Page 1

MAX 10 Plus User

Manual

1

www.terasic.com

May 31, 2019

Page 2

MAX 10 Plus User

Manual

2

www.terasic.com

May 31, 2019

CONTENTS

Chapter 1 MAX 10 Plus Development Kit ..................................................................4

1.1 Package Contents........................................................................................................................ 4

1.2 MAX 10 Plus System CD ........................................................................................................... 5

1.3 Getting Help ............................................................................................................................... 5

Chapter 2 Introduction of the MAX 10 Plus ...............................................................6

2.1 Layout and Components ............................................................................................................. 6

2.2 Block Diagram of the MAX 10 Plus .......................................................................................... 7

Chapter 3 Using the MAX 10 Plus .............................................................................10

3.1 Configuration of MAX 10 FPGA on MAX 10 Plus ................................................................. 10

3.2 Board Status Elements .............................................................................................................. 14

3.3 Clock Circuitry ......................................................................................................................... 15

3.4 Peripherals Connected to the FPGA ......................................................................................... 16

3.4.1 User Push-buttons, Switches, LEDs ...................................................................................... 16

3.4.2 7-segment Displays ................................................................................................................ 19

3.4.3 Power Monitor ....................................................................................................................... 20

3.4.4 2x6 TMD Expansion Header ................................................................................................. 21

3.4.5 24-bit Audio CODEC ............................................................................................................ 22

3.4.6 Two Analog Input SMA Connectors ..................................................................................... 23

3.4.7 DDR3 Memory ...................................................................................................................... 23

3.4.8 QSPI Flash ............................................................................................................................. 25

3.4.9 Ethernet .................................................................................................................................. 26

3.4.10 HDMI RX .............................................................................................................................. 28

3.4.11 2x10 ADC Header ................................................................................................................. 29

3.4.12 Potentiometer ......................................................................................................................... 30

3.4.13 On-board Microphone ............................................................................................................ 30

3.4.14 PS/2 Serial Port ...................................................................................................................... 30

Page 3

MAX 10 Plus User

Manual

3

www.terasic.com

May 31, 2019

3.4.15 Digital-to-Analog Converter (DAC) ...................................................................................... 31

3.4.16 UART to USB ........................................................................................................................ 32

3.4.17 Ambient Light Sensor ............................................................................................................ 33

3.4.18 Humidity and Temperature Sensor ........................................................................................ 33

3.4.19 Accelerometer Sensor ............................................................................................................ 34

3.4.20 Micro SD Card Socket ........................................................................................................... 35

3.4.21 Power Distribution System .................................................................................................... 35

Chapter 4 The MAX 10 Plus System Builder ...........................................................37

4.1 Introduction .............................................................................................................................. 37

4.2 General Design Flow ................................................................................................................ 37

4.3 Using MAX 10 Plus System Builder ........................................................................................ 38

Chapter 5 RTL Example Codes .................................................................................44

5.1 PS/2 Mouse Demonstration ...................................................................................................... 44

5.2 ADC Potentiometer .................................................................................................................. 46

5.3 DAC Demonstration ................................................................................................................. 48

5.4 ADC/MIC/LED Demonstration ................................................................................................ 51

Chapter 6 NIOS Based Example Codes ....................................................................54

6.1 Power Monitor .......................................................................................................................... 54

6.2 UART to USB Control LED ..................................................................................................... 58

6.3 SD Card Audio Demonstration ................................................................................................. 61

6.4 DDR3 SDRAM Test by Nios II ................................................................................................ 65

6.5 Ethernet Socket server .............................................................................................................. 68

6.6 Digital Accelerometer Demonstration ...................................................................................... 75

6.7 Humidity/Temperature Sensor .................................................................................................. 77

Chapter 7 Programming the Configuration Flash Memory ...................................79

7.1 Internal Configuration .............................................................................................................. 79

7.2 Using Dual Compressed Images............................................................................................... 81

7.3 Nios II Load In Single Boot Image .......................................................................................... 84

Page 4

MAX 10 Plus User

Manual

4

www.terasic.com

May 31, 2019

Chapter 1

MAX 10 Plus Development Kit

The MAX 10 Plus board from Terasic is a full featured embedded evaluation kit based upon the

MAX10 family of Intel FPGAs. It offers a comprehensive design environment with everything

embedded developers need to create a processing-based system.

The MAX 10 Plus board delivers an integrated platform that includes hardware, design tools,

intellectual property and reference designs for developing a wide range of audio, video and many

other exciting applications.

The fully integrated kit allows developers to rapidly customize their processor and IP to suit their

specific needs, rather than constraining their software around the fixed feature set of the processor.

The all-in-one embedded solution, the MAX 10 Plus, making the best use of the parallel nature of

FPGAs.

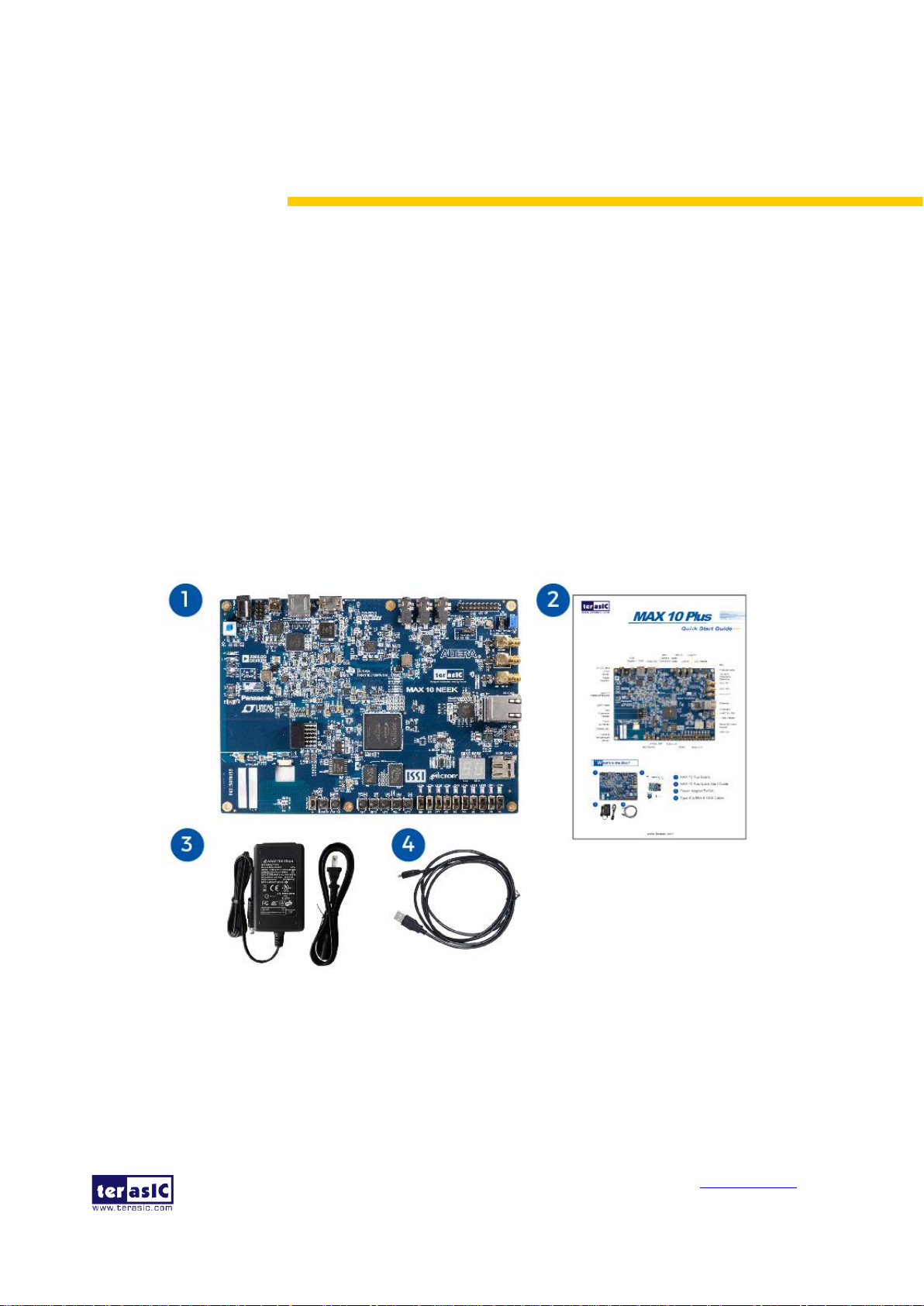

1.1 Package Contents

Figure 1-1 shows a photograph of the MAX 10 Plus board package.

Figure 1-1 The MAX 10 Plus Board Package Contents

The MAX 10 Plus board package includes:

1. MAX 10 Plus board

2. MAX 10 Plus Quick Start Guide

3. 5V DC power adapter

Page 5

MAX 10 Plus User

Manual

5

www.terasic.com

May 31, 2019

4. One USB cables (Type A to Mini-B) for USB control and FPGA programming and control

1.2 MAX 10 Plus System CD

The MAX 10 Plus System CD contains all the documents and supporting materials associated with

MAX 10 Plus, including the user manual, system builder, reference designs, and device datasheets.

Users can download this system CD from the link: http:// max10-plus.terasic.com/cd.

1.3 Getting Help

Here are the addresses where you can get help if you encounter any problems:

• Terasic Technologies

• 9F., No.176, Sec.2, Gongdao 5th Rd, East Dist, Hsinchu City, 30070. Taiwan

Email: support@terasic.com

Tel.: +886-3-575-0880

Website: max10-plus.terasic.com

Page 6

MAX 10 Plus User

Manual

6

www.terasic.com

May 31, 2019

Chapter 2

Introduction of the MAX 10 Plus

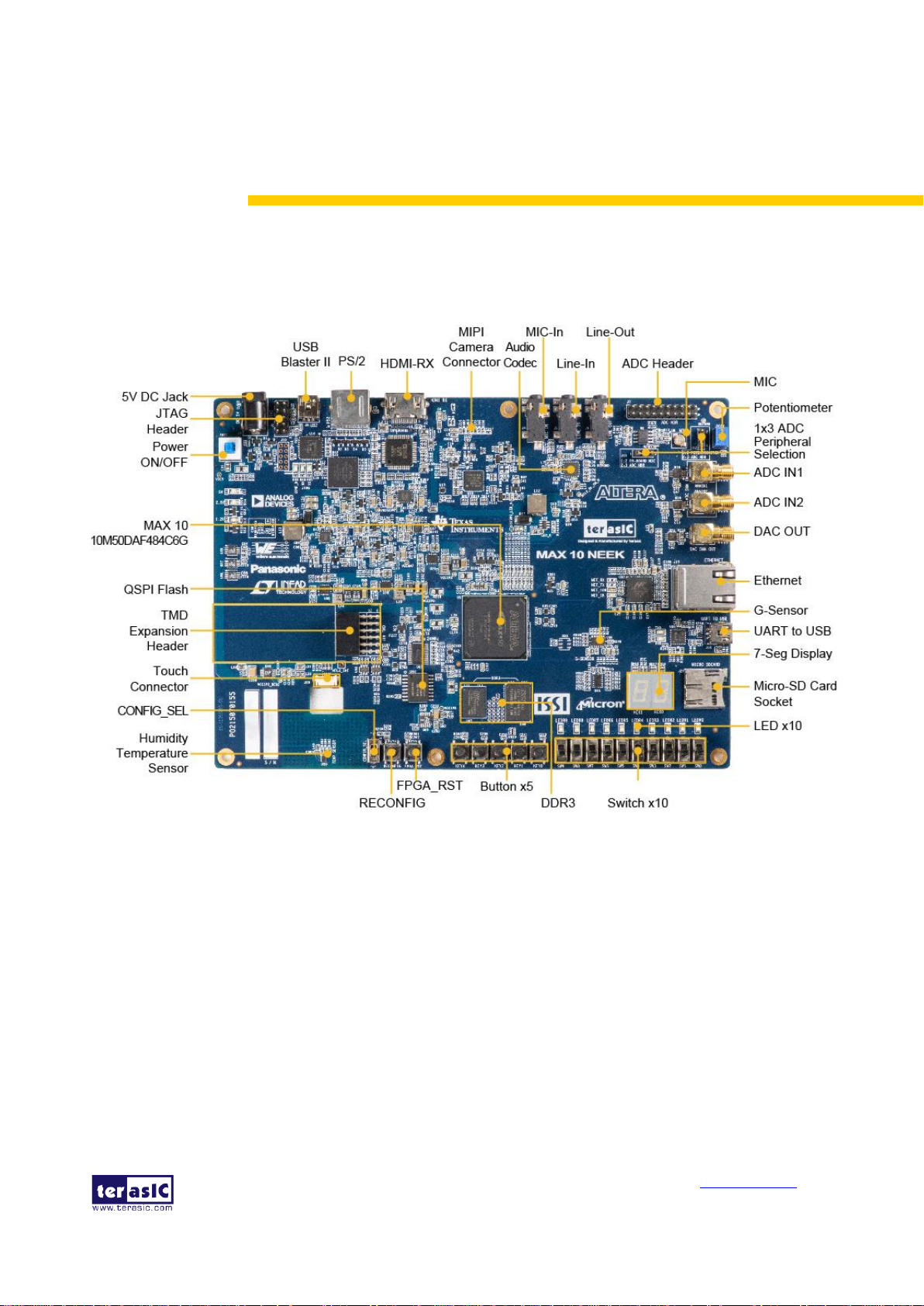

2.1 Layout and Components

Figure 2-1 shows a photograph of the board. It depicts the layout of the board and indicates the

location of the connectors and key components.

Figure 2-1 MAX 10 Plus Development Board (top view)

The MAX 10 Plus board has many features that allow users to implement a wide range of designed

circuits, from simple circuits to various multimedia projects.

The following hardware is provided on the board:

• Intel MAX® 10 10M50DAF484C6G device

• USB-Blaster II onboard for programming; JTAG Mode

• 256MB DDR3 SDRAM (64Mx16 and 128Mx8)

• 64MB QSPI Flash

• Micro SD card socket

• Five push-buttons

• Ten slide switches

Page 7

MAX 10 Plus User

Manual

7

www.terasic.com

May 31, 2019

• Ten red user LEDs

• Two 7-segment displays

• Three 50MHz clock sources from the clock generator

• 24-bit CD-quality audio CODEC with line-in, line-out jacks

• On-board microphone

• HDMI RX, incorporates HDM v1.4a features, including 3D video supporting

• Gigabit Ethernet PHY with RJ45 connector

• UART to USB, USB Mini-B connector

• One ambient light sensor

• One humidity and temperature sensor

• One accelerometer

• One external 16bit digital-to-analog converter (DAC) device with SMA output

• Potentiometer input to ADC

• Two MAX 10 FPGA ADC SMA inputs

• One 2x10 ADC header with 16 analog inputs connected to MAX10 ADCs

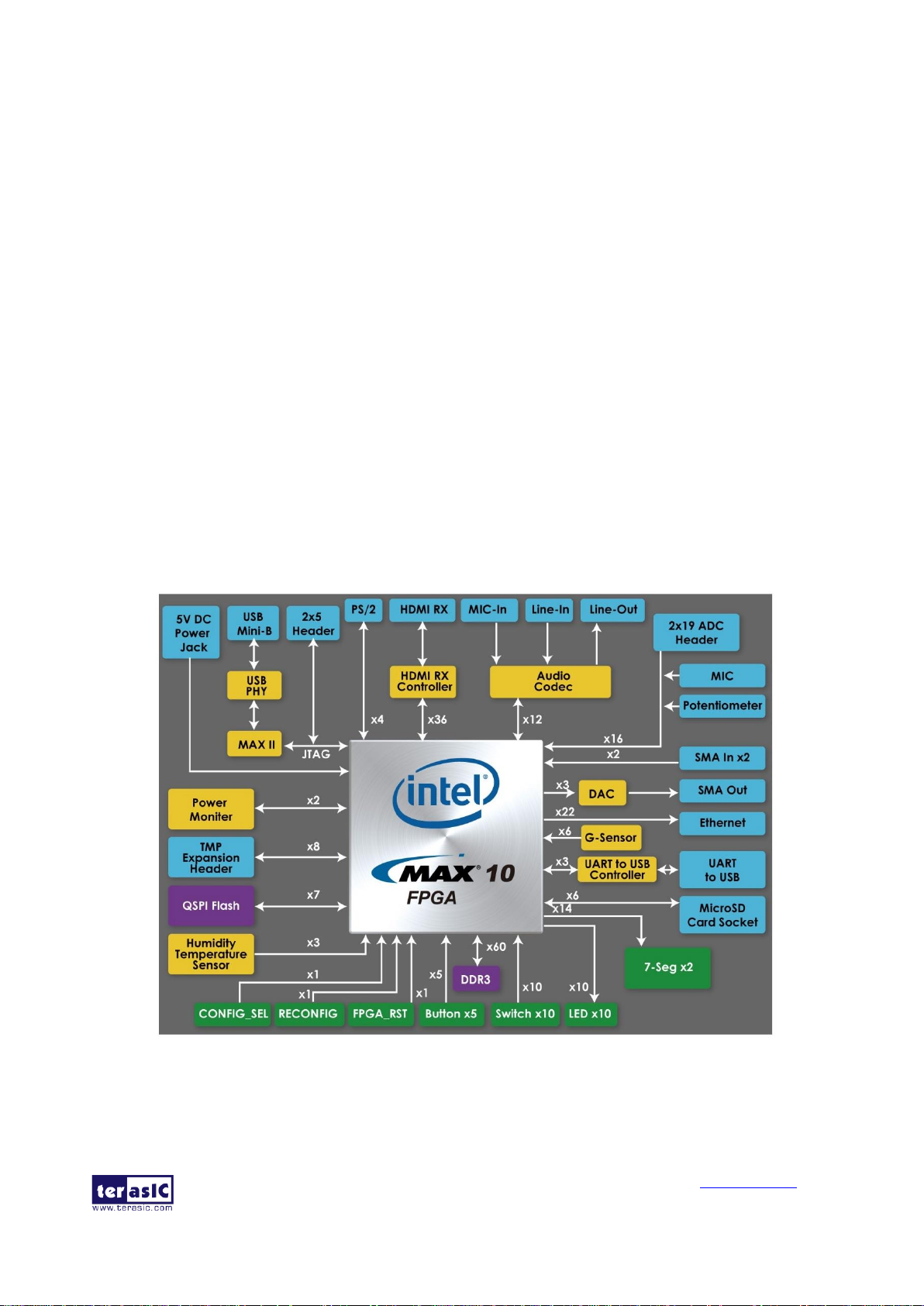

2.2 Block Diagram of the MAX 10 Plus

Figure 2-2 is the block diagram of the board. All the connections are established through the MAX

10 FPGA device to provide maximum flexibility for users. Users can configure the FPGA to

implement any system design.

Figure 2-2 Block Diagram of MAX 10 Plus Board

Page 8

MAX 10 Plus User

Manual

8

www.terasic.com

May 31, 2019

FPGA Device

• MAX 10 10M50DAF484C6G Device

• Integrated dual ADCs, each ADC supports 1 dedicated analog input and 8 dual function pins

• 50K programmable logic elements

• 1,638Kbits embedded memory

• 5,888Kbits user flash memory

• 4 PLLs

Configuration and Debug

• On-board USB-Blaster II (Mini USB type B connector)

• Optional JTAG direct via 10-pin header

• One slide switch for dual boot image selection

Memory Device

• 256MB DDR3 SDRAM (64Mx16 and 128Mx8)

• 512MB QSPI Flash

• Micro SD card socket

Communication and Expansion Header

• Gigabit Ethernet PHY with RJ45 connector

• UART to USB, USB Mini-B connector

• PS/2 mouse/keyboard connector

• 2x6 TMD (Terasic Mini Digital) Expansion Header

Audio

• 24-bit CD-quality audio CODEC with line-in, line-out jacks

Video Input

• HDMI RX, incorporates HDM v1.4a features, including 3D video supporting

Analog

• Two MAX 10 FPGA ADC SMA inputs

• Potentiometer input to ADC

• On-Board MIC input to ADC

• 2x10 ADC header with 16 analog inputs connected to MAX10 ADCs

• One DAC SMA output

Switches, Buttons, and Indicators

• Five push-buttons

• Ten slide switches

Page 9

MAX 10 Plus User

Manual

9

www.terasic.com

May 31, 2019

• Ten red user LEDs

• Two 7-segment displays

Sensors

• Ambient light sensor

• Humidity and temperature sensor

• Accelerometer

• Power monitor

Power

• 5V/3A DC input

Page 10

MAX 10 Plus User

Manual

10

www.terasic.com

May 31, 2019

Chapter 3

Using the MAX 10 Plus

This chapter provides an instruction to use the board and describes the peripherals.

3.1 Configuration of MAX 10 FPGA on MAX 10 Plus

There are two types of configuration method supported by MAX 10 Plus:

1. JTAG configuration: configuration using JTAG port.

JTAG configuration scheme allows you to directly configure the device core through JTAG pins -

TDI, TDO, TMS, and TCK pins. The Quartus II software automatically generates .sof that is used

for JTAG configuration with a download cable in the Quartus II software programmer.

2. Internal configuration: configuration using internal flash.

Before internal configuration, you need to program the configuration data into the configuration

flash memory (CFM) which provides non-volatile storage for the bit stream. The information is

retained within CFM even if the MAX 10 Plus is turned off. When the board is powered on, the

configuration data in the CFM is automatically loaded into the MAX 10 FPGA.

◼ JTAG Chain on MAX 10 Plus

The FPGA device can be configured through JTAG interface on MAX 10 Plus board, but the JTAG

chain must form a closed loop, which allows Quartus II programmer to the detect FPGA device.

Figure 3-1 illustrates the JTAG chain on MAX 10 Plus.

Figure 3-1 Path of the JTAG Chain

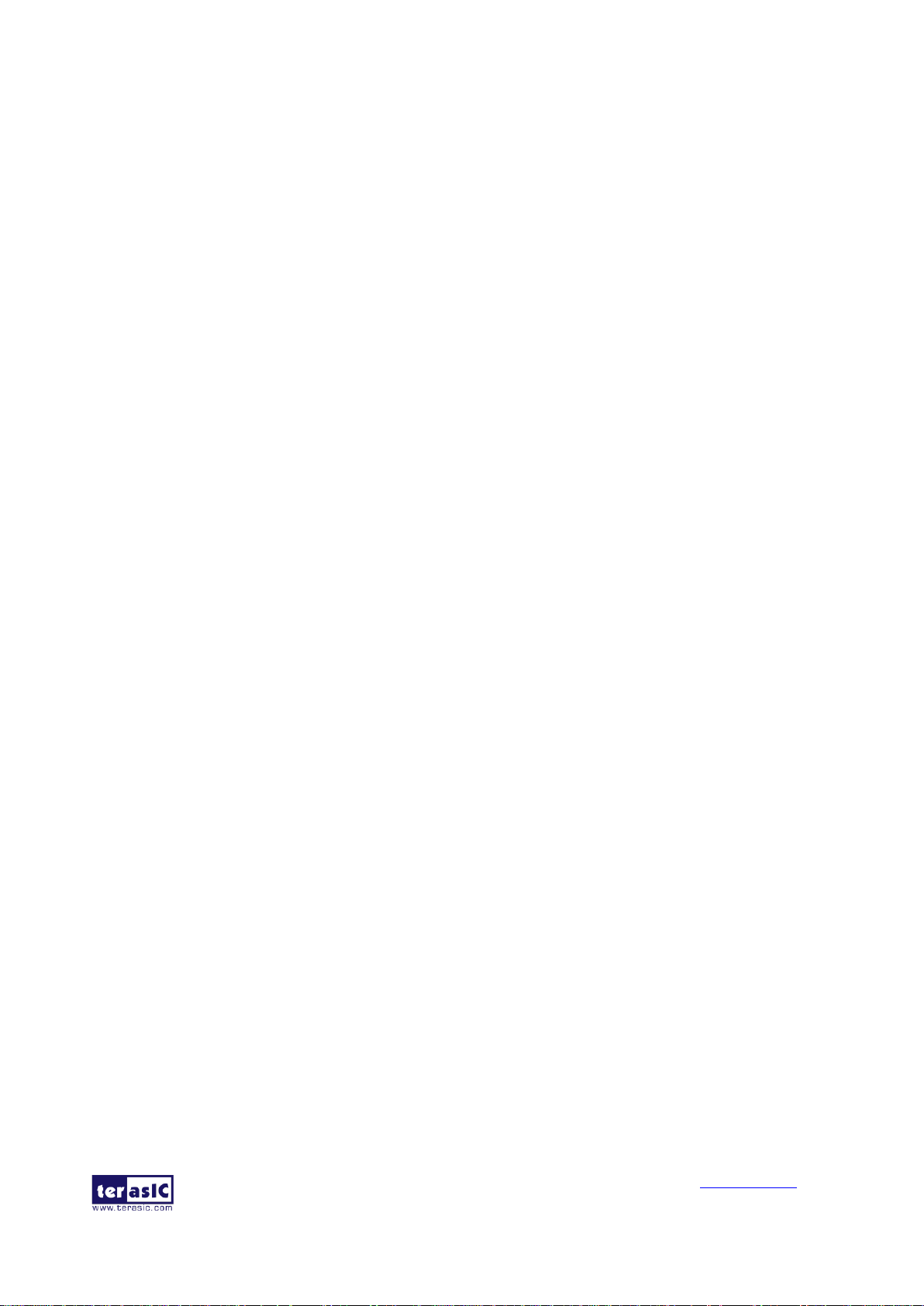

◼ Configure the FPGA in JTAG Mode

The following shows how the FPGA is programmed in JTAG mode step by step.

1. Open the Quartus II programmer and click Auto Detect, as circled in Figure 3-2.

Page 11

MAX 10 Plus User

Manual

11

www.terasic.com

May 31, 2019

Figure 3-2 Detect FPGA Device in JTAG Mode

2. Select detected device associated with the board, as circled in Figure 3-3.

Figure 3-3 Select 10M50DAES Device

3. FPGA is detected, as shown in Figure 3-4.

Page 12

MAX 10 Plus User

Manual

12

www.terasic.com

May 31, 2019

Figure 3-4 FPGA Detected in Quartus Programmer

4. Right click on the FPGA device and open the .sof file to be programmed, as highlighted in

Figure 3-5.

Figure 3-5 Open the .sof File to be Programmed into the FPGA Device

Page 13

MAX 10 Plus User

Manual

13

www.terasic.com

May 31, 2019

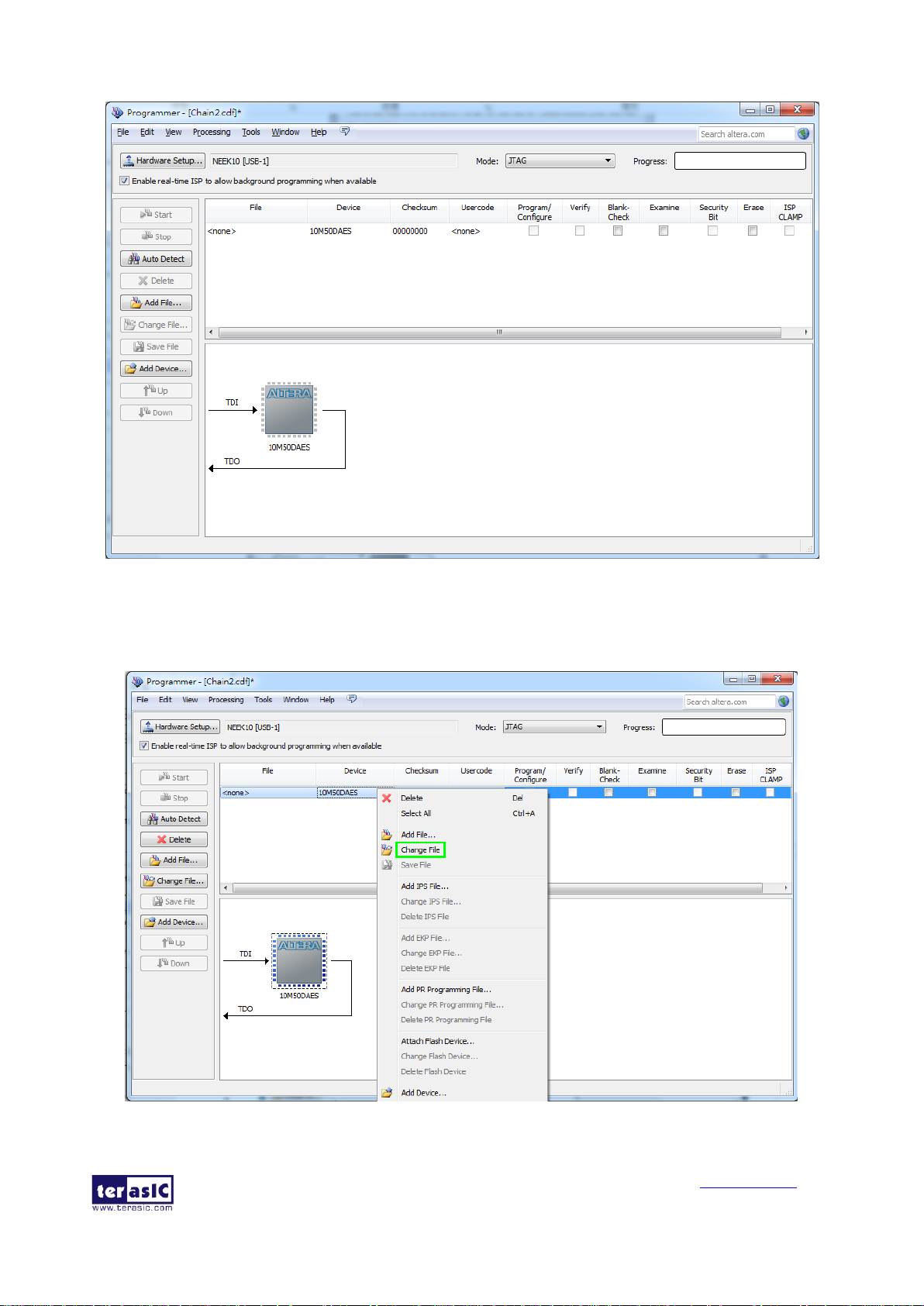

5. Select the .sof file to be programmed, as shown in Figure 3-6.

Figure 3-6 Select the .sof File to be Programmed into the FPGA Device

6. Click Program/Configure check box and then click Start button to download the .sof file

into the FPGA device, as shown in Figure 3-7.

Figure 3-7 Program. sof File into the FPGA Device

Page 14

MAX 10 Plus User

Manual

14

www.terasic.com

May 31, 2019

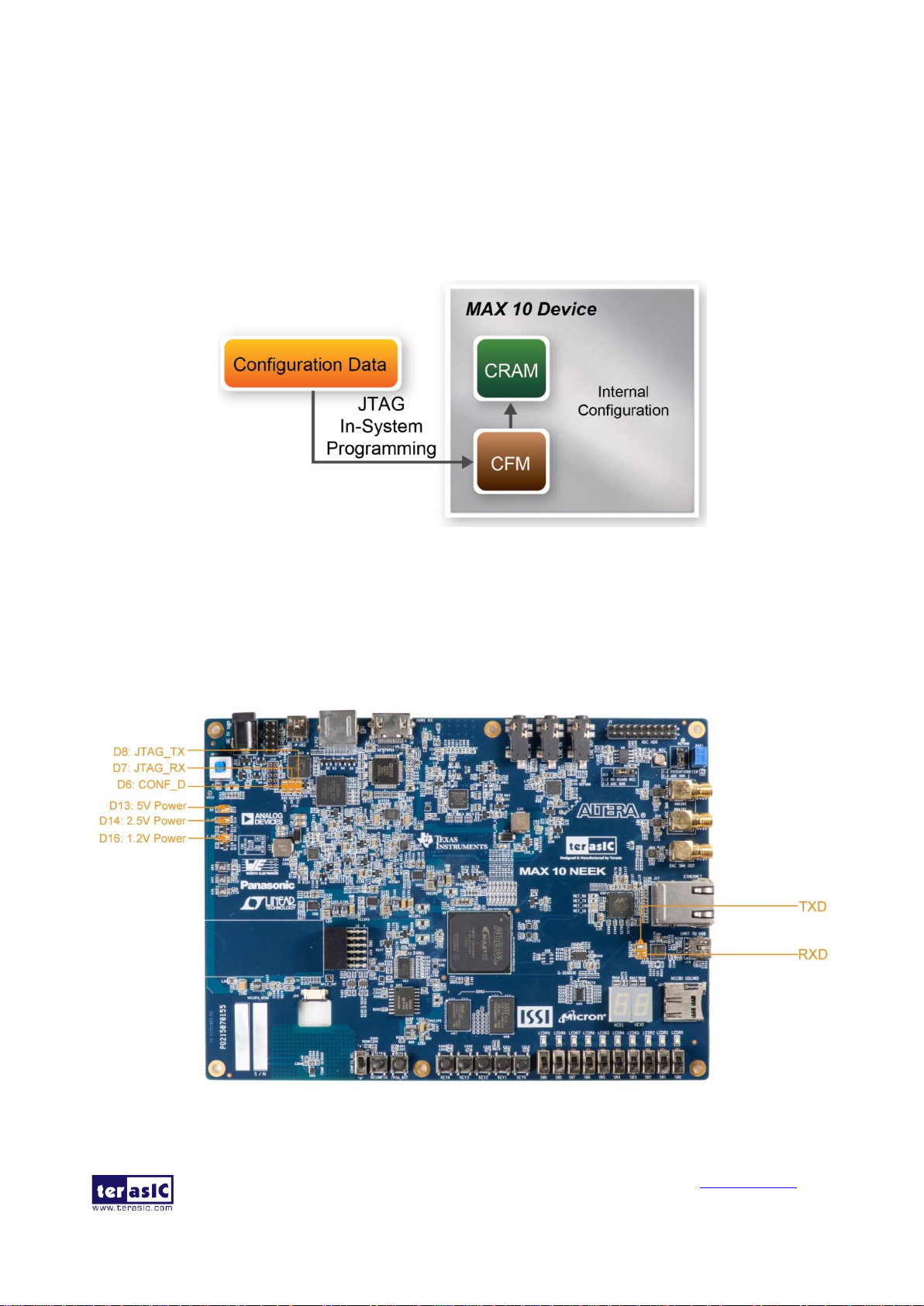

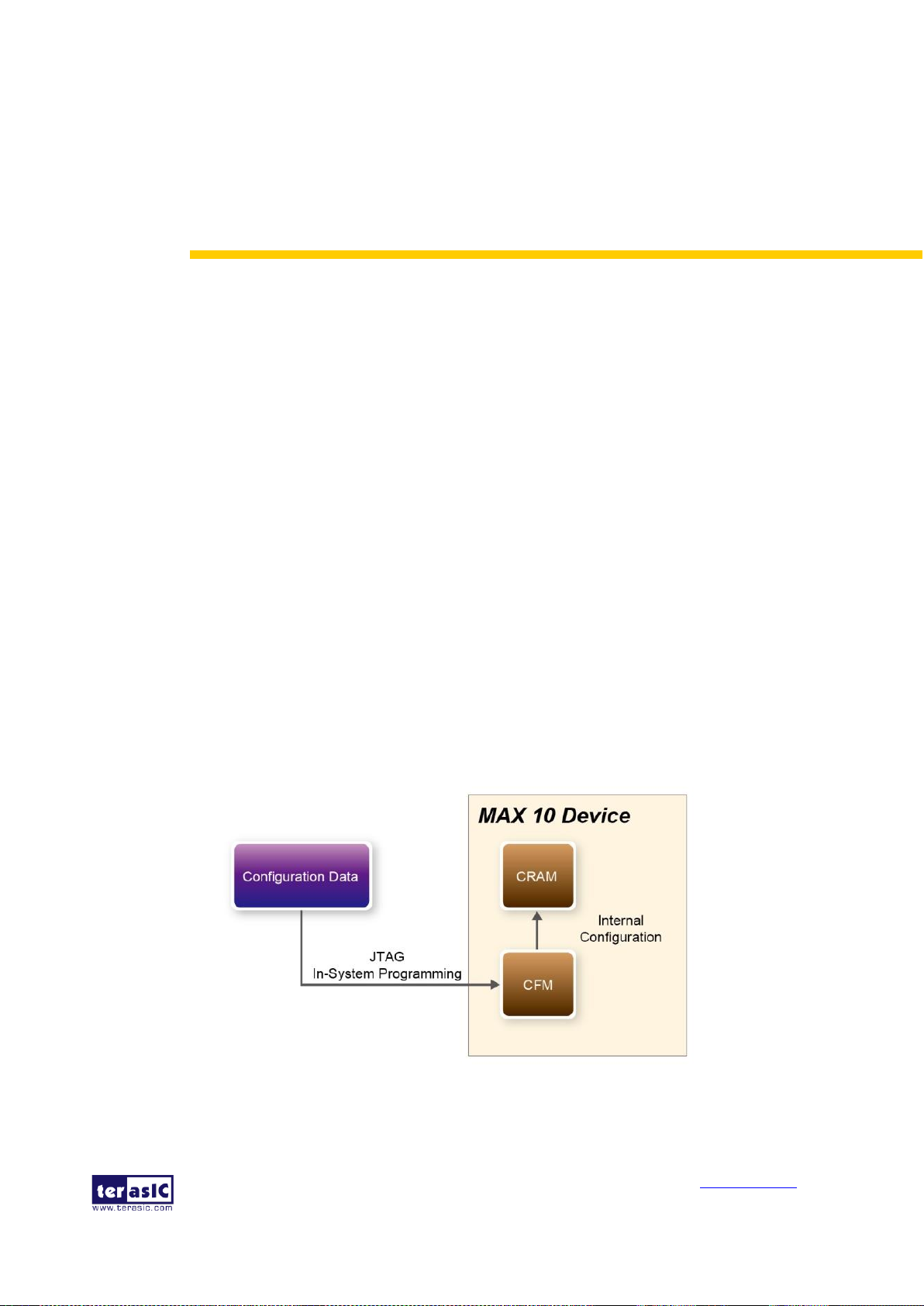

◼ Internal Configuration

• The configuration data to be written to CFM will be part of the programmer object file (.pof).

This configuration data is automatically loaded from the CFM into the MAX 10 devices when

the board is powered up.

• Please refer to Chapter 7 Programming the Configuration Flash Memory for the basic

programming instruction on the configuration flash memory (CFM).

Figure 3-8 High-Level Overview of Internal Configuration for MAX 10 Devices

3.2 Board Status Elements

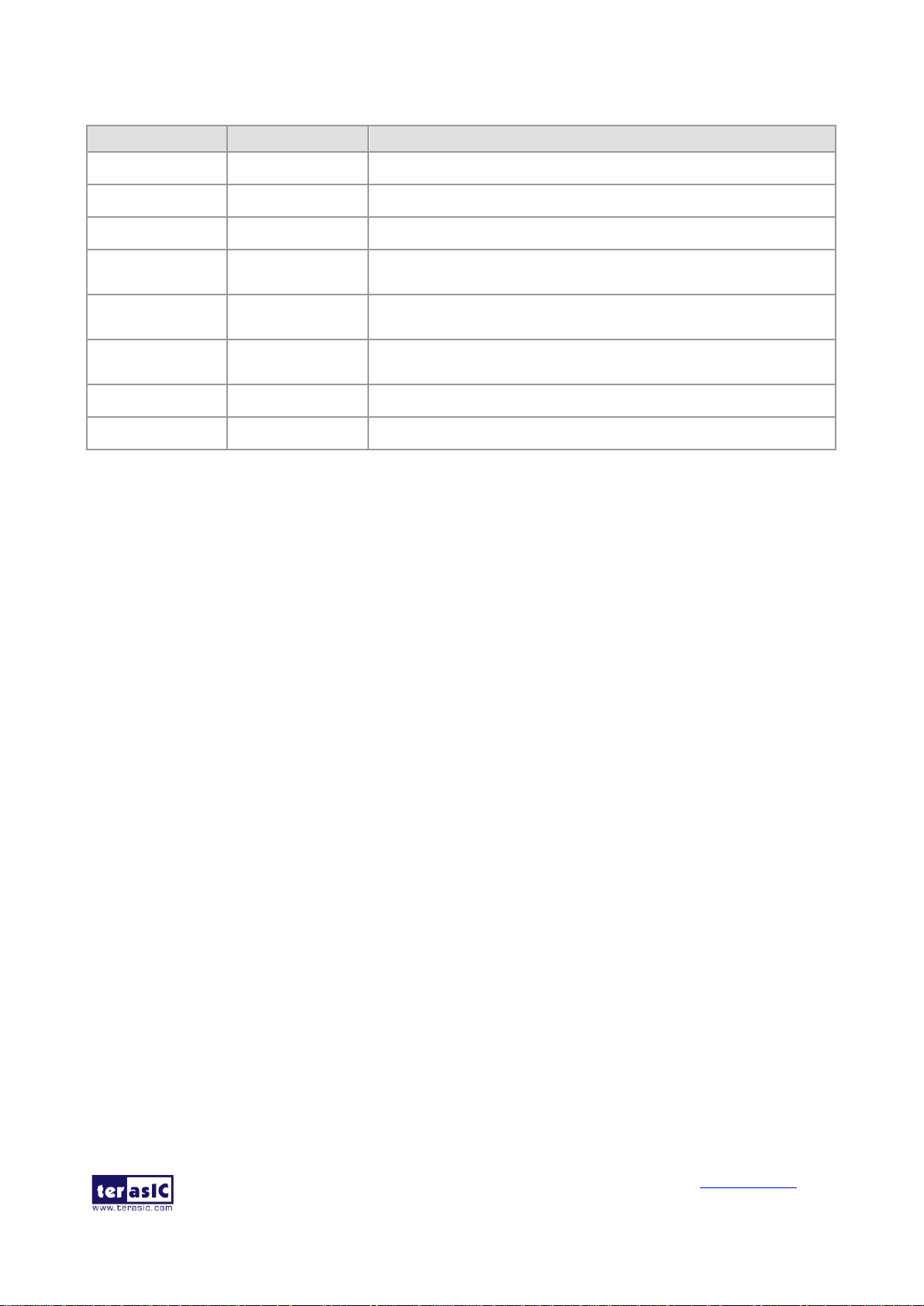

In addition to the 10 LEDs that FPGA device can control, there are 4 indicators which can indicate

the board status (See Figure 3-9), please refer the details in Table 3-1.

Figure 3-9 LED Indicators on MAX 10 Plus

Page 15

MAX 10 Plus User

Manual

15

www.terasic.com

May 31, 2019

Table 3-1 LED Indicators

Board Reference

LED Name

Description

D13

5V Power

Illuminate when 5V power is active.

D14

2.5V Power

Illuminate when 2.5V power is active.

D16

1.2V Power

Illuminate when 1.2V power is active.

D6

CONF_DONE

Illuminate when configuration data is loaded into MAX 10 device

without error.

D7

JTAG_RX

Illuminate during data is uploaded from MAX 10 device to PC through

UB2.

D8

JTAG_TX

Illuminate during configuration data is loaded into MAX 10 device

from UB2.

TXD

TXD

Illuminate during transmitting data via USB.

RXD

RXD

Illuminate during receiving data via USB.

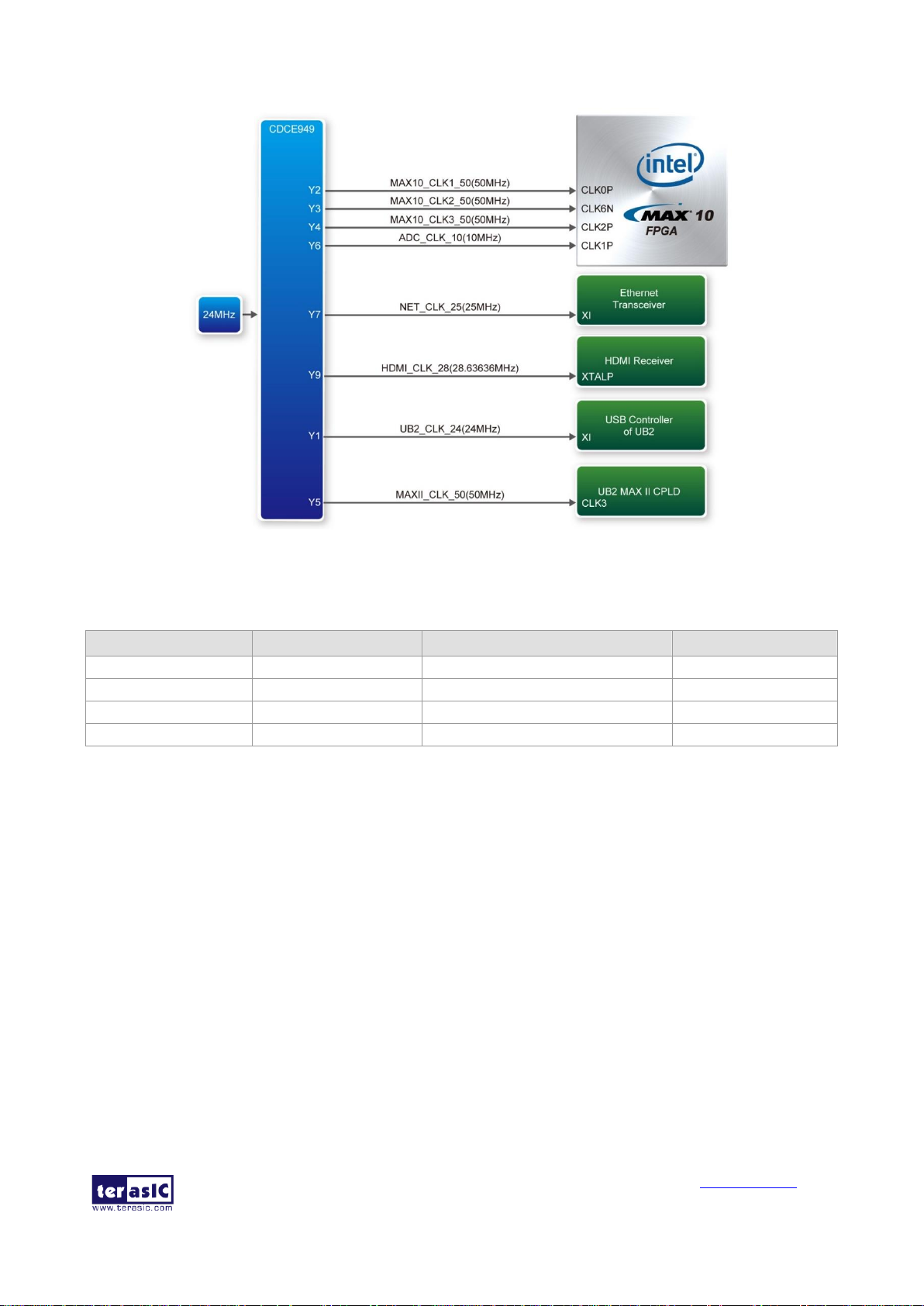

3.3 Clock Circuitry

Figure 3-10 shows the default frequency of all external clocks to the MAX 10 FPGA. A clock

generator is used to distribute clock signals with low jitter. The three 50MHz clock signals

connected to the FPGA are used as clock sources for user logic. One 25MHz clock signal is

connected to the clock input of Gigabit Ethernet Transceiver. One 24MHz clock signal is connected

to the clock inputs of USB microcontroller of USB Blaster II. One 28.63636MHz clock signal is

connected to the clock input of HDMI Receiver chip. The other 50MHz clock signal is connected to

MAX CPLD of USB Blaster II. One 10MHz clock signal is connected to the PLL1 and PLL3 of

FPGA, the outputs of these two PLLs can drive ADC clock. The associated pin assignment for

clock inputs to FPGA I/O pins is listed in Table 3-2.

Page 16

MAX 10 Plus User

Manual

16

www.terasic.com

May 31, 2019

Figure 3-10 Block Diagram of the Clock Distribution on MAX 10 Plus

Table 3-2 Pin Assignment of Clock Inputs

Signal Name

FPGA Pin No.

Description

I/O Standard

MAX10_CLK1_50

PIN_N5

50MHz clock input

2.5V

MAX10_CLK2_50

PIN_V9

50MHz clock input

3.3V

MAX10_CLK3_50

PIN_N14

50MHz clock input

1.5V

ADC_CLK_10

PIN_M9

10MHz clock input

3.3V

3.4 Peripherals Connected to the FPGA

This section describes the interfaces connected to the FPGA. User can control or monitor different

interfaces with user logic from the FPGA.

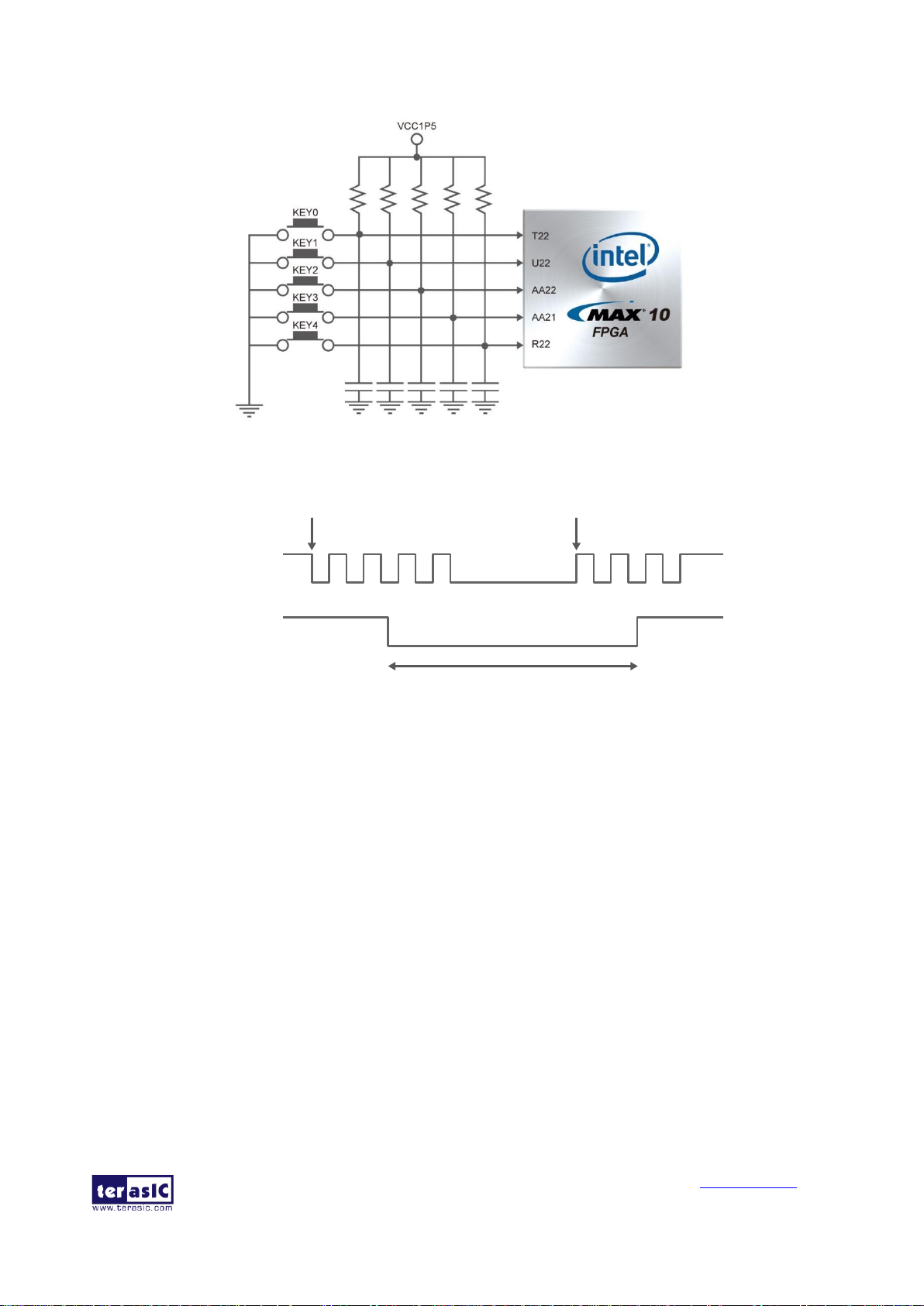

3.4.1 User Push-buttons, Switches, LEDs

The board has five push-buttons connected to the FPGA, as shown in Figure 3-11. MAX 10 devices

support Schmitt trigger input on all I/O pins. A Schmitt trigger feature introduces hysteresis to the

input signal for improved noise immunity, especially for signal with slow edge rate and act as

switch debounce in Figure 3-12 for the push-buttons connected.

Page 17

MAX 10 Plus User

Manual

17

www.terasic.com

May 31, 2019

Figure 3-11 Connections between the Push-buttons and the MAX 10 FPGA

Figure 3-12 Switch Debouncing

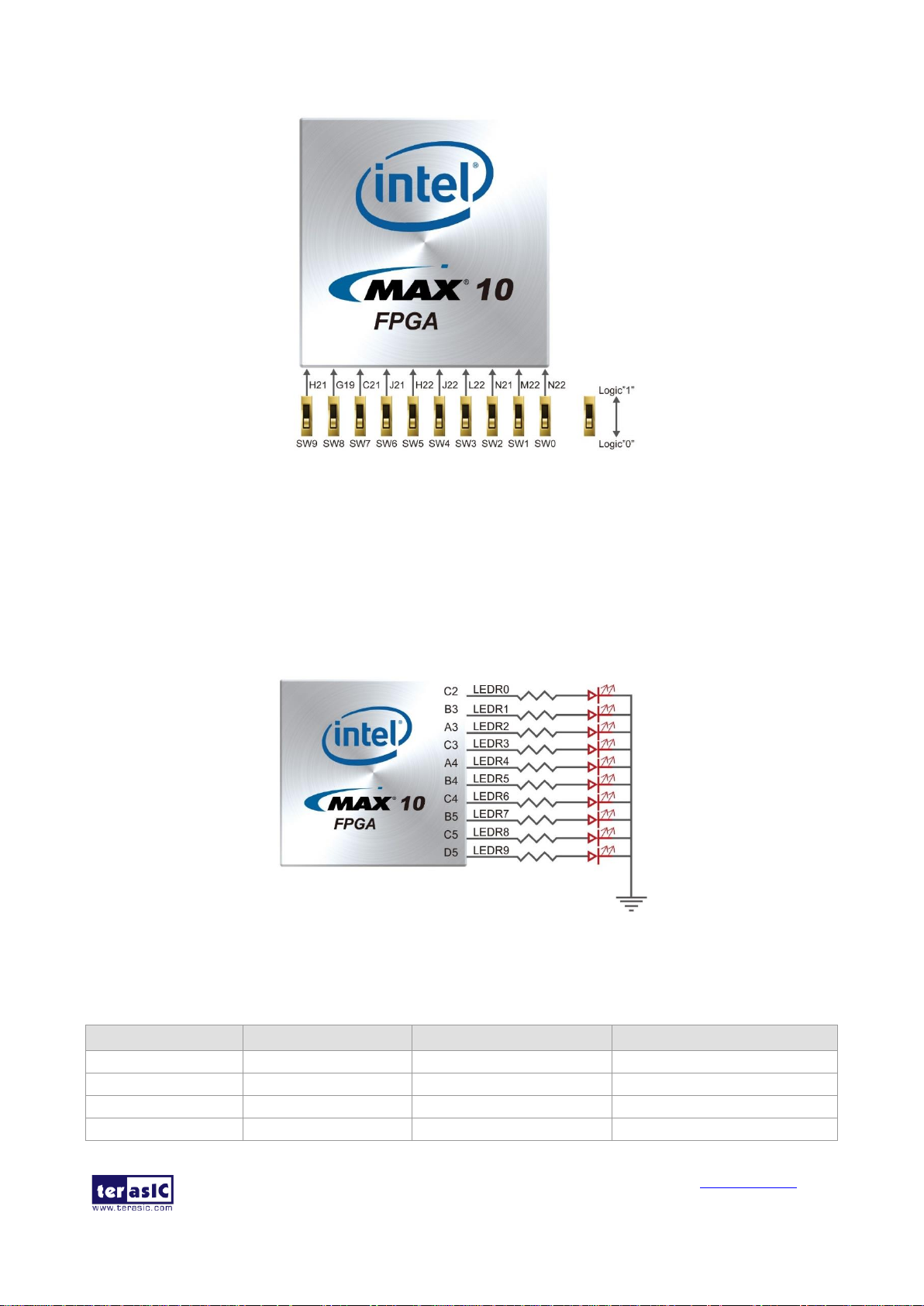

There are two ten switches connected to the FPGA, as shown in Figure 3-13. These switches are

used as level-sensitive data inputs to a circuit. Each switch is connected directly and individually to

the FPGA. When the switch is set to the DOWN position (towards the edge of the board), it

generates a low logic level to the FPGA. When the switch is set to the UP position, a high logic

level is generated to the FPGA.

Pushbutton releasedPushbutton depressed

Before

Debouncing

Schmitt Trigger

Debounced

Page 18

MAX 10 Plus User

Manual

18

www.terasic.com

May 31, 2019

Figure 3-13 Connections between the Slide Switches and the MAX 10 FPGA

There are also ten user-controllable LEDs connected to the FPGA. Each LED is driven directly and

individually by the MAX 10 FPGA; driving its associated pin to a high logic level or low level to

turn the LED on or off, respectively. Figure 3-14 shows the connections between LEDs and MAX

10 FPGA. Table 3-3, Table 3-4 and Table 3-5 list the pin assignment of user push-buttons, switches,

and LEDs.

Figure 3-14 Connections between the LEDs and the MAX 10 FPGA

Table 3-3 Pin Assignment of Push-buttons

Signal Name

FPGA Pin No.

Description

I/O Standard

KEY[0]

PIN_T22

Push-button[0]

1.5V

KEY[1]

PIN_U22

Push-button[1]

1.5V

KEY[2]

PIN_AA22

Push-button[2]

1.5V

KEY[3]

PIN_AA21

Push-button[3]

1.5V

Page 19

MAX 10 Plus User

Manual

19

www.terasic.com

May 31, 2019

KEY[4]

PIN_R22

Push-button[4]

1.5V

Table 3-4 Pin Assignment of Slide Switches

Signal Name

FPGA Pin No.

Description

I/O Standard

SW[0]

PIN_N22

Slide Switch[0]

1.5V

SW[1]

PIN_M22

Slide Switch[1]

1.5V

SW[2]

PIN_N21

Slide Switch[2]

1.5V

SW[3]

PIN_L22

Slide Switch[3]

1.5V

SW[4]

PIN_J22

Slide Switch[4]

1.5V

SW[5]

PIN_H22

Slide Switch[5]

1.5V

SW[6]

PIN_J21

Slide Switch[6]

1.5V

SW[7]

PIN_C21

Slide Switch[7]

1.5V

SW[8]

PIN_G19

Slide Switch[8]

1.5V

SW[9]

PIN_H21

Slide Switch[9]

1.5V

Table 3-5 Pin Assignment of LEDs

Signal Name

FPGA Pin No.

Description

I/O Standard

LEDR[0]

PIN_C2

LEDR [0]

3.3V

LEDR[1]

PIN_B3

LEDR [1]

3.3V

LEDR[2]

PIN_A3

LEDR [2]

3.3V

LEDR[3]

PIN_C3

LEDR [3]

3.3V

LEDR[4]

PIN_A4

LEDR [4]

3.3V

LEDR[5]

PIN_B4

LEDR [5]

3.3V

LEDR[6]

PIN_C4

LEDR [6]

3.3V

LEDR[7]

PIN_B5

LEDR [7]

3.3V

LEDR[8]

PIN_C5

LEDR [8]

3.3V

LEDR[9]

PIN_D5

LEDR [9]

3.3V

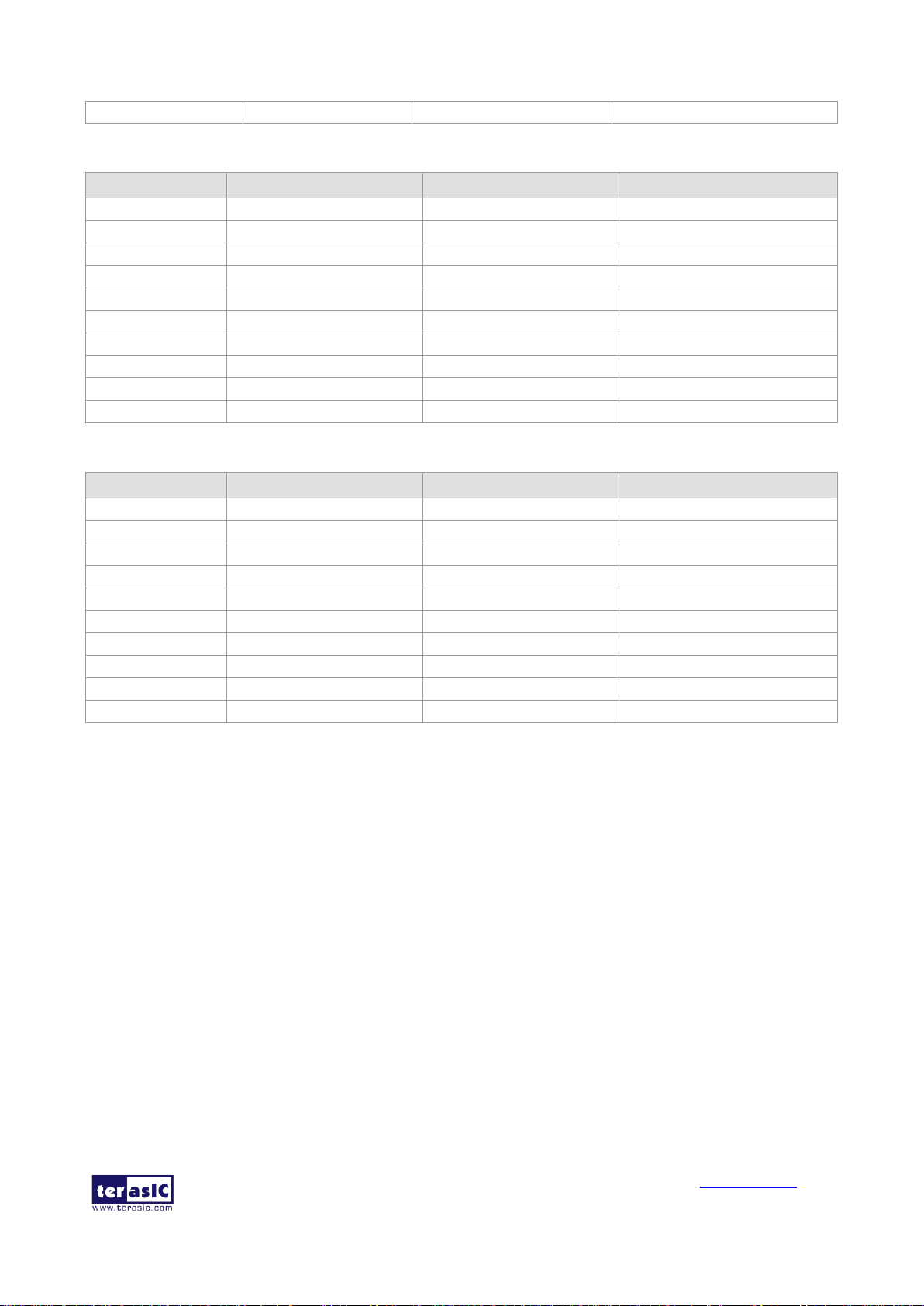

3.4.2 7-segment Displays

The MAX 10 Plus has two 7-segment displays. These displays are paired to display numbers in

various sizes. Figure 3-15 shows the connection of seven segments (common anode) to pins on

MAX 10 FPGA. The segment can be turned on or off by applying a low logic level or high logic

level from the FPGA, respectively.

Each segment in a display is indexed from 0 to 6, with corresponding positions given in Figure

3-15. Table 3-6 shows the pin assignment of FPGA to the 7-segment displays.

Page 20

MAX 10 Plus User

Manual

20

www.terasic.com

May 31, 2019

Figure 3-15 Connections between the 7-segment Display HEX0 and the MAX 10 FPGA

Table 3-6 Pin Assignment of 7-segment Displays

Signal Name

FPGA Pin No.

Description

I/O Standard

HEX0[0]

PIN_D6

Seven Segment Digit 0[0]

3.3V

HEX0[1]

PIN_A5

Seven Segment Digit 0[1]

3.3V

HEX0[2]

PIN_C6

Seven Segment Digit 0[2]

3.3V

HEX0[3]

PIN_A6

Seven Segment Digit 0[3]

3.3V

HEX0[4]

PIN_F7

Seven Segment Digit 0[4]

3.3V

HEX0[5]

PIN_D7

Seven Segment Digit 0[5]

3.3V

HEX0[6]

PIN_B7

Seven Segment Digit 0[6]

3.3V

HEX1[0]

PIN_C7

Seven Segment Digit 1[0]

3.3V

HEX1[1]

PIN_C8

Seven Segment Digit 1[1]

3.3V

HEX1[2]

PIN_D8

Seven Segment Digit 1[2]

3.3V

HEX1[3]

PIN_D10

Seven Segment Digit 1[3]

3.3V

HEX1[4]

PIN_E10

Seven Segment Digit 1[4]

3.3V

HEX1[5]

PIN_H11

Seven Segment Digit 1[5]

3.3V

HEX1[6]

PIN_E6

Seven Segment Digit 1[6]

3.3V

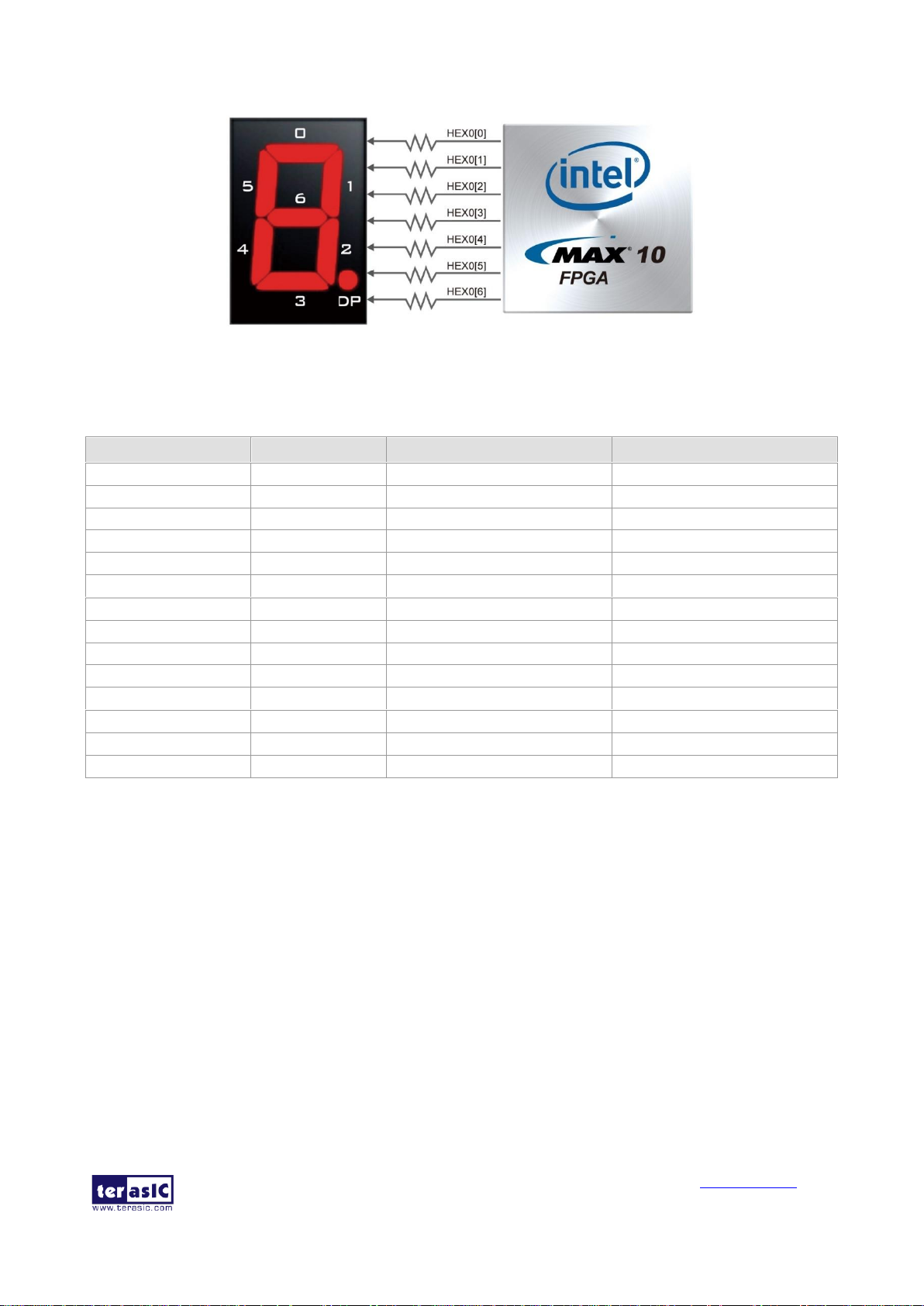

3.4.3 Power Monitor

The MAX 10 Plus has implemented three power monitor chips to monitor the FPGA core power

and VCCIO power voltage and current. Figure 3-16 shows the connection between the power

monitor chip and the MAX 10 FPGA. Through the I2C serial interface, the power monitor can be

configured to measure remote voltage and remote current. Programmable calibration value,

conversion times, and averaging, combined with an internal multiplier, enable direct readouts of

current in amperes and power in watts. Table 3-7 shows the pin assignment of power monitor I2C

bus.

Page 21

MAX 10 Plus User

Manual

21

www.terasic.com

May 31, 2019

Figure 3-16 Connections between the Power Monitor Chip and the MAX 10 FPGA

Table 3-7 Pin Assignment of Power Monitor I2C Bus

Signal Name

FPGA Pin No.

Description

I/O Standard

PM_I2C_SCL

PIN_E8

Power Monitor SCL

3.3V

PM_I2C_SDA

PIN_E9

Power Monitor SDA

3.3V

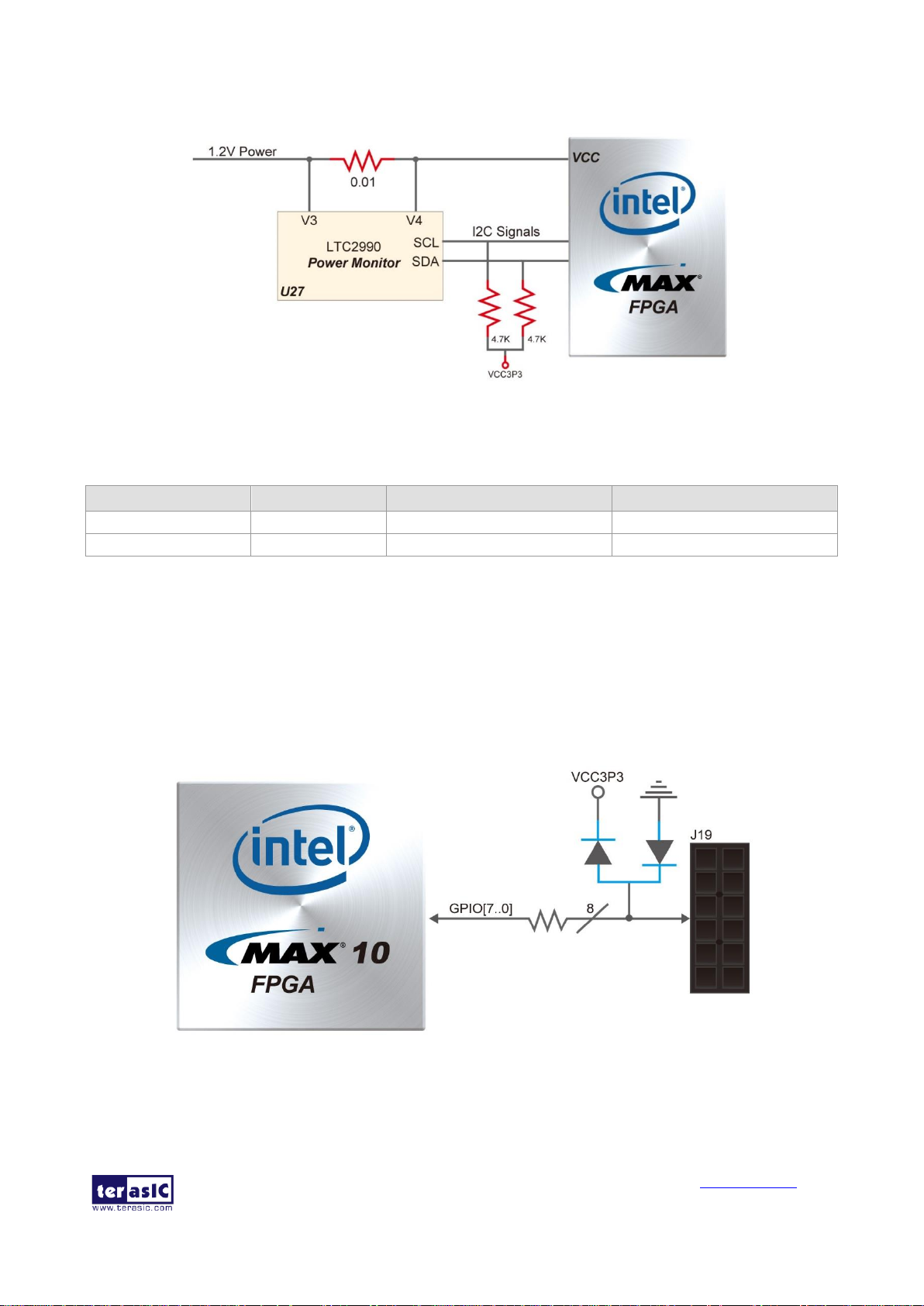

3.4.4 2x6 TMD Expansion Header

The board has one 2x6 TMD (Terasic Mini Digital) expansion header. The TMD header has 8

digital GPIO user pins connected to the MAX 10 FPGA, two 3.3V power pins and two ground pins.

There are two Transient Voltage Suppressor diode arrays used to implement ESD protection for 8

GPIO user pins.

Figure 3-17 shows the connection between the TMD header and MAX 10 FPGA. Table 3-8 shows

the pin assignment of 2x6 TMD header.

Figure 3-17 Connections between the 2x6 TMD Header and MAX 10 FPGA

Page 22

MAX 10 Plus User

Manual

22

www.terasic.com

May 31, 2019

Table 3-8 Pin Assignment of 2x6 TMD Header

Signal Name

FPGA Pin No.

Description

I/O Standard

GPIO[0]

PIN_Y17

GPIO Connection [0]

3.3V

GPIO[1]

PIN_AA17

GPIO Connection [1]

3.3V

GPIO[2]

PIN_V16

GPIO Connection [2]

3.3V

GPIO[3]

PIN_W15

GPIO Connection [3]

3.3V

GPIO[4]

PIN_AB16

GPIO Connection [4]

3.3V

GPIO[5]

PIN_AA16

GPIO Connection [5]

3.3V

GPIO[6]

PIN_Y16

GPIO Connection [6]

3.3V

GPIO[7]

PIN_W16

GPIO Connection [7]

3.3V

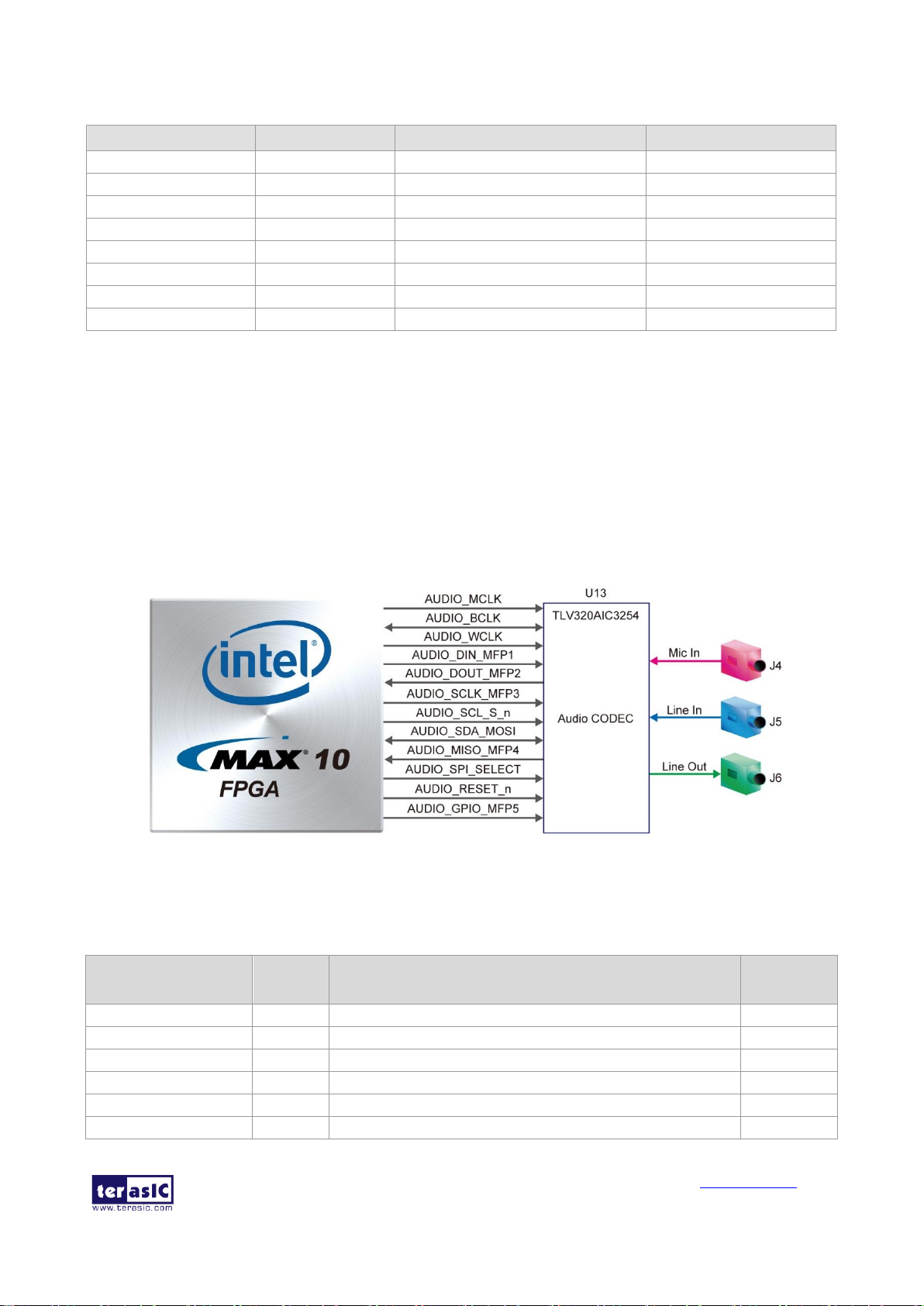

3.4.5 24-bit Audio CODEC

The MAX 10 Plus offers high-quality 24-bit audio via the Texas Instruments TLV320AIC3254

audio CODEC (Encoder/Decoder). This chip on MAX 10 Plus supports, line-in, line-out and

microphone-in ports with adjustable sample rate from 8KHz to 192KHz. The connection of the

audio circuitry to the FPGA is shown in Figure 3-18, and the associated pin assignment to the

FPGA is listed in Table 3-9. More information about the TLV320AIC3254 CODEC is available in

its datasheet, which can be found on the manufacturer’s website, or in the directory

\Datasheet\Audio CODEC of MAX 10 Plus System CD.

Figure 3-18 Connections between the FPGA and Audio CODEC

Table 3-9 Pin Assignment of Audio CODEC

Signal Name

FPGA

Pin No.

Description

I/O

Standard

AUDIO_MCLK

PIN_J11

Master output Clock

2.5V

AUDIO_BCLK

PIN_J12

Audio serial data bus (primary) bit clock

2.5V

AUDIO_WCLK

PIN_H12

Audio serial data bus (primary) word clock

2.5V

AUDIO_DIN_MFP1

PIN_J13

Audio serial data bus data output/digital microphone output

2.5V

AUDIO_DOUT_MFP2

PIN_H13

Audio serial data bus data input/general purpose input

2.5V

AUDIO_SCLK_MFP3

PIN_H14

SPI serial Clock/headphone-detect output

2.5V

Page 23

MAX 10 Plus User

Manual

23

www.terasic.com

May 31, 2019

AUDIO_SCL_SS_n

PIN_F15

I2C Clock/SPI interface mode chip-select signal

2.5V

AUDIO_SDA_MOSI

PIN_F16

I2C Data/SPI interface mode serial data output

2.5V

AUDIO_MISO_MFP4

PIN_E13

Serial data input/General purpose input

2.5V

AUDIO_SPI_SELECT

PIN_E14

Control mode select pin

2.5V

AUDIO_RESET_n

PIN_D13

Reset signal

2.5V

AUDIO_GPIO_MFP5

PIN_D14

General Purpose digital IO/CLKOUT input

2.5V

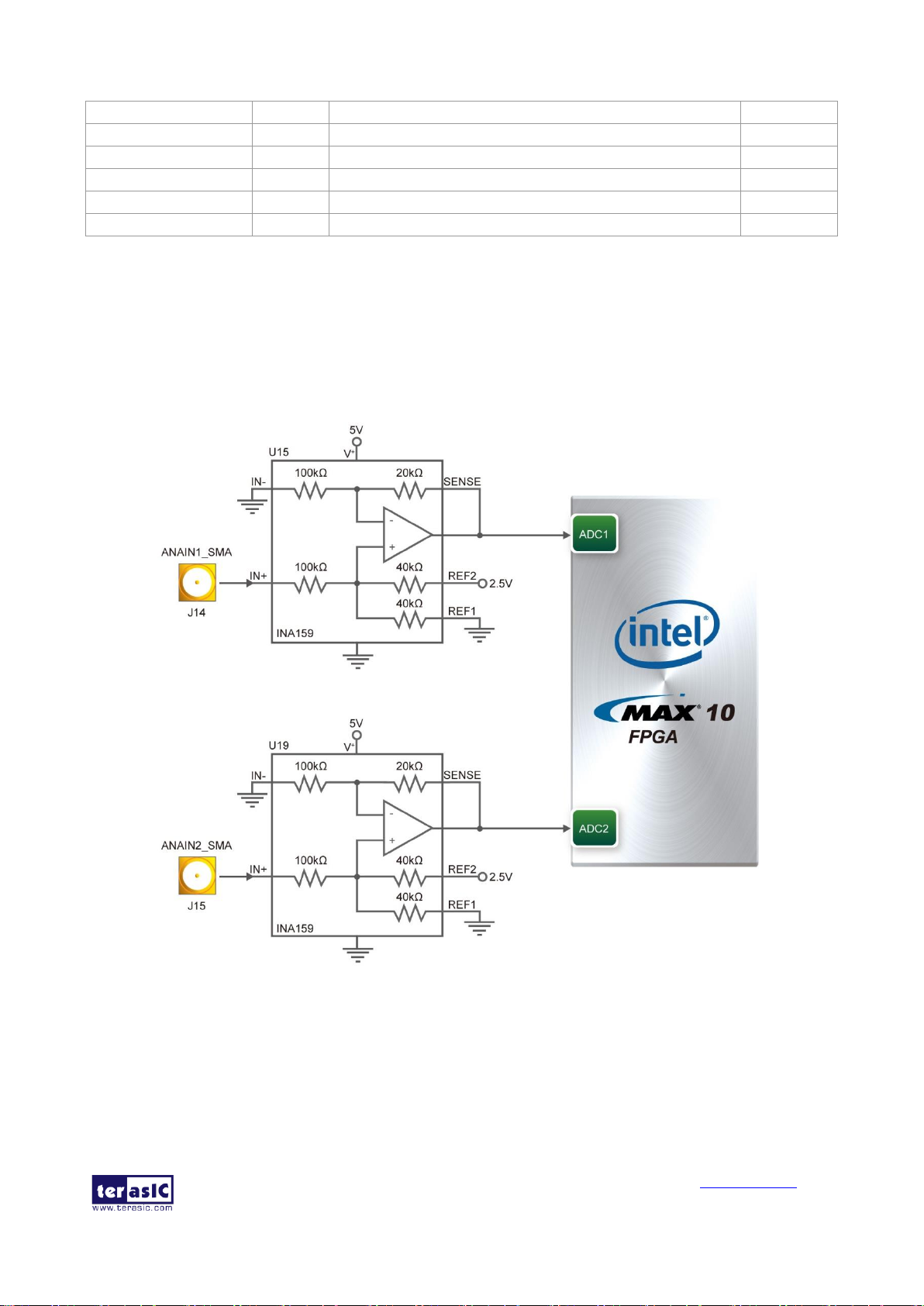

3.4.6 Two Analog Input SMA Connectors

The MAX 10 Plus implements two analog input SMA connectors. The analog inputs are amplified

and translated by Texas Instruments INA159 gain of 0.2 level translation difference amplifier, then

the amplifier’s outputs are fed to dedicated single-ended analog input pins for MAX 10 build-in

ADC1 and ADC2 respectively. With the amplifiers, the analog input of two SMAs support from

-6.25V to +6.25V range. Figure 3-19 shows the connection of SMA connectors to the FPGA.

Figure 3-19 Connection of SMA Connectors to the FPGA

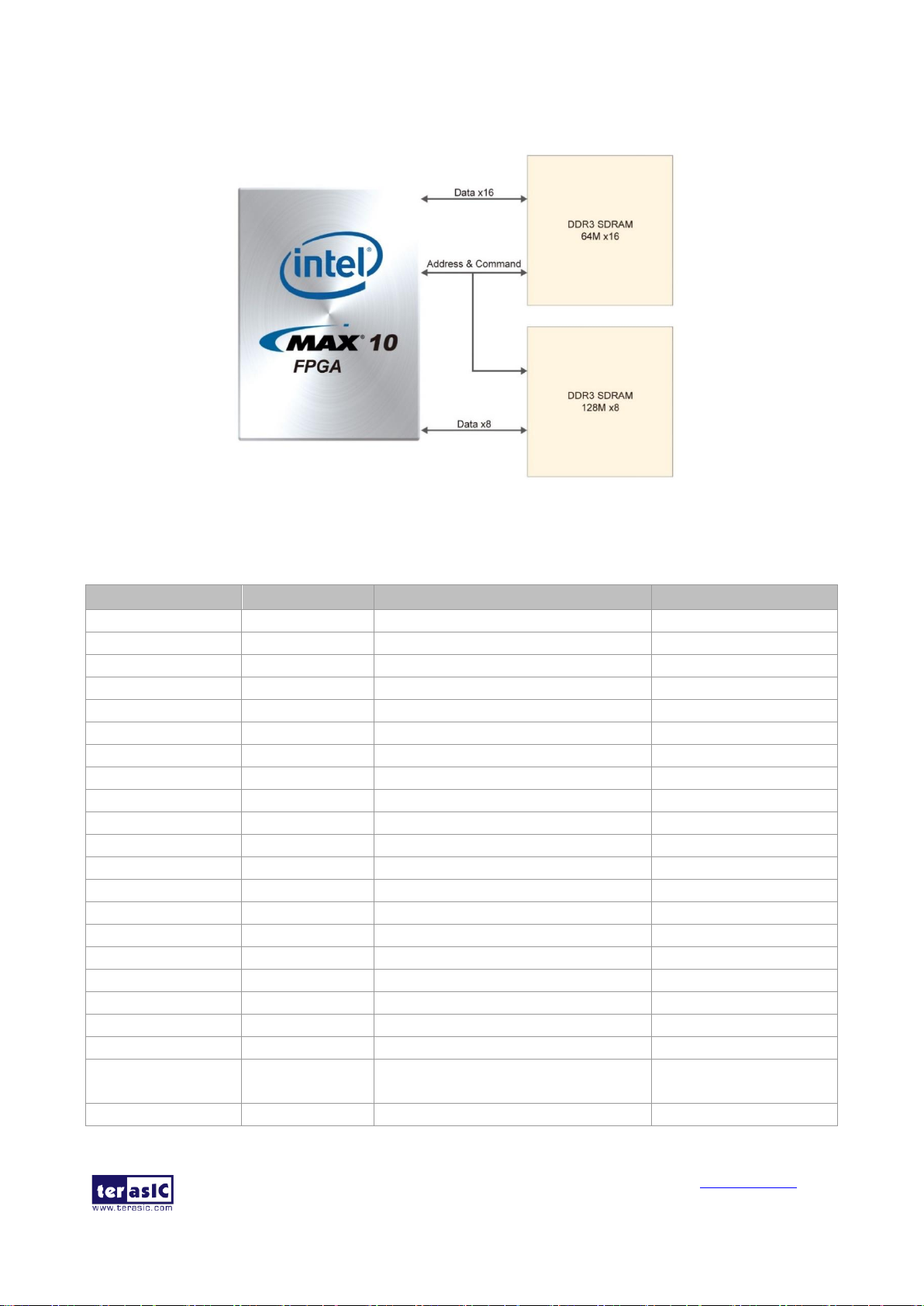

3.4.7 DDR3 Memory

The board supports 256MB of DDR3 SDRAM comprising of one 16bit (64Mx16) DDR3 device

and one 8bit (128Mx8) device. The DDR3 devices shipped with this board are running at 300MHz

with the soft IP of MAX 10 external memory interface solution. Figure 3-20 shows the connections

Page 24

MAX 10 Plus User

Manual

24

www.terasic.com

May 31, 2019

between the DDR3 and MAX 10 FPGA. Table 3-10 shows the DDR3 interface pin assignments.

Figure 3-20 Connections between the DDR3 and FPGA

Table 3-10 Pin Assignment of FPGA DDR3 Memory

Signal Name

FPGA Pin No.

Description

I/O Standard

DDR3_A[0]

PIN_U20

DDR3 Address[0]

SSTL-15 Class I

DDR3_A[1]

PIN_F19

DDR3 Address[1]

SSTL-15 Class I

DDR3_A[2]

PIN_V20

DDR3 Address[2]

SSTL-15 Class I

DDR3_A[3]

PIN_G20

DDR3 Address[3]

SSTL-15 Class I

DDR3_A[4]

PIN_F20

DDR3 Address[4]

SSTL-15 Class I

DDR3_A[5]

PIN_E20

DDR3 Address[5]

SSTL-15 Class I

DDR3_A[6]

PIN_E21

DDR3 Address[6]

SSTL-15 Class I

DDR3_A[7]

PIN_Y20

DDR3 Address[7]

SSTL-15 Class I

DDR3_A[8]

PIN_C22

DDR3 Address[8]

SSTL-15 Class I

DDR3_A[9]

PIN_D22

DDR3 Address[9]

SSTL-15 Class I

DDR3_A[10]

PIN_J14

DDR3 Address[10]

SSTL-15 Class I

DDR3_A[11]

PIN_E22

DDR3 Address[11]

SSTL-15 Class I

DDR3_A[12]

PIN_G22

DDR3 Address[12]

SSTL-15 Class I

DDR3_A[13]

PIN_D19

DDR3 Address[13]

SSTL-15 Class I

DDR3_A[14]

PIN_C20

DDR3 Address[14]

SSTL-15 Class I

DDR3_BA[0]

PIN_W22

DDR3 Bank Address[0]

SSTL-15 Class I

DDR3_BA[1]

PIN_Y21

DDR3 Bank Address[1]

SSTL-15 Class I

DDR3_BA[2]

PIN_Y22

DDR3 Bank Address[2]

SSTL-15 Class I

DDR3_CAS_n

PIN_U19

DDR3 Column Address Strobe

SSTL-15 Class I

DDR3_CKE

PIN_V18

Clock Enable pin for DDR3

SSTL-15 Class I

DDR3_CLK_n

PIN_E18

Clock n for DDR3

DIFFERENTIAL 1.5-V

SSTL Class I

DDR3_CLK_p

PIN_D18

Clock p for DDR3

Differential 1.5-V SSTL

Page 25

MAX 10 Plus User

Manual

25

www.terasic.com

May 31, 2019

Class I

DDR3_CS_n

PIN_W20

DDR3 Chip Select

SSTL-15 Class I

DDR3_DM[0]

PIN_J15

DDR3 Data Mask[0]

SSTL-15 Class I

DDR3_DM[1]

PIN_N19

DDR3 Data Mask[1]

SSTL-15 Class I

DDR3_DQ[0]

PIN_J18

DDR3 Data[0]

SSTL-15 Class I

DDR3_DQ[1]

PIN_H19

DDR3 Data[1]

SSTL-15 Class I

DDR3_DQ[2]

PIN_K20

DDR3 Data[2]

SSTL-15 Class I

DDR3_DQ[3]

PIN_H18

DDR3 Data[3]

SSTL-15 Class I

DDR3_DQ[4]

PIN_K18

DDR3 Data[4]

SSTL-15 Class I

DDR3_DQ[5]

PIN_H20

DDR3 Data[5]

SSTL-15 Class I

DDR3_DQ[6]

PIN_K19

DDR3 Data[6]

SSTL-15 Class I

DDR3_DQ[7]

PIN_J20

DDR3 Data[7]

SSTL-15 Class I

DDR3_DQ[8]

PIN_L18

DDR3 Data[8]

SSTL-15 Class I

DDR3_DQ[9]

PIN_M18

DDR3 Data[9]

SSTL-15 Class I

DDR3_DQ[10]

PIN_M14

DDR3 Data[10]

SSTL-15 Class I

DDR3_DQ[11]

PIN_N20

DDR3 Data[11]

SSTL-15 Class I

DDR3_DQ[12]

PIN_L20

DDR3 Data[12]

SSTL-15 Class I

DDR3_DQ[13]

PIN_M20

DDR3 Data[13]

SSTL-15 Class I

DDR3_DQ[14]

PIN_M15

DDR3 Data[14]

SSTL-15 Class I

DDR3_DQ[15]

PIN_L19

DDR3 Data[15]

SSTL-15 Class I

DDR3_DQ[16]

PIN_T19

DDR3 Data[15]

SSTL-15 Class I

DDR3_DQ[17]

PIN_R20

DDR3 Data[15]

SSTL-15 Class I

DDR3_DQ[18]

PIN_R15

DDR3 Data[15]

SSTL-15 Class I

DDR3_DQ[19]

PIN_P15

DDR3 Data[15]

SSTL-15 Class I

DDR3_DQ[20]

PIN_P19

DDR3 Data[15]

SSTL-15 Class I

DDR3_DQ[21]

PIN_P14

DDR3 Data[15]

SSTL-15 Class I

DDR3_DQ[22]

PIN_R14

DDR3 Data[15]

SSTL-15 Class I

DDR3_DQ[23]

PIN_P20

DDR3 Data[15]

SSTL-15 Class I

DDR3_DQS_n[0]

PIN_K15

DDR3 Data Strobe n[0]

Differential 1.5-V SSTL

Class I

DDR3_DQS_n[1]

PIN_L15

DDR3 Data Strobe n[1]

Differential 1.5-V SSTL

Class I

DDR3_DQS_p[0]

PIN_K14

DDR3 Data Strobe p[0]

Differential 1.5-V SSTL

Class I

DDR3_DQS_p[1]

PIN_L14

DDR3 Data Strobe p[1]

Differential 1.5-V SSTL

Class I

DDR3_ODT

PIN_V22

DDR3 On-die Termination

SSTL-15 Class I

DDR3_RAS_n

PIN_N18

DDR3 Row Address Strobe

SSTL-15 Class I

DDR3_RESET_n

PIN_B22

DDR3 Reset

SSTL-15 Class I

DDR3_WE_n

PIN_W19

DDR3 Write Enable

SSTL-15 Class I

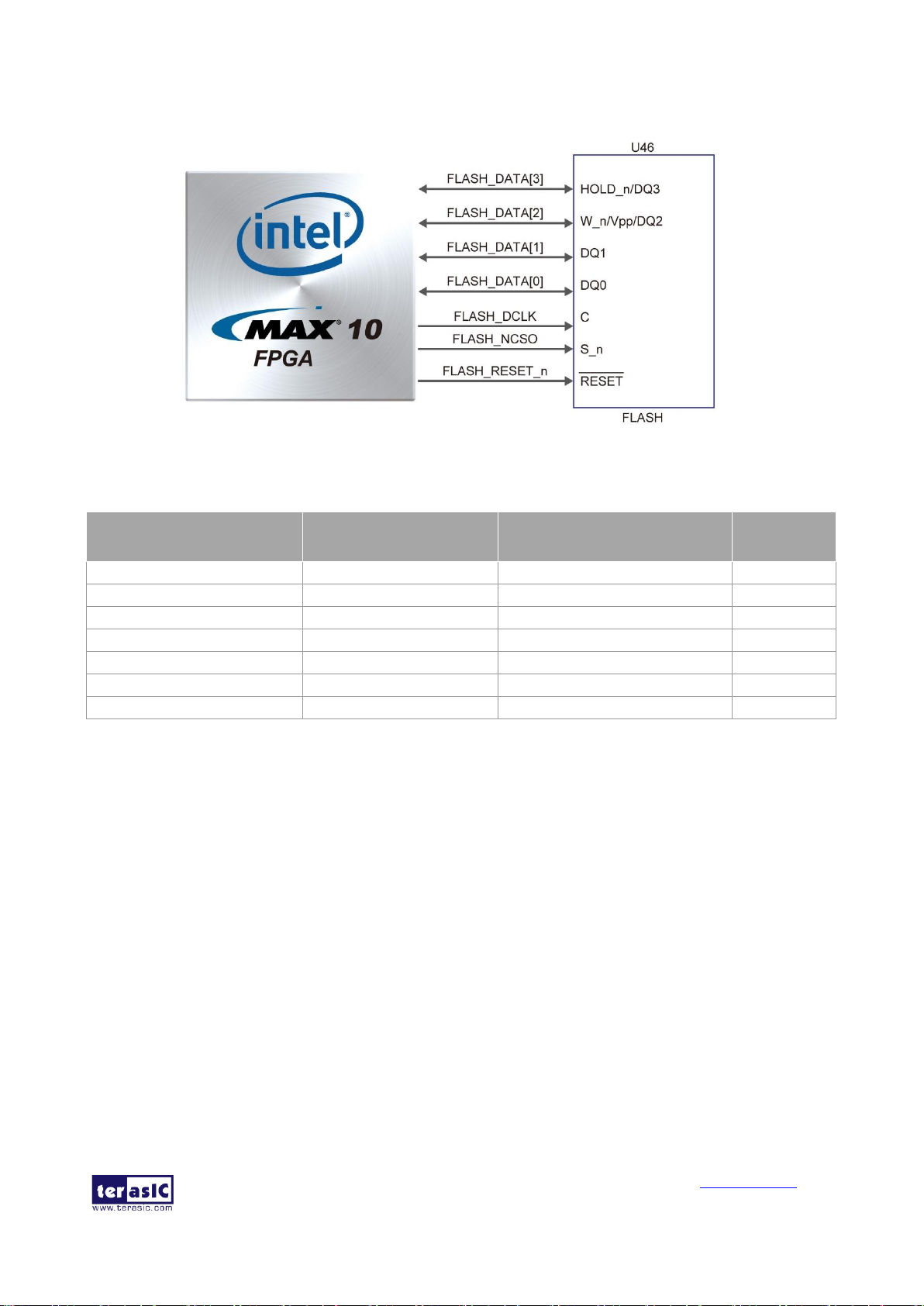

3.4.8 QSPI Flash

The MAX 10 Plus supports a 512M-bit serial NOR flash device for non-volatile storage, user data

and program. This device has a 4-bit data interface and uses 3.3V CMOS signaling standard.

Connections between MAX 10 FPGA and Flash are shown in Figure 3-21. Table 3-11 shows the

Page 26

MAX 10 Plus User

Manual

26

www.terasic.com

May 31, 2019

DDR3 interface pin assignments.

Figure 3-21 Connections between MAX 10 FPGA and QSPI Flash

Table 3-11 Pin Assignment of QSPI Flash

Signal Name

FPGA Pin No.

Description

I/O

Standard

FLASH_DATA[0]

PIN_AB18

FLASH Data[0]

3.3V

FLASH_DATA[1]

PIN_AA19

FLASH Data[1]

3.3V

FLASH_DATA[2]

PIN_AB19

FLASH Data[2]

3.3V

FLASH_DATA[3]

PIN_AA20

FLASH Data[3]

3.3V

FLASH_DCLK

PIN_AB17

FLASH Data Clock

3.3V

FLASH_NCSO

PIN_AB21

FLASH Chip Enable

3.3V

FLASH_RESET_n

PIN_AB20

FLASH Chip Reser

3.3V

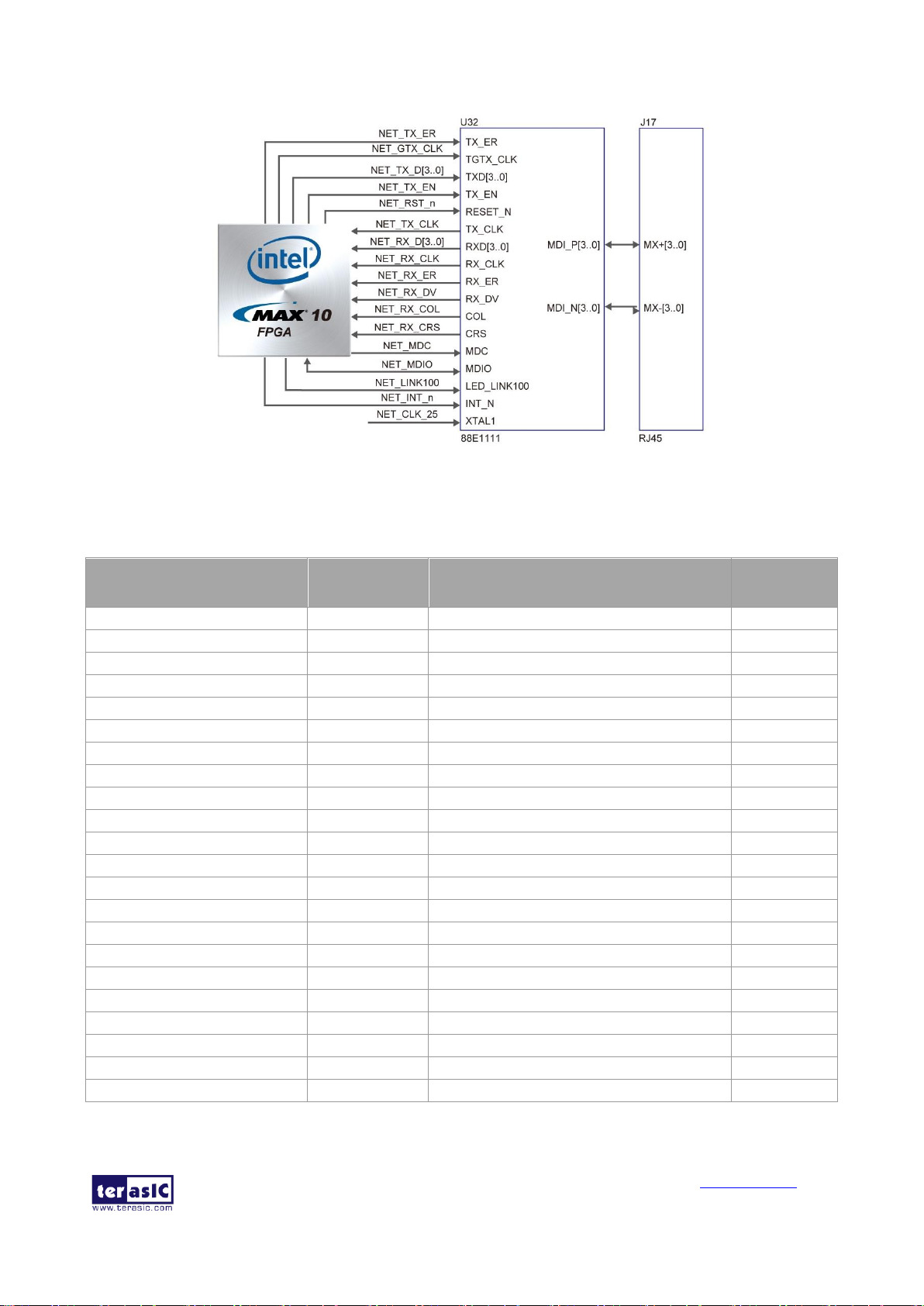

3.4.9 Ethernet

The board supports Gigabit Ethernet transfer by an external Marvell 88E1111 PHY chip. The

88E1111 chip with integrated 10/100/1000 Mbps Gigabit Ethernet transceiver support

GMII/MII/RGMII/TBI MAC interfaces. Figure 3-22 shows the connections between the MAX 10

FPGA, Ethernet PHY, and RJ-45 connector. The pin assignment associated to Gigabit Ethernet

interface is listed in Table 3-12.

Page 27

MAX 10 Plus User

Manual

27

www.terasic.com

May 31, 2019

Figure 3-22 Connections between the MAX 10 FPGA and Gigabit Ethernet

Table 3-12 Pin Assignment of Ethernet PHY

Signal Name

FPGA Pin No.

Description

I/O

Standard

NET_TX_EN

PIN_C10

GMII and MII transmit enable

2.5V

NET_TX_ER

PIN_C12

GMII and MII transmit error

2.5V

NET_TX_CLK

PIN_E11

MII transmit clock

3.3V

NET_TX_D[0]

PIN_A12

MII transmit data[0]

2.5V

NET_TX_D[1]

PIN_B12

MII transmit data[1]

2.5V

NET_TX_D[2]

PIN_A13

MII transmit data[2]

2.5V

NET_TX_D[3]

PIN_A14

MII transmit data[3]

2.5V

NET_RX_DV

PIN_A8

GMII and MII receive data valid

2.5V

NET_RX_ER

PIN_B8

GMII and MII receive data valid

2.5V

NET_RX_D[0]

PIN_A10

GMII and MII receive data[0]

2.5V

NET_RX_D[1]

PIN_B10

GMII and MII receive data[1]

2.5V

NET_RX_D[2]

PIN_A11

GMII and MII receive data[2]

2.5V

NET_RX_D[3]

PIN_B11

GMII and MII receive data[3]

2.5V

NET_RX_CLK

PIN_J10

GMII and MII receive clock

3.3V

NET_RST_n

PIN_C14

Hardware Reset Signal

2.5V

NET_MDIO

PIN_E12

Management Data

2.5V

NET_MDC

PIN_D12

Management Data Clock Reference

2.5V

NET_RX_COL

PIN_C9

GMII and MII collision

2.5V

NET_RX_CRS

PIN_A9

GMII and MII carrier sense

2.5V

NET_GTX_CLK

PIN_C11

GMII Transmit Clock

2.5

NET_LINK100

PIN_A7

Parallel LED output of 100BASE-TX link

2.5V

NET_INT_n

PIN_C13

Interrupt open drain output

2.5V

Page 28

MAX 10 Plus User

Manual

28

www.terasic.com

May 31, 2019

3.4.10 HDMI RX

The development board provides High Performance HDMI Receiver via the Analog Devices

ADV7611 which incorporates HDMI v1.4a features, including 3D video support, and 165MHz

supports all video formats up to 1080p and UXGA. The ADV7611 is controlled via a serial I2C bus

interface, which is connected to pins on the MAX 10 FPGA. A schematic diagram of the HDMI RX

circuitry is shown in Figure 3-23. Detailed information on using the ADV7611 HDMI RX is

available on the manufacturer’s website, or under the Datasheets\HDMI folder on the Kit System

CD.

Table 3-13 lists the HDMI Interface pin assignments and signal names relative to the MAX 10

device.

Figure 3-23 Connection between the MAX 10 FPGA and HDMI Receiver

Table 3-13 Pin Assignment of HDMI RX

Signal Name

FPGA Pin No.

Description

I/O Standard

HDMI_RX_D0

PIN_AA9

Video Pixel Output Port

3.3V

HDMI_RX_D1

PIN_AB9

Video Pixel Output Port

3.3V

HDMI_RX_D2

PIN_Y10

Video Pixel Output Port

3.3V

HDMI_RX_D3

PIN_AA10

Video Pixel Output Port

3.3V

HDMI_RX_D4

PIN_AB10

Video Pixel Output Port

3.3V

HDMI_RX_D5

PIN_Y11

Video Pixel Output Port

3.3V

HDMI_RX_D6

PIN_AA11

Video Pixel Output Port

3.3V

HDMI_RX_D7

PIN_AB11

Video Pixel Output Port

3.3V

HDMI_RX_D8

PIN_Y14

Video Pixel Output Port

3.3V

HDMI_RX_D9

PIN_AB15

Video Pixel Output Port

3.3V

HDMI_RX_D10

PIN_AA15

Video Pixel Output Port

3.3V

HDMI_RX_D11

PIN_W14

Video Pixel Output Port

3.3V

HDMI_RX_D12

PIN_V14

Video Pixel Output Port

3.3V

HDMI_RX_D13

PIN_V15

Video Pixel Output Port

3.3V

HDMI_RX_D14

PIN_U15

Video Pixel Output Port

3.3V

Page 29

MAX 10 Plus User

Manual

29

www.terasic.com

May 31, 2019

HDMI_RX_D15

PIN_AB14

Video Pixel Output Port

3.3V

HDMI_RX_D16

PIN_AA14

Video Pixel Output Port

3.3V

HDMI_RX_D17

PIN_AB13

Video Pixel Output Port

3.3V

HDMI_RX_D18

PIN_Y13

Video Pixel Output Port

3.3V

HDMI_RX_D19

PIN_AB12

Video Pixel Output Port

3.3V

HDMI_RX_D20

PIN_AA12

Video Pixel Output Port

3.3V

HDMI_RX_D21

PIN_W13

Video Pixel Output Port

3.3V

HDMI_RX_D22

PIN_W12

Video Pixel Output Port

3.3V

HDMI_RX_D23

PIN_V13

Video Pixel Output Port

3.3V

HDMI_RX_CLK

PIN_P11

Line-Locked Output Clock

3.3V

HDMI_RX_DE

PIN_W10

Data Enable Signal for Digital Video.

3.3V

HDMI_RX_HS

PIN_V12

Horizontal Synchronization

3.3V

HDMI_RX_VS

PIN_W11

Vertical Synchronization

3.3V

HDMI_RX_INT1

PIN_P12

Interrupt Signal

3.3V

HDMI_I2C_SCL

PIN_R13

I2C Clock

3.3V

HDMI_I2C_SDA

PIN_P13

I2C Data

3.3V

HDMI_MCLK

PIN_R12

Audio Master Output Clock

3.3V

HDMI_LRCLK

PIN_V11

Audio Left/Right Clock

3.3V

HDMI_SCLK

PIN_W8

Audio Serial Output Clock

3.3V

HDMI_AP

PIN_W9

Audio Output Pin

3.3V

HDMI_RX_RESET_n

PIN_AA13

System Reset Input

3.3V

3.4.11 2x10 ADC Header

The board has a 2x10 ADC header with sixteen analog inputs connected to FPGA ADC1 and ADC2

respectively. The 1x3 header J12 is used to select pin 18 of 2x10 header J7 or potentiometer input to

be connected to the channel 8 of FPGA ADC2. Short pin 1 and pin 2 of J12 to select potentiometer,

short pin 3 and pin 4 to select pin 18 of 2x10 header J7. The 1x3 header J13 is used to select pin 16

of 2x10 header J7 or on-board microphone to be connected to the channel 7 of FPGA ADC2. Short

pin 1 and pin 2 of J13 to select on-board microphone, short pin 3 and pin 4 to select pin 16 of 2x10

header J7. Figure 3-24 shows the connection of 2x10 ADC header and MAX 10 FPGA.

Page 30

MAX 10 Plus User

Manual

30

www.terasic.com

May 31, 2019

Figure 3-24 Connections between 2x10 ADC Header, Potentiometer, On-board Microphone

and MAX 10 FPGA

3.4.12 Potentiometer

Short pin 1 and pin 2 of J12 will select potentiometer for providing adjustable voltage to the

channel 8 of FPGA ADC2.

3.4.13 On-board Microphone

The board provides an on-board microphone for audio applications. Short pin 1 and pin 2 of J13 to

select on-board microphone to be connected to the channel 7 of FPGA ADC2. The output audio

signal from on-board microphone will be pre-amplified by audio operational amplifier OPA1612,

then fed into the FPGA ADC. Figure 3-24 shows the connection of on-board microphone and MAX

10 FPGA.

3.4.14 PS/2 Serial Port

The MAX 10 Plus comes with a standard PS/2 interface and a connector for a PS/2 keyboard or

mouse. Figure 3-25 shows the connection of PS/2 circuit to the FPGA. Users can use the PS/2

keyboard and mouse on the MAX 10 Plus simultaneously by a PS/2 Y-Cable, as shown in Figure

3-26. Instructions on how to use PS/2 mouse and/or keyboard can be found on various educational

websites. The pin assignment associated to this interface is shown in Table 3-14.

Note: If users connect only one PS/2 equipment, the PS/2 signals connected to the FPGA I/O

should be “PS2_CLK” and “PS2_DAT”.

Page 31

MAX 10 Plus User

Manual

31

www.terasic.com

May 31, 2019

Figure 3-25 Connections between the MAX 10 FPGA and PS/2

Figure 3-26 Y-Cable for Using Keyboard and Mouse Simultaneously

Table 3-14 Pin Assignment of PS/2

Signal Name

FPGA Pin No.

Description

I/O

Standard

PS2_CLK

PIN_V3

PS/2 Clock

3.3V

PS2_DAT

PIN_P3

PS/2 Data

3.3V

PS2_CLK2

PIN_U1

PS/2 Clock (reserved for second PS/2 device)

3.3V

PS2_DAT2

PIN_R3

PS/2 Data (reserved for second PS/2 device)

3.3V

3.4.15 Digital-to-Analog Converter (DAC)

The board provides a Texas Instruments DAC8551 16-bit digital-to-analog converter (DAC). It is a

small, low power, voltage output DAC. The DAC8551 used a versatile 3-wire serial interface that

operates at clock rates to 30MHz and is compatible with standard SPI, QSPI, Microwire and DSP

interfaces. The analog voltage output of DAC8551 is connected to a SMA connector. Figure 3-27

shows the connection between DAC and MAX 10 FPGA. The pin assignment associated to this

DAC is shown in Table 3-15.

Page 32

MAX 10 Plus User

Manual

32

www.terasic.com

May 31, 2019

Figure 3-27 Connection between DAC and MAX 10 FPGA

Table 3-15 Pin Assignment of DAC

Signal Name

FPGA Pin No.

Description

I/O Standard

DAC_SYNC_n

PIN_B2

Frame Sync Signal for Input Data

3.3V

DAC_SCLK

PIN_B1

Serial Clock Input

3.3V

DAC_DATA

PIN_A2

Serial Data Input

3.3V

3.4.16 UART to USB

The board has one UART interface connected for communication with the MAX 10 FPGA. This

interface doesn’t support HW flow control signals. The physical interface is implemented by

UART-USB onboard bridge from a FT232R chip to the host with an USB Mini-B connector. More

information about the chip is available on the manufacturer’s website, or in the directory

\Datasheets\UART TO USB of MAX 10 Plus system CD. Figure 3-28 shows the connections

between the MAX 10 FPGA, FT232R chip, and the USB Mini-B connector. Table 3-16 lists the pin

assignment of UART interface connected to the MAX 10 FPGA.

Figure 3-28 Connections between the HPS and FT232R Chip

Page 33

MAX 10 Plus User

Manual

33

www.terasic.com

May 31, 2019

Table 3-16 Pin Assignment of UART Interface

Signal Name

FPGA Pin No.

Description

I/O Standard

UART_RX

PIN_E16

FPGA UART Receiver

2.5V

UART_TX

PIN_E15

FPGA UART Transmitter

2.5V

UART_RESET_n

PIN_D15

Reset Signal for UART Device

2.5V

3.4.17 Ambient Light Sensor

The MAX 10 Plus has a Light-to-Digital Ambient Light Sensor (APDS-9301) that converts light

intensity to digital signal output capable of I2C interface. with I2C digital interface and

programmable-event interrupt output. The digital output of APDS-9301 will be input to the MAX

10 FPGA where illuminance I lux is derived using an empirical formula to approximate the

human-eye response. Figure 3-29 shows the connection of APDS-9301 to the MAX 10 FPGA.

Table 3-17 lists the Ambient Light Sensor pin assignments.

Figure 3-29 The Connections between the MAX 10 FPGA and Ambient Light Sensor

Table 3-17 Pin Assignment of Ambient Light Sensor

Signal Name

FPGA Pin No.

Description

I/O Standard

LSENSOR_SCL

PIN_M1

I2C Serial Clock

3.3V

LSENSOR_SDA

PIN_T3

I2C Serial Data

3.3V

LSENSOR_INT

PIN_M2

Interrupt signal from Sensor

3.3V

3.4.18 Humidity and Temperature Sensor

The MAX 10 Plus has a humidity and temperature sensor (HDC1000) that provides excellent

measurement accuracy at very low power. The HDC1000 sensor is placed at board edge and away

from the heat source of MAX 10 Plus so that user can make ambient temperature measurement

without heat interference from the heat source of MAX 10 Plus. Figure 3-30 shows the connection

of humidity and temperature sensor to MAX 10 FPGA. Table 3-18 lists the humidity and

temperature sensor pin assignments.

Page 34

MAX 10 Plus User

Manual

34

www.terasic.com

May 31, 2019

Figure 3-30 The Connections between the MAX 10 FPGA and Humidity and Temperature

Sensor

Table 3-18 Pin Assignment of Humidity and Temperature Sensor

Signal Name

FPGA Pin No.

Description

I/O Standard

RH_TEMP_I2C_SCL

PIN_Y18

I2C Clock for HDC1000 Sensor

3.3V

RH_TEMP_I2C_SDA

PIN_W18

I2C Data for HDC1000 Sensor

3.3V

RH_TEMP_DRDY_n

PIN_Y19

Data ready input from HDC1000 Sensor

3.3V

3.4.19 Accelerometer Sensor

The board comes with a digital accelerometer sensor module (ADXL345), commonly known as

G-sensor. This G-sensor is a small, thin, ultralow power assumption 3-axis accelerometer with

high-resolution measurement. Digitalized output is formatted as 16-bit in two’s complement and

can be accessed through I2C interface. The I2C address of accelerometer is 0xA6/0xA7. More

information about this chip can be found in its datasheet, which is available on manufacturer’s

website or in the directory \Datasheet folder of MAX 10 Plus system CD. Figure 3-31 shows the

connections between the MAX 10 FPGA and accelerometer. Table 3-19 lists the pin assignment of

accelerometer to the MAX 10 FPGA.

Figure 3-31 The Connections between the MAX 10 FPGA and Accelerometer Sensor

Page 35

MAX 10 Plus User

Manual

35

www.terasic.com

May 31, 2019

Table 3-19 Pin Assignment of Accelerometer Sensor

Signal Name

FPGA Pin No.

Description

I/O

Standard

GSENSOR_SDI

PIN_C15

I2C serial data/SPI serial data input/3-wire

interface serial dta output

2.5V

GSENSOR_SDO

PIN_B16

SPI serial data output/I2C less significant bit

of the device address

2.5V

GSENSOR_CS_n

PIN_C16

SPI enable, I2C/SPI mode selection: 1: SPI

idle mode/I2C communication enabled, 0:

SPI communication mode/I2C disabled

2.5V

GSENSOR_SCLK

PIN_A15

I2C serial clock/SPI serial port clock

2.5V

GSENSOR_INT1

PIN_B15

Interrupt pin 1

2.5V

GSENSOR_INT2

PIN_D17

Interrupt pin 2

2.5V

3.4.20 Micro SD Card Socket

The board supports Micro SD card interface with x4 data lines. It serves not only an external

storage for the HPS, but also an alternative boot option for MAX 10 Plus. Figure 3-32 shows

signals connected between the HPS and Micro SD card socket.

Table 3-20 lists the pin assignment of Micro SD card socket to the MAX 10 FPGA.

Figure 3-32 Connections between the MAX 10 FPGA and SD Card Socket

Table 3-20 Pin Assignment of Micro SD Card Socket

Signal Name

FPGA Pin No.

Description

I/O Standard

SD_CLK

PIN_A16

SD Clock

2.5V

SD_CMD

PIN_C18

SD Command Line

2.5V

SD_DATA[0]

PIN_A17

SD Data[0]

2.5V

SD_DATA[1]

PIN_A18

SD Data[1]

2.5V

SD_DATA[2]

PIN_B17

SD Data[2]

2.5V

SD_DATA[3]

PIN_C17

SD Data[3]

2.5V

3.4.21 Power Distribution System

The MAX 10 Plus is powered by Linear Technology’s power solution which provides

Page 36

MAX 10 Plus User

Manual

36

www.terasic.com

May 31, 2019

high-efficiency power management for FPGAs and SoCs. Figure 3-33 shows the power tree of

MAX 10 Plus. Note that the LCD interface are reserved.

Figure 3-33 Power Tree of MAX 10 Plus

Page 37

MAX 10 Plus User

Manual

37

www.terasic.com

May 31, 2019

Chapter 4

The MAX 10 Plus System Builder

This chapter introduces the MAX 10 Plus System Builder to help users get started in creating their

own projects in literally minutes. It also describes the design flow and includes an example for users

to get familiar with the tool.

4.1 Introduction

The MAX 10 Plus System Builder is a Windows-based utility. It is created to help users build a top

project for MAX 10 Plus within minutes. The generated Quartus II project files include:

• Quartus II project file (.qpf)

• Quartus II setting file (.qsf)

• Top-level design file (.v)

• Synopsis design constraints file (.sdc)

• Pin assignment document (.htm)

The above files generated by the MAX 10 Plus System Builder can also prevent situations that are

prone to compilation error when users manually edit the top-level design file or place pin

assignment. The common mistakes that users encounter are:

• Board is damaged due to incorrect bank voltage setting or pin assignment.

• Board is malfunctioned because of wrong device chosen, declaration of pin location, or the

direction is incorrect/forgotten.

• Performance degradation due to improper pin assignment.

4.2 General Design Flow

The design flow of building a Quartus II project for MAX 10 Plus using the MAX 10 Plus System

Builder is illustrated in Figure 4-1. It gives users an overview about the steps, starting from

launching the System Builder to configuring the FPGA. The left-hand side of the chart can be done

within minutes. After users enter the design requirements, the MAX 10 Plus System Builder will

generate Quartus II project files, Quartus II setting file, top-level design file, Synopsis design

constraint file, and the pin assignment document.

The top-level design file contains a top-level Verilog HDL wrapper for users to add their own

design/logic. The Quartus II setting file contains information such as FPGA device type, top-level

pin assignment, and the I/O standard for each user-defined I/O pin. These files can be modified

according to the project requirements. After the compilation is successful, users can download

the .sof file to the development board via JTAG interface using the Quartus II programmer.

Page 38

MAX 10 Plus User

Manual

38

www.terasic.com

May 31, 2019

Figure 4-1 Design Flow of Building a Project from the beginning to the end

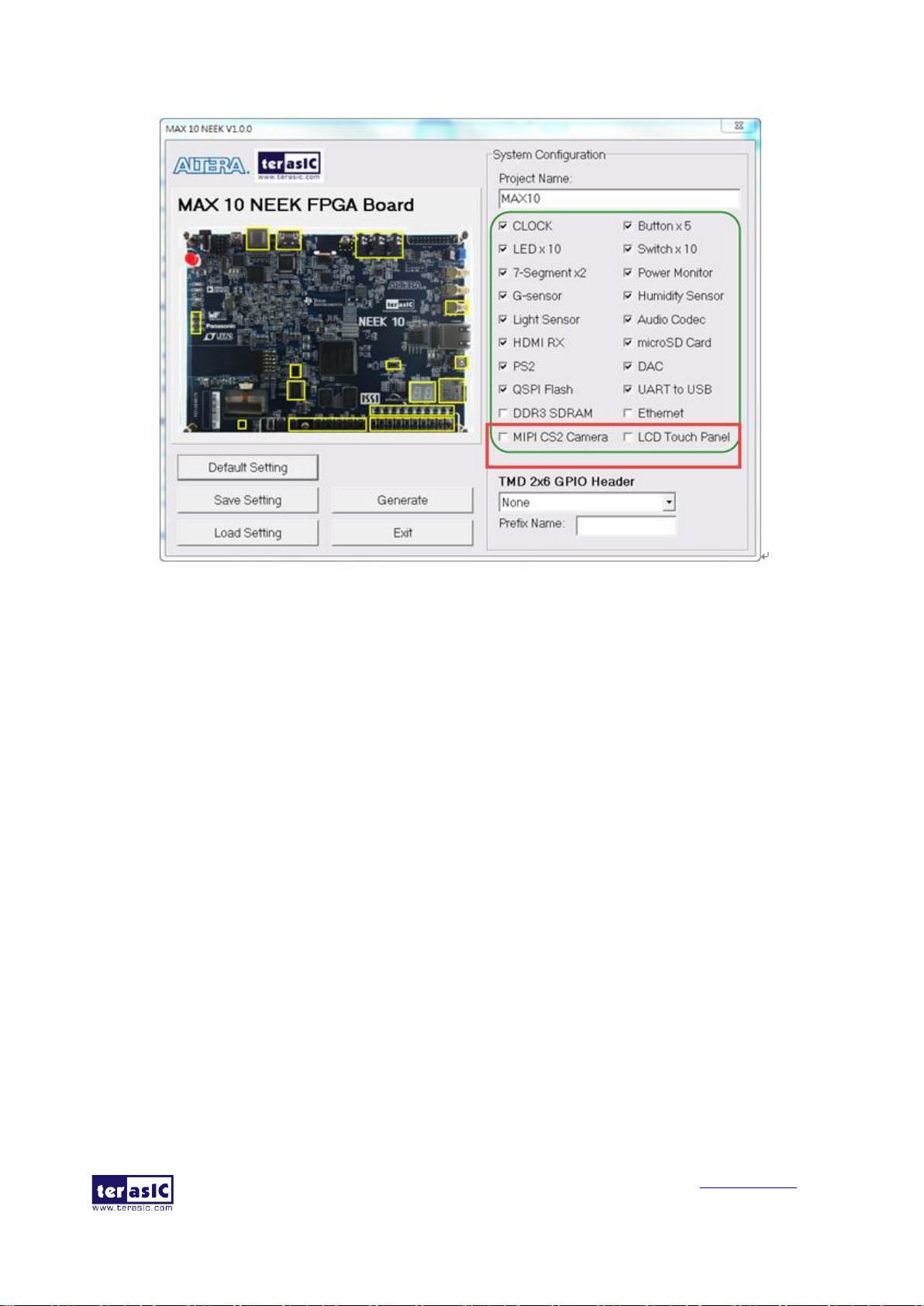

4.3 Using MAX 10 Plus System Builder

This section provides the procedures in details on how to use the MAX 10 Plus System Builder.

◼ Install and Launch the MAX 10 Plus System Builder

The MAX 10 Plus System Builder is located in the directory Tools\SystemBuilder of the MAX 10

Plus System CD. Users can copy the entire folder to a host PC without installing the utility. After

the execution of the MAX 10 Plus SystemBuilder.exe on the host PC, a window will pop up, as

shown in Figure 4-2.

Page 39

MAX 10 Plus User

Manual

39

www.terasic.com

May 31, 2019

Figure 4-2 The GUI of MAX 10 Plus System Builder

◼ Enter Project Name

The project name entered in the circled area, as shown in Figure 4-3, will be assigned automatically

as the name of the top-level design entity.

Page 40

MAX 10 Plus User

Manual

40

www.terasic.com

May 31, 2019

Figure 4-3 Enter the Project Name

◼ System Configuration

Users are given the flexibility in the System Configuration to include one or more onboard

peripherals in the project, as shown in Figure 4-4. If a component is enabled, the MAX 10 Plus

System Builder will automatically generate its associated pin assignment, including the pin name,

pin location, pin direction, and I/O standard.

Note: The MIPI CS2 Camera and LCD Touch Panel interfaces are reserved, users can choose to buy

MAX 10 NEEK instead if needed these two interfaces.

Page 41

MAX 10 Plus User

Manual

41

www.terasic.com

May 31, 2019

Figure 4-4 List of onboard Peripherals in System Configuration

◼ Project Settings

The MAX 10 Plus System Builder also provides the option to load a setting or save the current

board configuration in .cfg file, as shown in Figure 4-5.

Page 42

MAX 10 Plus User

Manual

42

www.terasic.com

May 31, 2019

Figure 4-5 Manage Project Settings

◼ Project Generation

When users press the Generate button, as shown in Figure 4-6, the MAX 10 Plus System Builder

will generate the corresponding Quartus II files and documents, as listed in Table 4-1.

Page 43

MAX 10 Plus User

Manual

43

www.terasic.com

May 31, 2019

Figure 4-6 Generate Quartus Project

Table 4-1 Files Generated by the MAX 10 Plus System Builder

No.

Filename

Description

1

<Project name>.v

Top-level Verilog HDL file for Quartus II

2

<Project name>.qpf

Quartus II project file

3

<Project name>.qsf

Quartus II setting file

4

<Project name>.sdc

Synopsis design constraints file for Quartus II

5

<Project name>.htm

Pin assignment document

Users can add custom logic into the project and compile the project in Quartus II to generate the

SRAM Object File (.sof).

Page 44

MAX 10 Plus User

Manual

44

www.terasic.com

May 31, 2019

Chapter 5

RTL Example Codes

This chapter provides examples of advanced designs implemented by RTL on the MAX 10 Plus

board. These reference designs cover the features of peripherals connected to the FPGA, such as

PS/2 mouse, ADC/DAC application. All the associated files can be found in the directory

\Demonstrations of System CD. Note: The output files generated after compilation in Quartus II

e.g. .sof and .pof files, are saved in the folder "output_files" under the directory of demo project.

5.1 PS/2 Mouse Demonstration

We offer this simple PS/2 controller coded in Verilog HDL to demonstrate bidirectional

communication between PS/2 controller and the device, the PS/2 mouse. You can treat it as a

how-to basis and develop your own controller that could accomplish more sophisticated instructions,

like setting the sampling rate or resolution, which need to transfer two data bytes.

More information about the PS/2 protocol can be found on various websites.

◼ Introduction

PS/2 protocol uses two wires for bi-directional communication. One is the clock line and the other

one is the data line. The PS/2 controller always has total control over the transmission line, but it is

the PS/2 device which generates the clock signal during data transmission.

◼ Data Transmission from Device to the Controller

After the PS/2 mouse receives an enabling signal at stream mode, it will start sending out

displacement data, which consists of 33bits. The frame data is cut into three sections and each of

them contains a start bit (always zero), eight data bits (with LSB first), one parity check bit (odd

check), and one stop bit (always one).

The PS/2 controller samples the data line at the falling edge of the PS/2 clock signal. This is

implemented by a shift register, which consists of 33bits, but please be cautious with the clock

domain crossing problem.

◼ Data Transmission from the Controller to Device

When the PS/2 controller wants to transmit data to device, it first pulls the clock line low for more

than one clock cycle to inhibit the current transmission process or to indicate the start of a new

transmission process, which is usually called as inhibit state. It then pulls low the data line before

releasing the clock line. This is called the request state. The rising edge on the clock line formed by

the release action can also be used to indicate the sample time point as for a start bit. The device

will detect this succession and generates a clock sequence in less than 10ms time. The transmit data

consists of 12bits, one start bit (as explained before), eight data bits, one parity check bit (odd

check), one stop bit (always one), and one acknowledge bit (always zero).

Page 45

MAX 10 Plus User

Manual

45

www.terasic.com

May 31, 2019

After sending out the parity check bit, the controller should release the data line, and the device will

detect any state change on the data line in the next clock cycle. If there’s no change on the data line

for one clock cycle, the device will pull low the data line again as an acknowledgement which

means that the data is correctly received.

After the power-on cycle of the PS/2 mouse, it enters into stream mode automatically and disable

data transmit unless an enabling instruction is received. Figure 5-1 shows the waveform while

communication happening on two lines.

Figure 5-1 Waveform of Clock and Data Signals during Data Transmission

◼ Design Tools

• Quartus II v15.0 64-bit

◼ Demonstration Source Code

• Project directory: ps2_mouse

• Bitstream used: ps2_mouse.sof

◼ Demonstration Batch File

• Demo batch file folder: Demonstrations\ps2_mouse\demo_batch

• Batch file: ps2_mouse.bat

• FPGA configuration file: ps2_mouse.sof

Page 46

MAX 10 Plus User

Manual

46

www.terasic.com

May 31, 2019

◼ Demonstration Setup

• Please make sure Quartus II and USB-Blaster II driver are installed on the host PC.

• Connect the USB cable from the USB-Blaster II port (J8) on the MAX 10 Plus board to the host

PC and power on the MAX 10 Plus board.

• Execute the demo batch file “ps2_mouse.bat” under the folder

Demonstrations\ps2_mouse\demo_batch\.

• Plug in the PS/2 mouse.

• Press KEY0 to enable data transfer.

• Press KEY1 to clear the display data cache.

• The 7-segment display shows X displacement when SW0 is low, and Y displacement when SW0

is high. The display should change when the PS/2 mouse moves.

• The LEDR [2:0] will blink according to Table 5-1 when the left-button, right-button, and/or

middle-button is pressed.

Table 5-1 Description of 7-segment Display and LED Indicators

Indicator Name

Description

LEDR0

Left button press indicator

LEDR1

Right button press indicator

LEDR2

Middle button press indicator

HEX0

Low byte of X/Y displacement

HEX1

High byte of X/Y displacement

5.2 ADC Potentiometer

Nowadays voltage and current monitors play a significant role in high-reliability system. Most of

applications can be implemented by an Analog-to-Digital Converter (ADC). MAX 10 Plus board

provides a potentiometer demonstration using the ADC in MAX10. This ADC solution consists of

hard IP blocks in MAX 10 device and soft logic through Intel Modular ADC IP core. Figure 5-2

shows the block diagram of ADC hard IP block in MAX10 device.

Figure 5-2 Block Diagram of ADC Hard IP Block

This demo uses 2nd ADC of MAX10 on channel 8. The ADC settings are shown in Figure 5-3.

Page 47

MAX 10 Plus User

Manual

47

www.terasic.com

May 31, 2019

Figure 5-3 Settings of ADC Hard IP

The MAX 10 Plus board has a Variable Resistor (VR) onboard, which acts as a potentiometer in this

demonstration. Figure 5-4 shows the block diagram of Power Monitor demonstration. The ADC

reference clock running at 10MHz is generated by PLL. It feeds into the ADC Hard IP in MAX10

device. The analog voltage input comes from the VR controls the voltage level. The control logic

within the ADC Hard IP reads the digitized voltage data. It then converts the data and displays the

level value on two 7-segments. Since none of the dot points of two 7-segments is connected to the

MAX 10, so HEX1 and HEX0 shows the decimal point and the first digit after the decimal point

respectively.

Figure 5-4 Block Diagram of ADC Potentiometer

◼ Design Tools

• Quartus II v15.0 64-bit

Page 48

MAX 10 Plus User

Manual

48

www.terasic.com

May 31, 2019

◼ Demonstration Source Code

• Project directory: Demonstrations\adc_potentionmeter

• Bitstream used: adc_potentionmeter.sof

◼ Demonstration Batch File

• Demo batch file folder: Demonstrations\adc_potentionmeter \demo_batch

• Batch file: test.bat

• FPGA configuration file: adc_potentionmeter.sof

◼ Demonstration Setup

• Please make sure Quartus II and USB-Blaster II driver are installed on the host PC.

• Connect the USB cable from the USB-Blaster II port (J8) on the MAX 10 Plus board to the host

PC.

• Power on the MAX 10 Plus board.

• Execute the demo batch file “test.bat” under the folder Demonstrations\ adc_potentionmeter

\demo_batch.

• Rotate the VR resistor POT1 with a screwdriver. HEX1 and HEX0 will display the voltage

value.

5.3 DAC Demonstration

This demonstration uses the 16-bit Digital to analog converter (DAC) built-in the MAX 10 device

to generate square wave in 8 difference frequencies. The signal coming out of the SMA connector

on MAX 10 Plus board is transmitted to the oscilloscope. The oscilloscope will display the square

wave in different frequencies by switching SW [2:0] on the MAX 10 Plus board.

◼ Function Block Diagram

Figure 5-5 is the function block diagram of this demonstration. The source data in parallel is

converted to serial data by the DAC16 module. The DAC chip (DAC8551) then converts the serial

data from digital to analog. The analog signal coming out of the DAC SMA connector is connected

to the oscilloscope and shown in square wave. Users can switch the SW0~2 to change the frequency

of the square wave.

Page 49

MAX 10 Plus User

Manual

49

www.terasic.com

May 31, 2019

Figure 5-5 Block Diagram of the DAC Demo

◼ Design Tools

• Quartus II v15.0 64-bit

◼ Demonstration Source Code

• Project directory: Demonstrations\ dac_sma

• Bitstream used: dac_sma.sof

◼ Demonstration Batch File

• Demo batch file folder: Demonstrations\ dac_sma\demo_batch

• Batch file: test.bat

• FPGA configuration file: dac_sma.sof

◼ Demonstration Setup

• Please make sure Quartus II and USB-Blaster II driver are installed on the host PC.

• Connect the USB cable from the USB-Blaster II port (J8) to the host PC.

• Plug in the 5V adapter to the MAX 10 Plus board and power it up.

• Execute the demo batch file “test.bat” from the directory \ dac_sma\demo_batch.

• Connect the probe of the oscilloscope to the DAC SMA OUT of the MAX 10 Plus board and

adjust the display until the square wave is visible, as Figure 5-6 and Figure 5-7.

• Switch SW [2:0] from 000 to 111 and the frequency of the square will be changing. The

square-wave frequency is twice higher. When SW [2:0]=000, the square wave frequency is

about 2.6KHz; When SW[2:0]=111, the frequency is about 112KHz.

Page 50

MAX 10 Plus User

Manual

50

www.terasic.com

May 31, 2019

Figure 5-6 Use the Oscilloscope to Observe the Square Wave

Figure 5-7 Probe DAC SMA OUT from the Oscilloscope

Page 51

MAX 10 Plus User

Manual

51

www.terasic.com

May 31, 2019

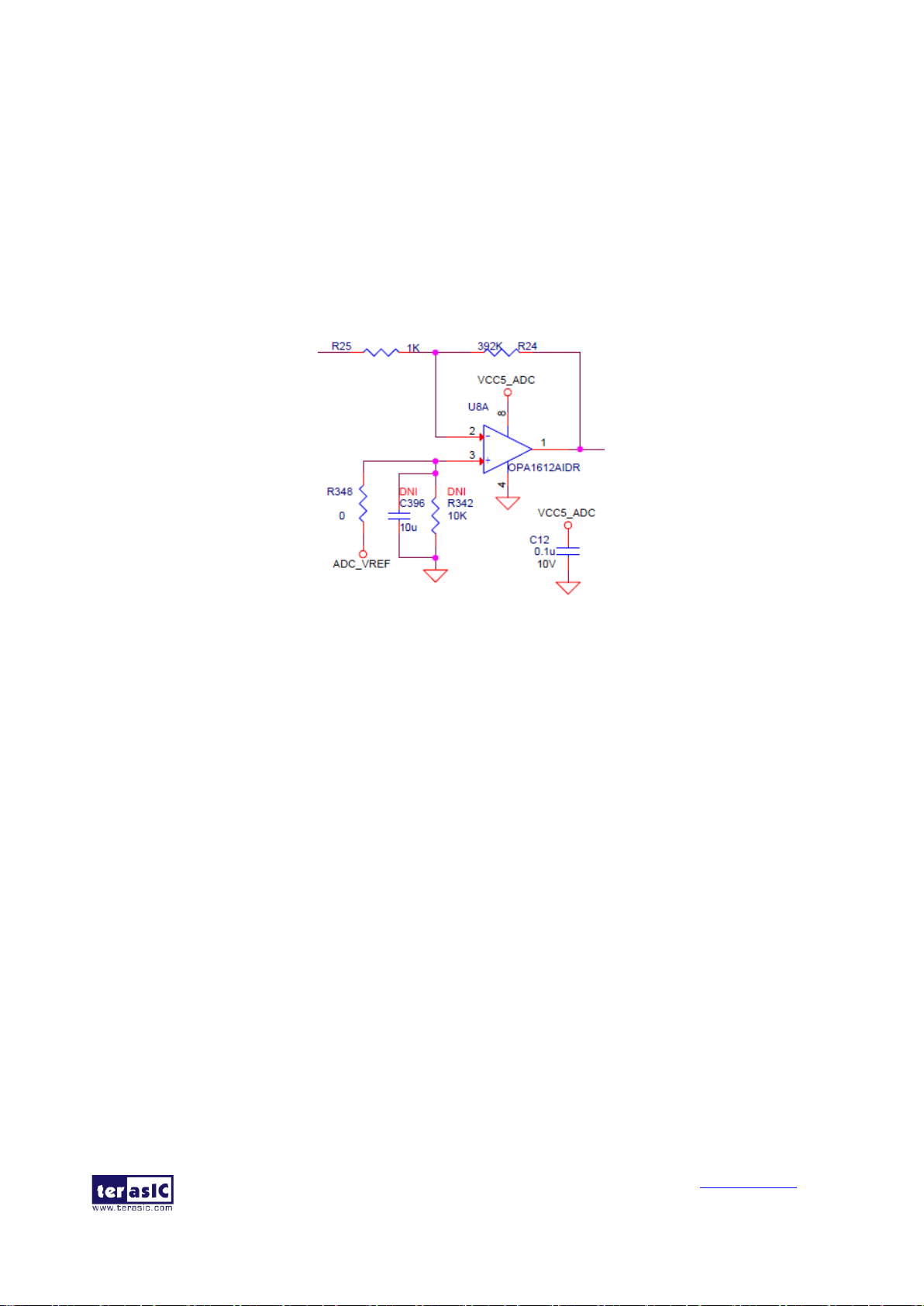

5.4 ADC/MIC/LED Demonstration

There is a high-sensitive microphone on the MAX 10 Plus board to receive the surrounding sound.

After the sound is collected and amplified approximately 392 times, as shown in Figure 5-8, it is

feed into the ADC of MAX 10 device. The digitized waveform will be displayed on the LED.

Meanwhile the signal will be sent to the Line-out via audio codec and DAC SMA OUT connector.

Both of which can be connected to an external speaker. The data will also be processed based on the

volume to be displayed on the 10 LEDs onboard.

Figure 5-8 Onboard Microphone Amplifier with Gain (R24/R25) = 392

◼ Function Block Diagram

Figure 5-9 is the function block diagram of this demonstration. The built-in MIC is amplified

approximately 392 times via two operational amplifiers. The signal is then feed into the ADC of

MAX 10 device for conversion. This demonstration uses the timing from the audio codec

((TLV320AIC3254) via I2S protocol to sync the entire system. The module SPI_CTL sets the

registers for the audio codec. The module SOUND_SUM syncs the digitized signal coming out of

the ADC of the MAX 10 device with the system and converts the data format i.e. adjust unsign

12-bit to sign 16-bit etc. The module DAC16 converts the digitized signal in parallel to 16-bit serial

format for the DAC chip (DAC8551) to the Line-out via audio codec (TLV320AIC3254). The

module LED_METER displays the volume of the sound on the 8 LEDs onboard.

Page 52

MAX 10 Plus User

Manual

52

www.terasic.com

May 31, 2019

Figure 5-9 Block Diagram of the ADC/MIC/LED Demonstration

◼ Design Tools

• Quartus II v15.0 64-bit

◼ Demonstration Source Code

• Project directory: Demonstrations\ adc_mic

• Bitstream used: adc_mic.sof

◼ Demonstration Batch File

• Demo batch file folder: Demonstrations\adc_mic\demo_batch

• Batch file: test.bat

• FPGA configuration file: adc_mic.sof

◼ Demonstration Setup

• Please make sure Quartus II and USB-Blaster II driver are installed on the host PC.

• Connect the USB cable from the USB-Blaster II port (J8) to the host PC.

• Plug in the 5V adapter to the MAX 10 Plus board and power it up.

• Execute the demo batch file “test.bat” from the directory \adc_mic \demo_batch.

• The sound wave from the MIC can be observed on the LED and probed through DAC SMA

OUT from the oscilloscope, or we can also connect external speaker to Line-out to hear the

sound, as Figure 5-10. The volume of the sound from the MIC is displayed digitally on

LEDR0~7, as Figure 5-11.

Page 53

MAX 10 Plus User

Manual

53

www.terasic.com

May 31, 2019

Figure 5-10 The Waveform of onboard MIC is Displayed on the Oscilloscope. Its Sound is

Played out from the Speaker

Figure 5-11 LEDR0~7 Displays the Volume Level of onboard MIC

Page 54

MAX 10 Plus User

Manual

54

www.terasic.com

May 31, 2019

Chapter 6

NIOS Based Example Codes

There are several NIOS based examples for users to get started and try them on the MAX 10 Plus

board. All the NIOS based examples can be found in the system CD under the folder named

Demonstrations. Users are free to use or modify these examples for personal use or education

purpose.

Note: The output files generated after compilation in Quartus II e.g. .sof and .pof files, are saved in

the folder "output_files" under the directory of demo project. The workspace of Nios II Eclipse

project is located in the folder "software" under the directory of demo project.

6.1 Power Monitor

The power monitor demo shows how to measure the power consumed through the onboard power

monitor chip LTC2990. There are three LTC2990 to monitor the following power rails:

• 3.3V VCCIO

• 2.5V Core

• 2.5V VCCIO

• 1.5V VCCIO

• 1.2V VCC

The power monitor chip LTC2990 communicates with the FPGA via I2C protocol. The I2C

OpenCore IP is used in this demonstration for the MAX 10 device to communicate with the three

LTC2990, which have different I2C slave address 98h, 9Ah, and 9Ch.

◼ Block Diagram

Figure 6-1 shows the system block diagram of this demonstration. The NIOS program is stored in

the onchip memory and the Nios II processor is running at 50MHz. The I2C library is located in the

files named I2C_core.cpp and I2C_core.h. The I2C OpenCore IP is located in the folder

“ip/i2c_opencores” under the project directory.

Page 55

MAX 10 Plus User

Manual

55

www.terasic.com

May 31, 2019

Figure 6-1 Block Diagram of Power Monitor Demonstration

Figure 6-2 illustrates the idea of how to measure the current for each power rail. A current sense

resistor R

SENSE

is added to the path of each power rail. LTC2990 measures the voltage difference

(V1-V2) and calculate the current based on the formula below:

Current = (V1-V2) / R

SENSE

The power consumption can be calculated by the following formula:

Power Consumption = VCC x Current = VCC x (V1-V2) / R

SENSE

Figure 6-2 Schematic of Current Sense

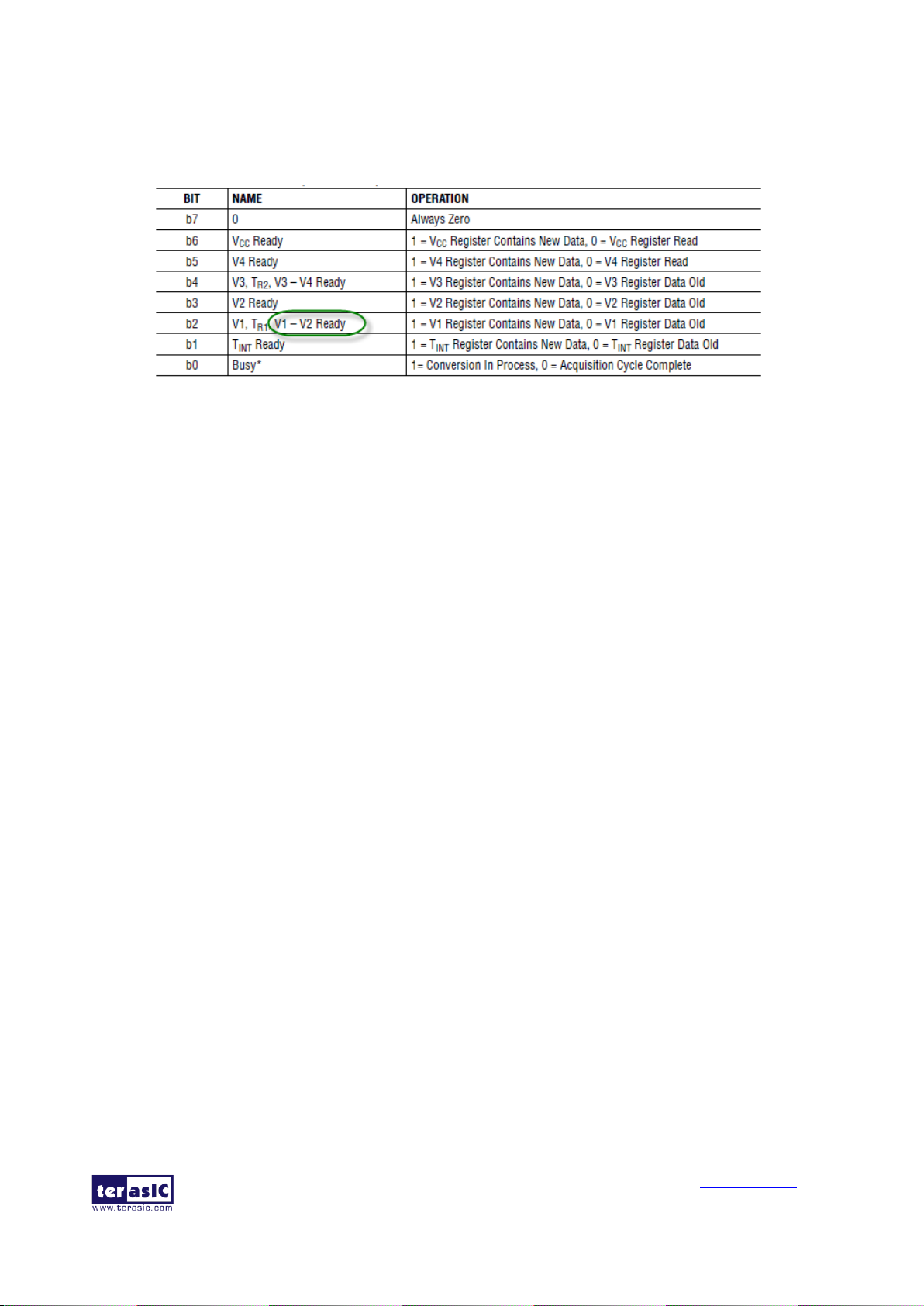

Figure 6-3 shows the register content of LTC2990. The voltage difference (V1-V2) measured are

written into two registers, MSB (register 06h) and LSB (register 07h). The most significant bit (7th

bit) of MSB register is the data_valid bit, which indicates whether the current register content has

been accessed since the result was last written to the register. This bit will be “set” i.e. 1 when the

register content is renewed and “cleared” i.e. 0 when the register content is accessed. Bit 6 of the

Page 56

MAX 10 Plus User

Manual

56

www.terasic.com

May 31, 2019

MSB register is the sign bit, Bit 5 through 0 represent the result of bits D[13:8] in two’s

complement conversion. The LSB register holds the conversion bits D[7:0]. The following

equations are used to convert the register values to get the differential voltage:

Figure 6-3 Register of LTC2990

Figure 6-4 shows the control register of LTC2990. The control register must be configured properly

to measure the voltage difference (V1-V2). Bits b[2:0] should be set to ‘110’ for measuring voltage

difference (V1-V2) and (V3-V4). Bits [4:3] should be set to 00 for all measurements.

Figure 6-4 Control Register of LTC2990

Page 57

MAX 10 Plus User

Manual

57

www.terasic.com

May 31, 2019

Figure 6-5 shows the status register of LTC2990. Bit b2 should be checked before reading the

voltage difference registers to make sure the measurement is finished and register values is the

latest for reading.

Figure 6-5 Status Register of LTC2990

◼ Design Tools

• Quartus II v15.0 64-bit

• Nios II Eclipse 15.0

◼ Demonstration Source Code

• Quartus project directory: Demonstrations\power_monitor_nios

• Nios II Eclipse project workspace: Demonstrations\power_monitor_nios\software

◼ Nios II Project Compilation

• Before you attempt to compile the reference design under Nios II Eclipse, make sure the project

is cleaned first by clicking ‘Clean’ from the ‘Project’ menu of Nios II Eclipse.

◼ Demonstration Batch File

• Demo batch file folder: Demonstrations\power_monitor_nios\demo_batch

• Batch file: test.bat

• FPGA configuration file: power_monitor_nios.sof

• Nios batch file: test.sh

• NIOS program: nios_app.elf

◼ Demonstration Setup

Please follow the procedures below to set up the demonstration:

• Please make sure Quartus II and USB-Blaster II driver are installed on the host PC.

• Connect the USB cable from the USB-Blaster II port (J8) on the MAX 10 Plus board to the host

PC.

• Power on the MAX 10 Plus board.

• Execute the demo batch file “test.bat” under the folder

Demonstrations\power_monitor_nios\demo_batch.

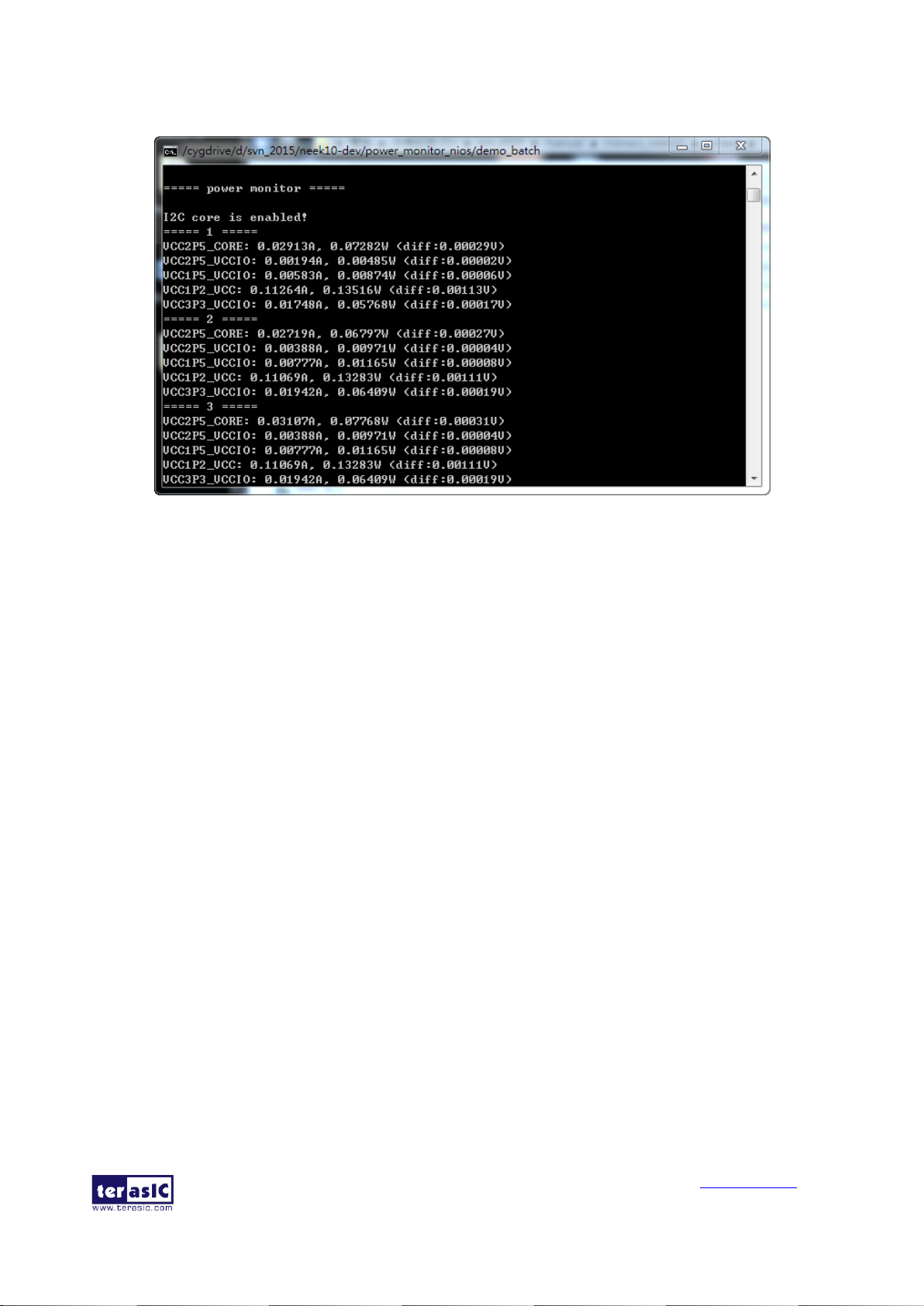

• Nios II terminal will display the measured power consumption measured, as shown in Figure

Page 58

MAX 10 Plus User

Manual

58

www.terasic.com

May 31, 2019

6-6.

Figure 6-6 Screenshot of Power_monitor_nios Demo

6.2 UART to USB Control LED

Many applications need communication with computer through common ports, the traditional

connector is RS232 which needs to connect to a RS232 cable. However, many personal computers

nowadays don't have the RS232 connector which makes it very inconvenient to develop projects.

The MAX 10 Plus board is designed to support UART communication through USB cable. The

UART to USB circuit is responsible for converting the data format. Developers can use a USB

cable rather than a RS232 cable to enable the communication between the FPGA and the host

computer. In this demonstration we will show you how to control the LEDRs by sending a

command on the computer putty terminal. The command is sent and received through a USB cable

to the FPGA. Note that in FPGA, the information was received and sent through a UART IP.

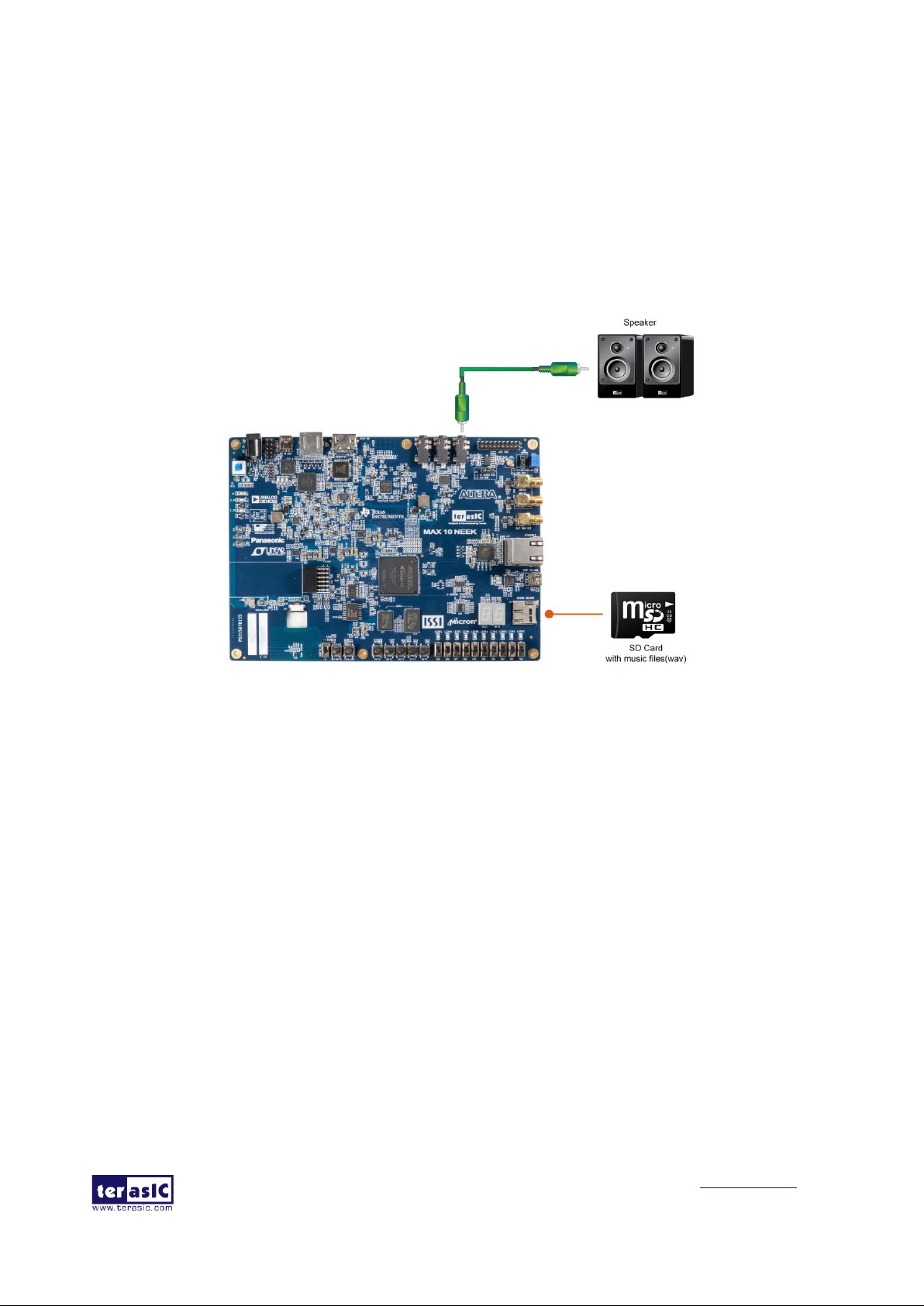

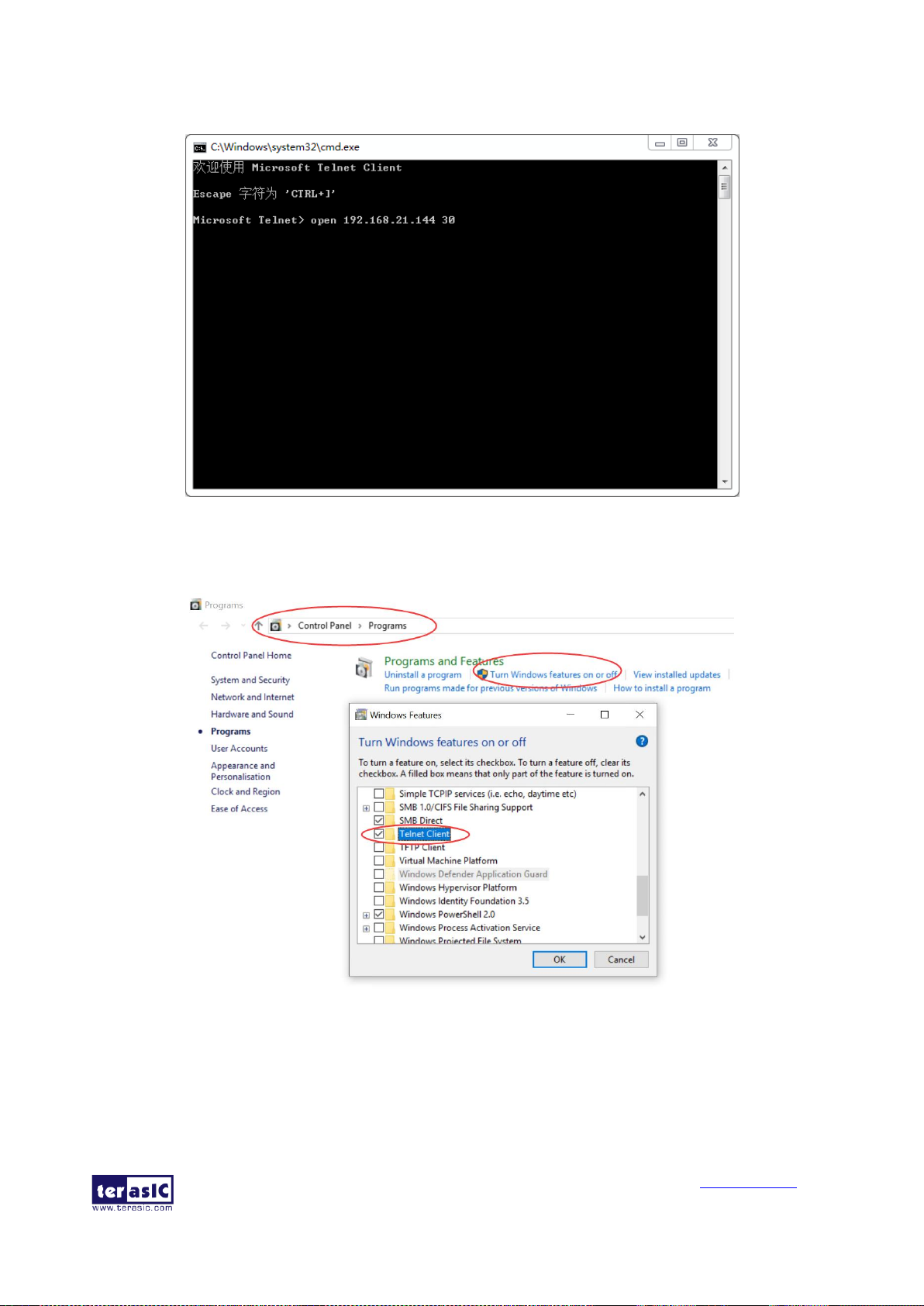

Figure 6-7 shows the hardware block diagram of this demonstration. The system requires a 50MHz