Page 1

DE5-Net User Manual

www.terasic.com

August 4, 2017

1

Page 2

DE5-Net User Manual

www.terasic.com

August 4, 2017

2

CONTENTS

CHAPTER 1

OVERVIEW

........................................................................................................................................ 4

1.1 GENERAL DESCRIPTION ............................................................................................................................................ 4

1.2 KEY FEATURES .......................................................................................................................................................... 5

1.3 BLOCK DIAGRAM ...................................................................................................................................................... 6

CHAPTER 2

BOARD COMPONENTS

.................................................................................................................. 10

2.1 BOARD OVERVIEW .................................................................................................................................................. 10

2.2 CONFIGURATION, STATUS AND SETUP ..................................................................................................................... 11

2.3 GENERAL USER INPUT/OUTPUT .............................................................................................................................. 14

2.4 TEMPERATURE SENSOR AND FAN CONTROL ............................................................................................................ 17

2.5 CLOCK CIRCUIT ...................................................................................................................................................... 18

2.6 RS-422 SERIAL PORT ................................ ................................ ................................................................ .............. 21

2.7 FLASH MEMORY ................................................................................................................................................... 22

2.8 DDR3 SO-DIMM ................................................................................................................................................... 25

2.9 QDRII+ SRAM ...................................................................................................................................................... 32

2.10 SPF+ PORTS .......................................................................................................................................................... 39

2.11 PCI EXPRESS ......................................................................................................................................................... 42

2.12 SATA ................................ ................................................................ ................................ .................................... 44

CHAPTER 3

SYSTEM BUILDER

......................................................................................................................... 48

3.1 INTRODUCTION ....................................................................................................................................................... 48

3.2 GENERAL DESIGN FLOW ......................................................................................................................................... 49

3.3 USING SYSTEM BUILDER ........................................................................................................................................ 50

CHAPTER 4

FLASH PROGRAMMING

................................................................................................................. 57

4.1 CFI FLASH MEMORY MAP ...................................................................................................................................... 57

4.2 FPGA CONFIGURE OPERATION ............................................................................................................................... 58

4.3 FLASH PROGRAMMING WITH USERS DESIGN .......................................................................................................... 58

4.4 RESTORE FACTORY SETTINGS ................................................................................................................................. 60

CHAPTER 5

PROGRAMMABLE OSCILLATOR

................................................................................................. 62

5.1 OVERVIEW .............................................................................................................................................................. 62

5.2 SI570 EXAMPLE BY RTL ......................................................................................................................................... 66

Page 3

DE5-Net User Manual

www.terasic.com

August 4, 2017

3

5.3 SI570 AND CDCM PROGRAMMING BY NIOS II ........................................................................................................ 73

CHAPTER 6

MEMORY REFERENCE DESIGN

.................................................................................................. 78

6.1 QDRII+ SRAM TEST ............................................................................................................................................. 78

6.2 DDR3 SDRAM TEST ............................................................................................................................................. 81

6.3 DDR3 SDRAM TEST BY NIOS II ............................................................................................................................ 83

CHAPTER 7

PCI EXPRESS REFERENCE DESIGN

....................................................................................... 87

7.1 PCI EXPRESS SYSTEM INFRASTRUCTURE ................................................................................................................ 87

7.2 FPGA PCI EXPRESS SYSTEM DESIGN ..................................................................................................................... 88

7.3 PC PCI EXPRESS SYSTEM DESIGN .......................................................................................................................... 93

7.4 FUNDAMENTAL COMMUNICATION ......................................................................................................................... 105

7.5 EXAMPLE 2: IMAGE PROCESS APPLICATION .......................................................................................................... 110

CHAPTER 8

TRANSCEIVER VERIFICATION

.................................................................................................. 115

8.1 TEST CODE ............................................................................................................................................................ 115

8.2 LOOPBACK FIXTURE ............................................................................................................................................. 115

8.3 TESTING ................................................................................................................................................................ 117

ADDITIONAL INFORMATION

................................................................................................................................... 119

Page 4

DE5-Net User Manual

www.terasic.com

August 4, 2017

4

Chapter 1

Overview

This chapter provides an overview of the DE5-Net Development Board and installation guide.

11..1

1

GGeenneerraall DDeessccrriippttiioonn

The Terasic DE5-Net Stratix V GX FPGA Development Kit provides the ideal hardware solution

for designs that demand high capacity and bandwidth memory interfacing, ultra-low latency

communication, and power efficiency. With a full-height, 3/4-length form-factor package, the

DE5-Net is designed for the most demanding high-end applications, empowered with the

top-of-the-line Altera Stratix V GX, delivering the best system-level integration and flexibility in

the industry.

The Stratix® V GX FPGA features integrated transceivers that transfer at a maximum of 12.5 Gbps,

allowing the DE5-Net to be fully compliant with version 3.0 of the PCI Express standard, as well as

allowing an ultra low-latency, straight connections to four external 10G SFP+ modules. Not relying

on an external PHY will accelerate mainstream development of network applications enabling

customers to deploy designs for a broad range of high-speed connectivity applications. For designs

that demand high capacity and high speed for memory and storage, the DE5-Net delivers with two

independent banks of DDR3 SO-DIMM RAM, four independent banks of QDRII+ SRAM,

high-speed parallel flash memory, and four SATA ports. The feature-set of the DE5-Net fully

supports all high-intensity applications such as low-latency trading, cloud computing,

high-performance computing, data acquisition, network processing, and signal processing.

Page 5

DE5-Net User Manual

www.terasic.com

August 4, 2017

5

11..2

2

KKeeyy FFeeaattuurreess

The following hardware is implemented on the DE5-Net board:

FPGA

Altera Stratix® V GX FPGA (5SGXEA7N2F45C2)

FPGA Configuration

On-Board USB Blaster II or JTAG header for FPGA programming

Fast passive parallel (FPPx32) configuration via MAX II CPLD and flash memory

General user input/output:

10 LEDs

4 push-buttons

4 slide switches

2 seven-segment displays

Clock System

50MHz Oscillator

Programmable oscillators Si570, CDCM61001 and CDCM61004

One SMA connector for external clock input

One SMA connector for clock output

Memory

DDR3 SO-DIMM SDRAM

QDRII+ SRAM

FLASH

Communication Ports

Four SFP+ connectors

Two Serial ATA host ports

Two Serial ATA device ports

PCI Express (PCIe) x8 edge connector

One RS422 transceiver with RJ45 connector

Page 6

DE5-Net User Manual

www.terasic.com

August 4, 2017

6

System Monitor and Control

Temperature sensor

Fan control

Power

PCI Express 6-pin power connector, 12V DC Input

PCI Express edge connector power

Mechanical Specification

PCI Express full-height and 3/4-length

11..3

3

BBlloocckk DDiiaaggrraamm

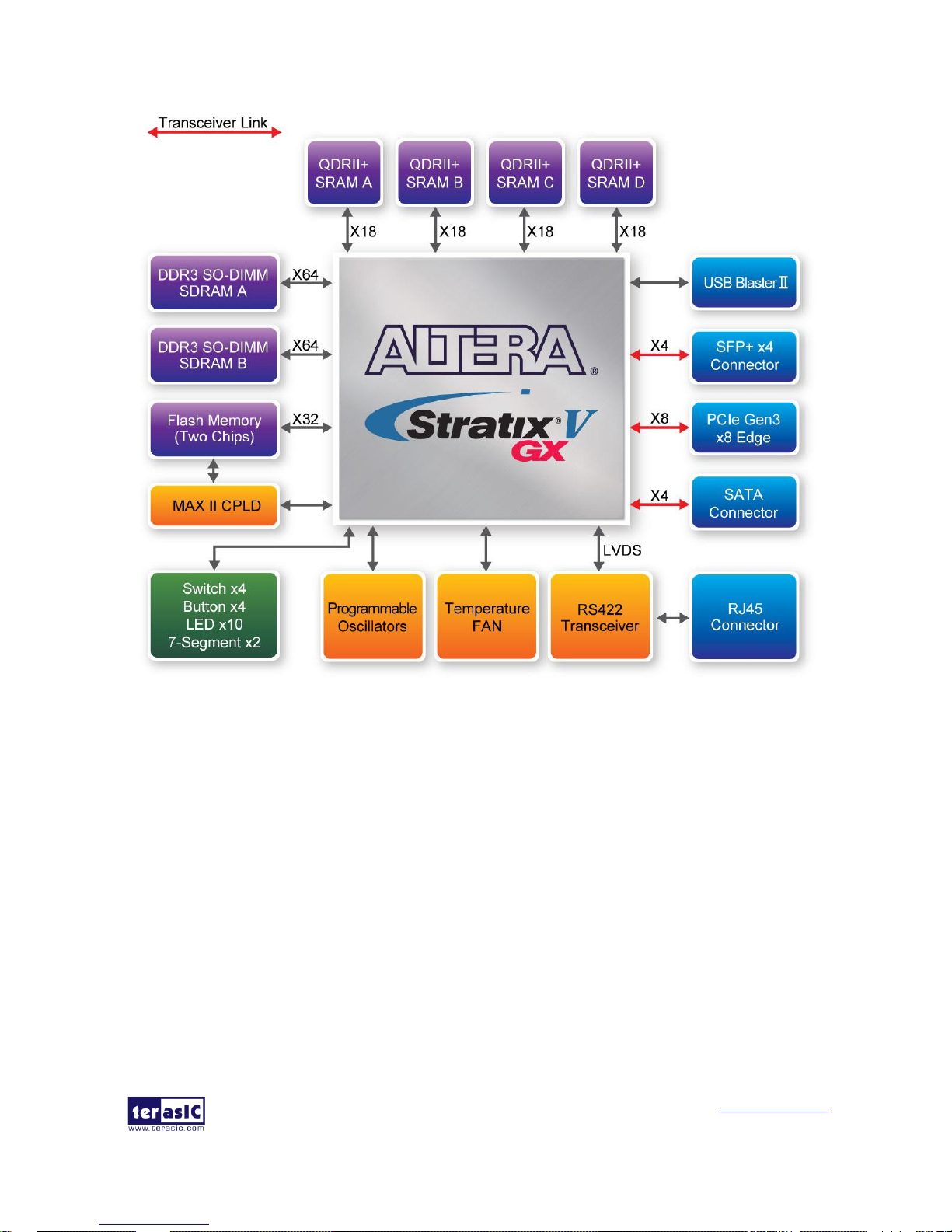

94H94HFigure 1-1 shows the block diagram of the DE5-Net board. To provide maximum flexibility for the

users, all key components are connected with the Stratix V GX FPGA device. Thus, users can

configure the FPGA to implement any system design.

Page 7

DE5-Net User Manual

www.terasic.com

August 4, 2017

7

Figure 1-1 Block diagram of the DE5-Net board

Below is more detailed information regarding the blocks in Figure 1-1.

Stratix V GX FPGA

5SGXEA7N2F45C2

622,000 logic elements (LEs)

50-Mbits embedded memory

48 transceivers (12.5Gbps)

512 18-bit x 18-bit multipliers

256 27-bit x 27-bit DSP blocks

Page 8

DE5-Net User Manual

www.terasic.com

August 4, 2017

8

2 PCI Express hard IP blocks

840 user I/Os

210 full-duplex LVDS channels

28 phase locked loops (PLLs)

JTAG Header and FPGA Configuration

On-board USB Blaster II or JTAG header for use with the Quartus II Programmer

MAXII CPLD EPM2210 System Controller and Fast Passive Parallel (FPP) configuration

Memory devices

32MB QDRII+ SRAM

Up to 8GB DDR3 SO-DIMM SDRAM

256MB FLASH

General user I/O

10 user controllable LEDs

4 user push buttons

4 user slide switches

2 seven-segment displays

On-Board Clock

50MHz oscillator

Programming PLL providing clock for 10G SFP+ transceiver

Programming PLL providing clock for SATA or 1G SFP+ transceiver

Four Serial ATA ports

SATA 3.0 standard at 6Gbps signaling rate

Page 9

DE5-Net User Manual

www.terasic.com

August 4, 2017

9

Four SFP+ ports

Four SFP+ connector (10 Gbps+)

PCI Express x8 edge connector

Support for PCIe Gen1/2/3

Edge connector for PC motherboard with x8 or x16 PCI Express slot

Power Source

PCI Express 6-pin DC 12V power

PCI Express edge connector power

Page 10

10

Chapter 2

Board Components

This chapter introduces all the important components on the DE5-Net.

22..1

1

BBooaarrdd OOvveerrvviieeww

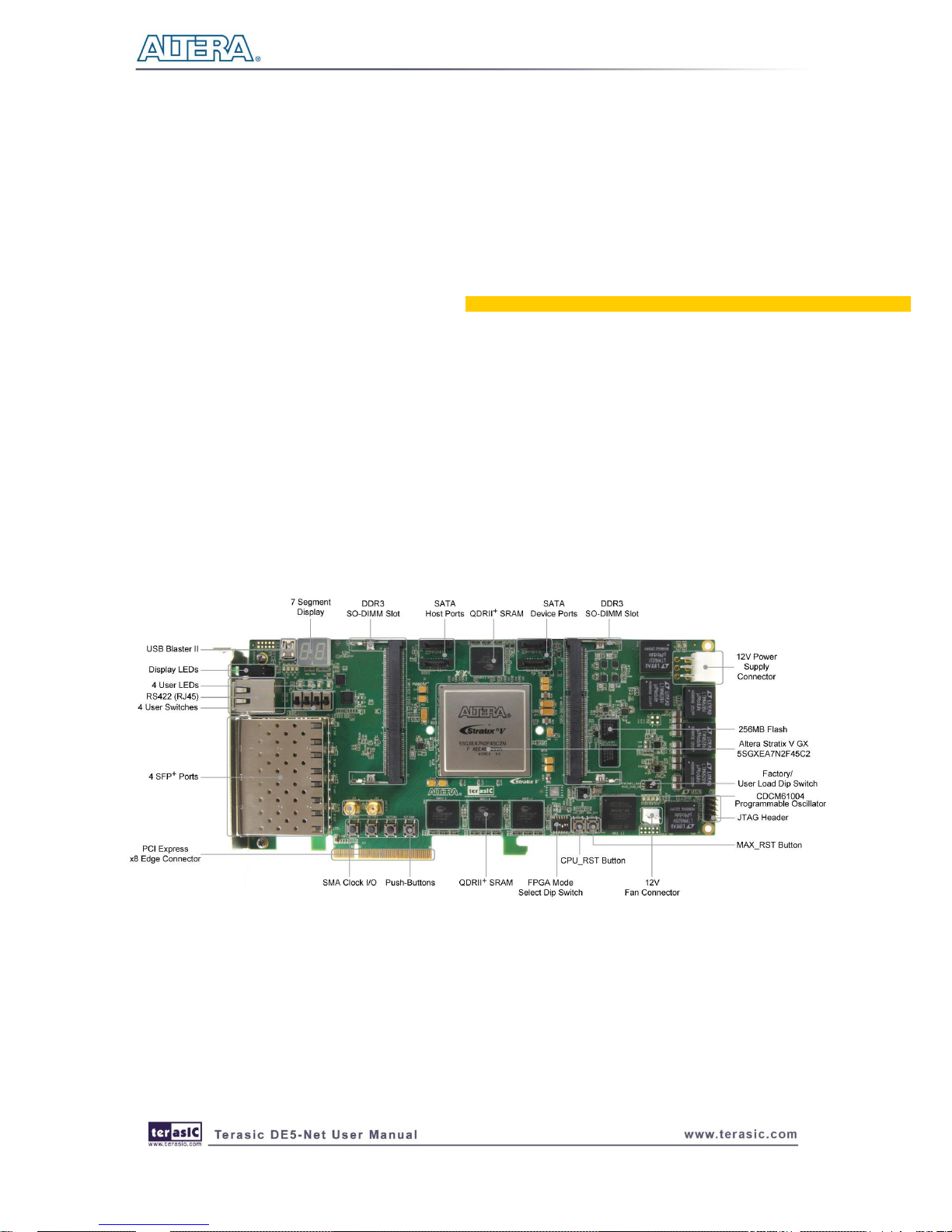

Figure 2-1 is the top and bottom view of the DE5-Net development board. It depicts the layout of

the board and indicates the location of the connectors and key components. Users can refer to this

figure for relative location of the connectors and key components.

Figure 2-1 FPGA Board (Top)

Page 11

DE5-Net User Manual

www.terasic.com

August 4, 2017

11

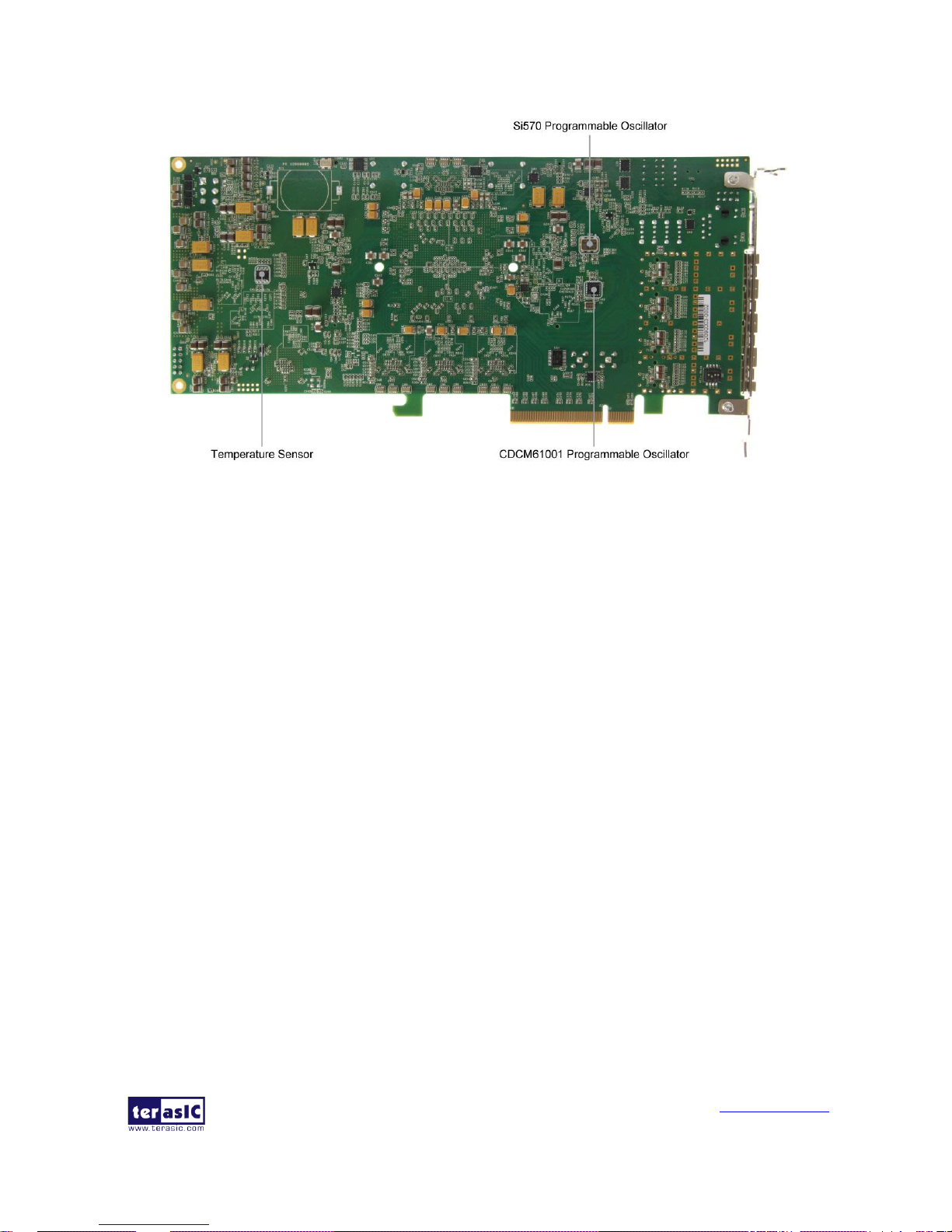

Figure 2-2 FPGA Board (Bottom)

22..2

2

CCoonnffiigguurraattiioonn,, SSttaattuuss aanndd SSeettuupp

Configure

The FPGA board supports two configuration methods for the Stratix V FPGA:

Configure the FPGA using the on-board USB-Blaster II.

Flash memory configuration of the FPGA using stored images from the flash memory on

power-up.

For programming by on-board USB-Blaster II, the following procedures show how to download a

configuration bit stream into the Stratix V GX FPGA:

Make sure that power is provided to the FPGA board

Connect your PC to the FPGA board using a mini-USB cable and make sure the USB-Blaster

II driver is installed on PC.

Launch Quartus II programmer and make sure the USB-Blaster II is detected.

In Quartus II Programmer, add the configuration bit stream file (.sof), check the associated

“Program/Configure” item, and click “Start” to start FPGA programming.

Page 12

DE5-Net User Manual

www.terasic.com

August 4, 2017

12

Status LED

The FPGA Board development board includes board-specific status LEDs to indicate board status.

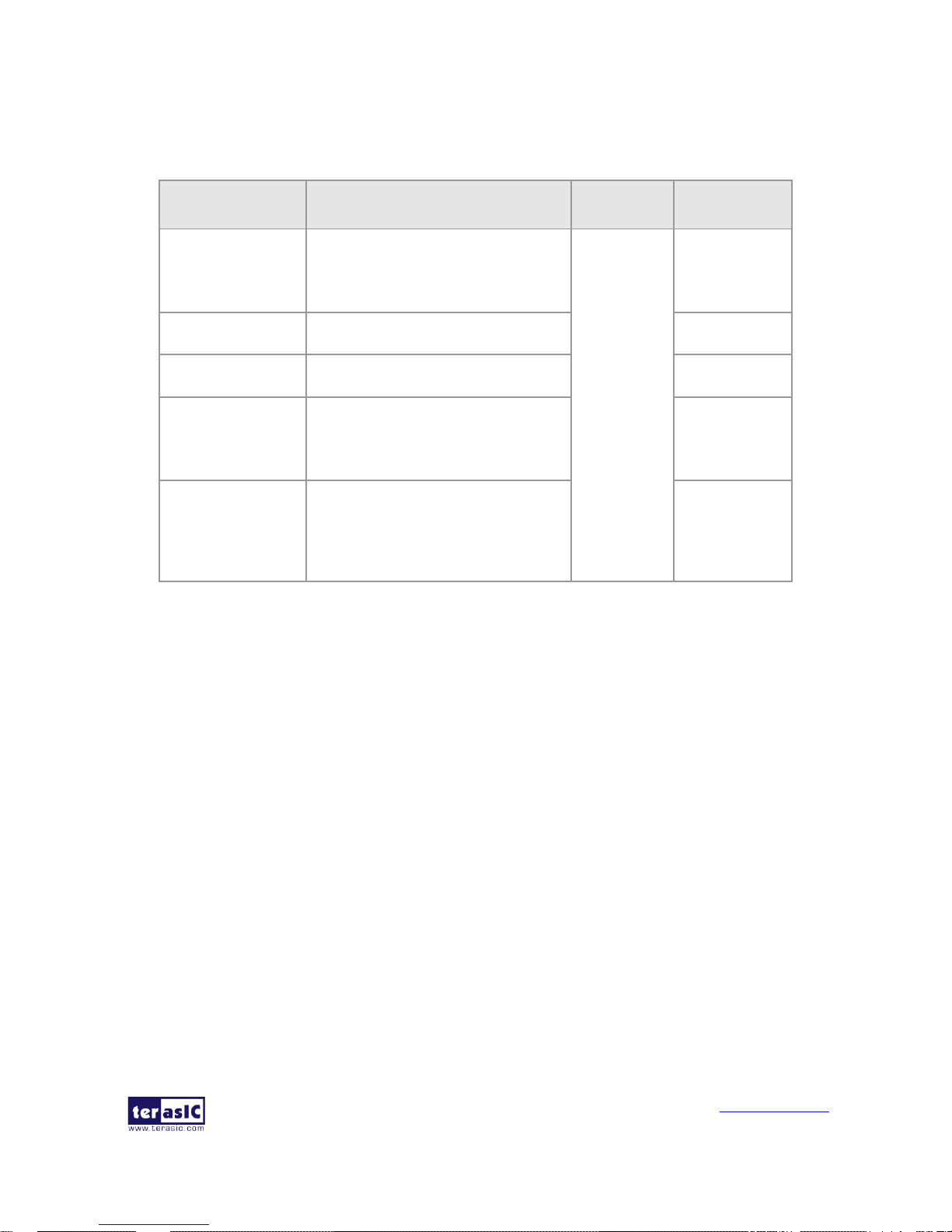

Please refer to Table 2-1 for the description of the LED indicator.

Table 2-1 Status LED

Board

Reference

LED Name

Description

D2

12-V Power

Illuminates when 12-V power is active.

D1

3.3-V Power

Illuminates when 3.3-V power is active.

D15

CONF DONE

Illuminates when the FPGA is successfully configured.

Driven by the MAX II CPLD EPM2210 System Controller.

D16

Loading

Illuminates when the MAX II CPLD EPM2210 System

Controller is actively configuring the FPGA. Driven by the

MAX II CPLD EPM2210 System Controller with the

Embedded Blaster CPLD.

D17

Error

Illuminates when the MAX II CPLD EPM2210 System

Controller fails to configure the FPGA. Driven by the MAX II

CPLD EPM2210 System Controller.

D18

PAGE

Illuminates when FPGA is configured by the factory

configuration bit stream.

Setup PCI Express Control DIP switch

The PCI Express Control DIP switch (SW7) is provided to enable or disable different

configurations of the PCIe Connector. Table 2-2 lists the switch controls and description.

Table 2-2 SW3 PCIe Control DIP Switch

Board

Reference

Signal Name

Description

Default

SW7.1

PCIE_PRSNT2n_x1

On : Enable x1 presence detect

Off: Disable x1 presence detect

Off

SW7.2

PCIE_PRSNT2n_x4

On : Enable x4 presence detect

Off: Disable x4 presence detect

Off

SW7.3

PCIE_PRSNT2n_x8

On : Enable x8 presence detect

Off: Disable x8 presence detect

On

Page 13

DE5-Net User Manual

www.terasic.com

August 4, 2017

13

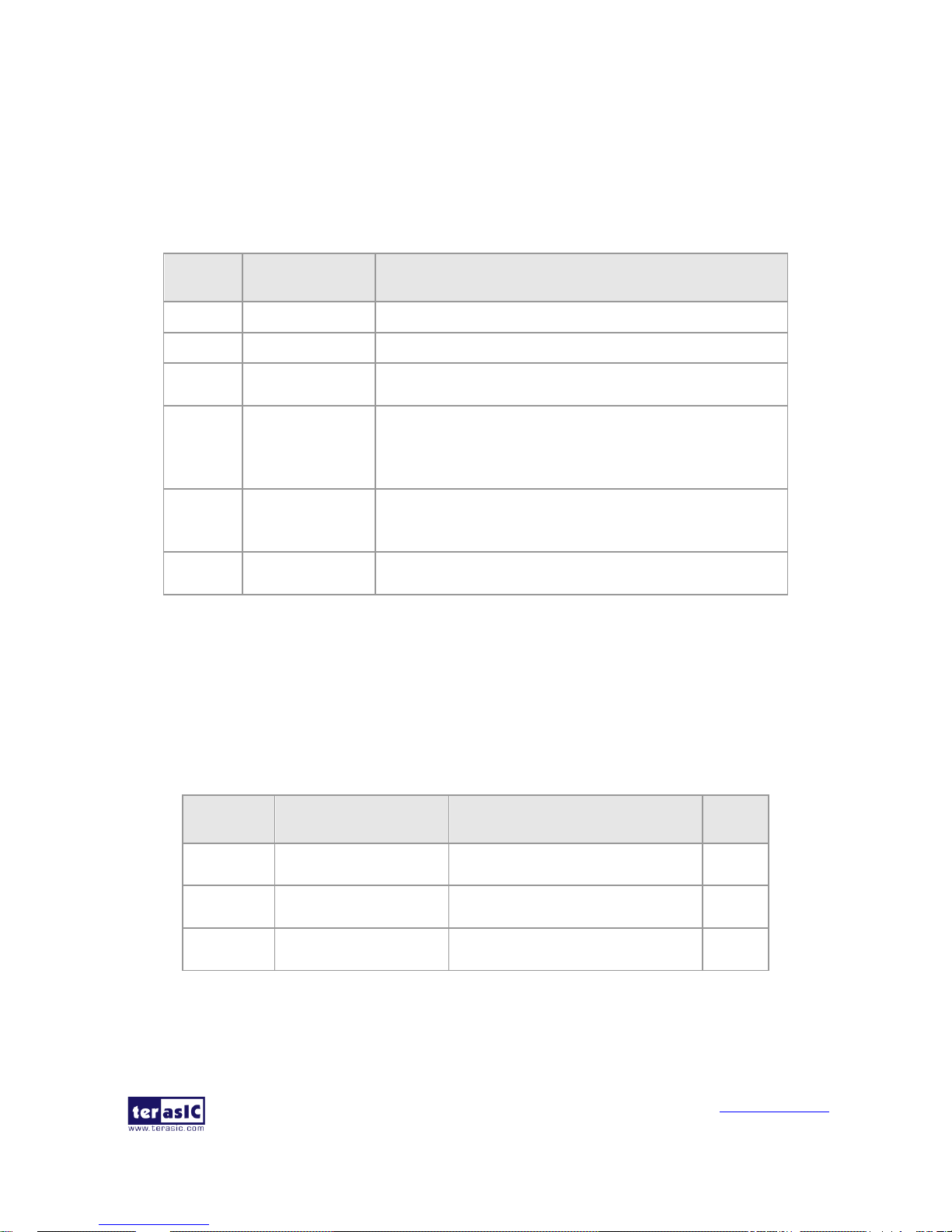

Setup Configure Mode Control DIP switch

The Configure Mode Control DIP switch (SW6) is provided to specify the configuration mode of

the FPGA. As currently only one mode is supported, please set all positions as shown in 9Figure 2-3.

Figure 2-3 6-Position DIP switch for Configure Mode

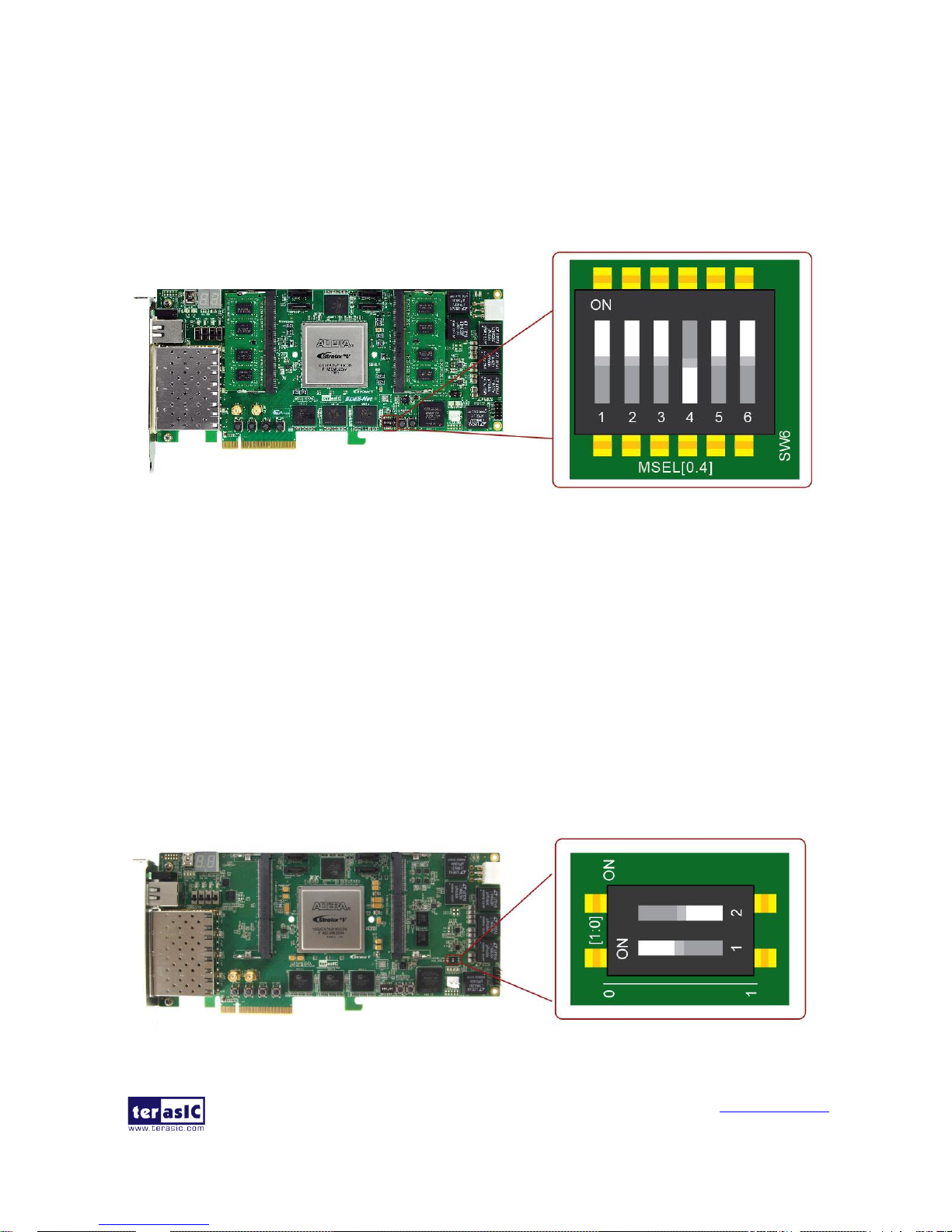

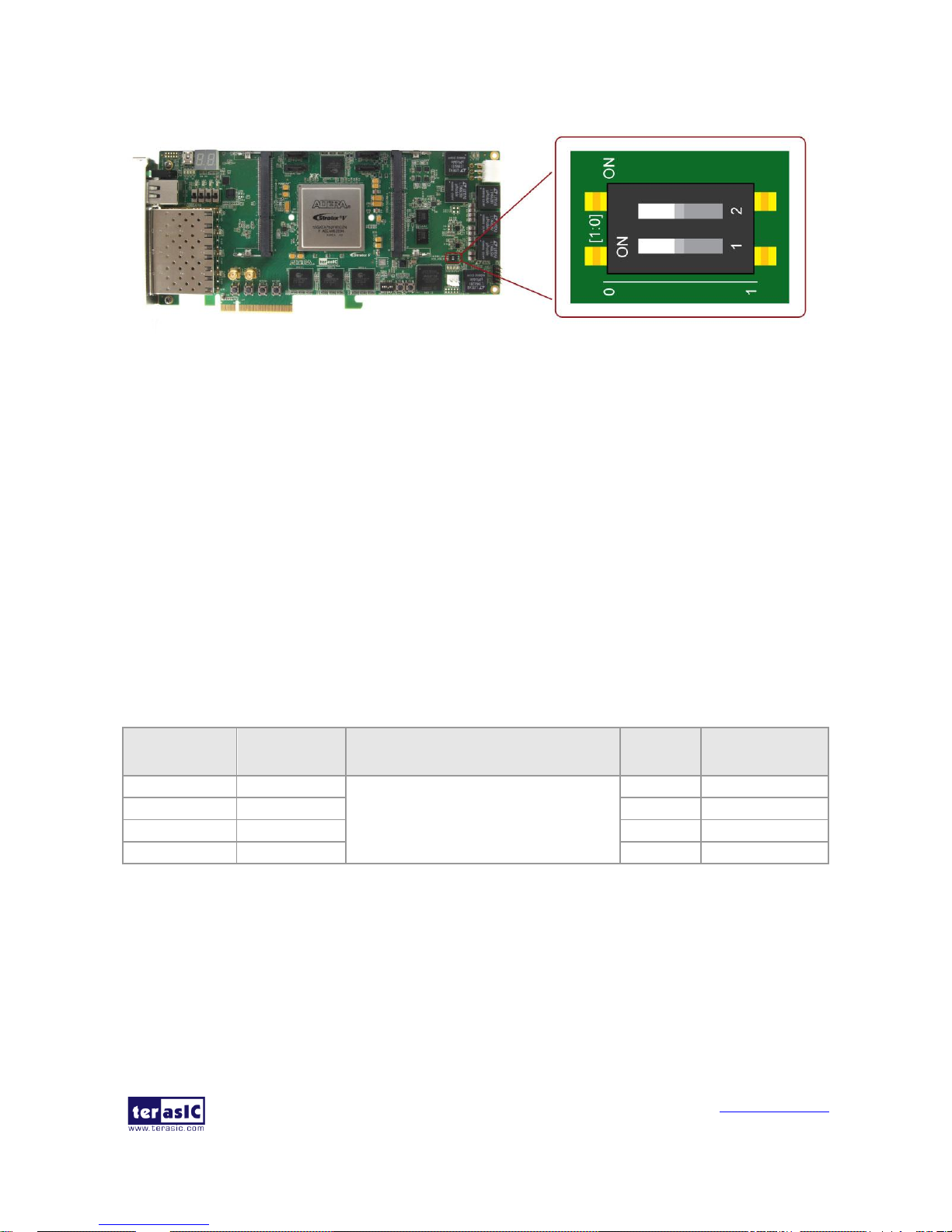

Select Flash Image for Configuration

The Image Select DIP switch (SW5) is provided to specify the image for configuration of the FPGA.

Setting Position 2 of SW5 to high (right) specifies the default factory image to be loaded, as shown

in Figure 2-4. Setting Position 2 of SW5 to low (left) specifies the DE5-Net to load a user-defined

image, as shown in 1Figure 2-5.

Figure 2-4 2-position DIP switch for Image Select – Factory Image Load

Page 14

DE5-Net User Manual

www.terasic.com

August 4, 2017

14

Figure 2-5 2-position DIP switch for Image Select – User Image Load

22..3

3

GGeenneerraall UUsseerr IInnppuutt//OOuuttppuutt

This section describes the user I/O interface to the FPGA.

User Defined Push-buttons

The FPGA board includes four user defined push-buttons that allow users to interact with the Stratix

V GX device. Each push-button provides a high logic level or a low logic level when it is not

pressed or pressed, respectively. Table 2-3 lists the board references, signal names and their

corresponding Stratix V GX device pin numbers.

Table 2-3 Push-button Pin Assignments, Schematic Signal Names, and Functions

Board

Reference

Schematic

Signal Name

Description

I/O

Standard

Stratix V GX

Pin Number

PB6

BUTTON0

High Logic Level when the button is

not pressed

2.5-V

PIN_AK15

PB5

BUTTON1

2.5-V

PIN_AK14

PB4

BUTTON2

2.5-V

PIN_AL14

PB3

BUTTON3

2.5-V

PIN_AL15

User-Defined Slide Switch

There are four slide switches on the FPGA board to provide additional FPGA input control. When a

slide switch is in the DOWN position or the UPPER position, it provides a low logic level or a high

logic level to the Stratix V GX FPGA, respectively, as shown in 0Figure 2-6.

Page 15

DE5-Net User Manual

www.terasic.com

August 4, 2017

15

Figure 2-6 4 Slide switches

Table 2-4 lists the signal names and their corresponding Stratix V GX device pin numbers.

Table 2-4 Slide Switch Pin Assignments, Schematic Signal Names, and Functions

Board

Reference

Schematic

Signal Name

Description

I/O

Standard

Stratix V GX

Pin Number

SW0

SW0

High logic level when SW in the UPPER

position.

1.8-V

PIN_B25

SW1

SW1

1.8-V

PIN_A25

SW2

SW2

1.8-V

PIN_B23

SW3

SW3

1.8-V

PIN_A23

User-Defined LEDs

The FPGA board consists of 10 user-controllable LEDs to allow status and debugging signals to be

driven to the LEDs from the designs loaded into the Stratix V GX device. Each LED is driven

directly by the Stratix V GX FPGA. The LED is turned on or off when the associated pins are

driven to a low or high logic level, respectively. A list of the pin names on the FPGA that are

connected to the LEDs is given in Table 2-5.

Table 2-5 User LEDs Pin Assignments, Schematic Signal Names, and Functions

Board

Reference

Schematic

Signal Name

Description

I/O

Standard

Stratix V GX

Pin Number

Page 16

DE5-Net User Manual

www.terasic.com

August 4, 2017

16

D8

LED0

Driving a logic 0 on the I/O port turns the LED

ON.

Driving a logic 1 on the I/O port turns the LED

OFF.

2.5-V

PIN_AW37

D9

LED1

2.5-V

PIN_AV37

D10

LED2

2.5-V

PIN_BB36

D11

LED3

2.5-V

PIN_BB39

D7-1

LED_BRACKET0

2.5-V

PIN_AH15

D7-3

LED_BRACKET1

2.5-V

PIN_AH13

D7-5

LED_BRACKET2

2.5-V

PIN_AJ13

D7-7

LED_BRACKET3

2.5-V

PIN_AJ14

J8-10

LED_RJ45_L

2.5-V

PIN_AG15

J8-12

LED_RJ45_R

2.5-V

PIN_AG16

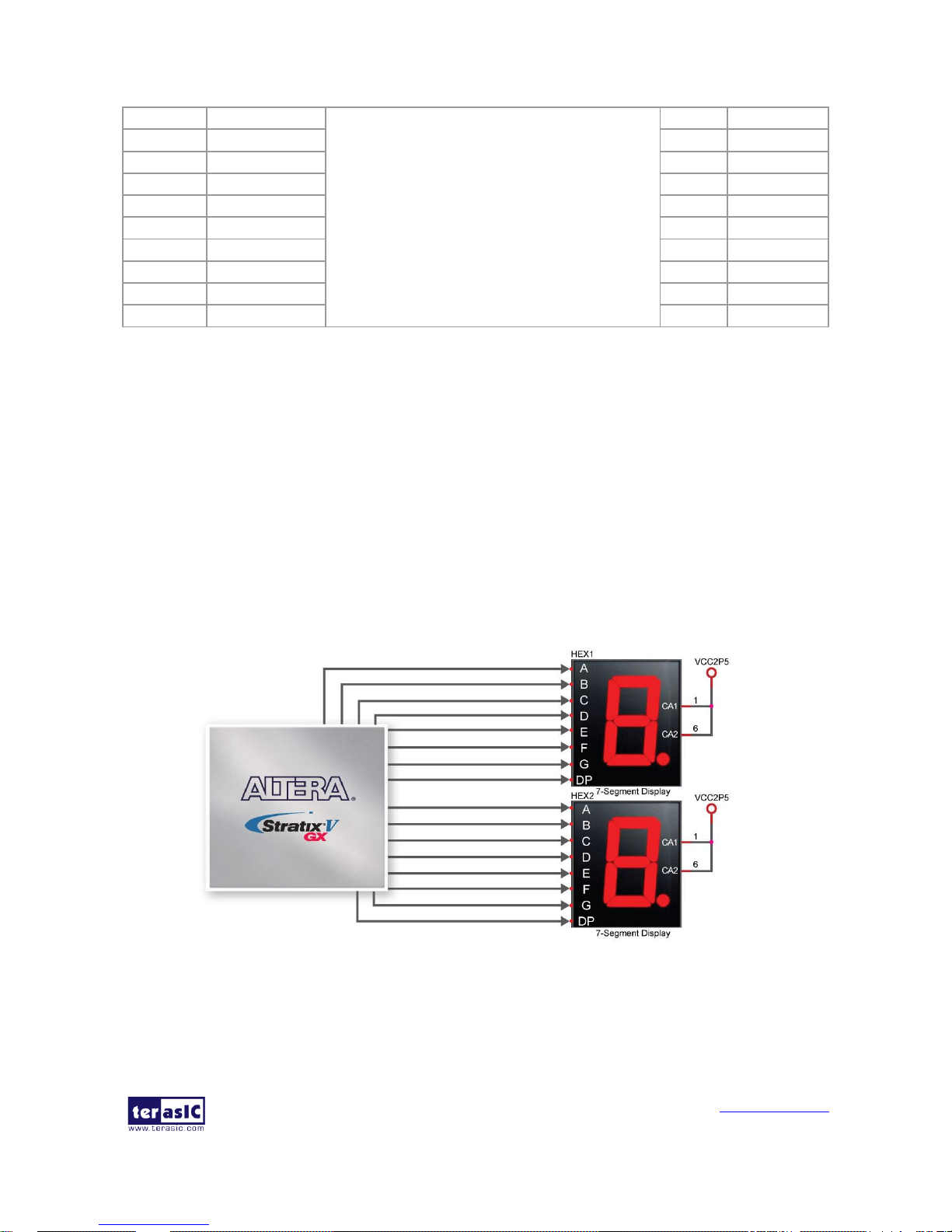

7-Segment Displays

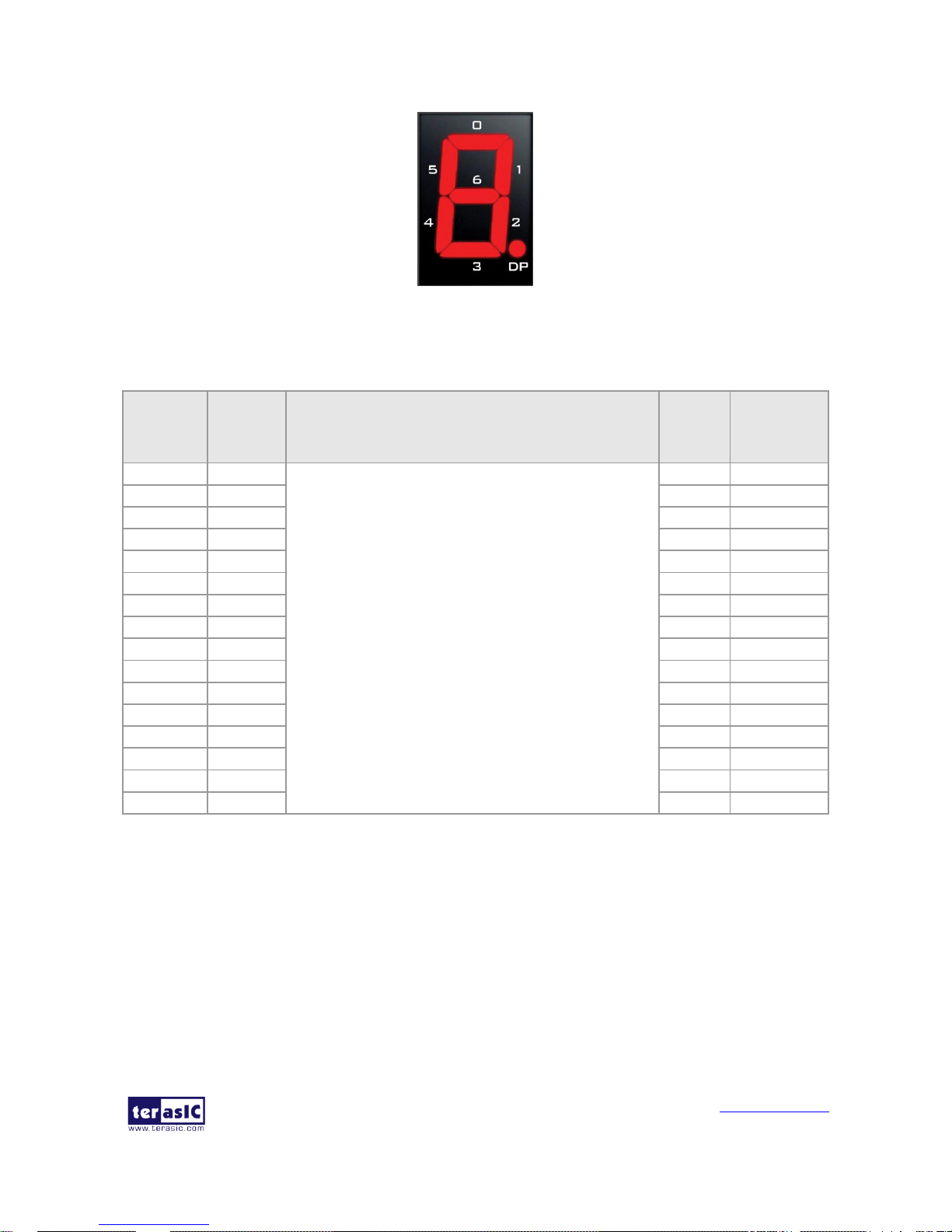

The FPGA board has two 7-segment displays. As indicated in the schematic in Figure 2-7, the

seven segments are connected to pins of the Stratix V GX FPGA. Applying a low or high logic level

to a segment will turn it on or turn it off, respectively.

Each segment in a display is identified by an index listed from 0 to 6 with the positions given in

Figure 2-8. In addition, the decimal point is identified as DP. Table 2-6 shows the mapping of the

FPGA pin assignments to the 7-segment displays.

Figure 2-7 Connection between 7-segment displays and Stratix V GX FPGA

Page 17

DE5-Net User Manual

www.terasic.com

August 4, 2017

17

Figure 2-8 Position and index of each segment in a 7-segment display

Table 2-6 User LEDs Pin Assignments, Schematic Signal Names, and Functions

Board

Reference

Schematic

Signal

Name

Description

I/O

Standard

Stratix V GX

Pin Number

HEX1

HEX1_D0

User-Defined 7-Segment Display. Driving logic 0 on

the I/O port turns the 7-segment signal ON. Driving

logic 1 on the I/O port turns the 7-segment signal

OFF.

1.5-V

PIN_H18

HEX1

HEX1_D1

1.5-V

PIN_G16

HEX1

HEX1_D2

1.5-V

PIN_F16

HEX1

HEX1_D3

1.5-V

PIN_A7

HEX1

HEX1_D4

1.5-V

PIN_B7

HEX1

HEX1_D5

1.5-V

PIN_C9

HEX1

HEX1_D6

1.5-V

PIN_D10

HEX1

HEX1_DP

1.5-V

PIN_E9

HEX0

HEX0_D0

1.5-V

PIN_G8

HEX0

HEX0_D1

1.5-V

PIN_H8

HEX0

HEX0_D2

1.5-V

PIN_J9

HEX0

HEX0_D3

1.5-V

PIN_K10

HEX0

HEX0_D4

1.5-V

PIN_K8

HEX0

HEX0_D5

1.5-V

PIN_K9

HEX0

HEX0_D6

1.5-V

PIN_N8

HEX0

HEX0_DP

1.5-V

PIN_P8

22..4

4

TTeemmppeerraattuurree SSeennssoorr aanndd FFaann CCoonnttrrooll

The FPGA board is equipped with a temperature sensor, MAX1619, which provides temperature

sensing and over-temperature alert. These functions are accomplished by connecting the

temperature sensor to the internal temperature sensing diode of the Stratix V GX device. The

temperature status and alarm threshold registers of the temperature sensor can be programmed by a

Page 18

DE5-Net User Manual

www.terasic.com

August 4, 2017

18

two-wire SMBus, which is connected to the Stratix V GX FPGA. In addition, the 7-bit POR slave

address for this sensor is set to ‘0011000b’.

An optional 3-pin +12V fan located on J15 of the FPGA board is intended to reduce the temperature

of the FPGA. Users can control the fan to turn on/off depending on the measured system

temperature. The FAN is turned on when the FAN_CTRL pin is driven to a high logic level.

The pin assignments for the associated interface are listed in Table 2-7.

Table 2-7 Temperature Sensor Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

TEMPDIODEp

Positive pin of temperature diode in

Stratix V

1.8-V

PIN_P6

TEMPDIODEn

Negative pin of temperature diode in

Stratix V

1.8-V

PIN_P7

TEMP_CLK

SMBus clock

2.5-V

PIN_D21

TEMP_DATAT

SMBus data

2.5-V

PIN_D20

TEMP_OVERT_n

SMBus alert (interrupt)

2.5-V

PIN_C22

TEMP_INT_n

SMBus alert (interrupt)

2.5-V

PIN_C21

FAN_CTRL

Fan control

2.5-V

PIN_AR32

22..5

5

CClloocckk CCiirrccuuiitt

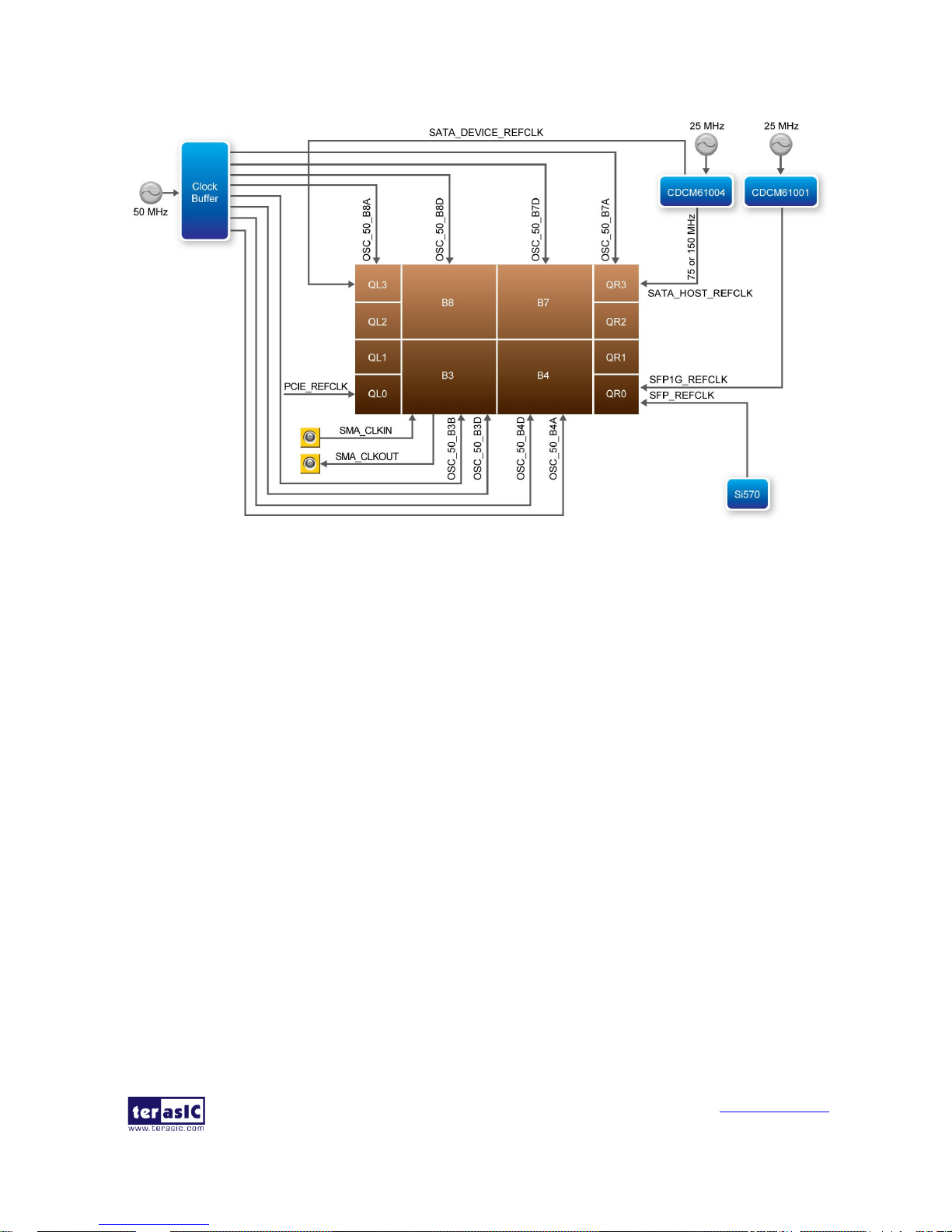

The development board includes one 50 MHz and three programmable oscillators. Figure 2-9

shows the default frequencies of on-board all external clocks going to the Stratix V GX FPGA. The

figures also show an off-board external clock from PCI Express Host to the FPGA.

Page 19

DE5-Net User Manual

www.terasic.com

August 4, 2017

19

Figure 2-9 Clock circuit of the FPGA Board

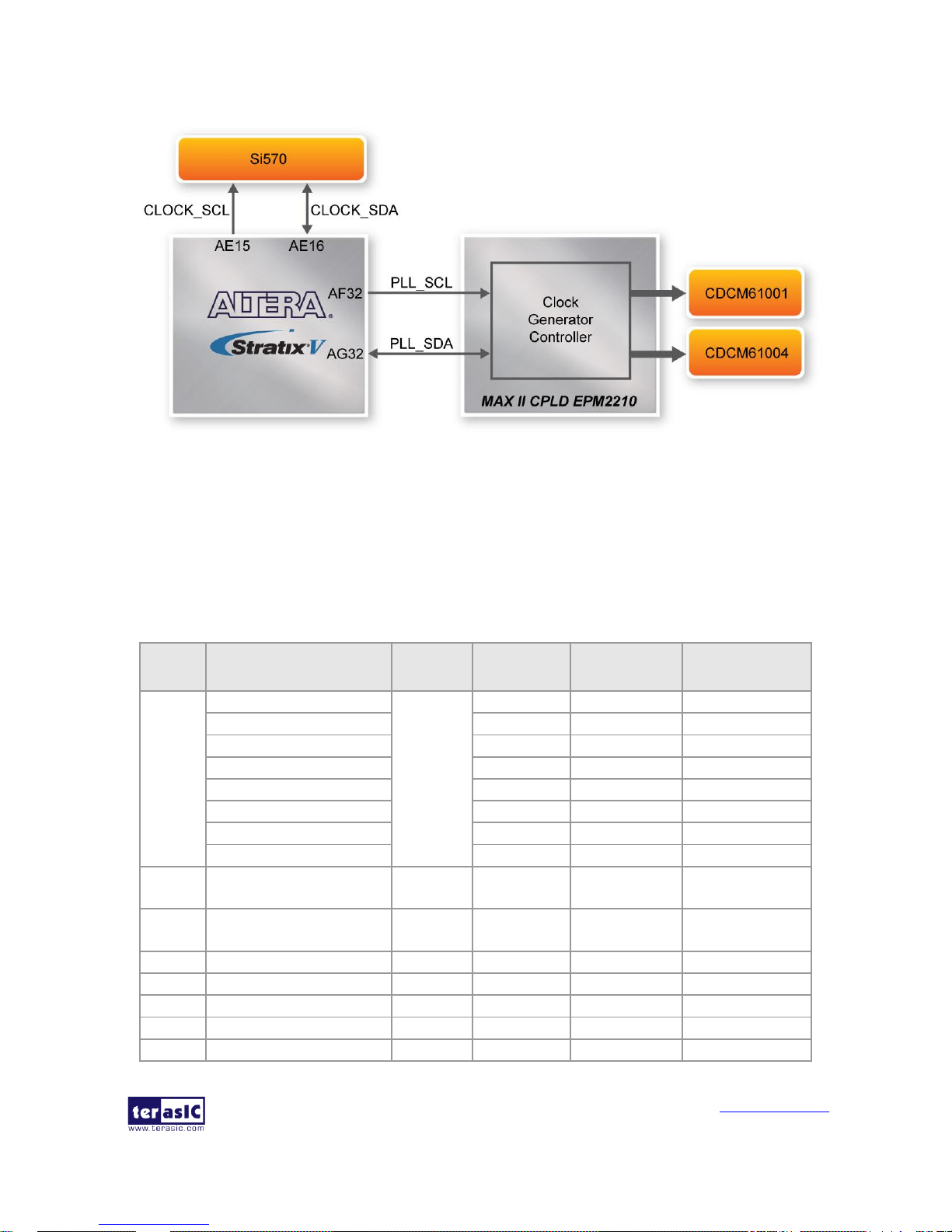

A clock buffer is used to duplicate the 50 MHz oscillator, so each bank of FPGA I/O bank 3/4/7/8

has two clock inputs. The three programming oscillators are low-jitter oscillators which are used to

provide special and high quality clock signals for high-speed transceivers. Figure 2-10 shows the

control circuits of programmable oscillators. The clock generator controller in the MAX II CPLD

can be used to program the CDCM61001 and CDCM61004 to generate 1G Ethernet SFP+ and

SATA reference clocks respectively. The Si570 programmable clock generator is programmed via

an I2C serial interface to generate the 10G Ethernet SFP+ reference clock. Two SMA connectors

provide external clock input and clock output respectively.

Page 20

DE5-Net User Manual

www.terasic.com

August 4, 2017

20

Figure 2-10 Control circuits of Programmable Oscillators

1Table 2-8 lists the clock source, signal names, default frequency and their corresponding Stratix V

GX device pin numbers.

Table 2-8 Clock Source, Signal Name, Default Frequency, Pin Assignments and Functions

Source

Schematic

Signal Name

Default

Frequency

I/O Standard

Stratix V GX Pin

Number

Application

Y4

OSC_50_B3B

50.0 MHz

2.5-V

PIN_AW35

OSC_50_B3D

1.8-V

PIN_BC28

OSC_50_B4A

1.8-V

PIN_AP10

OSC_50_B4D

1.8-V

PIN_AY18

OSC_50_B7A

1.5-V

PIN_M8

OSC_50_B7D

1.5-V

PIN_J18

OSC_50_B8A

1.5-V

PIN_R36

OSC_50_B8D

1.8-V

PIN_R25

J13

SMA_CLKIN

User

Defined

2.5V

PIN_BB33

External Clock

Input

J14

SMA_CLKOUT

User

Defined

2.5V

PIN_AV34

Clock Output

U49

SFP_REFCLK _p

100.0 MHz

LVDS

PIN_AK7

10G SFP+

U53

SFP1G_REFCLK_p

125.0 MHz

LVDS

PIN_AH6

1G SFP+

U28

SATA_HOST_REFCLK_p

125.0 MHz

LVDS

PIN_V6

SATA HOST

U28

SATA_DEVICE_REFCLK_p

125.0 MHz

LVDS

PIN_V39

SATA DEVICE

J17

PCIE_REFCLK_p

From Host

LVDS

PIN_AK38

PCI Express

Page 21

DE5-Net User Manual

www.terasic.com

August 4, 2017

21

Table 2-9 lists the programmable oscillator control pins, signal names, I/O standard and their

corresponding Stratix V GX device pin numbers.

Table 2-9 Programmable oscillator control pin, Signal Name, I/O standard, Pin Assignments

and Descriptions

Programmable

Oscillator

Schematic

Signal Name

I/O Standard

Stratix V GX Pin

Number

Description

Si570

(U49)

CLOCK_SCL

2.5-V

PIN_AE15

I2C bus, direct

connected with Si570

CLOCK_SDA

2.5-V

PIN_AE16

CDCM61001

(U53)

PLL_SCL

2.5-V

PIN_AF32

I2C bus, connected

with MAX II CPLD

PLL_SDA

2.5-V

PIN_AG32

CDCM61004

(U28)

PLL_SCL

2.5-V

PIN_AF32

I2C bus, connected

with MAX II CPLD

PLL_SDA

2.5-V

PIN_AG32

22..6

6

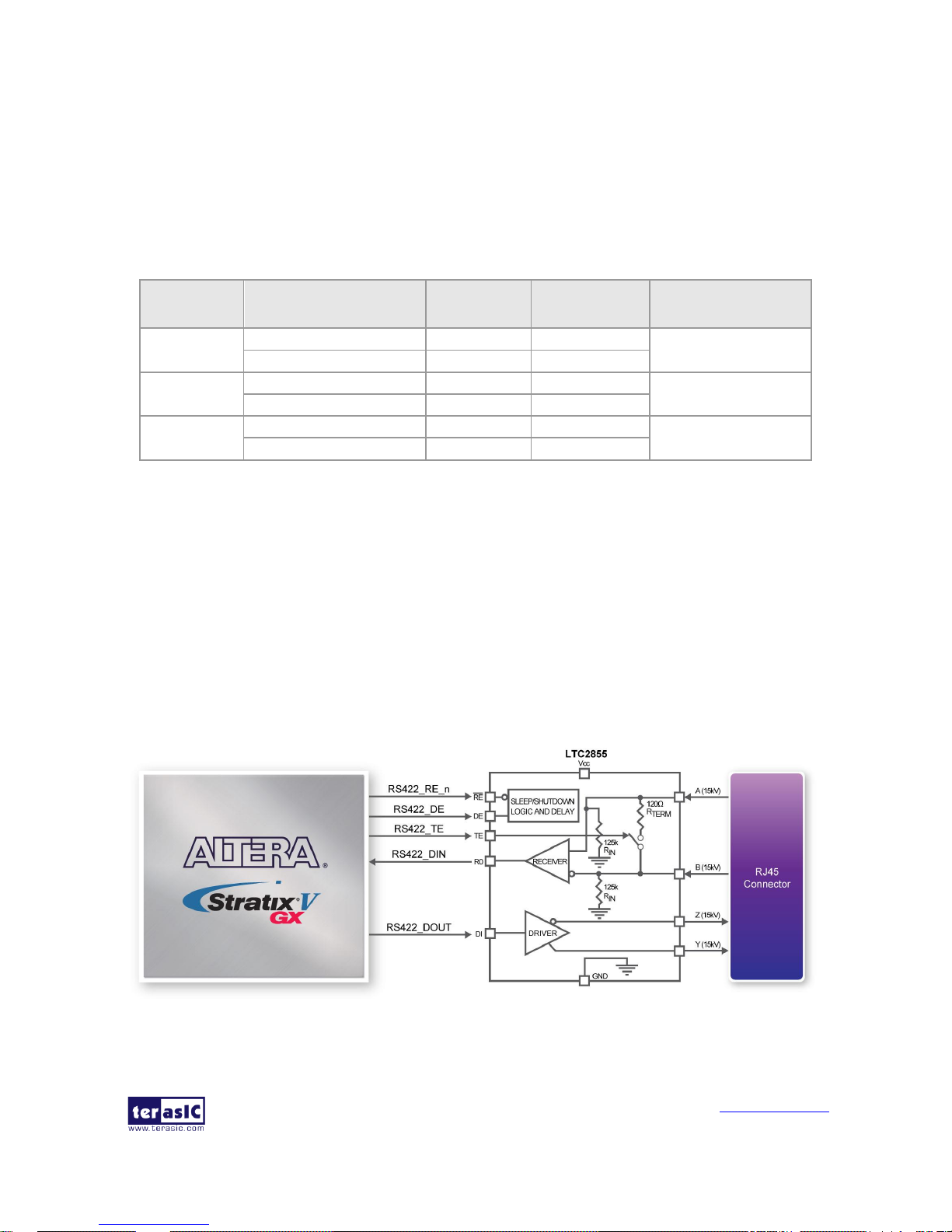

RRSS--442222 SSeerriiaall PPoorrtt

The RS-422 is designed to perform communication between boards, allowing a transmission speed

of up to 20 Mbps. Figure 2-11 shows the RS-422 block diagram of the development board. The

full-duplex LTC2855 is used to translate the RS-422 signal, and the RJ45 is used as an external

connector for the RS-422 signal.

Figure 2-11 Block Diagram of RS-422

Page 22

DE5-Net User Manual

www.terasic.com

August 4, 2017

22

Table 2-10 lists the RS-422 pin assignments, signal names and functions.

Table 2-10 RS-422 Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

RS422_DE

Driver Enable. A high on DE enables

the driver. A low input will force the

driver outputs into a high impedance

state.

2.5-V

PIN_AG14

RS422_DIN

Receiver Output. The data is send to

FPGA.

PIN_AE18

RS422_DOUT

Driver Input. The data is sent from

FPGA.

PIN_AE17

RS422_RE_n

Receiver Enable. A low enables the

receiver. A high input forces the

receiver output into a high impedance

state.

PIN_AF17

RS422_TE

Internal Termination Resistance

Enable. A high input will connect a

termination resistor (120Ω typical)

between pins A and B.

PIN_AF16

22..7

7

FFLLAASSHH MMeemmoorryy

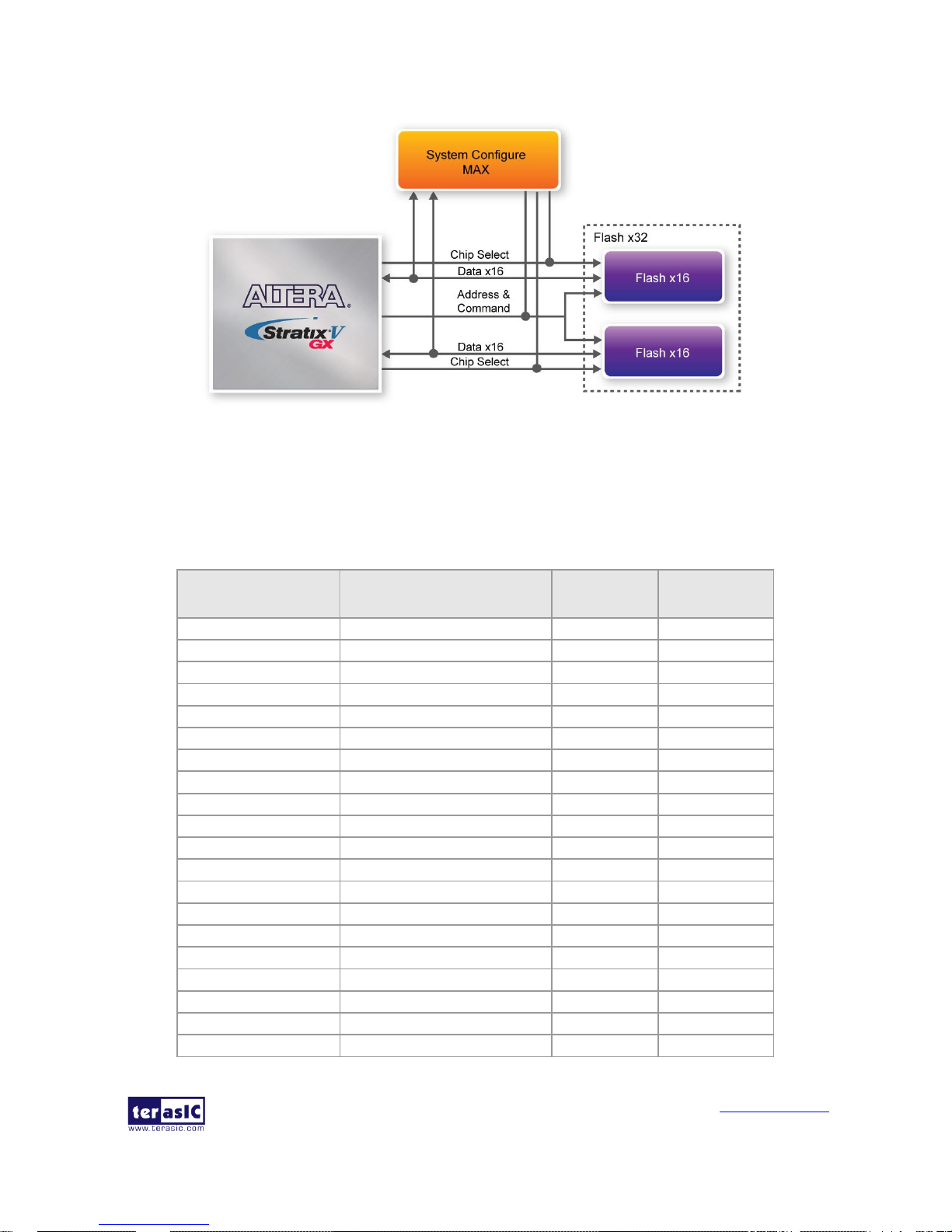

The development board has two 1Gb CFI-compatible synchronous flash devices for non-volatile

storage of FPGA configuration data, user application data, and user code space.

Each interface has a 16-bit data bus and the two devices combined allow for FPP x32 configuration.

This device is part of the shared flash and MAX (FM) bus, which connects to the flash memory and

MAX II CPLD (EPM2210) System Controller. Figure 2-12 shows the connections between the

Flash, MAX and Stratix V GX FPGA.

Page 23

DE5-Net User Manual

www.terasic.com

August 4, 2017

23

Figure 2-12 Connection between the Flash, Max and Stratix V GX FPGA

Table 2-11 lists the flash pin assignments, signal names, and functions.

Table 2-11 Flash Memory Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

FSM_A0

Address bus

2.5-V

PIN_AU32

FSM_A1

Address bus

2.5-V

PIN_AH30

FSM_A2

Address bus

2.5-V

PIN_AJ30

FSM_A3

Address bus

2.5-V

PIN_AH31

FSM_A4

Address bus

2.5-V

PIN_AK30

FSM_A5

Address bus

2.5-V

PIN_AJ32

FSM_A6

Address bus

2.5-V

PIN_AG33

FSM_A7

Address bus

2.5-V

PIN_AL30

FSM_A8

Address bus

2.5-V

PIN_AK33

FSM_A9

Address bus

2.5-V

PIN_AJ33

FSM_A10

Address bus

2.5-V

PIN_AN30

FSM_A11

Address bus

2.5-V

PIN_AH33

FSM_A12

Address bus

2.5-V

PIN_AK32

FSM_A13

Address bus

2.5-V

PIN_AM32

FSM_A14

Address bus

2.5-V

PIN_AM31

FSM_A15

Address bus

2.5-V

PIN_AL31

FSM_A16

Address bus

2.5-V

PIN_AN33

FSM_A17

Address bus

2.5-V

PIN_AP33

FSM_A18

Address bus

2.5-V

PIN_AT32

FSM_A19

Address bus

2.5-V

PIN_AT29

Page 24

DE5-Net User Manual

www.terasic.com

August 4, 2017

24

FSM_A20

Address bus

2.5-V

PIN_AP31

FSM_A21

Address bus

2.5-V

PIN_AR30

FSM_A22

Address bus

2.5-V

PIN_AU30

FSM_A23

Address bus

2.5-V

PIN_AJ31

FSM_A24

Address bus

2.5-V

PIN_AP30

FSM_A25

Address bus

2.5-V

PIN_AN31

FSM_A26

Address bus

2.5-V

PIN_AT30

FSM_D0

Data bus

2.5-V

PIN_AG26

FSM_D1

Data bus

2.5-V

PIN_AD33

FSM_D2

Data bus

2.5-V

PIN_AE34

FSM_D3

Data bus

2.5-V

PIN_AF31

FSM_D4

Data bus

2.5-V

PIN_AG28

FSM_D5

Data bus

2.5-V

PIN_AG30

FSM_D6

Data bus

2.5-V

PIN_AF29

FSM_D7

Data bus

2.5-V

PIN_AE29

FSM_D8

Data bus

2.5-V

PIN_AG25

FSM_D9

Data bus

2.5-V

PIN_AF34

FSM_D10

Data bus

2.5-V

PIN_AE33

FSM_D11

Data bus

2.5-V

PIN_AE31

FSM_D12

Data bus

2.5-V

PIN_AF28

FSM_D13

Data bus

2.5-V

PIN_AE30

FSM_D14

Data bus

2.5-V

PIN_AG29

FSM_D15

Data bus

2.5-V

PIN_AG27

FSM_D16

Data bus

2.5-V

PIN_AP28

FSM_D17

Data bus

2.5-V

PIN_AN28

FSM_D18

Data bus

2.5-V

PIN_AU31

FSM_D19

Data bus

2.5-V

PIN_AW32

FSM_D20

Data bus

2.5-V

PIN_BD32

FSM_D21

Data bus

2.5-V

PIN_AY31

FSM_D22

Data bus

2.5-V

PIN_BA30

FSM_D23

Data bus

2.5-V

PIN_BB30

FSM_D24

Data bus

2.5-V

PIN_AM29

FSM_D25

Data bus

2.5-V

PIN_AR29

FSM_D26

Data bus

2.5-V

PIN_AV31

FSM_D27

Data bus

2.5-V

PIN_AV32

FSM_D28

Data bus

2.5-V

PIN_BC31

FSM_D29

Data bus

2.5-V

PIN_AW30

FSM_D30

Data bus

2.5-V

PIN_BC32

FSM_D31

Data bus

2.5-V

PIN_BD31

FLASH_CLK

Clock

2.5-V

PIN_AL29

Page 25

DE5-Net User Manual

www.terasic.com

August 4, 2017

25

FLASH_RESET_n

Reset

2.5-V

PIN_AE28

FLASH_CE_n[0]

Chip enable of of flash-0

2.5-V

PIN_AE27

FLASH_CE_n[1]

Chip enable of of flash-1

2.5-V

PIN_BA31

FLASH_OE_n

Output enable

2.5-V

PIN_AY30

FLASH_WE_n

Write enable

2.5-V

PIN_AR31

FLASH_ADV_n

Address valid

2.5-V

PIN_AK29

FLASH_RDY_BSY_n[0]

Ready of flash-0

2.5-V

PIN_BA29

FLASH_RDY_BSY_n[1]

Ready of flash-1

2.5-V

PIN_BB32

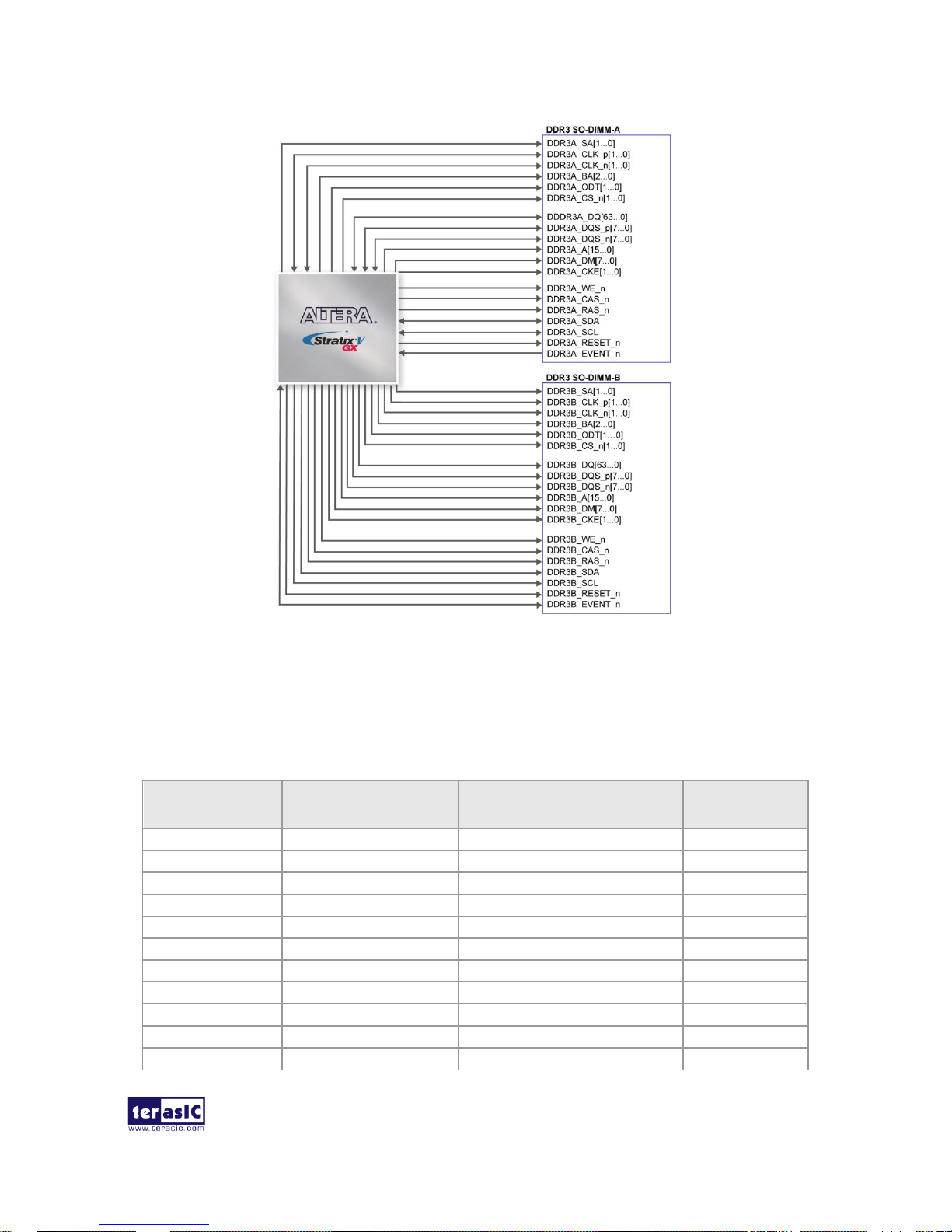

22..8

8

DDDDRR33 SSOO--DDIIMMMM

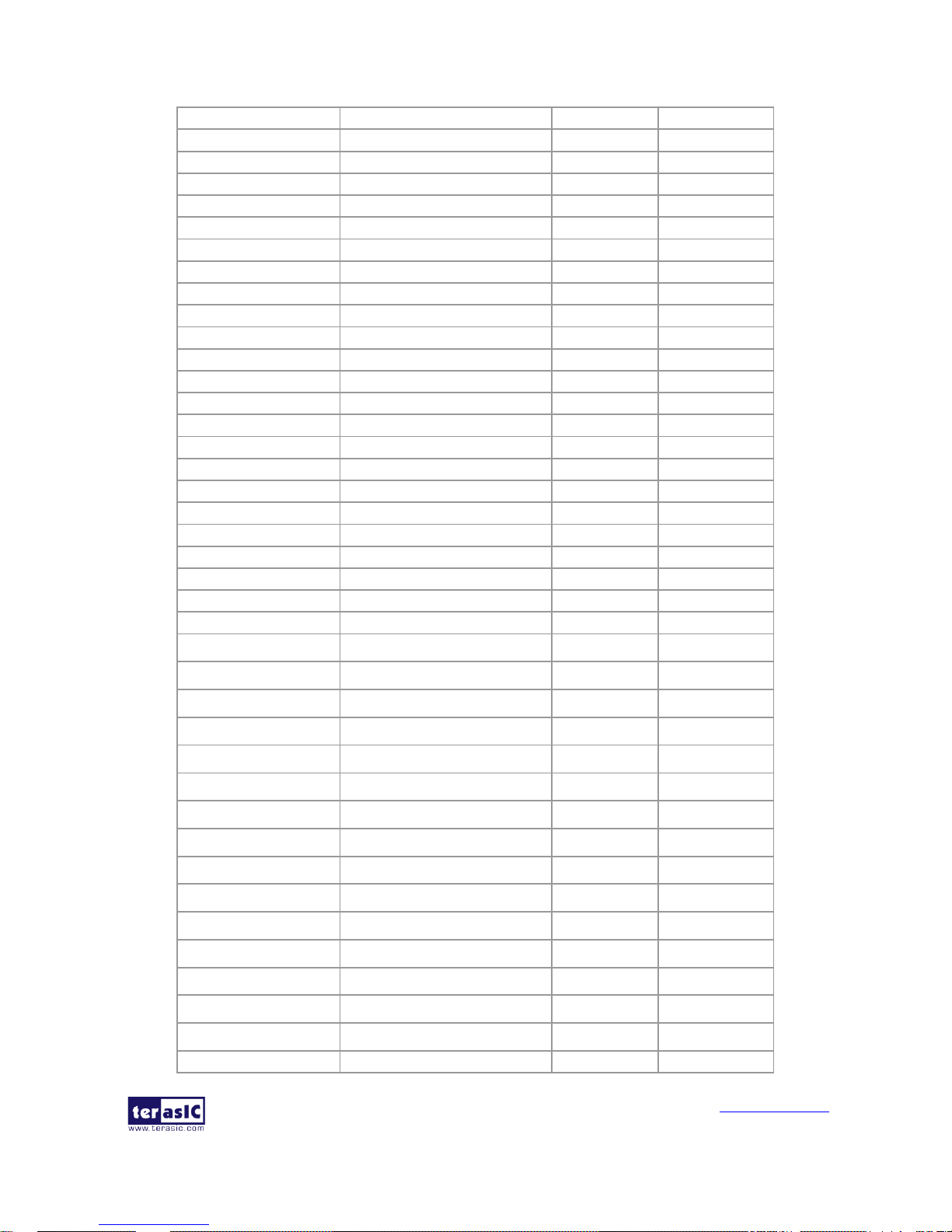

The development board supports two independent banks of DDR3 SDRAM SO-DIMM. Each

DDR3 SODIMM socket is wired to support a maximum capacity of 8GB with a 64-bit data bus.

Using differential DQS signaling for the DDR3 SDRAM interfaces, it is capable of running at up to

800MHz memory clock for a maximum theoretical bandwidth up to 102.4Gbps. Figure 2-13 shows

the connections between the DDR3 SDRAM SO-DIMMs and Stratix V GX FPGA.

Page 26

DE5-Net User Manual

www.terasic.com

August 4, 2017

26

Figure 2-13 Connection between the DDR3 and Stratix V GX FPGA

The pin assignments for DDR3 SDRAM SO-DIMM Bank-A and Bank-B are listed in 119H119HTable 2-12

and Table 2-13, in respectively.

Table 2-12 DDR3-A Bank Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

DDR3A_DQ0

Data [0]

SSTL-15 Class I

PIN_A35

DDR3A_DQ1

Data [1]

SSTL-15 Class I

PIN_A34

DDR3A_DQ2

Data [2]

SSTL-15 Class I

PIN_D36

DDR3A_DQ3

Data [3]

SSTL-15 Class I

PIN_C33

DDR3A_DQ4

Data [4]

SSTL-15 Class I

PIN_B32

DDR3A_DQ5

Data [5]

SSTL-15 Class I

PIN_D35

DDR3A_DQ6

Data [6]

SSTL-15 Class I

PIN_D33

DDR3A_DQ7

Data [7]

SSTL-15 Class I

PIN_E33

DDR3A_DQ8

Data [8]

SSTL-15 Class I

PIN_A32

DDR3A_DQ9

Data [9]

SSTL-15 Class I

PIN_A31

DDR3A_DQ10

Data [10]

SSTL-15 Class I

PIN_C30

Page 27

DE5-Net User Manual

www.terasic.com

August 4, 2017

27

DDR3A_DQ11

Data [11]

SSTL-15 Class I

PIN_D30

DDR3A_DQ12

Data [12]

SSTL-15 Class I

PIN_B29

DDR3A_DQ13

Data [13]

SSTL-15 Class I

PIN_E30

DDR3A_DQ14

Data [14]

SSTL-15 Class I

PIN_F31

DDR3A_DQ15

Data [15]

SSTL-15 Class I

PIN_G31

DDR3A_DQ16

Data [16]

SSTL-15 Class I

PIN_F35

DDR3A_DQ17

Data [17]

SSTL-15 Class I

PIN_G34

DDR3A_DQ18

Data [18]

SSTL-15 Class I

PIN_J33

DDR3A_DQ19

Data [19]

SSTL-15 Class I

PIN_J34

DDR3A_DQ20

Data [20]

SSTL-15 Class I

PIN_F34

DDR3A_DQ21

Data [21]

SSTL-15 Class I

PIN_E35

DDR3A_DQ22

Data [22]

SSTL-15 Class I

PIN_J31

DDR3A_DQ23

Data [23]

SSTL-15 Class I

PIN_K31

DDR3A_DQ24

Data [24]

SSTL-15 Class I

PIN_P34

DDR3A_DQ25

Data [25]

SSTL-15 Class I

PIN_R33

DDR3A_DQ26

Data [26]

SSTL-15 Class I

PIN_M34

DDR3A_DQ27

Data [27]

SSTL-15 Class I

PIN_L33

DDR3A_DQ28

Data [28]

SSTL-15 Class I

PIN_R34

DDR3A_DQ29

Data [29]

SSTL-15 Class I

PIN_T34

DDR3A_DQ30

Data [30]

SSTL-15 Class I

PIN_W34

DDR3A_DQ31

Data [31]

SSTL-15 Class I

PIN_V35

DDR3A_DQ32

Data [32]

SSTL-15 Class I

PIN_P33

DDR3A_DQ33

Data [33]

SSTL-15 Class I

PIN_P32

DDR3A_DQ34

Data [34]

SSTL-15 Class I

PIN_V33

DDR3A_DQ35

Data [35]

SSTL-15 Class I

PIN_V34

DDR3A_DQ36

Data [36]

SSTL-15 Class I

PIN_N31

DDR3A_DQ37

Data [37]

SSTL-15 Class I

PIN_M31

DDR3A_DQ38

Data [38]

SSTL-15 Class I

PIN_U32

DDR3A_DQ39

Data [39]

SSTL-15 Class I

PIN_U33

DDR3A_DQ40

Data [40]

SSTL-15 Class I

PIN_R31

DDR3A_DQ41

Data [41]

SSTL-15 Class I

PIN_W31

DDR3A_DQ42

Data [42]

SSTL-15 Class I

PIN_U30

DDR3A_DQ43

Data [43]

SSTL-15 Class I

PIN_P31

DDR3A_DQ44

Data [44]

SSTL-15 Class I

PIN_T31

DDR3A_DQ45

Data [45]

SSTL-15 Class I

PIN_Y32

DDR3A_DQ46

Data [46]

SSTL-15 Class I

PIN_T29

DDR3A_DQ47

Data [47]

SSTL-15 Class I

PIN_P30

DDR3A_DQ48

Data [48]

SSTL-15 Class I

PIN_H32

DDR3A_DQ49

Data [49]

SSTL-15 Class I

PIN_H31

DDR3A_DQ50

Data [50]

SSTL-15 Class I

PIN_L30

DDR3A_DQ51

Data [51]

SSTL-15 Class I

PIN_L29

DDR3A_DQ52

Data [52]

SSTL-15 Class I

PIN_F32

DDR3A_DQ53

Data [53]

SSTL-15 Class I

PIN_G32

DDR3A_DQ54

Data [54]

SSTL-15 Class I

PIN_M30

Page 28

DE5-Net User Manual

www.terasic.com

August 4, 2017

28

DDR3A_DQ55

Data [55]

SSTL-15 Class I

PIN_N29

DDR3A_DQ56

Data [56]

SSTL-15 Class I

PIN_U29

DDR3A_DQ57

Data [57]

SSTL-15 Class I

PIN_V28

DDR3A_DQ58

Data [58]

SSTL-15 Class I

PIN_Y28

DDR3A_DQ59

Data [59]

SSTL-15 Class I

PIN_W29

DDR3A_DQ60

Data [60]

SSTL-15 Class I

PIN_V30

DDR3A_DQ61

Data [61]

SSTL-15 Class I

PIN_V29

DDR3A_DQ62

Data [62]

SSTL-15 Class I

PIN_W28

DDR3A_DQ63

Data [63]

SSTL-15 Class I

PIN_Y27

DDR3A_DQS0

Data Strobe p[0]

Differential 1.5-V SSTL Class I

PIN_C34

DDR3A_DQS_n0

Data Strobe n[0]

Differential 1.5-V SSTL Class I

PIN_B34

DDR3A_DQS1

Data Strobe p[1]

Differential 1.5-V SSTL Class I

PIN_C31

DDR3A_DQS_n1

Data Strobe n[1]

Differential 1.5-V SSTL Class I

PIN_B31

DDR3A_DQS2

Data Strobe p[2]

Differential 1.5-V SSTL Class I

PIN_H35

DDR3A_DQS_n2

Data Strobe n[2]

Differential 1.5-V SSTL Class I

PIN_G35

DDR3A_DQS3

Data Strobe p[3]

Differential 1.5-V SSTL Class I

PIN_U35

DDR3A_DQS_n3

Data Strobe n[4]

Differential 1.5-V SSTL Class I

PIN_T35

DDR3A_DQS4

Data Strobe p[4]

Differential 1.5-V SSTL Class I

PIN_T33

DDR3A_DQS_n4

Data Strobe n[4]

Differential 1.5-V SSTL Class I

PIN_T32

DDR3A_DQS5

Data Strobe p[5]

Differential 1.5-V SSTL Class I

PIN_T30

DDR3A_DQS_n5

Data Strobe n[5]

Differential 1.5-V SSTL Class I

PIN_R30

DDR3A_DQS6

Data Strobe p[6]

Differential 1.5-V SSTL Class I

PIN_J30

DDR3A_DQS_n6

Data Strobe n[6]

Differential 1.5-V SSTL Class I

PIN_H30

DDR3A_DQS7

Data Strobe p[7]

Differential 1.5-V SSTL Class I

PIN_Y30

DDR3A_DQS_n7

Data Strobe n[7]

Differential 1.5-V SSTL Class I

PIN_Y29

DDR3A_DM0

Data Mask [0]

SSTL-15 Class I

PIN_C36

DDR3A_DM1

Data Mask [1]

SSTL-15 Class I

PIN_E32

DDR3A_DM2

Data Mask [2]

SSTL-15 Class I

PIN_H34

DDR3A_DM3

Data Mask [3]

SSTL-15 Class I

PIN_L32

DDR3A_DM4

Data Mask [4]

SSTL-15 Class I

PIN_N32

DDR3A_DM5

Data Mask [5]

SSTL-15 Class I

PIN_W32

DDR3A_DM6

Data Mask [6]

SSTL-15 Class I

PIN_K30

DDR3A_DM7

Data Mask [7]

SSTL-15 Class I

PIN_T28

DDR3A_A0

Address [0]

SSTL-15 Class I

PIN_M39

DDR3A_A1

Address [1]

SSTL-15 Class I

PIN_L35

DDR3A_A2

Address [2]

SSTL-15 Class I

PIN_N38

DDR3A_A3

Address [3]

SSTL-15 Class I

PIN_L36

DDR3A_A4

Address [4]

SSTL-15 Class I

PIN_H36

DDR3A_A5

Address [5]

SSTL-15 Class I

PIN_K29

DDR3A_A6

Address [6]

SSTL-15 Class I

PIN_D37

DDR3A_A7

Address [7]

SSTL-15 Class I

PIN_K35

DDR3A_A8

Address [8]

SSTL-15 Class I

PIN_K32

DDR3A_A9

Address [9]

SSTL-15 Class I

PIN_K37

DDR3A_A10

Address [10]

SSTL-15 Class I

PIN_M38

Page 29

DE5-Net User Manual

www.terasic.com

August 4, 2017

29

DDR3A_A11

Address [11]

SSTL-15 Class I

PIN_C37

DDR3A_A12

Address [12]

SSTL-15 Class I

PIN_K36

DDR3A_A13

Address [13]

SSTL-15 Class I

PIN_M33

DDR3A_A14

Address [14]

SSTL-15 Class I

PIN_K34

DDR3A_A15

Address [15]

SSTL-15 Class I

PIN_B38

DDR3A_RAS_n

Row Address Strobe

SSTL-15 Class I

PIN_P38

DDR3A_CAS_n

Column Address Strobe

SSTL-15 Class I

PIN_M36

DDR3A_BA0

Bank Address [0]

SSTL-15 Class I

PIN_M37

DDR3A_BA1

Bank Address [1]

SSTL-15 Class I

PIN_P39

DDR3A_BA2

Bank Address [2]

SSTL-15 Class I

PIN_J36

DDR3A_CK0

Clock p0

Differential 1.5-V SSTL Class I

PIN_G37

DDR3A_CK_n0

Clock n0

Differential 1.5-V SSTL Class I

PIN_F36

DDR3A_CK1

Clock p1

Differential 1.5-V SSTL Class I

PIN_J37

DDR3A_CK_n1

Clock n1

Differential 1.5-V SSTL Class I

PIN_H37

DDR3A_CKE0

Clock Enable pin 0

SSTL-15 Class I

PIN_E36

DDR3A_CKE1

Clock Enable pin 1

SSTL-15 Class I

PIN_B35

DDR3A_ODT0

On Die Termination[0]

SSTL-15 Class I

PIN_V36

DDR3A_ODT1

On Die Termination[1]

SSTL-15 Class I

PIN_W35

DDR3A_WE_n

Write Enable

SSTL-15 Class I

PIN_N37

DDR3A_CS_n0

Chip Select [0]

SSTL-15 Class I

PIN_P36

DDR3A_CS_n1

Chip Select [1]

SSTL-15 Class I

PIN_R28

DDR3A_RESET_n

Chip Reset

SSTL-15 Class I

PIN_H33

DDR3A_EVENT_n

Chip Temperature Event

SSTL-15 Class I

PIN_K19

DDR3A_SDA

Chip I2C Serial Clock

1.5V

PIN_P15

DDR3A_SCL

Chip I2C Serial Data Bus

1.5V

PIN_C15

Table 2-13 DDR3-B Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

DDR3B_DQ0

Data [0]

SSTL-15 Class I

PIN_Y17

DDR3B_DQ1

Data [1]

SSTL-15 Class I

PIN_W17

DDR3B_DQ2

Data [2]

SSTL-15 Class I

PIN_V15

DDR3B_DQ3

Data [3]

SSTL-15 Class I

PIN_T15

DDR3B_DQ4

Data [4]

SSTL-15 Class I

PIN_V13

DDR3B_DQ5

Data [5]

SSTL-15 Class I

PIN_V16

DDR3B_DQ6

Data [6]

SSTL-15 Class I

PIN_W14

DDR3B_DQ7

Data [7]

SSTL-15 Class I

PIN_U15

DDR3B_DQ8

Data [8]

SSTL-15 Class I

PIN_T17

DDR3B_DQ9

Data [9]

SSTL-15 Class I

PIN_T16

DDR3B_DQ10

Data [10]

SSTL-15 Class I

PIN_R16

Page 30

DE5-Net User Manual

www.terasic.com

August 4, 2017

30

DDR3B_DQ11

Data [11]

SSTL-15 Class I

PIN_P16

DDR3B_DQ12

Data [12]

SSTL-15 Class I

PIN_N16

DDR3B_DQ13

Data [13]

SSTL-15 Class I

PIN_M15

DDR3B_DQ14

Data [14]

SSTL-15 Class I

PIN_M14

DDR3B_DQ15

Data [15]

SSTL-15 Class I

PIN_L14

DDR3B_DQ16

Data [16]

SSTL-15 Class I

PIN_T14

DDR3B_DQ17

Data [17]

SSTL-15 Class I

PIN_U14

DDR3B_DQ18

Data [18]

SSTL-15 Class I

PIN_U11

DDR3B_DQ19

Data [19]

SSTL-15 Class I

PIN_T13

DDR3B_DQ20

Data [20]

SSTL-15 Class I

PIN_U12

DDR3B_DQ21

Data [21]

SSTL-15 Class I

PIN_R13

DDR3B_DQ22

Data [22]

SSTL-15 Class I

PIN_P13

DDR3B_DQ23

Data [23]

SSTL-15 Class I

PIN_N13

DDR3B_DQ24

Data [24]

SSTL-15 Class I

PIN_K12

DDR3B_DQ25

Data [25]

SSTL-15 Class I

PIN_J12

DDR3B_DQ26

Data [26]

SSTL-15 Class I

PIN_J10

DDR3B_DQ27

Data [27]

SSTL-15 Class I

PIN_H12

DDR3B_DQ28

Data [28]

SSTL-15 Class I

PIN_N11

DDR3B_DQ29

Data [29]

SSTL-15 Class I

PIN_M11

DDR3B_DQ30

Data [30]

SSTL-15 Class I

PIN_H10

DDR3B_DQ31

Data [31]

SSTL-15 Class I

PIN_H11

DDR3B_DQ32

Data [32]

SSTL-15 Class I

PIN_T10

DDR3B_DQ33

Data [33]

SSTL-15 Class I

PIN_R10

DDR3B_DQ34

Data [34]

SSTL-15 Class I

PIN_M12

DDR3B_DQ35

Data [35]

SSTL-15 Class I

PIN_L12

DDR3B_DQ36

Data [36]

SSTL-15 Class I

PIN_V10

DDR3B_DQ37

Data [37]

SSTL-15 Class I

PIN_V9

DDR3B_DQ38

Data [38]

SSTL-15 Class I

PIN_R12

DDR3B_DQ39

Data [39]

SSTL-15 Class I

PIN_P12

DDR3B_DQ40

Data [40]

SSTL-15 Class I

PIN_D14

DDR3B_DQ41

Data [41]

SSTL-15 Class I

PIN_C13

DDR3B_DQ42

Data [42]

SSTL-15 Class I

PIN_B14

DDR3B_DQ43

Data [43]

SSTL-15 Class I

PIN_B13

DDR3B_DQ44

Data [44]

SSTL-15 Class I

PIN_E14

DDR3B_DQ45

Data [45]

SSTL-15 Class I

PIN_F14

DDR3B_DQ46

Data [46]

SSTL-15 Class I

PIN_A14

DDR3B_DQ47

Data [47]

SSTL-15 Class I

PIN_A13

DDR3B_DQ48

Data [48]

SSTL-15 Class I

PIN_K13

DDR3B_DQ49

Data [49]

SSTL-15 Class I

PIN_K16

DDR3B_DQ50

Data [50]

SSTL-15 Class I

PIN_H13

DDR3B_DQ51

Data [51]

SSTL-15 Class I

PIN_H14

DDR3B_DQ52

Data [52]

SSTL-15 Class I

PIN_J13

DDR3B_DQ53

Data [53]

SSTL-15 Class I

PIN_J16

DDR3B_DQ54

Data [54]

SSTL-15 Class I

PIN_G13

Page 31

DE5-Net User Manual

www.terasic.com

August 4, 2017

31

DDR3B_DQ55

Data [55]

SSTL-15 Class I

PIN_F13

DDR3B_DQ56

Data [56]

SSTL-15 Class I

PIN_D11

DDR3B_DQ57

Data [57]

SSTL-15 Class I

PIN_C10

DDR3B_DQ58

Data [58]

SSTL-15 Class I

PIN_A10

DDR3B_DQ59

Data [59]

SSTL-15 Class I

PIN_B10

DDR3B_DQ60

Data [60]

SSTL-15 Class I

PIN_G11

DDR3B_DQ61

Data [61]

SSTL-15 Class I

PIN_F11

DDR3B_DQ62

Data [62]

SSTL-15 Class I

PIN_E11

DDR3B_DQ63

Data [63]

SSTL-15 Class I

PIN_E12

DDR3B_DQS0

Data Strobe p[0]

Differential 1.5-V SSTL Class I

PIN_Y16

DDR3B_DQS_n0

Data Strobe n[0]

Differential 1.5-V SSTL Class I

PIN_W16

DDR3B_DQS1

Data Strobe p[1]

Differential 1.5-V SSTL Class I

PIN_V17

DDR3B_DQS_n1

Data Strobe n[1]

Differential 1.5-V SSTL Class I

PIN_U17

DDR3B_DQS2

Data Strobe p[2]

Differential 1.5-V SSTL Class I

PIN_P14

DDR3B_DQS_n2

Data Strobe n[2]

Differential 1.5-V SSTL Class I

PIN_N14

DDR3B_DQS3

Data Strobe p[3]

Differential 1.5-V SSTL Class I

PIN_K11

DDR3B_DQS_n3

Data Strobe n[3]

Differential 1.5-V SSTL Class I

PIN_L11

DDR3B_DQS4

Data Strobe p[4]

Differential 1.5-V SSTL Class I

PIN_U9

DDR3B_DQS_n4

Data Strobe n[4]

Differential 1.5-V SSTL Class I

PIN_T9

DDR3B_DQS5

Data Strobe p[5]

Differential 1.5-V SSTL Class I

PIN_E15

DDR3B_DQS_n5

Data Strobe n[5]

Differential 1.5-V SSTL Class I

PIN_D15

DDR3B_DQS6

Data Strobe p[6]

Differential 1.5-V SSTL Class I

PIN_L15

DDR3B_DQS_n6

Data Strobe n[6]

Differential 1.5-V SSTL Class I

PIN_K14

DDR3B_DQS7

Data Strobe p[7]

Differential 1.5-V SSTL Class I

PIN_D12

DDR3B_DQS_n7

Data Strobe n[7]

Differential 1.5-V SSTL Class I

PIN_C12

DDR3B_DM0

Data Mask [0]

SSTL-15 Class I

PIN_R15

DDR3B_DM1

Data Mask [1]

SSTL-15 Class I

PIN_K15

DDR3B_DM2

Data Mask [2]

SSTL-15 Class I

PIN_V12

DDR3B_DM3

Data Mask [3]

SSTL-15 Class I

PIN_G10

DDR3B_DM4

Data Mask [4]

SSTL-15 Class I

PIN_T12

DDR3B_DM5

Data Mask [5]

SSTL-15 Class I

PIN_C16

DDR3B_DM6

Data Mask [6]

SSTL-15 Class I

PIN_H15

DDR3B_DM7

Data Mask [7]

SSTL-15 Class I

PIN_B11

DDR3B_A0

Address [0]

SSTL-15 Class I

PIN_G17

DDR3B_A1

Address [1]

SSTL-15 Class I

PIN_F17

DDR3B_A2

Address [2]

SSTL-15 Class I

PIN_N17

DDR3B_A3

Address [3]

SSTL-15 Class I

PIN_F19

DDR3B_A4

Address [4]

SSTL-15 Class I

PIN_N19

DDR3B_A5

Address [5]

SSTL-15 Class I

PIN_H16

DDR3B_A6

Address [6]

SSTL-15 Class I

PIN_M17

DDR3B_A7

Address [7]

SSTL-15 Class I

PIN_T18

DDR3B_A8

Address [8]

SSTL-15 Class I

PIN_H17

DDR3B_A9

Address [9]

SSTL-15 Class I

PIN_J19

DDR3B_A10

Address [10]

SSTL-15 Class I

PIN_C19

Page 32

DE5-Net User Manual

www.terasic.com

August 4, 2017

32

DDR3B_A11

Address [11]

SSTL-15 Class I

PIN_R18

DDR3B_A12

Address [12]

SSTL-15 Class I

PIN_K18

DDR3B_A13

Address [13]

SSTL-15 Class I

PIN_E18

DDR3B_A14

Address [14]

SSTL-15 Class I

PIN_T19

DDR3B_A15

Address [15]

SSTL-15 Class I

PIN_R19

DDR3B_RAS_n

Row Address Strobe

SSTL-15 Class I

PIN_H19

DDR3B_CAS_n

Column Address Strobe

SSTL-15 Class I

PIN_A17

DDR3B_BA0

Bank Address [0]

SSTL-15 Class I

PIN_C18

DDR3B_BA1

Bank Address [1]

SSTL-15 Class I

PIN_G19

DDR3B_BA2

Bank Address [2]

SSTL-15 Class I

PIN_M20

DDR3B_CK0

Clock p0

Differential 1.5-V SSTL Class I

PIN_B16

DDR3B_CK_n0

Clock n0

Differential 1.5-V SSTL Class I

PIN_A16

DDR3B_CK1

Clock p1

Differential 1.5-V SSTL Class I

PIN_E17

DDR3B_CK_n1

Clock n1

Differential 1.5-V SSTL Class I

PIN_D17

DDR3B_CKE0

Clock Enable pin 0

SSTL-15 Class I

PIN_P17

DDR3B_CKE1

Clock Enable pin 1

SSTL-15 Class I

PIN_V18

DDR3B_ODT0

On Die Termination[0]

SSTL-15 Class I

PIN_M18

DDR3B_ODT1

On Die Termination[1]

SSTL-15 Class I

PIN_A19

DDR3B_WE_n

Write Enable

SSTL-15 Class I

PIN_D18

DDR3B_CS_n0

Chip Select [0]

SSTL-15 Class I

PIN_B19

DDR3B_CS_n1

Chip Select [1]

SSTL-15 Class I

PIN_B17

DDR3B_RESET_n

Chip Reset

SSTL-15 Class I

PIN_T20

DDR3B_EVENT_n

Chip Reset

SSTL-15 Class I

PIN_K17

DDR3B_SDA

Chip I2C Serial Clock

1.5V

PIN_P19

DDR3B_SCL

Chip I2C Serial Data Bus

1.5V

PIN_P18

22..9

9

QQDDRRIIII++ SSRRAAMM

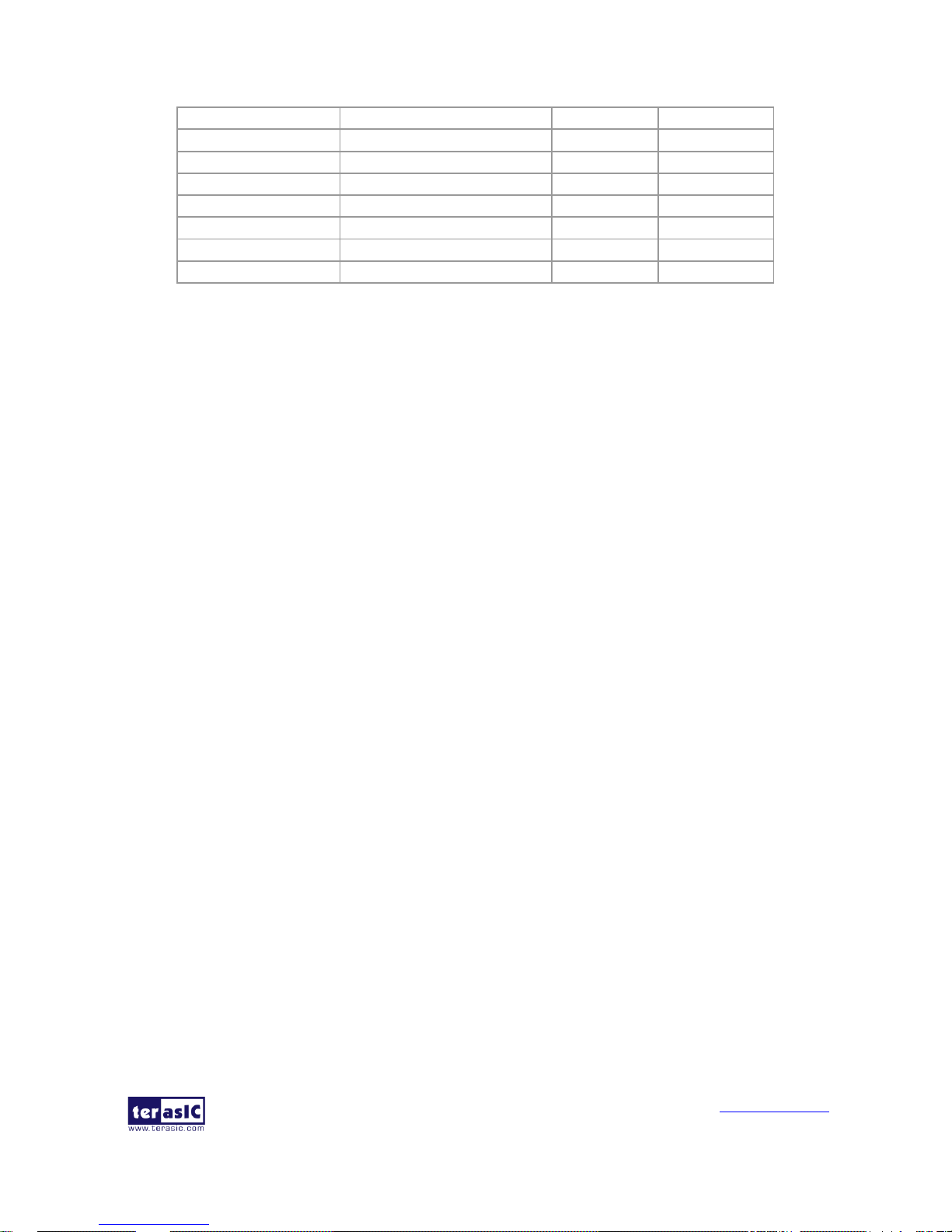

The development board supports four independent QDRII+ SRAM memory devices for very-high

speed and low-latency memory access. Each of QDRII+ has a x18 interface, providing addressing

to a device of up to a 8MB (not including parity bits). The QDRII+ has separate read and write data

ports with DDR signaling at up to 550 MHz.

Table 2-14, 1Table 2-15 and Table 2-16 lists the QDRII+ SRAM Bank A, B, C and D pin

assignments, signal names relative to the Stratix I GX device, in respectively.

Table 2-14 QDRII+ SRAM A Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

QDRIIA_A0

Address bus[0]

1.8-V HSTL Class I

PIN_AU29

Page 33

DE5-Net User Manual

www.terasic.com

August 4, 2017

33

QDRIIA_A1

Address bus[1]

1.8-V HSTL Class I

PIN_BA28

QDRIIA_A2

Address bus[2]

1.8-V HSTL Class I

PIN_AP27

QDRIIA_A3

Address bus[3]

1.8-V HSTL Class I

PIN_AK27

QDRIIA_A4

Address bus[4]

1.8-V HSTL Class I

PIN_AN27

QDRIIA_A5

Address bus[5]

1.8-V HSTL Class I

PIN_AM28

QDRIIA_A6

Address bus[6]

1.8-V HSTL Class I

PIN_AV28

QDRIIA_A7

Address bus[7]

1.8-V HSTL Class I

PIN_AY27

QDRIIA_A8

Address bus[8]

1.8-V HSTL Class I

PIN_BC29

QDRIIA_A9

Address bus[9]

1.8-V HSTL Class I

PIN_AU28

QDRIIA_A10

Address bus[10]

1.8-V HSTL Class I

PIN_AW27

QDRIIA_A11

Address bus[11]

1.8-V HSTL Class I

PIN_AY28

QDRIIA_A12

Address bus[12]

1.8-V HSTL Class I

PIN_BD28

QDRIIA_A13

Address bus[13]

1.8-V HSTL Class I

PIN_AV29

QDRIIA_A14

Address bus[14]

1.8-V HSTL Class I

PIN_AW29

QDRIIA_A15

Address bus[15]

1.8-V HSTL Class I

PIN_BB29

QDRIIA_A16

Address bus[16]

1.8-V HSTL Class I

PIN_BD29

QDRIIA_A17

Address bus[17]

1.8-V HSTL Class I

PIN_AL27

QDRIIA_A18

Address bus[18]

1.8-V HSTL Class I

PIN_AR27

QDRIIA_A19

Address bus[19]

1.8-V HSTL Class I

PIN_AL28

QDRIIA_A20

Address bus[20]

1.8-V HSTL Class I

PIN_AR28

QDRIIA_D0

Write data bus[0]

1.8-V HSTL Class I

PIN_AH28

QDRIIA_D1

Write data bus[1]

1.8-V HSTL Class I

PIN_AH27

QDRIIA_D2

Write data bus[2]

1.8-V HSTL Class I

PIN_AH25

QDRIIA_D3

Write data bus[3]

1.8-V HSTL Class I

PIN_AJ28

QDRIIA_D4

Write data bus[4]

1.8-V HSTL Class I

PIN_AJ27

QDRIIA_D5

Write data bus[5]

1.8-V HSTL Class I

PIN_AJ26

QDRIIA_D6

Write data bus[6]

1.8-V HSTL Class I

PIN_AJ25

QDRIIA_D7

Write data bus[7]

1.8-V HSTL Class I

PIN_AL25

QDRIIA_D8

Write data bus[8]

1.8-V HSTL Class I

PIN_AH24

QDRIIA_D9

Write data bus[9]

1.8-V HSTL Class I

PIN_AN25

QDRIIA_D10

Write data bus[10]

1.8-V HSTL Class I

PIN_AM26

QDRIIA_D11

Write data bus[11]

1.8-V HSTL Class I

PIN_AM25

QDRIIA_D12

Write data bus[12]

1.8-V HSTL Class I

PIN_AL26

QDRIIA_D13

Write data bus[13]

1.8-V HSTL Class I

PIN_AK26

QDRIIA_D14

Write data bus[14]

1.8-V HSTL Class I

PIN_AU27

QDRIIA_D15

Write data bus[15]

1.8-V HSTL Class I

PIN_AU26

QDRIIA_D16

Write data bus[16]

1.8-V HSTL Class I

PIN_AV26

QDRIIA_D17

Write data bus[17]

1.8-V HSTL Class I

PIN_AW26

QDRIIA_Q0

Read Data bus[0]

1.8-V HSTL Class I

PIN_AK23

QDRIIA_Q1

Read Data bus[1]

1.8-V HSTL Class I

PIN_BB26

QDRIIA_Q2

Read Data bus[2]

1.8-V HSTL Class I

PIN_BD26

QDRIIA_Q3

Read Data bus[3]

1.8-V HSTL Class I

PIN_BA24

QDRIIA_Q4

Read Data bus[4]

1.8-V HSTL Class I

PIN_AL23

QDRIIA_Q5

Read Data bus[5]

1.8-V HSTL Class I

PIN_AJ23

Page 34

DE5-Net User Manual

www.terasic.com

August 4, 2017

34

QDRIIA_Q6

Read Data bus[6]

1.8-V HSTL Class I

PIN_AL21

QDRIIA_Q7

Read Data bus[7]

1.8-V HSTL Class I

PIN_AK21

QDRIIA_Q8

Read Data bus[8]

1.8-V HSTL Class I

PIN_AJ22

QDRIIA_Q9

Read Data bus[9]

1.8-V HSTL Class I

PIN_AW24

QDRIIA_Q10

Read Data bus[10]

1.8-V HSTL Class I

PIN_BC26

QDRIIA_Q11

Read Data bus[11]

1.8-V HSTL Class I

PIN_AY25

QDRIIA_Q12

Read Data bus[12]

1.8-V HSTL Class I

PIN_AU24

QDRIIA_Q13

Read Data bus[13]

1.8-V HSTL Class I

PIN_AV25

QDRIIA_Q14

Read Data bus[14]

1.8-V HSTL Class I

PIN_AU25

QDRIIA_Q15

Read Data bus[15]

1.8-V HSTL Class I

PIN_AR25

QDRIIA_Q16

Read Data bus[16]

1.8-V HSTL Class I

PIN_AP24

QDRIIA_Q17

Read Data bus[17]

1.8-V HSTL Class I

PIN_AL24

QDRIIA_BWS_n0

Byte Write select[0]

1.8-V HSTL Class I

PIN_AJ24

QDRIIA_BWS_n1

Byte Write select[1]

1.8-V HSTL Class I

PIN_AT27

QDRIIA_K_P

Clock P

Differential 1.8-V HSTL Class I

PIN_AP25

QDRIIA_K_N

Clock N

Differential 1.8-V HSTL Class I

PIN_AR26

QDRIIA_CQ_P

Echo clock P

1.8-V HSTL Class I

PIN_AH22

QDRIIA_CQ_N

Echo clock N

1.8-V HSTL Class I

PIN_BA25

QDRIIA_RPS_n

Report Select

1.8-V HSTL Class I

PIN_AT26

QDRIIA_WPS_n

Write Port Select

1.8-V HSTL Class I

PIN_AK24

QDRIIA_DOFF_n

DLL enable

1.8-V HSTL Class I

PIN_AR23

QDRIIA_ODT

On-Die Termination

Input

1.8-V HSTL Class I

PIN_AN23

QDRII_QVLD

Valid Output

Indicator

1.8-V HSTL Class I

PIN_AM23

Table 2-15 QDRII+ SRAM B Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

QDRIIB_A0

Address bus[0]

1.8-V HSTL Class I

PIN_AR24

QDRIIB_A1

Address bus[1]

1.8-V HSTL Class I

PIN_BB23

QDRIIB_A2

Address bus[2]

1.8-V HSTL Class I

PIN_AK20

QDRIIB_A3

Address bus[3]

1.8-V HSTL Class I

PIN_AJ19

QDRIIB_A4

Address bus[4]

1.8-V HSTL Class I

PIN_AL20

QDRIIB_A5

Address bus[5]

1.8-V HSTL Class I

PIN_AG19

QDRIIB_A6

Address bus[6]

1.8-V HSTL Class I

PIN_AT23

QDRIIB_A7

Address bus[7]

1.8-V HSTL Class I

PIN_AU23

QDRIIB_A8

Address bus[8]

1.8-V HSTL Class I

PIN_AV23

QDRIIB_A9

Address bus[9]

1.8-V HSTL Class I

PIN_AM22

QDRIIB_A10

Address bus[10]

1.8-V HSTL Class I

PIN_AJ20

QDRIIB_A11

Address bus[11]

1.8-V HSTL Class I

PIN_AG20

QDRIIB_A12

Address bus[12]

1.8-V HSTL Class I

PIN_AW23

Page 35

DE5-Net User Manual

www.terasic.com

August 4, 2017

35

QDRIIB_A13

Address bus[13]

1.8-V HSTL Class I

PIN_BB24

QDRIIB_A14

Address bus[14]

1.8-V HSTL Class I

PIN_AY24

QDRIIB_A15

Address bus[15]

1.8-V HSTL Class I

PIN_BD23

QDRIIB_A16

Address bus[16]

1.8-V HSTL Class I

PIN_BC23

QDRIIB_A17

Address bus[17]

1.8-V HSTL Class I

PIN_AG21

QDRIIB_A18

Address bus[18]

1.8-V HSTL Class I

PIN_AM20

QDRIIB_A19

Address bus[19]

1.8-V HSTL Class I

PIN_AK18

QDRIIB_A20

Address bus[20]

1.8-V HSTL Class I

PIN_AN22

QDRIIB_D0

Write data bus[0]

1.8-V HSTL Class I

PIN_BB21

QDRIIB_D1

Write data bus[1]

1.8-V HSTL Class I

PIN_BD20

QDRIIB_D2

Write data bus[2]

1.8-V HSTL Class I

PIN_BC20

QDRIIB_D3

Write data bus[3]

1.8-V HSTL Class I

PIN_AR22

QDRIIB_D4

Write data bus[4]

1.8-V HSTL Class I

PIN_BB20

QDRIIB_D5

Write data bus[5]

1.8-V HSTL Class I

PIN_AU22

QDRIIB_D6

Write data bus[6]

1.8-V HSTL Class I

PIN_BA21

QDRIIB_D7

Write data bus[7]

1.8-V HSTL Class I

PIN_AY21

QDRIIB_D8

Write data bus[8]

1.8-V HSTL Class I

PIN_AW21

QDRIIB_D9

Write data bus[9]

1.8-V HSTL Class I

PIN_AT21

QDRIIB_D10

Write data bus[10]

1.8-V HSTL Class I

PIN_AR21

QDRIIB_D11

Write data bus[11]

1.8-V HSTL Class I

PIN_AP21

QDRIIB_D12

Write data bus[12]

1.8-V HSTL Class I

PIN_BD22

QDRIIB_D13

Write data bus[13]

1.8-V HSTL Class I

PIN_BC22

QDRIIB_D14

Write data bus[14]

1.8-V HSTL Class I

PIN_BA22

QDRIIB_D15

Write data bus[15]

1.8-V HSTL Class I

PIN_AV22

QDRIIB_D16

Write data bus[16]

1.8-V HSTL Class I

PIN_AY22

QDRIIB_D17

Write data bus[17]

1.8-V HSTL Class I

PIN_AW22

QDRIIB_Q0

Read Data bus[0]

1.8-V HSTL Class I

PIN_AR19

QDRIIB_Q1

Read Data bus[1]

1.8-V HSTL Class I

PIN_AM19

QDRIIB_Q2

Read Data bus[2]

1.8-V HSTL Class I

PIN_AL19

QDRIIB_Q3

Read Data bus[3]

1.8-V HSTL Class I

PIN_AM17

QDRIIB_Q4

Read Data bus[4]

1.8-V HSTL Class I

PIN_AL18

QDRIIB_Q5

Read Data bus[5]

1.8-V HSTL Class I

PIN_AN19

QDRIIB_Q6

Read Data bus[6]

1.8-V HSTL Class I

PIN_AU18

QDRIIB_Q7

Read Data bus[7]

1.8-V HSTL Class I

PIN_AK17

QDRIIB_Q8

Read Data bus[8]

1.8-V HSTL Class I

PIN_AL17

QDRIIB_Q9

Read Data bus[9]

1.8-V HSTL Class I

PIN_AG17

QDRIIB_Q10

Read Data bus[10]

1.8-V HSTL Class I

PIN_AJ18

QDRIIB_Q11

Read Data bus[11]

1.8-V HSTL Class I

PIN_AJ17

QDRIIB_Q12

Read Data bus[12]

1.8-V HSTL Class I

PIN_AG18

QDRIIB_Q13

Read Data bus[13]

1.8-V HSTL Class I

PIN_AU19

QDRIIB_Q14

Read Data bus[14]

1.8-V HSTL Class I

PIN_AW19

QDRIIB_Q15

Read Data bus[15]

1.8-V HSTL Class I

PIN_AV19

QDRIIB_Q16

Read Data bus[16]

1.8-V HSTL Class I

PIN_AP19

QDRIIB_Q17

Read Data bus[17]

1.8-V HSTL Class I

PIN_AN20

Page 36

DE5-Net User Manual

www.terasic.com

August 4, 2017

36

QDRIIB_BWS_n0

Byte Write select[0]

1.8-V HSTL Class I

PIN_AV20

QDRIIB_BWS_n1

Byte Write select[1]

1.8-V HSTL Class I

PIN_AU21

QDRIIB_K_p

Clock P

Differential 1.8-V HSTL Class I

PIN_AR20

QDRIIB_K_n

Clock N

Differential 1.8-V HSTL Class I

PIN_AT20

QDRIIB_CQ_p

Echo clock P

1.8-V HSTL Class I

PIN_AJ15

QDRIIB_CQ_n

Echo clock N

1.8-V HSTL Class I

PIN_AP18

QDRIIB_RPS_n

Report Select

1.8-V HSTL Class I

PIN_AW20

QDRIIB_WPS_n

Write Port Select

1.8-V HSTL Class I

PIN_AU20

QDRIIB_DOFF_n

PLL Turn Off

1.8-V HSTL Class I

PIN_AH19

QDRIIB_ODT

On-Die Termination

Input

1.8-V HSTL Class I

PIN_AH18

QDRIIB_QVLD

Valid Output Indicator

1.8-V HSTL Class I

PIN_AJ16

Table 2-16 QDRII+ SRAM C Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

QDRIIC_A0

Address bus[0]

1.8-V HSTL Class I

PIN_AV16

QDRIIC_A1

Address bus[1]

1.8-V HSTL Class I

PIN_AW16

QDRIIC_A2

Address bus[2]

1.8-V HSTL Class I

PIN_AP16

QDRIIC_A3

Address bus[3]

1.8-V HSTL Class I

PIN_AW9

QDRIIC_A4

Address bus[4]

1.8-V HSTL Class I

PIN_BD7

QDRIIC_A5

Address bus[5]

1.8-V HSTL Class I

PIN_BC7

QDRIIC_A6

Address bus[6]

1.8-V HSTL Class I

PIN_AR17

QDRIIC_A7

Address bus[7]

1.8-V HSTL Class I

PIN_AR18

QDRIIC_A8

Address bus[8]

1.8-V HSTL Class I

PIN_AT17

QDRIIC_A9

Address bus[9]

1.8-V HSTL Class I

PIN_BB9

QDRIIC_A10

Address bus[10]

1.8-V HSTL Class I

PIN_AH21

QDRIIC_A11

Address bus[11]

1.8-V HSTL Class I

PIN_AG20

QDRIIC_A12

Address bus[12]

1.8-V HSTL Class I

PIN_AU16

QDRIIC_A13

Address bus[13]

1.8-V HSTL Class I

PIN_BB8

QDRIIC_A14

Address bus[14]

1.8-V HSTL Class I

PIN_AT18

QDRIIC_A15

Address bus[15]

1.8-V HSTL Class I

PIN_AW17

QDRIIC_A16

Address bus[16]

1.8-V HSTL Class I

PIN_AV17

QDRIIC_A17

Address bus[17]

1.8-V HSTL Class I

PIN_AU8

QDRIIC_A18

Address bus[18]

1.8-V HSTL Class I

PIN_AT9

QDRIIC_A19

Address bus[19]

1.8-V HSTL Class I

PIN_AV8

QDRIIC_A20

Address bus[20]

1.8-V HSTL Class I

PIN_AN17

QDRIIC_D0

Write data bus[0]

1.8-V HSTL Class I

PIN_AG9

QDRIIC_D1

Write data bus[1]

1.8-V HSTL Class I

PIN_AG10

QDRIIC_D2

Write data bus[2]

1.8-V HSTL Class I

PIN_AG12

QDRIIC_D3

Write data bus[3]

1.8-V HSTL Class I

PIN_AG11

QDRIIC_D4

Write data bus[4]

1.8-V HSTL Class I

PIN_AV10

QDRIIC_D5

Write data bus[5]

1.8-V HSTL Class I

PIN_AH12

Page 37

DE5-Net User Manual

www.terasic.com

August 4, 2017

37

QDRIIC_D6

Write data bus[6]

1.8-V HSTL Class I

PIN_AK12

QDRIIC_D7

Write data bus[7]

1.8-V HSTL Class I

PIN_AL12

QDRIIC_D8

Write data bus[8]

1.8-V HSTL Class I

PIN_AJ12

QDRIIC_D9

Write data bus[9]

1.8-V HSTL Class I

PIN_AN12

QDRIIC_D10

Write data bus[10]

1.8-V HSTL Class I

PIN_AM13

QDRIIC_D11

Write data bus[11]

1.8-V HSTL Class I

PIN_AR12

QDRIIC_D12

Write data bus[12]

1.8-V HSTL Class I

PIN_AR13

QDRIIC_D13

Write data bus[13]

1.8-V HSTL Class I

PIN_AU9

QDRIIC_D14

Write data bus[14]

1.8-V HSTL Class I

PIN_AU10

QDRIIC_D15

Write data bus[15]

1.8-V HSTL Class I

PIN_AU11

QDRIIC_D16

Write data bus[16]

1.8-V HSTL Class I

PIN_AV11

QDRIIC_D17

Write data bus[17]

1.8-V HSTL Class I

PIN_AT12

QDRIIC_Q0

Read Data bus[0]

1.8-V HSTL Class I

PIN_BA12

QDRIIC_Q1

Read Data bus[1]

1.8-V HSTL Class I

PIN_AF14

QDRIIC_Q2

Read Data bus[2]

1.8-V HSTL Class I

PIN_AE13

QDRIIC_Q3

Read Data bus[3]

1.8-V HSTL Class I

PIN_AD14

QDRIIC_Q4

Read Data bus[4]

1.8-V HSTL Class I

PIN_AE12

QDRIIC_Q5

Read Data bus[5]

1.8-V HSTL Class I

PIN_AF11

QDRIIC_Q6

Read Data bus[6]

1.8-V HSTL Class I

PIN_AE11

QDRIIC_Q7

Read Data bus[7]

1.8-V HSTL Class I

PIN_AE10

QDRIIC_Q8

Read Data bus[8]

1.8-V HSTL Class I

PIN_AE9

QDRIIC_Q9

Read Data bus[9]

1.8-V HSTL Class I

PIN_BB11

QDRIIC_Q10

Read Data bus[10]

1.8-V HSTL Class I

PIN_AW11

QDRIIC_Q11

Read Data bus[11]

1.8-V HSTL Class I

PIN_AF10

QDRIIC_Q12

Read Data bus[12]

1.8-V HSTL Class I

PIN_AY12

QDRIIC_Q13

Read Data bus[13]

1.8-V HSTL Class I

PIN_AW10

QDRIIC_Q14

Read Data bus[14]

1.8-V HSTL Class I

PIN_AY10

QDRIIC_Q15

Read Data bus[15]

1.8-V HSTL Class I

PIN_BB12

QDRIIC_Q16

Read Data bus[16]

1.8-V HSTL Class I

PIN_BC10

QDRIIC_Q17

Read Data bus[17]

1.8-V HSTL Class I

PIN_BA10

QDRIIC_BWS_n0

Byte Write select[0]

1.8-V HSTL Class I

PIN_AJ11

QDRIIC_BWS_n1

Byte Write select[1]

1.8-V HSTL Class I

PIN_AJ10

QDRIIC_K_p

Clock P

Differential 1.8-V HSTL Class I

PIN_AP12

QDRIIC_K_n

Clock N

Differential 1.8-V HSTL Class I

PIN_AP13

QDRIIC_CQ_p

Echo clock P

1.8-V HSTL Class I

PIN_BC11

QDRIIC_CQ_n

Echo clock N

1.8-V HSTL Class I

PIN_AF13

QDRIIC_RPS_n

Report Select

1.8-V HSTL Class I

PIN_AH10

QDRIIC_WPS_n

Write Port Select

1.8-V HSTL Class I

PIN_AL11

QDRIIC_DOFF_n

PLL Turn Off

1.8-V HSTL Class I

PIN_AE14

QDRIIC_ODT

On-Die Termination

Input

1.8-V HSTL Class I

PIN_BD10

Page 38

DE5-Net User Manual

www.terasic.com

August 4, 2017

38

QDRIIC_QVLD

Valid Output Indicator

1.8-V HSTL Class I

PIN_BD11

Table 2-17 QDRII+ SRAM D Pin Assignments, Schematic Signal Names, and Functions

Schematic

Signal Name

Description

I/O Standard

Stratix V GX Pin

Number

QDRIID_A0

Address bus[0]

1.8-V HSTL Class I

PIN_N26

QDRIID_A1

Address bus[1]

1.8-V HSTL Class I

PIN_P28

QDRIID_A2

Address bus[2]

1.8-V HSTL Class I

PIN_N28

QDRIID_A3

Address bus[3]

1.8-V HSTL Class I

PIN_L26

QDRIID_A4

Address bus[4]

1.8-V HSTL Class I

PIN_K27

QDRIID_A5

Address bus[5]

1.8-V HSTL Class I

PIN_L27

QDRIID_A6

Address bus[6]

1.8-V HSTL Class I

PIN_U26

QDRIID_A7

Address bus[7]

1.8-V HSTL Class I

PIN_T26

QDRIID_A8

Address bus[8]

1.8-V HSTL Class I

PIN_T27

QDRIID_A9

Address bus[9]

1.8-V HSTL Class I

PIN_V27

QDRIID_A10

Address bus[10]

1.8-V HSTL Class I

PIN_U27

QDRIID_A11

Address bus[11]

1.8-V HSTL Class I

PIN_R27

QDRIID_A12

Address bus[12]

1.8-V HSTL Class I

PIN_P27

QDRIID_A13

Address bus[13]

1.8-V HSTL Class I

PIN_V25

QDRIID_A14

Address bus[14]

1.8-V HSTL Class I

PIN_V26

QDRIID_A15

Address bus[15]

1.8-V HSTL Class I

PIN_T25

QDRIID_A16

Address bus[16]

1.8-V HSTL Class I

PIN_P26

QDRIID_A17

Address bus[17]

1.8-V HSTL Class I

PIN_M27

QDRIID_A18

Address bus[18]

1.8-V HSTL Class I

PIN_M28

QDRIID_A19

Address bus[19]

1.8-V HSTL Class I

PIN_P29

QDRIID_A20

Address bus[20]

1.8-V HSTL Class I

PIN_D29

QDRIID_D0

Write data bus[0]

1.8-V HSTL Class I

PIN_H25

QDRIID_D1

Write data bus[1]

1.8-V HSTL Class I

PIN_H24

QDRIID_D2

Write data bus[2]

1.8-V HSTL Class I

PIN_H23

QDRIID_D3

Write data bus[3]

1.8-V HSTL Class I

PIN_J25

QDRIID_D4

Write data bus[4]

1.8-V HSTL Class I

PIN_J24

QDRIID_D5

Write data bus[5]

1.8-V HSTL Class I

PIN_K25

QDRIID_D6

Write data bus[6]

1.8-V HSTL Class I

PIN_D26

QDRIID_D7

Write data bus[7]

1.8-V HSTL Class I

PIN_F25

QDRIID_D8

Write data bus[8]

1.8-V HSTL Class I

PIN_G25

QDRIID_D9

Write data bus[9]

1.8-V HSTL Class I

PIN_N23

QDRIID_D10

Write data bus[10]

1.8-V HSTL Class I

PIN_P24

QDRIID_D11

Write data bus[11]

1.8-V HSTL Class I

PIN_P23

QDRIID_D12

Write data bus[12]

1.8-V HSTL Class I

PIN_L24

QDRIID_D13

Write data bus[13]

1.8-V HSTL Class I

PIN_R24

QDRIID_D14

Write data bus[14]

1.8-V HSTL Class I

PIN_U23

QDRIID_D15

Write data bus[15]

1.8-V HSTL Class I

PIN_U24

QDRIID_D16

Write data bus[16]

1.8-V HSTL Class I

PIN_T24

Page 39

DE5-Net User Manual

www.terasic.com

August 4, 2017

39

QDRIID_D17

Write data bus[17]

1.8-V HSTL Class I

PIN_T23

QDRIID_Q0

Read Data bus[0]

1.8-V HSTL Class I

PIN_C27

QDRIID_Q1

Read Data bus[1]

1.8-V HSTL Class I

PIN_A26

QDRIID_Q2

Read Data bus[2]

1.8-V HSTL Class I

PIN_B26

QDRIID_Q3

Read Data bus[3]

1.8-V HSTL Class I

PIN_F26

QDRIID_Q4

Read Data bus[4]

1.8-V HSTL Class I

PIN_G26

QDRIID_Q5

Read Data bus[5]

1.8-V HSTL Class I

PIN_C28

QDRIID_Q6

Read Data bus[6]

1.8-V HSTL Class I

PIN_A29

QDRIID_Q7

Read Data bus[7]

1.8-V HSTL Class I

PIN_A28

QDRIID_Q8

Read Data bus[8]

1.8-V HSTL Class I

PIN_B28

QDRIID_Q9

Read Data bus[9]

1.8-V HSTL Class I

PIN_G28

QDRIID_Q10

Read Data bus[10]

1.8-V HSTL Class I

PIN_F28

QDRIID_Q11

Read Data bus[11]

1.8-V HSTL Class I

PIN_D27

QDRIID_Q12

Read Data bus[12]

1.8-V HSTL Class I