Tennant T350 Users guide

T350

Stand-On Rider Scrubber

English EN

Operator Manual

Hygenic® Fully Cleanable Recovery Tank

Tennant True® Parts

®

a Tennant Technology

IRIS

Pro-Panel® Controls

Smart-Fill™ Automatic Battery Watering

Insta-Click™ Magnetic Disk

North America / International

For the latest Parts Manuals and other

language Operator Manuals, visit:

www.tennantco.com/manuals

R

9016417

Rev. 01 (02-2021)

*9016417*

INTRODUCTION

INTENDED USE

This manual is available for each new model. It provides

necessary operation and maintenance instructions.

Read this manual completely and

understand the machine before

operating or servicing it.

This machine will provide excellent service. However, the

best results will be obtained at minimum costs if:

• The machine is operated with reasonable care.

• The machine is maintained regularly - per the

maintenance instructions provided.

• The machine is maintained with manufacturer supplied or

equivalent parts.

To view, print or download manuals online visit

www.tennantco.com/manuals

PROTECT THE ENVIRONMENT

Please dispose of packaging materials

and used machine components such as

batteries in an environmentally safe way

according to your local waste disposal

regulations.

The T350 stand-on rider fl oor scrubber is intended for

commercial use, for example in hotels, schools, hospitals,

factories, shops, offi ces and rental businesses. It is

designed to scrub hard fl oor surfaces (concrete, tile, stone,

synthetic, etc.) in an indoor environment. This machine is

not intended for cleaning carpets. Use only recommended

pads/brushes and commercially available fl oor cleaning

detergents. Do not use this machine other than described

in the Operator Manual.

MACHINE DATA

Please fi ll out at time of installation for future reference.

Model No. -

Serial No. -

Installation Date -

MACHINE SERIAL NUMBER LOCATION

Always remember to recycle.

Tennant Company

10400 Clean Street

Eden Prairie, MN 55344-2650

Phone: (800) 553-8033

www.tennantco.com

1-STEP, Pro-Membrane, Severe Environment, Zone Settings, and

Quiet-Mode are trademarks of Tennant Company.

Trojan® and HydroLINIK® are registered trademark of Trojan Battery

Company.

Windows 7® is a registered trademark of the Microsoft Corporation.

This product may contain portions of software that have various 3rd party

licenses. More information can be found at:

www.tennantco.com/opensource

Specifi cations and parts are subject to change without notice.

Original Instructions, copyright 2017, 2021 TENNANT Company.

UNCRATING MACHINE

Carefully check machine for signs of damage. Report

damages at once to carrier. Contact distributor or Tennant

for missing items.

To uncrate the machine, remove straps, wheel blocks and

shipping brackets. Using the supplied ramp carefully back

the machine off the pallet. Make sure scrub head is in the

raised position.

ATTENTION: Do not remove machine from pallet

without using ramp, machine damage may occur.

ATTENTION: Due to the center of gravity being higher

(making it easier to tip machine) for machines without

batteries installed, use care when uncrating the

machine if it does not have batteries installed. Install

batteries before moving machine from pallet.

CONTENTS

CONTENTS

Introduction .....................................................2

Intended Use ...................................................2

Machine Data ..................................................2

Machine Serial Number Location ...............2

Uncrating Machine ..........................................2

Contents ................................................................3

Important Safety Instructions - Save These

Instructions ............................................................6

Operation .............................................................10

Machine Components ...................................11

Scrub Head Types.........................................11

Control Panel Components ...........................12

Pro-Membrane Control Panel Model ....12

Pro-Panel Control Model .......................13

Machine Symbols. .........................................14

Pro-Panel Symbols .......................................15

Installing Batteries .........................................16

Battery Specifi cations ...........................16

How The Machine Works ..............................17

Brush And Pad Information ...........................17

Machine Setup ..............................................18

Attaching Squeegee Assembly ................18

Installing Brushes / Pads ..........................19

Filling Solution Tank .................................20

Filling Severe Environment Detergent

Tank (Ec-H2o Model Option) ...............21

Ec-H2o Water Conditioning Cartridge

(Ec-H2o Model) ...................................22

Filling Automatic Battery Watering Tank

(Option) ...............................................23

Control Panel Operation ...............................24

Operation Of Controls -

Pro-Membrane Controls ......................24

1-Step Button ........................................24

Brush Pressure Button ..........................24

Solution Flow Button .............................24

Quiet-Mode Button (Option) ..................24

Severe Environment Button

(Ec-H2o Model Option) ....................25

Preset Zone Control Buttons .................25

Ec-H2o Button / Indicator (Option) ........26

Service Indicator ...................................26

Battery Discharge Indicator ...................26

Automatic Battery Watering Indicator

(Option) ............................................26

Brush Change Button ............................27

Vacuum Fan Button ..............................27

Operation Of Controls -

Pro-Panel Controls ..............................28

Home Screen ........................................28

Help Button ...........................................28

Login Screen .........................................28

Ec-H2o Indicator (Option) .....................29

1-Step Button ........................................29

Vacuum Fan Button ..............................29

Brush Pressure Button ..........................29

Solution Flow Button .............................30

Brush Change Button ............................30

Severe Environment Button

(Ec-H2o Model Option) ....................30

Quiet-Mode Button (Option) ..................31

Battery Discharge Indicator ...................31

Video Tutorial Button

(Operator Mode Home Screen) .......31

Preset Zone Control Buttons .................31

Service Indicator Button ........................32

Fault Screens ........................................32

Machine Operation ........................................34

Pre-Operation Checklist ...........................34

Operating Machine ...................................34

Double Scrubbing .....................................36

Emergency Shut-Off Button .....................37

While Operating Machine .........................37

Circuit Breaker Panel ...............................38

Hour Meter ...............................................38

Draining Tanks ..............................................39

Draining Recovery Tank ...........................39

Draining Solution Tank .............................40

Service Indicator Codes ................................41

On-Board Battery Charger Service

Indicator Codes ...................................42

Ec-H2o System Service Indicator Codes

(Option) ...............................................43

Maintenance ........................................................44

Maintenance Chart ...................................44

Machine Maintenance ...................................46

Yellow Touch Points ......................................46

After Daily Use .........................................46

After Weekly Use .....................................48

After Every 50 Hours Of Use ....................49

After Every 100 Hours Of Use ..................49

After Every 200 Hours Of Use ..................49

Electric Motors .........................................49

T350 9016417 (02-2021)

3

CONTENTS

Batteries ........................................................50

Maintenance-Free Batteries .....................50

Flooded (Wet) Lead-Acid Batteries ..........50

Checking Connections / Cleaning ............50

Charging Batteries ...................................51

Battery Charger Settings ..........................52

Changing On-Board Battery Charger

Settings (Pro-Membrane Model) ......52

Hydrolink® Battery Watering System

(Trojan® Battery Option) .....................54

Manual Battery Watering System

(Trojan® Battery Option) .....................55

Smart-Fill Automatic Battery Watering

(Option) ...............................................57

Battery Compartment Drain Valve ............58

Brush And Pad Replacement ........................59

Replacing Brush(Es) Or Pad(S) On

Pro-Panel Machines ............................59

Replacing Brush(Es) Or Pad(S) On

Pro-Membrane Panel Machines ..........61

Squeegee Blade Replacement .....................62

Replacing Squeegees On Machines With

20 In. (500 Mm) Scrub Heads .............62

Replacing Squeegees On Machines With

24 In. (600 Mm) Scrub Heads .............64

Ec-H2o Water Conditioning Cartridge

Replacement ..........................................66

Machine Jacking ...........................................67

Jacking Up The Front Of The Machine ....68

Jacking Up The Rear Of The Machine .....68

Pushing, Towing, And T ransporting The

Machine ..................................................69

Pushing And Towing The Machine ...........69

Transporting The Machine .......................69

Storing Machine ............................................70

Freeze Protection .....................................70

Machine Troubleshooting ..............................72

General Machine Dimensions/Capacties/

Performance ........................................................74

Supervisor Controls .............................................77

Pro-Membrane Control Panel Model ............77

Entering The Supervisor Control

Modes ..............................................77

Pro-Panel Controls Model .............................79

Entering The Supervisor Mode .............79

To Add / Edit Profi les .............................80

Enabling The Login Screen ...................82

Disabling The Login Screen ..................83

Changing The Factory-Assigned

Supervisor Login Code ....................84

Changing The Scrub Speed ..................85

Changing Preset Zone Control

Buttons .............................................85

Changing The On-Board Battery

Charger Settings

(Pro-Panel Model) ............................86

Calibrating The Touch ...........................86

4

T350 9016417 (02-2021)

CONTENTS

T350 9016417 (02-2021)

5

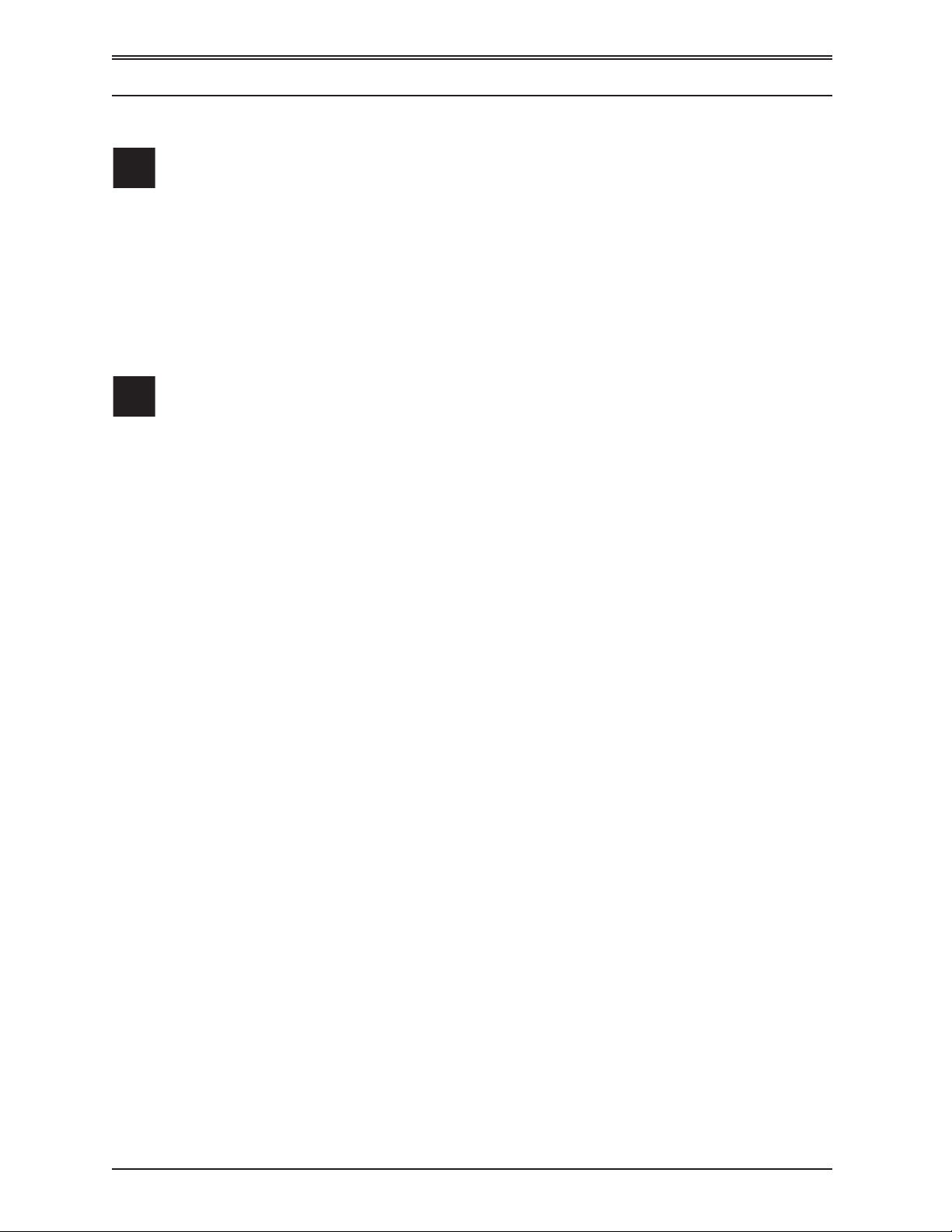

SAFETY

IMPORTANT SAFETY INSTRUCTIONS - SAVE THESE INSTRUCTIONS

The following precautions are used throughout this

manual as indicated in their descriptions:

WARNING: To warn of hazards or

unsafe practices that could result in

severe personal injury or death.

FOR SAFETY: To identify actions that must be

followed for safe operation of equipment.

The following information signals potentially

dangerous conditions to the operator. Know

when these conditions can exist. Locate all safety

devices on the machine. Report machine damage

or faulty operation immediately.

WARNING: To Reduce the Risk of Fire,

Explosion, Electric Shock or Injury:

- Read manual before operating machine.

- Do not use or pick up fl ammable materials

or reactive metals.

- Do not use near fl ammable liquids, vapors

or combustible dusts.

This machine is not equipped with an

explosion proof motor. The electric

motor will spark upon start up and during

operation which could cause a fl ash fi re

or explosion if machine is used in an

area where fl ammable vapors/liquids or

combustible dusts are present.

- Batteries emit hydrogen gas. Explosion

or fi re can result. Keep sparks and open

fl ame away when charging.

- Disconnect battery cables and charger

cord before cleaning and servicing

machine.

- Do not charge batteries with damaged

cord. Do not modify plug.

If the charger supply cord is damaged

or broken, it must be replaced by the

manufacturer or its service agent or a

similarly qualifi ed person in order to avoid

a hazard.

- Do not use outdoors. Store indoors.

IRIS Telemetry - This machine may be

equipped with technology that automatically

communicates over the cellular network. If the

machine will be operated where cell phone use

is restricted because of concerns related to

equipment interference, please contact a Tennant

representative for information on how to disable

the cellular communication functionality.

FOR SAFETY:

1. Do not operate machine:

- Unless trained and authorized.

- Unless operator manual is read and

understood.

- Unless mentally and physically capable of

following machine instructions.

- Under the infl uence of alcohol or drugs.

- While using a cell phone or other types of

electronic devices.

- With brake disabled.

- If not in proper operating condition.

- With pads or accessories not supplied or

approved by Tennant. The use of other pads

may impair safety.

- In outdoor areas. This machine is for indoor

use only.

- In areas where fl ammable vapors/liquids or

combustible dusts are present.

- In areas that are too dark to safely see the

controls or operate the machine.

- In areas with possible falling objects.

- Do not place weights or heavy objects on

the operator presence pedal and/or green

go pedal.

2. Before Starting Machine:

- Check machine for fl uid leaks.

- Make sure all safety devices are in place

and operate properly.

- Check steering for proper operation.

3. When using machine:

- Use only as described in this manual.

- Do not pick up burning or smoking debris,

such as cigarettes, matches or hot ashes.

- Go slowly on inclines and slippery surfaces.

- Follow site safety guidelines concerning wet

fl oors.

- Do not scrub on inclines that exceed 9%

grade or transport on inclines that exceed

9% grade.

- Do not turn on inclines or ramps

- Reduce speed when turning.

- Keep all parts of body inside operator station

while machine is moving.

6

T350 9016417 (02-2021)

SAFETY

- Always be aware of surroundings while

operating machine.

- Always allow head clearance when going

through doorways, low ceilings, and

overhangs.

- Drive slowly through doorways and narrow

openings, especially with the dual disk

model as squeegee extends beyond width

of machine.

- Do not access the video / help screens while

the machine is moving. (Pro-Panel)

- Use care when reversing machine.

- Keep children and unauthorized persons

away from machine.

- Do not allow machine to be used as a toy.

- Do not carry passengers on any part of the

machine.

- Report machine damage or faulty operation

immediately.

- Follow mixing, handling and disposal

instructions on chemical containers.

- Follow site safety guidelines concerning wet

fl oors.

4. Before leaving or servicing machine:

- Stop on level surface.

- Turn off machine and remove key.

5. When servicing machine:

- All work must be done with suffi cient lighting

and visibility.

- Keep work area well ventilated.

- Avoid moving parts. Do not wear loose

clothing, jewelry and secure long hair.

- Block machine tires before jacking machine

up.

- Jack machine up at designated locations

only. Support machine with jack stands.

- Use hoist or jack that will support the weight

of the machine.

- Do not push or tow the machine without an

operator controlling the machine.

- Do not push or tow the machine on inclines

with the brake disabled.

- Do not power spray or hose off machine

near electrical components.

- Disconnect battery connections and charger

cord before working on machine.

- Do not use incompatible battery chargers

as this may damage battery packs and

potentially cause a fi re.

- Inspect charger cord regularly for damage.

- Do not plug in charger if prongs are wet.

- Open recovery tank to vent batteries if

temperature is above 80ºF/27ºC when

charging batteries.

- Do not disconnect the off−board charger’s

DC cord from the machine receptacle when

the charger is operating. Arcing may result.

If the charger must be interrupted during

charging, disconnect the AC power supply

cord fi rst.

- Avoid contact with battery acid.

- Always follow site safety rules when

disposing battery compartment liquid.

- Keep all metal objects off batteries.

- Use a non−conductive battery removal

device.

- Use a hoist and adequate assistance when

lifting batteries.

- Battery installation must be done by trained

personnel.

- Follow site safety guidelines concerning

battery removal.

- All repairs must be performed by trained

personnel.

- Do not modify the machine from its original

design.

- Use Tennant supplied or approved

replacement parts.

- Wear personal protective equipment as

needed and where recommended in this

manual.

For Safety: wear protective gloves.

For Safety: wear eye protection.

6. When loading/unloading machine onto/off truck

or trailer:

- Drain tanks before loading machine.

- Use a ramp that can support the machine

weight and operator.

- Do not drive on a slippery ramp.

- Do not operate the machine on a ramp

incline that exceeds an 18% grade level.

- Use a winch if ramp incline exceeds an 18%

grade level.

- Lower scrub head and remove squeegee

before tying down machine.

- Block machine tires.

- Tie machine down to truck or trailer.

T350 9016417 (02-2021)

7

SAFETY

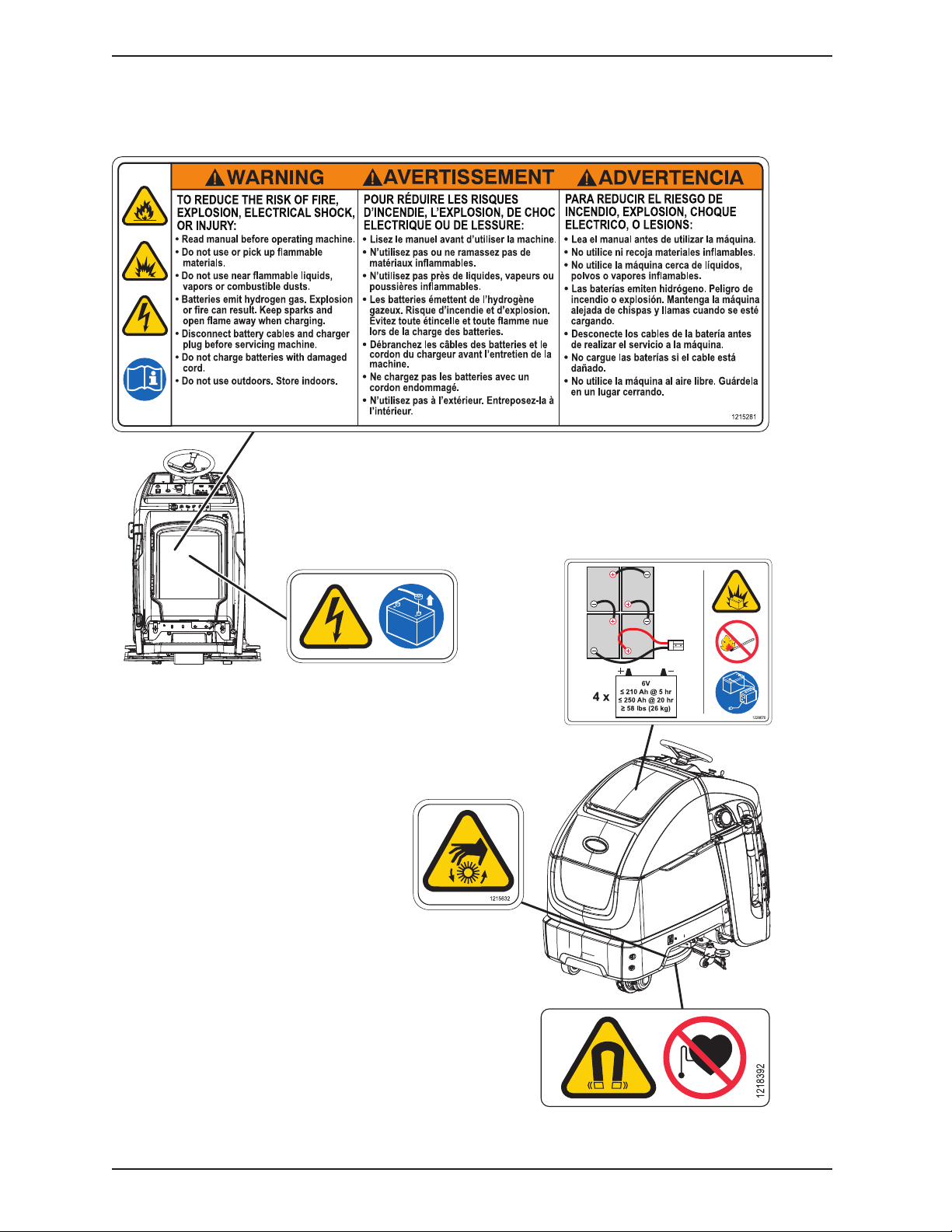

The following safety labels are mounted on the

machine in the locations indicated. Replace

damaged / missing labels.

WARNING LABEL - Located on access panel.

WARNING LABEL - Electrical

hazard. Disconnect battery

cables before servicing

machine.

Located on on-board battery

charger mounting plate.

WARNING LABEL - Spinning

brush. Keep hands away.

Located on top of scrub head.

WARNING LABEL - Batteries emit

hydrogen gas. Explosion or fi re can

result. Keep sparks and open fl ame

away when charging.

Located on bottom of recovery tank.

1204364

WARNING LABEL - Magnetic Field Hazard.

Magnetic pad driver/brush can be harmful to

those with pacemakers or medical implants.

Located on Insta-Click magnetic pad driver/brush.

8

T350 9016417 (02-2021)

SAFETY

T350 9016417 (02-2021)

9

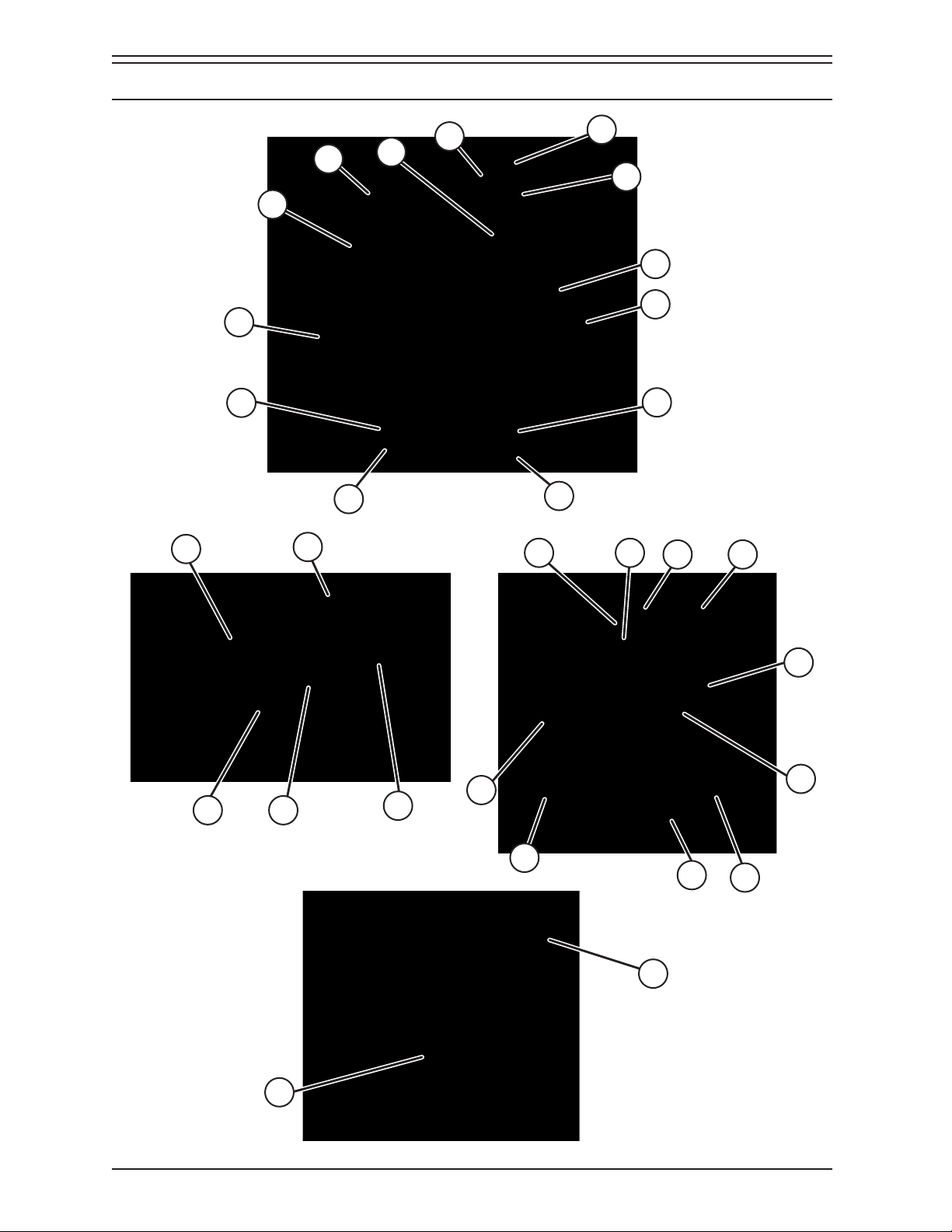

OPERATION

OPERATION

8

27

12

25

21 22

15

14

11

26

6

5

1

7

16

13

30

24

23

19

28

3

2

17

4

29

9

18

10

20

10

T350 9016417 (02-2021)

OPERATION

MACHINE COMPONENTS

1. Steering Wheel

2. Key switch

3. Forward / Reverse switch

4. Emergency shut-off button

5. Hour meter

6. Horn button

7. Control panel

8. Speed knob

9. Operator presence pedal

10. Green go pedal

11. Solution tank

12. Solution tank fi ll port

13. Solution tank level / drain hose

14. Recovery tank

15. Recovery tank cover

16. Recovery tank drain hose

17. Battery compartment

18. Automatic battery watering tank (option)

19. Severe Environment detergent tank

(option - with ec-H2O option only)

20. Detergent mixing ratio knob

(option - with ec-H2O option only)

21. ec-H2O module (option)

22. ec-H2O water conditioning cartridge

(option)

23. On-board battery charger (option)

24. Circuit breaker panel

25. Squeegee assembly

26. Scrub head

27. Scrub head skirt

28. On-board battery charger power cable

29. Access panel

30. Double scrub caster knob

SCRUB HEAD TYPES

20 in. 500 mm Single Disk

T350 9016417 (02-2021)

24 in. / 600 mm Dual Disk

11

OPERATION

CONTROL PANEL COMPONENTS

PRO-MEMBRANE CONTROL PANEL MODEL

1

14

10

1. Brush change button

2. Brush pressure button

3. 1-Step button

4. Solution fl ow button

5. Preset zone control buttons

6. Solution fl ow indicator

7. Vacuum fan button

8. Brush pressure indicator

9. Service indicator

10. ec-H2O Button (option)

11. Automatic battery watering indicator

(option)

12. Severe Environment button (option)

13. Quiet-mode button (option)

14. Battery discharge / fault code indicator

2

9111213

3 4

5

6

5

78

12

T350 9016417 (02-2021)

PRO-PANEL CONTROL MODEL

OPERATION

18

19

1

10

2 3 4

9

1617

15

5

7

8

11

12

6

1314

1. Help button

2. Battery discharge indicator (BDI)

3. Severe Environment button (option)

4. ec-H2O button / indicator (option)

5. Service indicator / button

6. Solution fl ow button

7. Quiet mode button (option)

8. 1-Step button

9. Vacuum fan button

10. Brush pressure button

11. Solution fl ow increase button

12. Solution fl ow indicator

13. Solution fl ow decrease button

14. Brush change button

15. Preset zone control buttons

16. Video tutorial button

17. Brush pressure decrease button

18. Brush pressure indicator

19. Brush increase button

T350 9016417 (02-2021)

13

OPERATION

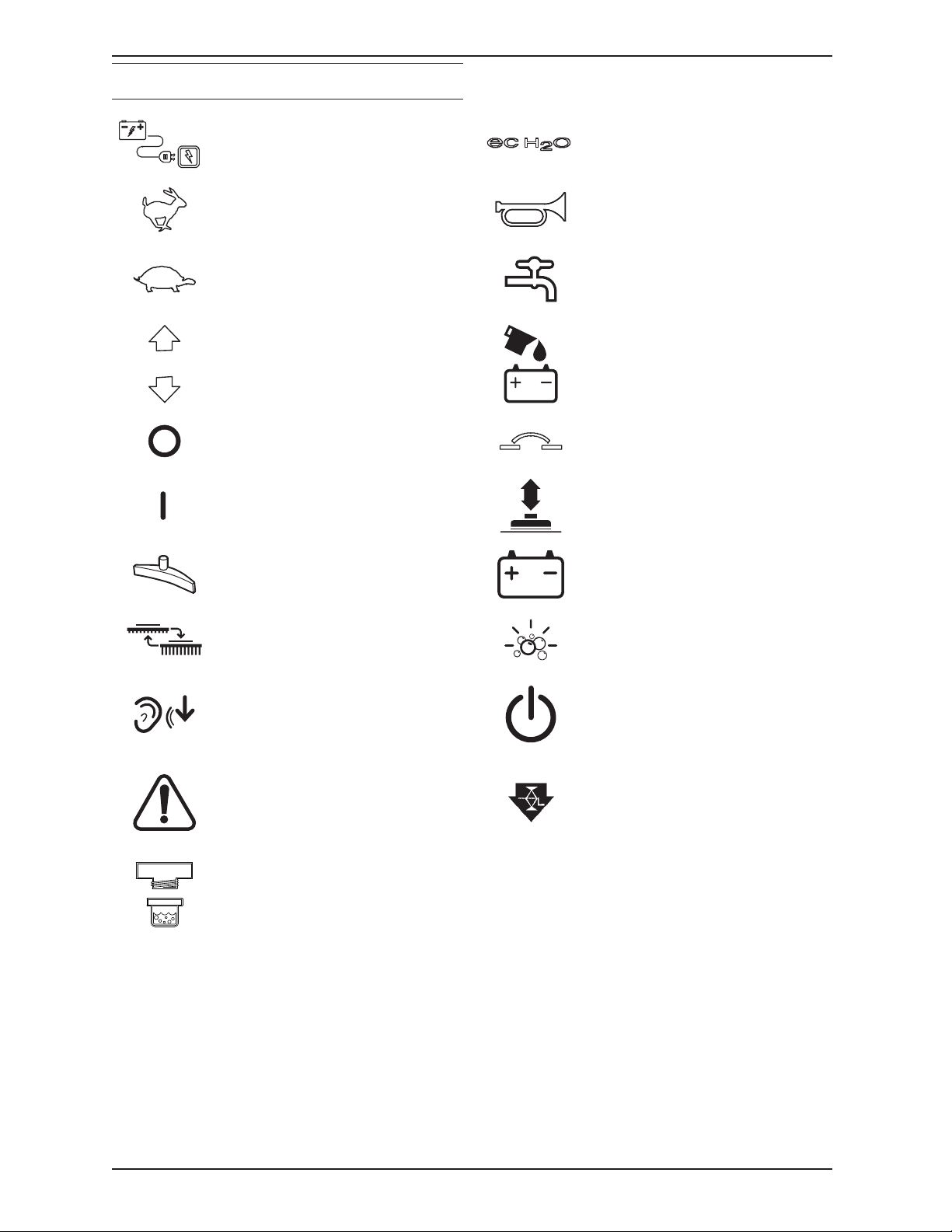

MACHINE SYMBOLS.

Battery charger ec-H2O scrubbing (option)

Fast scrub speed Horn

Slow scrub speed Solution fl ow

Direction (forward / reverse)

Key Off Circuit breaker

Key On Brush pressure

Vacuum fan Battery charge

Change brush Severe Environment (option)

Quiet mode (option) 1-Step

Service indicator Jack point

Automatic battery watering

(option)

14

Filter location

T350 9016417 (02-2021)

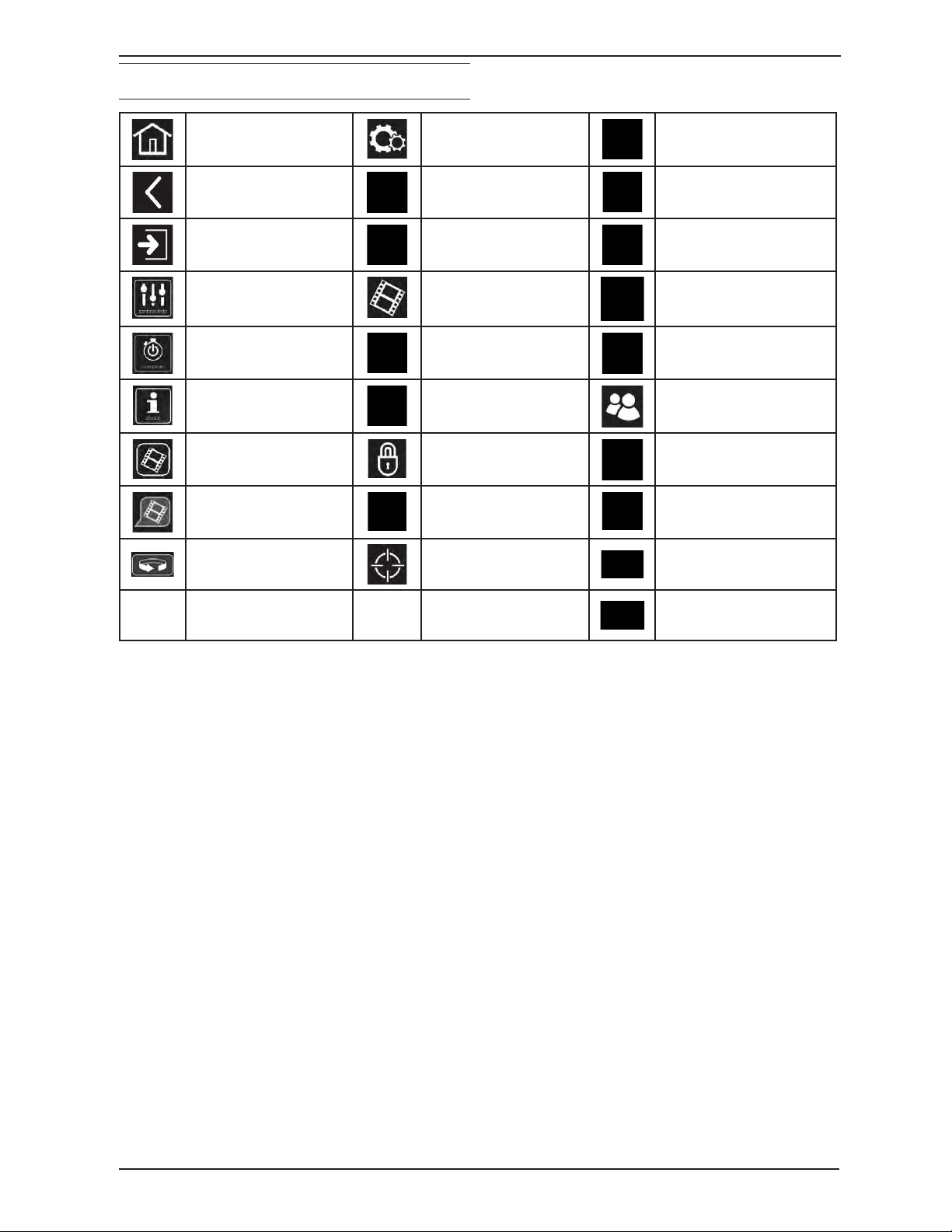

PRO-PANEL SYMBOLS

Home screen Machine Settings Factory reset

Back arrow Operator videos Operator

Login Supervisor menu Supervisor

Control help Video help Add profi le

Start-up video Add / Edit profi les Edit profi le

About Battery selection Copy profi le

Video list button Enable login Delete profi le

OPERATION

Video button Disable login User login

Video rotate view Calibrate touch Enter

Backspace

T350 9016417 (02-2021)

15

OPERATION

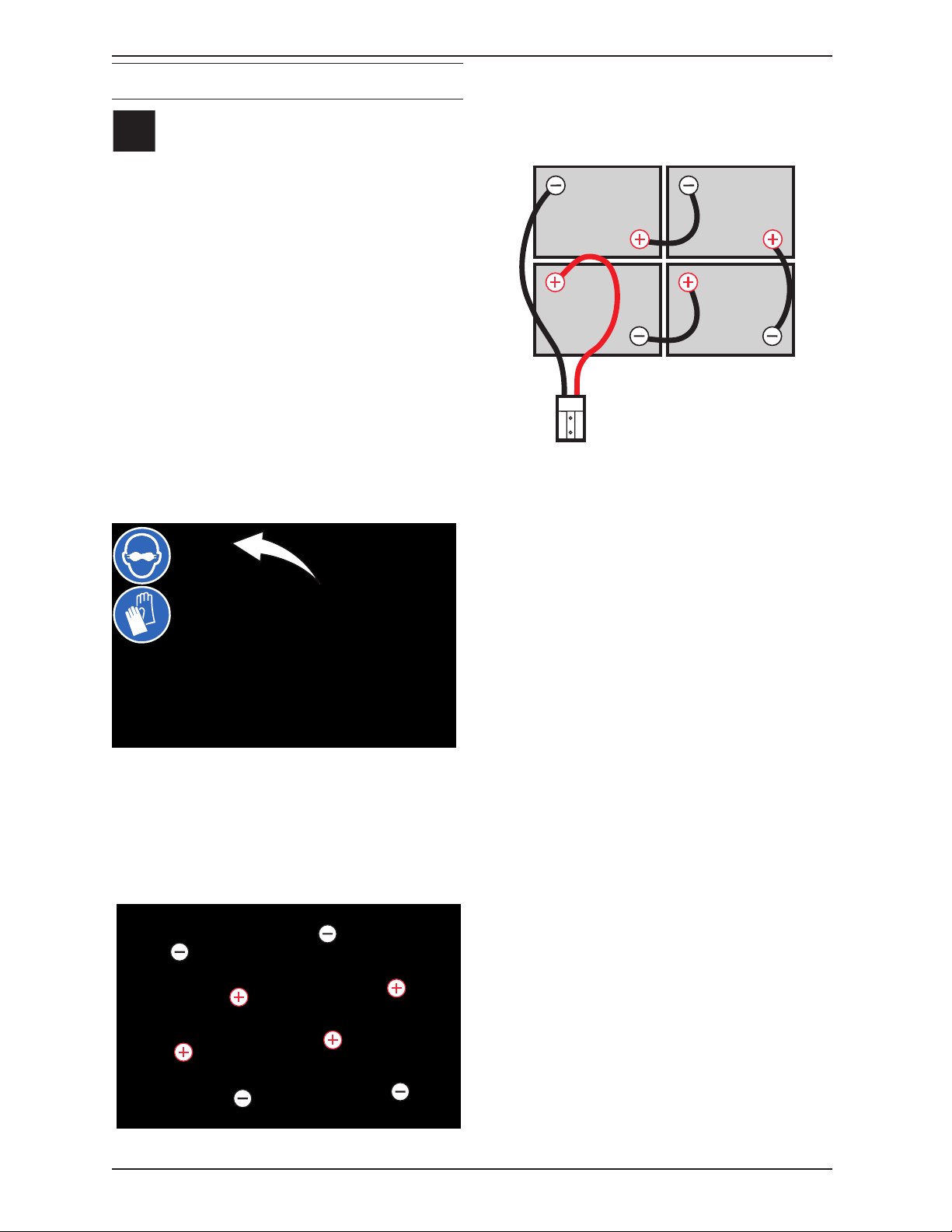

INSTALLING BATTERIES

WARNING: Batteries emit hydrogen

gas. Explosion or fi re can result. Keep

sparks and open fl ame away when

charging.

FOR SAFETY: When servicing machine, wear

appropriate personal protection equipment as

needed. Avoid contact with battery acid.

BATTERY SPECIFICATIONS

Requires four 6 volt deep-cycle batteries,

≤ 240 Ah @ 20 hr.

Contact distributor or Tennant for battery

recommendations.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, turn off

machine, and remove key.

1. Lift the recovery tank to access the battery

compartment.

3. Using the supplied battery post boots, connect

the cables to battery posts, RED TO POSITIVE

(+) & BLACK TO NEGATIVE (-). Tighten

cable connections to batteries per battery

manufacturer specifi cations.

BLACK

RED

IMPORTANT: Before charging batteries, make

sure the battery charger and the machine’s

battery discharge indicator are properly set for

battery type. Failure to properly set will result

in battery damage. See BATTERY CHARGER

SETTINGS.

2. Carefully install the batteries into the battery

compartment tray and arrange the battery

posts as shown.

FOR SAFETY: When servicing machine, use

a hoist or adequate assistance when lifting

batteries.

ATTENTION: Do not disconnect battery cables

while charger is plugged in, circuit board

damage may result.

ATTENTION: Batteries serve as a counterweight. Always maintain the minimum

counterweight to ensure machine stability and

traction.

IRIS Battery Charging Metrics Notifi cation:

Machines equipped with capability to report

battery charging data via IRIS are supplied with

a charger and set of batteries from the factory.

When a battery reaches its end of life and must

be replaced, Tennant highly recommends that

the same battery type be used to continue to

maximize the machines performance. In the event

a battery with a different amp hour (AH), type

(Flooded, AGM, Gel), or manufacturer is selected

for replacement please contact Tennant technical

service department for assistance in determining

the feasibility of the replacement batteries and

if so, selecting the correct charging profi le.

Availability of IRIS battery metric reporting is not

guaranteed with third party supplied batteries.

16

NOTE: If there is liquid in battery compartment,

drain battery compartment before installing

batteries. See BATTERY COMPARTMENT DRAIN

VALVE.

T350 9016417 (02-2021)

OPERATION

HOW THE MACHINE WORKS

Conventional scrubbing:

When using the conventional scrubbing mode,

water and detergent mixture from the solution tank

fl ows to the fl oor and the rotating brush(es)/pad(s)

scrub the fl oor clean. As the machine moves

forward, the squeegee with vacuum suction picks

up the dirty solution from the fl oor into the recovery

tank.

ec-H2O NanoClean Technology (option):

When using the ec-H2O NanoClean technology,

normal water passes through a module where it

is electrically converted into a cleaning solution.

The electrically converted water attacks the dirt,

allowing the machine to easily scrub away the

suspended soil. The converted water then returns

to normal water in the recovery tank.

BRUSH AND PAD INFORMATION

For best results, use the appropriate brush or

pad for the cleaning application. Listed below are

brushes and pads and the applications for which

each is best suited.

Stripping pad (Brown) - For stripping of fl oor

fi nish to prepare the fl oor for recoating.

Polypropylene Side Brush − For general

sweeping of light to medium debris.

Heavy duty stripping pad (Black) - Used for

aggressive stripping of heavy fi nishes/sealers, or

very heavy duty scrubbing.

Surface preparation pad (Maroon) - Used for

very aggressive chemical free removal of fl oor

fi nish to prepare the fl oor for re-coating.

Tufted pad driver - Standard pad driver has short

bristles, or “tufts,” on the back to hold the pad in

place. This driver works with all Tennant pads

except the black high productivity pad.

NOTE: The amount and type of soilage play an

important role in determining the type of brush or

pad to use. Contact a Tennant representative for

specifi c recommendations.

Soft nylon bristle scrub brush (White) -

Recommended for cleaning coated fl oors without

removing fi nish. Cleans without scuffi ng.

Polypropylene bristle scrub brush (Black) - This

general purpose polypropylene bristle scrub brush

is used for scrubbing lightly compacted soilage.

This brush works well for maintaining concrete,

wood and grouted tile fl oors.

Super abrasive bristle scrub brush (Gray) -

Nylon fi ber impregnated with abrasive grit to

remove stains and soilage. Strong action on any

surface. Performs well on buildup, grease, or tire

marks.

Polishing pad (White) - For maintaining highly

polished or burnished fl oors.

Buffi ng pad (Red) - For light duty scrubbing

without removing fl oor fi nish.

Scrubbing pad (Blue) − For medium to heavy

duty scrubbing. Removes dirt, spills, and scuffs.

T350 9016417 (02-2021)

17

OPERATION

MACHINE SETUP

ATTACHING SQUEEGEE ASSEMBLY

1. Lower the scrub head.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, turn off

machine, and remove key.

2. Rotate the squeegee carriage assembly to

the right side of the machine to access the

squeegee carriage.

5. Machines with 20 in. (500 mm) scrub

heads only: Be sure both squeegee tabs are

positioned above the scrub head skirt.

6. Connect the vacuum hose to the squeegee

assembly.

3. Align the squeegee carriage pins into the

squeegee assembly bracket.

4. Slide the squeegee assembly onto the

squeegee carriage until both squeegee

carriage pins are secured in the bracket.

7. Rotate and center the squeegee assembly

underneath the machine.

18

T350 9016417 (02-2021)

OPERATION

INSTALLING BRUSHES / PADS

1. Stand with both feet on the operator platform

(do not press the green go pedal), turn the

key to the ON position, and press the brush

change button to raise the scrub head to the

correct level for installing the pad(s).

Machines with Pro-Membrane controls:

Wait for the green LED light to stop fl ashing

and remain illuminated. See REPLACING

BRUSH(ES) PAD(S) ON PRO-MEMBRANE

MACHINES.

Machines with Pro-Panel controls: Follow

prompts on screen and wait for green

check mark to appear in the display. See

REPLACING BRUSH(ES) PAD(S) ON PROPANEL MACHINES.

WARNING: Magnetic Field Hazard.

Magnetic pad driver/brush can be

harmful to those with pacemakers or

medical implants.

Machines with 3-lug brush hubs: Position

the three lugs into the motor hub slots and

give the pad driver / brush a quick counterclockwise turn to engage hub.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, turn off

machine, and remove key.

2. Attach the pad to the pad driver before

installing the driver. Secure pad with centerlock.

3. Machines with magnetic brushes or pad

drivers: Position the brush under the scrub

head and lift the brush up onto the scrub head

until the magnet in the scrub head secures the

brush.

Replace pads or brushes when they no longer

clean effectively.

4. To remove the pad driver(s) / brush(es), repeat

Step 1, and then remove the brushes from

under the scrub head.

T350 9016417 (02-2021)

19

OPERATION

FILLING SOLUTION TANK

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, turn off

machine, and remove key.

1. Remove the cap from the solution tank.

2. Insert the fi ll hose into the yellow strainer and

ensure the hose is held securely into place in

the strainer.

3. Fill the solution tank with water until level

reaches the 53 L (14 G) mark on the solution

tank indicator.

ec-H2O Scrubbing (Option)- Fill solution

tank with only cool clean water (less than

70°F/21°C). Do not add conventional fl oor

cleaning detergents. An ec-H2O system fault

will occur if cleaning detergents are added.

Conventional Scrubbing - Fill solution tank

with water (not to exceed 60°C/140°F). Pour

a recommended cleaning detergent into the

solution tank according to mixing instructions

on the container.

ATTENTION: For Conventional Scrubbing, only

use commercially approved cleaning detergents.

Machine damage due to improper detergent usage

will void the manufacturer’s warranty.

WARNING: Flammable materials can

cause an explosion or fi re. Do not use

fl ammable materials in tank(s).

NOTE: Do not use the ec-H2O system when

there are conventional cleaning detergents in the

solution tank. Drain, rinse, and refi ll the solution

tank with clean cool water before operating the ecH2O system. Conventional cleaning detergents will

cause an ec-H2O system fault.

4. Turn off the water supply and remove the fi ll

hose from the yellow strainer.

5. Replace the cap on the solution tank.

20

T350 9016417 (02-2021)

OPERATION

FILLING SEVERE ENVIRONMENT DETERGENT

TANK (ec-H2O MODEL OPTION)

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, turn off

machine, and remove key.

1. Pull the access panel open to access the

Severe Environment tank.

2. Remove the Severe Environment tank from the

machine and set it on the fl oor.

3. Remove black cap from Severe Environment

tank and add a recommended cleaning

detergent at full concentration. Do not add

water.

WARNING: Flammable materials can

cause an explosion or fi re. Do not use

fl ammable materials in tank(s).

ATTENTION: Only use commercially approved

cleaning detergents in the Severe Environment

tank. Do not use cleaners based with d-limonene.

Machine damage due to improper detergent usage

will void the manufacturer’s warranty.

NOTE: Remove the Severe Environment tank from

the machine before fi lling the tank with detergent

to prevent damaging electronic components.

NOTE: To prevent from running out of detergent

while operating, it is recommended to refi ll the

Severe Environment tank when refi lling the

solution tank.

4. Replace cap on the Severe Environment tank.

5. Adjust the detergent mixing ratio knob

according to the cleaning detergent’s mixing

instructions.

T350 9016417 (02-2021)

21

OPERATION

ec-H2O WATER CONDITIONING CARTRIDGE

(ec-H2O MODEL)

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, turn off

machine, and remove key.

The ec-H2O system is equipped with a water

conditioning cartridge. The cartridge is designed

to protect the machine’s plumbing system from

potential scaling.

The cartridge is required to be replaced when it

reaches its maximum water usage or expiration

time on when the cartridge was activated, which

ever comes fi rst.

Depending on machine usage a new cartridge can

last anywhere from 12 to 24 months.

All cartridges are labeled with a manufacture date.

The shelf-life of an un-installed cartridge is one

year from manufacture date. For new cartridge

replacement, the ec-H2O module timer must be

reset. See ec-H2O WATER CONDITIONING

CARTRIDGE REPLACEMENT.

Pro-Panel Models

ATTENTION: During fi rst time use and after

replacing the water conditioning cartridge, the

ec-H2O system will automatically override the

selected solution fl ow rate for up to 75 minutes.

The control panel will signal the following code

when it’s time to replace the cartridge. The ec-H2O

icon will begin to blink blue and red. See SERVICE

INDICATOR CODES for further details.

Pro-Membrane Models

22

T350 9016417 (02-2021)

OPERATION

FILLING AUTOMATIC BATTERY WATERING

TANK (OPTION)

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, turn off

machine, and remove key.

1. Lift the recovery tank to access the automatic

battery watering tank. Drain recovery tank

before lifting tank.

2. Reposition the automatic battery watering tank

so that it can be easily fi lled.

4. Pour distilled water into tank. To avoid getting

water on sensitive components, use a funnel to

fi ll automatic battery watering tank.

FOR SAFETY: When using machine, only

use distilled water when fi lling the automatic

battery watering tank.

5. When the tank needs refi lling, the automatic

battery watering indicator will alert user to

add distilled water. See CONTROL PANEL

OPERATION for further details.

Pro-Membrane Model

3. Remove the blue cap from the automatic

battery watering tank.

T350 9016417 (02-2021)

Pro-Panel Model

6. Replace blue cap on automatic battery

watering tank and return the automatic battery

watering tank to the upright stowed position.

23

OPERATION

CONTROL PANEL OPERATION

The control panel operation can be set up with

lockout functionality by using the Supervisor

Controls feature. This will prevent the operator

from changing or saving the settings. See

SUPERVISOR CONTROLS instructions at the

back of the manual.

The supervisor controls feature will lower machine

variability for consistent, repeatable cleaning

results, provide machine quality assurance

regardless of user experience, and reduce user

training requirements.

OPERATION OF CONTROLS PRO-MEMBRANE CONTROLS

1-STEP BUTTON

With key turned on, press the 1-Step button to

activate the scrub function. The scrub head and

squeegee will lower to fl oor. Press button again

to stop the scrub function and to raise scrub head

and squeegee.

SOLUTION FLOW BUTTON

Press the solution fl ow button to increase or

decrease the solution fl ow rate. The solution fl ow

indicator will display fl ow setting. No LED = No

fl ow, One LED = Low fl ow, two LED’s = Medium

fl ow, three LED’s = High fl ow.

QUIET-MODE BUTTON (OPTION)

Press the Quiet-Mode button to reduce the

vacuum motor sound. The LED will illuminate

when activated. Press button again to turn off.

BRUSH PRESSURE BUTTON

Press the brush pressure button to increase or

decrease the brush pressure. The brush pressure

indicator will display the pressure setting. One LED

= Low pressure and two LED’s = High pressure.

24

T350 9016417 (02-2021)

OPERATION

SEVERE ENVIRONMENT BUTTON

(ec-H2O MODEL OPTION)

NOTE: When the Severe Environment mode is

turned on, the ec-H2O system will automatically

turn off and the brush pressure and solution

fl ow settings will increase to the high settings.

When turned off, the settings will revert back

to the original settings. When operating the

Severe Environment mode for extended periods,

if desired, the solution fl ow rate and the down

pressure can be decreased to a lower setting

to conserve solution and detergent usage and

optimize battery run time.

Press the Severe Environment button to deliver

a boost of cleaning detergent for areas with

excessive soil buildup.

Press button one time for a 30 second boost. A

green LED in the corner will blink slowly when

dispensing. During the last 5 seconds, the LED

will blink rapidly as an alert that the dispensing is

about to stop.

To deliver a continuous detergent boost, press and

hold button for 3 seconds until green LED turns

solid green. Press button at anytime to turn off.

PRESET ZONE CONTROL BUTTONS

Note: Zone 3 is only available on machines built

before serial number 11003113.

Use the zone control buttons to preset up to three

zones with different solution fl ow rates, brush

pressures, scrub speeds and scrub modes.

Zone 1 = Preset Zone Control Button 1

Zone 2 = Preset Zone Control Button 2

Zone 3 = Preset Zone Control Buttons 1 & 2

The zone control buttons are factory preset for

different scrubbing applications. To use Zone

3, press zone buttons 1 & 2 at the same time.

A green LED in the corner will turn on when

activated.

To alert user when Severe Environment tank is

empty, the bubbles icon will blink for 15 seconds. If

button is pressed when tank is empty, the bubbles

icon will continue to blink for 15 seconds until tank

is refi lled.

To preset the zone control buttons for different

scrubbing applications, select the desired settings

from list below, then press and hold the zone

button until the green LED blinks three times to

save preset. To preset zone 3, press and hold

zone buttons 1 & 2 at the same time.

- Brush pressure setting

- Solution fl ow rate

- Quiet-Mode on or off

- ec-H2O system on or off (option)

- Severe Environment mode on or off (option)

- Maximum scrub speed (see Supervisor

Controls)

NOTE: The Severe Environment mode and

ec-H2O system cannot be preset together.

T350 9016417 (02-2021)

25

OPERATION

ec-H2O BUTTON / INDICATOR (OPTION)

The ec-H2O system automatically turns on at each

key start. A blue ec-H2O indicator appears when

machine is equipped with the ec-H2O option. The

green LED illuminates when ec-H2O is activated.

To turn off the ec-H2O system, press the ec-H2O

button. The green LED indicator will disappear.

ec-H2O INDICATOR CONDITION

Solid green Normal operation

Blinking blue/red Water conditioning

cartridge expired.

Replace cartridge.

Solid or blinking red A system fault has

occurred. See Service

Indicator Codes.

NOTE: If a fault occurs to the ec-H2O system,

the machine may automatically turn off the ecH2O system and convert over to conventional

scrubbing. The service indicator icon will remain

solid red or continue to blink red until the ec-H2O

fault is serviced.

BATTERY DISCHARGE INDICATOR

The battery discharge indicator (BDI) displays the

charge level of the batteries while the machine is

operating. When the batteries are fully charged,

all fi ve indicators are lit. When the discharge level

reaches the red light, stop scrubbing and recharge

the batteries. When the red light begins to fl ash,

the scrub function will be disabled to protect the

batteries from total discharge. The machine will

still propel when the red light is fl ashing. This will

allow user to transport the machine to the charging

station.

AUTOMATIC BATTERY WATERING INDICATOR

(OPTION)

The automatic battery watering indicator will fl ash

when the battery watering tank is empty and needs

refi lling. To protect the batteries from damage, the

machine’s scrub function will be disabled after 10

hours of additional use if tank is not refi lled. When

the indicator fl ashes rapidly, the scrub function

will be disabled. Add distilled water and restart

key to clear the fl ashing indicator. See FILLING

AUTOMATIC BATTERY WATERING TANK.

SERVICE INDICATOR

When the machine or on-board battery charger

detects a fault, the service indicator will light up

and begin fl ashing. The battery discharge indicator

lights will also fl ash a fault code. See SERVICE

INDICATOR CODES to diagnose machine fault.

26

T350 9016417 (02-2021)

Loading...

Loading...