Tennsco EB-1-3072S-MGY, EB-2-3672C-MGY, EB-1-3672M-MGY, EB-2-3072S-MGY, EB-1-3072C-MGY User Manual

...

ASSEMBLY INSTRUCTIONS & PARTS MANUAL #1340397

ELECTRONIC WORKBENCH

Tennsco Corp., Dickson, TN 37056-1888 * (615) 446-8000

READ INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING

TO ASSEMBLE YOUR Tennsco ELECTRONIC WORKBENCH.

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE!

DESCRIPTION

Tennsco

electronic ass embly, tes ting, pr oduct de velopment an d

other u ses w here a ccess to multiple power outlets is

important. The workbench can use either 30" x 60", 30" x

72" wood tops or 36" x 72" steel tops (see below). Workbench

legs and frames are box formed for strength and r igidity.

Frame front panel has knockouts for four duplex receptacles

as well as a switch and circuit breakers (order optional wiring

kit separately). Removable cover behind r eceptacle panel

facilitates wiring and prevents contact with rear terminals.

Tennsco

two de pths a nd ar e pr e-drilled for mounting to var ious

workbench bases.

Steel Benchtops

surfaces, reinforced with channels at each end. There are

no exposed s harp edges or corners. A s teel s tringer is

included to provide extra rigidity.

Hard Maple Laminate Benchtops

laminated solid hard maple with a smooth oil-seal natural finish.

Plastic Laminate Benchtops

linen, m aintenance-free, h igh pr essure non- conductive

plastic l aminate o ver a com pressed w ood core w ith a

phenolic backer sheet.

Compressed Wood Benchtops

constructed of tempered hardboard top and bottom surfaces

laminated to a high density compr essed wood cor e. A

smooth, sealed finish gives a durable, non-porous surface.

Available options

included in these instructions.

e lectronic wo rkbenches a re des igned for

tops are available in a choice of two widths and

( S) ar e cons tructed of smo oth st eel

(W ) a re 1

5

⁄

(P) are 1

(C) ar e 1

ar e listed in the r eplacement par ts list

" thick with gr ey

8

3

⁄

" t hick

4

3

⁄

" thick and

4

SPECIFICATIONS

Overall Dimensions

All 3072 models .......................... 72"w x 30"d x 33

All 3672 models .......................... 72"w x 36"d x 33

Basic Construction

Steel Top

Top ..................................................12 gauge steel

Reinforcing Channels ......................14 gauge steel

Hard Maple Laminate Top

Top ..............................................Laminated Maple

Compressed Wood Top

Top ........ Hardboard with Compressed Wood Core

Plastic Laminate Top

Top ..............Laminated High Pressure Plastic with

Compressed Wood Core

Panel Legs.............................................16 gauge steel

Stringer ..................................................14 gauge steel

Wireway Cover ......................................20 gauge steel

Receptacle Panel...................................16 gauge steel

Back Panel.............................................16 gauge steel

Options Available:

Side and back rails Lower Shelf

Standard and electronic riser Stackable Drawer

1

⁄

"h

2

1

⁄

"h

2

GENERAL SAFETY INFORMATION

Some parts may hav e sharp edges. CA RE must be taken

when handling v arious pieces to avoid injury. F or safety,

wear a pair of work gloves when assembling or performing

any maintenance on workbench.

Step By Step Installation Instructions

(Proceed to next step on optional items not purchase)

Tools required: Slotted screwdriver, Phillips screwdriver, and 7/16" & 3/8" wrenches or nut drivers (use 2 people for assembly).

1. Place the panel legs (1) in an upright position as shown

in Figure 1 of the assembly drawings. The legs should

be plac ed appr oximately 53" apart for 60" units and

65" apart for 72" units.

2. Place r eceptacle p anel ( 2) i nside pa nel l egs an d

secure with four

1

⁄

4

"-20 x

5

⁄

" bolts and nuts. (Stringer

8

mounting holes go to the rear.)

3. Attach stringer (4) [provided with top] to back of panel

legs as shown. F asten with eight

1

⁄

4

"-20 x

5

⁄

" bolts,

8

nuts and washers.

4. Set back panel (3) inside panel legs and secure with

four

OPTIONAL

5.

1

⁄

4

"-20 x

5

⁄

" bolts and nuts.

8

Wiring Kit

5a. Install optional wir ing k it ( WK-1) into r eceptacle

panel using the ins tructions pr ovided with each

wiring kit.

DO NOT CONNECT POWER TO UNIT UNTIL

ENTIRE UNIT HAS BEEN ASSEMBLED.

6. Attach the wireway cover (5) to the back bottom flange

of the r eceptacle panel with four #10 sheet metal

screws.

7. Attach bench top ( 6) to fr ame ass embly using the

applicable instruction below:

Solid Maple Top; Compressed Wood on

Wood Top;

Plastic Lam inate Top

or

(Figure 2):

7a. Place bench top on a smooth, non-marring

surface with top side facing down.

7b. For 30" top, attach leg assembly to under

side of bench top thr ough pre- drilled holes .

3

⁄

Secure with #14 x

" wood screws: six in

4

each panel leg. Predilled holes on 36" top

will not line up with the holes on the leg

assembly.

NOTE: W hen installing a receptacle panel

(2) or back panel (3) on a wood top, use a

drill bit to drill

5/32"

pilot holes along the

front & b ack e dges of b enchtop.

Steel Top

(Figure 3):

7a. Place bench top on a smooth, non-marring

surface with top side facing down.

7b. Attach leg assembly to under side of bench

top thr ough punc hed holes . S ecure with

1

⁄

4

"-20 x

5

⁄

" bolts and nuts: one in second

8

hole fr om eac h cor ner of top; eight in

receptacle panel; and eight in back panel.

7c. Insert channel (7) in each end of bench top.

7d. Align bench top, panel legs , and channel

holes. Secure with four

1

⁄

4

"-20 x

5

⁄

" bolts.

8

Note fo ur w eld n uts ar e pr ovided on

channels.

8. Set bench assembly upright and recheck all nuts, bolts

and screws for tightness.

OPTIONAL

9.

Stackable Drawer Attachment (Figure 4):

9a. Remove drawer (15) from housing (16).

9b. Secure lock hasp (17) to housing top using the two

1

⁄

"-20 x

4

5

⁄

" bolts ex tended down fr om top of

8

housing.

9c. Secure long mounting brackets ( 14) to r ear of

housing, with br acket flanges tur ned downwar d,

1

⁄

using four

"-20 x

4

should ex tend 10

5

⁄

" bolts and nuts. B racket

8

1

⁄

" b ehind housing. ( NOTE:

2

When installing drawer onto a wood top, drawer is

secured dir ectly into the wood top; no mounting

brackets ar e us ed. H oles m ust be dr illed as

needed.)

9d.ENSURE TH AT WOR KBENCH POWER

SUPPLY IS NOT CONNE CTED B EFORE

PERFORMING NEXT STEP.

9e. Attach dr awer un it to wo rkbench by r emoving

wireway cov er fr om r eceptical ho using an d

aligning front slots in top of hous ing with holes in

receptacle panel (short mounting brackets are not

used). Secure with two

1

⁄

4

"-20 x

5

⁄

" bolts and nuts.

8

9f. Align holes in mounting brackets with holes in back

panel flange and secure with two

1

⁄

4

"-20 x

5

⁄

8

" bolts

and nuts.

9g. Replace wireway cover.

9h. Insert drawer in housing.

10.

OPTIONAL

OPTIONAL

11.

Riser Attachment

Standard Riser

(Figure 1):

10a. Secure riser shelf (9) to supports using two

bolts and nuts on each end.

10b. Secure riser supports (8) to top end, using

four bolts and nuts (or four #14 wood screws

for wood tops).

Electronic Riser

(Figure 5):

10a. Secure riser supports (8), to top end, using

four bolts and nuts (or four #14 wood screws

for wood tops).

10b. Install optional wiring kit into electronic riser

shelf (10) us ing ins tructions pr ovided with

each wiring kit.

DO NOT CONNECT POWER TO UNIT

UNTIL ENTIRE UNIT IS ASSEMBLED.

NOTE: If wi ring k it was not pur chased,

proceed to step 10c.

10c. Align holes in flanges of wireway trough (11)

with holes in riser shelf. Insert four #10 sheet

metal screws and tighten.

10d. Secure e lec tronic r iser s helf ( 10) t o

supports, using two bolts and nuts on each

end.

Riser to Riser:

10a. Secure riser supports to lower riser supports

with flange down, using four bolts and nuts.

10b. Secure r iser shelf to supports using two

bolts and nuts on each end.

Side and Back Rail Attachment

11a.

Bolt side rail (12) to the right side of top end

attachment with four bolts and nuts (for wood

tops, use #14 wood screws and drill holes as

needed). Be sure that the rounded corners of

side ra il are tow ard th e front of the

workbench.

11b. Repeat step 11a to install rail for left side.

11c. Place back rail (13) across back and around

the outside of the side rails. Secure to bench

top with fiv e bolts, nuts and washer s. ( For

wood tops use five #14 wood screws). Use

two bolts, nuts and washers at each end to

fasten to side rails.

LIMITED WARRANTY

Tennsco warrant s goods purchased hereunder to be f ree of

defects in materials and workmanship for a period of one (1) year

from t he date of shipment, hereunder. This warrant y shal l not

apply i n the event goods are dam aged as a result of misuse,

abuse, negl ect, acci dent, i mproper application, modification or

repair by persons not aut horized by S eller, where goods are

damaged duri ng shi pment, or where the date stamps on the

goods have been def aced, m odified or rem oved. UN LESS

CONSIDERED UNENFORCEABLE O R UNLAWF UL UNDER

APPLICABLE LAW:

a. ALL I MPLIED W ARRANTIES, INCLUDI NG BUT NO T

LIMITED TO WARRANTIES OR MERCHANT ABILITY AND

FITNESS FOR A PART ICULAR PURPOSE ARE HEREBY

EXCLUDED.

b.BUYERS REMEDY, IF ANY, FOR ANY DEFECTIVE GOODS

SHALL B E L IMITED T O A REF UND BY SELLER OR

REPLACEMENT OF THE G OODS AT SEL LER’S OPTION,

AND SHALL IN NO EVENT I NCLUDE DAMAG ES OF ANY

KIND, WHET HER I NCIDENTAL, CONSEQ UENTIAL OR

OTHERWISE.

NO GOOD S A CCEPTED FOR R ETURN WI THOUT P RIOR

APPROVAL. Sel ler shal l have the ri ght t o i nspect any goods

claimed to be defective at Buyers place of business or requi re

Buyer t o ret urn t he goods t o S eller f or i nspection on S eller’s

premises. Transport ation charges coveri ng returned goods wi ll

be borne by Seller only if such goods are proven to be defective,

are covered by this warranty and are returned within the warranty

period stated above.

TENNSCO CORPORATION

P.O. Box 1888

DICKSON, TN 37056-1888

(615) 446-8000 (800)

Hard Maple Laminate Benchtop Maintenance:

Clean when necessary with warm water, soap or detergent.

Wipe dry immediate ly. Sc ouring p owder, st eel w ool or

sandpaper can be used for stubborn stains and mars. Allow

a generous quantity of linseed oil or mineral oil to penetrate

all surfaces for five minutes before removing all excess oil.

Excessive dr yness or hum idity c an ca use c racks or

warping. Cracks should be filled w ith w ood filler, sa nded

smooth and re-oiled. Warping can be prevented by securely

attaching top to bench legs.

251-8184

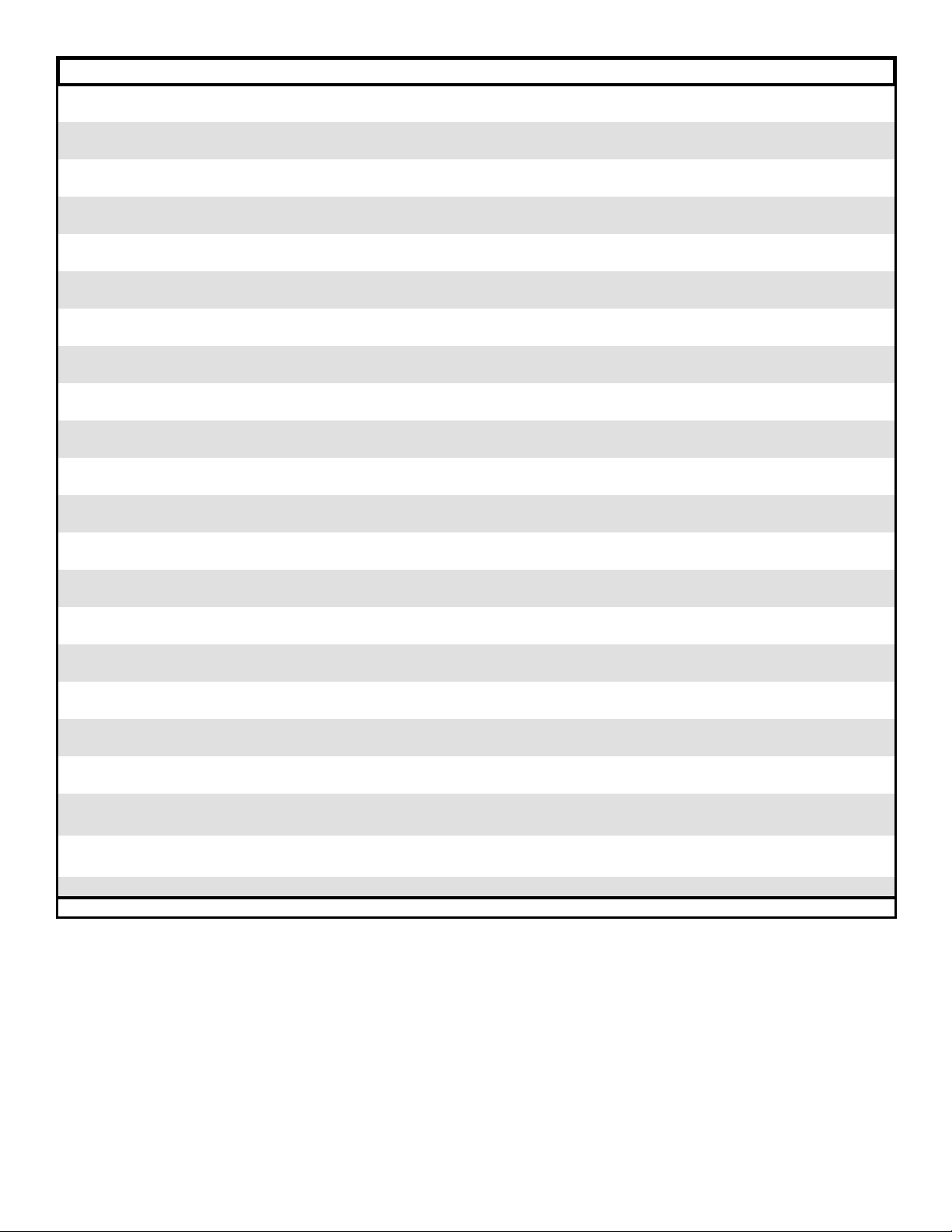

REF. NO. DESCRIPTION PART NUMBER QTY.

1 Panel Legs (All Units) LP-3230 1 (PR.)

2 Receptical Panel (All Units) WOP-72 1

3 Back Panel (All Units) 2221ABP-72 1

4 Stringer (60" Wide) WBS-60 1

Stringer (72" Wide) WBS-72 1

5 Wireway Cover (All Units) 221AWC-72 1

6 Steel Bench Top w/Stringer (30" x 60") T-3060 1

Steel Bench Top w/Stringer (30" x 72") T-3072 1

Steel Bench Top w/Stringer (36" x 72") T-3672 1

Compressed Wood on Wood Top w/Stringer (30" x 60") CT-3060 1

Compressed Wood on Wood Top w/Stringer (30" x 72") CT-3072 1

Compressed Wood on Wood Top w/Stringer (36" x 72") CT-3672 1

Plastic Laminate Top w/Stringer (30" x 60") PT-3060 1

Plastic Laminate Top w/Stringer (30" x 72") PT-3072 1

Plastic Laminate Top w/Stringer (36" x 72") PT-3672 1

Solid Maple Top w/Stringer (30" x 60") MT-3060 1

Solid Maple Top w/Stringer (30" x 72") MT-3072 1

Solid Maple Top w/Stringer (36" x 72") MT-3672 1

7 Top End Channel (Included w/Top)

8 Riser Support (All Units) WBRS-2 2

9 Riser Shelf (60" Wide) WBRS-60 1

Riser Shelf (72" Wide) WBRS-72 1

10 Electronic Riser Shelf (60" Wide) EWRS-6015 1

Electronic Riser Shelf (72" Wide) EWRS-7215 1

11 Wire trough (60" Wide) EWWT-60 1

Wire trough (72" Wide) EWWT-72 1

12 Side Rail (30" Deep Units) 189SS 2

Side Rail (36" Deep Units) 404SS 2

13 Back Rail (60" Wide) 189BS1 1

Back Rail (72" Wide) 404BS 1

14 Long Mounting Bracket (WBD-2) 976LB 2

15 Drawer (WBD-2) 976CDW 1

16 Drawer Housing (WBD-2) 976CDH 1

17 Padlock Hasp (WBD-2) 976H 1

18 Tray (WBD-2) 976T 1

19 Divider (WBD-2) WBDD-12 1

❈

❈

•

•

•

•

•

❈

Wiring Kit (not shown in figure) WK-1 1

Cam Lock CL-1 1

1

⁄

4

1

⁄

4

1

⁄

4

#14 x

#10 x

5

"-20 x

⁄

" Bolt

8

"-20 Nut

" Lockwasher

3

⁄

" Hex Head Slotted Wood Screw

4

1

⁄

" Sheetmetal Screw

2

♦

♦

♦

♦

♦

Optional Accessory

49B134

Tennsco makes every effort to ensure that all units ship complete with all parts and arrive undamaged.

However, should your unit contain missing or damaged parts, please contact your purchase location.

Loading...

Loading...