Page 1

733 South Bowen Street

Longmont, CO 80501

USA

Phone: (303) 702-1980

Fax: (303) 702-1982

E-mail: sales@tensitron.com

Web Site: www.tensitron.com

OPERATING INSTRUCTIONS

Model: TX-Series

Digital Tension Meter

Page 2

Page 2 TX Series Operating Instructions

Sec 1. SAFETY AND MAINTENANCE

WARNING: When using cordless, electronic instruments, always follow basic safety precautions to

reduce the risk of fire, electric shock and personal injury.

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE. Before use, ensure all users read and

understand this manual, as well as any labels packaged with or attached to the instrument.

1. KNOW YOUR INSTRUMENT. Read this manual carefully to learn your tension meter’s

applications and limitations, as well as the potential hazards associated with this type of

instrument.

2. AVOID DANGEROUS ENVIRONMENTS. Do not use your instrument in the presence of

explosive atmospheres (gaseous fumes, dust or flammable materials). Do not sub merge your

instrument in liquids.

3. USE THE RIGHT TOOL OR INSTRUMENT. Do not use this instrument to do a job for which it is

not recommended.

4. CHECK FOR DAMAGED PARTS. Inspect instrument before use. Check for any binding of

moving parts, improper mountings, broken parts and any other condition that may affect

operation. Do not use a damaged instrument. Tag damaged instrument “DO NOT USE” until

repaired. For repair, send instruments directly to Tensitron.

5. GUARD AGAINST ELECTRIC SHOCK.

6. MAINTAIN INSTRUMENT CAREFULLY. Protect instrument from water. Keep instrument dry,

clean and free from oil and grease. Do not lubricate. All roller bearings are sealed.

7. DO NOT USE INSTRUMENT IF it has received a sharp blow, been dropped or damaged in any

way. Do not disassemble. Incorrect reassembly may result in the risk of electric shock, fire or

exposure to battery fluids. If instrument is damaged return it to Tensitron for repair.

8. STANDARD POWER SUPPLY IS RATED FOR 120 VOLT AC ONLY and must be plugged into an

appropriate receptacle. For input voltages between 100 – 240V, use power supply P/N:

TX-15-PS-240.

9. DO NOT USE INSTRUMENT WHEN TEMPERATURE is below 40º F (5ºC) or above 105º F

(40ºC). Charging in direct sunlight or near a heat source will not produce a full charge and

may permanently damage battery pack. Unplug charger when not in use.

10. STORE INSTRUMENT AND CHARGER in a cool, dry place. Do not store where temperatures

may exceed 120ºF (50ºC) for storage times less than one month. The storage temperature

should not exceed 35ºC for storage times of more than one year. Never let LCD display or

battery pack assembly freeze.

11. WARNING: Only use battery pack assemblies pro vided by Tensitron with your meter (P/N:

TX-15). Other types of batteries may explode, causing personal injury and damage.

12. YEARLY CALIBRATION is recommended by Tensitron or sooner if the meter is worn,

damaged, or reading incorrectly. However, it is the responsibility of the user to establish a

suitable calibration interval, considering such factors as the user’s accuracy requirements,

requirements set by contract or regulation, and environmental factors such as frequency and

conditions of the meter’s use. Return instrument to Tensitron for calibration and service.

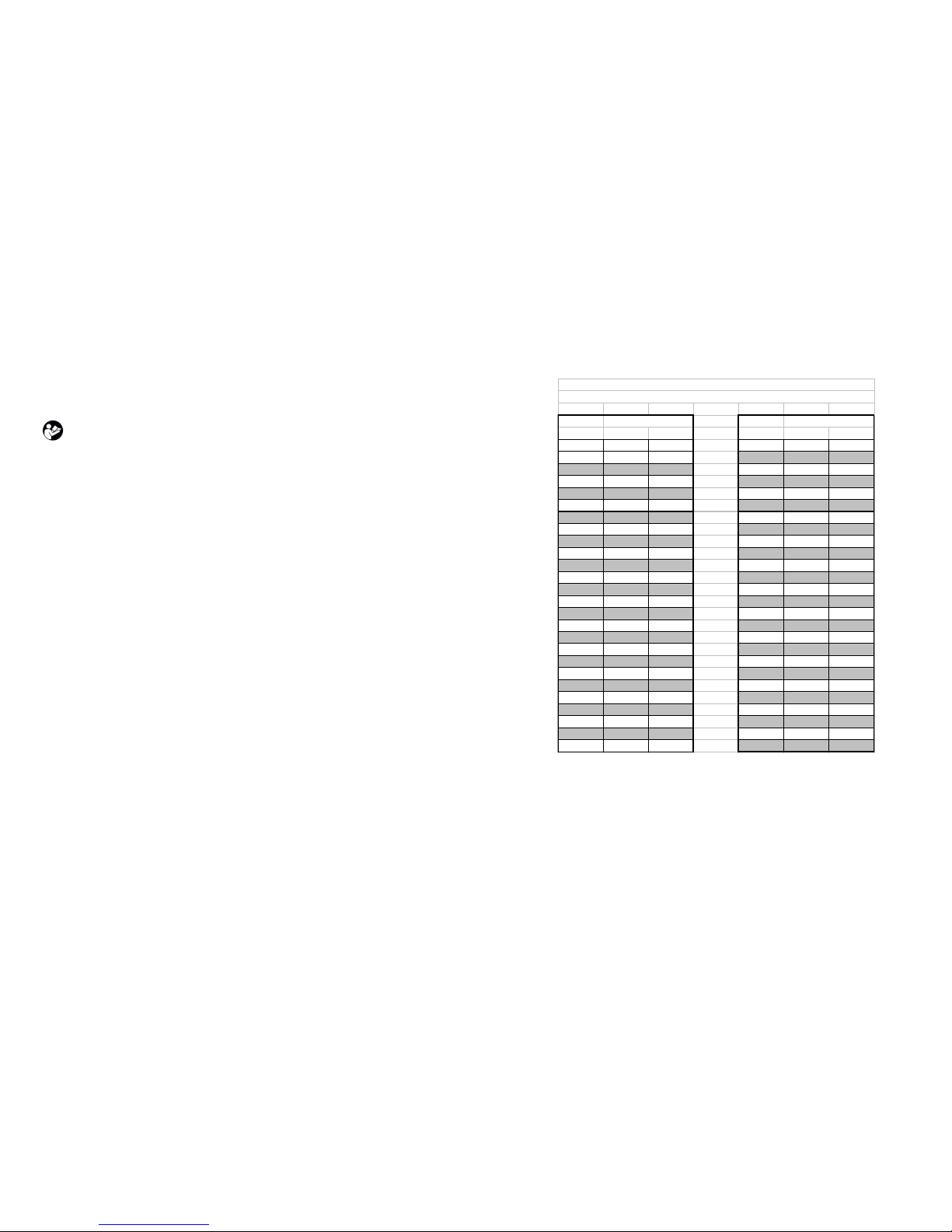

TX Series Operating Instructions Page 11

COPPER WIRE DIAMETERS

CONVERSION TABLE

Diame ters Diame ters

(nominal ) (nominal )

AWG

millim eter s

inches AWG

millim eter s

inches

25.0 0.455 0.01790 37.5 0.107 0.00421

25.5 0.429 0.01688 38.0 0.102 0.00396

26.0 0.404 0.01590 38.5 0.094 0.00370

26.5 0.381 0.01499 39.0 0.089 0.00353

27.0 0.361 0.01420 39.5 0.084 0.00330

27.5 0.340 0.01339 40.0 0.079 0.00314

28.0 0.320 0.01260 40.5 0.076 0.00299

28.5 0.302 0.01188 41.0 0.071 0.00280

29.0 0.287 0.01129 41.5 0.066 0.00259

29.5 0.269 0.01059 42.0 0.064 0.00249

30.0 0.254 0.01000 42.5 0.061 0.00240

30.5 0.241 0.00948 43.0 0.056 0.00222

31.0 0.226 0.00893 43.5 0.053 0.00208

31.5 0.213 0.00838 44.0 0.051 0.00198

32.0 0.203 0.00795 44.5 0.048 0.00188

32.5 0.191 0.00751 45.0 0.0447 0.00176

33.0 0.180 0.00708 46.0 0.0399 0.00157

33.5 0.170 0.00669 47.0 0.0356 0.00140

34.0 0.160 0.00630 48.0 0.0315 0.00124

34.5 0.150 0.00590 49.0 0.0282 0.00111

35.0 0.142 0.00561 50.0 0.0251 0.00099

35.5 0.135 0.00531 51.0 0.0224 0.00088

36.0 0.127 0.00500 52.0 0.0198 0.00077

36.5 0.119 0.00468 53.0 0.0178 0.00070

37.0 0.114 0.00445 54.0 0.0157 0.00061

Page 3

CHECKING ACCURACY. If you want to verify the accuracy of your instrument, simulate

a tension load on your material by suspending known weights to a sample length of the

same type of fine wire or filament. When you engage the meter this weight value should

display. Thus when a 500 gram weight is freely suspended from the material the tension

will be 500 grams, and your instrument should indicate 500 g.

Custom Calibrations for the TX-Series of Digital Tension Meters

Warning: The Custom Calibration feature is password protected. In order to

perform a Custom Calibration a series of key inputs are required. If you enter the

password sequence and the press Enter while an existing calibration in the menu is

selected/highlighted, it will void that current calibration selection.

PERFORMING A 5-POINT LINEARIZATION CALIBRATION

Step 1: From the Main Display press or arrows until you reach Setup. Press ENTER. Press the

arrow button until you reach Cal Tension. Press ENTER. The screen will display: Setup,

Calibrate Tension, Enter Password. You may obtain the password by emailing

service@tensitron.com. Now the screen will display Setup, Calibrate Tension and you will be able

to scroll down the list to select the description that you want to use for the new calibration. When this

new description is highlighted, press ENTER.

Step 2: Next you will be prompted ENTER WEIGHT 1. Using the and arrows select a

minimum tension value (do not use zero). Press ENTER. Select increasing weight values for

WEIGHT 2 THRU 4 (No. 4 being the maximum weight value). At each weight number select your

weight value using the and arrows. ENTER each selection. Next you will calibrate the instrument to

the weight values you just selected. (To simulate tension loads for calibration, take a sample length of your

material and suspend it from above. Next hang weights from your material in the weight values you previously

selected in “enter weights 1 through 4”.) Your instrument will now prompt you PLACE WEIGHT 0. With

zero tension applied to the instrument press ENTER. Next you will be prompted PLACE WEIGHT 1.

Suspend the exact weight value from your material that you previously selected. Engage instrument to

the tensioned material and then press ENTER. Next suspend weight value 2 from your material,

engage the instrument to your tensioned material and press ENTER. Repeat procedure for steps 3 and

4. Once you have entered the value for WEIGHT 4 you have finished the calibration and will be

returned to the Main Display. Your main display will now indicate the description of the calibration

you’ve just entered. This indicates you have now selected the calibration you just performed. To

change calibration use the or arrows until you reach SELECT MATERIAL. Follow procedures

outlined in Section 3.5. To change the description or name of your new calibration, see Section 4, No .

11

Page 10 TX Series Operating Instructions

Sec. 2. CHARGING INSTRUMENT BATTERIES.

1. Use only a Tensitron power supply to avoid damage to instrument. Connect power

supply cable to instrument.

2. Plug the power supply into a 120V AC outlet. (For input voltages between 100 – 240V, use

P/N: TX-15-PS-240.)

3. Fully charge battery prior to first use (approximately 8 hours).

4. Battery pack assembly cannot be overcharged, however instrument will remain on while

plugged into power supply.

5. Fully charged battery assemblies will operate approx. 9 hours +/- 20% depending upon

usage.

6. Battery charge level is indicated in the upper, right hand corner of display.

Sec. 3. OPERATION: QUICK START.

1. TURN UNIT ON by pressing ON button. Main display will indicate: Tension (in grams,

Newtons, cN or lbs), Material (with description of calibration selected), and Min and Max

values.

2. MOVE BETWEEN SCREENS by pressing either the UP or DOWN arrows. To make, or enter a

selection, depress the ENTER key. To exit a setting, depress the ESCAPE key.

3. ZERO THE INSTRUMENT before taking readings by pressing the key marked ZERO. When

zeroing the unit hold the instrument in the attitude in which it will be used, with no load or

speed applied to the instrument.

4. READING OF TENSION. Variations in materials and diameters affect tension readings. It is

essential to select the correct material and size (whether it be AWG wires, Fila ments, or

Custom Materials) from the calibration menu before use , or values may be incorrect. For

Textile use, either approximate your material diameter from the filament selection or

(preferably) use a custom calibration made directly to your material.

5. SELECT MATERIAL. From the Main Display (first screen seen when unit is turned on) use the

UP or DOWN keys until SELECT MATERIAL is displayed. Press ENTER. Next select your

material from: Wire, Filaments or Custom. After you’ve entered this selection you can now

select your material size (diameter) in Inches, mm or AWG (for wires). Remember to ENTER

your selection.

6. SELECTING TENSION UNITS IN LBS, NEWTONS OR GRAMS. Depress the UP or DOWN keys

until TENSION UNITS is displayed. Press ENTER. Next, select from: Grams, Newtons, LBS, or

cN (for the Models TX-125 only) and ENTER selection.

7. ENGAGE INSTRUMENT TO TENSIONED MATERIAL. For best accuracy hold the instrument in

the attitude the measurement will be taken in and depress ZERO. Then engage the tensioned

material by separating the rollers (squeeze the trigger assembly) and inserting onto your

material. Once material is in line with the three rollers slowly release the trigger until it

makes a full stop. Then note your reading.

TX Series Operating Instructions Page 3

Page 4

Sec. 4. ADDITIONAL TECHNICAL INFORMATION.

1. INDICATING SPEED. (Optional feature). From main display press the UP arrow once. Your display

will now show either feet per minute or meters per minute with both high and low values recorded.

2. LENGTH OF PART RUN. (Optional feature). From the main display press the UP arrow twice. Your

display will now indicate length of material run in either feet or meters.

3. CHANGING LENGTH OR SPEED UNITS. (Optional feature). From the main display depress either the

UP or DOWN keys until the display indicates: SETUP. Press Enter. Next use the UP and DOWN keys

until Length Units is displayed. Press ENTER and make your selection fro m Feet or Meters. Enter

Selection.

4. DATA LOGGING. (Optional feature). From the Main display use the UP or DOWN keys until Data

Logging is displayed. Press ENTER. Next, select Logging Rate and select Hz rate which your data

will be collected in (choices are from 1Hz to 100Hz). Next select Duration and select the time

period the data will be collected over by using the UP or DOWN keys. Finally select Begin Logging

when you are ready to collect your data. Note: You can stop collecting data at any time by simply

depressing ESC (escape). Collected data will remain in memory, regardless if instrument is turned

off, and will only be overwritten once new data is collected. To view collected data select View

Data Log and press ENTER. Logged Data can also be uploaded to your computer via the RS -232,

serial port. Refer to Sec 4.16, Uploading logged data, for specific instructions.

5. SPEEDING UP OR SLOWING DOWN DISPLAY LCD REFRESH RATES—DAMPENING ADJUSTMENT.

To help control oscillating tension display values the user can either speed up or slow down the

rate at which tension values refresh on the display. Using the UP or DOWN keys select SETUP and

press ENTER. Next select Dampening and after entering this selection, choose the refres h rate from:

1Hz, 2Hz or 5Hz. Remember to ENTER your selections.

6. AUDIO. Turn on or off Audio beep (with key inputs) by selecting: SETUP, then select Audio, and

finally either select ON or OFF.

7. BACKLIGHTING INTENSITY. Increase or decrease Backlighting intensity by selecting: SETUP, then

BACKLIGHT, and finally intensity level.

8. DISPLAY CONTRAST. Increase or decrease LCD display contrast by selecting: SETUP, then select

CONTRAST, and finally manipulate contrast using the UP or DOWN keys. Remember to ENTER your

new setting.

9. VERSION. Instrument Model No. along with Software version information can be viewed under

SETUP and then selecting Version.

10. CUSTOM CALIBRATIONS. Calibrations are password-protected to prevent unintended changes and

can only be preformed on Custom Calibration selections. All other calibrations under Wire and

Filament selections can only be reset by Tensitron. See Page 10 for step -by-step instructions to

perform this 5 point, dead weight calibration, or contact your Metrology Department or Tensitron

for assistance. Note 1. If you simply want to verify your instrument’s accuracy refer to Checking

Accuracy on Page 10.

11. CUSTOM CALIBRATION NAMES. Custom Calibrations (listed as Custom 0 - 9) can be renamed so

that the Main Display indicates your name for the calibration instead of Custom 1, 2, etc. Fro m the

Main Display use the UP and DOWN keys until SETUP is selected. P ress ENTER. Using the UP and

DOWN keys select Custom Names. Press ENTER. Next, using the UP and DOWN arrows select

calibration number, or previous name you wish to rename. Press ENTER. Using the UP and DOWN

keys select the number, letter or character for the beginning of your new name. Press ENTER.

Page 4 TX Series Operating Instructions

Page 4 TX Series Operating Instructions

MODEL RANGE RESOLUTION

TX-125 0-125 Grams 0.1 to 1 Grams

TX-1000 10-1000 Grams 1 to 5 Grams

TX-5000 50-5000 Grams 5 to 10 Grams

APPLICATION-SPECIFIC METERS

TX-5EDM 50-5000 Grams - For use on EDM wires.

Note: For tapes, webs and custom materials please provide thickness, width, or diameter with order.

AVAILABLE OPTIONS FOR ALL INSTRUMENTS:

Note: Add option designator to the end of the Model Number. (For example a Model TX-1000-S

denotes a standard TX-1000 with the optional Speed and Length function included.)

–R Custom Roller Option. Choose from numerous sizes of cylindrical, flanged, or U -shaped rollers.

Note: For tapes, webs, and custom materials please provide thickness, width, or diameter with

order.

–S Speed and Length Option. Indicate real-time speed in FPM, or MPM. Maximum measurable

speed is 9,999 FPM or 9,999 meters per minute, however line speeds in excess of 2,000 FPM are

generally unsafe for hand-held applications. Read length of part run in feet or meters. Maximum

length measuring up to 9,999 meters or feet.

–A Analog Output Option. For both speed and tension values. 0-5 VDC or 4 -20 mA with software

definable ending sequences. Provided with 10’ cable. Data is outputted at a rate of 40 Hz.

–E RS-232 Serial Output Option. Provided with 10’ cable to interface with your receiving device.

Select data sampling rate from 1, 2 or 5 Hz.

–D Data Logging Option. Capture and play back data within a user-defined time window. Select the

time window; then select the sampling rate (adjustable from 1-100 Hz) . After capturing the data,

review the data on the instrument’s display or upload it using the 10’ serial interface cable.

Instruments can be configured with any or all of these options.

ADDITIONAL OPTIONS FOR ALL METERS

Input real-time serial data into any Windows® application using the optional software WinWed ge

Pro for Windows®.

Euro Plug. P/N: TX-15-PS-240

Magnetic or rigid mounting bracket. P/N: TX-350

SPECIFICATIONS

Approximate weight .75 lbs (14 oz), depending upon configuration.

(5) Re-chargeable NIMH battery assembly and power supply provided. (For input voltages

between 100 – 240 V, use power supply P/N: TX-15-PS-240)

Durable, lightweight carrying case with protective foam inserts.

CE certification complying with heavy, industrial, immunity standards.

TX Series Operating Instructions Page 9

Page 5

v. In the Connect To dialog box that pops up next, go to the drop down menu labeled

“Connect Using:” and select the serial port you connected the cable to in step 2. It

is most likely that you are connected to COM1.

vi. In the COMx Properties dialog box that pops up next, set the “Bits per second:” to

9600, the “Data bits:” to 8, the “Parity:” to None, the “Stop bits:” to 1 and the “Flow

Control:” to None.

vii. Click the Apply button and then click the OK button.

viii. You should now see tension values appearing in the Hyper Terminal window.

ix. To download the data log data: Go to: Transfer > Capture text… and enter the

na me of the file that you wish to save the data to.

x. Next, click anywhere inside the Hyper Terminal window and then press ‘d’ on your

ke yboard. The data should download from the instrument to the file that you chose.

xi. When you are finished collecting data, close Hyper Terminal.

xii. To save the data in Microsoft Excel format, use Microsoft Excel to open the file you

saved the data log to and save it as an Excel file.

16. UPLOADING LOGGED DATA (Optional feature)) via RS-232, SERIAL COMMUNICATIONS.

a. Refer to the previous section, Sec 4.15, Serial Data Collection (RS-232 option) and

configure communication protocols as outlined. Note: step c has no effect on

transferring stored data and can be adjusted to any setting.

b. To retrieve, or upload logged data from the instrument, send a lower case d.

c. Collected data will remain in memory, regardless if instrument is turned off, until

overwritten with new data.

FEATURES

Large, easy to read backlit, graphic display with adjustable backlighting and contrast.

Display shows tension, name of calibration selected, running line minimum and maximum

tension values, and battery charge level.

Select tension values to display in Grams, lb, Newtons, or cN.

Instruments come with calibrations for numerous wire and filament sizes.

Up to 10 additional custom calibrations may be p rogrammed into instrument. (All calibrations

password protected.)

Choose your calibration by first highlighting and selecting the material (either wires, filaments, or

custom), then the units of measurement (inches, mm, AWG wire sizes, or custom). Lastly, select

the material size or gauge number a nd push “Enter”. The instrument automatically adjusts to the

calibration you’ve selected with a full-scale accuracy of +/- 1%. (Full-scale accuracy for custom

sizes is material specific.)

Selectable LCD refresh rates allow for stable digital readings.

Re-chargeable NIMH batteries and power supply provided. Approximately 9 hours of operation

per battery charge. Automatic shut-off after 10 minutes of non-use.

Instruments may be operated continuously while connected to power supply.

Numerous application-specific models available.

All instruments factor y-calibrated and ready for use. Calibration certificate included. All

calibration values traceable to National Standards.

All models typically available from stock.

Page 8 TX Series Operating Instructions

Follow the same procedure for each sequential letter or space of your new description. Continue

pressing ENTER until all spaces in the description have entered values. Once your new name has

been entered you will be returned to the SETUP screen. To select your new calibration follo w the

procedures outlined in Sec.3.5.

12. CALIBRATION OF SPEED. (Optional feature) From the Main Display press the UP and DOWN keys

until you reach SETUP. Press ENTER. Using the UP and DOWN keys select CALIBRATE L ENGTH.

Press ENTER. Next calibrate the speed function: Using a precise 20 foot length of your material

(20.0’), thread one end through the instrument’s three rollers and slowly pull exactly 20.0’ through

the instrument. (While you pull your 20’ length the instrument will count pulses on the display)

After pulling the 20’ length, press ENTER. Your instrument speed calibration is now complete.

13. MONITORING TENSION OR SPEED THROUGH THE ANALOG OUTPUT (Optional feature). Output

values are: 0 – 5 VDC or 4 – 20 mA. Connect Analog Output Cable to receptacle located on the

bottom side of instrument. Connect output cable leads to the analog input of your measurement or

control device. The RED lead is Voltage +, the WHITE lead is mA, and the BLACK lead is ground.

From the main display use the UP and DOWN keys until you reach SETUP. Press ENTER. Next

using the UP and DOWN arrows select ANALOG OUTPUT. Press ENTER. Using the UP and DOWN

arrows select from: ANALOG SPEED CURRENT, ANALOG SPEED VOLTAGE, ANALOG TENSION

CURRENT OR ANALOG TENSION VOLTAGE. Once correct selection is made press ENTER.

14. CALIBRATION OF ANALOG OUTPUT. From Main Display press the UP and DOWN keys until you

reach SETUP. Press ENTER. Press the UP and DOWN keys until you reach CALIBRATE ANALOG.

Press ENTER. Using the UP and DOWN keys adjust display to show the value at which the

instrument reads maximum current or voltage. Press ENTER.

15. SERIAL DATA COLLECTION (RS-232 option). Instruments outfitted with the optional RS-232 feature

(designated with a -E or –D in the part number) support serial communications as follo ws:

a. The baud rate is 9600 with no parity bit, 8 data bits, 1 stop bit (9600 8N1), and set “Flow

Control” to None.

b. Serial communications will work with most PCs with a cable up to 15 feet long.

c. Setting the dampening rate on the instrument to “1 Hz + Serial”, “2 Hz + Serial” or “5 Hz +

Serial” will cause the instrument to output the tension values at a rate of once, twice or five

times per second, respectively. The dampening rate can be set by going to the SETUP menu,

selecting DAMPENING, adjusting the value of the dampening rate with the UP a nd DOWN

buttons and then pressing the ENTER button.

d. The units output serially will be the same units that are selected in the “Tension Units” menu.

The currently selected tension units (such as Grams or Newtons) are also displayed on the

main tension screen.

e. Perform the following steps in order to log serial data from the instrument using

Hyper Terminal on a PC and put it into a Microsoft Excel spreadsheet:

i. Ensure the that the dampening rate is set to “1 Hz + Serial”, “2 Hz + Serial” or

“5 Hz + Serial”.

ii. Connect the serial cable from the instrument to a serial port on your PC.

iii. Go to the Windows Start Menu and choose Programs ->Accessories

>Co mmunications->Hyper Terminal

iv. In the Connection Description, dialog box that pops up, type in a name for the new

connection (any name will work) and press the OK button.

TX Series Operating Instructions Page 5

Page 6

FLOW CHART

MODEL: TX-SERIES DIGITAL INSTRUMENT

Use UP and Down keys to navigate main selections.

Use Enter to reach subscreens and Up and Down keys to make selections.

Material: ##

### ###

0.0

Grams

Min Max

Wire

Speed

(Optional)

Filament

Custom

Length

(Optional)

Select

Material

Tension

Units

Grams

lbs

Newtons

cN

Data

Logging

(Optional)

Logging

Rate

Begin

Logging

Duration

Calibrate

Analog

Calibrate

Length

Dampening

Setup

Custom

Names

Resolution

Audio

Length

Units

Calibrate

Tension

Back

Lighting

Contrast

Analog

Units

Version

(Optional)

Loading...

Loading...