Tennant S30 User Manual

S30

*

(Gas/LPG)

Sweeper

Operator Manual

SweepMaxR Plus

TennantTrueR Parts

IRISR a Tennant Technology

North America / International

For the latest parts manuals and other

language Operator manuals, visit:

www.tennantco.com/manuals

9004080

Rev. 12 (4−2017)

*9004080

INTRODUCTION

This manual is furnished with each new model. It provides necessary operation and maintenance instructions.

Read this manual completely and understand

the machine before operating or servicing it.

This machine will provide excellent service. However, the best results will be obtained at minimum costs if:

S The machine is operated with reasonable care.

S The machine is maintained regularly - per the machine maintenance instructions provided.

S The machine is maintained with manufacturer supplied or equivalent parts.

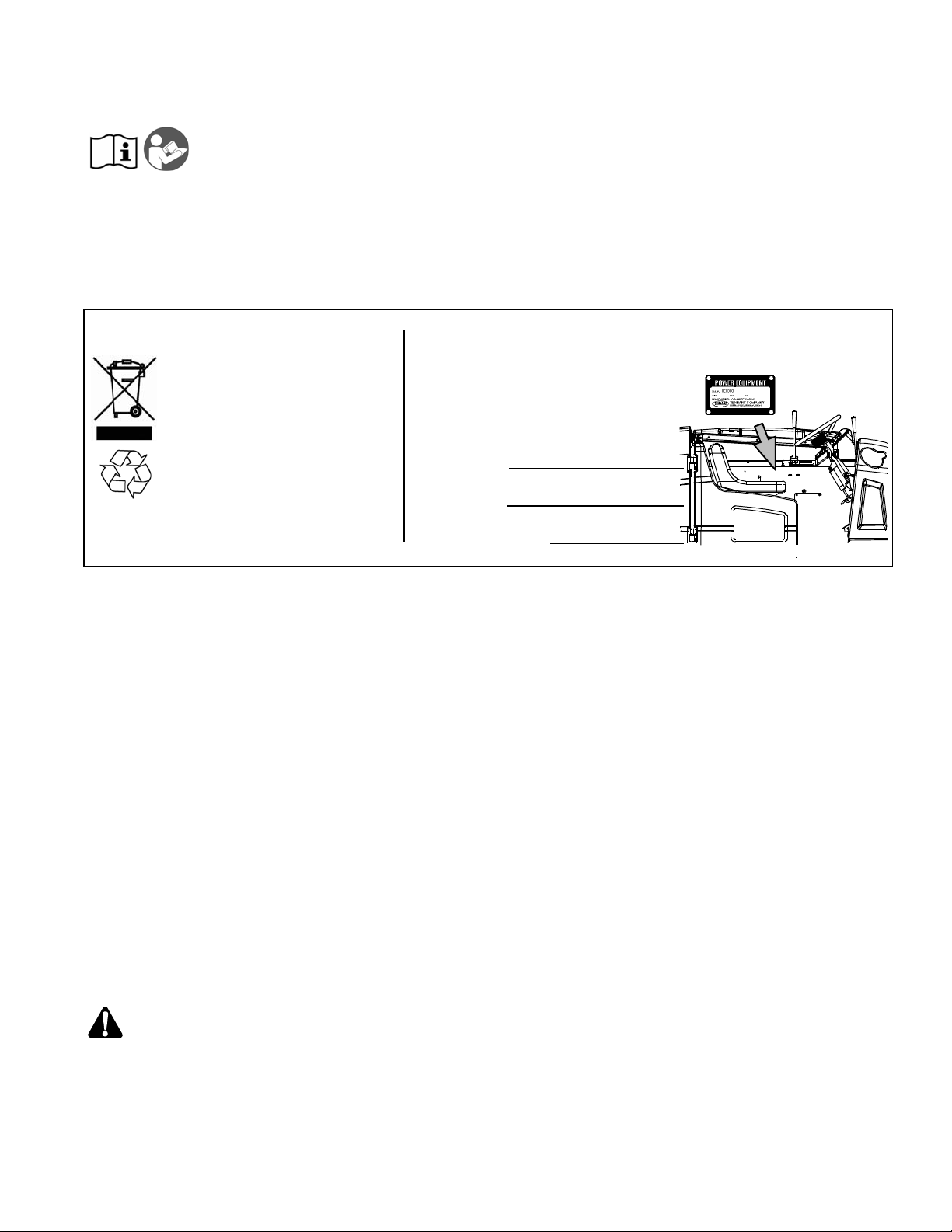

PROTECT THE ENVIRONMENT

Please dispose of packaging

materials, used components

Please fill out at time of installation

for future reference.

MACHINE DATA

such as batteries and fluids in

an environmentally safe way according to local waste disposal

regulations.

Always remember to recycle.

Model No. -

Serial No. -

Installation Date -

INTENDED USE

The S30 is an industrial rider machine designed to sweep hard surfaces (concrete, asphalt, stone, synthetic, etc).

Typical applications include industrial warehouses, manufacturing facilities, distribution facilities, stadiums, arenas,

convention centers, parking facilities, transportation terminals, and construction sites. Do not use this machine on soil,

grass, artificial turf, or carpeted surfaces. This machine can be used both indoors and outdoors, but ensure there is

adequate ventilation if used indoors. Do not use this machine other than described in this Operator Manual.

Tennant Company

PO Box 1452

Minneapolis, MN 55440

Phone: (800) 553- 8033

www.tennantco.com

CALIFORNIA PROPOSITION 65 WARNING:

Engine exhaust from this product contains chemicals known to the State of California to cause cancer,

birth defects, or other reproductive harm.

Thermo- Sentry, 1- STEP, EasyOpen, MaxPro, InstantAccess, II- Speed, Perma- Filter, Duramer, Lower Total Cost of Ownership, Touch- N- Go,

Watershield Dust Control and Cab Forward ErgoSpace are trademarks of Tennant Company.

Specifications and parts are subject to change without notice.

Original Instructions, Copyright E 2008, 2009, 2010, 2012, 2013 - 2017 TENNANT Company, Printed in U.S.A.

CONTENTS

CONTENTS

Safety Precautions 3.......................

Operation 7...............................

Machine Components 7..................

Controls And Instruments 8...............

Touch Panel (S30 Xp And X4) 9...........

Symbol Definitions 10.....................

Operation Of Controls 11..................

Directional Pedal 11...................

Brake Pedal 11.......................

Parking Brake Pedal 11................

Steering Column Tilt Pedal 11...........

Fuel Gauge 12........................

Gasoline Machines 12.................

LPG Machines 12.....................

Hour Meter 13........................

Supervisor Control Buttons

(S30 XP and X4) 13................

Engine Speed Controls 13..............

Vacuum Fan Controls (S30) 14..........

Vacuum Fan Controls (S30 XP and X4) 14

Contrast Control Button

(S30 XP and X4) 14................

Filter Shaker Control (S30) 15...........

Filter Shaker Control (S30 XP and X4) 15.

Operating / Hazard Light Switch 15......

Side Brush Light Switch (Option) 15......

Hopper Access Door 16................

Operator Seat 17......................

Deluxe Suspension Seat 17.............

Seat Belts 17.........................

Brush Information 18.....................

How The Machine Works 18...............

Pre−Operation Checklist 19................

Changing The LPG Tank 20...............

Starting The Machine 21..................

Turning Off The Machine 21...............

While Operating The Machine 22...........

Sweeping (S30) 23.......................

Sweeping (S30 XP and X4) 24.............

Emptying The Hopper 25..................

Engaging The Hopper Support Bar 26.......

Disengaging The Hopper Support Bar 27....

Display Module Fault Indicators (S30) 28....

Fault Indicator(s) (S30 XP and X4) 29.......

Dash Fault Indicators 30..................

Options 31..............................

Wand (Option) 31.....................

Heater / Air Conditioner

Controls (Option) 32................

Windshield Wiper Switch (Option) 32.....

Cab Light Switch (Option) 32............

Wet Side Brush Dust Control (Option) 33.

Tower Bumpers (Option) 34.............

Turn Signal Switch (Option) 34..........

Machine Troubleshooting 35...............

Page

Page

Maintenance 36.............................

Maintenance Chart 36....................

Lubrication 39...........................

Engine Oil 39..........................

Rear Wheel Support 39................

Steering Cylinder Bearing 39............

Hopper Lift Arm Bearings 39............

Front Wheel Bearings 39...............

Hydraulics 40............................

Hydraulic Fluid 41.....................

Hydraulic Hoses 41....................

Engine 42...............................

Cooling System 42....................

Air Filter Indicator 44...................

Air Filter 44............................

Fuel Filter (Gasoline) 45................

Fuel Filter (Lpg) 45....................

Electronic Pressure Regulator (Lpg)

(S/N 000000 − 005699) 46...........

Lpg Vaporizer 46......................

Spark Plugs − Gm Engines

(S/N 000000 − 005699) 46..........

Spark Plugs − Mitsubishi Engines

(S/N 005700 − ) 46..............

Engine Belt 47.........................

Timing Belt − Gm Engines

(S/N 000000 − 005699) 47..........

Camshaft And Balance Shaft Belts −

Mitsubishi Engines

(S/N 005700 − ) 47...........

Pcv System 47.........................

Battery 47...............................

Fuses And Relays 48.....................

Relay Panel Fuses And Relays 48.......

Engine Harness Fuses And Relays 49...

Cab Fuses (Cab Option) 49.............

Removing And Inspecting The Dust Filter

(S/N 000000 − 006500) 50..............

Removing And Inspecting The Dust Filter

(S/N 006501 − ) 51...............

Cleaning The Dust Filter 52................

Cleaning The Cyclone Assembly

(S/N 006501 − ) 52...............

Main Brush 53...........................

Replacing Or Rotating The Main Brush 53

Checking The Main Brush Pattern 55....

Adjusting The Main Brush Taper 55......

Adjusting The Main Brush Width 56......

Side Brush 56...........................

Replacing The Side Brush 56...........

Adjusting The Side Brush Pattern 57.....

Rotating And Replacing The Side

Brush Guard 57....................

S30 Gas/LPG 9004080 (4−2017)

1

CONTENTS

Skirts And Flaps 58.......................

Hopper Skirts 58......................

Brush Door Skirts 58...................

Rear Skirts 58........................

Recirculation Flap 58..................

Seals 59................................

Brush Door Seals 59...................

Hopper Seals 59......................

Hopper Inspection Door Seals 59........

Filter Chamber Inlet Seal 59............

Cyclonic Pre−Filter Seals 60............

Dust Return Seals

(S/N 000000 − 006500) 60...........

Dust Filter Seals

(S/N 000000 − 006500) 60...........

Vacuum Wand Door Seals (Option) 60...

Cyclonic Dust Tray Seals

(S/N 006501 − ) 61.............

Cyclone Perma−Filter

(S/N 006501 − ) 61.............

Cyclone Cover Seals

(S/N 006501 − ) 61.............

Cyclone Cover Access Port Seal

(S/N 006501 − ) 61............

Hopper Dust Filter Cover Seal

(S/N 006501 − ) 61............

Brakes And Tires 62......................

Brakes 62............................

Tires 62..............................

Rear Wheel 62........................

Propelling Motor 62.......................

Wet Side Brush Dust Control (Option) 63....

Filter Screen 63..........................

Spray Nozzles 63........................

Pushing, Towing, And Transporting

The Machine 64.......................

Pushing Or Towing The Machine 64......

Transporting The Machine 64...........

Machine Jacking 66......................

Storage Information 66....................

Freeze Protection For Wet Side Brush

Dust Control System 66................

Specifications 67............................

General Machine Dimensions/Capacities 67.

General Machine Performance 67..........

Power Type 68...........................

Hydraulic System 69......................

Steering 69..............................

Braking System 69.......................

Tires 69.................................

Machine Dimensions 70...................

Index 71...................................

Page

2

S30 Gas/LPG 9004080 (4−2017)

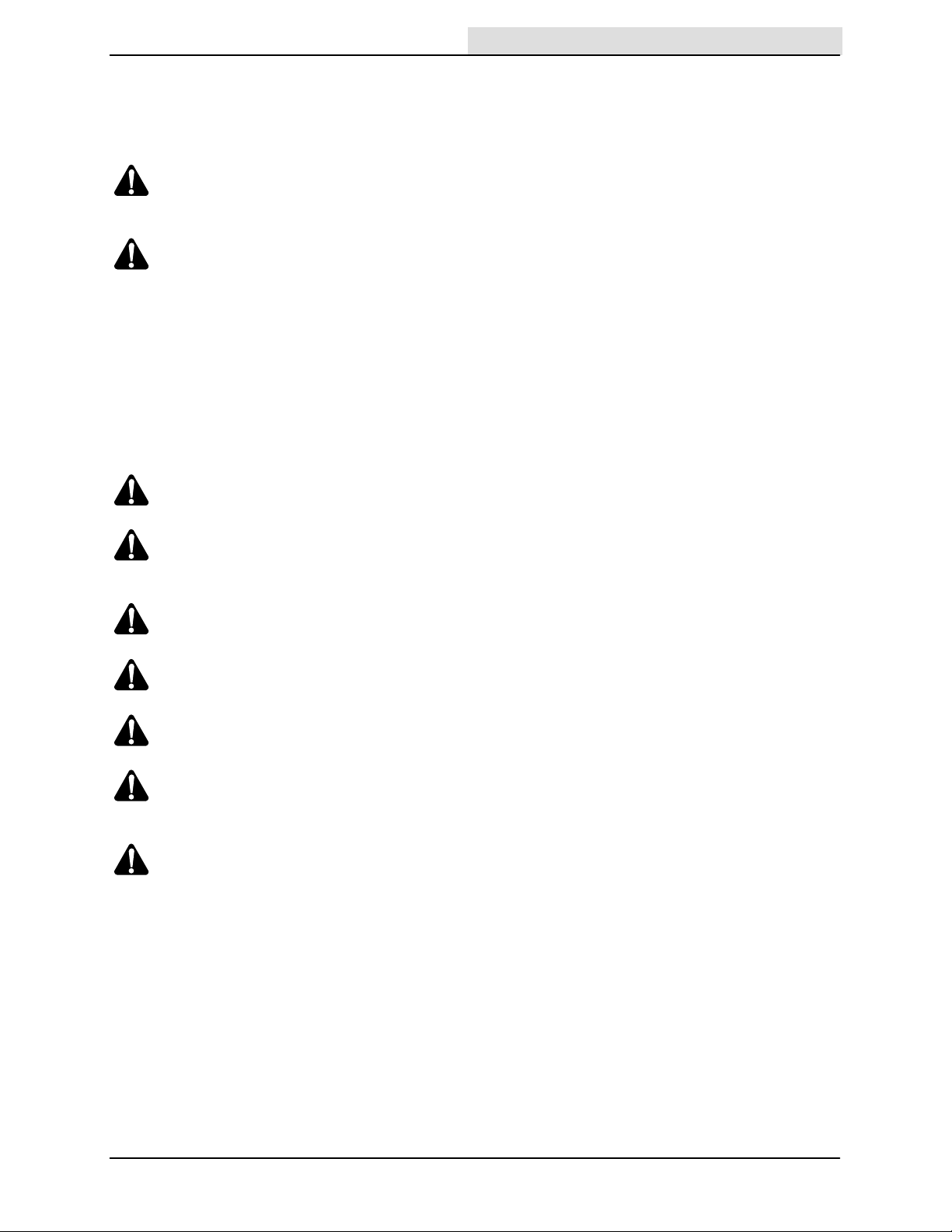

SAFETY PRECAUTIONS

IMPORTANT SAFETY INSTRUCTIONS − SAVE THESE INSTRUCTIONS

The following precautions are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or

unsafe practices that could result in

severe personal injury or death.

CAUTION: To warn of unsafe practices

that could result in minor or moderate

personal injury.

FOR SAFETY: To identify actions that must be

followed for safe operation of equipment.

The following information signals potentially

dangerous conditions to the operator. Know when

these conditions can exist. Locate all safety

devices on the machine. Report machine

damage or faulty operation immediately.

WARNING: Moving belt and fan. Keep

away.

WARNING: Machine emits toxic gases.

Serious injury or death can result.

Provide adequate ventilation.

WARNING: Raised hopper may fall.

Engage hopper support bar.

WARNING: Lift arm pinch point. Stay

clear of hopper lift arms.

WARNING: Burn hazard. Hot surface. Do

NOT touch.

WARNING: Accident may occur. Do not

operate vacuum or blower wand while

driving.

CAUTION: LPG engine will run for a

few seconds after key is turned off.

Apply parking brake before leaving

machine.

WARNING: This machine contains

chemicals known to the State of

California to cause cancer, birth defects,

or other reproductive harm.

This machine may be equipped with

technology that automatically communicates

over the cellular network. If this machine will

be operated where cell phone use is restricted

because of concerns related to equipment

interference, please contact a Tennant

representative for information on how to

disable the cellular communication

functionality.

FOR SAFETY:

1. Do not operate machine:

− Unless trained and authorized.

− Unless operator manual is read and

understood.

− Under the influence of alcohol or

drugs.

− While using a cell phone or other

types of electronic devices.

− Unless mentally and physically

capable of following machine

instructions.

− If it is not in proper operating

condition.

− Without filters in place.

− In areas where flammable

vapors/liquids or combustible dusts

are present.

− In areas that are too dark to safely see

the controls or operate the machine

unless operating / headlights are

turned on.

− In areas with possible falling objects

unless equipped with overhead guard.

2. Before starting machine:

− Check machine for fluid leaks

− Keep sparks and open flame away

from refueling area.

− Make sure all safety devices are in

place and operate properly.

− Check brakes and steering for proper

operation.

− Adjust seat and fasten seat belt (if

equipped).

3. When starting machine:

− Keep foot on brake and directional

pedal in neutral.

S30 Gas/LPG 9004080 (10−2016)

3

SAFETY PRECAUTIONS

4. When using machine:

− Use only as described in this manual.

− Do not pick up burning or smoking

debris, such as cigarettes, matches or

hot ashes

− Use brakes to stop machine.

− Go slow on inclines and slippery

surfaces.

− Do not sweep on ramp inclines that

exceed 14% grade or transport

(GVWR) on ramp inclines that exceed

17% grade.

− Reduce speed when turning.

− Keep all parts of body inside operator

station while machine is moving.

− Always be aware of surroundings

while operating machine.

− Use care when reversing machine.

− Move machine with care when hopper

is raised.

− Do not raise hopper when machine is

on an incline.

− Make sure adequate clearance is

available before raising hopper.

− Keep children and unauthorized

persons away from machine.

− Do not carry passengers on any part

of the machine.

− Always follow safety and traffic rules.

− Report machine damage or faulty

operation immediately.

− Avoid contact with battery acid.

− Avoid contact with hot engine coolant.

− Do not remove cap from radiator when

engine is hot.

− Allow engine to cool.

− Keep flames and sparks away from

fuel system service area. Keep area

well ventilated.

− Use cardboard to locate leaking

hydraulic fluid under pressure.

− All repairs must be performed by a

trained service mechanic.

− Do not modify the machine from its

original design.

− Use Tennant supplied or approved

replacement parts.

− Wear personal protective equipment

as needed and where recommended in

this manual.

For Safety: wear hearing protection.

For Safety: wear protective gloves.

For Safety: wear eye protection.

For Safety: wear protective dust mask.

5. Before leaving or servicing machine:

− Do not park near combustible

materials, dusts, gases, or liquids.

− Stop on level surface.

− Set parking brake.

− Turn off machine and remove key.

6. When servicing machine:

− All work must be done with sufficient

lighting and visibility.

− Keep work area well ventilated.

− Avoid moving parts. Do not wear loose

clothing, jewelry and secure long hair.

− Block machine tires before jacking

machine up.

− Jack machine up at designated

locations only. Support machine with

jack stands.

− Use hoist or jack that will support the

weight of the machine.

− Do not push or tow the machine

without an operator in the seat.

− Do not power spray or hose off

machine near electrical components.

− Disconnect battery connections before

working on machine.

7. When loading/unloading machine

onto/off truck or trailer:

− Empty debris hopper before loading

machine.

− Turn off machine and remove key.

− Use ramp, truck or trailer that will

support the weight of the machine and

operator.

− Do not load/unload on ramp inclines

that exceed 25% grade.

− Use winch. Do not drive the machine

onto/off the truck or trailer unless the

load height is 380 mm (15 in) or less

from the ground.

− Set parking brake after machine is

loaded.

− Block machine tires.

− Tie machine down to truck or trailer.

4

S30 Gas/LPG 9004080 (07−2014)

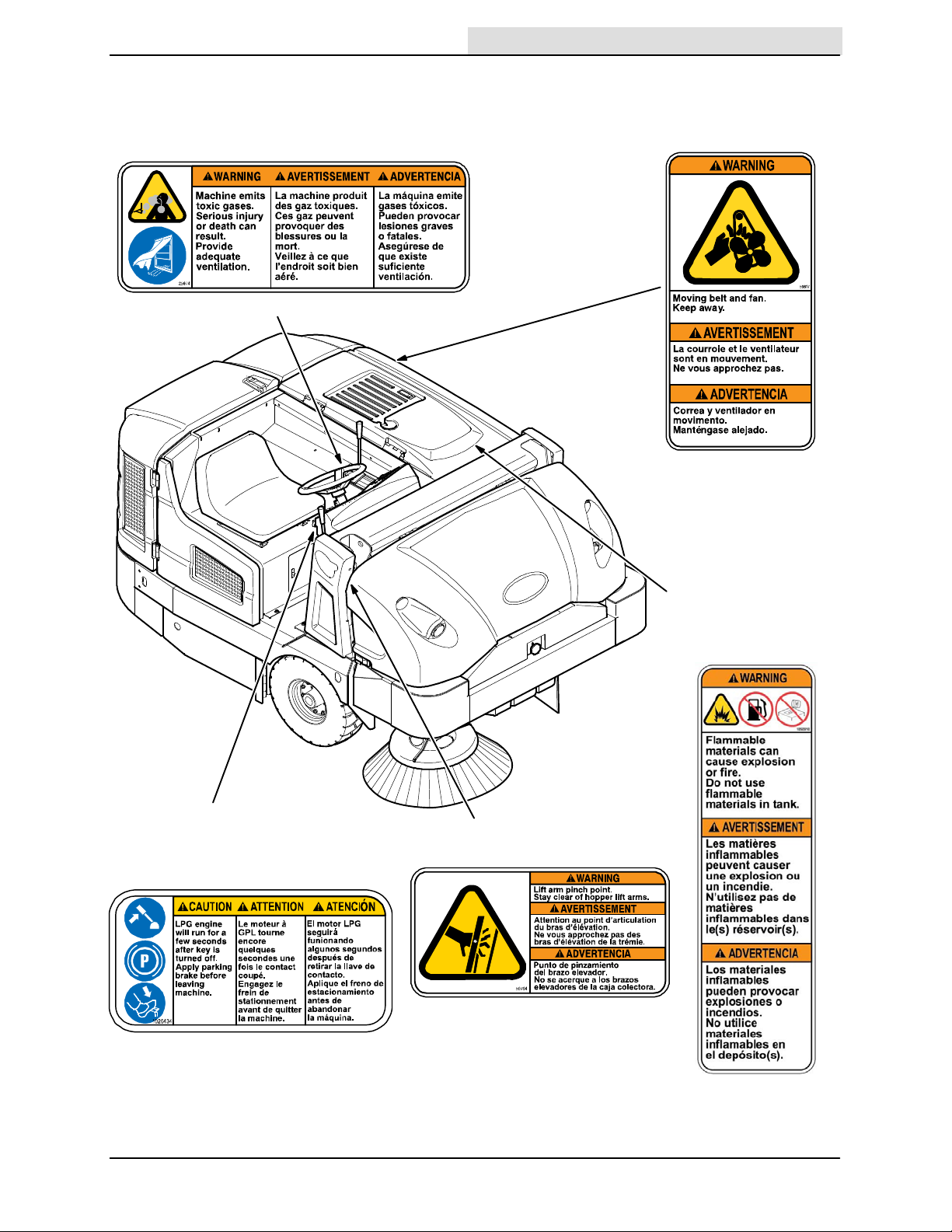

The safety labels appear on the machine in the

locations indicated. Replace damaged labels.

WARNING LABEL − Machine emits toxic gases.

Serious injury can result. Provide adequate ventilation.

Located on the side of the operator compartment.

SAFETY PRECAUTIONS

WARNING LABEL − Moving

belt and fan. Keep away.

Located on engine

belt guard.

CAUTION LABEL − LPG engine will

run for a few seconds after key is

turned off. Apply parking brake

before leaving machine.

WARNING LABEL −

Flammable materials

can cause explosion

or fire. Do not use

flammable materials

in tank.

WARNING LABEL − Lift arm pinch

point. Stay clear of hopper lift arms.

Located next to the ignition switch

on the instrument panel.

(LPG machines only)

S30 Gas/LPG 9004080 (4−2017)

Located on both hopper lift arms.

Located on the tank.

354590

5

SAFETY PRECAUTIONS

WARNING LABEL − Burn hazard. Do

NOT touch.

Located on the exhaust shield.

FOR SAFETY LABEL −

Read manual before

operating machine.

WARNING LABEL − Raised hopper may fall.

Engage hopper support bar.

Located on the hopper support bar.

Located on the side

of the operator

compartment.

WARNING LABEL − Raised hopper may fall.

Engage hopper support bar.

Located on the hopper lift arm.

WARNING LABEL − Accident may occur.

Do not operate vacuum or blower wand

while driving.

Located on the optional vacuum or blower

wand door.

354590

6

S30 Gas/LPG 9004080 (07−2014)

MACHINE COMPONENTS

OPERATION

OPERATION

9

8

7

6

1

2

3

4

5

14

15

10

13

1. Instrument panel

2. Front shroud

3. Hopper access door

4. Hopper

5. Side brush

6. Headlights

7. Main brush access door

8. Fuel tank

11

12

9. Operator seat

10. Rear engine shroud

11. Taillights

12. Side shroud

13. Hopper support bar

14. Top cover

15. Water tank (option)

S30 Gas/LPG 9004080 (4−2017)

7

OPERATION

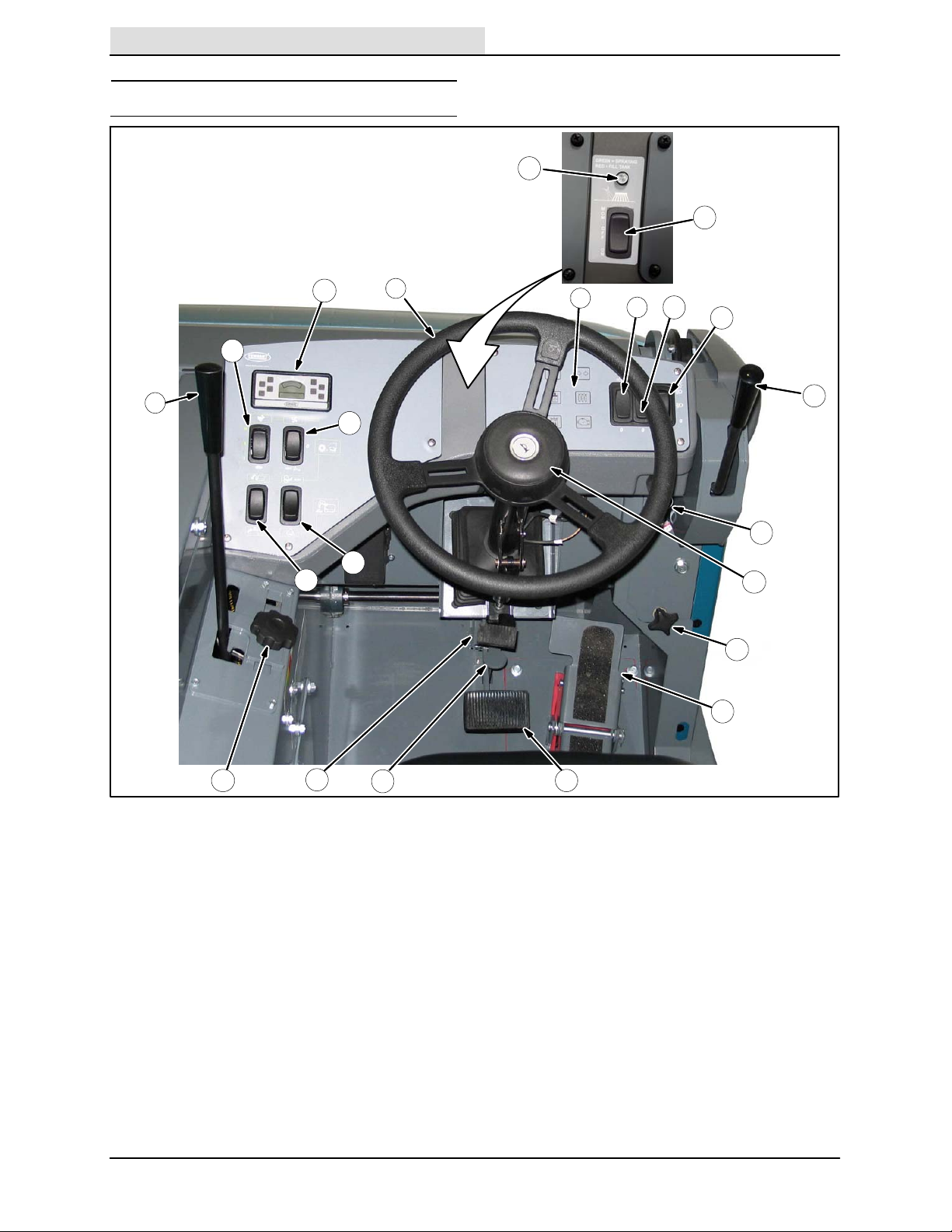

CONTROLS AND INSTRUMENTS

14

13

17

20

17

22

21

16

1

2

3

4

5

15

6

7

16

8

12

(All models)

1. Steering wheel

2. Dash fault indicator lights

3. Wand switch (option)

4. Side brush light switch (option)

5. Operating / hazard light switch

6. Ignition switch

7. Horn button

8. Directional pedal

9. Brake pedal

10. Parking brake pedal

11. Steering column tilt pedal

12. Main brush adjustment knob

13. Wet side brush dust control switch

(option)

14. Wet side brush dust control indicator

light (option)

8

11

10

9

(S30 only)

15. Side brush lever

16. Side brush adjustment knob

17. Main brush lever

18. Hopper door switch

19. Hopper raise / lower switch

20. Engine speed switch

21. Vacuum fan / filter shaker switch

22. Indicator panel

S30 Gas/LPG 9004080 (4−2017)

TOUCH PANEL (S30 XP and X4)

1

OPERATION

13

7

12

11

8

10

9

1. Supervisor control buttons

2. Hour meter / fuel indicator / fault code

indicator

3. Contrast control button

4. 1−STEP sweep button

5. Engine speed button

6. Vacuum fan button

7. Side brush button

8. Hopper door open button

9. Hopper door close button

10. Hopper lower button

11. Hopper raise button

12. Filter shaker button

13. Fault indicator light

2

4

6

5

3

S30 Gas/LPG 9004080 (2−2008)

9

OPERATION

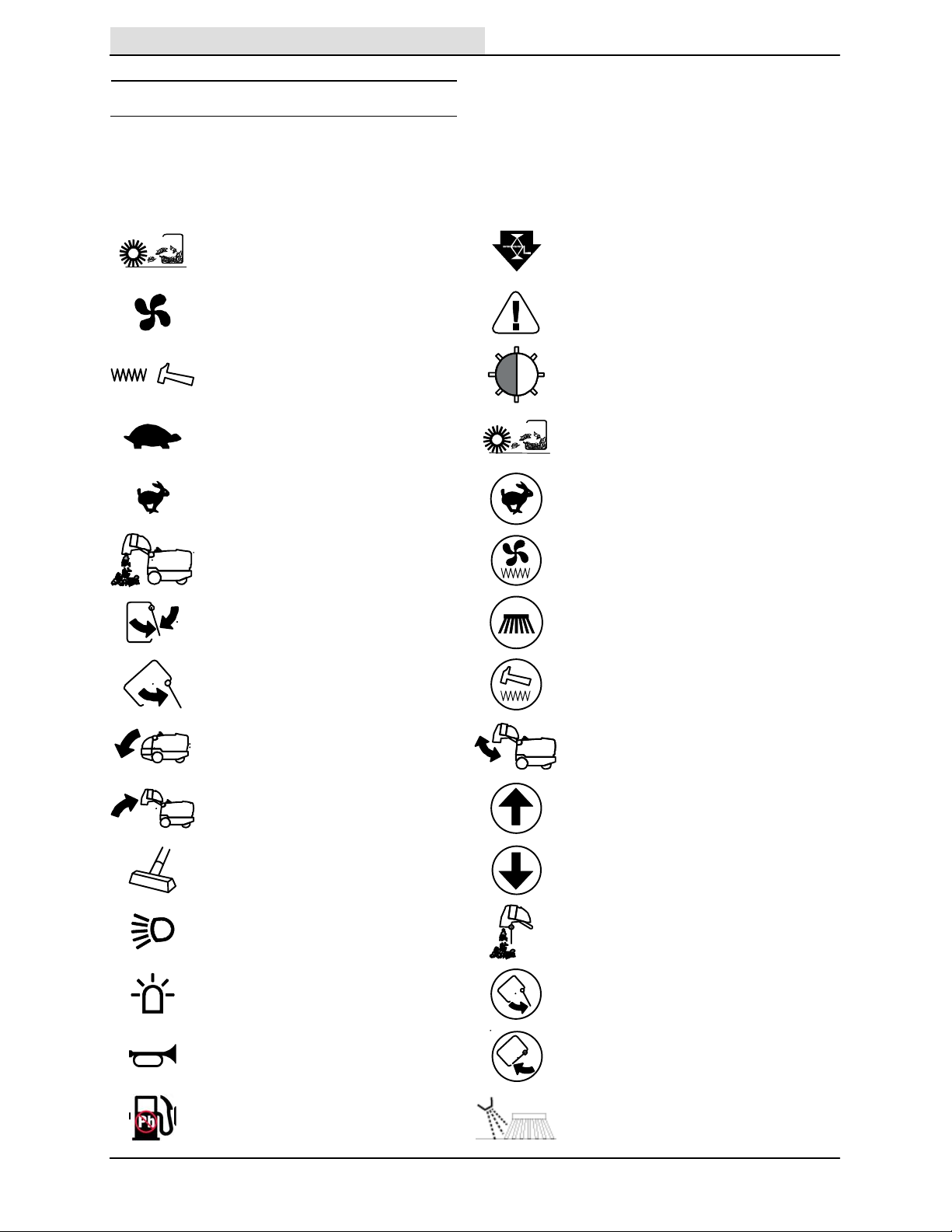

SYMBOL DEFINITIONS

These symbols are used on the machine to

identify controls, displays, and features. See also

Display Module Fault Indicators (S30) and Dash

Fault Indicators.

Sweep (S30) Jack point

Vacuum fan (S30) Fault indicator (S30 XP and X4)

Filter Shaker (S30) Contrast Control (S30 XP and X4)

Engine Idle Speed (S30) 1−STEP Sweep (S30 XP and X4)

Engine High speed (S30) Engine speed (S30 XP and X4)

Empty Hopper (S30) Vacuum fan (S30 XP and X4)

Hopper Door Automatic (S30) Side brush (S30 XP and X4)

Hopper Door Manual Open (S30) Filter shaker (S30 XP and X4)

Hopper Lower (S30) Hopper Up / Down (S30 XP and X4)

Hopper Raise (S30) Hopper raise (S30 XP and X4)

Wand Hopper lower (S30 XP and X4)

Operating lights Open/Close Hopper Door (S30 XP, X4)

Hazard light Hopper door open (S30 XP and X4)

10

Horn Hopper door close (S30 XP and X4)

Unleaded fuel only Wet side brush dust control (option)

S30 Gas/LPG 9004080 (4−2017)

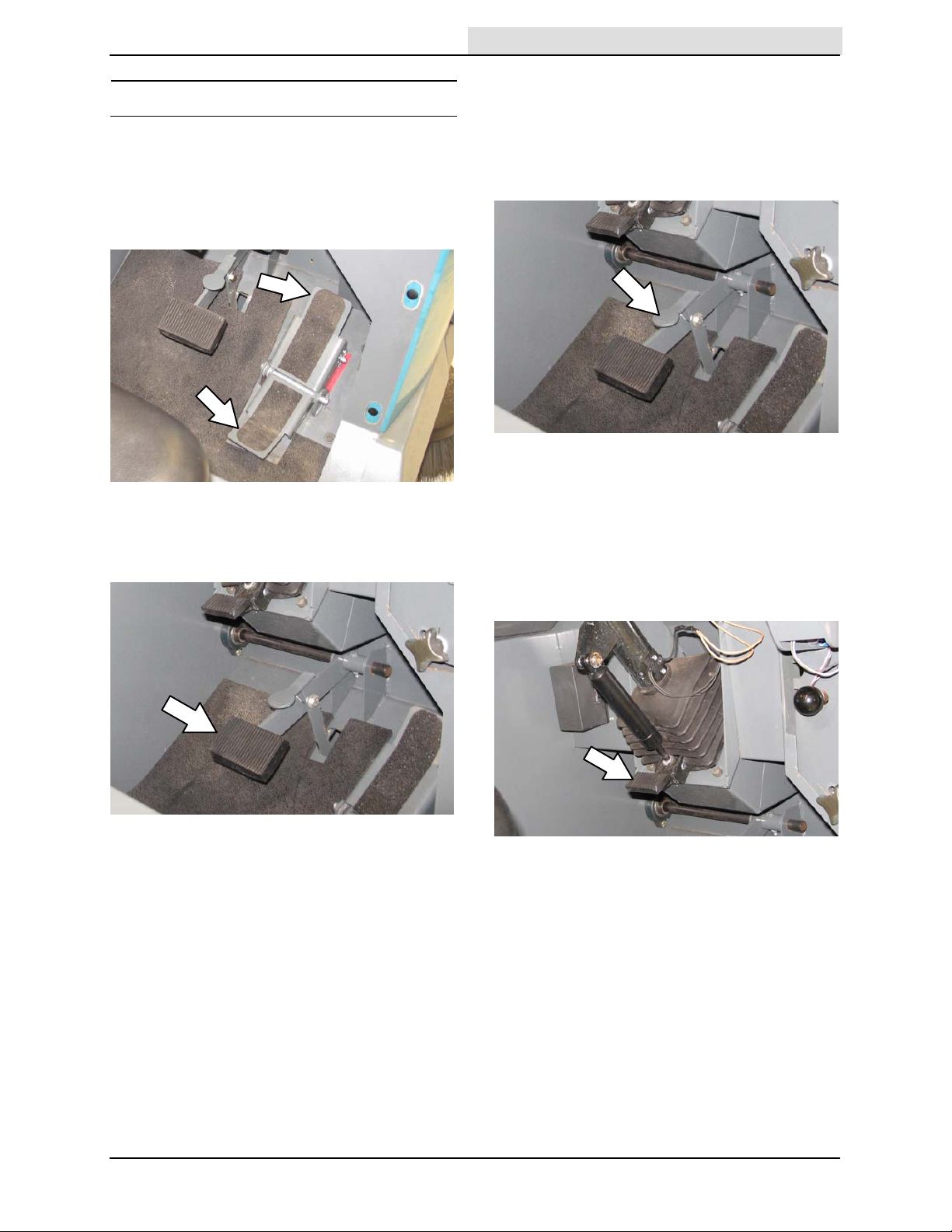

OPERATION OF CONTROLS

DIRECTIONAL PEDAL

Press the top of the Directional pedal to move

forward and the bottom of the pedal to move

backward. The pedal returns to the neutral

position when it is released.

OPERATION

PARKING BRAKE PEDAL

Press the Brake pedal down as far as possible

and use toe to lock the Parking brake pedal into

place. Press the Brake pedal to release the

parking brake. The Parking brake pedal will return

to the unlocked position.

STEERING COLUMN TILT PEDAL

BRAKE PEDAL

Press the Brake pedal to stop the machine.

1. Step on the Steering column tilt pedal and

adjust the steering column to the desired

position.

2. Release the Steering column tilt pedal to lock

in place.

S30 Gas/LPG 9004080 (2−2008)

11

OPERATION

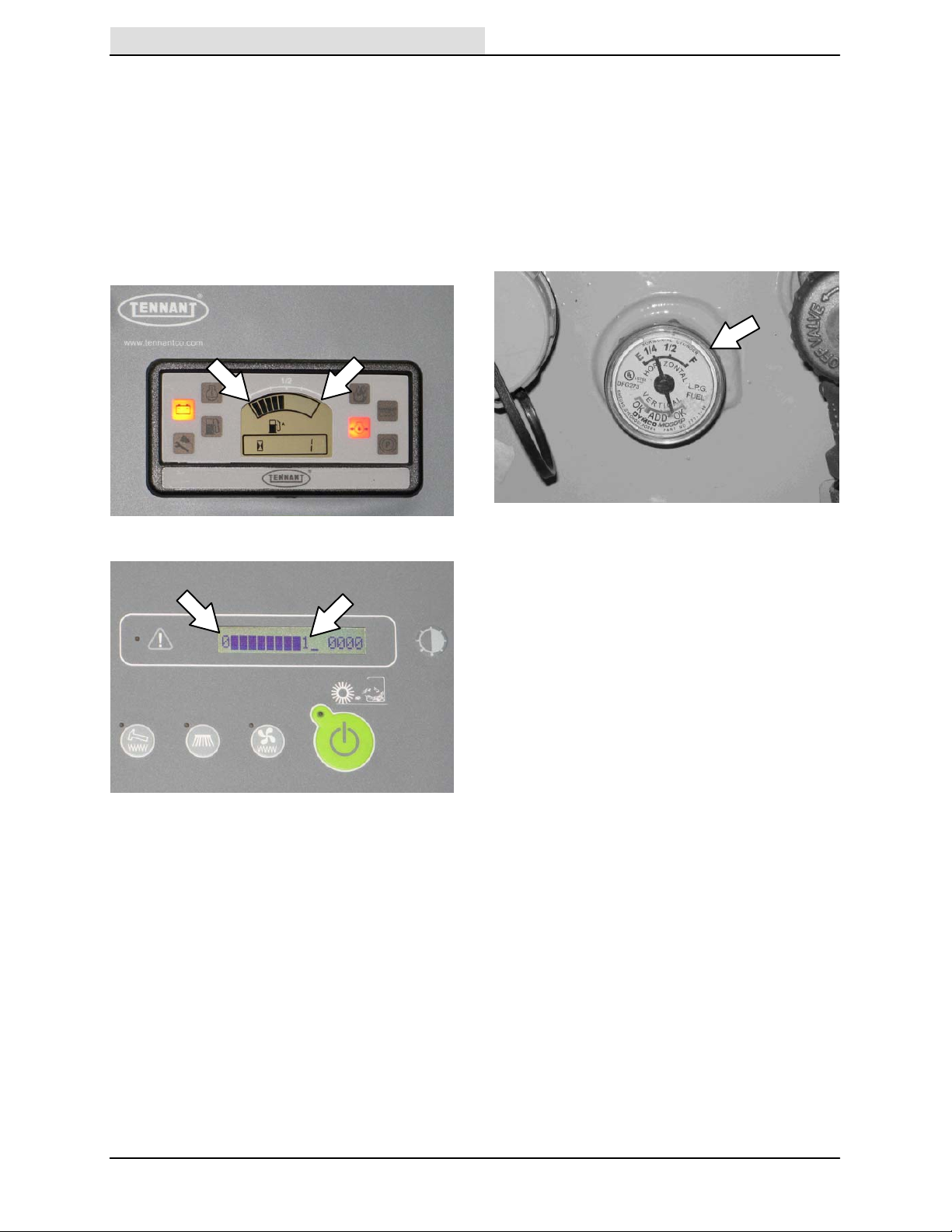

FUEL GAUGE

GASOLINE MACHINES

NOTE: Do not use leaded fuels. Leaded fuels will

permanently damage the system oxygen sensor

and catalytic converter.

The Fuel indicator displays the amount of fuel left

in the tank. The fuel level fault indicator will

illuminate when the fuel tank is near empty. Refer

to DISPLAY MODULE FAULT INDICATOR(S).

LPG MACHINES

For LPG machines, the Fuel indicator does NOT

display the amount of fuel in the LPG tank. It will

display all the indicator bars to show that some

fuel is in the tank. The fuel level fault indicator will

illuminate when the fuel level gets low. Refer to

DISPLAY MODULE FAULT INDICATOR(S).

The LPG fuel gauge on the tank displays the

amount of fuel in the LPG tank.

S30

S30 XP and X4

12

S30 Gas/LPG 9004080 (2−2008)

OPERATION

HOUR METER

The Hour meter records the hours the machine

was operated. Use this information to determine

machine service intervals.

S30

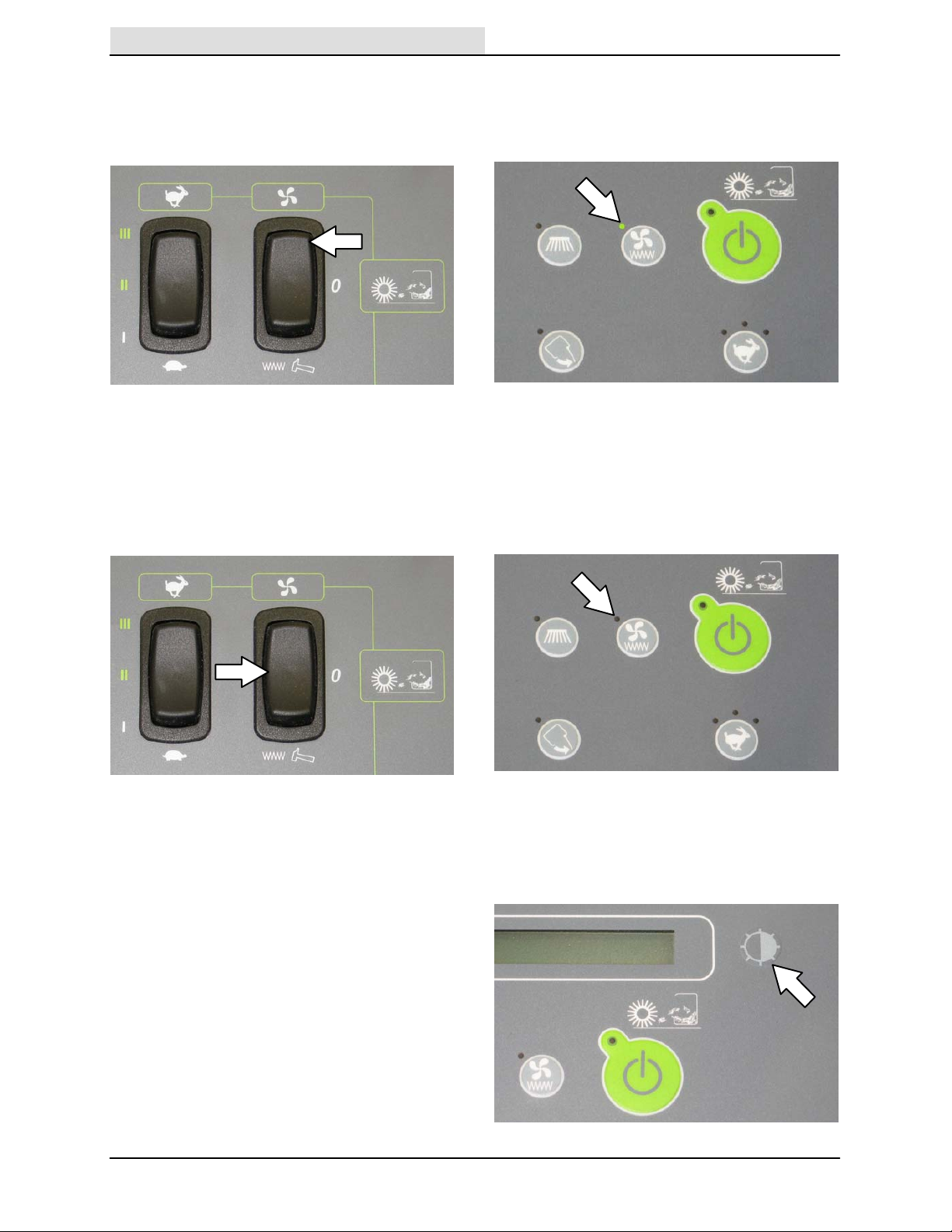

ENGINE SPEED CONTROLS

Idle Speed: This speed is for starting the

machine.

NOTE: S30 XP and X4 machines automatically

start in idle speed.

S30 S30 XP and X4

Medium (Fast 1) Speed: This speed is for general

sweeping.

S30 XP and X4

SUPERVISOR CONTROL BUTTONS

(S30 XP and X4)

The Supervisor Control buttons are for accessing

the configuration and diagnostic modes. Only

properly trained service personnel and TENNANT

representatives should access these modes.

S30 S30 XP and X4

High (Fast 2) Speed: This speed is for sweeping

light litter or moving quickly between areas.

S30 S30 XP and X4

S30 Gas/LPG 9004080 (2−2008)

13

OPERATION

VACUUM FAN CONTROLS (S30)

The vacuum fan automatically comes on when the

main brush is lowered with the Vacuum fan switch

in the automatic/on position.

NOTE: Turn off the vacuum fan when sweeping

over large wet areas or standing water. This

prevents the dust filter from getting wet while

sweeping.

Press the Vacuum fan switch to the middle

position to shut off the vacuum fan.

VACUUM FAN CONTROLS (S30 XP and X4)

The vacuum fan automatically comes on when the

1−STEP Sweep button is activated. The light next

to the Vacuum fan button will come on.

NOTE: Turn off the vacuum fan when sweeping

over large wet areas or standing water. This

prevents the dust filter from getting wet while

sweeping.

Press the Vacuum fan button to shut off the

vacuum fan. The light next to the button will go

out.

14

CONTRAST CONTROL BUTTON

(S30 XP and X4)

Press and hold the Contrast control button to

darken/lighten the LCD display.

S30 Gas/LPG 9004080 (2−2008)

OPERATION

FILTER SHAKER CONTROL (S30)

Press the Filter shaker switch. The filter shaker

will operate for 30 seconds.

FILTER SHAKER CONTROL (S30 XP and X4)

The filter shaker automatically activates for about

30 seconds when the 1−STEP Sweep button is

turned off.

Press the filter shaker switch to manually start the

30 second shaker cycle or to stop the shaker

cycle.

OPERATING / HAZARD LIGHT SWITCH

Operating and Hazard Lights On: Press the top of

the Operating / hazard light switch.

Operating Lights On: Press the Operating /

hazard light switch to the middle position.

All Lights Off: Press the bottom of the Operating /

hazard light switch.

SIDE BRUSH LIGHT SWITCH (OPTION)

Side Brush Lights On: Press the top of the Side

brush light switch to turn the side brush light on.

Side Brush Lights Off: Press the bottom of the

Side brush light switch to turn the side brush light

off.

S30 Gas/LPG 9004080 (2−2008)

15

OPERATION

HOPPER ACCESS DOOR

Use the hopper access door to dispose of debris

too large to be picked up by the machine while

sweeping.

Twist the hopper access door handle to loosen

the lock, lift the handle to disengage the lock, and

then lift the hopper access door open.

(SN 000000 − 006500)

Pull the hopper access door handle to open the

hopper access door. (SN 006501 − )

16

S30 Gas/LPG 9004080 (07−2014)

OPERATION

OPERATOR SEAT

The front−to−back adjustment lever adjusts the

seat position.

DELUXE SUSPENSION SEAT

The operator seat has three adjustments:

backrest angle, operator weight, and front to

back.

The backrest adjustment knob adjusts the angle

of the backrest.

The weight adjustment knob controls the firmness

of the operator seat. Use the gauge next to the

weight adjustment knob to help determine seat

firmness.

The front−to−back adjustment lever adjusts the

seat position.

S30 Gas/LPG 9004080 (2−2008)

SEAT BELTS

FOR SAFETY: Before starting machine, adjust

seat and fasten seat belt (if equipped).

17

OPERATION

BRUSH INFORMATION

For best results, use the correct brush type for the

cleaning application.

NOTE: The amount and type of soilage play an

important role in determining the type of brushes

to use. Contact a Tennant representative for

specific recommendations.

Polypropylene and Wire 8-double row Main

Brush − Recommended for general sweeping,

fine dust, and slightly impacted debris.

Polypropylene Sand Wedge Main Brush −

Recommended for heavy accumulation of sand

and other small particulates.

Polypropylene Window Main Brush −

Recommended for light litter, especially on

smooth floors.

Polypropylene 8-double row Main Brush −

Recommended for lighter duty sweeping

applications.

HOW THE MACHINE WORKS

Machines SN 000000 − 006500

Nylon 8-double row Main Brush −

Recommended for general sweeping, especially

on rough or irregular surfaces. Nylon has a long

wear life.

Nylon Full Fill Main Brush − Recommended for

accumulation of sand and other small particulates.

Nylon has a long wear life.

Nylon Patrol Main Brush − Recommended for

bulky debris swept at faster speeds.

Wire 8-double row Main Brush −

Recommended for general sweeping and slightly

impacted debris.

Natural Fiber and Full Fill Main Brush −

Recommended for accumulation of sand and

other small particulates.

Polypropylene Side Brush − Recommended for

general sweeping of light to medium debris.

Nylon Side Brush − Recommended for general

sweeping of rough or irregular surfaces. Nylon

has a long wear life.

Machines SN 006501 −

The steering wheel controls the direction of

machine travel. The directional pedal controls the

speed and forward/reverse direction. The brake

pedal slows and stops the machine.

The side brush sweeps debris into the path of the

main brush. The main brush sweeps debris from

the floor into the hopper. The vacuum system

pulls dust and air through the hopper and the dust

control system.

The machine also has a wet side brush dust

control option to help contain dust.

When sweeping is finished, shake the dust filter

and empty the hopper.

Flat Wire Side Brush − Recommended for

outdoor curb-side sweeping where dirt is heavy or

compacted.

18

S30 Gas/LPG 9004080 (4−2017)

PRE−OPERATION CHECKLIST

- Check the fuel level.

- Check the machine for fluid leaks.

- Check the condition of the main brushes.

Remove string, banding, plastic wrap, or other

debris wrapped around the brushes.

- Check the main brush compartment right

skirts and seals for damage and wear.

- Side Brush(es): Check the condition of the

brush. Remove string, banding, plastic wrap,

or other debris wrapped around the brush.

- Check the condition of the debris deflection

skirts.

- Check the hydraulic fluid level.

- Check the main brush compartment left skirts

and seals for damage and wear.

OPERATION

- Check the engine coolant level.

- Check the engine oil level.

- Check the radiator and hydraulic cooler fins

for debris.

- Check the horn, headlights, taillights, safety

lights, and backup alarm (if equipped).

- Check the brakes and steering for proper

operation.

- Check the service records to determine

maintenance requirements.

S30 Gas/LPG 9004080 (07−2016)

19

OPERATION

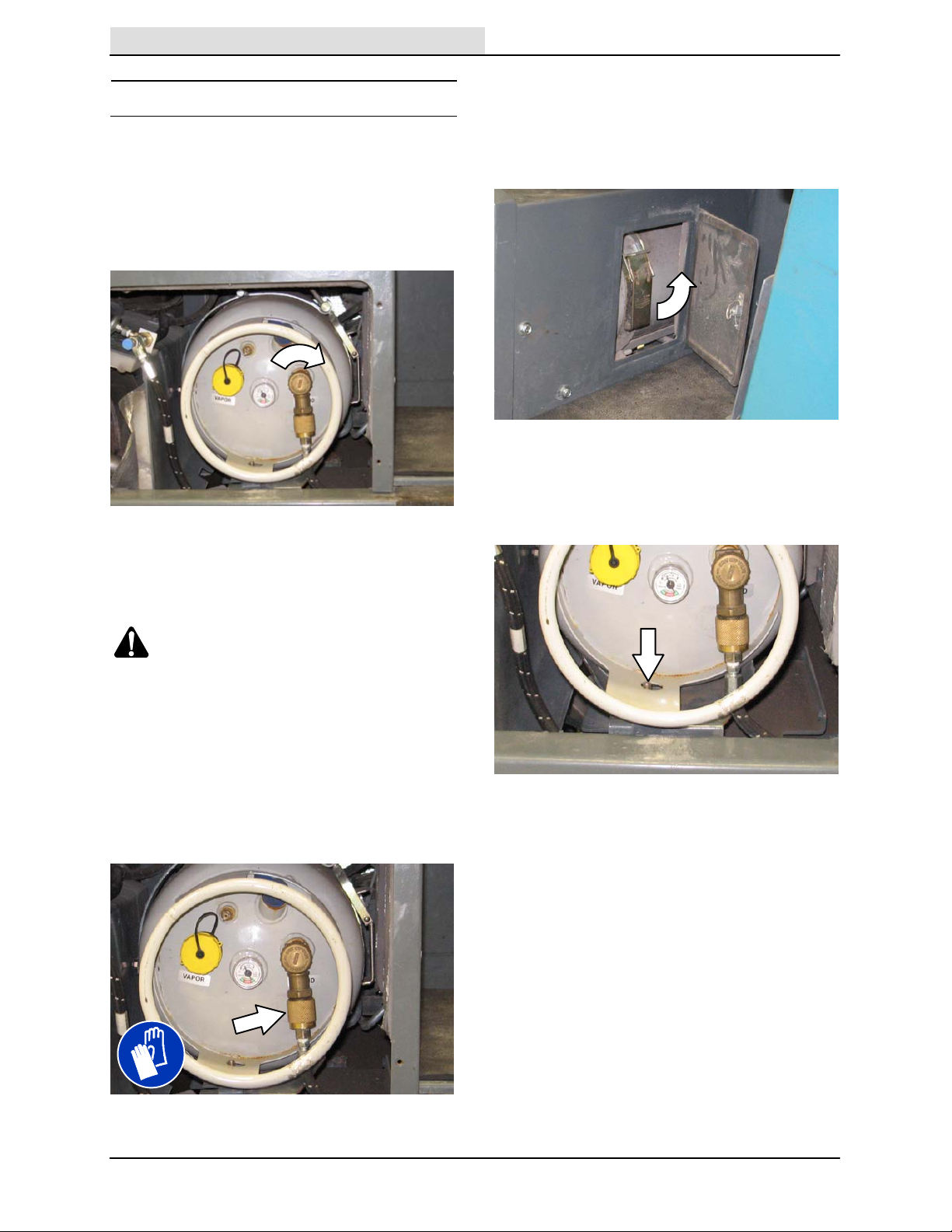

CHANGING THE LPG TANK

5. Open the LPG tank access door located in

front of the operator seat.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, set parking

brake, turn off machine, and remove key.

1. Open the side access door.

2. Close the LPG tank service valve.

3. Start the machine and operate the engine

until it stops from lack of fuel. Turn off the

machine.

6. Disengage the mounting strap, then remove

the locating pin and remove the empty LPG

fuel tank.

7. Align the hole in the tank collar with the

centering pin and carefully place the full LPG

tank onto the tray. Secure the tank with

mounting strap.

WARNING: Machine emits toxic gases.

Severe respiratory damage or

asphyxiation can result. Provide

adequate ventilation. Consult with your

regulatory authorities for exposure

limits. Keep engine properly tuned.

FOR SAFETY: When servicing machine, keep

flames and sparks away from fuel system

service area. Keep area well ventilated.

4. Put on gloves and remove the quick

disconnect tank coupling.

8. Connect the LPG fuel line to the tank service

coupling. Make sure the tank service coupling

is clean and undamaged and that it matches

the fuel line coupling.

9. Slowly open the tank service valve and check

for leaks. If a leak is found, immediately close

the service valve and inform the appropriate

personnel.

20

S30 Gas/LPG 9004080 (6−2008)

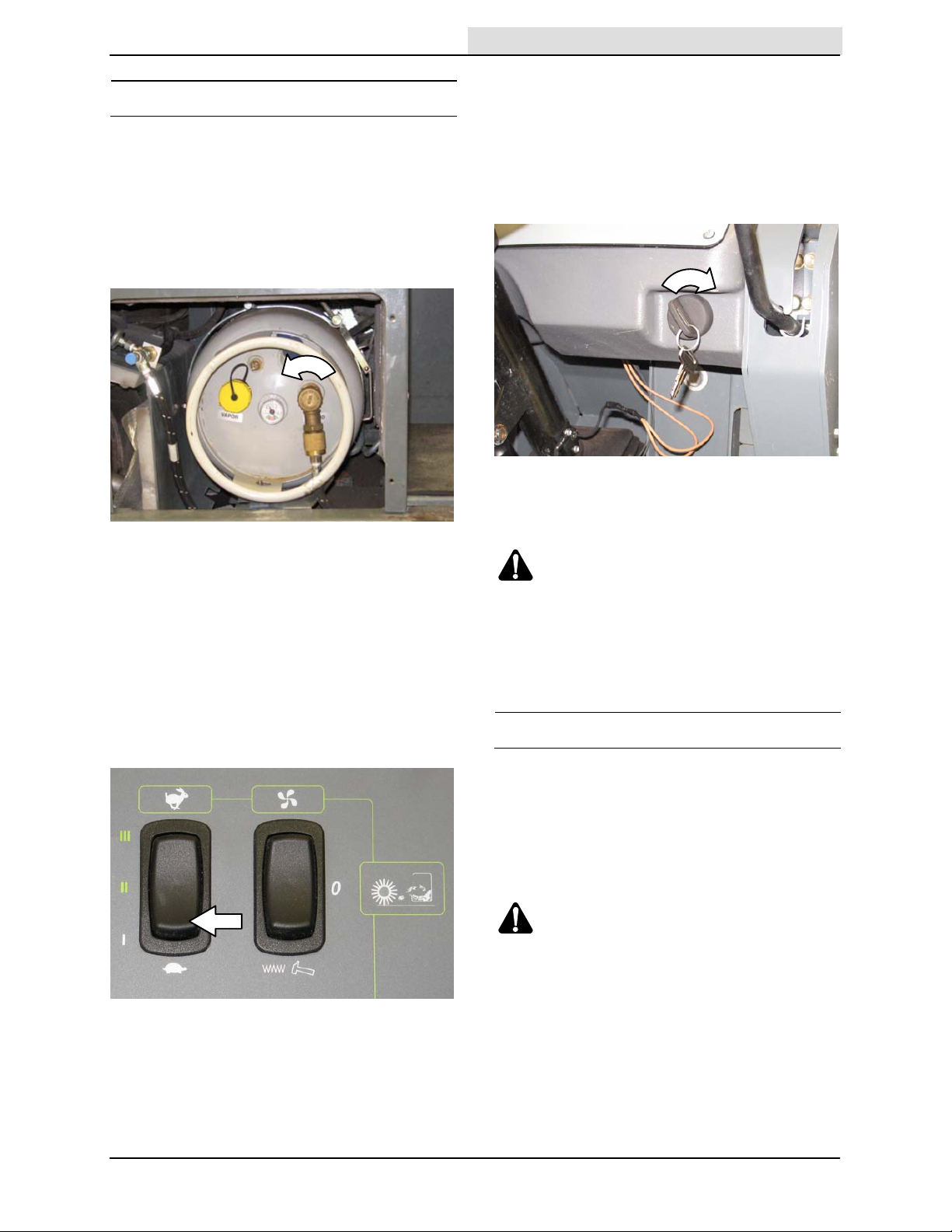

STARTING THE MACHINE

OPERATION

4. Turn the ignition switch key until the engine

starts.

1. LPG powered machines: Slowly open the

liquid service valve.

NOTE: Opening the service valve too quickly may

cause the service check valve to stop the flow of

LPG fuel. If the check valve stops the fuel flow,

close the service valve, wait a few seconds, and

slowly open the valve again.

2. Sit in the operator seat and press the brake

pedal or set the parking brake.

FOR SAFETY: When starting machine, keep

foot on brake and directional pedal in neutral.

NOTE: Do not operate the starter motor for more

than 10 seconds at a time or after the engine has

started. Allow the starter to cool 15−20 seconds

between starting attempts or damage to the

starter motor may occur.

5. Allow the engine and hydraulic system to

warm up for three to five minutes.

WARNING: Machine emits toxic gases.

Severe respiratory damage or

asphyxiation can result. Provide

adequate ventilation. Consult with your

regulatory authorities for exposure

limits. Keep engine properly tuned.

3. S30: Place the Engine speed switch into the

idle position.

S30 XP and X4: The engine will automatically

start in the idle speed.

6. Turn on lights.

TURNING OFF THE MACHINE

1. Stop the machine and turn off all sweeping

functions.

2. Turn the ignition switch key counter clockwise

to turn off the machine. Remain in the

operator seat until the engine is off.

CAUTION: LPG engine will run for a few

seconds after key is turned off. Apply

parking brake before leaving machine.

NOTE: To protect engine emission components

on LPG powered machines, the engine will

continue to operate for a few seconds after the

ignition switch is turned off.

FOR SAFETY: Before leaving or servicing

machine, do not park near combustible

materials, dust, gases, or liquids. Stop on

level surface, set parking brake, turn off

machine, and remove key.

S30 Gas/LPG 9004080 (01−2013)

21

OPERATION

WHILE OPERATING THE MACHINE

Pick up oversized debris before sweeping. Pick

up wire, string, twine, large pieces of wood, or any

other debris that could become wrapped around

or tangled in the brushes.

Drive as straight a path as possible. Avoid

bumping into posts or scraping the sides of the

machine. Overlap the sweep paths by several

centimeters (a few inches).

Avoid turning the steering wheel too sharply when

the machine is in motion. The machine is very

responsive to the movement of the steering wheel.

Avoid sudden turns, except in emergencies.

Adjust the machine speed and brush pressure.

Use the lowest brush pressure for best

performance.

Keep the machine moving to prevent damaging

floor finishes.

If poor cleaning performance is observed, stop

cleaning and refer to MACHINE

TROUBLESHOOTING in this manual.

Perform the Daily Maintenance Procedures after

each use (see MACHINE MAINTENANCE in this

manual).

Drive the machine slowly on inclines. Use the

brake pedal to control machine speed on

descending inclines. Sweep with the machine up

inclines rather than down inclines.

FOR SAFETY: When using machine, go slowly

on inclines and slippery surfaces.

Do not operate machine in areas where the

ambient temperature is above 43_ C (110_ F). Do

not operate sweeping functions in areas where

the ambient temperature is below freezing 0_ C

(32_ F). With the proper hydraulic fluid and a

machine warm−up period, the machine is capable

of operating at much lower temperatures.

FOR SAFETY: Do not sweep on ramp inclines

that exceed 14% grade or transport (GVWR)

on ramp inclines that exceed 17% grade.

22

S30 Gas/LPG 9004080 (07−2014)

Loading...

Loading...