PCA3 User Manual

www.terasic.com

February 8, 2018

1

CONTENTS

Chapter 1 Introduction ..................................................................................................................... 2

1.1 Package Contents ........................................................................................................................................ 2

1.2 Features....................................................................................................................................................... 3

1.3 Getting Help ............................................................................................................................................... 4

Chapter 2 Architecture ..................................................................................................................... 5

2.1 Layout and Components ............................................................................................................................. 5

2.2 Block Diagram of the PCA3 card ............................................................................................................... 6

Chapter 3 Card Components ........................................................................................................... 8

3.1 PCIe Edge Connector ................................................................................................................................. 8

3.2 PCIe Cable Connector .............................................................................................................................. 10

3.3 LEDs ......................................................................................................................................................... 14

3.4 Lane Re-driver IC ..................................................................................................................................... 14

Chapter 4 Setup Example .............................................................................................................. 16

4.1 Introduction .............................................................................................................................................. 16

4.2 PC PCI Express Software SDK ................................................................................................................ 16

4.3 Reference Design - Fundamental ............................................................................................................. 28

4.4 PCIe Reference Design – DDR3 .............................................................................................................. 34

Chapter 5 Appendix ..................................................................................................................... 41

5.1 Revision History ....................................................................................................................................... 41

5.2 Copyright Statement ................................................................................................................................. 41

PCA3 User Manual

www.terasic.com

February 8, 2018

2

Chapter 1

Introduction

PCA3 (PCIe Cable Adapter, Gen 3) is a conversion card to connect boards with your host PC. It can

support up to PCIe Gen 3 x4. Users with boards such as Terasic TR4 and TR5 can establish

high-speed data transmission through this card and the PCIe cable via PCIe connector to any host

PC. It provides automatic rate-detect and adaptation to PCIe Gen-1, Gen-2, and Gen-3 speeds.

11..1

1

PPaacckkaaggee CCoonntteennttss

Figure 1-1 The PCA3 package contents

The PCA3 package includes:

PCA3 card

System CD Download Guide

PCA3 User Manual

www.terasic.com

February 8, 2018

3

11..2

2

FFeeaattuurreess

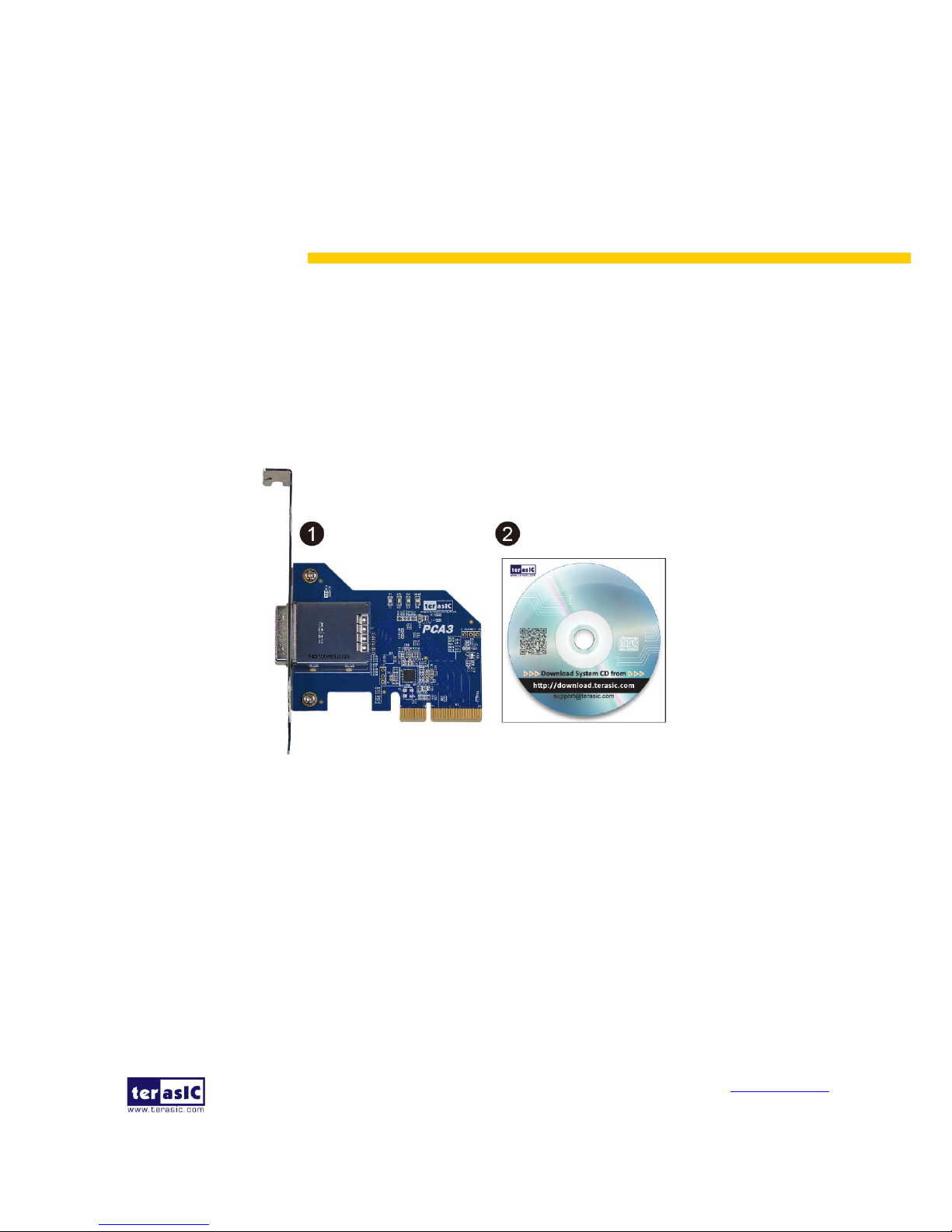

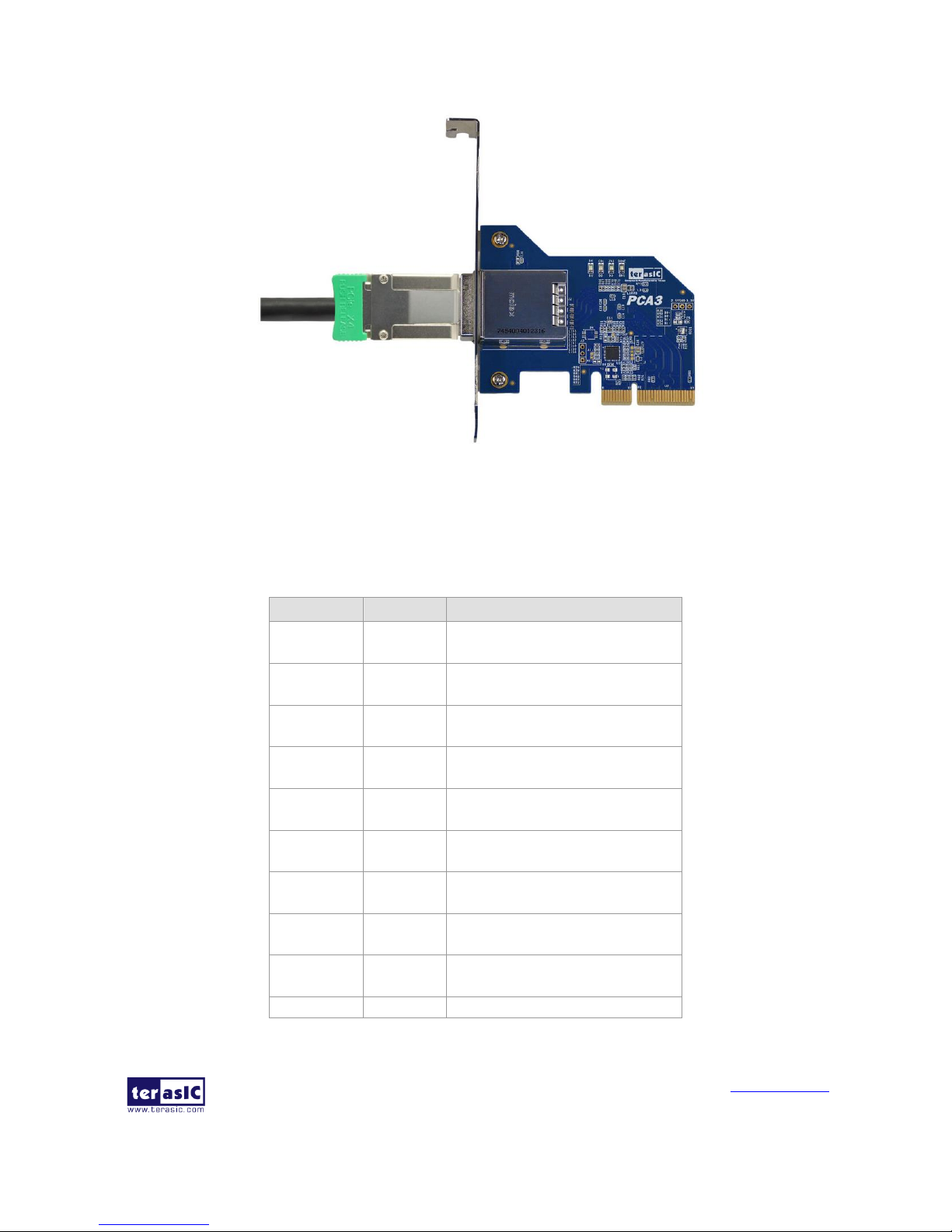

Figure 1- shows a photograph of the PCA3.

Figure 1-2 Exterior View

The key features of the card are listed below:

• Up to 8.0Gbps PCIe 3.0 Serial Re-Driver

• PCIe x4 Gen 3

• Adjustable receiver equalization

• Adjustable transmitter amplitude and de-emphasis

PCA3 User Manual

www.terasic.com

February 8, 2018

4

11..3

3

GGeettttiinngg HHeellpp

Here is information of how to get help if you encounter any problem:

Terasic Technologies

• Tel: +886-3-550-8800

• Email: support@terasic.com

PCA3 User Manual

www.terasic.com

February 8, 2018

5

Chapter 2

Architecture

This chapter provides information about architecture and block diagram of the PCA3 card.

22..1

1

LLaayyoouutt aanndd CCoommppoonneennttss

The picture of the Terasic PCIe x4 Cable Adapter (PCA3) is shown in Figure 2-1 and Figure 2-2. It

depicts the layout of the card and indicates the locations of the connectors and key components.

Figure 2-1 The PCA3 Card PCB and Component Diagram (top view)

PCA3 User Manual

www.terasic.com

February 8, 2018

6

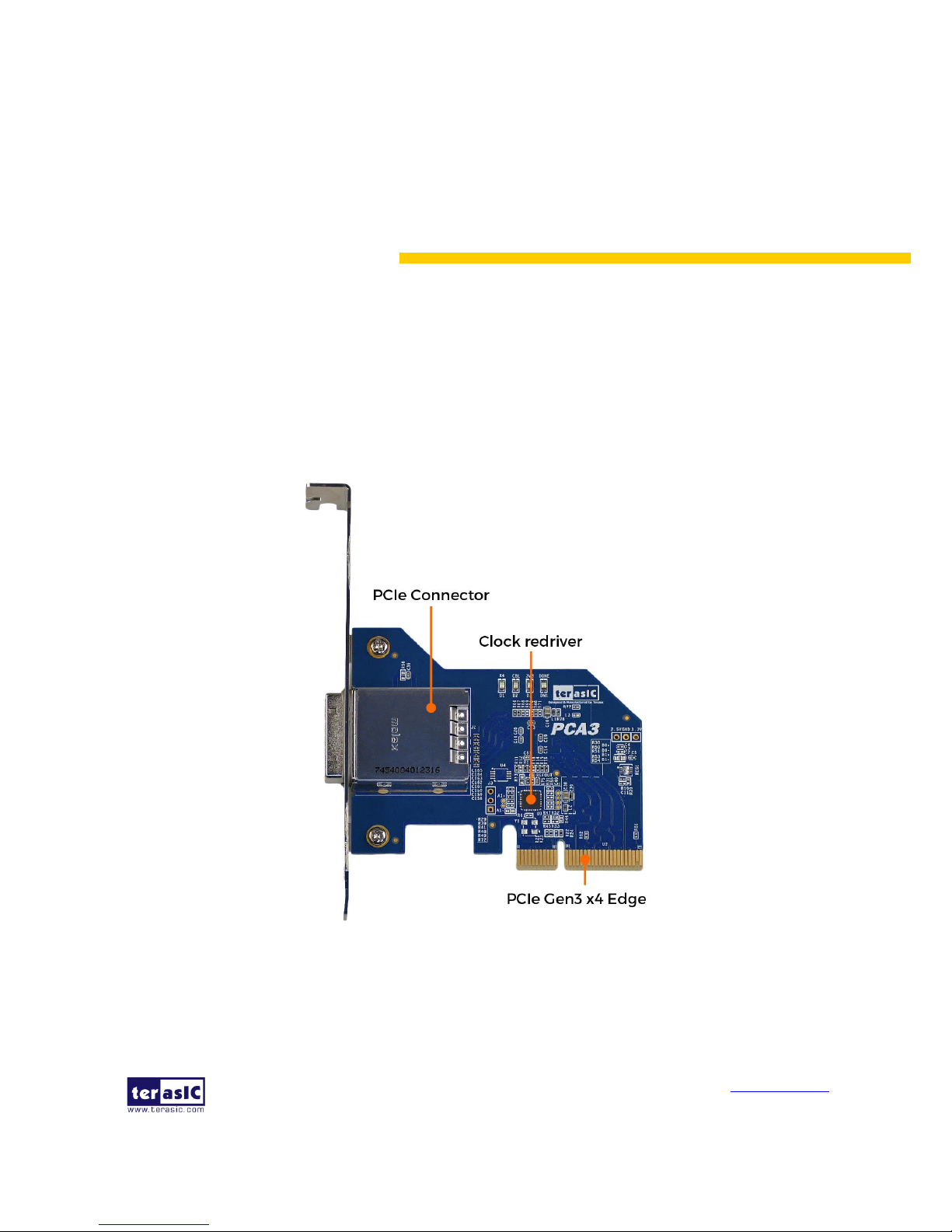

Figure 2-2 The PCA3 Card PCB and Component Diagram (bottom view)

22..2

2

BBlloocckk DDiiaaggrraamm ooff tthhee PPCCAA33 ccaarrdd

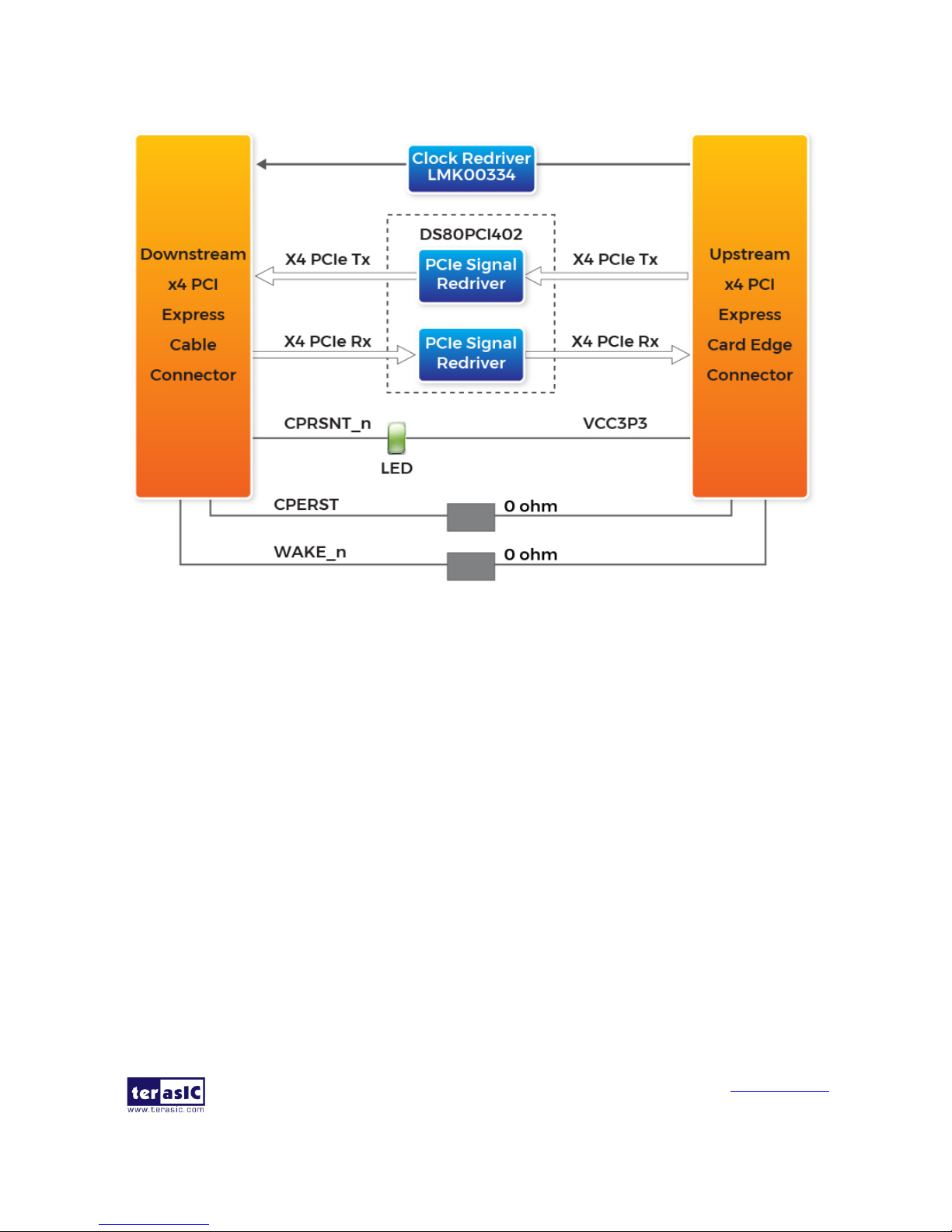

Figure 2-3 shows the block diagram of the PCA3 card.

PCA3 User Manual

www.terasic.com

February 8, 2018

7

Figure 2-3 Block Diagram of PCA3

PCA3 User Manual

www.terasic.com

February 8, 2018

8

Chapter 3

Card Components

This chapter describes the specifications of the onboard components.

33..1

1

PPCCIIee EEddggee CCoonnnneeccttoorr

This PCIe edge connector is used to connect the PCA3 with PC motherboard PCIe slot, as show

Figure 3-1 and Figure 3-2.

Figure 3-1 PCA3 Edge Connector

PCA3 User Manual

www.terasic.com

February 8, 2018

9

Figure 3-2 Plug the PCA3 into the PCIe slot of the Motherboard

The pins are defined as shown in Table 3-1 with side A on the top of the center-line on the solder

side of the card and side B on the bottom of the centerline on the component side of the card.

The PCIe interface pins PETpx, PETnx, PERpx, and PERnx are named with the following

convention: “PE” stands for PCIe high speed, “T” for Transmitter, “R” for Receiver, “p” for

positive (+), and “n” for negative (-).

Note that adjacent differential pairs are separated by two ground pins to manage the connector

crosstalk.

Table 3-1 gives the wiring information of the PCIe Edge connector.

Table 3-1 Pin assignments and descriptions on PCIe Edge connector

Pin Numbers

Side B

Side A

Name

Description

Name

Description

1

NC

NC

PRSNT1n

Hot-Plug presence

detect

2

NC

NC

NC

NC 3 NC

NC

NC

NC 4 GND

Ground

GND

Ground

5

SMCLK

System Clock

NC

NC

PCA3 User Manual

www.terasic.com

February 8, 2018

10

6

SMDAT

System Data Line

NC

NC 7 GND

Ground

NC

NC 8 VCC3P3

3.3V Power

NC

NC 9 NC

NC

VCC3P3

3.3V Power

10

3.3VAUX

3.3 V Auxiliary

Power

VCC3P3

3.3V Power

11

WAKE

NC

PERSTn

Fundamental

Reset

Mechanical Key

12

RSVD

Reserved

GND

Ground

13

GND

Ground

REFCLK+

Reference clock

(differential

pair)

14

PETp0

Transmitter

differential pair,

Lane 0

REFCLK15

PETn0

GND

Ground

16

GND

Ground

PERp0

Receiver

differential pair,

Lane 0

17

PRSNT2n

Hot-Plug presence

detect

PERn0

18

GND

Ground

GND

Ground

19

PETp1

Transmitter

differential pair,

Lane 1

RSVD

Reserved

20

PETn1

GND

Ground

21

GND

Ground

PERp1

Receiver

differential pair,

Lane 1

22

GND

Ground

PERn1

23

PETp2

Transmitter

differential pair,

Lane 2

GND

Ground

24

PETn2

GND

Ground

25

GND

Ground

PERp2

Receiver

differential pair,

Lane 2

26

GND

Ground

PERn2

27

PETp3

Transmitter

differential pair,

Lane 3

GND

Ground

28

PETn3

GND

Ground

29

GND

Ground

PERp3

Receiver

differential pair,

Lane 3

30

RSVD

Reserved

PERn3

31

PRSNT2n

Hot-Plug presence

detect

GND

Ground

32

GND

Ground

RSVD

Reserved

33..2

2

PPCCIIee CCaabbllee CCoonnnneeccttoorr

A PCIe cable connector is used to connect the PCIe x4 Cable and PCA cable connector, connect the

PCA3 User Manual

www.terasic.com

February 8, 2018

11

adapter by using a PCIe x4 Cable, as show Figure 3-3.

Figure 3-3 PCIe x4 Cable and PCA3

To purchase the PCIe x4 Cable, please refer to the url: PCIe_Cable.terasic.com.

Figure 3-4 shows the PCIe Cable connects PCA3 connector

PCA3 User Manual

www.terasic.com

February 8, 2018

12

Figure 3-4 PCIe Cable and PCA3 connector Connected

Table 3-2 gives the wiring information of the PCIe Cable connector.

Table 3-2 wiring information of the PCIe Cable connector

Pin Numbers

Name

Description

A1

GND

Ground reference for PCI

Express transmitter Lanes

A2

PETp0

Differential PCI Express

transmitter Lane 0

A3

PETn0

Differential PCI Express

transmitter Lane 0

A4

GND

Ground reference for PCI

Express transmitter Lanes

A5

PETp1

Differential PCI Express

transmitter Lane 1

A6

PETn1

Differential PCI Express

transmitter Lane 1

A7

GND

Ground reference for PCI

Express transmitter Lanes

A8

PETp2

Differential PCI Express

transmitter Lane 2

A9

PETn2

Differential PCI Express

transmitter Lane 2

A10

GND

Ground reference for PCI

PCA3 User Manual

www.terasic.com

February 8, 2018

13

Express transmitter Lanes

A11

PETp3

Differential PCI Express

transmitter Lane 3

A12

PETn3

Differential PCI Express

transmitter Lane 3

A13

GND

Ground reference for PCI

Express transmitter Lanes

A14

CREFCLK+

Differential 100MHz cable

reference clock

A15

CREFCLK-

Differential 100MHz cable

reference clock

A16

GND

Ground reference for PCI

Express transmitter Lanes

A17

SB_RTN

Signal return for single ended

sideband signals

A18

CPRSNTn

Used for detection of whether

a cable is installed and the

downstream subsystem is

powered

A19

CPWRON

Turns power on / off to slave type

downstream subsystems

B1

GND

Ground reference for PCI

Express transmitter Lanes

B2

PERp0

Differential PCI Express

receiver Lane 0

B3

PERn0

Differential PCI Express

receiver Lane 0

B4

GND

Ground reference for PCI

Express transmitter Lanes

B5

PERp1

Differential PCI Express

receiver Lane 1

B6

PERn1

Differential PCI Express

receiver Lane 1

B7

GND

Ground reference for PCI

Express transmitter Lanes

B8

PERp2

Differential PCI Express

receiver Lane 2

B9

PERn2

Differential PCI Express

receiver Lane 2

B10

GND

Ground reference for PCI

Express transmitter Lanes

B11

PERp3

Differential PCI Express

receiver Lane 3

B12

PERn3

Differential PCI Express

PCA3 User Manual

www.terasic.com

February 8, 2018

14

receiver Lane 3

B13

GND

Ground reference for PCI

Express transmitter Lanes

B14

PWR

+3.3VCable power

B15

PWR

+3.3VCable power

B16

PWR RTN

Cable power return

B17

PWR RTN

Cable power return

B18

CWAKEn

Power management signal for

wakeup events (optional)

B19

CPERSTn

Cable PERSTn

33..3

3

LLEEDDss

The PCA3 includes status LEDs, please refer to Table 3-3 for the status of the LED indicator.

Table 3-3 Status of the LED indicator

33..4

4

LLaannee RRee--ddrriivveerr IICC

A Lane Re-driver IC U1(DS80PCI402) is implemented on PCA3 card. In addition to supporting the

4-lane repeater function, DS80PCI402 chip also supports some modifiable parameters, such as

input equalization, internal Signal Detect Threshold and loopback function. These functions can be

set up by some of the resistances on PCA3 card, Figure 3-5 shows the resistances setting. Table 3-4

lists pin configuration and function.

Board

Reference

LED name

Description

D1

CBL

Cable PRSNT1n

D2

EDGE

Edge PRSNT1n

D3

POWER

Power LED

PCA3 User Manual

www.terasic.com

February 8, 2018

15

Figure 3-5 Resistances setting

Table 3-4 Pin configuration and function

Pin Numbers

Name

Description

19

EQA1

EQA1 control the level of equalization on the input pins. The pins are

active only when ENSMB is deasserted (low).

20

EQA0

EQA0 control the level of equalization on the input pins. The pins are

active only when ENSMB is deasserted (low).

21

RATE

RATE control pin selects GEN 1,2 and GEN 3 operating modes.

Tie 1kΩ to GND = GEN 1,2

FLOAT = AUTO Rate Select of Gen1/2 and Gen3 with de-emphasis

Tie 20kΩ to GND = GEN 3 without de-emphasis

Tied 1kΩ to VDD = RESERVED

22

RXDET

The RXDET pin controls the receiver detect function. Depending on the

input level, a 50Ω or > 50kΩ termination to the power rail is enabled.

23

LPBK

Controls the loopback function

Tie 1kΩ to GND = Root Complex Loopback (INA_n to OUTB_n)

Float = Normal Operation

Tie 1kΩ to VDD = End-point Loopback (INB_n to OUTA_n)

26

SD_TH/RD_EN

Controls the internal Signal Detect Threshold

PCA3 User Manual

www.terasic.com

February 8, 2018

16

Chapter 4

Setup Example

This chapter demonstrates how to use PCA3 daughtercard with FPGA host board. In the system CD,

we provide demonstration projects for Terasic TR4 and TR5 FPGA board. We will introduce how to

use PCA3 daughtercard and Terasic TR5 FPGA development board to communicate with the PC via

PCIe interface. For PCA3 with TR4 board, please refer to the CD

folder …/Demonstrations/TR4/doc/ for detailed document description.

44..1

1

IInnttrroodduuccttiioonn

The application reference design shows how to implement fundamental control and data transfer by

using PCIe port on the TR5. In the design, basic I/O is used to read or write the buttons and LEDs

on the TR5. High-speed data transfer is performed by DMA. Both Memory-Mapped and FIFO

memory types are demonstrated in the reference design. The demonstration also makes use of the

associated PCIe cable adapter card (PCA3). System Requirements

The following items are required for the PCA demonstration

• TR5 board x1

• PCA3 card x1

• PCIe x4 Cable x1

• PC x1

44..2

2

PPCC PPCCII EExxpprreessss SSooffttwwaarree SSDDKK

The CD contains a PC Windows based SDK to allow users to develop their 64-bits software

application on Windows XP/7/10 64-bits. The SDK is located in the “CDROM

\Demonstrations\TR5\PCIe_SW_KIT” folder which includes:

PCI Express Driver

PCI Express Library

PCA3 User Manual

www.terasic.com

February 8, 2018

17

PCI Express Examples

The kernel mode driver assumes the PCIe vender ID (VID) is 0x1172 and the device ID (DID) is

0xE003. If different VID and DID are used in the design, users need to modify the PCIe vender ID

(VID) and device ID (DID) in the driver INF file accordingly.

The PCI Express Library is implemented as a single DLL called TERASIC_PCIE_AVMM.DLL.

This file is a 64-bits DLL. With the DLL exported to the software API, users can easily

communicate with the FPGA. The library provides the following functions:

Basic Data Read and Write

Data Read and Write by DMA

For high performance data transmission, DMA is required as the read and write operations are

specified under the hardware design on the FPGA.

PCI Express Software Stack

Figure 7-8 shows the software stack for the PCI Express application software on 64-bit Windows.

The PCI Express driver incorporated in the DLL library is called TERASIC_PCIE_AVMM.dll.

Users can develop their applications based on this DLL. The altera_pcie_win_driver.sys kernel

driver is provided by Altera.

PCA3 User Manual

www.terasic.com

February 8, 2018

18

Figure 4-1 PCI Express Software Stack

Install PCI Express Driver on Windows

The PCIe driver is located in the folder:

“CDROM\Demonstrations\TR5\PCIe_SW_KIT\PCIe_Driver “

The folder includes the following four files:

Altera_pcie_win_driver.cat

Altera_pcie_win_driver.inf

Altera_pcie_win_driver.sys

WdfCoinstaller01011.dll

To install the PCI Express driver, execute the steps below:

1. Make sure the TR5 and the PC are both powered off.

2. Plug the PCIe adapter card(PCA3) into the PCIe slot on the PC motherboard. Use the PCIe

cable to connect to the TR5 PCIE connector and the PCA3 (See Figure 4-2 )

PCA3 User Manual

www.terasic.com

February 8, 2018

19

Figure 4-2 FPGA board connect to PC

3. Power on your TR5 board and the host PC

4. Make sure Altera Programmer and USB-Blaster II driver are installed

5. Execute test.bat in “CDROM\Demonstrations\TR5\PCIe_Fundamental\demo_batch” to

configure the FPGA

6. Restart windows Operation System

7. Click the Control Panel menu from the Windows Start menu. Click the Hardware and the

Sound item before clicking the Device Manager to launch the Device Manager dialog. There

will be a PCI Device ite m in the dialog, as shown in Figure 4-3. Move the mouse cursor to

the PCI Device item and right click it to select the Update Driver Software... item.

PCA3 User Manual

www.terasic.com

February 8, 2018

20

Figure 4-3 Screenshot of launching Update Driver Software dialog

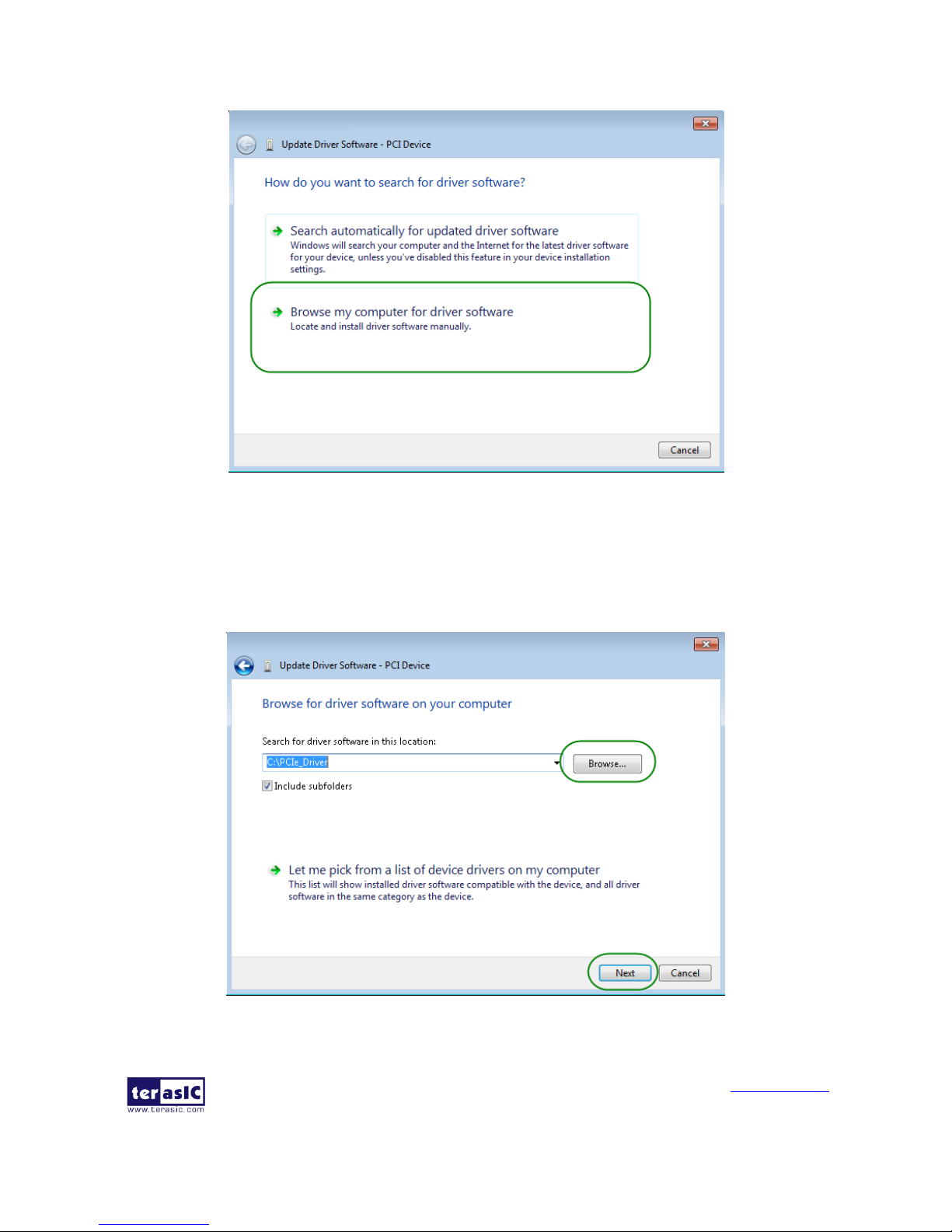

8. In the How do you want to search for driver software dialog, click Browse my computer

for driver software item, as shown in Figure 4-4. Click “OK” and then “Exit” to close the

installation program.

PCA3 User Manual

www.terasic.com

February 8, 2018

21

Figure 4-4 Dialog of Browse my computer for driver software

9. In the Browse for driver software on your computer dialog, click the Browse button to

specify the folder where altera_pcie_din_driver.inf is located, as shown in Figure 4-5 Click

the Next button.

Figure 4-5 Browse for driver software on your computer

PCA3 User Manual

www.terasic.com

February 8, 2018

22

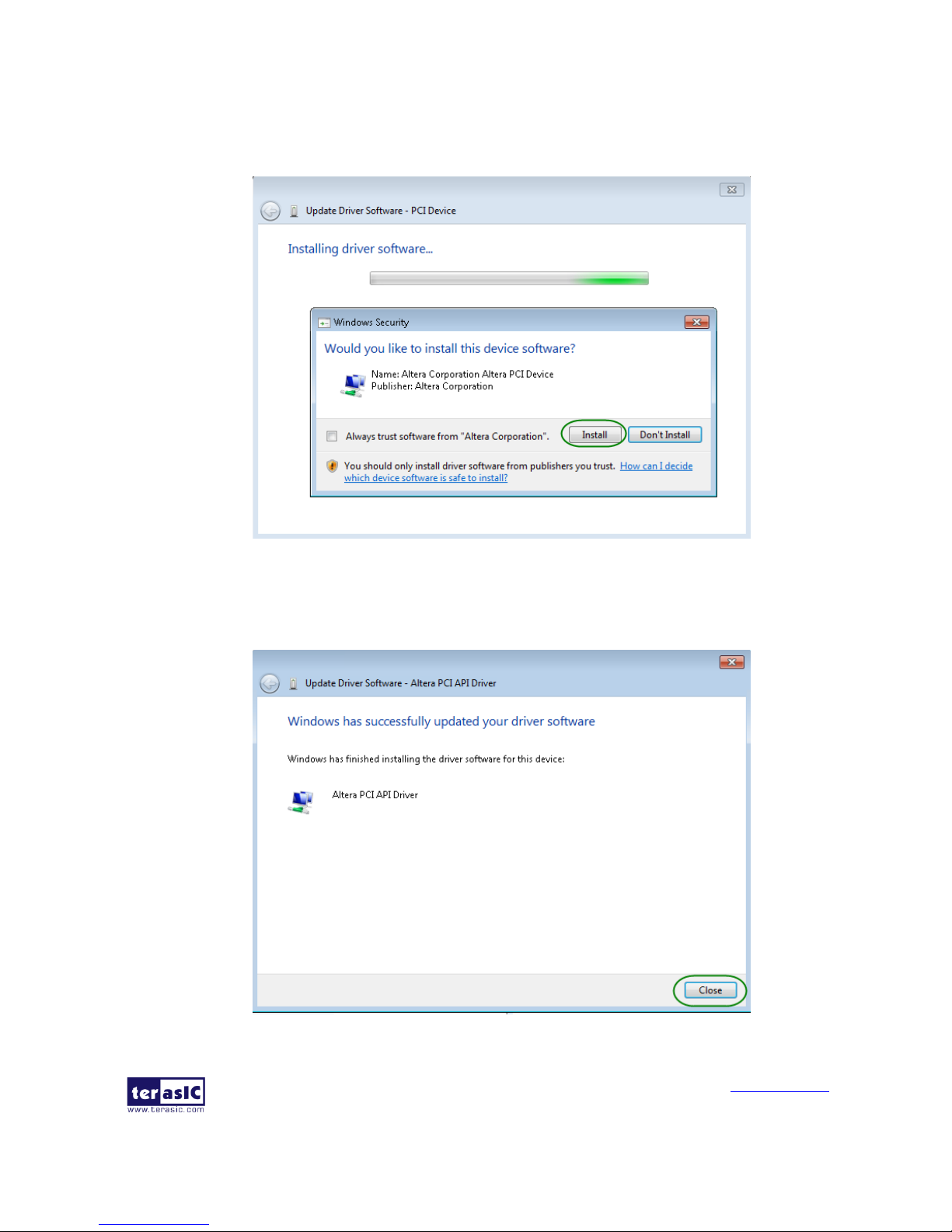

10. When the Windows Security dialog appears, as shown Figure 4-6 , click the Install button.

Figure 4-6 Click Install in the dialog of Windows Security

11. When the driver is installed successfully, the successfully dialog will appear, as shown in

Figure 4-7. Click the Close button.

PCA3 User Manual

www.terasic.com

February 8, 2018

23

Figure 4-7 Click Close when the installation of Altera PCI API Driver is complete

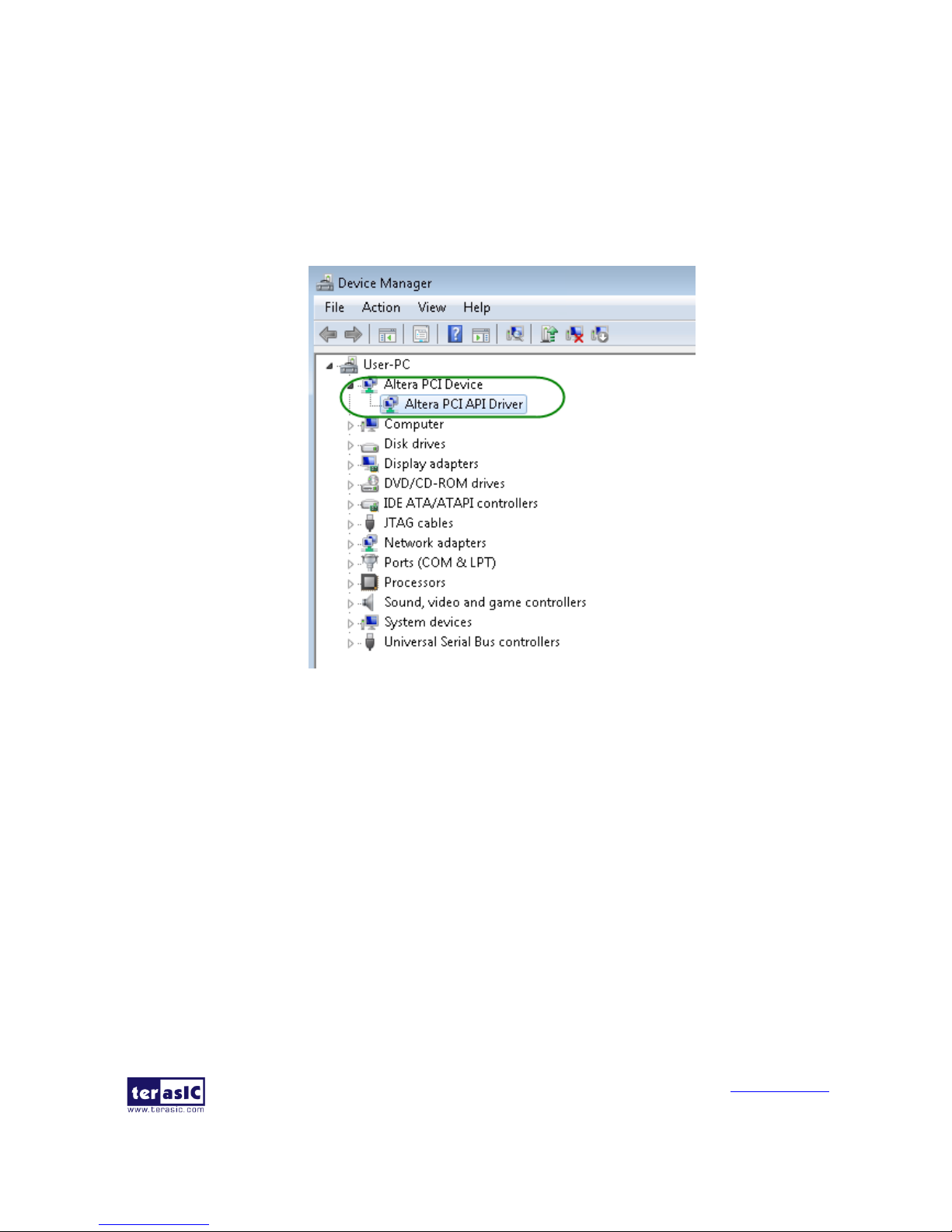

12. Once the driver is successfully installed, users can see the Altera PCI API Driver under the

device manager window, as shown in Figure 4-8.

Figure 4-8 Altera PCI API Driver in Device Manager

Create a Software Application

All necessary files to create a PCIe software application are located in the

CDROM\Demonstration\TR5\PCIe_SW_KIT\PCIe_Library, the files are as follows:

TERASIC_PCIE_AVMM.h

TERASIC_PCIE_AVMM.DLL (64-bit DLL)

Below lists the procedures to use the SDK files in users’ C/C++ project :

Create a 64-bit C/C++ project.

Include TERASIC_PCIE_AVMM.h in the C/C++ project.

PCA3 User Manual

www.terasic.com

February 8, 2018

24

Copy TERASIC_PCIE_AVMM.DLL to the folder where the project.exe is located.

Dynamically load TERASIC_PCIE_AVMM.DLL in C/C++ program. To load the DLL, please

refer to the PCIe fundamental example below.

Call the SDK API to implement the desired application.

TERASIC_PCIE.DLL/TERASIC_PCIEx64.DLL Software API

Users can easily communicate with the FPGA through the PCIe bus through the

TERASIC_PCIE_AVMM.DLL API. The details of API are described below:

PCIE_Open

Function:

Open a specified PCIe card with vendor ID, device ID, and matched card index.

Prototype:

PCIE_HANDLE PCIE_Open(

WORD wVendorID,

WORD wDeviceID,

WORD wCardIndex);

Parameters:

wVendorID:

Specify the desired vendor ID. A zero value means to ignore the vendor ID.

wDeviceID:

Specify the desired device ID. A zero value means to ignore the device ID.

wCardIndex:

Specify the matched card index, a zero based index, based on the matched vendor ID and

device ID.

Return Value:

Return a handle to presents specified PCIe card. A positive value is return if the PCIe card is

opened successfully. A value zero means failed to connect the target PCIe card.

This handle value is used as a parameter for other functions, e.g. PCIE_Read32.

Users need to call PCIE_Close to release handle once the handle is no more used.

PCIE_Close

Function:

Close a handle associated to the PCIe card.

Prototype:

void PCIE_Close(

PCIE_HANDLE hPCIE);

Parameters:

hPCIE:

PCA3 User Manual

www.terasic.com

February 8, 2018

25

A PCIe handle return by PCIE_Open function.

Return Value:

None.

PCIE_Read32

Function:

Read a 32-bit data from the FPGA board.

Prototype:

bool PCIE_Read32(

PCIE_HANDLE hPCIE,

PCIE_BAR PcieBar,

PCIE_ADDRESS PcieAddress,

DWORD * pdwData);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

PcieBar:

Specify the target BAR.

PcieAddress:

Specify the target address in FPGA.

pdwData:

A buffer to retrieve the 32-bit data.

Return Value:

Return TRUE if read data is successful; otherwise FALSE is returned.

PCIE_Write32

Function:

Write a 32-bit data to the FPGA Board.

Prototype:

bool PCIE_Write32(

PCIE_HANDLE hPCIE,

PCIE_BAR PcieBar,

PCIE_ADDRESS PcieAddress,

DWORD dwData);

Parameters:

PCA3 User Manual

www.terasic.com

February 8, 2018

26

hPCIE:

A PCIe handle return by PCIE_Open function.

PcieBar:

Specify the target BAR.

PcieAddress:

Specify the target address in FPGA.

dwData:

Specify a 32-bit data which will be written to FPGA board.

Return Value:

Return TRUE if write data is successful; otherwise FALSE is returned.

PCIE_DmaRead

Function:

Read data from the memory-mapped memory of FPGA board in DMA.

Prototype:

bool PCIE_DmaRead(

PCIE_HANDLE hPCIE,

PCIE_LOCAL_ADDRESS LocalAddress,

void *pBuffer,

DWORD dwBufSize

);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

LocalAddress:

Specify the target memory-mapped address in FPGA.

pBuffer:

A pointer to a memory buffer to retrieved the data from FPGA. The size of buffer should be

equal or larger the dwBufSize.

dwBufSize:

Specify the byte number of data retrieved from FPGA.

Return Value:

Return TRUE if read data is successful; otherwise FALSE is returned.

PCIE_DmaWrite

Function:

Write data to the memory-mapped memory of FPGA board in DMA.

PCA3 User Manual

www.terasic.com

February 8, 2018

27

Prototype:

bool PCIE_DmaWrite(

PCIE_HANDLE hPCIE,

PCIE_LOCAL_ADDRESS LocalAddress,

void *pData,

DWORD dwDataSize

);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

LocalAddress:

Specify the target memory mapped address in FPGA.

pData:

A pointer to a memory buffer to store the data which will be written to FPGA.

dwDataSize:

Specify the byte number of data which will be written to FPGA.

Return Value:

Return TRUE if write data is successful; otherwise FALSE is returned.

PCIE_ConfigRead32

Function:

Read PCIe Configuration Table. Read a 32-bit data by given a byte offset.

Prototype:

bool PCIE_ConfigRead32 (

PCIE_HANDLE hPCIE,

DWORD Offset,

DWORD *pdwData

);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

Offset:

Specify the target byte of offset in PCIe configuration table.

pdwData:

A 4-bytes buffer to retrieve the 32-bit data.

Return Value:

Return TRUE if read data is successful; otherwise FALSE is returned.

PCA3 User Manual

www.terasic.com

February 8, 2018

28

44..3

3

RReeffeerreennccee DDeessiiggnn -- FFuunnddaammeennttaall

The application reference design shows how to implement fundamental control and data transfer in

DMA. In the design, basic I/O is used to control the BUTTON and LED on the FPGA board.

High-speed data transfer is performed by DMA.

Demonstration Files Location

The demo file is located in the batch folder:

CDROM\demonstrations\TR5\PCIe_funcdamental\Demo_batch

The folder includes following files:

FPGA Configuration File: PCIe_funcdamental.sof

Download Batch file: test.bat

Windows Application Software folder : windows_app, includes

PCIE_FUNDAMENTAL.exe

TERASIC_PCIE_AVMM.dll

Demonstration Setup

1. Use the PCIe cable to connect to the TR5 PCIE connector and PCIe adapter card as

shown in Figure 4-9.

Figure 4-9 FPGA board connect to PC

PCA3 User Manual

www.terasic.com

February 8, 2018

29

2. Configure FPGA with PCIE_Fundamental.sof by executing the test.bat.

3. Install PCIe driver if necessary. The driver is located in the folder:

CDROM\Demonstration\TR5\PCIe_SW_KIT\PCIe_Driver.

4. Restart Windows

5. Make sure the Windows has detected the FPGA Board by checking the Windows

Control panel as shown in Figure 4-10.

Figure 4-10 Screenshot for PCIe Driver

6. Go to windows_app folder, execute PCIE_FUNDMENTAL.exe. A menu will appear

as shown in Figure 4-11.

Figure 4-11 Screenshot of Program Menu

7. Type 0 followed by a ENTER key to select Led Control item, then input 15 (hex 0x0f)

will make all led on as shown in Figure 4-12. If input 0(hex 0x00), all led will be

PCA3 User Manual

www.terasic.com

February 8, 2018

30

turned off.

Figure 4-12 Screenshot of LED Control

8. Type 1 followed by an ENTER key to select Button Status Read item. The button

status will be reported as shown in Figure 4-13.

Figure 4-13 Screenshot of Button Status Report

9. Type-2 followed by an ENTER key to select DMA Testing item. The DMA test result

will be reported as shown in Figure 4-14.

PCA3 User Manual

www.terasic.com

February 8, 2018

31

Figure 4-14 Screenshot of DMA Memory Test Result

10. Type 99 followed by an ENTER key to exit this test program

Development Tools

Quartus II 16.0

Visual C++ 2012

Demonstration Source Code Location

Quartus Project: Demonstrations\TR5\PCIE_Fundamental

Visual C++ Project: Demonstrations\TR5\PCIe_SW_KIT\PCIE_FUNDAMENTAL

PCA3 User Manual

www.terasic.com

February 8, 2018

32

FPGA Application Design

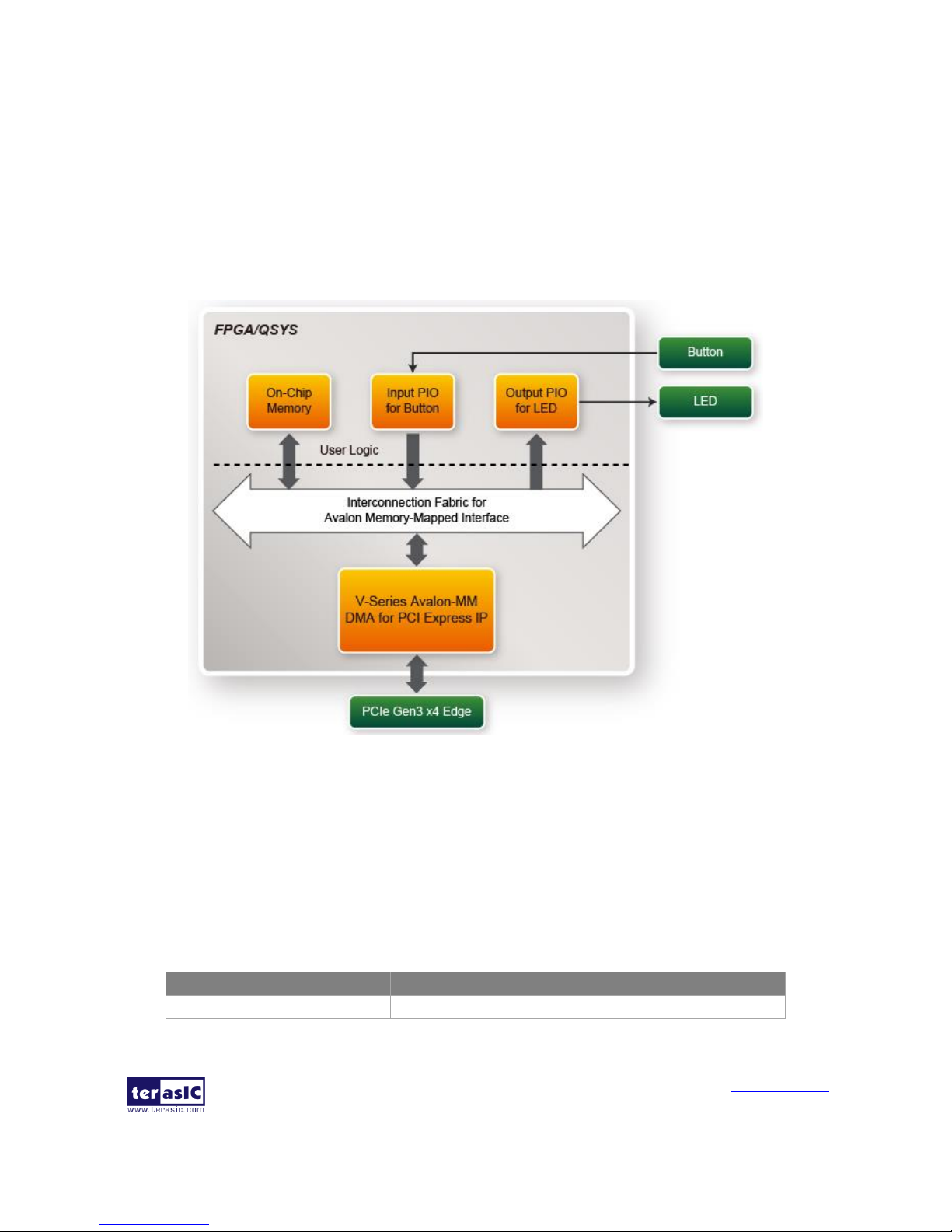

Figure 4-15 shows the system block diagram in the FPGA system. In the Qsys, Altera PIO

controller is used to control the LED and monitor the Button Status, and the On-Chip memory is

used for performing DMA testing. The PIO controllers and the On-Chip memory are connected to

the PCI Express Hard IP controller through the Memory-Mapped Interface.

Figure 4-15 Hardware block diagram of the PCIe reference design

Windows Based Application Software Design

The application software project is built by Visual C++ 2012. The project includes the following

major files:

Name

Description

PCIE_FUNDAMENTAL.cpp

Main program

PCA3 User Manual

www.terasic.com

February 8, 2018

33

PCIE.c

Implement dynamically load for

TERAISC_PCIE_AVMM.DLL

PCIE.h

TERASIC_PCIE_AVMM.h

SDK library file, defines constant and data structure

The main program PCIE_FUNDAMENTAL.cpp includes the header file "PCIE.h" and defines the

controller address according to the FPGA design.

The base address of BUTTON and LED controllers are 0x4000010 and 0x4000020 based on

PCIE_BAR4, respectively. The on-chip memory base address is 0x00000000 relative to the DMA

controller.

Before accessing the FPGA through PCI Express, the application first calls PCIE_Load to

dynamically load the TERASIC_PCIE_AVMM.DLL. Then, it calls the PCIE_Open to open the PCI

Express driver. The constant DEFAULT_PCIE_VID and DEFAULT_PCIE_DID used in

PCIE_Open are defined in TERASIC_PCIE_AVMM.h. If developer changes the Vender ID,the

Device ID, and the PCI Express IP, they also need to change the ID value defined in

TERASIC_PCIE_AVMM.h. If the return value of the PCIE_Open is zero, it means the driver

cannot be accessed successfully. In this case, please make sure:

The FPGA is configured with the associated bit-stream file and the host is rebooted.

The PCI express driver is loaded successfully.

The LED control is implemented by calling PCIE_Write32 API, as shown below:

The button status query is implemented by calling the PCIE_Read32 API, as shown below:

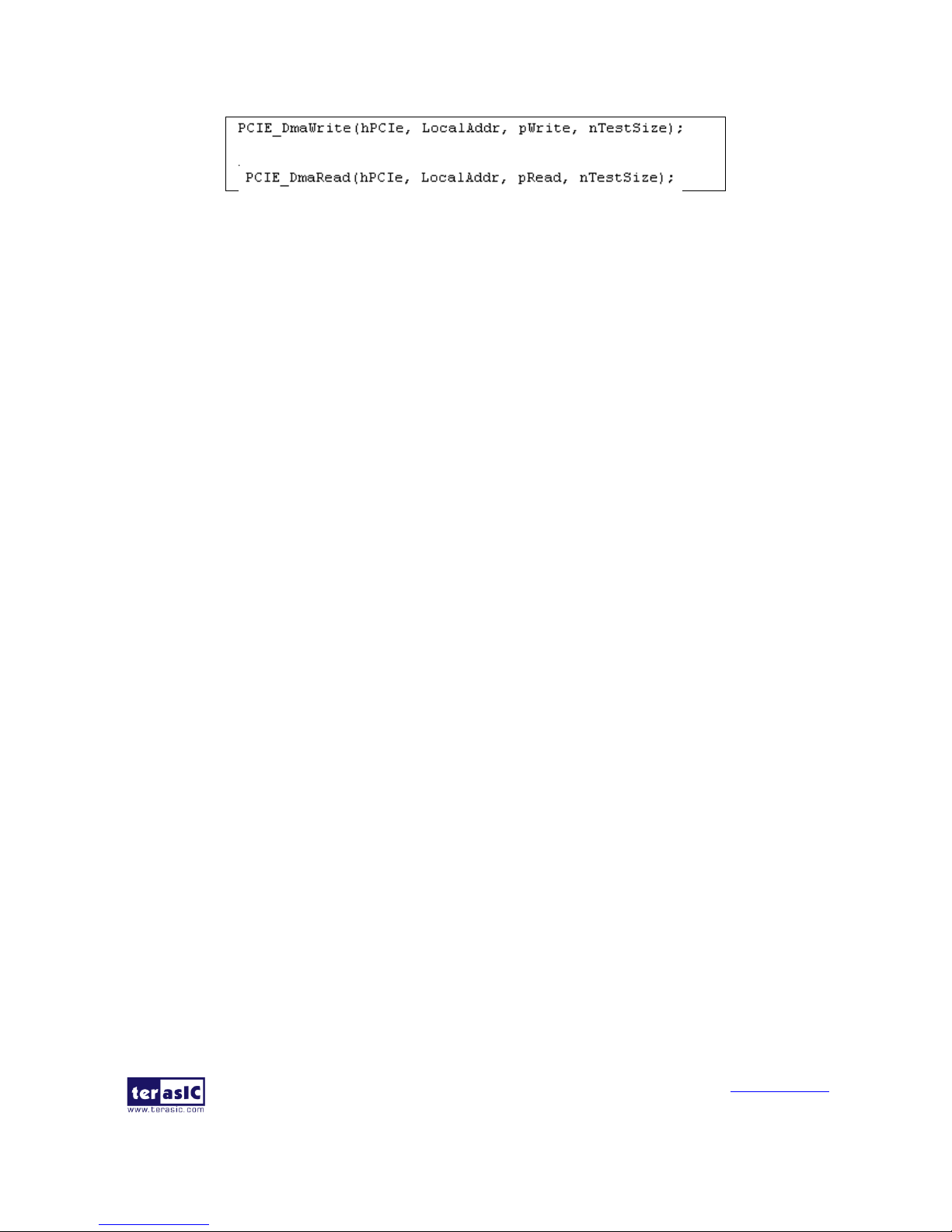

The memory-mapped memory read and write test is implemented by PCIE_DmaWrite and

PCIE_DmaRead API, as shown below:

PCA3 User Manual

www.terasic.com

February 8, 2018

34

44..4

4

PPCCIIee RReeffeerreennccee DDeessiiggnn –– DDDDRR33

The application reference design shows how to add DDR3 Memory Controllers into the PCIe

Quartus project based on the PCI_Fundamental Quartus project and perform 2GB data DMA for

both SODIMM. Also, this demo shows how to call “PCIE_ConfigRead32” API to check PCIe link

status.

Demonstration Files Location

The demo file is located in the batch folder:

CDROM\Demonstrations\TR5\PCIe_DDR3\Demo_batch

The folder includes following files:

FPGA Configuration File: PCIe_DDR3.sof

Download Batch file: test.bat

Windows Application Software folder: windows_app, includes

PCIE_DDR3.exe

TERASIC_PCIE_AVMM.dll

Demonstration Setup

1. Install both DDR3 1600 2GB SODIMM on the FPGA board.

2. Use the PCIe cable to connect to the TR5 PCIE connector and PCIe adapter card.

3. Configure FPGA with PCIE_DDR3.sof by executing the test.bat.

4. Install PCIe driver if necessary.

5. Restart Windows

6. Make sure the Windows has detected the FPGA Board by checking the Windows

Control panel.

PCA3 User Manual

www.terasic.com

February 8, 2018

35

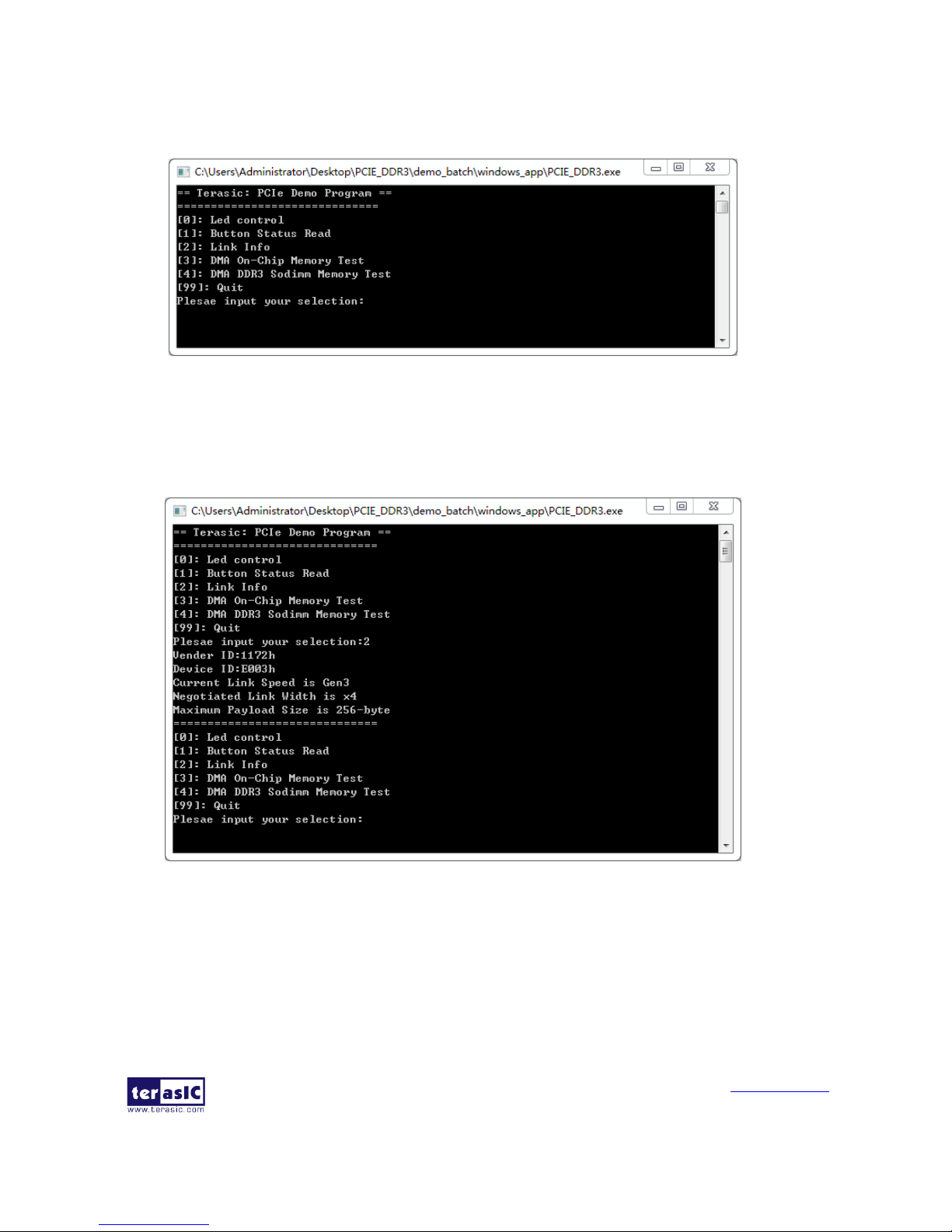

7. Goto windows_app folder, execute PCIE_DDR3.exe. A menu will appear as shown in

Figure 4-16.

Figure 4-16 Screenshot of Program Menu

8. Type 2 followed by the ENTER key to select Link Info item. The PICe link

information will be shown as in Figure 4-17. Gen3 link speed and x4 link width are

expected.

Figure 4-17 Screenshot of Link Info

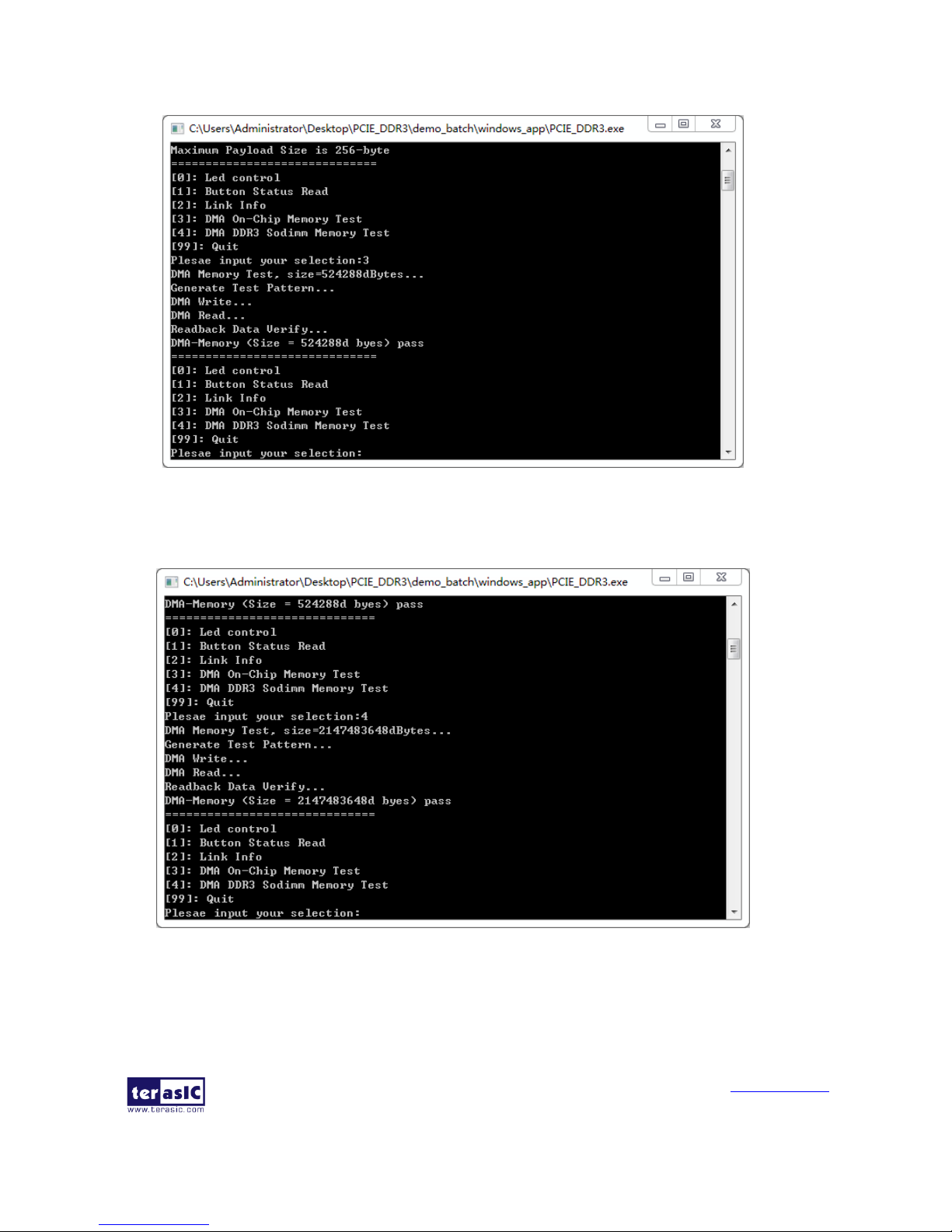

9. Type 3 followed by the ENTER key to select DMA On-Chip Memory Test item. The

DMA write and read test result will be reported as shown in Figure 4-18.

PCA3 User Manual

www.terasic.com

February 8, 2018

36

Figure 4-18 Screenshot of On-Chip Memory DMA Test Result

10. Type-4 followed by the ENTER key to select DMA DDR3 SODIMM Memory Test

item. The DMA write and read test result will be report as shown in Figure 4-19.

Figure 4-19 Screenshot of DDR3 SOSIMM Memory DAM Test Result

11. Type 99 followed by the ENTER key to exit this test program.

PCA3 User Manual

www.terasic.com

February 8, 2018

37

Development Tools

Quartus II 16.0

Visual C++ 2012

Demonstration Source Code Location

Quartus Project: Demonstrations\TR5\PCIE_DDR3

Visual C++ Project: Demonstrations\TR5\PCIe_SW_KIT\PCIe_DDR3

FPGA Application Design

Figure 4-20 shows the system block diagram in the FPGA system. In the Qsys, Altera PIO

controller is used to control the LED and monitor the Button Status, and the On-Chip memory and

DDR3 SODIMM Memory are used for performing DMA testing. The PIO controllers,the On-Chip

memory and DDR3 SODIMM Memory are connected to the PCI Express Hard IP controller

through the Memory-Mapped Interface.

PCA3 User Manual

www.terasic.com

February 8, 2018

38

Figure 4-20 Hardware block diagram of the PCIe DDR3 reference design

Windows Based Application Software Design

The application software project is built by Visual C++ 2012. The project includes the following

major files:

Name

Description

PCIE_DDR3.cpp

Main program

PCIE.c

Implement dynamically load for

TERAISC_PCIE_AVMM.DLL

PCIE.h

TERASIC_PCIE_AVMM.h

SDK library file, defines constant and data structure

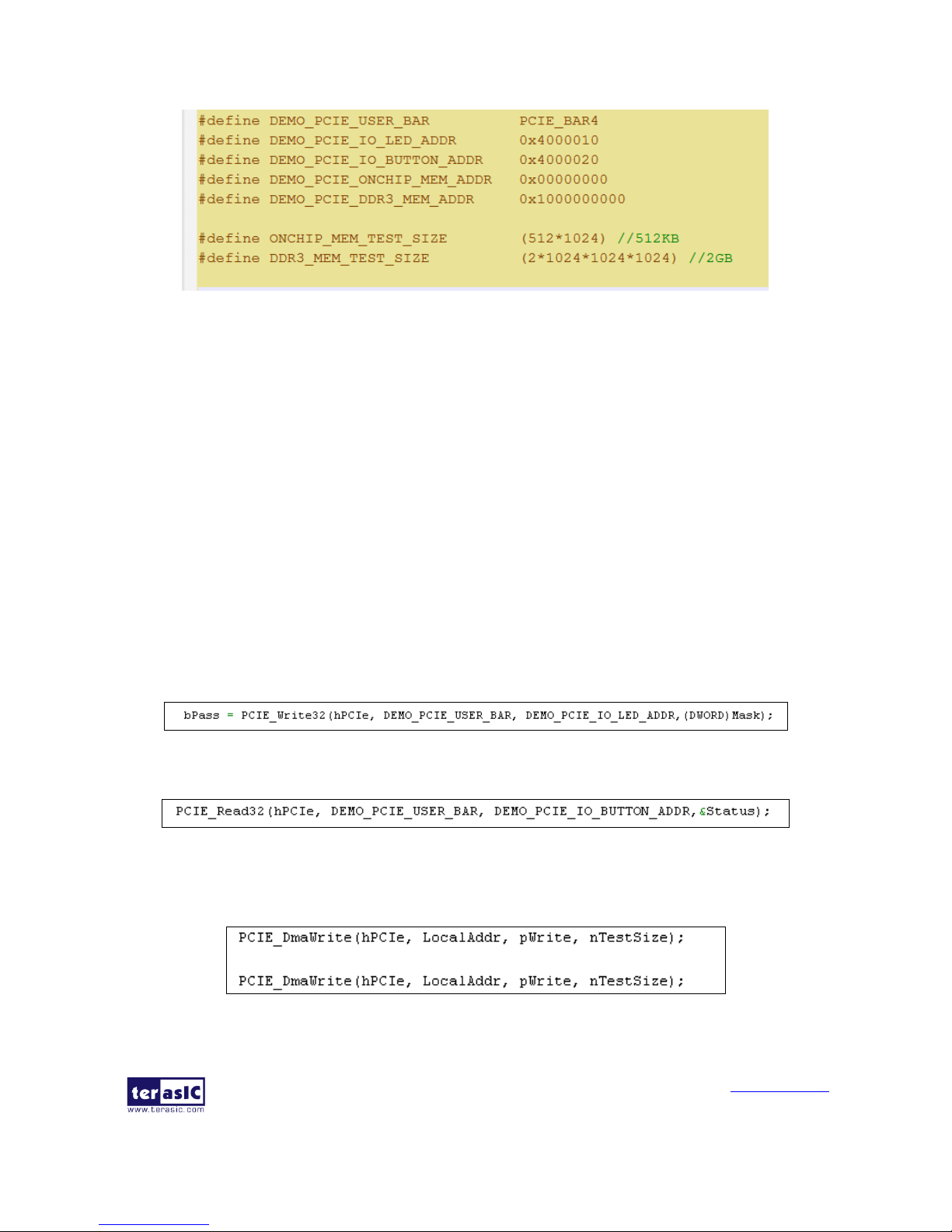

The main program PCIE_DDR3.cpp includes the header file "PCIE.h" and defines the controller

address according to the FPGA design.

PCA3 User Manual

www.terasic.com

February 8, 2018

39

The base address of BUTTON and LED controllers are 0x4000010 and 0x4000020 based on

PCIE_BAR4, respectively. The on-chip memory base address is 0x00000000 relative to the DMA

controller. The above definition is the same as those in the PCIe Fundamental demo.

Before accessing the FPGA through PCI Express, the application first calls PCIE_Load to

dynamically load the TERASIC_PCIE_AVMM.DLL. Then, it calls PCIE_Open to open the PCI

Express driver. The constant DEFAULT_PCIE_VID and DEFAULT_PCIE_DID used in

PCIE_Open are defined in TERASIC_PCIE_AVMM.h. If the developer changes the Vender ID,

Device ID, and PCI Express IP, they also need to change the ID value defined in

TERASIC_PCIE_AVMM.h. If the return value of PCIE_Open is zero, it means the driver cannot

be accessed successfully. In this case, please make sure:

The FPGA is configured with the associated bit-stream file and the host is rebooted.

The PCI express driver is loaded successfully.

The LED control is implemented by calling PCIE_Write32 API, as shown below:

The button status query is implemented by calling the PCIE_Read32 API, as shown below:

The memory-mapped memory read and write test is implemented by PCIE_DmaWrite and

PCIE_DmaRead API, as shown below:

PCA3 User Manual

www.terasic.com

February 8, 2018

40

The pcie link information is implemented by PCIE_ConfigRead32 API, as shown below:

PCA3 User Manual

www.terasic.com

February 8, 2018

41

Chapter 5

Appendix

55..1

1

RReevviissiioonn HHiissttoorryy

Version

Change Log

V1.0

Initial Version (Preliminary)

V1.1

Add section 1.1 package contents and modify

55..2

2

CCooppyyrriigghhtt SSttaatteemmeenntt

Copyright © 2017 Terasic Technologies. All rights reserved.

Loading...

Loading...