Page 1

TR5 User Manual

www.terasic.com

July 27, 2017

1

Page 2

TR5 User Manual

www.terasic.com

July 27, 2017

2

CONTENTS

CHAPTER 1

OVERVIEW

........................................................................................................................................ 4

1.1 GENERAL DESCRIPTION ............................................................................................................................................ 4

1.2 KEY FEATURES .......................................................................................................................................................... 4

1.3 BLOCK DIAGRAM ...................................................................................................................................................... 6

CHAPTER 2

BOARD COMPONENTS

.................................................................................................................... 9

2.1 BOARD OVERVIEW .................................................................................................................................................... 9

2.2 CONFIGURATION, STATUS AND SETUP ..................................................................................................................... 11

2.3 GENERAL USER INPUT/OUTPUT .............................................................................................................................. 17

2.4 TEMPERATURE SENSOR, FAN CONTROL AND POWER MONITOR .............................................................................. 21

2.5 CLOCK CIRCUIT ...................................................................................................................................................... 22

2.6 FLASH AND SSRAM MEMORY .............................................................................................................................. 25

2.7 DDR3 SO-DIMM ................................................................................................................................................... 28

2.8 FMC CONNECTORS ................................................................................................................................................. 32

2.9 SATA ...................................................................................................................................................................... 39

2.10 GPIO .................................................................................................................................................................... 40

2.11 PCI EXPRESS ......................................................................................................................................................... 43

CHAPTER 3

SYSTEM BUILDER

......................................................................................................................... 47

3.1 INTRODUCTION ....................................................................................................................................................... 47

3.2 GENERAL DESIGN FLOW ......................................................................................................................................... 48

3.3 USING SYSTEM BUILDER ........................................................................................................................................ 49

CHAPTER 4

FLASH PROGRAMMING

................................................................................................................. 59

4.1 CFI FLASH MEMORY MAP ...................................................................................................................................... 59

4.2 FPGA CONFIGURE OPERATION ............................................................................................................................... 60

4.3 FLASH PROGRAMMING WITH USERS DESIGN .......................................................................................................... 61

4.4 RESTORE FACTORY SETTINGS ................................................................................................................................. 64

CHAPTER 5

PROGRAMMABLE PLL

................................................................................................................... 65

5.1 CONFIGURE CDCM6208 AND LMK04096B IN RTL ............................................................................................... 65

Page 3

TR5 User Manual

www.terasic.com

July 27, 2017

3

5.2 NIOS II CONTROL FOR PLL/TEMPERATURE/POWER ................................................................................................. 80

CHAPTER 6

EXAMPLES OF ADVANCED DEMONSTRATION

...................................................................... 86

6.1 FLASH AND SSRAM TEST ...................................................................................................................................... 86

6.2 DDR3 SDRAM TEST ............................................................................................................................................. 89

6.3 DDR3 SDRAM TEST BY NIOS II ............................................................................................................................ 92

6.4 FAN SPEED CONTROL .............................................................................................................................................. 95

6.5 UART TO USB CONTROL ....................................................................................................................................... 98

CHAPTER 7

PCI EXPRESS REFERENCE DESIGN

..................................................................................... 103

7.1 PCI EXPRESS SYSTEM INFRASTRUCTURE .............................................................................................................. 103

7.2 PC PCI EXPRESS SOFTWARE SDK ........................................................................................................................ 104

7.3 REFERENCE DESIGN - FUNDAMENTAL ................................................................................................................... 116

7.4 PCIE REFERENCE DESIGN – DDR3 ....................................................................................................................... 123

CHAPTER 8

TRANSCEIVER VERIFICATION

................................................................................................ 130

8.1 FUNCTION OF THE TRANSCEIVER TEST CODE ....................................................................................................... 130

8.2 FUNCTION OF THE TRANSCEIVER TEST CODE ....................................................................................................... 130

8.1 TESTING ................................................................................................................................................................ 132

CHAPTER 9

FMC CONNECTORS PIN OUT

.................................................................................................... 135

ADDITIONAL INFORMATION

................................................................................................................................... 162

Page 4

TR5 User Manual

www.terasic.com

July 27, 2017

4

Chapter 1

Overview

This chapter provides an overview of the TR5 Development Board and installation guide.

1.1 General Description

The Terasic TR5 Stratix V GX FPGA Development Kit provides the ideal hardware solution for

designs that demand high capacity and bandwidth interface, ultra-low latency communication, high

pin count and power efficiency. With an iPass PCIe gen3 connector, the TR5 is designed for the most

demanding high-end applications, empowered with the Altera 28 nm Stratix V GX, delivering the

best system-level integration and flexibility in the industry.

The Stratix® V GX FPGA features integrated transceivers that transfer at a maximum of 12.5Gbps,

this allows the TR5 to be fully compliant with version 3.0 of the PCI Express standard. Not relying

on an external PHY will accelerate mainstream development of network applications enabling

customers to deploy designs for a broad range of high-speed connectivity applications. For designs

that demand high capacity and high speed for memory and storage, the TR5 delivers with one

independent bank of DDR3 SO-DIMM RAM, one ZBT SSRAM, and high-speed parallel flash

memory. The feature-set of the TR5 fully supports all high-intensity applications such as ASIC

verification, data acquisition, and signal processing.

1.2 Key Features

The following hardware is implemented on the TR5 board:

FPGA

Altera Stratix® V GX FPGA

5SGXEA7N2F45C2 /5SGXEABN3F45I3YY

Page 5

TR5 User Manual

www.terasic.com

July 27, 2017

5

FPGA Configuration

On-Board USB Blaster II or JTAG header for FPGA programming

Fast passive parallel (FPPx16) configuration via MAX II CPLD and flash memory

General user input/output:

4 LEDs

4 push-buttons

4 slide switches

Clock System

50MHz Oscillator

CDCM6208 Programmable PLL

LMK04096B Programmable PLL

SMA connector pairs for differential clock input and output

Memory

DDR3 SO-DIMM SDRAM

QDRII+ SRAM

FLASH

SD Card

Communication Ports

PCI Express (PCIe) x4 iPass connector

Serial ATA host and device ports

PCI Express (PCIe) x8 edge connector

One mini Uart to USB connector

System Monitor and Control

Temperature sensor

Fan control

Power monitor

Mechanical Specification

4 FPGA Mezzanine Card (FMC) Connectors

One 40-pin Expansion Header

Page 6

TR5 User Manual

www.terasic.com

July 27, 2017

6

Power

12V DC Input

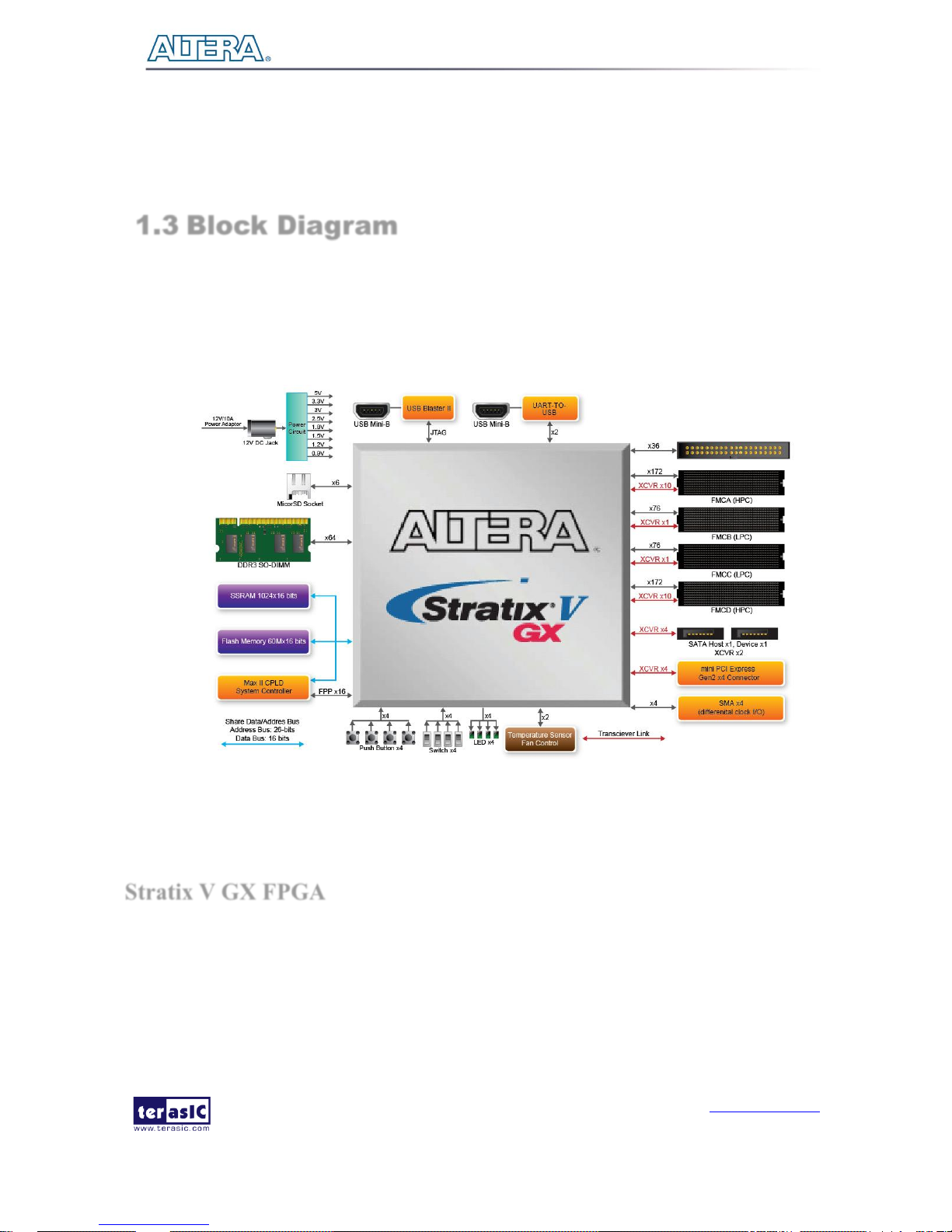

1.3 Block Diagram

94H94HFigure 1-1 shows the block diagram of the TR5 board. To provide maximum flexibility for the users,

all key components are connected with the Stratix V GX FPGA device. Thus, users can configure the

FPGA to implement any system design.

Figure 1-1 Block diagram of the TR5 board

Below is more detailed information regarding the blocks in 95H95HFigure 1-1.

Stratix V GX FPGA

5SGXEA7N2F45C2

622K logic elements (LEs)

57.16-Mbits embedded memory

Page 7

TR5 User Manual

www.terasic.com

July 27, 2017

7

48 transceivers (12.5Gbps)

512 18 x18 multipliers

256 Variable-precision DSP blocks

28 Fractional PLLs and 4DLLs

5SGXEABN3F45I3YY

952K logic elements (LEs)

62.96-Mbits embedded memory

48 transceivers (12.5Gbps)

704 18 x18 multipliers

352 Variable-precision DSP blocks

28 Fractional PLLs and 4DLLs

JTAG Header and FPGA Configuration

On-board USB Blaster II or JTAG header for use with the Quartus II Programmer

MAXII CPLD EPM2210 System Controller and Fast Passive Parallel (FPP) configuration

Memory devices

2MB ZBT SSRAM

Up to 8GB DDR3 SO-DIMM SDRAM

256MB FLASH

General user I/O

4 user controllable LEDs

4 user push buttons

4 user slide switches

On-Board Clock

Page 8

TR5 User Manual

www.terasic.com

July 27, 2017

8

50MHz oscillator

Programming PLL providing clock for FMC transceivers

Programming PLL providing clock for PCIe transceiver

Programming PLL providing clocks for DDR3 SDRAM

Two Serial ATA ports

SATA 3.0 standard at 6Gbps signaling rate

Four FMC Connectors

2 HPC (high-pin count) FMC connectors up to 172 x2 Single-end I/O

2 LPC (low-pin count) FMC connectors up to 76 x2 Single-end I/O

10 Transceiver Channels for HPC and 1 Transceiver Channel for LPC

FMC VITA 57.1 Compliant

Adjustable VADJ: 1.2V/1.5V/1.8V/2.5V/3.0V

Don’t support bidirectional LVDS due to Stratix V device only support single directional LVDS

One 40-pin GPIO Expansion Header

36 FPGA I/O pins; 4 power and ground lines

I/O standards: 3.3V (with level shift from 2.5V to 3.3V)

External PCI Express x4 iPass Connector

Support for PCIe x4 Gen1/2/3

iPass connector with x4 PCI Express slot

Power Source

DC 12V power adapter

Page 9

TR5 User Manual

www.terasic.com

July 27, 2017

9

Chapter 2

Board Components

This chapter introduces all the important components on the TR5.

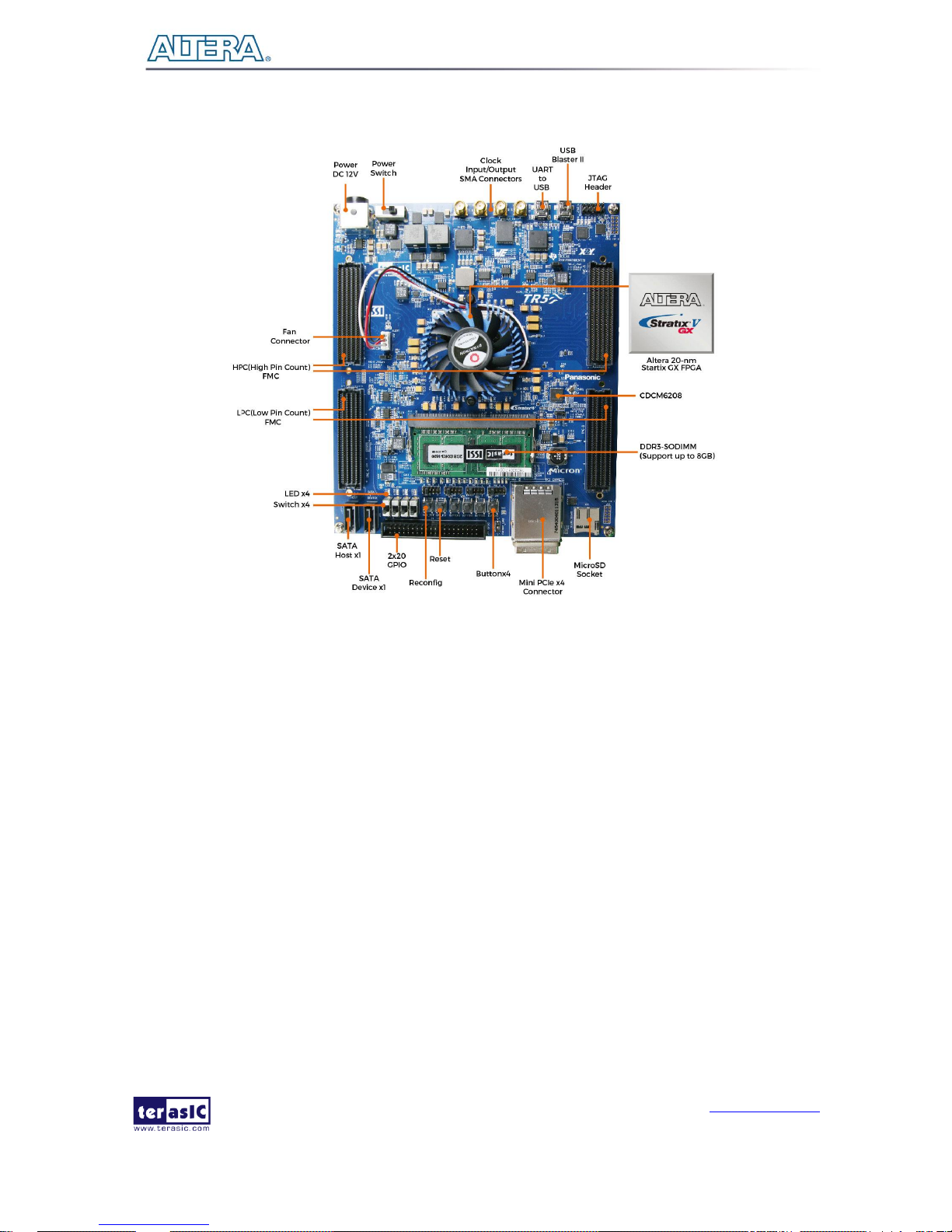

2.1 Board Overview

96H96HFigure 2-1 is the top and bottom view of the TR5 development board. It depicts the layout of the

board and indicates the location of the connectors and key components. Users can refer to this figure

for relative location of the connectors and key components.

Page 10

TR5 User Manual

www.terasic.com

July 27, 2017

10

Figure 2-1 FPGA Board (Top)

Page 11

TR5 User Manual

www.terasic.com

July 27, 2017

11

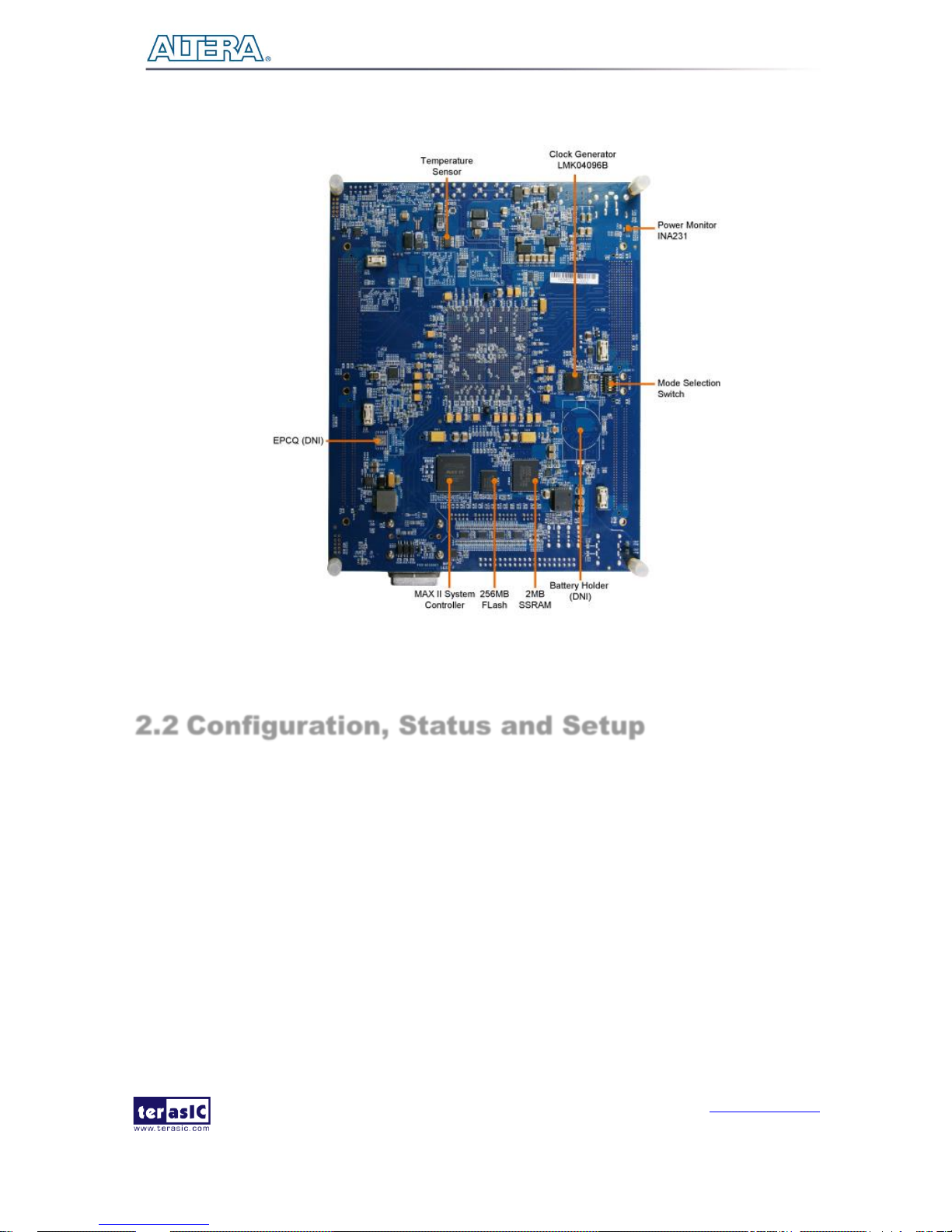

Figure 2-2 FPGA Board (Bottom)

2.2 Configuration, Status and Setup

Configure

The FPGA board supports two configuration methods for the Stratix V FPGA:

Configure the FPGA using the on-board USB-Blaster II.

Flash memory configuration of the FPGA using stored images from the flash memory on power-

up.

For programming by on-board USB-Blaster II, the following procedures show how to download a

configuration bit stream into the Stratix V GX FPGA:

Page 12

TR5 User Manual

www.terasic.com

July 27, 2017

12

Make sure that power is provided to the FPGA board.

Connect your PC to the FPGA board using a mini-USB cable and make sure the USB-Blaster II

driver is installed on PC.

Launch Quartus II programmer and make sure the USB-Blaster II is detected.

In Quartus II Programmer, add the configuration bit stream file (.sof), check the associated

“Program/Configure” item, and click “Start” to start FPGA programming.

Status LED

The FPGA Board development board includes board-specific status LEDs to indicate board status.

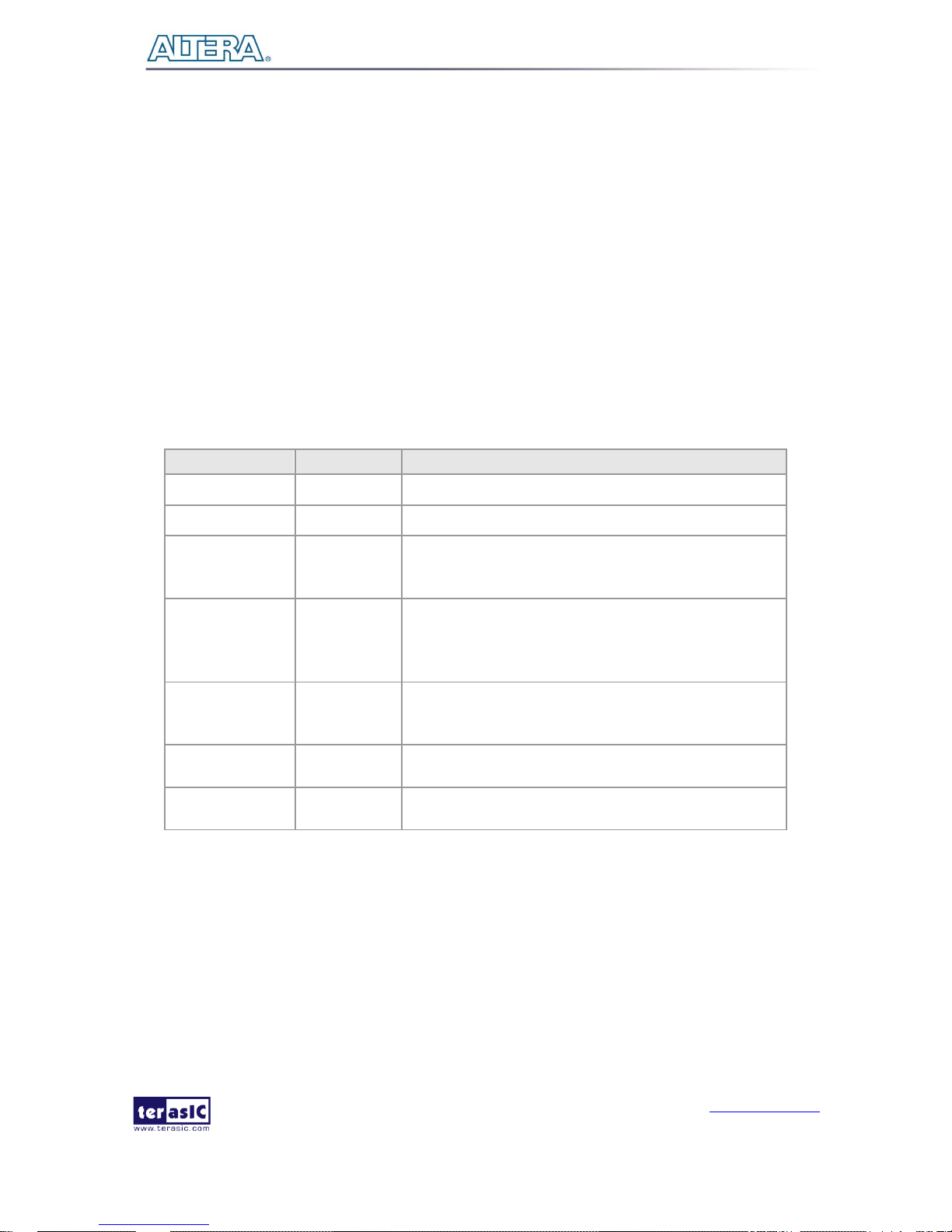

Please refer to 97H9HTable 2-1 for the description of the LED indicator.

Table 2-1 Status LED

Board Reference

LED Name

Description

D6

12-V Power

Illuminates when 12-V power is active.

D1

3.3-V Power

Illuminates when 3.3-V power is active.

D21

CONF_DONE

Illuminates when the FPGA is successfully configured.

Driven by the MAX II CPLD EPM2210 System

Controller.

D22

LOAD

Illuminates when the MAX II CPLD EPM2210 System

Controller is actively configuring the FPGA. Driven by

the MAX II CPLD EPM2210 System Controller with the

Embedded Blaster CPLD.

D23

ERROR

Illuminates when the MAX II CPLD EPM2210 System

Controller fails to configure the FPGA. Driven by the

MAX II CPLD EPM2210 System Controller.

D24

BOOT_PAGE

Illuminates when FPGA is configured by the factory

configuration bit stream.

D12~D20,D33~D35

FMC Voltage

Value Indicator

See Section 2.8 FMC Connectors

Setup Configure Mode Control DIP switch

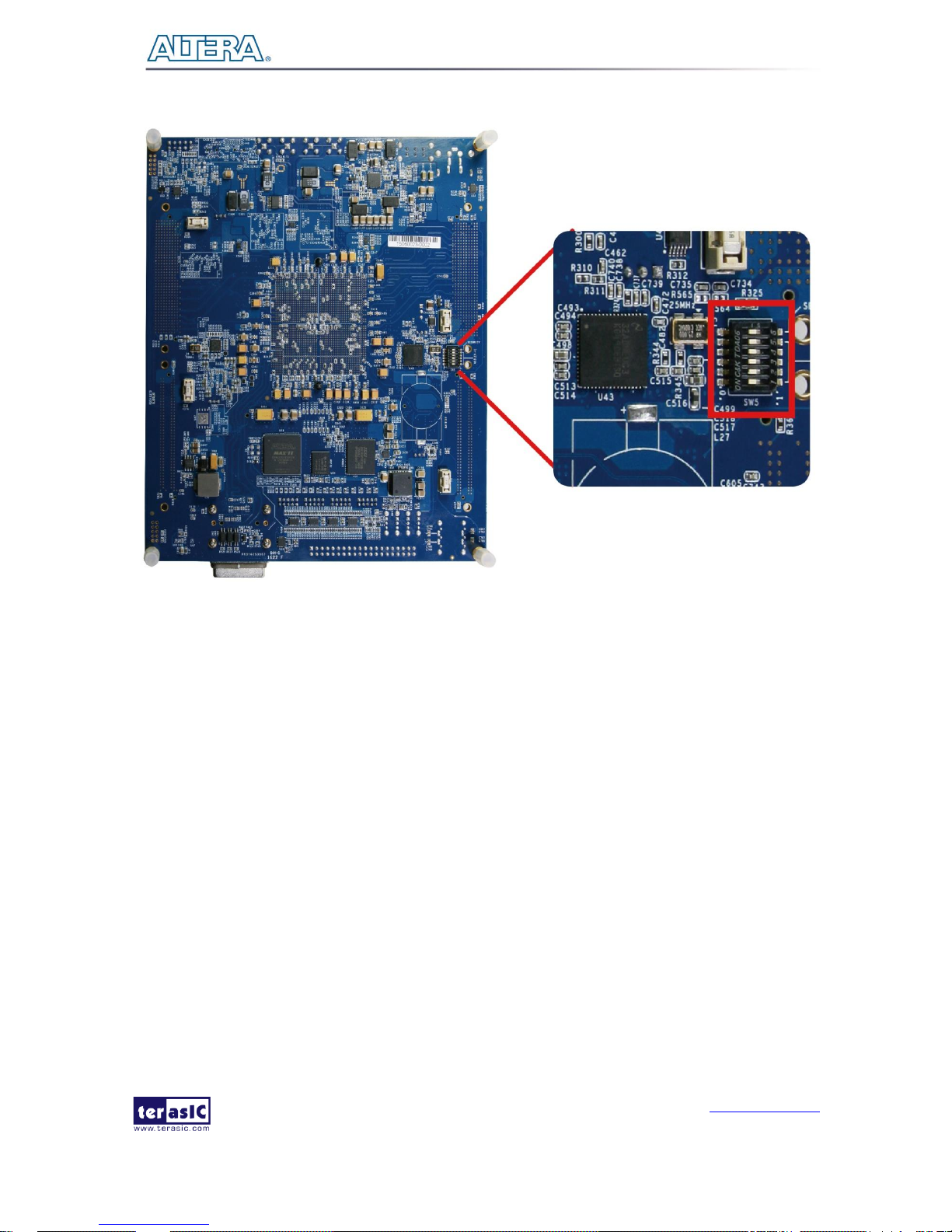

The Configure Mode Control DIP switch (SW5) is provided to specify the configuration mode of the

FPGA. As currently only one mode is supported, please set all positions as shown in 99H99HFigure 2-3.

Page 13

TR5 User Manual

www.terasic.com

July 27, 2017

13

Figure 2-3 4-Position DIP switch for Configure Mode

Select Flash Image for Configuration

The Image Select DIP switch (SW4) is provided to specify the image for configuration of the FPGA.

Setting SW4 to high (‘0’) specifies the default factory image to be loaded, setting SW4 to low (‘1’)

specifies the TR5 to load a user-defined image, as shown in 101H101HFigure 2-4.

Page 14

TR5 User Manual

www.terasic.com

July 27, 2017

14

Figure 2-4 2-position DIP switch for Image Select

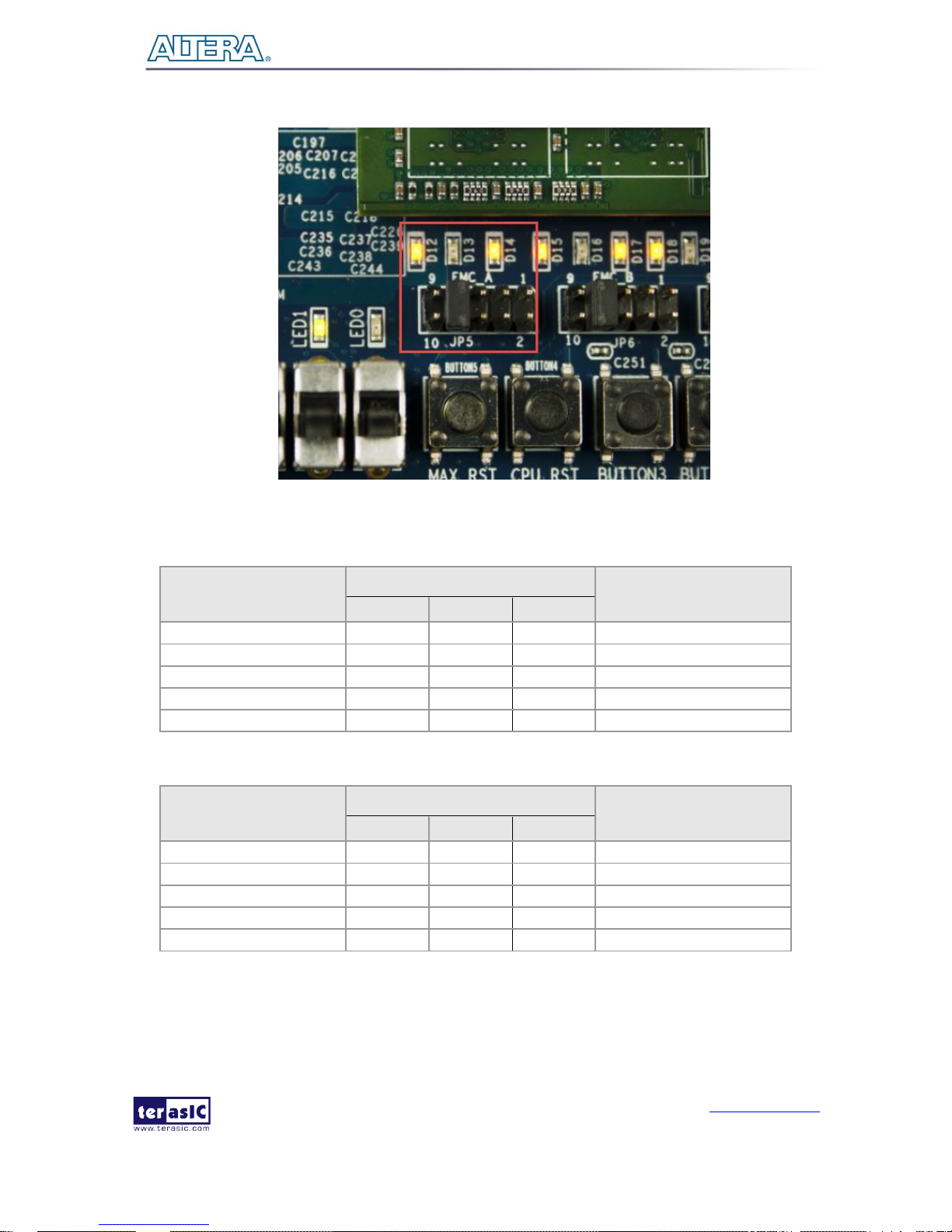

FMC VCCIO Voltage Setting Header

The I/O voltage of all the four FMC connectors is adjustable within 1.2/1.5/1.8/2.5/3.0V. For example,

user can adjust the I/O voltage to 2.5V to support LVDS differential I/O stand. The user can

independently control the voltage of FMCA~FMCD through JP5, JP6, JP7 and JP9. As shown in

Figure 2-5, make short circuit onto JP5 pin 7 and pin 8, the status of D12, D13 and D14 will be set

as “ON/OFF/ON” for representing the FMCA VCCIO is 2.5V. Table 2-2, Table 2-3, Table 2-4 and

Table 2-5 lists the voltage settings of the FMCA~FMCD VCCIO and their corresponding LED

display status.

Page 15

TR5 User Manual

www.terasic.com

July 27, 2017

15

Figure 2-5 FMC A VCCIO Voltage Setting to 2.5V

Table 2-2 FMC A VCCIO Voltage Setting

JP5 Setting

LED Status

FMC A VCCIO Voltage

D12

D13

D14

Short Pin 1 & 2

OFF

OFF

ON

1.2V

Short Pin 3 & 4

OFF

ON

OFF

1.5V

Short Pin 5 & 6

OFF

ON

ON

1.8V

Short Pin 7 & 8

ON

OFF

ON

2.5V(Default)

Short Pin 9 & 10

ON

ON

OFF

3.0V

Table 2-3 FMC B VCCIO Voltage Setting

JP6 Setting

LED Status

FMC B VCCIO Voltage

D15

D16

D17

Short Pin 1 & 2

OFF

OFF

ON

1.2V

Short Pin 3 & 4

OFF

ON

OFF

1.5V

Short Pin 5 & 6

OFF

ON

ON

1.8V

Short Pin 7 & 8

ON

OFF

ON

2.5V(Default)

Short Pin 9 & 10

ON

ON

OFF

3.0V

Page 16

TR5 User Manual

www.terasic.com

July 27, 2017

16

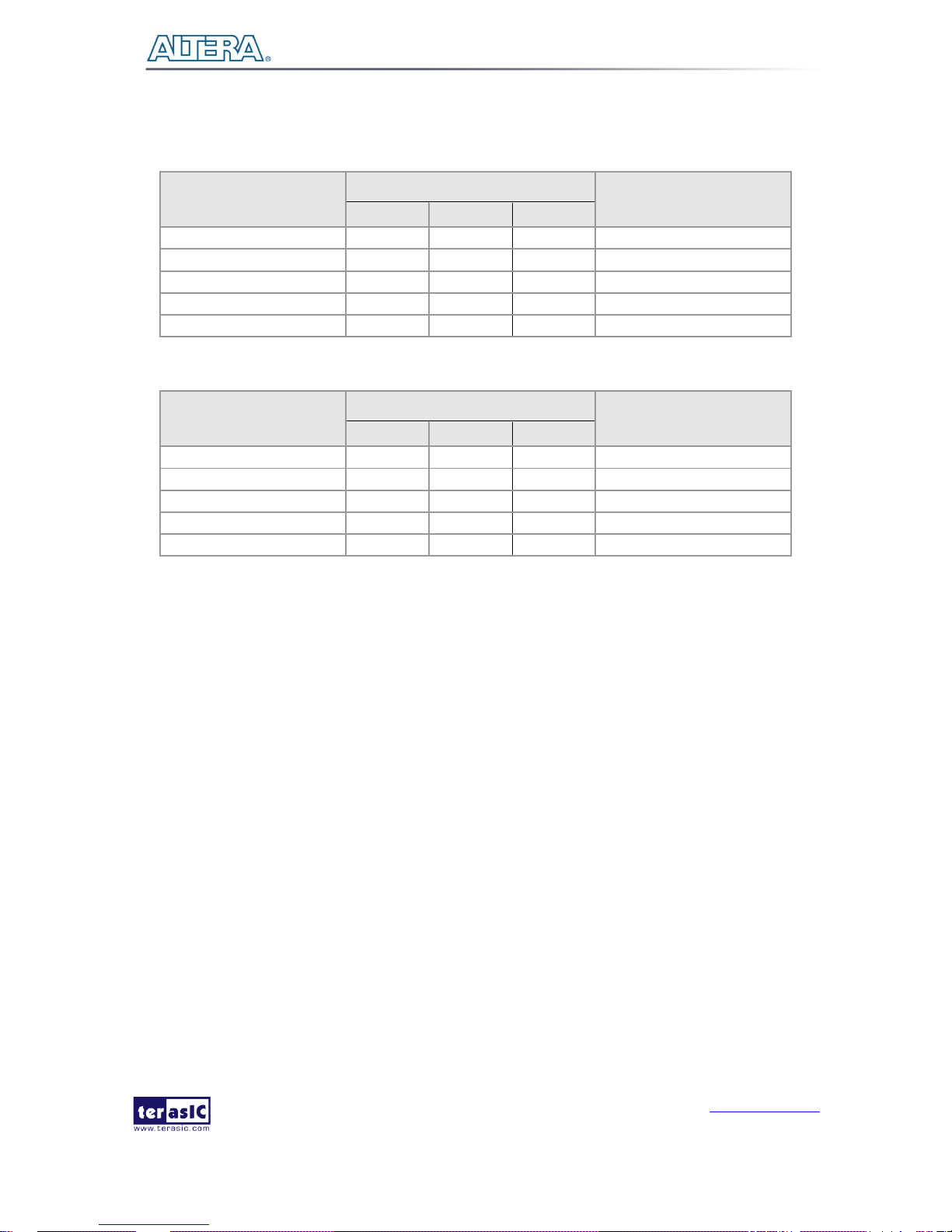

Table 2-4 FMC C VCCIO Voltage Setting

JP7 Setting

LED Status

FMC C VCCIO Voltage

D18

D19

D20

Short Pin 1 & 2

OFF

OFF

ON

1.2V

Short Pin 3 & 4

OFF

ON

OFF

1.5V

Short Pin 5 & 6

OFF

ON

ON

1.8V

Short Pin 7 & 8

ON

OFF

ON

2.5V(Default)

Short Pin 9 & 10

ON

ON

OFF

3.0V

Table 2-5 FMC D VCCIO Voltage Setting

JP9 Setting

LED Status

FMC D VCCIO Voltage

D33

D34

D35

Short Pin 1 & 2

OFF

OFF

ON

1.2V

Short Pin 3 & 4

OFF

ON

OFF

1.5V

Short Pin 5 & 6

OFF

ON

ON

1.8V

Short Pin 7 & 8

ON

OFF

ON

2.5V(Default)

Short Pin 9 & 10

ON

ON

OFF

3.0V

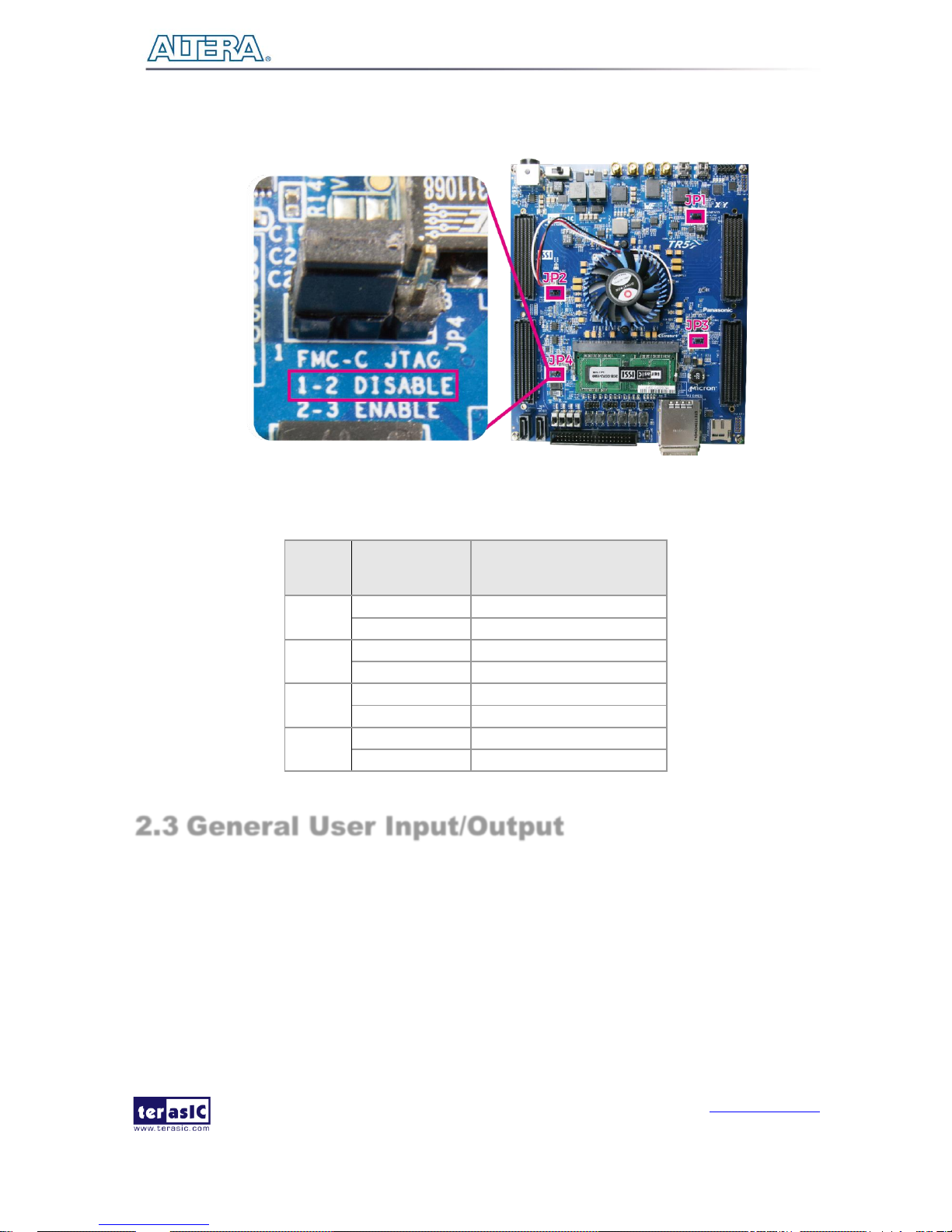

FMC JTAG Header

The TR5 supports individual JTAG interfaces on each FMC connector. This feature allows users to

extend the JTAG chain to FMC daughter cards. The JTAG signals on each FMC connector can be

removed or included in the active JTAG chain via 3-Pin header (See Figure 2-6). Table 2-6 lists the

setting of the headers and their associated interfaces. Note that if the JTAG interface on FMC

connector is enabled, make sure that the active JTAG chain must be a closed loop or the FPGA may

not be detected.

Page 17

TR5 User Manual

www.terasic.com

July 27, 2017

17

Figure 2-6 FMCC JTAG Header

Table 2-6 FMC JTAG Header Setting

Headers

Setting

Description

JP1

Short Pin 1 & 2

Disable FMCA JTAG

Short Pin 2 & 3

Enable FMCA JTAG

JP2

Short Pin 1 & 2

Disable FMCD JTAG

Short Pin 2 & 3

Enable FMCD JTAG

JP3

Short Pin 1 & 2

Disable FMCB JTAG

Short Pin 2 & 3

Enable FMCB JTAG

JP4

Short Pin 1 & 2

Disable FMCC JTAG

Short Pin 2 & 3

Enable FMCC JTAG

2.3 General User Input/Output

This section describes the user I/O interface to the FPGA.

User Defined Push-buttons

The FPGA board includes four user defined push-buttons that allow users to interact with the Stratix

V GX device. Each push-button provides a high logic level or a low logic level when it is not pressed

Page 18

TR5 User Manual

www.terasic.com

July 27, 2017

18

or pressed, respectively. 102H102HTable 2-7 lists the board references, signal names and their corresponding

Stratix V GX device pin numbers.

Table 2-7 Push-button Pin Assignments, Schematic Signal Names, and Functions

Board

Reference

Schematic

Signal Name

Description

I/O

Standard

Stratix V GX

Pin Number

BUTTON0

BUTTON0

High Logic Level when the button is

not pressed

1.5-V

PIN_BC7

BUTTON1

BUTTON1

1.5-V

PIN_BD7

BUTTON 2

BUTTON2

1.5-V

PIN_BB8

BUTTON 3

BUTTON3

1.5-V

PIN_BB9

User-Defined Slide Switch

There are four slide switches on the FPGA board to provide additional FPGA input control. When a

slide switch is in the DOWN position or the UPPER position, it provides a low logic level or a high

logic level to the Stratix V GX FPGA. The down position provides a low logic level and the upper

position provides a high logic level.

104H104HTable 2-8 lists the signal names and their corresponding Stratix V GX device pin numbers.

Table 2-8 Slide Switch Pin Assignments, Schematic Signal Names, and Functions

Board

Reference

Schematic

Signal Name

Description

I/O

Standard

Stratix V GX

Pin Number

SW0

SW0

High logic level when SW in the UPPER

position.

1.5-V

PIN_AT9

SW1

SW1

1.5-V

PIN_AU8

SW2

SW2

1.5-V

PIN_AK9

SW3

SW3

1.5-V

PIN_AL9

User-Defined LEDs

The FPGA board consists of four user-controllable LEDs to allow status and debugging signals to be

driven to the LEDs from the designs loaded into the Stratix V GX device. Each LED is driven directly

by the Stratix V GX FPGA. The LEDs are turned on or off when the associated pins are driven to a

low or high logic level, respectively. A list of the pin names on the FPGA that are connected to the

LEDs is given in 105H105HTable 2-9.

Page 19

TR5 User Manual

www.terasic.com

July 27, 2017

19

Table 2-9 User LEDs Pin Assignments, Schematic Signal Names, and Functions

Board

Reference

Schematic

Signal Name

Description

I/O

Standard

Stratix V GX

Pin Number

LED0

LED0

Driving a logic 0 on the I/O port turns the LED

ON.

Driving a logic 1 on the I/O port turns the LED

OFF.

1.5-V

PIN_AT32

LED1

LED1

1.5-V

PIN_BA31

LED2

LED2

1.5-V

PIN_AN27

LED3

LED3

1.5-V

PIN_AH27

UART-To-USB

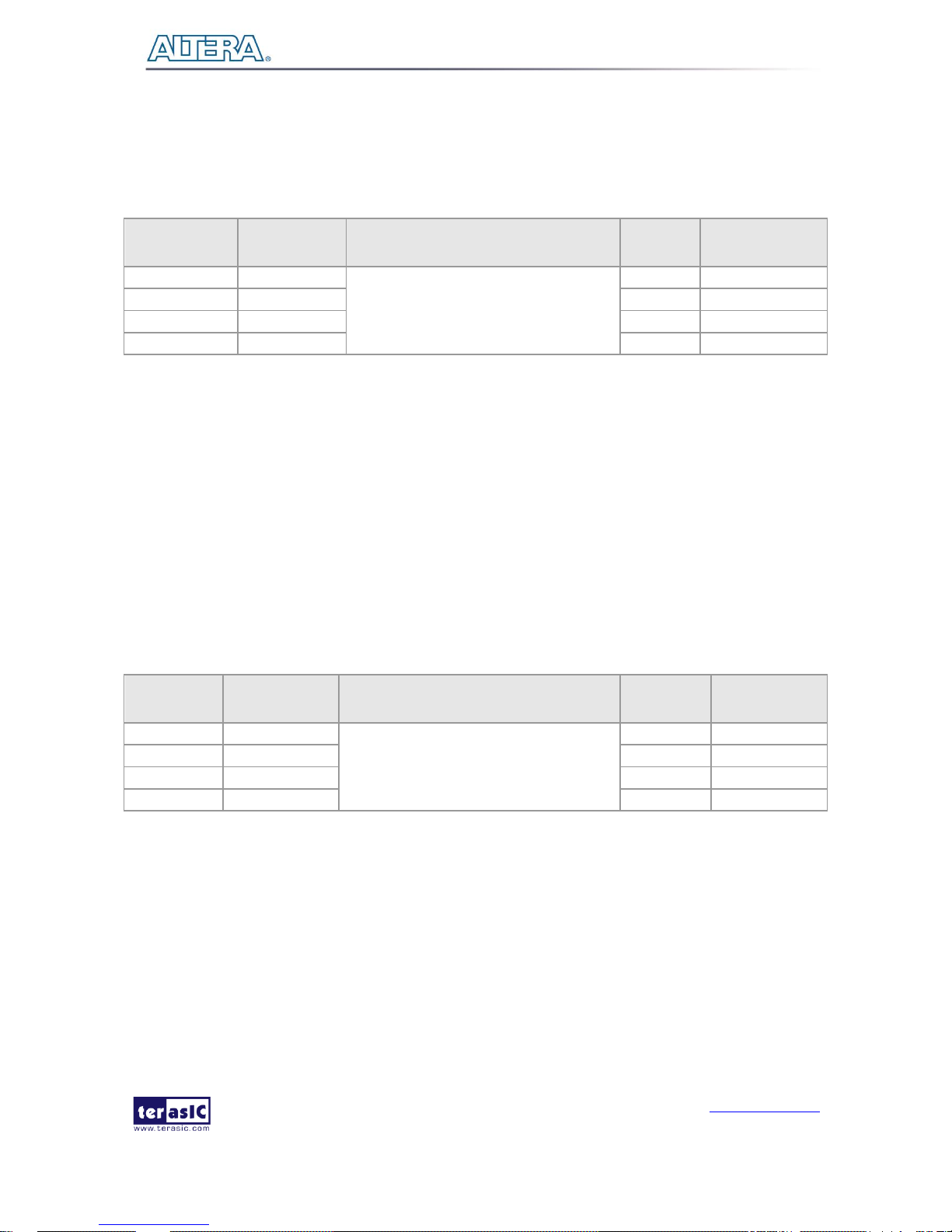

The UART is designed to perform communication between the board and the PC, allowing a

transmission speed of up to 3Mbps. This interface wouldn’t support HW flow control signals. The

physical interface is done using UART-USB on-board bridge from a FT232R chip and connects to

the host using a USB Type-B connector. For detailed information on how to use the transceiver, please

refer to the datasheet, which is available on the manufacturer’s website, or under the

Datasheets\FT232 folder on the Kit System CD. Figure 2-7 shows the related schematics, and Table

2-10 lists the UART pin assignments, signal names and functions.

Figure 2-7 Connection between UART-To-USB and Stratix V GX FPGA

Table 2-10 UART-To-USB Pin Assignments, Schematic Signal Names, and Functions

Board

Reference

Schematic

Signal

Name

Description

I/O Standard

Stratix V

GX Pin

Number

UART_TX

UART_TX

Uart TX output from FPGA

1.2/1.5/1.8/2.5/3.0-

PIN_T26

Page 20

TR5 User Manual

www.terasic.com

July 27, 2017

20

V

UART_RX

UART_RX

Uart RX input to FPGA

1.2/1.5/1.8/2.5/3.0V

PIN_T25

Micro SD-Card

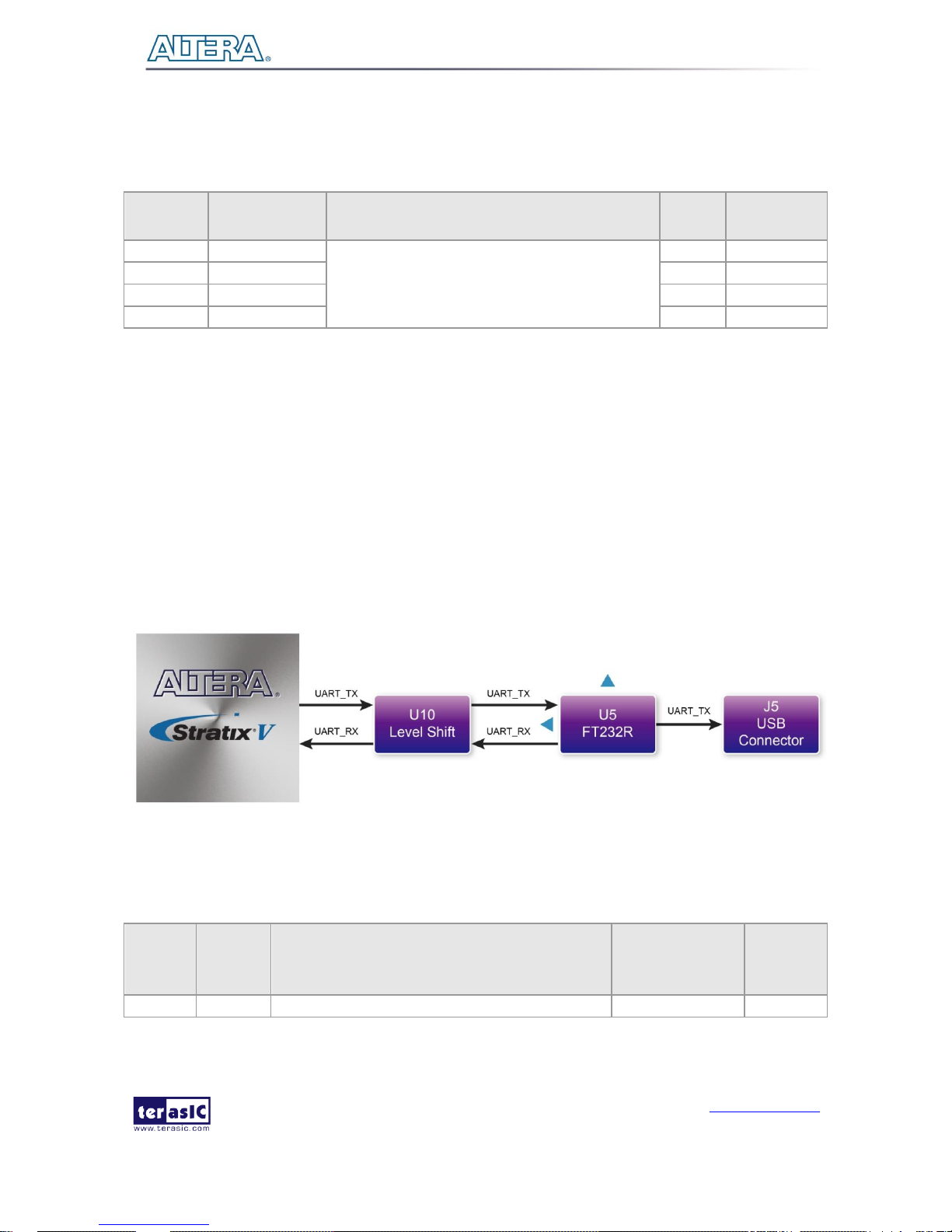

The development board supports Micro SD card interface using 4 data lines. Figure 2-8 shows the

related signals connections between the SD Card and Stratix V GX FPGA. Table 2-11 lists all the

associated pins

Figure 2-8 Connection between the SD Card Socket and Stratix V GX FPGA

Table 2-11 Micro SD Card Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal

Name

Description

I/O Standard

Stratix V

GX Pin

Number

SD_CLK

Serial Clock

1.5-V

PIN_BB39

SD_CMD

Command, Response

1.5-V

PIN_BA36

SD_DAT0

Serial Data 0

1.5-V

PIN_AV37

SD_DAT1

Serial Data 1

1.5-V

PIN_AY37

Page 21

TR5 User Manual

www.terasic.com

July 27, 2017

21

SD_DAT2

Serial Data 2

1.5-V

PIN_BB36

SD_DAT3

Serial Data 3

1.5-V

PIN_AW37

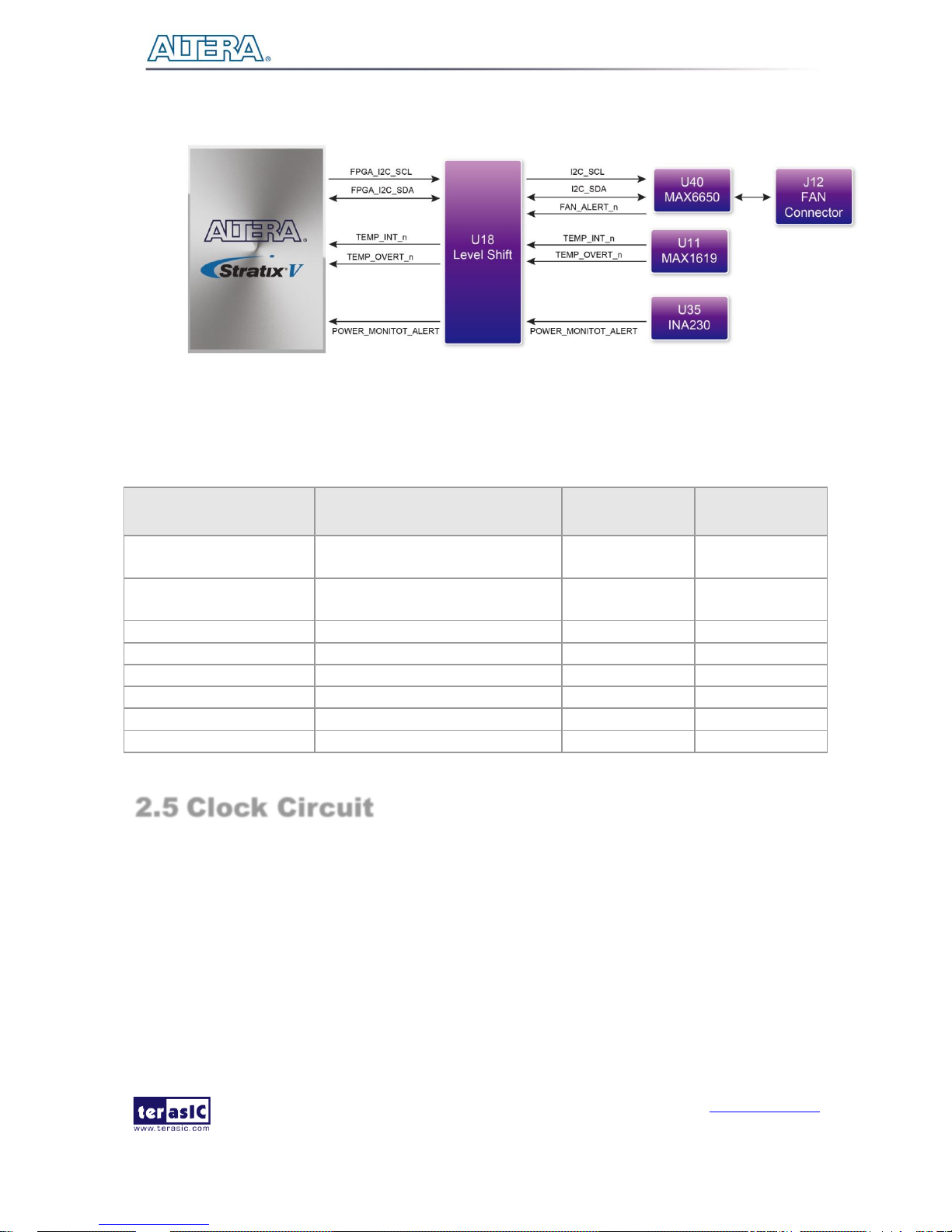

2.4 Temperature Sensor, Fan Control and Power

Monitor

The FPGA board is equipped with a temperature sensor, MAX1619, which provides temperature

sensing and over-temperature alert. These functions are accomplished by connecting the temperature

sensor to the internal temperature sensing diode of the Stratix V GX device. The temperature status

and alarm threshold registers of the temperature sensor can be programmed by a two-wire SMBus,

which is connected to the Stratix V GX FPGA. In addition, the 7-bit POR slave address for this sensor

is set to ‘0011000b’.

A 3-pin +12V fan located on J12 of the FPGA board is intended to reduce the temperature of the

FPGA. The board is equipped with a Fan-Speed regulator and monitor MAX6650 with an I2C/SMBus

interfaces, Users regulate and monitor the speed of fan depending on the measured system

temperature.

The TR5 has implemented a power monitor chip to monitor the board input power voltage and current.

Figure 2-9 shows the connection between the power monitor chip and the Stratix V GX FPGA. The

power monitor chip monitors both shunt voltage drops and board input power voltage allows user to

monitor the total board power consumption. Programmable calibration value, conversion times, and

averaging, combined with an internal multiplier, enable direct readouts of current in amperes and

power in watts. Note that, the temperature sensor, fan control and power monitor share the same

I2C/SMBUS.

Page 22

TR5 User Manual

www.terasic.com

July 27, 2017

22

Figure 2-9 Connections between the temperature sensor/fan control/power monitor and the

Stratix V GX FPGA

Table 2-12 Temperature Sensor and Fan Speed Control Pin Assignments, Schematic Signal

Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

TEMPDIODEp

Positive pin of temperature diode

in Stratix V

-

PIN_P6

TEMPDIODEn

Negative pin of temperature diode

in Stratix V

-

PIN_P7

FPGA_I2C_SCL

SMBus clock

1.5-V

PIN_AN11

FPGA_I2C_SDA

SMBus data

1.5-V

PIN_AP9

TEMP_OVERT_n

SMBus alert (interrupt)

1.5-V

PIN_AR9

TEMP_INT_n

SMBus alert (interrupt)

1.5-V

PIN_AT8

POWER_MONITOR_ALERT

Active-high ALERT input

1.5-V

PIN_AY9

FAN_ALERT_n

Active-low ALERT input

1.5-V

PIN_AM11

2.5 Clock Circuit

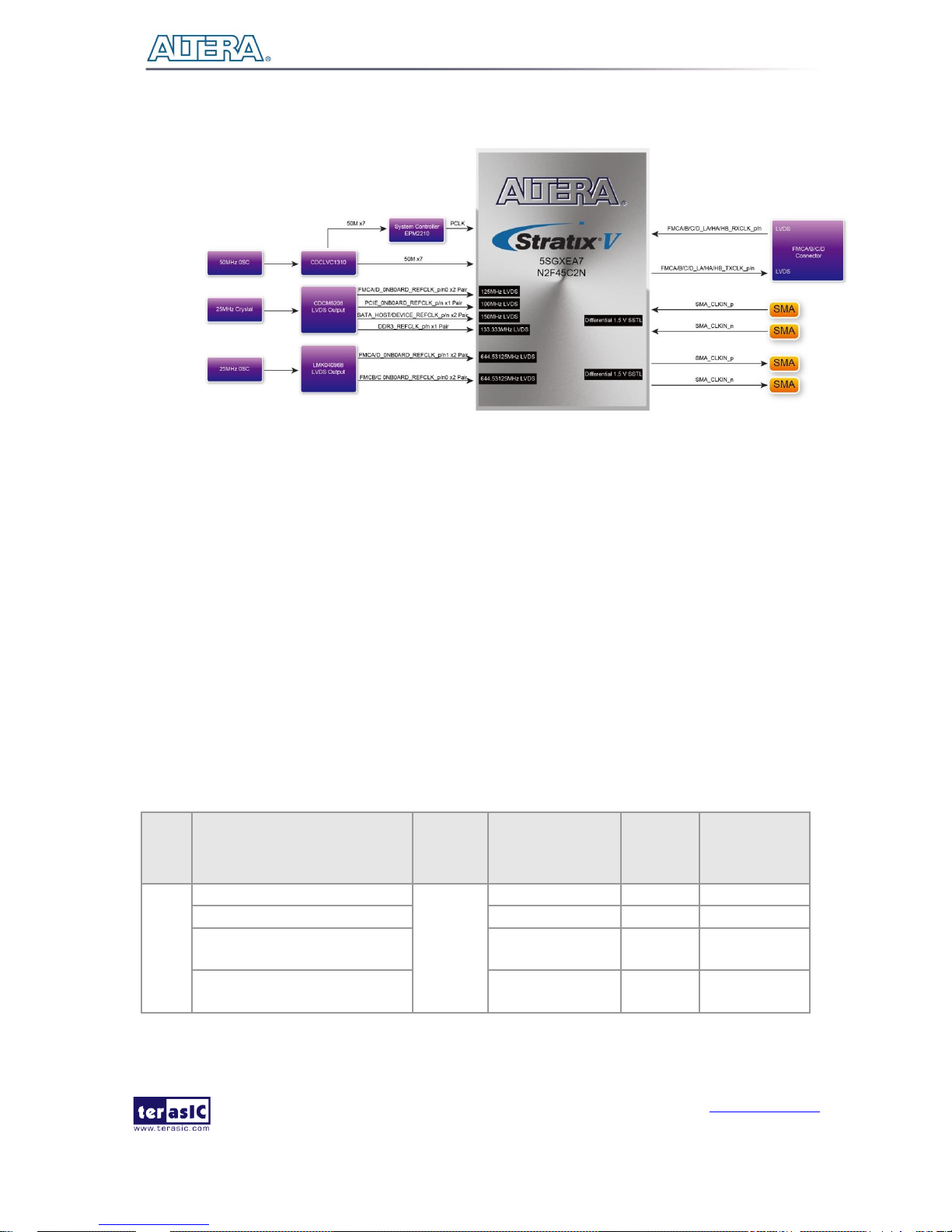

The development board includes one 50 MHz and two programmable clock generators. Figure 2-10

shows the default frequencies of on-board all external clocks going to the Stratix V GX FPGA.

Page 23

TR5 User Manual

www.terasic.com

July 27, 2017

23

Figure 2-10 Clock circuit of the FPGA Board

A clock buffer is used to duplicate the 50 MHz oscillator, so there are seven 50MHz clocks fed into

seven different FPGA banks. The two programming clock generators are low-jitter oscillators which

are used to provide special and high quality clock signals for high-speed transceivers and high

bandwidth memory. Through I2C serial interface, the clock generator controllers in the Stratix V GX

FPGA can be used to program the CDCM6208 and LMK04096B to generate PCIe, SATA and high

bandwidth memory reference clocks respectively. Two SMA connectors and Four FMC connectors

provide external differential clock input(s) and clock output(s) respectively.

112H112HTable 2-9 lists the clock source, signal names, default frequency and their corresponding Stratix V

GX device pin numbers.

Table 2-9 Clock Source, Signal Name, Default Frequency, Pin Assignments and Functions

Source

Schematic

Signal Name

Default

Frequency

I/O Standard

Stratix V

GX Pin

Number

Application

Y1

CLK_50_B3B

50.0 MHz

1.5-V

PIN_AW35

CLK_50_B4A

1.5-V

PIN_AP10

CLK_50_B4D

1.2/1.5/1.8/2.5/3.0V

PIN_AY18

CLK_50_B7A

1.2/1.5/1.8/2.5/3.0V

PIN_M8

Page 24

TR5 User Manual

www.terasic.com

July 27, 2017

24

CLK_50_B7D

1.2/1.5/1.8/2.5/3.0V

PIN_J18

CLK_50_B8A

1.2/1.5/1.8/2.5/3.0V

PIN_R36

CLK_50_B8D

1.2/1.5/1.8/2.5/3.0V

PIN_R25

J3

SMA_CLKIN_p

User

Defined

1.5-V

PIN_BC8

External Clock

Input

J4

SMA_CLKIN_n

User

Defined

1.5-V

PIN_BD8

Clock Output

J1

SMA_CLKOUT_p

User

Defined

1.5-V

PIN_AV8

J2

SMA_CLKOUT_n

User

Defined

1.5-V

PIN_AW9

U21

FMCA_ONBOARD_REFCLK_p0

125 MHz

LVDS

PIN_Y38

FMCA port xcvr

reference clock

FMCD_ONBOARD_REFCLK_p0

125 MHz

LVDS

PIN_Y7

FMCD port xcvr

reference clock

PCIE_ONBOARD_REFCLK_p

100 MHz

LVDS

PIN_AH39

PCIe reference

clock

SATA_DEVICE_REFCLK_p

150 MHz

LVDS

PIN_AK7

SATA Device

reference clock

SATA_HOST_REFCLK_p

150 MHz

PIN_BB33

SATA Host

reference clock

DDR3_REFCLK_p

133.333

MHz

DDR3

reference clock

U43

FMCA_ONBOARD_REFCLK_p1

644.53125

MHz

LVDS

PIN_T38

FMCA port xcvr

reference clock

FMCD_ONBOARD_REFCLK_p1

644.53125

MHz

LVDS

PIN_T7

FMCD port xcvr

reference clock

FMCC_ONBOARD_REFCLK_p0

644.53125

MHz

LVDS

PIN_AD39

FMCB port xcvr

reference clock

FMCC_ONBOARD_REFCLK_p1

644.53125

MHz

LVDS

PIN_AD6

FMCC port xcvr

reference clock

113H113HTable 2-10 lists the programmable oscillator control pins, signal names, I/O standard and their

corresponding Stratix V GX device pin numbers.

Table 2-10 Programmable oscillator control pin, Signal Name, I/O standard, Pin

Assignments and Descriptions

Page 25

TR5 User Manual

www.terasic.com

July 27, 2017

25

Programmable

Oscillator

Schematic

Signal Name

I/O Standard

Stratix V GX Pin

Number

Description

CDCM6208

(U21)

CLOCK_SCL

2.5-V

PIN_AR25

I2C bus, connected

with CDCM6208

CLOCK_SDA

2.5-V

PIN_BC25

LMK04906B

(U43)

LMK04906_CLK

2.5-V

PIN_AT24

I2C bus master output

only, connected with

LMK04096B

LMK04906_DATAIN

2.5-V

PIN_BD25

LMK04906_DATAOUT

1.5-V

PIN_BC29

I2C bus master input

signal

LMK04906_LE

1.5-V

PIN_AT33

LMK04096B PLL

locked signal

2.6 FLASH and SSRAM Memory

The development board has a 1G bit CFI-compatible synchronous flash device for non-volatile

storage of FPGA configuration data, user application data, and user code space, and a 2M byte ZBT

SSRAM for data Cache.

The flash has a 16-bit data bus and allow for FPP x16 configuration. This device is part of the

shared flash and MAX (FM) bus, which connects to the flash memory and MAX II CPLD

(EPM2210) System Controller. The SSRAM also has a 16-bit data bus and share address and data

bus with the flash. 1Figure 2-11 shows the connections between the Flash, SSRAM, MAX and

Stratix V GX FPGA.

Page 26

TR5 User Manual

www.terasic.com

July 27, 2017

26

Figure 2-11 Connection between the Flash, Max and Stratix V GX FPGA

117H117HTable 2-11 lists the flash pin assignments, signal names, and functions.

Table 2-13 Flash Memory Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX

Pin Number

FSM_A1

Address bus

2.5V

PIN_AE11

FSM_A2

Address bus

2.5V

PIN_AD14

FSM_A3

Address bus

2.5V

PIN_AE14

FSM_A4

Address bus

2.5V

PIN_AE10

FSM_A5

Address bus

2.5V

PIN_AF10

FSM_A6

Address bus

2.5V

PIN_AE12

FSM_A7

Address bus

2.5V

PIN_AF11

FSM_A8

Address bus

2.5V

PIN_AG13

FSM_A9

Address bus

2.5V

PIN_AJ10

FSM_A10

Address bus

2.5V

PIN_AF13

FSM_A11

Address bus

2.5V

PIN_AE13

FSM_A12

Address bus

2.5V

PIN_AJ11

FSM_A13

Address bus

2.5V

PIN_BD11

FSM_A14

Address bus

2.5V

PIN_AW10

FSM_A15

Address bus

2.5V

PIN_AF14

Page 27

TR5 User Manual

www.terasic.com

July 27, 2017

27

FSM_A16

Address bus

2.5V

PIN_AY12

FSM_A17

Address bus

2.5V

PIN_AY10

FSM_A18

Address bus

2.5V

PIN_BD10

FSM_A19

Address bus

2.5V

PIN_BB12

FSM_A20

Address bus

2.5V

PIN_BA12

FSM_A21

Address bus

2.5V

PIN_BA10

FSM_A22

Address bus

2.5V

PIN_BC11

FSM_A23

Address bus

2.5V

PIN_AE9

FSM_A24

Address bus

2.5V

PIN_AW11

FSM_A25

Address bus

2.5V

PIN_BC10

FSM_A26

Address bus

2.5V

PIN_BB11

FSM_D0

Data bus

2.5V

PIN_AG10

FSM_D1

Data bus

2.5V

PIN_AH10

FSM_D2

Data bus

2.5V

PIN_AG11

FSM_D3

Data bus

2.5V

PIN_AK12

FSM_D4

Data bus

2.5V

PIN_AV10

FSM_D5

Data bus

2.5V

PIN_AR12

FSM_D6

Data bus

2.5V

PIN_AL12

FSM_D7

Data bus

2.5V

PIN_AR13

FSM_D8

Data bus

2.5V

PIN_AG9

FSM_D9

Data bus

2.5V

PIN_AH12

FSM_D10

Data bus

2.5V

PIN_AG12

FSM_D11

Data bus

2.5V

PIN_AL11

FSM_D12

Data bus

2.5V

PIN_AN12

FSM_D13

Data bus

2.5V

PIN_AU9

FSM_D14

Data bus

2.5V

PIN_AM13

FSM_D15

Data bus

2.5V

PIN_AJ12

FLASH_CLK

Flash Clock

2.5V

PIN_AU11

FLASH_RESET_n

Flash Reset, active low

2.5V

PIN_AV25

FLASH_CE_n

Flash Chip enable,active low

2.5V

PIN_AU24

FLASH_OE_n

Flash Output enable, active

low

2.5V

PIN_AP12

FLASH_WE_n

Flash Write enable, active low

2.5V

PIN_AT12

FLASH_ADV_n

Flash Address valid, active

low

2.5V

PIN_BD26

FLASH_RDY_BSY_n

Flash ready output

2.5V

PIN_AU25

SSRAM_CLK

SSRAM Clock

2.5V

PIN_AP13

SSRAM_CKE_n

SSRAM Clock enable, active

low

2.5V

PIN_AW24

SSRAM_CE_n

SSRAM Chip enable, active

low

2.5V

PIN_AP24

Page 28

TR5 User Manual

www.terasic.com

July 27, 2017

28

SSRAM_WE_n

Flash Write enable, active low

2.5V

PIN_AV11

SSRAM_OE_n

Flash output enable, active

low

2.5V

PIN_AU10

SSRAM_ADV

Flash Address valid, active

high

2.5V

PIN_BC26

SSRAM_BWA_n

SSRAM Byte Write enable

2.5V

PIN_AY25

SSRAM_BWB_n

SSRAM Byte Write enable

2.5V

PIN_BA24

FLASH_CLK

Clock

2.5V

PIN_T9

FLASH_RESET_n

Reset

2.5V

PIN_C17

FLASH_CE_n

Chip enable of of flash-0

2.5V

PIN_H10

Chip enable of of flash-1

2.5V

PIN_N16

FLASH_OE_n

Output enable

2.5V

PIN_C16

FLASH_WE_n

Write enable

2.5V

PIN_U10

FLASH_ADV_n

Address valid

2.5V

PIN_H7

FLASH_RDY_BSY_n

Ready of flash-0

2.5V

PIN_J8

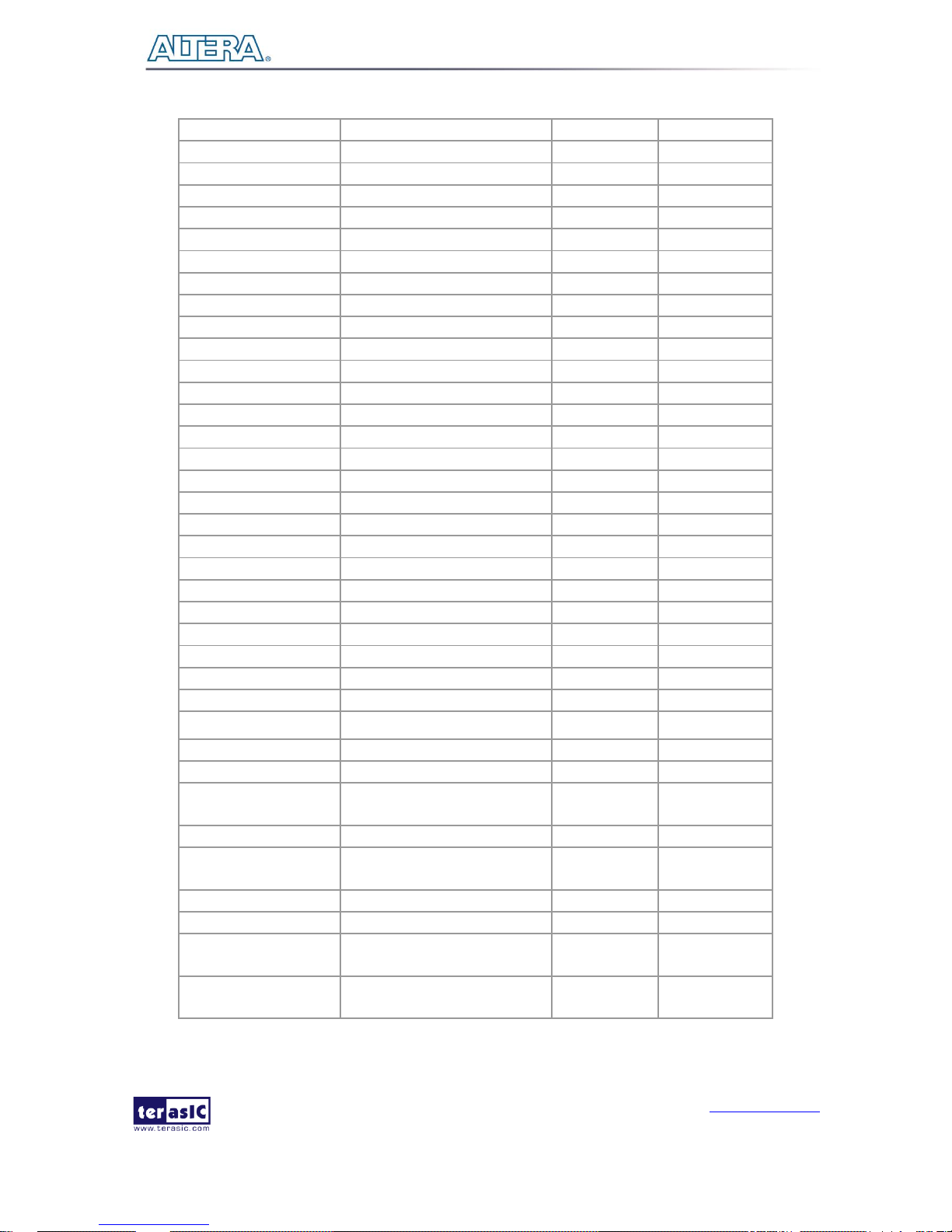

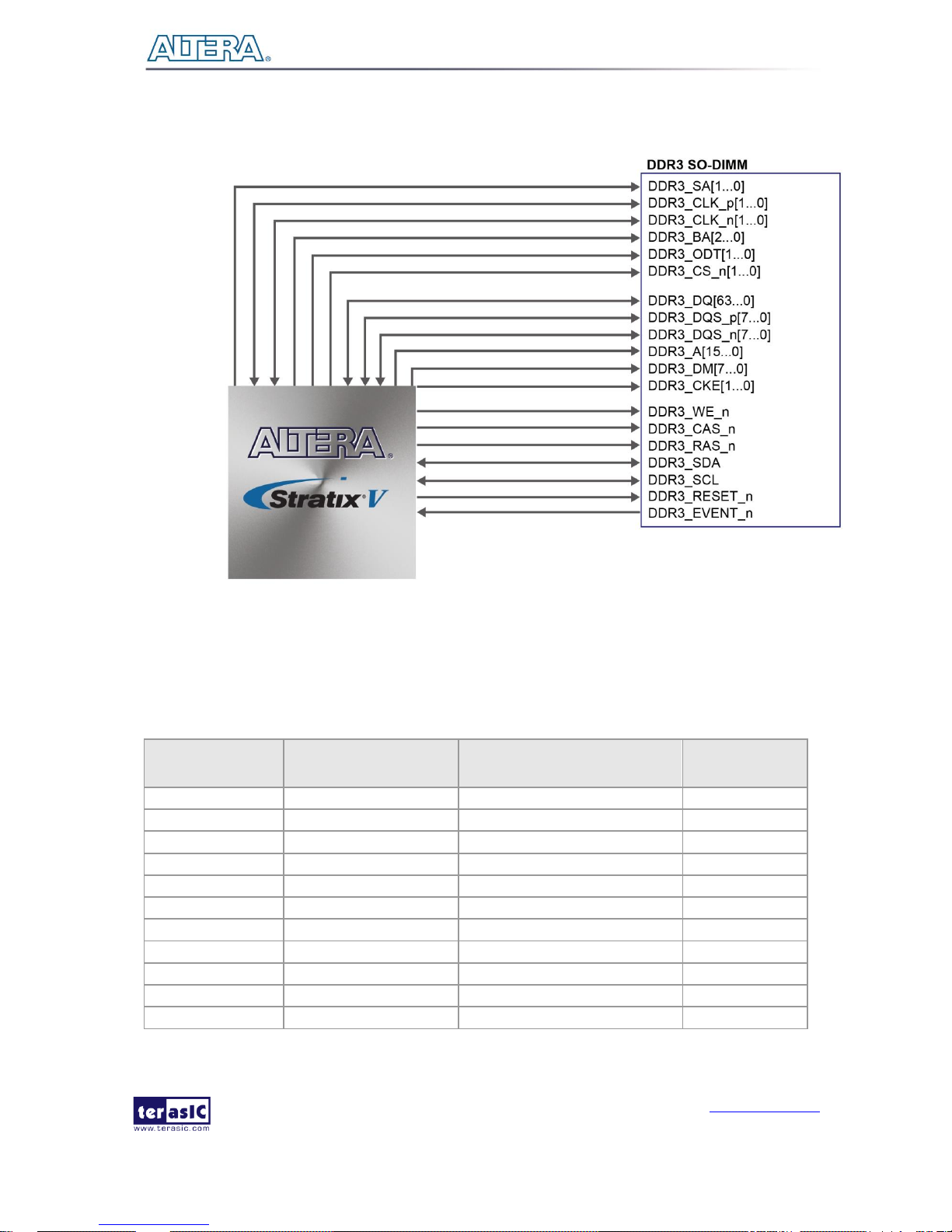

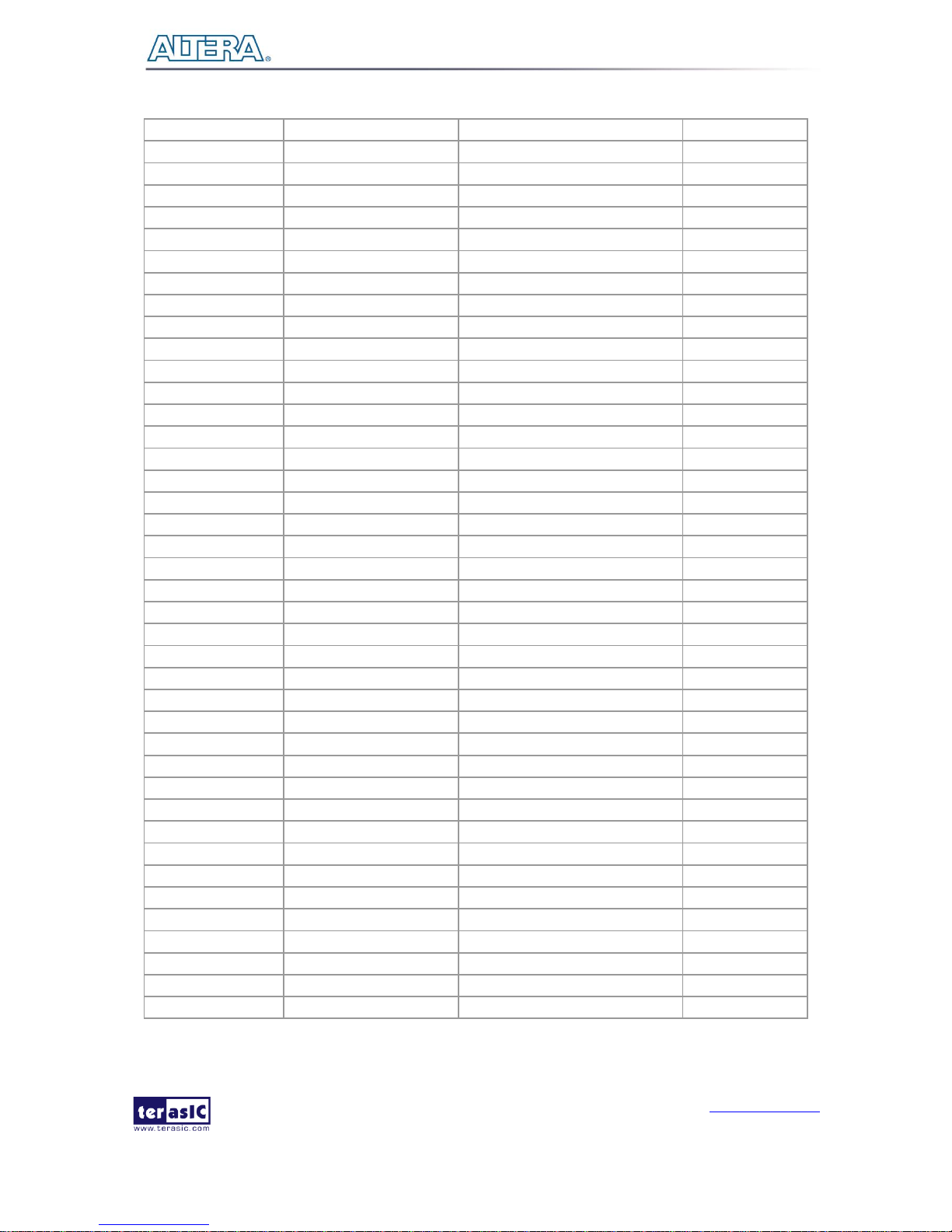

2.7 DDR3 SO-DIMM

The development board supports DDR3 SDRAM SO-DIMM. The DDR3 SODIMM socket is wired

to support a maximum capacity of 8GB with a 64-bit data bus. Using differential DQS signaling for

the DDR3 SDRAM interfaces, it is capable of running at up to 800MHz memory clock for a maximum

theoretical bandwidth up to 95.4Gbps. Figure 2-12 shows the connections between the DDR3

SDRAM SO-DIMMs and Stratix V GX FPGA.

Page 29

TR5 User Manual

www.terasic.com

July 27, 2017

29

Figure 2-12 Connection between the DDR3 and Stratix V GX FPGA

The pin assignments for DDR3 SDRAM SO-DIMM are listed in Table 2-14.

Table 2-14 DDR3 Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

DDR3_DQ0

Data [0]

SSTL-15 Class I

PIN_AH31

DDR3_DQ1

Data [1]

SSTL-15 Class I

PIN_AJ31

DDR3_DQ2

Data [2]

SSTL-15 Class I

PIN_AN30

DDR3_DQ3

Data [3]

SSTL-15 Class I

PIN_AP30

DDR3_DQ4

Data [4]

SSTL-15 Class I

PIN_AH30

DDR3_DQ5

Data [5]

SSTL-15 Class I

PIN_AJ30

DDR3_DQ6

Data [6]

SSTL-15 Class I

PIN_AR30

DDR3_DQ7

Data [7]

SSTL-15 Class I

PIN_AT30

DDR3_DQ8

Data [8]

SSTL-15 Class I

PIN_AM29

DDR3_DQ9

Data [9]

SSTL-15 Class I

PIN_AN28

DDR3_DQ10

Data [10]

SSTL-15 Class I

PIN_AP28

Page 30

TR5 User Manual

www.terasic.com

July 27, 2017

30

DDR3_DQ11

Data [11]

SSTL-15 Class I

PIN_AR29

DDR3_DQ12

Data [12]

SSTL-15 Class I

PIN_AU31

DDR3_DQ13

Data [13]

SSTL-15 Class I

PIN_AV32

DDR3_DQ14

Data [14]

SSTL-15 Class I

PIN_AW32

DDR3_DQ15

Data [15]

SSTL-15 Class I

PIN_AV31

DDR3_DQ16

Data [16]

SSTL-15 Class I

PIN_AF28

DDR3_DQ17

Data [17]

SSTL-15 Class I

PIN_AF29

DDR3_DQ18

Data [18]

SSTL-15 Class I

PIN_AG30

DDR3_DQ19

Data [19]

SSTL-15 Class I

PIN_AG29

DDR3_DQ20

Data [20]

SSTL-15 Class I

PIN_AG28

DDR3_DQ21

Data [21]

SSTL-15 Class I

PIN_AG27

DDR3_DQ22

Data [22]

SSTL-15 Class I

PIN_AG26

DDR3_DQ23

Data [23]

SSTL-15 Class I

PIN_AG25

DDR3_DQ24

Data [24]

SSTL-15 Class I

PIN_BC31

DDR3_DQ25

Data [25]

SSTL-15 Class I

PIN_BC32

DDR3_DQ26

Data [26]

SSTL-15 Class I

PIN_BB30

DDR3_DQ27

Data [27]

SSTL-15 Class I

PIN_BD31

DDR3_DQ28

Data [28]

SSTL-15 Class I

PIN_BD32

DDR3_DQ29

Data [29]

SSTL-15 Class I

PIN_BA30

DDR3_DQ30

Data [30]

SSTL-15 Class I

PIN_AY31

DDR3_DQ31

Data [31]

SSTL-15 Class I

PIN_AW30

DDR3_DQ32

Data [32]

SSTL-15 Class I

PIN_BB29

DDR3_DQ33

Data [33]

SSTL-15 Class I

PIN_BB27

DDR3_DQ34

Data [34]

SSTL-15 Class I

PIN_BA27

DDR3_DQ35

Data [35]

SSTL-15 Class I

PIN_AW27

DDR3_DQ36

Data [36]

SSTL-15 Class I

PIN_AY28

DDR3_DQ37

Data [37]

SSTL-15 Class I

PIN_BA28

DDR3_DQ38

Data [38]

SSTL-15 Class I

PIN_AW29

DDR3_DQ39

Data [39]

SSTL-15 Class I

PIN_AY27

DDR3_DQ40

Data [40]

SSTL-15 Class I

PIN_AT27

DDR3_DQ41

Data [41]

SSTL-15 Class I

PIN_AN25

DDR3_DQ42

Data [42]

SSTL-15 Class I

PIN_AM25

DDR3_DQ43

Data [43]

SSTL-15 Class I

PIN_AL25

DDR3_DQ44

Data [44]

SSTL-15 Class I

PIN_AW26

DDR3_DQ45

Data [45]

SSTL-15 Class I

PIN_AV26

DDR3_DQ46

Data [46]

SSTL-15 Class I

PIN_AU27

DDR3_DQ47

Data [47]

SSTL-15 Class I

PIN_AM26

DDR3_DQ48

Data [48]

SSTL-15 Class I

PIN_AU28

DDR3_DQ49

Data [49]

SSTL-15 Class I

PIN_AU29

DDR3_DQ50

Data [50]

SSTL-15 Class I

PIN_AM28

DDR3_DQ51

Data [51]

SSTL-15 Class I

PIN_AL27

Page 31

TR5 User Manual

www.terasic.com

July 27, 2017

31

DDR3_DQ52

Data [52]

SSTL-15 Class I

PIN_AV28

DDR3_DQ53

Data [53]

SSTL-15 Class I

PIN_AV29

DDR3_DQ54

Data [54]

SSTL-15 Class I

PIN_AL28

DDR3_DQ55

Data [55]

SSTL-15 Class I

PIN_AK27

DDR3_DQ56

Data [56]

SSTL-15 Class I

PIN_AK24

DDR3_DQ57

Data [57]

SSTL-15 Class I

PIN_AJ24

DDR3_DQ58

Data [58]

SSTL-15 Class I

PIN_AH24

DDR3_DQ59

Data [59]

SSTL-15 Class I

PIN_AH25

DDR3_DQ60

Data [60]

SSTL-15 Class I

PIN_AH28

DDR3_DQ61

Data [61]

SSTL-15 Class I

PIN_AJ28

DDR3_DQ62

Data [62]

SSTL-15 Class I

PIN_AL26

DDR3_DQ63

Data [63]

SSTL-15 Class I

PIN_AK26

DDR3_DQS0

Data Strobe p[0]

Differential 1.5-V SSTL Class I

PIN_AL30

DDR3_DQS_n0

Data Strobe n[0]

Differential 1.5-V SSTL Class I

PIN_AL31

DDR3_DQS1

Data Strobe p[1]

Differential 1.5-V SSTL Class I

PIN_AK30

DDR3_DQS_n1

Data Strobe n[1]

Differential 1.5-V SSTL Class I

PIN_AL29

DDR3_DQS2

Data Strobe p[2]

Differential 1.5-V SSTL Class I

PIN_AE27

DDR3_DQS_n2

Data Strobe n[2]

Differential 1.5-V SSTL Class I

PIN_AE28

DDR3_DQS3

Data Strobe p[3]

Differential 1.5-V SSTL Class I

PIN_AY30

DDR3_DQS_n3

Data Strobe n[4]

Differential 1.5-V SSTL Class I

PIN_BA29

DDR3_DQS4

Data Strobe p[4]

Differential 1.5-V SSTL Class I

PIN_BC28

DDR3_DQS_n4

Data Strobe n[4]

Differential 1.5-V SSTL Class I

PIN_BD28

DDR3_DQS5

Data Strobe p[5]

Differential 1.5-V SSTL Class I

PIN_AT26

DDR3_DQS_n5

Data Strobe n[5]

Differential 1.5-V SSTL Class I

PIN_AU26

DDR3_DQS6

Data Strobe p[6]

Differential 1.5-V SSTL Class I

PIN_AR27

DDR3_DQS_n6

Data Strobe n[6]

Differential 1.5-V SSTL Class I

PIN_AR28

DDR3_DQS7

Data Strobe p[7]

Differential 1.5-V SSTL Class I

PIN_AJ25

DDR3_DQS_n7

Data Strobe n[7]

Differential 1.5-V SSTL Class I

PIN_AJ26

DDR3_DM0

Data Mask [0]

SSTL-15 Class I

PIN_AU32

DDR3_DM1

Data Mask [1]

SSTL-15 Class I

PIN_AU30

DDR3_DM2

Data Mask [2]

SSTL-15 Class I

PIN_AK29

DDR3_DM3

Data Mask [3]

SSTL-15 Class I

PIN_BB32

DDR3_DM4

Data Mask [4]

SSTL-15 Class I

PIN_BD29

DDR3_DM5

Data Mask [5]

SSTL-15 Class I

PIN_AR26

DDR3_DM6

Data Mask [6]

SSTL-15 Class I

PIN_AP27

DDR3_DM7

Data Mask [7]

SSTL-15 Class I

PIN_AJ27

DDR3_A0

Address [0]

SSTL-15 Class I

PIN_AM32

DDR3_A1

Address [1]

SSTL-15 Class I

PIN_AF31

DDR3_A2

Address [2]

SSTL-15 Class I

PIN_AJ33

DDR3_A3

Address [3]

SSTL-15 Class I

PIN_AE31

DDR3_A4

Address [4]

SSTL-15 Class I

PIN_AP33

Page 32

TR5 User Manual

www.terasic.com

July 27, 2017

32

DDR3_A5

Address [5]

SSTL-15 Class I

PIN_AG32

DDR3_A6

Address [6]

SSTL-15 Class I

PIN_AN33

DDR3_A7

Address [7]

SSTL-15 Class I

PIN_AK33

DDR3_A8

Address [8]

SSTL-15 Class I

PIN_AF32

DDR3_A9

Address [9]

SSTL-15 Class I

PIN_AH33

DDR3_A10

Address [10]

SSTL-15 Class I

PIN_AE30

DDR3_A11

Address [11]

SSTL-15 Class I

PIN_BA33

DDR3_A12

Address [12]

SSTL-15 Class I

PIN_AG33

DDR3_A13

Address [13]

SSTL-15 Class I

PIN_AD32

DDR3_A14

Address [14]

SSTL-15 Class I

PIN_BA34

DDR3_A15

Address [15]

SSTL-15 Class I

PIN_AY33

DDR3_RAS_n

Row Address Strobe

SSTL-15 Class I

PIN_AJ32

DDR3_CAS_n

Column Address Strobe

SSTL-15 Class I

PIN_AE33

DDR3_BA0

Bank Address [0]

SSTL-15 Class I

PIN_AE29

DDR3_BA1

Bank Address [1]

SSTL-15 Class I

PIN_AK32

DDR3_BA2

Bank Address [2]

SSTL-15 Class I

PIN_AE34

DDR3_CK0

Clock p0

Differential 1.5-V SSTL Class I

PIN_AR31

DDR3_CK_n0

Clock n0

Differential 1.5-V SSTL Class I

PIN_AR32

DDR3_CK1

Clock p1

Differential 1.5-V SSTL Class I

PIN_AV34

DDR3_CK_n1

Clock n1

Differential 1.5-V SSTL Class I

PIN_AW33

DDR3_CKE0

Clock Enable pin 0

SSTL-15 Class I

PIN_AF34

DDR3_CKE1

Clock Enable pin 1

SSTL-15 Class I

PIN_AY34

DDR3_ODT0

On Die Termination[0]

SSTL-15 Class I

PIN_AN31

DDR3_ODT1

On Die Termination[1]

SSTL-15 Class I

PIN_AM31

DDR3_WE_n

Write Enable

SSTL-15 Class I

PIN_AE32

DDR3_CS_n0

Chip Select [0]

SSTL-15 Class I

PIN_AP31

DDR3_CS_n1

Chip Select [1]

SSTL-15 Class I

PIN_AD33

DDR3_RESET_n

Chip Reset

SSTL-15 Class I

PIN_AR33

DDR3_EVENT_n

Chip Temperature Event

SSTL-15 Class I

PIN_AU35

DDR3_SDA

Chip I2C Serial Clock

1.5V

PIN_AJ29

DDR3_SCL

Chip I2C Serial Data Bus

1.5V

PIN_AT29

2.8 FMC Connectors

The FPGA Mezzanine Card (FMC) interface provides a mechanism to extend the peripheral-set of an

FPGA host board by means of add-on daughter cards, which can address today’s high speed signaling

requirements as well as low-speed device interface support. The FMC interfaces support JTAG, clock

Page 33

TR5 User Manual

www.terasic.com

July 27, 2017

33

outputs and inputs, high-speed serial I/O (transceivers), and single-ended or differential signaling.

The detailed specifications of the FMC connectors are described below:

4 FMC Connector

There are four FMC connectors on the TR5 board are: FMCA, FMCB, FMCC, FMCD. Both FMCA

and FMCD are High Pin Count (HPC) size of connectors and FMCB and FMCC are Low Pin Count

(LPC) size of connectors (See Figure 2-12). The HPC connector on TR5 board can provides 172

user-define, single-ended signals (include clock signals) and 10 serial transceiver pairs (See Figure

2-14). The LPC connector can provides 76 user-define, single-ended signals (include clock signals)

and 1 serial transceiver pairs (See Figure 2-15). The HPC and LPC connectors use the same

mechanical connector. The only difference is which signals are actually populated. Thus, cards with

LPC connectors can be plugged into HPC sites. Please note that some standard FMC cards may not

work with TR5 due to unidirectional LVDS due to Stratix V device.

Page 34

TR5 User Manual

www.terasic.com

July 27, 2017

34

Figure 2-13 FMC connectors on TR5 board

Figure 2-14 Pin-Out of the high pin count FMC connector

Page 35

TR5 User Manual

www.terasic.com

July 27, 2017

35

Figure 2-15 Pin-Out of the low pin count FMC connector

Clock Interface

Due to the limitation of the FPGA clock input pin numbers, not all the FMC ports have same clock

interface.

Page 36

TR5 User Manual

www.terasic.com

July 27, 2017

36

Table 2-15 shows the FPGA dedicated clock input pin placement on each FMC port.

Page 37

TR5 User Manual

www.terasic.com

July 27, 2017

37

Table 2-15 FMC clock interface distribution

FMC Clock in/out pin

name

FPGA Clock Input Pin Placement

FMCA

FMCB

FMCC

FMCD

CLK0_M2C_P

I/O

CLK22p

I/O

I/O

CLK0_M2C_N

I/O

CLK22n

I/O

I/O

CLK1_M2C_P

I/O

CLK23p

I/O

CLK15p

CLK1_M2C_N

I/O

CLK23n

I/O

CLK15n

HA01_P_CC

CLK17p

N/A

N/A

CLK14p

HA01_N_CC

CLK17n

N/A

N/A

CLK14n

LA01_P_CC

CLK19p

CLK21p

CLK7p

CLK13p

LA01_N_CC

CLK19n

CLK21n

CLK7n

CLK13n

Please note that, all the dedicated clock pin of the FPGA are connected to external termination

resistors (See Figure 2-16 ). IF users want to us these I/O as single-end standard, pleaser remove

these resistors.

Figure 2-16 Termination resistors on FMC clock I/Os

Page 38

TR5 User Manual

www.terasic.com

July 27, 2017

38

Power Supply

The TR5 board provides 12V, 3.3V and VCCIO_FMC power through FMC ports. Table 2-16

indicates the maximum power consumption for all FMC ports. Please note that this table shows the

total max current limit for all six ports, not just for one.

Also, the 12V DC power supplies from the FMC ports have fuses for protection. Users who don’t

need the power from the FMC can remove these fuses to cut the power on connector.

CAUTION. Before powering on the TR5 board with a daughter card, please check to see if there is

a short circuit between the power pins and FPGA I/O.

Table 2-16 Power Supply of the FMC

Supplied Voltage

Max. Current Limit

12V

3A

3.3V

3A

VCCIO_FMC

FMCA : 12A ; FMCB/FMCC/FMCD : 6A

Adjustable I/O Standards

The FPGA I/O standards of the FMC ports can be adjusted by configuring the header position. Each

port can be individually adjusted to 1.5V, 1.8V, 2.5V or 3.0V via jumpers on the TR5 board. For

detailed setting, please refer to Section 2.2.

JTAG Chain on FMC

Figure 2-17 shows the JTAG chain loop of the TR5 board. The JTAG interface on the FMC connectors

can be activated through four 3-pin headers. For detailed setting, please refer to Section 2.2.

Page 39

TR5 User Manual

www.terasic.com

July 27, 2017

39

Figure 2-17 JTAG Chain for a Standalone TR5

Component Information of the FMC Connector

Table 2-17 shows the manufacture and part numbers of the FMC connector.

Table 2-17 Component information of the FMC connector

Connector Type

Manufacturer

Part Number

Female

(For Mother Board)

High Pin Count(HPC)

SAMTEC

ASP-134486-01

Low Pin Count(LPC)

SAMTEC

ASP-134603-01

Male

High Pin Count(HPC)

SAMTEC

ASP-134488-01

Page 40

TR5 User Manual

www.terasic.com

July 27, 2017

40

(For Daughter Board)

Low Pin Count(LPC)

SAMTEC

ASP-134604-01

2.9 SATA

The two Serial ATA (SATA) ports are available on the FPGA development board which are computer

bus standard with a primary function of transferring data between the motherboard and mass storage

devices (such as hard drives, optical drives, and solid-state disks). Supporting a storage interface is

just one of many different applications for which an FPGA can be used in storage appliances. The

Stratix V GX device can bridge different protocols such as bridging simple bus I/Os like PCI Express

(PCIe) to SATA or network interfaces such as Gigabit Ethernet (GbE) to SATA. The SATA interface

supports SATA 3.0 standard with connection speed of 6 Gbps based on Stratix V GX device with

integrated transceivers compliant to SATA electrical standards.

The two Serial ATA (SATA) ports include one available port for device and one available port for

host capable of implementing SATA solution with a design that consists of both host and target (device

side) functions. Figure 2-18 124H124Hshows the connections between the SATA and Stratix V GX FPGA.

Figure 2-18 Connection between the SATA and Stratix V GX FPGA

125H125HTable 2-18, list the SATA pin assignments and signal names relative to the Stratix V GX device.

Page 41

TR5 User Manual

www.terasic.com

July 27, 2017

41

Table 2-18 SATA Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V

GX Pin

Number

SATA_HOST_REFCLK_p

SATA Host reference clock

1.4-V PCML

PIN_AH6

SATA_HOST_TX_p

SATA Host transmitter data

1.4-V PCML

PIN_AU4

SATA_HOST_RX_p

SATA Host Receiver data

1.4-V PCML

PIN_AY2

SATA_DEVICE_REFCLK_p

SATA Device reference clock

1.4-V PCML

PIN_AK7

SATA_DEVICE_TX_p

SATA Device transmitter data

1.4-V PCML

PIN_AY6

SATA_DEVICE_RX_p

SATA Device Receiver data

1.4-V PCML

PIN_BB2

2.10 GPIO

The TR5 Board provides a 40-pin expansion header. The header connects directly to 36 pins of the

Stratix V GX FPGA, and also provides DC +5V (VCC5), DC +3.3V (VCC3P3), and two GND pins.

Figure 2-19 shows the I/O distribution of the GPIO connector. The maximum power consumption of

the daughter card that connects to GPIO port is shown in Table 2-19.

Figure 2-19 GPIO Pin Arrangement

Table 2-19 Power Supply of the Expansion Header

Page 42

TR5 User Manual

www.terasic.com

July 27, 2017

42

Supplied Voltage

Max. Current Limit

5V

2A

3.3V

3A

Each pin on the expansion headers is connected to a level shift that provides an I/O voltage level shift

from 2.5V to 3.3V for the daughter card. Figure 2-20 shows the level-shift circuitry for only one of

the pin on the header, but this circuitry is included for all 36 data pins.

Figure 2-20 Connections between the GPIO connector and Stratix V GX FPGA

Table 2-20 shows all the pin assignments of the GPIO connector.

Table 2-20 GPIO Pin Assignments, Schematic Signal Names, and Functions

Signal Name

Description

I/O Stand

Stratix V GX Pin Number

GPIO[0]

GPIO Connection

DATA[0]

2.5V

PIN_AU36

GPIO[1]

GPIO Connection

DATA[1]

2.5V

PIN_AE36

GPIO[2]

GPIO Connection

DATA[2]

2.5V

PIN_AF35

GPIO[3]

GPIO Connection

DATA[3]

2.5V

PIN_AE35

GPIO[4]

GPIO Connection

DATA[4]

2.5V

PIN_AN36

GPIO[5]

GPIO Connection

DATA[5]

2.5V

PIN_AP36

Page 43

TR5 User Manual

www.terasic.com

July 27, 2017

43

GPIO[6]

GPIO Connection

DATA[6]

2.5V

PIN_AG34

GPIO[7]

GPIO Connection

DATA[7]

2.5V

PIN_AK35

GPIO[8]

GPIO Connection

DATA[8]

2.5V

PIN_AN34

GPIO[9]

GPIO Connection

DATA[9]

2.5V

PIN_AH34

GPIO[10]

GPIO Connection

DATA[10]

2.5V

PIN_AL35

GPIO[11]

GPIO Connection

DATA[11]

2.5V

PIN_AH22

GPIO[12]

GPIO Connection

DATA[12]

2.5V

PIN_AP34

GPIO[13]

GPIO Connection

DATA[13]

2.5V

PIN_AJ23

GPIO[14]

GPIO Connection

DATA[14]

2.5V

PIN_AJ34

GPIO[15]

GPIO Connection

DATA[15]

2.5V

PIN_AJ22

GPIO[16]

GPIO Connection

DATA[16]

2.5V

PIN_AK23

GPIO[17]

GPIO Connection

DATA[17]

2.5V

PIN_AL23

GPIO[18]

GPIO Connection

DATA[18]

2.5V

PIN_AL24

GPIO[19]

GPIO Connection

DATA[19]

2.5V

PIN_AK21

GPIO[20]

GPIO Connection

DATA[20]

2.5V

PIN_AM23

GPIO[21]

GPIO Connection

DATA[21]

2.5V

PIN_AL21

GPIO[22]

GPIO Connection

DATA[22]

2.5V

PIN_AN23

GPIO[23]

GPIO Connection

DATA[23]

2.5V

PIN_AU23

GPIO[24]

GPIO Connection

DATA[24]

2.5V

PIN_AR24

GPIO[25]

GPIO Connection

DATA[25]

2.5V

PIN_BA25

GPIO[26]

GPIO Connection

DATA[26]

2.5V

PIN_AR23

Page 44

TR5 User Manual

www.terasic.com

July 27, 2017

44

GPIO[27]

GPIO Connection

DATA[27]

2.5V

PIN_BB24

GPIO[28]

GPIO Connection

DATA[28]

2.5V

PIN_BC23

GPIO[29]

GPIO Connection

DATA[29]

2.5V

PIN_AT23

GPIO[30]

GPIO Connection

DATA[30]

2.5V

PIN_AV23

GPIO[31]

GPIO Connection

DATA[31]

2.5V

PIN_BD23

GPIO[32]

GPIO Connection

DATA[32]

2.5V

PIN_BB26

GPIO[33]

GPIO Connection

DATA[33]

2.5V

PIN_AW23

GPIO[34]

GPIO Connection

DATA[34]

2.5V

PIN_AY24

GPIO[35]

GPIO Connection

DATA[35]

2.5V

PIN_BB23

2.11 PCI Express

The TR5 development board features one PCIe Express downstream interfaces (x4 lane) which are

designed to interface with a PC motherboard x4 slot via PCIe cable and PCIe adapter card. Utilizing

built-in transceivers on a Stratix V GX device, it is able to provide a fully integrated PCI Expresscompliant solution for multi-lane (x4) applications. With the PCI Express hard IP block incorporated

in the Stratix V GX device, it will allow users to implement simple and fast protocols, as well as

saving logic resources for logic applications.

The PCI Express interface supports complete PCI Express Gen1 at 2.5Gbps/lane, Gen2 at

5.0Gbps/lane, and Gen3 at 8.0Gbps/lane protocol stack solution compliant to PCI Express base

specification 3.0 that includes PHY-MAC, Data Link, and transaction layer circuitry embedded in

PCI Express hard IP blocks.

To use PCIe interface, two external associated devices will be needed to establish a link with PC.

First, a PCIe half-height add-in host card with a PCIe x4 cable connector called PCA (PCIe Cabling

Adapter Card and See Figure 2-21) will be used to plug into the PCIe slot on a mother board. Then,

Page 45

TR5 User Manual

www.terasic.com

July 27, 2017

45

a PCIe x4 cable (See Figure 2-22) will be used to connect TR5 board and PCIe add-in card as shown

in Figure 2-23, the longest length is up to 3 meters. These two associated devices are not included in

TR5 kit. To purchase the PCA card as well as the external cable, please refer to Terasic website

pca.terasic.com and PCIe_Cable.terasic.com.

Figure 2-21 PCIe Cabling Adaptor(PCA) card

Page 46

TR5 User Manual

www.terasic.com

July 27, 2017

46

Figure 2-22 PCIe External Cable

Figure 2-23 PCIe Link Setup between TR5 and PC

Figure 2-24 PCI Express Pin Connection

128H128HTable 2-22 summarizes the PCI Express pin assignments of the signal names relative to the Stratix

Page 47

TR5 User Manual

www.terasic.com

July 27, 2017

47

V GX FPGA.

Table 2-22 PCI Express Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

PCIE_REFCLK_p

PCIe reference clock

HCSL

PIN_AK38

PCIE_PREST_n

PCIe present ,active low

1.5-V

PIN_AU33

PCIE_WAKE_n

PCIe wake

1.5-V

PIN_BD35

PCIE_TX_p[0]

PCIe Transmitter data p0

1.4-V PCML

PIN_AY39

PCIE_RX_p[0]

PCIe Receiver data p0

1.4-V PCML

PIN_BB43

PCIE_TX_p[1]

PCIe Transmitter data p1

1.4-V PCML

PIN_AV39

PCIE_RX_p[1]

PCIe Receiver data p1

1.4-V PCML

PIN_BA41

PCIE_TX_p[2]

PCIe Transmitter data p2

1.4-V PCML

PIN_AT39

PCIE_RX_p[2]

PCIe Receiver data p2

1.4-V PCML

PIN_AW41

PCIE_TX_p[3]

PCIe Transmitter data p3

1.4-V PCML

PIN_AU41

PCIE_RX_p[3]

PCIe Receiver data p3

1.4-V PCML

PIN_AY43

Page 48

TR5 User Manual

www.terasic.com

July 27, 2017

48

Chapter 3

System Builder

This chapter describes how users can create a custom design project on the FPGA board by using the

Software Tools – System Builder.

3.1 Introduction

The System Builder is a Windows based software utility, designed to assist users to create a Quartus

II project for the FPGA board within minutes. The generated Quartus II project files include:

Quartus II Project File (.qpf)

Quartus II Setting File (.qsf)

Top-Level Design File (.v)

External PLL Controller (.v)

Synopsis Design Constraints file (.sdc)

Pin Assignment Document (.htm)

The System Builder not only can generate the files above, but can also provide error-checking rules

to handle situation that are prone to errors. The common mistakes that users encounter are the

following:

Board damaged for wrong pin/bank voltage assignment.

Board malfunction caused by wrong device connections or missing pin counts for connected

ends.

Performance that has dropped because of improper pin assignments.

Page 49

TR5 User Manual

www.terasic.com

July 27, 2017

49

3.2 General Design Flow

This section will introduce the general design flow to build a project for the FPGA board via the

System Builder. The general design flow is illustrated in the HFigure 3-1.

Users should launch System Builder and create a new project according to their design requirements.

When users complete the settings, the System Builder will generate two major files which include

top-level design file (.v) and the Quartus II setting file (.qsf).

The top-level design file contains top-level Verilog wrapper for users to add their own design/logic.

The Quartus II setting file contains information such as FPGA device type, top-level pin assignment,

and I/O standard for each user-defined I/O pin.

Finally, the Quartus II programmer must be used to download SOF file to the FPGA board using

JTAG interface.

Page 50

TR5 User Manual

www.terasic.com

July 27, 2017

50

Figure 3-1 The general design flow of building a design

3.3 Using System Builder

This section provides the detail procedures on how the System Builder is used.

Install and launch the System Builder

The System Builder is located in the directory: "Tools\SystemBuilder" in the System CD. Users can

copy the whole folder to a host computer without installing the utility. Before using the System

Builder, execute the SystemBuilder.exe on the host computer as appears in HFigure 3-2.

Page 51

TR5 User Manual

www.terasic.com

July 27, 2017

51

Figure 3-2 The System Builder window

Select Board Type and Input Project Name

Select the target board type (TR5_A7 or TR5_AB ) and input project name as show in HFigure 3-3.

Project Name:

Specify the project name as it is automatically assigned to the name of the top-level design entity.

Page 52

TR5 User Manual

www.terasic.com

July 27, 2017

52

Figure 3-3 The Quartus Project Name

System Configuration

Under System Configuration users are given the flexibility of enabling their choice of components

on the FPGA as shown in HFigure 3-4. Each component of the FPGA board is listed where users can

enable or disable a component according to their design by simply marking a check or removing the

check in the field provided. If the component is enabled, the System Builder will automatically

generate the associated pin assignments including the pin name, pin location, pin direction, and I/O

standards.

Page 53

TR5 User Manual

www.terasic.com

July 27, 2017

53

Note: The pin assignments for some components (e.g. DDR3 and SATA) require associated controller

codes in the Quartus project otherwise Quartus will result in compilation errors. Therefore, do not

select them if they are not necessary in your design. To use the DDR3 controller, please refer to the

DDR3 SDRAM demonstration in Chapter 6.

Figure 3-4 System Configuration Group

Programmable PLL

There are two external plls on-board that provide reference clocks for the following signals:

FMCA_ONBOARD_REFCLK

FMCD_ONBOARD_REFCLK

PCIE_ONBOARD_REFCLK

Page 54

TR5 User Manual

www.terasic.com

July 27, 2017

54

DDR3_REFCLK

SATA_DEVICE_REFCLK

SATA_HOST_REFCLK

FMCB_ONBOARD_REFCLK

FMCC_ONBOARD_REFCLK

To use these clocks, users can select the desired frequency on the Programmable Oscillator group, as

shown in Figure 3-5. FMC, DDR3, PCIe or SATA must be checked before users can start to specify

the desired frequency in the programmable oscillators.

As the Quartus project is created, the System Builder automatically generates the associated controller

according to users’ desired frequency in Verilog which facilitates users’ implementation as no

additional control code is required to configure the programmable oscillator.

Note: If users need to dynamically change the frequency, they would need to modify the generated

control code themselves.

Page 55

TR5 User Manual

www.terasic.com

July 27, 2017

55

Figure 3-5 External Programmable PLLs

Project Setting Management

The System Builder also provides functions to restore default setting, loading a setting, and saving

users’ board configuration(s) file, as shown in HFigure 3-6. Users can save the current board

configuration information into a .cfg file and load it to the System Builder.

Page 56

TR5 User Manual

www.terasic.com

July 27, 2017

56

Figure 3-6 Project Settings

Project Generation

When users press the Generate button, the System Builder will generate the corresponding Quartus

II files and documents as listed in the HTable 3-1 in the directory specified by the user.

Table 3-1 The files generated by System Builder

No.

Filename

Description

1

<Project name>.v

Top level Verilog file for Quartus II

2

CDCM6208_controller (*)

CDCM6208 External PLL controller IP

Page 57

TR5 User Manual

www.terasic.com

July 27, 2017

57

3

LMK04096B_controller(*)

LMK04096B External PLL controller IP

4

<Project name>.qpf

Quartus II Project File

5

<Project name>.qsf

Quartus II Setting File

6

<Project name>.sdc

Synopsis Design Constraints file for Quartus II

7

<Project name>.htm

Pin Assignment Document

(*) The CDCM6208_controller is a folder which contains the verilog files for CDCM6208

configuration.

(*) The LMK04096B_controller is a folder which contains the verilog files for LMK04096B

configuration.

Users can use Quartus II software to add custom logic into the project and compile the project to

generate the SRAM Object File (.sof).

For CDCM6208, the Controller will be instantiated in the Quartus II top-level file as listed below:

Page 58

TR5 User Manual

www.terasic.com

July 27, 2017

58

For LMK04096B, the Controller will be instantiated in the Quartus II top-level file as listed below:

Page 59

TR5 User Manual

www.terasic.com

July 27, 2017

59

If dynamic configuration for the oscillator is required, users need to modify the code according to

users’ desired behavior.

Page 60

TR5 User Manual

www.terasic.com

July 27, 2017

60

Chapter 4

Flash Programming

As you develop your own project using the Altera tools, you can program the flash memory device

so that your own design loads from flash memory into the FPGA on power up. This chapter will

describe how to use Altera Quartus II Programmer Tool to program the common flash interface (CFI)

flash memory device on the FPGA board. The Stratix V X GX FPGA development board ships with

the CFI flash device preprogrammed with a default factory FPGA configuration for running the

Parallel Flash Loader design example.

4.1 CFI Flash Memory Map

140H140HTable 4-1 shows the default memory contents of a 1Gb (128MB) CFI flash device. The flash device

has a 16-bit data bus. For the factory default code to run correctly and update designs in the user

memory, this memory map must not be altered.

Table 4-1 Flash Memory Map (Byte Address)

Block Description

Size(KB)

Address Range

PFL option bits

64

0x00030000 – 0x0003FFFF

Factory hardware

41984

0x00040000 – 0x0293FFFF

User hardware

41984

0x02940000 – 0x0523FFFF

Factory software

23424

0x05240000 – 0x0691FFFF

User software and data

23424

0x06920000 – 0x07FFFFFF

For user application, user hardware can be stored with start address 0x02940000, and the user’s

software is suggested to be stored with start address 0x06920000. The QuartusII Programmer is

used for programming the flash. Before programming, users need to bundle their .sof files and NIOS

II .elf files together and then convert them into the .pof file which is used by the Convert

Page 61

TR5 User Manual

www.terasic.com

July 27, 2017

61

Programming File tool. Before Bundle, user should translate the .elf to .hex at first with NIOS II

EDS tool and nios2-elf-objcopy tool. For convenience, the System CD contains a batch file for file

translation and flash programming with users given .sof and .elf files.

4.2 FPGA Configure Operation

Here is the procedure to enable FPGA configuration from Flash:

1. Please make sure the FPGA configuration data has been stored in the CFI flash.

2. Set the FPGA configuration mode to FPPx16 mode by setting SW5 MSEL[0:4] as 00000 as

shown in Figure 4-1.

3. Specify the configuration of the FPGA using the default Factory Configuration or User

Configuration by setting SW4 according to Figure 4-2.

4. Power on the FPGA board or press MAX_RST button if board is already powered on

5. When configuration is completed, the green Configure Done LED D21 will light. If there is

error, the red Configure Error LED D23 will light.

Figure 4-1 MSEL[0:4] set to “00000”

Page 62

TR5 User Manual

www.terasic.com

July 27, 2017

62

Figure 4-2 Configuration Image Selection

4.3 Flash Programming with Users Design

Users can program the flash memory device so that a custom design loads from flash memory into

the FPGA on power up. For convenience, the translation and programming batch files are available

on the Demonstrations/flash_programming/flash_programming_batch folder in the System CD.

There folder contains five files as shown in 142H142HTable 4-2

Table 4-2 Content of flash_programming_batch folder

Files Name

Description

TR5_PFL.sof

Parallel Flash Loader Configuration File

flash_program.bat

Top batch file to generate and download the .pof file

build_hex.sh

Translate .elf into .hex file

output_file.cof

input file for convert

program_flash.cdf

Input file for download

factory.sof

Factory Hardware design file for Hello Demo

factory.elf

Factory Software design file for Hello Demo

user.sof

User Hardware design file

Page 63

TR5 User Manual

www.terasic.com

July 27, 2017

63

User.elf

User Software design file

To apply the batch file to users’ .sof and .elf file, users can change the .sof filename in the

output_file.cof file and .elf filename in the build_hex.sh as shown in 143H143HFigure 4-3.

Figure 4-3 Change to users’ .sof and .elf filename

If your design does not contain a NIOS II processor, users can change the content “Child_OpMask(6

1 0 1 1 0 0)” to “Child_OpMask(6 1 0 1 0 0 0)” of program_flash.cdf file as shown in Figure 4-4.

Figure 4-4 Disable .elf translation and programming

If your design includes a NIOS II processor and the NIOS II program is stored on external memory,

users must to perform following items so the NIOS II program can be boot from flash successfully:

1. QSYS should include a Flash controller for the CFI Flash on the development board. Please

ensure that the base address of the controller is 0x00, as shown in Figure 4-5.

Page 64

TR5 User Manual

www.terasic.com

July 27, 2017

64

2. In NIOS II processor options, select FLASH as reset vector memory and specify 0x06920000

as reset vector, as shown in Figure 4-6.

Figure 4-5 Flash Controller Settings in QSYS

Figure 4-6 Reset Vector Settings for NIOS II Processor

For implementation detail, users can refer the Hello example located in the CD folder:

Demonstrations/ Hello

Page 65

TR5 User Manual

www.terasic.com

July 27, 2017

65

4.4 Restore Factory Settings

This section describes how to restore the original factory contents to the flash memory device on the

FPGA development board. Perform the following instructions:

1. Make sure the Nios II EDS and USB-Blaster II driver are installed.

2. Make sure the FPGA board and PC are connected with a UBS Cable.

3. Power on the FPGA board.

4. Copy the “Demonstrations/flash_programming/factory_programming_batch” folder under

the CD to your PC’s local drive.

5. Execute the batch file flash_program.bat to start flash programming.

6. Power off the FPGA Board.

7. Set FPGA configure mode as FPPx16 Mode by setting SW5 MSEL[0:4] to 00000.

8. Specify configuration of the FPGA to Factory Hardware by setting the FACTORY_LOAD

dip in SW4 to the ‘0’ position.

9. Power on the FPGA Board, and the Configure Done LED should light.

Except for programming the Flash with the default code PFL, the batch file also writes PFL (Parallel

Flash Loader) Option Bits data into the address 0x30000. The option bits data specifies 0x2940000

as start address of your hardware design.