Tennant OS3 User Manual

ON−SITE GENERATOR

GENERADOR IN SITU

GÉNÉRATEUR SUR SITE

English Operator Manual EN

Español Manual del operario ES

Français Manuel de l’Opérateur FR

North America / International

To view, print or download

the latest manual, visit:

www.tennantco.com/manuals

DM20036

Rev. 00 (3-2014)

*DM20036*

INTRODUCTION

This manual is furnished with each new model. It provides necessary operation and maintenance instructions.

Read this manual completely and understand

the machine before operating or servicing it.

This machine will provide excellent service. However, the best results will be obtained at minimum costs if:

The machine is operated with reasonable care.

The machine is maintained regularly - per the machine maintenance instructions provided.

The machine is maintained with manufacturer supplied or equivalent parts.

PROTECT THE ENVIRONMENT

Please dispose of packaging materials,

used machine components such as

batteries and fluids in an

environmentally safe way according to

local waste disposal regulations.

Always remember to recycle.

Please fill out at time of installation for future reference.

Model No. −

Serial No. −

Installation Date −

MACHINE DATA

INTENDED USE

This machine is designed solely for creating, storing and dispensing Orbio MultiSurface and MultiMicro solution for

internal professional use only. Not for resale. Buyer is responsible for ensuring that the solutions are labeled and

used in accordance with local health and safety regulations. Not intended for human consumption.

Orbio Technologies

701 North Lilac Drive

Minneapolis, MN 55440

Phone: (800) 553−8033 or (763) 513−2850

www.orbio.com

MultiMicro is a trademark of Tennant Company.

Specifications and parts are subject to change without notice.

Original Instructions, copyright 2014 Orbio Technologies from TENNANT COMPANY, Printed in U.S.A.

CONTENTS

OPERATION EN

Important Safety Instructions − Save These

Instructions 2...........................

Grounding Instructions 3....................

Operation 5...............................

Machine Components 5..................

Display Panel Indicators 6................

How The Machine Works 7...............

While Operating The Machine 7...........

Cleaning Solution

(Top Positions Indicated In Blue) 7......

Antimicrobial Solution

(Bottom Positions Indicated In Yellow) 8.

Operating The Orbio Dispenser 8..........

Filling Bottles 8......................

Filling Buckets And Equipment 9.......

Indicators 10.............................

Service Required Indicator 10...........

Ready To Dispense Indicator

(Home Screen) 10..................

Machine Initializing Indicator 10.........

Tanks Filling Indicator 10...............

Wait To Dispense Indicator 10...........

Water Temperature Too Hot Indicator 11..

Add Salt Indicator 11...................

Quantity Dispensed Indicator 11.........

Information Touch Button 12............

Service Information Touch Button 12.....

Troubleshooting 13.......................

Page

Page

Maintenance 14.............................

Filling The Salt Reservoir 14...............

Replacing Wear Components 15...........

Replacing The Ph Probe 15.............

Replacing The E−Cell 17...............

Replacing The Manifold 19.............

Testing The Antimicrobial Solution 21.......

Testing The Cleaning Solution 22...........

Satellite Systems 23......................

Connecting And Disconnecting

Transport Containers 24.............

Connecting 24........................

Disconnecting 24......................

Using The Transport Container

Wall Hook 24......................

Specifications 25............................

Os3 Generator 25........................

Os3 Water Softener 25....................

Power 25................................

Dispensing System 25....................

Generation System 25....................

Wear Components 26.....................

Satellite System − Transport Containers 26..

Satellite System − Dispensing System 26....

Satellite System − Water Softener 26.......

Machine Dimensions 27...................

Os3 DM20036 (3−2014)

1

EN OPERATION

IMPORTANT SAFETY INSTRUCTIONS − SAVE THESE INSTRUCTIONS

The following precautions are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or

unsafe practices that could result in

severe personal injury or death.

FOR SAFETY: To identify actions that must be

followed for safe operation of equipment.

This machine is designed solely for creating,

storing, and dispensing Orbio

cleaner and MultiMicro 200 Solution.

The following information signals potentially

dangerous conditions to the operator or

equipment. Read this manual carefully. Know

when these conditions can exist. Locate all safety

devices on the machine. Then, take necessary

steps to train machine operators. Report machine

damage or faulty operation immediately. Do not

use the machine if it is not in proper operating

condition.

WARNING: Electrical Hazard

− Do not operate with damaged power

cord.

− Unplug power cord before servicing

machine.

− Do not modify plug. If the power cord

is damaged or broken, it must be

replaced by the manufacturer or its

service agent or a similarly qualified

person in order to avoid a hazard.

WARNING: Electrical Shock Hazard.

Do not use outdoors. Do not expose to

rain / moisture. Store indoors.

MultiSurface

FOR SAFETY:

1. Do not operate machine:

− Unless trained and authorized.

− Unless operator manual is read and

understood.

− Under the influence of alcohol or

drugs

− Unless mentally and physically

capable of following machine

instructions.

− If it is not in proper operating

condition.

− In outdoor areas. This machine is for

indoor use only.

2. When using machine:

− Use only as described in this manual.

− Do not use water softener as a step.

− Keep children and unauthorized

persons away from machine.

− Do not allow to be used as a toy.

− Follow site safety guidelines

concerning wet floors.

3. When servicing machine:

− Unplug cord from wall outlet.

− All work must be done with sufficient

lighting and visibility.

− All repairs must be done by trained

personnel.

− Do not modify the machine from its

original design.

− Use Tennant supplied parts or

approved replacement parts.

− Do not remove e−module unless

operator manual is read and

understood.

This machine may be equipped with

technology that automatically communicates

over the cellular network. If this machine will

be operated where cell phone use is restricted

because of concerns related to equipment

interference, please contact a Tennant

representative for information on how to

disable the cellular communication

functionality.

2

OS3 DM20036 (3−2014)

4. When using MultiSurface Cleaner:

− Do not mix with other cleaning

products.

− Do not drink.

− Refer to SDS (Safety Data Sheet) for

additional safety information and

precautions.

− Wear personal protection safety

equipment as needed.

5. When using MultiMicro 200 Solution:

− Do not mix this product with ammonia

or acid, which will product chlorine

gas.

− Do not mix with other cleaning

products.

− Do not drink.

− Refer to SDS (Safety Data Sheet) for

additional safety information and

precautions.

− Wear personal protection safety

equipment as needed.

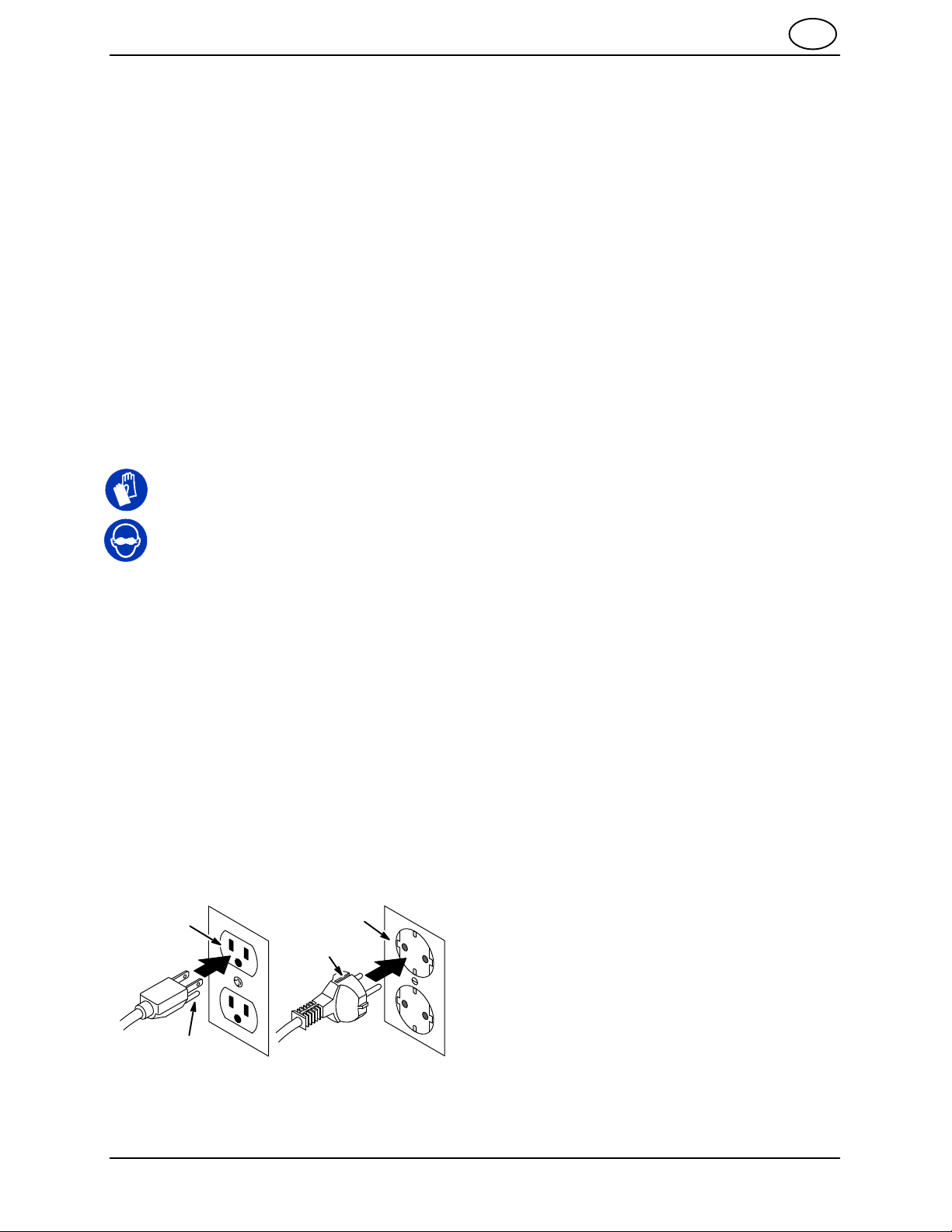

For Safety: wear protective gloves.

OPERATION EN

For Safety: wear eye protection.

GROUNDING INSTRUCTIONS

Equipment must be grounded. If it should

malfunction or break down, grounding

provides a path of least resistance for

electrical current to reduce the risk of

electrical shock. This equipment is equipped

with a cord having an equipment−grounding

conductor and grounding plug. The plug

must be plugged into a Ground Fault Circuit

Interrupter (GFCI)−protected outlet or adapter

that is properly installed in accordance with

all local codes and ordinances. Do not remove

ground pin; if missing, replace plug before

use.

Grounded 3

Hole Outlet

Grounded Outlet

Grounding

Edge/hole

Ground Pin

120V

OS3 DM20036 (3−2014)

220V/230V/240V

3

EN OPERATION

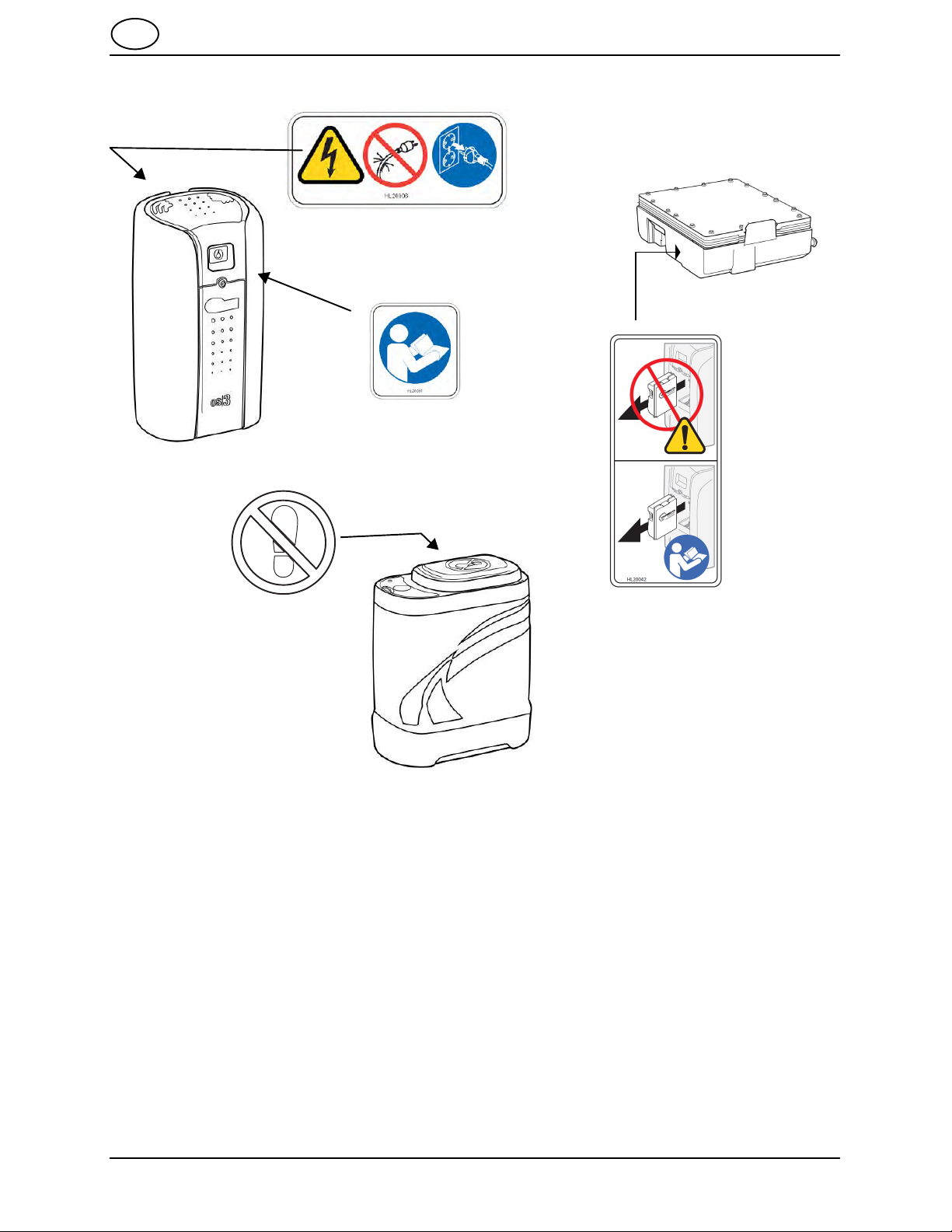

The safety labels appear on the equipment in the

locations indicated. Replace damaged labels.

WARNING: Electrical hazard.

Do not use with damaged cord.

Unplug cord before servicing.

FOR SAFETY: Do not

operate machine unless

operator manual is read

and understood.

FOR SAFETY: When

using machine, do not

use water softener as

a step.

FOR SAFETY: When

servicing machine, do not

remove e−module unless

operator manual is

read and understood.

4

OS3 DM20036 (3−2014)

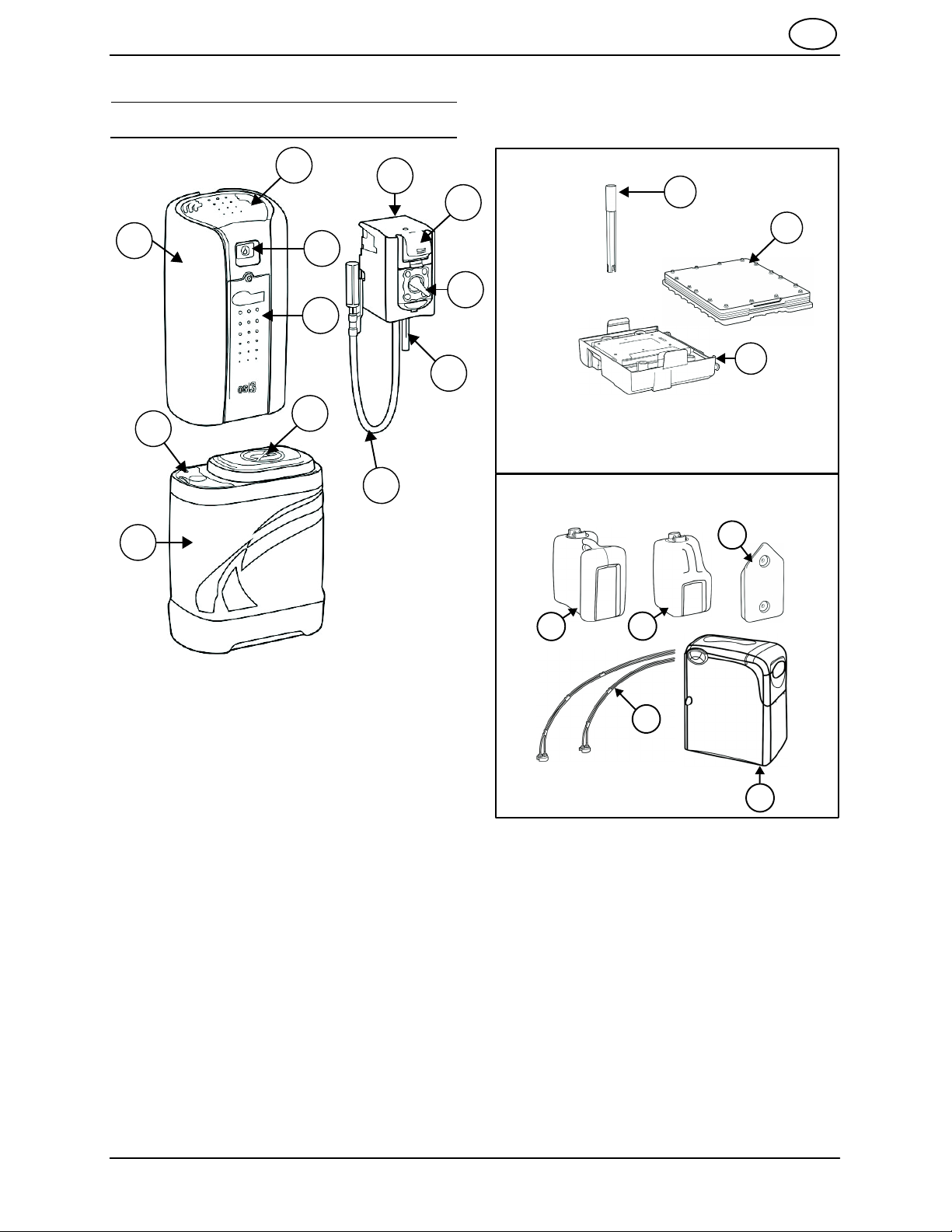

MACHINE COMPONENTS

OPERATION EN

OPERATION

F

A

H

D

E

I

C

L

G

J

Located behind front access panel

The e−cell and manifold are assembled

WEAR COMPONENTS

M

Located under

top cover

O

N

together as the “e−module.”

K

SATELLITE COMPONENTS

(OPTIONAL)

B

R

A. os3 generator

B. os3 water softener

C. Dispenser

D. Touch screen display

E. Front access panel with panel lock

F. Top cover

G. Selector knob and selector panel

H. Salt reservoir cover

I. Water softener cover

J. Bottle fill tube

K. Bucket and equipment fill tube

L. Dispenser button

PQ

S

T

M. PH probe

N. e−cell

O. Manifold

P. Transport container (large)

Q. Transport container (small)

R. Wall hook

S. Satellite tubing kit

T. Satellite system water softener

OS3 DM20036 (3−2014)

5

EN OPERATION

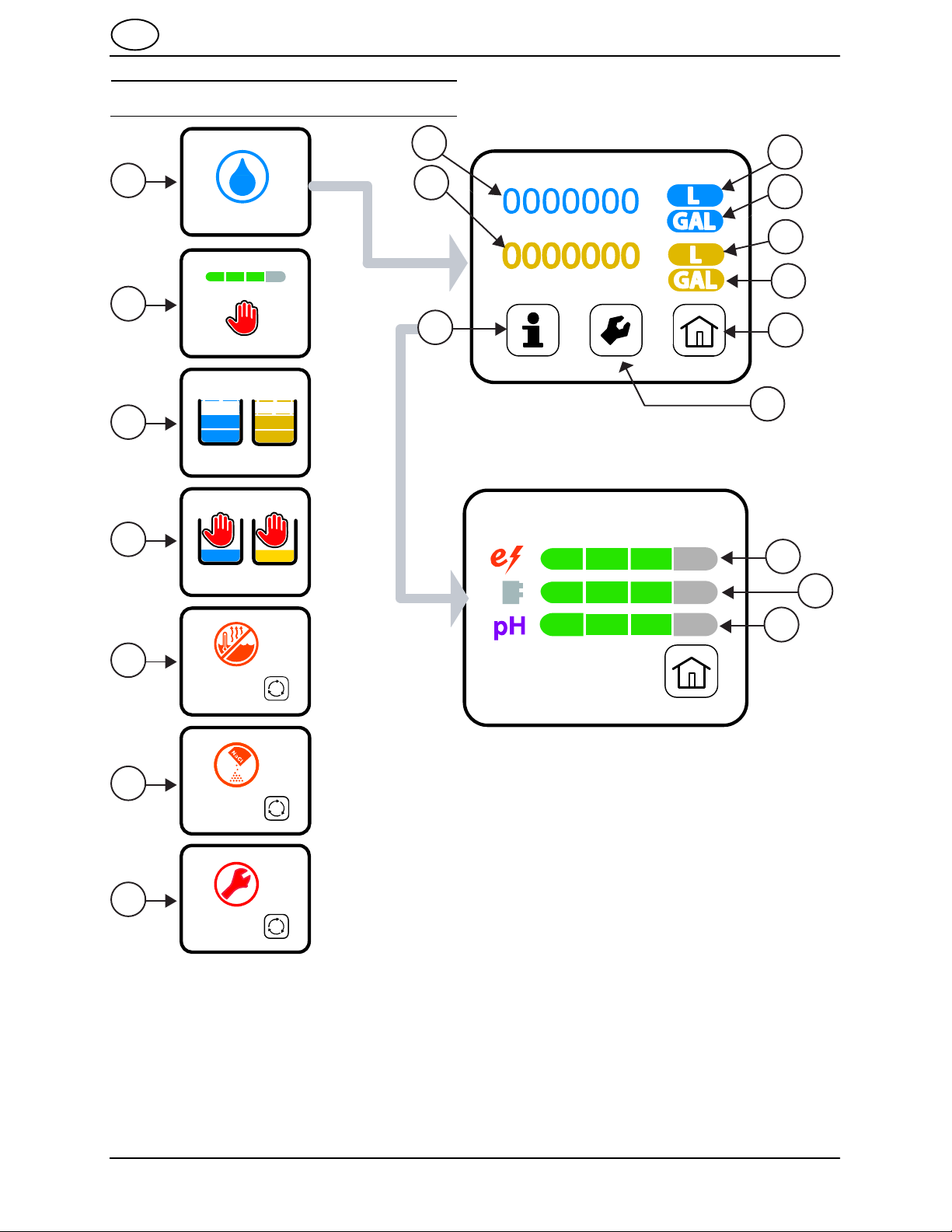

DISPLAY PANEL INDICATORS

H

A

B

C

D

I

N

Quantity dispensed indicators:

J

K

J

K

L

M

Wear component indicators:

O

E

F

G

A. Ready to Dispense indicator (Home)

B. Machine initializing indicator

C. Tanks filling indicator

D. Wait to dispense indicator

E. Water temperature too hot indicator

F. Add Salt indicator

G. Service required indicator

H. MultiSurface Cleaner solution generated

(diluted)

I. Multimicro 200 Solution generated (diluted)

P

Q

J. Liter indicator

K. Gallon indicator

L. Home touch button

M. Service information touch button

N. Information touch button

O. e−cell status indicator

P. Manifold Status indicator

Q. PH probe status indicator

6

OS3 DM20036 (3−2014)

OPERATION EN

HOW THE MACHINE WORKS

The Orbio os3 is an on−site generator that

produces cleaning and antimicrobial solutions for

institutional and commercial use. The os3 uses

electrolysis to convert water and salt into low

concentrations of sodium hydroxide (NaOH) for

cleaning and hypochlorous acid (HOCL) for

antimicrobial applications. These solutions are

diluted through the os3 dispenser as ready to use

products. No additional dilution is required.

NOTE: Store MultiSurface Cleaner and MultiMicro

200 Solution in a room/location where the

temperature is between 50−110° F (10−43° C).

WHILE OPERATING THE MACHINE

Periodically check the display panel indicators to

ensure there are no service alerts that need to be

cleared. Conditions must be cleared before the

os3 can be used again. Avoid running the system

completely out of salt. Add water softener salt to

the reservoir on a routine basis as the salt supply

is consumed. When the add salt indicator is

displayed the machine will stop until salt is added.

Refer to the Filling the Salt Reservoir section of

this manual.

The operator is responsible for ensuring that the

solutions are at the proper pH and concentration

levels. Refer to TESTING THE ANITMICROBIAL

SOLUTION and TESTING THE CLEANING

SOLUTION in the Maintenance section of this

manual for proper testing procedures.

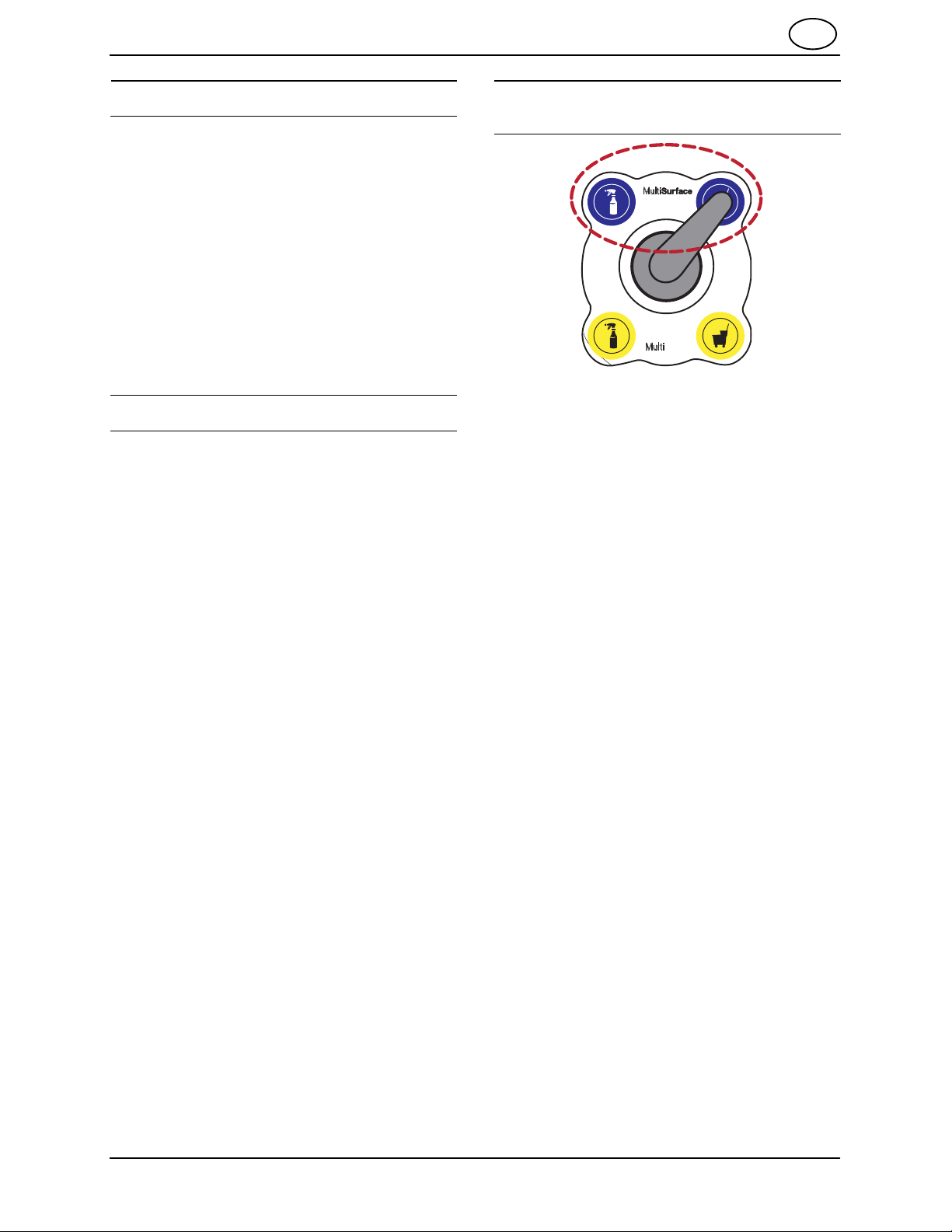

CLEANING SOLUTION

(top positions indicated in blue)

Multi

CLEANER

Multi

Micro

200

MultiSurface Cleaner is the cleaning solution

produced by the os3. MultiSurface Cleaner will

clean most soiled or dirty surfaces (wool, nylon

and polyester carpeting, glass, stainless steel,

other metal, ceramic, laminate, painted surfaces,

and other non−porous surfaces), but is not

recommended for cleaning heavy petroleum

based oils and greases.

NOTE: Always check carpet manufacturer

specifications for color stability and shrinkage

properties before using a water−based solution on

carpeting.

Do not dilute MultiSurface cleaning solution with

water. Water will diminish the cleaning

effectiveness. MultiSurface cleaner is ready to

use after dispensing.

FOR SAFETY: Do not mix MultiSurface

cleaning solution with conventional cleaning

chemicals. Do not drink. Refer the SDS (Safety

Data Sheet) for additional safety information

and precautions.

OS3 DM20036 (3−2014)

MultiSurface cleaner will remain effective for 30

days or more when stored in a clean, sealed

container. Test the cleaning solution to verify the

pH level is at the correct level if the solution has

been stored for longer than 30 days. Refer to the

Testing the Cleaning Solution in MAINTENANCE

for additional testing information.

7

EN OPERATION

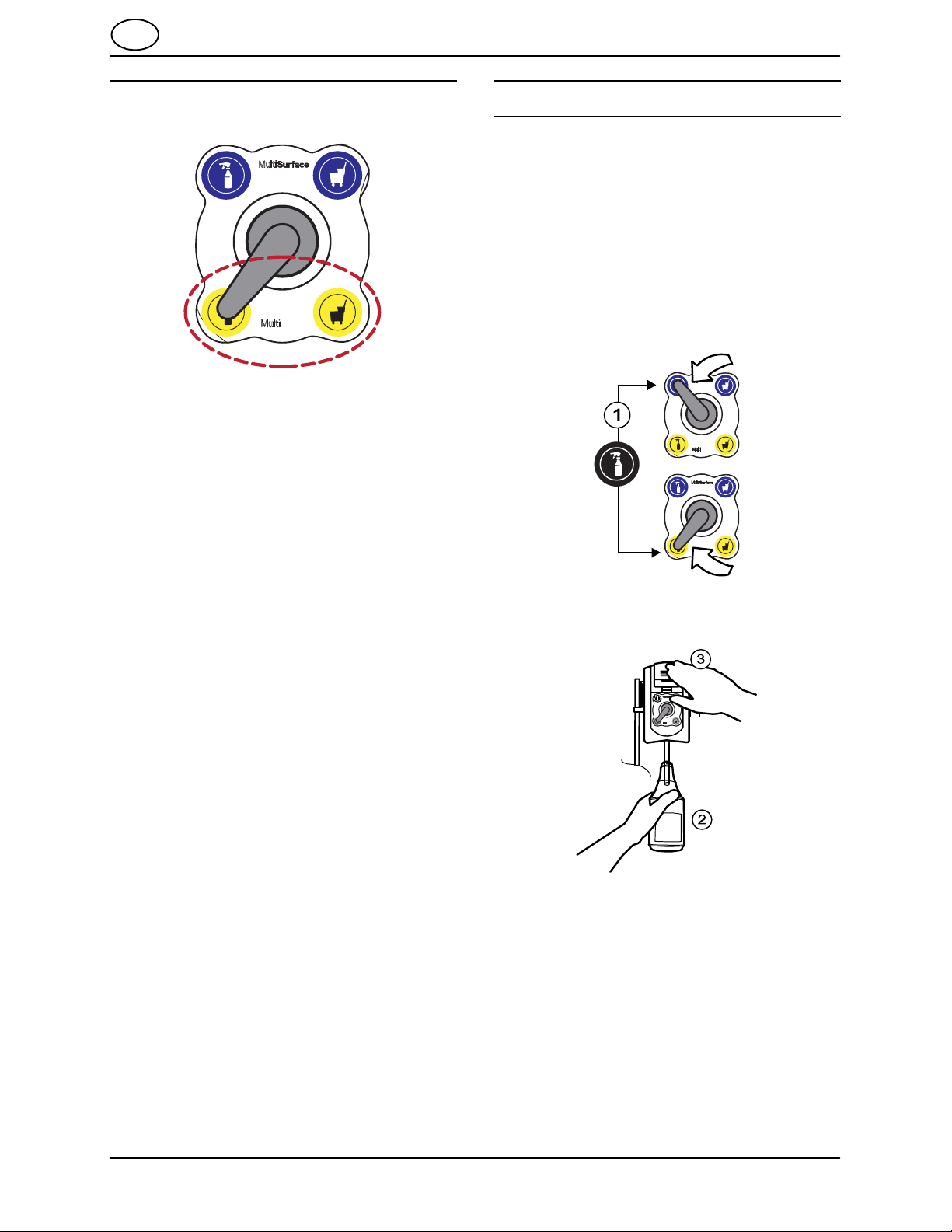

ANTIMICROBIAL SOLUTION

(bottom positions indicated in yellow)

Multi

CLEANER

Multi

Micro

200

MultiMicro is the antimicrobial solution generated

by the os3. The os3 dilutes this solution and

dispenses MultiMicro 200, the ready to use form

containing 200 ppmavailable chlorine. MultiMicro

200 is an effective disinfecting and sanitizing

solution. Do not dilute MultiMicro 200 with water.

The solution is ready to use after being dispensed

from the Orbio dispenser.

MultiMicro 200 stored in a spray bottle or sealed

container is effective for up to 7 days. Discard

expired solution.

MultiMicro Concentrate has a stability of 30 days.

To ensure proper concentration levels, the

MultiMicro tank must be evacuated at least every

30 days. Evacuate the MultiMicro Concentrate

using the MultiMicro 200 bucket fill position. Drain

until the Wait to Dispense indicator displays.

Dispose the solution according to local waste and

disposal regulations.

OPERATING THE ORBIO DISPENSER

The Orbio os3 and satellite systems are equipped

with a four position dispenser.

FOR SAFETY: Do not operate machine unless

operator’s manual is read and understood. Do

not drink. Refer to SDS (Safety Data Sheet) for

additional safety information and precautions.

FILLING BOTTLES

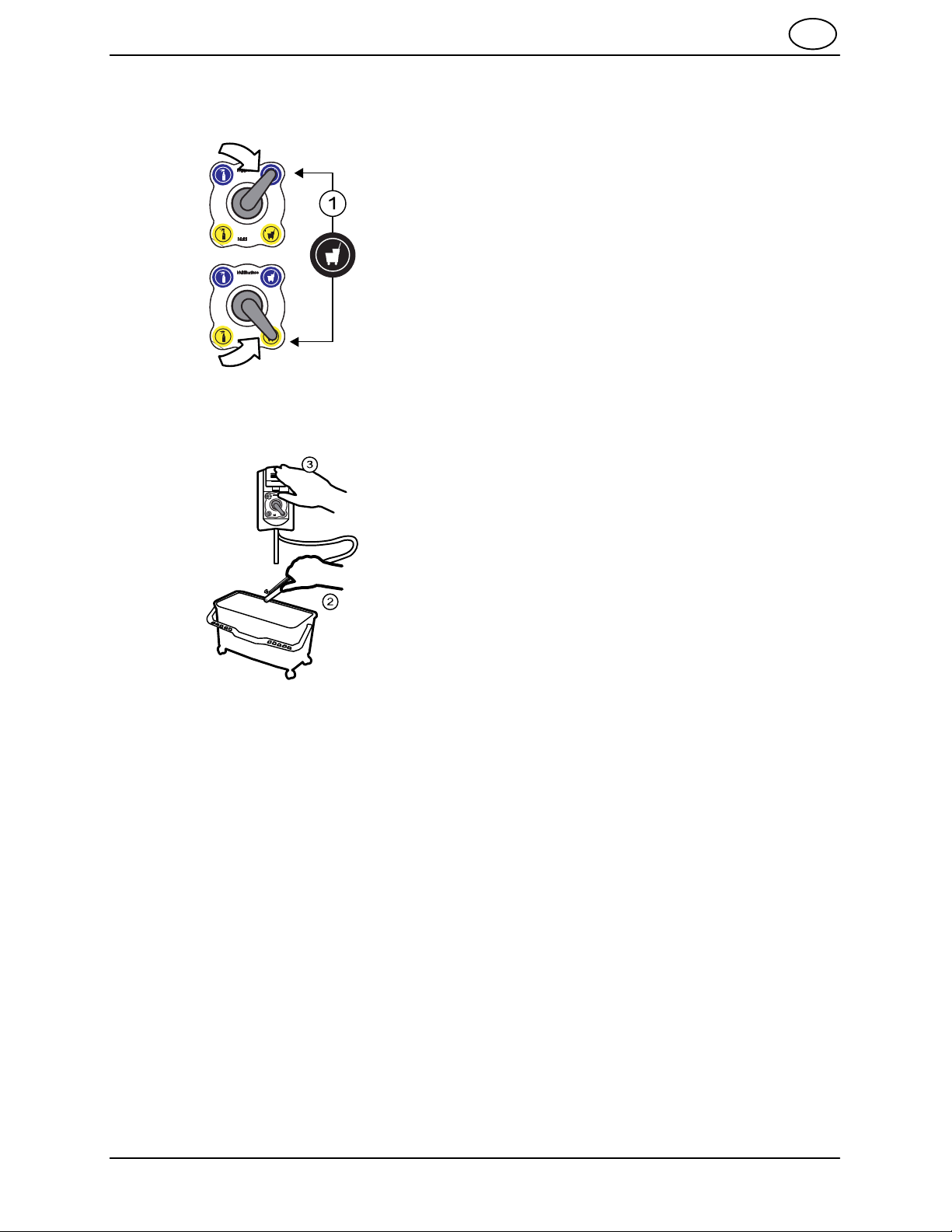

1. Turn selector knob to the bottle fill position for

MultiMicro 200 or MultiSurface Cleaner.

Multi

CLEANER

Multi

Micro

200

Multi

CLEANER

Multi

Micro

200

2. Insert bottle fill nozzle into the spray bottle.

3. Push the dispenser button to fill the bottle.

Multi

CLEANER

Micro

Multi

200

FOR SAFETY: Do not mix MultiMicro 200 with

ammonia or acid which will produce chlorine

gas. Do not mix with other cleaning products.

Refer to the SDS (Safety Data Sheet) for

additional safety information and precautions.

NOTE: For application information and

antimicrobial claims, refer to the use directions

detailed on the os3 generator label.

8

NOTE: Only use clean bottles properly labeled

with labels provided with this machine. Do not use

non−labeled or mis−labeled bottles.

Refer to the MultiMicro 200 and MultiSurface

Cleaner bottle labels for instructions for use.

OS3 DM20036 (3−2014)

FILLING BUCKETS AND EQUIPMENT

1. Turn selector knob to the bucket fill position

for MultiMicro 200 or MultiSurface Cleaner.

Multi

CLEANER

Micro

Multi

200

Multi

CLEANER

Multi

Micro

200

2. Unhook bucket/equipment fill hose from

dispenser and insert into container to be filled.

3. Push the dispenser button to fill the container.

OPERATION EN

Multi

CLEANER

Multi

Micro

200

The dispenser button can be locked into position

for filling large containers. Tap the dispenser

button to unlock.

Refer to the MultiMicro 200 and MultiSurface

Cleaner bottle labels for instructions for use.

OS3 DM20036 (3−2014)

9

EN OPERATION

INDICATORS

This machine is equipped with visual indicators on

the touch screen to alert the operator that there is

a condition that may need to be cleared.

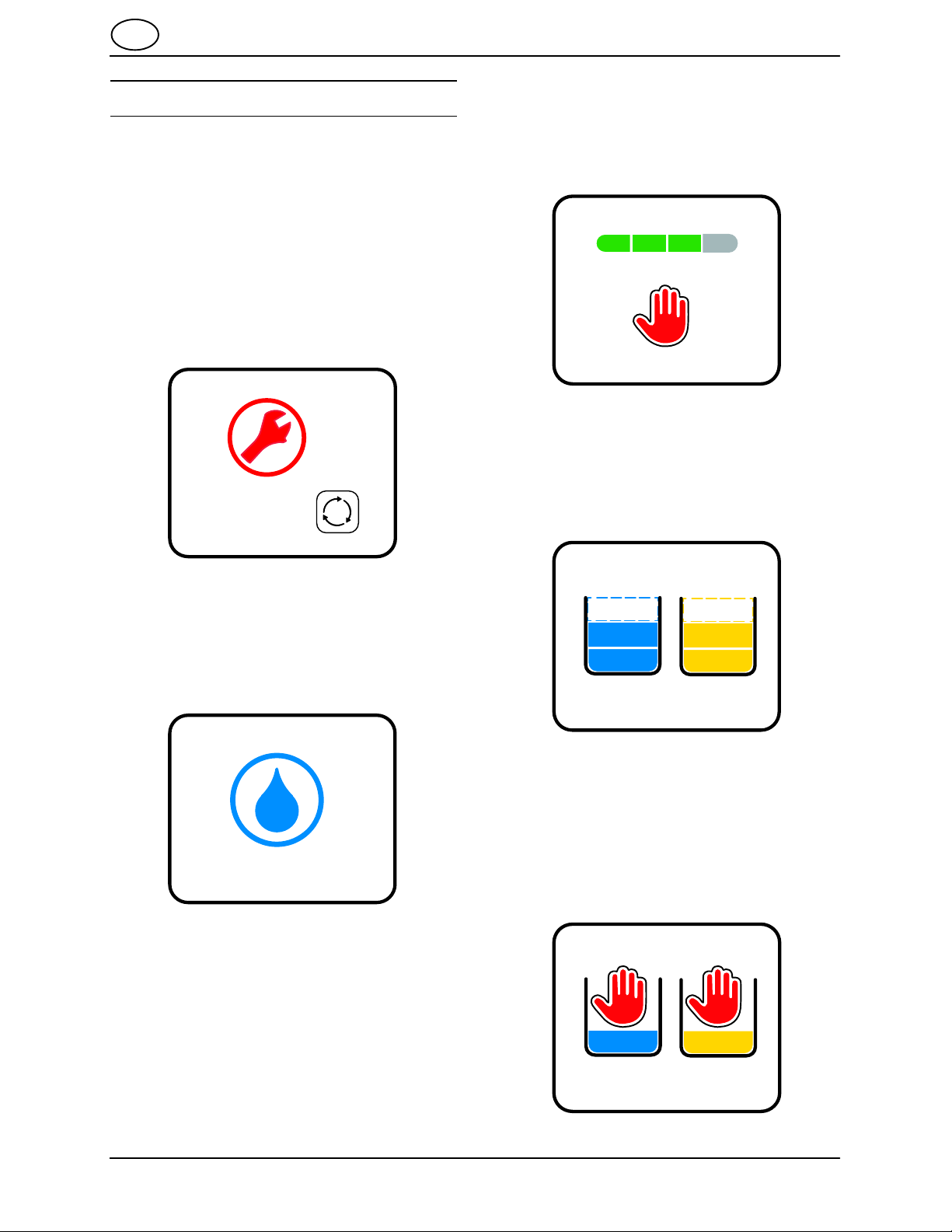

SERVICE REQUIRED INDICATOR

The service required indicator illuminates when

The os3 needs to be serviced. In some instances

an error code will be displayed under the indicator.

Stop using the machine. Refer to the TROUBLE

SHOOTING section of this manual to determine

the cause of the condition.

MACHINE INITIALIZING INDICATOR

The machine initializing indicator displays during

start−up and system reset. Progress bar indicates

the machine is processing information. Wait while

the machine completes the initialization process.

TANKS FILLING INDICATOR

The tanks filling indicator displays when one or

both tanks are filling with solution. This indicator is

for informational purposes only. The system may

be used while this indicator is displayed.

READY TO DISPENSE INDICATOR (Home

Screen)

The ready to dispense indicator is displayed when

both of the tanks are full of concentrate solution

and the machine is powered.

WAIT TO DISPENSE INDICATOR

The wait to dispense indicator is displayed when

one or both tanks are empty. Do not dispense

MultiSurface Cleaner (blue bars) or MultiMicro

200 (yellow bars) if the associated indicator is

displayed. One solution may be ready to dispense

while the other is not.

10

OS3 DM20036 (3−2014)

OPERATION EN

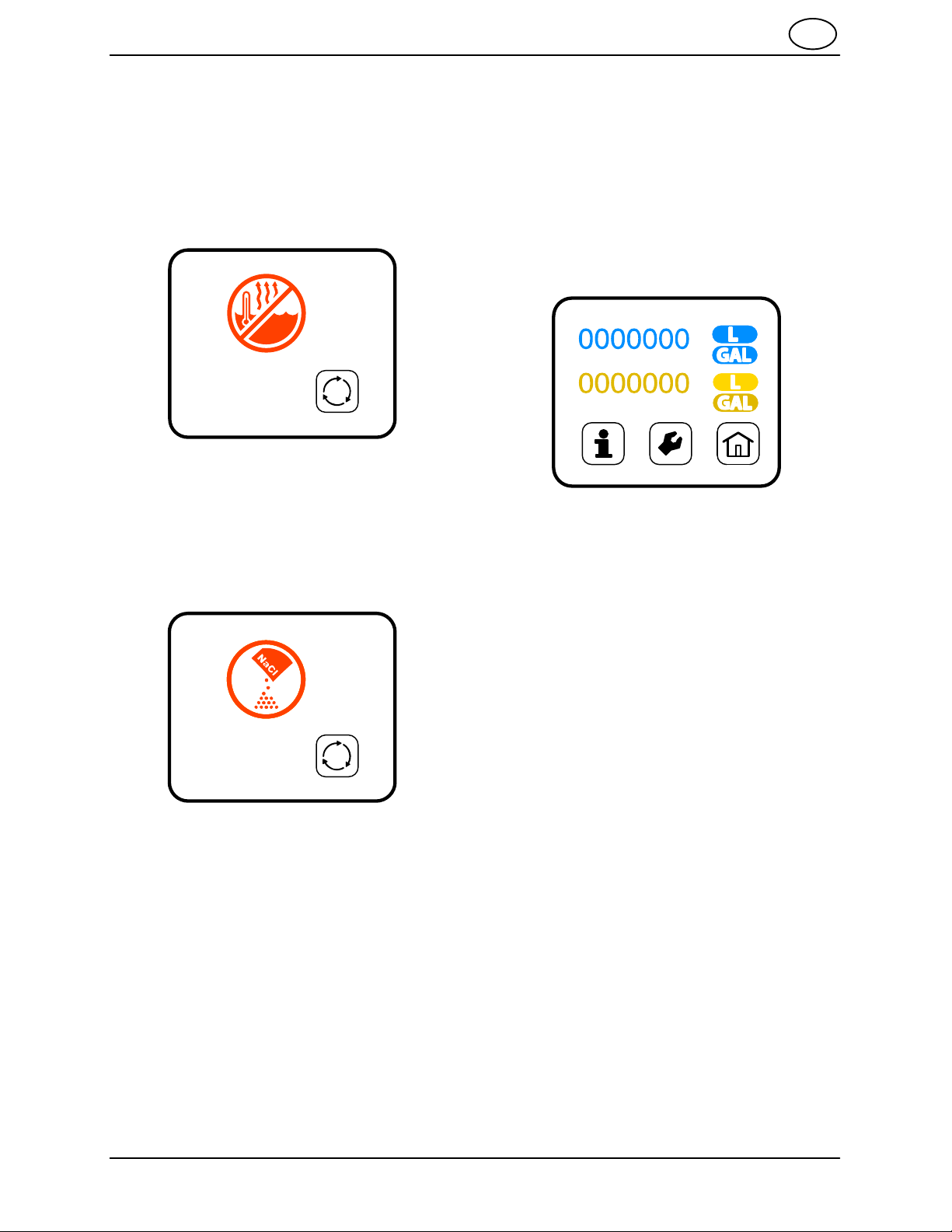

WATER TEMPERATURE TOO HOT INDICATOR

The water temperature too hot indicator is

displayed when the water supply to the machine

is too hot. Turn off the hot water and ensure there

is a dedicated cold water supply. Press the reset

button after changing the water supply to cold

water. System will not function until condition is

cleared.

ADD SALT INDICATOR

The add salt indicator is displayed when the salt

supply in the salt reservoir is low. Add salt to the

reservoir when the indicator is displayed. Refer to

Filling the Salt Reservoir in MAINTENANCE.

System will not function until condition is cleared.

QUANTITY DISPENSED INDICATOR

The quantity dispensed indicator displays the

amount of diluted solution generated in both liters

and gallons. The display will automatically

alternate between the liter and gallon equivalent

amounts. MultiSurface Cleaner is indicated in

blue, and MultiMicro 200 is indicated in yellow.

Touch the ready to dispense (home) screen to

access the quantity dispensed indicator.

OS3 DM20036 (3−2014)

11

EN OPERATION

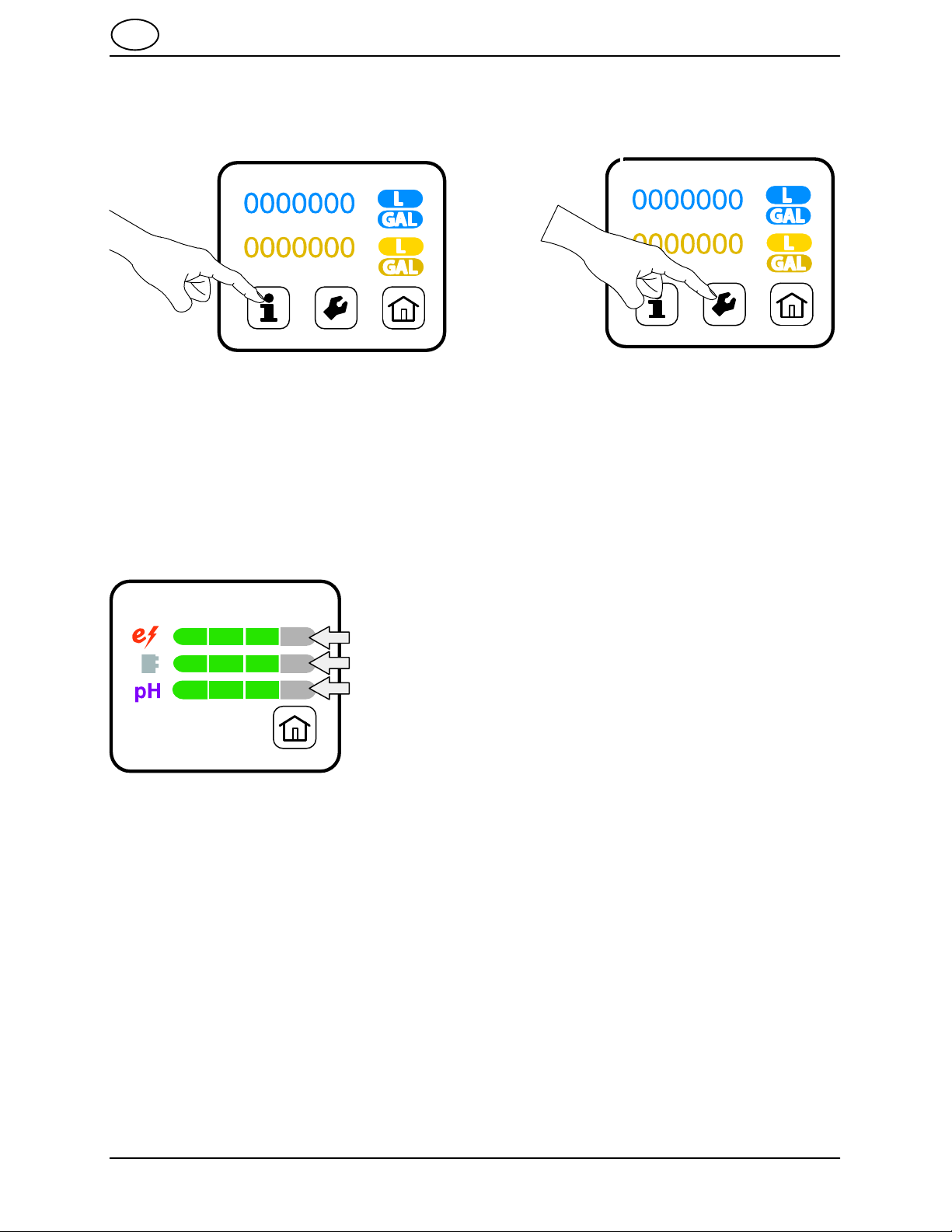

INFORMATION TOUCH BUTTON

Touch the information touch button to navigate to

the wear component indicators panel.

The wear component indicators panel displays the

status of the e−cell, manifold, and pH probe. The

progress bars indicate wear life. Order a new

component when the final segment of a progress

bar is yellow. Replace the component when the

segment is red.

Refer to Replacing Wear Components in

MAINTENANCE for instructions on replacing

these system components.

SERVICE INFORMATION TOUCH BUTTON

This button is used for trained service personnel

to access data for system troubleshooting.

e−cell status

manifold status

pH probe status

12

OS3 DM20036 (3−2014)

OPERATION EN

TROUBLESHOOTING

Problem Cause Remedy

No solution flow from dispenser. No water supply.

Screen is blank. No power.

Low salt indicator will not clear

after multiple resets.

SYS120 error No water to system.

EC110 Water too cold. Ensure all system components

COM110 Communication error between

COM100 Circuit board (power board) not

WS100 Possible lack of water to system. Ensure water is turned on.

PCB120 Expired pH probe. Replace pH probe.

PM100 Ambient temperature too hot. Machine must be in an

Chlorine test paper strips show

low

ppm of MultiMicro 200.

pH test paper strips show pH of

MultiSurface Cleaner less than

10.

Solution leaking from os3 Loose or damaged fitting.

Water softener overflows Obstruction or malfunction Turn off water, unplug machine,

No salt.

System requires flush. Dispense 19 Liters (5 Gallons) of

water softener and generator.

connected.

Call technical support.

Call technical support.

Damaged salt reservoir or

storage tanks.

Turn on water

Check for kinked or bent water

lines.

Check power cord connections at

both ends. Confirm cord is

connected to outlet and power

supply.

Power supply switch is turned off

(in rear of machine).

GFCI outlet tripped. Reset outlet.

Add salt to reservoir.

Check for salt bridge in reservoir.

Break loose to provide salt to

system.

Turn on water.

Check for kinked or pinched

hoses.

solution through the dispenser

and cycle power.

and water supply is above 5 C

(41 F). Warm system and press

reset.

Check DB9 cable that connects

water softener and generator.

Check connections on both

softener and generator.

Unplug machine. Press power

board and firmly seat into slot

(next to e−module).

environment less than 100 C

(230 F) to operate. Resolve

temperature and reset.

Turn off water, unplug machine,

and call technical support.

and call technical support.

See Indicators in the OPERATION section of this manual for instruction on machine indicators.

If a problem cannot be resolved with the associated remedy, or an error code is displayed that is not

listed in this troubleshooting guide, contact Tennant Company Technical Support at 1−800−553−8033.

OS3 DM20036 (3−2014)

13

EN OPERATION

MAINTENANCE

FILLING THE SALT RESERVOIR

Fill the salt reservoir with salt whenever the add

salt indicator is displayed. Use standard water

softener salt pellets (solar or evaporated).

Do not use rock salt to fill the salt reservoir.

1. Remove the cover from the salt reservoir.

4. Press the reset touch button and allow the

system to generate solution. The pump will

operate at a high rate while generating

solution. Multiple resets may be required

before the condition is cleared.

2. Pour the bag of salt into the salt reservoir. Fill

the salt reservoir to approximately 50mm

(2inches) below the salt reservoir opening.

3. Reinstall the cover onto the salt reservoir.

14

OS3 DM20036 (3−2014)

REPLACING WEAR COMPONENTS

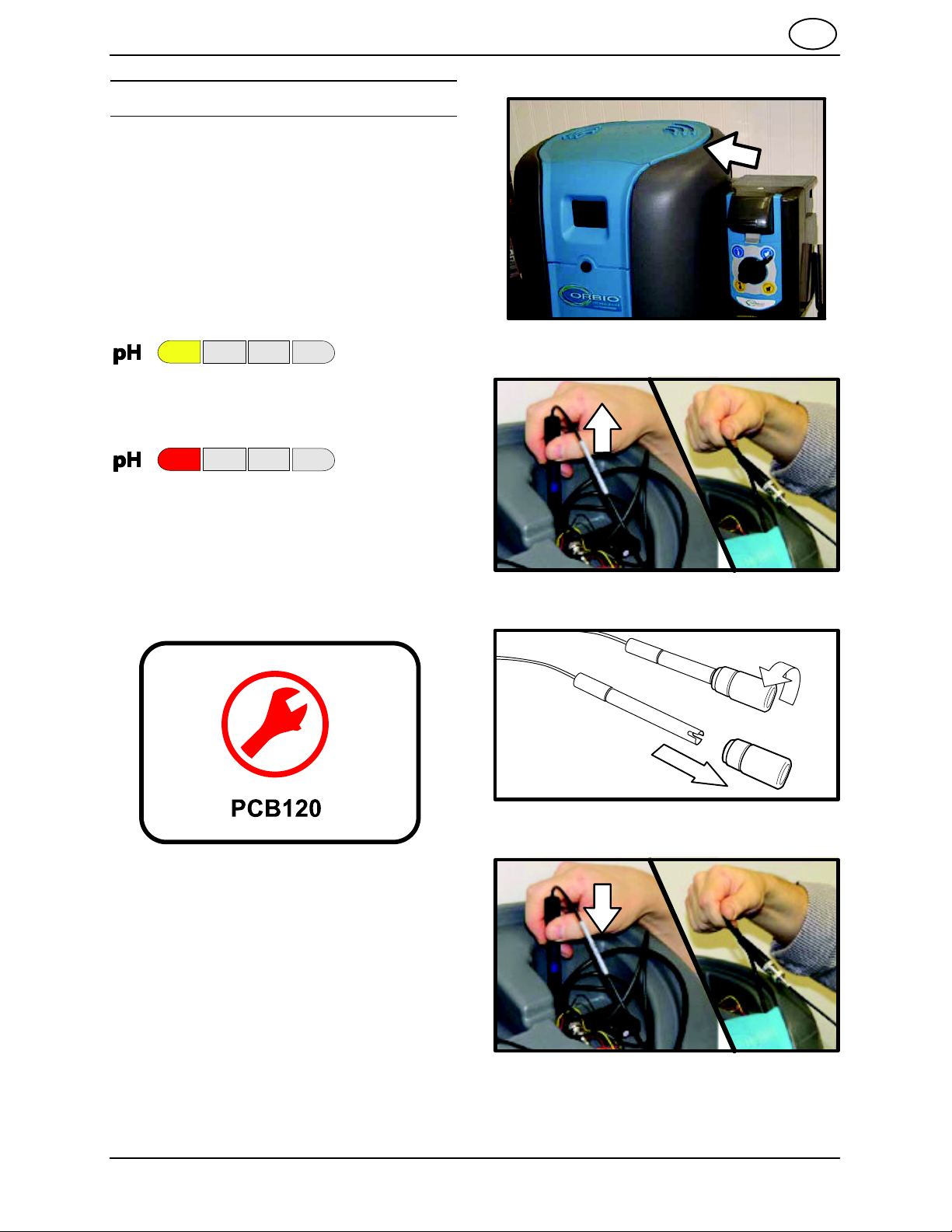

REPLACING THE pH PROBE

Requires service kit AS20052 PH PROBE

REPLACEMENT

Replace the pH probe annually. The machine will

not function with an expired pH probe. When the

remaining progress bar is displayed in yellow,

order the replacement kit. Install new pH probe

when segment turns red after one year of

operation.

Order new pH probe

(yellow)

OPERATION EN

1. Remove top cover.

2. Disconnect existing pH probe, remove and

discard.

Replace pH probe

(red)

When the pH probe expires, the machine will not

operate and the PCB120 error code will be

displayed:

Installing a new pH probe will clear this condition.

To prevent machine down time replace the pH

probe immediately when the last wear indicator

segment turns red. This error code can be

preempted by replacing the probe during yellow

status.

3. Remove and discard saline vial from

replacement pH probe.

4. Install new pH probe in pocket on top of

machine and connect to wire harness:

OS3 DM20036 (3−2014)

15

EN OPERATION

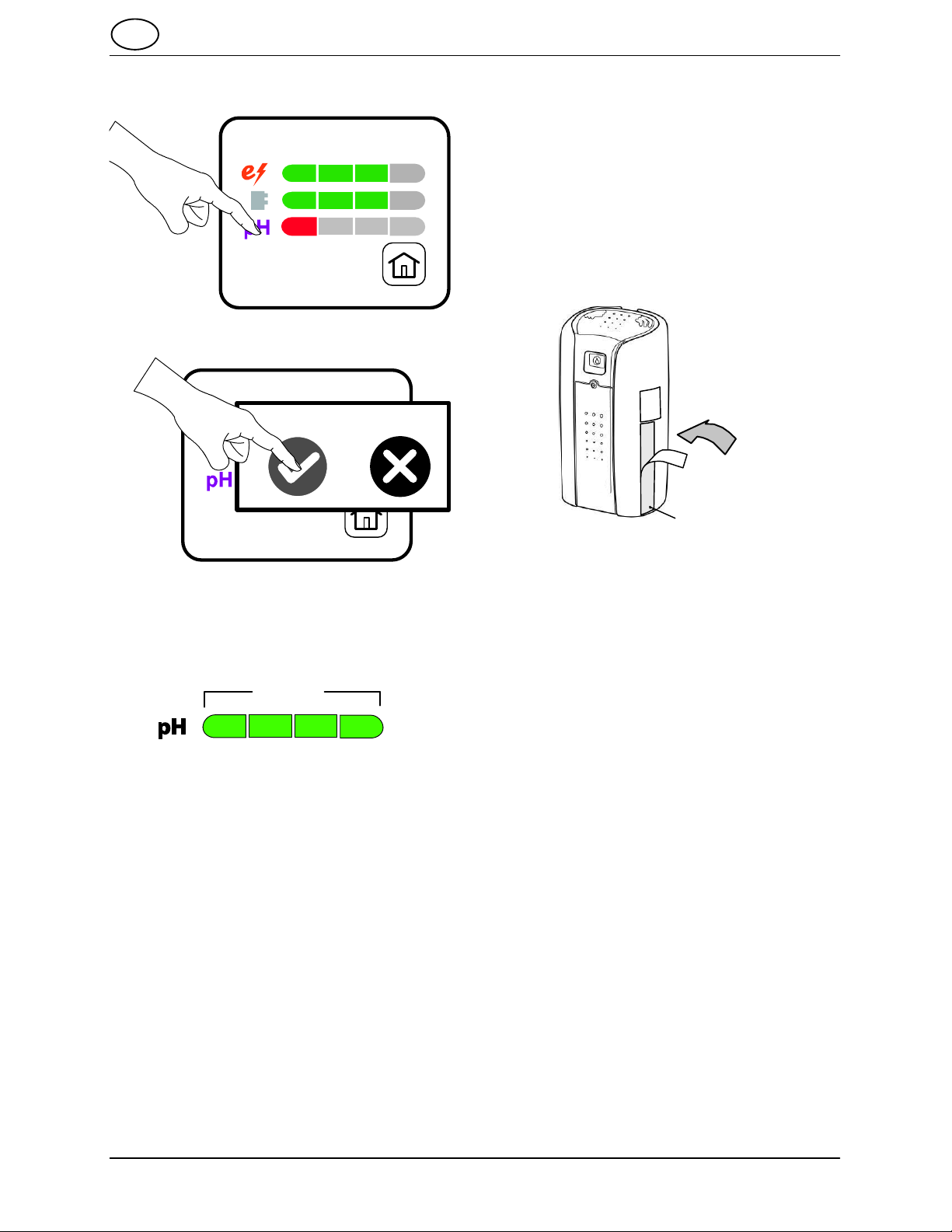

5. Press pH icon on touchscreen.

6. Confirm new pH probe installation.

pH

8. Reinstall the top cover.

9. Update product label.

Place the MultiMicro Directions for Use label

included in the pH probe service kit over the

existing label if the revision level number on the

replacement label is greater. The label is located

on the lower right hand side of the os3 generator.

Note: The pH probe service kit may contain more

than one MultiMicro

Select the appropriate label by country.

Directions for Use label.

Revision #

7. Verify correct installation on the Wear

Component Status Indicator Panel. All

segments on the progress bar will display as

green indicating a new pH probe.

GREEN

16

OS3 DM20036 (3−2014)

OPERATION EN

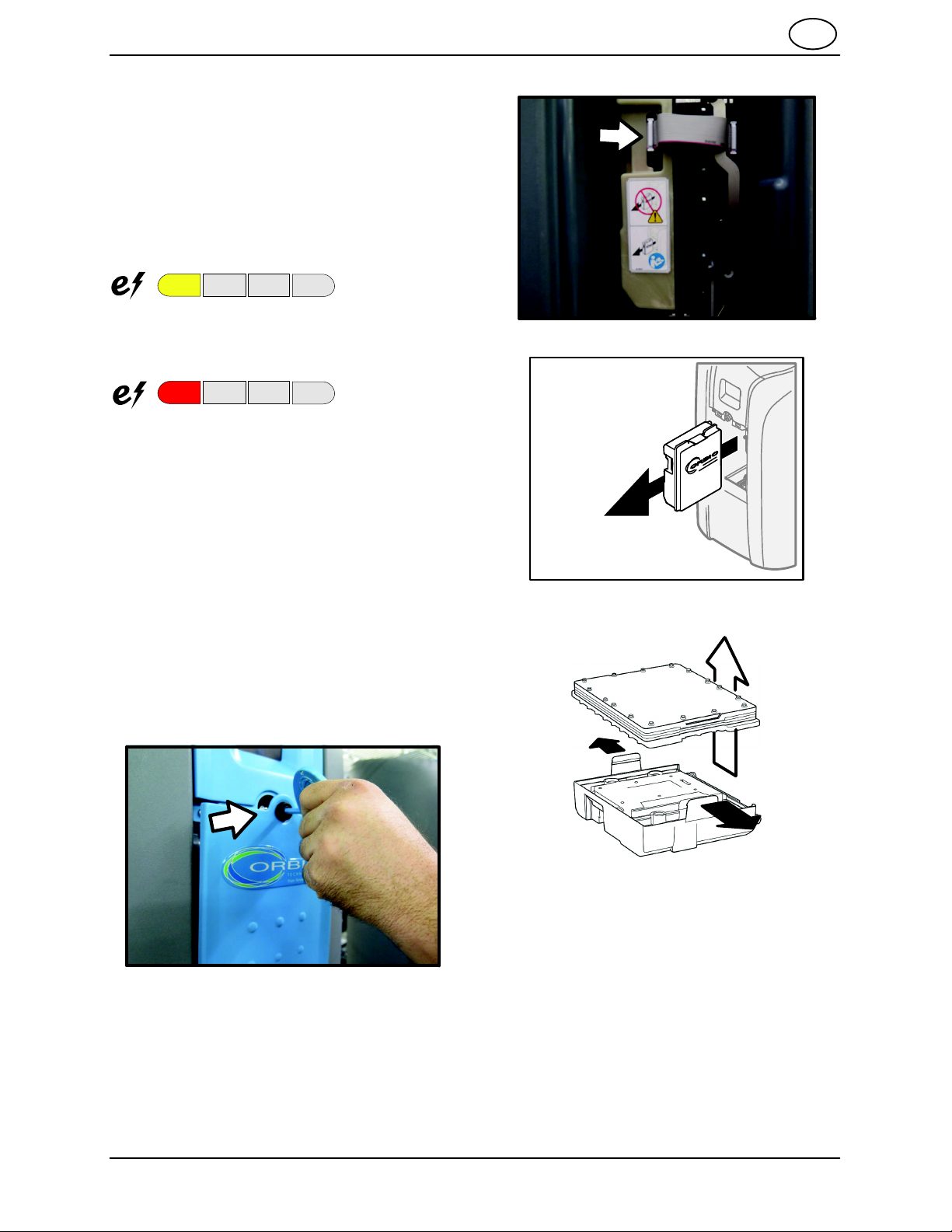

REPLACING THE e−CELL

Requires service kit AS20041 E−CELL

REPLACEMENT

Refer to the Wear Component Indicators panel on

the touch screen display for status of system wear

components. Order a replacement e−cell when

the remaining segment on the progress bar turns

yellow. Replace the e−cell when the the segment

turns red.

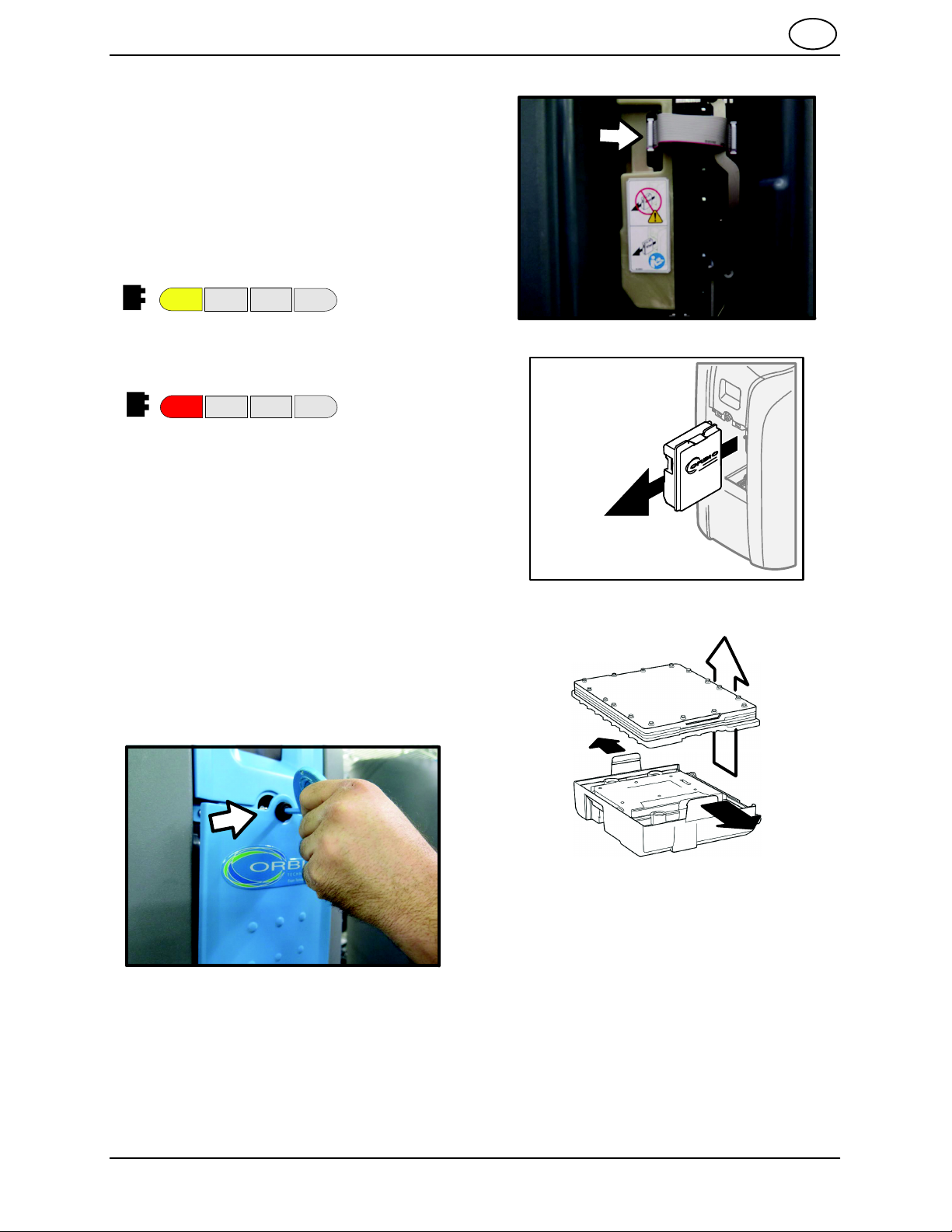

Order new e−cell

(yellow)

Replace e−cell

(red)

1. Disconnect power cord from outlet.

5. Disconnect ribbon cable.

6. With a firm grip pull out e−module from os3.

FOR SAFETY: When servicing machine

unplug cord from wall outlet.

2. Turn off water.

3. Dispense either the MultiSurface or

MultiMicro solution into a bucket or a drain

to depressurize the system.

4. Remove front access panel using the access

key.

7. Flex tabs on manifold and separate from

e−cell. Dispose of old e−cell properly.

OS3 DM20036 (3−2014)

17

EN OPERATION

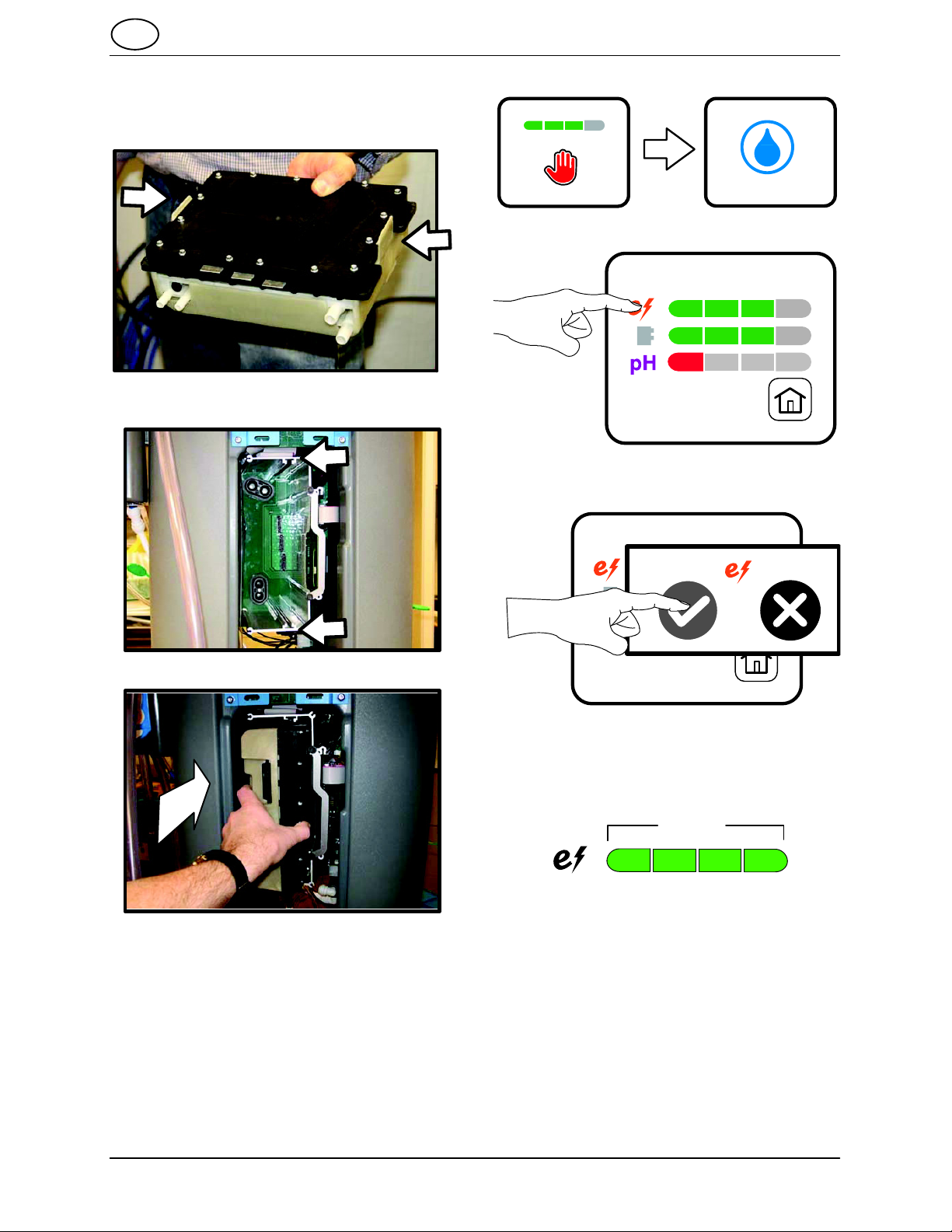

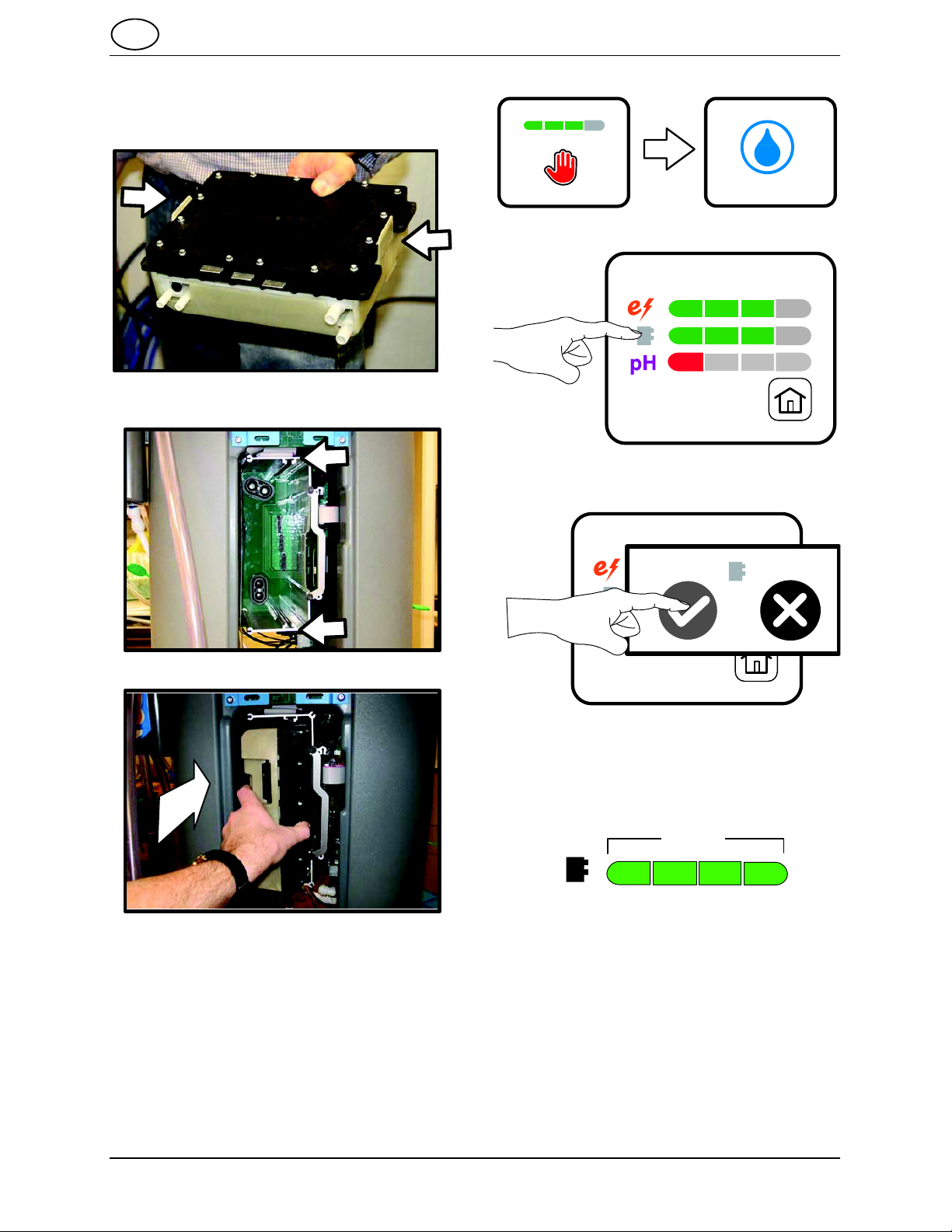

8. Install new e−cell onto manifold. Note port

and connector locations. Be sure the snaps

hold the e−cell and manifold securely

together.

9. Engage e−module into rails on chassis. Press

firmly until fully seated.

14.Wait to complete initialization.

15.Press e−cell icon on touchscreen.

16.Confirm new e−cell installation.

10.Reconnect ribbon cable.

11.Turn on water.

12.Power machine by plugging into outlet.

13.Check for leaks.

18

17.Verify correct installation on the Wear

Component Status Indicators panel. All

segments on the progress bar will display as

green indicating a new e−cell.

GREEN

18.Reinstall front access panel and secure with

key.

OS3 DM20036 (3−2014)

OPERATION EN

REPLACING THE MANIFOLD

Requires service kit AS20044 MANIFOLD

REPLACEMENT

Refer to the Wear Components Indicators panel

on the touch screen display for status of system

wear components. Order a replacement manifold

when the remaining segment of the progress bar

turns yellow. Replace the manifold when the

segment turns red.

Order new manifold

(yellow)

Replace manifold

(red)

1. Disconnect cord from outlet.

5. Disconnect ribbon cable.

6. With a firm grip pull out e−module from os3.

FOR SAFETY: When servicing machine

unplug cord from wall outlet.

2. Turn off water.

3. Dispense either the MultiSurface or

MultiMicro solution into a bucket or a drain

to depressurize the system.

4. Remove front access panel using the access

key.

7. Flex tabs on manifold and separate from

e−cell. Dispose of old e−cell properly.

OS3 DM20036 (3−2014)

19

EN OPERATION

8. Install e−cell onto new manifold. Note port

and connector locations. Be sure the snaps

hold the e−cell and manifold securely

together.

9. Engage e−module into rails on chassis. Press

firmly until fully seated.

14.Wait to complete initialization.

15.Press manifold icon on touchscreen.

16.Confirm new manifold installation.

10.Reconnect ribbon cable.

11.Turn on water.

12.Power machine by plugging into outlet.

13.Check for leaks.

20

17.Verify correct installation on the Wear

Component Status Indicators panel. All

segments on the progress bar will display as

green indicating a new manifold.

GREEN

18.Reinstall front access panel and secure with

key.

OS3 DM20036 (3−2014)

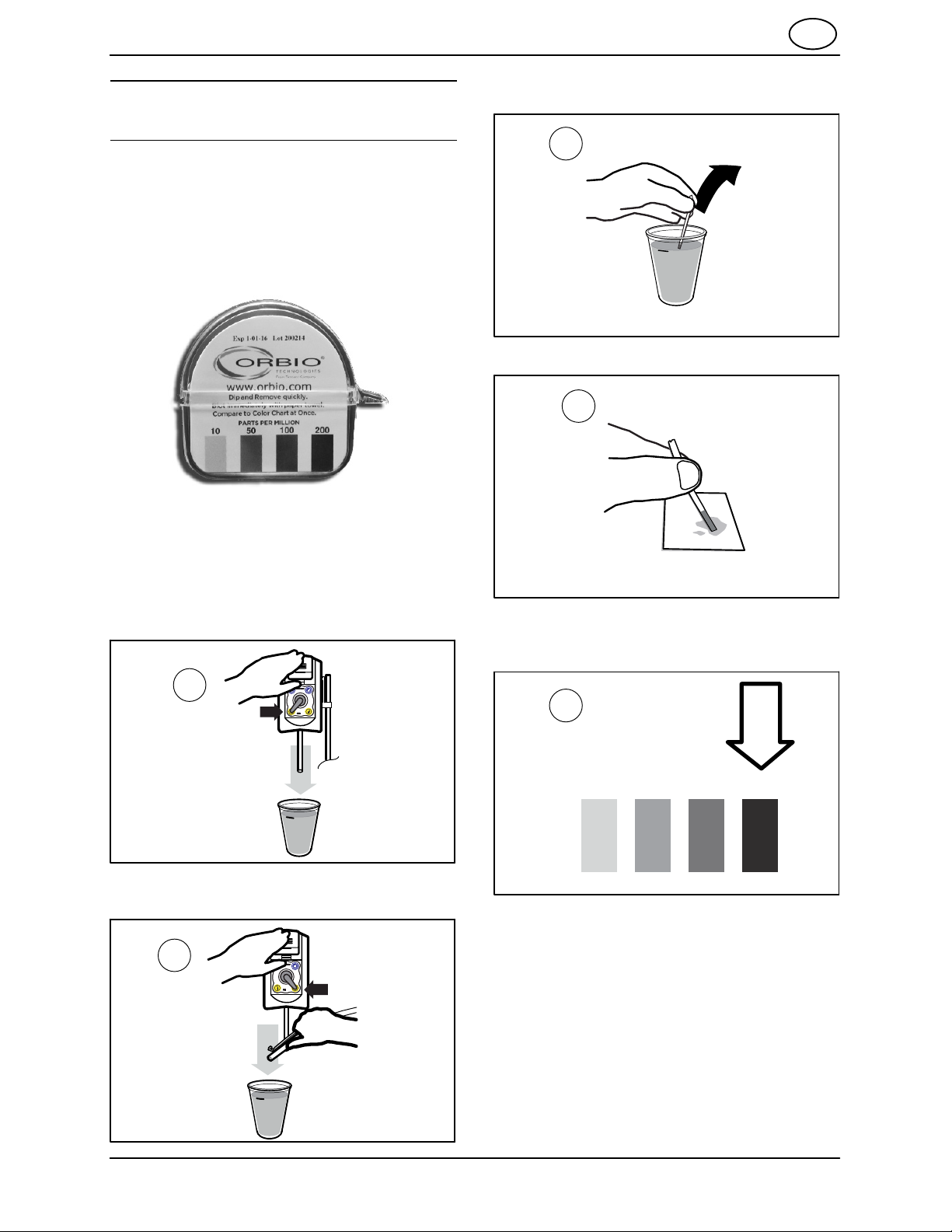

TESTING THE ANTIMICROBIAL

SOLUTION

Test MultiMicro 200 solution to verify proper

dilution through the Orbio dispenser. This

procedure will test both the bottle and bucket fill

metering tips.

Tools required: Orbio Chlorine Test Paper and 2

clean 240 cc (8 oz.) containers.

OPERATION EN

3. Using a chlorine test strip for each container,

dip and remove quickly.

3

4. Blot immediately.

4

Orbio Chlorine Test Paper

If the solution test paper does not indicate 200

ppm contact technical support. Discard solution

that does not pass this test procedure.

1. Fill one container with solution from the bottle

fill tube.

Multi

1

2. Fill the second container with solution from

the bucket fill tube.

CLEANER

Multi

Micro

200

5. Compare to color chart on test paper

container. “200” indicates correct

concentration.

5

OK

10 50 100 200

2

OS3 DM20036 (3−2014)

Multi

CLEANER

Multi

Micro

200

21

EN OPERATION

TESTING THE CLEANING SOLUTION

3. Using a pH test strip for each container, dip

and remove quickly.

Test MultiSurface Cleaner to verify proper dilution

through the Orbio dispenser. This procedure will

test both the bottle and bucket fill metering tips.

Tools required: Orbio pH Test Paper and 2 clean

240 cc (8 oz.) containers.

Orbio pH Test Paper

If the solution has a pH less than 10, discard the

solution. This test method can also be used to

test solution that has been stored for more than

60 days.

1. Fill one container with solution from the bottle

fill tube.

1

Multi

CLEANER

Multi

Micro

200

3

4. Blot immediately.

4

5. Compare to color chart on test paper

container. “10” or greater indicates adequate

pH level.

254

1

pH0

5

36

2. Fill the second container with solution from

the bucket fill tube.

2 Multi

CLEANER

Multi

Micro

200

22

pH7

891011

12 13

OK

OS3 DM20036 (3−2014)

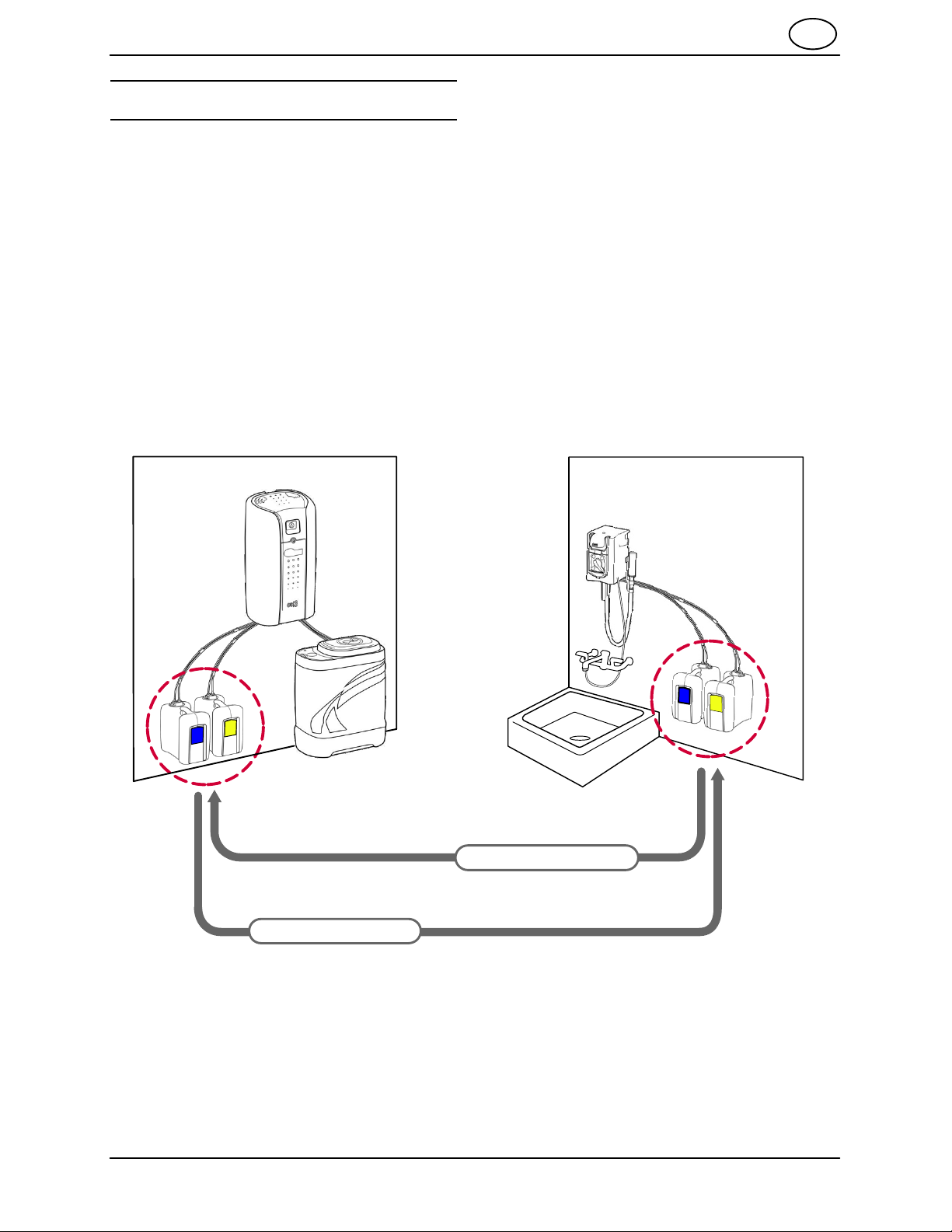

SATELLITE SYSTEMS

The os3 system may be equipped with one or

more satellite systems. The satellite systems

allow dilution of MultiMicro Concentrate and

MultiSurface Concentrate in remote locations

through an Orbio Technologies dispenser.

Orbio transport containers are filled at the os3

generator and moved to the satellite station

location where the concentrate is diluted into a

RTU (ready−to−use) solution. When empty,

transport containers are returned to the os3

generator to be filled. The empty container is

replaced with a full container at the satellite

station.

OPERATION EN

Only completely emptied transport containers

should filled at the os3 generator. Any remaining

amount of either MultiMicro Concentrate or

MultiSurface Concentrate can be evacuated by

diluting the concentrate with water through the

satellite system dispenser. Dispose of according

to local waste disposal regulations.

Note: Do not refill partially empty containers. The

residual solution in the transport container will

compromise the shelf life and effectiveness of the

concentrate.

MultiSurface Concentrate can be stored in a

transport container for 90 days.

MultiMicro Concentrate can be stored in a

transport container for 30 days.

os3 Generator (filling station)

transport

containers

os3 Satellite (dispensing station)

transport

containers

empty containers

OS3 DM20036 (3−2014)

full containers

23

EN OPERATION

CONNECTING AND DISCONNECTING

TRANSPORT CONTAINERS

Quick−connect caps attach the transport

containers to the os3 generator and satellite

systems. The caps are color coded to ensure

correct installation. MultiMicro 200 connecting

caps are yellow, and MultiSurface connecting

caps are blue.

NOTE: Caps are designed to prevent access to

the concentrate solution. Do not attempt to

remove the caps from the container.

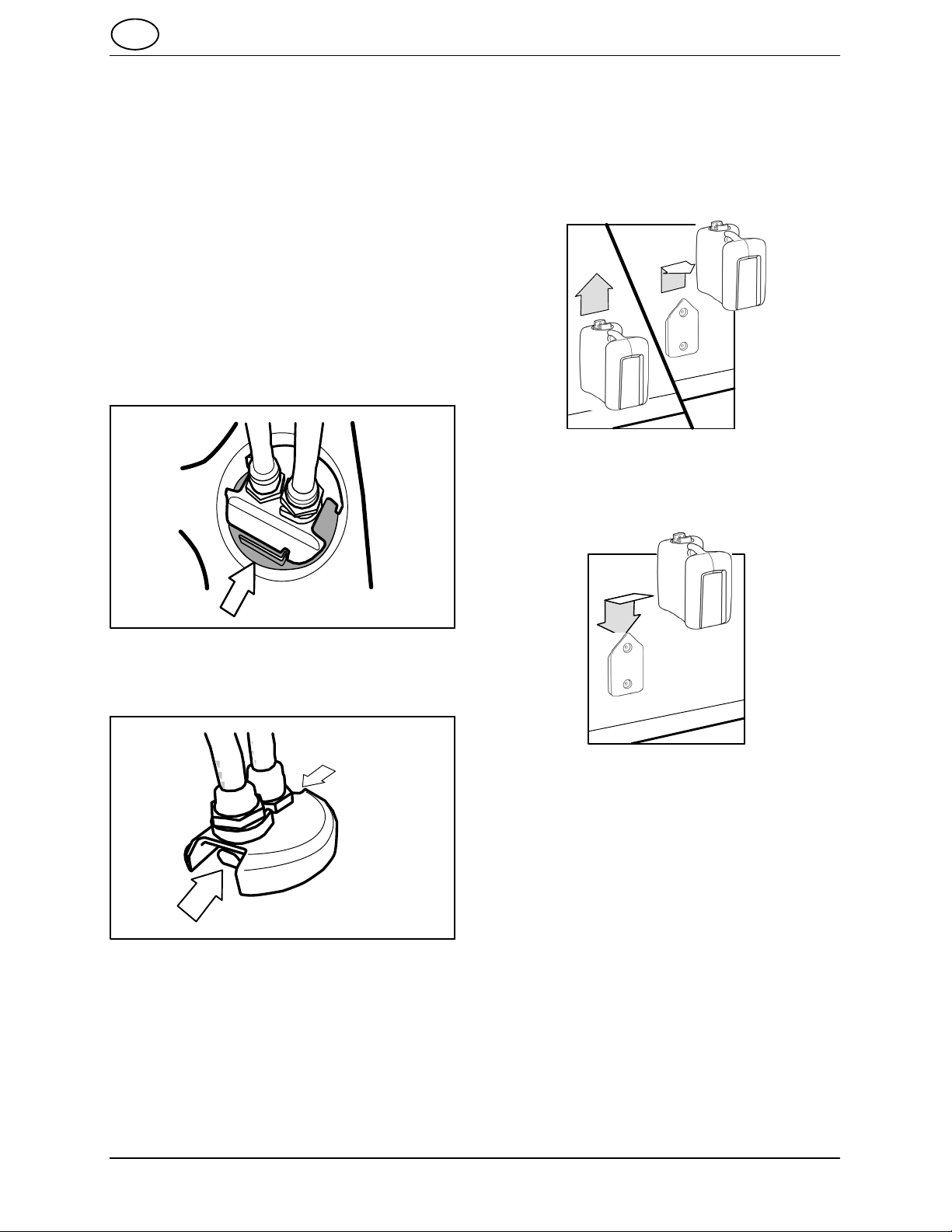

CONNECTING

Align section of cap with “L” shaped key on the

transport container. Push firmly until the cap locks

to the receptacle on the container.

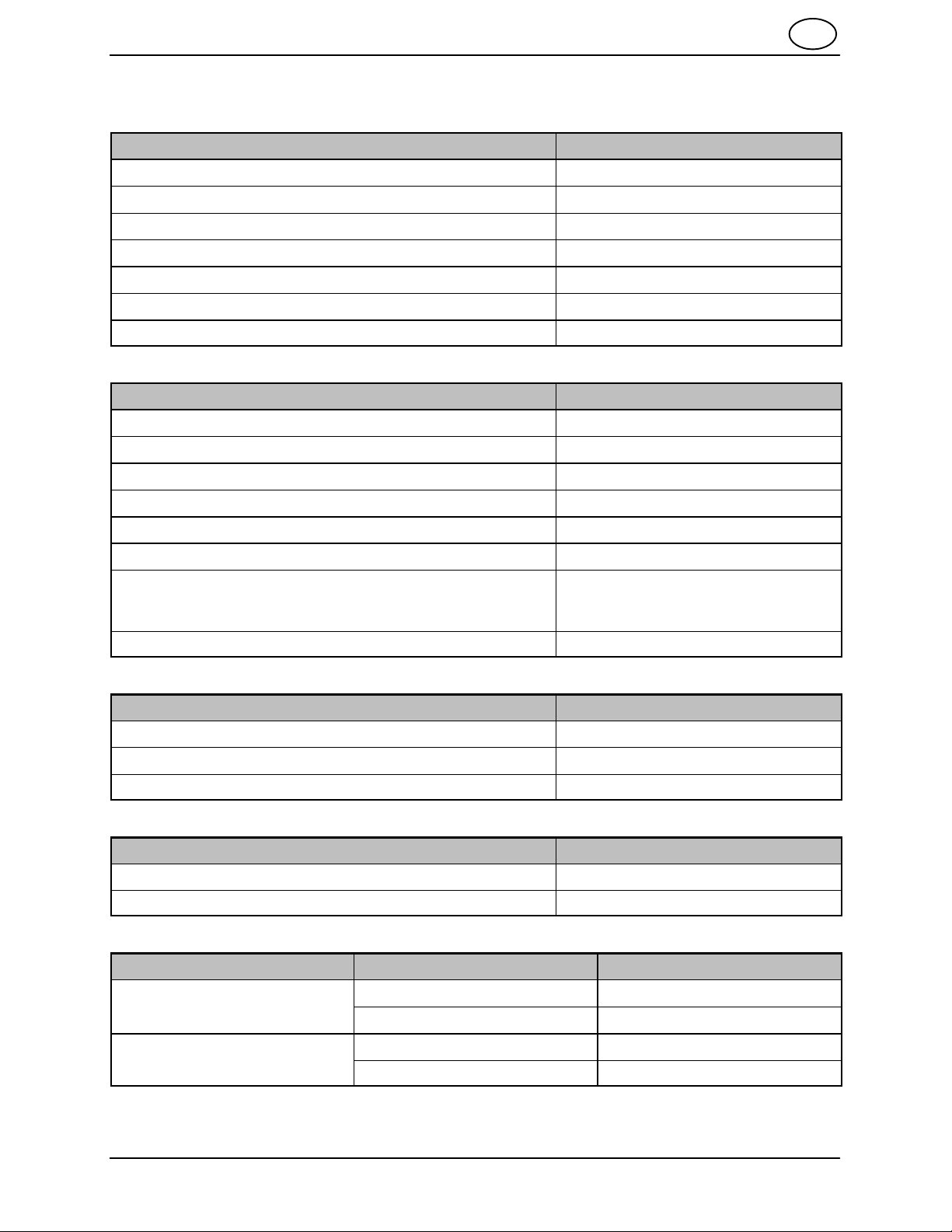

USING THE TRANSPORT CONTAINER WALL

HOOK

Transport containers may be secured to the wall

with an os3 wall hook.

To remove a container from the wall hook, lift the

container up slightly and then away

To install the container on an os3 wall hook,

position the transport container immediately

above the wall hook and slowly lower the

transport container until the hook engages.

ALIGNMENT KEY

DISCONNECTING

With thumb and forefinger, squeeze release tabs

on cap and lift cap away from transport container.

RELEASE TABS

Note: Do not stack transport containers when on

wall hook.

For additional accessories and information

about Orbio satellite systems for the os3, see a

sales representative or go to www.orbio.com.

24

OS3 DM20036 (3−2014)

OPERATION EN

SPECIFICATIONS

os3 GENERATOR

Item Measure

Depth 356 mm (14 in)

Width (with dispenser attached) 610 mm (24 in)

Width (without dispenser attached) 457 mm (18 in)

Height 813 mm (32 in)

Weight (empty) 18 kg (40 lbs)

Weight (filled with solution) 47 kg (103 lbs)

Operating ambient temperature 10°−43° C (50°−110° F)

os3 Water Softener

Item Measure

Depth 356 mm (14 in)

Width (with dispenser attached) 610 mm (24 in)

Height 686 mm (27 in)

Weight (empty) 20 kg (44 lbs)

Weight (filled with solution) 112 kg (247 lbs)

Operating ambient temperature 10°−43° C (50°−110° F)

Salt type Standard water softener pellets (solar

or evaporated) −

Not rock salt or crystals

Salt reservoir capacity 68 kg (150 lbs)

POWER

Item Measure

Circuit Required (min) 15A

Input AC voltage 120V/60Hz

Input AC voltage (International) 230V/50Hz

DISPENSING SYSTEM

Item Measure

MultiSurface Cleaner pH (RTU) 10−11.5

MultiMicro 200 pH (RTU) 6−8

GENERATION SYSTEM

Solution Type Item Measure

MultiSurface Concentrate

MultiMicro 200 Concentrate

Generator tank capacity 19 L (5 gal)

MultiSurface Concentrate pH 12.2−12.49

Generator tank capacity 13 L (3.5 gal)

MultiMicro 200 Concentrate pH 5−6

25OS3 DM20036 (4−2014)