Apollo Carrier Board

User Manual

1

www.terasic.com

May 8, 2020

Apollo Carrier Board

User Manual

1

www.terasic.com

May 8, 2020

CONTENTS

Chapter 1 Overview .......................................................................................................... 3

1.1 General Description ............................................................................................................................... 3

1.2 Key Features........................................................................................................................................... 4

1.3 Block Diagram ....................................................................................................................................... 4

Chapter 2 Board Components ......................................................................................... 5

2.1 Board Overview ..................................................................................................................................... 5

2.2 Power Input and Switch ......................................................................................................................... 5

2.3 General User Input and Output .............................................................................................................. 6

2.4 Clock Generator ................................................................................................................................... 11

2.5 QSFP28 Ports ....................................................................................................................................... 12

2.6 PCI Express .......................................................................................................................................... 14

2.7 USB Downstream Port ......................................................................................................................... 15

Chapter 3 Board Assembly ............................................................................................. 17

3.1 SAMTEC JOM..................................................................................................................................... 17

3.2 Assembly .............................................................................................................................................. 18

3.3 Disassembly ......................................................................................................................................... 20

Chapter 4 Setup Thunderbolt3 ...................................................................................... 23

4.1 Hardware Requirement ........................................................................................................................ 23

4.2 Thunderbolt 3 Test on Windows OS .................................................................................................... 24

4.3 Detect PCIe Device in the FPGA ......................................................................................................... 26

Chapter 5 PCI Express Reference Design for Windows .............................................. 28

5.1 PCI Express System Infrastructure ...................................................................................................... 28

5.2 PC PCI Express Software SDK ............................................................................................................ 29

5.3 PCI Express Software Stack ................................................................................................................. 29

5.4 PCI Express Library API ...................................................................................................................... 34

5.5 PCIe Reference Design - DDR4........................................................................................................... 39

Chapter 6 Transceiver Verification ................................................................................ 47

Apollo Carrier Board

User Manual

2

www.terasic.com

May 8, 2020

6.1 Transceiver Test Code .......................................................................................................................... 47

6.2 QSFP28 Ports ....................................................................................................................................... 47

6.3 40G Ethernet Example ......................................................................................................................... 48

Chapter 7 Additional Information................................................................................. 54

7.1 Getting Help ......................................................................................................................................... 54

Apollo Carrier Board

User Manual

3

www.terasic.com

May 8, 2020

T

Chapter 1

Overview

his chapter provides an overview of the Apollo Carrier board and installation guide.

1.1 General Description

Apollo Carrier board is a Carrier board design for Terasic Apollo S10 SoM board. Apollo Carrier

board and Apollo S10 SoM board communication via FMC and FMC+ connectors. Apollo Carrier

board provides 12V DC power for Apollo S10 via SAMTEC 2x6 connector.

Figure 1-1 Apollo S10 SoM and Carrier board

Apollo Carrier Board

User Manual

4

www.terasic.com

May 8, 2020

1.2 Key Features

The following hardware is implemented on the Apollo Carrier board:

Carrier board for Apollo S10 SoM

Power input: 12V DC via PCIe 2x4 power connector

Provides 12V DC to S10 via SAMTEC 2x6 power connector

Signals connect to S10 via FMC+(J1) and FMC connectors

PCIe Gen3 x4 via Thunderbolt 3 (Type-C connector)

USB Downstream port via Thunderbolt 3 (Type-A connector)

Two QSFP28 connectors (40G Ethernet)

Clock generator to provide reference clock for transceiver IP

LED x4, Button x2, Switch x2

2x20 3.3V GPIO expansion header

HDMI-TX Port. Not function now, reserved for future

1.3 Block Diagram

Figure 1-2 shows the block diagram of the Apollo Carrier board.

Figure 1-2 Block Diagram of the Apollo Carrier Board

Apollo Carrier Board

User Manual

5

www.terasic.com

May 8, 2020

T

Chapter 2

Board Components

his chapter introduces all the important components on the Apollo Carrier Board.

2.1 Board Overview

Figure 2-1 is the top view of the Apollo Carrier Board. It depicts the layout of the board and

indicates the location of the connectors and key components. Users can refer to this figure for

relative location of the connectors and key components.

2.2 Power Input and Switch

Figure 2-2 shows the 12V DC power input and power switch on the Carrier board. The 12V DC

power is input via 2x4 PCIe power connector.

Figure 2-1 Apollo Carrier Board (top view)

Apollo Carrier Board

User Manual

6

www.terasic.com

May 8, 2020

Figure 2-2 Position of 12V DC Input and Power Switch

After Apollo S10 and Apollo Carrier Board are assembled, please:

Always make Apollo S10 SoM power switch on.

Do not use the 2x4 PCIe power connector on Apollo S10.

2.3 General User Input and Output

This section describes the user I/O interface of the Carrier board.

User Defined Button/Switch/LED

There are two buttons, two switches, and four LEDs on the Carrier board, as shown in Figure 2-3.

Figure 2-3 User Button, Switch and LED

Apollo Carrier Board

User Manual

7

www.terasic.com

May 8, 2020

Schematic

Signal Name

Description

I/O Standard

FMC

Pin Num.

Apollo S10

FPGA Pin Num.

LED[0]

Driving logic 0 on the I/O port turns

the LED ON. Driving logic 1 on the

I/O port turns the LED OFF.

1.8 V

D17

PIN_E21

LED[1]

1.8 V

D18

PIN_D21

LED[2]

1.8 V

H19

PIN_G19

LED[3]

1.8 V

H20

PIN_F19

SW[0]

High logic level when SW in the

UPPER position.

1.8 V

D14

PIN_G20

SW[1]

1.8 V

D15

PIN_H20

KEY[0]

High Logic Level when the button is

not pressed

1.8 V

C14

PIN_J21

KEY[1]

1.8 V

C15

PIN_H21

Table 2-1 General User I/O Pin Assignments, Schematic Signal Names, and Functions

2x20 GPIO Header (Timing Expansion Header)

The board has one 2x20 GPIO headers. Each header has 36 user pins connected to the FMC

connector via voltage level translator (See Figure 2-4). The 2x20 GPIO I/ o standard can support

three I / O standards including 1.8, 2.5 and 3.3V. Users can select the desired voltage setting

through the JP2 header (See Figure 2-5 and Table 2-2). It also comes with DC +5V (VCC5), DC

+3.3V (VCC3P3), and two GND pins. Figure 2-6 and Figure 2-7 show the I/O distribution of the

GPIO connector. The maximum power consumption allowed for a daughter card connected to the

GPIO ports is shown in Table 2-3 and Table 2-4 shows all the pin assignments of the GPIO

connector. The pin-out of JP1 is shown in

Figure 2-4 Connection between 2x20 GPIO and Apollo S10 SoM

Apollo Carrier Board

User Manual

8

www.terasic.com

May 8, 2020

JP2 Setting

FMC I/O Standard

3.3V(Default Setting)

2.5V

Figure 2-5 Location of the JP2

Table 2-2 Header setting for I/O standard of the JP2

Apollo Carrier Board

User Manual

9

www.terasic.com

May 8, 2020

1.8V

Figure 2-6 Pin 1 of the GPIO header

Figure 2-7 Pin-out of 2x20 GPIO Header JP1

Apollo Carrier Board

User Manual

10

www.terasic.com

May 8, 2020

JP2 Setting

FMC I/O Standard

5V

1A (depend on the power adapter

specification.)

3.3V

1.5A

Schematic

Signal Name

Description

I/O Standard

FMC

Pin Num.

Apollo S10

FPGA Pin Num.

FMC_GPIO_D[0]

GPIO Connection[0]

3.3(Default)/2.5/1.8V

G6

PIN_J20

FMC_GPIO_D[1]

GPIO Connection[1]

3.3(Default)/2.5/1.8V

G33

PIN_C23

FMC_GPIO_D[2]

GPIO Connection[2]

3.3(Default)/2.5/1.8V

D8

PIN_E18

FMC_GPIO_D[3]

GPIO Connection[3]

3.3(Default)/2.5/1.8V

H32

PIN_G24

FMC_GPIO_D[4]

GPIO Connection[4]

3.3(Default)/2.5/1.8V

G34

PIN_B23

FMC_GPIO_D[5]

GPIO Connection[5]

3.3(Default)/2.5/1.8V

G31

PIN_H22

FMC_GPIO_D[6]

GPIO Connection[6]

3.3(Default)/2.5/1.8V

H31

PIN_F24

FMC_GPIO_D[7]

GPIO Connection[7]

3.3(Default)/2.5/1.8V

H29

PIN_J24

FMC_GPIO_D[8]

GPIO Connection[8]

3.3(Default)/2.5/1.8V

C27

PIN_K23

FMC_GPIO_D[9]

GPIO Connection[9]

3.3(Default)/2.5/1.8V

G28

PIN_R23

FMC_GPIO_D[10]

GPIO Connection[10]

3.3(Default)/2.5/1.8V

G30

PIN_G22

FMC_GPIO_D[11]

GPIO Connection[11]

3.3(Default)/2.5/1.8V

C26

PIN_J23

FMC_GPIO_D[12]

GPIO Connection[12]

3.3(Default)/2.5/1.8V

D27

PIN_F22

FMC_GPIO_D[13]

GPIO Connection[13]

3.3(Default)/2.5/1.8V

D26

PIN_E22

FMC_GPIO_D[14]

GPIO Connection[14]

3.3(Default)/2.5/1.8V

H28

PIN_K24

FMC_GPIO_D[15]

GPIO Connection[15]

3.3(Default)/2.5/1.8V

D24

PIN_A24

FMC_GPIO_D[16]

GPIO Connection[16]

3.3(Default)/2.5/1.8V

C23

PIN_C20

FMC_GPIO_D[17]

GPIO Connection[17]

3.3(Default)/2.5/1.8V

D23

PIN_B24

FMC_GPIO_D[18]

GPIO Connection[18]

3.3(Default)/2.5/1.8V

G15

PIN_A19

FMC_GPIO_D[19]

GPIO Connection[19]

3.3(Default)/2.5/1.8V

C22

PIN_D20

FMC_GPIO_D[20]

GPIO Connection[20]

3.3(Default)/2.5/1.8V

G18

PIN_F17

FMC_GPIO_D[21]

GPIO Connection[21]

3.3(Default)/2.5/1.8V

D21

PIN_C18

FMC_GPIO_D[22]

GPIO Connection[22]

3.3(Default)/2.5/1.8V

G19

PIN_E17

FMC_GPIO_D[23]

GPIO Connection[23]

3.3(Default)/2.5/1.8V

C19

PIN_F21

FMC_GPIO_D[24]

GPIO Connection[24]

3.3(Default)/2.5/1.8V

G21

PIN_B18

FMC_GPIO_D[25]

GPIO Connection[25]

3.3(Default)/2.5/1.8V

C18

PIN_F20

FMC_GPIO_D[26]

GPIO Connection[26]

3.3(Default)/2.5/1.8V

G22

PIN_B19

FMC_GPIO_D[27]

GPIO Connection[27]

3.3(Default)/2.5/1.8V

D20

PIN_C17

FMC_GPIO_D[28]

GPIO Connection[28]

3.3(Default)/2.5/1.8V

H22

PIN_A22

FMC_GPIO_D[29]

GPIO Connection[29]

3.3(Default)/2.5/1.8V

G27

PIN_P23

Table 2-3 Voltage and Max. Current Limit of GPIO Header

Table 2-4 2x20 GPIO Pin Assignments, Schematic Signal Names, and Functions

Apollo Carrier Board

User Manual

11

www.terasic.com

May 8, 2020

FMC_GPIO_D[30]

GPIO Connection[30]

3.3(Default)/2.5/1.8V

G24

PIN_A17

FMC_GPIO_D[31]

GPIO Connection[31]

3.3(Default)/2.5/1.8V

H26

PIN_A21

FMC_GPIO_D[32]

GPIO Connection[32]

3.3(Default)/2.5/1.8V

H23

PIN_B22

FMC_GPIO_D[33]

GPIO Connection[33]

3.3(Default)/2.5/1.8V

H25

PIN_A20

FMC_GPIO_D[34]

GPIO Connection[34]

3.3(Default)/2.5/1.8V

G16

PIN_B20

FMC_GPIO_D[35]

GPIO Connection[35]

3.3(Default)/2.5/1.8V

G25

PIN_B17

Schematic

Signal Name

Description

I/O Standard

Default Freq.

FMC

Pin Num.

Apollo S10

FPGA Pin Num.

FMCP_REFCLK_p

Reference clock FMC+

connector

LVDS

644.53125MHz

G6

PIN_AM41

QSFP28A_REFCLK_p

Reference clock for

QSFP28A

LVDS

644.53125MHz

G33

PIN_AM38

QSFP28B_REFCLK_p

Reference clock for

QSFP28B

LVDS

644.53125MHz

D8

PIN_T41

Si5340A_I2C_SCL

I2C clock bus of the

clock generator

1.8V

--

H32

PIN_AU34

Si5340A_I2C_SDA

I2C data bus of the

clock generator

1.8V

--

G34

PIN_AU33

SI5340A_OE_n

Enable output of the

clock generator

1.8V

--

G31

PIN_BG38

SI5340A_RST_n

Reset of the clock

1.8V

--

H31

PIN_BG37

2.4 Clock Generator

The Carrier board includes one Si5340A clock generator to provide reference clock for FPGA

transceiver IP as shown in Figure 2-8. To enable the clock generator, developers must well control

the control pins Si5340A_OE_n and Si5340A_RST_n on the Si5340A.

Figure 2-8 Si5340A of the Carrier Board

Table 2-5 Clock Generator Pin Assignments, Schematic Signal Names, and Functions

Apollo Carrier Board

User Manual

12

www.terasic.com

May 8, 2020

generator

Schematic

Signal Name

Description

I/O Standard

FMC

Pin Num.

Apollo S10

FPGA Pin Num.

QSFP28A_INTERRUPT_

Interrupt

1.8 V

H32

PIN_BF3

QSFP28A_LP_MODE

Low Power Mode

1.8 V

H31

PIN_BG3

QSFP28A_MOD_PRS_n

Module Present

1.8 V

G30

PIN_BC3

QSFP28A_MOD_SEL_n

Module Select

1.8 V

H28

PIN_BF3

QSFP28A_RST_n

Module Reset

1.8 V

H29

PIN_BF3

QSFP28A_SCL

2-wire serial interface clock

1.8 V

D26

PIN_BD3

QSFP28A_SDA

2-wire serial interface data

1.8 V

D27

PIN_BD3

QSFP28A_REFCLK_p

QSFP28A transceiver reference

clock p

LVDS

L8

PIN_AM3

QSFP28A_RX_p[0]

Receiver data of channel 0

HSSI

DIFFERENTIAL I/O

Z32

PIN_AL4

QSFP28A_RX_p[1]

Receiver data of channel 1

HSSI

DIFFERENTIAL I/O

Y34

PIN_AH4

QSFP28A_RX_p[2]

Receiver data of channel 2

HSSI

DIFFERENTIAL I/O

Z36

PIN_AF4

QSFP28A_RX_p[3]

Receiver data of channel 3

HSSI

Y38

PIN_AG4

2.5 QSFP28 Ports

The Carrier board has two independent 40G QSFP28 connectors that use one transceiver channel

each from the Stratix 10 FPGA device. These modules take in serial data from the Stratix 10 FPGA

device and transform them to optical signals. The board includes cage assemblies for the QSFP28

connectors. Figure 2-9 shows the connections between the QSFP28 and Stratix 10 FPGA.

Figure 2-9 Connection between the QSFP28 and Stratix 10 FPGA

Table 2-6 QSP28A/B Pin Assignments, Schematic Signal Names, and Functions

Apollo Carrier Board

User Manual

13

www.terasic.com

May 8, 2020

DIFFERENTIAL I/O

QSFP28A_TX_p[0]

Transmitter data of channel 0

HSSI

DIFFERENTIAL I/O

M26

PIN_AK4

QSFP28A_TX_p[1]

Transmitter data of channel 1

HSSI

DIFFERENTIAL I/O

M30

PIN_AL4

QSFP28A_TX_p[2]

Transmitter data of channel 2

HSSI

DIFFERENTIAL I/O

M34

PIN_AJ4

QSFP28A_TX_p[3]

Transmitter data of channel 3

HSSI

DIFFERENTIAL I/O

M38

PIN_AF4

QSFP28B_INTERRUPT_

Interrupt

1.8 V

H37

PIN_BJ3

QSFP28B_LP_MODE

Low Power Mode

1.8 V

G34

PIN_BG3

QSFP28B_MOD_PRS_n

Module Present

1.8 V

H38

PIN_BJ3

QSFP28B_MOD_SEL_n

Module Select

1.8 V

G31

PIN_BC3

QSFP28B_RST_n

Module Reset

1.8 V

H34

PIN_BJ3

QSFP28B_SCL

2-wire serial interface clock

1.8 V

H35

PIN_BJ3

QSFP28B_SDA

2-wire serial interface data

1.8 V

G33

PIN_BH3

QSFP28B_REFCLK_p

QSFP28B transceiver reference

clock p

LVDS

L4

PIN_T41

QSFP28B_RX_p[0]

Receiver data of channel 0

HSSI

DIFFERENTIAL I/O

M14

PIN_G43

QSFP28B_RX_p[1]

Receiver data of channel 1

HSSI

DIFFERENTIAL I/O

M10

PIN_D45

QSFP28B_RX_p[2]

Receiver data of channel 2

HSSI

DIFFERENTIAL I/O

M6

PIN_C43

QSFP28B_RX_p[3]

Receiver data of channel 3

HSSI

DIFFERENTIAL I/O

M2

PIN_A43

QSFP28B_TX_p[0]

Transmitter data of channel 0

HSSI

DIFFERENTIAL I/O

Z8

PIN_F49

QSFP28B_TX_p[1]

Transmitter data of channel 1

HSSI

DIFFERENTIAL I/O

Y6

PIN_G47

QSFP28B_TX_p[2]

Transmitter data of channel 2

HSSI

DIFFERENTIAL I/O

Z4

PIN_E47

QSFP28B_TX_p[3]

Transmitter data of channel 3

HSSI

DIFFERENTIAL I/O

Y2

PIN_C47

Apollo Carrier Board

User Manual

14

www.terasic.com

May 8, 2020

Schematic

Signal Name

Description

I/O Standard

FMC

Pin Num.

Apollo S10

FPGA Pin Num.

PCIE_REFCLK_p

Reference clock input

LVDS

B20

PIN_AT41

PCIE_RX_p[0]

Receive bus

HSSI DIFFERENTIAL I/O

C6

PIN_BH41

PCIE_RX_p[1]

Receive bus

HSSI DIFFERENTIAL I/O

A2

PIN_BJ43

PCIE_RX_p[2]

Receive bus

HSSI DIFFERENTIAL I/O

A6

PIN_BG43

PCIE_RX_p[3]

Receive bus

HSSI DIFFERENTIAL I/O

A10

PIN_BE43

PCIE_TX_p[0]

Transmit bus

HSSI DIFFERENTIAL I/O

C2

PIN_BJ46

PCIE_TX_p[1]

Transmit bus

HSSI DIFFERENTIAL I/O

A22

PIN_BF45

PCIE_TX_p[2]

Transmit bus

HSSI DIFFERENTIAL I/O

A26

PIN_BG47

PCIE_TX_p[3]

Transmit bus

HSSI DIFFERENTIAL I/O

A30

PIN_BE47

2.6 PCI Express

The Carrier board is designed to fit entirely into a PC motherboard with PCI Express Gen3 x4 via

Thunderbolt 3 Port. Utilizing built-in transceivers on a Stratix 10 device, it is able to provide a fully

integrated PCI Express-compliant solution for multi-lane (x1, x4) applications. With the PCI Express

hard IP block incorporated in the Stratix 10 device, it will allow users to implement simple and fast

protocol, as well as saving logic resources for logic application. Figure 2-10 presents the pin

connection established between the Stratix 10 and PCI Express.

The PCI Express interface supports complete PCI Express Gen1 at 2.5Gbps/lane, Gen2 at

5.0Gbps/lane, and Gen3 at 8.0Gbps/lane protocol stack solution compliant to PCI Express base

specification 3.0 that includes PHY-MAC, data Link, and transaction layer circuitry embedded in PCI

Express hard IP blocks.

Figure 2-10 PCI Express Pin Connection

Table 2-7 QSP28A/B Pin Assignments, Schematic Signal Names, and Functions

Apollo Carrier Board

User Manual

15

www.terasic.com

May 8, 2020

2.7 USB Downstream Port

The Thunderbolt controller on the Apollo carrier board not only allows the FPGA and Host PC to

establish PCIe interface connections through a Thounderbolt3 cable, but also provides another

expansion port for a USB downstream port (See Figure 2-11). The purpose of this USB

downstream port is mainly for connecting the USB blaster II circuit of the Apollo S10 board. When

the Apollo S10 module is connected to the carrier, user can use a mini USB cable to connect the

USB blaster II circuit (a mini USB connector) on the Apollo S10 module and the USB downstream

connector (a Type A USB connector) of the carrier board (See Figure 2-12 ). In this way, users can

use a thunderbolt3 cable to allow the host pc to establish a JTAG connection with the FPGA via the

USB downstream port of the carrier board to the USB blaster II circuit of the module board. It can

eliminate the need for a mini USB cable to connect to the host PC(See Figure 2-13).

Figure 2-11 Thunderbolt3 expansion interface on the carrier board

Apollo Carrier Board

User Manual

16

www.terasic.com

May 8, 2020

Figure 2-12 Connection setup for USB downstream port (Carrier board) to USB Blaster II Port

(Module board)

Figure 2-13 JTAG connection via USB downstream port

Apollo Carrier Board

User Manual

17

www.terasic.com

May 8, 2020

No.

Description

QTY

Photo

1

M 2.5 x 6mm Screw

4

T

Chapter 3

Board Assembly

his chapter describes how to assemble Apollo Carrier Board with Apollo S10. SAMTEC

JSOM standoff is used for board stacking.

3.1 SAMTEC JOM

SAMTEC JSOM standoff, as shown in Figure 3-1, is used for board stacking. Four JSOM standoff

are required to assemble Apollo S10 SoM and Apollo Carrier Board. Each JSOM standoff is

consistent with four components. The Apollo S10 kit includes four JSOM standoff as shown in Table

3-1. Table 3-2 lists the tools required to assemble Apollo S10 and Apollo Carrier Board with JSOM

standoff.

Figure 3-1 SAMTEC JSOM

Table 3-1 JSOM Components

Apollo Carrier Board

User Manual

18

www.terasic.com

May 8, 2020

2

JSOM-B

4

3

JSOM-T

4

4

Hex Nut

4

No.

Description

QTY

Photo

1

Philips Screwdriver

1 2

1.5mm Hex Key

1 3

5.0mm Hex Socket

1

Table 3-2 Tools for Assembly

3.2 Assembly

Below are the procedures to assemble the Apollo S10 SoM and Apollo Carrier Board or user can

users can refer to the video “How to assemble Apollo S10 with carrier board” to assemble the board.

1. Use Philips Screwdriver and 5.0mm Hex Socket to screw four M2.5 Screws into four

JSOM-B on Apollo S10, as show in Figure 3-2.

2. Use a Hex Key to screw four JSOM-T into four JSOM -B as shown in Figure 3-3.

3. Place Apollo Carrier Board over the four TSOM-T as shown in Figure 3-4.

4. Press Apollo Carrier Board and Apollo S10 to combine the FMC connectors tightly,

JSOM-T is bulged on the Apollo Carrier Board as shown in Figure 3-5.

5. Use a Hex Key to screw four Hex Nut into the four TSOM-T as shown in Figure 3-6.

Apollo Carrier Board

User Manual

19

www.terasic.com

May 8, 2020

Figure 3-2 Assemble M2.5 Screws and JSOM-B on Apollo S10

Figure 3-3 Assemble JSOM-T to JSOM-B

Figure 3-4 Place Apollo Carrier Board over four JSOM-T

Apollo Carrier Board

User Manual

20

www.terasic.com

May 8, 2020

Figure 3-5 Push Apollo Carrier Board onto JSOM-T

Figure 3-6 Assemble Hex Nut to JSOM-T

3.3 Disassembly

Here are the procedures to disassemble with Apollo S10 SoM and Apollo Carrier Board or user can

users can refer to the video “How to disassemble Apollo S10 with carrier board” to disassemble the

board.

1. Unscrew four Hex Nut as shown in Figure 3-7.

2. Unscrew four JSOM-T. Note, as shown in Figure 3-8. Take turns to rotate the four

JSOM-T one turn at a time until you hear the FMC connector separating sound.

3. Unscrew four JSOM-B as shown in Figure 3-9.

Apollo Carrier Board

User Manual

21

www.terasic.com

May 8, 2020

Figure 3-7 Disassemble Hex Nut

Figure 3-8 Disassemble JSOM-T to JSOM-B

Apollo Carrier Board

User Manual

22

www.terasic.com

May 8, 2020

Figure 3-9 Unscrew JSOM-B

Apollo Carrier Board

User Manual

23

www.terasic.com

May 8, 2020

T

Chapter 4

Setup Thunderbolt3

hunderbolt 3 is unique communication path between the Host PC and Apollo Carrier board.

As shown in Figure 4-1, while the Apollo S10 SoM is connected to the carrier board to form

the Apollo Developer Kit. With a Thunderbolt 3 cable, host pc can communicate with the

FPGA on the developer kit via PCIe interface (PCIe design is required in the FPGA). For the

OpenCL applications with the Intel FPGA, the PCIe bus is the main interface for communicating and

transferring data with the host PC. The thunderbolt3 port on the Apollo Developer Kit allows the

user to build PCIe connection for the FPGA and the host PC via a thunderbolt3 cable.

Therefore, a host PC equipment with thunderbolt 3 port is required to work with the Apollo

Developer Kit for PCIe applications. This chapter will show user how to setup thunderbolt 3

connection between the Host PC and the Apollo Developer Kit for the first time.

This chapter describes how to set up a Thunderbolt 3 connection in windows and test whether the

PCIe device can be detected. Note, the current Linux PCIe driver provided by Terasic does not

support connection via Thunderbolt 3. So the Linux part is not introduced for the time being.

4.1 Hardware Requirement

Figure 4-1 PCI Express Pin Connection

A Host PC with Thunderbolt 3 Port is required to perform PCIe Applications. The

PC should be:

Built-in Thunderbolt 3 Port or with Thunderbotl3 Card Installed.

Windows Installed

Thunderbolt 3 driver installed

Apollo Carrier Board

User Manual

24

www.terasic.com

May 8, 2020

An Apollo Developer Kit (Apollo S10 SoM + Apollo Carrier board)

A Thunderbolt 3 Cable as shown in Figure 4-2

Figure 4-2 Thunderbolt 3 Cable

4.2 Thunderbolt 3 Test on Windows OS

Below shows the procedure when the Apollo Developer Kit is first time to plug into the thunderbolt 3

port of the Host PC.

1. Make sure your Host PC had installed Thunderbolt 3 Driver (The Thunderbolt Control Center is

installed).

2. Plug DC Power to power on the Apollo Developer Kit.

3. Connect Apollo Developer Kit and host PC by a Thunderbolt 3 cable.

Apollo Carrier Board

User Manual

25

www.terasic.com

May 8, 2020

Figure 4-3 Plug the Thunderbolt 3 cable to the Apollo Developer Kit

4. When the host pc connects to the Apollo Developer Kit with Thunderbolt 3 cable for the first

time. Windows should detect a Thunderbolt Device and you will see a “New Thunderbolt

device has been connected” message appear in the bottom right corner of your screen as

shown in Figure 4-4. Click the message to approve the device.

Figure 4-4 New Thunderbolt devices have been attached" message

Note that if this message does not appear, user can reconnect the thunderbolt 3 cable

between the Apollo Developer Kit and Host PC or power off and on the Apollo Developer Kit. If

the message still doesn't appear, please refer the following link to solve:

http://www.terasic.com.tw/wiki/Apollo_S10_SoM_Setup_Thunderbolt3_connection_win10

5. A Thunderbolt Dialog window will appear as shown in Figure 4-5. Select “Always Connected”

and click OK button.

Apollo Carrier Board

User Manual

26

www.terasic.com

May 8, 2020

Figure 4-5 Approve Thunderbolt device window

4.3 Detect PCIe Device in the FPGA

Once the Thunderbolt 3 connection is established between host and Apollo develop kit, if there is no

PCIe design in the FPGA, the device manager in win10 on the host side will not detect the PCIe

device. User first needs to program the PCIe design to the FPGA, then re-establish the Thunderbolt

3 connection to the host that allow the host to detect the PCIe device in the FPGA.

Below we introduce the use of a Terasic PCIe demo to demonstrate the detection of a PCIe device

on the host.

1. Prepare a Apollo S10 Develop kit (Apollo S10 SoM connected with the Apollo Carrier board).

2. Remove the Micro SD card on the Apollo S10 SoM.

3. Make sure the Mini USB cable is connected between the USB connector (J8) of the Apollo S10

SoM and host PC.

4. Power on the Apollo S10 Develop kit.

5. Execute the batch file “test.sh” from the path “/Demonstration/PCIe_DDR4/demo_batch/” in

Apollo Carrier Board

User Manual

27

www.terasic.com

May 8, 2020

the system CD to program the FPGA with the PCIe design.

6. Connect the Thunderbolt 3 cable between USB type C connector (J8) in the carrier board and

host PC. Make sure your board and host has established the Thunderbolt connection setting

as described in the section 4.2.

7. Open the Device Manager in the Win10, you may see an unknown “PCI Device” (See Figure

4-6 ), that means the PCIe design is detected by the host via Thunderbolt 3 interface. If the PCI

device does not appear in the Device Manager, please re-plug the Thunderbolt cable again

then check again.

8. Next, to install the PCIe driver for FPGA design, please refer to the section 5.3 for detailed.

Figure 4-6 PCI Device in the Device Manager

Apollo Carrier Board

User Manual

28

www.terasic.com

May 8, 2020

P

Chapter 5

PCI Express Reference

Design for Windows

CI Express is commonly used in consumer, server, and industrial applications, to link

motherboard-mounted peripherals. From this demonstration, it will show how the PC

Windows and FPGA communicate with each other through the PCI Express interface. Stratix

10 Hard IP for PCI Express with Avalon-MM DMA IP is used in this demonstration. For detail

about this IP, please refer to Intel document ug_s10_pcie_avmm.pdf. Note, before user start to use

the PCIe design with the Apollo Develop kit, please refer to the section 4.3 to setup Thunderbolt 3

connection first.

5.1 PCI Express System Infrastructure

Figure 5-1 shows the infrastructure of the PCI Express System in this demonstration. It consists of

two primary components: FPGA System and PC System. The FPGA System is developed based on

Stratix 10 Hard IP for PCI Express with Avalon-MM DMA. The application software on the PC side is

developed by Terasic based on Altera’s PCIe kernel mode driver.

Figure 5-1 Infrastructure of PCI Express System

Apollo Carrier Board

User Manual

29

www.terasic.com

May 8, 2020

5.2 PC PCI Express Software SDK

The FPGA System CD contains a PC Windows based SDK to allow users to develop their 64-bit

software application on 64-bits Windows 7 or Window XP. The SDK is located in the

"CDROM\Demonstrations\PCIe_SW_KIT\Windows" folder which includes:

PCI Express Driver

PCI Express Library

PCI Express Examples

The kernel mode driver assumes the PCIe vendor ID (VID) is 0x1172 and the device ID (DID) is

0xE003. If different VID and DID are used in the design, users need to modify the PCIe vendor ID

(VID) and device ID (DID) in the driver INF file accordingly.

The PCI Express Library is implemented as a single DLL named TERASIC_PCIE_AVMM.DLL. This

file is a 64-bit DLL. When the DLL is exported to the software API, users can easily communicate

with the FPGA. The library provides the following functions:

Basic data read and write

Data read and write by DMA

For high performance data transmission, Altera AVMM DMA is required as the read and write

operations, which are specified under the hardware design on the FPGA.

5.3 PCI Express Software Stack

Figure 5-2 shows the software stack for the PCI Express application software on 64-bit Windows.

The PCIe library module TERASIC_PCIE_AVMM.dll provides DMA and direct I/O access allowing

user application program to communicate with FPGA. Users can develop their applications based

on this DLL. The altera_pcie_win_driver.sys kernel driver is provided by Intel.

Apollo Carrier Board

User Manual

30

www.terasic.com

May 8, 2020

Figure 5-2 PCI Express Software Stack

Install PCI Express Driver on Windows

The PCIe driver is locate in the folder:

"CDROM\Demonstrations\PCIe_SW_KIT\Windows\PCIe_Driver"

The folder includes the following four files:

Altera_pcie_win_driver.cat

Altera_pcie_win_driver.inf

Altera_pcie_win_driver.sys

WdfCoinstaller01011.dll

To install the PCI Express driver, please execute the steps below:

1. Connect the Apollo develop kit and the host PC with Thunderbolt 3 cable.

2. Make sure the Intel Programmer and USB-Blaster II driver are installed

3. Execute test.bat in "CDROM\Demonstrations\PCIe_DDR4\demo_batch" to configure the

FPGA

4. Pull the Thunderbot3 cable off form the host, then pull the cable in again for redetect the

PCIe device.

5. Click the Control Panel menu from Windows Start menu. Click the Hardware and Sound

item before clicking the Device Manager to launch the Device Manager dialog. There will be

a PCI Device item in the dialog, as shown in Figure 5-3. Move the mouse cursor to the PCI

Apollo Carrier Board

User Manual

31

www.terasic.com

May 8, 2020

Device item and right click it to select the Updated Driver Software... items.

Figure 5-3 Screenshot of launching Update Driver Software… dialog

6. In the How do you want to search for the driver software dialog, click Browse my

computer for driver software item, as shown in Figure 5-4.

Figure 5-4 Dialog of Browse my computer for the driver software

Apollo Carrier Board

User Manual

32

www.terasic.com

May 8, 2020

7. In the Browse for driver software on your computer dialog, click the Browse button to

specify the folder where altera_pcie_din_driver.inf is located, as shown in Figure 5-5. Click

the Next button.

Figure 5-5 Browse for the driver software on your computer

8. When the Windows Security dialog appears, as shown Figure 5-6, click the Install button.

9. When the driver is installed successfully, the successfully dialog will appear, as shown in

Figure 5-6 Click Install in the dialog of Windows Security

Figure 5-7. Click the Close button.

Apollo Carrier Board

User Manual

33

www.terasic.com

May 8, 2020

Figure 5-7 Click Close when the installation of the Altera PCI API Driver is complete

10. Once the driver is successfully installed, users can see the Altera PCI API Driver under the

device manager window, as shown in Figure 5-8.

Figure 5-8 Altera PCI API Driver in Device Manager

Apollo Carrier Board

User Manual

34

www.terasic.com

May 8, 2020

Function:

Open a specified PCIe card with vendor ID, device ID, and matched card index.

Prototype:

PCIE_HANDLE PCIE_Open(

uint8_t wVendorID,

uint8_t wDeviceID,

uint8_t wCardIndex);

Parameters:

wVendorID:

Specify the desired vendor ID. A zero value means to ignore the vendor ID.

wDeviceID:

Specify the desired device ID. A zero value means to ignore the device ID.

wCardIndex:

Specify the matched card index, a zero based index, based on the matched vendor ID and

Create a Software Application

All the files needed to create a PCIe software application are located in the directory

CDROM\demonstration\PCIe_SW_KIT\Windows\PCIe_Library. It includes the following files:

TERASIC_PCIE_AVMM.h

TERASIC_PCIE_AVMM.DLL (64-bit DLL)

Below lists the procedures to use the SDK files in users’ C/C++ project :

1. Create a 64-bit C/C++ project.

2. Include TERASIC_PCIE_AVMM.h in the C/C++ project.

3. Copy TERASIC_PCIE_AVMM.DLL to the folder where the project.exe is located.

4. Dynamically load TERASIC_PCIE_AVMM.DLL in C/C++ program. To load the DLL, please

refer to the PCIe fundamental example below.

5. Call the SDK API to implement the desired application.

Users can easily communicate with the FPGA through the PCIe bus through the

TERASIC_PCIE_AVMM.DLL API. The details of API are described below:

5.4 PCI Express Library API

Below shows the exported API in the TERASIC_PCIE_AVMM.DLL. The API prototype is defined in

the TERASIC_PCIE_AVMM.h.

Note: the Linux library terasic_pcie_qsys.so also use the same API and header file.

PCIE_Open

Apollo Carrier Board

User Manual

35

www.terasic.com

May 8, 2020

device ID.

Return Value:

Return a handle to presents specified PCIe card. A positive value is return if the PCIe card is

opened successfully. A value zero means failed to connect the target PCIe card.

This handle value is used as a parameter for other functions, e.g. PCIE_Read32.

Users need to call PCIE_Close to release handle once the handle is no longer used.

Function:

Close a handle associated to the PCIe card.

Prototype:

void PCIE_Close(

PCIE_HANDLE hPCIE);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

Return Value:

None.

Function:

Read a 32-bit data from the FPGA board.

Prototype:

bool PCIE_Read32(

PCIE_HANDLE hPCIE,

PCIE_BAR PcieBar,

PCIE_ADDRESS PcieAddress,

uint32_t *pdwData);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

PcieBar:

Specify the target BAR.

PcieAddress:

Specify the target address in FPGA.

pdwData:

A buffer to retrieve the 32-bit data.

Return Value:

PCIE_Close

PCIE_Read32

Apollo Carrier Board

User Manual

36

www.terasic.com

May 8, 2020

Return true if read data is successful; otherwise false is returned.

Function:

Write a 32-bit data to the FPGA Board.

Prototype:

bool PCIE_Write32(

PCIE_HANDLE hPCIE,

PCIE_BAR PcieBar,

PCIE_ADDRESS PcieAddress,

uint32_t dwData);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

PcieBar:

Specify the target BAR.

PcieAddress:

Specify the target address in FPGA.

dwData:

Specify a 32-bit data which will be written to FPGA board.

Return Value:

Return true if write data is successful; otherwise false is returned.

Function:

Read an 8-bit data from the FPGA board.

Prototype:

bool PCIE_Read8(

PCIE_HANDLE hPCIE,

PCIE_BAR PcieBar,

PCIE_ADDRESS PcieAddress,

uint8_t *pByte);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

PcieBar:

Specify the target BAR.

PcieAddress:

PCIE_Write32

PCIE_Read8

Apollo Carrier Board

User Manual

37

www.terasic.com

May 8, 2020

Specify the target address in FPGA.

pByte:

A buffer to retrieve the 8-bit data.

Return Value:

Return true if read data is successful; otherwise false is returned.

Function:

Write an 8-bit data to the FPGA Board.

Prototype:

bool PCIE_Write8(

PCIE_HANDLE hPCIE,

PCIE_BAR PcieBar,

PCIE_ADDRESS PcieAddress,

uint8_t Byte);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

PcieBar:

Specify the target BAR.

PcieAddress:

Specify the target address in FPGA.

Byte:

Specify an 8-bit data which will be written to FPGA board.

Return Value:

Return true if write data is successful; otherwise false is returned.

Function:

Read data from the memory-mapped memory of FPGA board in DMA.

Maximal read size is (4GB-1) bytes.

Prototype:

bool PCIE_DmaRead(

PCIE_HANDLE hPCIE,

PCIE_LOCAL_ADDRESS LocalAddress,

void *pBuffer,

uint32_t dwBufSize

);

Parameters:

PCIE_Write8

PCIE_DmaRead

Apollo Carrier Board

User Manual

38

www.terasic.com

May 8, 2020

hPCIE:

A PCIe handle return by PCIE_Open function.

LocalAddress:

Specify the target memory-mapped address in FPGA.

pBuffer:

A pointer to a memory buffer to retrieved the data from FPGA. The size of buffer should be

equal or larger the dwBufSize.

dwBufSize:

Specify the byte number of data retrieved from FPGA.

Return Value:

Return true if read data is successful; otherwise false is returned.

Function:

Write data to the memory-mapped memory of FPGA board in DMA.

Prototype:

bool PCIE_DmaWrite(

PCIE_HANDLE hPCIE,

PCIE_LOCAL_ADDRESS LocalAddress,

void *pData,

uint32_t dwDataSize

);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

LocalAddress:

Specify the target memory mapped address in FPGA.

pData:

A pointer to a memory buffer to store the data which will be written to FPGA.

dwDataSize:

Specify the byte number of data which will be written to FPGA.

Return Value:

Return true if write data is successful; otherwise false is returned.

Function:

Read PCIe Configuration Table. Read a 32-bit data by given a byte offset.

Prototype:

bool PCIE_ConfigRead32 (

PCIE_DmaWrite

PCIE_ConfigRead32

Apollo Carrier Board

User Manual

39

www.terasic.com

May 8, 2020

PCIE_HANDLE hPCIE,

uint32_t Offset,

uint32_t *pdwData

);

Parameters:

hPCIE:

A PCIe handle return by PCIE_Open function.

Offset:

Specify the target byte of offset in PCIe configuration table.

pdwData:

A 4-bytes buffer to retrieve the 32-bit data.

Return Value:

Return true if read data is successful; otherwise false is returned.

5.5 PCIe Reference Design - DDR4

The application reference design shows how to add the DDR4 Memory Controllers for the on board

DDR4A and DDR4B banks into the PCIe Quartus project and perform 16GB data DMA for both

SODIMM. Also, this demo shows how to call “PCIE_ConfigRead32” API to check PCIe link status.

Demonstration Files Location

The demo file is located in the batch folder:

CDROM\Demonstrations\PCIe_DDR4\demo_batch

The folder includes following files:

FPGA Configuration File: S10C_top.sof

Download Batch file: test.bat

Windows Application Software folder: windows_app, includes

PCIE_DDR4.exe

TERASIC_PCIE_AVMM.dll

Demonstration Setup

1. Connect the Apollo develop kit and the host PC with Thunderbolt 3 cable.

2. Make sure the Intel Programmer and USB-Blaster II driver are installed.

3. Execute test.bat in "CDROM\Demonstrations\PCIe_DDR4\demo_batch" to configure the FPGA

4. Install the PCIe driver if necessary. The driver is located in the folder:

CDROM\Demonstration\PCIe_SW_KIT\Windows\PCIe_Driver.

5. Pull the Thunderbot3 cable off form the host, then pull the cable in again for redetect the PCIe

device

6. Make sure that Windows has detected the FPGA Board by checking the Windows Device

Manager as shown in Figure 5-9.

Apollo Carrier Board

User Manual

40

www.terasic.com

May 8, 2020

Figure 5-9 Screenshot for PCIe Driver

7. Go to windows_app folder, execute PCIE_DDR4.exe. A menu will appear as shown in Figure

5-10.

8. Type 0 or 1 can control the LED ON/OFF or read the status of the button of the Apollo develop

kit.

9. Type 2 followed by the ENTER key to select the Link Info item. The PCIe link information will be

shown as in Figure 5-11. Gen3 link speed and x3 link width are expected.

Figure 5-10 Screenshot of Program Menu

Apollo Carrier Board

User Manual

41

www.terasic.com

May 8, 2020

Figure 5-11 Screenshot of Link Info

10. Type 3 followed by the ENTER key to select DMA On-Chip Memory Test item. The DMA write

and read test result will be reported as shown in Figure 5-12.

Figure 5-12 Screenshot of On-Chip Memory DMA Test Result

11. Type 4 followed by the ENTER key to select the DMA DDR4A Bank Memory Test item. The DMA

write and read test result will be reported as shown in Figure 5-13.

Apollo Carrier Board

User Manual

42

www.terasic.com

May 8, 2020

12. Type 5 followed by the ENTER key to select the DMA DDR4B bank Memory Test item. The DMA

write and read test result will be reported as shown in Figure 5-14.

Figure 5-13 Screenshot of the DDR4A Bank Memory DMA Test Result

Apollo Carrier Board

User Manual

43

www.terasic.com

May 8, 2020

Figure 5-14 Screenshot of the DDR4B Bank Memory DMA Test Result

13. Type 99 followed by the ENTER key to exit this test program.

Development Tools

Quartus Prime 19.1 Pro Edition

Visual C++ 2012

Demonstration Source Code Location

Quartus Project: Demonstrations\PCIE_DDR4

Visual C++ Project: Demonstrations\PCIe_SW_KIT\Windows\PCIe_DDR4

Apollo Carrier Board

User Manual

44

www.terasic.com

May 8, 2020

Name

Description

PCIE_DDR4.cpp

Main program

PCIE.c

Implement dynamically load for

TERAISC_PCIE_AVMM.DLL

PCIE.h

TERASIC_PCIE_AVMM.h

SDK library file, defines constant and data structure

FPGA Application Design

Figure 5-15 shows the system block diagram in the FPGA system. In the Platform Designer

(formerly Qsys), the PIO controller is used to control the LED and monitor the Button Status, and

the On-Chip memory is used for performing DMA testing. The PIO controllers and the On-Chip

memory are connected to the PCI Express Hard IP controller through the Memory-Mapped

Interface.

Figure 5-15 Hardware block diagram of the PCIe_DDR4 reference design

Windows Based Application Software Design

The application software project is built by Visual C++ 2012. The project includes the following

major files:

The main program PCIE_DDR4.cpp includes the header file "PCIE.h" and defines the controller

address according to the FPGA design.

Apollo Carrier Board

User Manual

45

www.terasic.com

May 8, 2020

The base address of BUTTON and LED controllers are 0x4000010 and 0x4000020 based on

PCIE_BAR4, respectively. The on-chip memory base address is 0x00000000 relative to the DMA

controller. The above definitions are the same as those in the PCIe Fundamental demo.

Before accessing the FPGA through PCI Express, the application first calls PCIE_Load to

dynamically load the TERASIC_PCIE_AVMM.DLL. Then, it calls PCIE_Open to open the PCI

Express driver. The constant DEFAULT_PCIE_VID and DEFAULT_PCIE_DID used in the

PCIE_Open are defined in TERASIC_PCIE_AVMM.h. If developers change the Vendor ID and

Device ID and PCI Express IP, they also need to change the ID value defined in

TERASIC_PCIE_AVMM.h. If the return value of PCIE_Open is zero, it means the driver cannot be

accessed successfully. In this case, please make sure:

The FPGA is configured with the associated bit-stream file and the host is rebooted.

The PCI express driver is loaded successfully.

The LED control is implemented by calling PCIE_Write32 API, as shown below:

The button status query is implemented by calling the PCIE_Read32 API, as shown below:

The memory-mapped memory read and write test is implemented by PCIE_DmaWrite and

PCIE_DmaRead API, as shown below:

Apollo Carrier Board

User Manual

46

www.terasic.com

May 8, 2020

The PCIe link information is implemented by PCIE_ConfigRead32 API, as shown below:

Apollo Carrier Board

User Manual

47

www.terasic.com

May 8, 2020

T

Chapter 6

Transceiver Verification

his chapter describes how to verify the FPGA transceivers via the QSFP28 connector. A

40Gbps loopback test code called alt_e40 which is available in the System CD. The source

code is also available in the in the system CD.

6.1 Transceiver Test Code

The transceiver test code is used to verify the transceiver channels via the QSPF28 ports through

an external loopback method. The transceiver channels are verified with the data rates 10.3125

Gbps for the FPGA with PRBS31 test pattern.

6.2 QSFP28 Ports

To enable an external loopback of the transceiver channels, QSFP28 loopback fixtures, as shown in

Figure 6-1, are required. The fixture is available at:

https://multilaneinc.com/product/ml4002-28/

Figure 6-1 QSFP28 Loopback fixtures

Figure 6-2 shows the FPGA board with four QSFP28 loopback fixtures installed.

Apollo Carrier Board

User Manual

48

www.terasic.com

May 8, 2020

Figure 6-2 QSFP28 Loopback fixtures in the Apollo Develop kit

6.3 40G Ethernet Example

This 40G Ethernet example is generated according to the documents Stratix 10 Low Latency 40G

Ethernet Design Example User Guide. The Stratix 10 LL(Low Latency) 40GbE IP is used in the

example design. This example executes the external loopback test through one of the QSFP28

ports on the FPGA main board. A QSFP28 loopback fixture is required to perform this

demonstration. Figure 6-3 shows the block diagram of this demonstration.

Apollo Carrier Board

User Manual

49

www.terasic.com

May 8, 2020

Item

Description

Project Location

CDROM/Demonstrations/alt_e40

Quartus Project

CDROM/Demonstrations/alt_e40/hardware_test_design

FPGA Bit Stream

CDROM/Demonstrations/alt_e40/hardware_test_design/output_files/eth_ex_40g.sof

Demo Batch

CDROM/Demonstrations/alt_e40/demo_batch

Test Scrip File

CDROM/Demonstrations/alt_e40/hardware_test_design/hwtest/main.tcl

Quartus Version

Quartus Prime 19.4 Pro Edition

Figure 6-3 Block diagram of 40GbE demo

Project Information

The Project information is shown in the table below.

Demonstration Setup

Here is the procedure to setup the demonstration. A QSFP28 loopback fixture is required for this

demonstration. If you don’t have a QSFP28 loopback fixture, please use run_test instead of

run_external_test in the following demonstration procedure. The run_test is used to enable

transceiver serial loopback for internal loopback.

1. Make sure your host PC has installed the Quartus 19.4 Pro edition.

2. Insert a QSFP28 loopback fixture into the QSFP28-A port on the Apollo carrier board, as

shown in Figure 6-2.

Apollo Carrier Board

User Manual

50

www.terasic.com

May 8, 2020

3. Connect the host PC to the FPGA board using a mini-USB cable. Please make sure the

USB-Blaster II driver is installed on the host PC.

4. Make sure the USB-Blaster II is detected correctly.

5. Go to the path: System_CD/Demonstration/alt_e40/demo_batch/. Execute the batch file

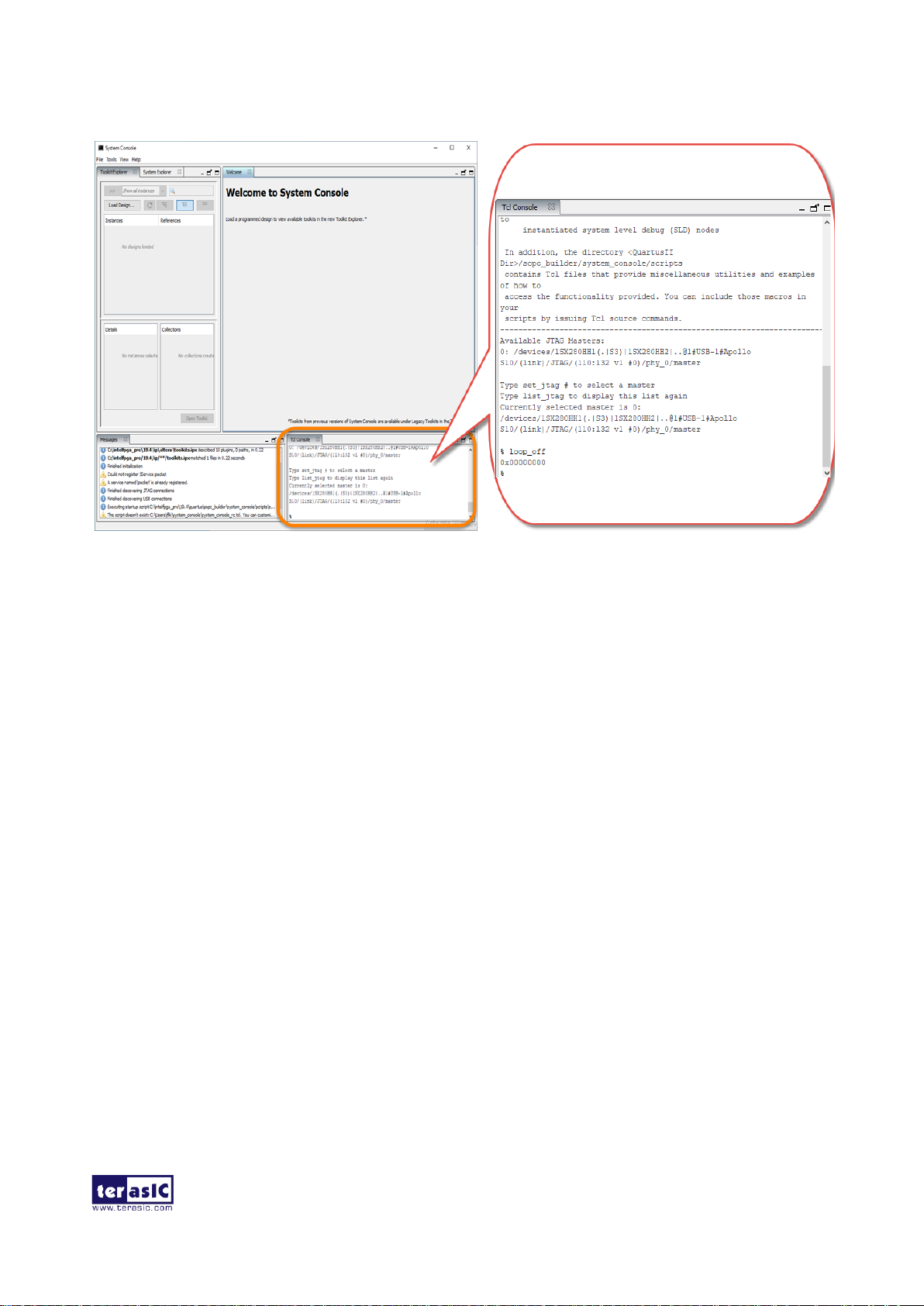

“test.bat” to program the FPGA and run the Tcl file (See Figure 6-4). The Tcl file will open the

Quartus tool “System Console” automatically(See Figure 6-5).

Figure 6-4 Execute demo batch file

Apollo Carrier Board

User Manual

51

www.terasic.com

May 8, 2020

Figure 6-5 Launch the System Console for Ethernet 40G Demo

6. If you have a QSFP28 loopback fixture installed, type “loop_off” to turns off internal serial

loopback. Otherwise, type “loop_on” to turn on internal serial loopback(See Figure 6-4).

Apollo Carrier Board

User Manual

52

www.terasic.com

May 8, 2020

Figure 6-6 Enter command for test

7. Type “start_pkt_gen” to starts the packet generator.

8. Type “chkmac_stats” to display the values in the MAC statics counters, as shown in Figure

6-7.

Apollo Carrier Board

User Manual

53

www.terasic.com

May 8, 2020

Figure 6-7 Ethernet 40G loopback test report for RX and TX

Apollo Carrier Board

User Manual

54

www.terasic.com

May 8, 2020

Date

Version

Changes

2020.04

First publication

2020.04

V1.1

Add chapter 5 &6

2020.05

V1.2

Add assemble and disassemble

board video in chapter 3

Chapter 7

Additional Information

7.1 Getting Help

Here are the addresses where you can get help if you encounter problems:

Terasic Technologies

9F., No.176, Sec.2, Gongdao 5th Rd,

East Dist, HsinChu City, Taiwan, 30070

Email: support@terasic.com

Web: www.terasic.com

Revision History

Loading...

Loading...