Tennsco Q-Line Shelving User Manual

ASSEMBLY INSTRUCTIONS & PARTS MANUAL #2060699

Q LINE INDUSTRIAL SHELVING, OPEN STYLE

Installation Instructions

Tennsco Corp., Dickson, TN 37056-1888 (615) 446-8000

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE!

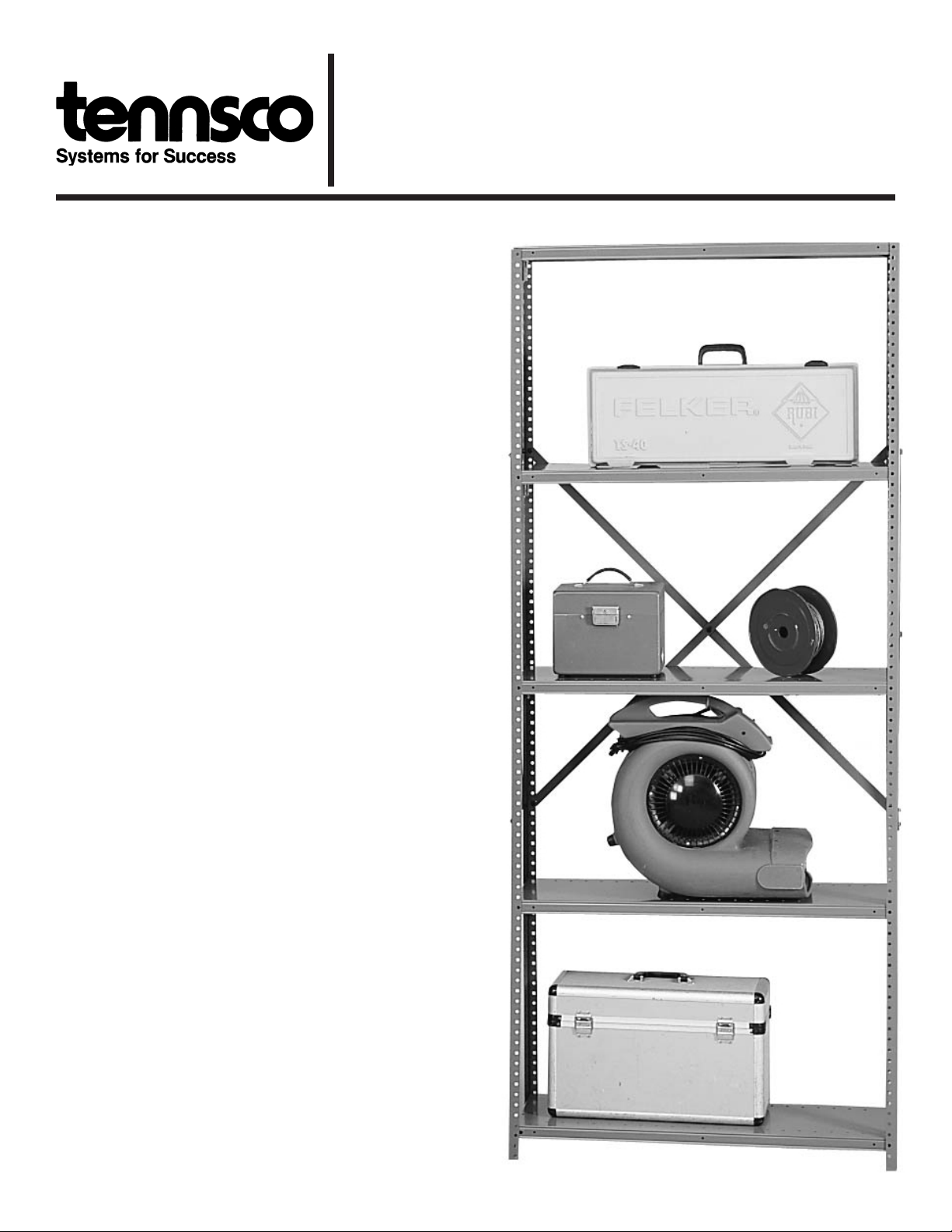

Congratulations on your purchase of

Q Line Industrial Shelving from Tennsco!

Q Line shelving is designed for storage

applications that demand strength and

versatility. Available in a variety of heights,

widths and depths, with either open or

closed ends and backs, Q Line shelving is

the answer for your heavy-duty storage

needs.

Q Line's unique box-formation shelving

structure provides added strength that

makes it the strongest shelf in its class.

The baked-on enamel finish assures years

of trouble-free service, even under the

most demanding situations. Compression

clips provide boltless shelf attachment,

making adding new shelves easy and

convenient. Shelves can be adjusted

quickly and easily in 1" increments,

providing versatility.

Units can be used stand-alone, bolted side

to side, or bolted back to back to suit

your needs.

A wide variety of accessory items are

available to suit your requirements,

whether your needs are within the office

or the factory.

GENERAL SAFETY INFORMATION

Some parts may have sharp edges. CARE

must be taken when handling various pieces to

avoid injury. For safety, wear a pair of work

gloves when assembling or performing any

maintenance on shelving.

PK-2060699

ASSEMBLY OF Q LINE INDUSTRIAL SHELVING

Tools Needed: A 7/16" nut driver or socket and a flathead screwdriver. Label holder requires a Phillips screwdriver.

Requires one or two people for assembly. Approximate assembly time: 2 people, 15 to 30 minutes per station.

1. The reference numbers used throughout this

sheet refer to the illustration on the back cover.

This is to help you to identify the various parts as

they are mentioned. NOTE: Number of shelves

per unit varies depending on unit purchased.

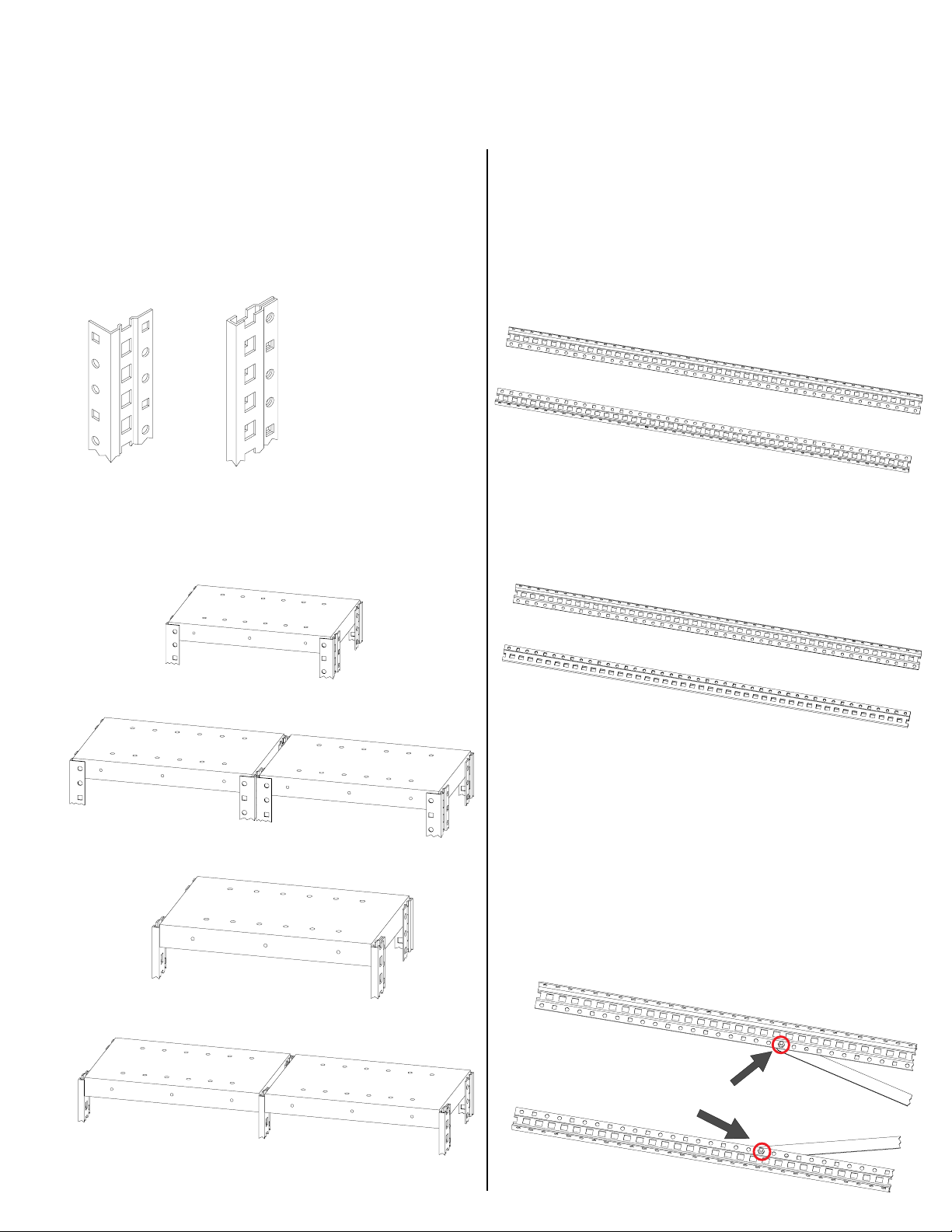

2. Q Line uprights come in three different styles, as

shown below:

Offset

Angle Post

(OAP)

These three upright styles may be used in

several different combinations. In order to better

understand these instructions, please examine the

following configurations to determine which type

of installation you will be assembling:

Standard

Beaded Post

(BTP)

3. Create the right side of the shelving units by

laying two uprights side by side on a flat

surface. Be sure that the short side of the

OAP upright(s) (Ref. No. 1a) is facing up, as

shown in Figure 3A.

IMPORTANT: One side of the upright is longer

than the other, and contains two sets of holes.

When laying the uprights side by side, this

long side should be flat on the floor, and the

short side should be pointing into

the air.

3a

(If your unit will use BTP or HBP uprights in

the front (Ref. Nos. 1b or 1c), be sure to

select the proper upright and that the open

edge is facing the OAP upright, as shown

below in Figure 3B.)

A. Single unit with

four Offset Angle Posts

B. Two or more units with four

Offset Angle Posts each

C. Single unit with two

Offset Angle Posts in rear and

two Standard or Heavy Beaded Posts in front.

OAP in back;

3b

BTP in front

4. Attach the two side sway braces (Ref. Nos.

2a or 2b), beginning in the 20th hole from the

top of each upright (approximately 20" from

the top), using two

(Ref. No. 6). The side sway braces attach

to the longer side of the uprights (the

side with two sets of holes). Bolt the braces

into the small holes near the edge of the

uprights as shown in circles at below. Note

the hole pattern of two round holes and then

one square hole, repeating every 3", which

should help facilitate proper placement of the

1

/4-20 x 5/8 bolts and nuts

bolts. Finger tighten only

at this point.

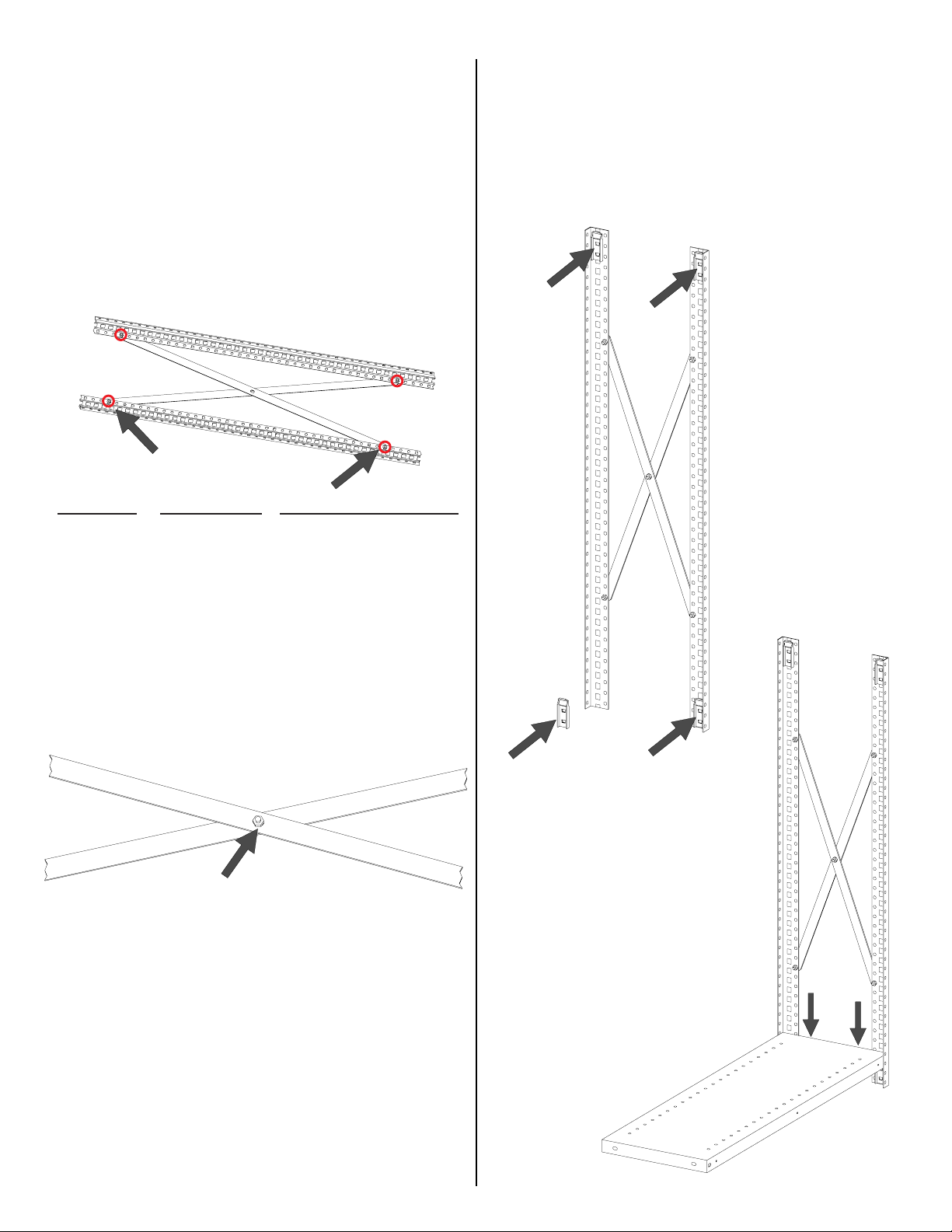

D. Two or more units using Standard or

Heavy Beaded Posts in front.

5. Attach the other end of both sway braces. The

information below will help you to know how

many holes should be between the top and

bottom of the sway braces. Count the holes

carefully, as an incorrect count will cause the

upright to be the wrong depth to hold the

shelves.

EXAMPLE:

12" deep unit has 34 holes

between bolts

Unit Depth Brace Length Distance Between Bolts

12" 36

15" 36

18" 36

24" 36

30" 43

36" 43

7

/8" 36 holes (35")

7

/8" 35 holes (34")

7

/8" 34 holes (33")

7

/8" 30 holes (29")

5

/8" 34 holes (33")

5

/8" 28 holes (27")

8. Have an associate hold one upright while you

place four shelf clips (Ref. No. 3) in the top

and bottom holes of each post, as shown

below.

6. Place one

1

/4-20 x 5/8 bolt and nut in the hole

where the two sway braces cross. Insert the

bolt from the outside of the uprights, so that the

nut will be inside the unit. Again, finger tighten

only for the time being.

7. Repeat steps 3 through 6 for the left uprights.

Again, be sure to note the type of uprights you

should be using (according to the illustrations in

step 2) for your type of installation. If you have

purchased an adder unit such as the example

in Figure 2D, please note that only ONE BTP or

HBP is used in between the units.

You should now have complete left and right

sides of your shelving unit, with sway brace

bolts and nuts still finger-tightened only.

9. Place a shelf (Ref. No. 4a or

4b) onto the bottom two clips.

Loading...

Loading...