Tennant M30 User Manual

M30

*

Home

Find...

Go To..

(Gas/LPG)

Scrubber−Sweeper

Operator Manual

The Safe Scrubbing Alternative

Hygenic Fully Cleanable Tanks

FloorSmart Integrated Cleaning System

ES Extended Scrub System

North America / International

www.tennantco.com

9003943

Rev. 07 (6-2011)

*9003943

This manual is furnished with each new model. It provides necessary operation and maintenance instructions.

Home

Find...

Go To..

Read this manual completely and understand

the machine before operating or servicing it.

This machine will provide excellent service. However, the best results will be obtained at minimum costs if:

The machine is operated with reasonable care.

The machine is maintained regularly - per the machine maintenance instructions provided.

The machine is maintained with manufacturer supplied or equivalent parts.

PROTECT THE ENVIRONMENT

Please dispose of packaging materials,

old machine components such as

batteries, hazardous fluids including

antifreeze and oil, in an

environmentally safe way according to

local waste disposal regulations.

Always remember to recycle.

MACHINE DATA

Please fill out at time of installation for future reference.

Model No. −

Serial No. −

Machine Options −

Sales Rep. −

Sales Rep. phone no. −

Customer Number −

Installation Date −

Tennant Company

PO Box 1452

Minneapolis, MN 55440

Phone: (800) 553−8033 or (763) 513−2850

www.tennantco.com

CALIFORNIA PROPOSITION 65 WARNING:

Engine exhaust from this product contains chemicals known to the State of California to cause cancer,

birth defects, or other reproductive harm.

Thermo−Sentry, Touch−N−Go, 1−STEP, Clean−Wedge, Variable Drain Valve, EasyOpen, Grip−n−Go, MaxPro, Dura−Track, SmartRelease,

InstantAccess, Duramer, FaST−PAK, ErgoSpace and Lower Total Cost of Ownership are US registered and unregistered trademarks of Tennant Company.

Specifications and parts are subject to change without notice.

Copyright 2008−2011 TENNANT Company, Printed in U.S.A.

CONTENTS

Home

Find...

Go To..

CONTENTS

Safety Precautions 3.......................

Operation 7...............................

Machine Components 7..................

Controls And Instruments 8...............

Touch Panel 9..........................

Symbol Definitions 10.....................

Operation Of Controls 11..................

Charging System Indicator 11...........

Engine Oil Pressure Indicator 11........

Check Engine Indicator 11..............

Parking Brake Indicator (Option) 11......

Setting The Engine Speed 12...........

Side Brush (Option) 12.................

Fuel Indicator 12......................

Gasoline Machines 12.................

LPG Machines 12.....................

Hour Meter 13........................

Supervisor Control Buttons 13...........

Operating Lights 13....................

Hazard Light (Option) 13...............

Operator Seat 14......................

Seat Belts 14.........................

Steering Column Tilt Knob 15...........

Brake Pedal 15.......................

Parking Brake Pedal 15................

Directional Pedal 15...................

Squeegee Protectors (Option) 15........

How The Machine Works 16...............

Brush Information 16.....................

While Operating The Machine 17...........

Pre−operation Checklist 18................

Changing The Lpg Tank 19................

Starting The Machine 20..................

Turning Off The Machine 20...............

Filling The Solution Tank 21................

Foam Scrubbing (FaST Mode) /

ec−H2O Scrubbing (ec−H2O Mode) 21

Conventional Scrubbing Mode 21........

ES (Extended Scrub) Mode

With Auto−fill 22....................

ES (Extended Scrub) Mode − Manually

Filling Tanks 22.....................

Setting Scrub Modes 23...................

Setting FaST Mode 23.................

Setting ES (Extended Scrub) Mode 23...

Setting ec−H2O Mode 23...............

Setting Brush Pressure 24..............

Setting Solution Flow 24................

Conventional, FaST, And ec−H2O

Solution Flow 24....................

ES (Extended Scrub) Solution Flow 24...

Scrubbing 25..........................

Double Scrubbing 26.....................

Water Pickup Mode (No Scrubbing) 27......

Page

Page

Sweeping 27..........................

Emptying The Hopper 29..................

Engaging Hopper Support Pin 30...........

Disengaging Hopper Support Pin 30........

Removing The Hopper Dust Filter 31........

Cleaning The Hopper And Debris Screen 32.

Draining And Cleaning The

Recovery Tank 34.....................

Draining The Recovery Tank With

The Drain Hose 34..................

Draining The Recovery Tank With The

Drain Plug 35......................

Draining And Cleaning The Solution Tank 37.

Fault Indicator(s) 39......................

Conditions / Warnings 40..................

Options 41..............................

Spray Nozzle (Option) 41...............

Vacuum Wand (Option) 42..............

High Pressure Washer (Option) 43.......

Machine Troubleshooting 45...............

Maintenance 47.............................

Maintenance Chart 48....................

Lubrication 50...........................

Engine Oil 50.........................

Squeegee Caster Bearings 50..........

Front Wheel Support Bearing 50.........

Steering Cylinder Bearing 50............

Hopper Lift Arm Pivots 51..............

Hopper Door Pivots 51.................

Torque Tubes 51......................

Hydraulics 52..........................

Hydraulic Fluid 52.....................

Hydraulic Hoses 53....................

Engine 53...............................

Cooling System 53....................

Air Filter 54..........................

Fuel Filter (LPG) 54....................

Electronic Pressure Regulator (LPG) 55..

Fuel Filter (Gasoline) 55................

Engine Belt 55........................

Spark Plugs 55........................

Timing Belt 55........................

Battery 56...............................

Fuses And Relays 56.....................

Relay Panel Fuses And Relays 57.......

Engine Harness Fuses And Relays 58...

Optional Relays 58....................

Circuit Breakers (sc−H2O) 58...........

Cleaning The Hopper Dust Filter 58.........

Thermo−Sentry 58.....................

Main Brushes 59.........................

Replacing Or Rotating The

Main Brushes 59...................

Checking The Main Brush Pattern 61....

Adjusting The Main Brush Taper 62......

Adjusting The Main Brush Width 62......

M30 9003943 (4−10)

1

CONTENTS

Home

Find...

Go To..

Side Brush (Option) 63....................

Replacing The Side Brush 63...........

FaST System 63.........................

Replacing The FaST−PAK Carton 63.....

Cleaning The FaST Supply Hose

Connector 64......................

Cleaning The FaST System

Filter Screen 64....................

Replacing The FaST System Filters 64...

ec−H2O Module Flush Procedure 65........

Cleaning The ec−H2O Filter Screen 66......

Squeegee Blades 67......................

Replacing (Or Rotating) The Rear

Squeegee Blades 67................

Replacing Or Rotating The Side

Squeegee Blades 69................

Replacing The Side Brush Squeegee

Blade (S/N 000000−001278)

(Option) 71........................

Replacing Or Adjusting The Side Brush

Squeegee Blade (S/N 001279− )

(Option) 72........................

Leveling The Rear Squeegee 73.........

Adjusting The Rear Squeegee Blade

Deflection 74.......................

Skirts And Seals 75.......................

Scrub Head Skirt 75...................

Recovery Tank Seal 75.................

Solution Tank Seals 75.................

Brakes And Tires 76......................

Brakes 76..........................

Parking Brake 76......................

Tires 76..............................

Front Wheel 76.......................

Propelling Motor 76.......................

Pushing, Towing, And Transporting

The Machine 77.......................

Pushing Or Towing The Machine 77......

Transporting The Machine 77...........

Machine Jacking 79......................

Storage Information 79....................

Freeze Protection (Machines Without

ec−H2O System) 80................

Freeze Protection (Machines With

ec−H2O System) 80................

Priming The ec−H2O System 82........

Specifications 83..........................

General Machine Dimensions/Capacities 83.

General Machine Performance 83..........

Hydraulic System 83......................

Steering 84..............................

Power Type 84..........................

Tires 84.................................

FaST System 85.........................

ec−H2O System 85.......................

Machine Dimensions 86...................

Page

2

M30 9003943 (4−10)

SAFETY PRECAUTIONS

Home

Find...

Go To..

SAFETY PRECAUTIONS

The following precautions are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or

unsafe practices that could result in

severe personal injury or death.

CAUTION: To warn of unsafe practices

that could result in minor or moderate

personal injury.

FOR SAFETY: To identify actions that must be

followed for safe operation of equipment.

Do not use the machine other than described in

this Operator Manual. The machine is not

designed for use on public roads.

The following information signals potentially

dangerous conditions to the operator or

equipment:

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tank.

WARNING: Flammable materials or

reactive metals can cause an explosion

or fire. Do not pickup.

WARNING: Moving belt and fan. Keep

away.

WARNING: Engine emits toxic gases.

Serious injury or death can result.

Provide adequate ventilation.

WARNING: Raised hopper may fall.

Engage hopper support pin.

WARNING: Lift arm pinch point. Stay

clear of hopper lift arms.

WARNING: Burn hazard. Hot surface. Do

NOT touch.

WARNING: Do not spray people or

animals. Severe personal injury can

result. Wear eye protection. Hold

sprayer with two hands.

CAUTION: LPG engine will run for a

few seconds after key is turned off.

Apply parking brake before leaving

machine.

CALIFORNIA PROPOSITION 65

WARNING: Engine exhaust from this

product contains chemicals known to

the State of California to cause cancer,

birth defects, or other reproductive

harm.

FOR SAFETY:

1. Do not operate machine:

− Unless trained and authorized.

− Unless operator manual is read and

understood.

− Unless mentally and physically

capable of following machine

instructions.

− If it is not in proper operating

condition.

− In flammable or explosive areas.

− In areas with possible falling objects

unless equipped with overhead guard.

2. Before starting machine:

− Check for fuel, oil, and liquid leaks.

− Keep sparks and open flame away

from refueling area.

− Make sure all safety devices are in

place and operate properly.

− Check brakes and steering for proper

operation.

− Adjust seat and fasten seat belt.

3. When starting machine:

− Keep foot on brake and directional

pedal in neutral.

4. When using machine:

− Do not pick up burning or smoking

debris, such as cigarettes, matches or

hot ashes

− Use brakes to stop machine.

− Go slow on inclines and slippery

surfaces.

− Use care when reversing machine.

− Move machine with care when hopper

is raised.

− Make sure adequate clearance is

available before raising hopper.

− Do not carry passengers on machine.

− Always follow safety and traffic rules.

− Report machine damage or faulty

operation immediately.

− Follow mixing, handling and disposal

instructions on chemical containers.

Follow safety guidlines concerning

−

wet floors.

M30 9003943 (6−11)

3

SAFETY PRECAUTIONS

Home

Find...

Go To..

5. Before leaving or servicing machine:

− Stop on level surface.

− Set parking brake.

− Turn off machine and remove key.

6. When servicing machine:

− Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves.

− Block machine tires before jacking

machine up.

− Jack machine up at designated

locations only. Support machine with

jack stands.

− Use hoist or jack that will support the

weight of the machine.

− Wear eye and ear protection when

using pressurized air or water.

− Disconnect battery connections before

working on machine.

− Avoid contact with battery acid.

− Avoid contact with hot engine coolant.

− Do not remove cap from radiator when

engine is hot.

− Allow engine to cool.

− Keep flames and sparks away from

fuel system service area. Keep area

well ventilated.

− Use cardboard to locate leaking

hydraulic fluid under pressure.

− Wear protective gloves and eye

protection when handling vinegar.

− Use Tennant supplied or approved

replacement parts.

7. When loading/unloading machine

onto/off truck or trailer:

− Turn off machine.

− Use truck or trailer that will support

the weight of the machine.

− Use winch. Do not drive the machine

onto/off the truck or trailer unless the

load height is 380 mm (15 in) or less

from the ground.

− Set parking brake after machine is

loaded.

− Block machine tires.

− Tie machine down to truck or trailer.

4

M30 9003943 (4−10)

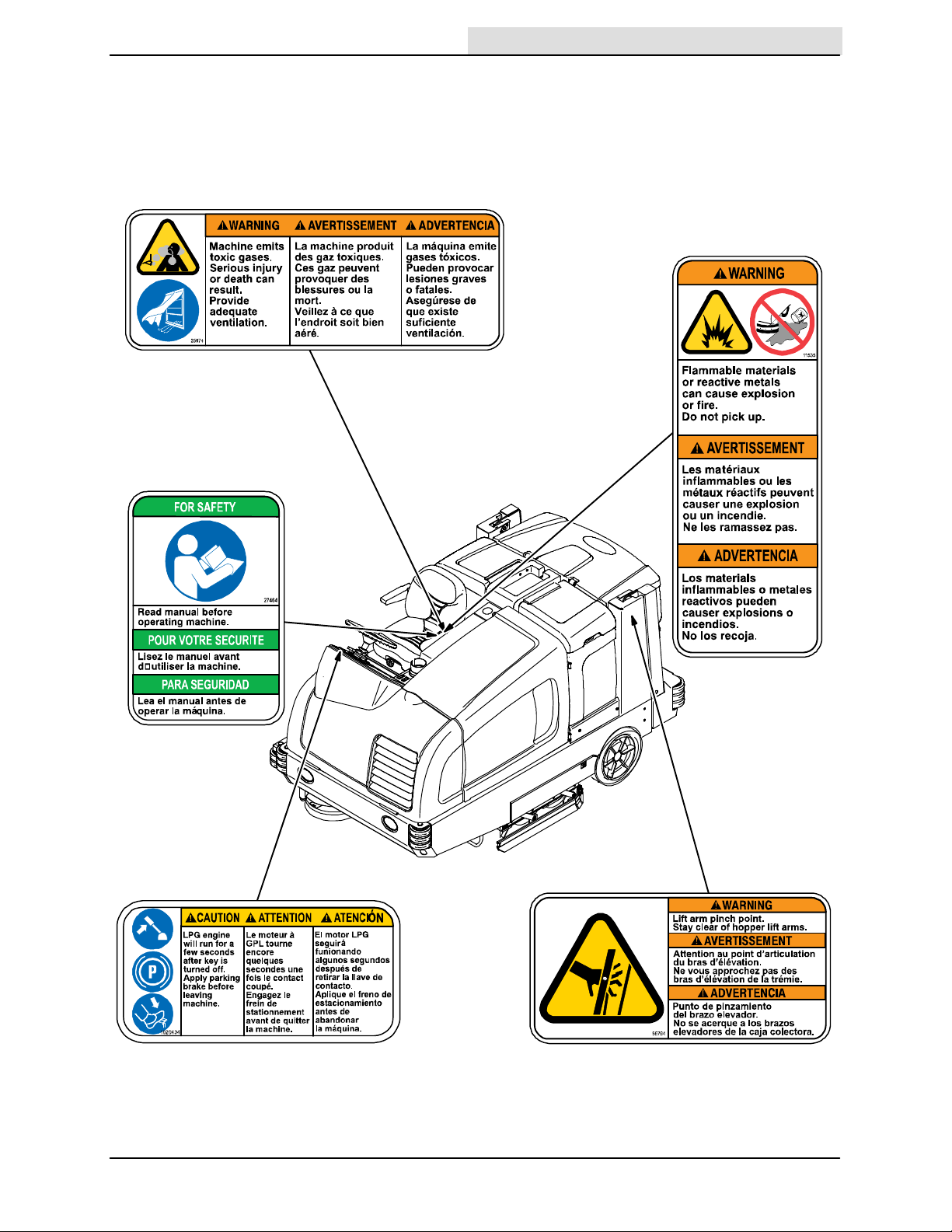

The following safety labels are mounted on the

Home

Find...

Go To..

machine in the locations indicated. If these or any

labels become damaged or illegible, install a new

label in its place.

SAFETY PRECAUTIONS

EMISSIONS LABEL − Located on the side of the

operator compartment.

FOR SAFETY LABEL −

Located on the side of the

operator compartment.

FLAMMABLE

SPILLS LABEL −

Located on the side

of the operator

compartment.

LPG ENGINE LABEL − Located next to

the ignition switch on the instrument

panel. (LPG machines only)

M30 9003943 (1−08)

HOPPER LIFT ARMS LABEL − Located

on both hopper lift arms.

5

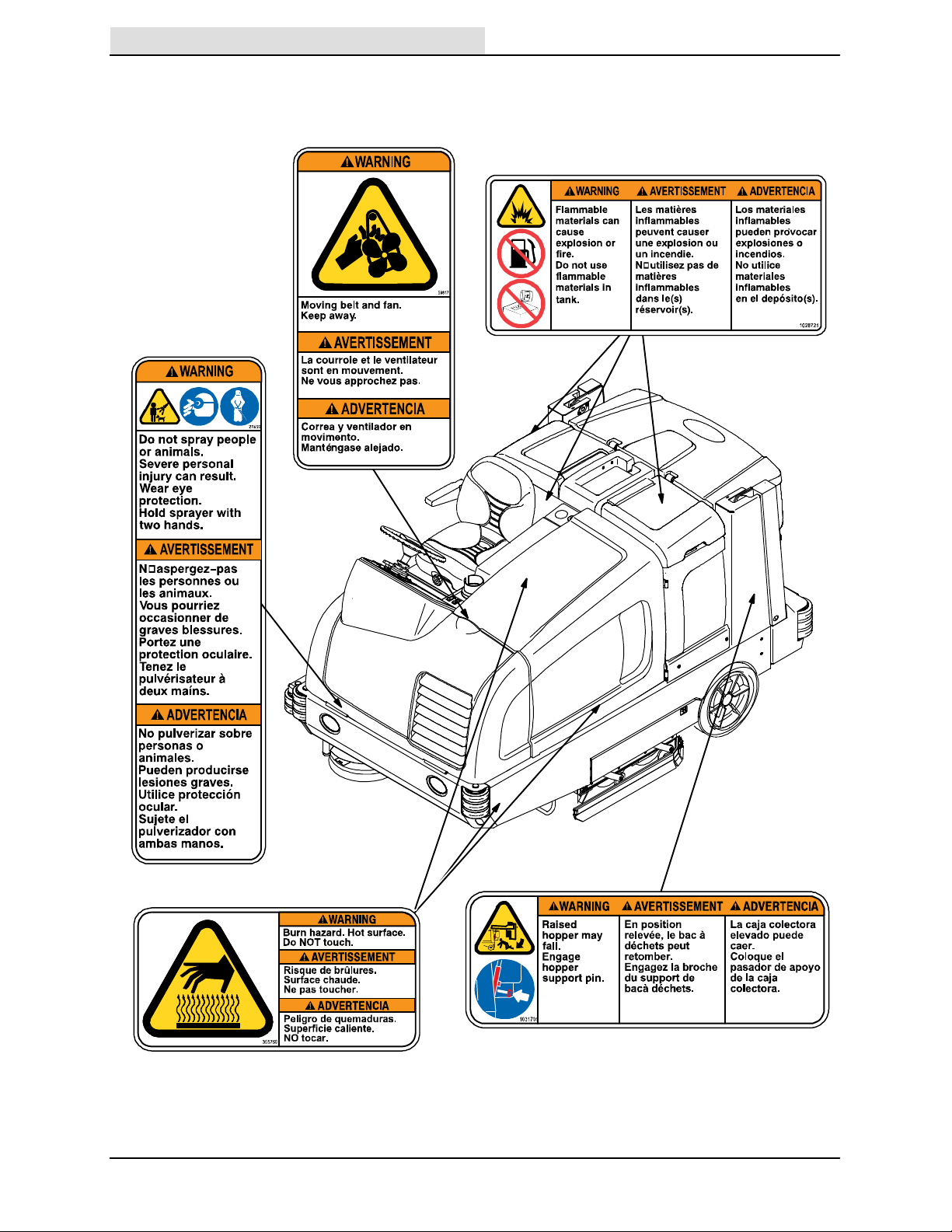

SAFETY PRECAUTIONS

Home

Find...

Go To..

FAN AND BELT LABEL −

Located on engine

compartment panel.

HIGH PRESSURE

SPRAY HAZARD

LABEL − Located

on frame of

machine.

FLAMMABLE MATERIALS LABEL −

Located next to the solution tank covers

and on the detergent tank.

HOT SURFACE LABEL − Located on

the side of the bumper, on the exhaust

shield, and on the hydraulic reservoir.

6

RAISED HOPPER LABEL − Located on both

hopper lift arms.

354589

M30 9003943 (1−08)

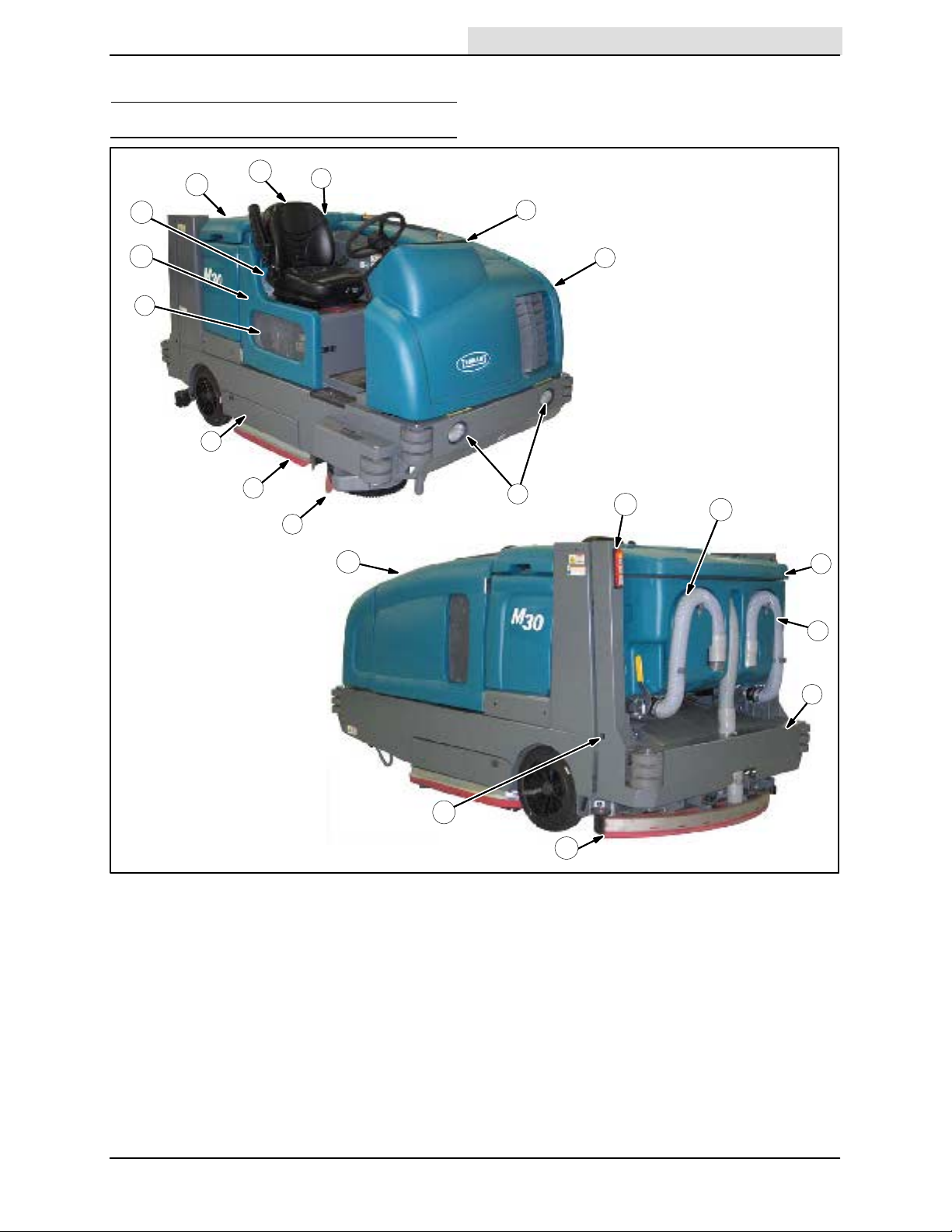

MACHINE COMPONENTS

Home

Find...

Go To..

OPERATION

OPERATION

J

K

I

H

G

F

E

L

A

B

C

D

T

M

N

O

A. Instrument panel

B. Front shroud

C. Headlights

D. Side brush (option)

E. Side squeegee

F. Scrub head access door

G. Fuel tank

H. Seat shroud

I. FaST carton, or ES detergent tank, or

ec−H2O System Module compartment

(option)

J. Solution tank cover

P

Q

S

R

K. Operator seat

L. Spray wand − nozzle behind seat (option)

M. Taillights

N. Recovery tank drain hose

O. Recovery tank cover

P. Solution tank drain hose

Q. Hopper

R. Rear squeegee

S. Hopper safety pin

T. Engine cover

M30 9003943 (4−10)

7

OPERATION

Home

Find...

Go To..

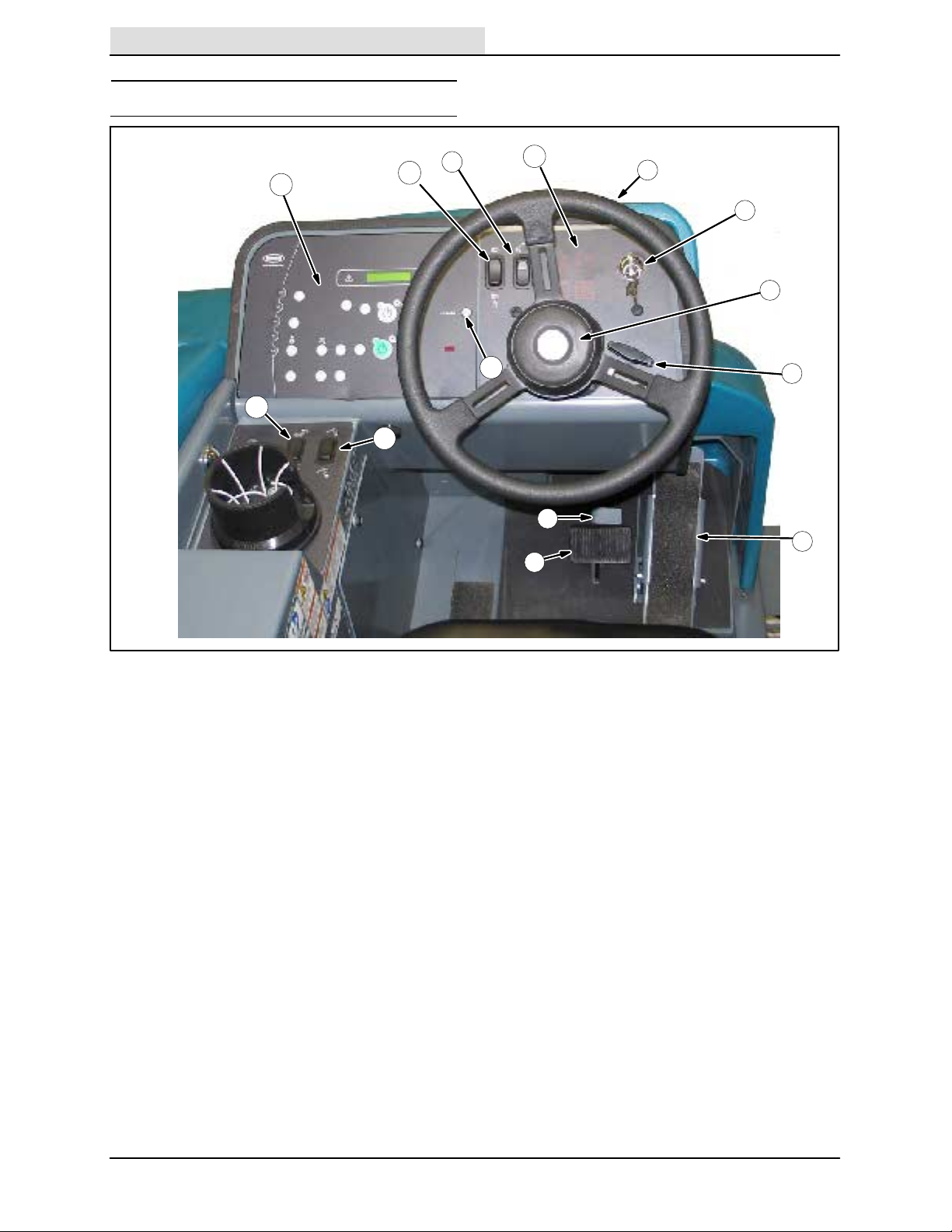

CONTROLS AND INSTRUMENTS

L

J

I

K

H

M

N

G

F

A

B

C

D

E

A. Steering wheel

B. Ignition switch

C. Horn button

D. Steering column tilt knob

E. Directional pedal

F. Brake pedal

G. Parking brake pedal

H. Hopper door open / close switch

I. Hopper raise / lower switch

J. Touch panel

K. Operating / Hazard Lights switch

L. Spray nozzle switch (option)

M. Engine indicator lights

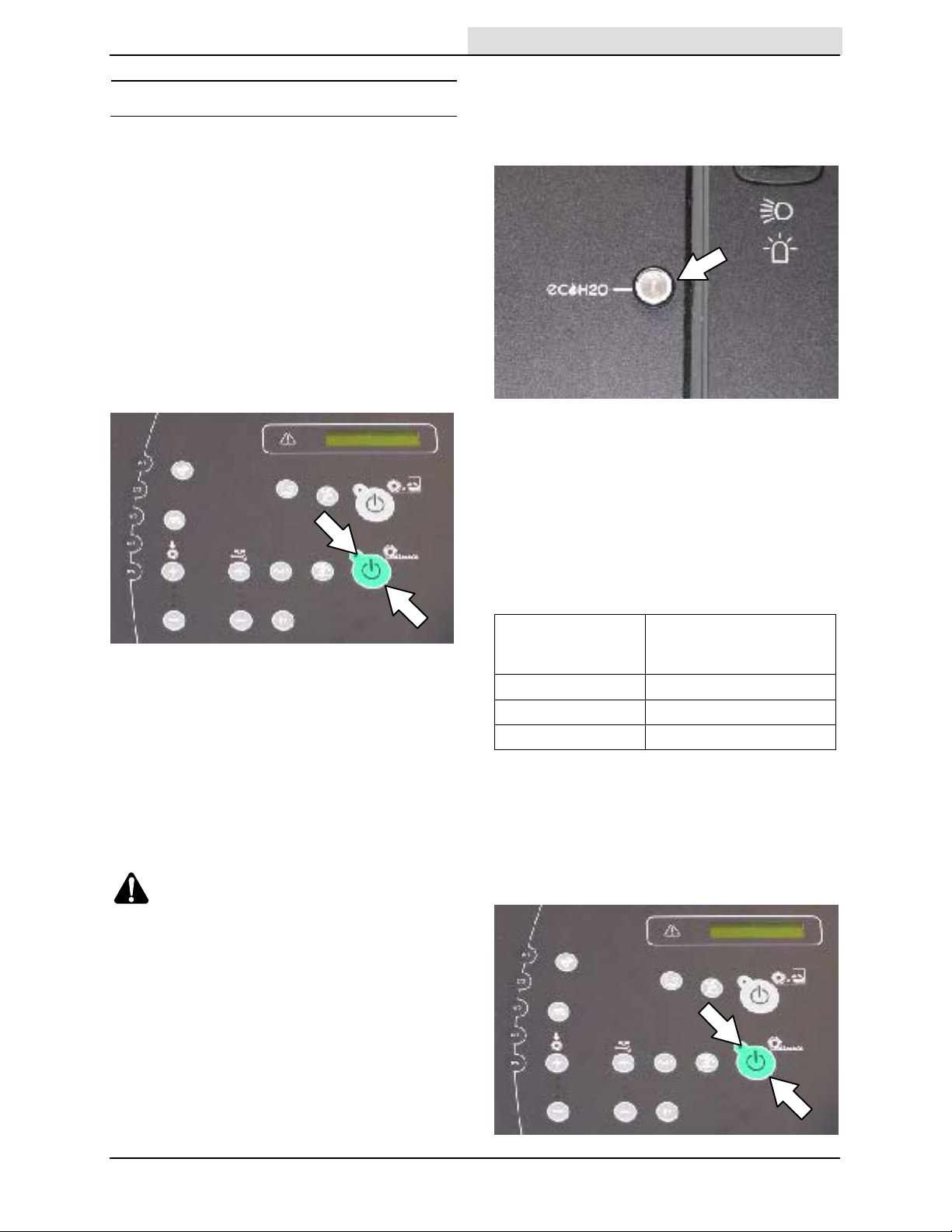

N. ec−H2O system indicator light (option)

8

M30 9003943 (4−10)

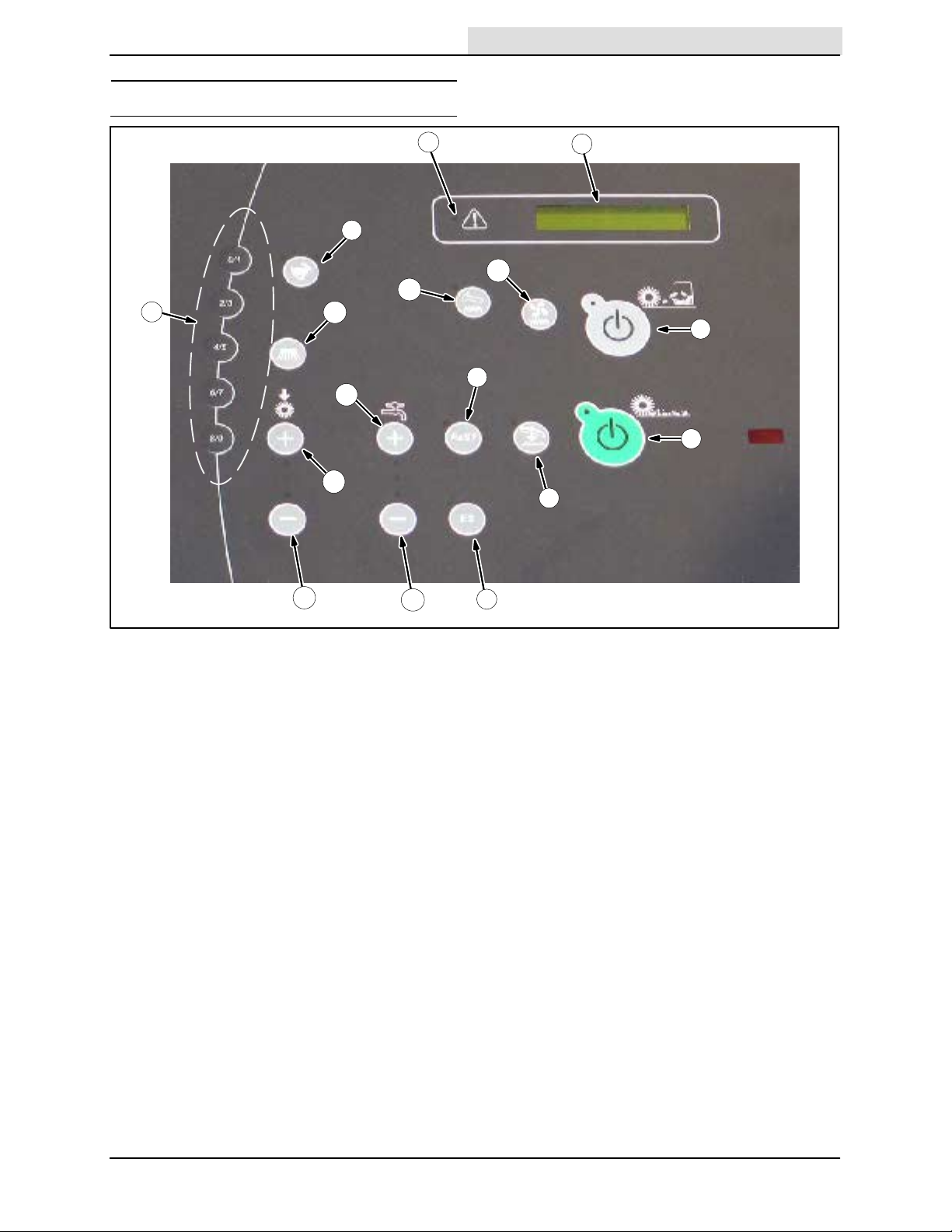

TOUCH PANEL

Home

Find...

Go To..

OPERATION

A

O

M

L

P

N

G

H

J

B

C

D

E

K

A. Fault indicator light

B. Hour meter / fuel indicator / fault code

indicator

C. 1−STEP sweep button

D. 1−STEP scrub button

E. Scrub vacuum fan / squeegee button

F. ES (Extended Scrub) button (option)

G. FaST button (option)

ec−H2O button (option)

H. Solution increase button (+)

I. Solution decrease button (−)

J. Brush pressure increase button (+)

K. Brush pressure decrease button (−)

L. Filter shaker button

M. Sweep vacuum fan button

N. Side brush button (option)

O. Engine speed button

P. Supervisor control buttons

I

F

M30 9003943 (4−10)

9

OPERATION

Home

Find...

Go To..

SYMBOL DEFINITIONS

These symbols are usd on the machine to identify

controls, displays, and features.

Hazard light Engine speed

Operating lights Side brush

Spray nozzle Main brush pressure

Hopper door open Solution flow

Hopper door close Increase

Hopper raise Decrease

Hopper lower Charging system

Fault indicator Engine oil pressure (000000−001138)

Filter shaker Engine oil pressure (001139− )

Sweep vac fan Check engine

Scrub vac fan/squeegee Parking Brake (001139− )

1−STEP sweep Horn

1−STEP scrub Jack point

10

ES (extended scrub) Unleaded fuel only

FaST (foam scrubbing) ec−H2O (option)

M30 9003943 (4−10)

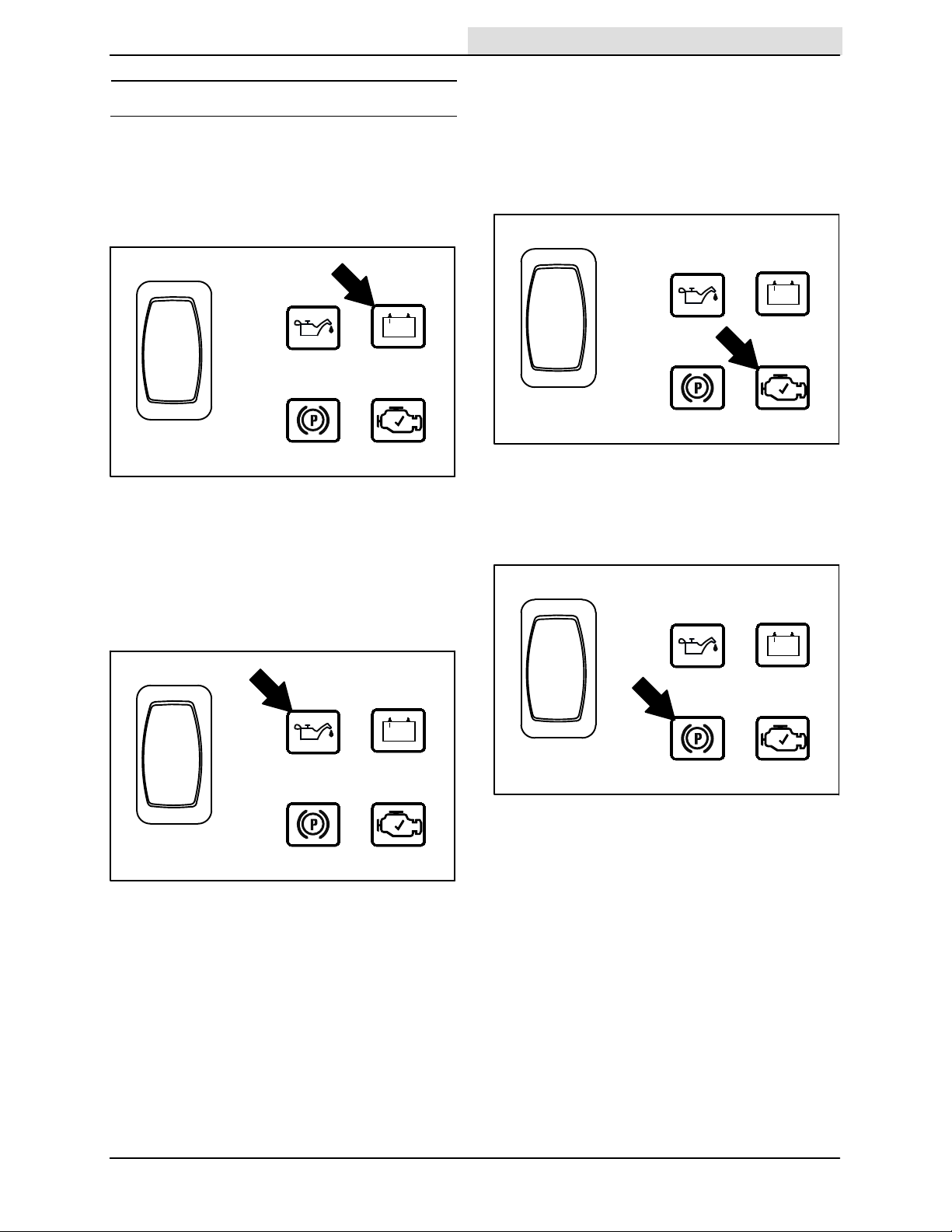

OPERATION OF CONTROLS

Home

Find...

Go To..

CHARGING SYSTEM INDICATOR

OPERATION

CHECK ENGINE INDICATOR

The Check engine indicator comes on when the

engine control system detects a fault during

machine operation.

The Charging system indicator comes on when

the alternator is not operating within the normal

range. If this indicator comes on, stop the

machine immediately and correct the problem.

ENGINE OIL PRESSURE INDICATOR

The Engine oil pressure indicator comes on when

the engine oil pressure falls below the normal

operating pressure. If this indicator comes on,

stop the machine immediately and correct the

problem.

If this indicator comes on, contact a Tennant

service representative.

PARKING BRAKE INDICATOR (OPTION)

The parking brake indicator comes on when the

parking brake is engaged.

M30 9003943 (6−09)

11

OPERATION

Home

Find...

Go To..

SETTING THE ENGINE SPEED

The engine speed is controlled automatically

when either the 1−STEP Scrub button or 1−STEP

Sweep button is pressed. When not sweeping or

scrubbing, press the Engine Speed button to

increase the engine RPM for increased travel

speed. Press the Engine Speed button again to

reduce the engine RPM. The two lights above the

button indicate engine speed setting. When one

light is lit the engine is in the low setting. When

two lights are lit the engine is in the high setting.

FUEL INDICATOR

GASOLINE MACHINES

For gasoline machines, the Fuel indicator displays

the amount of fuel left in the tank. The fault

indicator will flash and a low fuel message will

appear when the tank is near empty.

NOTE: Do not use leaded fuels. Leaded fuels will

permanently damage the system oxygen sensor

and catalytic converter.

SIDE BRUSH (OPTION)

The side brush allows users to sweep or scrub

difficult to reach corners and areas near walls.

The side brush also widens the scrubbing/

sweeping path.

With the 1−STEP Scrub button or 1−STEP Sweep

button activated, press the Side brush button to

lower and start the side brush. The light next to

the button will come on. When finished using the

side brush, press the button again to raise and

stop the side brush. The light next to the button

will turn off. The machine will default to the last

setting used when it is powered on or off.

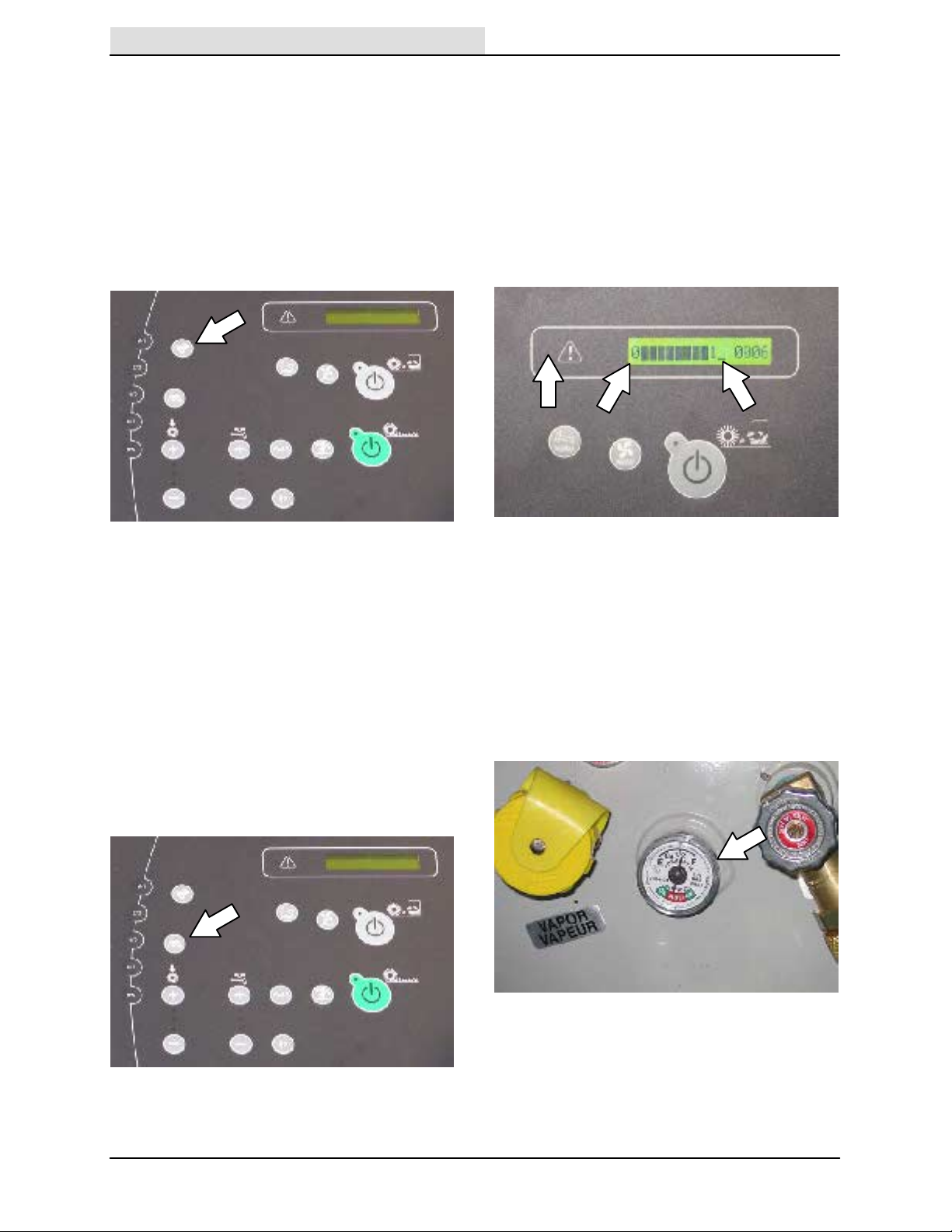

LPG MACHINES

For LPG machines, the Fuel indicator does NOT

display the amount of fuel in the LPG tank. It will

display all the indicator bars to show that some

fuel is in the tank. When the LPG tank is near

empty, the fault indicator will flash and a low fuel

message will appear.

The LPG fuel gauge on the tank displays the

amount of fuel in the LPG tank.

12

M30 9003943 (1−08)

OPERATION

Home

Find...

Go To..

HOUR METER

The Hour meter records the hours the machine

was operated. Use this information to determine

machine service intervals.

SUPERVISOR CONTROL BUTTONS

The Supervisor Control buttons are for accessing

the configuration and diagnostic modes. Only

properly trained service personnel and TENNANT

representatives should access these modes.

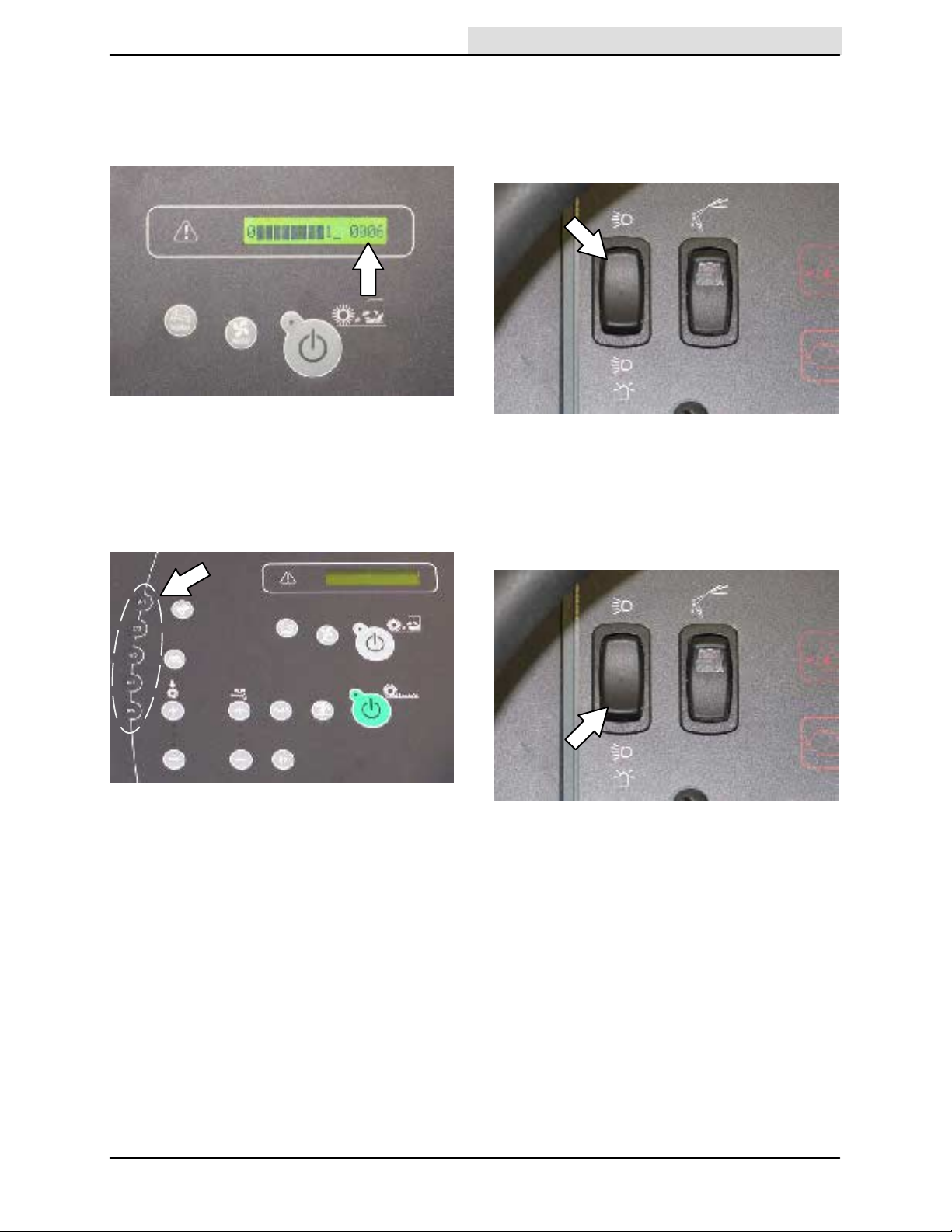

OPERATING LIGHTS

Push the top of the Operating / hazard light switch

to turn on the headlights and taillights. Return the

light switch to the center position to turn off the

lights.

HAZARD LIGHT (OPTION)

Press the bottom of the Operating / hazard light

switch to turn on the hazard light, headlights, and

taillights. Return the light switch to the center

position to turn off the lights.

M30 9003943 (1−08)

13

OPERATION

Home

Find...

Go To..

OPERATOR SEAT

The operator seat has three adjustments:

backrest angle, operator weight, and front to

back.

The backrest adjustment knob adjusts the angle

of the backrest.

Increase angle: Turn the angle adjustment knob

counterclockwise.

The front−to−back adjustment lever adjusts the

seat position.

Adjust: Pull the lever out and slide the seat to the

desired position. Release the lever to lock the

seat into place.

SEAT BELTS

FOR SAFETY: Before starting machine, adjust

seat and fasten seat belt.

Decrease angle: Turn the angle adjustment knob

clockwise.

The weight adjustment knob controls the firmness

of the operator seat.

Increase firmness: Turn the weight adjustment

knob clockwise.

Decrease firmness: Turn the weight adjustment

knob counterclockwise.

Use the gauge next to the weight adjustment knob

to help determine seat firmness for the operator.

14

M30 9003943 (1−08)

OPERATION

Home

Find...

Go To..

STEERING COLUMN TILT KNOB

1. Pull the Steering column tilt knob and adjust

the steering column to the desired height.

2. Release the Steering column tilt handle.

BRAKE PEDAL

Press the Brake pedal to stop the machine.

DIRECTIONAL PEDAL

Press the top of the Directional pedal to move

forward and the bottom of the pedal to move

backward. The backup lights will come on when

the machine is in reverse. The pedal returns to

the neutral position when it is released.

NOTE: An audible alarm will sound and the

backup light will flash when backing the machine if

equipped with the optional backup alarm.

PARKING BRAKE PEDAL

Press the Brake pedal down as far as possible

and use toe to lock the Parking brake pedal into

place. Press the Brake pedal to release the

parking brake. The Parking brake pedal will return

to the unlocked position.

SQUEEGEE PROTECTORS (OPTION)

The rear and side squeegee protectors help

protect the rear squeegee from being damaged.

To engage the rear squeegee protector, pull the

pin, lower the protector bar, and reinsert the pin.

M30 9003943 (1−08)

15

OPERATION

Home

Find...

Go To..

HOW THE MACHINE WORKS

This machine can effectively scrub or sweep dirty

floors. The 1−STEP Scrub button and 1−STEP

Sweep button make it possible to immediately

begin scrubbing or sweeping.

The 1−STEP Sweep button operates all the dry

sweeping functions (without scrubbing). The

1−STEP Scrub button operates all the scrubbing

functions. (The machine also sweeps while

scrubbing).

When in the conventional Scrub mode, a water

and detergent mixture is used to scrub the floor.

When in the optional FaST (Foam scrubbing)

mode, the FaST scrubbing system mixes the

FaST−PAK concentrate with a small amount of

water, creating a large volume of expanded wet

foam. The FaST system can be used with all

double scrubbing and heavy duty scrubbing

applications.

When in the optional ES (Extended Scrub) mode,

the dirty solution in the recovery tank is filtered

through the ES system and returned to the

solution tank for reuse. Detergent is then injected

into the returned solution to revitalize the cleaning

capability of the solution.

BRUSH INFORMATION

For best results, use the correct brush type for the

cleaning application. Listed below are the brushes

and the applications for which each is best suited.

NOTE: The amount and type of soilage play an

important role in determining the type of brushes

to use. Contact a Tennant representative for

specific recommendations.

PolyPro brush − Heavy duty polypropylene

bristles provide a more aggressive cleaning

performance and can more easily lift compacted

dirt, debris, and sand while offering excellent

scrubbing performance.

Polypropylene brush − General purpose

polypropylene bristles lift lightly compacted dirt

without scuffing high-gloss coated floors.

Polyester brush − Softer general purpose

polyester bristles lift light debris while sweeping

and gently clean while scrubbing. Perfect for

sensitive floor surfaces. Polyester does not

absorb water so it is preferred over Nylon in wet

applications.

Super AB brush − Nylon fiber impregnated with

abrasive grit to remove stains and compacted dirt.

Aggressive action on any surface. Performs well

on buildup, grease, or tire marks.

When in the optional ec−H2O (electrically

converted water) mode, normal water passes

through a module where it is oxygenated and

charged with an electric current. The electrically

converted water changes into a blended acidic

and alkaline solution forming a neutral pH cleaner.

The converted water attacks the dirt, breaks it into

smaller particles, and pulls it off the floor surface

allowing the machine to easily scrub away the

suspended soil. The converted water then returns

to normal water in the recovery tank . The

ec−H2O system can be used with all double

scrubbing and heavy duty scrubbing applications.

16

M30 9003943 (4−10)

WHILE OPERATING THE MACHINE

Home

Find...

Go To..

Pick up oversized debris before scrubbing or

sweeping. Pick up wire, string, twine, large pieces

of wood, or any other debris that could become

wrapped around or tangled in the brushes.

Drive as straight a path as possible. Avoid

bumping into posts or scraping the sides of the

machine. Overlap the scrub/sweep paths by

several centimeters (a few inches).

Avoid turning the steering wheel too sharply when

the machine is in motion. The machine is very

responsive to the movement of the steering wheel.

Avoid sudden turns, except in emergencies.

Adjust the machine speed, brush pressure, and

solution flow as required when scrubbing. Use the

lowest brush pressure and solution flow settings

for best performance. If the machine is equipped

with the FaST or ec−H2O system, use the FaST

or ec−H2O system for the best scrubbing results.

OPERATION

Keep the machine moving to prevent damaging

floor finishes.

If poor cleaning performance is observed, stop

cleaning and refer to MACHINE

TROUBLESHOOTING in this manual.

Perform the Daily Maintenance Procedures after

each use (see MACHINE MAINTENANCE in this

manual).

Drive the machine slowly on inclines. Use the

brake pedal to control machine speed on

descending inclines. Scrub with the machine up

inclines rather than down inclines.

FOR SAFETY: When using machine, go slow

on inclines and slippery surfaces.

The maximum rated incline for scrubbing with the

machine is 6 or 11%. The maximum rated incline

during transport of the machine is 8 or 14%.

M30 9003943 (4−10)

17

OPERATION

Home

Find...

Go To..

PRE−OPERATION CHECKLIST

Check the hydraulic fluid level.

Check the fuel level.

Check the condition of the main brushes.

Remove string, banding, plastic wrap, or other

debris wrapped around the brushes.

FaST Scrubbing: Check the FaST−PAK

concentrate agent level. Replace carton as

needed. See the INSTALLING THE

FaST−PAK CARTON section of the manual.

FaST Scrubbing: Ensure all conventional

cleaning agents are drained and rinsed from

the solution tank.

FaST Scrubbing: Ensure the solution tank is

filled with clear cool water only.

Check the main brush compartment right

skirts, seals, and squeegee for damage and

wear.

Side Brush Option: Check the condition of the

brush. Remove string, banding, plastic wrap,

or other debris wrapped around the brush.

Side Brush Option: Check the condition of the

side brush skirt or squeegee.

Check the radiator and hydraulic cooler fins

for debris.

Check the engine coolant level.

Check the engine oil level.

Check the main brush compartment left skirts,

seals, and squeegee for damage and wear.

Check the left solution tank cover seal for

damage and wear.

Check the recovery tank cover seal for

damage and wear.

Check the headlights, taillights, and safety

lights.

Check the brakes and steering for proper

operation.

Check the service records to determine

maintenance requirements.

Clean the vacuum fan debris filter.

Drain and clean the recovery tank.

ES Option: Drain and clean the solution tank,

float sensor, and ES filter.

Check the right solution tank cover seal for

damage and wear.

Check the condition of the hopper dust filter

and seals.

Clean the hopper and the debris screen.

Check the squeegee hose for debris or

blockage.

Check the squeegees for damage, wear, and

deflection adjustment.

18

M30 9003943 (1−08)

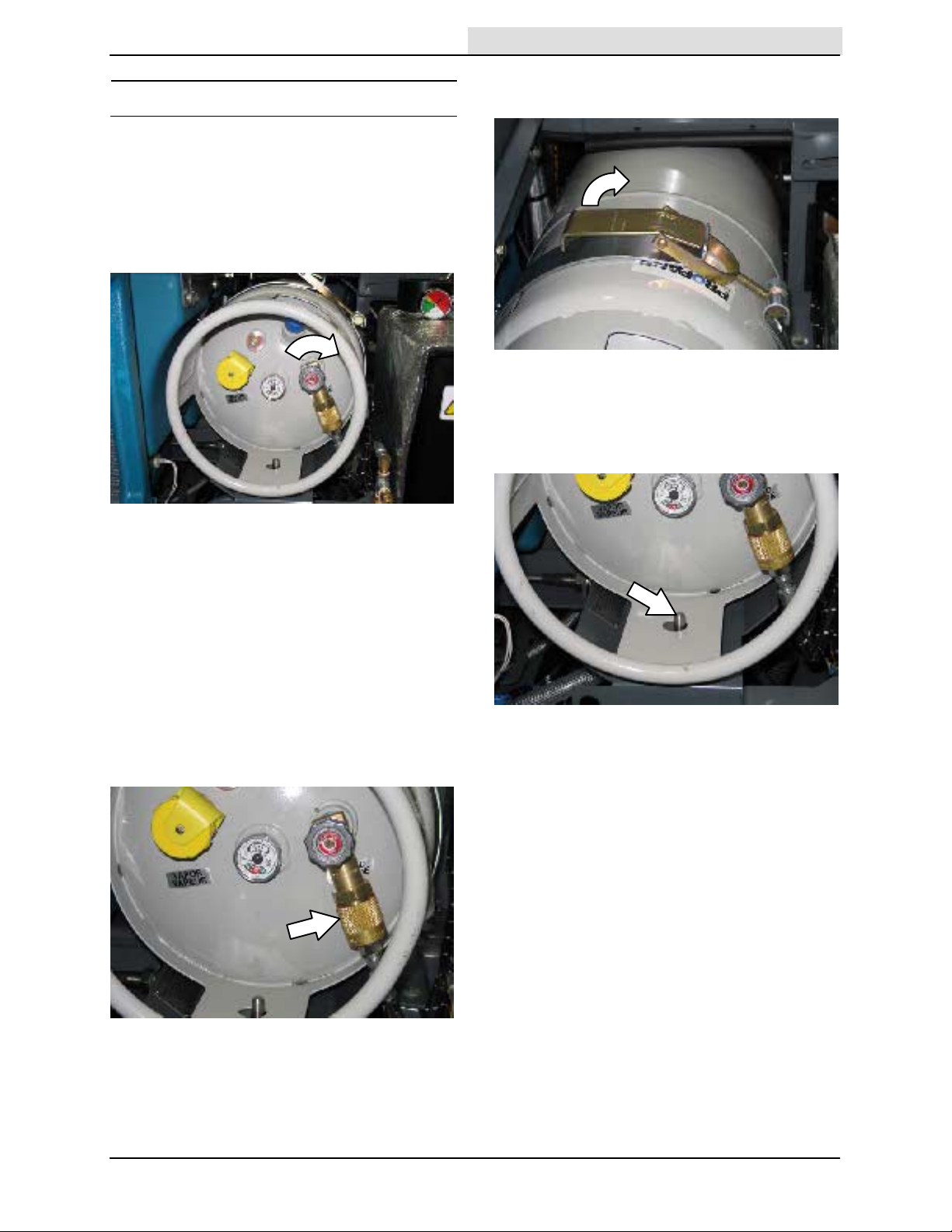

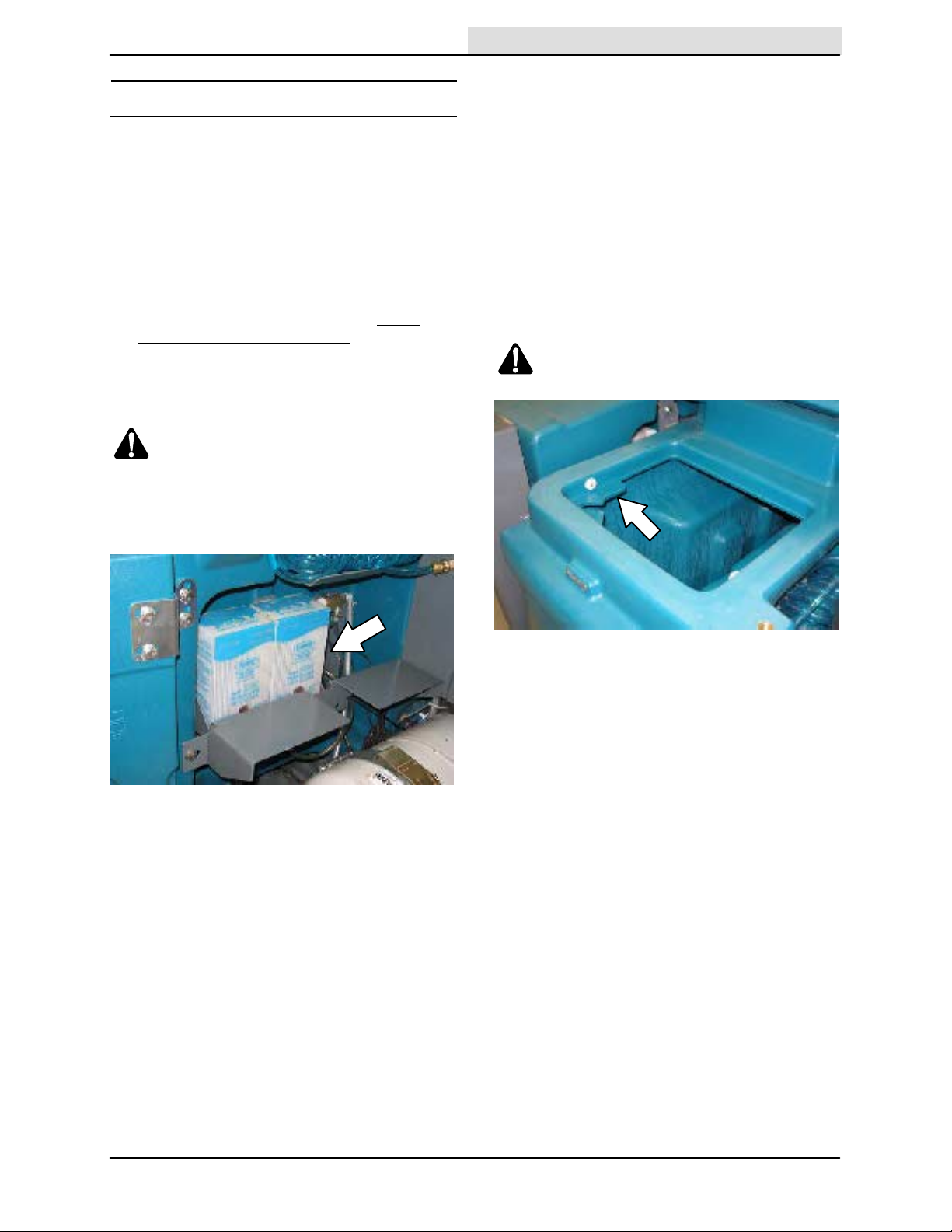

CHANGING THE LPG TANK

Home

Find...

Go To..

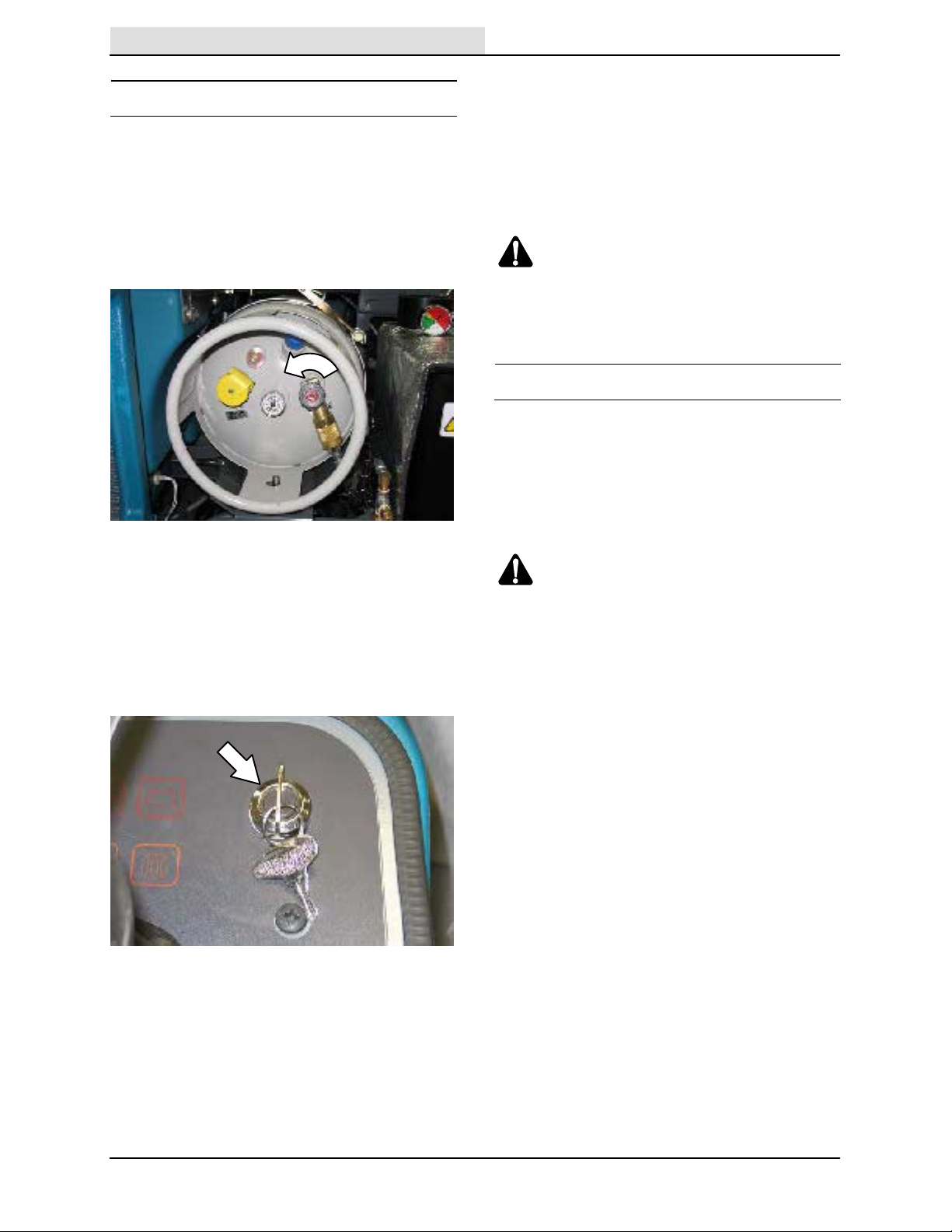

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, set parking

brake, and turn off machine.

1. Open the side access door.

2. Close the LPG tank service valve.

OPERATION

6. Disengage the mounting strap and remove

the empty LPG fuel tank.

7. Align the hole in the tank collar with the

centering pin and carefully place the full LPG

tank onto the tray. Secure the tank with

mounting strap.

3. Start the machine and operate the engine

until it stops from lack of fuel. Turn off the

machine.

4. Lift the operator seat open and engage the

seat latch so the seat remains open.

FOR SAFETY: When servicing machine, keep

flames and sparks away from fuel system

service area. Keep area well ventilated.

5. Put on gloves and remove the quick

disconnect tank coupling.

8. Connect the LPG fuel line to the tank service

coupling. Make sure the tank service coupling

is clean and undamaged and that it matches

the fuel line coupling.

9. Slowly open the tank service valve and check

for leaks. If a leak is found, immediately close

the service valve and inform the appropriate

personnel.

M30 9003943 (1−08)

19

OPERATION

Home

Find...

Go To..

STARTING THE MACHINE

1. LPG powered machines: Slowly open the

liquid service valve.

NOTE: Opening the service valve too quickly may

cause the service check valve to stop the flow of

LPG fuel. If the check valve stops the fuel flow,

close the service valve, wait a few seconds, and

slowly open the valve again.

NOTE: Do not operate the starter motor for more

than 10 seconds at a time or after the engine has

started. Allow the starter to cool 15−20 seconds

between starting attempts or damage to the

starter motor may occur.

4. Allow the engine and hydraulic system to

warm up for three to five minutes.

WARNING: Engine emits toxic gases.

Severe respiratory damage or

asphyxiation can result. Provide

adequate ventilation. Consult with your

regulatory authorities for exposure

limits. Keep engine properly tuned.

TURNING OFF THE MACHINE

1. Stop the machine and turn off all scrubbing/

sweeping functions.

2. Turn the ignition switch key counter clockwise

to turn off the machine. Remain in the

operator seat until the engine is off.

2. Sit in the operator seat and press the brake

pedal or set the parking brake.

FOR SAFETY: When starting machine, keep

foot on brake and directional pedal in neutral.

3. Turn the ignition switch key until the engine

starts.

CAUTION: LPG engine will run for a few

seconds after key is turned off. Apply

parking brake before leaving machine.

NOTE: To protect engine emission components

on LPG powered machines, the engine will

continue to operate for a few seconds after the

ignition switch is turned off.

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, set parking

brake, and turn off machine.

20

M30 9003943 (1−08)

FILLING THE SOLUTION TANK

Home

Find...

Go To..

FOAM SCRUBBING (FaST MODE) / ec−H2O

SCRUBBING (ec−H2O MODE)

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, set parking

brake, and turn off machine.

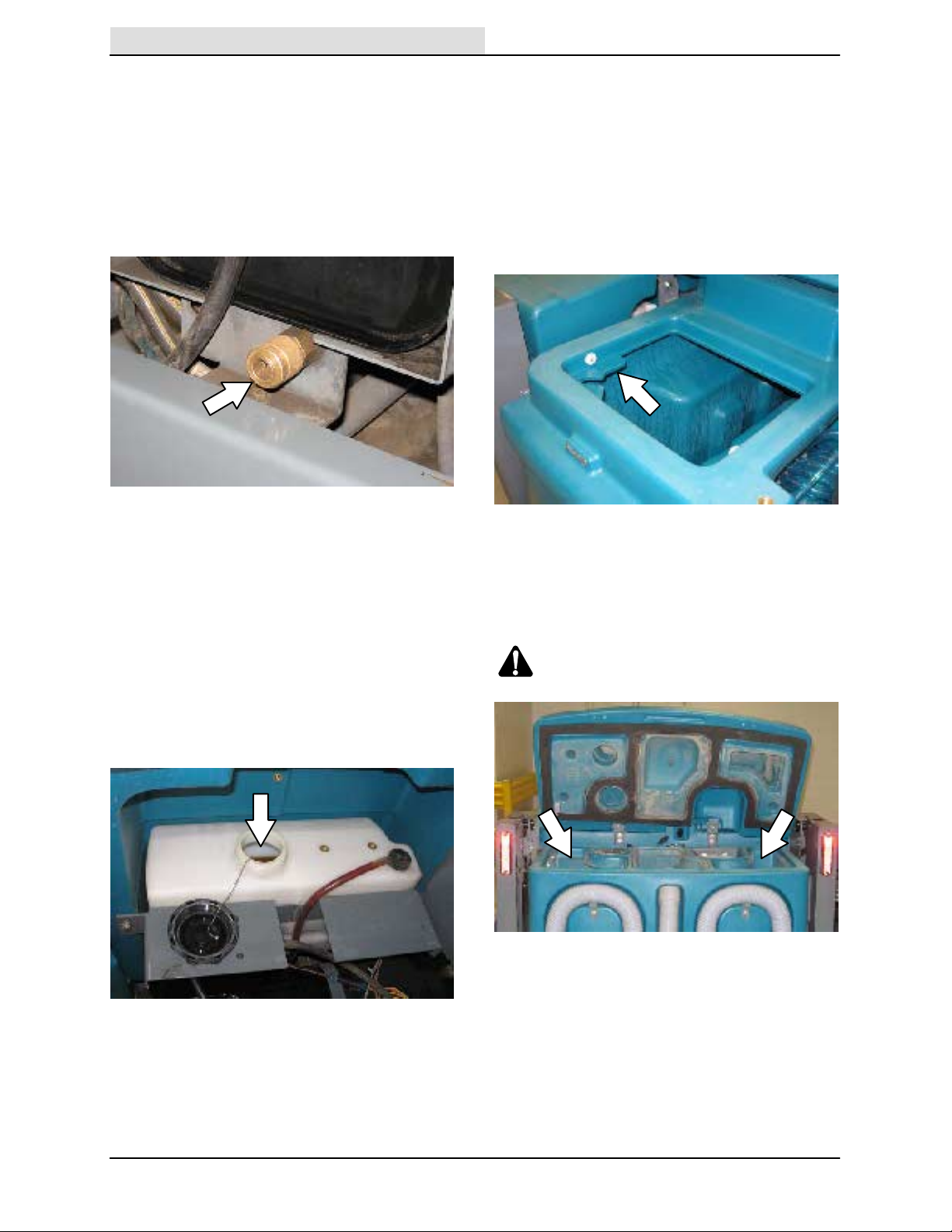

1. Open either the left or right solution tank fill

cover.

2. Fill the solution tank with only clean COOL

WATER (less than 21C / 70F). DO NOT use

hot water or add any conventional floor

cleaning detergents or FaST system failure

may result.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tank(s).

NOTE: To install or change the FaST−PAK

carton, see the REPLACING THE FaST−PAK

CARTON section of the manual.

OPERATION

CONVENTIONAL SCRUBBING MODE

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, set parking

brake, and turn off machine.

1. Open either the left or right solution tank fill

cover.

2. Partially fill solution tank with water (not to

exceed 60C / 140F). Pour the required

amount of detergent into the solution tank. Fill

the solution tank with water until the level is

just below the indicator tab.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tank(s).

NOTE: Do not use the FaST or ec−H2O system

when there are conventional cleaning detergents

in the solution tank. Drain, rinse, and refill the

solution tank with clear cool water before

operating the FaST or ec−H2O system.

Conventional cleaning detergents may cause a

FaST or ec−H2O system failure.

ATTENTION: For Conventional Scrubbing,

only use recommended cleaning detergents.

Machine damage due to improper detergent

usage will void the manufacturer’s warranty.

NOTE: Pour a recommended foam control

solution into the recovery tank if excessive foam

appears. For specific detergent

recommendations, contact a TENNANT

representative.

M30 9003943 (4−10)

21

OPERATION

Home

Find...

Go To..

ES (EXTENDED SCRUB) MODE WITH

AUTO−FILL

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, set parking

brake, and turn off machine.

1. Connect the hose from the water source (not

to exceed 60C / 140F) to the auto−fill

connection.

ES (EXTENDED SCRUB) MODE − MANUALLY

FILLING TANKS

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, set parking

brake, and turn off machine.

1. Open either the left or right solution tank

cover and fill the solution tank with water (not

to exceed 60C / 140F) until the level is just

below the indicator tab.

2. Turn the ignition switch to the on position

(without starting) and turn on the water

source. The auto−fill automatically fills the

tanks to the proper level.

3. Fill the detergent tank with the proper

detergent.

ATTENTION: For ES Scrubbing, only use

recommended low−foaming cleaning

detergents. Machine damage due to the use of

improper detergent will void the

manufacturer’s warranty.

2. Open the recovery tank cover and fill the

recovery tank with water (not to exceed 60C

/ 140F) until the recovery tank is

approximately half full.

WARNING: Flammable materials can

cause an explosion or fire. Do not use

flammable materials in tank(s).

22

M30 9003943 (1−08)

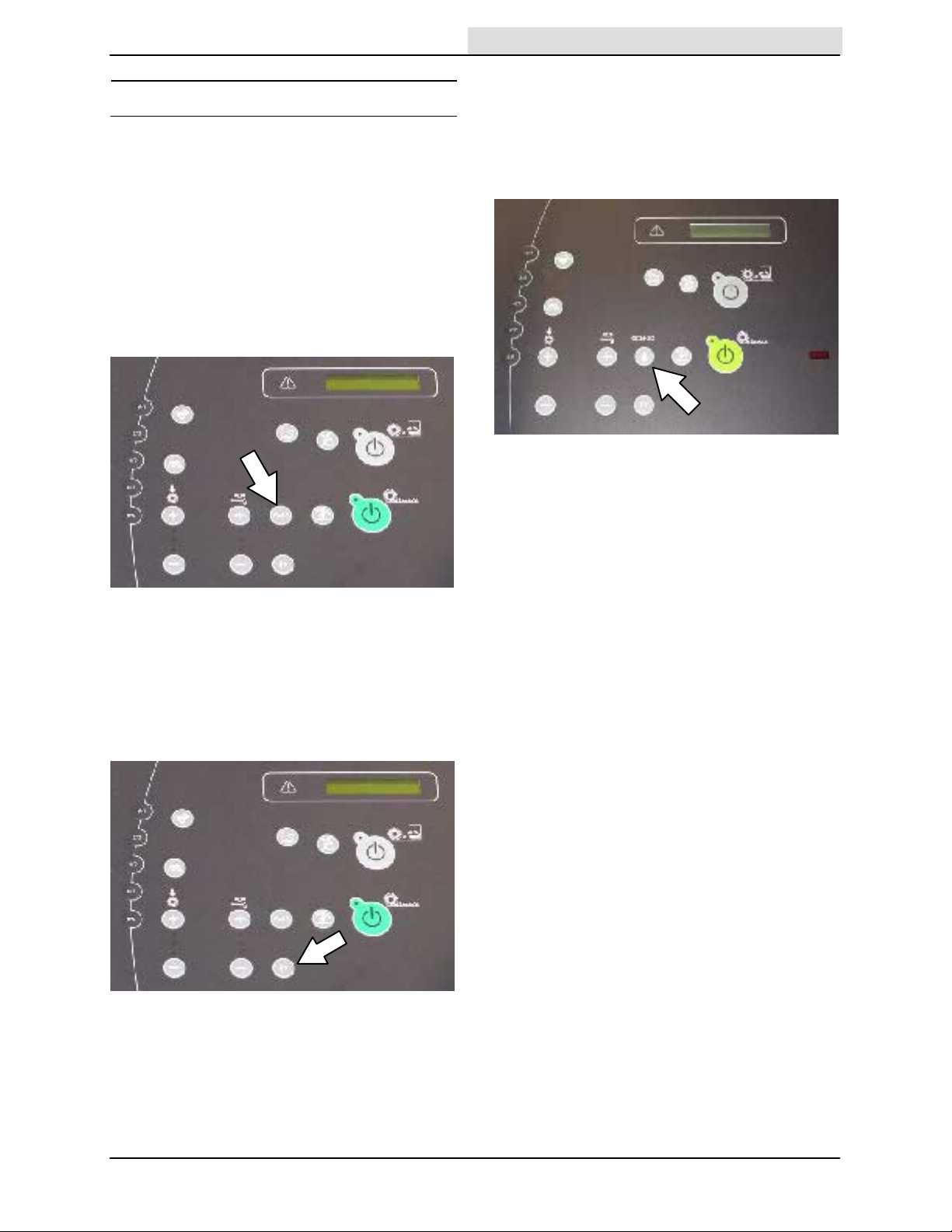

SETTING SCRUB MODES

Home

Find...

Go To..

Before scrubbing, determine which scrub mode

will be used (FaST, ES or conventional). Then set

the scrub brush pressure and adjust the solution

flow levels.

SETTING FaST MODE

The FaST button enables the FaST system to

come on when the 1−STEP Scrub button is

activated. The light next to the button will come

on. The machine will default to the last setting

used when it is powered on or off.

OPERATION

SETTING ec−H2O MODE

The ec−H2O button enables the ec−H2O system

to come on when the 1−STEP Scrub button is

activated. The light next to the button will come

on. The machine will default to the last setting

used when it is powered on or off.

NOTE: Storage or transporting machines

equipped with ec−H2O in freezing temperatures

requires special procedures. Follow the freeze

protection procedure located in the STORAGE

INFORMATION section.

SETTING ES (EXTENDED SCRUB) MODE

The ES button enables the ES system to come on

when the 1−STEP Scrub button is activated. The

light next to the button will come on. The machine

will default to the last setting used when it is

powered on or off.

NOTE: When the ES system is turned on there is

a slight delay before the ES pump begins

operating.

M30 9003943 (4−10)

23

OPERATION

Home

Find...

Go To..

SETTING BRUSH PRESSURE

Under normal cleaning conditions, the brush

pressure should be set to the minimum setting

(the bottom light). Under heavy grime conditions,

the brush pressure can be set to a higher setting.

Travel speed and floor conditions will affect

cleaning performance.

With the 1−STEP Scrub button or the 1−STEP

Sweep button activated, press either the Brush

Pressure increase button (+) or the Brush

Pressure decrease button (−) to set the brush

pressure for the surface being cleaned. If brushes

are worn, it may be necessary to increase the

brush pressure. The machine will default to the

last setting used when it is powered on or off.

SETTING SOLUTION FLOW

With the 1−STEP Scrub button activated, press

either Solution increase button (+) or Solution

decrease button (−) to set the solution flow level.

Travel speed and floor conditions will affect

scrubbing performance. The machine will default

to the last setting used when the machine is

powered on or off.

NOTE: In the ES and FaST modes, the solution

flow buttons control both the solution AND

detergent flow levels.

To turn off all solution and detergent flow, press

the Solution decrease button (−) until all indicator

lights are off.

CONVENTIONAL, FaST, AND ec−H2O

SOLUTION FLOW

Under normal soilage conditions the solution flow

level should be set to the lowest setting (the

bottom light). Under heavy grime conditions, the

solution flow level should be set to the higher

settings (middle or top lights).

ES (EXTENDED SCRUB) SOLUTION FLOW

For ES machines, the detergent flow is turned

off when the solution flow is in the lowest

setting (one light). Under normal soilage

conditions, the solution flow level should be

alternated between the middle and lowest setting.

The middle setting (two lights) allows solution

AND detergent flow. The lowest setting (one light)

allows solution flow WITHOUT adding detergent.

Detergent does not have to be continuously

added with the solution flow to attain effective

scrubbing results.

24

M30 9003943 (4−10)

SCRUBBING

Home

Find...

Go To..

The 1−STEP Scrub button operates all the

scrubbing functions. (The machine also wet

sweeps while scrubbing).

FOR SAFETY: Do not operate machine, unless

operator manual is read and understood.

1. Start the machine.

NOTE: Make sure the scrub modes / settings are

set before scrubbing.

2. Press the 1−STEP Scrub button. The light on

the button will come on. All the preset

scrubbing functions will turn on.

OPERATION

ec−H2O Model: If an alarm sounds and the

ec−H2O system indicator light begins to blink red,

the ec−H2O module must be flushed to resume

ec−H2O operation (See ec−H2O MODULE

FLUSH PROCEDURE).

NOTE: When the alarm sounds and the light

blinks red, the machine will bypass the ec−H2O

system. To continue scrubbing, press the ec−H2O

button to turn off the ec−H2O system.

NOTE: DO NOT turn on the FaST or ec−H2O

system during conventional scrubbing.

Conventional cleaning detergents could cause a

FaST or ec−H2O system failure. Drain, rinse, and

refill the solution tank with cool clean water before

operating the FaST or ec−H2O system.

3. Release the parking brake, then press the

Directional pedal to begin scrubbing.

WARNING: Flammable materials or

reactive metals can cause an explosion

or fire. Do not pick up.

FOR SAFETY: When using machine, go slow

on inclines and slippery surfaces.

ATTENTION: (ec−H2O model) Do not allow

solution tank to run dry. ec−H2O module

failure may result if operated without water for

an extended period.

ec−H2O SYSTEM

INDICATOR LIGHT

CODE

Solid green Normal operation

Blinking red Flush ec−H2O module

Solid red Contact Service Center

4. Release the directional pedal and press the

brake pedal to stop the machine.

5. Press the 1−STEP Scrub button to stop

scrubbing. The light next to the button will go

off and scrubbing functions will stop after a

short delay.

CONDITION

NOTE: The squeegee automatically rises when

the machine is driven backwards. This prevents

damaging the squeegee.

NOTE:The ec−H2O system indicator light will not

turn on until the machine starts scrubbing.

M30 9003943 (4−10)

25

OPERATION

Home

Find...

Go To..

DOUBLE SCRUBBING

For heavily soiled areas, use the double scrubbing

method.

Double scrubbing can be performed using the

FaST SCRUBBING SYSTEM (option),

ec−H2O SCRUBBING SYSTEM (option) or

CONVENTIONAL SCRUBBING methods.

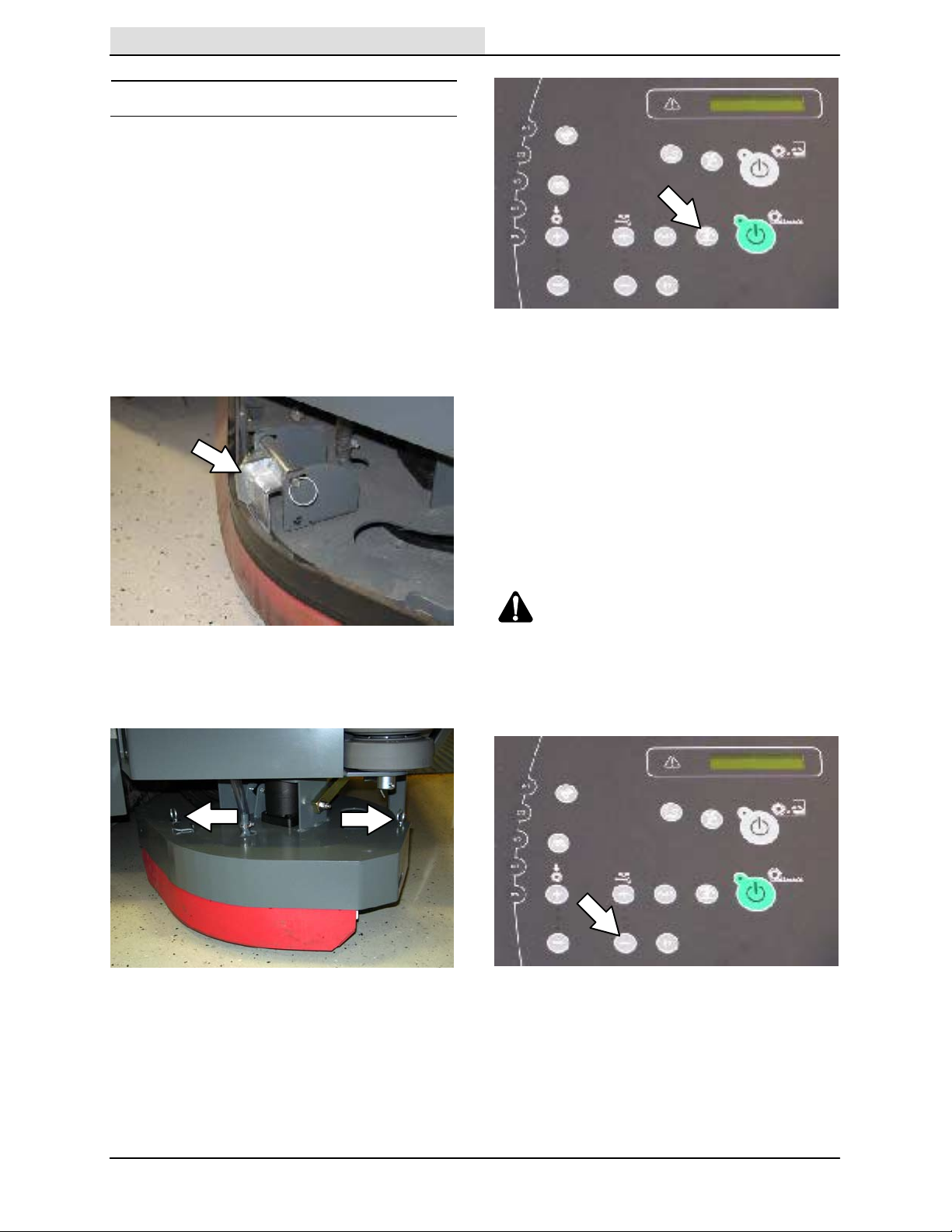

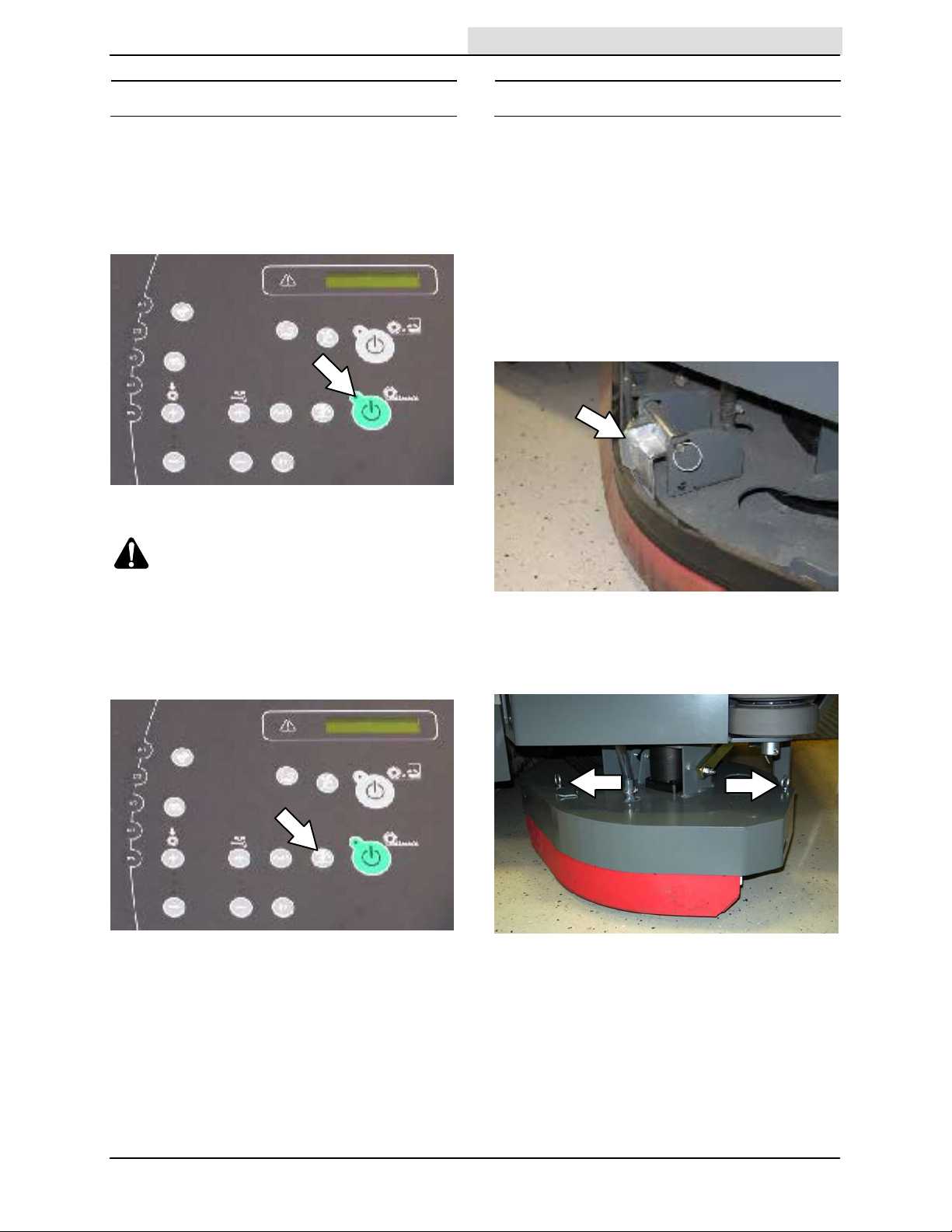

Side brush option (S/N 000000−001278): Before

double scrubbing, manually lock the side brush

squeegee into the raised position. Pull the pin

from the side brush squeegee bracket, manually

raise the side squeegee to the upper position,

then reinsert the brush pin.

FOR SAFETY: When using machine, go slow

on inclines and slippery surfaces.

Let the cleaning solution soak on the floor for

5−15 minutes. Then place the side squeegee into

the lower position and lock into place with the pin.

Press the Scrub vacuum fan/squeegee button

again to lower the squeegee and turn on the

vacuum fan. The light above the button will come

on. Scrub the floor a second time to pick up the

cleaning solution.

Side brush option (S/N 001279− ): Before

double scrubbing, remove the side brush bumper.

Pull the pins and remove the squeegee bumper.

Press the 1−STEP Scrub button, and then the

Scrub vacuum fan/squeegee button. The light

above the Scrub vacuum fan/squeegee button will

turn off, the squeegee will rise, and the vacuum

fan will stop operating. Scrub the heavily soiled

area.

WARNING: Flammable materials or

reactive metals can cause an explosion

or fire. Do not pick up.

NOTE: To turn off the solution flow when

scrubbing the area a second time, repeatedly

press the Solution decrease button (−) until all

lights above the button are off.

NOTE: Double scrubbing is not recommended in

areas where the cleaning solution will run under

racks or damage products.

26

M30 9003943 (4−10)

OPERATION

Home

Find...

Go To..

WATER PICKUP MODE (NO SCRUBBING)

The machine can be used to pick up water or

non−flammable liquid spills without scrubbing.

To pick up water or non−flammable liquid spills,

make sure the 1−STEP Scrub button is not

activated. The light next to the button must be off.

WARNING: Flammable materials or

reactive metals can cause an explosion

or fire. Do not pick up.

SWEEPING

NOTE: The 1−STEP Sweep button operates all

the sweeping functions (without scrubbing).

FOR SAFETY: Do not operate machine, unless

operator manual is read and understood.

Side brush option (S/N 000000−001278): Before

sweeping, manually lock the side brush squeegee

into the raised position. Pull the pin from the side

brush squeegee bracket, manually raise the side

squeegee to the upper position, then reinsert the

brush pin.

Press the Scrub vacuum fan/squeegee button.

The light above the button will come on, the

squeegee will lower, and the vacuum fan will start

operating. Pick up the water or non−flammable

liquid spill.

Side brush option (S/N 001279− ): Before

sweeping, remove the side brush bumper. Pull the

pins and remove the squeegee bumper.

M30 9003943 (4−10)

27

Loading...

Loading...