Tennsco Z-Line Low Profile Boltless Shelving User Manual

ASSEMBLY INSTRUCTIONS & PARTS MANUAL #1950912

Z-Line Low Profile Boltless Shelving

Installation Instructions

Tennsco Corp., Dickson, TN 37056-1888 • (615) 446-8000

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE!

Congratulations on your purchase of Z-Line

Low Profile Boltless Shelving from Tennsco!

Z-Line's interlocking keyhole design not only

makes installation fast and easy but

eliminates the need for clips, gussets, sway

braces or other hardware commonly used in

conventional shelving. This allows completely

free access to your stored materials from all

sides of the unit.

Z-Line Low Profile Shelving is available in a

variety of heights, depths and widths for

virtually any application. And starter and

adder units allow for joining shelving units

together.

SHELF LOAD CAPACITIES

36" wide units 600 lbs. per shelf

42" wide units 550 lbs. per shelf

48" wide units 500 lbs. per shelf

GENERAL SAFETY INFORMATION

Some parts may have sharp edges. CARE must

be taken when handling the pieces to avoid injury.

For safety, wear a pair of work gloves when

assembling or performing any maintenance on

shelving.

LIMITED WARRANTY

Tennsco warrants goods purchased hereunder to be free of defects in materials and workmanship for a period of one (1) year from the date of shipment,

hereunder. This warranty shall not apply in the event goods are damaged as a result of misuse, abuse, neglect, accident, improper application, modification

or repair by persons not authorized by Seller, where goods are damaged during shipment, or where the date stamps on the goods have been defaced,

modified or removed. UNLESS CONSIDERED UNENFORCEABLE OR UNLAWFUL UNDER APPLICABLE LAW:

a. ALL IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE HEREBY EXCLUDED:

b. BUYERS REMEDY, IF ANY, FOR ANY DEFECTIVE GOODS SHALL BE LIMITED TO A REFUND BY SELLER OR REPLACEMENT OF THE

GOODS AT SELLER’S OPTION, AND SHALL IN NO EVENT INCLUDE DAMAGES OF ANY KIND, WHETHER INCIDENTAL, CONSEQUENTIAL

OR OTHERWISE.

NO GOODS ACCEPTED FOR RETURN WITHOUT PRIOR APPROVAL. Seller shall have the right to inspect any goods claimed to be defective at Buyers

place of business or require Buyer to return the goods to Seller for inspection on Seller’s premises. Transportation charges covering returned goods

will be borne by Seller only if such goods are proven to be defective, are covered by this warranty and are returned within the warranty period stated

above.

TENNSCO CORP., P.O. BOX 1888, DICKSON, TN 37056-1888

(615) 446-8000 (800) 251-8184

PK-1950912

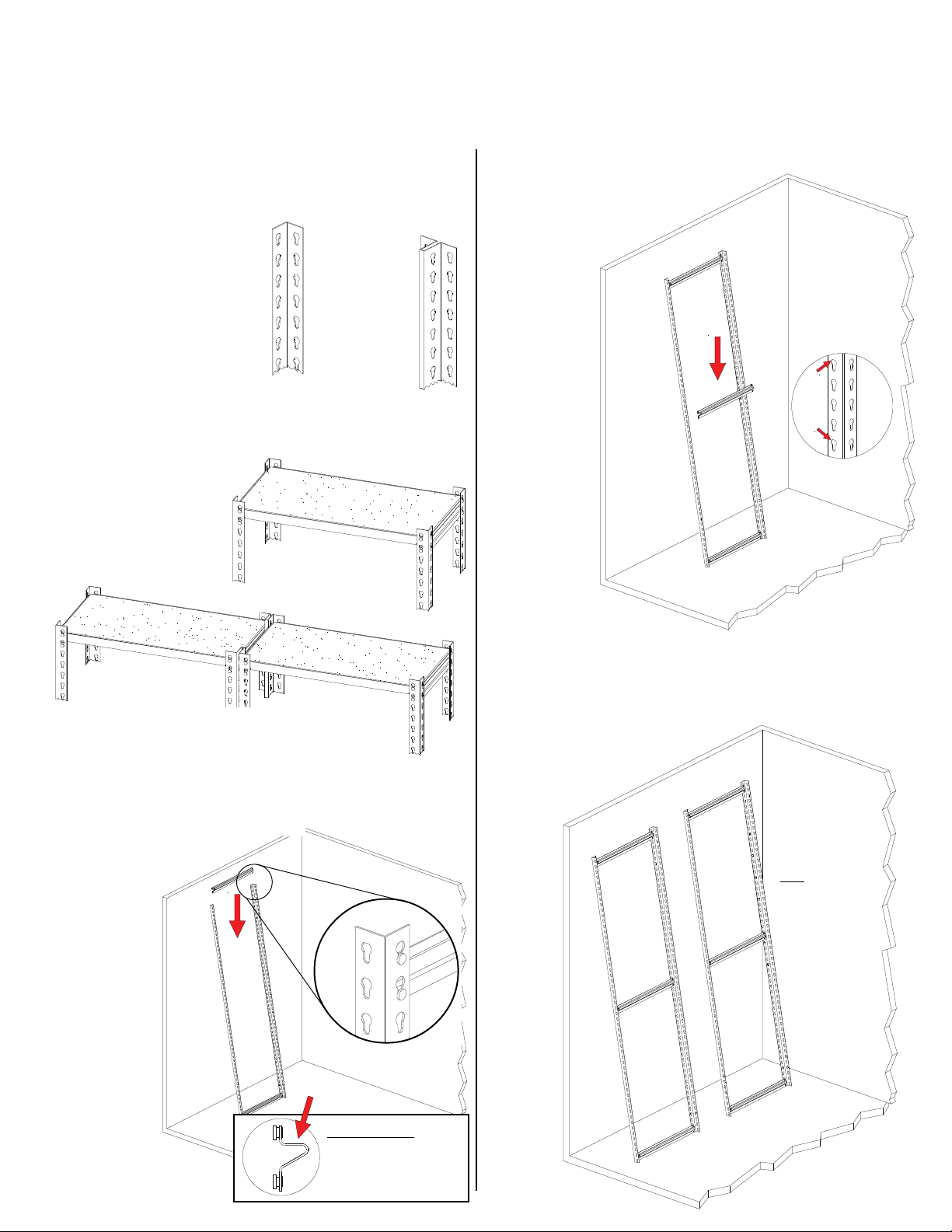

ASSEMBLY OF BOLTLESS LOW PROFILE SHELVING

Tool Needed: A rubber mallet for seating the shelf supports into the uprights. Two people

recommended for assembly. Approximate assembly time: 15 to 30 minutes per shelving section.

1. The reference numbers used throughout this

sheet refer to the illustration on the back cover.

This is to help you to identify the various parts as

they are mentioned.

2. Depending upon whether

Angle Post

(EUR)

you are assembling a

single unit or an adder

unit, you may have one

or both of the styles of

upright shown at right:

"T" Post

(ZTP)

A single unit will use EUR angle posts for all four

uprights, as shown below in Figure A. If you plan

on assembling multiple sections, however, you

should build the starter unit with two ZTP

"T" posts on one end

(which will provide

common posts for

adjacent sections),

as shown in Figure B.

EUR

B. Two or more units with Angle Posts (EUR) on

each end and "T" Posts (ZTP) connecting each unit.

A. Single unit with

four Angle Posts (EUR).

ZTP

3. With help from an associate, or using a wall for

support, connect two EUR uprights (Ref. No. 1a)

together with two front-to-back end supports (Ref.

No. 2), one at the top and one

at the bottom. When

inserting supports,

be sure the

rivets are

fully seated

in the keyhole slots,

as shown.

NOTE: The

uprights

must be

positioned

so that the

narrow part

of the slots

is toward the floor,

as shown in the inset.

NOTE: Inset is shown

from opposite side.

IMPORTANT: The

support MUST be

inserted so that the flat

surface is on top as

shown in profile at left!

EUR

4. Place a third front-to-back end support in the

middle slots of the two uprights.

This forms one end of the

shelving unit.

NOTE: There

will be only

three (3)

front-toback end

supports

NOTE: Every

fourth keyhole

slot is shaped

differently (with a

flattened top) for

easier alignment

of supports (see

below).

per unit

end, as

shown.

These are

used for

rigidity

and are

not needed

at every

shelf level.

5. Repeat steps 3 and

4 to construct a second set of unit ends.

NOTE: If you are planning to install an adder

unit, this second end should consist of ZTP

Uprights (Ref. No. 1b) to act as an intermediate

assembly. Carefully

re-read through

step 2 to better

understand

this.

NOTE: If

assembling a

ZTP upright

assembly (for an

adder unit), place

the front-to-back

shelf supports on

both sides of the

"T" post, for a

total of six VDRS

front-to-back

supports instead

of three.

is flattened at top

Every 4th hole

Loading...

Loading...