ADC-SoC

User Manual

1

www.terasic.com

December 22, 2016

ADC-SoC

User Manual

1

www.terasic.com

December 22, 2016

CONTENTS

Chapter 1 ADC-SoC Development Kit ............................................................... 3

1.1 Package Contents ............................................................................................................................. 3

1.2 ADC-SoC System CD ...................................................................................................................... 4

1.3 Getting Help ..................................................................................................................................... 4

Chapter 2 Introduction of the ADC-SoC Board ................................................... 5

2.1 Layout and Components ................................................................................................................... 5

2.2 Block Diagram of the ADC-SoC Board ........................................................................................... 7

Chapter 3 Using the ADC-SoC Board .............................................................. 10

3.1 Settings of FPGA Configuration Mode .......................................................................................... 10

3.2 Configuration of Cyclone V SoC FPGA on ADC-SoC .................................................................. 11

3.3 Board Status Elements .................................................................................................................... 16

3.4 Board Reset Elements..................................................................................................................... 17

3.5 Clock Circuitry ............................................................................................................................... 19

3.6 Peripherals Connected to the FPGA ............................................................................................... 20

3.6.1 User Push-buttons, Switches and LEDs ............................................................................. 20

3.6.2 2x20 GPIO Expansion Headers .......................................................................................... 23

3.6.3 Arduino Uno R3 Expansion Header ................................................................................... 24

3.6.4 A/D Converter and Analog Input ...................................................................................... 26

3.6.5 High-Speed A/D Converter ................................................................................................ 28

3.7 Peripherals Connected to Hard Processor System (HPS) ............................................................... 31

3.7.1 User Push-buttons and LEDs ............................................................................................. 31

3.7.2 Gigabit Ethernet ................................................................................................................ 32

3.7.3 UART ................................................................................................................................. 33

3.7.4 DDR3 Memory ................................................................................................................... 34

3.7.5 Micro SD Card Socket ........................................................................................................ 36

ADC-SoC

User Manual

2

www.terasic.com

December 22, 2016

3.7.6 USB 2.0 OTG PHY ............................................................................................................... 37

3.7.7 G-sensor ............................................................................................................................ 38

3.7.8 LTC Connector ................................................................................................................... 39

3.7.9 Real-Time Clock ................................................................................................................. 40

Chapter 4 Examples For FPGA ....................................................................... 43

4.1 ADC-SoC Factory Configuration ................................................................................................... 43

4.2 LTC2308 ADC Reading ................................................................................................................. 44

4.3 HIGH SPEED ADC AD9254 ......................................................................................................... 47

Chapter 5 Examples for HPS SoC ............................................................. 50

5.1 Users LED and KEY ...................................................................................................................... 50

5.2 I2C Interfaced G-sensor ................................................................................................................. 56

Chapter 6 Examples for using both HPS SoC and FGPA ............................. 59

6.1 HPS Control FPGA LED ................................................................................................................ 59

Chapter 7 Programming the EPCS Device ........................................................ 63

7.1 Before Programming Begins .......................................................................................................... 63

7.2 Convert .SOF File to .JIC File ........................................................................................................ 63

7.3 Write JIC File into the EPCS Device ............................................................................................. 68

7.4 Erase the EPCS Device .................................................................................................................. 69

7.5 EPCS Programming via nios-2-flash-programmer ......................................................................... 70

Chapter 8 Appendix A ....................................................................................... 71

8.1 Revision History ............................................................................................................................. 71

8.2 Copyright Statement ....................................................................................................................... 71

ADC-SoC

User Manual

3

www.terasic.com

December 22, 2016

PPaacckkaaggee CCoonntteennttss

Chapter 1

ADC-SoC

Development Kit

The ADC-SoC Development Kit presents a robust hardware design platform built around the Intel

System-on-Chip (SoC) FPGA, which combines the latest dual-core Cortex-A9 embedded cores

with industry-leading programmable logic for ultimate design flexibility. Users can now leverage

the power of tremendous re-configurability paired with a high-performance, low-power processor

system. Intel’s SoC integrates an ARM-based hard processor system (HPS) consisting of processor,

peripherals and memory interfaces tied seamlessly with the FPGA fabric using a high-bandwidth

interconnect backbone. The ADC-SoC development board is equipped with high-speed DDR3

memory, high-speed and low-speed Analog-to-Digital capabilities, Ethernet networking, and much

more that promise many exciting applications.

The ADC-SoC Development Kit contains all the tools needed to use the board in conjunction with a

computer that runs the Microsoft Windows XP or later.

1.1

Figure 1-1 shows a photograph of the ADC-SoC package.

Figure 1-1 The ADC-SoC package contents

ADC-SoC

User Manual

4

www.terasic.com

December 22, 2016

AADDCC--SSooCC SSyysstteemm CCDD

GGeettttiinngg HHeellpp

The ADC-SoC package includes:

The ADC-SoC development board

USB cable Type A to Mini-B for FPGA programming or UART control

USB cable Type A to Micro-B for USB OTG connect to PC

5V DC power adapter

microSD Card (Installed)

1.2

The ADC-SoC System CD contains all the documents and supporting materials associated with

ADC-SoC, including the user manual, system builder, reference designs, and device datasheets.

Users can download this system CD from the link: http://ADC-SoC.terasic.com/cd.

1.3

Here is the address where you can get help if you encounter any problems:

Terasic Technologies

9F., No.176, Sec.2, Gongdao 5th Rd, East Dist, Hsinchu City, 30070. Taiwan

Email: support@terasic.com

Tel.: +886-3-575-0880

Website: ADC-SoC.terasic.com

ADC-SoC

User Manual

5

www.terasic.com

December 22, 2016

LLaayyoouutt aanndd CCoommppoonneennttss

Chapter 2

Introduction of the

ADC-SoC Board

This chapter provides an introduction to the features and design characteristics of the board.

2.1

Figure 2-1 and Figure 2-2 shows a photograph of the board. It depicts the layout of the board and

indicates the location of the connectors and key components.

Figure 2-1 ADC-SoC development board (top view)

ADC-SoC

User Manual

6

www.terasic.com

December 22, 2016

Figure 2-2 ADC-SoC development board (bottom view)

The ADC-SoC board has many features that allow users to implement a wide range of designed

circuits, from simple circuits to various multimedia projects.

The following hardware is provided on the board:

FPGA

Cyclone® V SE 5CSEMA4U23C6N device

Serial configuration device – EPCS128

USB-Blaster II onboard for programming; JTAG Mode

2 push-buttons

4 slide switches

8 green user LEDs

Three 50MHz clock sources from the clock generator

One 40-pin expansion header

One Arduino expansion header (Uno R3 compatibility), can connect with Arduino shields.

One 10-pin Analog input expansion header. (shared with Arduino Analog input)

500Ksps A/D converter, 4-wire SPI interface with FPGA

Two high speed 14-bit AD Converter with 150MSPS

ADC-SoC

User Manual

7

www.terasic.com

December 22, 2016

BBlloocckk DDiiaaggrraamm ooff tthhee AADDCC--SSooCC BBooaarrdd

HPS (Hard Processor System)

925MHz Dual-core ARM Cortex-A9 processor

1GB DDR3 SDRAM (32-bit data bus)

1 Gigabit Ethernet PHY with RJ45 connector

USB OTG port, USB Micro-AB connector

Micro SD card socket

Accelerometer (I2C interface + interrupt)

UART to USB, USB Mini-B connector

Warm reset button and cold reset button

One user button and one user LED

LTC 2x7 expansion header

RTC (Real-time clock)

2.2

Figure 2-3 is the block diagram of the board. All the connections are established through the

Cyclone V SoC FPGA device to provide maximum flexibility for users. Users can configure the

FPGA to implement any system design.

Figure 2-3 Block diagram of ADC-SoC

ADC-SoC

User Manual

8

www.terasic.com

December 22, 2016

FFPPGGAA DDeevviiccee

CCoonnffiigguurraattiioonn aanndd DDeebbuug

g

MMeemmoorryy DDeevviiccee

CCoommmmuunniiccaattiioonn

CCoonnnneeccttoorrss

AADDCC

HHiigghh--SSppeeeedd AADDCC

Detailed information about Figure 2-3 are listed below.

Cyclone V SoC 5CSEMA4U23C6N Device

Dual-core ARM Cortex-A9 (HPS)

40K programmable logic elements

2,460 Kbits embedded memory

5 fractional PLLs

2 hard memory controllers

Serial configuration device – EPCS128 on FPGA

Onboard USB-Blaster II (Mini-B USB connector)

1GB (2x256Mx16) DDR3 SDRAM on HPS

Micro SD card socket on HPS

One USB 2.0 OTG (ULPI interface with USB Micro-AB connector)

UART to USB (USB Mini-B connector)

10/100/1000 Ethernet

One 40-pin expansion headers

Arduino expansion header

One 10-pin ADC input header

One LTC connector (one SPI Master, one I2C and one GPIO interface )

12-Bit Resolution, 500Ksps Sampling Rate. SPI Interface.

8-Channel Analog Input. Input Range : 0V ~ 4.096V.

14-Bit Resolution, 150MSPS Sampling Rate.

Two channel Input with SMA connector.

ADC-SoC

User Manual

9

www.terasic.com

December 22, 2016

SSwwiittcchheess,, BBuuttttoonnss,, aanndd IInnddiiccaattoorrss

SSeennssoorrss

RReeaall--TTiimmee CClloocckk

PPoowweerr

3 user Keys (FPGA x2, HPS x1)

4 user switches (FPGA x4)

9 user LEDs (FPGA x8, HPS x 1)

2 HPS reset buttons (HPS_RESET_n and HPS_WARM_RST_n)

G-Sensor on HPS

On-Board Real-Time Clock (RTC).

On-Board battery holder for RTC.

5V DC input

ADC-SoC

User Manual

10

www.terasic.com

December 22, 2016

SSeettttiinnggss ooff FFPPGGAA CCoonnffiigguurraattiioonn MMooddee

Chapter 3

Using the ADC-SoC

Board

This chapter provides an instruction to use the board and describes the peripherals.

3.1

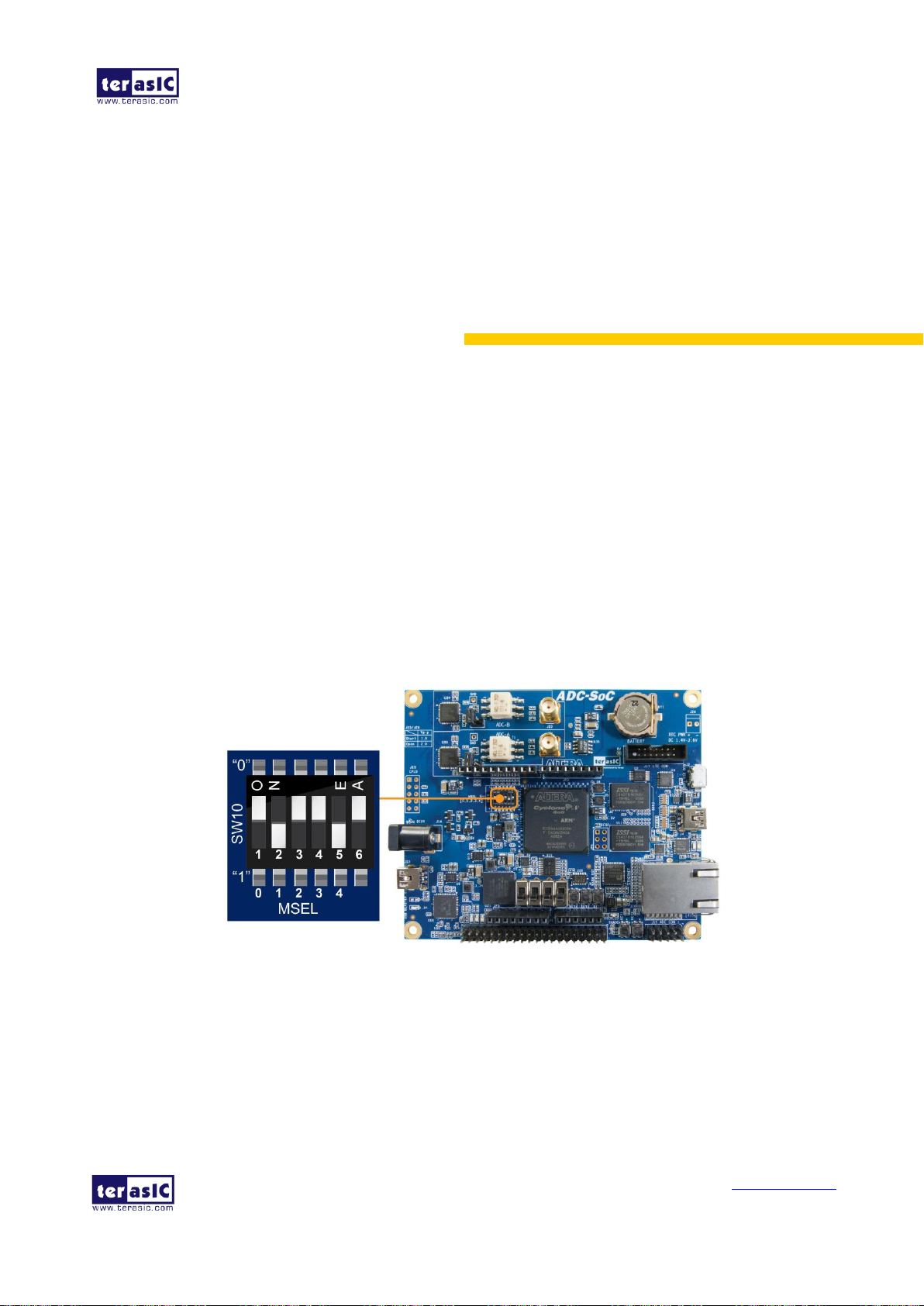

When the ADC-SoC board is powered on, the FPGA can be configured from EPCS or HPS.

The MSEL[4:0] pins are used to select the configuration scheme. It is implemented as a 6-pin DIP

switch SW10 on the ADC-SoC board, as shown in Figure 3-1.

Table 3-1 shows the relation between MSEL[4:0] and DIP switch (SW10).

Figure 3-1 DIP switch (SW10) setting of FPP x32 mode

ADC-SoC

User Manual

11

www.terasic.com

December 22, 2016

Board Reference

Signal Name

Description

Default

SW10.1

MSEL0

Use these pins to set the FPGA

Configuration scheme

ON (“0”)

SW10.2

MSEL1

OFF (“1”)

SW10.3

MSEL2

ON (“0”)

SW10.4

MSEL3

ON (“0”)

SW10.5

MSEL4

OFF (“1”)

SW10.6

N/A

N/A

N/A

Configuration

SW10.1

MSEL0

SW10.2

MSEL1

SW10.3

MSEL2

SW10.4

MSEL3

SW10.5

MSEL4

SW10.6

Description

AS

ON

OFF

ON

ON

OFF

N/A

FPGA configured from EPCS

FPPx32 (Default)

ON

OFF

ON

OFF

ON

N/A

FPGA configured from HPS

software: Linux (default)

FPPx16

ON

ON

ON

ON

ON

N/A

FPGA configured from HPS

software: U-Boot, with image

stored on the SD card, like

LXDE Desktop or console Linux

with frame buffer edition.

CCoonnffiigguurraattiioonn ooff CCyycclloonnee VV SSooCC FFPPGGAA oonn AADDCC--SSooCC

Table 3-1 FPGA Configuration Mode Switch (SW10)

Table 3-2 shows MSEL[4:0] setting for FPGA configure, and default setting is FPPx32 mode on

ADC-SoC.

Figure 3-1 shows MSEL[4:0] setting of AS mode, which is also the default setting on ADC-SoC

board. When the board is powered on and MSEL[4:0] set to “10010”, the FPGA is configured

from EPCS, which is pre-programmed with the default code. If developers wish to configure FPGA

from an application software running on Linux, the MSEL[4:0] needs to be set to “01010” before

the programming process begins. If developers using the "Linux Console with frame buffer" or

"Linux LXDE Desktop" SD Card image, the MSEL[4:0] needs to be set to “00000” before the

board is powered on.

Table 3-2 MSEL Pin Settings for FPGA Configure of ADC-SoC

3.2

There are two types of programming method supported by ADC-SoC:

1. JTAG programming: It is named after the IEEE standards Joint Test Action Group.

ADC-SoC

User Manual

12

www.terasic.com

December 22, 2016

The configuration bit stream is downloaded directly into the Cyclone V SoC FPGA. The FPGA will

retain its current status as long as the power keeps applying to the board; the configuration

information will be lost when the power is off.

2. AS programming: The other programming method is Active Serial configuration.

The configuration bit stream is downloaded into the serial configuration device (EPCS128), which

provides non-volatile storage for the bit stream. The information is retained within EPCS128 even if

the ADC-SoC board is turned off. When the board is powered on, the configuration data in the

EPCS128 device is automatically loaded into the Cyclone V SoC FPGA.

JTAG Chain on ADC-SoC Board

The FPGA device can be configured through JTAG interface on ADC-SoC board, but the JTAG

chain must form a closed loop, which allows Quartus II programmer to the detect FPGA device.

Figure 3-2 illustrates the JTAG chain on ADC-SoC board.

Figure 3-2 Path of the JTAG chain

Configure the FPGA in JTAG Mode

There are two devices (FPGA and HPS) on the JTAG chain. The following shows how the FPGA is

programmed in JTAG mode step by step.

Open the Quartus II programmer and click “Auto Detect”, as circled in Figure 3-3

ADC-SoC

User Manual

13

www.terasic.com

December 22, 2016

Figure 3-3 Detect FPGA device in JTAG mode

Select detected device associated with the board, as circled in Figure 3-4.

Figure 3-4 Select 5CSEMA4 device

Both FPGA and HPS are detected, as shown in Figure 3-5.

ADC-SoC

User Manual

14

www.terasic.com

December 22, 2016

Figure 3-5 FPGA and HPS detected in Quartus programmer

Right click on the FPGA device and open the .sof file to be programmed, as highlighted in Figure

3-6.

Figure 3-6 Open the .sof file to be programmed into the FPGA device

Select the .sof file to be programmed, as shown in Figure 3-7.

ADC-SoC

User Manual

15

www.terasic.com

December 22, 2016

Figure 3-7 Select the .sof file to be programmed into the FPGA device

Click “Program/Configure” check box and then click “Start” button to download the .sof file into

the FPGA device, as shown in Figure 3-8.

Configure the FPGA in AS Mode

Figure 3-8 Program .sof file into the FPGA device

ADC-SoC

User Manual

16

www.terasic.com

December 22, 2016

BBooaarrdd SSttaattuuss EElleemmeennttss

The ADC-SoC board uses a serial configuration device (EPCS128) to store configuration data for

the Cyclone V SoC FPGA. This configuration data is automatically loaded from the serial

configuration device chip into the FPGA when the board is powered up.

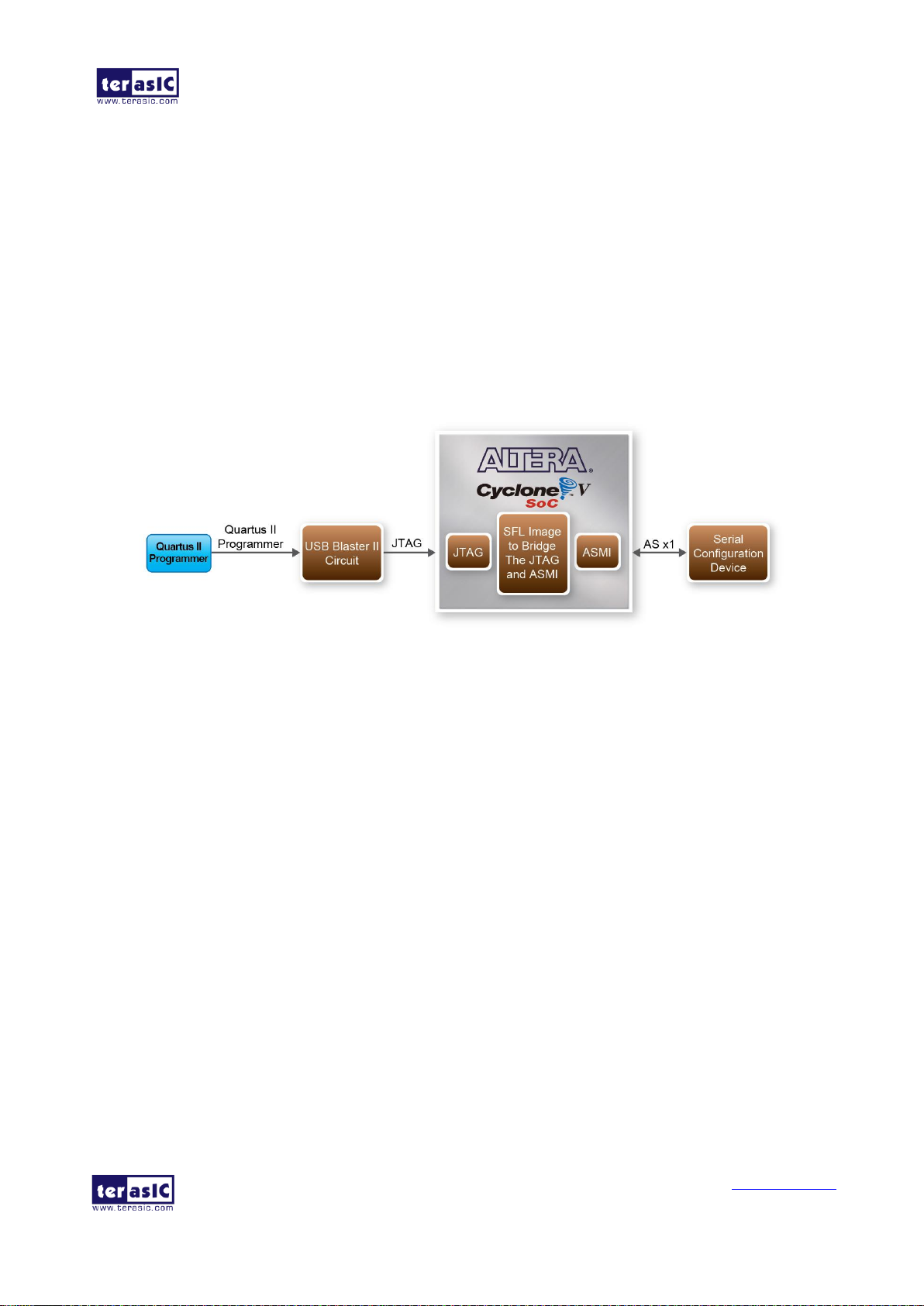

Users need to use Serial Flash Loader (SFL) to program the serial configuration device via JTAG

interface. The FPGA-based SFL is a soft intellectual property (IP) core within the FPGA that bridge

the JTAG and Flash interfaces. The SFL Megafunction is available in Quartus II. Figure 3-9 shows

the programming method when adopting SFL solution.

Please refer to Chapter 8: Steps of Programming the Serial Configuration Device for the basic

programming instruction on the serial configuration device.

Figure 3-9 Programming a serial configuration device with SFL solution

3.3

In addition to the 9 LEDs that FPGA/HPS device can control, there are 6 indicators which can

indicate the board status (as shown in Figure 3-10), please refer the details in Table 3-3.

ADC-SoC

User Manual

17

www.terasic.com

December 22, 2016

Board Reference

LED Name

Description

LED9

3.3-V Power

Illuminate when 3.3V power is active.

LED10

CONF_DONE

Illuminates when the FPGA is successfully configured.

LED11

JTAG_TX

Illuminate when data is transferred from JTAG to USB Host.

LED12

JTAG_RX

Illuminate when data is transferred from USB Host to JTAG.

TXD

UART TXD

Illuminate when data is transferred from FT232R to USB Host.

RXD

UART RXD

Illuminate when data is transferred from USB Host to FT232R.

BBooaarrdd RReesseett EElleemmeennttss

Figure 3-10 LED Indicators on ADC-SoC

Table 3-3 LED Indicators

3.4

There are two HPS reset buttons on ADC-SoC, HPS (cold) reset and HPS warm reset, as shown in

Figure 3-11. Table 3-4 describes the purpose of these two HPS reset buttons. Figure 3-12 is the

reset tree for ADC-SoC.

ADC-SoC

User Manual

18

www.terasic.com

December 22, 2016

Board Reference

Signal Name

Description

KEY4

HPS_RESET_N

Cold reset to the HPS, Ethernet PHY and USB host device.

Active low input which resets all HPS logics that can be reset.

KEY3

HPS_WARM_RST_N

Warm reset to the HPS block. Active low input affects the

system reset domain for debug purpose.

Figure 3-11 HPS cold reset and warm reset buttons on ADC-SoC

Table 3-4 Description of Two HPS Reset Buttons on ADC-SoC

Figure 3-12 HPS reset tree on ADC-SoC board

ADC-SoC

User Manual

19

www.terasic.com

December 22, 2016

CClloocckk CCiirrccuuiittrryy

Signal Name

FPGA Pin No.

Description

I/O Standard

FPGA_CLK1_50

PIN_V11

50 MHz clock input

3.3V

FPGA_CLK2_50

PIN_Y13

50 MHz clock input

3.3V

3.5

Figure 3-13 shows the default frequency of all external clocks to the Cyclone V SoC FPGA. A

clock generator is used to distribute clock signals with low jitter. The two 50MHz clock signals

connected to the FPGA are used as clock sources for user logic. Three 25MHz clock signal are

connected to two HPS clock inputs, and the other one is connected to the clock input of Gigabit

Ethernet Transceiver. One 24MHz clock signal is connected to the USB controller for USB Blaster

II circuit and FPGA. One 24MHz clock signals are connected to the clock inputs of USB OTG PHY.

The associated pin assignment for clock inputs to FPGA I/O pins is listed in Table 3-5.

Figure 3-13 Block diagram of the clock distribution on ADC-SoC

Table 3-5 Pin Assignment of Clock Inputs

ADC-SoC

User Manual

20

www.terasic.com

December 22, 2016

FPGA_CLK3_50

PIN_E11

50 MHz clock input (share with FPGA_CLK1_50)

3.3V

HPS_CLK1_25

PIN_E20

25 MHz clock input

3.3V

HPS_CLK2_25

PIN_D20

25 MHz clock input

3.3V

PPeerriipphheerraallss CCoonnnneecctteedd ttoo tthhee FFPPGGAA

Pushbutton releasedPushbutton depressed

Before

Debouncing

Schmitt Trigger

Debounced

3.6

This section describes the interfaces connected to the FPGA. Users can control or monitor different

interfaces with user logic from the FPGA.

3.6.1 User Push-buttons, Switches and LEDs

The board has two push-buttons connected to the FPGA, as shown in Figure 3-14. Schmitt trigger

circuit is implemented and act as switch debounce in Figure 3-15 for the push-buttons connected.

The two push-buttons named KEY0 and KEY1 coming out of the Schmitt trigger device are

connected directly to the Cyclone V SoC FPGA. The push-button generates a low logic level or

high logic level when it is pressed or not, respectively. Since the push-buttons are debounced, they

can be used as clock or reset inputs in a circuit.

Figure 3-14 Connections between the push-buttons and the Cyclone V SoC FPGA

Figure 3-15 Switch debouncing

ADC-SoC

User Manual

21

www.terasic.com

December 22, 2016

There are four slide switches connected to the FPGA, as shown in Figure 3-16. These switches are

not debounced and to be used as level-sensitive data inputs to a circuit. Each switch is connected

directly and individually to the FPGA. When the switch is set to the DOWN position (towards the

edge of the board), it generates a low logic level to the FPGA. When the switch is set to the UP

position, a high logic level is generated to the FPGA.

Figure 3-16 Connections between the slide switches and the Cyclone V SoC FPGA

There are also eight user-controllable LEDs connected to the FPGA. Each LED is driven directly

and individually by the Cyclone V SoC FPGA; driving its associated pin to a high logic level or low

level to turn the LED on or off, respectively. Figure 3-17 shows the connections between LEDs and

Cyclone V SoC FPGA. Table 3-6, Table 3-7 and Table 3-8 list the pin assignment of user

push-buttons, switches, and LEDs.

Figure 3-17 Connections between the LEDs and the Cyclone V SoC FPGA

ADC-SoC

User Manual

22

www.terasic.com

December 22, 2016

Signal Name

FPGA Pin No.

Description

I/O Standard

SW[0]

PIN_Y11

Slide Switch[0]

3.3V

SW[1]

PIN_AA11

Slide Switch[1]

3.3V

SW[2]

PIN_AD5

Slide Switch[2]

3.3V

SW[3]

PIN_AE6

Slide Switch[3]

3.3V

Signal Name

FPGA Pin No.

Description

I/O Standard

KEY[0]

PIN_AH17

Push-button[0]

3.3V

KEY[1]

PIN_AH16

Push-button[1]

3.3V

Signal Name

FPGA Pin No.

Description

I/O Standard

LED[0]

PIN_W15

LED [0]

3.3V

LED[1]

PIN_AA24

LED [1]

3.3V

LED[2]

PIN_V16

LED [2]

3.3V

LED[3]

PIN_V15

LED [3]

3.3V

LED[4]

PIN_AF26

LED [4]

3.3V

LED[5]

PIN_AE26

LED [5]

3.3V

LED[6]

PIN_Y16

LED [6]

3.3V

LED[7]

PIN_AA23

LED [7]

3.3V

Table 3-6 Pin Assignment of Slide Switches

Table 3-7 Pin Assignment of Push-buttons

Table 3-8 Pin Assignment of LEDs

ADC-SoC

User Manual

23

www.terasic.com

December 22, 2016

Supplied Voltage

Max. Current Limit

5V

1A (depend on the power adapter specification.)

3.3V

1.5A

GPIO 1 (JP7)

PIN_Y15

GPIO_1[0]

1 2

GPIO_1[1]

PIN_AC24

PIN_AA15

GPIO_1[2]

3 4

GPIO_1[3]

PIN_AD23

PIN_AG28

GPIO_1[4]

5 6

GPIO_1[5]

PIN_AF28

PIN_AE25

GPIO_1[6]

7 8

GPIO_1[7]

PIN_AF27

PIN_AG26

GPIO_1[8]

9 10

GPIO_1[9]

PIN_AH27

5V

11 12

GND PIN_AG25

GPIO_1[10]

13 14

GPIO_1[11]

PIN_AH26

PIN_AH24

GPIO_1[12]

15 16

GPIO_1[13]

PIN_AF25

PIN_AG23

GPIO_1[14]

17 18

GPIO_1[15]

PIN_AF23

PIN_AG24

GPIO_1[16]

19 20

GPIO_1[17]

PIN_AH22

PIN_AH21

GPIO_1[18]

21 22

GPIO_1[19]

PIN_AG21

PIN_AH23

GPIO_1[20]

23 24

GPIO_1[21]

PIN_AA20

PIN_AF22

GPIO_1[22]

25 26

GPIO_1[23]

PIN_AE22

PIN_AG20

GPIO_1[24]

27 28

GPIO_1[25]

PIN_AF21

3.3V

29 30

GND PIN_AG19

GPIO_1[26]

31 32

GPIO_1[27]

PIN_AH19

PIN_AG18

GPIO_1[28]

33 34

GPIO_1[29]

PIN_AH18

PIN_AF18

GPIO_1[30]

35 36

GPIO_1[31]

PIN_AF20

PIN_AG15

GPIO_1[32]

37 38

GPIO_1[33]

PIN_AE20

PIN_AE19

GPIO_1[34]

39 40

GPIO_1[35]

PIN_AE17

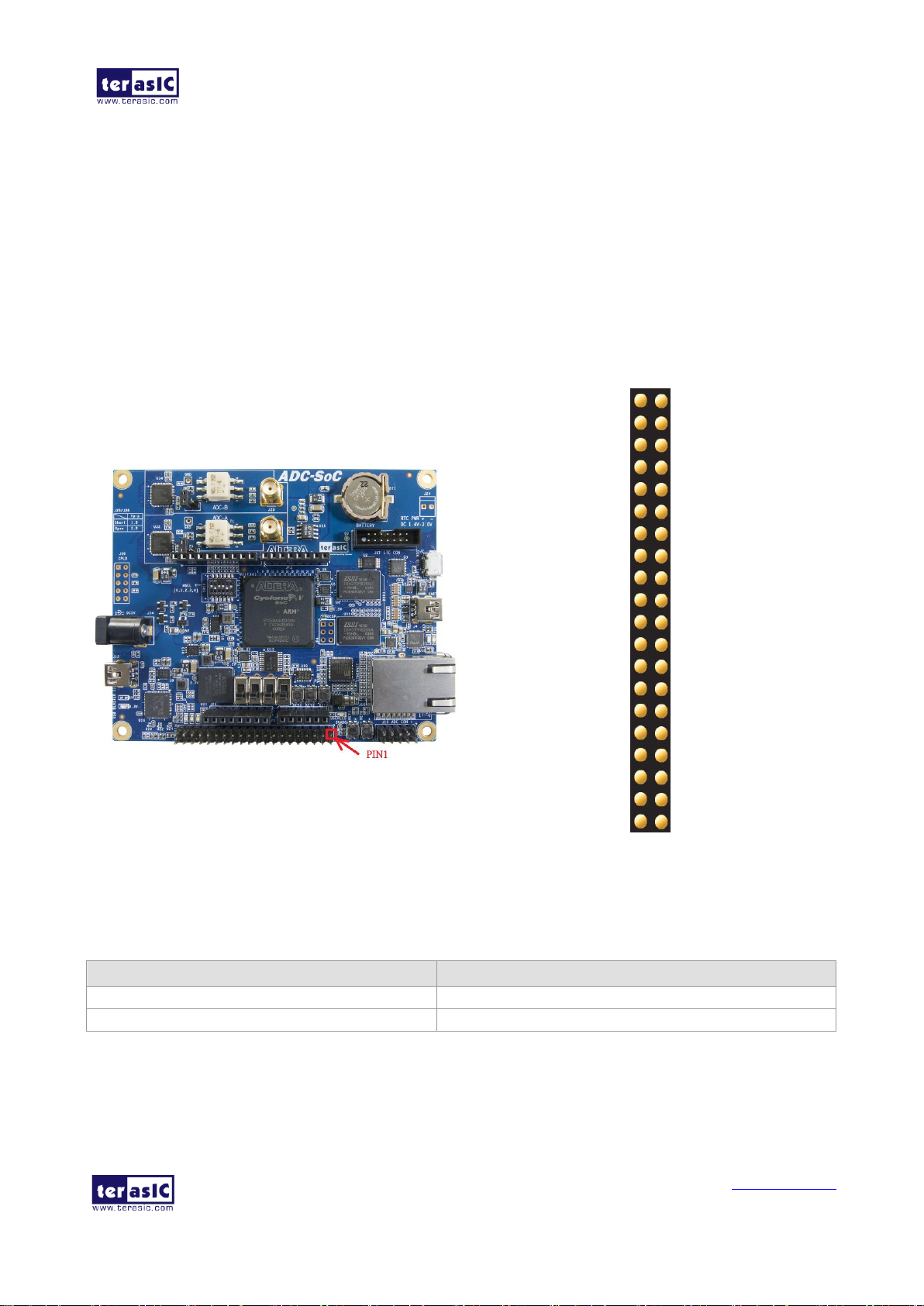

3.6.2 2x20 GPIO Expansion Headers

The board has one 40-pin expansion headers. Each header has 36 user pins connected directly to the

Cyclone V SoC FPGA. It also comes with DC +5V (VCC5), DC +3.3V (VCC3P3), and two GND

pins. Figure 3-18 shows the I/O distribution of the GPIO connector. The maximum power

consumption allowed for a daughter card connected to one or two GPIO ports is shown in Table 3-9

and Table 3-10 shows all the pin assignments of the GPIO connector.

Figure 3-18 GPIO Pin Arrangement

Table 3-9 Voltage and Max. Current Limit of Expansion Header(s)

ADC-SoC

User Manual

24

www.terasic.com

December 22, 2016

Signal Name

FPGA Pin No.

Description

I/O Standard

GPIO_1[0]

PIN_Y15

GPIO Connection 1[0]

3.3V

GPIO_1[1]

PIN_AC24

GPIO Connection 1[1]

3.3V

GPIO_1[2]

PIN_AA15

GPIO Connection 1[2]

3.3V

GPIO_1[3]

PIN_AD23

GPIO Connection 1[3]

3.3V

GPIO_1[4]

PIN_AG28

GPIO Connection 1[4]

3.3V

GPIO_1[5]

PIN_AF28

GPIO Connection 1[5]

3.3V

GPIO_1[6]

PIN_AE25

GPIO Connection 1[6]

3.3V

GPIO_1[7]

PIN_AF27

GPIO Connection 1[7]

3.3V

GPIO_1[8]

PIN_AG26

GPIO Connection 1[8]

3.3V

GPIO_1[9]

PIN_AH27

GPIO Connection 1[9]

3.3V

GPIO_1[10]

PIN_AG25

GPIO Connection 1[10]

3.3V

GPIO_1[11]

PIN_AH26

GPIO Connection 1[11]

3.3V

GPIO_1[12]

PIN_AH24

GPIO Connection 1[12]

3.3V

GPIO_1[13]

PIN_AF25

GPIO Connection 1[13]

3.3V

GPIO_1[14]

PIN_AG23

GPIO Connection 1[14]

3.3V

GPIO_1[15]

PIN_AF23

GPIO Connection 1[15]

3.3V

GPIO_1[16]

PIN_AG24

GPIO Connection 1[16]

3.3V

GPIO_1[17]

PIN_AH22

GPIO Connection 1[17]

3.3V

GPIO_1[18]

PIN_AH21

GPIO Connection 1[18]

3.3V

GPIO_1[19]

PIN_AG21

GPIO Connection 1[19]

3.3V

GPIO_1[20]

PIN_AH23

GPIO Connection 1[20]

3.3V

GPIO_1[21]

PIN_AA20

GPIO Connection 1[21]

3.3V

GPIO_1[22]

PIN_AF22

GPIO Connection 1[22]

3.3V

GPIO_1[23]

PIN_AE22

GPIO Connection 1[23]

3.3V

GPIO_1[24]

PIN_AG20

GPIO Connection 1[24]

3.3V

GPIO_1[25]

PIN_AF21

GPIO Connection 1[25]

3.3V

GPIO_1[26]

PIN_AG19

GPIO Connection 1[26]

3.3V

GPIO_1[27]

PIN_AH19

GPIO Connection 1[27]

3.3V

GPIO_1[28]

PIN_AG18

GPIO Connection 1[28]

3.3V

GPIO_1[29]

PIN_AH18

GPIO Connection 1[29]

3.3V

GPIO_1[30]

PIN_AF18

GPIO Connection 1[30]

3.3V

GPIO_1[31]

PIN_AF20

GPIO Connection 1[31]

3.3V

GPIO_1[32]

PIN_AG15

GPIO Connection 1[32]

3.3V

GPIO_1[33]

PIN_AE20

GPIO Connection 1[33]

3.3V

GPIO_1[34]

PIN_AE19

GPIO Connection 1[34]

3.3V

GPIO_1[35]

PIN_AE17

GPIO Connection 1[35]

3.3V

Table 3-10 Show all Pin Assignment of Expansion Headers

3.6.3 Arduino Uno R3 Expansion Header

The board provides Arduino Uno revision 3 compatibility expansion header which comes with four

ADC-SoC

User Manual

25

www.terasic.com

December 22, 2016

independent headers. The expansion header has 17 user pins (16pins GPIO and 1pin Reset)

connected directly to the Cyclone V SoC FPGA. 6-pins Analog input connects to ADC, and also

provides DC +9V (VCC9), DC +5V (VCC5), DC +3.3V (VCC3P3 and IOREF), and three GND

pins.

Please refer to Figure 3-19 for detailed pin-out information. The blue font represents the Arduino

Uno R3 board pin-out definition.

The 16 GPIO pins are provided to the Arduino Header for digital I/O. Table 3-11 lists the all the pin

assignments of the Arduino Uno connector (digital), signal names relative to the Cyclone V SoC

FPGA.

Figure 3-19 lists the all the pin-out signal name of the Arduino Uno connector.

The blue font represents the Arduino pin-out definition.

ADC-SoC

User Manual

26

www.terasic.com

December 22, 2016

Schematic

Signal Name

FPGA Pin No.

Description

Specific features

For Arduino

I/O Standard

Arduino_IO0

PIN_AG13

Arduino IO0

RXD

3.3-V

Arduino_IO1

PIN_AF13

Arduino IO1

TXD

3.3-V

Arduino_IO2

PIN_AG10

Arduino IO2

3.3-V

Arduino_IO3

PIN_AG9

Arduino IO3

3.3-V

Arduino_IO4

PIN_U14

Arduino IO4

3.3-V

Arduino_IO5

PIN_U13

Arduino IO5

3.3-V

Arduino_IO6

PIN_AG8

Arduino IO6

3.3-V

Arduino_IO7

PIN_AH8

Arduino IO7

3.3-V

Arduino_IO8

PIN_AF17

Arduino IO8

3.3-V

Arduino_IO9

PIN_AE15

Arduino IO9

3.3-V

Arduino_IO10

PIN_AF15

Arduino IO10

SS

3.3-V

Arduino_IO11

PIN_AG16

Arduino IO11

MOSI

3.3-V

Arduino_IO12

PIN_AH11

Arduino IO12

MISO

3.3-V

Arduino_IO13

PIN_AH12

Arduino IO13

SCK

3.3-V

Arduino_IO14

PIN_AH9

Arduino IO14

SDA

3.3-V

Arduino_IO15

PIN_AG11

Arduino IO15

SCL

3.3-V

Arduino_Reset_n

PIN_AH7

Reset signal, low active.

3.3-V

Table 3-11 Pin Assignments for Arduino Uno Expansion Header connector

Besides 16 pins for digital GPIO, there are also 6 analog inputs on the Arduino Uno R3 Expansion

Header (ADC_IN0 ~ ADC_IN5). Consequently, we use ADC LTC2308 from Linear Technology on

the board for possible future analog-to-digital applications. We will introduce in the next section.

3.6.4 A/D Converter and Analog Input

The ADC-SoC has an analog-to-digital converter (LTC2308).

The LTC2308 is a low noise, 500ksps, 8-channel, 12-bit ADC with a SPI/MICROWIRE compatible

serial interface. This ADC includes an internal reference and a fully differential sample-and-hold

circuit to reduce common mode noise. The internal conversion clock allows the external serial

output data clock (SCK) to operate at any frequency up to 40MHz.

It can be configured to accept eight input signals at inputs ADC_IN0 through ADC_IN7. These

eight input signals are connected to a 2x5 header, as shown in Figure 3-20.

ADC-SoC

User Manual

27

www.terasic.com

December 22, 2016

Figure 3-20 Signals of the 2x5 Header

These Analog inputs are shared with the Arduino's analog input pin (ADC_IN0 ~ ADC_IN5),

Figure 3-21 shows the connections between the FPGA, 2x5 header, Arduino Analog input, and the

A/D converter.

More information about the A/D converter chip is available in its datasheet. It can be found on

manufacturer’s website or in the directory \Datasheet\ADC of ADC-SoC system CD.

Figure 3-21 Connections between the FPGA, 2x5 header, and the A/D converter

ADC-SoC

User Manual

28

www.terasic.com

December 22, 2016

Signal Name

FPGA Pin No.

Description

I/O Standard

ADC_SCK

PIN_V10

Serial Data Clock

3.3V

ADC_SDO

PIN_AD4

Serial Data Out (ADC to FPGA)

3.3V

ADC_SDI

PIN_AC4

Serial Data Input (FPGA to ADC)

3.3V

ADC_CONVST

PIN_U9

Conversion Start

3.3V

Table 3-12 Pin Assignment of ADC

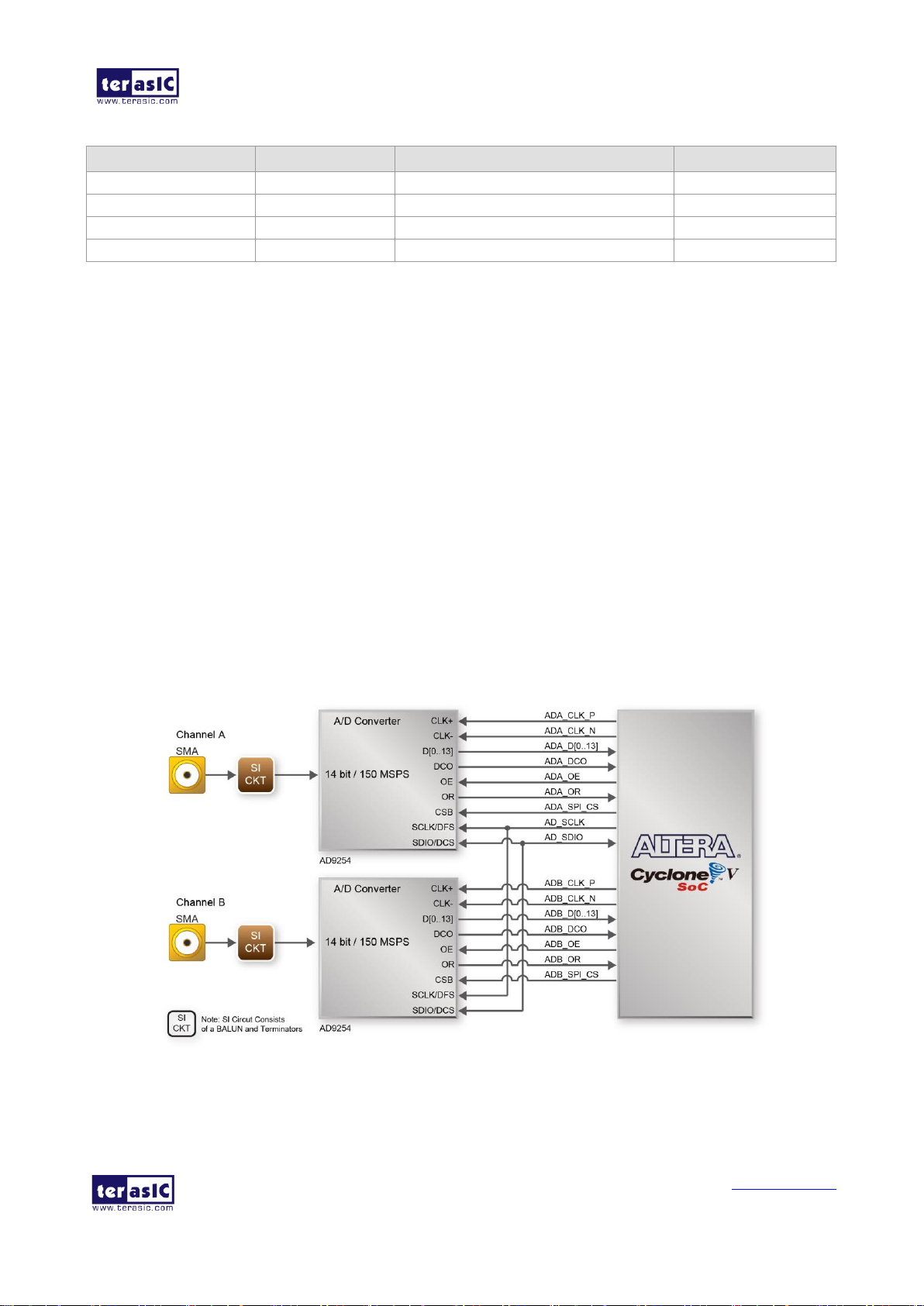

3.6.5 High-Speed A/D Converter

This board is populated with two A/D converters, which are ADI AD9254 devices, for high speed

and high-performance applications. The device uses a multistage differential pipeline architecture

with output error correction logic to provide 14-bit accuracy at 150 MSPS data rate and guarantees

no missing codes over the full operating temperature range.

The inputs to these A/D converters are transformer-coupled to create a balanced input. The

signal-to-noise ratio for the system is up to 72 dB for input signals from 1 MHz to the Nyquist

frequency of the converter. The maximum differential input voltage to the converter is 2Vpp. Usable

voltage input to the SMA connector is approximately 512 mV when it’s driven from a 50 Ohm

source.

Figure 3-22 shows the connections between the FPGA, High-Speed ADC, and SMA connector.

Table 3-13 lists the pin assignment of ADC interface connected to the FPGA.

Figure 3-22 Connections between the FPGA and High-Speed ADC.

ADC-SoC

User Manual

29

www.terasic.com

December 22, 2016

Signal Name

FPGA Pin No.

Description

I/O Standard

ADA_CLK_P

PIN_AG5

Clock Input (+)

3.3V

ADA_CLK_N

PIN_AH4

Clock Input (-)

3.3V

ADA_D0

PIN_AC22

Data Output Bit 0

3.3V

ADA_D1

PIN_AC23

Data Output Bit 1

3.3V

ADA_D2

PIN_AD17

Data Output Bit 2

3.3V

ADA_D3

PIN_AH3

Data Output Bit 3

3.3V

ADA_D4

PIN_AF7

Data Output Bit 4

3.3V

ADA_D5

PIN_AH13

Data Output Bit 5

3.3V

ADA_D6

PIN_AF4

Data Output Bit 6

3.3V

ADA_D7

PIN_AH14

Data Output Bit 7

3.3V

ADA_D8

PIN_AE9

Data Output Bit 8

3.3V

ADA_D9

PIN_AE7

Data Output Bit 9

3.3V

ADA_D10

PIN_AE8

Data Output Bit 10

3.3V

ADA_D11

PIN_AE4

Data Output Bit 11

3.3V

ADA_D12

PIN_AE23

Data Output Bit 12

3.3V

ADA_D13

PIN_AE24

Data Output Bit 13

3.3V

ADA_DCO

PIN_V12

Data Clock Output

3.3V

ADA_OE

PIN_Y17

Output Enable (Active Low)

3.3V

ADA_OR

PIN_AG14

Out-of-Range Indicator

3.3V

ADA_SPI_CS

PIN_AA19

Serial Port Interface Chip Select

(Active Low)

3.3V

ADA_PWDN

PIN_Y18

Power-Down (Not Connection )

3.3V

ADB_CLK_P

PIN_E8

Clock Input (+)

3.3V

ADB_CLK_N

PIN_D8

Clock Input (-)

3.3V

ADB_D0

PIN_AH2

Data Output Bit 0

3.3V

ADB_D1

PIN_AH5

Data Output Bit 1

3.3V

ADB_D2

PIN_AF5

Data Output Bit 2

3.3V

ADB_D3

PIN_AG6

Data Output Bit 3

3.3V

ADB_D4

PIN_AF6

Data Output Bit 4

3.3V

ADB_D5

PIN_AH6

Data Output Bit 5

3.3V

ADB_D6

PIN_AF8

Data Output Bit 6

3.3V

ADB_D7

PIN_AF9

Data Output Bit 7

3.3V

ADB_D8

PIN_AF10

Data Output Bit 8

3.3V

ADB_D9

PIN_AF11

Data Output Bit 9

3.3V

ADB_D10

PIN_AD10

Data Output Bit 10

3.3V

ADB_D11

PIN_AE11

Data Output Bit 11

3.3V

ADB_D12

PIN_AD11

Data Output Bit 12

3.3V

ADB_D13

PIN_AE12

Data Output Bit 13

3.3V

ADB_DCO

PIN_D12

Data Clock Output

3.3V

ADB_OE

PIN_T12

Output Enable (Active Low)

3.3V

ADB_OR

PIN_AD12

Out-of-Range Indicator

3.3V

ADB_SPI_CS

PIN_AD19

Serial Port Interface Chip Select

(Active Low)

3.3V

Table 3-13 Pin Assignment of High-Speed ADC AD9254 devices.

ADC-SoC

User Manual

30

www.terasic.com

December 22, 2016

ADB_PWDN

PIN_T13

Power-Down (Not Connection )

3.3V

AD_SCLK

PIN_T11

Serial Port Interface (SPI) Clock

(Serial Port Mode)

3.3V

AD_SDIO

PIN_U11

Serial Port Interface (SPI) Data

Input/output (Serial Port Mode)

3.3V

Part reference

Jumper Status

Description

Input range

J25

Open

Set VREF = 1.0 V

Differential Span to 2.0 Vpp

2.0 Vpp

Short

Set VREF = 0.5 V

Differential Span to 1.0 Vpp

1.0 Vpp

J26

Open

Set VREF = 1.0 V

Differential Span to 2.0 Vpp

2.0 Vpp

Short

Set VREF = 0.5 V

Differential Span to 1.0 Vpp

1.0 Vpp

J21 (Channel A) and J23 (Channel B) are standard through-hole SMA connectors used to interface

the AD9254 A/D converter input with SMA cables, as shown in Figure 3-23. Users can connect the

input signal through the SMA connector via a 50 ohm coaxial cable.

J25 (Channel A) and J26 (Channel B) are 2-pin jumpers for the selection of input range, as shown in

Figure 3-23. The input range is adjustable by varying the reference voltage applied to the AD9254,

using either the internal reference or an externally applied reference voltage. The input span of the

ADC tracks reference voltage changes linearly.

When the jumper is open, the SENSE pin is connected to ground through a 1K resistor and the

reference amplifier switch is connected to the internal resistor divider. This would set the VREF to

1.0V and Differential Span to 2.0Vpp.

When the jumper is shorted, the SENSE pin is connected to the VREF and this would switch the

reference amplifier input to the SENSE pin. The completed loop will provide a 0.5V reference

output and set the Differential Span to 1.0Vpp.

Table 3-14 lists the details of each combination for the jumper settings.

The datasheet of ADI AD9254 contains more information about the A/D converter chip. It is

available from the manufacturer’s website or in the directory \Datasheet\ADC of ADC-SoC system

CD.

Table 3-14 Jumper settings for the selection of input range

ADC-SoC

User Manual

31

www.terasic.com

December 22, 2016

PPeerriipphheerraallss CCoonnnneecctteedd ttoo HHaarrdd PPrroocceessssoorr SSyysstteemm ((HHPPSS))

33..77..1

1

UUsseerr PPuusshh--bbuuttttoonnss aanndd LLEEDDss

Signal Name

FPGA Pin No.

HPS GPIO

Register/bit

Function

HPS_KEY

PIN_J18

GPIO54

GPIO1[25]

I/O

Figure 3-23 SMA connectors and jumper locations on the board.

3.7

This section introduces the interfaces connected to the HPS section of the Cyclone V SoC FPGA.

Users can access these interfaces via the HPS processor.

Similar to the FPGA, the HPS also has its set of switches, buttons, LEDs, and other interfaces

connected exclusively. Users can control these interfaces to monitor the status of HPS.

Table 3-15 gives the pin assignment of all the LEDs, switches, and push-buttons.

Table 3-15 Pin Assignment of LEDs, Switches and Push-buttons

ADC-SoC

User Manual

32

www.terasic.com

December 22, 2016

HPS_LED

PIN_A20

GPIO53

GPIO1[24]

I/O

33..77..2

2

GGiiggaabbiitt EEtthheerrnneett

Signal Name

FPGA Pin No.

Description

I/O Standard

HPS_ENET_TX_EN

PIN_A12

GMII and MII transmit enable

3.3V

HPS_ENET_TX_DATA[0]

PIN_A16

MII transmit data[0]

3.3V

HPS_ENET_TX_DATA[1]

PIN_J14

MII transmit data[1]

3.3V

HPS_ENET_TX_DATA[2]

PIN_A15

MII transmit data[2]

3.3V

HPS_ENET_TX_DATA[3]

PIN_D17

MII transmit data[3]

3.3V

HPS_ENET_RX_DV

PIN_J13

GMII and MII receive data valid

3.3V

The board supports Gigabit Ethernet transfer by an external Micrel KSZ9031RN PHY chip and

HPS Ethernet MAC function. The KSZ9031RN chip with integrated 10/100/1000 Mbps Gigabit

Ethernet transceiver also supports RGMII MAC interface. Figure 3-24 shows the connections

between the HPS, Gigabit Ethernet PHY, and RJ-45 connector.

The pin assignment associated to Gigabit Ethernet interface is listed in Table 3-16. More

information about the KSZ9031RN PHY chip and its datasheet, as well as the application notes,

which are available on the manufacturer’s website.

Figure 3-24 Connections between the HPS and Gigabit Ethernet

Table 3-16 Pin Assignment of Gigabit Ethernet PHY

ADC-SoC

User Manual

33

www.terasic.com

December 22, 2016

HPS_ENET_RX_DATA[0]

PIN_A14

GMII and MII receive data[0]

3.3V

HPS_ENET_RX_DATA[1]

PIN_A11

GMII and MII receive data[1]

3.3V

HPS_ENET_RX_DATA[2]

PIN_C15

GMII and MII receive data[2]

3.3V

HPS_ENET_RX_DATA[3]

PIN_A9

GMII and MII receive data[3]

3.3V

HPS_ENET_RX_CLK

PIN_J12

GMII and MII receive clock

3.3V

HPS_ENET_RESET_N

PIN_B14

Hardware Reset Signal

3.3V

HPS_ENET_MDIO

PIN_E16

Management Data

3.3V

HPS_ENET_MDC

PIN_A13

Management Data Clock Reference

3.3V

HPS_ENET_INT_N

PIN_B14

Interrupt Open Drain Output

3.3V

HPS_ENET_GTX_CLK

PIN_J15

GMII Transmit Clock

3.3V

LED (State)

LED (Definition)

Link /Activity

LEDG

LEDY

LEDG

LEDY

H H OFF

OFF

Link off

L H ON

OFF

1000 Link / No Activity

Toggle

H

Blinking

OFF

1000 Link / Activity (RX, TX)

H L OFF

ON

100 Link / No Activity

H

Toggle

OFF

Blinking

100 Link / Activity (RX, TX)

L L ON

ON

10 Link/ No Activity

Toggle

Toggle

Blinking

Blinking

10 Link / Activity (RX, TX)

33..77..3

3

UUAARRTT

There are two LEDs, green LED (LEDG) and yellow LED (LEDY), which represent the status of

Ethernet PHY (KSZ9031RN). The LED control signals are connected to the LEDs on the RJ45

connector. The state and definition of LEDG and LEDY are listed in Table 3-17. For instance, the

connection from board to Gigabit Ethernet is established once the LEDG lights on.

Table 3-17 State and Definition of LED Mode Pins

The board has one UART interface connected for communication with the HPS. This interface

doesn’t support HW flow control signals. The physical interface is implemented by UART-USB

onboard bridge from a FT232R chip to the host with an USB Mini-B connector. More information

about the chip is available on the manufacturer’s website, or in the directory

\Datasheets\UART_TO_USB of ADC-SoC system CD. Figure 3-25 shows the connections between

the HPS, FT232R chip, and the USB Mini-B connector. Table 3-18 lists the pin assignment of

UART interface connected to the HPS.

ADC-SoC

User Manual

34

www.terasic.com

December 22, 2016

Signal Name

FPGA Pin No.

Description

I/O Standard

HPS_UART_RX

PIN_A22

HPS UART Receiver

3.3V

HPS_UART_TX

PIN_B21

HPS UART Transmitter

3.3V

HPS_CONV_USB_N

PIN_C6

Reserve

3.3V

33..77..4

4

DDDDRR33 MMeemmoorryy

Signal Name

FPGA Pin No.

Description

I/O Standard

HPS_DDR3_A[0]

PIN_C28

HPS DDR3 Address[0]

SSTL-15 Class I

HPS_DDR3_A[1]

PIN_B28

HPS DDR3 Address[1]

SSTL-15 Class I

HPS_DDR3_A[2]

PIN_E26

HPS DDR3 Address[2]

SSTL-15 Class I

HPS_DDR3_A[3]

PIN_D26

HPS DDR3 Address[3]

SSTL-15 Class I

HPS_DDR3_A[4]

PIN_J21

HPS DDR3 Address[4]

SSTL-15 Class I

HPS_DDR3_A[5]

PIN_J20

HPS DDR3 Address[5]

SSTL-15 Class I

Figure 3-25 Connections between the HPS and FT232R Chip

Table 3-18 Pin Assignment of UART Interface

The DDR3 devices connected to the HPS are the exact same model as the ones connected to the

FPGA. The capacity is 1GB and the data bandwidth is in 32-bit, comprised of two x16 devices with

a single address/command bus. The signals are connected to the dedicated Hard Memory Controller

for HPS I/O banks and the target speed is 400 MHz. Table 3-19 lists the pin assignment of DDR3

and its description with I/O standard.

Table 3-19 Pin Assignment of DDR3 Memory

ADC-SoC

User Manual

35

www.terasic.com

December 22, 2016

HPS_DDR3_A[6]

PIN_C26

HPS DDR3 Address[6]

SSTL-15 Class I

HPS_DDR3_A[7]

PIN_B26

HPS DDR3 Address[7]

SSTL-15 Class I

HPS_DDR3_A[8]

PIN_F26

HPS DDR3 Address[8]

SSTL-15 Class I

HPS_DDR3_A[9]

PIN_F25

HPS DDR3 Address[9]

SSTL-15 Class I

HPS_DDR3_A[10]

PIN_A24

HPS DDR3 Address[10]

SSTL-15 Class I

HPS_DDR3_A[11]

PIN_B24

HPS DDR3 Address[11]

SSTL-15 Class I

HPS_DDR3_A[12]

PIN_D24

HPS DDR3 Address[12]

SSTL-15 Class I

HPS_DDR3_A[13]

PIN_C24

HPS DDR3 Address[13]

SSTL-15 Class I

HPS_DDR3_A[14]

PIN_G23

HPS DDR3 Address[14]

SSTL-15 Class I

HPS_DDR3_BA[0]

PIN_A27

HPS DDR3 Bank Address[0]

SSTL-15 Class I

HPS_DDR3_BA[1]

PIN_H25

HPS DDR3 Bank Address[1]

SSTL-15 Class I

HPS_DDR3_BA[2]

PIN_G25

HPS DDR3 Bank Address[2]

SSTL-15 Class I

HPS_DDR3_CAS_n

PIN_A26

DDR3 Column Address Strobe

SSTL-15 Class I

HPS_DDR3_CKE

PIN_L28

HPS DDR3 Clock Enable

SSTL-15 Class I

HPS_DDR3_CK_n

PIN_N20

HPS DDR3 Clock

Differential 1.5-V SSTL Class I

HPS_DDR3_CK_p

PIN_N21

HPS DDR3 Clock p

Differential 1.5-V SSTL Class I

HPS_DDR3_CS_n

PIN_L21

HPS DDR3 Chip Select

SSTL-15 Class I

HPS_DDR3_DM[0]

PIN_G28

HPS DDR3 Data Mask[0]

SSTL-15 Class I

HPS_DDR3_DM[1]

PIN_P28

HPS DDR3 Data Mask[1]

SSTL-15 Class I

HPS_DDR3_DM[2]

PIN_W28

HPS DDR3 Data Mask[2]

SSTL-15 Class I

HPS_DDR3_DM[3]

PIN_AB28

HPS DDR3 Data Mask[3]

SSTL-15 Class I

HPS_DDR3_DQ[0]

PIN_J25

HPS DDR3 Data[0]

SSTL-15 Class I

HPS_DDR3_DQ[1]

PIN_J24

HPS DDR3 Data[1]

SSTL-15 Class I

HPS_DDR3_DQ[2]

PIN_E28

HPS DDR3 Data[2]

SSTL-15 Class I

HPS_DDR3_DQ[3]

PIN_D27

HPS DDR3 Data[3]

SSTL-15 Class I

HPS_DDR3_DQ[4]

PIN_J26

HPS DDR3 Data[4]

SSTL-15 Class I

HPS_DDR3_DQ[5]

PIN_K26

HPS DDR3 Data[5]

SSTL-15 Class I

HPS_DDR3_DQ[6]

PIN_G27

HPS DDR3 Data[6]

SSTL-15 Class I

HPS_DDR3_DQ[7]

PIN_F28

HPS DDR3 Data[7]

SSTL-15 Class I

HPS_DDR3_DQ[8]

PIN_K25

HPS DDR3 Data[8]

SSTL-15 Class I

HPS_DDR3_DQ[9]

PIN_L25

HPS DDR3 Data[9]

SSTL-15 Class I

HPS_DDR3_DQ[10]

PIN_J27

HPS DDR3 Data[10]

SSTL-15 Class I

HPS_DDR3_DQ[11]

PIN_J28

HPS DDR3 Data[11]

SSTL-15 Class I

HPS_DDR3_DQ[12]

PIN_M27

HPS DDR3 Data[12]

SSTL-15 Class I

HPS_DDR3_DQ[13]

PIN_M26

HPS DDR3 Data[13]

SSTL-15 Class I

HPS_DDR3_DQ[14]

PIN_M28

HPS DDR3 Data[14]

SSTL-15 Class I

HPS_DDR3_DQ[15]

PIN_N28

HPS DDR3 Data[15]

SSTL-15 Class I

HPS_DDR3_DQ[16]

PIN_N24

HPS DDR3 Data[16]

SSTL-15 Class I

HPS_DDR3_DQ[17]

PIN_N25

HPS DDR3 Data[17]

SSTL-15 Class I

HPS_DDR3_DQ[18]

PIN_T28

HPS DDR3 Data[18]

SSTL-15 Class I

HPS_DDR3_DQ[19]

PIN_U28

HPS DDR3 Data[19]

SSTL-15 Class I

HPS_DDR3_DQ[20]

PIN_N26

HPS DDR3 Data[20]

SSTL-15 Class I

HPS_DDR3_DQ[21]

PIN_N27

HPS DDR3 Data[21]

SSTL-15 Class I

HPS_DDR3_DQ[22]

PIN_R27

HPS DDR3 Data[22]

SSTL-15 Class I

HPS_DDR3_DQ[23]

PIN_V27

HPS DDR3 Data[23]

SSTL-15 Class I

ADC-SoC

User Manual

36

www.terasic.com

December 22, 2016

HPS_DDR3_DQ[24]

PIN_R26

HPS DDR3 Data[24]

SSTL-15 Class I

HPS_DDR3_DQ[25]

PIN_R25

HPS DDR3 Data[25]

SSTL-15 Class I

HPS_DDR3_DQ[26]

PIN_AA28

HPS DDR3 Data[26]

SSTL-15 Class I

HPS_DDR3_DQ[27]

PIN_W26

HPS DDR3 Data[27]

SSTL-15 Class I

HPS_DDR3_DQ[28]

PIN_R24

HPS DDR3 Data[28]

SSTL-15 Class I

HPS_DDR3_DQ[29]

PIN_T24

HPS DDR3 Data[29]

SSTL-15 Class I

HPS_DDR3_DQ[30]

PIN_Y27

HPS DDR3 Data[30]

SSTL-15 Class I

HPS_DDR3_DQ[31]

PIN_AA27

HPS DDR3 Data[31]

SSTL-15 Class I

HPS_DDR3_DQS_n[0]

PIN_R16

HPS DDR3 Data Strobe n[0]

Differential 1.5-V SSTL Class I

HPS_DDR3_DQS_n[1]

PIN_R18

HPS DDR3 Data Strobe n[1]

Differential 1.5-V SSTL Class I

HPS_DDR3_DQS_n[2]

PIN_T18

HPS DDR3 Data Strobe n[2]

Differential 1.5-V SSTL Class I

HPS_DDR3_DQS_n[3]

PIN_T20

HPS DDR3 Data Strobe n[3]

Differential 1.5-V SSTL Class I

HPS_DDR3_DQS_p[0]

PIN_R17

HPS DDR3 Data Strobe p[0]

Differential 1.5-V SSTL Class I

HPS_DDR3_DQS_p[1]

PIN_R19

HPS DDR3 Data Strobe p[1]

Differential 1.5-V SSTL Class I

HPS_DDR3_DQS_p[2]

PIN_T19

HPS DDR3 Data Strobe p[2]

Differential 1.5-V SSTL Class I

HPS_DDR3_DQS_p[3]

PIN_U19

HPS DDR3 Data Strobe p[3]

Differential 1.5-V SSTL Class I

HPS_DDR3_ODT

PIN_D28

HPS DDR3 On-die Termination

SSTL-15 Class I

HPS_DDR3_RAS_n

PIN_A25

DDR3 Row Address Strobe

SSTL-15 Class I

HPS_DDR3_RESET_n

PIN_V28

HPS DDR3 Reset

SSTL-15 Class I

HPS_DDR3_WE_n

PIN_E25

HPS DDR3 Write Enable

SSTL-15 Class I

HPS_DDR3_RZQ

PIN_D25

External reference ball for

output drive calibration

1.5 V

33..77..5

5

MMiiccrroo SSDD CCaarrdd SSoocckkeett

The board supports Micro SD card interface with x4 data lines. It serves not only an external

storage for the HPS, but also an alternative boot option for ADC-SoC board. Figure 3-26 shows

signals connected between the HPS and Micro SD card socket.

Table 3-20 lists the pin assignment of Micro SD card socket to the HPS.

ADC-SoC

User Manual

37

www.terasic.com

December 22, 2016

Signal Name

FPGA Pin No.

Description

I/O Standard

HPS_SD_CLK

PIN_B8

HPS SD Clock

3.3V

HPS_SD_CMD

PIN_D14

HPS SD Command Line

3.3V

HPS_SD_DATA[0]

PIN_C13

HPS SD Data[0]

3.3V

HPS_SD_DATA[1]

PIN_B6

HPS SD Data[1]

3.3V

HPS_SD_DATA[2]

PIN_B11

HPS SD Data[2]

3.3V

HPS_SD_DATA[3]

PIN_B9

HPS SD Data[3]

3.3V

33..77..6

6

UUSSBB 22..00 OOTTGG PPHHYY

Figure 3-26 Connections between the FPGA and SD card socket

Table 3-20 Pin Assignment of Micro SD Card Socket

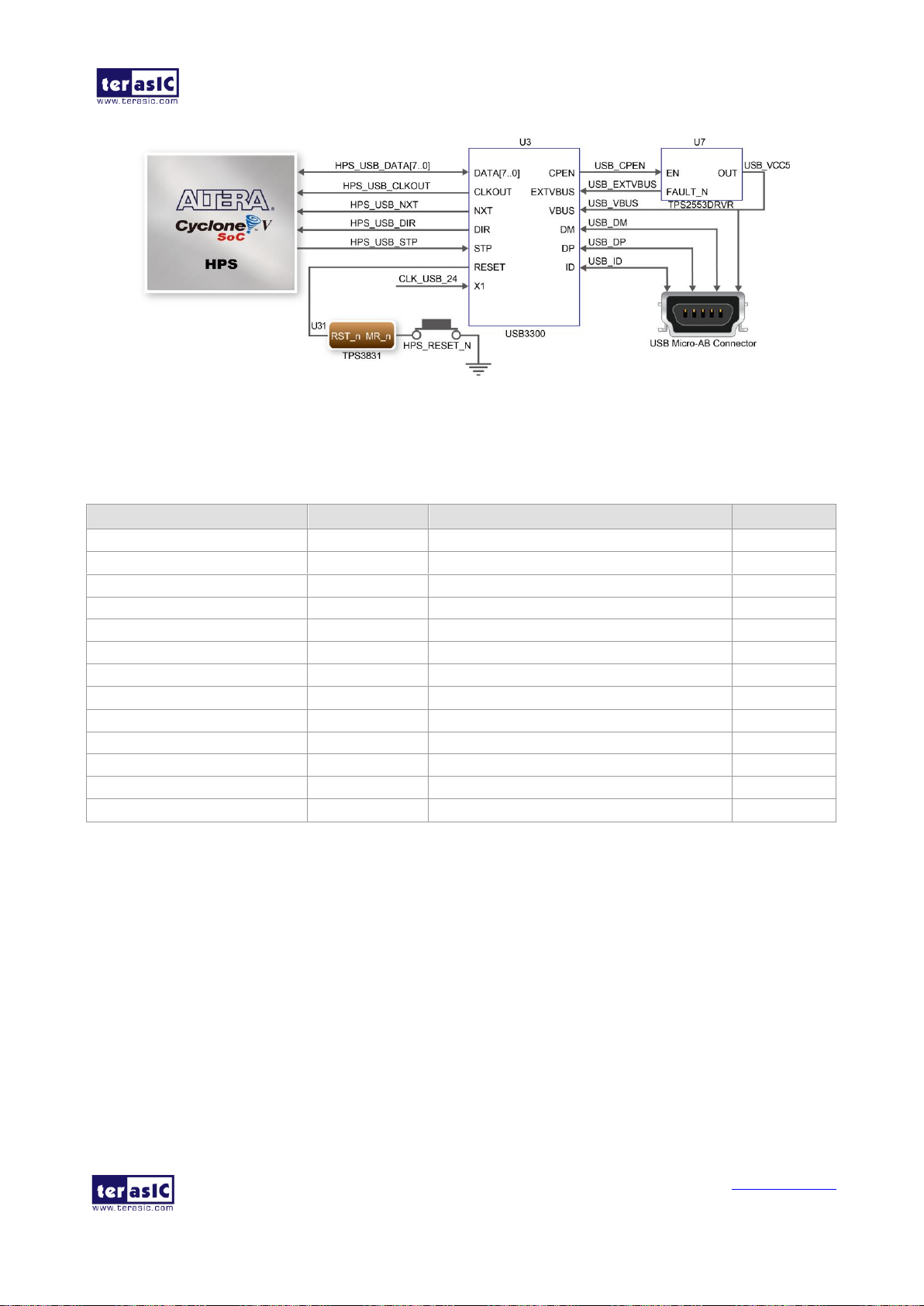

The board provides USB interfaces using the SMSC USB3300 controller. A SMSC USB3300

device in a 32-pin QFN package device is used to interface to a single Type AB Micro-USB

connector. This device supports UTMI+ Low Pin Interface (ULPI) to communicate to USB 2.0

controller in HPS. As defined by OTG mode, the PHY can operate in Host or Device modes. When

operating in Host mode, the interface will supply the power to the device through the Micro-USB

interface. Figure 3-27 shows the connections of USB PTG PHY to the HPS. Table 3-21 lists the pin

assignment of USB OTG PHY to the HPS.

ADC-SoC

User Manual

38

www.terasic.com

December 22, 2016

Signal Name

FPGA Pin No.

Description

I/O Standard

HPS_USB_CLKOUT

PIN_G4

60MHz Reference Clock Output

3.3V

HPS_USB_DATA[0]

PIN_C10

HPS USB_DATA[0]

3.3V

HPS_USB_DATA[1]

PIN_F5

HPS USB_DATA[1]

3.3V

HPS_USB_DATA[2]

PIN_C9

HPS USB_DATA[2]

3.3V

HPS_USB_DATA[3]

PIN_C4

HPS USB_DATA[3]

3.3V

HPS_USB_DATA[4]

PIN_C8

HPS USB_DATA[4]

3.3V

HPS_USB_DATA[5]

PIN_D4

HPS USB_DATA[5]

3.3V

HPS_USB_DATA[6]

PIN_C7

HPS USB_DATA[6]

3.3V

HPS_USB_DATA[7]

PIN_F4

HPS USB_DATA[7]

3.3V

HPS_USB_DIR

PIN_E5

Direction of the Data Bus

3.3V

HPS_USB_NXT

PIN_D5

Throttle the Data

3.3V

HPS_USB_RESET

PIN_H12

HPS USB PHY Reset

3.3V

HPS_USB_STP

PIN_C5

Stop Data Stream on the Bus

3.3V

33..77..7

7

GG--sseennssoorr

Figure 3-27 Connections between the HPS and USB OTG PHY

Table 3-21 Pin Assignment of USB OTG PHY

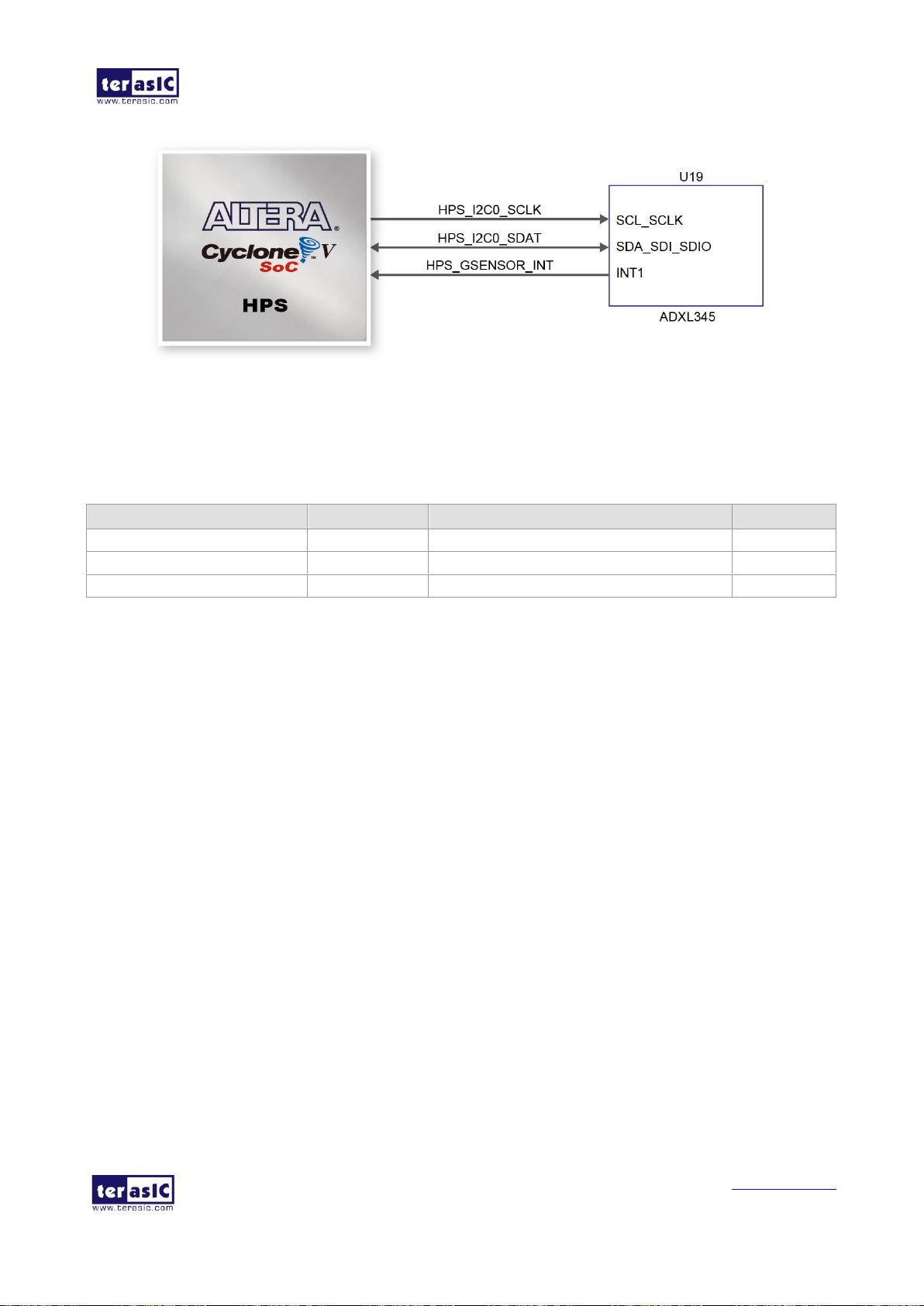

The board comes with a digital accelerometer sensor module (ADXL345), commonly known as

G-sensor. This G-sensor is a small, thin, ultralow power assumption 3-axis accelerometer with

high-resolution measurement. Digitalized output is formatted as 16-bit in two’s complement and

can be accessed through I2C interface. The I2C address of G-sensor is 0xA6/0xA7. More

information about this chip can be found in its datasheet, which is available on manufacturer’s

website or in the directory \Datasheet\G-Sensor folder of ADC-SoC system CD. Figure 3-28 shows

the connections between the HPS and G-sensor. Table 3-22 lists the pin assignment of G-senor to

the HPS.

ADC-SoC

User Manual

39

www.terasic.com

December 22, 2016

Signal Name

FPGA Pin No.

Description

I/O Standard

HPS_GSENSOR_INT

PIN_A17

HPS GSENSOR Interrupt Output

3.3V

HPS_I2C0_SCLK

PIN_C18

HPS I2C0 Clock

3.3V

HPS_I2C0_SDAT

PIN_A19

HPS I2C0 Data

3.3V

33..77..8

8

LLTTCC CCoonnnneeccttoorr

Figure 3-28 Connections between HPS and G-Sensor device.

Table 3-22 Pin Assignment of G-senor

The board has a 14-pin header, which is originally used to communicate with various daughter

cards from Linear Technology. It is connected to the SPI Master and I2C ports of HPS. The

communication with these two protocols is bi-directional. The 14-pin header can also be used for

GPIO, SPI, or I2C based communication with the HPS. Connections between the HPS and LTC

connector are shown in Figure 3-29, and the pin assignment of LTC connector is listed in Table

3-23.

ADC-SoC

User Manual

40

www.terasic.com

December 22, 2016

Signal Name

FPGA Pin No.

Description

I/O Standard

HPS_LTC_GPIO

PIN_H13

HPS LTC GPIO

3.3V

HPS_I2C1_SCLK

PIN_B21

HPS I2C1 Clock

3.3V

HPS_I2C1_SDAT

PIN_A21

HPS I2C1 Data

3.3V

HPS_SPIM_CLK

PIN_C19

SPI Clock

3.3V

HPS_SPIM_MISO

PIN_B19

SPI Master Input/Slave Output

3.3V

HPS_SPIM_MOSI

PIN_B16

SPI Master Output /Slave Input

3.3V

HPS_SPIM_SS

PIN_C16

SPI Slave Select

3.3V

33..77..9

9

RReeaall--TTiimmee CClloocckk

Figure 3-29 Connections between the HPS and LTC connector

Table 3-23 Pin Assignment of LTC Connector

This board is populated with a real-time clock (RTC) DS1339C, which is a low-power clock / date

device manufactured by MAXIM. The clock/date provides seconds, minutes, hours, day, date,

month, and year information. The date at the end of the month is automatically adjusted for months

less than 31 days, including correction for leap year. The clock operates in either 24-hour or 12-hour

format with AM/PM indicator.

ADC-SoC

User Manual

41

www.terasic.com

December 22, 2016

Signal Name

FPGA Pin No.

Description

I/O Standard

HPS_I2C0_SCLK

PIN_C18

HPS I2C0 Clock

3.3V

HPS_I2C0_SDAT

PIN_A19

HPS I2C0 Data

3.3V

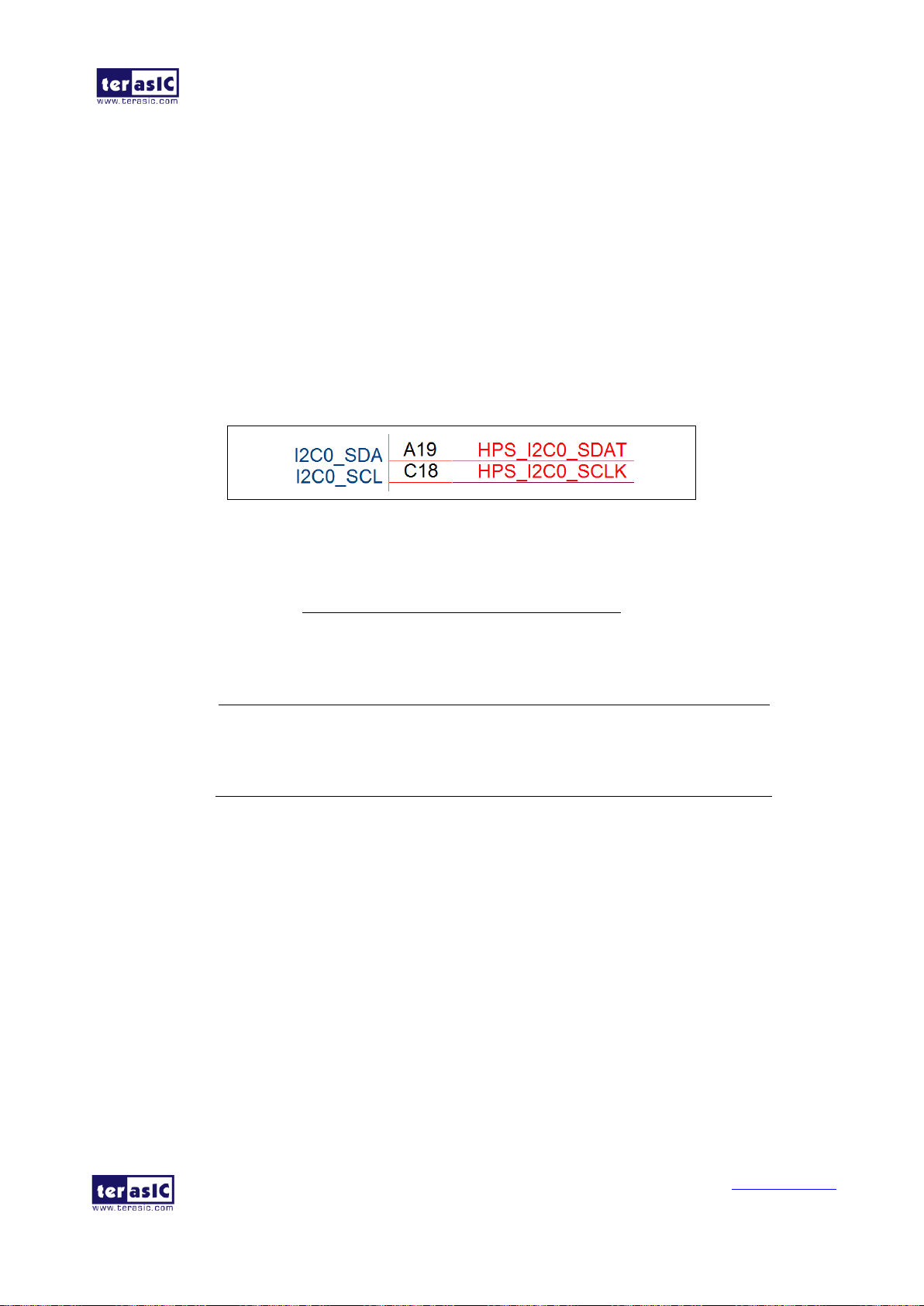

The I2C address of RTC is 0xD0/0xD1 and its I2C bus is shared with the G-sensor (ADXL345).

The datasheet of DS1339C has more information about this chip. It is available on manufacturer’s

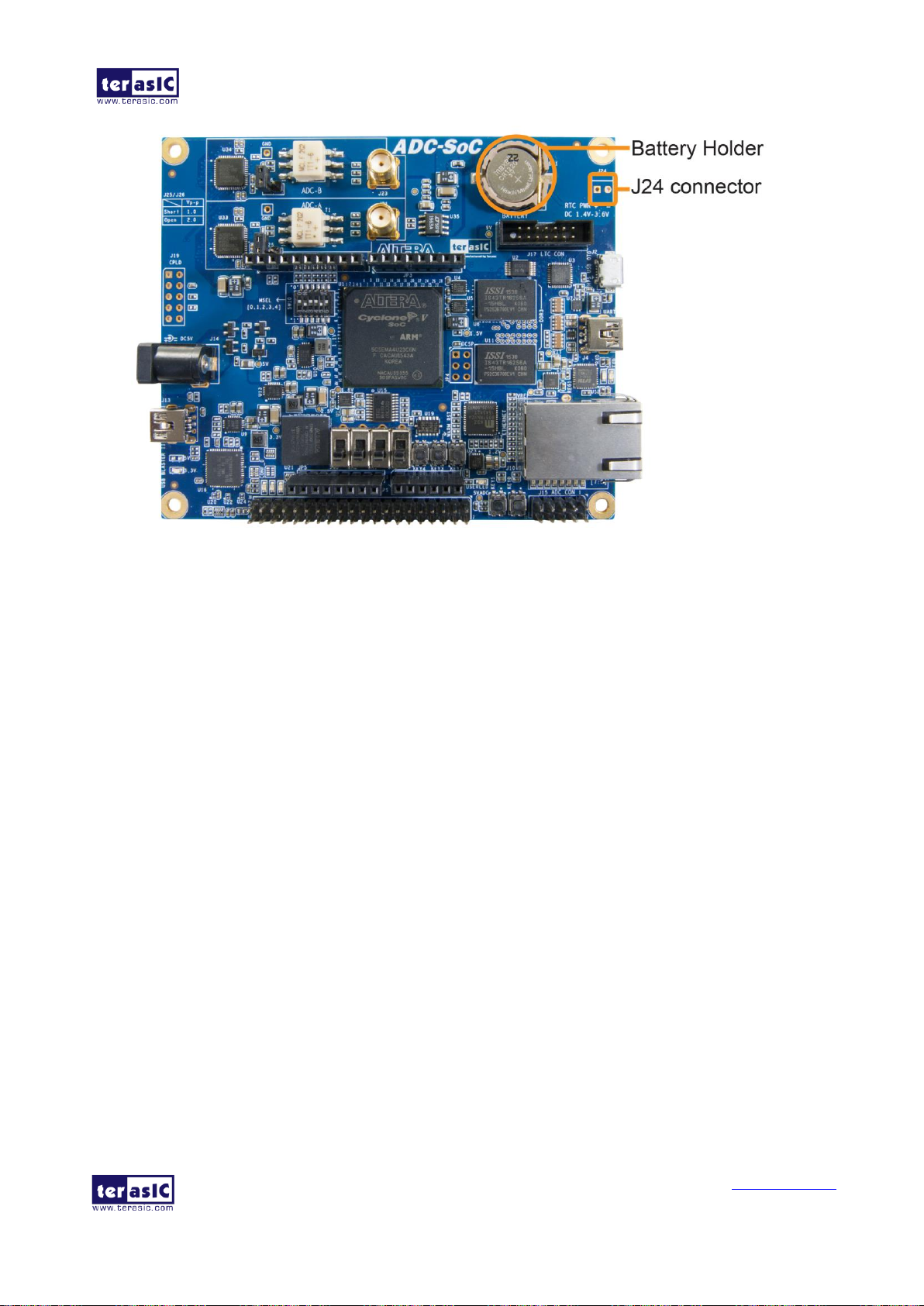

website or in the directory \Datasheet\RTC folder of ADC-SoC system CD. Figure 3-30 shows the

connections between the HPS and G-sensor / RTC. Table 3-24 lists the pin assignment of RTC to

the HPS.

The RTC device allows the system to maintain accurate time after the main power is turned off.

This board also provides a battery holder for the unit to run after the power is turned off. Users need

to install a CR1220 button cell battery in the battery holder. Users can also solder a connector (pitch

2.54) at the J24 position using an external power supply (input voltage range 1.4V to 3.6V) for the

RTC to run. The battery holder and J24 connector are located at the top right of the board, as shown

in Figure 3-31.

Table 3-24 Pin Assignment of RTC

Figure 3-30 Connections between HPS and G-Sensor / RTC device.

ADC-SoC

User Manual

42

www.terasic.com

December 22, 2016

Figure 3-31 battery holder and J24 connector location.

ADC-SoC

User Manual

43

www.terasic.com

December 22, 2016

AADDCC--SSooCC FFaaccttoorryy CCoonnffiigguurraattiioonn

Chapter 4

Examples For FPGA

This chapter provides examples of advanced designs implemented by RTL or Qsys on the

ADC-SoC board. These reference designs cover the features of peripherals connected to the FPGA,

such as A/D Converter. All the associated files can be found in the directory \Demonstrations\FPGA

of ADC-SoC System CD.

Installation of Demonstrations

Install the demonstrations on your computer:

Copy the folder Demonstrations to a local directory of your choice. It is important to make sure the

path to your local directory contains NO space. Otherwise it will lead to error in Nios II.

Note Quartus II v16.1 or later is required for all ADC-SoC demonstrations to support Cyclone V

SoC device.

4.1

The ADC-SoC board has a default configuration bit-stream pre-programmed, which demonstrates

some of the basic features on board. The setup required for this demonstration and the location of its

files are shown below.

Demonstration Setup, File Locations, and Instructions

Project directory: ADC_SOC_Default

Bitstream used: ADC_SOC_Default.sof or ADC_SOC_Default.jic

Power on the ADC-SoC board with the USB cable connected to the USB-Blaster II port. If

necessary (that is, if the default factory configuration is not currently stored in the EPCS

device), download the bit stream to the board via JTAG interface.

You should now be able to observe the LEDs are blinking.

For the ease of execution, a demo_batch folder is provided in the project. It is able to not only

ADC-SoC

User Manual

44

www.terasic.com

December 22, 2016

LLTTCC22330088 AADDCC RReeaaddiinngg

load the bit stream into the FPGA in command line, but also program or erase .jic file to the

EPCS by executing the test.bat file shown in Figure 4-1

If users want to program a new design into the EPCS device, the easiest method is to copy the

new .sof file into the demo_batch folder and execute the test.bat. Option “2” will convert

the .sof to .jic and option”3” will program .jic file into the EPCS device.

Figure 4-1 Command line of the batch file to program the FPGA and EPCS device

4.2

This demonstration illustrates steps to evaluate the performance of the 8-channel 12-bit A/D

Converter LTC2308. The DC 5.0V on the 2x5 header is used to drive the analog signals by a

trimmer potentiometer. The voltage can be adjusted within the range between 0 and 4.096V. The

12-bit voltage measurement is displayed on the NIOS II console. Figure 4-2 shows the block

diagram of this demonstration.

If the input voltage is -2.0V ~ 2.0V, a pre-scale circuit can be used to adjust it to 0 ~ 4V.

ADC-SoC

User Manual

45

www.terasic.com

December 22, 2016

Figure 4-2 Block diagram of ADC reading

Figure 4-3 depicts the pin arrangement of the 2x5 header. This header is the input source of ADC

convertor in this demonstration. Users can connect a trimmer to the specified ADC channel

(ADC_IN0 ~ ADC_IN7) that provides voltage to the ADC convert. The FPGA will read the

associated register in the convertor via serial interface and translates it to voltage value to be

displayed on the Nios II console.

Figure 4-3 Pin distribution of the 2x5 Header for the ADC

ADC-SoC

User Manual

46

www.terasic.com

December 22, 2016

System Requirements

The following items are required for this demonstration.

ADC-SoC board x1

Trimmer Potentiometer x1

Wire Strip x3

Demonstration File Locations

Hardware project directory: ADC_SOC_ADC

Bitstream used: ADCSOC_ADC.sof

Software project directory: ADC_SOC_ADC \software

Demo batch file : ADC_SOC_ADC \demo_batch\ test.bat

Demonstration Setup and Instructions

Connect the trimmer to corresponding ADC channel on the 2x5 header, as shown in Figure 4-4,

as well as the +5V and GND signals. The setup shown above is connected to ADC channel 0.

Execute the demo batch file test.bat to load the bitstream and software execution file to the

FPGA.

The Nios II console will display the voltage of the specified channel voltage result information

Figure 4-4 Hardware setup for the ADC reading demonstration

ADC-SoC

User Manual

47

www.terasic.com

December 22, 2016

HHIIGGHH SSPPEEEEDD AADDCC AADD99225544

4.3

This demo takes the waveform of an external signal generator as the input of ADC-SoC via ADC-A

and/or ADC-B through SMA_A and/or SMA_B connector, respectively. Users can observe the

original incoming waveform and the rectified waveform by the FPGA simultaneously. Figure 4-5

shows the block diagram of this demonstration.

Figure 4-5 Block diagram of HIGH-SPEED-ADC

The function of each block is listed below:

PLL: This block takes the 50MHz clock on ADC-SoC and generates the SYS_CLK (150MHz) for

the two ADC IC and FPGA.

ADC-A/B: These blocks represent the two AD9254 IC on ADC-SoC. Each one is 14-bit high-speed

parallel Analog-to-Digital converter. .

TWO_CH_ADC_SYNC: This block synchronizes the data of AD9254 with SYS_CLK.

ADC_RD_DET: This block has two functions performed by the two submodules. (1) the module

WAVE_RECT takes the absolute value of incoming waveform. (2) the module SIGNAL_DET

serves as the detector of incoming signal, which generates 1 or 0, depending on the absolute value

of incoming signal is greater or less than the threshold, respectively.

USB_Blaster : This block establishes connection to the host PC and it can be used to observe the

waveform of incoming signal in real time and the rectified waveform in SignalTap II in Quartus

software.

ADC-SoC

User Manual

48

www.terasic.com

December 22, 2016

System Requirements

The following items are required for this demonstration.

ADC-SoC Board x1

Signal Generator x1

SMA Cable x1

Demonstration File Locations

Hardware project directory: ADC_SoC_HIGH_SPEED_ADC

Bitstream used: ADC_SoC_HIGH_SPEED_ADC.sof

Demo batch file : ADC_SoC_HIGH_SPEED_ADC\demo_batch\ test.bat

SignalTapeII file : ADC_SoC_HIGH_SPEED_ADC\demo_batch\ViewWave.stp

Demonstration Setup and Instructions

Connect the output of a signal generator to the SMA connector J21 (ADC-A) or J23 (ADC-B)

of ADC-SoC, as shown in Figure 4-6.

Figure 4-6 Hardware setup for the HIGH-SPEED-ADC

Connect the 5V adapter to the J14 of ADC-SoC. Connect the J13 of ADC-SoC to the host PC

Execute the demo batch file test.bat to load the bitstream file to the FPGA.

Open ViewWave.stp and click RUN to observe the waveform change of incoming signal in real

via mini USB cable.

ADC-SoC

User Manual

49

www.terasic.com

December 22, 2016

time, as shown in Figure 4-7. The LED0 and LED1 correspond to ADC-A and ADC-B,

respectively. They will lit when the incoming signal exceeds the threshold.

Signal comes in from Channel A

Signal comes in from Channel B

Figure 4-7 SignalTape II viewer for the HIGH-SPEED-ADC

(1) SADA_D and SADB_D correspond to the 14-bit incoming parallel data from the two

AD9254 IC.

(2) PD_A and PD_B represent the absolute values of the two ADC.

(3) HAVE_A and HAVE_B are either 1 or 0, depending on the absolute value of ADC is greater

or less than the threshold, respectively.

ADC-SoC

User Manual

50

www.terasic.com

December 22, 2016

UUsseerrss LLEEDD aanndd KKEEYY

Chapter 5

Examples for

HPS SoC

This chapter provides several C-code examples based on the Terasic Linux BPS. These examples

demonstrate major features of peripherals connected to HPS interface on ADC-SoC board such as

users LED/KEY, I2C interfaced G-sensor. All the associated files can be found in the directory

Demonstrations/SOC of the ADC-SoC System CD.

Installation of the Demonstrations

To install the demonstrations on the host computer:

Copy the directory Demonstrations into a local directory of your choice. SoC EDS v16.1 is

required for users to compile the c-code project.

5.1

This demonstration shows how to control the users LED and KEY by accessing the register of

GPIO controller through the memory-mapped device driver. The memory-mapped device driver

allows developer to access the system physical memory.

Function Block Diagram

Figure 5-1 shows the function block diagram of this demonstration. The users LED and KEY are

connected to the GPIO1 controller in HPS. The behavior of GPIO controller is controlled by the

register in GPIO controller. The registers can be accessed by application software through the

memory-mapped device driver, which is built into SoC Linux.

ADC-SoC

User Manual

51

www.terasic.com

December 22, 2016

Figure 5-1 Block diagram of GPIO demonstration

Block Diagram of GPIO Interface

The HPS provides three general-purpose I/O (GPIO) interface modules. Figure 5-2 shows the block

diagram of GPIO Interface. GPIO[28..0] is controlled by the GPIO0 controller and GPIO[57..29] is

controlled by the GPIO1 controller. GPIO[70..58] and input-only GPI[13..0] are controlled by the

GPIO2 controller.

GPIO Register Block

The behavior of I/O pin is controlled by the registers in the register block. There are three 32-bit

Figure 5-2 Block diagram of GPIO Interface

ADC-SoC

User Manual

52

www.terasic.com

December 22, 2016

registers in the GPIO controller used in this demonstration. The registers are:

gpio_swporta_dr: write output data to output I/O pin

gpio_swporta_ddr: configure the direction of I/O pin

gpio_ext_porta: read input data of I/O input pin

The gpio_swporta_ddr configures the LED pin as output pin and drives it high or low by writing

data to the gpio_swporta_dr register. The first bit (least significant bit) of gpio_swporta_dr

controls the direction of first IO pin in the associated GPIO controller and the second bit controls

the direction of second IO pin in the associated GPIO controller and so on. The value "1" in the

register bit indicates the I/O direction is output, while the value "0" in the register bit indicates the

I/O direction is input.

The first bit of gpio_swporta_dr register controls the output value of first I/O pin in the associated

GPIO controller, the second bit controls the output value of second I/O pin in the associated GPIO

controller and so on. The value "1" in the register bit indicates the output value is high, and the

value "0" indicates the output value is low.

The status of KEY can be queried by reading the value of gpio_ext_porta register. The first bit

represents the input status of first IO pin in the associated GPIO controller, and the second bit

represents the input status of second IO pin in the associated GPIO controller and so on. The value

"1" in the register bit indicates the input state is high, and the value "0" indicates the input state is

low.

GPIO Register Address Mapping

The registers of HPS peripherals are mapped to HPS base address space 0xFC000000 with 64KB

size. The registers of the GPIO1 controller are mapped to the base address 0xFF708000 with 4KB

size, and the registers of the GPIO2 controller are mapped to the base address 0xFF70A000 with

4KB size, as shown in Figure 5-3.

ADC-SoC

User Manual

53

www.terasic.com

December 22, 2016

#include <stdio.h>

#include <unistd.h>

#include <fcntl.h>

#include <sys/mman.h>

Figure 5-3 GPIO address map

Software API

Developers can use the following software API to access the register of GPIO controller.

open: open memory mapped device driver

mmap: map physical memory to user space

alt_read_word: read a value from a specified register

alt_write_word: write a value into a specified register

munmap: clean up memory mapping

close: close device driver.

Developers can also use the following MACRO to access the register

alt_setbits_word: set specified bit value to one for a specified register

alt_clrbits_word: set specified bit value to zero for a specified register

The program must include the following header files to use the above API to access the registers of

GPIO controller.

ADC-SoC

User Manual

54

www.terasic.com

December 22, 2016

#include "hwlib.h"

#include "socal/socal.h"

#include "socal/hps.h"

#include "socal/alt_gpio.h"

LED and KEY Control

Figure 5-4 shows the HPS users LED and KEY pin assignment for the ADC-SoC board. The LED

is connected to HPS_GPIO53 and the KEY is connected to HPS_GPIO54. They are controlled by

the GPIO1 controller, which also controls HPS_GPIO29 ~ HPS_GPIO57.

Figure 5-4 Pin assignment of LED and KEY

Figure 5-5 shows the gpio_swporta_ddr register of the GPIO1 controller. The bit-0 controls the

pin direction of HPS_GPIO29. The bit-24 controls the pin direction of HPS_GPIO53, which

connects to HPS_LED, the bit-25 controls the pin direction of HPS_GPIO54, which connects to

HPS_KEY , and so on. The pin direction of HPS_LED and HPS_KEY are controlled by the bit-24

and bit-25 in the gpio_swporta_ddr register of the GPIO1 controller, respectively. Similarly, the

output status of HPS_LED is controlled by the bit-24 in the gpio_swporta_dr register of the

GPIO1 controller. The status of KEY can be queried by reading the value of the bit-24 in the

gpio_ext_porta register of the GPIO1 controller.

The following mask is defined in the demo code to control LED and KEY direction and LED’s

Figure 5-5 gpio_swporta_ddr register in the GPIO1 controller

ADC-SoC

User Manual

55

www.terasic.com

December 22, 2016

#define USER_IO_DIR (0x01000000)

#define BIT_LED (0x01000000)

#define BUTTON_MASK (0x02000000)

alt_setbits_word( ( virtual_base +

( ( uint32_t )( ALT_GPIO1_SWPORTA_DDR_ADDR ) &

( uint32_t )( HW_REGS_MASK ) ) ), USER_IO_DIR );

alt_setbits_word( ( virtual_base +

( ( uint32_t )( ALT_GPIO1_SWPORTA_DR_ADDR ) &

( uint32_t )( HW_REGS_MASK ) ) ), BIT_LED );

alt_read_word( ( virtual_base +

( ( uint32_t )( ALT_GPIO1_EXT_PORTA_ADDR ) &

( uint32_t )( HW_REGS_MASK ) ) ) );

output value.

The following statement is used to configure the LED associated pins as output pins.

The following statement is used to turn on the LED.

The following statement is used to read the content of gpio_ext_porta register. The bit mask is used

to check the status of the key.

Demonstration Source Code

Build tool: SoC EDS V16.1

Project directory: \Demonstration\SoC\hps_gpio

Binary file: hps_gpio

Build command: make ('make clean' to remove all temporal files)

Execute command: ./hps_gpio

Demonstration Setup

Connect a USB cable to the USB-to-UART connector (J4) on the ADC-SoC board and the host

PC.

Copy the executable file "hps_gpio" into the microSD card under the "/home/root" folder in

Linux.

Insert the booting micro SD card into the ADC-SoC board.

Power on the ADC-SoC board.

ADC-SoC

User Manual

56

www.terasic.com

December 22, 2016

II22CC IInntteerrffaacceedd GG--sseennssoorr

Launch PuTTY and establish connection to the UART port of Putty. Type "root" to login

Linux.