Tennant 6500D User Manual

6500D

Home

Find...

Go To..

Operator Manual

330290

Rev. 06

*330290*

This manual is furnished with each new TENNANT Model 6500D. It provides necessary operating and

Home

Find...

Go To..

preventive maintenance instructions. Read this manual completely and understand the machine before

operating or servicing it.

This machine will provide excellent service. However, the best results will be obtained at minimum

costs if:

D The machine is operated with reasonable care.

D The machine is maintained regularly -- per the maintenance instructions provided.

D The machine is maintained with TENNANT supplied or approved parts.

Manual Number -- 330290

Revision: 06

Published: 9--02

CALIFORNIA PROPOSITION 65 WARNING:

Engine exhaust from this product contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive harm.

Copyright E 1998, 1999, 2000, 2001, 2002 TENNANT, Printed in U.S.A.

CONTENTS

Home

Find...

Go To..

CONTENTS

SAFETY PRECAUTIONS 3.................

OPERATION 6............................

OPERATOR RESPONSIBILITY 6.........

MACHINE COMPONENTS 9.............

CONTROL PANEL SYMBOLS 10..........

CONTROLS AND INSTRUMENTS 12......

OPERATION OF CONTROLS 14..........

DIRECTIONAL PEDAL 14..............

BRAKE PEDAL 15....................

PARKING BRAKE LEVER 15...........

HORN BUTTON 15....................

MAIN BRUSH AND SIDE BRUSH

LEVER 16.........................

HOPPER DOOR LEVER 17............

HOPPER LIFT LEVER 18..............

MAIN BRUSH POSITION LEVER 19....

MAIN BRUSH DOWN PRESSURE

KNOB 21..........................

MAIN BRUSH ADJUSTMENT KNOB 22..

TURN SIGNAL SWITCH (OPT ION) 23...

HOPPER TEMPERATURE LIGHT --

THERMO SENTRYt 24............

ENGINE WATER TEMPERATURE

LIGHT 24..........................

ENGINE OIL PRESSURE LIGHT 25.....

CHARGING SYSTEM LIGHT 25........

HOPPER DOOR LIGHT 26.............

CLOGGED FILTER LIGHT 26..........

CLOGGED FILTER LIGHT (OPTION) 26.

GLOW PLUG LIGHT 27................

HOURMETER 27.....................

FUEL LEVEL GAUGE 27...............

HAZARD LIGHT SWITCH (OPTION) 28..

OPERATING LIGHTS SWITCH 28......

OPERATING/HAZARD LIGHTS

SWITCH 28........................

VACUUM FAN SWITCH 29.............

FILTER SHAKER SWITCH 29..........

V ACUUM FAN/FILTER SHAKER

SWITCH 29........................

ENGINE SPEED SWITCH 30...........

STEERING WHEEL 32................

STEERING COLUMN TILT LEVER 32...

IGNITION SWITCH 33.................

SIDE BRUSH POSITION LEVER 34.....

SIDE BRUSH DOWN PRESSURE

KNOB 35..........................

Page

Page

CIRCUIT BREAKERS 36...............

FUSES 36............................

CIRCUIT BREAKERS 37...............

LATCHES 38.........................

HOPPER SUPPORT BAR 38...........

OPERATOR SEAT 39..................

HEATER KNOB (OPTION) 39..........

AIR CONDITIONING SWITCH

(OPTION) 39......................

WINDSHIELD WIPER SWITCH

(OPTION) 40......................

DOME LIGHT SWITCH (OPTION) 40....

HEATER SWITCH (OPT ION) 40........

PRESSURIZER SWITCH (OPTION) 40..

HOW THE MACHINE WORKS 41..........

PRE-OPERATION CHECKLIST 41.........

STARTING THE MACHINE 43.............

SWEEPING AND BRUSH INFORMATION 45

SWEEPING 46..........................

STOP SWEEPING 48....................

EMPTYING THE HOPPER 50.............

STOP THE MACHINE 52.................

POST-OPERATION CHECKLIST 53........

ENGAGING HOPPER SUPPORT BAR 54..

DISENGAGING HOPPER SUPPORT BAR 55

OPERATION ON INCLINES 56............

OPTIONS 57............................

VACUUM WAND 57...................

BLOWER WAND 63...................

HE ATER VA LV E 64....................

MACHINE TROUBLESHOOTING 65.......

MAINTENANCE 66.........................

MAINTENANCE CHART 66...............

LUBRICATION 68........................

ENGINE 68...........................

REAR WHEEL SUPPORT 68...........

HOPPER BEARINGS 69...............

FRONT WHEEL BEARINGS 69.........

HYDRAULICS 70........................

HYDRAULIC FLUID RESERVOIR 70....

HYDRAULIC FLUID 70................

HYDRAULIC HOSES 71...............

PROPELLING MOTOR 71..............

ENGINE 72.............................

COOLING SYSTEM 72................

AIR FIL TER INDICAT OR 73............

AIR FILTER 73........................

FUEL FILTER 74......................

FUEL PIPES 74.......................

PRIMING FUEL SYSTEM 74...........

BATTERY 75............................

6500D 330290 (9-- 01)

1

CONTENTS

Home

Find...

Go To..

BELTS AND CHAINS 75..................

ENGINE FAN BELT 75.................

STATIC DRAG CHAIN 75..............

DEBRIS HOPPER 76.....................

HOPPER DUST FILTER 76.............

TO REPLACE HOPPER DUST FILTER 77

THERMO SENTRYt 79..................

BRUSHES 80............................

MAIN BRUSH 80......................

TO REPLACE MAIN BRUSH 81......

TO CHECK AND ADJUST MAIN

BRUSH PATTERN 83...........

SIDE BRUSH 87......................

TO REPLACE SIDE BRUSH 88......

SIDE BRUSH GUARD 88...........

SKIRTS AND SEALS 89..................

HOPPER LIP SKIRTS 89...............

HOPPER SIDE SKIRT 89..............

BRUSH DOOR SKIRTS 89.............

REAR SKIRTS 90.....................

SIDE BRUSH DUST CONTROL SKIRTS

(OPTION) 90......................

BRUSH DOOR SEALS 90..............

HOPPER SEALS 91...................

HOPPER INSPECTION DOOR SEAL 91.

HOPPER DOOR SEALS 91............

HOPPER COVER SEAL

(Metal Hoppers) 92.................

HOPPER DUST SEAL

(Metal Hoppers) 92.................

HOPPER VACUUM FAN SEAL

(Metal Hoppers) 92.................

HOPPER FILTER SEALS 92............

BRAKES AND TIRES 93..................

SERVICE BRAKES 93.................

PARKING BRAKE 93..................

REAR WHEEL 93.....................

PUSHING, TOWING, AND TRANSPORTING

THE MACHINE 94.....................

PUSHING OR TOWING THE MACHINE 94

TRANSPORTING THE MACHINE 94....

MACHINE JACKING 97...................

STORING MACHINE 97..................

SPECIFICATIONS 98.......................

GENERAL MACHINE

DIMENSIONS/CAPACITIES 98.........

GENERAL MACHINE PERFORMANCE 98..

POWER TYPE 99........................

STEERING 99...........................

HYDRAULIC SYSTEM 99.................

BRAKING SYSTEM 99...................

TIRES 99...............................

MACHINE DIMENSIONS 100.................

INDEX 100.................................

Page

2

6500D 330290 (9-- 02)

SAFETY PRECAUTIONS

Home

Find...

Go To..

SAFETY PRECAUTIONS

The following precautions are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or

unsafe practices which could result in

severe personal injury or death.

FOR SAFETY: To identify actions which

must be followed for safe operation of

equipment.

The machine is suited to sweep disposable

debris. Do not use the machine other than

described in this Operator Manual. The machine

is not designed for use on public roads.

The following information signals potentially

dangerous conditions to the operator or

equipment:

WARNING: Engine emits toxic gases.

Severe respiratory damage or

asphyxiation can result. Provide

adequate ventilation. Consult with your

regulatory authorities for exposure

limits. Keep engine properly tuned.

WARNING: Raised hopper may fall.

Engage hopper support bar.

WARNING: Lift arm pinch point. Stay

clear of hopper lift arms.

WARNING: Moving belt and fan. Keep

away.

FOR SAFETY:

1. Do not operate machine:

-- Unless trained and authorized.

-- Unless operator manual is read and

understood.

-- If it is not in proper operating

condition.

-- In flammable or explosive areas unless

designed for use in those areas.

-- In areas with possible falling objects

unless equipped with overhead guard.

3. When starting machine:

-- Keep foot on brake and directional

pedal in neutral.

4. When using machine:

-- Use brakes to stop machine.

-- Go slow on inclines and slippery

surfaces.

-- Use care when reversing machine.

-- Move machine with care when hopper

is raised.

-- Make sure adequate clearance is

available before raising hopper.

-- Do not carry passengers on machine.

-- Always follow safety and traffic rules.

-- Report machine damage or faulty

operation immediately.

5. Before leaving or servicing machine:

-- Stop on level surface.

-- Set parking brake.

-- Turn off machine and remove key.

6. When servicing machine:

-- Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves.

-- Block machine tires before jacking

machine up.

-- Jack machine up at designated

locations only. Block machine up with

jack stands.

-- Use hoist or jack that will support the

weight of the machine.

-- Wear eye and ear protection when

using pressurized air or water.

-- Disconnect battery connections before

working on machine.

-- Avoid contact with battery acid.

-- Avoid contact with hot engine coolant.

-- Allow engine to cool.

-- Keep flames and sparks away from

fuel system service area. Keep area

well ventilated.

-- Use cardboard to locate leaking

hydraulic fluid under pressure.

-- Use TENNANT supplied or approved

replacement parts.

2. Before starting machine:

-- Check for fuel, oil, and liquid leaks.

-- Keep sparks and open flame away

from refueling area.

-- Make sure all safety devices are in

place and operate properly.

-- Check brakes and steering for proper

operation.

6500D 330290 (9-- 02)

3

SAFETY PRECAUTIONS

Home

Find...

Go To..

7. When loading/unloading machine

onto/off truck or trailer:

-- Turn off machine.

-- Use truck or trailer that will support

the weight of the machine.

-- Use winch. Do not drive the machine

onto/off the truck or trailer unless the

load height is 380 mm (15 in) or less

from the ground.

-- Set parking brake after machine is

loaded.

-- Block machine tires.

-- Tie machine down to truck or trailer.

4

6500D 330290 (9-- 02)

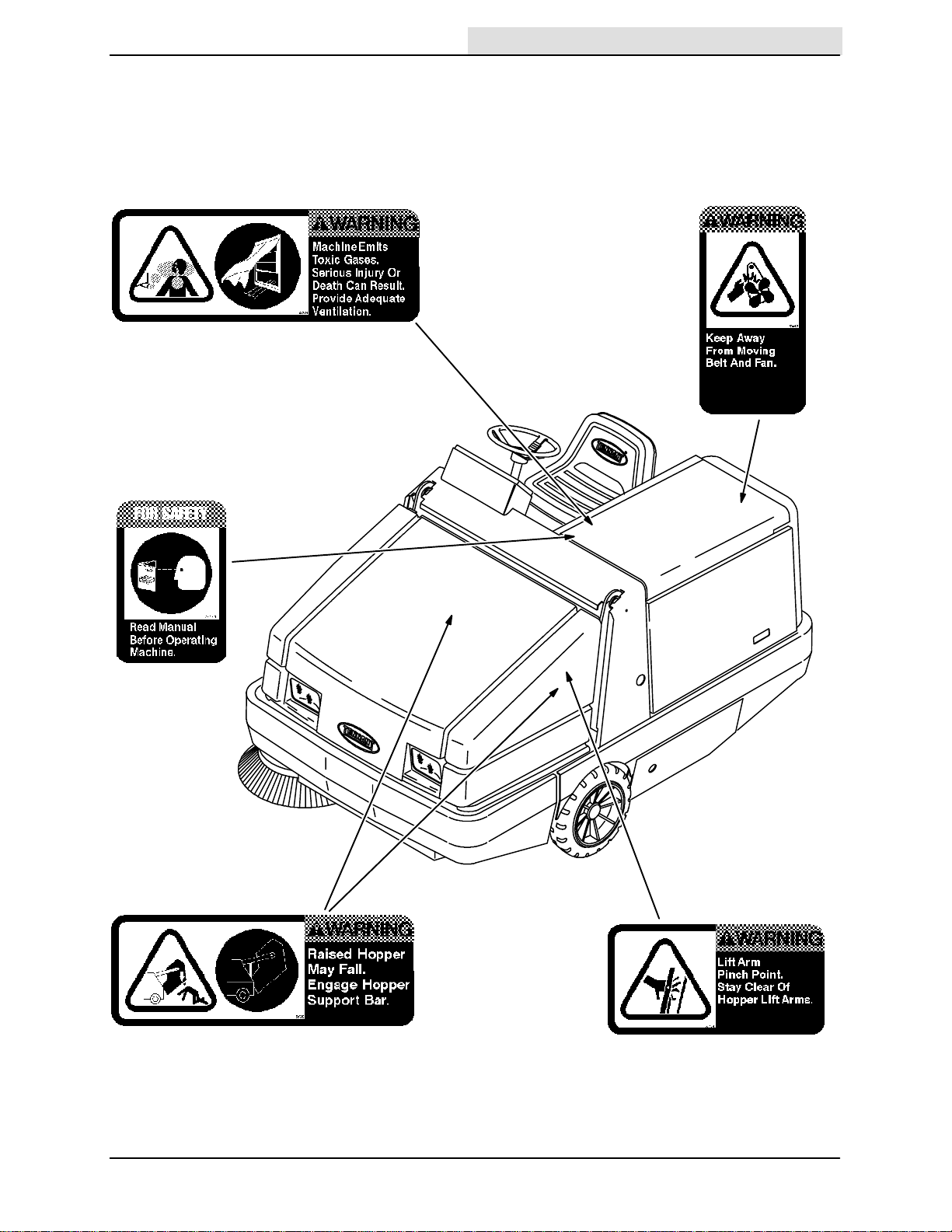

The following safety labels are mounted on the

Home

Find...

Go To..

machine in the locations indicated. If these or any

label becomes damaged or illegible, install a new

label in its place.

SAFETY PRECAUTIONS

EMISSIONS LABEL -- LOCATED ON THE SIDE

PANEL OF THE OPERATOR COMPARTMENT.

FOR SAFETY LABEL -- LOCATED ON

THE SIDE PANEL OF THE OPERATOR

COMPARTMENT.

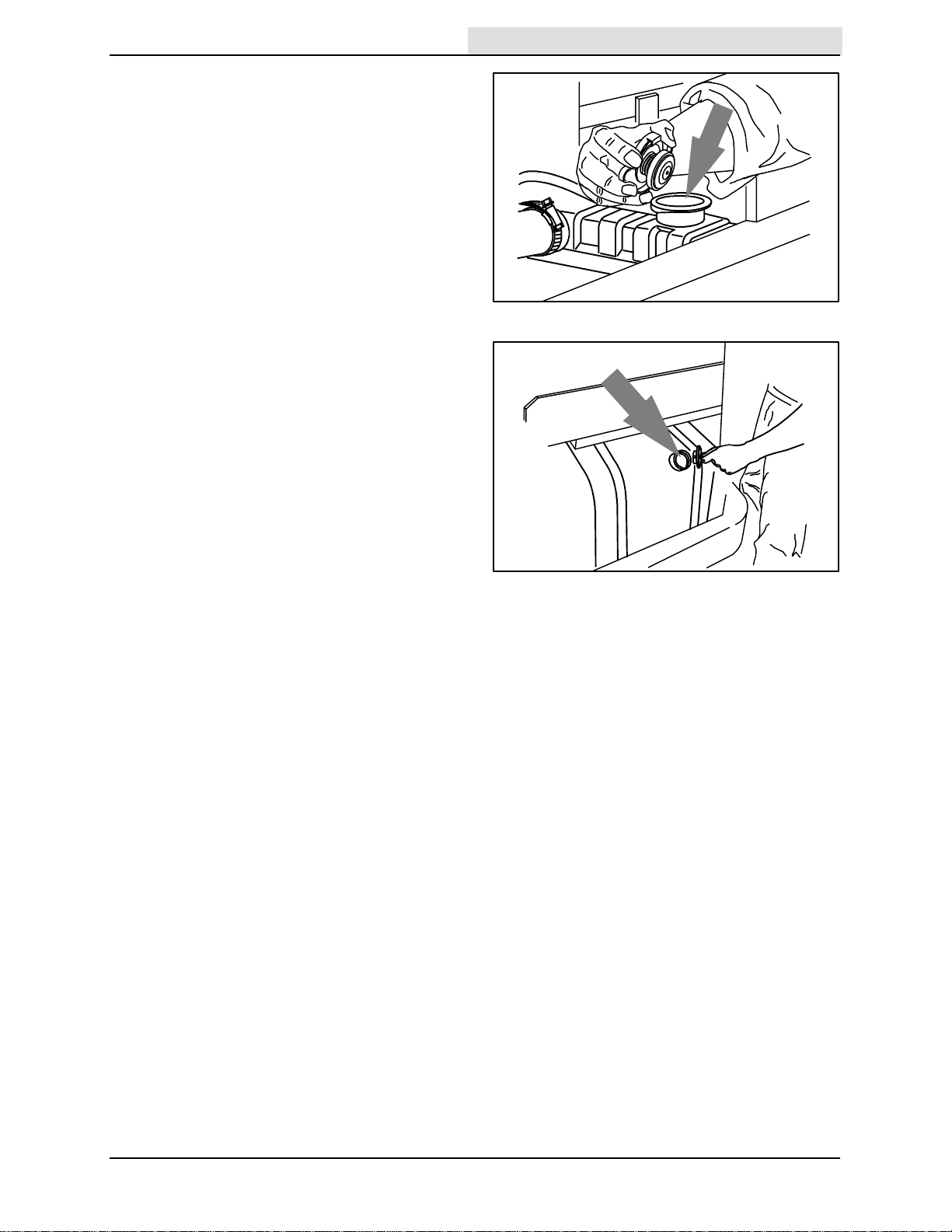

ENGINE FAN AND BELT LABEL -LOCATED ON THE RADIATOR SHROUD.

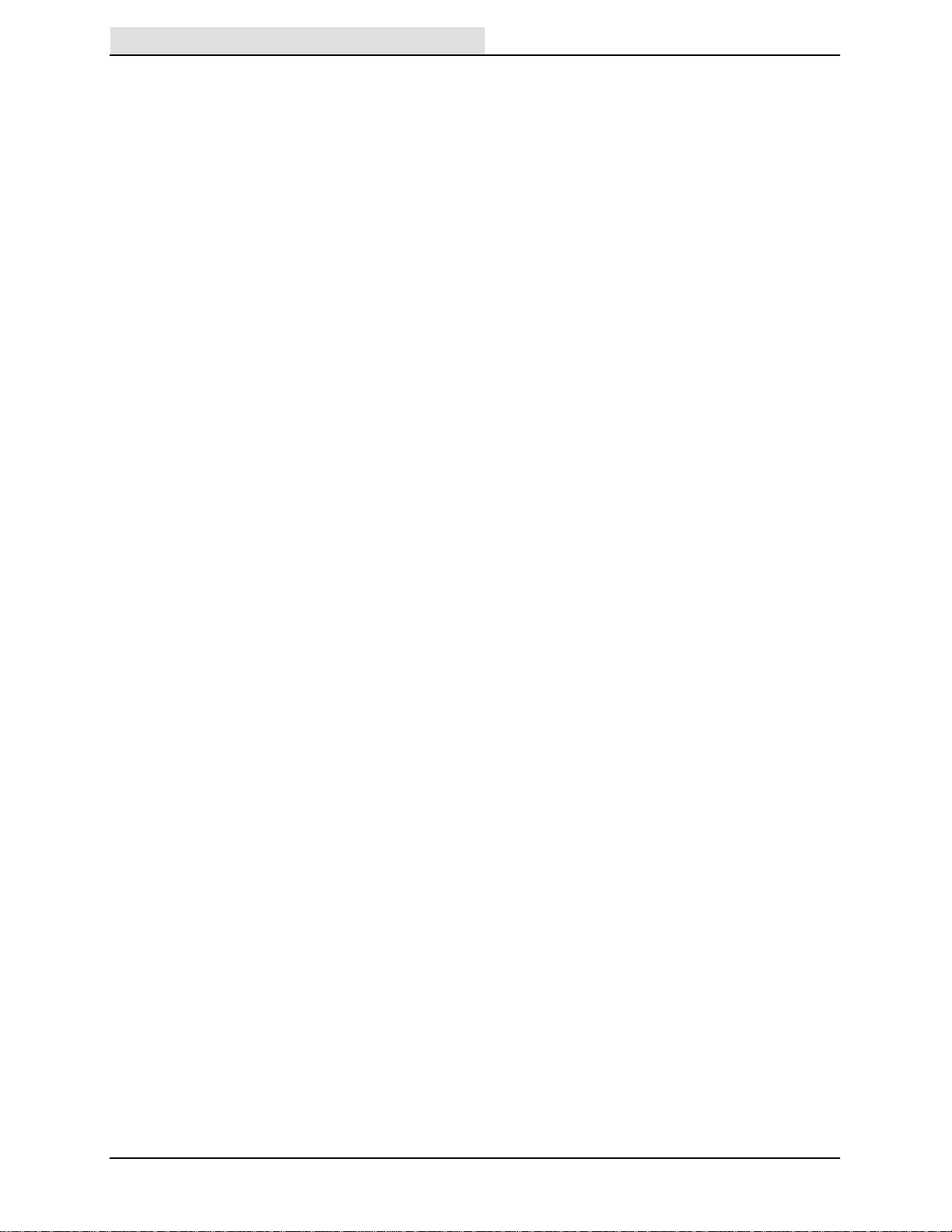

HOPPER SUPPORT BAR LABEL -- LOCATED

ON THE HOPPER SUPPORT BAR AND ON

BOTH HOPPER LIFT ARMS.

6500D 330290 (5-- 98)

07748

HOPPER LIFT ARMS LABEL -- LOCATED

ON BOTH HOPPER LIFT ARMS.

5

OPERATION

Home

Find...

Go To..

OPERATOR RESPONSIBILITY

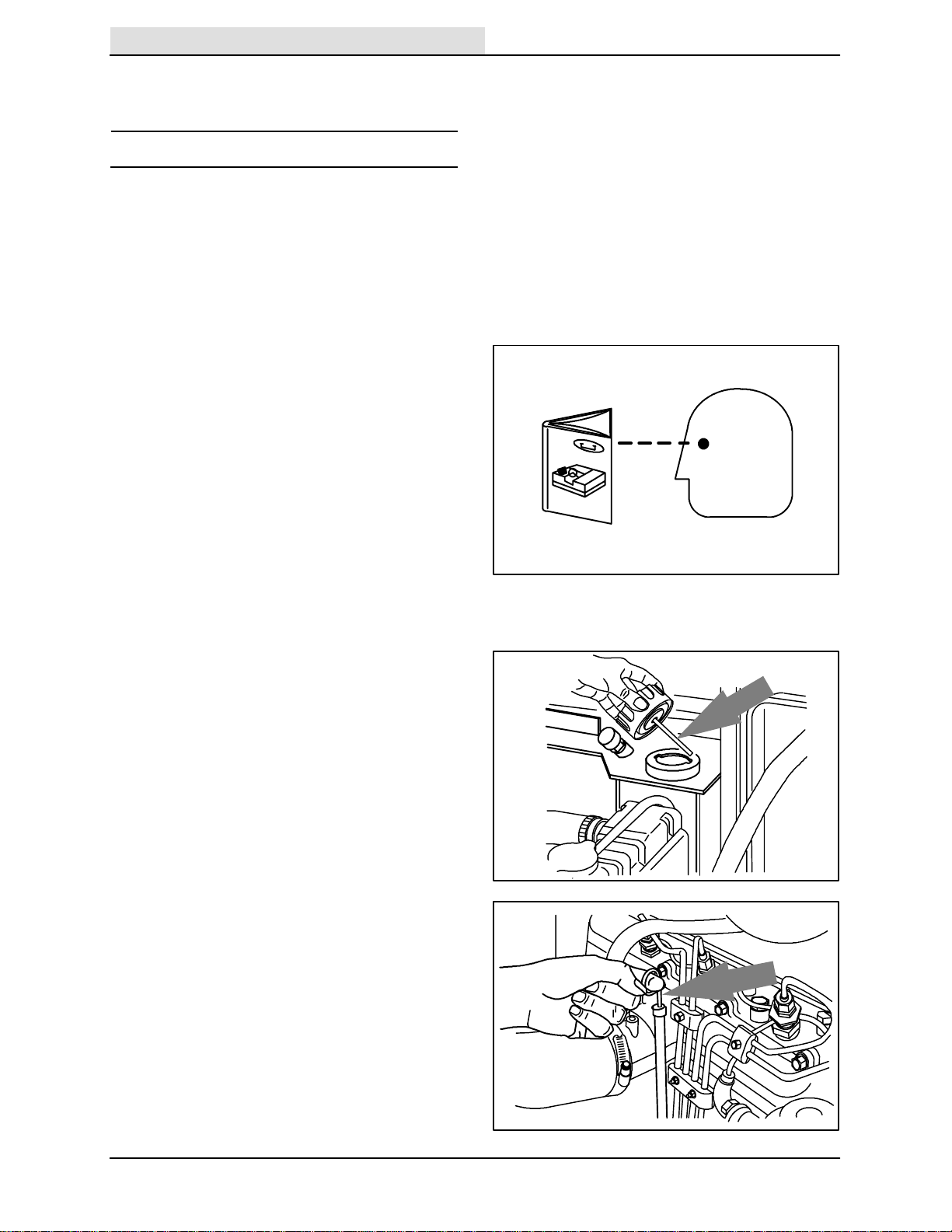

- The operator’s responsibility is to take care

of the daily maintenance and checkups of

the machine to keep it in good working

condition. The operator must inform the

service mechanic or supervisor when the

required maintenance intervals occur as

stated in the MAINTENANCE section of this

manual.

- Read this manual carefully before operating

this machine.

FOR SAFETY: Do not operate machine,

unless operation manual is read and

understood.

OPERATION

- Check the machine for shipping damage.

Check to make sure machine is complete

per shipping instructions.

- Check the hydraulic fluid level in the

hydraulic reservoir.

- Check the engine oil level.

07324

07750

08431

6

6500D 330290 (5-- 98)

- Check the radiator coolant level.

Home

Find...

Go To..

FOR SAFETY: When servicing machine,

avoid contact with hot engine coolant.

- Fill the fuel tank.

FOR SAFETY: When servicing machine,

keep flames and sparks away from fuel

system service area. Keep area well

ventilated.

OPERATION

07752

07753

6500D 330290 (9-- 01)

7

OPERATION

Home

Find...

Go To..

- LPG powered machines: Install the LPG fuel

tank on the machine. See CHANGING AN

LPG FUEL TANK.

- After the first 50 hours of operation, follow

the recommended procedures stated in the

MAINTENANCE CHART.

- Keep your machine regularly maintained by

following the maintenance information in this

manual. We recommend taking advantage

of a regularly scheduled service contract

from your TENNANT representative.

- Order parts and supplies directly from your

authorized TENNANT representative. Use

the parts manual provided when ordering

parts.

8

6500D 330290 (9-- 01)

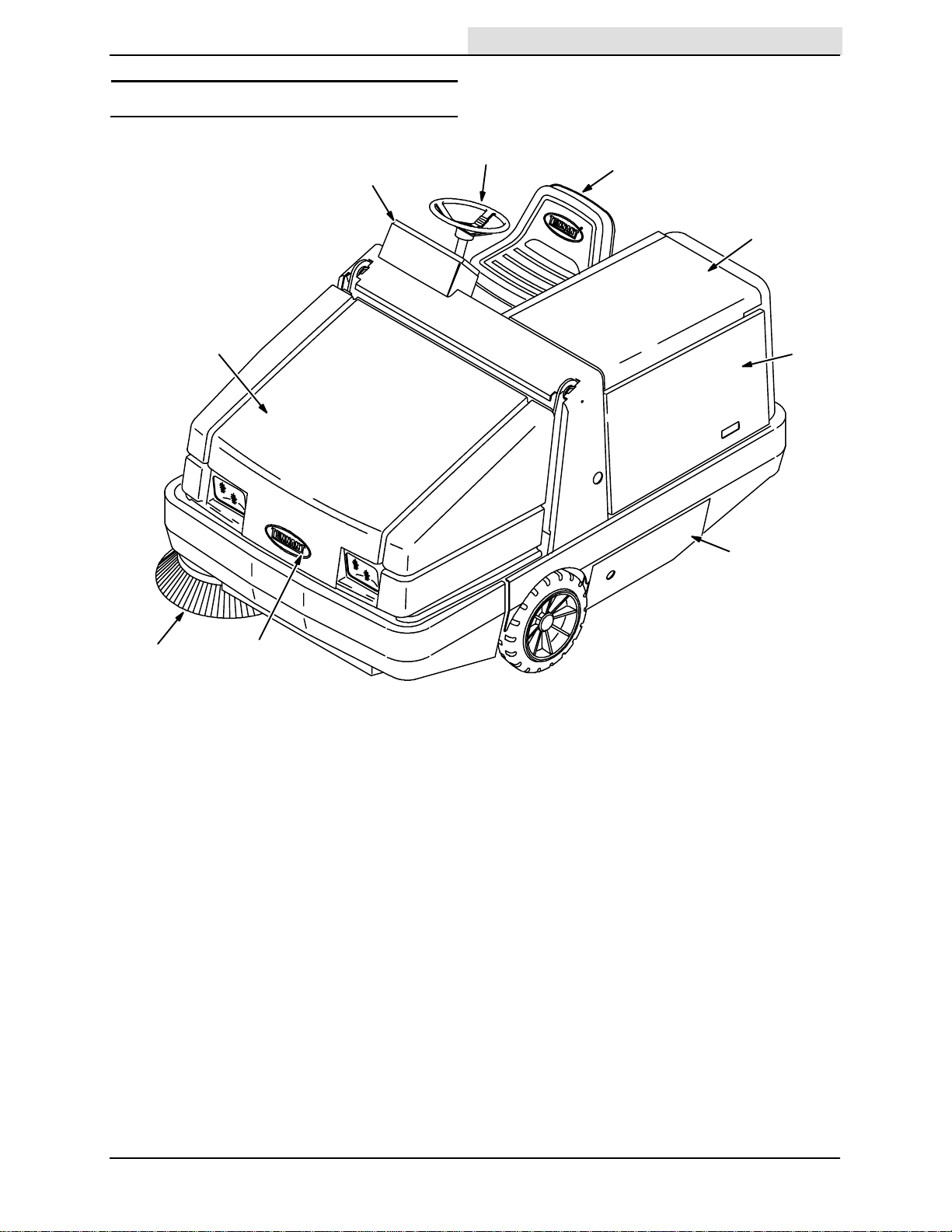

MACHINE COMPONENTS

Home

Find...

Go To..

OPERATION

B

I

F

A

C

D

E

H

G

07748

A. Operator Seat

B. Steering Wheel

C. Engine Cover

D. Engine Side Door

E. Main B rush Access Door

F. Hopper Cover

G. Hopper Access Cover

H. Side Brush

I. Instrument Panel

6500D 330290 (5-- 98)

9

OPERATION

Home

Find...

Go To..

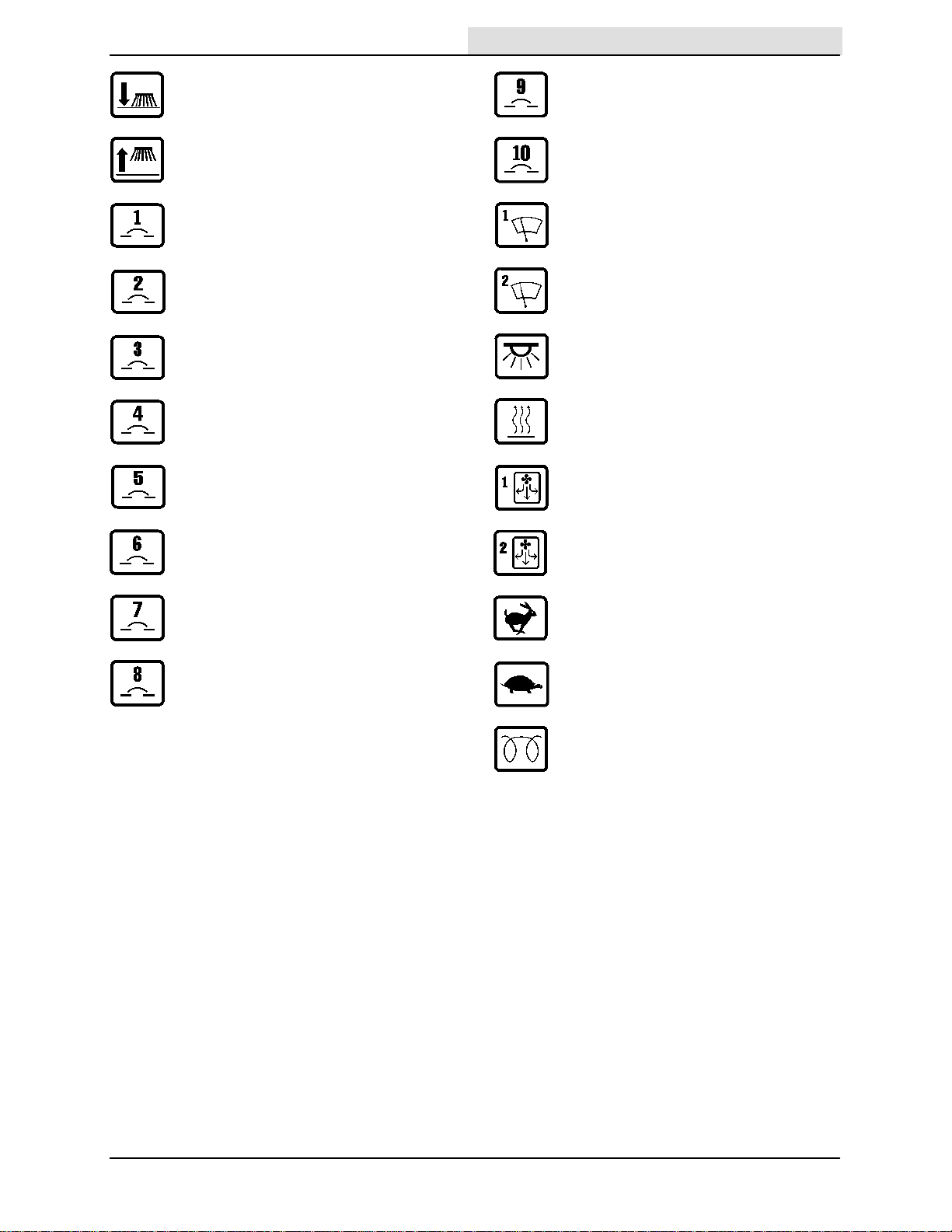

CONTROL PANEL SYMBOLS

These symbols identify controls and displays on

the machine:

Main and Side Brushes On Charging System

Main Brush On Engine Oil Pressure

Hopper Door Open Engine Water Temperature

Hopper Door Close Hopper Temperature -- Thermo Sentryt

Hopper Down Hopper Temperature --Thermo Sentryt

Hopper Up Filter Clogged

Horn Hopper Door Closed

Main Brush Down Pressure Light Fuel

Main Brush Down Pressure Heavy Hourmeter

Main Brush Float Hazard Light

Main Brush Down Filter Shaker

Main Brush Up Operating Lights

10

Side Brush Down Pressure Light Fan

Side Brush Down Pressure Heavy Engine Speed

6500D 330290 (9-- 01)

Side Brush Down Circuit Breaker 9

Home

Find...

Go To..

Side Brush Up Circuit Breaker 10

Circuit Breaker 1 Windshield Wiper Slow

Circuit Breaker 2 Windshield Wiper Fast

Circuit Breaker 3 Dome Light

Circuit Breaker 4 Heater

OPERATION

Circuit Breaker 5 Cab Pressurizer Slow

Circuit Breaker 6 Cab Pressurizer Fast

Circuit Breaker 7 Engine speed (fast)

Circuit Breaker 8 Engine speed (slow)

Diesel Preheat

6500D 330290 (9-- 01)

11

OPERATION

Y

Home

Find...

Go To..

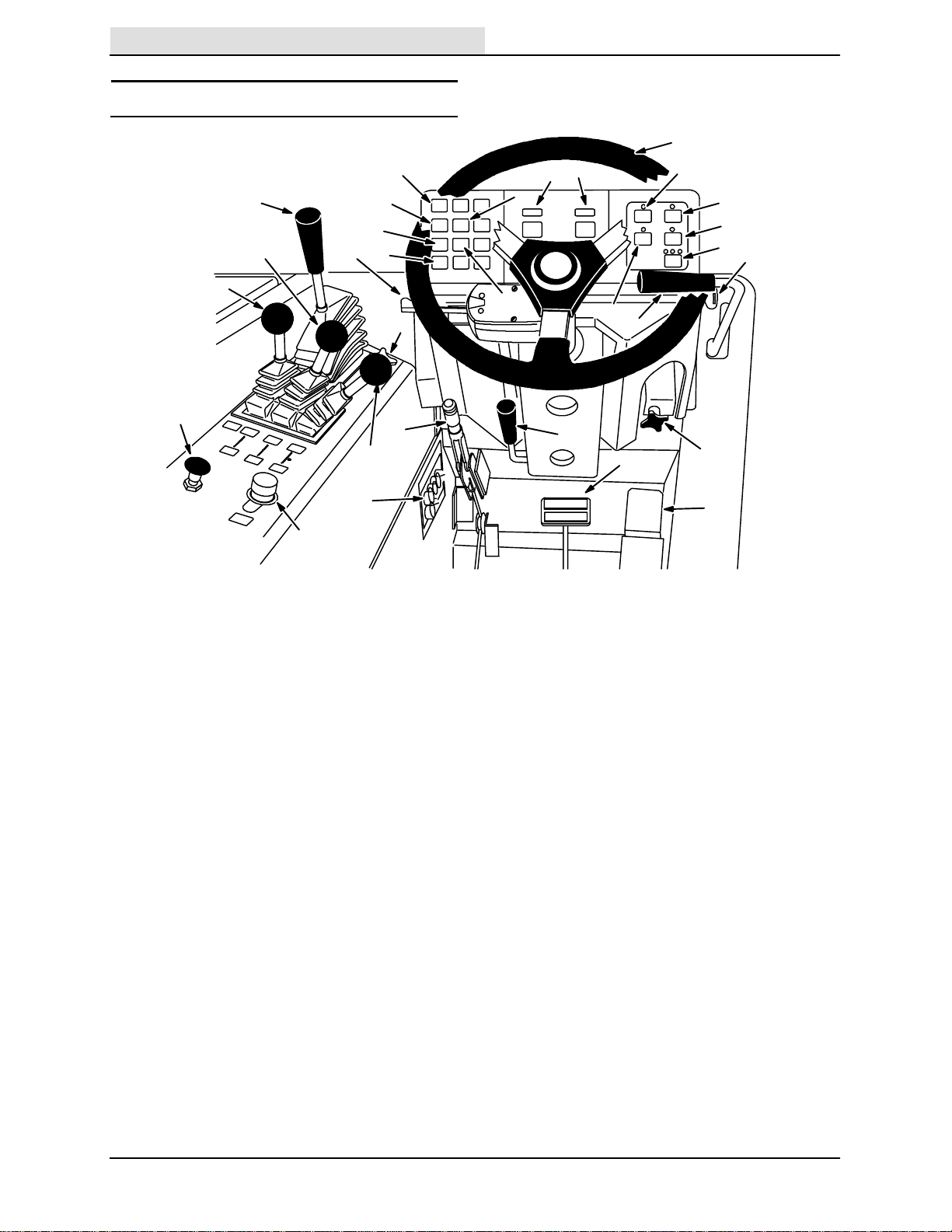

CONTROLS AND INSTRUMENTS

For machines below serial number 020000

O

I

G

F

N

M

L

K

J

S

R

Q

P

X

Z

T

U

V

W

AA

E

D

A. Directional Pedal

B. Brake Pedal

C. Parking Brake Lever

D. Horn Button

E. Engine Choke Knob

F. Main Brush And Side Brush Lever

G. Hopper Door Lever

H. Hopper Lift Lever

I. Main Brush Position Lever

J. Main Brush Down Pressure Knob

K. Turn Signal Switch (Option)

L. Hopper Temperature Light -- Thermo Sentryt

M. Engine Water Temperature Light

N. Engine Oil Pressure Light

O. Charging System Light

P. Hopper Door Light

Q. Clogged Filter Light

R. Fuel Level Gauge

S. Hourmeter

T. Hazard Light Switch (Option)

U. Operating Light Switch

V. Vacuum Fan Switch

W. Engine Speed Switch

X. Filter Shaker Switch

Y. Steering Wheel

Z. Side Brush Position Lever

AA. Ignition Switch

BB.Side Brush Down Pressure Knob

CC.Steering Column Tilt Lever

DD.Circuit Breakers

DD

C

H

CC

B

BB

A

08047

12

6500D 330290 (3-- 99)

For machines with serial number 020000 and above

Home

Find...

Go To..

OPERATION

K

O

P

H

I

E

F

BB

G

D

M

L

Q

C

N

S

AA

T

R

B

U

V

Y

X

W

Z

A

A. Directional Pedal

B. Brake Pedal

C. Parking Brake Lever

D. Horn Button

E. Main Brush And Side Brush Lever

F. Hopper Door Lever

G. Hopper Lift Lever

H. Main Brush Position Lever

I. Main Brush Down Pressure Knob

J. Turn Signal Switch (Not Pictured)

K. Hopper Temperature Light -- Thermo Sentryt

L. Engine Water T emperature Light

M. Engine Oil Pressure Light

N. Charging System Light

O. Hopper Door Light

P. Clogged Filter Light (Option)

Q. Glow Plug light

R. Hourmeter

S. Fuel Gauge

T. Operating/Hazard Lights Switch

U. Vacuum Fan/Filter Shaker Switch

V. Engine Speed Switch

W. Steering Wheel

X. Side Brush Position Lever

Y. I g n i t i o n S w i t c h

Z. Side Brush Down Pressure Knob

AA. Circuit Breakers

BB.Steering Column Tilt Lever (Option)

6500D 330290 (9-- 02)

13

OPERATION

Home

Find...

Go To..

OPERATION OF CONTROLS

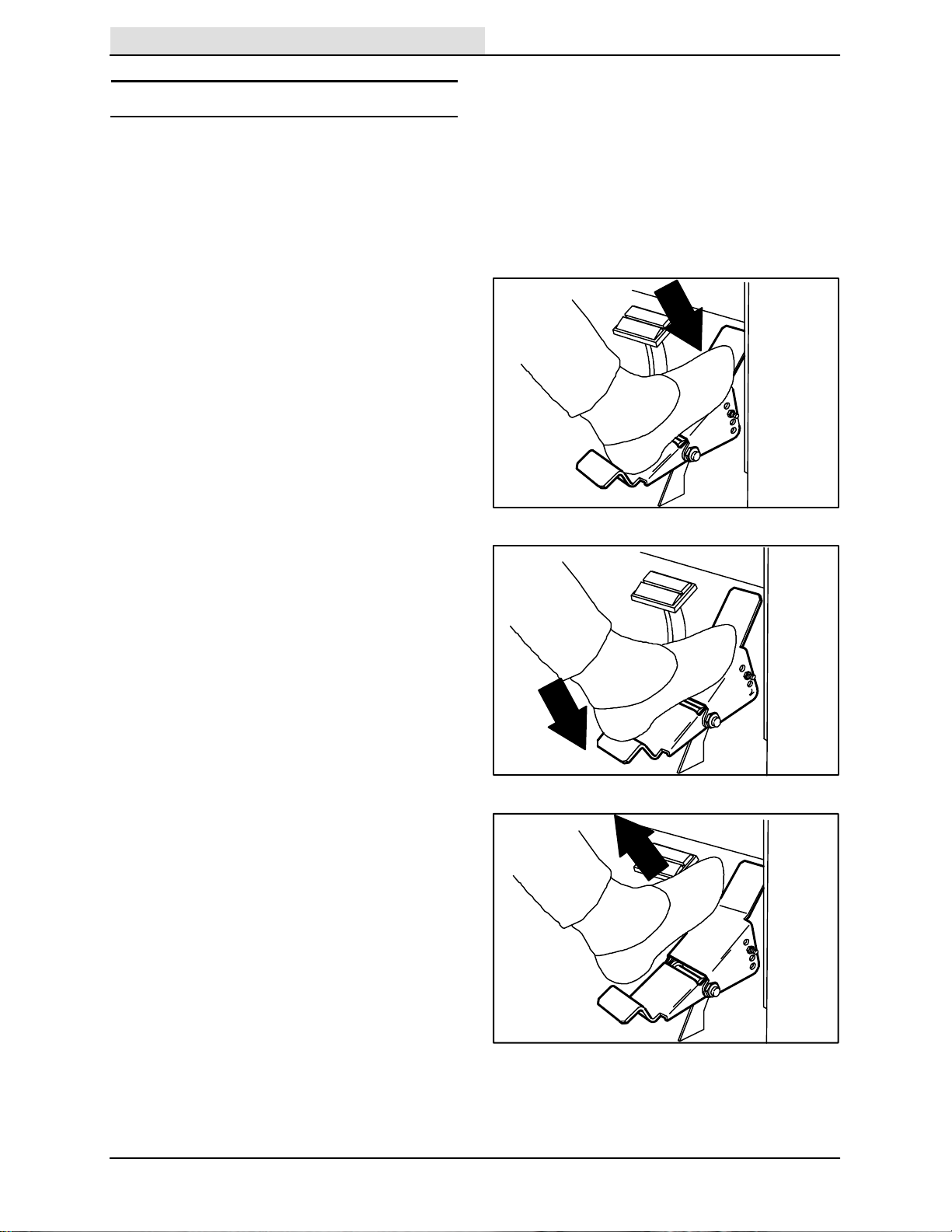

DIRECTIONAL PEDAL

The directional pedal controls direction of travel

and the propelling speed of the machine. You

change the speed of the machine with the

pressure of your foot; the harder you press the

faster the machine travels.

Forward: Press the top of the directional pedal

with the toe of your foot.

Reverse: Press the bottom of the directional

pedal with the heel of your foot.

Neutral: Take your foot off the directional pedal

and it will return to the neutral position.

07790

07791

14

07792

6500D 330290 (5-- 98)

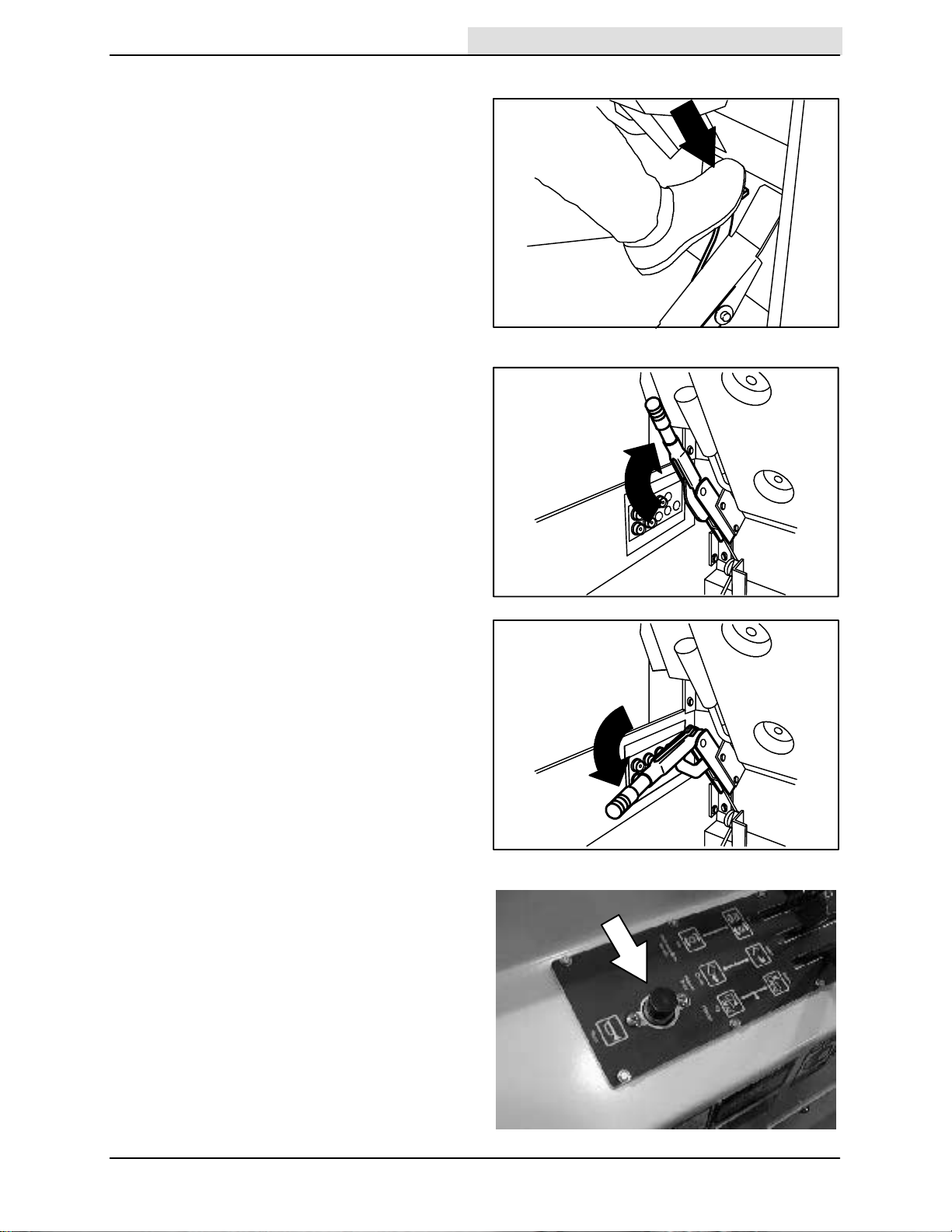

BRAKE PEDAL

Home

Find...

Go To..

The brake pedal stops the machine.

Stop: Take your foot off the directional pedal and

let it return to the neutral position. Step on the

brake pedal.

PARKING BRAKE LEVER

The parking brake lever sets and releases the

front wheel brakes.

Set: Pull the parking brake lever up.

FOR SAFETY: Before leaving or

servicing machine; stop on level

surface, set parking brake, turn off

machine and remove key.

OPERATION

07754

Release: Push the parking brake lever down.

HORN BUTTON

The horn button operates the horn.

Sound: Press the button.

07794

07793

6500D 330290 (9-- 01)

15

OPERATION

Home

Find...

Go To..

MAIN BRUSH AND SIDE BRUSH LEVER

The main brush and side brush lever controls the

main brush and side brush rotation.

Main Brush and Side Brush On: Push the main

brush and side brush lever into the On position.

Main Brush and Side Brush Off: Pull the main

brush and side brush lever into the middle

position.

Main Brush On: Pull the main brush and side

brush lever into the On position.

NOTE: Always raise the main brush when the

machine is not being operated for some time. This

prevents the main brush from getting a flat spot.

16

6500D 330290 (9-- 01)

HOPPER DOOR LEVER

Home

Find...

Go To..

The hopper door lever opens and closes the

hopper door and dust door. Open the hopper door

when sweeping. Close the hopper door when

emptying the hopper to control debris and dust.

Open: Push the hopper door lever into the Open

position and leave it there.

Hold: Release the hopper door lever into the

middle position.

OPERATION

Close: Pull and hold the hopper door lever into

the Close position.

NOTE: The hopper door will not close if the main

brush, side brush, and vacuum fan are operating.

6500D 330290 (9-- 01)

17

OPERATION

Home

Find...

Go To..

HOPPER LIFT LEVER

The hopper lift lever raises and lowers the hopper.

Up: Pull and hold the hopper lift lever into the Up

position.

WARNING: Raised hopper may fall.

Engage hopper support bar.

NOTE: The hopper will not raise if the main brush,

side brush, and vacuum fan are operating.

Hold: Release the hopper lift lever up and into the

middle position.

Down: Push and hold the hopper lift lever into the

Down position.

18

6500D 330290 (9-- 01)

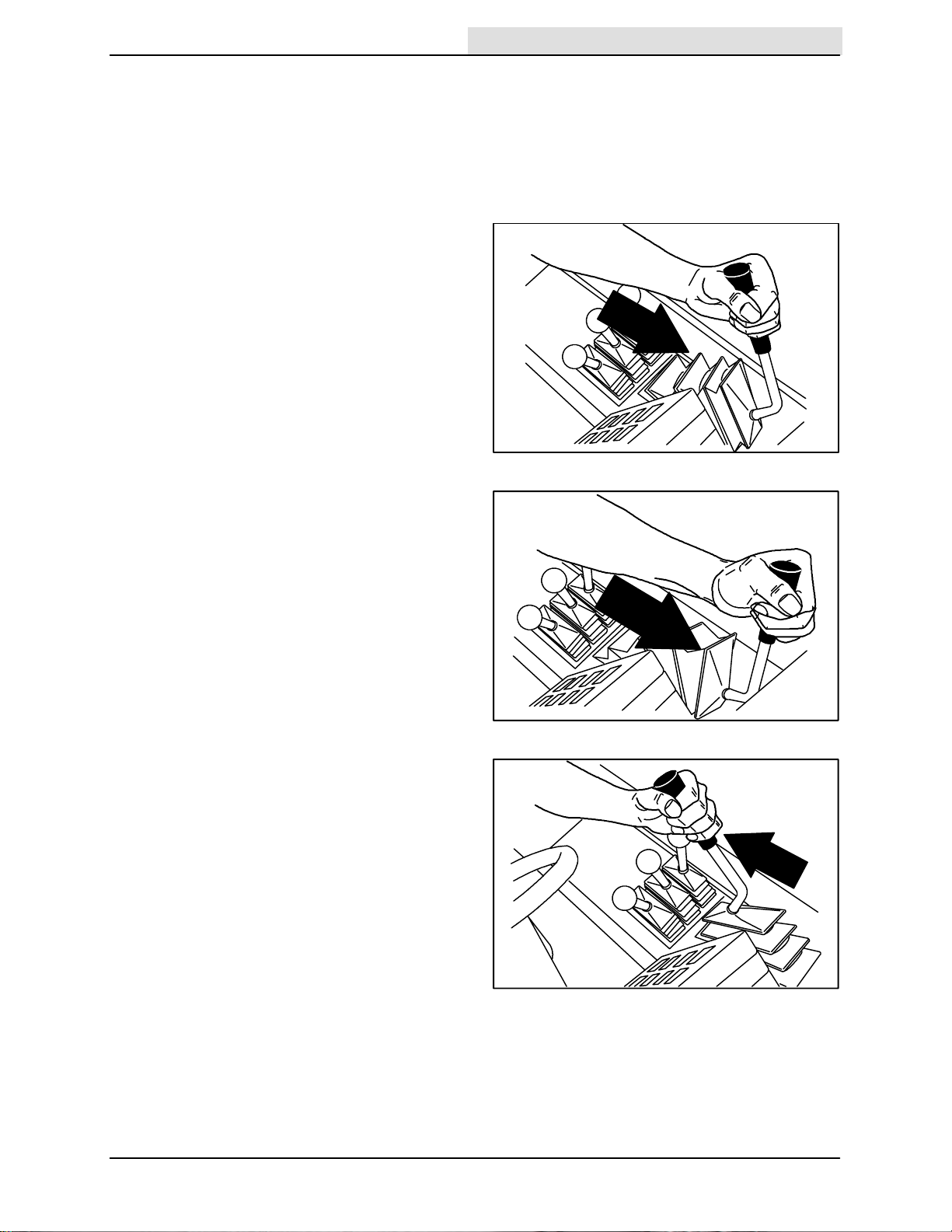

MAIN BRUSH POSITION LEVER

Home

Find...

Go To..

(For machines below serial number 020000)

The main brush position lever lowers and raises

the main brush. The main brush can be lowered

into two sweeping positions; down and float.

Down is used for general sweeping. Float is used

when sweeping extremely uneven surfaces.

Down: Pull the main brush position lever back

and to the left and over into the Down position.

Float: Pull the main brush position lever back and

to the left and over into the Float position.

OPERATION

07782

Up: Pull the main brush position lever all the way

back and to the right into the up position.

6500D 330290 (9-- 01)

07783

07784

19

OPERATION

Home

Find...

Go To..

MAIN BRUSH POSITION LEVER (For

machines serial number 020000 and above)

The main brush position lever lowers and raises

the main brush. The main brush can be lowered

into one sweeping position, which is set by the

main brush adjustment knob.

Down: Pull the main brush position lever back

and to the left and over into the down position.

Up: Pull the main brush position lever all the way

back and to the right into the Up position.

20

6500D 330290 (9-- 01)

MAIN BRUSH DOWN PRESSURE KNOB

Home

Find...

Go To..

(For machines below serial number 020000)

The main brush down pressure knob changes the

main brush contact with the sweeping surface.

Heavy: Turn the main brush down pressure knob

counter-clockwise.

Light: Turn the main brush down pressure knob

clockwise.

OPERATION

6500D 330290 (9-- 01)

21

OPERATION

Home

Find...

Go To..

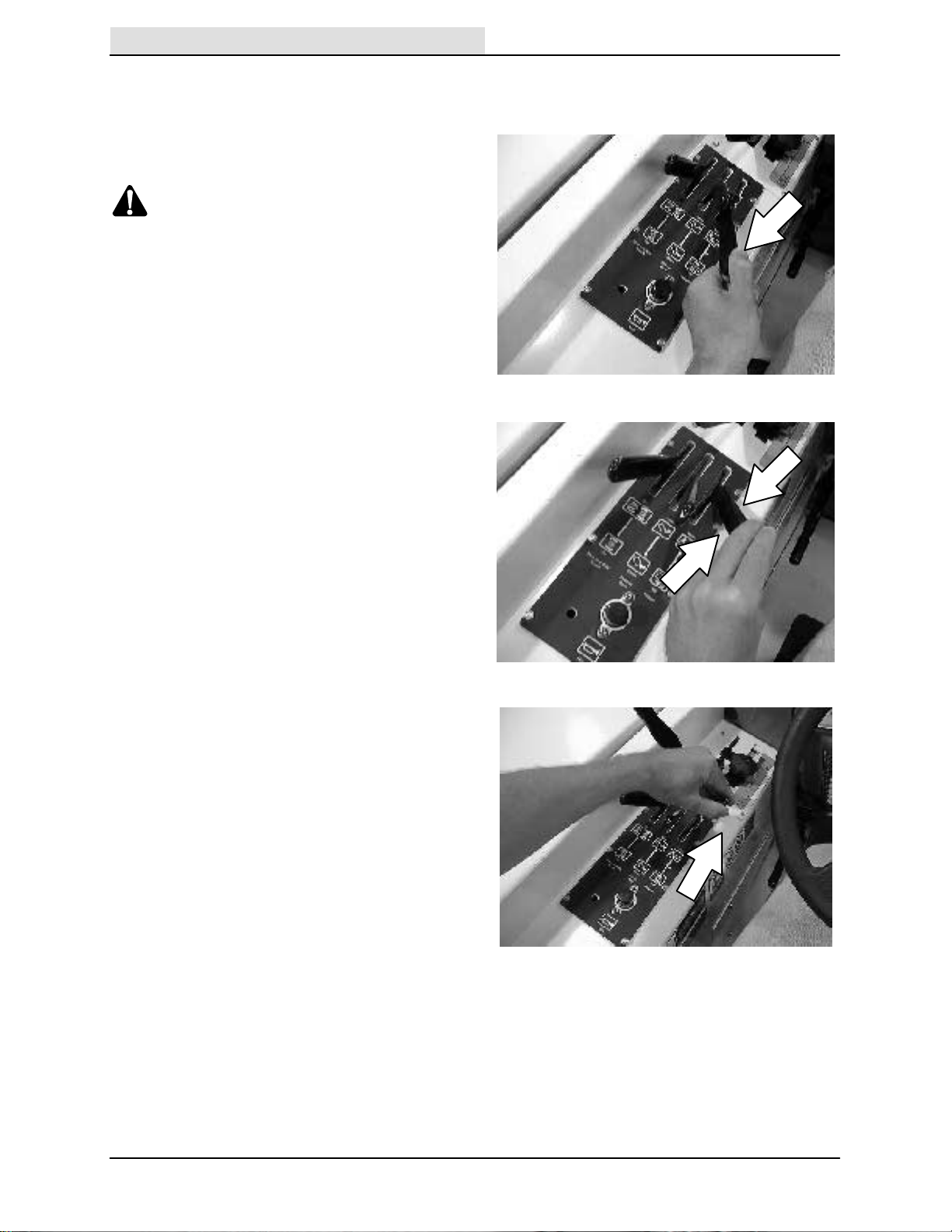

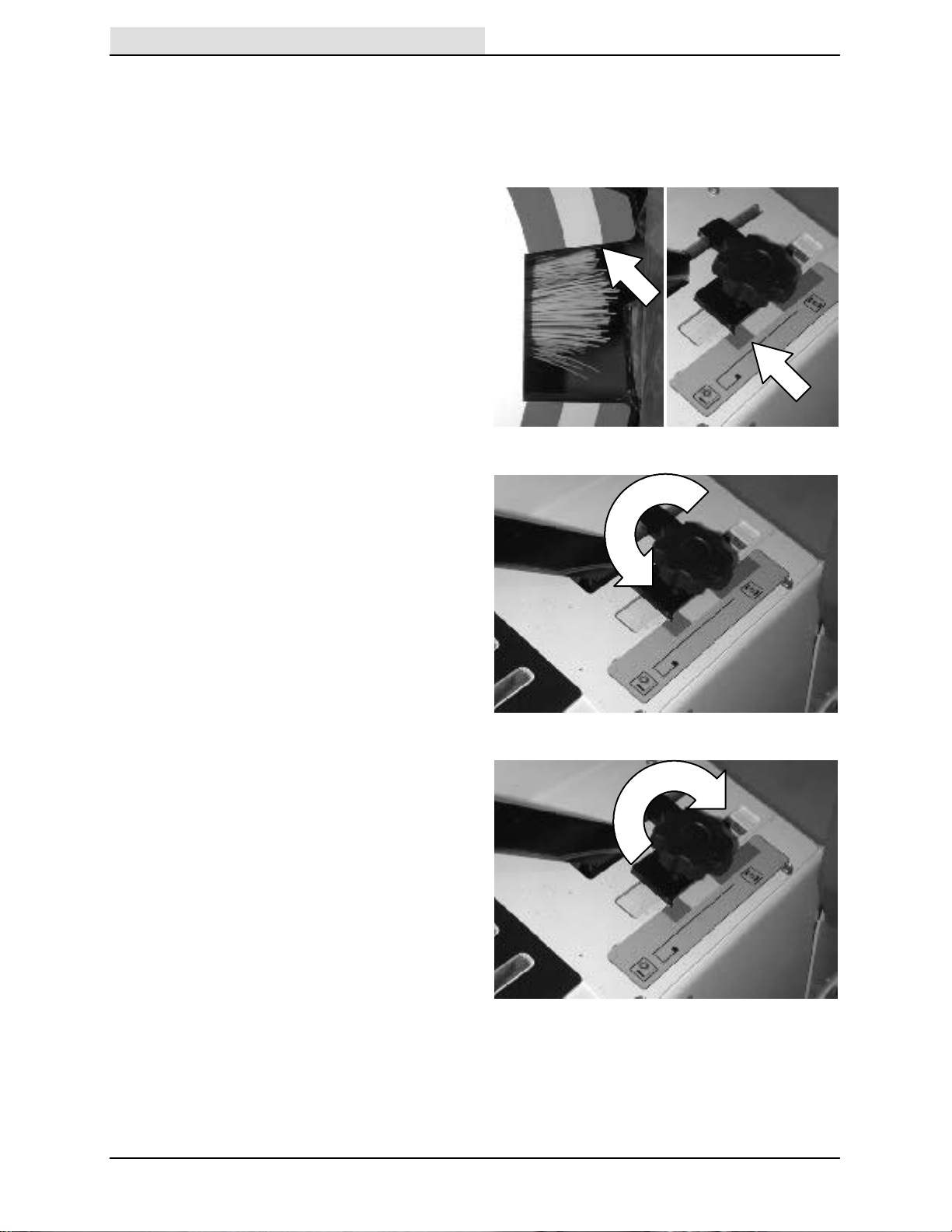

MAIN BRUSH ADJUSTMENT KNOB (For

machines serial number 020000 and above)

The main brush adjustment knob controls the

amount of contact the main brush has with the

sweeping surface.

Note the length of the main brush bristles with the

color band on the brush idler plate before moving

the main brush adjustment knob.

Align the pointer from the plate located under the

knob, to match the same color band as the brush

idler plate.

Loosen adjustment knob: Turn the adjustment

plate knob counter--clockwise until the plate can

slide along the adjustment panel.

Secure adjustment knob: Turn the adjustment

plate knob clockwise until the knob is hand tight

and the plate cannot slide in the adjustment panel.

22

6500D 330290 (9-- 01)

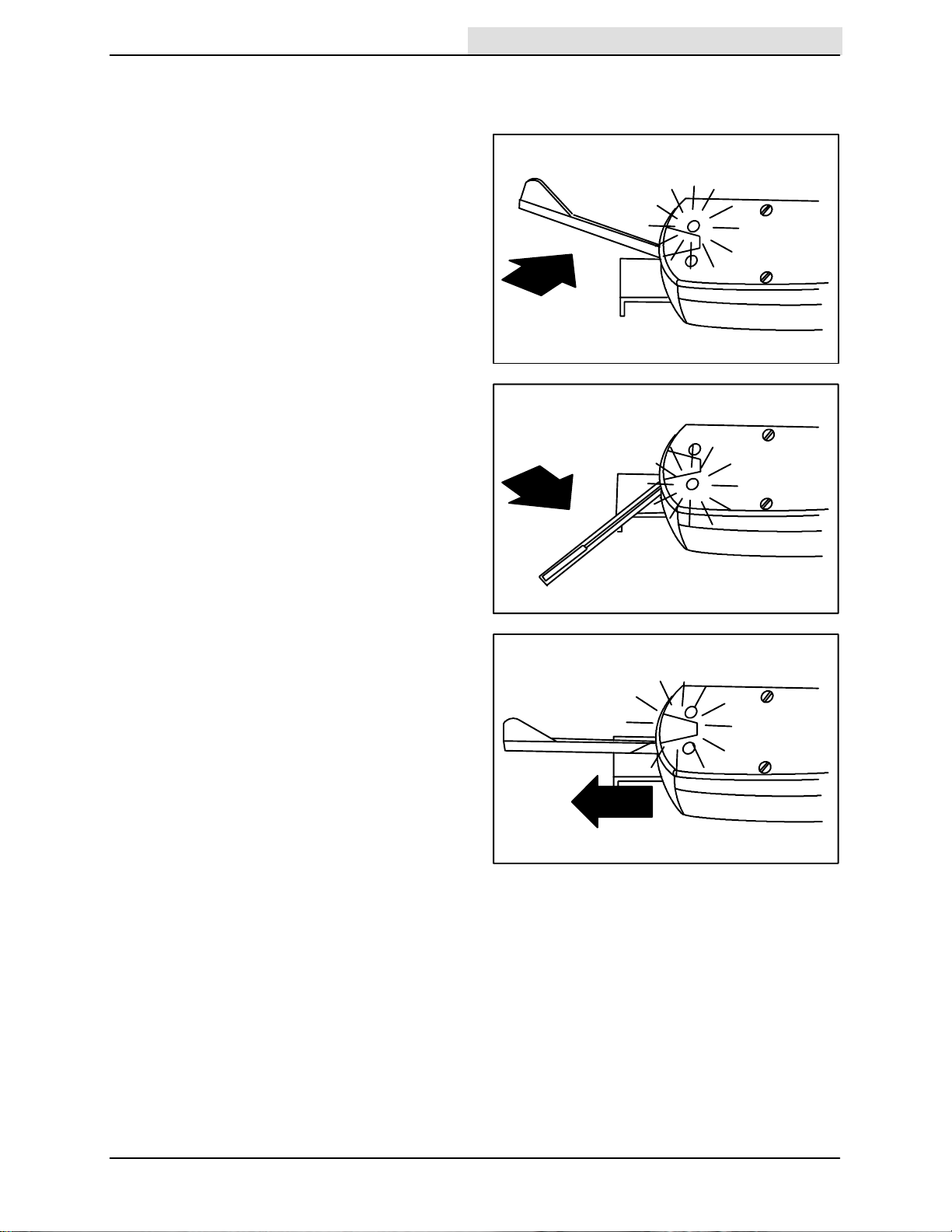

TURN SIGNAL SWITCH (OPTION)

Home

Find...

Go To..

The turn signal switch operates the turn signals.

Right: Push the switch lever forward.

Left: Pull the switch lever back.

OPERATION

06487

Flashers: Pull out the knob.

06488

06745

6500D 330290 (9-- 01)

23

OPERATION

0776

0

Home

Find...

Go To..

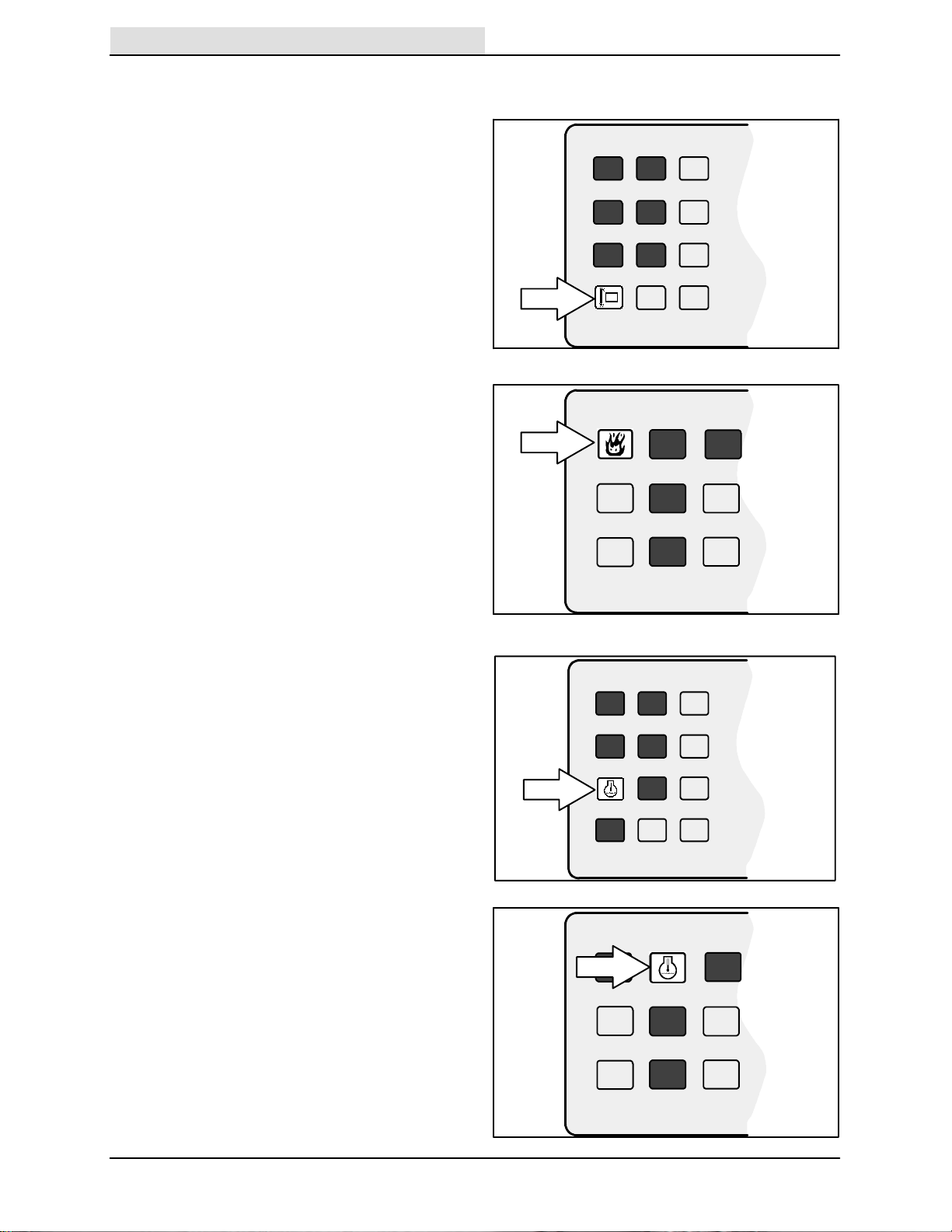

HOPPER TEMPERATURE LIGHT -- THERMO

SENTRYt

The hopper temperature light comes on when

there is too much heat in the hopper, possibly

from a fire. The Thermo Sentry will stop the

vacuum fan.

The Thermo Sentryt has to be reset manually,

see THERMO SENTRY in MAINTENANCE.

(For machines below serial number 020000)

The light location is as shown.

(For machines serial number 020000 and

above)

The light location is as shown.

ENGINE WATER TEMPERATURE LIGHT

The engine water temperature light comes on

when the temperature of the engine coolant is

more than 107_ C (225_ F). Stop operating the

machine. Locate the problem and have it

corrected.

(For machines below serial number 020000)

The light location is as shown.

(For machines serial number 020000 and

above)

The light location is as shown.

07759

24

6500D 330290 (9-- 01)

ENGINE OIL PRESSURE LIGHT

Home

Find...

Go To..

The engine oil pressure light comes on when the

engine oil pressure falls below 35 kPa (5 psi).

Stop operating the machine. Locate the problem

and have it corrected.

(For machines below serial number 020000)

The light location is as shown.

(For machines serial number 020000 and

above)

The light location is as shown.

OPERATION

07758

CHARGING SYSTEM LIGHT

The charging system light comes on when the

existing voltage potential of the battery is not

within normal range -- 10 to 14 Volts. Stop

operating the machine. Locate the problem and

have it corrected.

(For machines below serial number 020000)

The light location is as shown.

(For machines serial number 020000 and

above)

The light location is as shown.

07757

6500D 330290 (9-- 01)

25

OPERATION

Home

Find...

Go To..

HOPPER DOOR LIGHT

The hopper door light comes on when the hopper

door is closed. Make sure the hopper door is open

and the hopper door light is off, before sweeping

with the machine.

(For machines below serial number 020000)

The light location is as shown.

(For machines serial number 020000 and

above)

The light location is as shown.

07763

CLOGGED FILTER LIGHT

The clogged filter light comes on when the hopper

dust filter is clogged.

To clean the filter, press the filter shaker switch. If

the clogged filter light remains lit, manually clean

the hopper dust filter. See HOPPER DUST

FILTER in MAINTENANCE.

(For machines below serial number 020000)

The light location is as shown.

CLOGGED FILTER LIGHT (OPTION)

(For machines serial number 020000 and

above)

The light location is as shown.

07762

26

6500D 330290 (9-- 01)

GLOW PLUG LIGHT (For machines serial

Home

Find...

Go To..

number 020000 and above ONLY)

The glow plug light comes on when the ignition

switch is turned counterclockwise to the preheat

position. The light will go out when the engine is

ready to start.

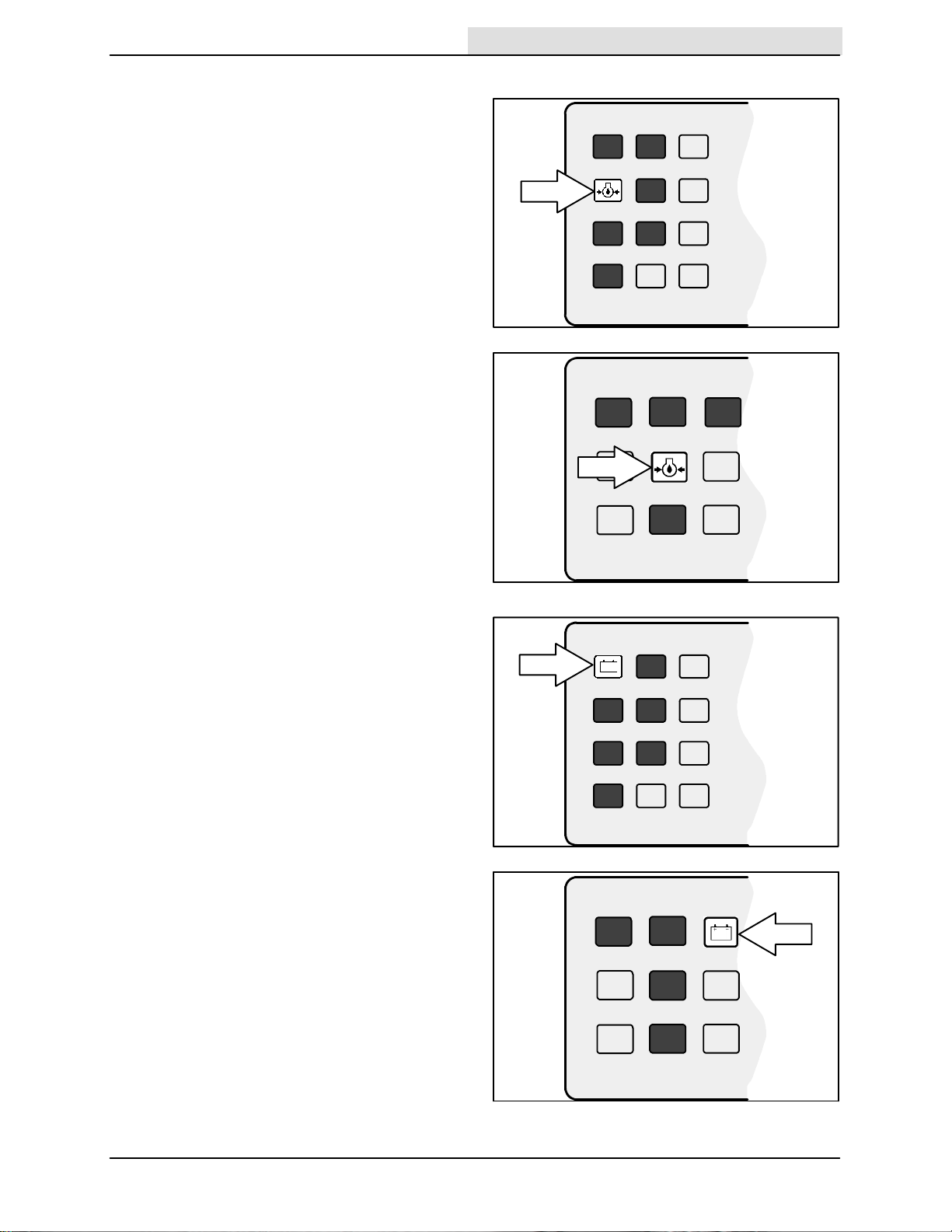

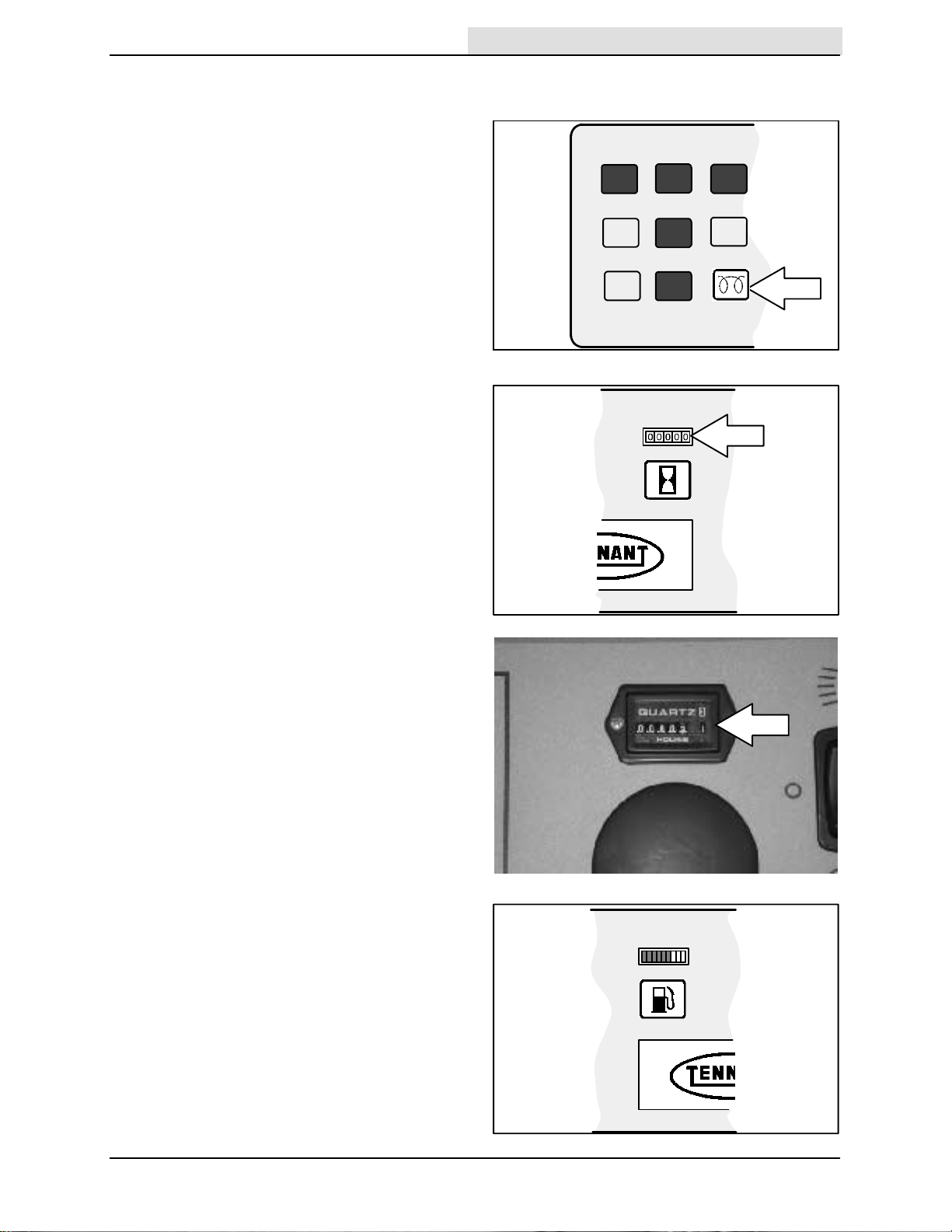

HOURMETER

The hourmeter records the number of hours the

machine has been operated. Use this information

to determine machine maintenance intervals.

(For machines below serial number 020000)

The light location is as shown.

OPERATION

(For machines serial number 020000 and

above)

The light location is as shown.

FUEL LEVEL GAUGE (For machines below

serial number 020000)

The fuel level gauge indicates how much fuel is in

the fuel tank with a segmented LED light. When

the tank is full, all ten of the segments are lit. As

the fuel tank empties, the segments shut off. The

fuel tank is empty when all ten of the segments

have shut off.

NOTE: Do not let the fuel tank empty completely.

Air can enter the fuel system. The fuel system will

need bleeding before the next engine start.

07765

6500D 330290 (9-- 01)

07764

27

OPERATION

Home

Find...

Go To..

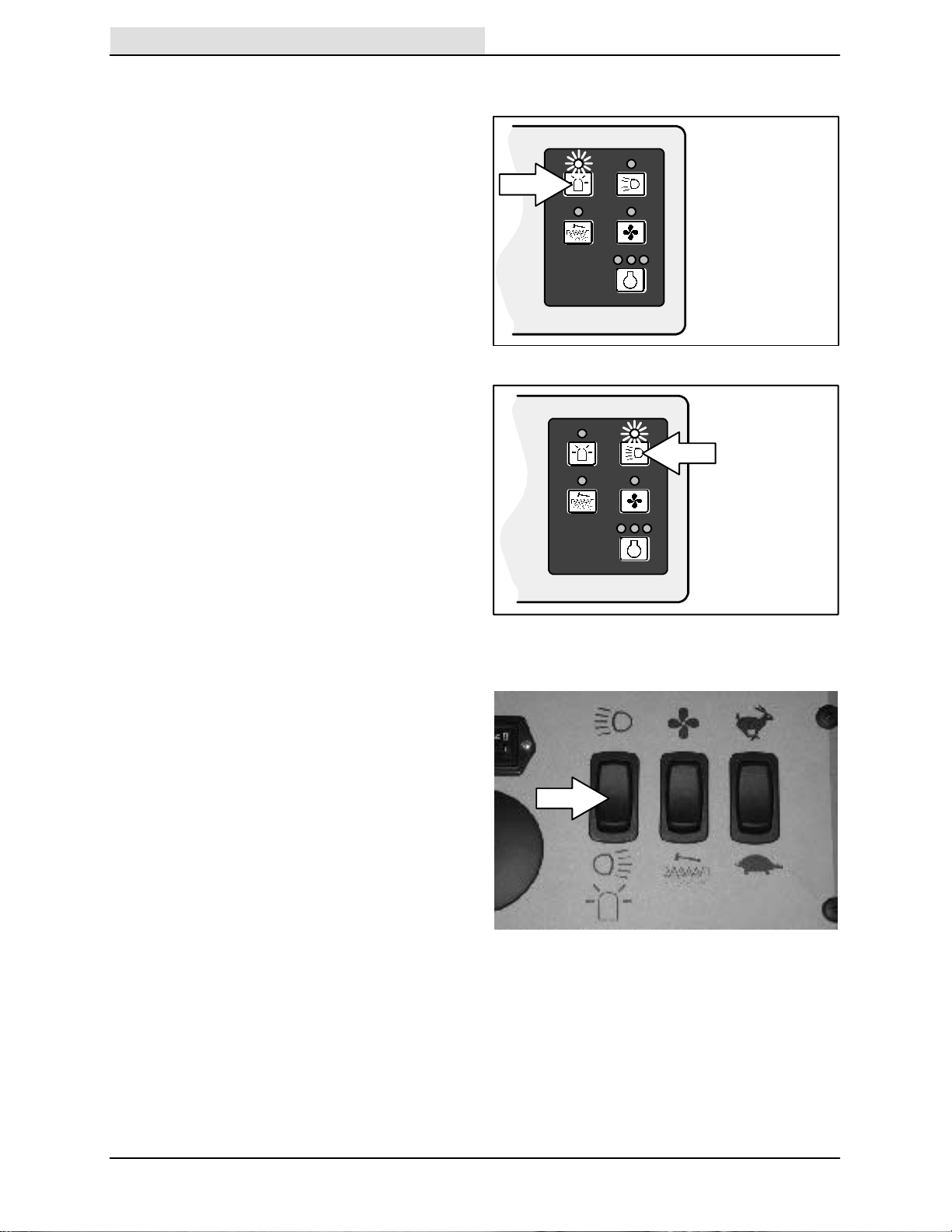

HAZARD LIGHT SWITCH (OPTION)

(For machines below serial number 020000)

The hazard light switch powers on and off the

hazard light.

On: Press the hazard light switch. The indicator

light above the switch will come on.

Off: Press the hazard light switch. The indicator

light above the switch will go off.

OPERATING LIGHTS SWITCH

(For machines below serial number 020000)

The operating lights switch powers on and off the

headlights and taillights.

On: Press the operating lights switch. The

indicator light above the switch will come on.

Off: Press the operating lights switch. The

indicator light above the switch will go off.

OPERATING/HAZARD LIGHTS SWITCH (For

machines serial number 020000 and above)

The operating/hazard light switch powers on and

off the operating/hazard lights.

Operating Lights On: Press the top of the switch.

Operating/Hazard Lights On: Press the bottom of

the switch.

07766

07768

Off: Press the switch to the middle off position.

28

6500D 330290 (9-- 01)

Loading...

Loading...