Tennant 355E User Manual

355E

Home

Find...

Operator Manual

MM306

This manual is furnished with each new TENNANT Model 355E. It provides necessary operating and

Home

Find...

preventive maintenance instructions. Read this manual completely and understand the machine before

operating or servicing it.

This machine will provide excellent service. However, the best results will be obtained at minimum

costs if:

The machine is operated with reasonable care.

The machine is maintained regularly – per the maintenance instructions provided.

The machine is maintained with TENNANT supplied or approved parts.

Manual Number – MM306

Revision: 08

Published:3–97

Copyright 1992, 1993, 1994, 1995, 1996, 1997 TENNANT, Printed in U.S.A.

CONTENTS

Home

Find...

CONTENTS

SAFETY PRECAUTIONS 3. . . . . . . . . . . . . . . . .

OPERATION 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATOR RESPONSIBILITY 5. . . . . . . . .

MACHINE COMPONENTS 6. . . . . . . . . . . . .

CONTROL PANEL SYMBOLS 7. . . . . . . . . .

CONTROLS AND INSTRUMENTS 9. . . . . .

OPERATION OF CONTROLS 10. . . . . . . . . .

DIRECTIONAL PEDAL 10. . . . . . . . . . . . . .

DIRECTIONAL PEDAL TOE ANGLE

(OPTION) 11. . . . . . . . . . . . . . . . . . . . . .

BRAKE PEDAL 11. . . . . . . . . . . . . . . . . . . .

PARKING BRAKE LEVER 11. . . . . . . . . . .

HORN BUTTON 12. . . . . . . . . . . . . . . . . . . .

BRUSH PRESSURE GAUGE 12. . . . . . . .

MAIN BRUSH AND SIDE BRUSH

LEVER 13. . . . . . . . . . . . . . . . . . . . . . . . .

HOPPER DOOR LEVER 14. . . . . . . . . . . .

HOPPER LIFT LEVER 15. . . . . . . . . . . . . .

MAIN BRUSH POSITION LEVER 16. . . .

MAIN BRUSH DOWN PRESSURE

KNOB 17. . . . . . . . . . . . . . . . . . . . . . . . . .

POWER KILL SWITCH 17. . . . . . . . . . . . . .

HOPPER TEMPERATURE LIGHT –

THERMO SENTRY 18. . . . . . . . . . . .

HOPPER DOOR LIGHT 18. . . . . . . . . . . . .

CLOGGED FILTER LIGHT 18. . . . . . . . . .

MAIN BRUSH SHUT DOWN LIGHT 18. .

BATTERY DISCHARGE INDICATOR 19.

HOURMETER 19. . . . . . . . . . . . . . . . . . . . .

HAZARD LIGHT SWITCH (OPTION) 19. .

OPERATING LIGHTS SWITCH 19. . . . . .

VACUUM FAN SWITCH 20. . . . . . . . . . . . .

FILTER SHAKER SWITCH 20. . . . . . . . . .

STEERING WHEEL 20. . . . . . . . . . . . . . . .

SIDE BRUSH POSITION LEVER 21. . . . .

ON-OFF SWITCH 22. . . . . . . . . . . . . . . . . .

SIDE BRUSH DOWN PRESSURE

KNOB 23. . . . . . . . . . . . . . . . . . . . . . . . . .

STEERING COLUMN TILT LEVER 23. . .

CIRCUIT BREAKERS 24. . . . . . . . . . . . . . .

LATCHES 24. . . . . . . . . . . . . . . . . . . . . . . . .

OPERATOR SEAT 25. . . . . . . . . . . . . . . . . .

HOPPER SUPPORT BAR 26. . . . . . . . . . .

HOW THE MACHINE WORKS 27. . . . . . . . . .

PRE-OPERATION CHECKLIST 27. . . . . . . . .

STARTING THE MACHINE 28. . . . . . . . . . . . .

SWEEPING AND BRUSH INFORMATION 29

SWEEPING 30. . . . . . . . . . . . . . . . . . . . . . . . . .

STOP SWEEPING 32. . . . . . . . . . . . . . . . . . . .

EMPTYING THE HOPPER 33. . . . . . . . . . . . .

STOP THE MACHINE 35. . . . . . . . . . . . . . . . .

POST-OPERATION CHECKLIST 36. . . . . . . .

Page

Page

ENGAGING HOPPER SUPPORT BAR 37. .

DISENGAGING HOPPER SUPPORT BAR 38

OPERATION ON INCLINES 39. . . . . . . . . . . .

OPTIONS 40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIE-DOWNS 40. . . . . . . . . . . . . . . . . . . . . . .

MACHINE TROUBLESHOOTING 41. . . . . . .

MAINTENANCE 42. . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE CHART 42. . . . . . . . . . . . . . .

LUBRICATION 44. . . . . . . . . . . . . . . . . . . . . . . .

PROPELLING GEARBOX 44. . . . . . . . . . .

REAR WHEEL SUPPORT BEARING 44.

STEERING LINK 44. . . . . . . . . . . . . . . . . . .

FRONT WHEEL BEARINGS 45. . . . . . . . .

HYDRAULICS 45. . . . . . . . . . . . . . . . . . . . . . . .

HYDRAULIC FLUID RESERVOIR 45. . . .

HYDRAULIC FLUID 46. . . . . . . . . . . . . . . .

HYDRAULIC HOSES 47. . . . . . . . . . . . . . .

BATTERIES 47. . . . . . . . . . . . . . . . . . . . . . . . . .

CHARGING THE BATTERIES 48. . . . . . .

BELTS AND CHAINS 50. . . . . . . . . . . . . . . . . .

VACUUM FAN DRIVE BELT 50. . . . . . . . .

STATIC DRAG CHAIN 50. . . . . . . . . . . . . .

DEBRIS HOPPER 51. . . . . . . . . . . . . . . . . . . . .

HOPPER DUST FILTER 51. . . . . . . . . . . . .

TO REPLACE HOPPER DUST

FILTER 52. . . . . . . . . . . . . . . . . . . . . .

THERMO SENTRY 53. . . . . . . . . . . . . . .

BRUSHES 54. . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAIN BRUSH 54. . . . . . . . . . . . . . . . . . . . . .

TO REPLACE MAIN BRUSH 54. . . . . .

TO CHECK AND ADJUST MAIN

BRUSH PATTERN 55. . . . . . . . . . . .

SIDE BRUSH 57. . . . . . . . . . . . . . . . . . . . . .

TO REPLACE SIDE BRUSH 58. . . . . .

SIDE BRUSH GUARD 58. . . . . . . . . . . . . .

SKIRTS AND SEALS 59. . . . . . . . . . . . . . . . . .

HOPPER LIP SKIRTS 59. . . . . . . . . . . . . . .

HOPPER SIDE SKIRT 59. . . . . . . . . . . . . .

BRUSH DOOR SKIRTS 59. . . . . . . . . . . . .

REAR SKIRTS 60. . . . . . . . . . . . . . . . . . . . .

BRUSH DOOR SEALS 60. . . . . . . . . . . . . .

HOPPER SEALS 60. . . . . . . . . . . . . . . . . . .

HOPPER INSPECTION DOOR SEAL 60.

HOPPER DOOR SEALS 61. . . . . . . . . . . .

HOPPER COVER SEAL 61. . . . . . . . . . . . .

HOPPER DUST SEAL 61. . . . . . . . . . . . . .

HOPPER VACUUM FAN SEAL 61. . . . . . .

BRAKES AND TIRES 62. . . . . . . . . . . . . . . . . .

SERVICE BRAKES 62. . . . . . . . . . . . . . . . .

PARKING BRAKE 62. . . . . . . . . . . . . . . . . .

TIRES 62. . . . . . . . . . . . . . . . . . . . . . . . . . . .

REAR WHEEL 62. . . . . . . . . . . . . . . . . . . . .

355E MM306 (3–96)

1

CONTENTS

Home

Find...

PUSHING OR TOWING MACHINE 62. . . . . .

MACHINE JACKING 63. . . . . . . . . . . . . . . . . . .

ELECTRIC MOTORS 63. . . . . . . . . . . . . . . . . .

STORING MACHINE 63. . . . . . . . . . . . . . . . . .

SPECIFICATIONS 64. . . . . . . . . . . . . . . . . . . . . . .

GENERAL MACHINE PERFORMANCE 64. .

POWER TYPE 65. . . . . . . . . . . . . . . . . . . . . . . .

STEERING 65. . . . . . . . . . . . . . . . . . . . . . . . . . .

HYDRAULIC SYSTEM 65. . . . . . . . . . . . . . . . .

BRAKING SYSTEM 65. . . . . . . . . . . . . . . . . . .

TIRES 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INDEX 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

2

355E MM306 (5–95)

SAFETY PRECAUTIONS

Home

Find...

SAFETY PRECAUTIONS

The following precautions are used throughout

this manual as indicated in their description:

WARNING: To warn of hazards or

unsafe practices which could result in

severe personal injury or death.

FOR SAFETY: To identify actions which

must be followed for safe operation of

equipment.

The machine is suited to sweep disposable

debris. Do not use the machine other than

described in this Operator Manual. The machine

is not designed for use on public roads.

The following information signals potentially

dangerous conditions to the operator or

equipment:

FOR SAFETY:

1. Do not operate machine:

– Unless trained and authorized.

– Unless operator manual is read and

understood.

– If it is not in proper operating

condition.

– In flammable or explosive areas unless

designed for use in those areas.

– In areas with possible falling objects

unless equipped with overhead guard.

2. Before starting machine:

– Check for fuel, oil, and liquid leaks.

– Keep sparks and open flame away

from refueling area.

– Make sure all safety devices are in

place and operate properly.

– Check brakes and steering for proper

operation.

3. When starting machine:

– Keep foot on brake and directional

pedal in neutral.

– Do not carry passengers on machine.

– Always follow safety and traffic rules.

– Report machine damage or faulty

operation immediately.

5. Before leaving or servicing machine:

– Stop on level surface.

– Set parking brake.

– Turn off machine and remove key.

6. When servicing machine:

– Avoid moving parts. Do not wear loose

jackets, shirts, or sleeves.

– Block machine tires before jacking

machine up.

– Jack machine up at designated

locations only. Block machine up with

jack stands.

– Use hoist or jack of adequate capacity

to lift machine.

– Wear eye and ear protection when

using pressurized air or water.

– Disconnect battery connections before

working on machine.

– Avoid contact with battery acid.

– Use cardboard to locate leaking

hydraulic fluid under pressure.

– Use TENNANT supplied or approved

replacement parts.

WARNING: Batteries emit hydrogen gas.

Explosion or fire can result. Keep

sparks and open flame away. Keep

covers open when charging.

WARNING: Hazardous voltage. Shock

can result. Disconnect batteries before

working on machine. Only qualified

personnel should work inside panel.

WARNING: Raised hopper may fall.

Engage hopper support bar.

WARNING: Lift arm pinch point. Stay

clear of hopper lift arms.

4. When using machine:

– Use brakes to stop machine.

– Go slow on inclines and slippery

surfaces.

– Use care when reversing machine.

– Move machine with care when hopper

is raised.

– Make sure adequate clearance is

available before raising hopper.

355E MM306 (12–92)

3

SAFETY PRECAUTIONS

Home

Find...

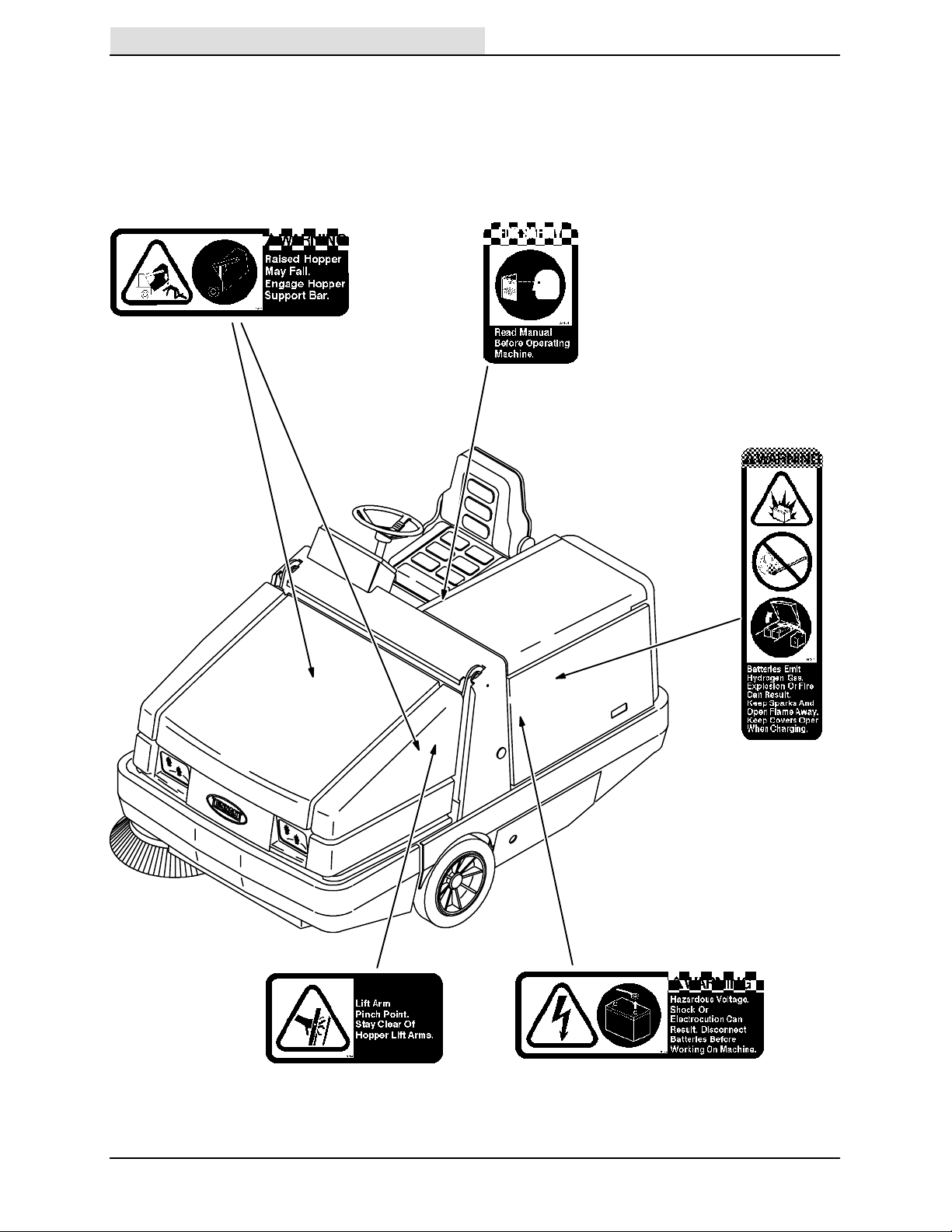

The following safety labels are mounted on the

machine in the locations indicated. If these or any

label becomes damaged or illegible, install a new

label in its place.

HOPPER SUPPORT BAR LABEL – LOCATED

ON THE HOPPER SUPPORT BAR AND ON

BOTH HOPPER LIFT ARMS.

FOR SAFETY LABEL – LOCATED ON THE

SIDE PANEL OF THE OPERATOR

COMPARTMENT.

BATTERY CHARGING LABEL – LOCATED ON

THE RELAY PANEL NEXT TO THE

BATTERIES.

HOPPER LIFT ARMS LABEL – LOCATED ON

BOTH HOPPER LIFT ARMS.

4

07985

HARARDOUS VOLTAGE LABEL – LOCATED

ON THE ELECTRICAL COMPONENTS BOX

COVER.

355E MM306 (6–93)

OPERATOR RESPONSIBILITY

Home

Find...

The operator’s responsibility is to take care

of the daily maintenance and checkups of

the machine to keep it in good working

condition. The operator must inform the

service mechanic or supervisor when the

required maintenance intervals occur as

stated in the MAINTENANCE section of this

manual.

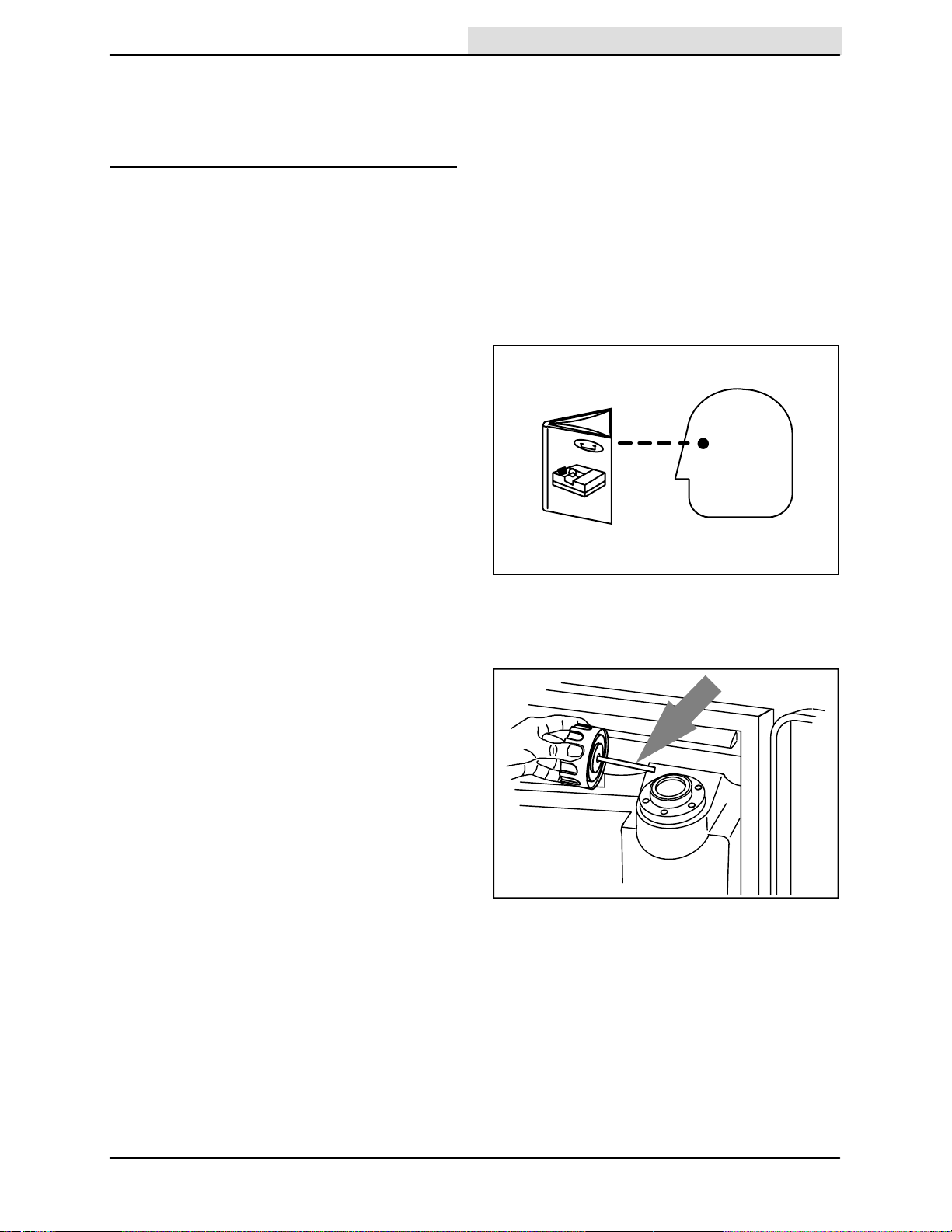

Read this manual carefully before operating

this machine.

FOR SAFETY: Do not operate machine,

unless operation manual is read and

understood.

OPERATION

OPERATION

Check the machine for shipping damage.

Check to make sure machine is complete

per shipping instructions.

Check the hydraulic fluid level in the

hydraulic reservoir.

After the first 50 hours of operation, follow

the recommended procedures stated in the

MAINTENANCE CHART.

Keep your machine regularly maintained by

following the maintenance information in this

manual. We recommend taking advantage

of a regularly scheduled service contract

from your TENNANT representative.

Order parts and supplies directly from your

authorized TENNANT representative. Use

the parts manual provided when ordering

parts.

07324

08218

355E MM306 (12–92)

5

OPERATION

Home

Find...

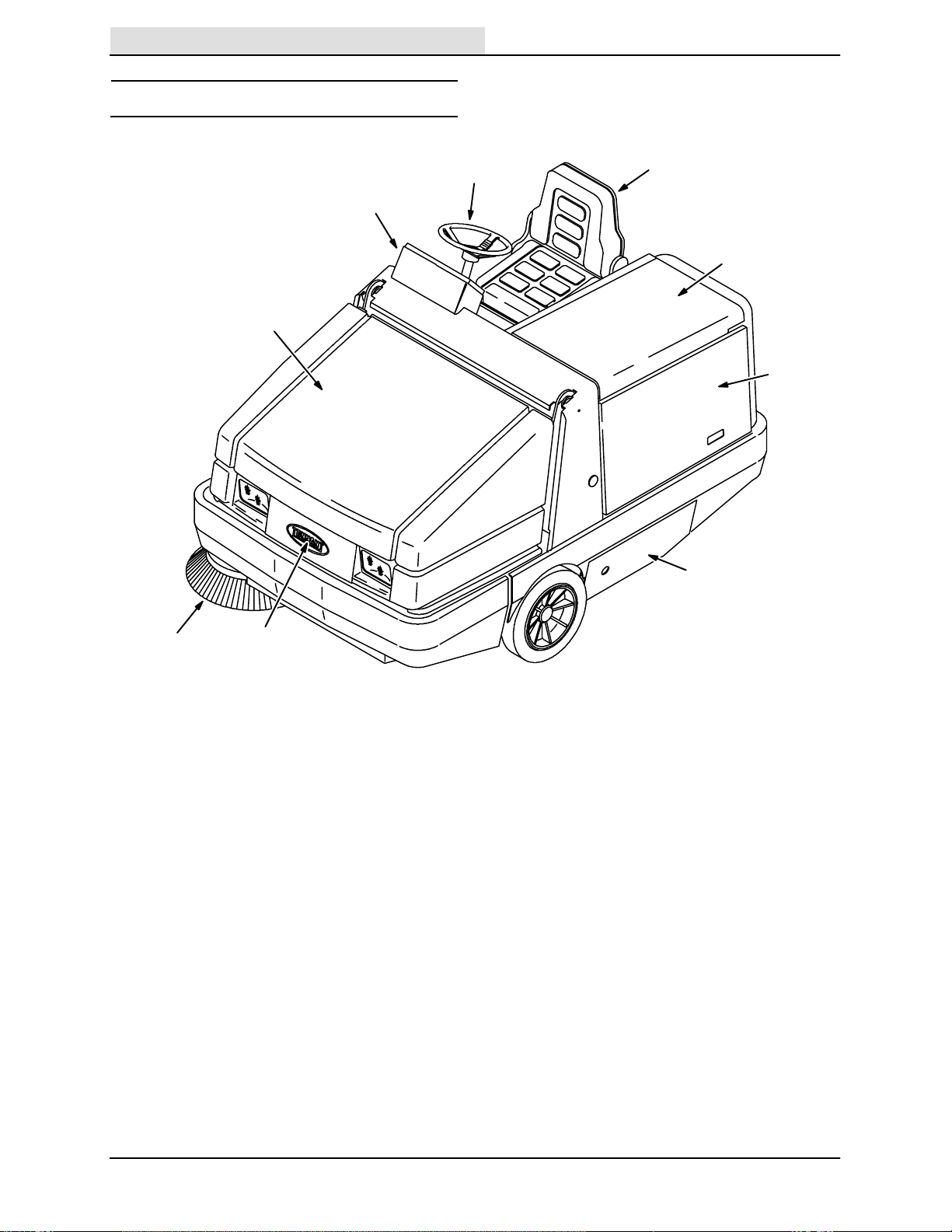

MACHINE COMPONENTS

B

I

F

A

C

D

E

H

G

07985

A. Operator Seat F. Hopper Cover

B. Steering Wheel G. Hopper Access Cover

C. Battery Cover H. Side Brush

D. Side Door I. Instrument Panel

E. Main Brush Access Door

6

355E MM306 (6--93)

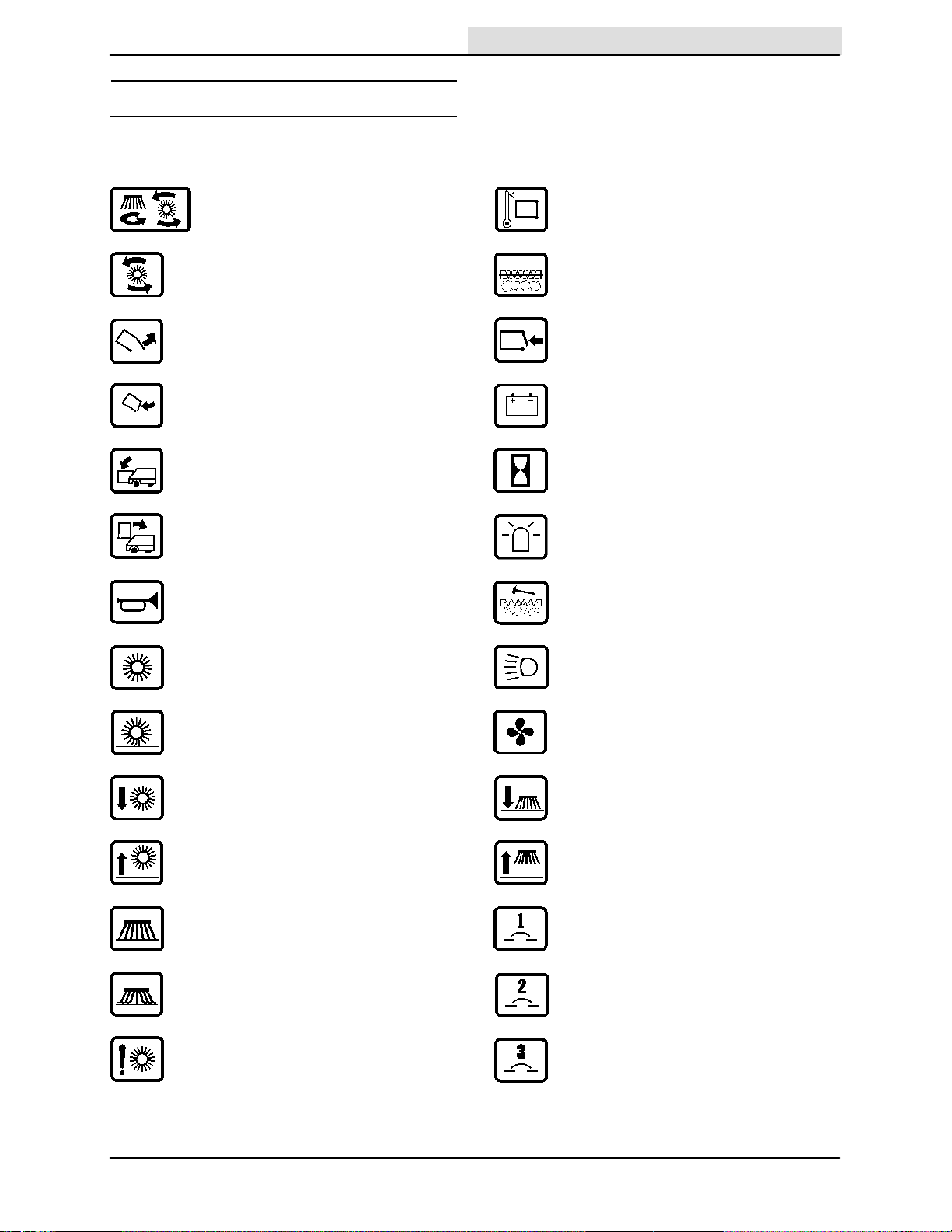

CONTROL PANEL SYMBOLS

Home

Find...

These symbols identify controls and displays on

the machine:

Main and Side Brushes On Hopper Temperature – Thermo Sentry

Main Brush On Filter Clogged

Hopper Door Open Hopper Door Closed

Hopper Door Close Battery

Hopper Down Hourmeter

OPERATION

Hopper Up Hazard Light

Horn Filter Shaker

Main Brush Down Pressure Light Operating Lights

Main Brush Down Pressure Heavy Fan

Main Brush Down Side Brush Down

Main Brush Up Side Brush Up

Side Brush Down Pressure Light Circuit Breaker 1

Side Brush Down Pressure Heavy Circuit Breaker 2

Main Brush Down Force Circuit Breaker 3

355E MM306 (12–92)

7

OPERATION

Home

Find...

Circuit Breaker 4

Circuit Breaker 5

Circuit Breaker 6

Circuit Breaker 7

Circuit Breaker 8

8

355E MM306 (12–92)

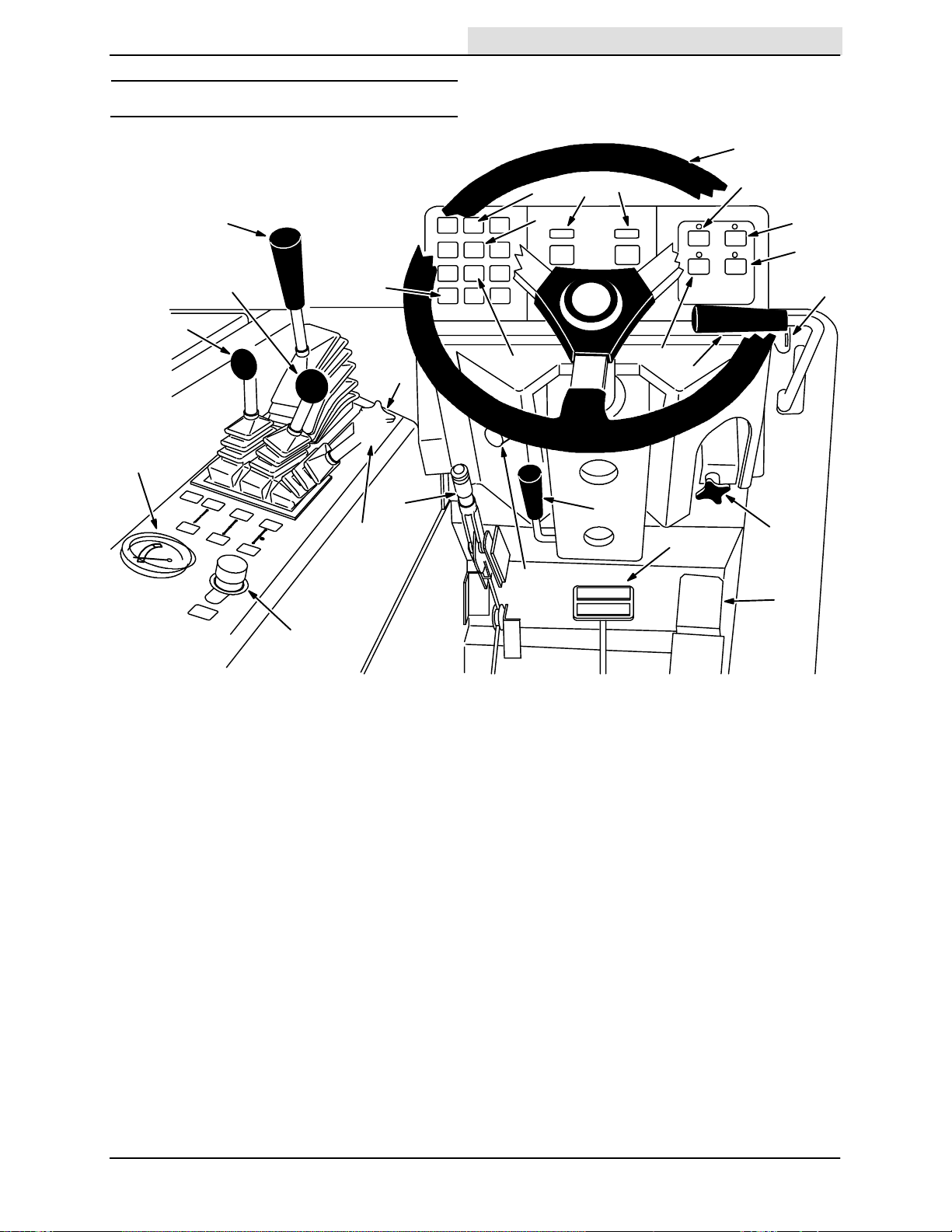

CONTROLS AND INSTRUMENTS

Home

Find...

OPERATION

U

P

O

L

I

G

F

Z

K

J

C

H

M

N

Y

D

R

V

B

Q

S

T

W

X

A

E

A. Directional Pedal N. Hopper Door Light

B. Brake Pedal O. Battery Discharge Indicator

C. Parking Brake Lever P. Hourmeter

D. Power Kill Switch Q. Hazard Light Switch (Option)

E. Horn Button R. Filter Shaker Switch

F. Main Brush And Side Brush Lever S. Operating Light Switch

G. Hopper Door Lever T. Vacuum Fan Switch

H. Hopper Lift Lever U. Steering Wheel

I. Main Brush Position Lever V. Side Brush Position Lever

J. Main Brush Down Pressure Knob W. On-Off Switch

K. Hopper Temperature Light -- X. Side Brush Down Pressure Knob

Thermo Sentryt Y. Steering Column Tilt Lever

L. Main Brush Shut Down Light Z. Brush Pressure Gauge

M. Clogged Filter Light

08219

355E MM306 (3-- 96)

9

OPERATION

Home

Find...

OPERATION OF CONTROLS

DIRECTIONAL PEDAL

The directional pedal controls direction of travel

and the propelling speed of the machine. You

change the speed of the machine with the

pressure of your foot; the harder you press the

faster the machine travels.

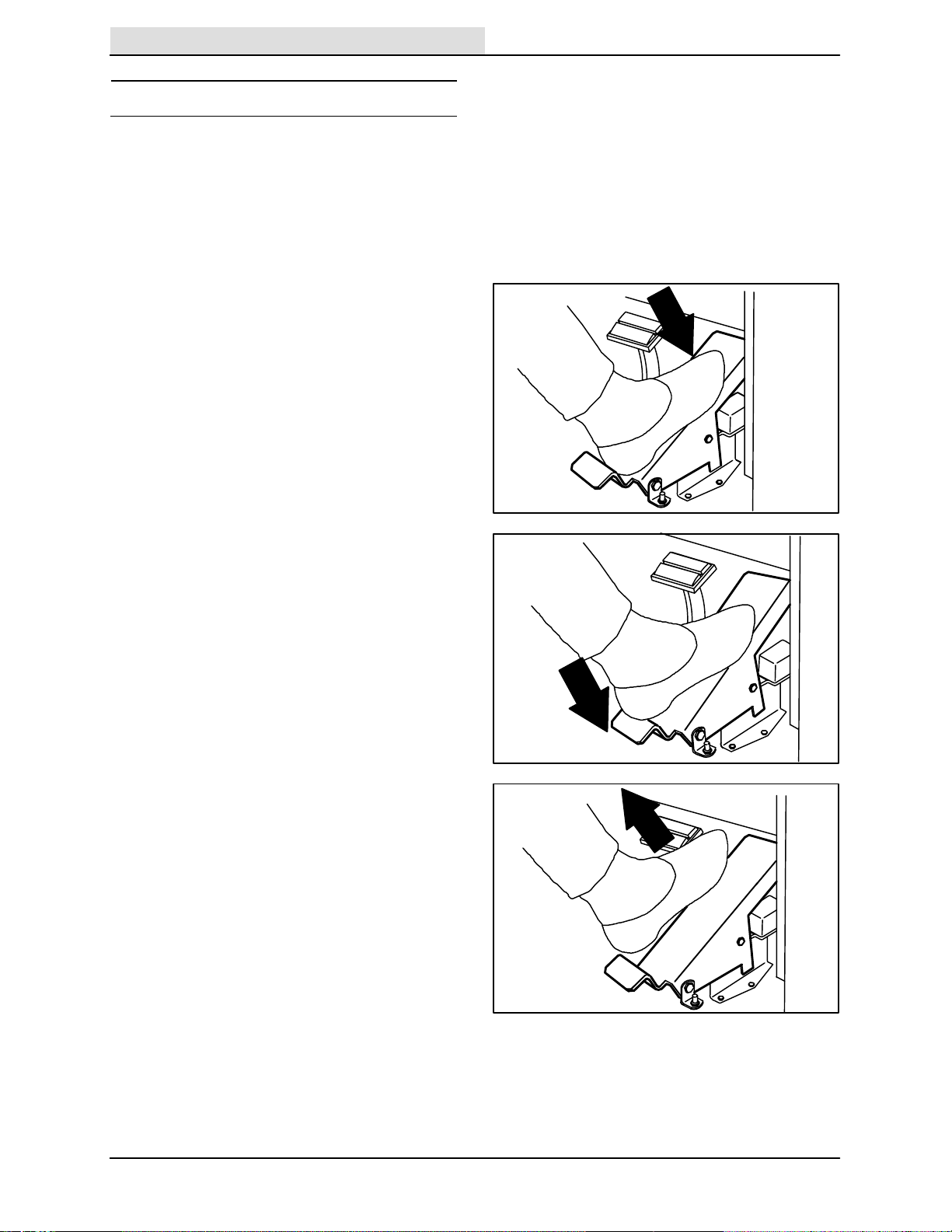

Forward: Press the top of the directional pedal

with the toe of your foot.

Reverse: Press the bottom of the directional

pedal with the heel of your foot.

Neutral: Take your foot off the directional pedal

and it will return to the neutral position.

NOTE: When changing direction from forward to

reverse using the directional pedal, the machine

will move a short distance forward before

changing direction. Use the brakes to stop the

machine.

08225

08226

FOR SAFETY: When using machine, use

brakes to stop machine.

10

08227

355E MM306 (12–92)

DIRECTIONAL PEDAL TOE ANGLE (OPTION)

Home

Find...

The directional pedal toe angle allows you to

adjust of the pedal toe angle. Remove the clevis

pin, move the top of the pedal to the angle

needed, and slide the clevis pin through the

adjustment holes.

OPERATION

BRAKE PEDAL

The brake pedal stops the machine.

Stop: Take your foot off the directional pedal and

let it return to the neutral position. Step on the

brake pedal.

PARKING BRAKE LEVER

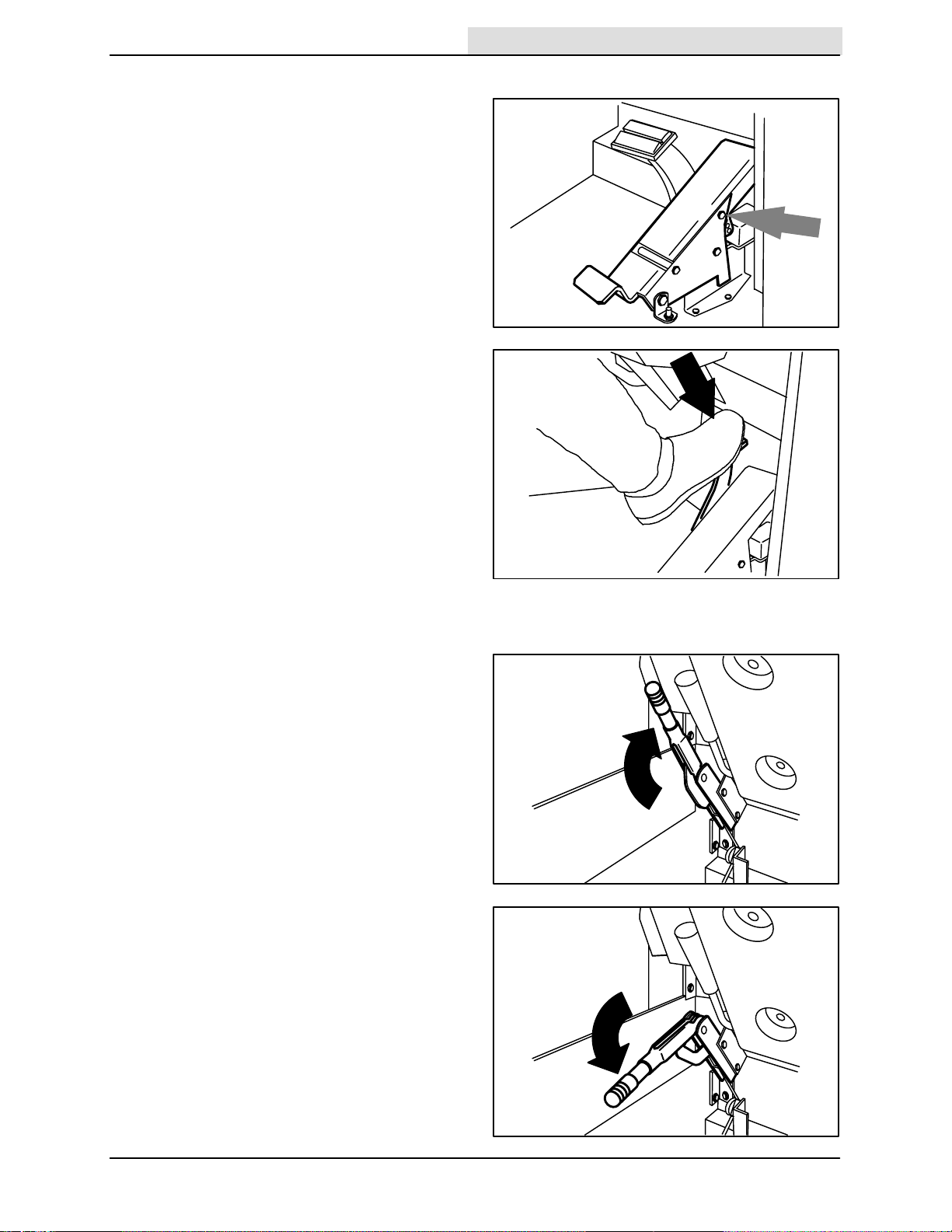

The parking brake lever sets and releases the

front wheel brakes.

Set: Pull the parking brake lever up.

FOR SAFETY: Before leaving or

servicing machine; stop on level

surface, set parking brake, turn off

machine and remove key.

08292

08234

Release: Push the parking brake lever down.

355E MM306 (12–92)

08224

08223

11

OPERATION

Home

Find...

HORN BUTTON

The horn button operates the horn.

Sound: Press the button.

BRUSH PRESSURE GAUGE

The brush pressure gauge shows the pressure of

the main brush against the floor. The needle

should be in the green zone. If the needle is in the

red zone, reduce the main brush pressure with

the main brush pressure knob.

NOTE: The brush pattern should be 50 to 75 mm

(2.0 to 3.0 in).

08220

08221

12

355E MM306 (12–92)

MAIN BRUSH AND SIDE BRUSH LEVER

Home

Find...

The main brush and side brush lever controls the

main brush and side brush rotation.

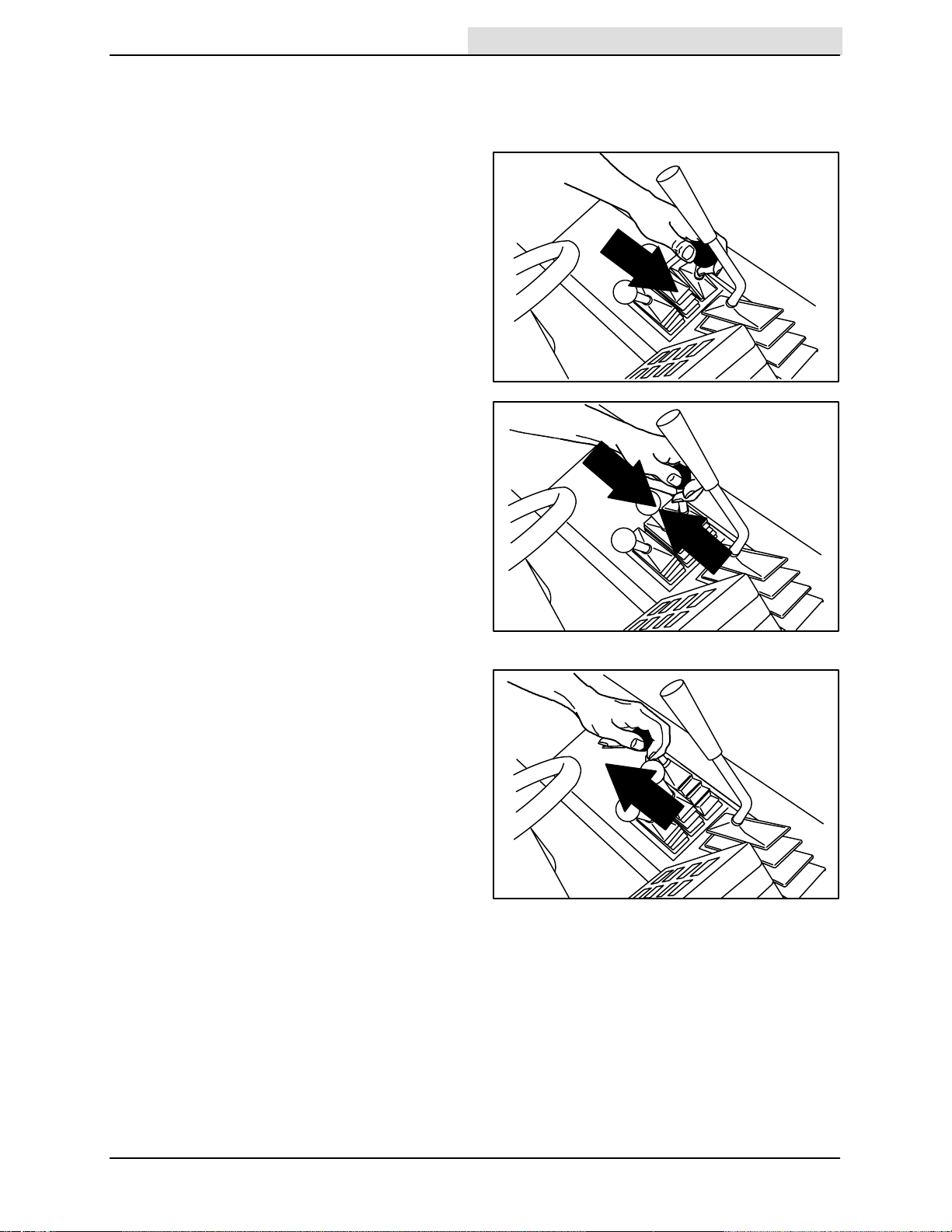

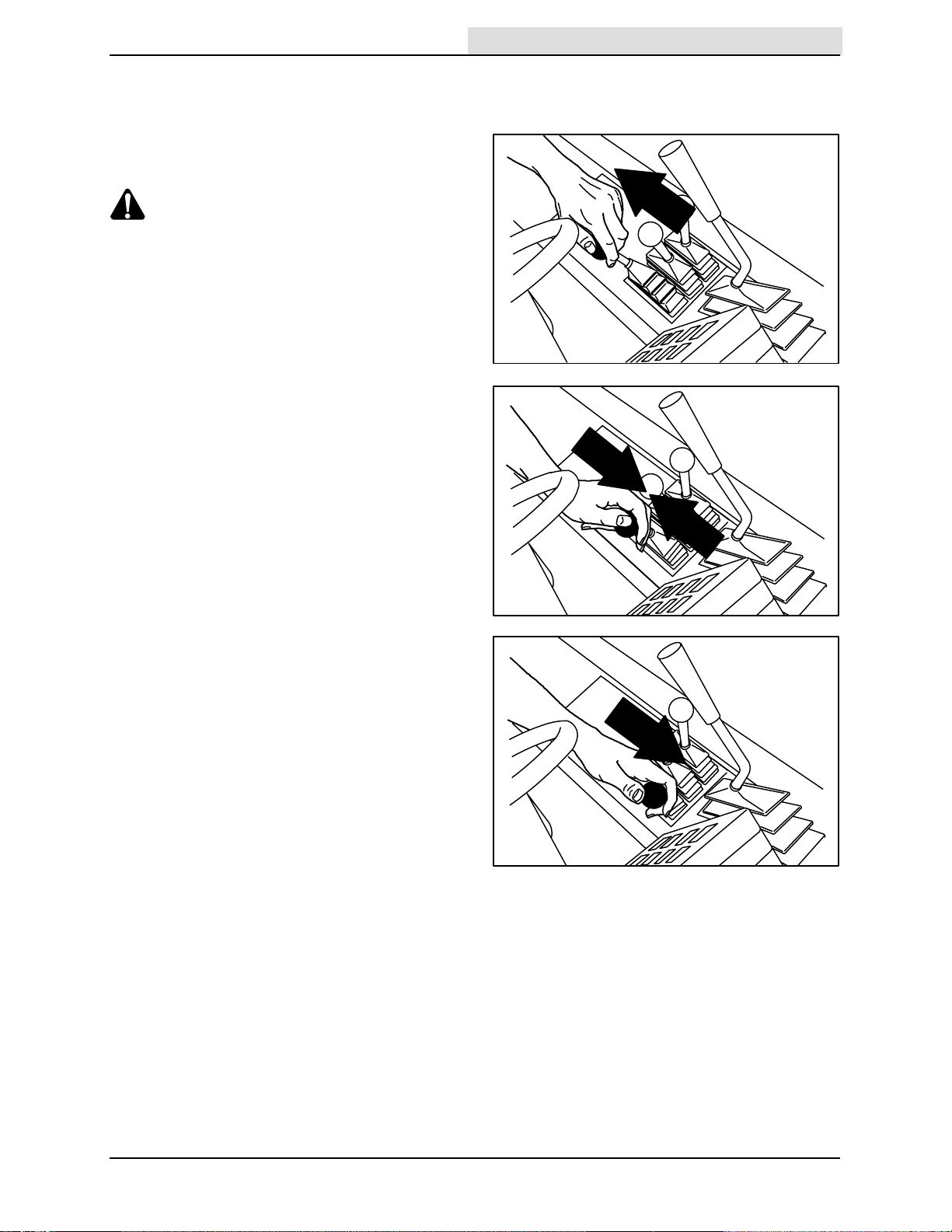

Main Brush and Side Brush On: Push the main

brush and side brush lever into the On position.

Main Brush and Side Brush Off: Pull the main

brush and side brush lever into the middle

position.

OPERATION

07773

Main Brush On: Pull the main brush and side

brush lever into the On position.

NOTE: Always raise the main brush when the

machine is not being operated for some time. This

prevents the main brush from getting a flat spot.

07774

07775

355E MM306 (12–92)

13

OPERATION

Home

Find...

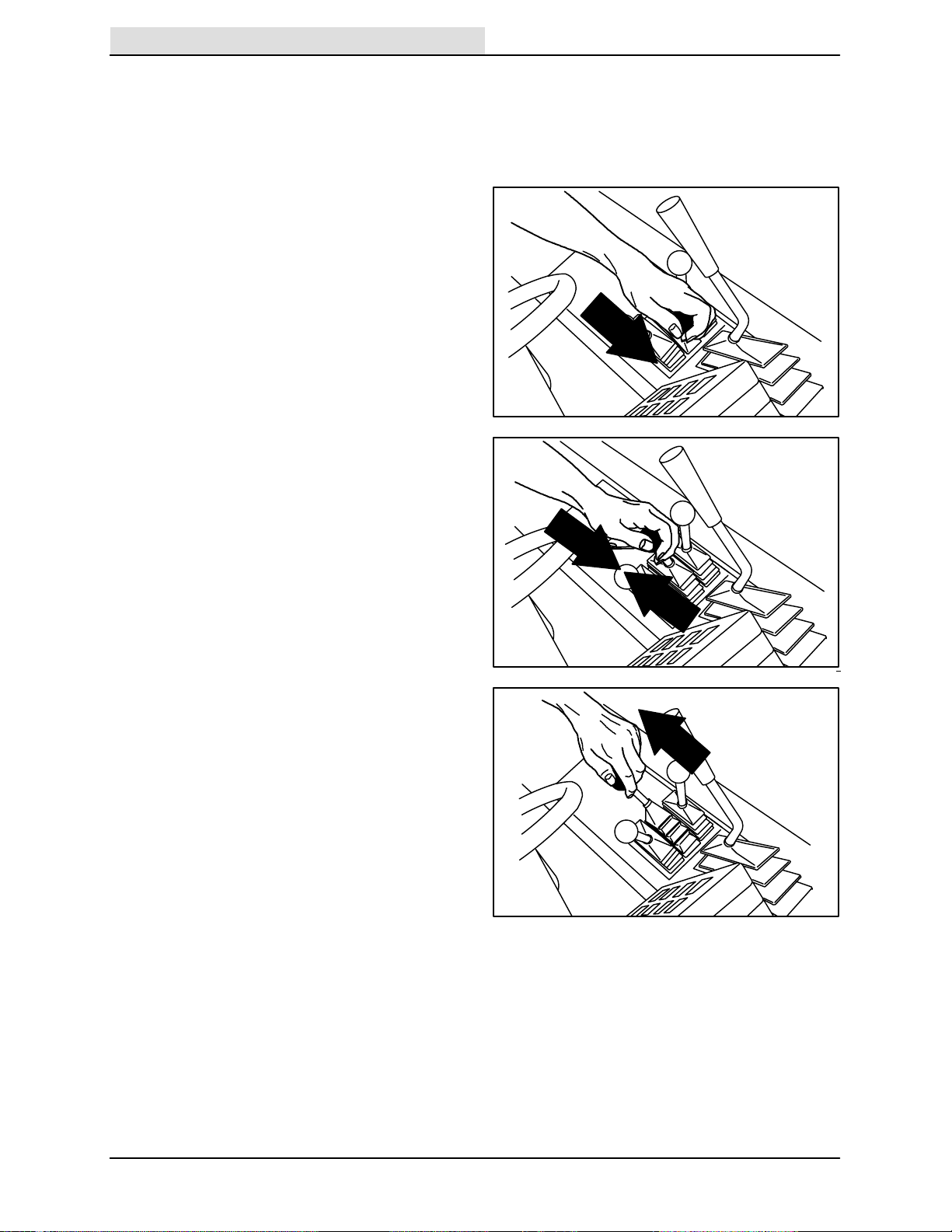

HOPPER DOOR LEVER

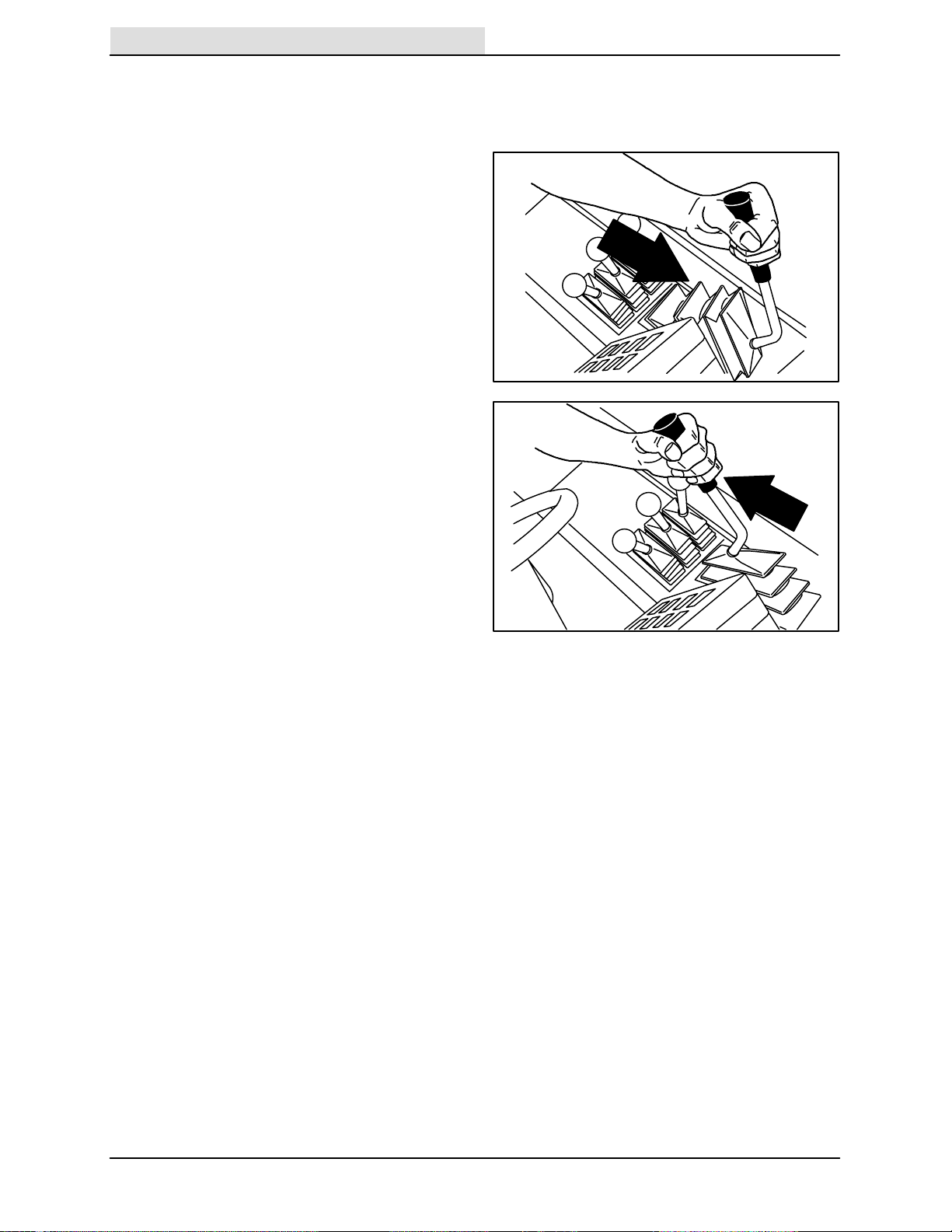

The hopper door lever opens and closes the

hopper door. Open the hopper door when

sweeping. Close the hopper door when emptying

the hopper to control debris and dust.

Open: Push the hopper door lever into the Open

position and leave it there.

Hold: Release the hopper door lever into the

middle position.

07776

Close: Pull and hold the hopper door lever into

the Close position.

NOTE: The hopper door will not close if the main

brush and side brush are operating.

07777

07778

14

355E MM306 (5–94)

HOPPER LIFT LEVER

Home

Find...

The hopper lift lever raises and lowers the hopper.

Up: Pull and hold the hopper lift lever into the Up

position.

WARNING: Raised hopper may fall.

Engage hopper support bar.

NOTE: The hopper will not raise if the main brush

and side brush are operating.

Hold: Release the hopper lift lever up and into the

middle position.

OPERATION

07779

Down: Push and hold the hopper lift lever into the

Down position.

07780

07781

355E MM306 (12–92)

15

OPERATION

Home

Find...

MAIN BRUSH POSITION LEVER

The main brush position lever lowers and raises

the main brush.

Down: Pull the main brush position lever back

and to the left into the Down position.

Up: Pull the main brush position lever all the way

back and to the right into the Up position.

07782

07784

16

355E MM306 (12–92)

MAIN BRUSH DOWN PRESSURE KNOB

Home

Find...

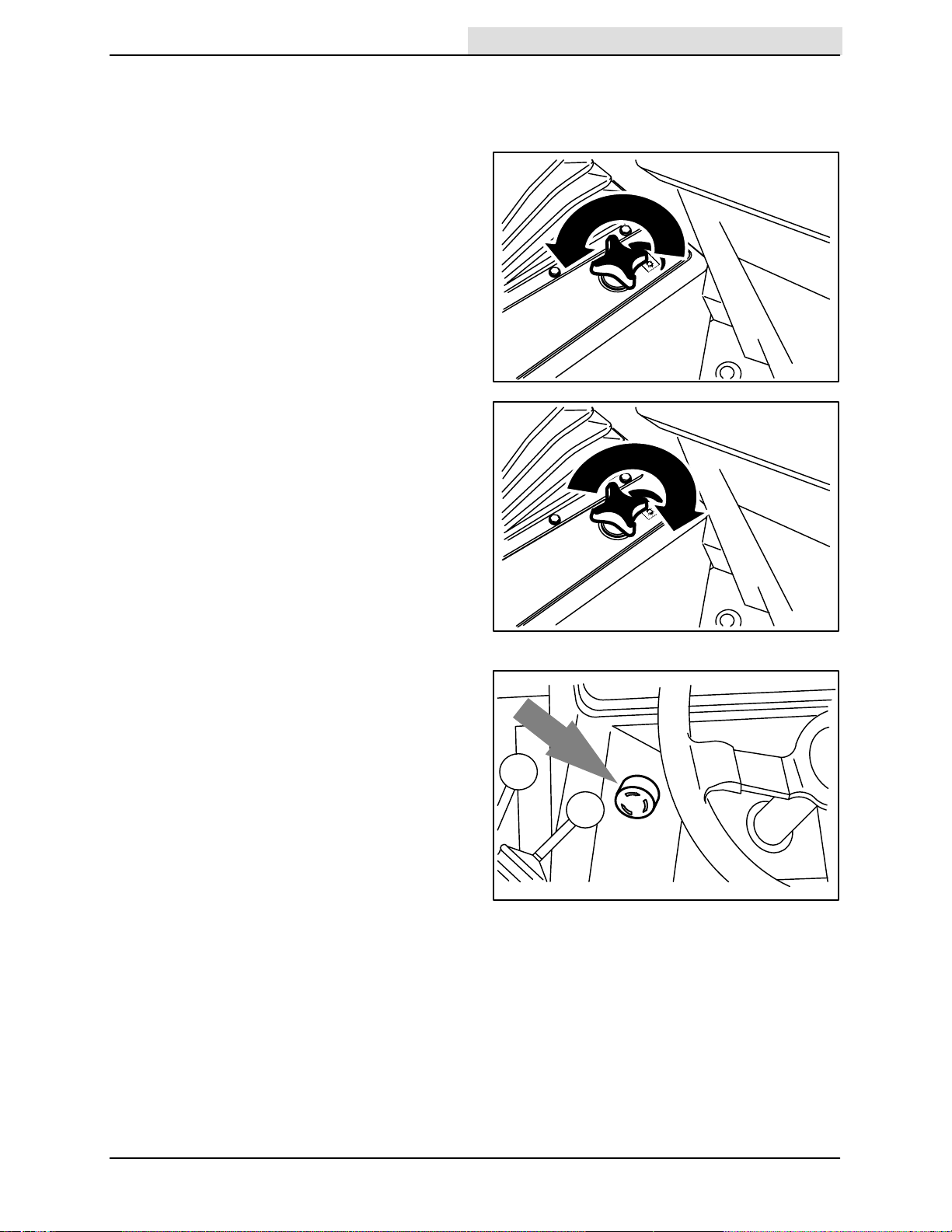

The main brush down pressure knob changes the

main brush contact with the sweeping surface.

Heavy: Turn the main brush down pressure knob

counter-clockwise.

Light: Turn the main brush down pressure knob

clockwise.

OPERATION

07787

POWER KILL SWITCH

The power kill switch halts all power to the

machine.

Halt: Hit the power kill switch.

Restart: Turn the power kill switch to the right to

release the switch. Turn the on-off switch key fully

clockwise, then release the switch key.

07788

08237

355E MM306 (12–92)

17

OPERATION

Home

Find...

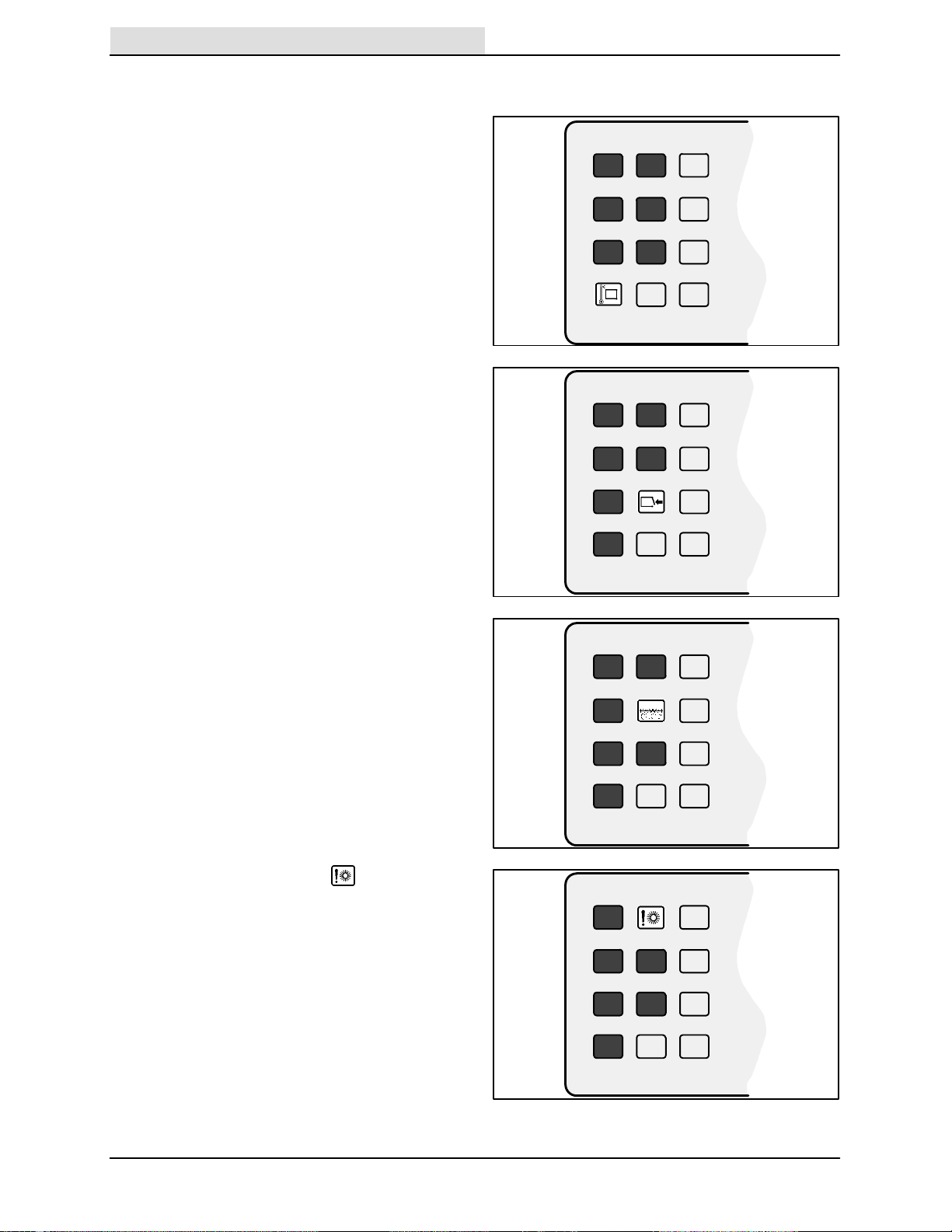

HOPPER TEMPERATURE LIGHT – THERMO

SENTRY

The hopper temperature light comes on when

there is too much heat in the hopper, possibly

from a fire. The Thermo Sentry will stop the

vacuum fan.

The Thermo Sentry has to be reset manually,

see THERMO SENTRY in MAINTENANCE.

HOPPER DOOR LIGHT

The hopper door light comes on when the hopper

door is closed. Make sure the hopper door is open

and the hopper door light is off, before sweeping

with the machine.

CLOGGED FILTER LIGHT

The clogged filter light comes on when the hopper

dust filter is clogged.

To clean the filter, press the filter shaker switch. If

the clogged filter light remains lit, manually clean

the hopper dust filter. See HOPPER DUST

FILTER in MAINTENANCE.

07760

07763

MAIN BRUSH SHUT DOWN LIGHT

The main brush shut down light comes on

when there is excessive down pressure for the

main brush, or there is a problem with the main

and side brush hydraulic motor circuit. The brush

pressures can be reduced with the main brush

and side brush pressure knobs.

18

07762

07761

355E MM306 (12–92)

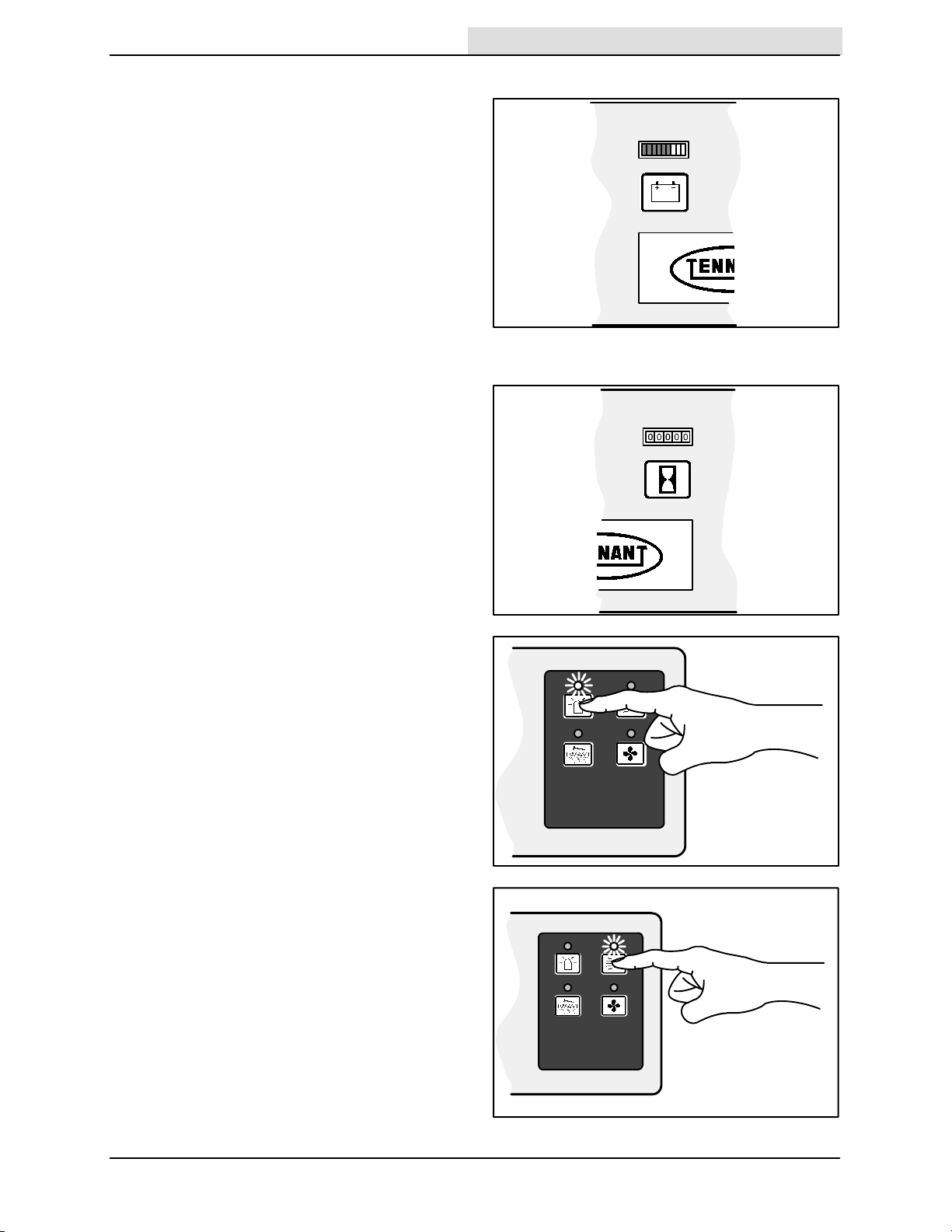

BATTERY DISCHARGE INDICATOR

Home

Find...

The battery discharge indicator shows the charge

level of the batteries with a segmented LED light.

When the batteries are fully charged, all of the

segments are lit. As the batteries discharge, the

segments shut off.

Recharge the batteries when the last two

segments are flashing.

NOTE: The reading of the battery discharge

indicator is not accurate when the machine is first

powered on. Operate the machine a few minutes

before reading the charge level of the batteries.

HOURMETER

The hourmeter records the number of hours the

machine has been operated. Use this information

to determine machine maintenance intervals.

OPERATION

08233

HAZARD LIGHT SWITCH (OPTION)

The hazard light switch powers on and off the

hazard light.

On: Press the hazard light switch. The indicator

light above the switch will come on.

Off: Press the hazard light switch. The indicator

light above the switch will go off.

OPERATING LIGHTS SWITCH

The operating lights switch powers on and off the

headlights and taillights.

On: Press the operating lights switch. The

indicator light above the switch will come on.

Off: Press the operating lights switch. The

indicator light above the switch will go off.

07765

08228

355E MM306 (12–92)

08230

19

OPERATION

Home

Find...

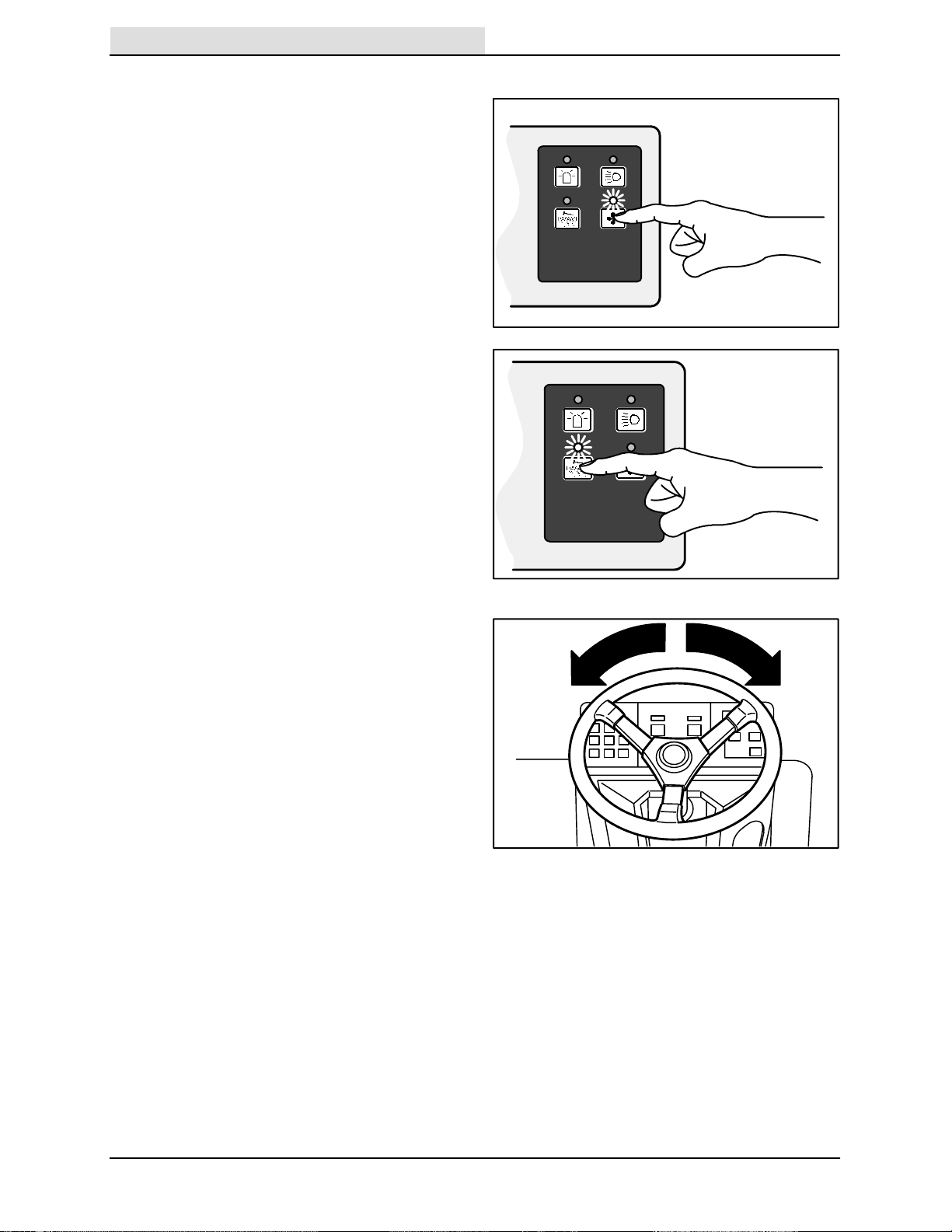

VACUUM FAN SWITCH

The vacuum fan switch starts and stops the

vacuum fan.

Start: Press the vacuum fan switch. The indicator

light above the switch will come on.

Stop: Press the vacuum fan switch. The indicator

light above the switch will go off.

FILTER SHAKER SWITCH

The filter shaker switch starts the hopper dust

filter shaker. The shaker automatically operates

for 40 seconds.

Start: Press the filter shaker switch. The indicator

light will remain on while the filter shaker is

operating.

NOTE: The vacuum fan shuts off while the filter

shaker is operating.

STEERING WHEEL

The steering wheel controls the machine’s

direction. The machine is very responsive to the

steering wheel movements.

Left: Turn the steering wheel to the left.

Right: Turn the steering wheel to the right.

08231

08229

20

07801

355E MM306 (12–92)

Loading...

Loading...