Tennsco ADD-A-TRACK LATERAL SYSTEM User Manual

PART LIST FOR ADD-A-TRACK

REF. NO. DESCRIPTION QUANTITY

1 Leveling Screw 5/16-18 X 1" 16

2 Track Assembly 4

3 Floor Plate 8

4 Roll Pin 2

5 Track Splice Channel 2

3

6 10-32 x 1

7 10-32 Hex Nut 2

8 Rubber Bumper 4

9 Deck Cover ( for Track Spreader Panel ) 2

10 Track Spreader Panel 2

11 Deck Cover ( for Track Assembly ) 2

12 Ramp Plate 2

13 Track End Plate 4

14 End Plate Angle 4

15 #14 Machine Screw 8

16 Top Track 4

17 8-32 x 1/2 Hex Head Machine Screw 10

18 8-32 Plate Nut 10

19 Roller Guide Channel 2

20 Base of Upright on L&T unit *not included with ADD-A-TRACK system

21 Mobile Carriage 2

22

23

1

/4-20 x 1 1/2 Hex Head Bolt 12

1

/4-20 Hex Nut 12

24 Stabilizer Support Angle for front unit 1

25 Stabilizer Roller Bracket Assembly for middle unit 1

26 Stabilizer Cover/Roller Bracket Assembly 1

27

We make every effort to ensure that all units ship complete and arrive undamaged. However, should your

unit contain missing or damaged parts, replacements may be obtained directly from us. To obtain proper

replacement parts, follow the instructions below, or fill out the form at www.tennsco.com/partsorder.html.

TO OBTAIN PROPER REPLACEMENT PARTS, PLEASE PROVIDE THE FOLLOWING INFORMATION:

●●

●

●●

Model Number Purchase Date

●●

●

●●

Description of part(s) needed and part Your company name

number(s) as shown in Parts List (above) Contact person's name

●●

●

●●

Color (i.e. Medium Grey, Sand, etc.) Company the product was purchased from

●●

●

●●

Was item missing, or was it damaged?

Tennsco Corp., P.O. Box 1888, Dickson, TN 37056-1888 E-mail address: info@tennsco.com

If requesting parts by telephone, ask for customer service and have as much of the above information ready as possible.

1

/4-20 x 1/2 Bolt 4

Customer Service: (866) 446-8686 Fax: (866) 445-7260

/4 Hex Head Screw 2

●●

●

●●

●●

●

●●

●●

●

●●

●●

●

●●

ASSEMBLY INSTRUCTIONS & PARTS MANUAL #1130303

ADD-A-TRACK LATERAL SYSTEM

FOR USE WITH L&T SHELVING

Tennsco Corp., Dickson, TN 37056-1888 • (615) 446-8000

RETAIN INSTRUCTIONS FOR FUTURE REFERENCE!

LIMITED WARRANTY

Tennsco warrants goods purchased hereunder to be free of defects in materials and workmanship for a period of one (1) year from the date of shipment, hereunder.

This warranty shall not apply in the event goods are damaged as a result of misuse, abuse, neglect, accident, improper application, modification or repair by

persons not authorized by Seller, where goods are damaged during shipment, or where the date stamps on the goods have been defaced, modified or removed.

UNLESS CONSIDERED UNENFORCEABLE OR UNLAWFUL UNDER APPLICABLE LAW:

a. ALL IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED TO WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE HEREBY EXCLUDED:

b. BUYERS REMEDY, IF ANY, FOR ANY DEFECTIVE GOODS SHALL BE LIMITED TO A REFUND BY SELLER OR REPLACEMENT OF THE GOODS

AT SELLER’S OPTION, AND SHALL IN NO EVENT INCLUDE DAMAGES OF ANY KIND, WHETHER INCIDENTAL, CONSEQUENTIAL OR

OTHERWISE.

NO GOODS ACCEPTED FOR RETURN WITHOUT PRIOR APPROVAL. Seller shall have the right to inspect any goods claimed to be defective at Buyers place

of business or require Buyer to return the goods to Seller for inspection on Seller’s premises. Transportation charges covering returned goods will be borne

by Seller only if such goods are proven to be defective, are covered by this warranty and are returned within the warranty period stated above.

TENNSCO Corp., P.O. BOX 1888, DICKSON, TN 37056-1888

(615) 446-8000 or (866) 446-8686 (toll free)

Website: www.tennsco.com E-mail: Info@tennsco.com

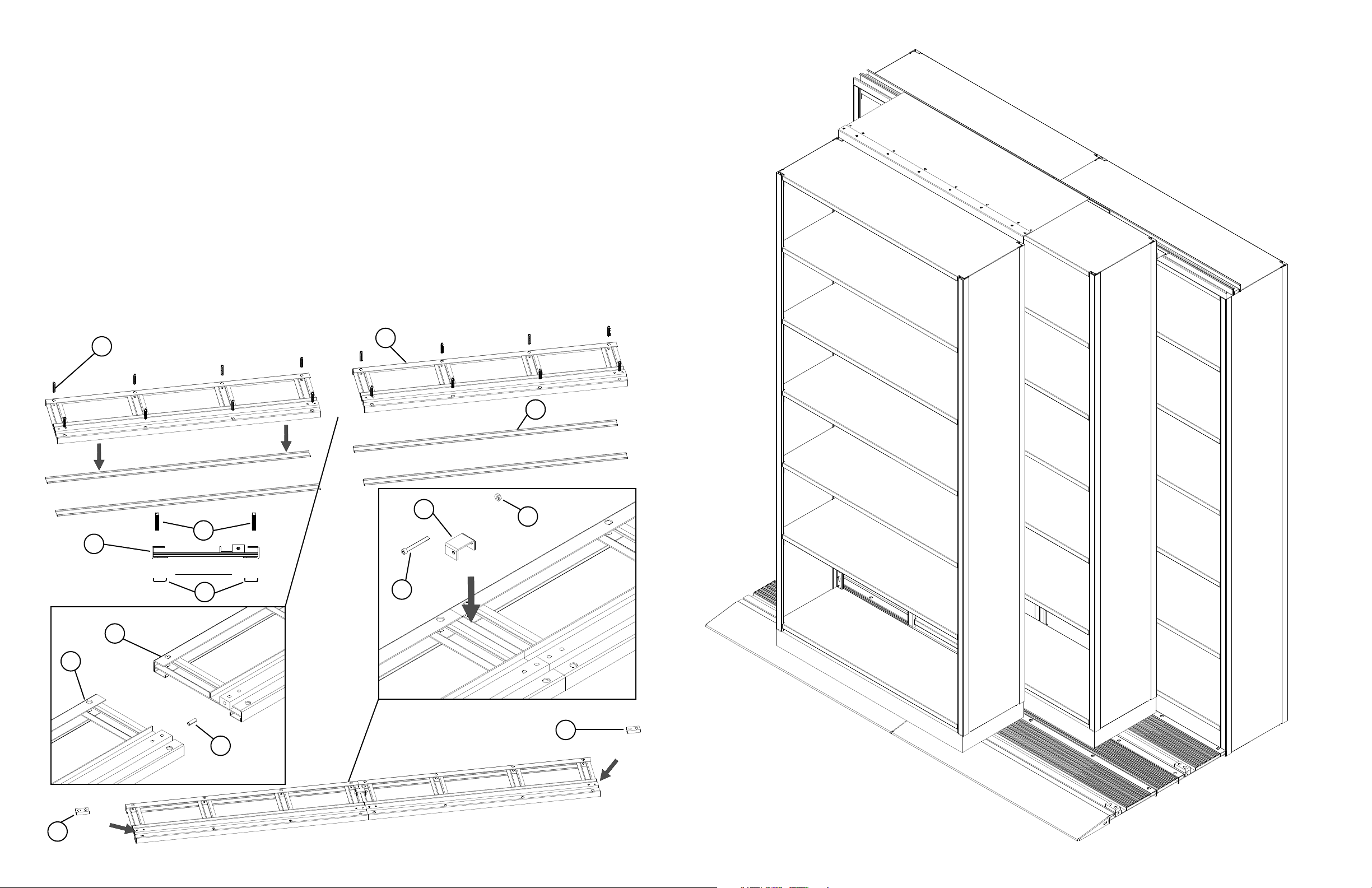

STEP 1) Locate the Leveling Screws (#1) (a quantity of 8 will be required for the 36" units, and 10 for the 48").

Thread them into the Track Assembly (#2) through the weld nuts with the socket facing up. Adjust all screws into

their upper most position. Continue this procedure until each Track Assembly in the system is complete.

STEP 2) Locate the Floor Protecting Channels (#3) on the floor with the “U” facing up; two (2) will be needed for each

Track Assembly. Approximate the position for the Floor Protector Channels (#3) and lay them in place. Next lay the

Track Assemblies on top of the channels. The leveling screws should be directly on top of the channels.

STEP 3) Locate the Roll Pin (#4) and drive it into the hole drilled at the end of each track. This is designed to fit very

tightly and will require a ball peen hammer. The opening will only permit the Roll Pin to be driven in partially; the

remaining portion of the Roll Pin will fit into the opening in the next Track Assembly. Position the next Track Assembly in place; make sure you have a tight fit to insure smooth operation.

STEP 4) Once you have joined the Track Assemblies together, locate the Track Splice Channel (#5). Install the

Track Splice Channel over the flange at the rear of the Track Assembly and secure using a 10 - 32 x 1 3/4 hex head

screw (#6), external tooth lock washer, and 1/4 x 20 hex nut (#7). Tighten firmly making sure that each track is

secure to the next.

STEP 5) Install the Rubber Bumpers (#8) at the end of each Track Assembly run, using two- (2) 1/4 x 1/2 self-tapping

screws. If these are not installed the carriage will roll off the end of the track.

1

2

3

5

7

1

2

End View

3

6

2

2

8

4

8

Completed ADD-A-TRACK System

Loading...

Loading...