Page 1

ALL WC-SERIES METERS ARE SHIPPED CALIBRATED, CERTIFIED, AND READY FOR USE.

Arrests are provided at 1-1/2 revolutions to avoid overstraining.

NOTE: This instrument is extremely sensitive to the force of gravity upon it.

This meter has been calibrated using free-hanging weights on a vertical axis.

THUS, READINGS FOR THIS INSTRUMENT WILL FLUCTUATE DEPENDING ON THE ANGLE AT

WHICH THE METER IS HELD.

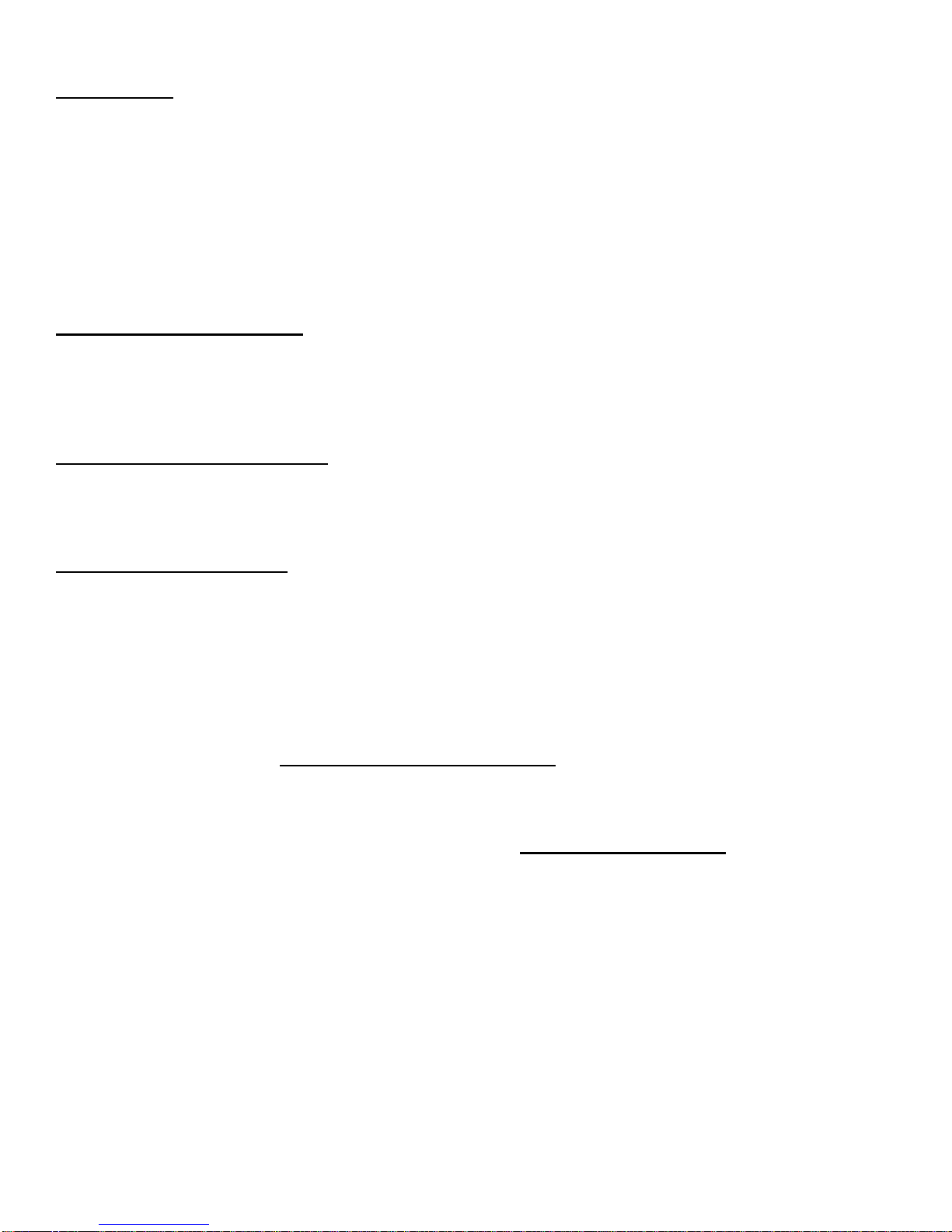

To compensate for vertical or horizontal position: Hold instrument in position to be used. The

material should go over the center sensing roller and under the outside guide rollers.

Loosen bezel lock-screw. Turn dial to zero setting. Retighten lock-screw.

DO NOT PLACE THUMB ON THE INDICATOR SENSING BLOCK.

This instrument has a linear dial. The dial reading is a reference to the load

applied – not exact tension. For instance, calibrating to a specific material,

using a 50 lb weight on a 10" wide strip of material, the dial reading denotes a

tension of 5 pli.

If necessary to determine the exact pli tension, use the Calibration

Procedure described below. Stiffness and thickness will affect the dial

readings; therefore, separate calibrations are necessary for each different

stiffness and thickness, even if the material is the same.

CALIBRATION PROCEDURE:

Suspend a 10" wide strip of your material from overhead. Apply the maximum safe load for the

material (ex: 100 lbs on a 10" wide strip equals 10 pli; 50 lbs equals 5 pli, etc.). Care should be taken

when applying weight to the material.

Hold the tension meter so that one reference roller is above the other. Loosen bezel

lock-screw. Turn dial bezel to zero setting. Retighten lock-screw.

Clip the tension meter onto the loaded material. Slide the meter up and down on the material, while

carefully holding the handle completely down. Note the reading.

OPERATING INSTRUCTIONS FOR SHEET TENSION METER

WC-SERIES

Page 2

OPERATION:

Clip the meter onto your material while holding the handle completely down. The dial reading should

be the same as noted at time of calibration.

To determine existing pli readings, take a dial reading under performance conditions. Suspend a 10"

wide strip of the same material from overhead. Clip on the tension meter. Add known weights until

the dial reading matches performing conditions. Divide the total of the applied weights by the material

width. The resulting figure is the actual pli tension.

CARE AND MAINTENANCE:

Do not apply pressure to indicator sensing block.

Keep clean and free of dust.

DO NOT OIL DIAL INDICATOR.

If handle becomes stiff, apply a slight drop of oil or grease onto the contact point.

If necessary, oil or grease can be applied to contact rollers and hinge pins.

CALIBRATION INTERVAL:

Tensitron recommends calibration by the manufacturer at one-year intervals, or sooner if the meter is

worn, damaged, or reading incorrectly. However, it is the responsibility of the user to establish a

suitable calibration interval, considering such factors as the user’s accuracy requirements,

requirements set by contract or regulation, and environmental factors such as frequency and

conditions of the meter’s use.

If service is required, return to:

Tensitron Tel: (303) 702-1980

733 South Bowen Street Fax: (303) 702-1982

Longmont, CO 80501 E-Mail: service@tensitron.com

Loading...

Loading...