Teradyne Z1880-2, Z1880-1, Z1866, Z1860-NB, Z1888 Site Preparation Manual

...

Z1800-Series

Site Preparation Guide

Teradyne, Inc.

Assembly Test/Walnut Creek

2625 Shadelands Drive

Publication Number 1800M123 Copyright Teradyne, Inc.

●

Walnut Creek, CA 94598-2597

Product Warranty

Trademarks

THE STANDARD TERADYNE WARRANTY CONSTITUTES THE ONLY REPRESENTATION OR

WARRANTY MADE BY TERADYNE WITH RESPECT TO ANY EQUIPMENT, GOODS OR

SERVICES SUPPLIED BY TERADYNE. TERADYNE MAKES NO OTHER WARRANTIES OR

REPRESENTATIONS, EXPRESSED OR IMPLIED, IN FACT OR IN LAW, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT WILL TERADYNE BE LIABLE FOR INCIDENTAL, SPECIAL OR

CONSEQUENTIAL PENALTIES OR DAMAGES, INCLUDING LOST PROFITS, OR PENALTIES

AND/OR DAMAGES FOR DELAY IN DELIVERY OR FAILURE TO GIVE NOTICE OF DELAY,

EVEN IF TERADYNE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Due to an ongoing policy of constantly updating equipment and procedures, the contents of this

document are subject to change without notice.

Teradyne assumes no responsibility for errors or for any damages that result from the

implementation of the procedures described in this publication. Teradyne also reserves the right to

make changes in its products without incurring any obligation to incorporate such changes in units

previously sold or shipped. Teradyne makes no commitment to update nor to keep current the

information contained in this document.

Teradyne assumes no responsibility for the use of any circuitry other than the circuitry embodied as

a Teradyne product. No other circuit patent licenses are implied.

This software system consists of computer software and documentation. It contains trade secrets

and confidential information which are proprietary to Teradyne, Inc. Its use or disclosure in whole or

in part without the express written permission of Teradyne, Inc. is prohibited.

This software system is also an unpublished work protected under the copyright laws of the United

States of America. If this work becomes published, the following notice shall apply:

Copyright © 1998 Teradyne, Inc. All Rights Reserved.

The following are trademarks or registered trademarks of Teradyne and may be used to describe

only Teradyne, Inc., Assembly Test/Walnut Creek products:

APC

AutoLoad

AutoLocate

BoardWatch

Boundary Scan Intelligent

Diagnostics (BSID)

CapScan

Component Designer (CDES)

DeltaScan

FrameScan

FrameScan Plus

HostLink

Inline Device Programmer

(ILDP)

InterScan

MultiScan II

PentaVision

PRISM

ProcessWatch

Programmer Efficiency

Package (PEP)

Quick-Check

Safecracker

Spectrum 8800-Series

T est Toolbox

Tester-Aided Instruction

TestQA

VICTORY

VP/VXI

WaveScan

Z1800-Series

Borland and Paradox are trademarks of Borland International, Inc.

C++ and UNIX are registered trademarks of AT&T Bell Laboratory.

Codewright is a trademark of Premia Corporation.

ETHERNET is a trademark of Xerox Corporation.

FABmaster is a registered trademark of FABMASTER S.A.

HP-UX is a registered trademark of Hewlett-Packard Company.

IBM, MicroChannel, and PS/2 are registered trademarks of International Business Machines, Inc.

LabWindows, LabWindows/CVI, NI-488.2, and NI-VXI are trademarks of National Instruments

Corporation.

Microsoft, MS-DOS, QuickC, Windows 95, and WindowsNT are either registered trademarks or

trademarks of Microsoft Corporation in the United States and/or other countries.

Okidata and Microline are registered trademarks of Oki Electric Industry Company, Ltd.

OS-9 and Microware are registered trademarks of Microware Systems Corporation.

SunOS and Solaris are registered trademarks of Sun Microsystems, Inc.

VAX and VMS are registered trademarks of Digital Corporation.

Z1800-S

Manual History

ERIES

S

P

ITE

REPARATION

Fourth Edition, September 1998

Z1888 and Z1803 information added

Third Edition, January 1997

Change to vacuum requirement

Second Edition, May 1996

Changes to tester power requirements in the "Plan the Tester Site" and "Z1800-Series

Site Preparation Checklist" sections

First Edition, April 1996

G

UIDE

Additional copies of this manual may be obtained from Teradyne.

Publications No. 1800M123

© 1996, 1997, 1998 Teradyne Inc., Assembly Test/Walnut Creek

2625 Shadelands Drive . Walnut Creek, CA 94598 . (925) 932.6900

Customer Service Hotline (800) 457-8326

C

ONTENTS

Z1800-Series Site Preparation Guide

Planning the Tester Site......................................................................... 1

General Specifications ..................................................................... 2

Z1890............................................................................................... 3

Z1888............................................................................................... 4

Z1884............................................................................................... 5

Z1880 Plus: Z1880-1 and Z1880-2 .................................................. 6

Z1866............................................................................................... 7

Z1860-NB......................................................................................... 8

Z1860 LCT ....................................................................................... 9

Z1860............................................................................................. 10

Z1850............................................................................................. 11

Z1840............................................................................................. 12

Z1820............................................................................................. 13

Z1805 and Z1808........................................................................... 14

Z1803 Plus: Z1803-1 and Z1803-2 ................................................ 15

Z1800............................................................................................. 16

PRISM-Z Option............................................................................. 17

Uncrating and Positioning the Tester................................................... 18

Z1890, Z1888, Z1880, Z1808, Z1805 and Z1803 Plus with the

PRISM-Z Option............................................................................. 18

Z1890, Z1880, Z1808, and Z1805 ................................................. 20

Z1884............................................................................................. 20

Z1860, Z1860-NB, Z1850, Z1840, Z1820, and Z1800................... 21

Vacuum System Design....................................................................... 23

Environmental Requirements......................................................... 23

Vacuum System Installation Types................................................ 23

Pipe Selection ................................................................................ 27

Valve Selection and Placement ..................................................... 28

Gauge Placement .......................................................................... 28

Vacuum System Installation........................................................... 29

Leak Testing................................................................................... 30

Computer Requirements...................................................................... 30

Board Assignment Recommendations................................................. 31

Z1800-Series Site Preparation Checklist

•

•

•

•

•

•

•

•

•

Z1800-S

Planning the T ester Site

ERIES

Note: Systems Currently in Production

S

P

ITE

REPARATION

The Z1800-Series Site Preparation Guide contains site requirements and system

specifications for the Z1800-Series test systems and vacuum pump options. It also provides

details for the installation of vacuum systems for one or many test systems.

The last page is a checklist for Teradyne customers and field personnel to help determine if

the location is ready for a new tester installation.

In a busy production environment, place the tester near the main flow of boards in the

assembly line. The board repair and fixture storage areas should be located nearby. In lowto-medium production rate areas, provide ample room for carts containing board boxes and

movement of product to and from the tester.

AC power cords for all testers are 15 feet long with an NEMA L5–30P connector. Locate

your tester within 10 feet of a source of 47–63 Hz, single-phase AC power. In locations

outside of the United States, adjust the line conditioner transformer to the local AC line

voltage. The transformer has taps to accommodate incoming voltages between 100 and 240

VAC. Refer to your tester-specific system reference for information on adjusting the line

conditioner taps.

Position your printer and computer close to the tester. The following is a list of Bosch

Frame accessories/options for mounting the printer, the computer, the mouse or track ball,

and other items. Dimensions shown will add to the overall system footprint. All options

will fit within the specified Service Access boundary.

Bosch Frame Tilt Option, PN 046-932-01

Tabletop Extension (9 in. x 48 in., non-tilted), PN 046-937-01

Tabletop Extension (9 in. x 48 in., 15-degree tilt), PN 046-937-02

Tabletop Extension for Optional Bays (9 in. x 38 in.), PN 046-940-00

Tabletop Extension for Mouse or Track Ball (9 in. x 15 in., non-tilted),

PN 046-943-01

Tabletop Extension for Mouse or Track Ball (9 in. x 15 in., tilted),

PN 046-943-01

Printer Shelf (8 in. x 14 in., tilted)

Computer Mounting Frame

Rear Shelf (9 in. x 48 in.)

G

UIDE

Z1888, Z1884, Z1860-NB, and Z1803 Plus.

If your plant has a central vacuum supply, locate your tester within 10 feet of a vacuum

outlet. If your plant does not have a central vacuum supply, Teradyne’s 41 CFM vacuum

pump is available as an option.

2

General Specifications

Testers Item Specified

Teradyne

Provides

AC MAINS Z1860-NB, Z1880, Z1884,

Z1888, Z1890

Z1800, Z1803, Z1805, Z1808,

Z1820, Z1840, Z1850, Z1860,

Z1860 LCT, Z1866

AC MAINS Circuit Breaker Z1860-NB, Z1880, Z1884,

Z1888, Z1890

Z1800, Z1803, Z1805, Z1808,

Z1820, Z1840, Z1850, Z1860,

Z1860 LCT, Z1866

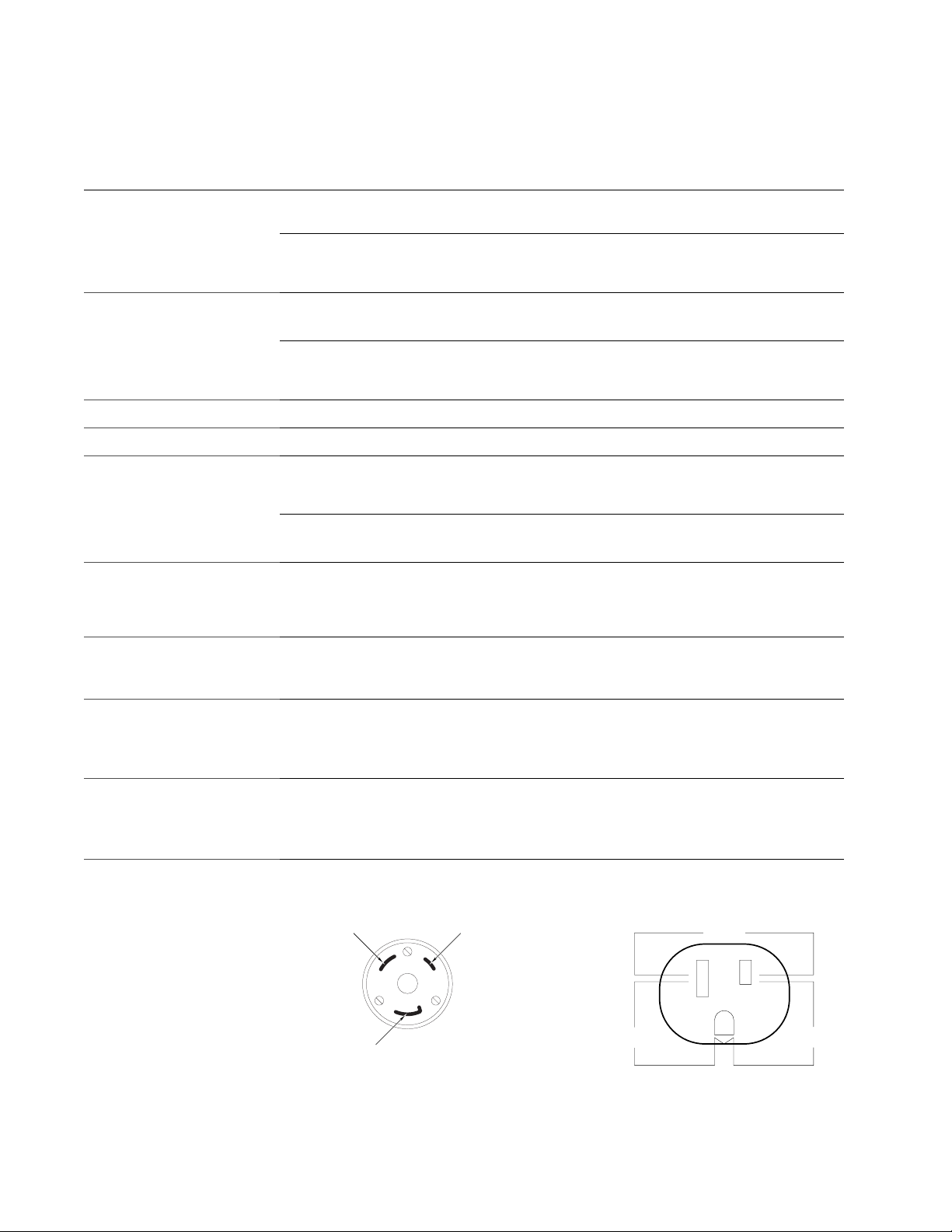

AC MAINS Receptacle All models

AC MAINS Cord Connector All models

Main AC Input Breaker Z1803, Z1805, Z1808,

Z1860-NB, Z1880, Z1884,

Z1888, Z1890

Z1800, Z1820, Z1840, Z1850,

Z1860, Z1866, Z1860 LCT

Vacuum Supply All models

Vacuum Pump Power All models using Teradyne’s

41 CFM vacuum pump

100–240VAC, 3.0kVA, 3-wire, 50–60Hz (range of 47–

63Hz), single-phase

100–240VAC, 1.8kVA, 3-wire, 50–60Hz (range of 47–

63Hz), single-phase

• 100–130VAC requires minimum of 25A breaker

• 200–240VAC requires minimum of 13A breaker

• 100–130VAC requires minimum of 15A breaker

• 200–240VAC requires minimum of 7.5A breaker

NEMA L5-30R

NEMA L5-30P

• 100–130 VAC requires 25A breaker PN 090-156-00

• 200–240 VAC requires 13A breaker PN 090-186-00

• 100–130 VAC requires 15A breaker PN 087-11X-00

• 200–240 VAC requires 7.5A breaker PN 087-12X-00

41 CFM pump capacity recommended.

1 in. NPT male thread within 10 ft. of system.

Minimum vacuum lev el of 20 in. of mercury available to

the system at all times.

Line voltage of 190–460 VAC, 2.2 kVA, 30 Amp , 4-wire,

50 or 60Hz, 3-phase.

X

X

X

X

X

Vacuum Power Connectors All models

Environmental Requirements All models

AC MAINS Wiring Color Codes AC Outlets on Tester

Brown (HOT) Blue (NEUTRAL)

Green (GROUND)

• Low Voltage 190–230 VAC uses 250 VAC, 20 Amp,

4-wire, NEMA L15-20P

• High Voltage 380–460 VAC uses 480 VAC, 20 Amp,

4-wire, NEMA L16-20P

Ambient temperature: 64˚–89˚F (18˚–32˚C)

Relative humidity: 20–70% non-condensing

Vacuum pump operating temperature range: 32˚–

122˚F (0˚–50˚C)

120 Volts

NEUTRAL HOT

Less than

1 Volt

GND

X

120

Volts

3

Z1890

Uncrated Dimensions

Crate Dimensions

Weight Crated (approximate) 1225 lb (556 kg)

Weight (approximate)

AC MAINS

AC MAINS Circuit Breaker

AC MAINS Receptacle

AC MAINS Cord Connector

Main AC Input Breaker

Vacuum Supply

Vacuum Pump Power

Vacuum Power Connectors

Environmental Requirements Ambient temperature: 64˚–89˚F (18˚–32˚C)

Note:

Also see “PRISM-Z Option” on page 17 if applicable.

32.5 in. (83 cm) H x 34.5 in. (88 cm) D x 48 in. (122 cm) L

62 in. (158 cm) H x 45 in. (114 cm) D x 59 in. (150 cm) L

1000 lb (454 kg)

100–240VAC, 3.0kVA, 3-wire, 50–60Hz (range of 47–63Hz), single-phase

• 100–130VAC requires minimum of 25A breaker

• 200–240VAC requires minimum of 13A breaker

NEMA L5-30R

NEMA L5-30P

• 100–130 VAC requires 25A breaker PN 090-156-00

• 200–240 VAC requires 13A breaker PN 090-186-00

41 CFM pump capacity recommended. 1 in. NPT male thread within 10 ft. of system.

Minimum vacuum level of 20 in. of mercury available to the system at all times.

Line voltage of 190–460 VAC, 2.2 kVA, 30 Amp, 4-wire, 50 or 60Hz, 3-phase.

• Low Voltage 190–230 VAC uses 250 VAC, 20 Amp, 4-wire, NEMA L15-20P

• High Voltage 380–460 VAC uses 480 VAC, 20 Amp, 4-wire, NEMA L16-20P

Relative humidity: 20–70% non-condensing

Vacuum pump operating temperature range: 32˚–122˚F (0˚–50˚C)

Teradyne Provides

X

X

X

X

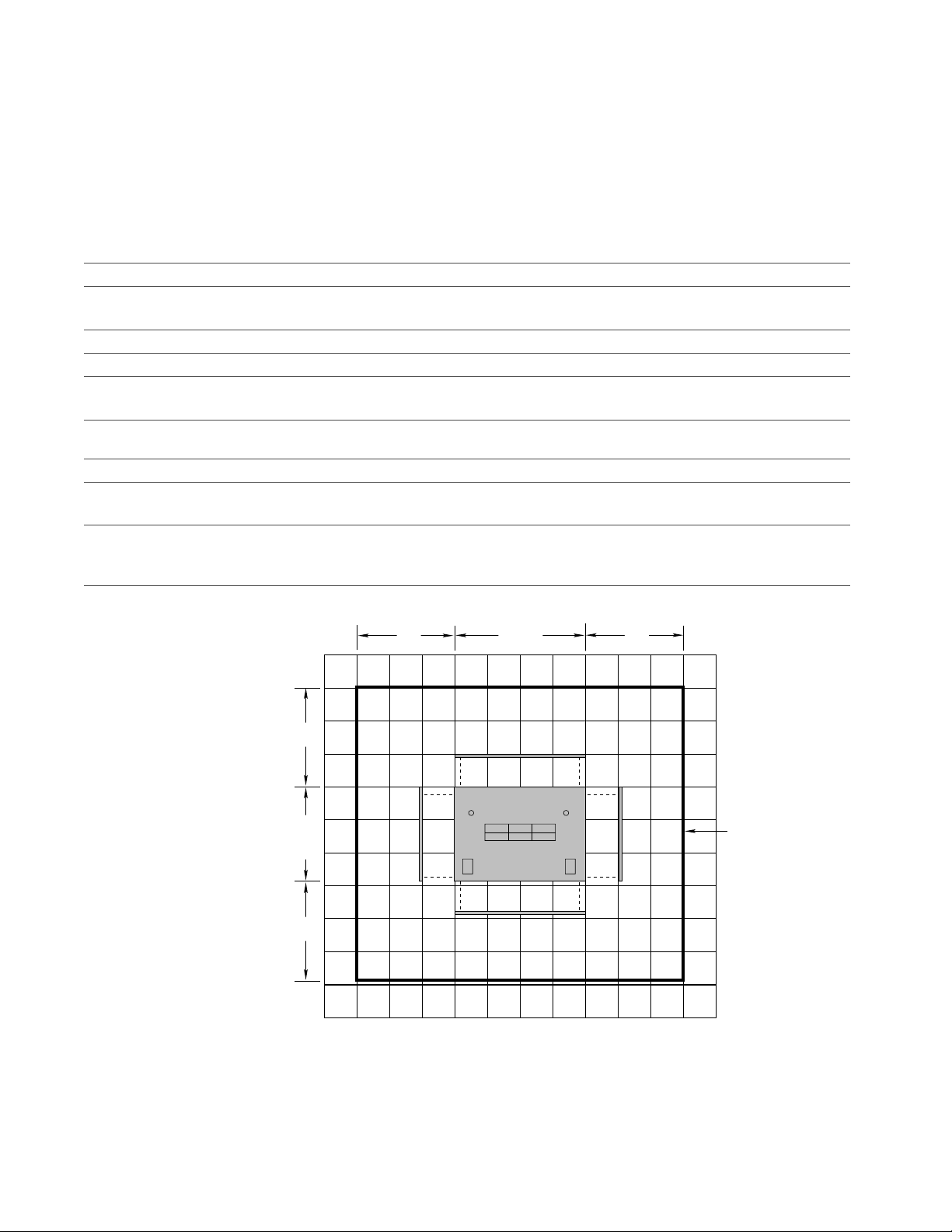

Floor Space Required

36"36"

34.5"

88 cm

36"

48"

122 cm

36"

36” service

36" service

access

boundary

access

Z1800-Series Site Preparation Guide

4

Z1888

Uncrated Dimensions

Crate Dimensions

32.5 in. (83 cm) H x 34.5 in. (88 cm) D x 48 in. (122 cm) L

62 in. (158 cm) H x 45 in. (114 cm) D x 59 in. (150 cm) L

Weight Crated (approximate) 1225 lb (556 kg)

Weight (approximate)

External AC Power

1000 lb (454 kg)

8.5 in. (21cm) H x 22.5 in. (57cm) D x 8.5 in. (21cm) L

Line Conditioner

AC MAINS

AC MAINS Circuit Breaker

100–240VAC, 3.0kVA, 3-wire, 50–60Hz (range of 47–63Hz), single-phase

• 100–130VAC requires minimum of 25A breaker

• 200–240VAC requires minimum of 13A breaker

AC MAINS Receptacle

AC MAINS Cord Connector

Main AC Input Breaker

NEMA L5-30R

NEMA L5-30P

• 100–130 VAC requires 25A breaker PN 090-156-00

• 200–240 VAC requires 13A breaker PN 090-186-00

Vacuum Supply

41 CFM pump capacity recommended. 1 in. NPT male thread within 10 ft. of system.

Minimum vacuum level of 20 in. of mercury available to the system at all times.

Vacuum Pump Power

Vacuum Power Connectors

Line voltage of 190–460 VAC, 2.2 kVA, 30 Amp, 4-wire, 50 or 60Hz, 3-phase.

• Low Voltage 190–230 VAC uses 250 VAC, 20 Amp, 4-wire, NEMA L15-20P

• High Voltage 380–460 VAC uses 480 VAC, 20 Amp, 4-wire, NEMA L16-20P

Environmental Requirements Ambient temperature: 64˚–89˚F (18˚–32˚C)

Relative humidity: 20–70% non-condensing

Vacuum pump operating temperature range: 32˚–122˚F (0˚–50˚C)

Teradyne Provides

X

X

X

X

X

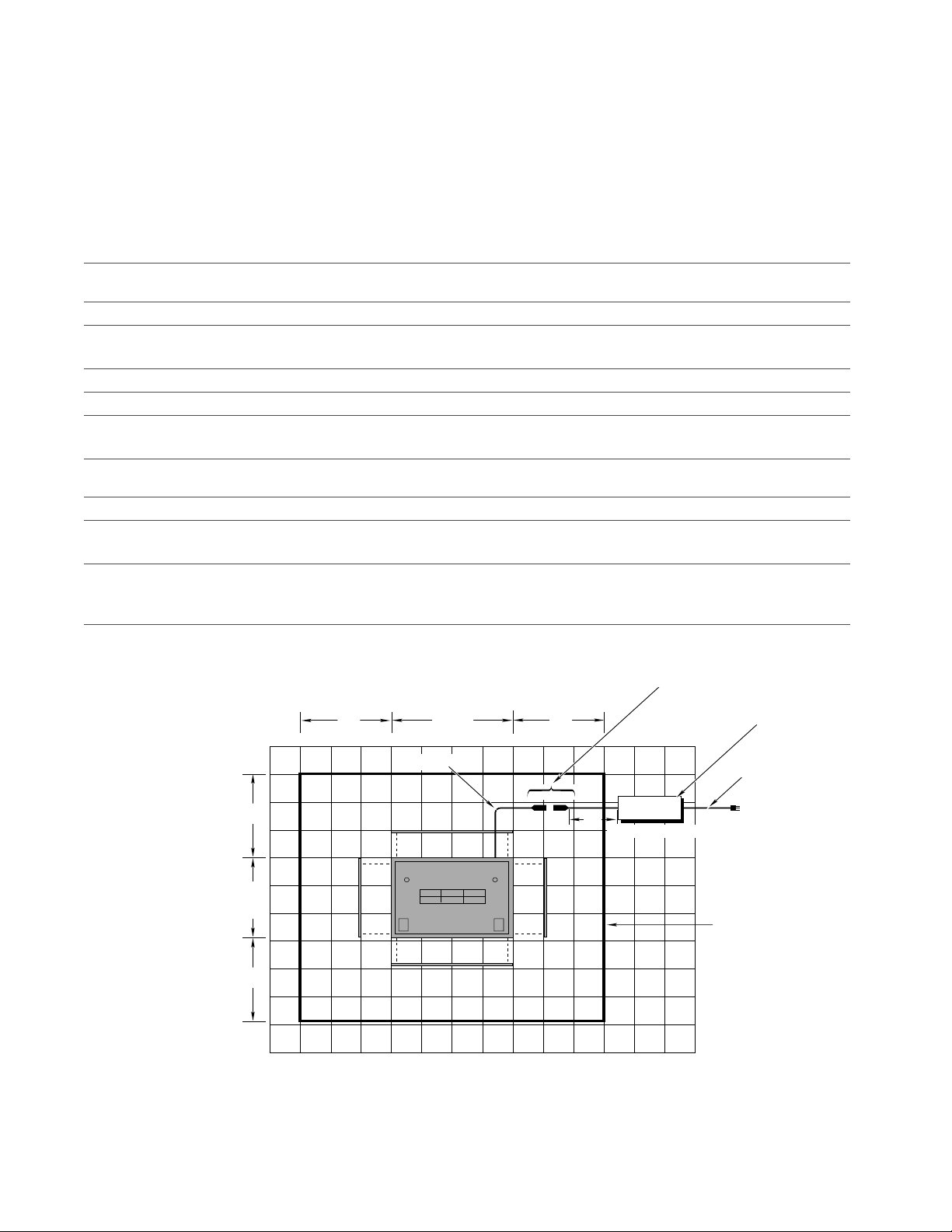

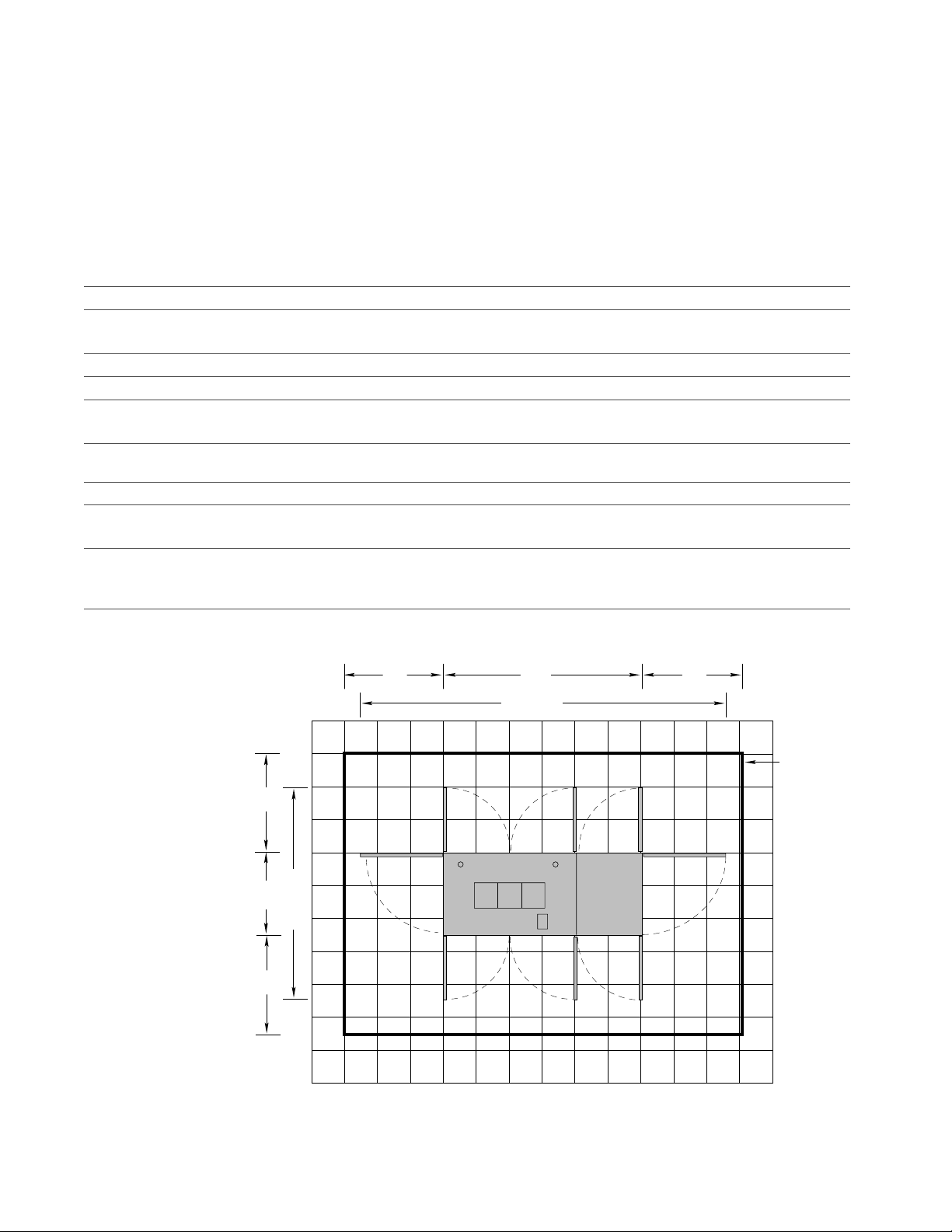

Floor Space Required

Important:

Note: Bosch-Frame systems use connector which is approximately

36"

34.5"

36"

88 cm

36"

3-4 inches in diameter and 10-12 inches in lenth when connected.

This connector is not used on Z1840 and Z1860 PRIZM-Z installations.

48"

122 cm

15' Cord

Connector is approximately 3.5“ in diameter

and 11“ in length when connected.

36"

Conditioner

12''

See EMF Caution

AC Line

8.5"H × 22.5"D × 8.5"L

15' Cord

To AC Mains

36" service

access and

EMF

perimeter

The AC line conditioner must be a minimum of 36“ from the system console. If it is within the 36“ EMF

service perimeter, degradation of analog (PRISM-Z) measurements may occur.

5

Z1884

Important:

The Z1884 requires a forklift to remove it from the crate.

Uncrated Dimensions Test Head Bay: 46.5 in. (118 cm) H x 49.5 in. (125 cm) D x 54.25 in. (138 cm) L

Power Bay: 35 in. (89 cm) H x 39.25 in. (99 cm) D x 24 in. (61 cm) L

Crate Dimensions Test Head Bay: 60 in. (152 cm) H x 64 in. (163 cm) D x 68 in. (173 cm) L

Power Bay: 46 in. (117 cm) H x 31 in. (79 cm) D x 46 in. (117 cm) L

Weight Crated (approximate) 1800 lb (817 kg)

Weight (approximate)

AC MAINS

AC MAINS Circuit Breaker

1400 lb (635 kg)

100–240VAC, 3.0kVA, 3-wire, 50–60Hz (range of 47–63Hz), single-phase

• 100–130VAC requires minimum of 25A breaker

• 200–240VAC requires minimum of 13A breaker

AC MAINS Receptacle

AC MAINS Cord Connector

Main AC Input Breaker

NEMA L5-30R

NEMA L5-30P

• 100–130 VAC requires 25A breaker PN 090-156-00

• 200–240 VAC requires 13A breaker PN 090-186-00

Vacuum Supply

41 CFM pump capacity recommended. 1 in. NPT male thread within 10 ft. of system.

Minimum vacuum level of 20 in. of mercury available to the system at all times.

Vacuum Pump Power

Vacuum Power Connectors

Line voltage of 190–460 VAC, 2.2 kVA, 30 Amp, 4-wire, 50 or 60Hz, 3-phase.

• Low Voltage 190–230 VAC uses 250 VAC, 20 Amp, 4-wire, NEMA L15-20P

• High Voltage 380–460 VAC uses 480 VAC, 20 Amp, 4-wire, NEMA L16-20P

Environmental Requirements Ambient temperature: 64˚–89˚F (18˚–32˚C)

Relative humidity: 20–70% non-condensing

Vacuum pump operating temperature range: 32˚–122˚F (0˚–50˚C)

Teradyne Provides

X

X

X

X

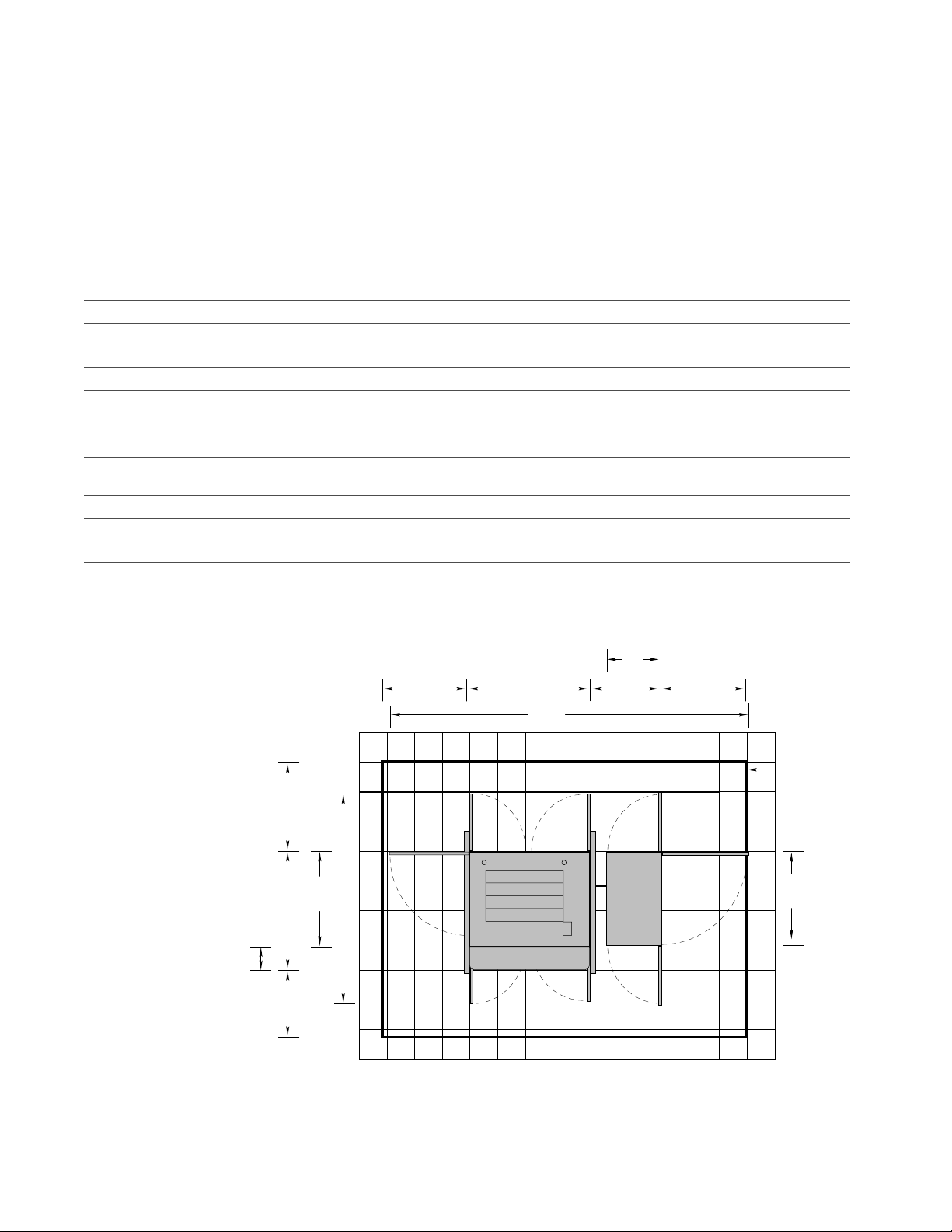

Floor Space Required

36"

49.5"

10.25

36"

(Table top extension)

93"

39.25"

236 cm

24"

40" 40"

54.25"

164.25"

442 cm

30"

36” service

36" service

access

access

boundary

39.25"

Z1800-Series Site Preparation Guide

6

Z1880 Plus: Z1880-1

Also see “PRISM-Z Option” on page 17 if applicable.

and Z1880-2

Uncrated Dimensions 32.5 in. (83 cm) H x 34.5 in. (88 cm) D x 48 in. (122 cm) L

Crate Dimensions 62 in. (158 cm) H x 45 in. (114 cm) D x 59 in. (150 cm) L

Weight Crated (approximate) Z1880-1: 800 lb (364 kg)

Weight (approximate) Z1880-1: 600 lb (273 kg)

AC MAINS 100–240VAC, 3.0kVA, 3-wire, 50–60Hz (range of 47–63Hz), single-phase X

AC MAINS Circuit Breaker • 100–130VAC requires minimum of 25A breaker

AC MAINS Receptacle NEMA L5-30R

AC MAINS Cord Connector NEMA L5-30P X

Main AC Input Breaker • 100–130 VAC requires 25A breaker PN 090-156-00

Vacuum Supply 41 CFM pump capacity recommended. 1 in. NPT male thread within 10 ft. of system.

Vacuum Pump Power Line voltage of 190–460 VAC, 2.2 kVA, 30 Amp, 4-wire, 50 or 60Hz, 3-phase.

Vacuum Power Connectors • Low Voltage 190–230 VAC uses 250 VAC, 20 Amp, 4-wire, NEMA L15-20P

Environmental Requirements Ambient temperature: 64˚–89˚F (18˚–32˚C)

Note:

Z1880-2: 1225 lb (556 kg

Z1880-2: 1000 lb (454 kg)

Teradyne Provides

• 200–240VAC requires minimum of 13A breaker

• 200–240 VAC requires 13A breaker PN 090-186-00

Minimum vacuum level of 20 in. of mercury available to the system at all times.

• High Voltage 380–460 VAC uses 480 VAC, 20 Amp, 4-wire, NEMA L16-20P

Relative humidity: 20–70% non-condensing

Vacuum pump operating temperature range: 32˚–122˚F (0˚–50˚C)

X

X

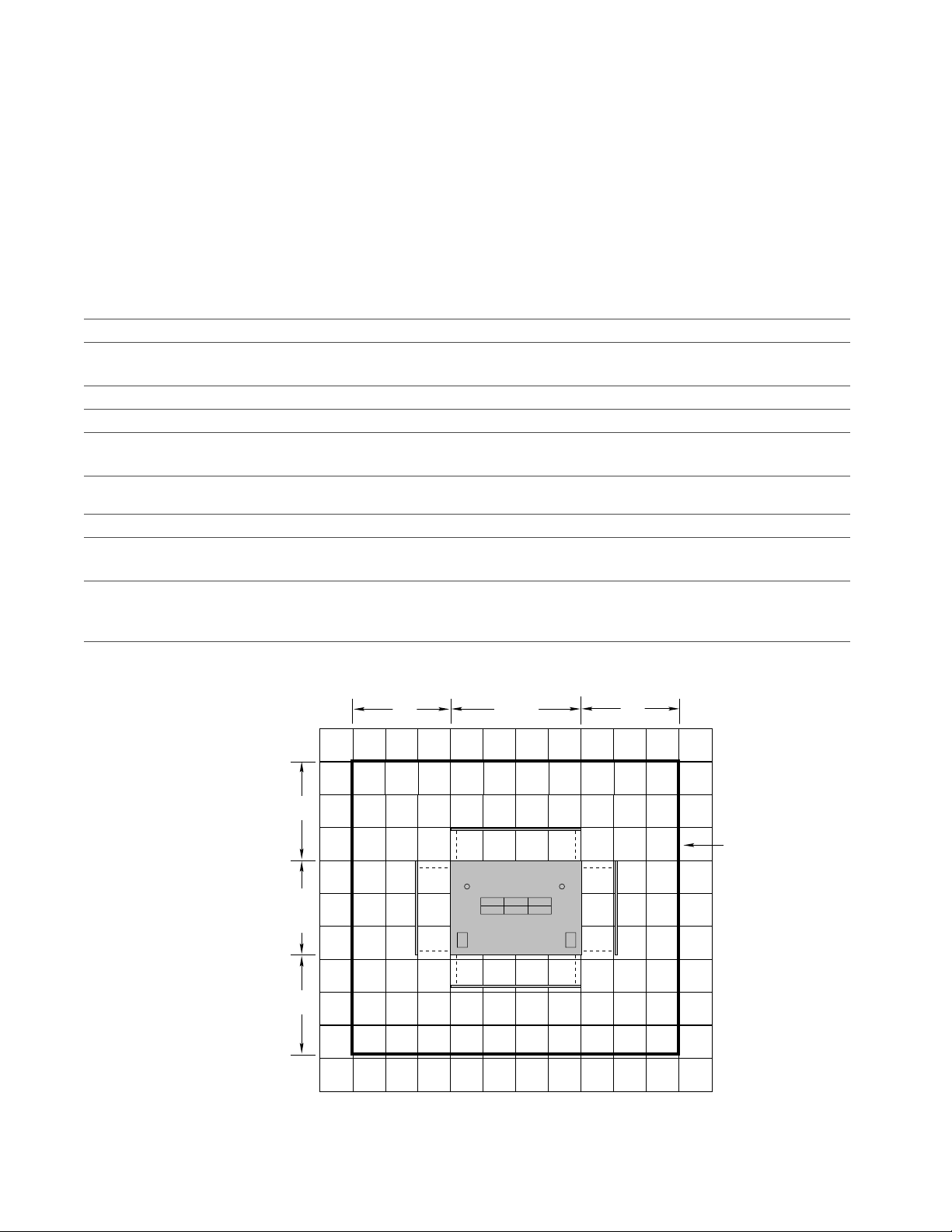

Floor Space Required

36"36"

34.5"

88 cm

36"

48"

122 cm

36"

36” service

36" service

access

access

boundary

Z1866

Uncrated Dimensions 28 in. (71 cm) H x 33.5 in. (85 cm) D x 73 in. (186 cm) L

Crate Dimensions 50 in. (127 cm) H x 43 in. (110 cm) D x 83 in. (211 cm) L

Weight Crated (approximate) 1250 lb (567 kg)

Weight (approximate) 1000 lb (454 kg)

Power Requirements Two AC service supply outlets

Teradyne Provides

AC MAINS 100–240VAC, 1.8kVA, 3-wire, 50–60Hz (range of 47–63Hz), single-phase X

AC MAINS Circuit Breaker • 100–130VAC requires minimum of 15A breaker

• 200–240VAC requires minimum of 7.5A breaker

AC MAINS Receptacle NEMA L5-30R

AC MAINS Cord Connector NEMA L5-30P X

Main AC Input Breaker • 100–130 VAC requires 15A breaker PN 087-11x-00

• 200–240 VAC requires 7.5A breaker PN 087-12x-00

Vacuum Supply 41 CFM pump capacity recommended. 1 in. NPT male thread within 10 ft. of system.

Minimum vacuum level of 20 in. of mercury available to the system at all times.

Vacuum Pump Power Line voltage of 190–460 VAC, 2.2 kVA, 30 Amp, 4-wire, 50 or 60Hz, 3-phase.

Vacuum Power Connectors • Low Voltage 190–230 VAC uses 250 VAC, 20 Amp, 4-wire, NEMA L15-20P

• High Voltage 380–460 VAC uses 480 VAC, 20 Amp, 4-wire, NEMA L16-20P

Environmental Requirements Ambient temperature: 64˚–89˚F (18˚–32˚C)

Relative humidity: 20–70% non-condensing

Vacuum pump operating temperature range: 32˚–122˚F (0˚–50˚C)

7

X

X

Floor Space Required

36"33.5"

36"

79.5"

199.38 cm

36" 73" 36"

130"

331.25 cm

36” service

36" service

access

access

boundary

Z1800-Series Site Preparation Guide

Loading...

Loading...