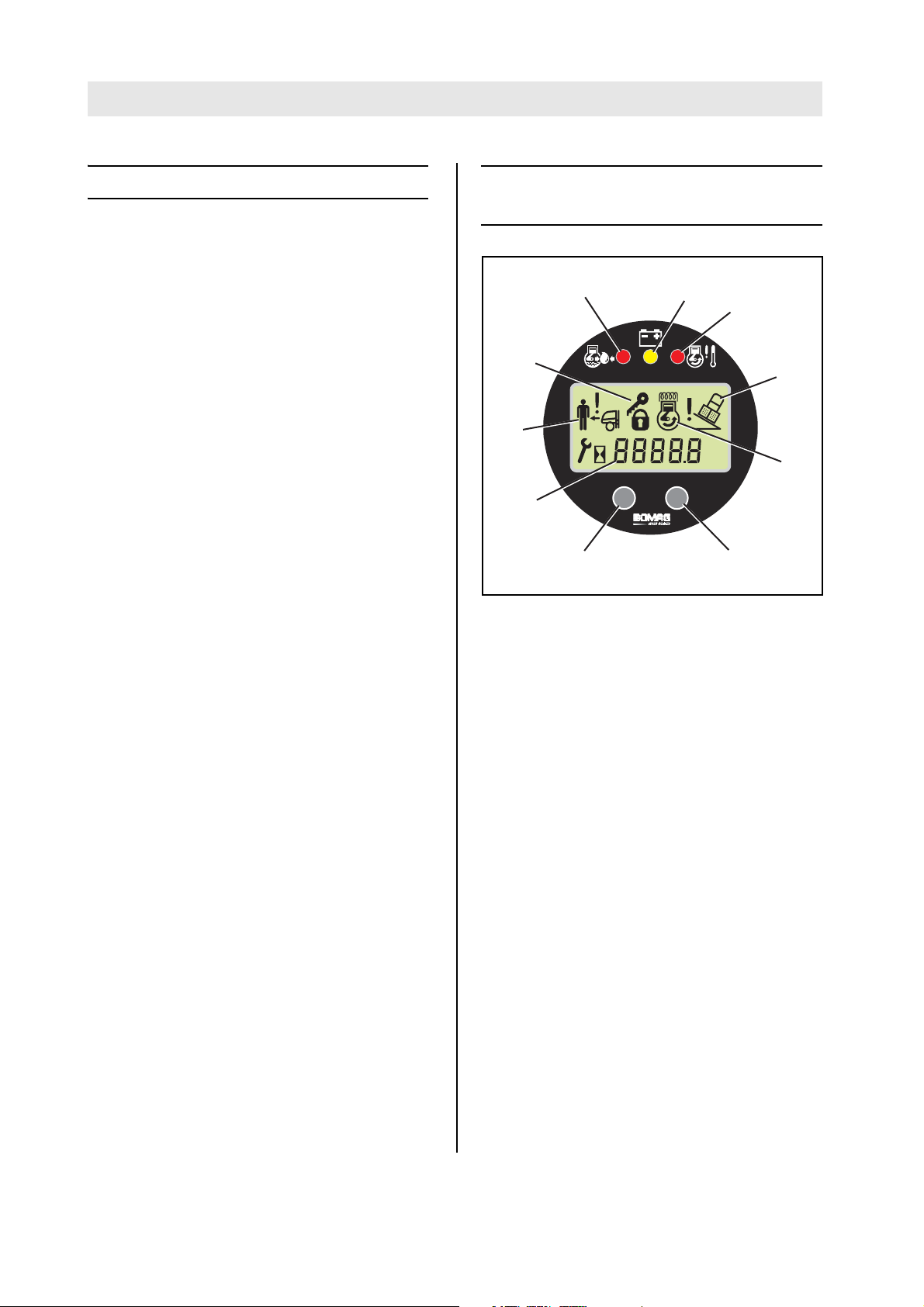

Fig. 13

No. 3 = Toggle switch for cable remote con-

trol/radio remote control

Position left = Cable remote control

Position right = Radio remote control

*

Fig. 12

No. 2 = Fuse box

F119 = (20A) Fuse for starter motor

F103 = (10A) Fuse potential 15

F14 = (25A) Fuse for engine solenoid

F54 = (5A) Fuse for cable remote control

F67 = (25A) Fuse control (potential 30)

F48 = (30A) Preheating

Fig. 14

No. 4 = Main battery switch

Disconnects the ground contact in the electric circuit of the machine.

If the power pack of the radio remote control is to

be charged, the main battery switch must remain

switched on when the engine is shut down.

* Optional equipment

BOMAG 27BMP 8500

Indicators and Controls

i

Note

720158

MIN

MAX

AUTOMATIC

720141

Fig. 15

No. 5 = Steering lever

Middle position = Straight ahead

Position left = Driving to the left

Position right = Driving to the right

Vibration switches off automatically when the travel lever is

returned to position "0"

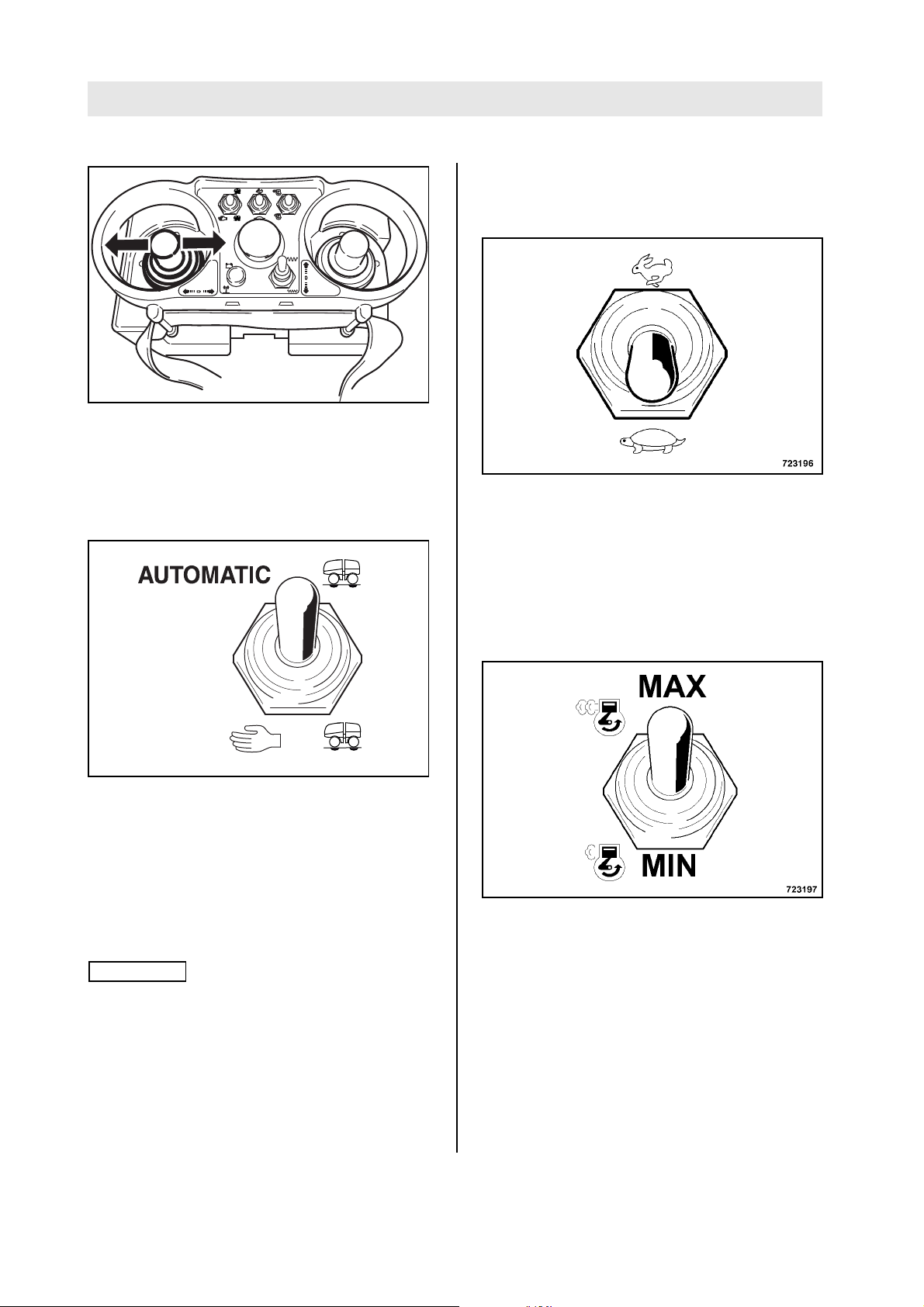

Fig. 17

No. 7 = Toggle switch, travel ranges

Position "turtle" = 1. Travel speed range: 0 ... 1.3

km/h

Position "rabbit" = 2nd travel speed range: 0 ...

2.7 km/h, driving with vibration

not possible

Fig. 16

No. 6 = Toggle switch, vibration automatic/

manual

Position Manual = Vibration comes on when

switching on the toggle switch

for vibration in high/low amplitude.

Machine switches automatically to speed range 1

AUTOMATIC position = Vibration comes on automati-

cally when moving the travel

lever, after the toggle switch

for vibration with high/low amplitude has been actuated to

any desired position.

Fig. 18

No. 8 = Toggle switch, engine speed

Position "MIN" = idle speed of engine

Position "MAX" = maximum engine speed

BOMAG28 BMP 8500

Indicators and Controls

720159

MIN

MAX

AUTOMATIC

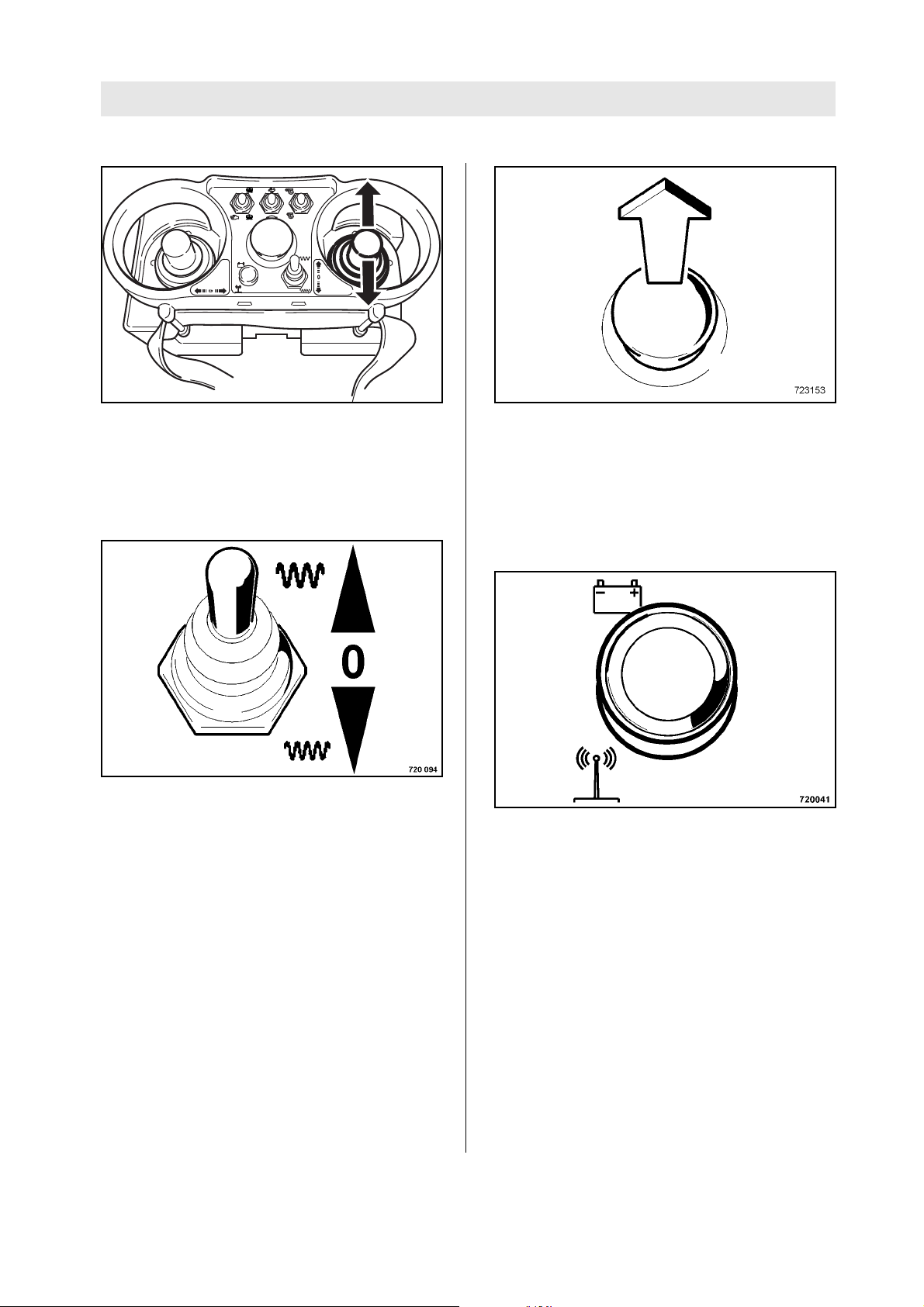

Fig. 19

No. 9 = Travel lever

Middle position = Stop position

Position front = Forward travel

Position rear = Reverse travel

Fig. 20

No. 10 = Toggle switch for vibration high/low

amplitude

Position "front" = high amplitude

Position "middle" = vibration switched off

Position "rear" = low amplitude

Fig. 21

No. 11 = Emergency stop push button

actuated = transmitter and diesel engine

will be switched off.

unlocked = switches the transmitter on

when the ignition is switched

on.

Fig. 22

No. 12 = Control light data transfer/power

pack radio remote control

Flashes green when the transmitter is switched

on.

Lights red when the accumulator voltage drops too

low.

BOMAG 29BMP 8500

Indicators and Controls

!

Caution

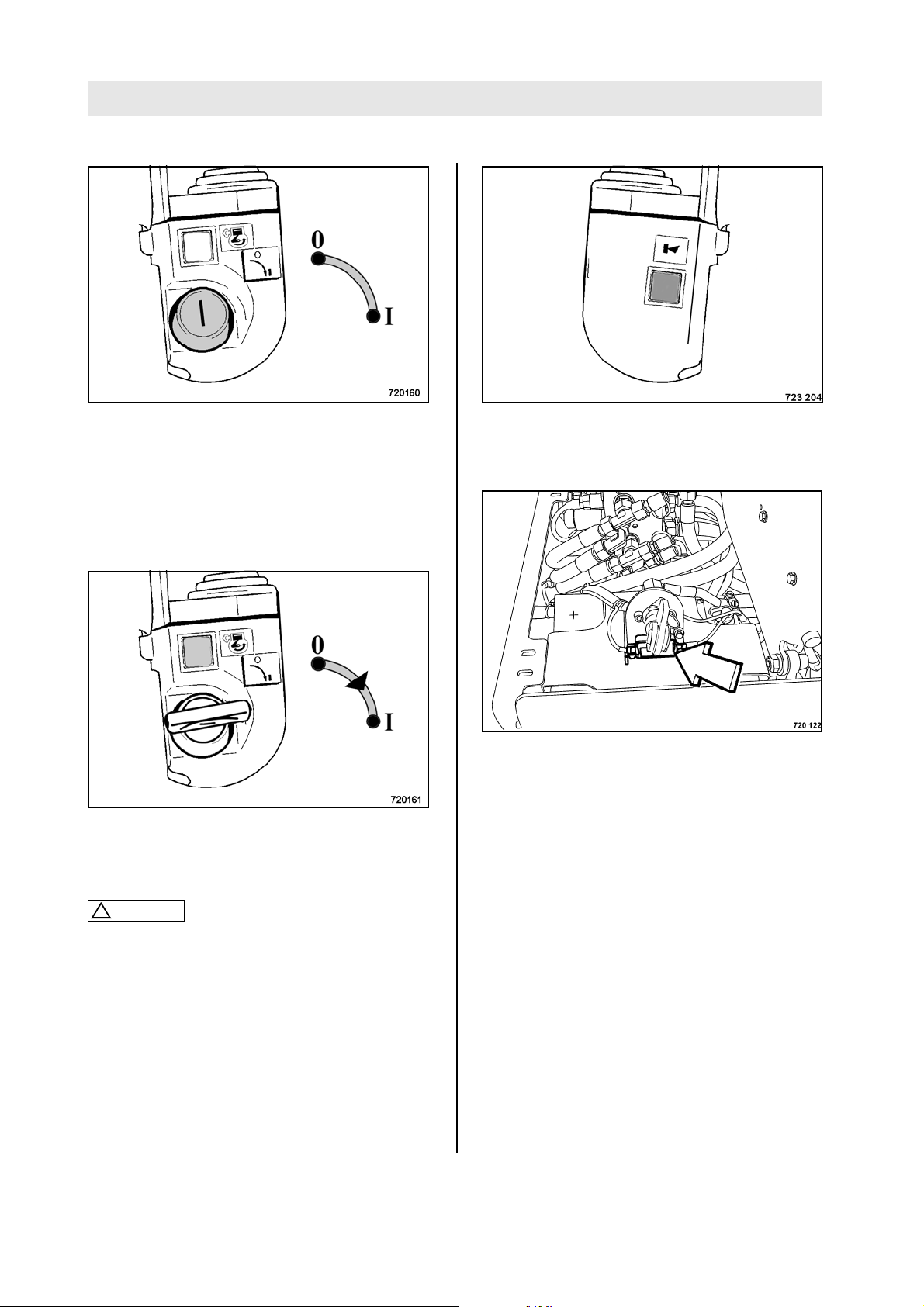

Fig. 23

No. 13 = Ignition switch

Position 0 = Ignition/engine off, key can be

pulled out

Position I = Ignition on, charge control and

oil pressure warning lights are

on.

Fig. 24

No. 14 = Start button

To start the engine in ignition switch position "I".

Fig. 25

No. 15 = Horn button

to signalize a danger situation.

Fig. 26

No. 16 = Main fuse for battery

80A = (F00)

Perform the starting process for maximum 15

to 20 seconds without interruption and pause

for about 1 minute between starting attempts.

Should the engine not start in this time, perform trouble shooting and rectify the cause.

BOMAG30 BMP 8500

4Operation

BOMAG 31BMP 8500

Operation

!

Danger

i

Note

4.1 General

If you are not yet acquainted with the controls

and indicating elements on this machine you

should thoroughly read chapter 3 “Indicators

and control elements” before starting work.

All indicators and control elements are described in detail in this chapter.

4.2 Tests before taking into operation

Before the everyday use or before a longer working period the following tests and inspections must

be performed.

Danger of injury!

Please observe strictly the safety regulations

in chapter 2 of these operating and maintenance instructions.

l Park the machine on ground as level as possi-

ble.

l The operator must become acquainted with

the size of the safety field.

Check:

l fuel tank and fuel lines for leaks

l engine, radiator and hydraulic system for leaks

l screw joints for tight fit

l machine for condition, cleanliness, damage

l Function of remote control and emergency

stop.

l presence of the appropriate operating and

maintenance instructions

l proper maintenance of the machine

For a description of the following tasks refer to the

chapter "maintenance every 10 operating hours".

l Engine oil level, top up if necessary

l Hydraulic oil level, top up if necessary.

l Fuel level, top up if necessary.

l Fuel filter, drain water

l Coolant level, top up if necessary

BOMAG32 BMP 8500

Operation

!

Caution

!

Danger

4.3 BOSS safety system

Function

Fig. 27

The machine is surrounded by 2 spherical electromagnetic safety fields (Fig. 27). If the machine operator with the remote control enters into the field,

which stretches in travel direction, the machine will

stop immediately.

Danger of squashing!

Only operators carrying the associated remote

control are protected.

There is no protection for persons laying on

the ground.

l Shift the travel lever to neutral position and exit

the field, which corresponds with the travel direction.

l Operate the machine to the opposite direction

(picture), so that the operator is no longer in

the safety field of the machine.

The operator must become acquainted with

the size of the safety field before he starts operation.

If an operator is between 2 machines in both

safety fields, both corresponding travel directions of the associated machines will be

stopped. The operator must leave the safety

field to be able to move the machine again.

The minimum distance between operator and

machine must be 2 m. When falling short of a

distance of 1.2 m, the corresponding travel direction will be stopped.

BOMAG 33BMP 8500

Operation

! Danger

!

Danger

!

Caution

720162

720165

4.4 Starting the engine

Wear your personal noise protection means

(ear defenders) before starting operation.

Exhaust gases are highly dangerous!

Always ensure an adequate supply of fresh air

when starting and operating in closed rooms

and trenches!

In this chapter it is assumed that the operator

is fully acquainted with the function of the different control elements on the machine.

Fig. 29

l For cable operation of the machine switch the

toggle switch (Fig. 29) to the left.

l Open the rear hood.

Fig. 28

l Switch on the main battery switch (Fig. 28).

l Strap the control to your body and plug the spi-

ral cable into the remote control, if required.

Fig. 30

l For radio operation of the machine switch the

toggle switch (Fig. 30) to the right.

Fig. 31

l If necessary unlock the emergency stop switch

(Fig. 31).

BOMAG34 BMP 8500

Fig. 32

!

Caution

i

Note

i

Note

i

Note

i

Note

!

Caution

720153

0

720154

10s

720155

START

l Set the vibration toggle switch (Fig. 32) to po-

sition "0".

Operation

The control emits two short buzzer signals. This indicates that the control is ready for operation.

If the buzzer does not sound, there must be a fault

in the control or the power pack of the control is

empty.

All normal work functions can only be operated

from a defined neutral position, i.e. the respective

control elements must be in rest position when

switching the sender on. If this is not true, the engine cannot be started.

Fig. 33

l Switch on the ignition (Fig. 33).

l Under cold outside temperatures preheat for

Do not use any starting aid spray .

With the ignition switch in position "I" the machine

type code will appear in the display module for approx. 3 seconds.

The machine will emit a short horn signal. This indicates that the machine is ready for operation.

If the horn does not sound, there must be fault on

the machine.

Fig. 34

l Press the start button to start the engine(Fig.

34).

approx. 10 seconds before starting.

Run the engine warm for a short while before

starting work. Do not rev up a cold engine to

high idle speed/full load speed.

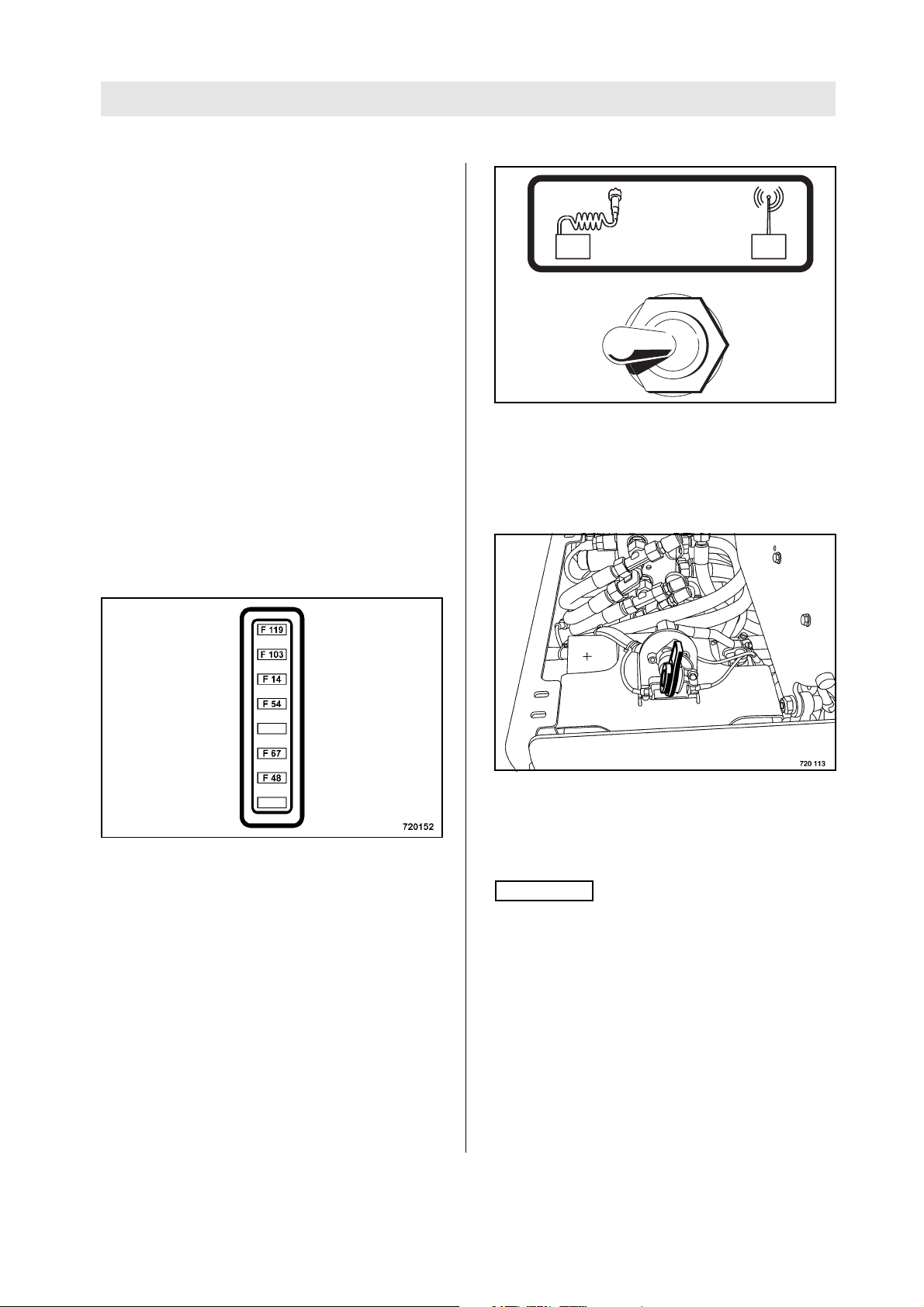

Starting with jump wires

l Open the rear hood.

BOMAG 35BMP 8500

Operation

!

Caution

!

Danger

Fig. 35

l Switch on the main battery switch (Fig. 35).

Fig. 36

A wrong connection will cause severe damage

in the electric system.

l Bridge the machine only with a 12 Volt battery.

l When starting with an external battery connect

the plus poles (Fig. 36) first and the minus

poles (ground cable) after.

4.5 Driving the machine (cable

remote control)

Danger of accident!

Before starting to drive make sure that the

drive range is absolutely safe.

Wet and loose soils considerably reduce the

ground adhesion of the machine on inclinations and slopes.

Do not drive up and down inclinations exceeding the maximum gradability of the machine

(see technical data).

Slowly return the travel lever towards neutral

when driving down slopes.

Before starting to drive check the function of

the remote control.

During operation of the machine with remote

control the operator must always stay behind

or beside the machine. Specified directions apply only if the operator is standing behind the

machine. If the operator is standing in front of

the machine all machine movements will be

opposite to the movement of the control lever.

The machine must only be operated with remote control strapped to the body.

The machine must only be operated within the

field of vision of the operator.

The minimum distance between operator and

machine must be 2 m.

l Do not overstretch the spiral cable.

l Start the engine as described above

l After starting disconnect the cable from the mi-

nus poles (ground cable) first and from the

plus poles last.

l Fold the control box back in and close the

hood.

BOMAG36 BMP 8500

Operation

i

Note

720162

720156

MAX

MIN

720157

Fig. 37

l Before starting the engine switch the toggle

switch for cable/radio remote control (Fig. 37)

to the left to position "Cable remote control"

l Start the engine.

Fig. 38

l Turn the rotary switch for engine speed (Fig.

38) to position MAX.

If the machine is not operated over a period of 10

seconds, the engine will be switched to "Ecomode" (low idle speed).

Fig. 39

l Switch the toggle switch for travel speed rang-

es (Fig. 39) to the desired speed range.

Fig. 40

l Actuate the travel lever (Fig. 40).

The machines drives with a speed which corresponds with the displacement of the travel control

levers.

Standstill = Travel lever in middle position

Forward travel = Shift the travel lever forward

Reverse travel = Pull the travel lever back

The engine will return to high idle as soon as either

the steering or travel lever is actuated.

BOMAG 37BMP 8500

Operation

!

Caution

Stopping the machine

Fig. 41

l Travel lever (Fig. 41) in middle position. The

machine will brake.

Steering the machine

Rests of concrete, clay or mortar may damage

the bellows on travel levers and sealing caps

on toggle switches, so that water can enter.

Do not use a water jet or a high pressure or

steam cleaner for cleaning.

l After work clean the cable remote control with

a clean cloth or brush.

l Check the state of bellows and sealing caps at

regular intervals, have replaced by an expert,

if necessary.

Fig. 42

l Actuate the travel levers (Fig. 42) accordingly.

Straight ahead = Steering lever in middle posi-

tion

To drive to the

right = Move the travel lever to the

right

To drive to the

left = Move the travel lever to the left

Cleaning after use

Keep the cable remote control clean.

BOMAG38 BMP 8500

Operation

!

Danger

!

Caution

!

Danger

4.6 Safety inspection for the cable remote control

This safety inspection must be performed regularly

once every week, especially after longer breaks.

Danger of injury!

Make sure that there are no persons within the

danger zone.

Rests of mortar or concrete may restrict the

movement of the travel control levers. Check

from time to time (with the sender switched

off!) whether both travel control levers return

reliably to their neutral position when being released.

4.7 Switching the vibration on

and off

Risk of damage!

When compacting with vibration you must

check the effect of nearby buildings and underground supply lines (gas, water, sewage,

electric power), if necessary stop compaction

with vibration.

Do not activate the vibration on hard (frozen,

concrete) ground. Danger of bearing damage!

Automatic

Fig. 43

l With the machine shut down actuate and hold

one of the travel levers 1 or 2 (Fig. 43).

l Try to start the diesel engine.

The diesel engine must not start.

l Return the travel lever to neutral position (rest

position).

l Start the engine and actuate the control lever

again.

The functions must now work as usual.

l Operate the emergency stop switch (3).

The machine must stop and the engine must be

shut down.

Fig. 44

l Set the vibration switch (Fig. 44) to "Automat-

ic".

Fig. 45

l Choose the amplitude (Fig. 45).

BOMAG 39BMP 8500

Operation

Fig. 46

l Move the travel lever (Fig. 46) forward or back.

The machine starts to move and the vibration

switches on automatically.

The vibration will switch off when the machine

comes to a halt.

Manual

Fig. 47

l Set the vibration switch (Fig. 47) to position

”Manual”.

Fig. 48

l Choose the amplitude (Fig. 48).

Vibration switches on.

BOMAG40 BMP 8500

4.8 Shut down the engine

! Danger

l Switch the vibration off, if necessary.

Fig. 49

l Change to idle speed (Fig. 49) and let the en-

gine run for another few minutes for cooling.

Operation

Fig. 51

l Pull off the ignition key (Fig. 51) and store it in

a safe place.

Fig. 50

l Turn the ignition switch (Fig. 50) to position

"0".

Fig. 52

l Switch off and pull out the main battery switch

(Fig. 52).

l Plug the safety cap on the lock.

Danger of accident!

Secure the machine against unauthorized use.

BOMAG 41BMP 8500

Operation

!

Caution

!

Danger

!

Danger

4.9 Shutting down the engine

manually

If the engine is not automatically shut down

when turning the ignition switch to position

"0", you may switch it off manually.

You should immediately investigate the cause

for the engine not shutting down and repair the

machine accordingly.

Fig. 53

l Turn the ignition switch (Fig. 53) to position

"0".

Fig. 55

l Keep the hand lever (Fig. 55) on the engine

depressed, until the engine shuts down.

l Open the rear hood.

Fig. 56

l Switch off and pull out the main battery switch

(Fig. 56).

l Remove the guard.

l Close engine hood and rear hood again.

Danger of accident!

Secure the machine against unauthorized use.

Fig. 54

l Pull off the ignition key (Fig. 54) and store it in

a safe place.

l Fold the engine hood open

BOMAG42 BMP 8500

4.10 Starting operation of the ra-

!

Danger

!

Caution

!

Caution

i

Note

!

Danger

dio remote control

The minimum distance between operator and

machine must be 2 m.

Use the transmitter only if the type approval

has been granted.

Operation

Fig. 58

l Turn the ignition switch to position "0" (Fig. 58)

and pull it off.

Fig. 57

l Set the toggle switch (Fig. 57) to remote con-

trol position.

Inserting the replacement power pack

Change the power pack only when the sender

is switched off.

Fig. 59

l Insert the replacement power pack into the re-

ceptacle (Fig. 59) and let it click into place.

Make sure the power pack clicks into place.

Duty time with a fully charged power pack:

approx. 100 hours

Switching on the transmitter

Life hazard!

In order to avoid unauthorized operation of the

machine do not leave the activated transmitter

unattended.

Operate the transmitter only if the machine is

in your field of vision.

BOMAG 43BMP 8500

Operation

i

Note

i

Note

i

Note

All normal work functions can only be operated

from a defined neutral position, i.e. the respective

control elements must be in rest position when

switching the sender on. If this is not true, the engine cannot be started.

l Strap the transmitter to your body, adjust the

belts accordingly.

Fig. 60

l If necessary unlock the emergency stop switch

(Fig. 60).

The radio remote control is equipped with a restart lock.

Fig. 62

l Switch on the ignition (Fig. 62).

The green control light on the transmitter starts to

flash and a buzzer signal sounds. The transmitter

is ready for operation.

After a period of approx. 5 to 10 seconds the signal

horn on the machine starts to sound.

The machine is now ready for operation.

Fig. 61

l Set the vibration toggle switch (Fig. 61) to po-

sition "0".

Starting the engine

Before starting the engine both travel levers and

the vibration control lever must be in rest position

(neutral).

Fig. 63

l Press the start button to start the engine (Fig.

63).

Run the engine warm for a short while before starting work.

BOMAG44 BMP 8500

Long distance shut-down

i

Note

! Danger

i

Note

!

Caution

Fig. 64

If the distance (Fig. 64) between and transmitter

and receiver exceeds 30 m, the machine will stop.

To continue travelling reduce the distance and restart the machine.

Operation

Fig. 65

If the battery voltage drops down to a too low level

during operation (power pack discharged), the red

warning light on the control (Fig. 65) will light up

approx. 10 minutes before the engine is shut

down. The warning buzzer starts to sound approx.

1 minute before the shut down

Work function

Life hazard!

Move the machine only when it is directly in

sight.

The functions of operating elements and controls are identical with the ones for the cable

remote control (see previous description).

Drive the machine to a safe place as soon as possible, so that it will not stop all of a sudden.

If necessary switch over to operation with cable remote control and plug the spiral cable into the remote control. During cable operation of the

machine the power pack is automatically charged.

Replace or recharge the power pack.

Switching off the transmitter (engine)

Do not shut the engine down all of a sudden

from full load, but let it idle for a while in position "Min" for temperature equalization.

If the radio remote control is not going to be

used for a longer period of time we strictly recommend to take the batteries out of the transmitter and to recharge them approx. every four

weeks. This avoids complete discharging and

prolongs the lifetime of the power packs.

BOMAG 45BMP 8500

Operation

i

Note

!

Caution

Fig. 66

l Turn the ignition key (Fig. 66) to position "0".

Transmitter and engine will be switched off after

two seconds, the green control light on the transmitter goes out.

Fig. 67

l Switch off and pull out main battery switch 1

(Fig. 67).

l Plug the safety cap on the lock.

Fig. 68

l Pull off the ignition key (Fig. 68) and store it in

a safe place.

If the power pack of the remote control is to be recharged via the remote control cable, the main

battery switch (Fig. 67) must be switched on.

Cleaning after use

Keep the radio remote control clean.

Rests of concrete, clay or mortar may damage

the bellows on travel levers and sealing caps

on toggle switches, so that water can enter.

Do not use a water jet or a high pressure or

steam cleaner for cleaning.

l After work clean the transmitter with a clean

cloth or brush.

l Check the state of bellows and sealing caps at

regular intervals, have replaced by an expert,

if necessary.

BOMAG46 BMP 8500

Operation

i

Note

!

Danger

!

Caution

i

Note

i

Note

i

Note

4.11 Replacing, recharging the

radio remote control power

pack

As standard the power pack is recharged in the

machine through the spiral cable. A separate battery charger is available as an option. The recharging time is approx. 6 hours.

Operate the battery charger only in dry rooms

at temperatures of min. 0 °C to max. 40 °C!

A charged power pack is a concentrated energy source! Do not store charged power packs

in a tool box or similar, because metal parts

may cause a short circuit. Short circuits may

also be caused by keys etc. in a trouser pocket.

Charging the power pack in the machine

Fig. 69

l Switch off the transmitter (Fig. 69) with the ig-

nition key.

l Plug the spiral cable into the transmitter

Change the power pack only when the sender

is switched off.

Before connecting the battery charger make

sure that the mains voltage is in accordance

with the specifications mentioned on the battery charger.

Strictly follow the operating instructions for

the battery charger.

Ageing of the power pack reduces the discharging

capacity and therefore the operating time of the

sender.

The full discharging capacity is only reached after

several charging cycles.

As the charging of the power pack succeeds, the

charging current drops, so that overcharging of the

power pack is almost impossible. However, if the

control is switched off for a couple of days (holidays, bad weather) you should also disconnect the

charging unit from the mains supply or switch off

the main battery switch.

Fig. 70

l The main battery switch (Fig. 70) must be

switched on.

The power pack recharging time is approx. 6

hours.

BOMAG 47BMP 8500

Operation

i

Note

Charging the power pack with the external battery charger

Fig. 71

l Switch off the transmitter (Fig. 71) with the ig-

nition key.

Fig. 73

l Push lock 1 (Fig. 73) on the mains unit of the

battery charger forward and pull plug (2) upward out of the mains unit.

Fig. 72

l Press the power pack forward and lift it out of

the housing (Fig. 72).

Fig. 74

l Plug the corresponding plug (Fig. 74) onto the

mains unit of the battery charger.

The type of plug to be chosen depends on the

country. Observe local conditions and regulations.

BOMAG48 BMP 8500

Fig. 75

i

Note

!

Danger

!

Caution

l Insert the power pack into the battery charger

(Fig. 75).

Operation

4.12 Safety inspection for the radio remote control

This safety inspection must be performed regularly

once every week, especially after longer breaks.

Danger of injury!

Make sure that there are no persons within the

danger zone.

Rests of mortar or concrete may restrict the

movement of the travel control levers. Check

from time to time (with the sender switched

off!) whether both travel control levers return

reliably to their neutral position when being released.

Fig. 76

l Connect the battery charger to a power source

(Fig. 76).

The two light emitting diodes on battery charger

and mains unit must light up.

The power pack recharging time is approx. 6

hours.

When charging is completed the green LED on the

charger will start to flash.

Fig. 77

l With the transmitter switched off actuate and

hold one of the travel levers 1 or 2 (Fig. 77).

l Switch on the transmitter and try to start the

diesel engine.

The diesel engine must not start.

l Return the travel lever to neutral position (rest

position).

l Start the engine and actuate the travel lever

again.

The functions must now work as usual.

l Operate the emergency stop switch (3).

The machine must stop and the engine must be

shut down.

BOMAG 49BMP 8500

Operation

!

Caution

h

720163

F

1

F

2

4.13 Switching off of the radio remote control in case of radio interferences

The radio remote control is automatically switched

off whenever the radio connection to the receiver

is interrupted or disturbed for more than 2 seconds.

Resetting the control after switching

off by radio interference

l Step into the radio transmission range of the

machine.

4.14 Switching ECO-mode on

and off

Input of code numbers

The code can only be entered when the engine

is shut down.

Fig. 78

l Switch on the ignition (Fig. 78) and restart the

machine.

Operation can be resumed.

Fig. 79

l Switch on the ignition (Fig. 79).

l Open the flap in the rear hood.

Fig. 80

l Keep both function keys F

the display module depressed for two seconds.

The display shows "0000", whereby the first digit is

flashing.

und F2 (Fig. 80) in

1

l The value of the flashing digit can be in-

creased by pressing the function key F

BOMAG50 BMP 8500

.

1

Operation

i

Note

!

Caution

i

Note

i

Note

l If the value "9" is displayed and the function

key F

is pressed again, the display will jump

1

back to the value "0".

l When pressing the function key F

the flashing

2

digit will move one digit to the right.

l If the fourth digit in the display is flashing func-

tion key F

is pressed again to confirm the en-

2

try.

The desired function is now executed or the desired value is displayed.

l To cancel the display function you must either

enter code number "0000" or switch off the ignition.

Setting ECO-mode

l Enter "5055" to start the procedure.

l Enter "5057" to switch off ECO-mode or

"5058" to switch on ECO-mode.

l Enter "5056" to finish the procedure.

Input code "5059" is used to display the status of

ECO-mode.

4.15 Entering the machine type

code

After replacing the machine control (BLM) the

machine type code must be entered again.

The machine must not be operated with a

wrong type settings, as otherwise the correct

function of the control can no longer be assured.

The code can only be entered when the engine

is shut down.

A description of the procedure for entering code

numbers can be found in the chapter "Switching

ECO-mode on or off".

l Enter "7010" to start the procedure.

This code number activates the function "Adjusting machine type“. The display module now permanently shows code "7010".

l Enter "7104".

Fig. 81

l Switch off the ignition (Fig. 81).

The display module now permanently shows code

"7104".

l Enter "7011" to finish the procedure.

This code number confirms the entered machine

type.

After having confirmed the machine type the control switches off, restarts automatically after 3 seconds and is then ready for starting.

Whenever switching the ignition on the machine

type will appear in the display module for 3 seconds.

BOMAG 51BMP 8500

Operation

4.16 Teaching the BOSS safety

system transponder

When replacing a defective remote control only

units with a completely black housing must be

used. Please follow the described procedure when

installing new components of the radio system or

the safety system (BOSS):

l Shut down the engine,

l switch off the main battery switch,

l replace defective components,

l switch on the main battery switch,

l plug the spiral cable into the remote control.

Fig. 83

l Turn the ignition switch to position I (Fig. 83),

charge control lamp and oil pressure control

lamp come on.

l Move the remote control out of the safety field.

l The safety field control lamp goes out at the

latest after 2 seconds.

Fig. 82

l Turn the tumbler switch for the cable remote

control to position "Left", cable operation (Fig.

82).

The machine is now ready for operation.

BOMAG52 BMP 8500

Operation

!

Caution

!

Danger

! Danger

4.17 Assembling/removing the

drum extension

Assembly

Fig. 84

l Attach drum extensions 2 (Fig. 84) to the

drums, turn three fastening screws (1) into

each drum and tighten.

Removal

l Unscrew the fastening screws and take off the

drum extensions.

l Turn the fastening screws back into the drum

and fasten.

4.18 Loading and transport

Danger of accident! Life hazard!

Use only stable loading ramps of sufficient

load bearing capacity. The ramp inclination

must be less than the gradability of the machine.

Make sure that persons are not endangered by

the machine tipping or sliding off.

Always engage the articulation lock before

loading, lifting and transporting the machine.

Use only safe lifting gear of sufficient load

bearing capacity Minimum lifting capacity of

lifting gear: see operating weight in chapter

"Technical Data".

For lifting the machine attach the lifting gear

only to the lifting eye provided for this purpose.

Check lifting eye for damage before use. Do

not use a damaged or in any other way impaired lifting eye.

The machine must not swing about when being lifted.

Do not step or stand under suspended loads.

Lash the machine down, so that it is secured

against rolling, sliding and turning over.

In order to protect the threads turn the fastening screws into the drums, even after removing

the drum extensions.

Danger of turning over!

When using drums with a working width of 610

mm the second speed range must not be

switched on.

Fig. 85

l After driving the machine on the transport ve-

hicle pull out the locking bolt (1) (Fig. 85) and

engage the articulation lock in the locking eye

(2). Let the locking bolt click into place.

BOMAG 53BMP 8500

Operation

!

Danger

Fig. 86

Use the central lifting facility (Fig. 86) to lift the machine.

Danger of accident!

The machine cannot be steered if the articulation lock is applied.

l After transport release the articulation lock

again and store it in the receptacle.

Fig. 87

l Position of centre of gravity (Fig. 87).

Fig. 88

l Drive the machine onto the transport vehicle

and lash it down by the two lashing eyes (Fig.

88).

BOMAG54 BMP 8500

5 Maintenance

BOMAG 55BMP 8500

Maintenance

Environment

5.1 General notes on maintenance

When performing maintenance work always comply with the appropriate safety regulations.

Thorough maintenance of the machine guarantees far longer safe functioning of the machine and

prolongs the lifetime of important components.

The effort needed for this work is only little compared with the problems that may arise when not

observing this rule.

The terms right/left correspond with travel direction forward.

l Always clean machine and engine thoroughly

before starting maintenance work.

l For maintenance work stand the machine on

level ground.

l Always remove the main battery switch for all

maintenance work.

l Perform maintenance work only with the motor

switched off.

l Relieve hydraulic pressures before working on

hydraulic lines.

l Before working on electric parts of the ma-

chine disconnect the battery and cover it with

insulation material.

l When working in the area of the articulated

joint attach the articulation lock (transport

lock).

During maintenance work catch all oils and fuels and do not let them seep into the ground or

into the sewage system. Dispose of oils and fuels environmentally.

Keep used filters in a separate waste container

and dispose of environmentally.

Catch biodegradable oils separately.

Notes on the fuel system

The lifetime of the diesel engine depends to a

great extent on the cleanliness of the fuel.

l Keep fuel free of contaminants and water,

since this will damage the injection elements

of the engine.

l Drums with inside zinc lining are not suitable to

store fuel.

l When choosing the storage place for fuel

make sure that spilled fuel will not harm the environment.

l Do not let the hose stir up the slurry at the bot-

tom of the drum.

l The fuel drum must rest for a longer period of

time before drawing off fuel.

l The rest in the drum is not suitable for the en-

gine and should only be used for cleaning purposes.

Notes on the performance of the engine

On diesel engines both combustion air and fuel injection quantities are thoroughly adapted to each

other and determine power, temperature level and

exhaust gas quality of the engine.

If your engine has to work permanently in "thin air"

(at higher altitudes) and under full load, you should

consult the customer service of BOMAG or the

customer service of the engine manufacturer.

Notes on the cooling system

Prepare and check coolant with highest care,

since otherwise the engine may be damaged by

corrosion, cavitation and freezing.

The coolant is prepared by mixing a cooling system protection agent (ethylene glycol) into the

coolant.

Mixing with cooling system protection agent is

necessary in all climatic zones. It prevents corrosion, lowers the freezing point and raises the boiling point of the coolant.

Notes on the hydraulic system

During maintenance work on the hydraulic system

cleanliness is of major importance. Make sure that

no dirt or other contaminating substances can enter into the system. Small particles can produce

flutes in valves, cause pumps to seize, clog nozzles and pilot bores, thereby making expensive repairs inevitable.

l If, during the daily inspection of the oil level the

hydraulic oil level is found to have dropped,

check all lines, hoses and components for

leaks.

BOMAG56 BMP 8500

Maintenance

!

Caution

l Seal leaks immediately. If necessary inform

the responsible customer service.

l We recommend to use the BOMAG filling and

filtering unit with fine filter to fill the system.

This ensures finest filtration of the hydraulic

oil, prolongs the lifetime of the hydraulic oil filter and protects the hydraulic system.

l Clean fittings, filler covers and the area around

such parts before disassembly to avoid entering of dirt.

l Do not leave the tank opening unnecessarily

open, but cover it so that nothing can fall in.

5.2 Fuels and lubricants

Engine oil

Quality

Lubrication oils are classified according to their

performance and quality class. Oils according to

other comparable specifications may be used.

If low sulphur fuel (< 0.05%) is used, you must only

use engine oils of API

CG-4, CH-4 and CI-4.

For operation of an engine with high sulphur fuels

it is recommended to use an engine oil of classification CF or higher with a total base number of at

least 10.

Engine oils of classification CJ-4 must not be

used!

Oil viscosity

Since lubrication oil changes its viscosity with the

temperature, the ambient temperature at the operating location of the engine is of utmost importance when choosing the viscosity class (SAEclass) .

Optimal operating conditions can be achieved by

using the following oil viscosity chart as a reference.

*

-classification CF, CF-4,

Ambient temperature Viscosity

SAE 30

over 25 °C!

SAE10W-30

SAE 15W-40

SAE 20

0°C to 25°C

SAE10W-30

SAE 15W-40

below 0 °C SAE 10

SAE10W-30

SAE 15W-40

* American Petroleum Institute

BOMAG 57BMP 8500

Maintenance

!

Caution

!

Danger

Oil change intervals

The longest permissible time a lubrication oil

should remain in an engine is 1 year. If the following oil change intervals are not reached over a period of 1 year, the oil change should be performed

at least once per year, irrespective of the operating

hours reached.

API: CF, CF-4,

CG-4,CH-4 and

CI-4 = 250 operating hours

Fuels

Quality

Cetan index number: The recommended minimum

index number for the Cetan value is 45. A Cetan

index number higher than 50 should preferably be

used, especially at ambient temperatures below 20 °C and when working at altitudes of 1500 m

and more.

Diesel fuel specifications: With respect to the percentage (ppm) of sulphur the fuel used in the engine must comply with all relevant exhaust

emission regulations in the are of use of the engine.

It is highly recommended to use a fuel with a sulphur content of less than 0,10 % (1000 ppm).

When using a diesel fuel with a high sulphur content of 0.50 % (5000 ppm) to 1.0 % (10.000 ppm),

the engine oil change intervals must behalved.

Do not use any fuels with a sulphur content of

more than 1,0 % (10000 ppm).

It is recommended to use diesel fuel that complies

with the specifications EN590 or ASTM D975.

Diesel fuel with the designation no. 2-D is a destillate fuel with low volatility, which is especially suitable for industrial engines and heavy-duty

commercial vehicles (SAE J313 JUN87).

Since KUBOTA diesel engines with a rated power

of less than 56 kW (75 HP) comply with the exhaust emission standard of EPA